Patents

Literature

48 results about "Potassium polymetaphosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium polymetaphosphate. [pə′tas·ē·əm päl·e‚med·ə′fäs‚fāt] (inorganic chemistry) (KPO3)n White powder with a molecular weight up to 500,000; used in foods as a fat emulsifier and moisture-retaining agent.

Environment-friendly microbial fertilizer for farmland income increase

The invention discloses an environment-friendly microbial fertilizer for farmland income increase. The environment-friendly microbial fertilizer comprises the following substances in parts by weight: 35-45 parts of chicken manure, 10-15 parts of sweet potato powder, 20-35 parts of peat, 9-16 parts of calcium superphosphate, 7-10 parts of potassium sulphate, 0.1-0.2 part of spherical bacillus powder, 35-45 parts of rice straw, 30-40 parts of rice bran, 1-2 parts of amino acid, 0.5-1.0 part of chitin, 0.1-0.2 part of atrialNatriuretie polypeptide, 3-7 parts of potassium polymetaphosphate, 2-9 parts of potassium pyrophosphate, 3-4 parts of sodium aluminum phosphate, 1-6 parts of calcium hydrophosphate, 2-6 parts of calcium phosphate, 3-4 parts of calcium pyrophosphate, 5-9 parts of humic acid and 0.1-0.3 part of verticicladiella powder. The environment-friendly microbial fertilizer disclosed by the invention does not contain a large number of nutrient elements, and can provide multiple kinds of nutritional ingredients for crops after being used through the key function of contained microorganisms.

Owner:QINGDAO ZHAXI BIOLOGICAL TECH

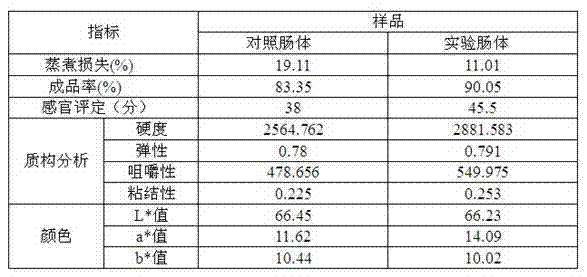

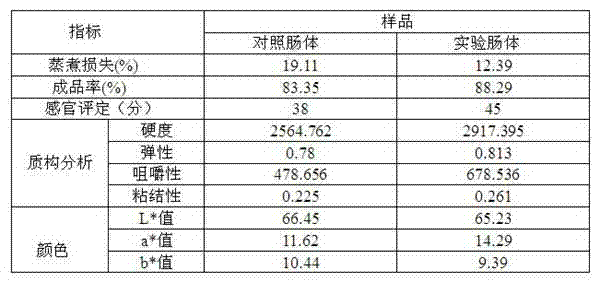

Efficient water-holding color retention agent for meat products, and preparing and using methods thereof

The invention provides an efficient water-holding color retention agent for meat products, and a preparing method and a using method of the efficient water-holding color retention agent. The raw materials of the water-holding color retention agent comprise sodium tripolyphosphate, trisodium pyrophosphate, potassium polymetaphosphate, disodium dihydrogen pyrophosphate, sodium pyrophosphate, sodium hexametaphosphate, D-sodium isoascorbiate, gluconolactone and salt. The trisodium pyrophosphate in the raw materials has better miscibility and a neutral pH value, and the pH value and the dissolving capacity of a phosphate system can be changed through adding appropriate trisodium pyrophosphate; a potassium polymetaphosphate aqueous solution has certain viscosity, so that juice seeping out from the meat products is reduced, and meanwhile the potassium polymetaphosphate aqueous solution has high metal ion chelating capability, can effectively chelate metal ions when being matched and used together with other components, can reduce oxidative rancidity during meat product processing and enable color-protecting components to play effect effectively, and the appropriate pH value can ensure that protein swelling is promoted to reach an optimal yield to effectively resolve the water binding capacity of the actomyosin, so that the meat products are endowed with excellent mouthfeel and sensory quality.

Owner:北京美添前景科技有限公司

Preparation method of organic microbial fertilizer

InactiveCN105622229AImprove the environmentPromote healthy and sustainable developmentBio-organic fraction processingOrganic fertiliser preparationBiotechnologyChinese agriculture

The invention discloses a preparation method of an organic microbial fertilizer. The organic microbial fertilizer comprises by weight, 26-35 parts of livestock and poultry night soil, 13-18 parts of sweet potato flour, 10-17 parts of wheat middling, 25-40 parts of straws, 30-40 parts of peat soil, 25-35 parts of weathered coal, 10-15 parts of mushrooms, 10-15 parts of algae, 12-16 parts of freshwater mussel powder, 20-30 parts of wood chips, 5-10 parts of honey, 1-2 parts of composite vitamins, 1-3 parts of composite amino acids, 5-8 parts of potassium polymetaphosphate, 1-2 parts of trace elements, 7-13 parts of potassium mineral powder, 10-16 parts of phosphate rock powder, 1-2 parts of humic acid, 5-8 parts of ammonium sulfate, 12-15 parts of borax, 3-7 parts of zinc sulfate, 5-8 parts of sodium carbonate and 7-10 parts of fatty acid acetic anhydride. The preparation method well solves the disadvantages of long fermentation period, and short viability time, activity insufficiency and difficult preservation of bacterial strains, The organic microbial fertilizer meets nutrition required by growth of crops, improves soil environment, has two purposes, and well promotes the sustainable healthy development of Chinese agriculture production.

