Patents

Literature

38results about How to "Prevent rust spots" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

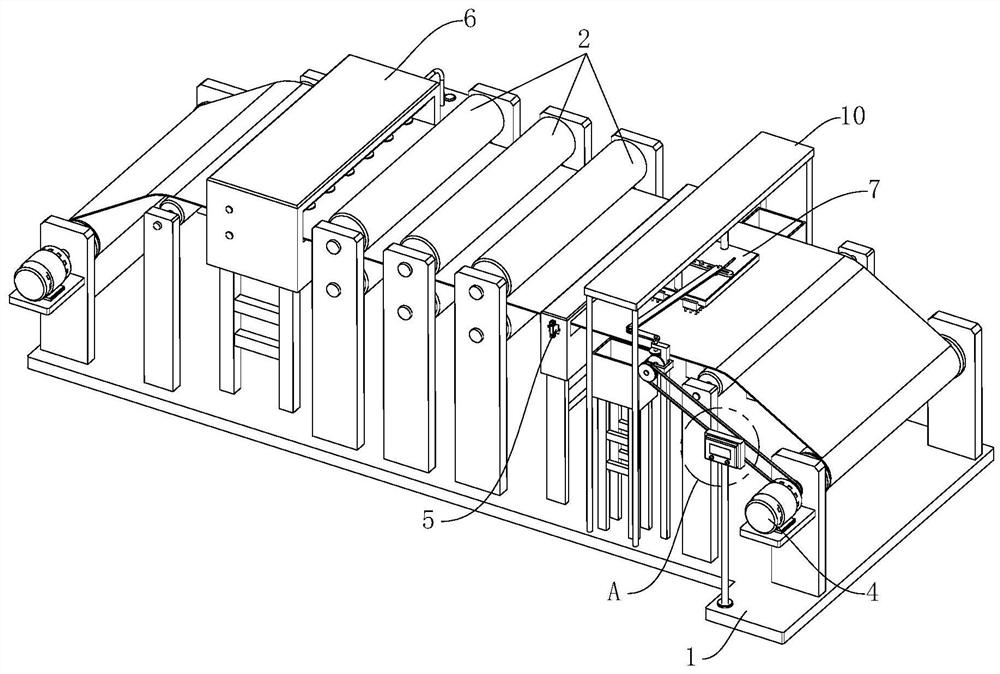

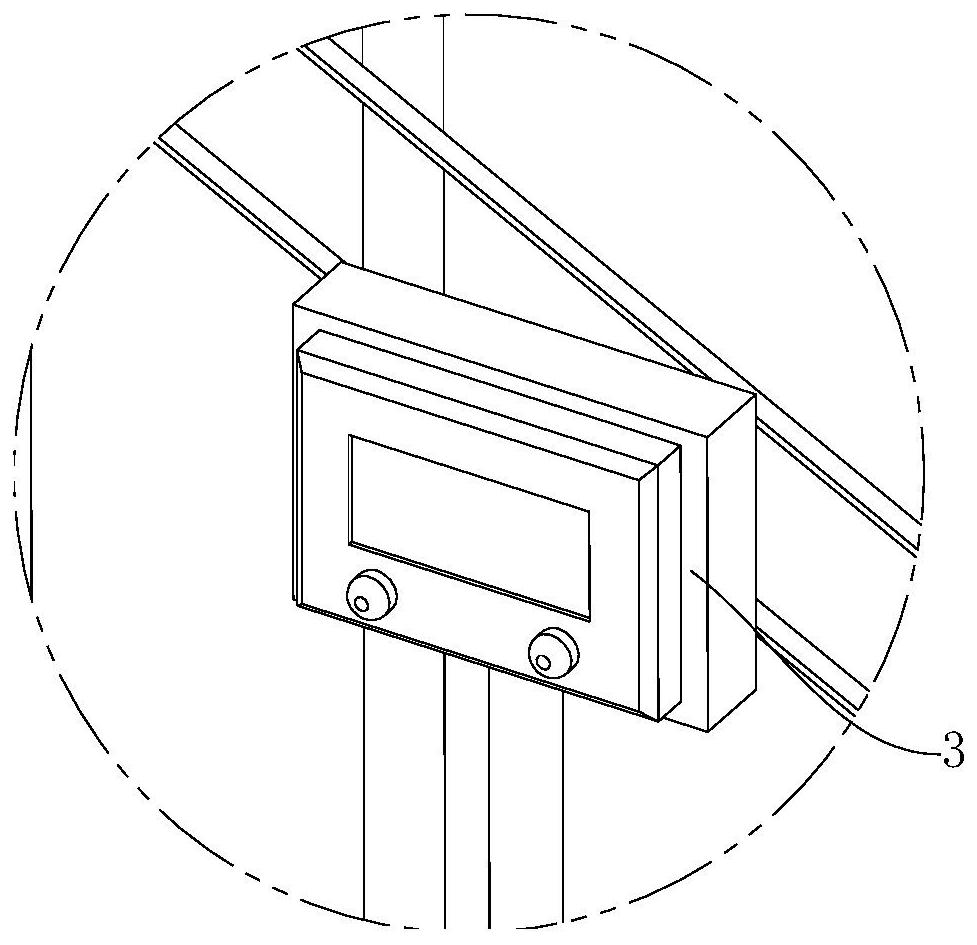

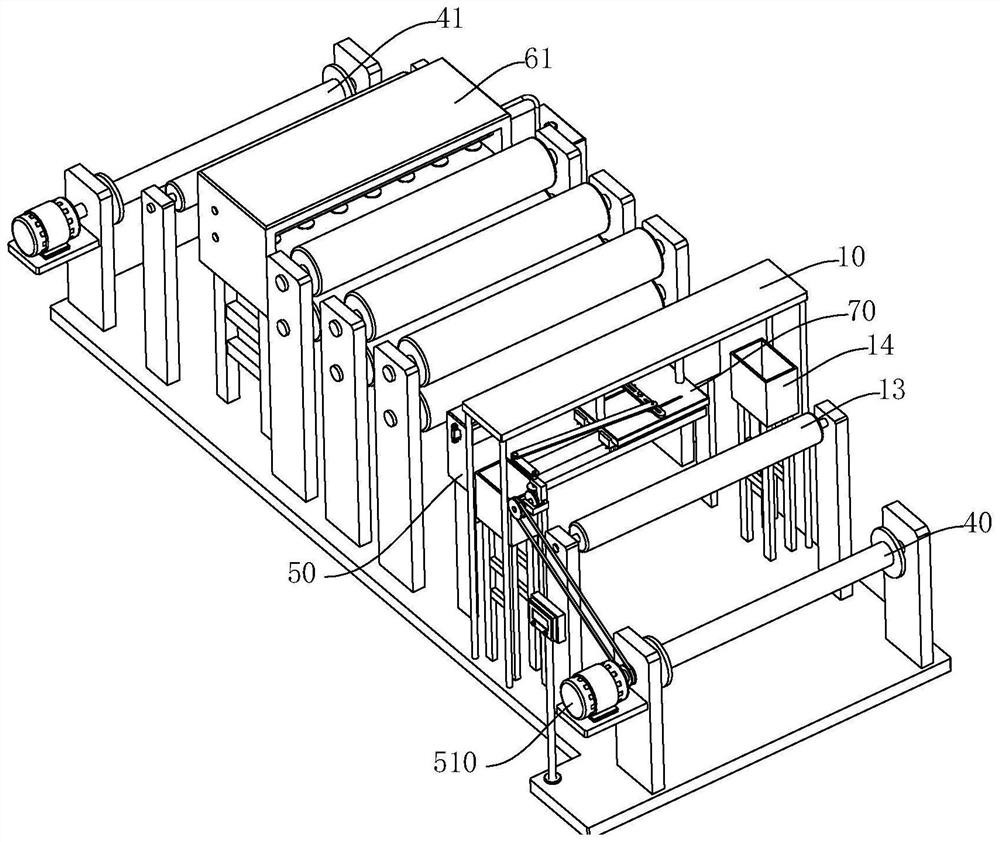

Working method of protective guide device for steel strip cold rolling

ActiveCN112658042APlay a guiding roleEasy to adjustGuiding/positioning/aligning arrangementsWork treatment devicesForeign matterElectric machine

The invention relates to the field of stainless steel strips, in particular to a protective guide device for steel strip cold rolling and a working method. The protective guide device comprises a base and a cold rolling mechanism, and further comprises a controller, a conveying mechanism, a guide mechanism, a cooling mechanism and a cleaning mechanism, the conveying mechanism comprises an unwinding roller, a winding roller and two stepping motors; and the cleaning mechanism comprises a bearing plate, a connecting rod assembly and two brushes, the guide mechanism comprises a first supporting table and two limiting assemblies, the cooling mechanism is arranged at the top of the base to be used for cooling a cold-rolled steel strip and comprises a containing box, a second supporting table and an air spraying assembly, and the stepping motors and the air spraying assembly are electrically connected with the controller. According to the protective guide device for steel strip cold rolling and the working method, foreign matter can be effectively and thoroughly discharged and collected, the guide mechanism is convenient to disassemble, assemble and adjust, the requirement for guiding steel strips with different widths can be met, meanwhile, water resource waste can be effectively avoided, and the cooling effect is improved.

