Method for transferring polymer particles among gas-phase polymerization reactors

A polymer particle, gas-phase polymerization technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problem that the contact time and gas velocity of the purified gas and the polymer particles cannot be adjusted, the effect of purification cannot be known, and the monitoring cannot be performed. Purification process and other problems, to achieve the effect of shortening the action cycle, simplifying the transfer steps, and increasing the transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

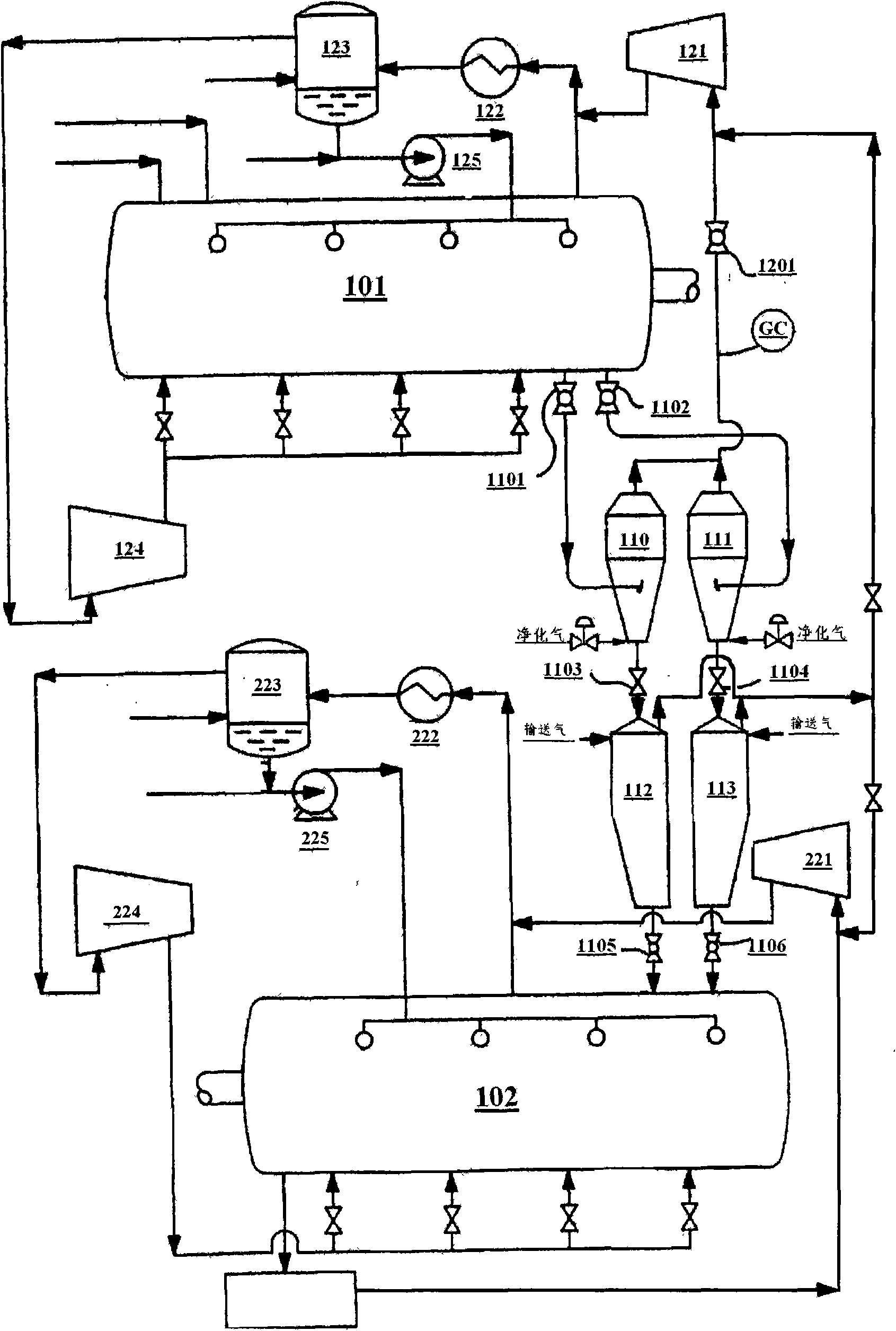

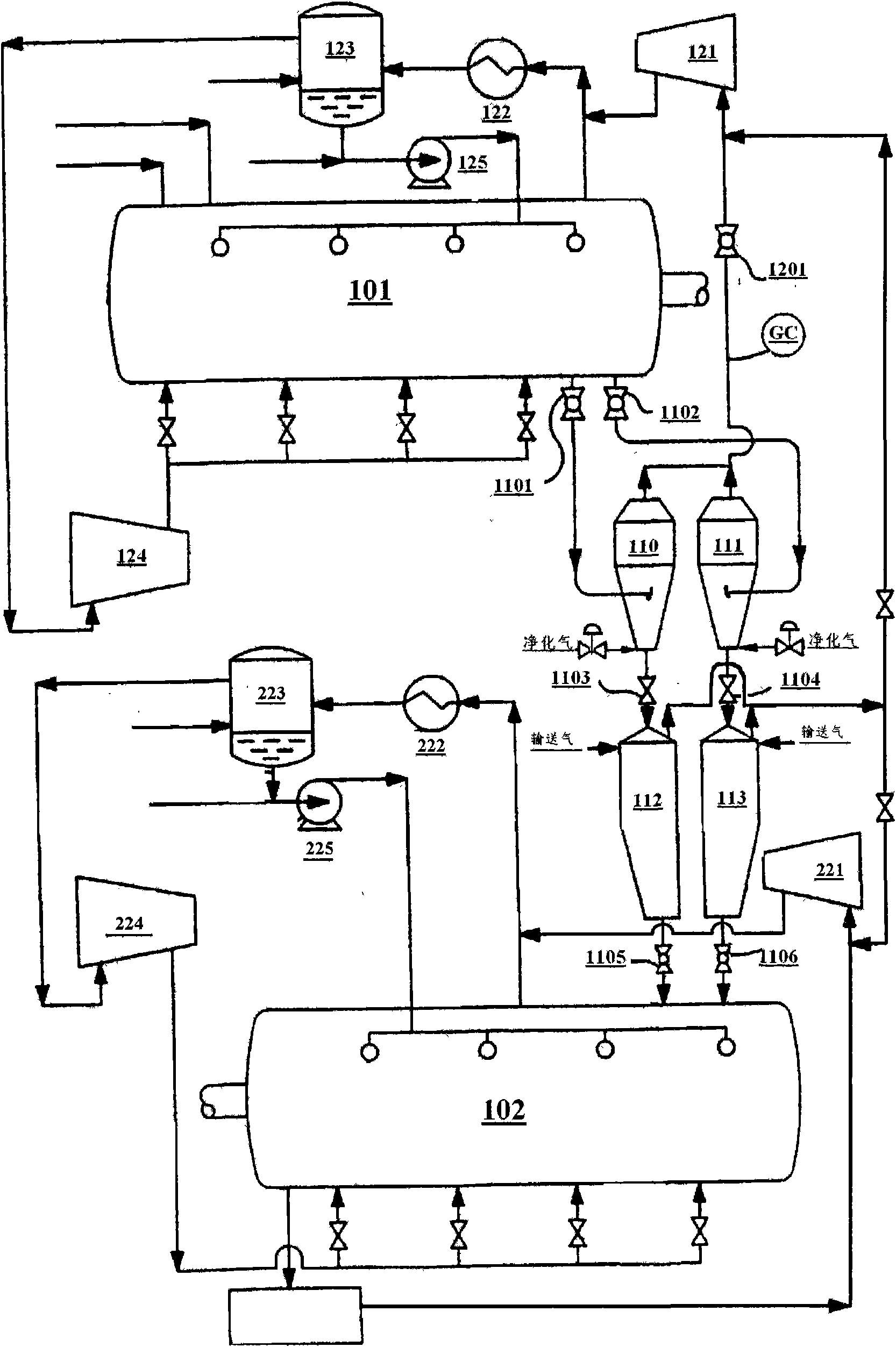

[0028] In two gas phase polymerization reactors arranged in series, propylene monomer is subjected to continuous gas phase polymerization, normally producing a solid homopolymer, with low molar content of hydrogen present in the upstream and downstream reactors. According to the present invention, only one of the two trains is used to transfer the polypropylene pellets, and a cycle time of 1 minute is used. Propylene monomer was used as purge gas, and propylene monomer was used as transport gas. The tail gas from the transfer tank is discharged to the inlet of the tail gas compressor 121 .

Embodiment 2

[0030] In two gas phase polymerization reactors arranged in series, propylene monomer is subjected to continuous gas phase polymerization, normally producing a solid homopolymer, with low molar content of hydrogen present in the upstream and downstream reactors. According to the present invention, the discharge valves 1101 and 1102 of reactor 101 use valves with adjustable openings to continuously discharge materials, instead of using pulse mode, the addition of purified gas and tail gas recovery are also carried out continuously, and only one of the two rows of equipment is used for transfer For pellets of polypropylene, a cycle time of 1 minute was used. Propylene monomer was used as purge gas, and propylene monomer was used as transport gas. The tail gas from the transfer tank is discharged to the inlet of the tail gas compressor 121 .

Embodiment 3

[0032] In two gas phase polymerization reactors arranged in series, propylene monomer is subjected to continuous gas phase polymerization, normally producing a solid homopolymer, with low molar content of hydrogen present in the upstream and downstream reactors. According to the invention, the polypropylene pellets were transferred using two trains of equipment simultaneously, using a cycle time of 1 minute. Propylene monomer was used as purge gas, and propylene monomer was used as transport gas. The tail gas from the transfer tank is discharged to the inlet of the tail gas compressor 121 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com