Owner:武汉赛润科技有限公司

High-efficiency organic biofertilizer

InactiveCN103351232AHigh organic contentNutritional diversityFertilizer mixturesSodium aluminum phosphatePoultry manure

The invention discloses a high-efficiency organic biofertilizer which is characterized by comprising the following components in parts by weight: 50-90 parts of livestock and poultry manure, 4-9 parts of sodium dihydrogen phosphate, 5-6 parts of disodium hydrogen phosphate, 6-15 parts of sodium polyphosphate, 0.5-1.0 part of chitosan, 0.1-0.2 part of atrial natriuretic peptide, 3-7 parts of potassium polymetaphosphate, 2-9 parts of potassium pyrophosphate, 3-4 parts of sodium aluminum phosphate, 1-6 parts of calcium hydrogen phosphate, 2-6 parts of calcium phosphate, 3-4 parts of calcium pyrophosphate, 5-9 parts of humic acid and 0.1-0.3 part of verticicladiella powder. The biofertilizer contains rich beneficial microbes, has the advantages of comprehensive and balanced nutrients and persistent effect, and can enhance the organic matter content in soil.

Owner:QINGDAO ZHAXI BIOLOGICAL TECH

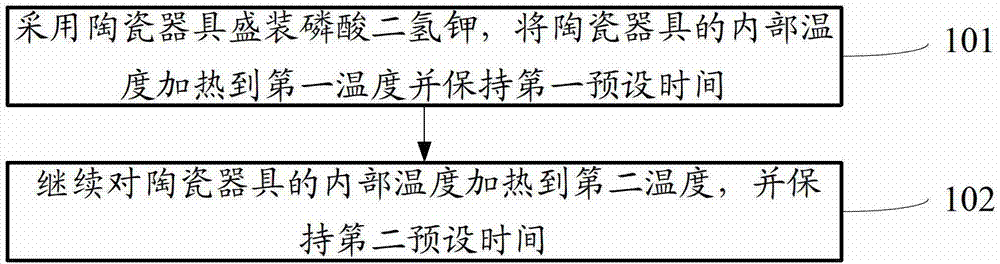

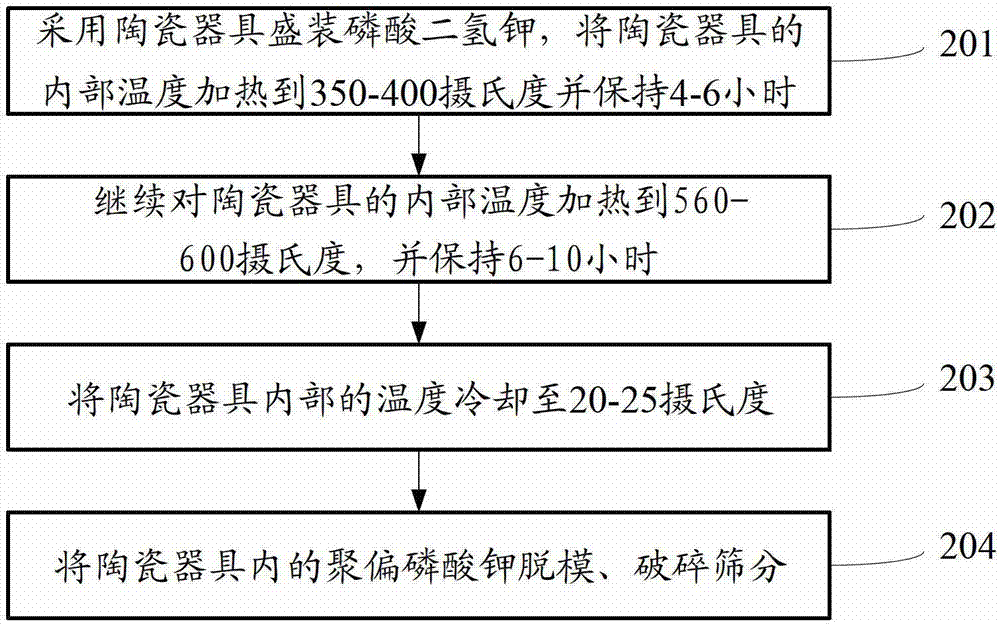

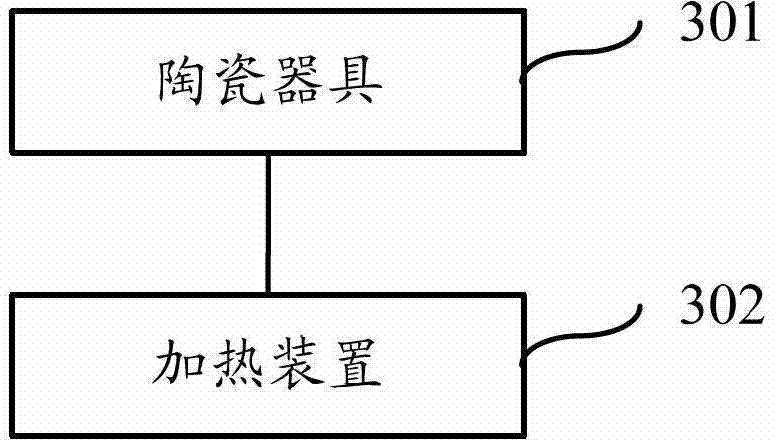

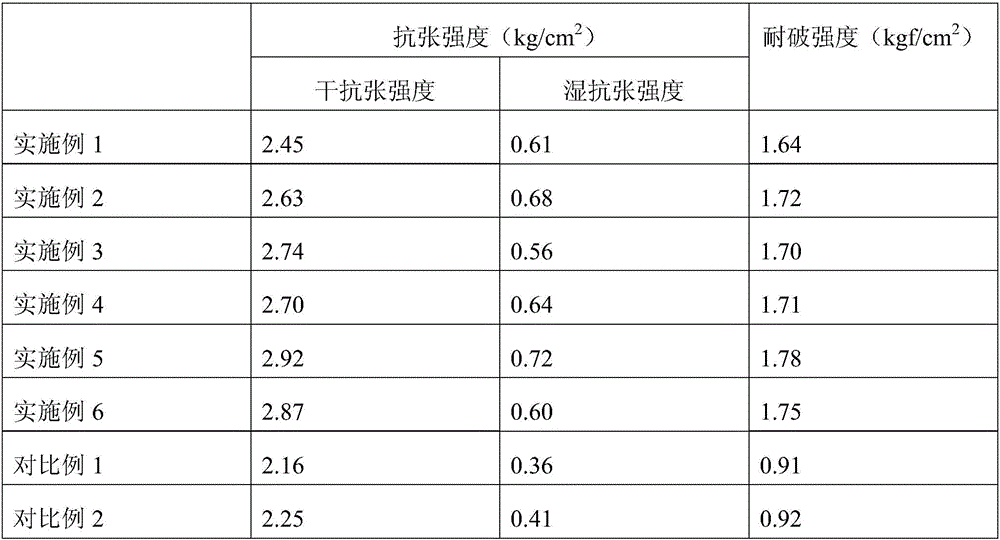

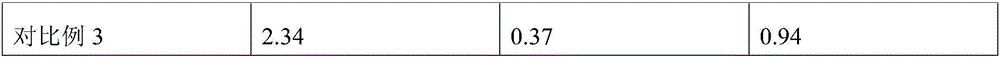

Production method and production equipment of potassium polymetaphosphate

ActiveCN102897740APurity effectReduce the impact of purityPhosphorus compoundsChemical productsMonopotassium phosphate

The invention relates to a chemical product production technology, and in particular relates to a production method and production equiopment of potassium polymetaphosphate. The production method of the potassium polymetaphosphate comprises the following steps: holding monopotassium phosphate with a ceramic container; and heating the inner part of the ceramic container to a first temperature, and maintaining the first temperature for a first preset time. The production equipment of the potassium polymetaphosphate comprises a ceramic container and a heating device, wherein the ceramic container is used for holding monopotassium phosphate; the heating device is used for heating the inner part of the ceramic container which is used for holding the monopotassium phosphate to the first temperature and also for maintaining the first temperature for the first preset time; and the inner part of the ceramic container is heated to a second temperature and maintained for a second preset time. According to the production method and production equiopment of potassium polymetaphosphate, the influence of metal ions on the purity of potassium polymetaphosphate can be reduced.

Owner:YUNNAN ADDIPHOS TECH CO LTD

Bio-organic fertilizer

InactiveCN104446885AImprove immune functionPromote growthCalcareous fertilisersAlkali orthophosphate fertiliserNematodeMonopotassium phosphate