Owner:唐山市融德冷轧镀锌有限公司

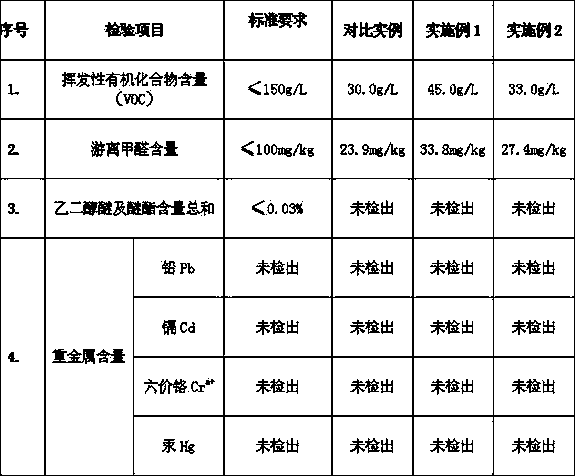

Water-based metallic paint with rustproof function for outer walls and preparation method thereof

ActiveCN103965726AWith anti-rust functionImprove waterproof performanceAnti-corrosive paintsWater basedEmulsion

The invention provides water-based metallic paint with a rustproof function for outer wall painting. The water-based metallic paint comprises the following components in parts by weight: 40-60% of silicone resin emulsion, 1-2% of film-forming agent, 10-20% of pearl pigment, 0.5-1% of flash-rust inhibitor, 0.3-0.6% of dispersant, 0.2-0.4% of wetting agent, 0.2-0.5% of defoaming agent, 0.3-1.0% of thickener, 0-5% of extinction powder and 25-35% of deionized water, wherein the silicone resin emulsion is water dilution type pure silicone resin emulsion, and the flash-rust inhibitor is modified zinc chelate. The water-based metallic paint provided by the invention has the advantages that the pure silicone resin emulsion is used as a film-forming agent, and meanwhile, the modified zinc chelate is added to the metallic paint and serves as the flash-rust inhibitor, so that a paint film has a good rustproof property, good stain resistance weather resistance and a very good decoration effect on outer walls and prolongs the service life of the walls relatively well. The invention aslo provides a preparation method with the rustproof function for the outer walls.

Owner:广东龙湖科技股份有限公司

Repair method for car paint

The invention provides a repair method for car paint, and relates to the technical field of cars. The repair method for the car paint comprises the following steps of (1) pretreatment of damaged partsof the car paint, (2) spraying of a painting make-up agent, (3) spraying of colored paint, (4) spraying of varnish and (5) grinding and polishing. The repair method for the car paint repairs the damaged parts of the car paint, the whole repair process is simple and easy to realize, the effect is obvious, time for painting make-up is short, the working efficiency is improved, and the time-saving and labor-saving effect is achieved.

Owner:广西速道汽车维修服务有限公司

Cleaning process of optical glass lens

InactiveCN110802079AExcellent corrosion inhibitionImprove rust resistanceSpectales/gogglesNon-ionic surface-active compoundsPyridiniumOptical glass

The invention discloses a cleaning process of an optical glass lens. Firstly, cleaning fluid is combined with high-voltage pulse electric field treatment and double-frequency ultrasonic wave alternatetreatment for cleaning, oil dirt, dirt and other contaminants on the surface of the optical glass lens can be effectively removed, high-voltage pulse electric field treatment cooperates with taurinedihydroxyethyl amine oxide and cetyl pyridinium chloride in the cleaning fluid, mildew on the surface of the optical glass lens can be effectively killed, a good vibration effect is achieved through the cooperation of high-voltage pulse electric field treatment and double-frequency ultrasonic wave alternate treatment, the oil dirt, the dirt and other contaminants on the surface of the optical glass lens can be effectively separated out, and the cleaning effect is improved; and then deionized water is combined with double-frequency microwave alternate treatment and double-frequency ultrasonic wave alternate treatment for washing, the oil dirt, the dirt and other contaminants on the surface of the optical glass lens can be further removed through the vibrating performance of double-frequencymicrowave alternate treatment and double-frequency ultrasonic wave alternate treatment, and the cleaning efficiency is improved.

Owner:江苏鸿晨集团有限公司

Waterborne antirust agent

InactiveCN108251197AAnti-rust for a long timePrevent rust spotsLubricant compositionAntistatic agentEmulsion

The application discloses a waterborne antirust agent, which is prepared from the following raw materials in parts by weight, 15-95 parts of alkyd resin, 25-76 parts of cycloalkyl base oil, 25-70 parts of acrylic resin, 24-85 parts of waterborne acrylic emulsion, 34-75 parts of fatty acid amide, 35-95 parts of a silane coupling agent, 25-85 parts of polyisobutene, 20-45 parts of polyvinyl chlorideresin, 15-75 parts of glutamic acid and 10-85 parts of an antistatic agent. Therefore, the antirust agent is longer in rust protection time, and can prevent rusty spots from forming on the surface ofa material again after being used; the waste antirust agent can be conveniently disposed and discharged; the waterborne antirust agent meets the environmental protection requirements, is free from pollution to equipment, is non-corrosive, effectively lowers the production cost, and is safe and reliable to use.

Owner:丁春香

Water-based antirust and antifouling paint used on wall surface and preparation method thereof

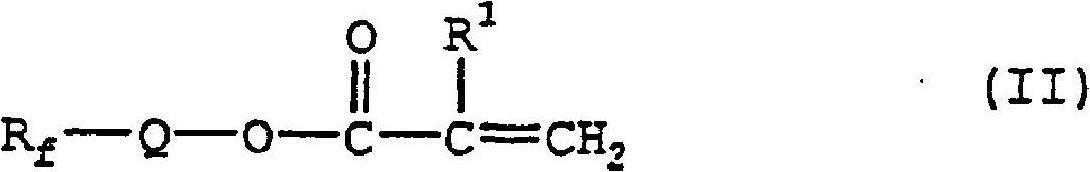

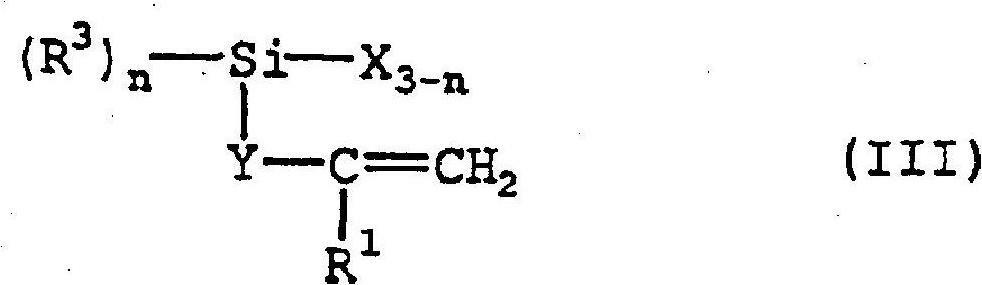

InactiveCN102690561ASimple construction operationAnti-fouling abilityAntifouling/underwater paintsPaints with biocidesSolventEmulsion

The invention relates to a type of water-based antirust and antifouling paint used on a wall surface. The paint contains the following components in parts by weight: 20-60 parts of film forming substance, 1-10 parts of film-forming additive, 0.5-2 parts of copolymer of unsaturated monomer which contains fluoro aliphatic groups and unsaturated silane monomer, 0-5 parts of cosolvent, 0.1-1 part of corrosion inhibitor and appropriate amount of water. The invention further designs a preparation method of the paint. The water-based paint used for preventing rust and dirt on the wall surface is environment-friendly and economic; the water-based paint and common wall surface emulsion paints have the same the construction ways. The paint disclosed by the invention can prevent rust on the wall surface, has the capability of resisting stains and can reach better beautifying and decoration effects. The paint is an excellent paint which is used on the wall surface and is antirust, antifouling, environment-friendly and economic.

