A kind of method for preparing methyl acetoacetate

A technology of methyl acetoacetate and methanol solution, which is applied in the preparation of ketene/polyketene, chemical recovery, etc., can solve the problems that the catalyst cannot be recycled, the purification process is complicated, and the production efficiency is low, so as to achieve cost reduction, purity and Effect of high ratio and reduction of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further elaborate the technical means and effects that the present invention adopts to achieve the intended purpose of the invention, the specific implementation, features and effects of the method for preparing methyl acetoacetate proposed according to the present invention are described in detail below.

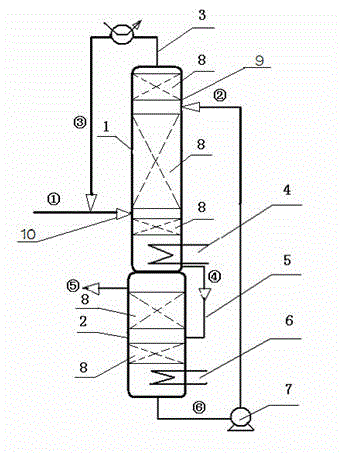

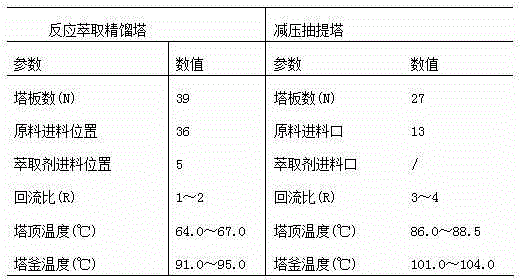

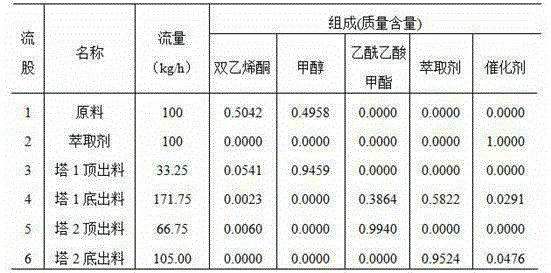

[0017] Such as figure 1 The extractive distillation reaction tower shown includes a reactive extraction rectification tower 1, a vacuum extraction tower 2 is arranged at the lower part of the reactive extraction distillation tower 1, and the bottom of the vacuum extraction tower 2 is connected to the reactive extraction rectification tower through an external circulation pump 7. The extraction agent feed port 9 in the upper part of tower 1, the discharge port 5 at the bottom of the reactive extraction distillation tower is connected to the middle part of the vacuum extraction tower 2, and the top discharge port 3 of the reactive extraction distillation tow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com