The invention discloses a bio-organic fertilizer. The bio-organic fertilizer is characterized by comprising the following substances in parts by weight: 90-120 parts of excrements of livestock, 15-20 parts of sodium dihydrogen phosphate, 9-12 parts of disodium hydrogen phosphate, 8-12 parts of sodium polyphosphate, 2-3 parts of chitin, 5-9 parts of pachystachys lutea saw dust, 3-5 parts of rambler rose saw dust, 4-6 parts of banana shrub saw dust, 8-11 parts of potassium metaphosphate, 3-9 parts of diammonium phosphate, 9-15 parts of Chinese pyrola herb, 4-6 parts of inula flower, 2-6 parts of common yam rhizome, 5 parts of potassium dihydrogen phosphate and 2-7 parts of anhydrous calcium chloride. The bio-organic fertilizer is capable of realizing plant growth, promoting the plant growth, inhibiting the growth of various bacteria in soil and inhibiting the growth of various nematodes or soft insects in soil by improving the own immune function of plants, promoting plant growth and improving the own conditions of the soil.

Owner:曲少春

Aqueous softener

InactiveCN104891686AGuarantee the vividness of dyeingFully softenedTreatment using complexing/solubilising chemicalsPyrophosphateFatty alcohol

The invention discloses an aqueous softener which comprises, by weight, 20-25 parts of sodium tripolyphosphate, 15-20 parts of sodium dihydrogen phosphate, 15-20 parts sodium pyrophosphate, 10-15 parts of citric acid, 10-12 parts of dimethyl ethanolamine, 8-10 parts of fatty alcohol polyoxyethylene ether, 10-12 parts of monoethanolamine, 8-10 parts of sodium methacrylate, 10-15 parts of potassium polymetaphosphate, 8-10 parts of rosin resin and 10-12 parts of phenolic resin. The aqueous softener has the advantages that the softener is used for printing and dyeing fabric and clothing materials in the textile industry, hard water can be softened sufficiently, clothing material dying brightness is well guaranteed during printing and dyeing, and standard printing and dyeing is achieved.

Owner:梁胜光

Slurry for loudspeaker cone paper

The invention discloses slurry for loudspeaker cone paper, and belongs to the technical field of electroacoustic products. The slurry is mainly formed by the mixing and stirring of the following raw materials by weight: 45-65 parts of wood pulp, 15-30 parts of sisal hemp, 10-20 parts of cotton pulp, 10-20 parts of kapok, 0.3-1 parts of bulletproof fiber, 0.1-0.8 parts of wool, 0.05-0.5 parts of glass fiber, 2-8 parts of dye, 1-5 parts of salt, 3-8 parts of waterproof agent, 3-8 parts of hardening agent, 3-8 parts of flexibilizer, 3-8 parts of conditioning agent, 0.5-5 parts of potassium polymetaphosphate, 0.5-5 parts of polyoxyethylene, 0.5-5 parts of urea resin, 0.2-3 parts of chitinous substances, 0.2-3 parts of pineapple fiber. The slurry is good in decontamination and antiwrinkling capabilities, and is good in force of flocculation, toughness and strength, thereby enabling cone paper made of the slurry to be good in sound effect, greatly improving the antiwrinkling capability and mechanical performance, and prolonging the service life.

