Patents

Literature

82results about "Preparation from ketenes/polyketenes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

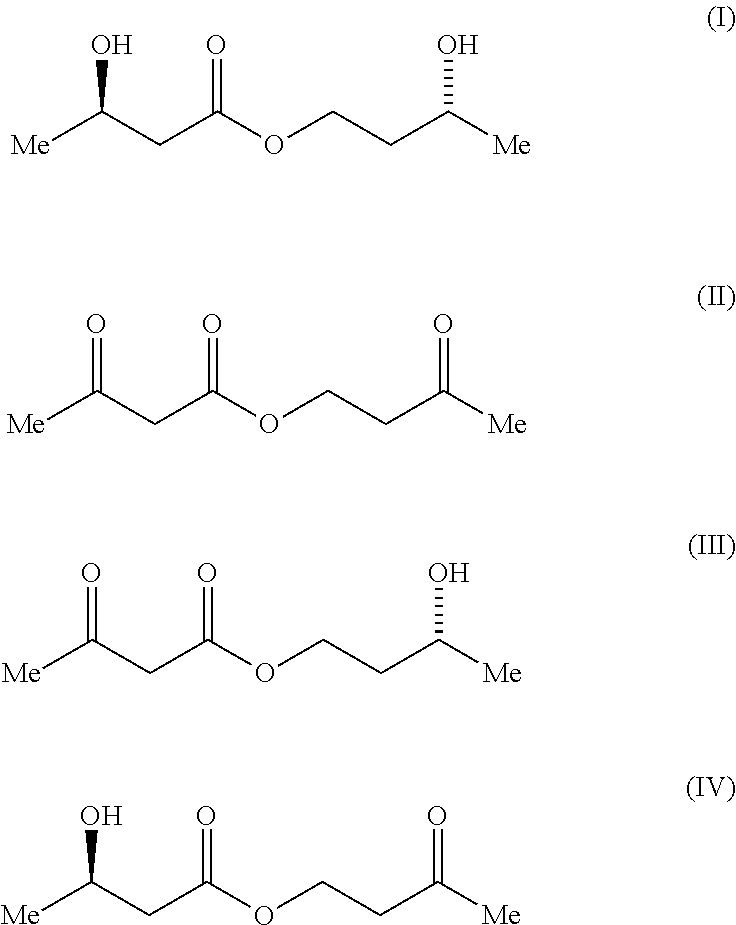

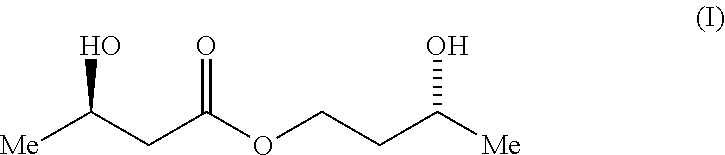

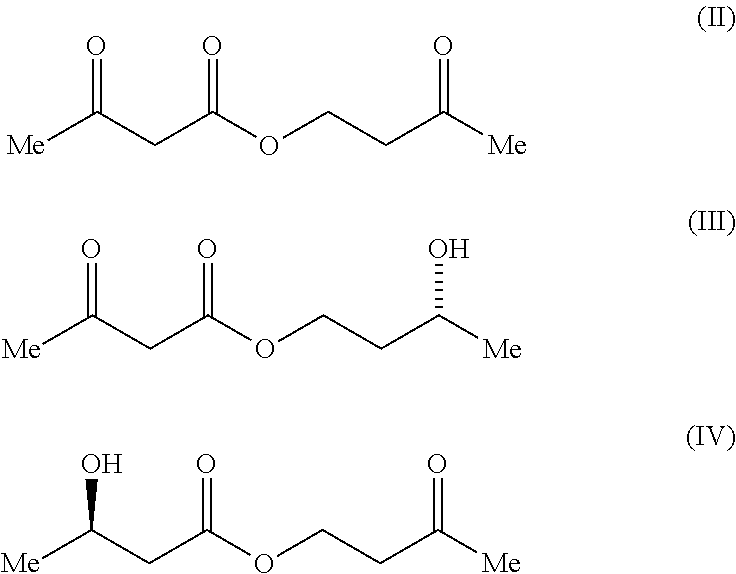

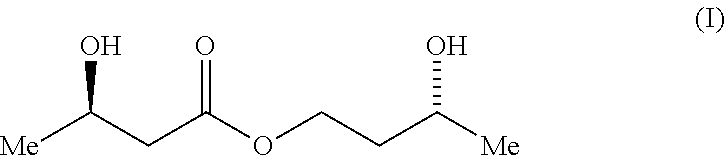

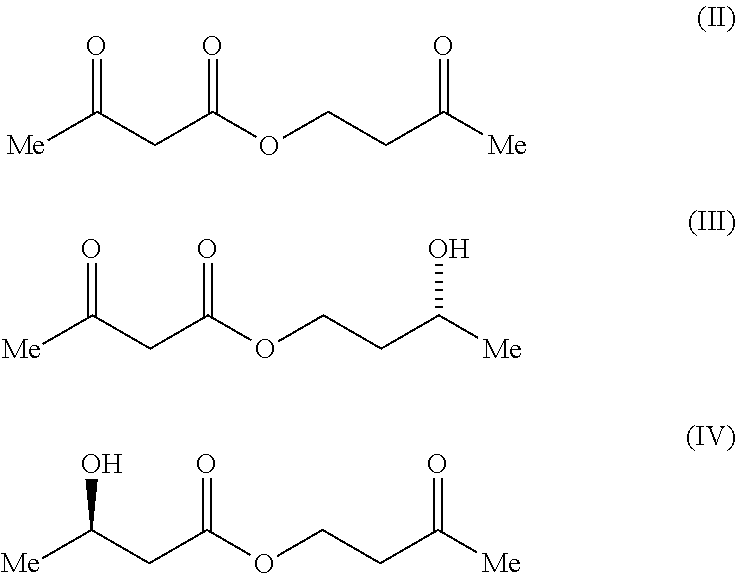

Process For The Preparation of (3R)-Hydroxybutyl (3R) -Hydroxybutyrate By Enzymatic Enantioselective Reduction Employing Lactobacillus Brevis Alcohol Dehydrogenase

ActiveUS20120064611A1Preparation from ketenes/polyketenesOxidoreductasesHydroxybutyric acidLactobacillus brevis

Owner:OXFORD UNIV INNOVATION LTD +1

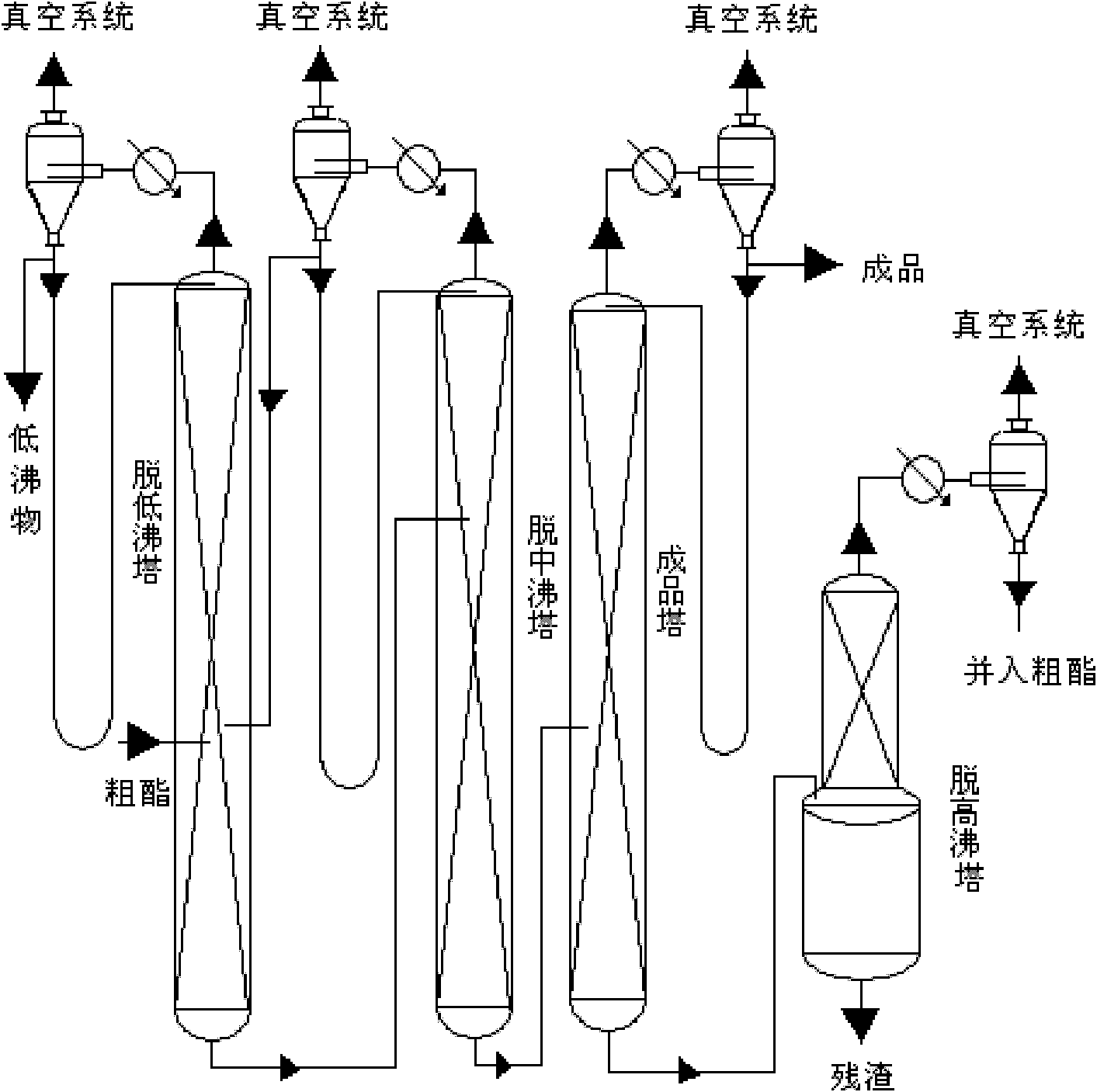

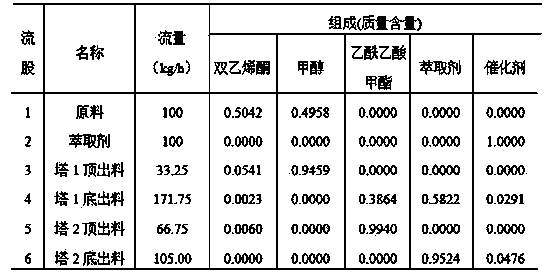

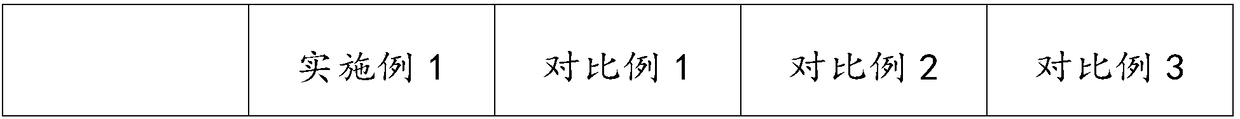

A kind of production method of methyl acetoacetate

ActiveCN102276464AHigh purityThe four-column continuous negative pressure rectification of the high boiling column obtains a high purity with a content of 99.7%Preparation from ketenes/polyketenesAcetic acidEsterification reaction

The invention relates to a method for producing methyl acetoacetate. The method is characterized by comprising the following steps of: (1) performing esterification reaction of crude diketene and methanol at the temperature of between 20 and 150 DEG C, wherein in the esterification reaction, one of tertiary amine, an ethylidene-amine-containing compound or an alkaline compound is used as a catalyst; and (2) rectifying a product generated in the esterification reaction in the step (1) continuously in four towers under negative pressure to prepare methyl acetoacetate. In the method, the esterification reaction of the crude diketene is adopted, and the diketene is not needed to be rectified and purified, so energy consumption is low, the yield is high, the catalyst is easy to obtain, reaction conditions are mild, the process is safe and a product has high content and the yield of the product is high, and the method is suitable for large-scale industrial production.

