Patents

Literature

142 results about "Diketene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

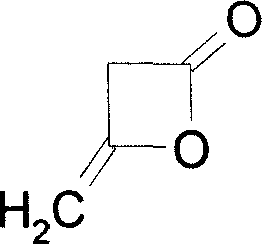

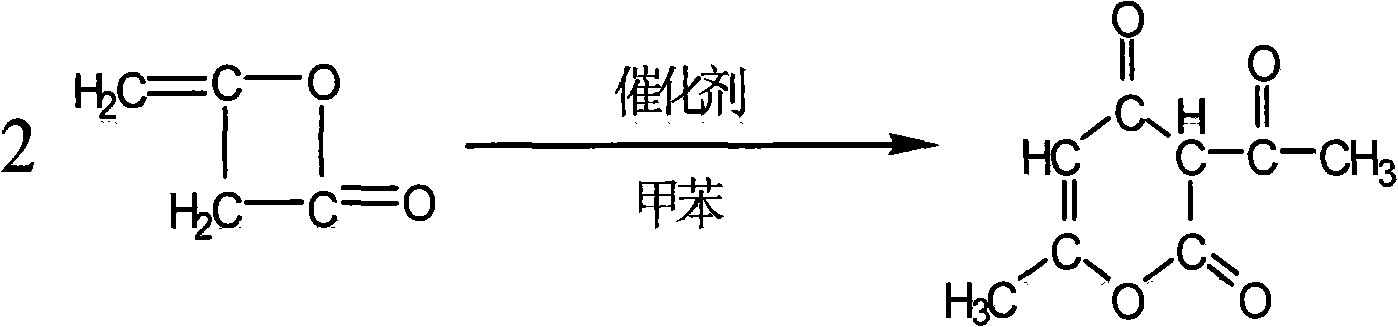

Diketene is an organic compound with the molecular formula C₄H₄O₂, and which is sometimes written as (CH₂CO)₂. It is formed by dimerization of ketene, H₂C=C=O (IUPAC name: ethenone). Diketene is a member of the oxetane family. It is used as a reagent in organic chemistry. It is a colorless liquid.

