Super fine corn flour processing device and processing method

A processing device and corn flour technology, applied in the field of food processing, can solve the problems of low efficiency and high processing cost, and achieve the effects of improving the removal rate, improving processing efficiency, and facilitating separation and transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

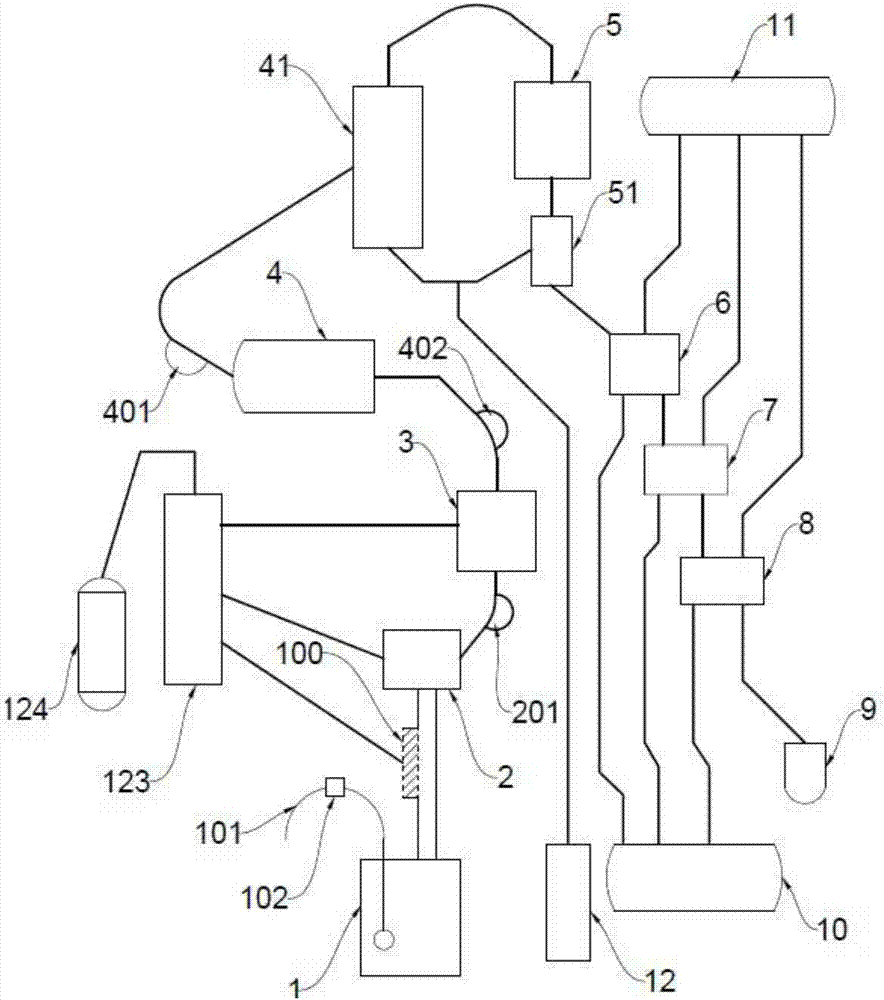

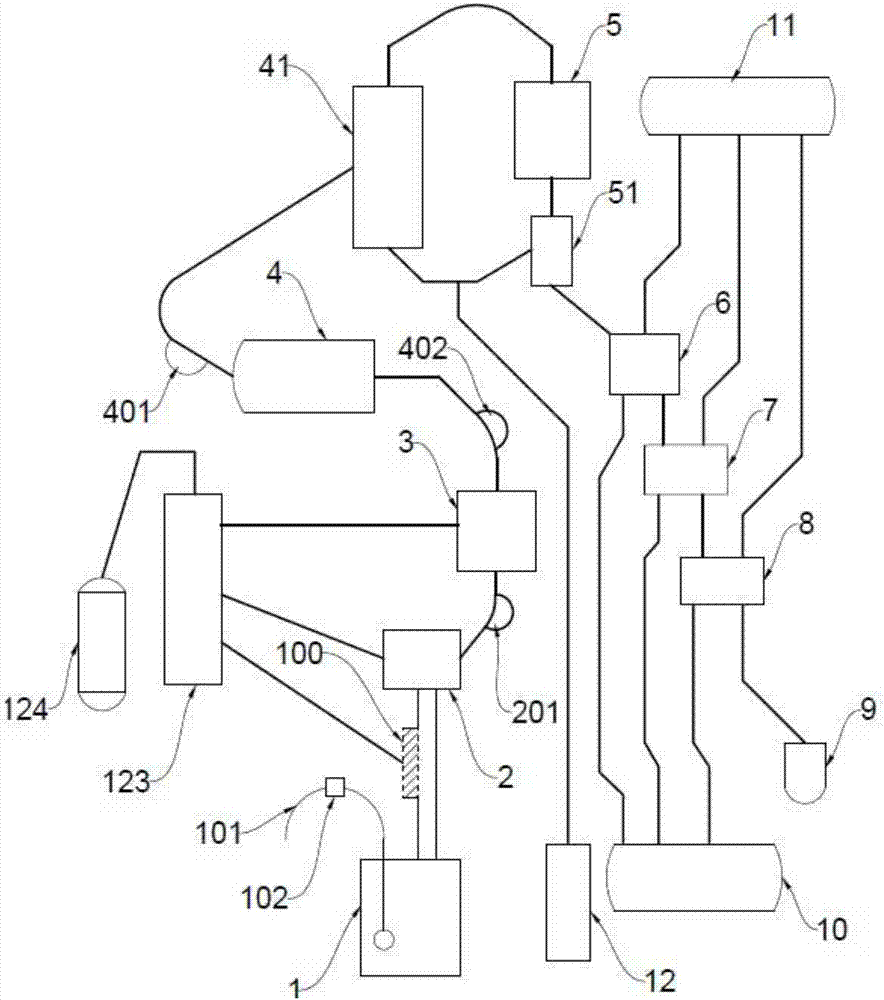

[0031] See attached figure 1 The present invention is further described.

[0032] The invention relates to an ultra-fine corn flour processing device, which is characterized in that the structure includes a corn storage bin (1), a first-level deslagging machine (2), a second-level deslagging machine (3), a Primary embryo selection machine (4), secondary embryo selection machine (5), primary crusher (6), secondary crusher (7), vibrating screening machine (8) and rack type corn splitting shearer (9 ); Described cog type corn divider shearer (9) is internally integrated with multi-layer screening net;

[0033] A dedusting fan (123) is arranged on the left side of the first-stage slag removing machine (2), and the dedusting fan (123) is externally connected to a water film dedusting tower (124);

[0034] The side wall of the connecting pipe between the corn storage bin (1) and the primary deslagging machine (2) is provided with a mesh-shaped isolation plate (100), and the corn s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com