Owner:NANTONG ACETIC ACID CHEM

Methods for Producing Fluorine-Containing Hydroxyaldehyde, Fluorine-Containing Propanediol, and Fluorine-Containing Alcohol Monomer

ActiveUS20150361026A1High yieldMild conditionsPreparation by oxidation reactionsOrganic compound preparationPolymer scienceOrganic base

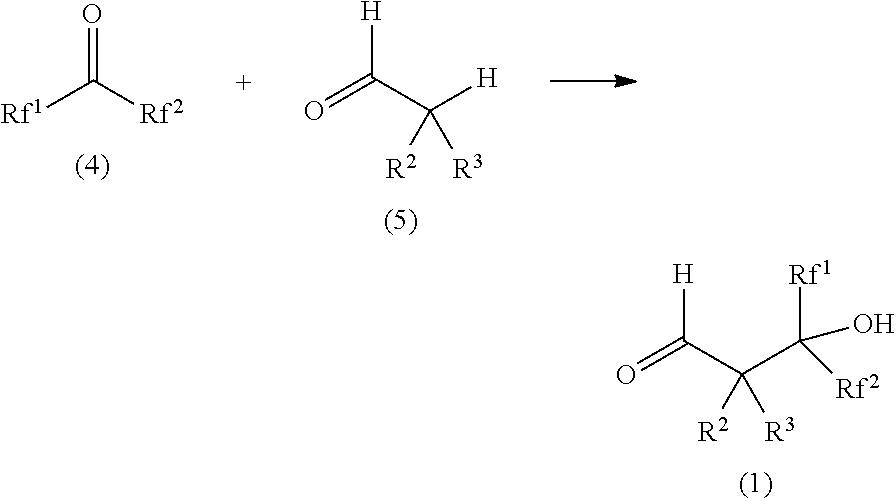

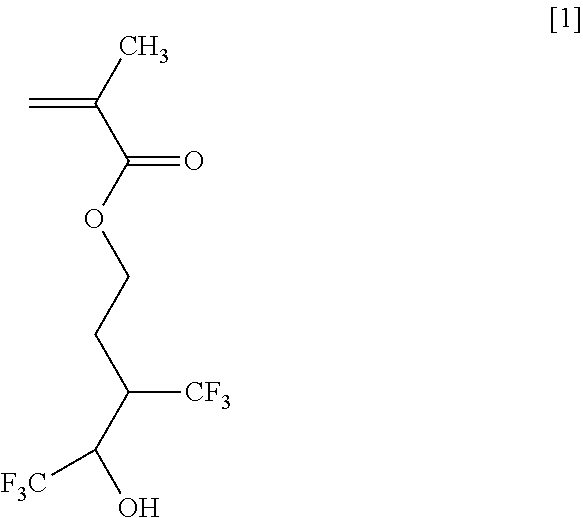

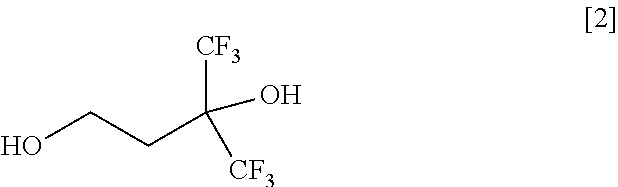

As shown by the following reaction formula, disclosed is a fluorine-containing hydroxyaldehyde production method, including the step of obtaining a fluorine-containing hydroxyaldehyde represented by the general formula (1) by reacting a fluorine-containing ketone represented by the general formula (4) and an aldehyde represented by the general formula (5) in the presence of an organic base selected from a heterocyclic compound which contains a nitrogen atom in its ring or a tertiary amine. By this production method, it is possible to obtain the fluorine-containing hydroxyaldehyde in a high yield. Furthermore, it is possible to easily obtain in high yields a fluorine-containing propanediol, which is a derivative of this fluorine-containing hydroxyaldehyde, and a fluorine-containing alcohol monomer by using the same.

Owner:CENT GLASS CO LTD

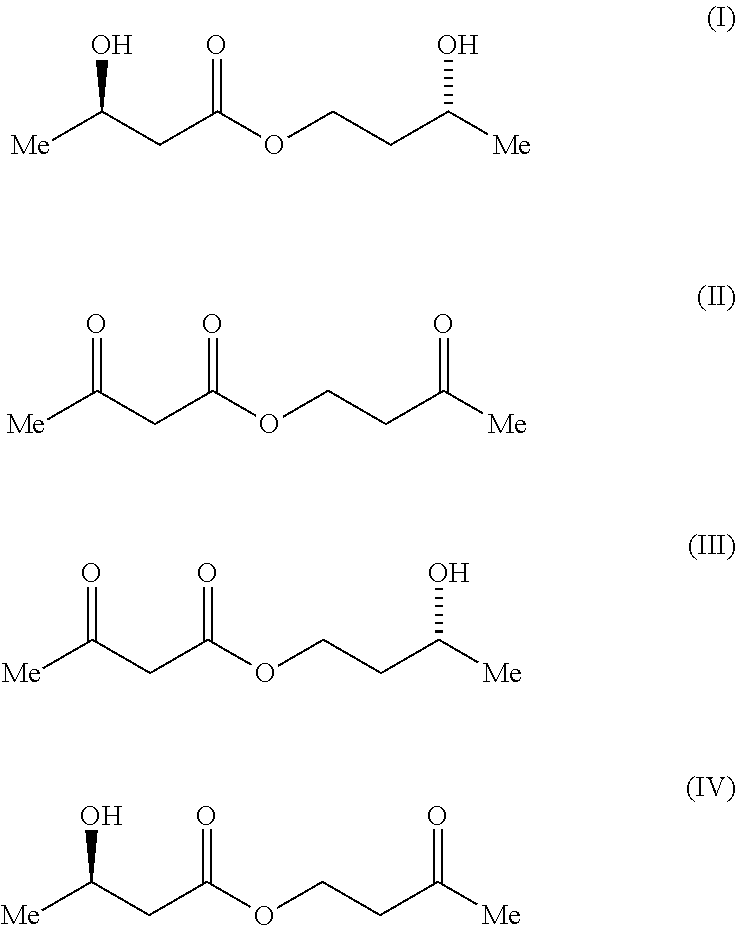

Process for the preparation of (3R)-hydroxybutyl (3R)-hydroxybutyrate by enzymatic enantioselective reduction employing Lactobacillus brevis alcohol dehydrogenase

ActiveUS9034613B2Preparation from ketenes/polyketenesOxidoreductasesLactobacillus brevisEnantio selectivity

Owner:OXFORD UNIV INNOVATION LTD +1

Preparation method of methyl acetoacetate

ActiveCN103450017AImprove stabilityReduce consumptionPreparation from ketenes/polyketenesAcetic acidNitrate

The invention provides a preparation method of methyl acetoacetate. The preparation method sequentially comprises the following steps of: (1) fully dissolving methanol and a catalyst, then adding the mixture into an esterification reaction kettle, heating up, and dropwise adding ketene dimer; (2) after completing dropwise addition, insulating, and cooling to produce crude methyl acetoacetate; (3) rectifying the crude product to obtain the finished methyl acetoacetate. The preparation method is characterized in that the catalyst in the step (1) is an amine type ionic liquid catalyst which is selected from one or more of n-butylamine nitrate, n-butylamine acetate, ethylamine nitrate, ethylamine acetate, propylamine nitrate and propylamine acetate. According to the preparation method of methyl acetoacetate, the amine type ionic liquid catalyst is researched and is good in stability, the stability of methyl acetoacetate is enhanced under the action of the catalyst, the rectification yield of a product can be improved, the technological operations are simple, the raw material consumption is reduced, and the catalyst has obvious advantages and a positive effect.

Owner:NANTONG ACETIC ACID CHEM

Preparation method of ethyl acetoacetate

ActiveCN103450018AImprove stabilityReduce consumptionPreparation from ketenes/polyketenesAcetic acidNitrate

The invention provides a preparation method of ethyl acetoacetate. The preparation method sequentially comprises the following steps of: (1) fully dissolving ethanol and a catalyst, then adding the mixture into an esterification reaction kettle, heating up, and dropwise adding ketene dimer; (2) after completing dropwise addition, insulating, and cooling to produce crude ethyl acetoacetate; (3) rectifying the crude product to obtain the finished ethyl acetoacetate. The preparation method is characterized in that the catalyst in the step (1) is an amine type ionic liquid catalyst which is selected from one or more of n-butylamine nitrate, n-butylamine acetate, ethylamine nitrate, ethylamine acetate, propylamine nitrate and propylamine acetate. According to the preparation method of ethyl acetoacetate, the amine type ionic liquid catalyst is researched and is good in stability, the stability of ethyl acetoacetate is enhanced under the action of the catalyst, the rectification yield of a product can be improved, the technological operations are simple, the raw material consumption is reduced, and the catalyst has obvious advantages and positive effects.

Owner:NANTONG ACETIC ACID CHEM

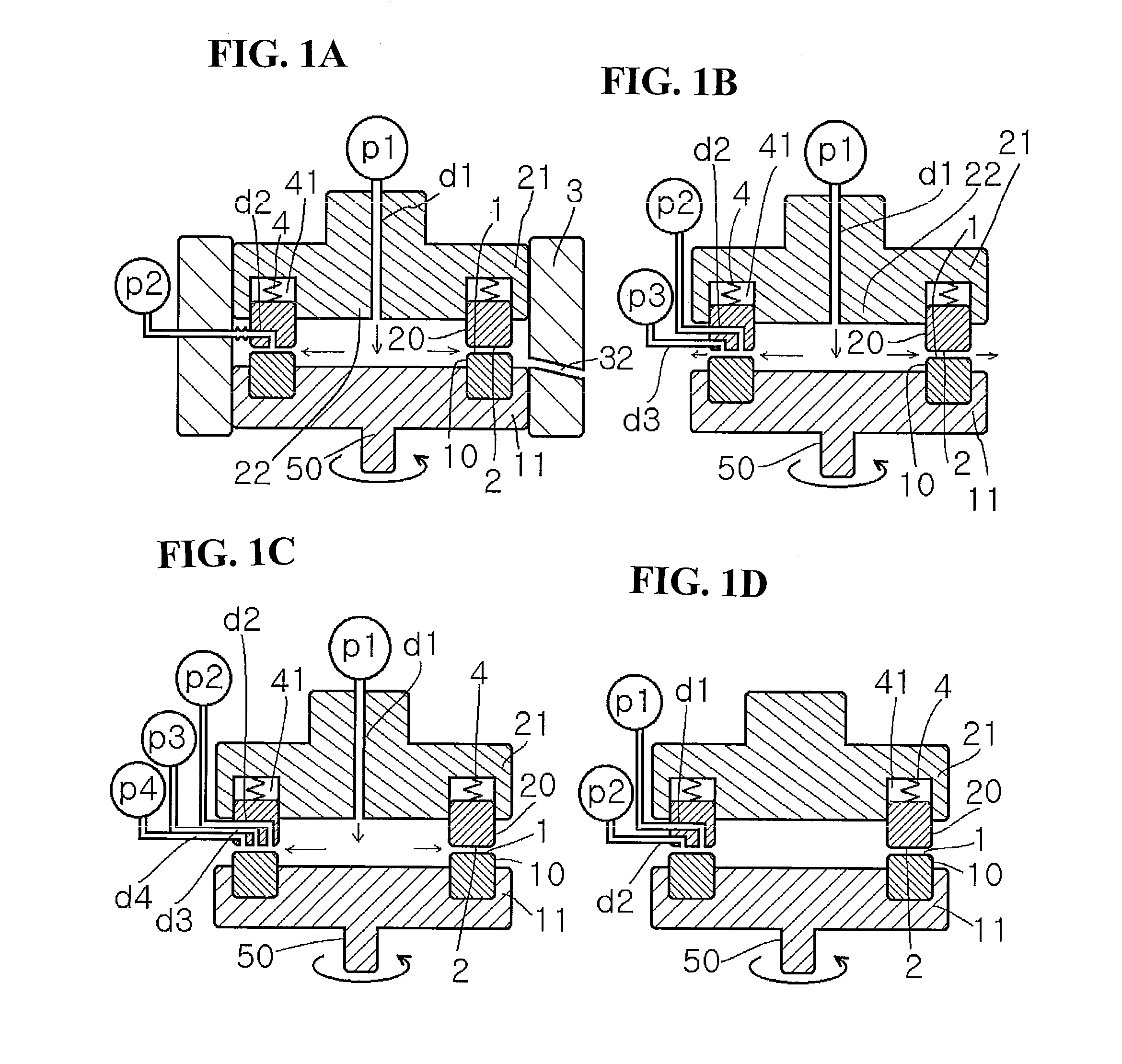

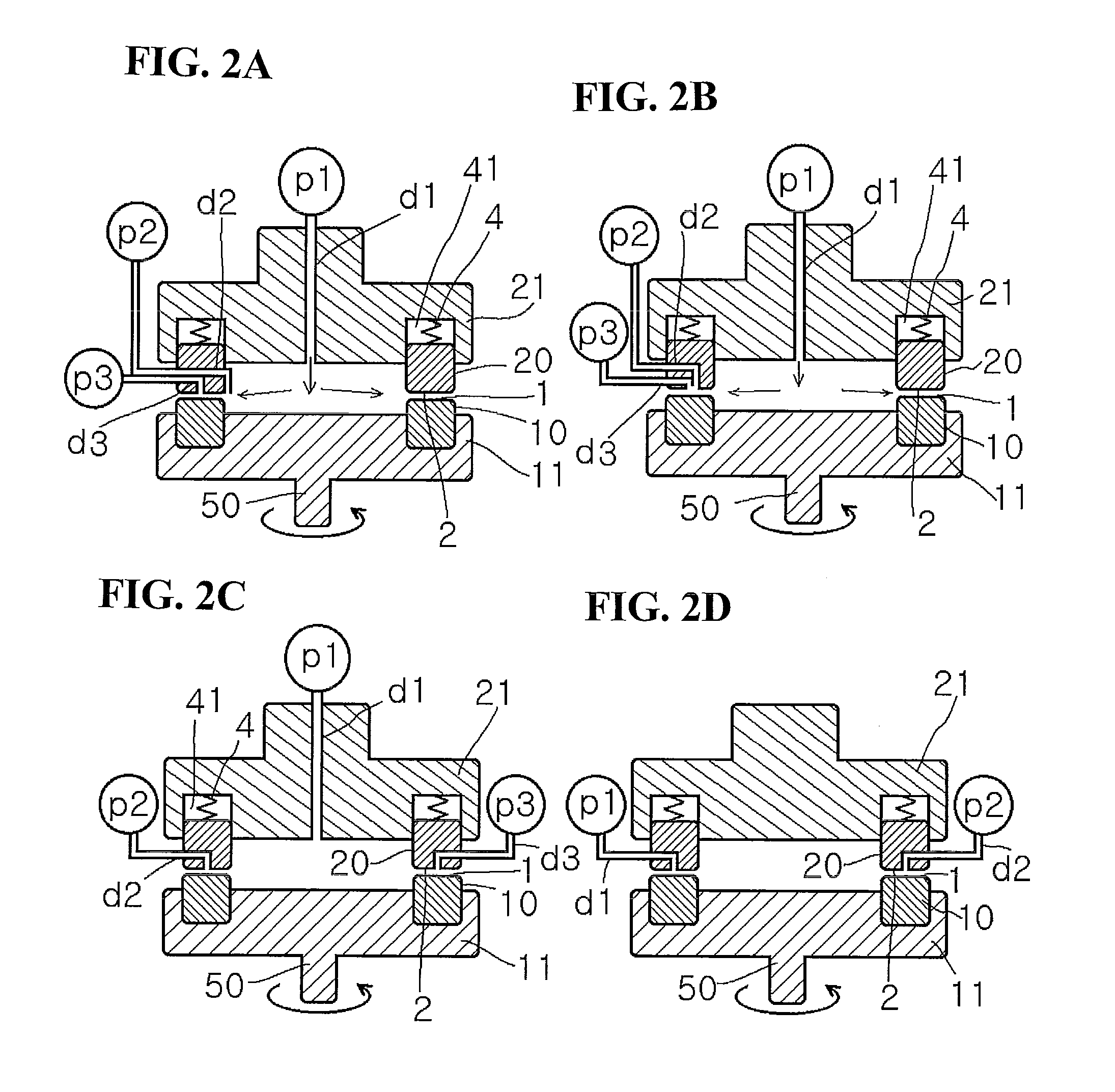

Method for producing organic compound and organic compound obtained by the method

