Production device of metal surface treatment liquid

A technology for metal surface treatment and production equipment, applied in transportation and packaging, chemical/physical processes, dissolution, etc., can solve problems such as inability to add, and achieve the effect of reducing risk, avoiding danger or waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

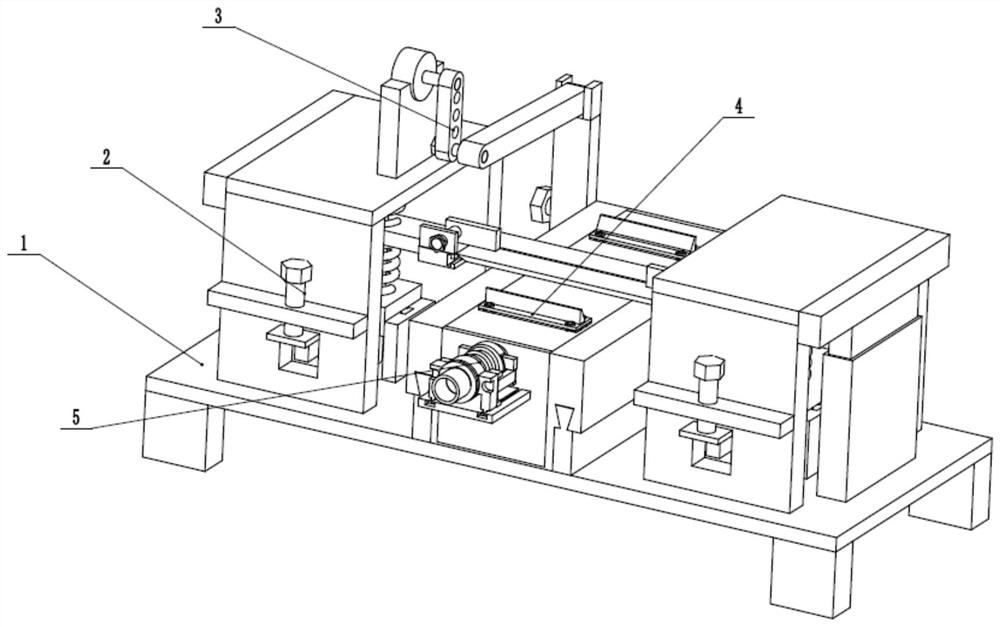

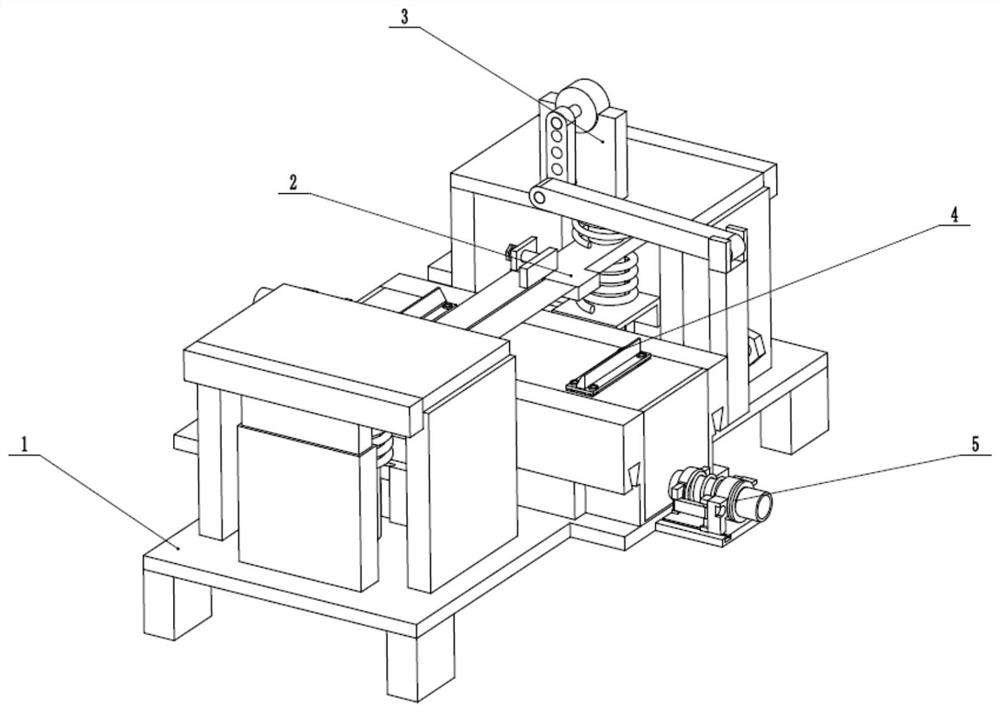

[0032] Such as Figure 1 to Figure 12As shown, the metal surface treatment liquid production device includes a production frame 1, an adjustment dispenser 2, a motion adder 3, a flow mixing box 4 and two quantitative discharge pipes 5, and the adjustment dispenser 2 is fixedly connected to the production machine On the frame 1, the motion adder 3 is fixedly connected to the upper end of the production frame 1, and the motion adder 3 is fixedly connected to the flow mixing box 4 through bolts, and the flow mixing box 4 is slidingly connected to the production frame 1. Two quantitative discharge pipes 5 are respectively fixedly connected and communicated with the front and rear ends of the flow mixing box 4, and the upper end of the flow mixing box 4 is fitted with the adjustment dispenser 2. Control the reciprocating distance of the flow mixing box 4 on the production frame 1 by the motion adder 3, and then control the amount of inflow and discharge of the two quantitative disc...

specific Embodiment approach 2

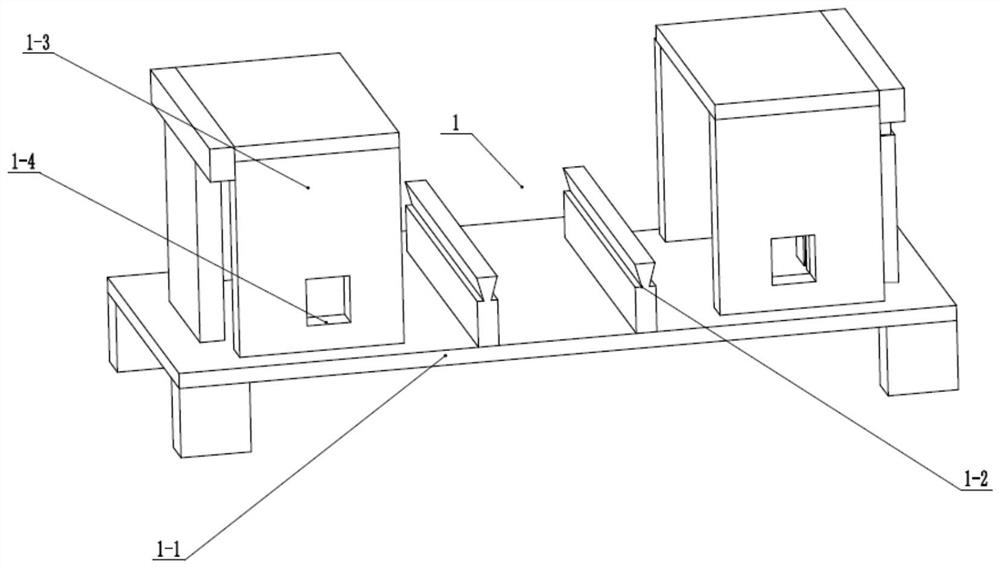

