SiO2 irregular nanocrystal network structure and preparation method thereof

A network structure, nanocrystal technology, applied in nanotechnology, silicon dioxide, coatings, etc., can solve problems such as performance and application are not well proven, and achieve high yield, simple operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] SiO according to the present invention 2 The preparation method of irregular nano crystal network structure, its steps are as follows:

[0032] The first step: pre-clean the substrate substrate and the loaded quartz tube. The substrate substrate needs to be ultrasonically cleaned with acetone, and then cleaned with deionized water. The quartz tube is wiped clean with alcohol cotton.

[0033] The second step: the SiO 2 After the mixed powder of S powder and S powder is evenly ground, put it into one end of the quartz tube as the reaction source, then place the pretreated substrate along the quartz tube at a distance of 20-30 cm from the reaction source, and finally put the reaction The source and substrate quartz tubes are put into a tube furnace with protective gas Ar.

[0034] Step 3: Heat up the tube furnace until the temperature of the reaction source reaches the reaction temperature, and the substrate temperature reaches the deposition temperature, keep warm for 1...

Embodiment 1

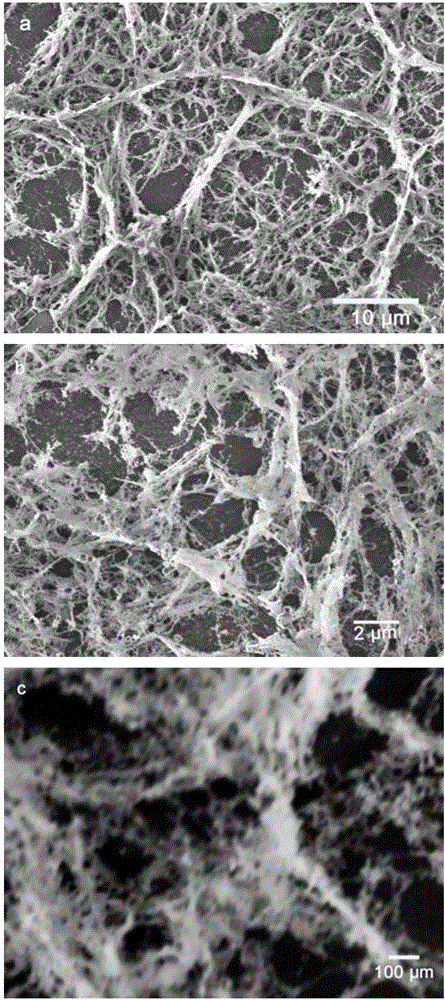

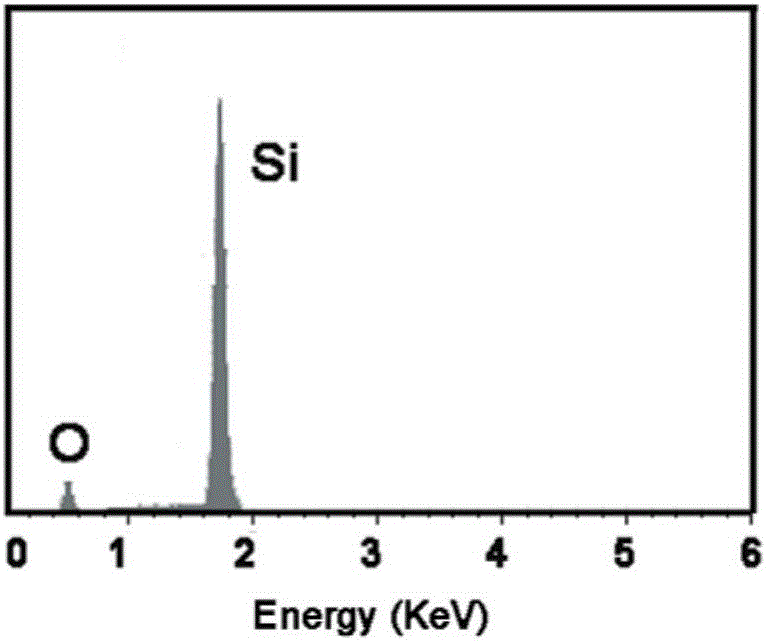

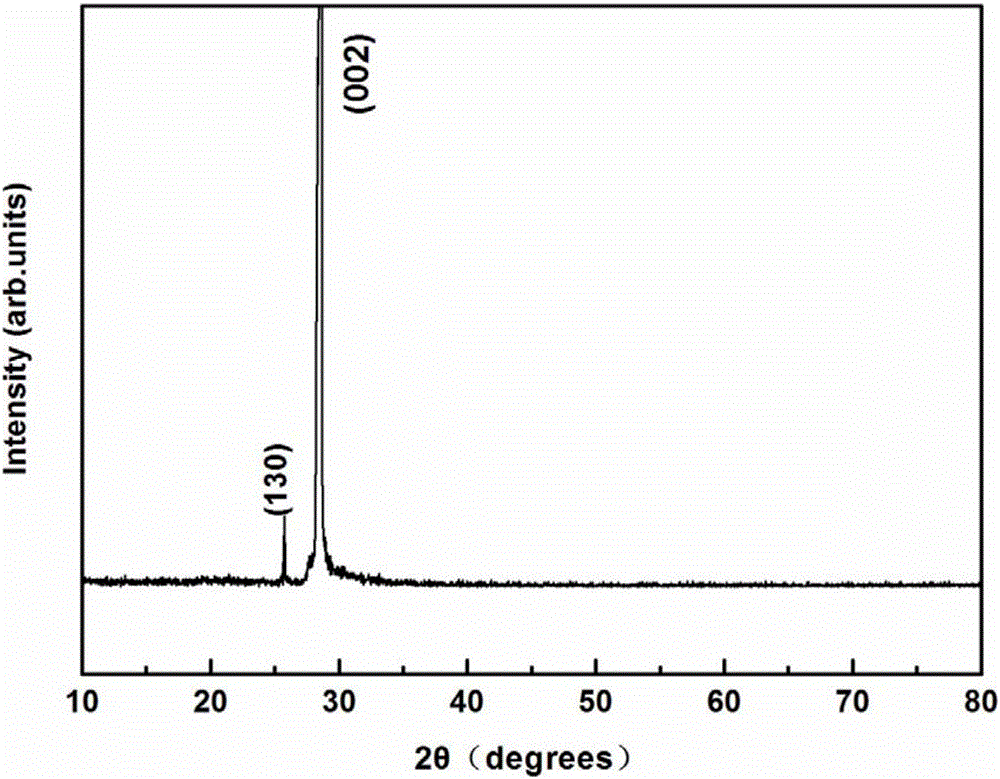

[0044] 0.75 g of sulfur powder with a purity of 99.99% and 0.75 g of silica powder with a purity of 99.99% were uniformly ground with a mortar and mixed thoroughly, and then put into the closed end of a single-opened quartz tube as a reaction source; n-type Si (111 ) The substrate is cleaned