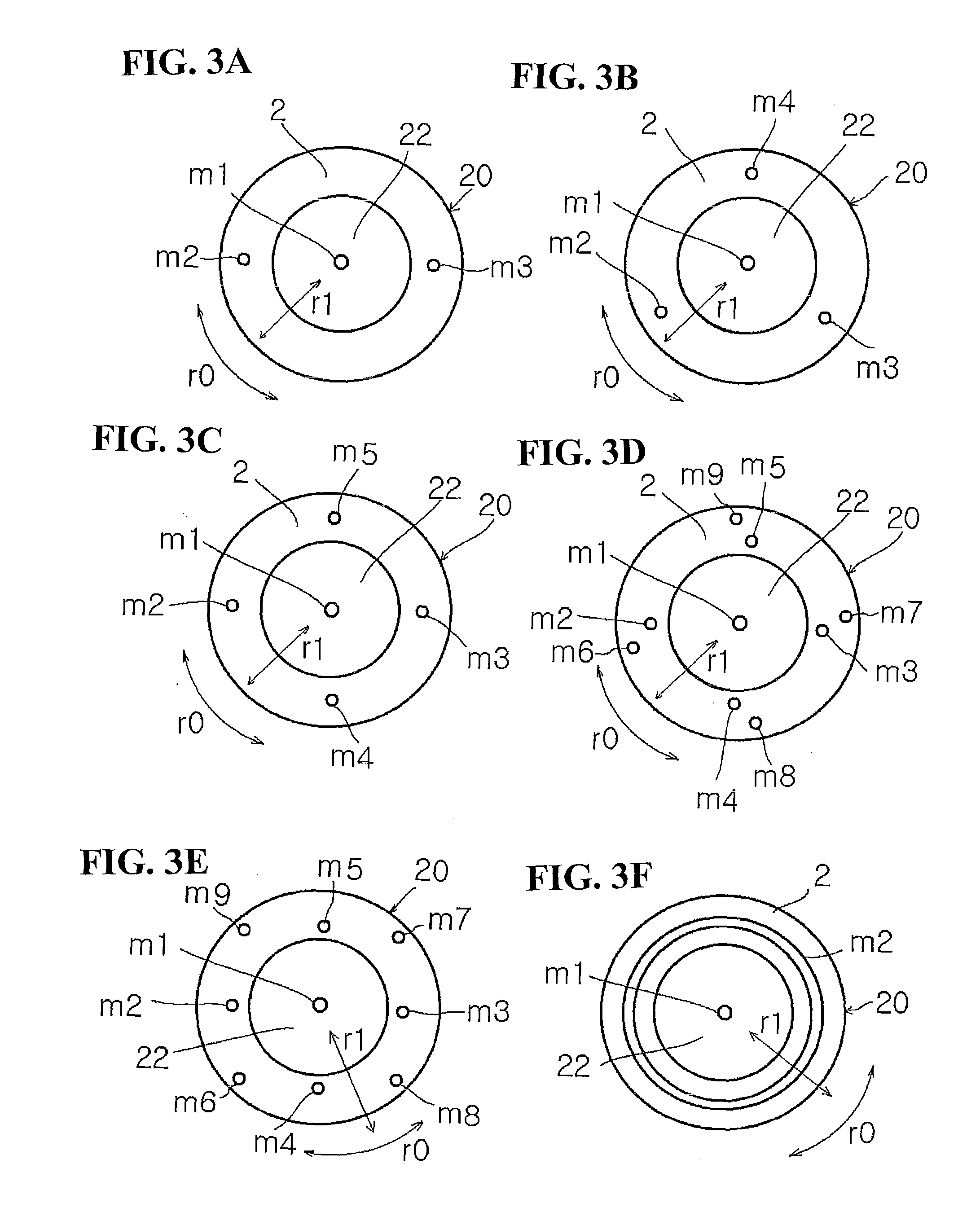

ActiveUS8592498B2Improve the level ofHigh reaction yieldCarboxylic acid nitrile preparationRotary stirring mixersProduction rateOrganic reaction

Disclosed herein are a reaction method and a production method of an organic compound which are capable of achieving high reaction selectivity according to the purpose and a high production rate of a target substance. The methods include at least two fluids, wherein at least one kind of the fluids is a fluid containing at least one organic compound and at least one kind of the fluids other than the above fluid is a fluid containing at least one reactant in the form of a liquid or solution, and the respective fluids join together in a thin film fluid foamed between processing surfaces arranged to be opposite to each other so as to be able to approach to and separate from each other, at least one of which rotates relative to the other, whereby an organic reaction is performed in the thin film fluid.

Owner:M TECH CO LTD

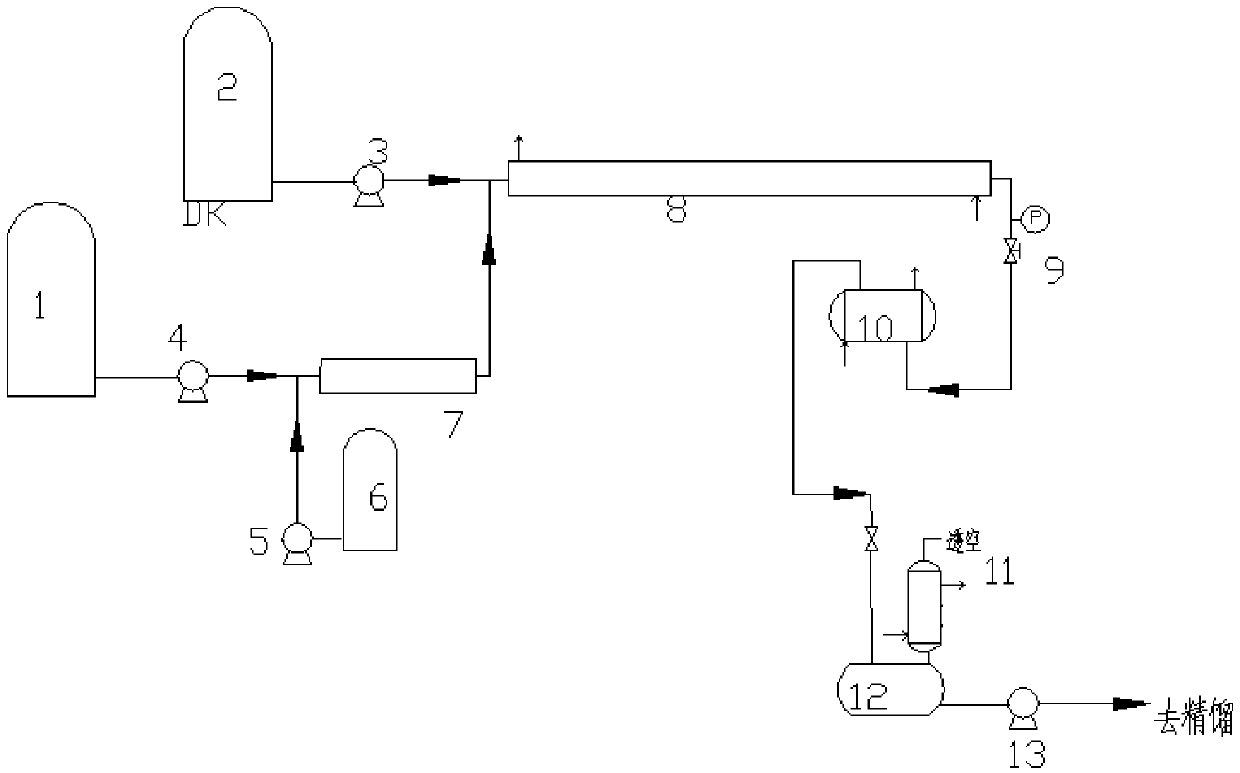

Method for continuously producing methyl acetoacetate by using micro-channel reactor

InactiveCN111039785AExtended service lifeShort reaction timePreparation from ketenes/polyketenesWater methanolPtru catalyst

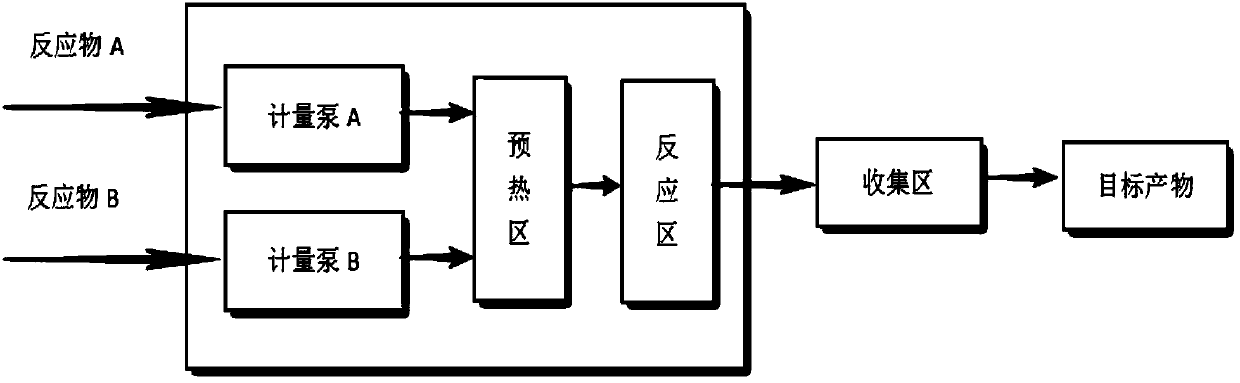

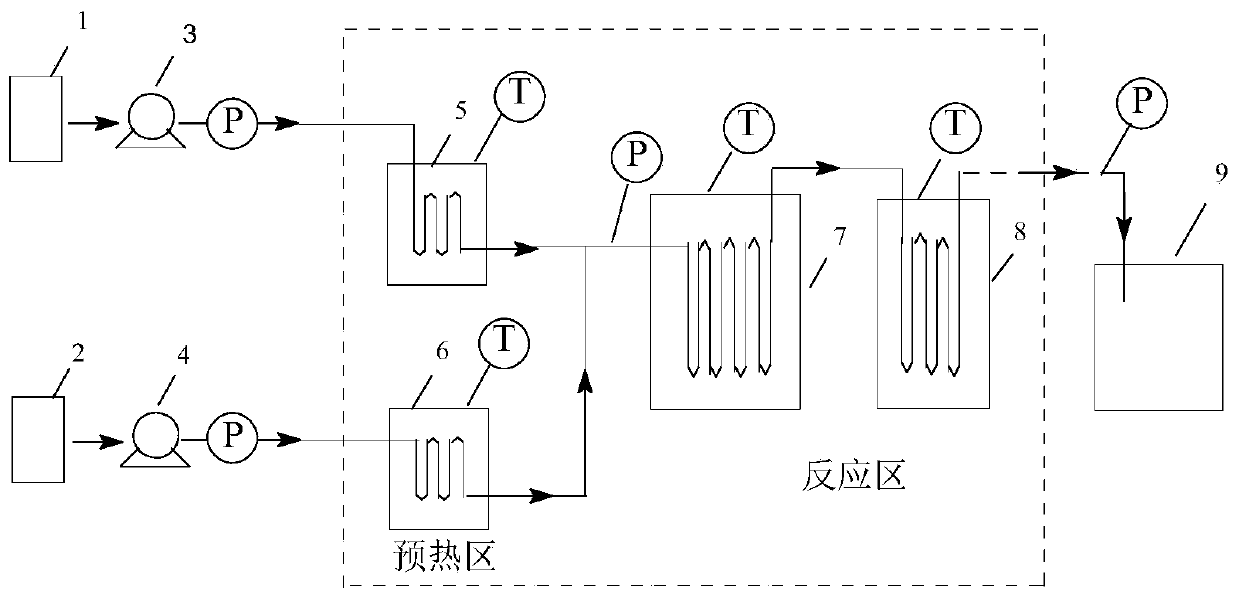

The invention discloses a method for continuously producing methyl acetoacetate by using a micro-channel reactor, and belongs to the technical field of organic synthesis processes. Diketene and absolute methanol are used as raw materials, an acid or alkali is used as a catalyst, and the preparation process of methyl acetoacetate is continuously completed in a micro-channel reactor system. According to the method, after materials are fed into a micro-channel reactor through metering pumps, preheating, mixing, reacting and separation are performed to obtain a methyl acetoacetate product. In themethod, the temperature and the residence time during the reaction process can be strictly controlled, the reaction temperature can be accurately controlled so as to prevent temperature runaway, and the safety of the reaction apparatus can be improved; due to the strong mass transfer effect of the micro-channel reactor, the mass transfer effect among the raw materials in the reaction system is enhanced, and the reaction efficiency is greatly improved.