Owner:广西玉林市禹力音响配件有限公司

Green biofertilizer for producing safe agricultural products

The invention discloses a green biofertilizer for producing safe agricultural products, which is characterized by comprising the following components in parts by weight: 20-30 parts of chicken manure, 50-70 parts of pig manure, 15-25 parts of rice bran, 0.01-0.02 part of microelement, 0.5-1.0 part of chitosan, 0.1-0.2 part of atrial natriuretic peptide, 3-7 parts of potassium polymetaphosphate, 2-9 parts of potassium pyrophosphate, 3-4 parts of sodium aluminum phosphate, 1-6 parts of calcium hydrogen phosphate, 2-6 parts of calcium phosphate, 3-4 parts of calcium pyrophosphate, 5-9 parts of humic acid and 0.1-0.3 part of verticicladiella powder. Compared with the prior art, the invention adopts the natural materials containing abundant minerals, such as the chicken manure, ground phosphorite, shell powder, shredded crop straw, rice bran and the like, so the soil does not agglomerate any more, and the problem of straw incineration pollution is solved.

Owner:QINGDAO ZHAXI BIOLOGICAL TECH

Paper pulp

ActiveCN106930148AImprove bulkImprove damping performanceOrganic non-cellulose fibresWater-repelling agents additionGlass fiberPulp and paper industry

The invention discloses paper pulp, and belongs to the technical field of electro-acoustic products. The paper pulp is mainly prepared by mixing and stirring the following raw materials in parts by weight: 45-65 parts of wood pulp, 15-30 parts of sisal hemp, 10-20 parts of cotton pulp, 10-20 parts of bombax malabaricum flowers, 0.3-1 part of bulletproof fibers, 0.1-0.8 part of wool, 0.05-0.5 part of glass fibers, 2-8 parts of dye, 1-5 parts of table salt, 3-8 parts of a water-proofing agent, 3-8 parts of a hardener, 3-8 parts of a flexibilizer, 3-8 parts of an adjusting agent, 0.1-1 part of sodium polystyrene sulfonate, 0.1-1 part of poly dimethyl diallyl ammonium chloride and 0.1-0.5 part of potassium polymetaphosphate. The cohesive force, the tenacity and the intensity of the paper pulp are favorable, cone paper made from the paper pulp not only has soft sound quality, but also has favorable mechanical properties, and the service life is prolonged.

Owner:江西红井电子科技有限公司

High-quality willow softening agent

InactiveCN106239670ALow elastic modulusImprove toughnessWood treatment detailsPretreatment apparatusAlkaneGlycerol

The invention discloses a high-quality willow softening agent. The softening agent is made of following components including nano diatomite, ammonia-water, potassium chloride, sorbitol, potassium polymetaphosphate, glycerol, seconary alkane sulphonate sodium, a flixweed tansymustard seed extracting solution and water. According to the willow softening agent, the ammonia-water, the nano diatomite, the potassium chloride and the potassium polymetaphosphate are compounded, in cooperation with the cooperative interactions of the flixweed tansymustard seed extracting solution and the glycerol, the obtained softening effect is good, the treatment time is short, and safety is high; and through the coordinative cooperation effect of the all components, a willow workpiece treated by the willow softening agent is high in strength after drying shaping, toughness is good, the structure is compact, the surface is smooth, and the added use value of willows is greatly improved.

Owner:阜南县中泰工艺品有限公司

Agricultural quick-release microbial fertilizer

InactiveCN103351237AImprove water absorptionImprove water retentionFertilizer mixturesMagnesium phosphateSludge

Owner:QINGDAO ZHAXI BIOLOGICAL TECH

High-performance elm softener

InactiveCN106142267ALow elastic modulusEasy accessWood treatment detailsPretreatment apparatusGlycerolPotassium

The invention discloses a high-performance elm wood softener, which is made of the following ingredients: sodium borate, ammonia solution, potassium chloride, sodium lauryl sulfate, potassium polymetaphosphate, glycerol, triethanolamine, and Artemisia persica seed extract liquid, water. The elm wood softener prepared by the present invention is compounded with ammonia water, sodium borate, potassium chloride, and potassium polymetaphosphate, and then combined with the synergistic interaction between the extract of Artemisia persicae seed and glycerol, the softening effect is good, and the treatment Less time and high safety, the strength of the shaped elm wood workpiece is increased by more than 48% on average, and the structure is compact, which solves the problem of strength reduction caused by ordinary wood softeners.

