Patents

Literature

57 results about "Tribasic potassium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

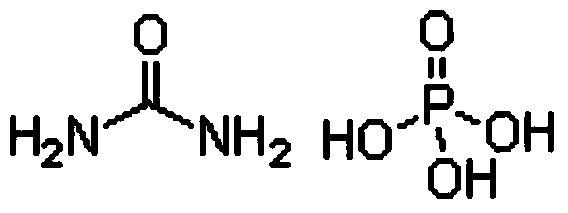

Tripotassium phosphate, also called potassium phosphate tribasic, is a water-soluble ionic salt which has the chemical formula K3PO4.

Methods for coagulating collagen using phosphate brine solutions

InactiveUS7078068B2Shorten drying timePhosphatesPeptide/protein ingredientsDisodium phosphateDipotassium phosphate

Owner:ICL PERFORMANCE PROD

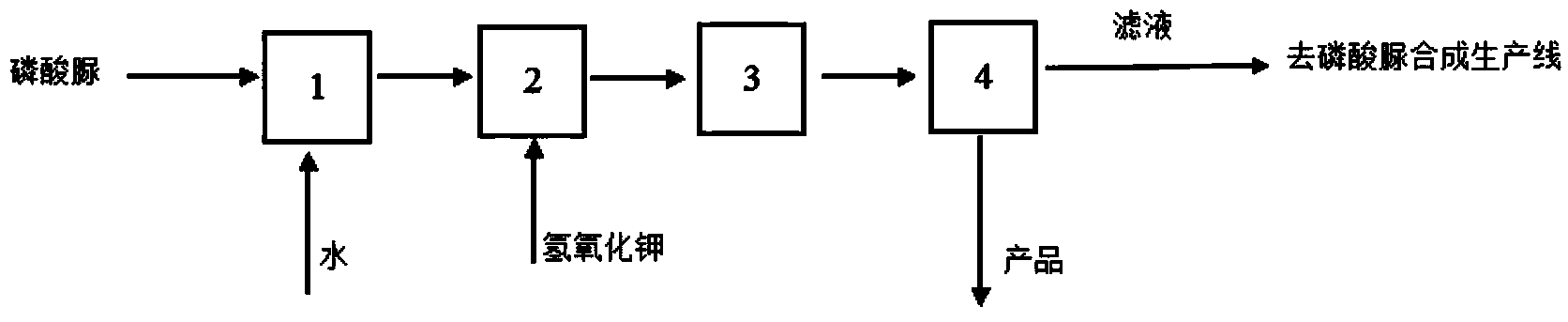

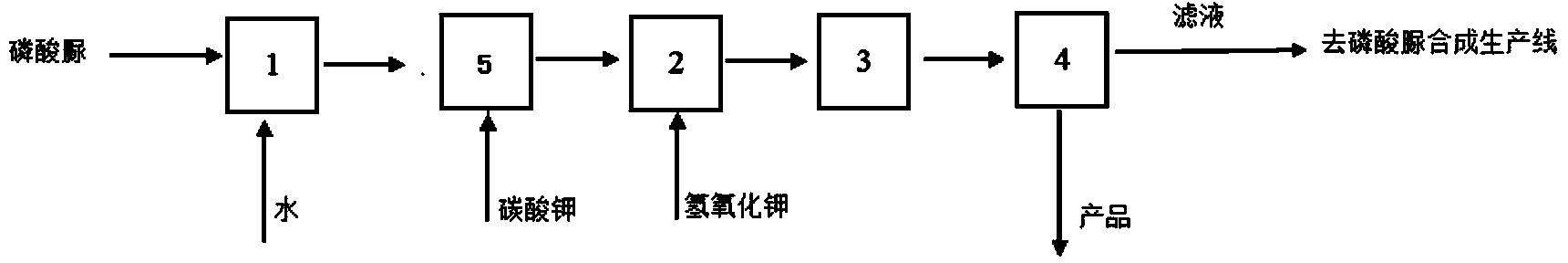

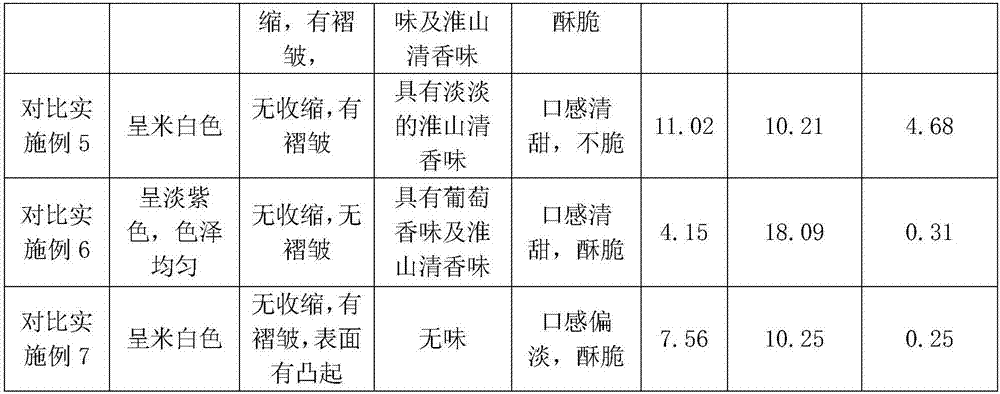

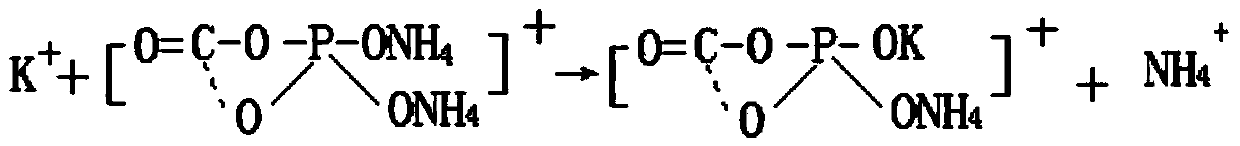

Production method for tripotassium phosphate

InactiveCN104016324AReduce manufacturing costEasy to getPhosphorus compoundsHigh energyPotassium hydroxide

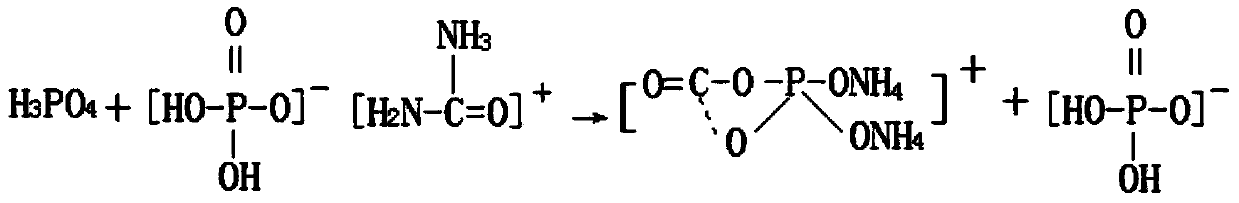

The invention relates to the technical field of chemical engineering, and particularly relates to a production method for tripotassium phosphate. A tripotassium phosphate product is prepared by directly reacting urea phosphate and potassium hydroxide according to a molar ratio of 1: 2.95-3.05 for 30-60 min at a reaction temperature of 40-80 DEG C, with stirring at a stirring speed of 30 r / min. The tripotassium phosphate product is prepared by directly reacting urea phosphate and potassium hydroxide, so that the whole process has no requirements for high energy consumption; raw materials can be obtained relatively easily; a process route is short and simple; and production cost of tripotassium phosphate is reduced. By adjusting the process route and controlling reaction conditions, the produced tripotassium phosphate completely meets a first level standard of industrial tripotassium phosphate.

Owner:GUIYANG KAILIN FERTILIZER CO LTD +1

Method for preparing light porous particle controlled release fertilizer

ActiveCN104262005AImprove water absorptionGood fertilizer effectAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphateDipotassium phosphate

The invention discloses a method for preparing a light porous particle controlled release fertilizer. The method comprises the following steps: uniformly mixing CRT screen glass powder, 5-20 percent of monopotassium phosphate, dipotassium phosphate, potassium sulfate, tripotassium phosphate, potassium chloride, zinc dihydrogen phosphate, diammonium hydrogen phosphate, ammonium dihydrogen phosphate, cobalt oxide and manganese oxide, pressing, molding, feeding the mixture into a roller kiln at the temperature of 650-660 DEG C, and preserving the temperature to be 780-790 DEG C for 15-30 minutes; and reducing the temperature to be 50-80 DEG C or below at a rate of 100-200 DEG C per minute, thereby obtaining the light porous particle controlled release fertilizer. The light porous particle controlled release fertilizer prepared by the invention can be widely applied to the fields of indoor horticulture, urban gardening, street planting and farmlands. The preparation process is simple in operating process and low in cost, the production cost of the controlled release fertilizer can be effectively reduced, the environment is protected, wastes are changed into valuable materials, and the light porous particle controlled release fertilizer is suitable for large-scale industrial production and has obvious economic benefits and environmental protection benefits.

Owner:广西丰岭肥业有限公司

Delayed coagulation method of kalium-based magnesium phosphate cement

ActiveCN102659450AEffective adjustment of clotting timeControllable clotting timeMagnesium phosphatePotassium

The invention discloses a delayed coagulation method of kalium-based magnesium phosphate cement, and aims to delay the coagulating time of the magnesium phosphate cement to improve hydration degree and mechanical property of the cement. The delayed coagulation method includes the steps of firstly, adding water in alkaline phosphate to dissolve the same and secondly, adding kalium-based magnesium phosphate cement into the alkaline phosphate solution. The doping mass of the alkaline phosphate accounts for 2-6% of mass of magnesium compound, potassium phosphate and boron oxide in the kalium-based magnesium phosphate cement. By the aid of dipotassium phosphate, coagulating time of the magnesium phosphate cement can be optionally adjusted in 20 minutes to 50 minutes, and the magnesium phosphate cement can be suitably used as quick repair material for civil structures at normal temperature. By the aid of tripotassium phosphate, the coagulating time of the kalium-based magnesium phosphate cement can be optionally adjusted in 40 minutes to 2.5 hours, and the kalium-based magnesium phosphate cement is suitable for various projects at normal and high temperatures.

