Zirconium and method for preparing zirconium

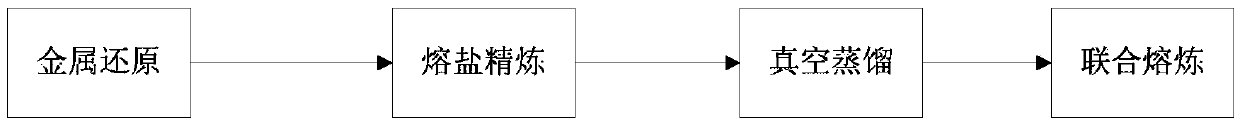

A zirconium oxide and metal heat technology, applied in the field of zirconium preparation, can solve the problems such as the difficulty of simple and efficient industrial production of zirconium, and achieve the effect of reducing oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation of zirconium is carried out by this method. First, 180g of metal Ca, 200g of ZrO 2 (Zirconium oxide particle size is 20 mesh, hafnium content is 95ppm), 300g of anhydrous calcium chloride, mixed and reacted at 950°C for 3 hours, and the calcium chloride used is calcined at 500°C for 8 hours. The reduction reaction product is washed with water until no bubbles are generated to remove calcium oxide, so that unreacted metal Ca is converted into Ca(OH) 2 , Get the water-washed mixture. Then wash the water-washing mixture with 0.8mol / L acetic acid solution three times in sequence, and then wash with pure water until the pH of the solution is neutral, filter to remove the water, and then use absolute ethanol to suction filter twice, and finally in an argon atmosphere Medium and dry. Primary zirconium obtained after drying.

[0041] Add primary zirconium to 500gCaCl 2 And 10gCa molten salt, in an argon atmosphere, after holding at 950°C for 8 hours, the product i...

Embodiment 2

[0047] The preparation of zirconium is carried out by this method, and 200 g of metal Mg, 200 g of ZrO 2 (Its ZrO 2 The particle size is 50 mesh, and the hafnium content is 70ppm), 360g of sodium chloride, mixed and reacted at 1000°C for 2 hours. After the furnace is released, the metal thermal reduction reaction product is washed three times with 0.2mol / L HCl, and then pure water Wash the solution until the pH value of the solution is neutral, filter to remove the water, then use anhydrous ethanol to suction filter twice, and finally dry in an argon atmosphere to remove impurities. Primary zirconium obtained after drying.

[0048] Add primary zirconium to 500gCaCl 2 And 20gCa molten salt, in an argon atmosphere, after holding at 900°C for 8 hours, the product is washed with water to neutrality, filtered and dried to obtain secondary zirconium.

[0049] Put the secondary zirconium into a vacuum furnace when the vacuum degree is greater than 10 -5 Under the conditions, heat to 800°C...

Embodiment 3

[0055] This method is used to prepare zirconium, and 80g of metal CaH 2 , 200g of ZrO 2 (The particle size is 100 mesh, and the hafnium content is 55ppm), 160g of calcium chloride, mixed and reacted at 900°C for 3 hours. After the furnace is released, the metal thermal reduction reaction product is washed with water until no more bubbles are emitted to obtain a water-washed mixture , And then washed with 1mol / L acetic acid three times, then washed with pure water until the pH value of the solution is neutral, filtered to remove water, and then filtered twice with absolute ethanol, and finally dried in an argon atmosphere. Primary zirconium obtained after drying.

[0056] Add primary zirconium to 400gCaCl 2 And 10gCa molten salt, in an argon atmosphere, after holding at 1000°C for 5 hours, the product is washed with water to neutrality, filtered and dried to obtain secondary zirconium.

[0057] Put the secondary zirconium into a vacuum furnace when the vacuum degree is greater than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com