Owner:CHANGZHOU UNIV

Production method for carrying out low boiling point recycling on ethyl acetoacetate

ActiveCN106748788AReduce lossHigh yieldOrganic compound preparationPreparation from ketenes/polyketenesRefluxAcetic acid

The invention discloses a production method for carrying out low boiling point recycling on ethyl acetoacetate. The production method comprises the following steps: adding ethyl alcohol and a catalyst triethylene diamine in a reaction kettle; carrying out heating reflux; dropwise adding diketene; keeping warm; cooling a reaction solution after a reaction is completed; adding concentrated sulfuric acid; keeping warm; filtering; carrying out continuous rectification on filtrate; rectifying to obtain a low-boiling-point substance; adding acid in the low boiling point for esterifying; rectifying to obtain the low-boiling-point substance at normal pressure after carrying out the heating reflux for 1 to 2 hours; stopping rectifying after rising the kettle temperature to be 115 to 125 DEG C; cooling to 40 to 50 DEG C; neutralizing by using solid base; enabling a neutralized material to enter a conventional negative pressure rectifying system, and rectifying to obtain an ethyl acetoacetate finished product, wherein the content of the ethyl acetoacetate finished product is greater than 99.0 percent, the acidity is smaller than 0.05 percent, and the product recovery rate is 95 percent or above. According to the production method disclosed by the invention, loss of the ethyl acetoacetate is reduced, the total yield of the ethyl acetoacetate is increased, a resource can be recycled and reutilized, and the cost is reduced.

Owner:NANTONG ACETIC ACID CHEM

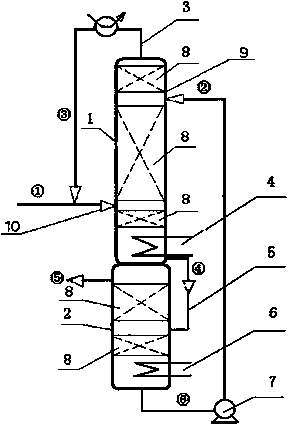

Process of continuously producing methyl acetoacetate

InactiveCN105384631AFast outputIncrease finished productOrganic compound preparationPreparation from ketenes/polyketenesAcetic acidNitrogen

The invention discloses a process of continuously producing methyl acetoacetate and relates to the technical field of production of chemical raw materials. The production process comprises the following steps of firstly, welding a separation board at the middle of an esterification reactor for separating the esterification reactor into a cooling bin and an insulating bin; secondly, adding a methyl acetoacetate finished product into the esterification reactor to serve as a bottom material in the reactor, and meanwhile, simultaneously dropping DK and methanol into the cooling bin; thirdly, realizing water cooling and air cooling in the cooling bin; after the cooling bin is cooled, realizing pressurization; after pressurization, enabling a product to overflow to the inside of the insulating bin through an overflow pipe; during overflowing, adding diketene on the overflow pipe; fourthly, when the product in the insulation bin reaches a certain amount, transferring the methyl acetoacetate to the inside of a rectifying tower through a transfer pump; fifthly, vacuumizing the inside of the rectifying tower for exhausting air, and meanwhile, inputting nitrogen, and rectifying the methyl acetoacetate in a reflux state to obtain a final product at the moment. According to the process disclosed by the invention, quick production can be realized, the finished product output is improved, the accuracy in control is realized, and the time and the cost are saved.

Owner:JIANGSU TIANCHENG BIOCHEM PROD

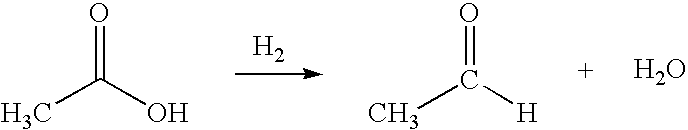

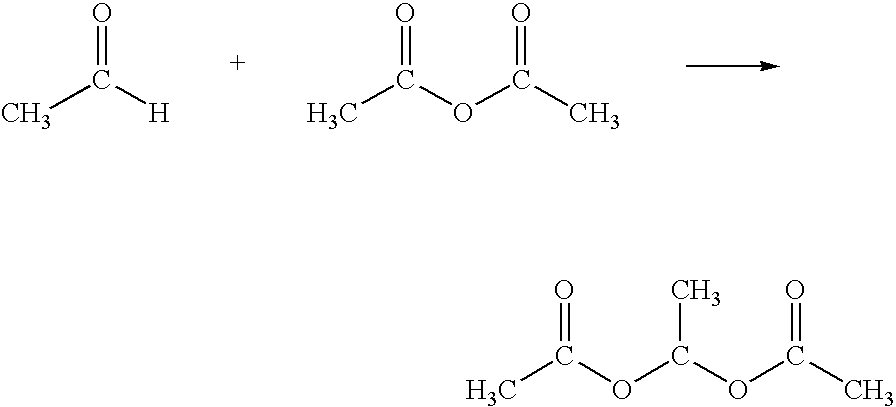

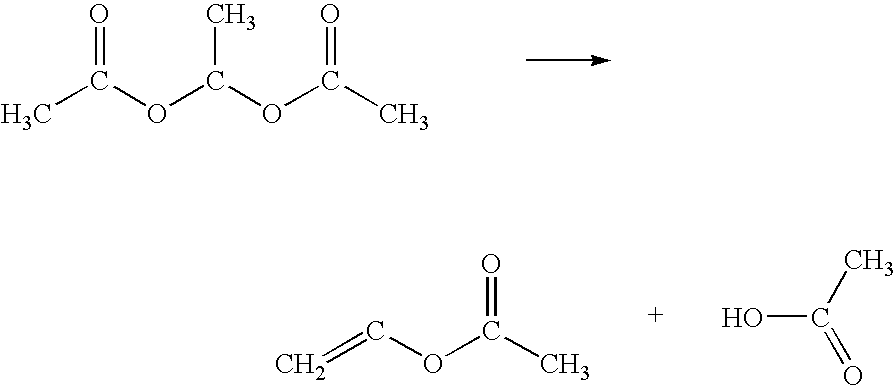

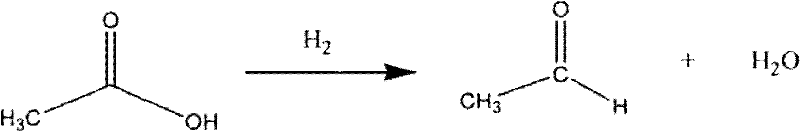

Integrated process for the production of vinyl acetate from acetic acid via acetaldehyde

This invention provides an integrated multistep economical process for the production of vinyl acetate monomer (VAM) from acetic acid in the vapor phase. First, acetic acid is selectively hydrogenated over a hydrogenating catalyst composition to form acetaldehyde. Acetaldehyde so formed can be converted to ethylidene diacetate via reaction with acetic anhydride. In a subsequent step so formed ethylidene diacetate is thermally decomposed to form VAM and acetic acid. Alternatively, acetaldehyde formed in the first step can selectively be reacted with ketene to form VAM. In an embodiment of this invention reaction of acetic acid and hydrogen over platinum and iron supported on silica selectively produces acetaldehyde in a vapor phase at a temperature of about 300° C., which is selectively hydrogenated over platinum supported catalyst to form ethanol and dehydrated over NAFION catalyst to form ethylene at a temperature of about 185° C., which is mixed with molecular oxygen, acetic acid and reacted over a palladium / gold / potassium catalyst supported on titania to form VAM at a temperature of about 150° C. to 170° C.

Owner:CELANESE INT CORP

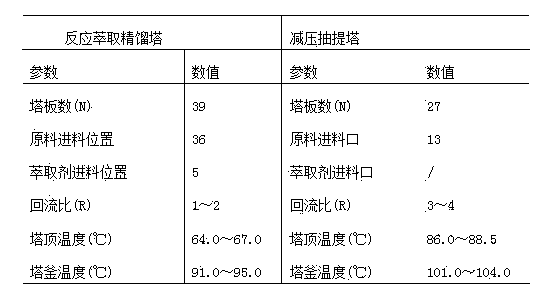

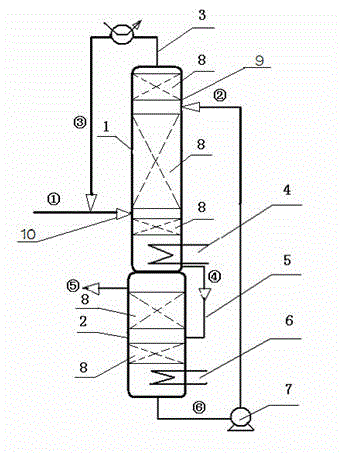

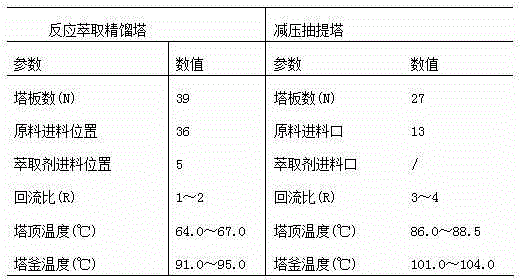

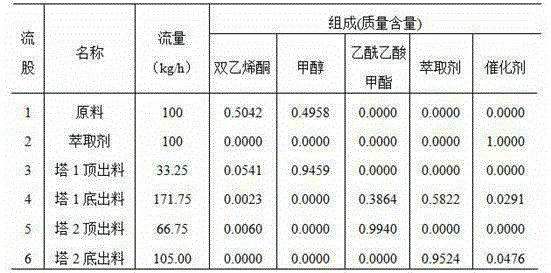

Method for preparing methyl acetoacetate

InactiveCN103864616AHigh purityRaise the ratioPreparation from ketenes/polyketenesCarboxylic acid esters separation/purificationRefluxAcetic acid

The invention discloses a method for preparing methyl acetoacetate. The method comprises the following steps: adding a catalyst once, continuously adding ketene dimer and a methanol solution through a raw material feeding hole, continuously adding an extraction agent through an extraction agent feeding hole, simultaneously adding two materials into a reaction-extraction rectifying tower, and starting heating; carrying out total reflux so as to obtain the methanol solution through the tower top of the reaction-extraction rectifying tower and obtain a mixed liquid of the methyl acetoacetate, the catalyst and the extraction agent through the tower bottom of the reaction-extraction rectifying tower, and enabling the mixed liquid to flow into a decompression extraction tower from a tower-bottom discharging hole, so as to obtain a target product, namely the methyl acetoacetate from the tower top of the decompression extraction tower. Due to the arrangement of the reaction-extraction rectifying tower and the decompression extraction tower, the methyl acetoacetate is prepared by virtue of a reaction-rectification and extraction-separation integrated reaction, the materials are fed once, and the catalyst and the extraction agent can be recycled, so that the operation is simple, the cost is lowered, the purity and rate of the prepared methyl acetoacetate are high, and the energy consumption is reduced.

