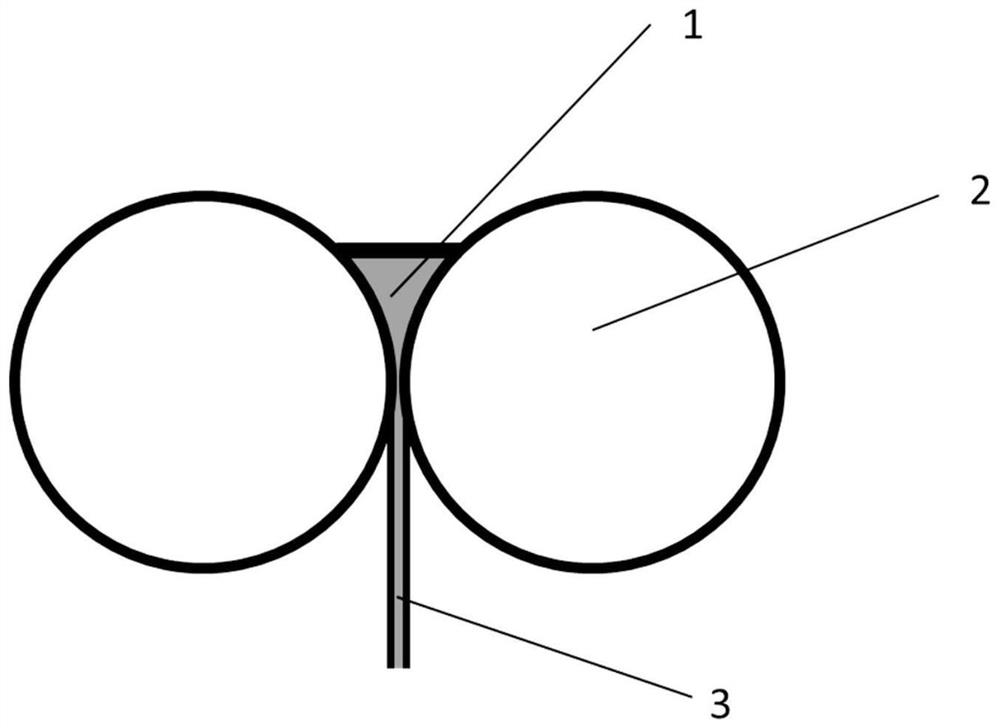

Method for controlling thickness stability of cast strip in twin-roll thin-strip continuous casting

A twin-roll thin strip continuous casting and stability technology, which is applied in the field of controlling the thickness stability of the cast strip in twin-roll thin strip continuous casting, can solve problems such as difficulty in casting strip thickness and difficult control of cast strip thickness stability, and achieve stable Control the thickness of the cast strip, improve the surface quality and the stability of hot rolling, and improve the effect of the surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

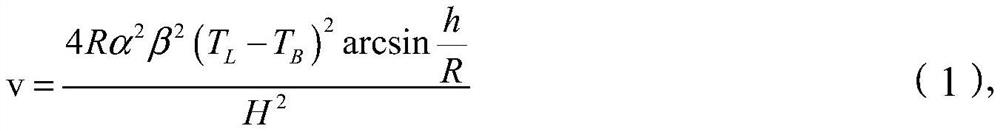

[0036] The thickness H of the twin-roll thin strip continuous casting is set to 2.0mm, the height of the molten pool h is 230mm, the radius R of the casting rolls is 545mm, and the temperature of the molten steel in the molten pool is T L is 1690°C, the solidus temperature T of the molten steel being cast B is 1535°C, and the empirical parameter α related to the heat transfer of casting rolls is 1.6*10 -4 , and the empirical parameter β related to molten steel composition is 0.13, through the formula The calculated real-time casting speed v is 2.46m / s, and the casting-rolling force CF is 4kN.

[0037] In this embodiment 1, through the real-time control of the casting speed and the control of the casting and rolling force, the thickness fluctuation of the cast strip during the continuous casting process is small, and the stability of the obtained cast strip is improved.

Embodiment 2

[0039] The thickness H of the twin-roll thin strip continuous casting is set to 1.5mm, the height h of the molten pool is 195mm, the radius R of the casting roll is 463mm, and the temperature of the molten steel in the molten pool is T L is 1640°C, the solidus temperature T of the molten steel being cast B is 1448°C, and the empirical parameter α related to the heat transfer of casting rolls is 1.1*10 -4 , and the empirical parameter β related to molten steel composition is 0.08, through the formula The calculated real-time casting speed v is 1.02m / s, and the casting-rolling force CF is 10kN.

[0040] In Example 2, through the real-time control of the casting speed and the control of the casting and rolling force, the thickness fluctuation of the cast strip during the continuous casting process is small, and the stability of the obtained cast strip is improved.

Embodiment 3

[0042] The thickness H of the twin-roll thin strip continuous casting is set to 2.5mm, the height h of the molten pool is 158mm, the radius R of the casting rolls is 498mm, and the temperature of the molten steel in the molten pool is T L is 1615°C, the solidus temperature T of the molten steel being cast B is 1489°C, and the empirical parameter α related to the heat transfer of casting rolls is 1.5*10 -4 , and the empirical parameter β related to molten steel composition is 0.3, through the formula The calculated real-time casting speed v is 3.31m / s, and the casting-rolling force CF is 16kN.

[0043]In Example 3, through the real-time control of the casting speed and the control of the casting and rolling force, the fluctuation of the thickness of the cast strip during the continuous casting process is small, and the stability of the obtained cast strip is improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com