Owner:NANJING UNIV OF TECH

Composite plant active beverage capable of treating gout and manufacturing method thereof

InactiveCN108159312AImprove biological enzyme activityEfficientOrganic active ingredientsDispersion deliverySodium bicarbonateTreatment effect

The invention discloses a composite plant active beverage capable of treating gout and a manufacturing method thereof. The main material of the beverage is composed of following components in percentage by weight: 5 to 25% of endive, 5 to 25% of root of kudzu vine, 5 to 25% of cape jasmine, 5 to 25% of wolfberry, 5 to 25% of coix seed, 5 to 25% of lily, 5 to 25% of mulberry leaf, and 5 to 25% of licorice root. The auxiliary material is added into a water stock solution and comprises following components in percentage by weight: 2 to 10% of potassium carbonate, 2 to 10% of tripotassium phosphate, 2 to 10% of sea salt, 2 to 10% of sodium hydroxide, 2 to 10% of sodium bicarbonate, 0.5 to 5% of magnesium gluconate, 0.5 to 5% of zinc gluconate, and 0.5 to 5% of ferrous gluconate. Based on the functions of plants and Chinese medicine theories, plant active components are made into a water solution, then the water solution is combined with multiple mineral substances and trace elements to prepare the beverage, the beverage can be diluted before drinking, and the curative effect is very good.

Owner:大连美通生物技术有限公司

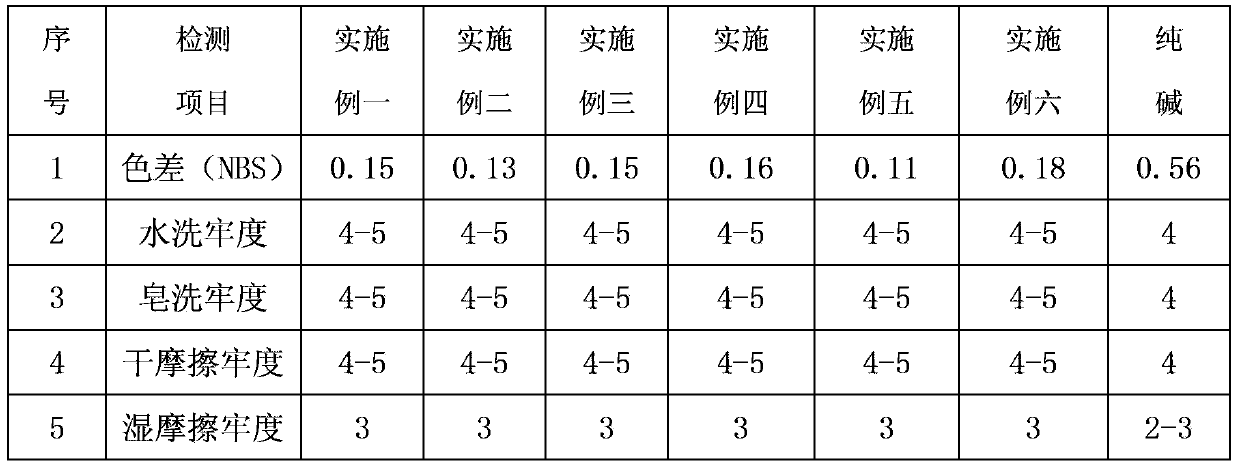

Reactive dye accelerant and preparation method for same

The invention discloses a reactive dye accelerant. The reactive dye accelerant is characterized by comprising, in parts by weight, 18-22 parts of granular sodium hydroxide, 9-13 parts of trisodium phosphate, 16-18 parts of tripotassium phosphate, 7-9 parts of sodium metasilicate, 40-55 parts of sodium carbonate, 5-10 parts of sodium lignin sulfonate, and 1-3 parts of an ionic liquid. The preparation method comprises the following steps of: pouring raw materials in a stirring kettle according to the proportion, stirring for 5-15 minutes at a speed of 20-40 r / min and in the condition of a temperature of 20-30 DEG C, and then obtaining the reactive dye accelerant. The reactive dye accelerant has the advantages of being capable of promoting the level dyeing of a reactive dye and increasing the colour yield of the reactive dye, thus improving the fastness of a dyed product and reducing the number of cleaning times of the dyed product, and beneficial to reduce the labour intensity of workers, reduce the cost of a dyeing process, and reduce pollution to environment; meanwhile, the reactive dye accelerant is convenient to dissolve, suitable for various reactive dyes and various equipment, and simple in preparation method.

Owner:NINGBO JIANGBEI DONGLI AUX CHEM

Alkaline Antioxidant Mineral Water

InactiveUS20130122150A1Beneficial to human healthEasy to operatePackagingBeer brewingSea saltAmino acid

An alkaline antioxidant mineral water comprises tripotassium phosphate and multiple healthful minerals in water, which is free of chlorine, fluoride, and heavy metals. The alkaline mineral water further includes organic potassium, calcium, zinc, magnesium, selenium and 79 trace minerals from ancient sea salt. The trace minerals are taken from the low-sodium technically-processed magnesium chloride marine deposits and chelated with amino acids. The amino acids are obtained from a non-animal source which is suitable for vegetarian and persons who are allergic to animal proteins. The alkaline antioxidant mineral water neutralizes and eliminates the excess acids in human body, thus improving blood circulation. In addition, it provides electrolytes and minerals, which are beneficial to human body.

Owner:KIM ROBERT

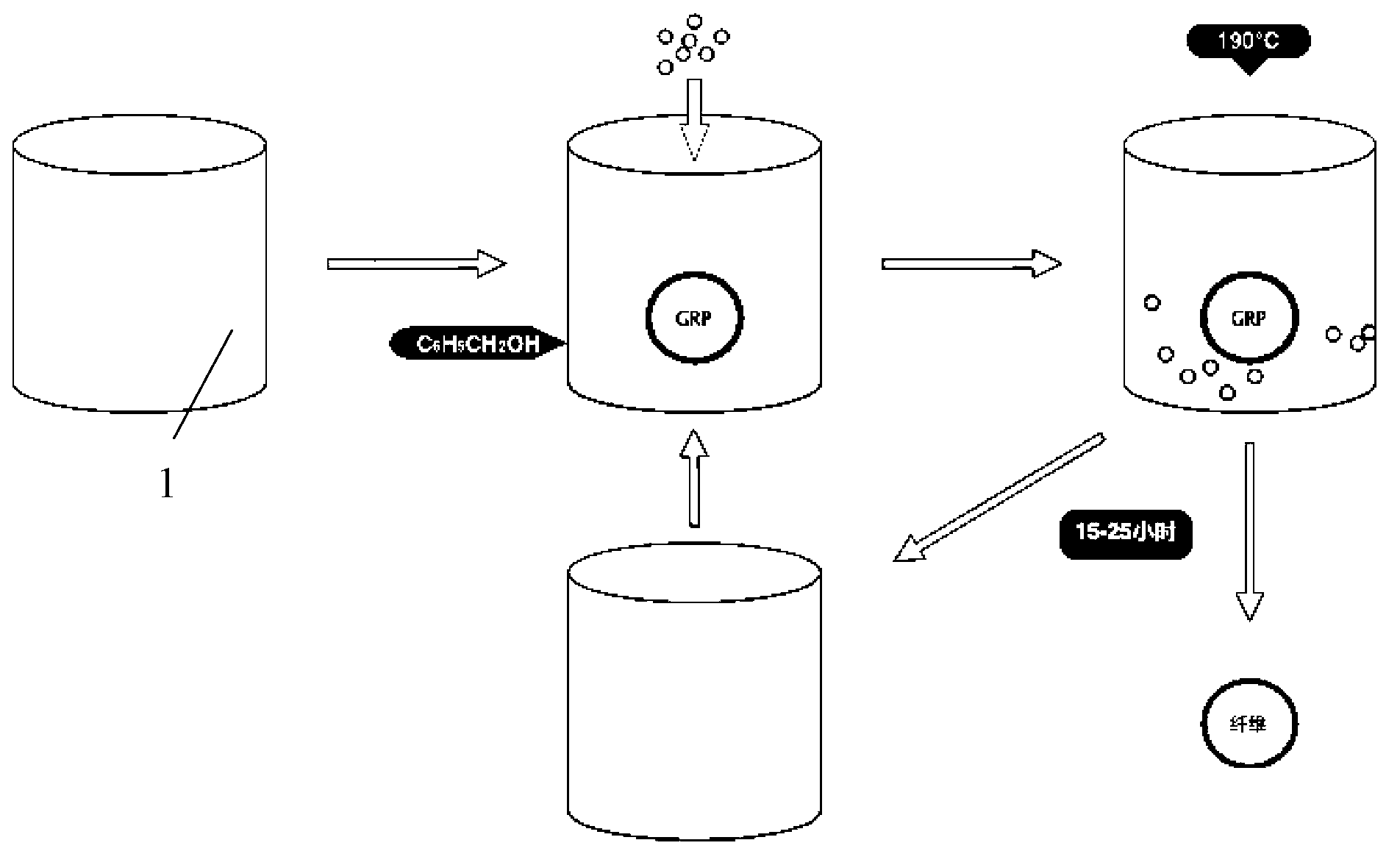

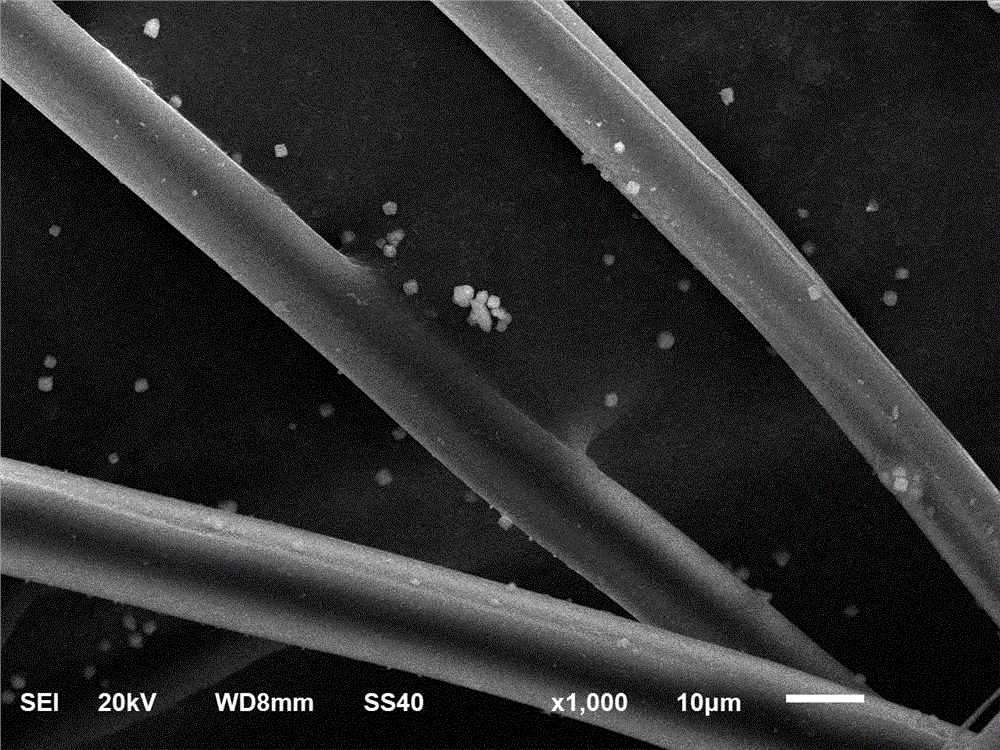

Degradation method of resin matrix glass fiber reinforced plastic composite materials

InactiveCN102838776AAdvantages of degradation methodLow costGlass making apparatusProductsGlass fiberFood additive

The invention provides a degradation method of resin matrix glass fiber reinforced plastic composite materials. The resin matrix glass fiber reinforced plastic composite materials are soaked in benzyl alcohol serving as a solvent under an ordinary pressure, simultaneously tripotassium phosphate is added to serve as a catalyst, then treatment is carried out at a temperature of 190 DEG C for 15-25 hours, and the resin matrix glass fiber reinforced plastic composite materials are degraded into glass fibers and resin. The degradation method of resin matrix glass fiber reinforced plastic composite materials has the following advantages: (1) the used degradation material benzyl alcohol is a food additive, is non-toxic, free of harm, low in cost and wide in source; (2) a degradation process is carried out under the ordinary pressure and has low requirements on equipment; (3) the degradation solvent and the catalyst can be repeatedly used so that the treatment cost is low; and (4) the degradation process cannot damage components in the resin matrix glass fiber reinforced plastic composite materials, such as the glass fibers, can recover the components, and can be used in fields with low strength requirements.