Owner:NANJING NORMAL UNIVERSITY

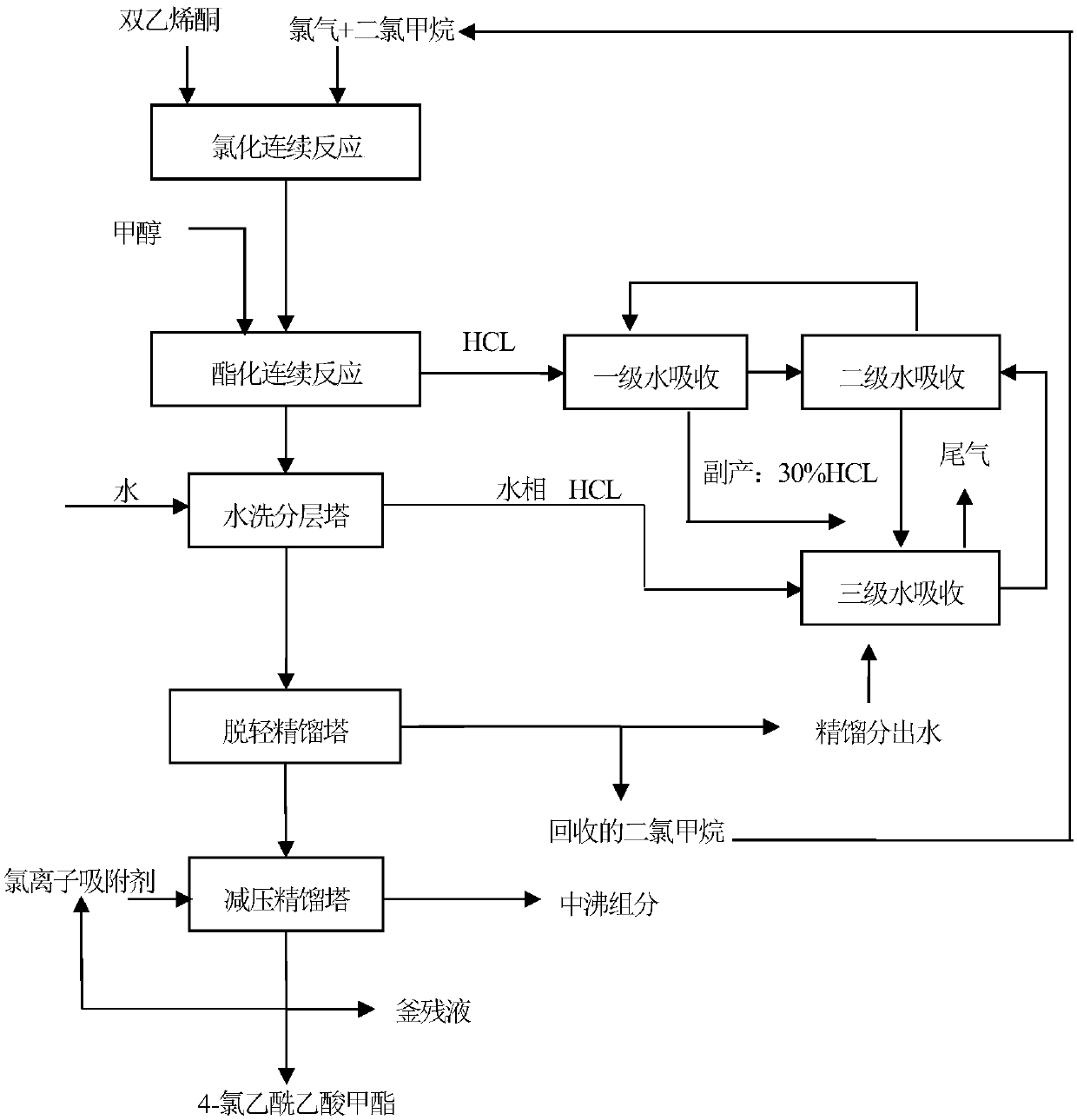

Post-treatment method for continuously synthesizing methyl 4-chloroacetoacetate

ActiveCN107915631AHigh purityNothing producedChlorine/hydrogen-chloride purificationOrganic compound preparationSeparation technologyDiketene

The invention belongs to the field of chemical engineering and in particular relates to a post-treatment method for continuously synthesizing methyl 4-chloroacetoacetate. The post-treatment method comprises the following steps: taking diketene, chlorine gas, dichloromethane and methanol as raw materials; inoculating HCl tail gas generated in a process of synthesizing the methyl 4-chloroacetoacetate into a three-grade HCl absorption system; carrying out esterification reaction to obtain a dichloromethane solution of the methyl 4-chloroacetoacetate; adding the dichloromethane solution into a water-washing layering tower; after carrying out water washing, removing the three-grade HCl absorption system from a water phase; after conveying an organic phase into a light component rectifying tower, continuously feeding the organic phase into a negative-pressure rectifying tower from a tower kettle through a feeding pump, so as to obtain a methyl 4-chloroacetoacetate finished product. A byproduct of the HCl absorption system is 25 to 30 percent industrial hydrochloric acid and can be used for selling. The light component rectifying tower and a decompression rectifying tower are used for continuously rectifying and separating a solvent and the product; the solvent can be recycled and applied; a separation technology is green and environmentally friendly and the rectifying efficiency is greatly improved.