Owner:TIANCHANG YINHU PAINT

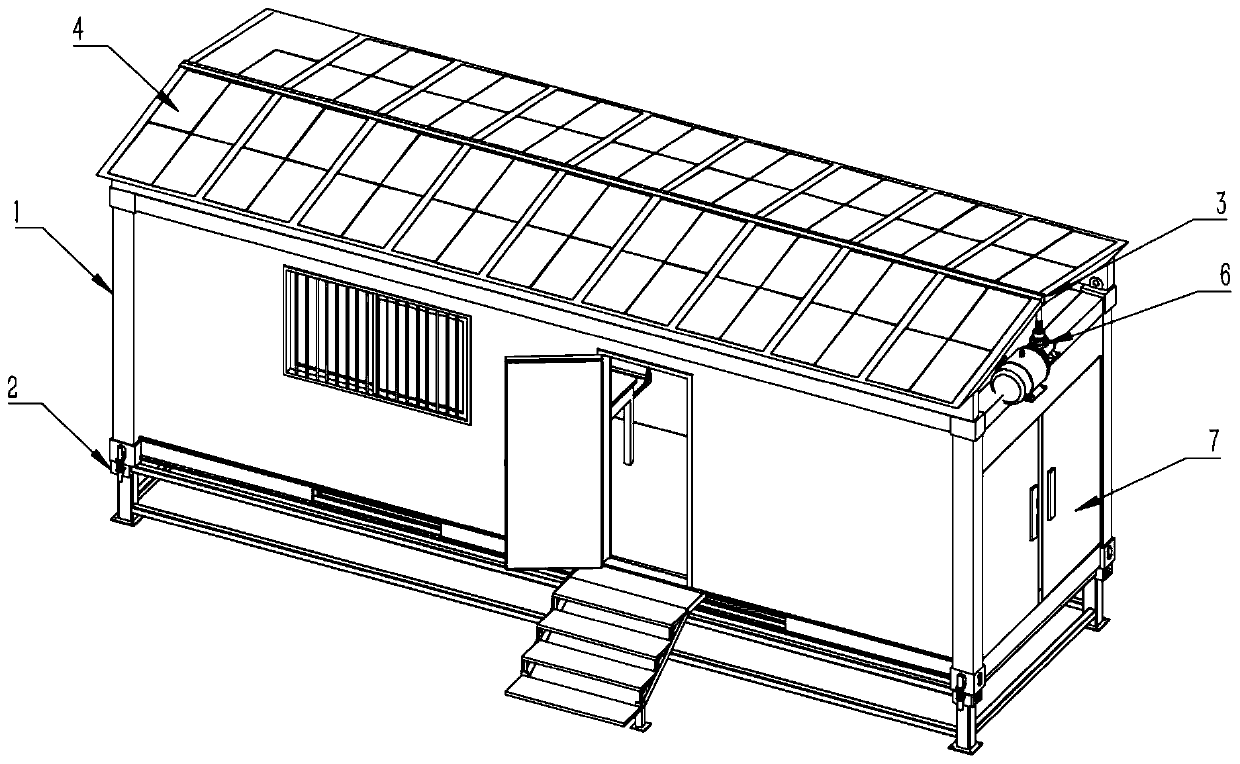

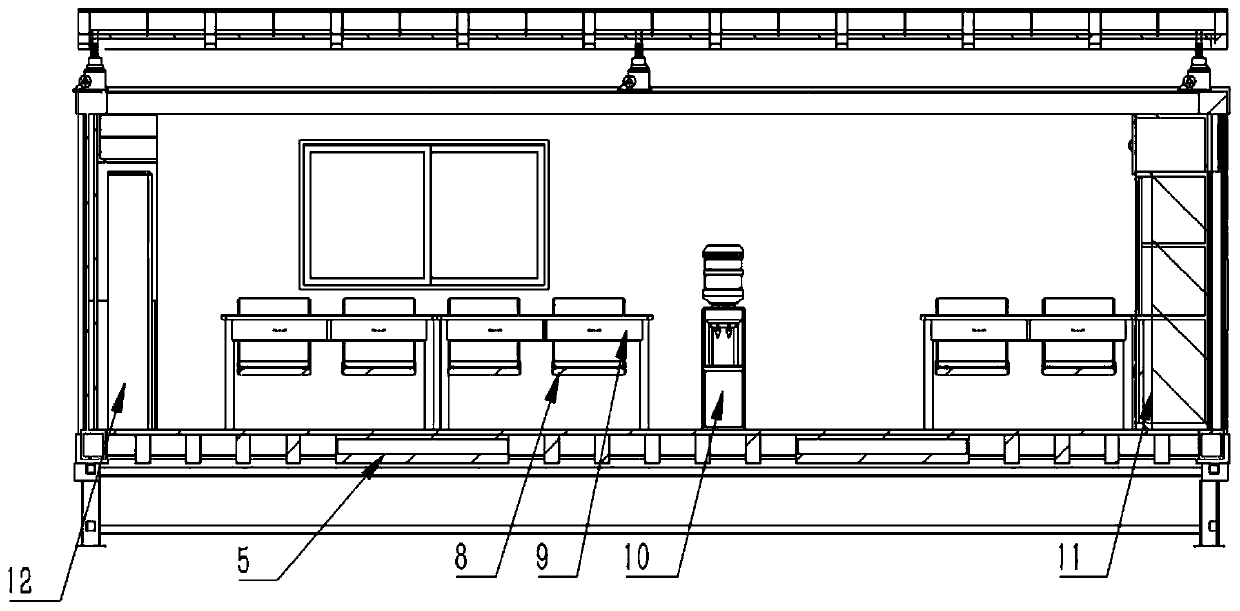

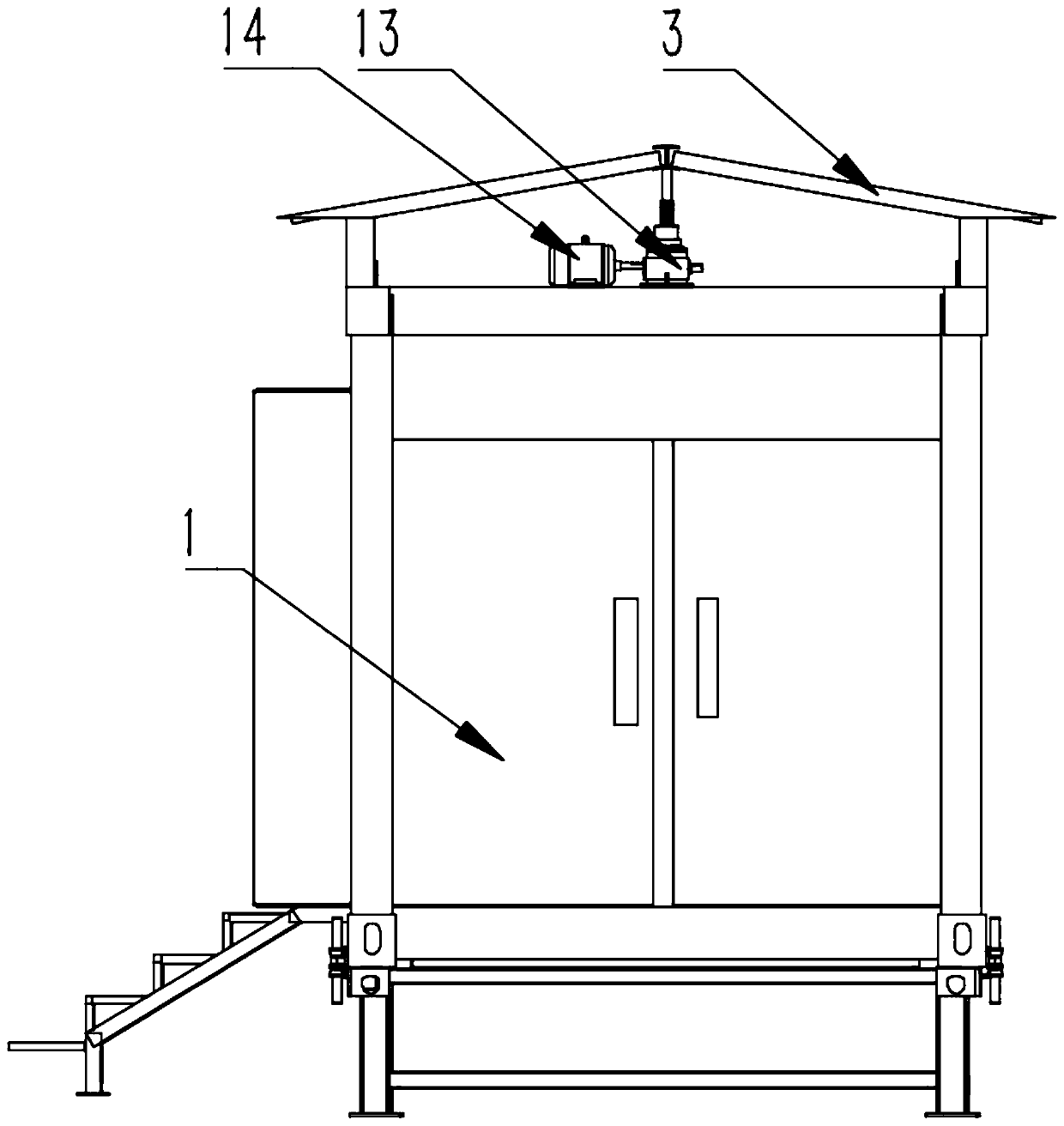

Mobile working container

InactiveCN111335675APrevent rust spotsReduce power consumptionPhotovoltaic supportsSolar heating energyEavesStructural engineering

The invention discloses a mobile working container. The mobile working container comprises a container shell, eaves which are symmetrically arranged at the top of the container shell, solar photovoltaic panels which are arranged at the tops of the eaves, a pressure power generation device which is arranged at the bottom of the container shell, and a plurality of lifting assemblies which are arranged between the container shell and the eaves. The multiple lifting assemblies are distributed along the symmetric line of the eaves. The lifting assemblies comprise folding baffles, supporting parts,bearing parts and elevators which are fixedly connected from top to bottom. The eaves and the bearing parts are fixedly connected. According to the mobile working container, the liftable eaves are adopted, and when the eaves are descended to the plane, transportation can be facilitated; and when being ascended and folded into a slope top, the eaves can effectively prevent rainwater on the top fromscouring a container outer body, rusty spots are prevented and the service life is prolonged.

Owner:SHANGHAI MARITIME UNIVERSITY

Piston one-time forming process method

InactiveCN108655389APrevent rust spotsSmooth outer surfaceTransportation and packagingMetal-working apparatusWaxPiston

The invention discloses a piston one-time forming process method. The method comprises the step that blank materials are prepared, wherein mixed materials are provided, and the mixed materials comprise the components of 100-200 kg of iron powder, 12-20 kg of copper powder, 7-10 kg of graphite, 10-15 kg of kaolin, 1-5 kg of manganese sulfide, 5-10 kg of differential wax, 0.2-0.5 kg of bobbin oil and 5-10 kg of a binding agent. The method has the advantages that the prepared materials are adopted during pressing one-time forming so that the strength of a piston can be guaranteed, the preparationprocess of the piston can be more efficient, the use requirements of different fields are met, the binding agent is added in the material proportioning process, so that the prepared materials of themethod are more adhesive, and the phenomenon that the center of the pressed piston is prone to being hollow and bloated during pressing is avoided.

Owner:扬州汇峰新材料有限公司

High-efficiency metal cleaning solution

InactiveCN107747100APrevent rust spotsOvercoming the disadvantages of depleting the ozone layerPolyethylene glycolFatty alcohol

The invention relates to a high-efficiency metal cleaning solution. The high-efficiency metal cleaning solution is composed of the following components in parts by mass: 40-48 parts of polyoxyethylene fatty alcohol, 1-3 parts of trisodium phosphate, and 5-9 parts of sodium nitrite , 3-7 parts of polyethylene glycol, 2-5 parts of iron pyrophosphate, 50-55 parts of deionized water. This solution can not only quickly clean the stains on the metal surface, but also effectively prevent the generation of rust spots on the metal surface, and has a long-term anti-rust and maintenance effect on the cleaned metal. It is especially suitable for transportation such as bearings, tractors, and automobiles. Cleaning and maintenance of parts of tools or engine parts.

Owner:中科协创环境科技江苏有限公司

Metal brightening and descaling cleaning agent