Owner:天津市天联滨海复合材料有限公司

Organic granular water-soluble fertilizer and preparation method thereof

InactiveCN107986876AIncrease profitAvoid cloggingMagnesium fertilisersAlkali orthophosphate fertiliserPhosphateWater insoluble

The invention provides organic granular water-soluble fertilizer and a preparation method thereof, and relates to the field of fertilizer. The organic granular water-soluble fertilizer comprises the following components in parts by weight: 65 to 70 percent of ammonium sulfate, 9 to 14 percent of urea, 5 to 10 percent of potassium nitrate, 5 to 6 percent of monoammonium phosphate, 2.5 to 5 percentof potassium fulvic acid, 3 to 4.5 percent of magnesium sulfate, 1.5 to 2 percent of molasses liquid, 0.2 to 1.2 percent of trace element, 0.5 to 5 percent of tripotassium phosphate and 0.5 to 2 percent of ethanediamine sodium dio-phenyl acetate. The organic granular water-soluble fertilizer has rich and balanced nutrition, and can effectively reduce the water-insoluble matter content, rapidly increase the dissolution speed, increase the utilization rate of the fertilizer and avoid blockage of a drop irrigation pipeline.

Owner:崔凯

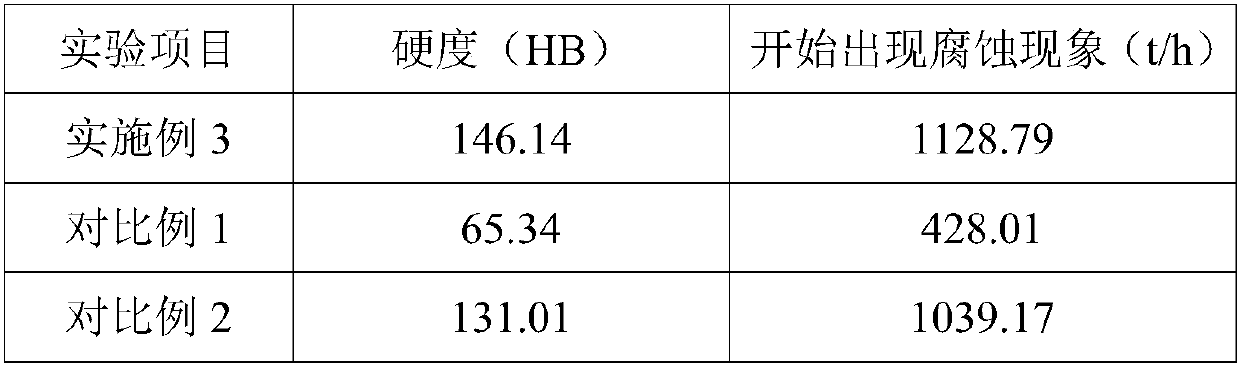

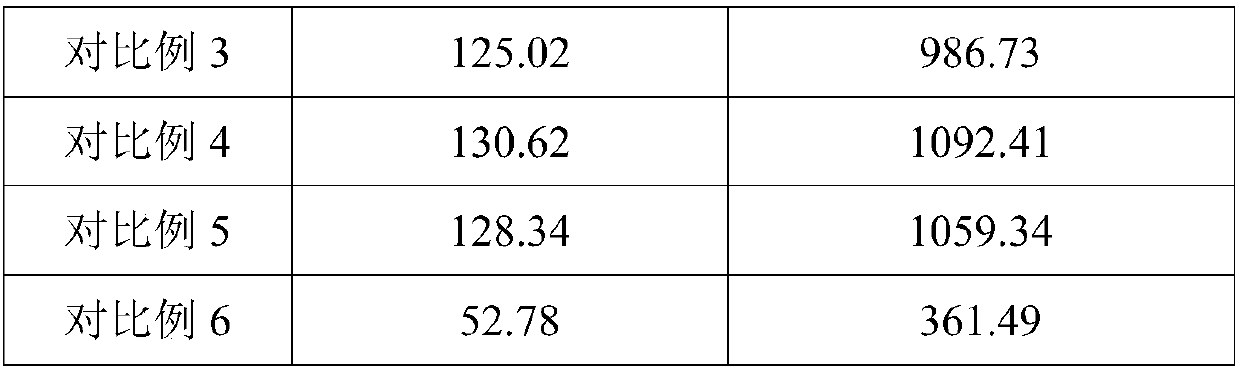

Preparation technique of aluminum alloy material with good oxidation resistance

The invention discloses a preparation technique of an aluminum material with good oxidation resistance, and belongs to the technical field of aluminum alloy material preparation. Raw materials of thealuminum alloy material with good oxidation resistance comprises aluminum, yttrium oxide, praseodymium oxide, copper, iron, cobalt, beryllium, magnesium, titanium, strontium, zinc, chrome, silicon nitride, graphene, tripotassium phosphate, 2-ethyl methacrylate, p-hydroxybenzenesulfonic acid, barium stearate and a 701 power enhancer. The aluminum alloy material with good oxidation resistance is obtained through steps including smelting, refining, casting, press molding and straightening and the like. The aluminum alloy material is high in hardness, oxidation resistance and corrosion resistance.

Owner:广西丰达三维科技有限公司

Corrosion-resisting aluminum alloy material

The invention discloses a corrosion-resisting aluminum alloy material, and belongs to the technical field of aluminum alloy material preparing. The corrosion-resisting aluminum alloy material comprises following raw materials of aluminum, yttrium oxide, praseodymium oxide, copper, iron, cobalt, beryllium, magnesium, titanium, strontium, zinc, chromium, silicon nitride, graphene, tripotassium phosphate, 2-ethyl methacrylate, p-hydroxybenzenesulfonic acid, barium stearate and a 701 powder enhancer. The corrosion-resisting aluminum alloy material is prepared through the steps of smelting, refining, casting, die pressing straightening and the like. The corrosion-resisting aluminum alloy material is high in hardness, and the oxidization resisting performance and the corrosion resisting performance are high.