Owner:NANTONG ACETIC ACID CHEM +1

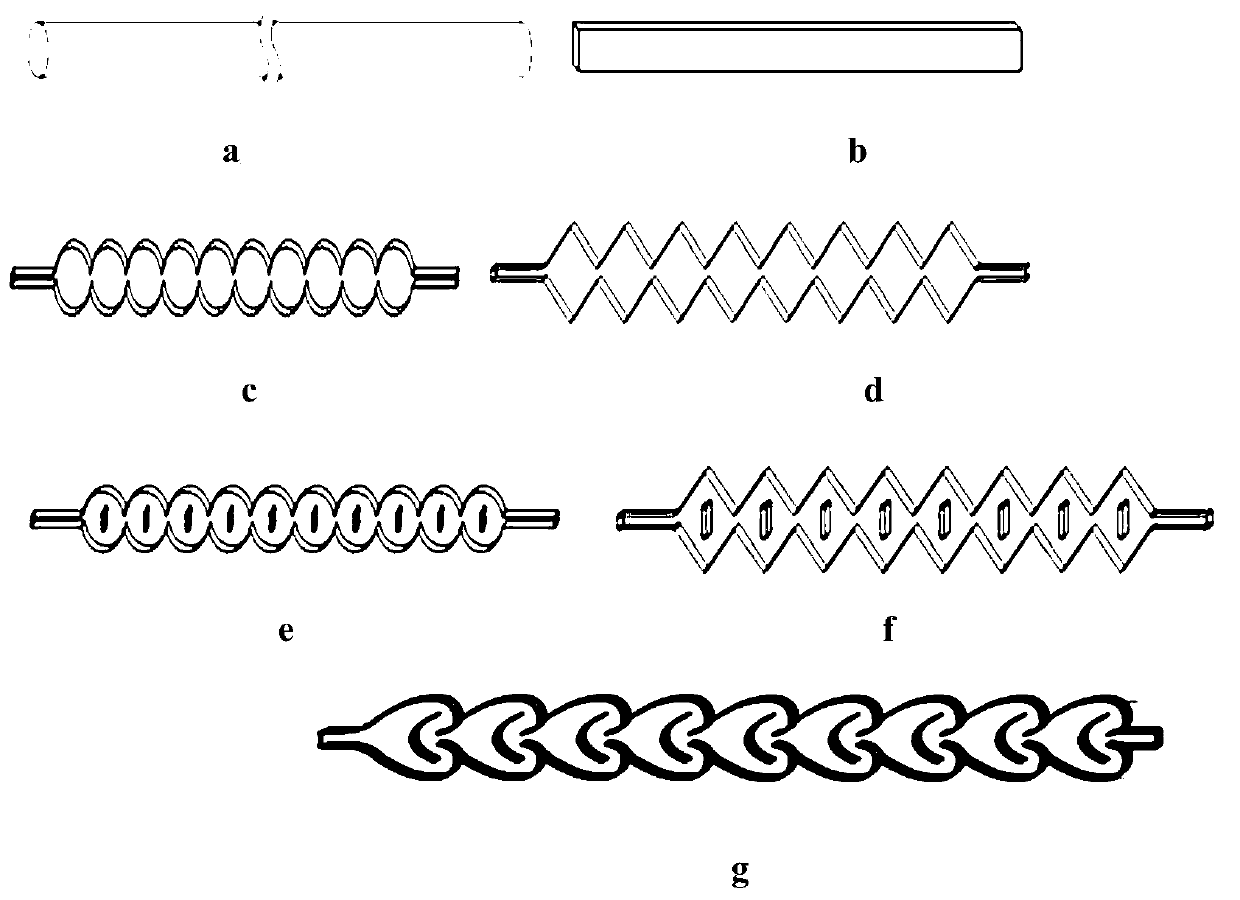

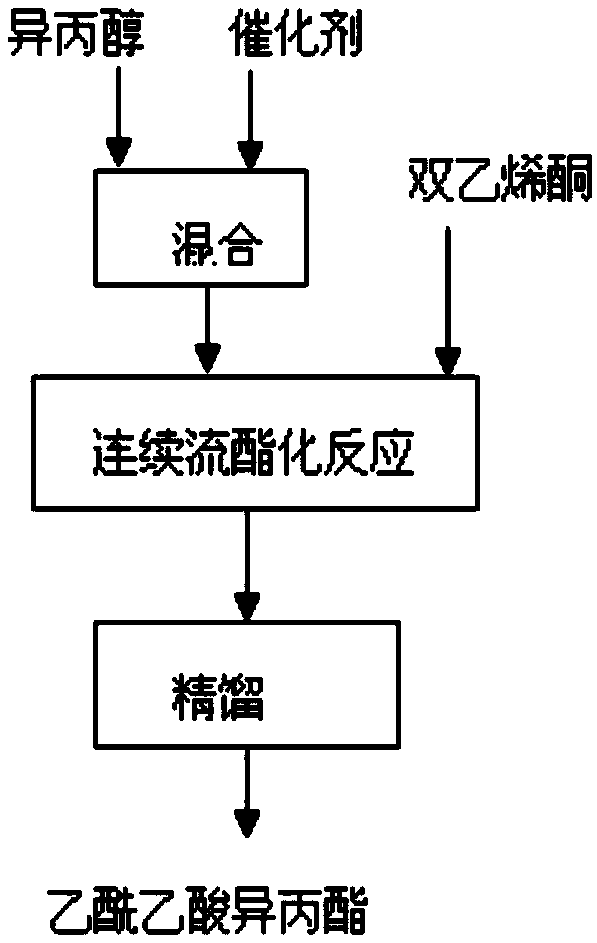

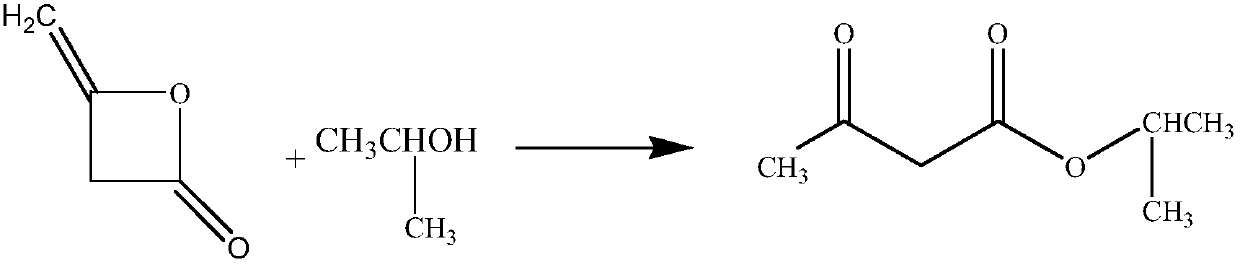

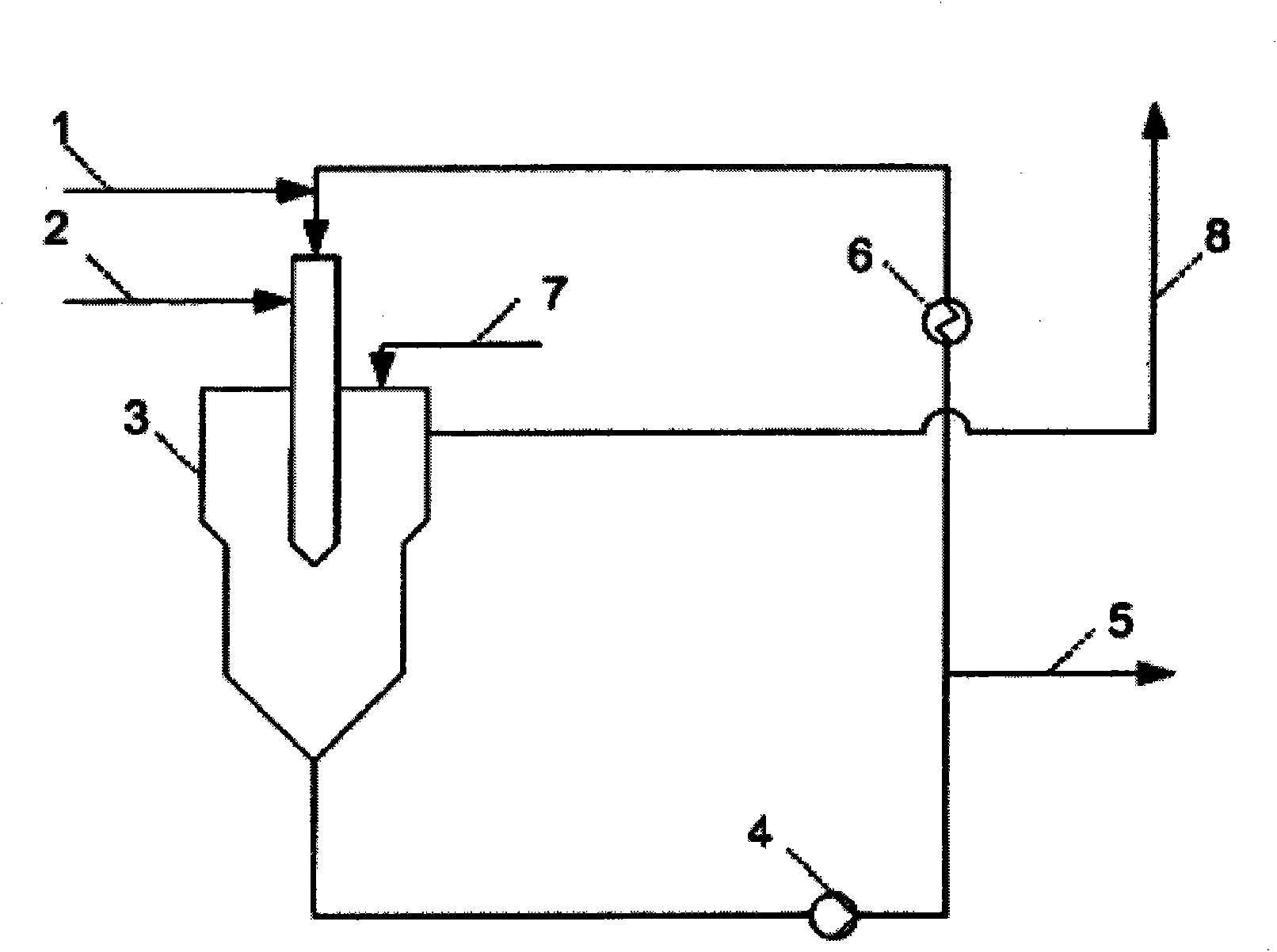

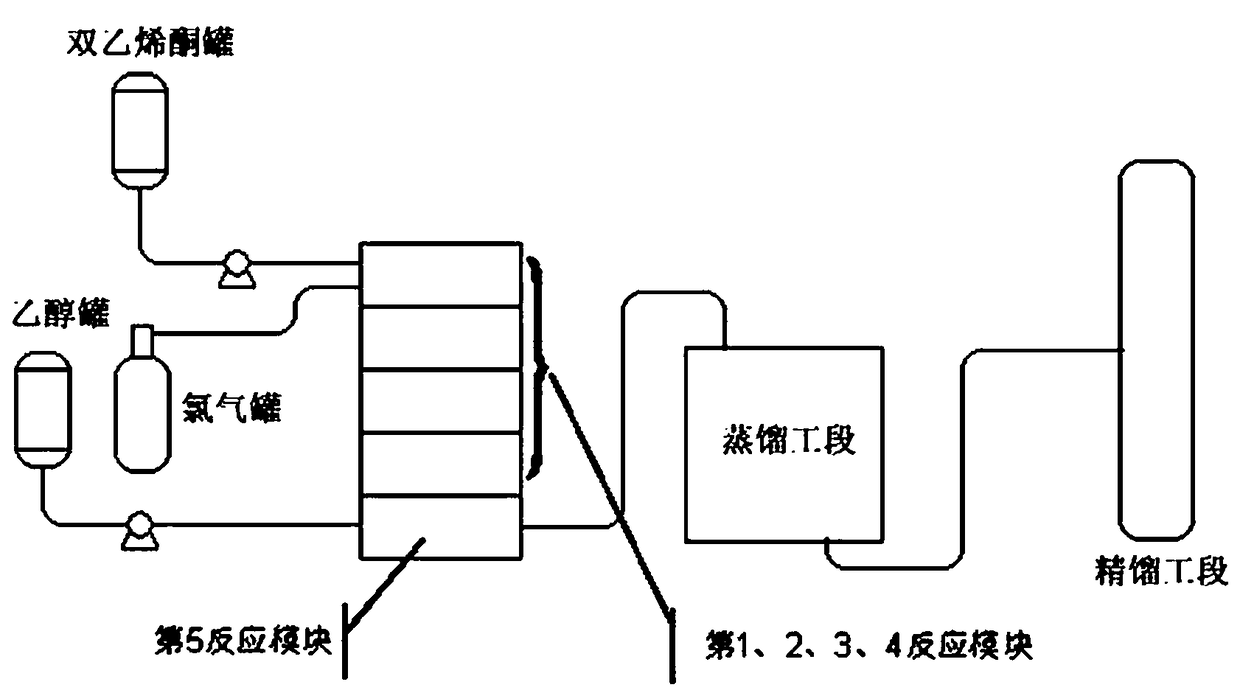

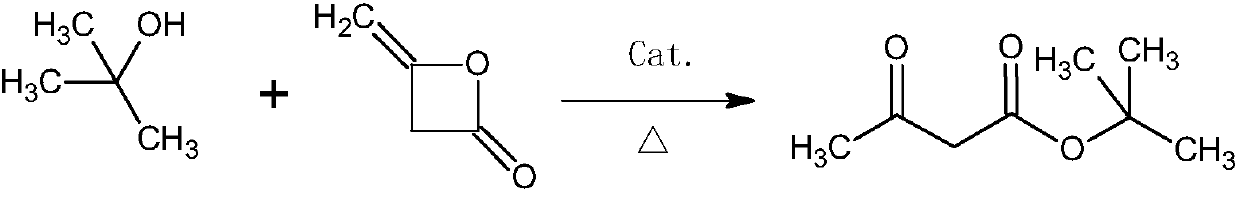

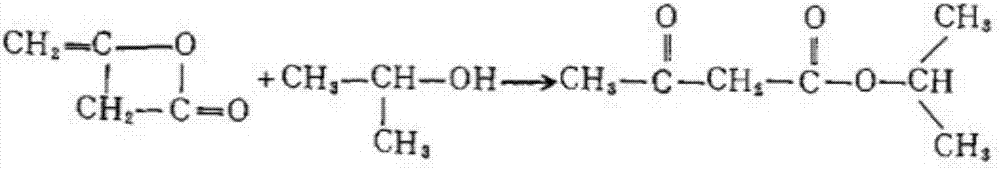

Tube type continuous flow reaction device and preparation method of isopropyl acetoacetate

InactiveCN110294674AReduce generationHigh yieldOrganic compound preparationPreparation from ketenes/polyketenesBuffer tankProcess engineering

The invention provides a tube type continuous flow reaction device. The tube type continuous flow reaction device is characterized in that an isopropanol metering tank is connected with a catalyst mixing section through an isopropanol metering pump, and a catalyst metering tank is connected between the isopropanol metering tank and the catalyst mixing section; the other end of the catalyst mixingsection and a diketene metering tank are respectively connected with a tube type continuous flow reactor; the other end of the tube type continuous flow reactor is sequentially connected with a crudeester condenser, a crude ester buffer tank and a crude ester feeding pump; a pressure pump is arranged between the tube type continuous flow reactor and the crude ester condenser, and a hollow condenser is arranged on the crude ester buffer tank. The invention also provides a method using the tube type continuous flow reaction device to prepare the isopropyl acetoacetate. The tube type continuousflow reaction device has the advantages that a technology using the tube type continuous flow reactor to prepare the isopropyl acetoacetate is studied, so that the reaction staying time is greatly shortened, the side reaction is reduced, and the yield rate and content of the product are increased; furthermore, the difficulty in rectification separation is decreased, the production cost is reduced,and the safety risk in production is greatly decreased.

Owner:NANTONG ACETIC ACID CHEM

Technology method capable of continuously carrying out methyl acetoacetate production

InactiveCN104262153AReduce energy consumptionIncrease contentOrganic compound preparationPreparation from ketenes/polyketenesThermal insulationSlag

The invention discloses a technology method capable of continuously carrying out methyl acetoacetate production, and relates to the technology field of chemical raw material production. The technology production comprises the following steps: adding a methyl acetate finished product into an esterification reactor as a reactor substrate, simultaneously dropwise adding DK and methanol into the reactor; cooling the sleeve of the esterification reactor; keeping on dropwise adding until the fluid in the esterification reactor starts to overflow to the thermal insulation reactor; adding diketene from the overflow pipe; when the fluid in the thermal insulation reactor reaches a certain amount, making the methyl acetoacetate in the thermal insulation reactor overflow to the thermal insulation transfer tank at a constant temperature; pumping the coarse methyl acetoacetate in the thermal insulation transfer tank to a rectifying tower; feeding the coarse product into the rectifying tower from the middle of the rectifying tower, increasing the vacuum degree, carrying out rectification under a certain reflux state so as to obtain finished products; and discharging light components from the tower top, finished products from the middle of the tower, and slag from the tower bottom. The provided technology method is capable of improving work efficiency, greatly increasing the production power, reducing part of steam energy consumption, and saving the equipment investment, can carry out rectification in one tower, and thus reduces the steam energy consumption, moreover the operation is easy to control, and products with a high content are more easily obtained.

Owner:JIANGSU TIANCHENG BIOCHEM PROD

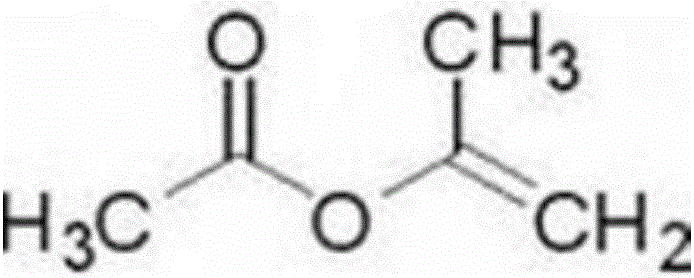

Energy-saving efficient isopropenyl acetate synthesis method

ActiveCN105777540AImprove responseIncrease productivityChemical industryPreparation from ketenes/polyketenesSynthesis methodsEthenone

The invention discloses an energy-saving efficient isopropenyl acetate synthesis method which comprises the following steps: (1) feeding acetic acid into a container, performing heating treatment on the acetic acid so as to generate an ethenone gas from the acetic acid in a catalytic cracking manner, introducing the ethenone gas into a cooler; (2) feeding an acetone solution into a mixing dish, simultaneously feeding a catalyst into the mixing dish, mixing, uniformly stirring, pumping the mixed liquid into the cooler by using a metering pump; (3) conveying the mixed gas in the cooler into a synthesis reaction tower, and enabling the mixed gas to generate a reaction gas in the synthesis reaction tower; and (4) condensing the generated reaction gas so as to obtain a coarse product, refining the coarse product, cooling, crystallizing and drying, thereby obtaining a product. According to the energy-saving efficient isopropenyl acetate synthesis method disclosed by the invention, the ethenone gas and the acetone steam are enabled to have homogeneous reaction directly, so that the reaction efficiency is effectively improved, the transfer amount of acetone is greatly reduced, and the comprehensive utilization rate is increased.

Owner:衢州伟荣药化股份有限公司

Wethod for preparation acetylacetic ester

Nitrogen-containing cyclic organic bases are used as catalysts in a method for the production of acetoacetic acid esters by reacting diketene with a benzyl alcohol in presence of a solvent.

Owner:DAICEL CHEM IND LTD

Process for the preparation of alkyl 3,3-dialkoxypropionates

InactiveCN101842344AOrganic compound preparationPreparation from ketenes/polyketenesPropionateFormate

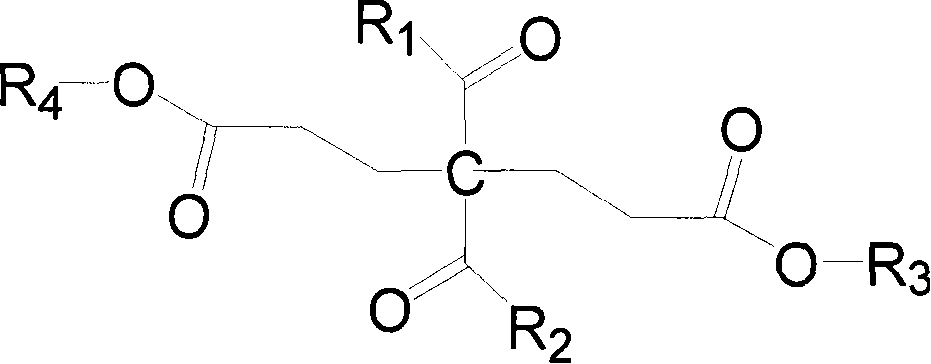

The present invention relates to a continuous process for preparing alkyl 3,3-dialkoxy-propionates of the formula (RO)2CHCH2CO2R, wherein R is C1-6 alkyl, by reacting ketene with an ortho formate of formula (RO)3CH in the presence of an acidic catalyst, characterized in that the reaction is carried out in a loop reactor.

Owner:LONZA LTD

Microchannel reaction method of 4-chloroethyl acetoacetate and device

ActiveCN109503381AReduce generationShort stayOrganic compound preparationPreparation from ketenes/polyketenesDistillationReaction temperature

The invention relates to a microchannel reaction method of 4-chloroethyl acetoacetate and a device. The method is characterized by comprising the following steps: 1. mixing a ketene dimer and dichloromethane according to the volume ratio of (2 to 3.6): 1 in a ketene dimer tank, then, carrying out charging from a first reaction module at a flow velocity of 10mL / min to 25mL / min, introducing chlorinegas to the first reaction module, and controlling the chlorine gas pressure to 0.25MPa to 0.3MPa, the flow velocity to 1,500mL / min to 7,500mL / min and the reaction temperature to -18 DEG C to 3 DEG C;2. introducing anhydrous ethanol to a fifth reaction module when a chlorination reaction solution enters the fifth reaction module, and controlling the flow velocity to 6mL / min to 10mL / min and the reaction temperature to 40 DEG C to 70 DEG C; 3. subjecting an esterification reaction solution come from the fifth reaction module to distillation and rectification sequentially, thereby obtaining the4-chloroethyl acetoacetate. The method and the device have the advantages that both a chlorination reaction and an esterification reaction are carried out in a microchannel reactor, the reaction speedis high, the production capacity is large, and the reaction temperature is easier to control; chlorine gas is not dissolved in an organic solvent, so that the reaction is more thorough, and the efficiency is higher; a stabilizer is not required to be added, so that the difficulty of subsequent solid waste treatment is lowered; the residence time of materials during reaction is short, and thus, the occurrence of side reactions is reduced.