The invention relates to a bright metal rust removal cleaning agent, which is composed of the following components in parts by mass: 16-23 parts of potassium stearate, 5-9 parts of sodium hydroxide, imidazoline amphoteric surfactant 7-12 parts, 1-4 parts of hydroxyethylene diphosphate, 3-7 parts of ethanol, 3-7 parts of ethylene glycol butyl ether, 65-75 parts of water. This method can not only quickly melt all kinds of oil stains attached to the metal surface, but also separate the oil stain from the metal surface, which is convenient for cleaning and cleaning. Effectively reduce the production cost of enterprises.

Owner:中科协创环境科技江苏有限公司

Novel photothermal conversion paint for laser quenching and preparation method thereof

InactiveCN108003737AFast film formationReduce temperature gradientPolyurea/polyurethane coatingsElectrically-conductive paintsCoating adhesionMaterials science

The invention belongs to the field of paint for a laser process, and particularly relates to novel photothermal conversion paint for laser quenching and a preparation method thereof. The novel photothermal conversion paint is prepared from the following raw materials in parts by weight: 15 to 20 parts of silicon carbide, 10 to 15 parts of micron aluminum powder, 10 to 15 parts of carbon nano tubes, 3 to 5 parts of graphite, 5 to 10 parts of chromic oxide, 5 to 10 parts of photosensitive polyurethane, 5 to 10 parts of waterborne acrylate emulsion and 30 to 40 parts of absolute ethyl alcohol. The novel photothermal conversion paint effectively solves some common problems that in the laser quenching process of the existing coating, the light absorbance rate is low; the heat conduction is poor; the coating adhesive force is low; the coating drying is slow; solutions can easily corrode the metal surface; the coating particles are large, so that the quenching thickness and hardness are not uniform; the quenching effect is not ideal, and the like. Particularly, the laser paint has high photosensitivity; the light absorbance of the metal surface can be obviously improved.

Owner:SHENYANG DALU LASER TECH

Cleaning agent for remanufacturing mechanical equipment

InactiveCN104403850APrevent rust spotsEasy to cleanSurface-active non-soap compounds and soap mixture detergentsPhosphateHazardous substance

The invention discloses a cleaning agent for remanufacturing mechanical equipment. The cleaning agent comprises the following raw materials in parts by weight: triethanolamine, a surfactant, potassium nitrate, oleic diethanola mide borate ester, phosphate, a degreasing agent, a conditioner for metal surface, sodium gluconate, glycerol, diatomaceous earth, a defoamer, a dispersing agent, a flame retardant and a thickening agent, wherein the defoamer is dimethyl silicone oil; the dispersing agent is polyacrylic acid; the phosphate is one or several kinds of trisodium phosphate, tripotassium phosphate, disodium phosphate, sodium tripolyphosphate or potassium tripolyphosphate; the surfactant is fatty alcohol polyethylene ether, lauryl alcohol ethylamine or alkyl sulfate. The cleaning agent disclosed by the invention is high in cleaning capability and short in cleaning time; labor force is reduced; labor hour is shortened; the working efficiency is improved; the corrosion to the equipment is lower; the reduction of the cost for the equipment is facilitated; oil stains and rusty strains on the surface of the equipment can be thoroughly cleaned; the reforming of the rusty strains on the surface of the mechanical equipment is prevented; the cleaning agent is safe and reliable for use, and no toxic or harmful substances are generated.