[0034] Such as Figure 1 to Figure 12 As shown, this embodiment will further illustrate Embodiment 1. The production frame 1 includes a fixed base 1-1, two fixed T-shaped sliders 1-2, two fixed frames 1-3 and two limiters. Position sliding groove 1-4, two fixed T-shaped sliders 1-2 are evenly fixedly connected on the fixed base 1-1, and two fixed frames 1-3 are respectively fixedly connected to the two upper ends of the fixed base 1-1. On the side, the rear end of the fixed frame 1-3 is provided with a through limit sliding slot 1-4.

specific Embodiment approach 3

[0036] Such as Figure 1 to Figure 12 As shown, this embodiment will further explain the second embodiment. The adjustable dispenser 2 includes two sets of longitudinally fixed sliding seats 2-1, two adjustable sliding frames 2-2, and two limit sliding tables 2- 3. Two adjusting bolts 2-4, two fixed threaded seats 2-5, two spring shafts 2-6, two buffer top plates 2-7, two lower springs 2-8 and two upper springs 2-9 Two groups of longitudinally fixed sliding seats 2-1 are respectively fixedly connected to the lower ends of the inner walls of the two fixed frames 1-3, and the adjustable sliding frame 2-2 is connected to the vertically fixed sliding seats 2-1 through the sliding block longitudinally, and the limit The sliding table 2-3 is fixedly connected to the adjustable sliding frame 2-2 and is slidably connected in the limiting sliding groove 1-4, and the lower end of the adjusting bolt 2-4 is rotatably connected in the limiting sliding table 2-3 and passed through The thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com