Microbial fuel cell for nitrogen and phosphorus removal of sewage treatment plant and sewage treatment method

A sewage treatment method and technology of a sewage treatment plant, applied in biochemical fuel cells, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as high investment, high energy consumption, and increased cost of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

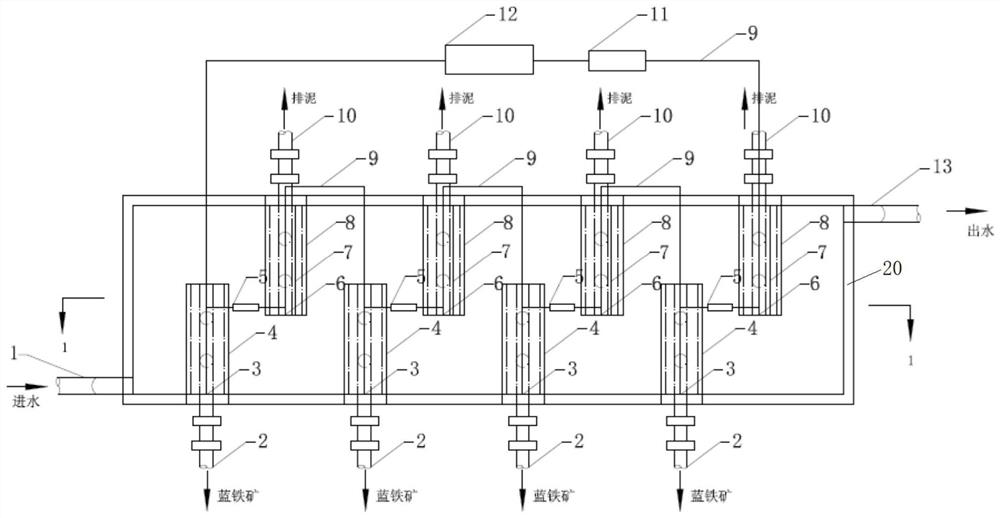

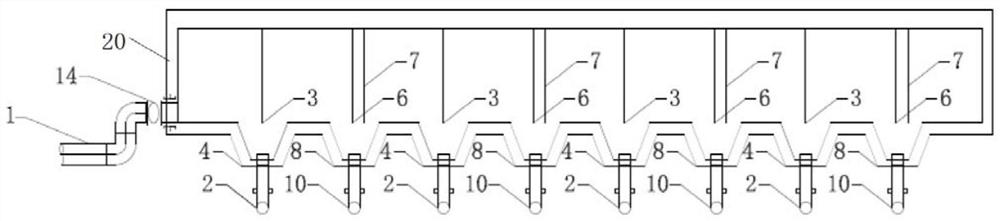

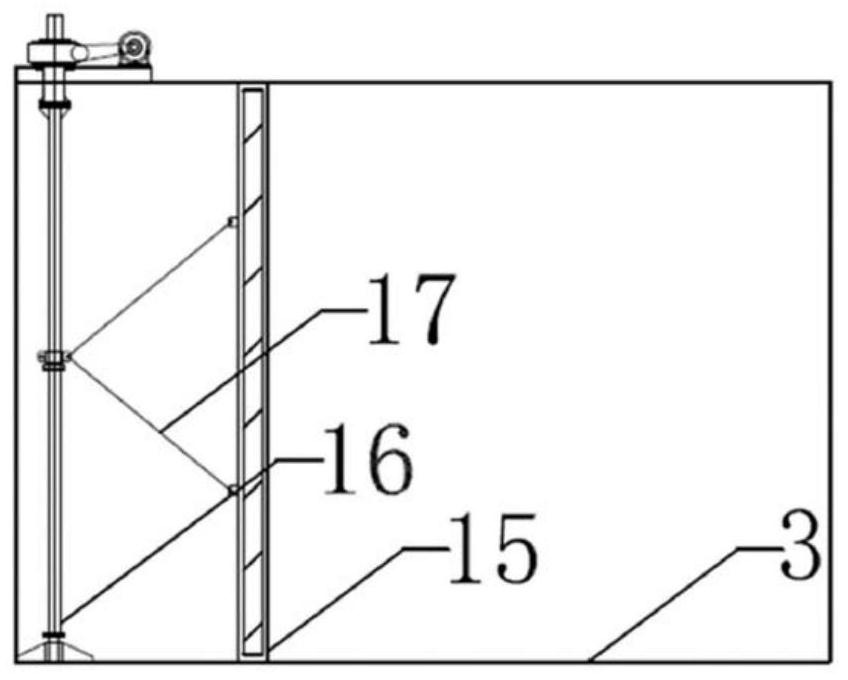

[0047] like figure 1 and figure 2 shown, combined with image 3 and Figure 4 , the microbial fuel cell used for denitrification and phosphorus removal in sewage treatment plants in this embodiment includes a nitrogen and phosphorus removal pool 20, and the nitrogen and phosphorus removal pool 20 is provided with a water inlet 1 and a water outlet 13, and the nitrogen and phosphorus removal pool 20 There are multiple sets of denitrification and phosphorus removal units inside along the direction of water flow; each group of denitrification and phosphorus removal units includes iron plates 3 and carbon felts 6 arranged sequentially along the direction of water flow inside the denitrification and phosphorus removal pool 20, and carbon felts 6 are attached with Denitrification biofilm 18, denitrification and phosphorus removal pool 20 are respectively provided with collecting bucket 4 and sludge bucket 8 under the iron pole plate 3 and carbon felt 6, and the iron pole plate 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com