Owner:阜南县中泰工艺品有限公司

Preparation method of instant and highly-efficient phosphate for food ingredients

InactiveCN110236171AInstantImprove qualityInorganic compound food ingredientsFood dryingDipotassium hydrogen phosphateSodium phosphates

The invention discloses a preparation method of instant and highly-efficient phosphate for food ingredients, and relates to the technical field of phosphate preparation. The preparation method includes the following steps: mixing sodium phosphate monomer, dispersing cosolvent potassium phosphate and water into homogeneous phase material liquid, subjecting the homogeneous phase material liquid to spraying granulation and drying dehydration, and finally obtaining the instant highly-efficient phosphate product for food ingredients. The sodium phosphate monomer is one or two or more than two kinds of monomer sodium phosphate; the dispersing cosolvent potassium phosphate is potassium triphosphate, potassium pyrophosphate, potassium polymetaphosphate, potassium dihydrogen phosphate, dipotassium hydrogen phosphate, tribasic potassium phosphate or potassium polyphosphate; the addition of dispersing cosolvent potassium phosphate accounts for 5%-10% of the total weight of sodium phosphate monomer and dispersing cosolvent potassium phosphate. The product obtained by the method can reach homogeneous phase mixing at the molecular level, and the obtained product is easy to disperse, free of agglomeration or absorption of moisture, good in mouthfeel, excellent in dissolution speed and capable of giving full play to a synergistic effect.

Owner:江苏恒世食品科技有限公司

Biological pesticide capable of controlling pest source

InactiveCN104522063AGrowth inhibitionInhibition of reproductionBiocideDisinfectantsDiseaseBenzoyl peroxide

The invention discloses a biological pesticide capable of controlling a pest source. The biological pesticide comprises the following components in parts by weight: 9-15 parts of beauveria bassiana, 34-44 parts of matrine, 12-32 parts of altenusin, 10-20 parts of sunflower seed oil, 55-69 parts of tea saponin, 1-3 parts of sodium methylene bis-naphthalene sulfonate, 5-8 parts of benzoyl peroxide, 5-7 parts of avermectin, 3-4 parts of methacrylic acid, 11-17 parts of potassium polymetaphosphate and 20-30 parts of silicone oil. Due to use of natural plant extracts, the biological pesticide provided by the invention can be used for inhibiting the growth and reproduction of pests and diseases, and the sterilization efficiency is high; except for crops, the pesticide is effective against common aphids and red spiders of flowers and the like, so that the pests are eliminated from the source.

Owner:QINGDAO LAOXIANG TEA PROD

Continuous dynamic polymerization large-scale production method for high-viscosity non-caking potassium polymetaphosphate

ActiveCN105692577AImprove efficiencyImprove liquidityPhosphorus compoundsPotassium MetaphosphateRotary furnace

The invention discloses a continuous dynamic polymerization large-scale production method for high-viscosity non-caking potassium polymetaphosphate.The method includes: adding a phosphorus containing material and a potassium containing material into a neutralizing tank, stirring for complete reaction, preparing neutralization liquid, and controlling a PH value in 3.0-5.0; transferring the liquid to a smelting furnace with a high-temperature-resistant corrosion-resistance liner directly or after concentration and crystallization or drying and dewatering, performing high-temperature melting at the temperature of 850-1000 DEG C; after materials in the smelting furnace is completely melted, discharging out of the smelting furnace, quickly cooling and solidifying, and grinding to 20 meshes below; transferring to a stainless steel rotary furnace for sintering reaction at the temperature of 450-650 DEG C for 0.5-2.0h, and discharging to obtain the high-viscosity non-caking potassium polymetaphosphate.The high-viscosity non-caking potassium polymetaphosphate can be produced by existing conventional phosphate production equipment, and high efficiency, method simplicity and convenience in implementation are realized.

Owner:江苏恒世食品科技有限公司

Agricultural soil improvement biological fertilizer

InactiveCN104402587AImprove water absorptionImprove water retentionBioloigcal waste fertilisersMagnesium phosphate fertilisersMagnesium phosphateMagnesium orthophosphate

The invention discloses an agricultural soil improvement biological fertilizer which is characterized by including the following materials in parts by weight: 28-30 parts of urea, 5-9 parts of ammonium sulfate, 11-18 parts of potassium polymetaphosphate, 2-9 parts of chinaberry bark, 5-8 parts of loquat leaf, 2-8 parts of castanopsis fargesii sawdust, 1-6 parts of robur sawdust, 4-8 parts of magnesium phosphate, 5-11 parts of manganese hypophosphite, 12-24 parts of flax straw, 25-30 parts of hemp straw, 45-50 parts of sunflower straw and 0.01-0.03 part of bdellovibrio powder. The agricultural soil improvement biological fertilizer has good water absorption performance, good water retention properties, and comprehensive plant nutrition elements, and can improve the soil physical properties and restore soil fertility.

Owner:曲少春

Preparation method of organic microbial fertilizer

InactiveCN106748066AImprove the environmentPromote healthy and sustainable developmentAnimal corpse fertilisersExcrement fertilisersBiotechnologyAcetic anhydride

The invention discloses a preparation method of organic microbial fertilizer. 26-35 parts of livestock and poultry manure, 13-18 parts of sweet potato powder, 10-17 parts of clear flour, 25-40 parts of straw, 30-40 parts of peat soil, 25-35 parts of weathered coal, 10-15 parts of mushrooms, 10-15 parts of algae, 12-16 parts of mussel powder, 20-30 parts of wood chips, 5-10 parts of molasses, 1-2 parts of multivitamins, 1-3 parts of compound amino acid, 5-8 parts of potassium polymetaphosphate, 1-2 parts of trace elements, 7-13 parts of potassium ore powder, 10-16 parts of phosphorus ore powder, 1-2 parts of humic acid, 5-8 parts of ammonium sulfate, 12-15 parts of borax, 3-7 parts of zinc sulfate, 5-8 parts of sodium carbonate and 7-10 parts of fatty acid acetic anhydride are taken.. The preparation method of the organic microbial fertilizer is used to effectively overcome the defects that the organic microbial fertilizer is long in fermentation period, short in strain survival time, insufficient in activity and not easy to preserve. The organic microbial fertilizer has the advantages of improving the soil environment while providing the nutrition needed by the growth of crops, thus obtaining double benefits, and accordingly well promoting the sustainable and healthy development of the agricultural production in China.