Owner:广西丰达三维科技有限公司

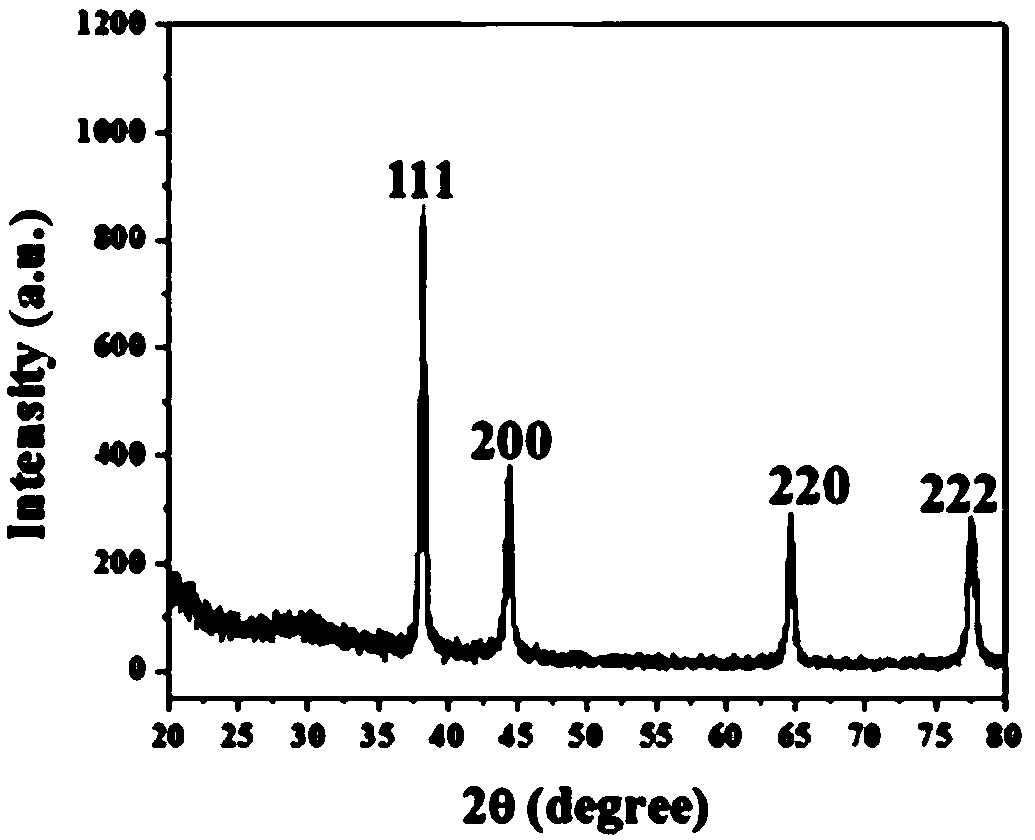

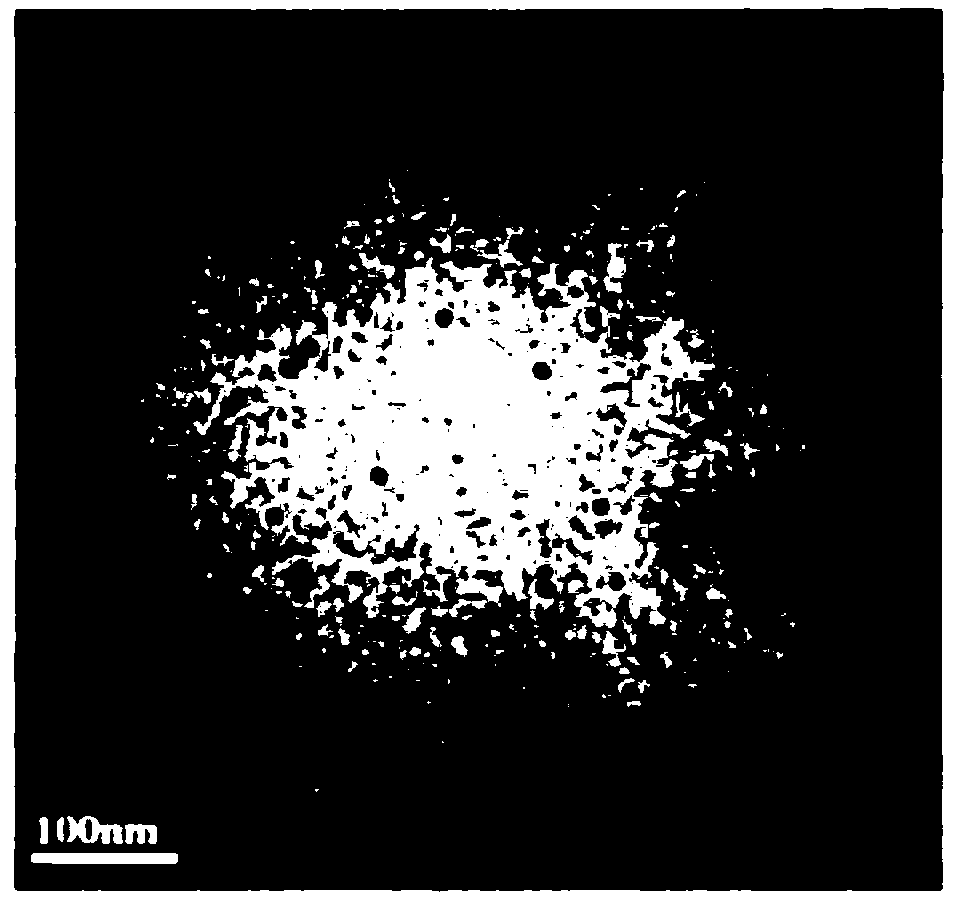

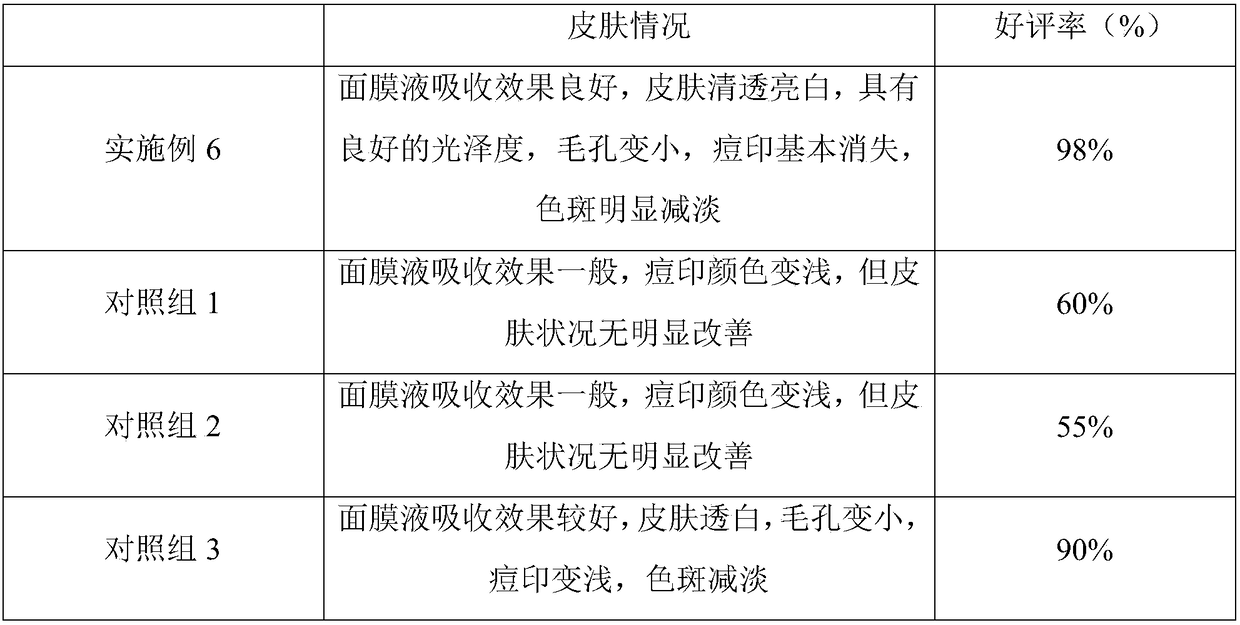

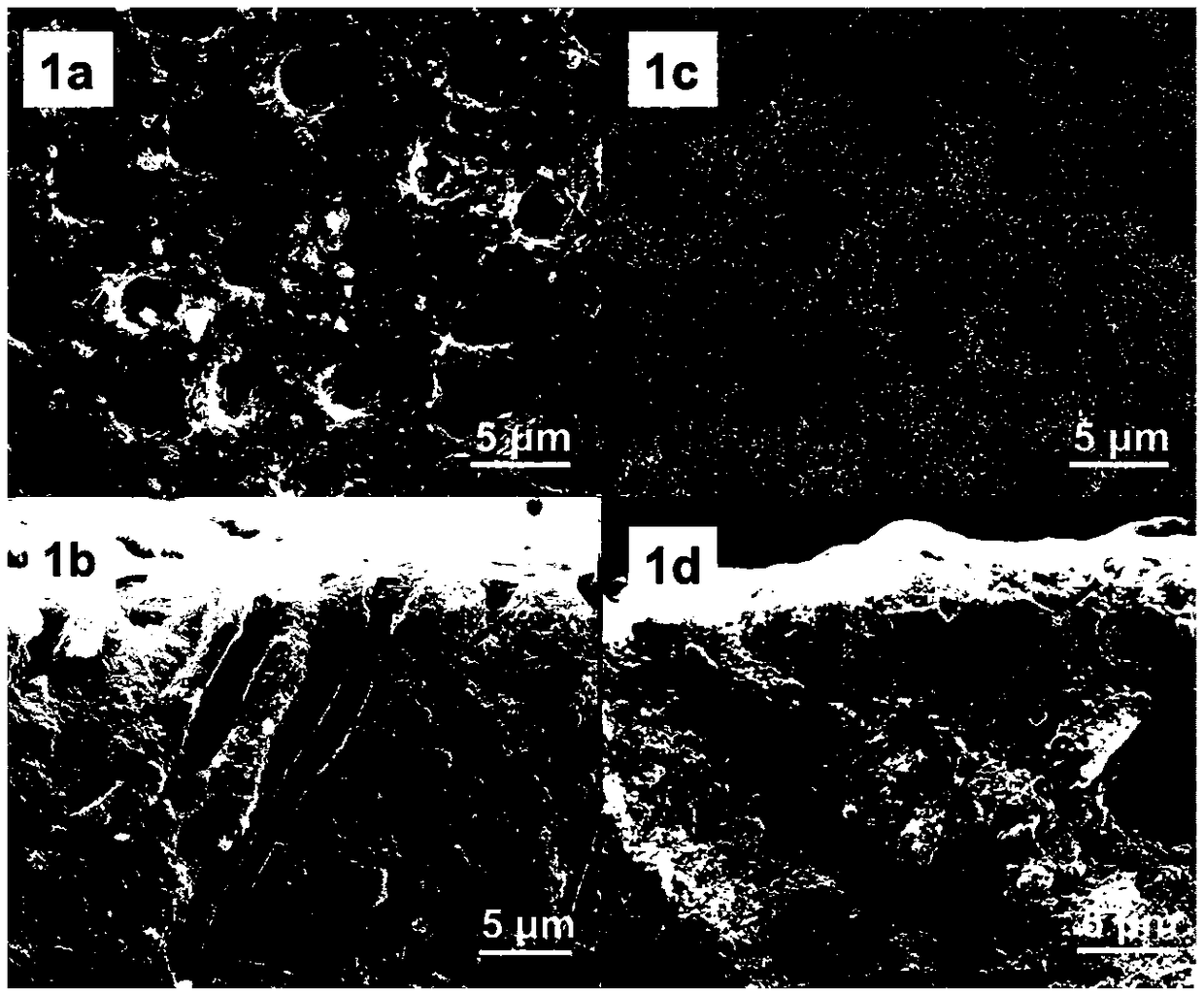

Facial mask liquor containing gold nano negative ion collagen, facial mask and preparation method of facial mask liquor containing gold nano negative ion collagen

InactiveCN109431832ADelay agingAvoid allergiesCosmetic preparationsToilet preparationsSkin colorDeep level

The invention discloses facial mask liquor containing gold nano negative ion collagen, a facial mask and a preparation method of the facial mask liquor containing the gold nano negative ion collagen.The facial mask liquor is prepared from the following raw materials in percentage by weight: 0.1-2% of nano gold, 1-10% of collagen, 5-8% of butanediol, 3-6% of glycerine, 2-5% of sodium hyaluronate,2-5% of polydimethylsiloxane, 1-3% of nicotinamide, 2-5% of vitamin E, 1-4% of ubiquinone, 0.2-2.5% of tripotassium phosphate, 1-4% of essence and the balance of water. While the facial mask disclosedby the invention is attached on a skin surface layer, effective components with functions of moisturizing, whitening,anti-aging and the like in skincare products are also fed to the skin bottom layer, and are very good in affinity with surrounding tissues, so that the skin can be sufficiently moisturized; stains can be faded deeper; a dark and yellow phenomenon of the skin is alleviated; the skinis fair-complexioned, tender, and moisturized from inside to outside; skin cell activity can be quickly improved within only 30 minutes; andthe facial skin is whitened, moisturized, nourished and recovered, and therefore, the facial skin is refreshing, is smooth and tender, is fair-complexioned and compact, and is attractive.