Owner:ANHUI JINGHE IND

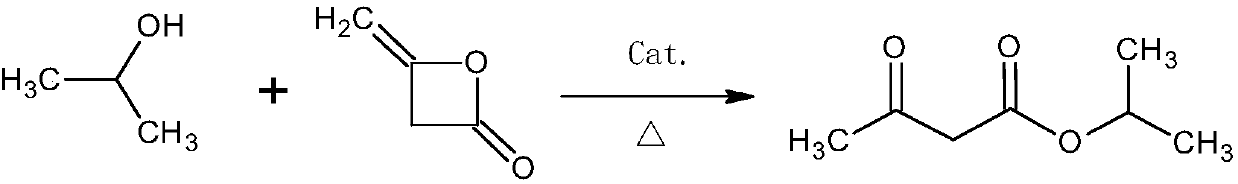

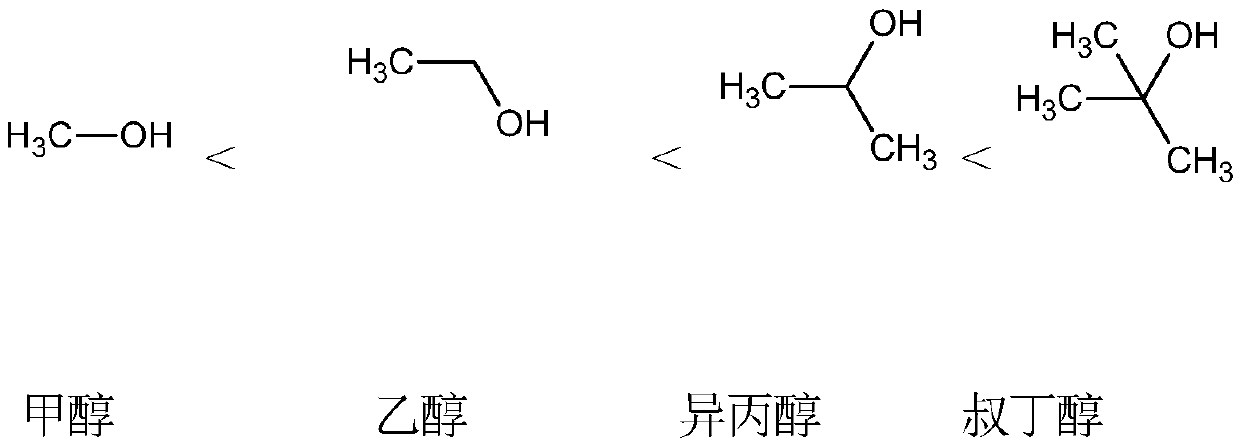

Preparation technology of isopropyl acetoacetate

InactiveCN107840802AHigh reactivityImprove stabilityPreparation from ketenes/polyketenesDistillationThermal insulation

The invention discloses a preparation technology of isopropyl acetoacetate. The preparation technology comprises the following steps: adding isopropanol and a catalyst into a reaction vessel, whereinthe catalyst is selected from aliphatic amine catalysts or tertiary amine catalysts; or the catalyst is prepared by mixing one or more of the aliphatic amine catalysts and the tertiary amine catalysts; raising the temperature to 20 to 100 DEG C, dropwise adding diketene, controlling the reaction temperature in the reaction process at 20 to 150 DEG C; after dropwise adding is finished, controllingthe temperature at 20 to 150 DEG C and carrying out thermal insulation for 0.5 to 6 hours, thus obtaining raw isopropyl acetoacetate, wherein the molar ratio of the isopropanol to the diketene is (1 to 1.8) to 1 and the adding amount of the catalyst is 0.1 to 1 weight percent of the total amount. By adopting a combined amine catalyst to carry out esterification reaction of the diketene and the isopropanol, the influence of steric hindrance of the isopropanol is reduced and the yield of esterification is improved; meanwhile, the difficulty of subsequent separation is reduced. After distillation, the yield of esterification liquid reaches 95 percent and the content of the esterification liquid reaches 99 percent or above.

Owner:NANTONG ACETIC ACID CHEM

Method for preparing acetoacetoxy ethyl methacrylate

InactiveCN105541625AResolve separation difficultiesHigh purityOrganic compound preparationPreparation from ketenes/polyketenes(Hydroxyethyl)methacrylateDistillation

The invention discloses a method for preparing acetoacetoxy ethyl methacrylate, which comprises the following steps: mixing hydroxyethyl methacrylate, a polymerization inhibitor, a catalyst and a solvent, and dropwisely adding ketene dimer at 30-160 DEG C; and after the dropwise addition is finished, carrying out thermal reaction under the temperature condition above until the reaction finishes; and after the thermal reaction finishes, distilling to remove the solvent, and continuing distillation to obtain the acetoacetoxy ethyl methacrylate. The method is simple in technique. The product has the advantages of high yield, high purity and stable quality.

Owner:WEIFANG KEMAI CHEM CO LTD

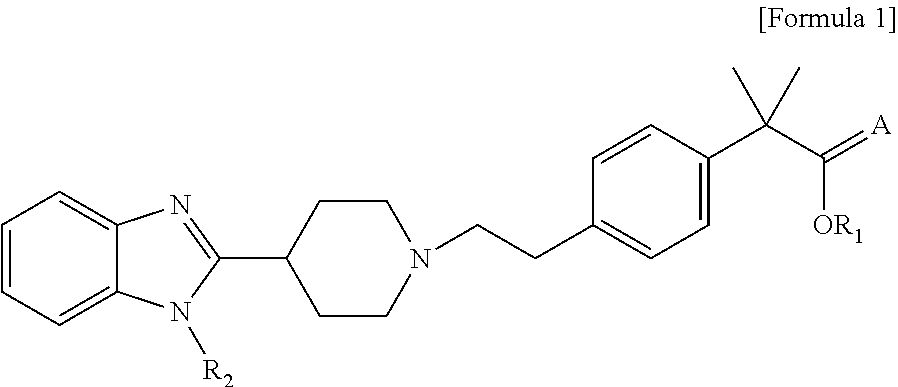

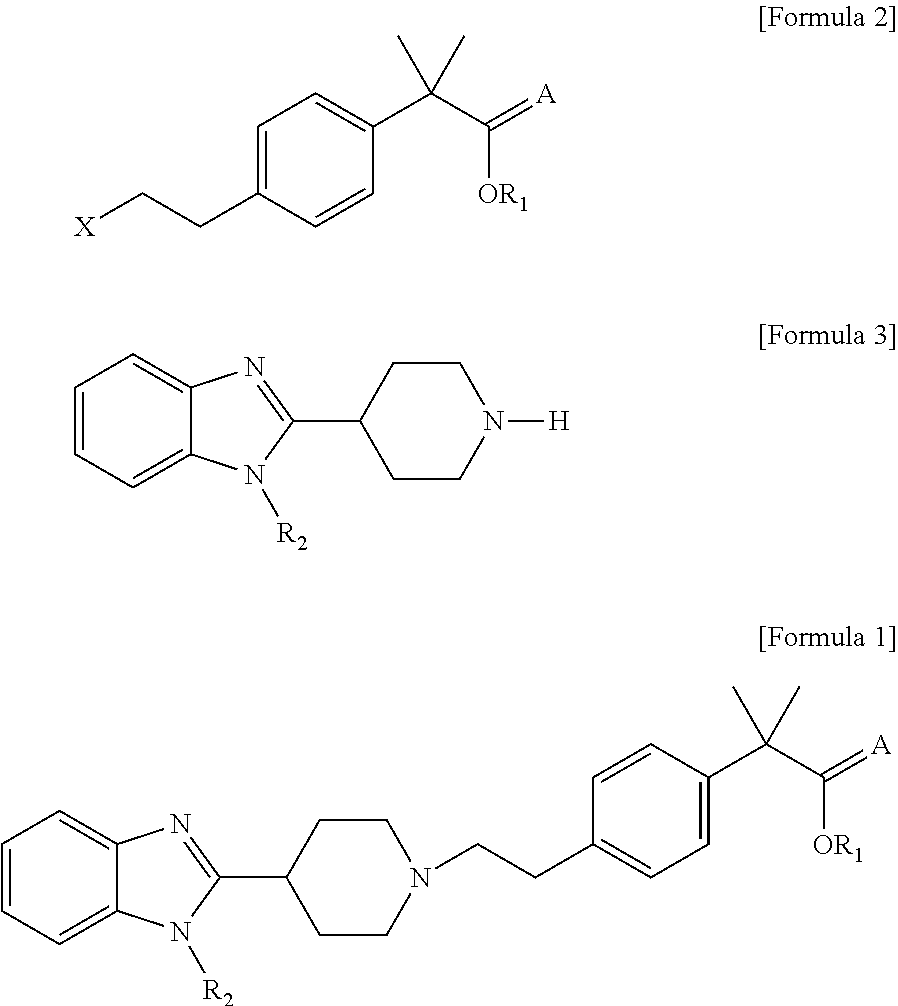

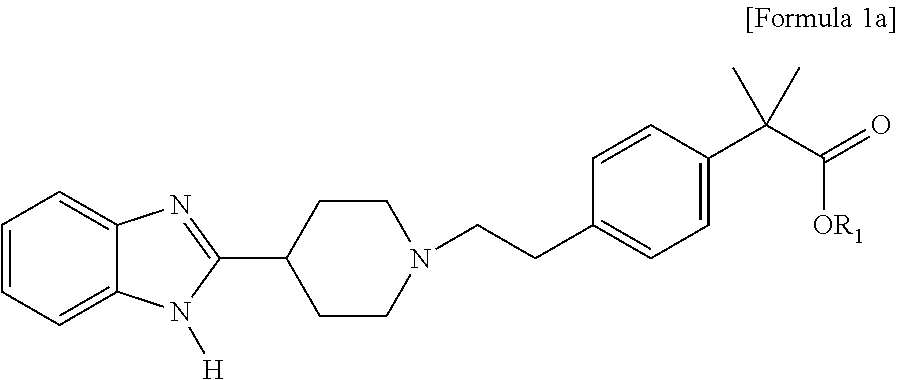

Process for preparation of 2-methyl-2′ phenylpropionic acid derivatives and novel intermediate compounds

The present invention relates to a process for preparing 2-methyl-2′-phenylpropionic acid derivatives showing antihistamine activity in more simplified way, intermediate compounds and their preparation processes used therefor. According to the present invention, pharmaceutically useful 2-methyl-2′-phenylpropionic acid derivatives can be prepared with high yield and purity on industrial scale.

Owner:YUHAN

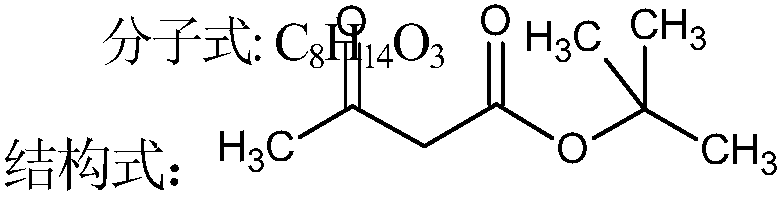

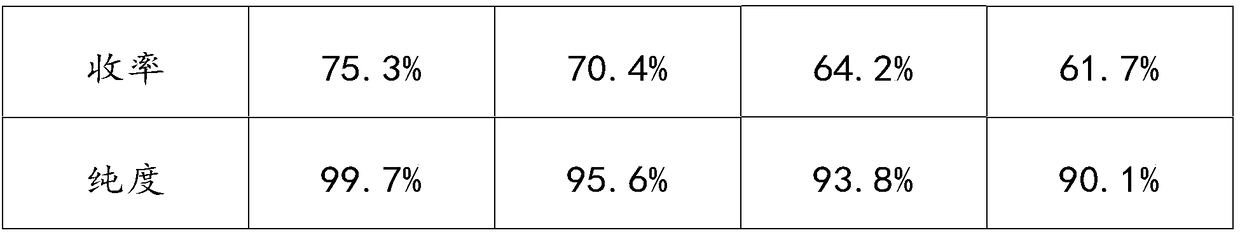

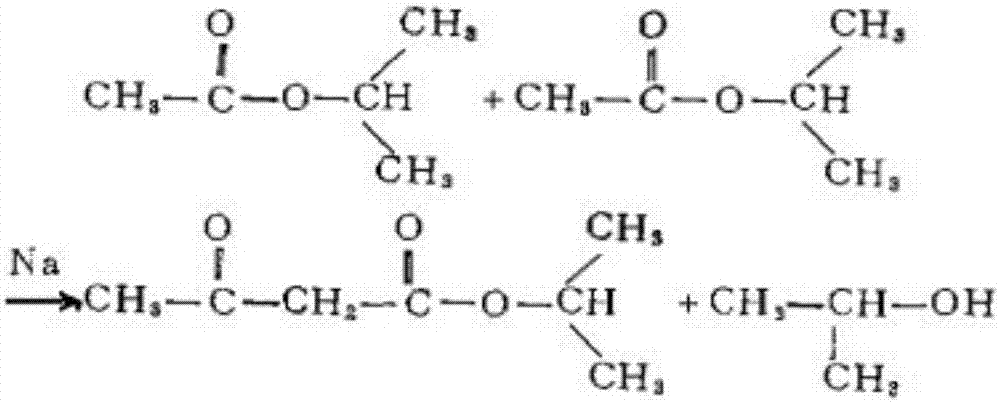

Synthesis method of tert-butyl acetoacetate

InactiveCN107827749AHigh reactivityReduce steric hindrance effectPreparation from ketenes/polyketenesCorrosionFatty amine

The invention discloses a synthesis method of tert-butyl acetoacetate. The method comprises the following steps that tertiary butanol and catalysts are added into a reaction container; the catalysts are selected from aliphatic amine catalysts or tertiary amine catalysts; or the catalysts are fatty amine catalysts and tertiary amine catalysts; the catalysts are one kind of catalysts or several kinds of catalysts proportioned at any proportion; the temperature is raised to 20 to 120 DEG C; diketene is dropwise added; in the reaction process, the reaction temperature is controlled to be 20 to 150DEG C; after the dripping is completed, the temperature is controlled at 20 to 150 DEG C; heat insulation is performed for 0.5 to 8 hours to obtain tert-butyl acetoacetate raw ester; the mole ratio of the tertiary butanol to the diketene is (1 to 2) to1; the addition of the catalyst is 0.1 weight percent to 2 weight percent of the total amount. The process is used for synthesizing the tert-butylacetoacetate; the conversion rate of the diketene reaches 100 percent; the finished product yield reaches 94 percent or higher; the product content reaches 99 percent or higher. By using the process,the synthesis yield is greatly improved; the preparation cost is reduced; meanwhile, the three-waste quantity is reduced; no corrosion is caused on the equipment; better economic and environment-friendly effects can be achieved.