Owner:李志强

Biological fertilizer improving soil

InactiveCN104402648ASimple structureGood effectAlkali orthophosphate fertiliserExcrement fertilisersSodium aluminum phosphatePotassium

A disclosed biological fertilizer improving soil is characterized by comprising the following substances in parts by weight: 200-250 parts of paddy rice straw, 120-130 parts of chicken manure, 150-170 parts of pig manure, 50-60 parts of rice bran, 1-3 parts of trace elements, 3-7 parts of potassium polymetaphosphate, 2-9 parts of potassium pyrophosphate, 13-20 parts of sodium aluminum phosphate, 1-6 parts of calcium hydrogen phosphate, 11-18 parts of calcium phosphate, 25-30 parts of calcium pyrophosphate, 0.1-0.2 part of rhodococcus powder, 0.1-0.2 part of pityrosporion ovale powder, and 0.1-0.2 part of humic acid. The biological fertilizer is non-toxic, harmless and free of pollution, is capable of comprehensively providing nitrogen, phosphorus and potassium for crops, does not cake soil, is capable of improving soil structure, has relatively strong water retention capability, and has relatively excellent effect and relatively long fertilizer efficiency especially aiming at dry crops.

Owner:曲少春

Special biofertilizer for tea trees

InactiveCN103708942AMeeting short- and long-term nutrient needsIncrease productionFertilizer mixturesSodium aluminum phosphateScapharca subcrenata

The invention discloses a special biofertilizer for tea trees. The special biofertilizer contains the following substances in parts by weight: 15-20 parts of ammonium nitrate, 9-12 parts of potassium sulfate, 0.1-0.2 part of lactobacillus powder, 10-15 parts of highland barley straw powder, 30-45 parts of horse bean straw powder, 60-80 parts of wheat straw powder, 8-12 parts of scapharca subcrenata shell powder, 3-9 parts of surface clamshell powder, 3-5 parts of ginkgo wood sawdust, 3-6 parts of oak wood sawdust, 2-4 parts of potassium polymetaphosphate, 3-8 parts of potassium pyrophosphate, 4-8 parts of sodium aluminum phosphate, 0.1-0.2 part of nitrobacterium powder, 0.1-0.2 part of rhizobium powder, 3-6 parts of zinc sulfate and 2-5 parts of sepiolite. The special biofertilizer is reasonable in formula and balanced in nutrition, is safe and pollution-free and fully meets the short / long-term nutrient requirements of the tea trees, balanced fertilization can be achieved, the soil can be improved, the environment can be protected, the yield of tea can be effectively increased, and the quality of the tea can be effectively improved.

Owner:QINGDAO LAOXIANG TEA PROD

Biomass fertilizer for tea trees

InactiveCN103708944AMeeting short- and long-term nutrient needsIncrease productionFertilizer mixturesSodium aluminum phosphateNitrifying bacteria

The invention discloses a biomass fertilizer for tea trees. The biomass fertilizer is characterized by containing the following substances in parts by weight: 25-30 parts of mica powder, 15-20 parts of ammonium nitrate, 10-15 parts of diammonium phosphate, 5-9 parts of calcium dihydrogen phosphate, 10-20 parts of wheat straw powder, 12-15 parts of peanut straw powder, 15-19 parts of mung bean stalk powder, 1-3 parts of humic acid, 0.1-0.3 part of amino acid, 0.3-0.6 part of chitin, 15-20 parts of peanut cakes, 15-20 parts of castor cakes, 2-4 parts of potassium polymetaphosphate, 3-8 parts of potassium pyrophosphate, 4-8 parts of sodium aluminum phosphate, 0.1-0.2 part of nitrobacterium powder, 0.1-0.2 part of rhizobium powder, 3-6 parts of zinc sulfate and 2-5 parts of sepiolite. The biomass fertilizer is reasonable in formula and balanced in nutrition, is safe and pollution-free and fully meets the short / long-term nutrient requirements of the tea trees, balanced fertilization can be achieved, the soil can be improved, the environment can be protected, the yield of tea can be effectively increased, and the quality of the tea can be effectively improved.

Owner:QINGDAO LAOXIANG TEA PROD

Organic microbial fertilizer

InactiveCN105622285AImprove the environmentPromote healthy and sustainable developmentFertilizer mixturesBiotechnologyFeces

The invention discloses an organic microbial fertilizer. The organic microbial fertilizer is prepared from, by weight, 26-35 parts of livestock and poultry night soil, 13-18 parts of sweet potato flour, 10-17 parts of wheat middling, 25-40 parts of straws, 30-40 parts of peat soil, 25-35 parts of weathered coal, 10-15 parts of mushrooms, 10-15 parts of algae, 12-16 parts of freshwater mussel powder, 20-30 parts of wood chips, 5-10 parts of honey, 1-2 parts of composite vitamins, 1-3 parts of composite amino acids, 5-8 parts of potassium polymetaphosphate, 1-2 parts of trace elements, 7-13 parts of potassium mineral powder, 10-16 parts of phosphate rock powder, 1-2 parts of humic acid, 5-8 parts of ammonium sulfate, 12-15 parts of borax, 3-7 parts of zinc sulfate, 5-8 parts of sodium carbonate and 7-10 parts of fatty acid acetic anhydride. The organic microbial fertilizer meets nutrition required by growth of crops, improves soil environment, has two purposes, and well promotes the sustainable healthy development of Chinese agriculture production.