and placed in a position 20-25 cm away from the reaction source along the quartz tube, put the quartz tube with the reaction source and the substrate into the tube furnace, and introduce 20 sccm of protective gas Ar; open the tube The heating component of the type furnace, so that the temperature of the reaction source in the furnace reaches 1000 °C, the substrate temperature is about 890-940 °C, and maintains a constant temperature for 1.5 hrs; after the experiment, stop the gas supply, take out the quartz tube and drop it to room temperature under atmospheric conditions, that is, White flocculent SiO was grown on the substrate 2 Irregular nanocrystal network, see figure 1 . figure 1 Me...

Embodiment 2

[0046] 0.75 g of sulfur powder with a purity of 99.99% and 0.75 g of silica powder with a purity of 99.99% were uniformly ground with a mortar to make them fully mixed and then put into the closed end of a single-opened quartz tube as a reaction source; a quartz glass plate was used as a lining Clean the bottom and place it along the quartz tube at a distance of 21-26 cm from the reaction source, put the quartz tube with the reaction source and substrate into the tube furnace, and pass in 20 sccm of protective gas Ar; turn on the tube furnace The temperature-raising component is used to make the temperature of the reaction source in the furnace reach 1000 °C, the temperature of the substrate is about 890-940 °C, and maintain a constant temperature for 2 hrs; after the experiment, stop the gas supply, take out the quartz tube and drop it to room temperature under atmospheric conditions, that is, in the substrate White flocculent SiO grows on the bottom 2 Irregular nanonets. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com