Owner:NANTONG ACETIC ACID CHEM

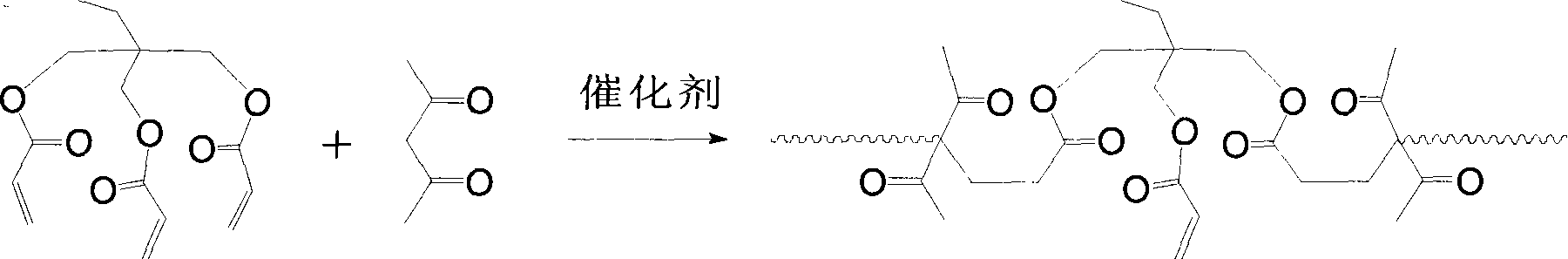

Method for synthesizing same carbon dicarbonyl photosensitive resin

InactiveCN101173017AAvoid catalysisGood storage stabilityPreparation from ketenes/polyketenesCoatingsOligomerPotassium fluoride

The invention relates to a synthetic method of dicarbonyl sensitization resin with carbon, which comprises the steps that a polyol acrylic ester monomer and a Beta-dicarbonyl compound are mixed evenly, and then a reaction insoluble solid basic catalyst for mixing and heating is added to lead the multielement acrylic ester monomer and the Beta-dicarbonyl compound with agile methylene to act Michael reaction, and filtrating is held after finishing the reaction to lead the solid basic catalyst and the product resin to be separated. The catalysis system of the invention comprises an insolubility catalyst with alkali characteristic, such as alumina loaded with potassium fluoride and alkali negative ion exchange resin. The solid basic catalyst effectively promotes the Michael reaction and is convenient for filtrating after reaction, and the solid basic catalyst is removed from product oligomer, thereby avoiding the further influence to the product resin by an alkali catalyst to enable the storage stability of the product resin to be improved. The addition resin can realize rapid light curing under the condition of having no photo-initiator, and also can be used for photo-cured coating and printing ink blending.

Owner:GUANGDONG BOSSIN NOVEL MATERIALS TECH CO LTD

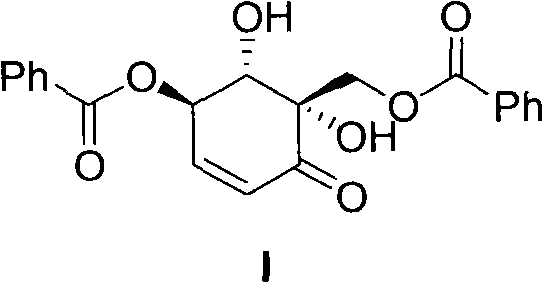

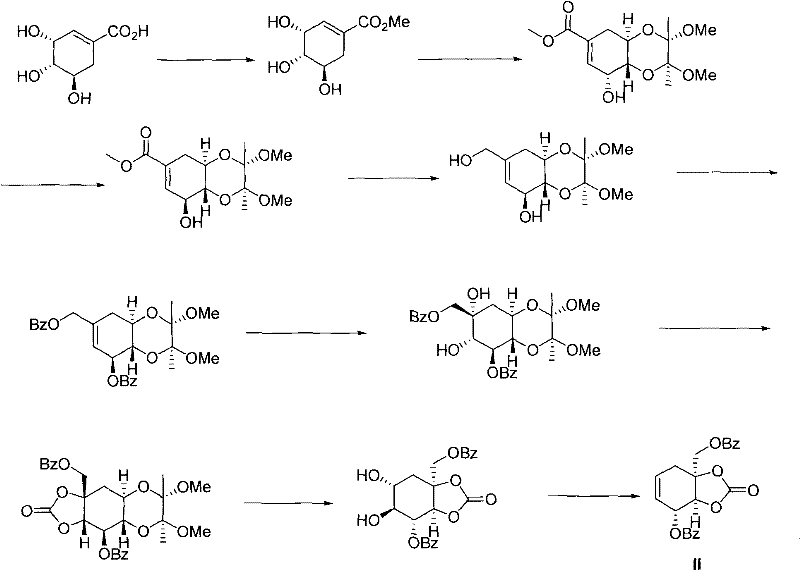

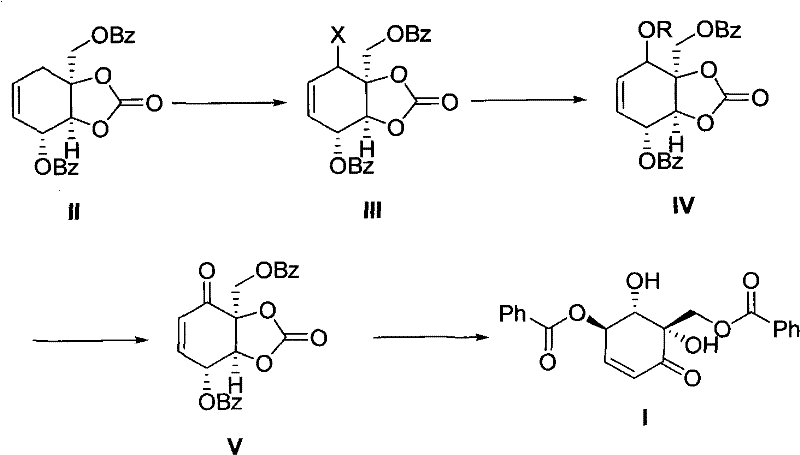

Novel production process for chemical synthesis of zeylenone

InactiveCN102675110AEasy to understandPreparation from ketenes/polyketenesChemistryChemical synthesis

The invention discloses a novel production process for chemical synthesis of zeylenone. The chemical name of the zeylenone is (4R, 5S, 6S)-4-(benzoyloxy)-6-[(benzoyloxy) methyl]-5, 6-dihydroxy-2-cyclohexen-1-one. The CAS number of the zeylenone is 193410-84-3. According to the novel production process for the chemical synthesis of the zeylenone, production cost can be reduced, yield of pharmaceutical chemicals of the zeylenone can be improved, and an effective preparation method of the novel chemical medicine can be provided.

Owner:苏州世林医药技术发展有限公司

Integrated process for the production of vinyl acetate from acetic acid via acetaldehyde

InactiveCN102272088APreparation by ester-hydroxy reactionOrganic compound preparationAcetic anhydrideGas phase

The present invention provides an economical, multi-step integrated process for the production of vinyl acetate monomer (VAM) from acetic acid in the gas phase. First, acetic acid is selectively hydrogenated over a hydrogenation catalyst composition to form acetaldehyde. Acetaldehyde formed can be converted to ethylene diacetate by reaction with acetic anhydride. The ethylene diacetate formed in the next step is thermally decomposed to form VAM and acetic acid. Alternatively, the acetaldehyde formed in the first step can be selectively reacted with ketene to form VAM. In one embodiment of the present invention, on platinum and iron supported on silica, acetic acid and hydrogen react selectively in the gas phase at a temperature of about 300 °C to form acetaldehyde, which is selected on a platinum-supported catalyst. Hydrogenation to form ethanol and dehydration to form ethylene at a temperature of about 185°C over NAFION catalyst, which is mixed with molecular oxygen and acetic acid and heated on palladium / gold / potassium supported on titania at a temperature of about 150°C to 170°C The catalyst reacts to form VAM.

Owner:CELANESE INT CORP

Processes for producing 3-amino crotonic acid cinnamyl ester and cilnidipine in large scale

ActiveCN109053473AEnsure safetyGuaranteed purityOrganic compound preparationPreparation from ketenes/polyketenesCilnidipineAcetic acid

The invention relates to the field of pharmaceutical synthesis and particularly, relates to processes for producing 3-amino crotonic acid cinnamyl ester and cilnidipine in a large scale. The process for producing 3-amino crotonic acid cinnamyl ester in a large scale comprises the following steps of: dropwise adding diketene in batches at a rate of dropwise adding 10kg of diketene in 30 to 40 minutes, wherein the amount of diketene added in each batch is not greater than 10kg; after detecting online that content of cinnamyl acetoacetate obtained by the reaction in each batch accords with the requirement, directly performing an amination reaction. Safety of a production workshop is ensured by adding diketene in batches; meanwhile, the reaction is guaranteed to be sufficiently performed by controlling the adding rate of diketene so as to ensure purity and yield of prepared 3-amino crotonic acid cinnamyl ester; moreover, by detecting purity of cinnamyl acetoacetate on line, use of distillation is avoided, so that industrial cost is further reduced.

Owner:董小林

Preparation method of isopropyl acetoacetate

InactiveCN107986966AIncrease profitThorough responseOrganic compound preparationPreparation from ketenes/polyketenesAcetic acidDiketene

The invention relates to a preparation method of isopropyl acetoacetate. The preparation method comprises the following steps of using diketene and islpropanol as starting materials, performing esterification to synthesize coarse isopropyl acetoacetate under catalysis action of a self-made catalyst with graphene as a carrier, then rectifying to obtain the finished product. Due to use of the self-made catalyst with graphene as the carrier, the reaction is thorough and is easy to control; generated byproduct isopropyl ether in the coarse isopropyl acetoacetate is controlled less than 1%, so thatthe reaction yield and product quality are improved, the yield and product purity of isopropyl acetoacetate are 93% or more and 98% or more respectively, up by 10% and 15% respectively in comparisonwith the method using sulfuric acid as the catalyst; the use ratio of the raw materials is improved, waste materials are reduced, environment protection investment is reduced, and the product cost islowered.

Owner:SHANDONG HUIHAI PHARMA & CHEM

Preparation method of methyl acetoacetate

ActiveCN103450017BImprove stabilityReduce consumptionPreparation from ketenes/polyketenesAcetic acidNitrate

The invention provides a preparation method of methyl acetoacetate. The preparation method sequentially comprises the following steps of: (1) fully dissolving methanol and a catalyst, then adding the mixture into an esterification reaction kettle, heating up, and dropwise adding ketene dimer; (2) after completing dropwise addition, insulating, and cooling to produce crude methyl acetoacetate; (3) rectifying the crude product to obtain the finished methyl acetoacetate. The preparation method is characterized in that the catalyst in the step (1) is an amine type ionic liquid catalyst which is selected from one or more of n-butylamine nitrate, n-butylamine acetate, ethylamine nitrate, ethylamine acetate, propylamine nitrate and propylamine acetate. According to the preparation method of methyl acetoacetate, the amine type ionic liquid catalyst is researched and is good in stability, the stability of methyl acetoacetate is enhanced under the action of the catalyst, the rectification yield of a product can be improved, the technological operations are simple, the raw material consumption is reduced, and the catalyst has obvious advantages and a positive effect.

Owner:NANTONG ACETIC ACID CHEM

A kind of method for preparing methyl acetoacetate

InactiveCN103864616BHigh purityRaise the ratioPreparation from ketenes/polyketenesChemical recyclingAcetic acidTower

The invention discloses a method for preparing methyl acetoacetate. The method comprises the following steps: adding a catalyst once, continuously adding ketene dimer and a methanol solution through a raw material feeding hole, continuously adding an extraction agent through an extraction agent feeding hole, simultaneously adding two materials into a reaction-extraction rectifying tower, and starting heating; carrying out total reflux so as to obtain the methanol solution through the tower top of the reaction-extraction rectifying tower and obtain a mixed liquid of the methyl acetoacetate, the catalyst and the extraction agent through the tower bottom of the reaction-extraction rectifying tower, and enabling the mixed liquid to flow into a decompression extraction tower from a tower-bottom discharging hole, so as to obtain a target product, namely the methyl acetoacetate from the tower top of the decompression extraction tower. Due to the arrangement of the reaction-extraction rectifying tower and the decompression extraction tower, the methyl acetoacetate is prepared by virtue of a reaction-rectification and extraction-separation integrated reaction, the materials are fed once, and the catalyst and the extraction agent can be recycled, so that the operation is simple, the cost is lowered, the purity and rate of the prepared methyl acetoacetate are high, and the energy consumption is reduced.

Owner:NANJING NORMAL UNIVERSITY

Popular searches

Fermentation Photomechanical apparatus Carbonyl compound preparation Group 5/15 element organic compounds Transportation and packaging Coupling reaction in azo dyes Hydrocarbon by metathesis reaction Carboxylic acid amides preparation Group 3/13 element organic compounds Chemical/physical/physico-chemical processes

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com