Owner:河南科斗新材料研究院有限公司

DNA (deoxyribonucleic acid) preservation solution for oral swabs and method for preparing DNA preservation solution

The invention discloses DNA (deoxyribonucleic acid) preservation solution for oral swabs. The DNA preservation solution comprises, by weight-to-volume ratio, trihydroxymethyl aminomethane, sodium alginate, tripotassium phosphate, zinc gluconate, ethylene diamine tetraacetic acid disodium, L-carnitine, valine, natural preservatives, vitamin e, normal saline, stevioside, sodium polystyrene sulfonateand sodium dihydrogen phosphate. Deionized water is used as a solvent for the DNA preservation solution. The DNA preservation solution has the advantages that the DNA preservation solution is preservation solution pertinently for the oral swabs, and oral cells can be effectively preserved by the DNA preservation solution; the DNA preservation solution is hygienic, and bacterium breeding can be prevented; the preservation time is longer than 3-5 times the preservation time of envelopes; a method for preparing the DNA preservation solution is simple and has a good social value.

Owner:南京普维康生物科技有限公司

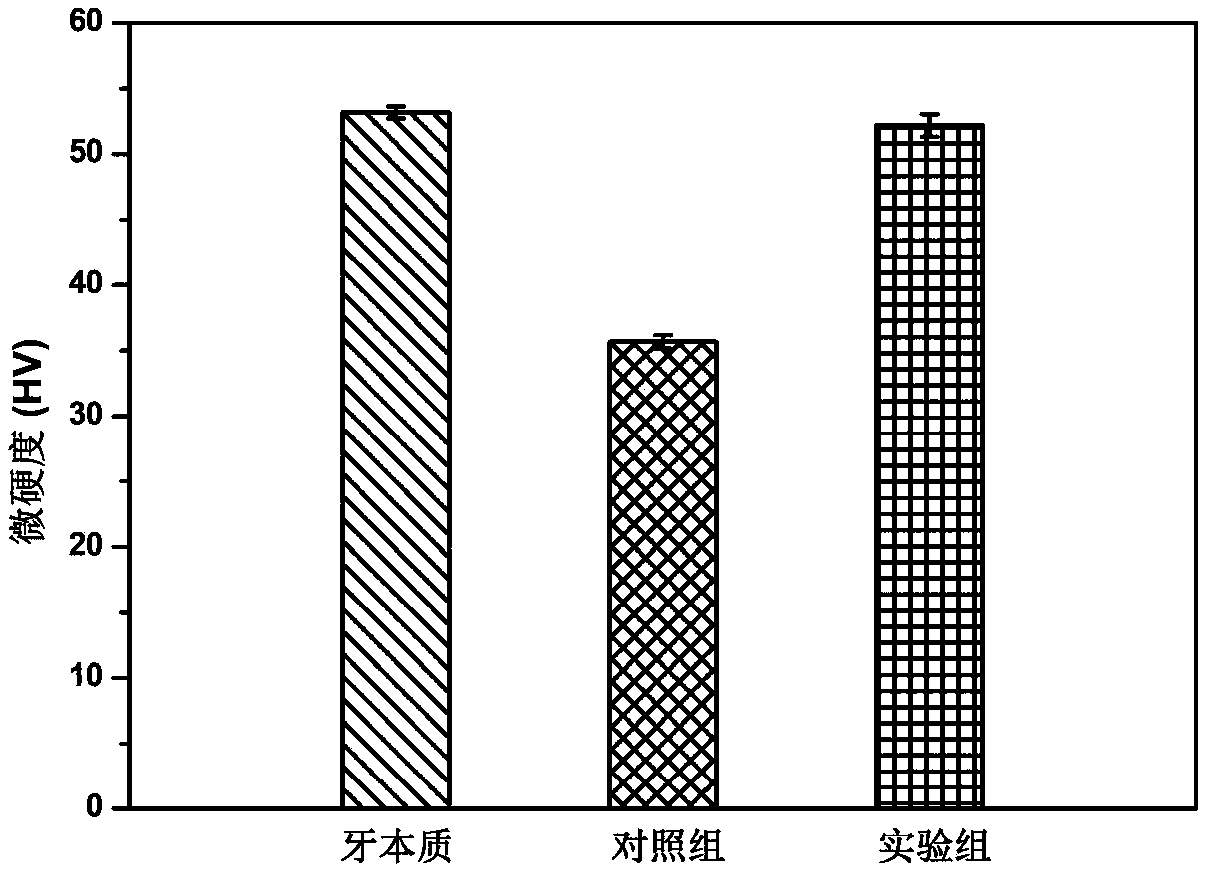

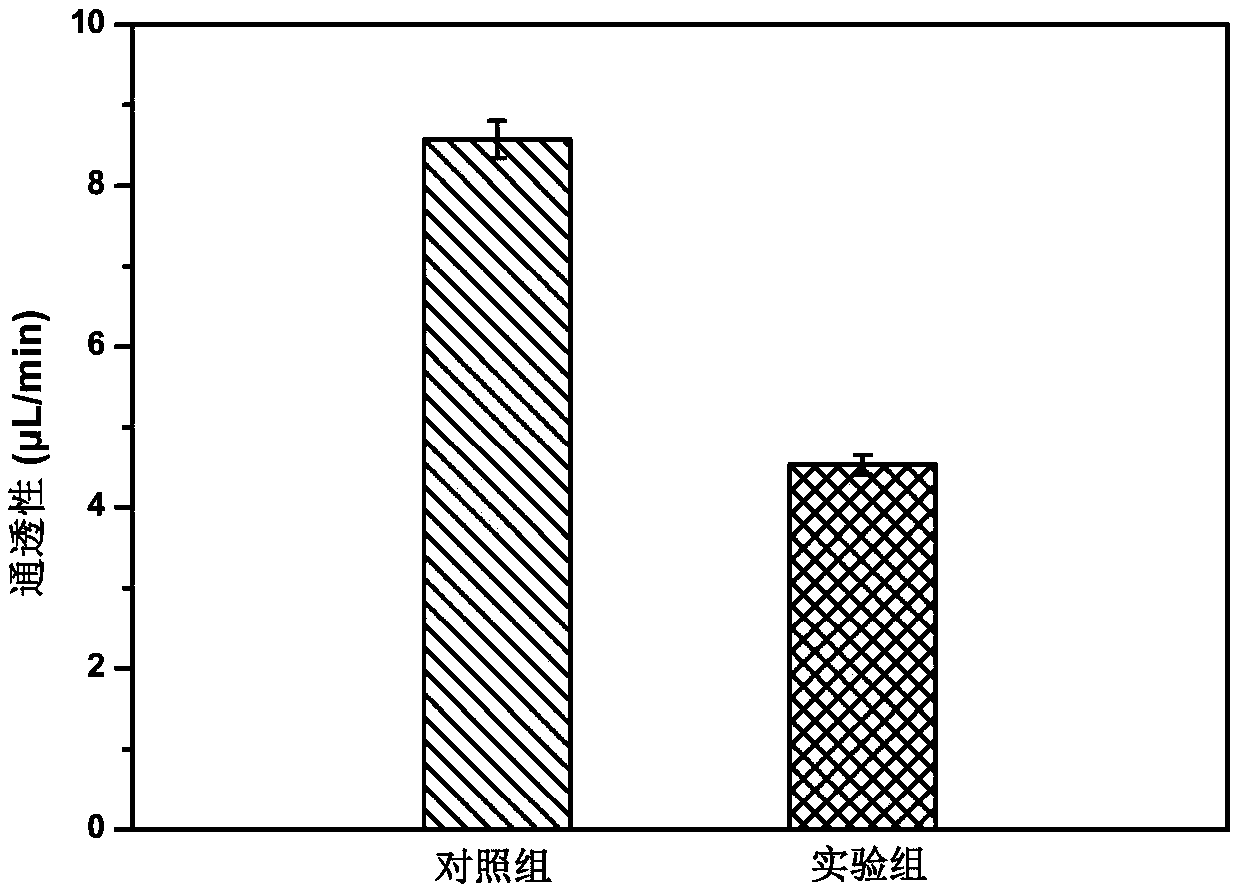

Bionic mineralized repairing desensitizer

InactiveCN108852855ARapid desensitizationLong-acting desensitizationImpression capsMedical preparationsPolyamidePolyethylene glycol

The invention provides a bionic mineralized repairing desensitizer and a using method thereof. The bionic mineralized repairing desensitizer is characterized by comprising 1-100000 ppm dendritic macromolecule, 1%-50% of bioactive glass, 0.1%-20% of tripotassium phosphate, 1%-5% of glycerinum, 30%-70% of polyethylene glycol, 0.5%-8% of xanthan gum, 1%-10% of titanium dioxide, 0.1%-1% of essence, 0.1%-2% of sodium saccharin, 0.1%-1% of ethylparaben, and 1%-8% of lauryl sulfate. The dendritic macromolecule comprises hydroxyl-terminated, carboxyl-terminated, phosphate radical-terminated or amino-terminated 0-5-generation polyamide-amine dendritic macromolecules; and the bioactive glass comprises (CaO)x(NaO2)y(SiO2)z(P2O5)1-x-y-z, wherein x is equal to 0.25-0.45, y is equal to 0-1, and z is equal to 0.34-0.64. The invention further provides a using method of the bionic mineralized repairing desensitizer. The bionic mineralized repairing desensitizer is scraped into a medical device capableof being matched with teeth to be uniformly distributed, and is bitten in a mouth for 1 min and longer, and the medical device comprises a foam denture, a thermoplastic denture and a teeth whitening strip and the like which are seen in the market; and the fact shows that the bionic mineralized repairing desensitizer can close exposed dentin deeply for a long time, so that long-acting desensitization is realized, and the dentin hypersensitivity is relieved.

Owner:成都爱睿康乐医疗器械有限公司

Preparation method of instant and highly-efficient phosphate for food ingredients

InactiveCN110236171AInstantImprove qualityInorganic compound food ingredientsFood dryingDipotassium hydrogen phosphateSodium phosphates

The invention discloses a preparation method of instant and highly-efficient phosphate for food ingredients, and relates to the technical field of phosphate preparation. The preparation method includes the following steps: mixing sodium phosphate monomer, dispersing cosolvent potassium phosphate and water into homogeneous phase material liquid, subjecting the homogeneous phase material liquid to spraying granulation and drying dehydration, and finally obtaining the instant highly-efficient phosphate product for food ingredients. The sodium phosphate monomer is one or two or more than two kinds of monomer sodium phosphate; the dispersing cosolvent potassium phosphate is potassium triphosphate, potassium pyrophosphate, potassium polymetaphosphate, potassium dihydrogen phosphate, dipotassium hydrogen phosphate, tribasic potassium phosphate or potassium polyphosphate; the addition of dispersing cosolvent potassium phosphate accounts for 5%-10% of the total weight of sodium phosphate monomer and dispersing cosolvent potassium phosphate. The product obtained by the method can reach homogeneous phase mixing at the molecular level, and the obtained product is easy to disperse, free of agglomeration or absorption of moisture, good in mouthfeel, excellent in dissolution speed and capable of giving full play to a synergistic effect.

