Copper alloy cold-rolling emulsion composition

An emulsion, copper alloy technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of emulsion corrosion, insufficient lubricating performance, poor surface quality, etc. The effect of high stress and oil film strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The components are blended according to the following mass percentages:

[0020] components

[0021] 2,6-di-tert-butyl mixed phenol (T502)

[0022] The sum of the mass percentages of the above components is 100%.

Embodiment 2

[0024] The components are blended according to the following mass percentages:

[0025] components

[0026] The sum of the mass percentages of the above components is 100%.

Embodiment 3

[0028] The components are blended according to the following mass percentages:

[0029] components

Mass percentage content

No. 10 total loss system oil

margin

[0030] The mass ratio is 50% OPE-10 and 50% NPE50 composite

20%

2,6-di-tert-butyl mixed phenol (T502)

1%

Mass ratio of 50% soybean oil and 50% butyl oleate compound

6%

Vulcanized Cottonseed Oil

7%

Monosulfide n-Butyl Phosphate (T311)

5%

50% benzotriazole (T706) compounded with 50% lanolin by mass

1%

100ppm

4%

Sodium Petroleum Sulfonate (T702)

1.5%

[0031] The sum of the mass percentages of the above components is 100%.

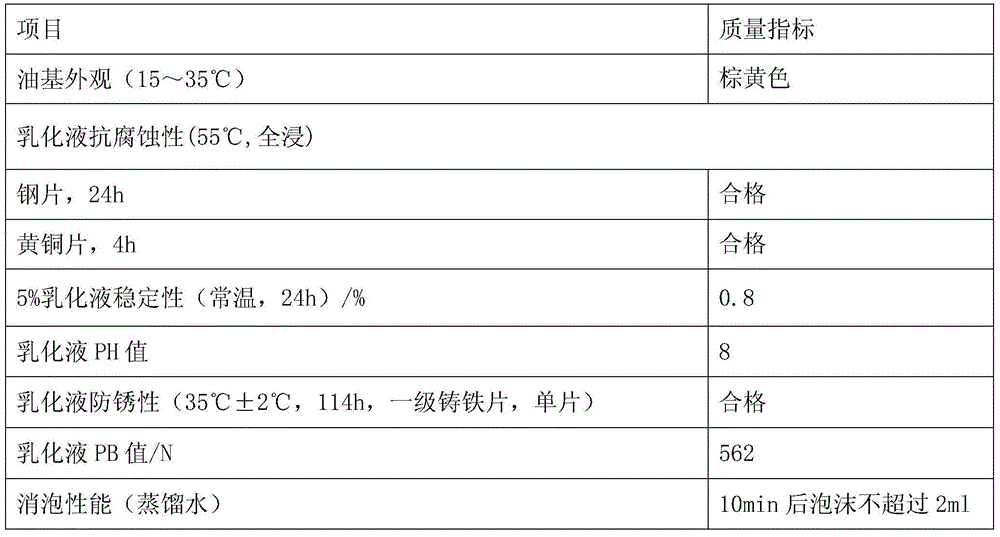

[0032] The main physical and chemical index of embodiment 3 products:

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com