Owner:芜湖中艺科技服务有限公司

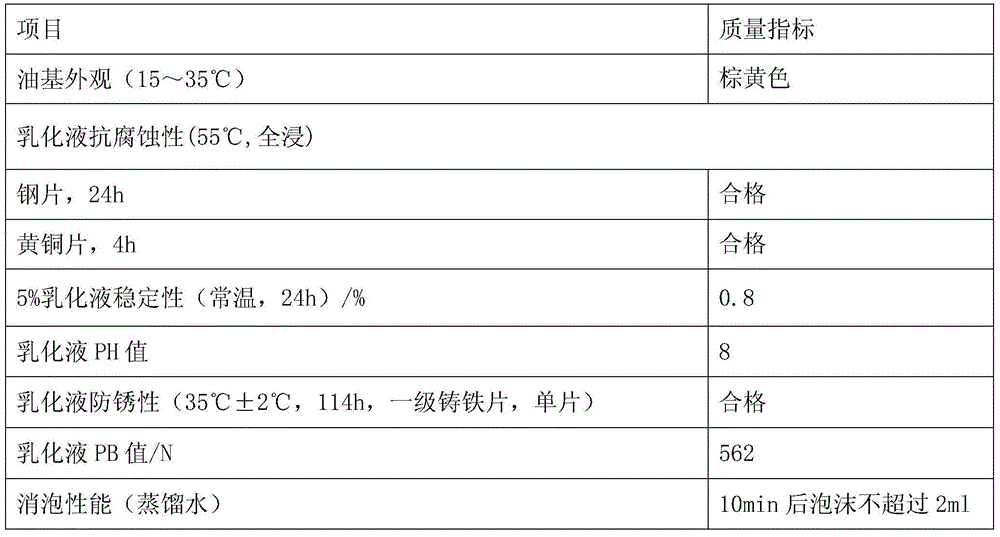

Copper alloy cold-rolling emulsion composition

InactiveCN104962371AImproved Thickness StabilityImprove cooling effectLubricant compositionAntioxidantChemical stability

The invention discloses a copper alloy cold-rolling emulsion composition which uses 10# total loss system oil as base oil matched with multiple additives, including an emulsifier, an antioxidant, an oily agent, an extreme pressure agent, an antiwear additive, a corrosion inhibitor, a defoaming agent, an assistant and a reinforcing agent. The composition has the advantages of favorable adhesion property, favorable wear resistance, favorable shear resistance, favorable emulsifying stability, high extreme pressure property, stable oil film thickness, favorable cooling property, favorable flowability, favorable wettability, favorable lubricating property, high oil film strength and lower flow shear stress, enhances the surface smoothness and specification precision of the metal, has certain chemical stability, ensures the use and cleaning convenience, and has the capacity for preventing pitting and surface defects.

Owner:GUANGXI UNIV

Preparation method and application of low-temperature oxygen bleaching composite activator

The invention discloses a preparation method of a low-temperature oxygen bleaching composite activator. The preparation method comprises the following steps: firstly, preparing N-[4-(triethylanmine methyl) benzoyl] caprolactam chloride and sodium nonanoyloxybenzene sulfonate, and then mixing and compounding to obtain the low-temperature oxygen bleaching composite activator. The preparation method of the low-temperature oxygen bleaching composite activator is simple, feasible and low in preparation cost; according to the prepared low-temperature oxygen bleaching composite activator, the fabric is subjected to efficient bleaching by bleaching and scouring in a low-temperature near-neutral condition; and the bleaching system can have the advantage of saving energy sources, and does not cause obvious injuries to the fabric.

Owner:SUZHOU CHENHENG WEAVING

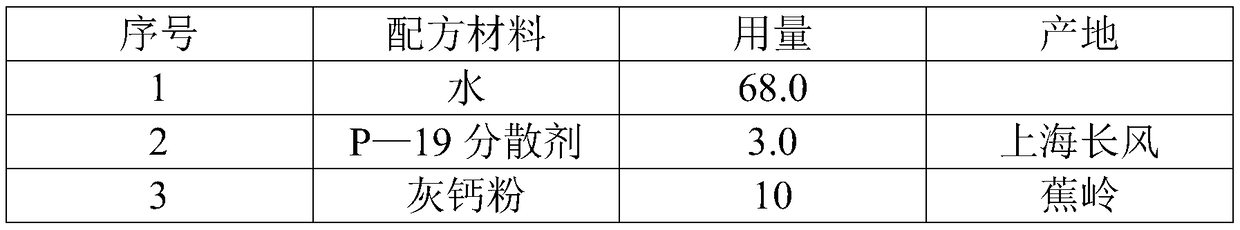

Metal roof rustproof waterproof repairing paste

The invention discloses a metal roof rustproof waterproof repairing paste, which comprises, by weight, 65-70 parts of water, 2.0-4.0 parts of an aqueous pigment dispersing agent, 8-18 parts of ash calcium powder, 8-18 parts of titanium dioxide, 60-90 parts of zinc phosphate, 25-50 parts of aluminum tripolyphosphate, 450-600 parts of an emulsion, 250-350 parts of heavy calcium powder, 5.5-8.5 partsof anti-flashrust aid, 3.0-5.0 parts of a defoamer, 2.0-3.5 parts of an anticorrosion agent, and 4.0-6.0 parts of a rheological aid. According to the present invention, the metal roof rustproof waterproof repairing paste can form the firm protection layer using iron phosphate as the main body, and the protection layer is densely passivated and insoluble in water so as to provide good anti-rust effect; and the emulsion has advantages of good elasticity, good flexibility and good weather resistance, cannot subjected to thermal expansion and cold contraction, can resist crack, and can form the dense hydrophobic film during the drying so as to provide good waterproof effect.

Owner:陈德芳

Environment-friendly automobile hub antirust agent

The invention discloses an environment-friendly automobile hub antirust agent. The environment-friendly automobile hub antirust agent comprises, by weight, 20-95 parts of calcium stearate, 10-60 partsof oxalic acid, 25-55 parts of phytosterol, 15-70 parts of 1-hydroxybenzotriazole, 20-70 parts of chlorhexidine hydrochloride, 20-75 parts of barium sulfate, 35-110 parts of chlorinated paraffin, 15-40 parts of calcium hydroxide, 10-80 parts of sodium acetate and 15-60 parts of sodium alga acid. Accordingly, the antirust agent is long in antirust time, and rust spots can be prevented from being formed on the material surface again after usage; and treatment and discharging of the waste antirust agent are convenient, the environment protection requirement is met, no pollution and no corrosionare caused to equipment, the production cost is effectively reduced, and usage is safe and reliable.

Owner:丁春香

Environment-friendly antirust agent for bicycle chains

InactiveCN108129932AAnti-rust for a long timePrevent rust spotsAnti-corrosive paintsSulfonateAcrylic resin

The invention discloses an environment-friendly antirust agent for bicycle chains. The environment-friendly antirust agent for bicycle chains comprises the following components in parts by weight: 15to 80 parts of sulfur, 30 to 120 parts of a potassium nitrite solution with the concentration of 30%, 25 to 80 parts of acrylic resin, 20 to 90 parts of boron nitride, 30 to 90 parts of sodium sulfonate, 40 to 80 parts of glycerol methyl ether, 50 to 120 parts of ammonium phosphate, 20 to 80 parts of silicon dioxide, 10 to 50 parts of a flatting agent and 20 to 55 parts of sodium nitrite. Therefore, the antirust agent is relatively long in antirust time, and rust can be prevented from being formed on the surface of the material again after the antirust agent is used; a waste antirust agent ismore convenient to treat and discharge, the environmental requirement is met, the antirust agent is free of pollution to equipment and free of corrosion, the production cost is effectively reduced, and the antirust is safe and reliable to use.

Owner:丁春香

Environment-friendly rust inhibitor applied to surfaces of bending machines

InactiveCN108148490AAnti-rust for a long timePrevent rust spotsAnti-corrosive paintsPolyether coatingsSodium acetateSodium molybdate

The invention discloses an environment-friendly rust inhibitor applied to surfaces of bending machines. The rust inhibitor is prepared from the following raw materials in parts by weight: 15-75 partsof calcium stearate, 20-60 parts of nonylphenol polyoxyethylene ether, 25-95 parts of sodium molybdate, 25-80 parts of alkylbenzyloxyamine, 20-75 parts of sodium sulfonate, 20-75 parts of barium sulfate, 25-80 parts of potassium tetraborate, 15-70 parts of anionic surfactants, 10-80 parts of sodium acetate and 25-55 parts of 2,3-dihydrodecafluoropentane. The rust inhibitor is long in rust inhibition time; after the rust inhibitor is applied to the surface, the rust inhibitor is capable of preventing the surface of the material from forming rusty spots again; the waste rust inhibitor can be conveniently treated and discharged; the requirement of environmental protection is met; the rust inhibitor is free of pollution and corrosion to equipment, can effectively reduce the production cost, and is safe and reliable to use.