Owner:江苏恒世食品科技有限公司

Alkaline Mineral Booster With Antioxidants

InactiveUS20130122140A1Maximizing health benefitBenefit maximizationAnimal feeding stuffFood shapingDietary supplementAntioxidant

A highly alkaline, ultra-low sodium antioxidant mineral additive of saturated tripotassium phosphate may be used as an additive to dosages such as concentrated drops, tablets, capsules, bottled water, beverages or other dosage forms. The alkaline antioxidant mineral additive further includes organic potassium, calcium, zinc, magnesium, selenium and 79 trace minerals from ancient sea salt. The trace minerals are taken from the low-sodium technically-processed magnesium chloride marine deposits and chelated with amino acids. The amino acids are from a non-animal source which is suitable for vegetarian and persons who are allergic to animal proteins. The alkaline antioxidant mineral additive, which is considered nutritionally nil in sodium content, can be used as a concentrated aqueous drop or dried and used as an additive for dietary supplement dosage forms including tablets, capsules, bottled water, beverages and others.

Owner:KIM ROBERT

Electrolytic method for preparing potassium dihydrogen phosphate

The invention discloses an electrolytic method for preparing potassium dihydrogen phosphate, and is characterized in that a saturated or nearly saturated potassium chloride solution and a dipotassium hydrogen phosphate solution with a concentration of 1-8 mol / L, or a mixed solution of potassium dihydrogen phosphate and dipotassium hydrogen phosphate, or a mixed solution of dipotassium hydrogen phosphate and tripotassium phosphate, or a mixed solution of tripotassium phosphate and potassium hydroxide, are added into an electrolytic tank; under the conditions of a reaction temperature being 40-100 DEG C and an electrolyzing voltage being 2.1-5 V, continuous electrolysis is carried out to obtain a cathode complete solution; through concentration separation, a solid (or a heavy paste) is recycled into the electrolysis system; after a clear solution neutralizes a phosphoric acid, evaporation concentration, cooling crystallization, filtering, and drying are carried out to obtain a product potassium dihydrogen phosphate; a mother solution is neutralized by a catholyte after the electrolysis, and then returns to the electrolytic tank to undergo electrolysis; and at the same time, a chlorine gas and a hydrogen gas are by-products. The method of the invention overcomes the deficiencies of a high reaction temperature, high corrosion of equipment, high environmental pollution of the extraction method, a high material cost, and the like in the traditional complex decomposition method.

Owner:SICHUAN UNIV

Water-soluble fertilizer having effects for dredging pipeline and resisting obstruction used for drip irrigation system and application method thereof

InactiveCN107266205AImprove solubilityAvoid condensationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersDrip irrigationWater soluble

The invention provides a water-soluble fertilizer having effects for dredging pipeline and resisting obstruction used for a drip irrigation system, which belongs to the field of an agricultural fertilizer. The water-soluble fertilizer comprises the following components: 2-7 parts of a chelating agent, 3-8 parts of a pH conditioning agent, 50-95 parts of a scale inhibitor, and 1-1.5 parts of a sanitizing agent; wherein, the scale inhibitor is one or more of potassium pyrophosphate, tripotassium phosphate, ATMP, HEDP sodium salt or PBTCA.Na4; while fertilizing, the water-soluble fertilizer has the effects for dredging pipeline and resisting scales.

Owner:陕西彤山生物科技有限公司

Preparation method of ammonium salt lead storage battery electrolyte

InactiveCN105762420AImprove the level of cleaner productionImprove securityFinal product manufactureLead-acid accumulators constructionButylated hydroxytolueneSodium salt

The invention belongs to the preparation method of ammonium salt lead storage battery electrolyte. The preparation method comprises the following steps: stirring mother liquor under room temperature, and adding EDTA, an anti-ageing agent, 2-mercapto benzimidazole diallyl sulfide, an antioxidant, 2,6-butylated hydroxytoluene, tripotassium phosphate and sodium salt in sequence to prepare a mixed liquor; stirring the mixed liquor until the temperature reaches 40DEG C, and leaving to stand for 30-40 minutes; adding a buffer solution into the mixed liquor for stirring for 10-15 minutes, and leaving to stand for 20-25 minutes; adding pure water into the mixed liquor to dilute until the solution density reaches 1.1-1.3g / cm<3>, stirring for 30 minutes, and leaving to stand for 12 hours to obtain a semi-finished product; feeding the semi-finished product into crystallization equipment to obtain ammonium salt; adding pure water into the ammonium salt to dilute the ammonium salt. The preparation method has the advantages of being simple and reasonable in technological process, effectively improving the cleaning and production level of enterprises, effectively improving the safety performance of lead storage batteries and prolonging the service life of the lead storage batteries.

