Material layer thickness characterization method based on grate cooler hydraulic pressure

A technology of material layer thickness and grate cooler, which is applied in the field of cement industry, can solve the problems of staying in the experimental research stage and difficult promotion, and achieve the effects of improving heat recovery efficiency, considerable economic benefits, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1. PID control

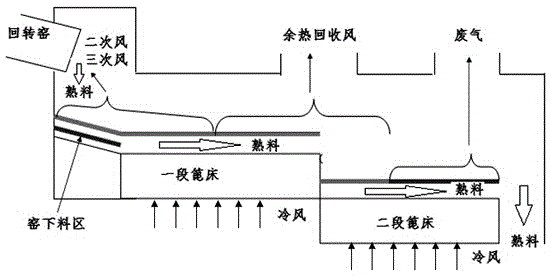

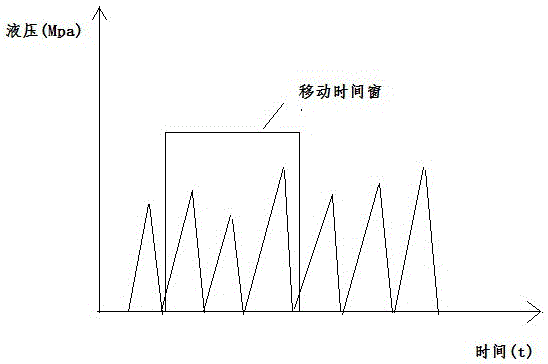

[0045]The hydraulic signal of the first-stage grate cooler is used as the controlled variable, and the grate speed of the first-stage grate cooler is used as the manipulated variable, and a PID loop is constructed to realize the automatic adjustment of the grate speed of the first-stage grate cooler, thereby improving the stability of the grate-cooler material layer thickness.

Embodiment 2

[0046] Example 2. Model Predictive Control

[0047] Taking the hydraulic signals of the first-stage, second-stage and third-stage grate coolers as the controlled variables, and the grate speed of the first-stage, second-stage, and third-stage grate coolers as the manipulated variables, a model predictive controller is constructed to realize the control of the first-stage, second-stage, and third-stage grate coolers. The coordinated adjustment of the grate speed of the cooler improves the stability of the material layer thickness of the first, second and third stage grate coolers, so that the working conditions of the whole grate cooler tend to be stable, and the heat recovery efficiency is greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com