Owner:丁春香

Antirust agent for carbon steel

The invention discloses an antirust agent for carbon steel. The antirust agent comprises, by weight, 15-85 parts of hydroxyethyl oleoimidazoline, 25-65 parts of sodium molybdate, 25-60 parts of sodiumcitrate, 38-85 parts of oleoyl sarcosine, 34-75 parts of tri-n-butylamine, 35-85 parts of silane coupling agent, 25-85 parts of polyisobutene, 20-45 parts of polyvinyl chloride resin, 15-75 parts ofglutamic acid and 10-85 parts of power increasing agent. Therefore, the antirust time of the antirust agent is long, and rust spots can be prevented from being formed on the surface of the material again after the antirust agent is in use; the waste antirust agent is convenient to process and discharge, environmental protection requirements are met, no pollution or corrosion is caused to equipment, the production cost is effectively reduced, and use is safe and reliable.

Owner:仪征锐翼机械科技有限公司

Environment-friendly rust inhibitor for train rails

The invention discloses an environment-friendly rust inhibitor for train rails. The rust inhibitor comprises the following components of, by weight, 25-90 parts of isocyanate prepolymer, 20-75 parts of acrylic polyol resin, 25-70 parts of butyl acetate, 14 -80 parts of water-based acrylic emulsion, 35-95 parts of sodium sulfonate, 35 -80 parts of trichloro ethylene, 20-85 parts of polyisobutene, 20-75 parts of polyvinyl chloride resin, 10-75 parts of ethylenediamine tetraacetic acid and 20-80 parts of the power-increasing agent. Therefore, the rust-proof time of the rust inhibitor is relatively long, and the surface of the material is prevented from forming rusty spots again after being used; the treatment and emission of the wasted rust inhibitor are facilitated, the environment-friendlyrequirement is met, the equipment is free of pollution and corrosion, the production cost is effectively reduced, and the device is safe and reliable to use.

Owner:丁春香

Antirust agent for motor rotor

The invention discloses an antirust agent for a motor rotor. The antirust agent comprises, by weight, 20-85 parts of calcium stearate, 30-80 parts of sebacic acid, 25-55 parts of sodium molybdate, 25-60 parts of 1-hydroxybenzotriazole, 40-75 parts of sodium sulfonate, 20-75 parts of barium sulfate, 55-90 parts of potassium tetraborate, 25-40 parts of calcium hydroxide, 10-50 parts of sodium acetate and 15-65 parts of bamboo carbon fiber. Accordingly, the antirust time of the antirust agent is long, and rust spots can be prevented from being formed on the material surface again after usage; treatment and discharging of the waste antirust agent are convenient, and the environment protection requirement is met; and equipment is not polluted or corroded, the production cost is effectively reduced, and usage is safe and reliable.

Owner:丁春香

Powerful antirust agent

InactiveCN111100729AAnti-rust for a long timePrevent rust spotsAdditivesIsobutanolPolyvinyl chloride

The invention discloses a powerful antirust agent, which comprises the following components (by weight): 15-95 parts of trisodium phosphate, 25-65 parts of hydroxyethyl oleoyl imidazoline, 25-60 partsof nitrilotriethanolamine, 32-85 parts of isobutanol, 34-75 parts of fatty acid amide, 35-95 parts of a silane coupling agent, 25-85 parts of polyisobutene, 20-45 parts of polyvinyl chloride resin, 15-75 parts of glutamic acid and 10-85 parts of an electricity increasing agent. Therefore, the antirust time of the antirust agent is long, and rust spots can be prevented from being formed again on the surface of a material after use of the antirust agent; treatment and emission of the of the antirust agent are convenient; the antirust agent meets the environmental requirement, is pollution-freeto equipment and is non-corrosive; and the production cost is effectively reduced, and the use is safe and reliable.

Owner:仪征锐翼机械科技有限公司

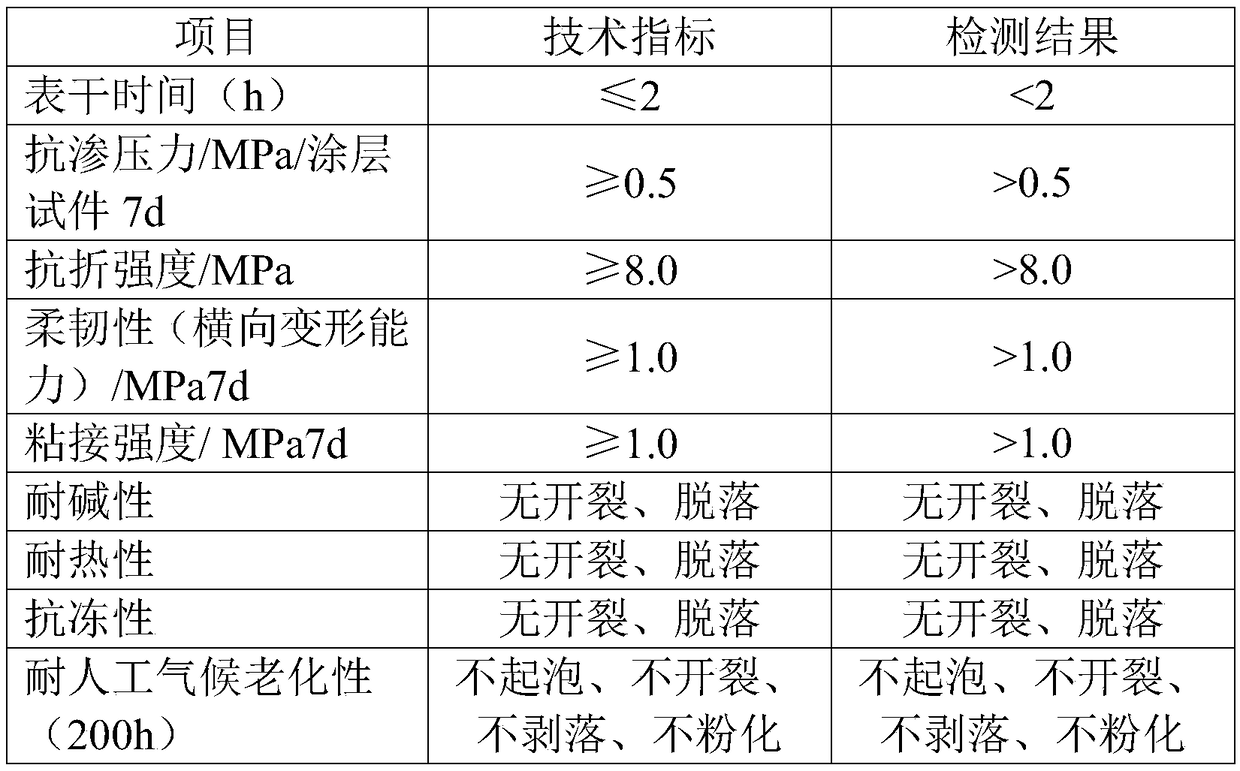

Stone surface protective coating and preparation method thereof

The invention discloses a surface protecting coating of a stone. The coating is composed of the following components in parts by weight: 1000 parts of cyclohexane, 5-15 parts of triethylene glycol methyl ether, 10-100 parts of nano silicon dioxide, 80-180 parts of vinyl blocked dimethyl siloxane, 2-15 parts of perfluoromethyl vinyl ether and 20-60 parts of a polystyrene-polybutadiene-polystyrene block copolymer. After applying the surface protecting coating of the stone disclosed by the invention, effects of blocking moisture migration and diffusion of salt and alkali can be exerted, so that various diseases such as water spots, saltpetering, rust and cracks after a natural stone is in contact with cement mortar can be avoided better, the bonding strength can be increased, and the service life of the natural stone, in particular of the natural stone for building decoration, is greatly prolonged. The coating has quite good economical benefit and application prospect.