Owner:HENAN INST OF SCI & TECH

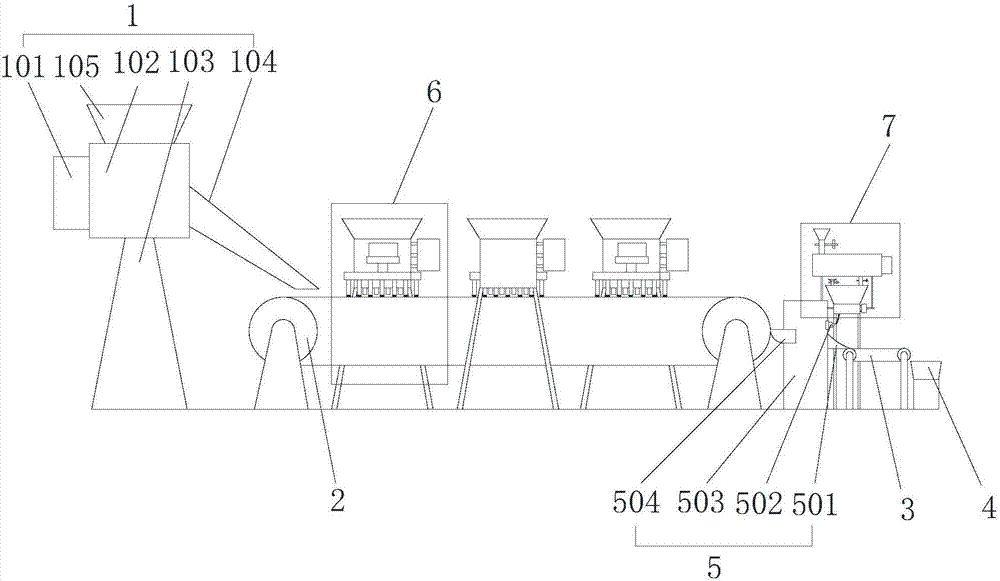

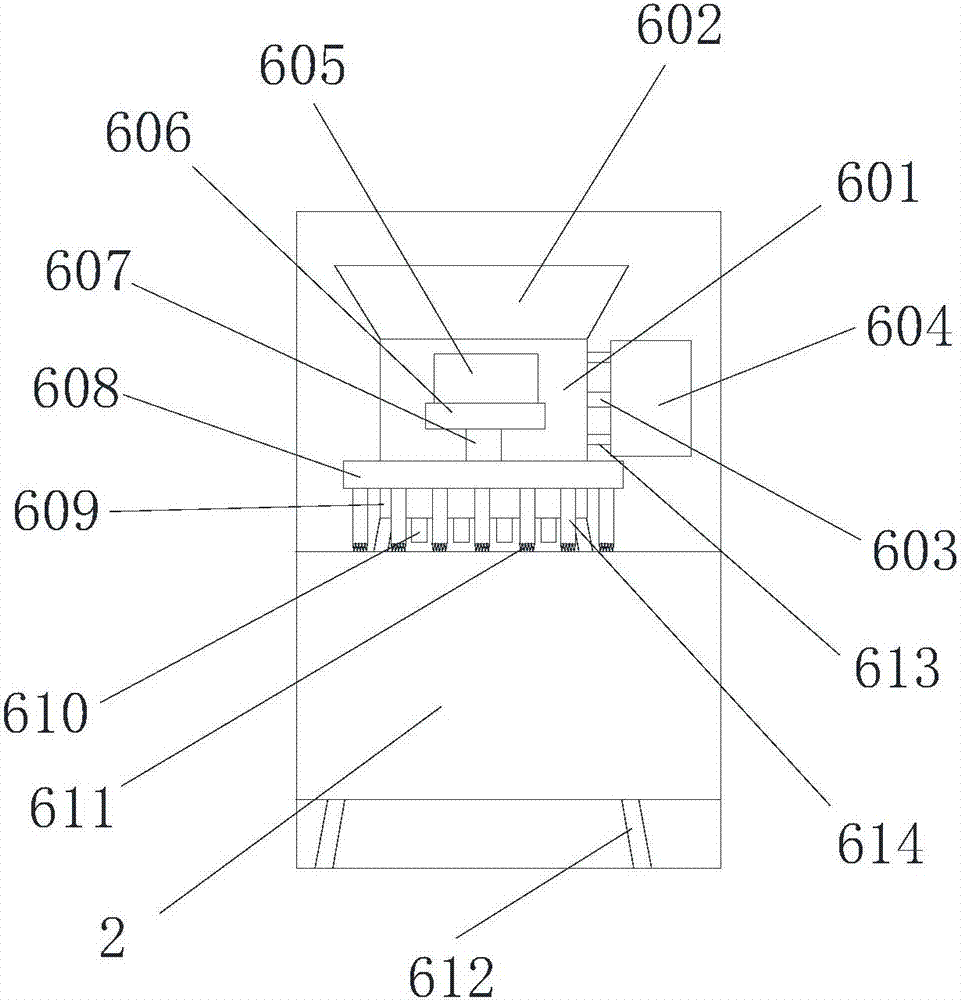

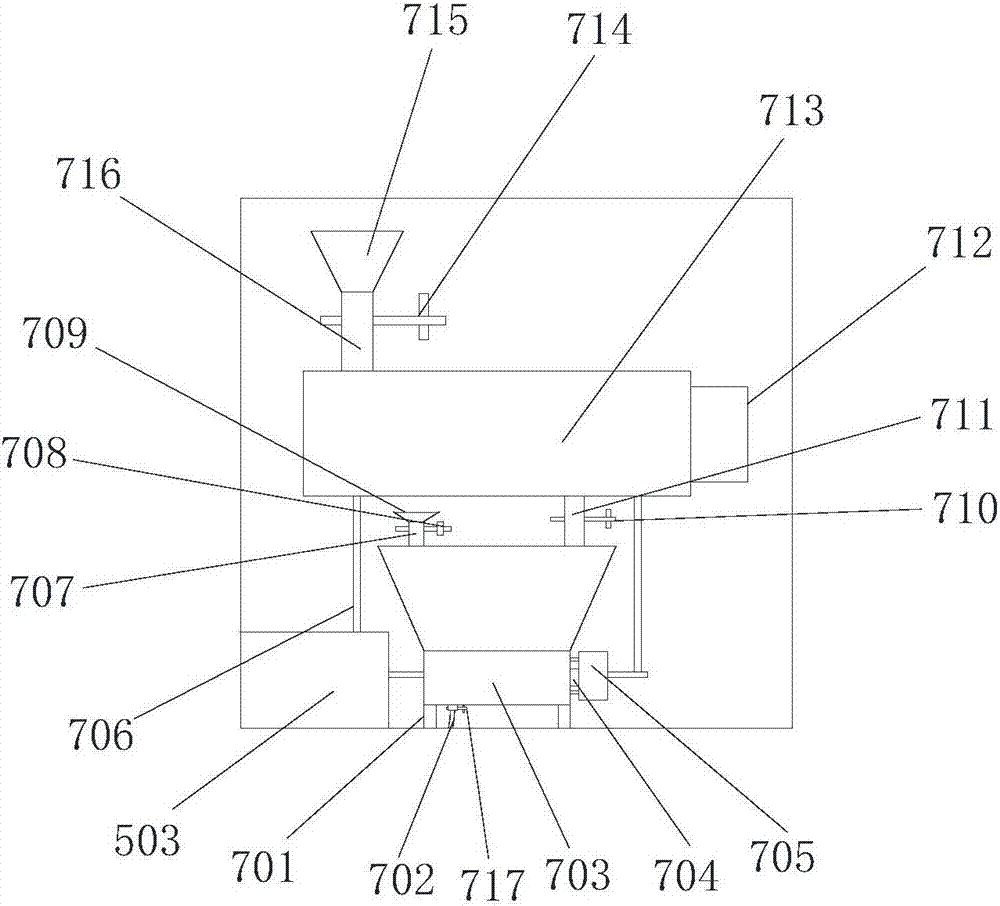

Char-based slow-release compound fertilizer special for cotton and preparation system and method of compound fertilizer

InactiveCN107188721APromote photosynthesisImprove qualityClimate change adaptationAlkali orthophosphate fertiliserNeodymium chlorideEuropium

The invention discloses a char-based slow-release compound fertilizer special for cotton. Raw materials of the fertilizer include urea, a calcium magnesium phosphate fertilizer, a magnesium-potassium sulfate fertilizer, biochar powder, lignin zinc carbonate, disodium octoborate tetrahydrate, manganese chloride, ammonium ferrous sulfate, europium chloride, neodymium chloride and N-phosphorotriamide. The invention further provides a preparation system and method of the compound fertilizer. The preparation method is simple and efficient, and the raw materials are fully mixed and are good in quality. The obtained compound fertilizer is abundant in nutrients, lasting and coordinated in nutrient element release, and high in nutrient utilization efficiency. The fertilizer can improve physical and chemical properties of soil, improve soil fertility, and promote soil microorganism diversity.

Owner:ANHUI SIERTE FERTILIZER IND

Compound nutrient conditioner for roots of plants

InactiveCN106187433AReduce water transpirationImprove drought resistanceMagnesium fertilisersAlkali orthophosphate fertiliserManganese6-Furfurylaminopurine

The invention relates to a compound nutrient conditioner for roots of plants, which includes a liquid A, a liquid B, a liquid C and water according to the mass ratio of 23:18:7:130, wherein the liquid A includes calcium nitrate, ferric chloride, amino acid chelated magnesium and water; the liquid B includes boric acid, ferrous sulfate, tripotassium phosphate, manganese sulfate, copper sulfate, zinc sulfate, ammonium dihydrogen phosphate, ammonium molybdate and water; the liquid C includes gibberellins, 6-furfurylaminopurine, [alpha]-naphthylacetic acid and water. The compound nutrient conditioner contains abundant nutrients, various microelement and growth hormones, is beneficial to scientific fertilization and achieves high quality and high yield.

Owner:江苏挚信花卉发展有限公司

Alkaline booster with antioxidants

InactiveUS20120207883A1Improve buffering effectStimulate kidney 's functionFood preservationAnimal feeding stuffDietary supplementAntioxidant

A highly alkaline, ultra-low sodium solution of saturated tripotassium phosphate may be used as an additive to dosages such as concentrated drops, tablets, capsules, bottled water, beverages or other dosage forms. The additive further includes organic potassium, calcium, zinc, magnesium, selenium and 79 trace minerals from ancient sea salt. The trace minerals are taken from the low-sodium technical magnesium chloride marine deposits and chelated with amino acids. The amino acids are from a non-animal source which is suitable for vegetarian and persons who are allergic to animal proteins. The additive, which is considered nutritionally nil in sodium content, can be used as a concentrated aqueous drop or dried and used as an additive for dietary supplement dosage forms including tablets, capsules, bottled water, beverages and others.

Owner:KIM ROBERT

Aluminum alloy material used for mechanical and electrical products

The invention discloses an aluminum alloy material used for mechanical and electrical products. The aluminum alloy material includes following raw materials including, by weight, 285 parts of aluminum, 10 parts of yttrium oxide, 4 parts of praseodymium oxide, 5 parts of copper, 6 parts of iron, 14 parts of cobalt, 3 parts of beryllium, 12 parts of magnesium, 8 parts of titanium, 6 parts of strontium, 16 parts of zinc, 5 parts of chromium, 18 parts of silicon nitride, 1.5 parts of graphene, 5 parts of tripotassium phosphate, 1.8 parts of 2-ethyl methacrylate, 4.2 parts of phenol-4-sulfonic acid, 3 parts of barium stearate and 2.6 parts of a 701 powder reinforcing agent. The aluminum alloy material used for the mechanical and electrical products is prepared through the steps of smelting, refining, casting, press mould straightening and the like. The aluminum alloy material used for the mechanical and electrical products is high in hardness, high in oxidation resistance and corrosion resistance and capable of being widely applied to the mechanical and electrical products.

Owner:广西丰达三维科技有限公司

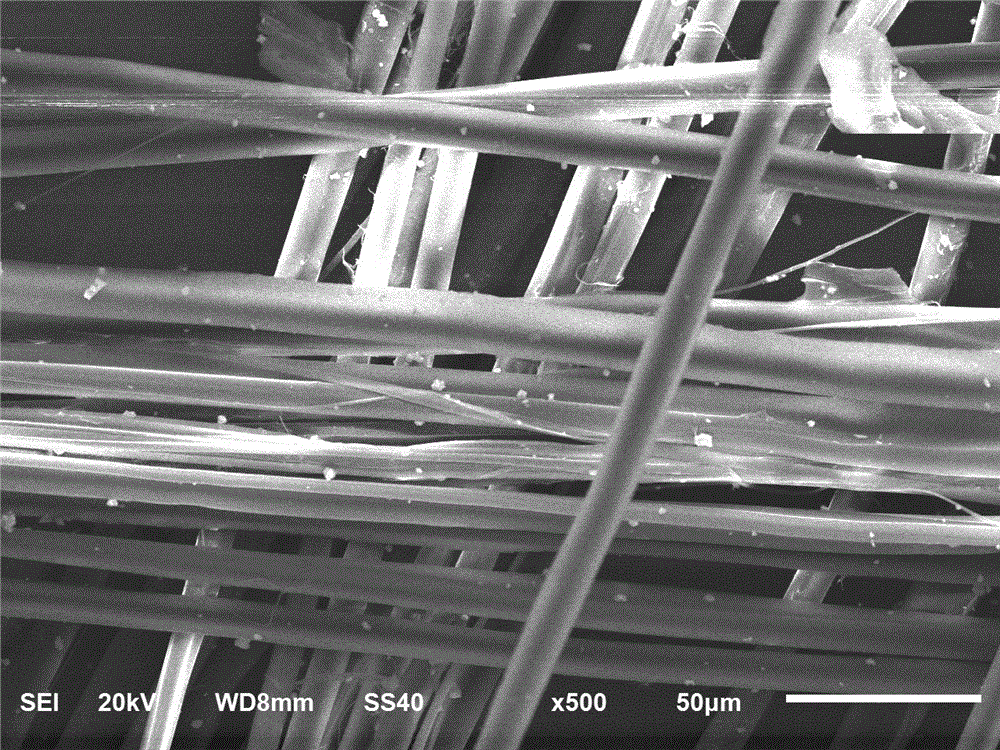

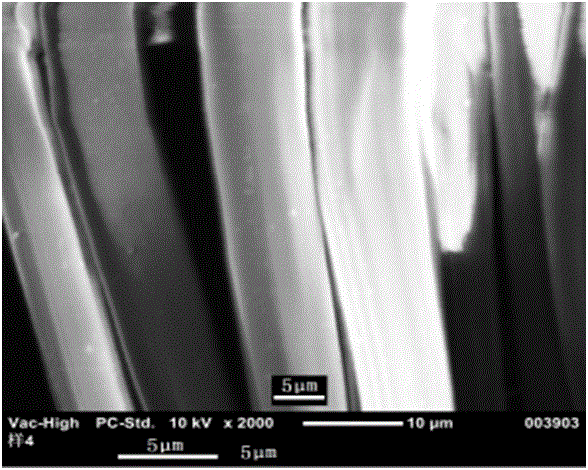

Fiber division method of silk fibroin fibers

The invention belongs to the technical field of preparation of nano materials and relates to a fiber division method of silk fibroin fibers, aiming at solving the problems that a fiber division effect on the silk fibroin fibers is not good when only ultrasonic waves are used so that the yield of the silk fibroin nano fibers keeps a relatively low level all the time. The fiber division method of the silk fibroin fibers comprises the following steps: adding the silk fibroin fibers into a soaking solution and soaking to obtain soaked fibers; carrying out fiber division on the soaked fibers in a treatment solution by using the ultrasonic waves to obtain a rough product; and finally, removing the treatment solution in the rough product to obtain the silk fibroin nano fibers, wherein the soaking solution is a water solution of sodium carbonate and alkali metal phosphate, the treatment solution is the soaking solution or water, the alkali metal phosphate is trisodium phosphate or tripotassium phosphate, and the concentration of the sodium carbonate and the alkali metal phosphate is 0.05%-5%. With the adoption of the technical scheme, the technical problems above can be effectively solved.