Owner:武汉赛润科技有限公司

Process for preparing food-grade potassium metaphosphate by virtue of melting arsenic removal solid potassium dihydrogen phosphate

The invention relates to a process for preparing food-grade potassium metaphosphate by virtue of arsenic removal on molten potassium dihydrogen phosphate. The process comprises the following steps: under a heating and stirring condition, reacting haloid acid with molten potassium dihydrogen phosphate so as to generate an arsonium halide substance with a low boiling point, performing subliming, directly further heating molten potassium dihydrogen phosphate subjected to arsenic removal for dehydration polymerization reaction, thereby obtaining the food-grade potassium metaphosphate. By virtue of adopting the method, the process has the beneficial effects that 1) the method is convenient in operation process, and solid-phase molten potassium dihydrogen phosphate subjected to arsenic removal is capable of facilitating preparation of the food-grade potassium metaphosphate; 2), the arsenic removal process can be connected with a subsequent potassium polymetaphosphate process, and two workshop sections are seamlessly connected, so that heating melting after cooling of the potassium dihydrogen phosphate subjected to arsenic removal can be avoided, and energy losses brought by repeated heating are reduced; 3) the process for preparing the food-grade potassium metaphosphate by virtue of melting arsenic removal on potassium dihydrogen phosphate does not need crystallization and filtration processes and is free from waste water discharge; and 4), the viscosity of the food-grade potassium metaphosphate is up to 6.5mPa.s-15mPa.s.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Compound fertilizer for soil improvement

InactiveCN104387165AImprove qualitySuppression of soil borne diseasesSuperphosphatesAlkali orthophosphate fertiliserBacillus thuringiensisPeat

The invention discloses a compound fertilizer for soil improvement. The compound fertilizer is characterized by containing the following substances in parts by weight: 0.01-0.02 part of azotobacter powder, 21-30 parts of sweet potato flour, 45-50 parts of peat, 9-16 parts of calcium superphosphate, 0.01-0.02 part of bacillus sphaericus powder, 40-50 parts of rice straws, 3-7 parts of potassium polymetaphosphate, 8-13 parts of ammonium dihydrogen phosphate, 0.01-0.02 part of bacillus siliceous, 0.03-0.07 part of bacillus cereus, 6-7 parts of litchi seed, 3-5 parts of shelled cedar seed, 0.001-0.002 part of bacillus thuringiensis, 20-25 parts of chicken manure and 19-26 parts of wheat bran. The compound fertilizer disclosed by the invention integrates production increase, high efficiency, long acting, quality improvement, soil improvement and soil-borne disease inhibition, is low in cost and simple in process, is residue-free and pollution-free and has relatively good popularization and application prospects.

Owner:曲少春

Preparation method of organic microbial fertilizer

InactiveCN107793276AImprove the environmentPromote healthy and sustainable developmentBio-organic fraction processingAnimal corpse fertilisersBiotechnologyAcetic anhydride

The invention discloses a preparation method of an organic microbial fertilizer, comprising: taking 26-35 parts of livestock excrement, 13-18 parts of sweet potato flour, 10-17 parts of flour middling, 25-40 parts of straws, 30-40 parts of peat soil, 25-35 parts of weathered coal, 10-15 parts of mushrooms, 10-15 parts of algae, 12-16 parts of clam powder, 20-30 parts of sawdust, 5-10 parts of molasses, 1-2 parts of vitamin complex, 1-3 parts of amino acid complex, 5-8 parts of potassium polymetaphosphate, 1-2 parts of trace elements, 7-13 parts of potassium ore powder, 10-16 parts of phosphorus ore powder, 1-2 parts of humic acid, 5-8 parts of ammonium sulfate, 12-15 parts of borax, 3-7 parts of zinc sulfate, 5-8 parts of sodium carbonate, and 7-10 parts of fatty acid acetic anhydride. Thedefects such as long fermenting period, short bacterial survival time, poor activity and storage difficulty are well overcome. The organic microbial fertilizer can provide nutrition required by the growth of crops, can also improve soil environment, realizes a double purpose, and can well promote sustainable healthy development of agricultural production of China.

Owner:郭家玉

Method for producing anti-crushing granular sodium tripolyphosphate

The invention provides a method for producing anti-crushing granular sodium tripolyphosphate. The method comprises the following steps: (1) a neutralization reaction: adding water into a neutralization pot for heating, adding soda ash, carrying out stirring to completely dissolve the soda ash, raising the temperature of a formed solution to 40-50 DEG C, slowly adding phosphoric acid under stirring, adjusting the K value of neutralized slurry to 2.8+ / -0.1, then adding potassium metaphosphate and sodium hexametaphosphate, carrying out a reaction for 45 min and then carrying out filtering to obtain viscous slurry for subsequent usage; (2) drying and dehydration: conveying the viscous slurry obtained after neutralization to a drying tower for atomization and dehydration at 130+ / -10 DEG C; and(3) polymerization: sending the dried and dehydrated raw material back to a rotary polymerization furnace for polymerization at 210+ / -10 DEG C so as to obtain the anti-crushing granular sodium tripolyphosphate. The production method provided by the invention has the advantages of low raw material cost, simple process, easy industrialization and easy availability of raw materials; and the preparedgranular sodium tripolyphosphate has high anti-crushing strength and is not damaged in structure during transportation and storage.