Owner:佛山市元通胶粘实业有限公司

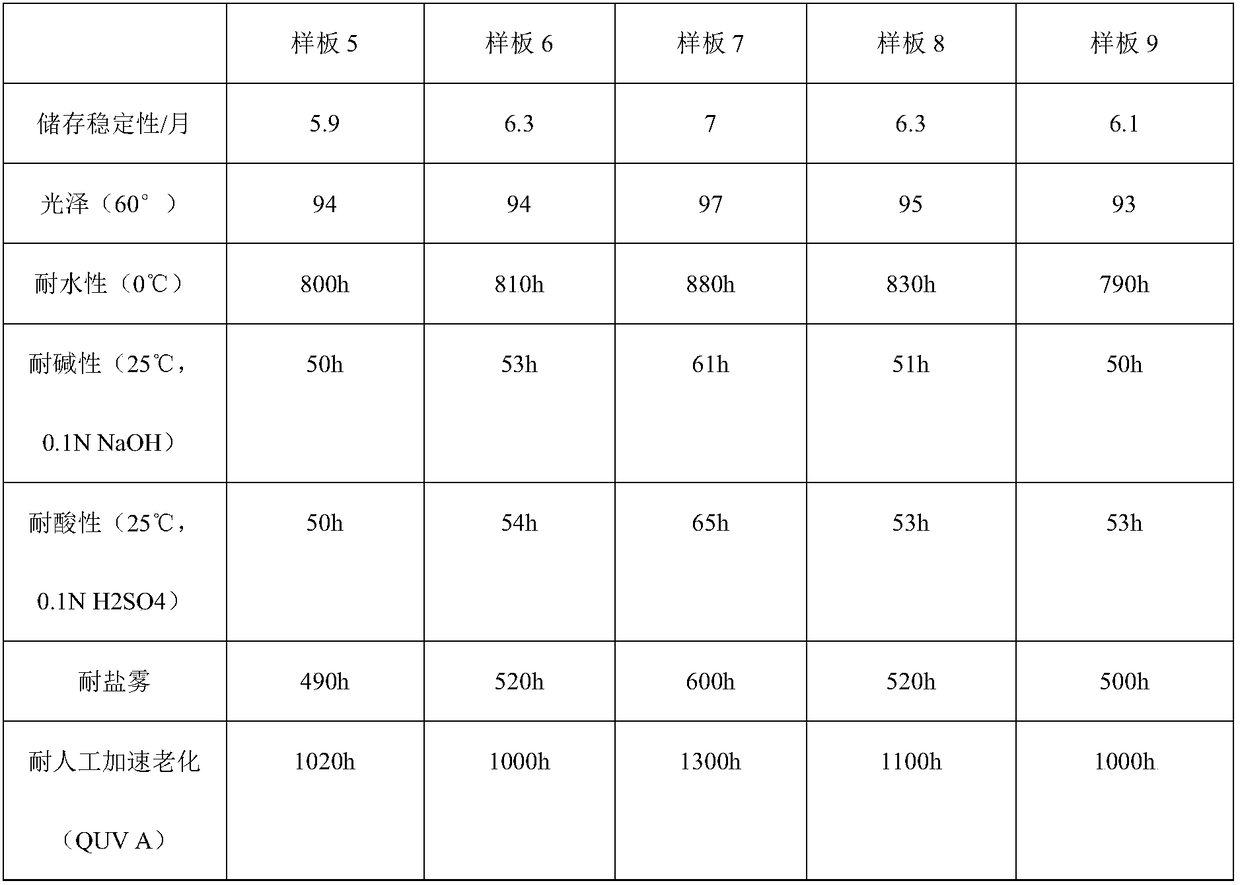

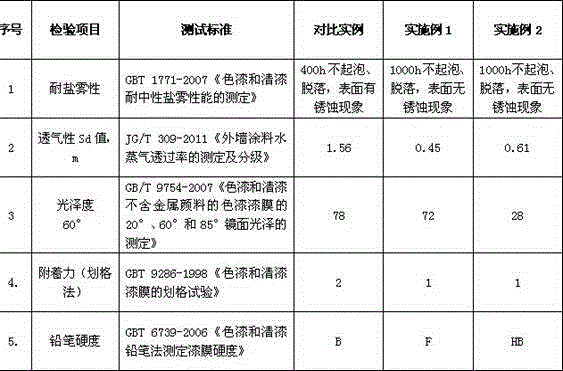

Aqueous bottom-side rust-coated highlight anticorrosive coating and preparation method thereof

ActiveCN109096814AImprove adhesionImprove rust resistanceAnti-corrosive paintsEmulsionCarboxylic acid

The invention discloses an aqueous bottom-side rust-coated highlight anticorrosive coating and a preparation method thereof. Polyenoic acid ester monomers other than acrylic acid and monomers with functional groups which have carboxylic acid reactivity and can participate in a reaction in a phased mode are added in acrylic emulsion. The coating has excellent adhesion on the surface of rusted iron,can be coated with rust, and further has the characteristics of uniformity of the bottom surface; and more importantly, the prepared coating has good coating gloss, good storage stability, and good corrosion resistance.

Owner:北京红狮科技发展有限公司

Antirust agent for gears

InactiveCN108219674AAnti-rust for a long timePrevent rust spotsWax coatingsAnti-corrosive paintsCelluloseWax

The invention discloses an antirust agent for gears. The antirust agent is prepared from the following materials in parts by weight: 10 to 55 parts of titanium dioxide, 30 to 66 parts of highlightingwax, 10 to 40 parts of acrylic resin, 14 to 60 parts of HS-30000 cellulose, 34 to 70 parts of sodium sulfonate, 35 to 80 parts of bauxite, 20 to 65 parts of polyisobutene, 20 to 45 parts of 1,2-diethoxy estersil ethane, 10 to 55 parts of flattening agent and 10 to 50 parts of boric acid. Therefore, the antirust agent has longer antirust time; after being used, the antirust agent can prevent rust from being generated on the surface of a material again; treatment and emission of the waste antirust agent are convenient; the antirust agent can meet environmental requirements, has no pollution andno corrosion to equipment, effectively reduces production cost and has safety and reliability in use.

Owner:丁春香

Environment-friendly antirust agent for carbon steel

The invention discloses an environment-friendly antirust agent for carbon steel. The environment-friendly antirust agent comprises, by weight, 20-80 parts of quartz powder, 20-120 parts of ziziphus jujube mill, 10-80 parts of acrylic resin, 10-60 parts of lithopone, 20-70 parts of sodium sulfonate, 30-90 parts of sodium metasilicate pentahydrate, 10-110 parts of polyisobutene, 20-80 parts of D-limonene, 10-50 parts of a flatting agent and 10-70 parts of silica sol. Thus, the antirust time of the antirust agent is long, and rust spots can be prevented from occurring to the surfaces of materialsagain after the antirust agent is used; and treatment and discharging of the waste antirust agent are convenient, the environment protection requirements are met, equipment is not contaminated, corrosion is avoided, the production cost is effectively reduced, and the antirust agent is safe and reliable to use.

Owner:丁春香

Stone maintenance agent

PendingCN114015302AAvoid erosionExtended service lifeAntifouling/underwater paintsPaints with biocidesAdhesivePyrrolidinones

The invention discloses a stone maintenance agent which comprises the following components in percentage by mass: 30%-45% of a maintenance agent, 5%-10% of an isolating agent, 3%-5% of an antioxidant, 5%-10% of a waterproof agent, 1%-3% of an adhesive, 3%-5% of a rust remover, 1%-3% of a preservative and the balance of oily emulsion. The stone maintenance agent provided by the invention is mainly characterized in that the preparation process is simple, the raw material cost is low, an antioxidant is adopted to form an anti-oxidation layer on the surface of stone, and polyvinylpyrrolidone and polyvinyl alcohol are matched for use, so that a formed film is flat in edge and uniform and compact in texture, and the stone maintenance agent is short in film forming time, and meanwhile, the waterproof agent is added, corrosion of water to the stone is avoided, the service life of the stone is prolonged, meanwhile, the preservative is added, breeding of bacteria can be effectively inhibited, and rusty spots on the surface of the stone are avoided.

Owner:深圳市思创力石材护理有限公司

Environmental-friendly anti-rust agent for gears

The invention discloses an environmental-friendly anti-rust agent for gears. The environmental-friendly anti-rust agent comprises, by weight, 15-55 parts of titanium dioxide, 20-66 parts of sodium trisilicate, 5-40 parts of acrylic resin, 10-60 parts of sodium gluconate, 24-70 parts of sodium sulfonate, 15-80 parts of bauxite, 10-65 parts of trisodium phosphate, 20-45 parts of 1,2-diethoxysilicateethane, 10-75 parts of colloidal silica and 10-70 parts of boric acid. Therefore, the antirust agent has the longer-lasting effect and is capable of preventing rust spots from forming again on the surface of the material after use; and it is convenient to dispose and discharge a waste antirust agent, the requirements of environmental protection are met, the pollution to equipment is avoided, no corrosion exists, the production cost is lowered effectively, and the use is safe and reliable.