Owner:SOUTHWEST UNIVERSITY

Method for removing harmful gas and heavy metal in carbon black tail gas

ActiveCN103203181AAchieve recyclabilityExtended service lifeOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationParticulatesGas heater

The invention discloses a method for removing harmful gas and heavy metal in carbon black tail gas. A catalyst is good in internal recycling effect, and long in service life. The method comprises the steps of: firstly, mixing deadwood, fallen leaves and yeast wastewater according to the ratio, and laying aside for 5-120 hours; taking out the deadwood and fallen leaves in the mixture when the CO2 content released in the mixture is lower than 120-180mg / kg.h; extruding and pelletizing by a squeezing granulator, forming (2-3mm)*(3-5mm) of particulate matters; drying the particulate matters in a microwave dryer and removing 60-80% of moisture; putting into a heat-tube GGH (gas-gas heater) packing chamber, stewing for 3-10 hours to activate in nitrogen of 200-350 DEG C; adding one or more of monopotassium phosphate KH2PO4, dipotassium phosphate K2HPO4, tripotassium phosphate K3PO4 or potassium pyrophosphate K4P2O7 to yeast wastewater, preparing modified yeast water; feeding the improved yeast water into the heat-tube GGH packing chamber at the flow speed of 0.2-0.6m / s from top to bottom, and removing the harmful gas and heavy metal in the carbon black tail gas by the cross action with high-temperature carbon black tail gas at 101-350 DEG C from bottom to top.

Owner:山西永东化工股份有限公司

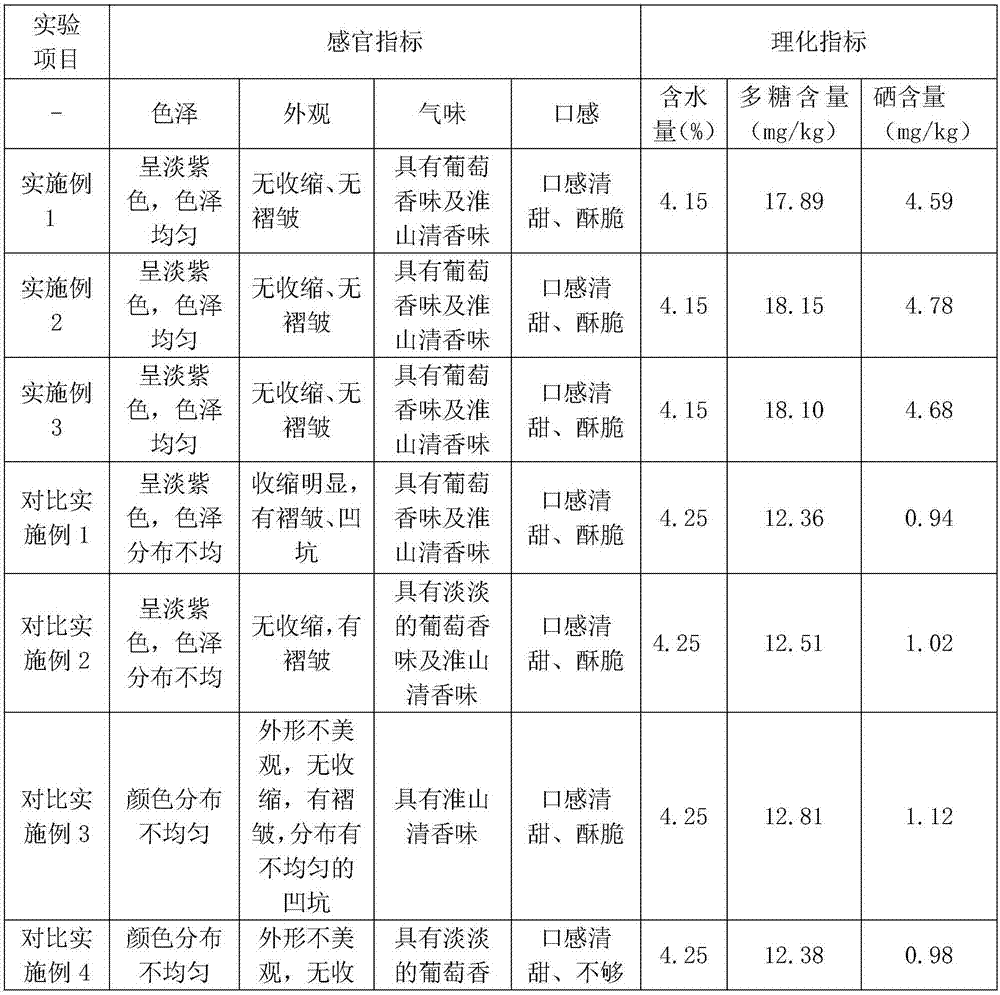

Secondary pretreatment immersion solution and application thereof in preparing selenium-rich instant Chinese yam slices

InactiveCN107361333AIncrease selenium contentImprove surface activityFood ingredient functionsWrinkle skinFatty acid

The invention discloses a secondary pretreatment immersion solution and application thereof in preparing selenium-rich instant Chinese yam slices. The secondary pretreatment immersion solution is prepared from the following raw materials in parts by weight: sucrose esters of fatty acids, glyceryl monostearate, D-mannitol, tripotassium phosphate, propylene glycol and water. The secondary pretreatment immersion solution is applied to preparation of the selenium-rich instant Chinese yam slices, and the sensory indexes and physical and chemical indexes of the prepared selenium-rich instant Chinese yam slices are better than the sensory indexes and physical and chemical indexes of Chinese yam slices prepared in the prior art; and in addition, the selenium-rich instant Chinese yam slices have fresh color, crisp mouthfeel, beautiful and smooth surfaces, no shrinkage, no wrinkles, high selenium content, high nutritional value, low water ratio and convenience in eating.

Owner:钦州市浦北广发食品有限公司

Cleaning agent for remanufacturing mechanical equipment

InactiveCN104403850APrevent rust spotsEasy to cleanSurface-active non-soap compounds and soap mixture detergentsPhosphateHazardous substance

The invention discloses a cleaning agent for remanufacturing mechanical equipment. The cleaning agent comprises the following raw materials in parts by weight: triethanolamine, a surfactant, potassium nitrate, oleic diethanola mide borate ester, phosphate, a degreasing agent, a conditioner for metal surface, sodium gluconate, glycerol, diatomaceous earth, a defoamer, a dispersing agent, a flame retardant and a thickening agent, wherein the defoamer is dimethyl silicone oil; the dispersing agent is polyacrylic acid; the phosphate is one or several kinds of trisodium phosphate, tripotassium phosphate, disodium phosphate, sodium tripolyphosphate or potassium tripolyphosphate; the surfactant is fatty alcohol polyethylene ether, lauryl alcohol ethylamine or alkyl sulfate. The cleaning agent disclosed by the invention is high in cleaning capability and short in cleaning time; labor force is reduced; labor hour is shortened; the working efficiency is improved; the corrosion to the equipment is lower; the reduction of the cost for the equipment is facilitated; oil stains and rusty strains on the surface of the equipment can be thoroughly cleaned; the reforming of the rusty strains on the surface of the mechanical equipment is prevented; the cleaning agent is safe and reliable for use, and no toxic or harmful substances are generated.

Owner:芜湖中艺科技服务有限公司

Sugar increasing and coloring liquid fertilizer and preparation method thereof

InactiveCN109336663APromote growthPrevent evaporationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPotassiumTribasic potassium phosphate

The invention belongs to the technical field of fertilizer production and in particular relates to a sugar increasing and coloring liquid fertilizer and a preparation method thereof. The sugar increasing and coloring liquid fertilizer comprises the following raw materials: 100-180 parts of potassium fulvic acid, 400-550 parts of tripotassium phosphate, 150-220 parts of potassium silicate, 30-50 parts of chloride-free amino acid, 40-60 parts of mint leaves and 10-25 parts of complexed titanium. When being applied to fruits and vegetables to be colored, the sugar increasing and coloring liquid fertilizer provided by the invention is capable of not only well coloring the fruits and vegetables, but also increasing the sugar of the fruits and the vegetables, so that the fruits and the vegetables have naturally mature fruit powder and gloss, and are good in quality.

Owner:郑州启汇果品有限公司

Production method for preparing tripotassium phosphate and by-producing special fertilizer for litchi

InactiveCN104291294AMeets requirementsAvoid pollutionPhosphorus compoundsFertilizer mixturesCollocationChemical industry

The invention relates to the technical field of chemical industry, and particularly relates to a production method for preparing tripotassium phosphate and by-producing a special fertilizer for litchi. According to the production method, the effective absorption amount of nitrogen, phosphorus and potassium elements is analyzed according to the fertilizer requirement of litchi, and element content is regulated and collocated in a production process course, so that a prepared compounded-form compound fertilizer can furthest meet the requirement of the litchi, excessively high cost caused due to improper element collocation in the production of the compound fertilizer is reduced, and environmental pollution caused by that the compound fertilizer is solidified by adding excessive elements to soil is further prevented; and the impurity removal cost needed when a tripotassium phosphate product is prepared by adopting the traditional wet-process phosphoric acid method is made up, so that the purity of the prepared tripotassium phosphate product reaches more than 95%, the production cost is reduced by 93%, and outstanding economic benefit is achieved.

Owner:GUIZHOU KAILIN GRP CO LTD +2

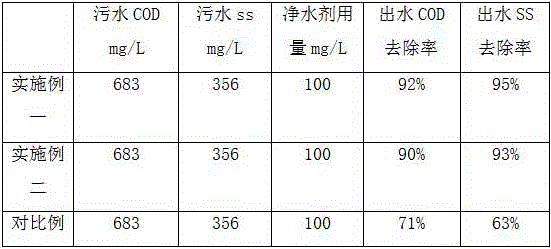

Preparation method of composite flocculant for wastewater purification

InactiveCN105776467ARaw materials are easy to getLow priceWater/sewage treatment by flocculation/precipitationSodium BentoniteSulfate

The invention discloses a preparation method of a composite flocculant for wastewater purification. The composite flocculant is prepared from the following raw materials in parts by weight: 32 to 40 parts of modified bentonite, 18 to 24 parts of a polymeric flocculant, 5 to 12 parts of tripotassium phosphate and 6 to 11 parts of calcium sulfate. The method comprises the following steps: (1) preparing the raw materials in parts by weight; (2) performing homogeneous mixing, namely mixing the modified bentonite and the polymeric flocculant in a high-speed homogeneous mixer, observing mixed granularity distribution under a 1,000* microscope after a certain time, and determining that the mixed granularity distribution is qualified if the mixing homogeneity is equal to or higher than 98 percent; (3) loading the tripotassium phosphate and the calcium sulfate in a ball mill, starting the ball mill for 30 minutes, adding the materials homogeneously mixed in Step (2) in batches after the time, and performing ball milling for 60 to 90 minutes to obtain a water purifying agent. The composite flocculant is high in yield and low in total cost, the preparation and using methods are both simple and easy, and the TDS, electrical conductivity and COD of wastewater can be obviously reduced only with a small dosage of the composite flocculant.

Owner:徐亚萍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com