Owner:HUBEI XINGFA CHEM GRP CO LTD

Thick-rust-filling-type over-rust treating fluid

InactiveCN104911602AImprove conversion abilityQuick conversionDipotassium hydrogen phosphateBenzoic acid

The invention discloses a thick-rust-filling-type over-rust treating fluid which is composed of the following raw materials: 3-5 parts of sodium alginate, 4-5 parts of sodium benzoate, 5-6 parts of benzoic acid, 5-10 parts of isobutyric acid, 3-5 parts of potassium polymetaphosphate, 5-8 parts of butylated hydroxytoluene, 6-8 parts of butylhydroxy methylbenzene, 7-10 parts of olein, 6-8 parts of dipotassium hydrogen phosphate, 6-8 parts of potassium hydroxide, 8-10 parts of hydrofluoric acid, 6-8 parts of sodium hexametaphosphate, 5-8 parts of disodium hydrogen phosphate, 10-12 parts of citric acid, 10-12 parts of zirconium oxychloride, 8-12 parts of zirconium dioxide, 8-10 parts of ammonium heptamolybdate, 9-12 parts of sodium hydrosulfite, 10-12 parts of boric acid, 6-8 parts of fatty alcohol polyethenoxy ether, 5-6 parts of alkylphenol polyoxyethylene, 40-50 parts of methyl pyrrolidone, 45-50 parts of polyvinyl butyral and 120-150 parts of deionized water. The thick-rust-filling-type over-rust treating fluid can implement quick conversion inside the rust layer even if the rust layer is thick, ensures every part of the rust layer to be completely converted, greatly enhances the conversion effect of the over-rust treating fluid, and enhances the firmness of the chelated film after the thick rust layer is treated.

Owner:司徒建辉

Biological fertilizer for childhood tea tree

InactiveCN103708948AHave side effectsNo side effectsFertilizer mixturesBacillus thuringiensisAdditive ingredient

The invention discloses a biological fertilizer for a childhood tea tree. The biological fertilizer is characterized by comprising the following substances in parts by weight: 25-30 parts of potato straw powder, 45-50 parts of duck manure, 10-12 parts of bean dregs, 2-9 parts of bone meal, 3-6 parts of nitro humic acid, 5-9 parts of potassium chloride, 0.002-0.003 parts of azotobacter powder, 0.001-0.002 parts of phosphorus bacteria powder, 0.001-0.002 parts of potassium bacteria powder, 3-6 parts of powdered rock phosphate, 2-6 parts of potassium ore powder, 15-20 parts of cotton straw powder, 10-20 parts of korean pine wood chips, 10-14 parts of black walnut wood chips, 3-5 parts of ginkgo wood chips, 3-6 parts of oak wood chips, 2-4 parts of potassium polymetaphosphate and 0.001-0.003 parts of bacillus thuringiensis var powder. The biological fertilizer has the beneficial effects that the fertilizer disclosed by the invention contains a plurality of nutrients such as an organic fertilizer, an inorganic fertilizer and the like, is free of toxicity, free of a side effect, free of residue, free of drug resistance and free of environmental pollution, growth of tea is facilitated, the nutritional ingredients required by the tea can be obviously supplied, the tea quality is improved, the content of substances beneficial to a human body in the tea is increased, and the soil can be improved.

Owner:QINGDAO LAOXIANG TEA PROD

A process for preparing food-grade potassium metaphosphate by melting and removing arsenic with solid potassium dihydrogen phosphate

The invention relates to a process for preparing food-grade potassium metaphosphate by virtue of arsenic removal on molten potassium dihydrogen phosphate. The process comprises the following steps: under a heating and stirring condition, reacting haloid acid with molten potassium dihydrogen phosphate so as to generate an arsonium halide substance with a low boiling point, performing subliming, directly further heating molten potassium dihydrogen phosphate subjected to arsenic removal for dehydration polymerization reaction, thereby obtaining the food-grade potassium metaphosphate. By virtue of adopting the method, the process has the beneficial effects that 1) the method is convenient in operation process, and solid-phase molten potassium dihydrogen phosphate subjected to arsenic removal is capable of facilitating preparation of the food-grade potassium metaphosphate; 2), the arsenic removal process can be connected with a subsequent potassium polymetaphosphate process, and two workshop sections are seamlessly connected, so that heating melting after cooling of the potassium dihydrogen phosphate subjected to arsenic removal can be avoided, and energy losses brought by repeated heating are reduced; 3) the process for preparing the food-grade potassium metaphosphate by virtue of melting arsenic removal on potassium dihydrogen phosphate does not need crystallization and filtration processes and is free from waste water discharge; and 4), the viscosity of the food-grade potassium metaphosphate is up to 6.5mPa.s-15mPa.s.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Biological fertilizer for removing alkalis and restraining salts

InactiveCN104402591AImproved generation sourceRaise the pHAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersMiddle medullaPhosphate

A disclosed biological fertilizer for removing alkalis and restraining salts is characterized by comprising the following substances in parts by weight: 60-70 parts of peat, 150-200 parts of corn straw, 9-11 parts of semen cassiae, 2-8 parts of medulla junci, 12-23 parts of potassium polymetaphosphate, 12-25 parts of ammonium bicarbonate, 12-20 parts of rock phosphate powder, 0.1-0.2 part of polypeptide, 1-2 parts of nitrogen, phosphor and potassium elements, 2-8 parts of potassium dihydrogen phosphate, 11-13 parts of diammonium hydrogenphosphate, 1-3 parts of calcium dihydrogen phosphate, and 1-2 parts of boric acid. The biological fertilizer possesses the effects of both inorganic and organic fertilizers, relatively effectively radically improves the generation source of soil organic microbes and soil acid-base property, and also is capable of generating active substances, stimulating crop growth and immobilizing nitrogen in air.

Owner:曲少春

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com