Owner:丁春香

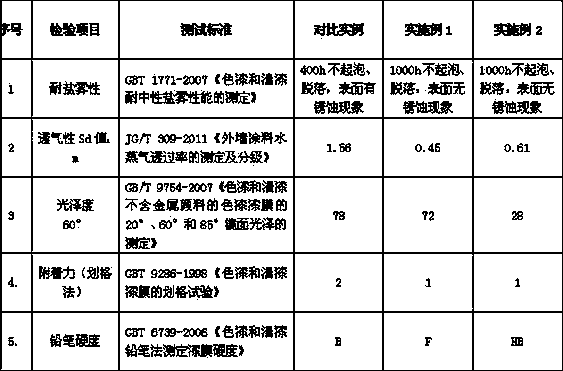

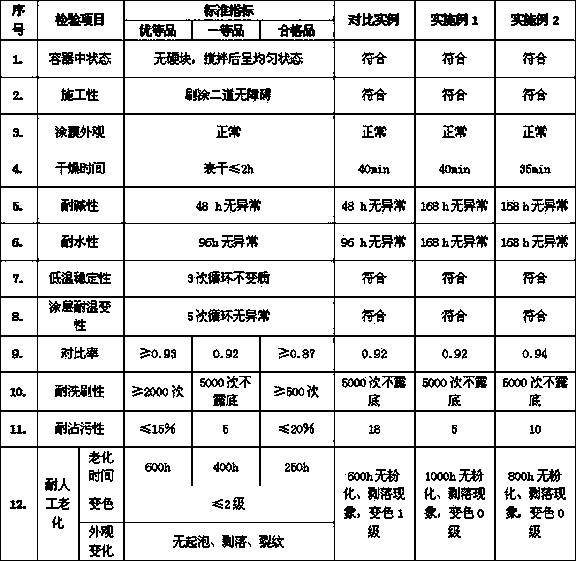

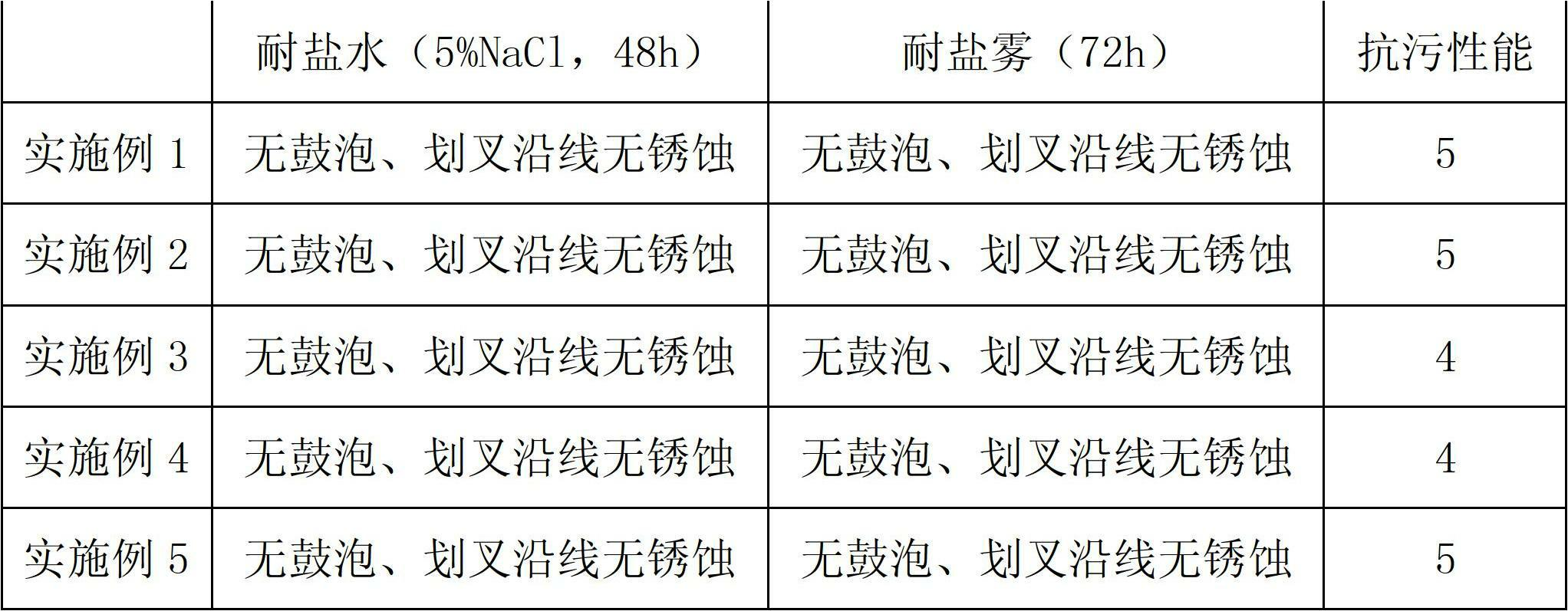

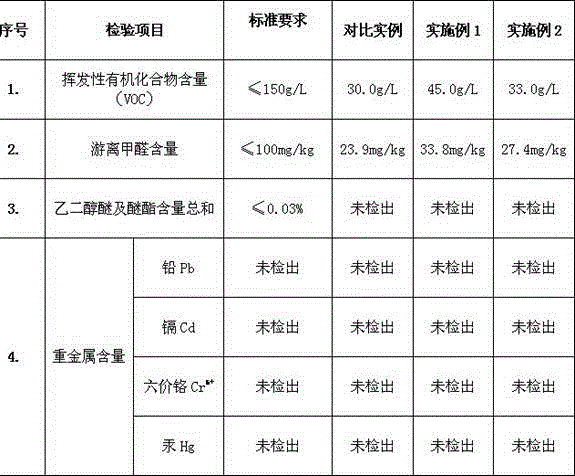

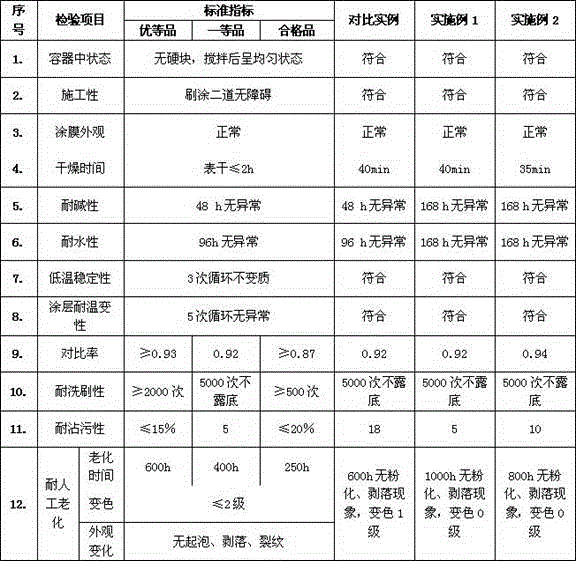

A kind of exterior wall water-based metallic paint with antirust function and preparation method thereof

ActiveCN103965726BImprove waterproof performanceImprove breathabilityAnti-corrosive paintsWater basedDefoaming Agents

The invention provides water-based metallic paint with a rustproof function for outer wall painting. The water-based metallic paint comprises the following components in parts by weight: 40-60% of silicone resin emulsion, 1-2% of film-forming agent, 10-20% of pearl pigment, 0.5-1% of flash-rust inhibitor, 0.3-0.6% of dispersant, 0.2-0.4% of wetting agent, 0.2-0.5% of defoaming agent, 0.3-1.0% of thickener, 0-5% of extinction powder and 25-35% of deionized water, wherein the silicone resin emulsion is water dilution type pure silicone resin emulsion, and the flash-rust inhibitor is modified zinc chelate. The water-based metallic paint provided by the invention has the advantages that the pure silicone resin emulsion is used as a film-forming agent, and meanwhile, the modified zinc chelate is added to the metallic paint and serves as the flash-rust inhibitor, so that a paint film has a good rustproof property, good stain resistance weather resistance and a very good decoration effect on outer walls and prolongs the service life of the walls relatively well. The invention aslo provides a preparation method with the rustproof function for the outer walls.

Owner:广东龙湖科技股份有限公司

A kind of high-gloss anti-corrosion coating with rust coating on water-based bottom surface and preparation method thereof

ActiveCN109096814BImprove adhesionImprove rust resistanceAnti-corrosive paintsPolymer scienceEmulsion

The invention discloses an aqueous bottom-side rust-coated highlight anticorrosive coating and a preparation method thereof. Polyenoic acid ester monomers other than acrylic acid and monomers with functional groups which have carboxylic acid reactivity and can participate in a reaction in a phased mode are added in acrylic emulsion. The coating has excellent adhesion on the surface of rusted iron,can be coated with rust, and further has the characteristics of uniformity of the bottom surface; and more importantly, the prepared coating has good coating gloss, good storage stability, and good corrosion resistance.

Owner:北京红狮科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com