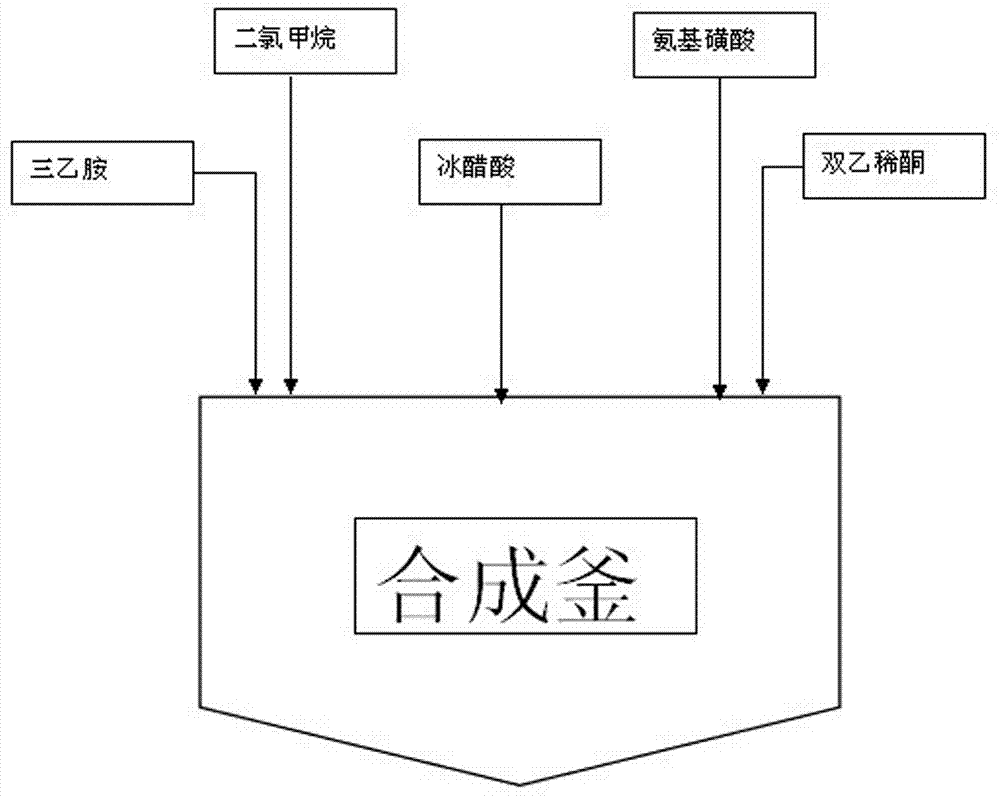

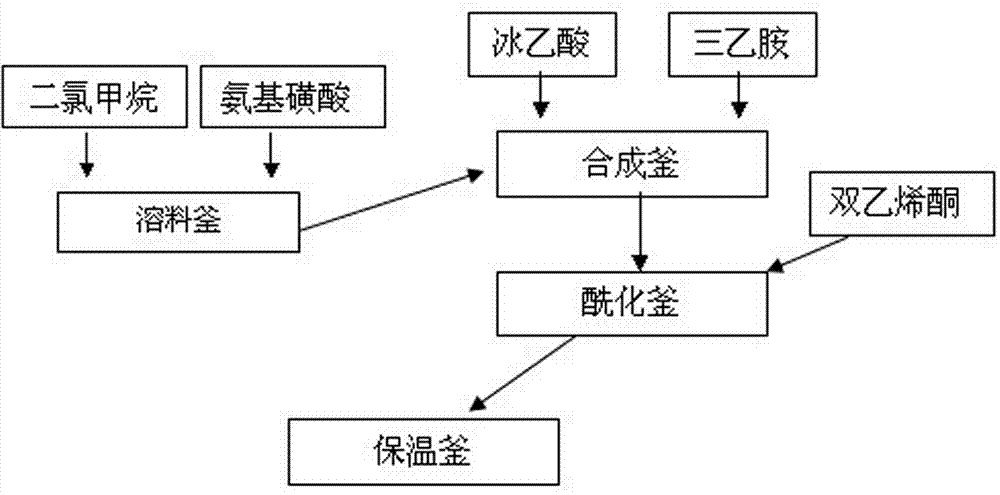

Acesulfame synthesis and acylation production process

InactiveCN103570592AReduce labor intensityImprove continuitySulfuric acid amide preparationAcetic acidEconomic benefits

The invention relates to an acesulfame synthesis and acylation production process, which comprises the following steps of a, putting a sulfamic acid and dichloromethane into a dissolving kettle, and pumping a mixture into a synthesis kettle; b, adding dropwise triethylamine into the synthesis kettle, adding dropwise a glacial acetic acid, and performing natural reaction for 1 hour after the glacial acetic acid is added dropwise; c, placing reactants in the synthesis kettle into an acylation kettle, and adding dropwise diketene for an acylation reaction; and d, after the diketene is added dropwise, circulating a product subjected to the acylation reaction for 1 hour in the acylation kettle, placing into a heat-preservation kettle, performing natural reaction for 1 hour to generate an acetoacetyl-N-sulfonate intermediate, and feeding the acetoacetyl-N-sulfonate intermediate to a sulfonation section for use. The acesulfame synthesis and acylation production process has the advantages that 1, a stepwise reaction mode is adopted, so that compared with a conventional single-kettle production process, the method has the characteristics of production operation continuity and high reaction stability; 2, a multi-kettle stepwise production mode is adopted, so that the production efficiency is greatly improved, the reaction efficiency of the whole production flow is optimized, and the economic benefits of an enterprise are significantly improved.

Owner:ANHUI JINGHE IND

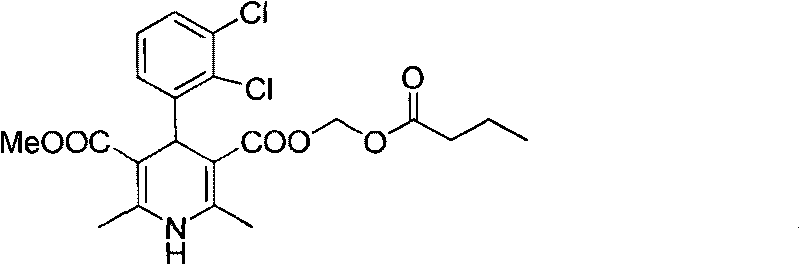

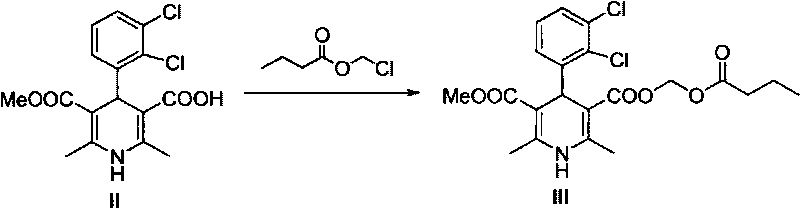

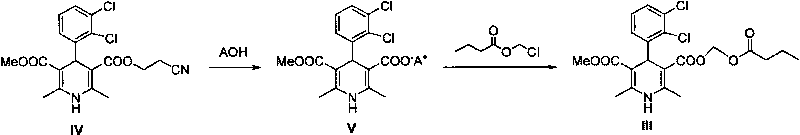

Method for preparing butyrate clevidipine

Owner:SUN YAT SEN UNIV +1

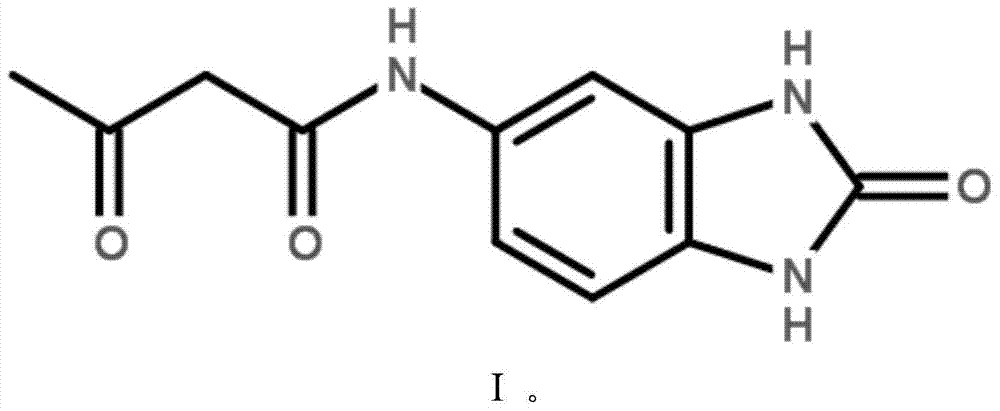

Production process of 5-acetyl acetamino benzimidazolone

The invention relates to a technology for producing 5-acetyl amido benzimidazolone. The condensation process is as follows: o-phenylendiamine, carbamide, water and concentrated sulfuric acid are added into a condensation reaction kettle step by step, the pH value is controlled to between 6 and 7, and benzimidazolone is obtained by drying the mixture; the nitration process is as follows: the benzimidazolone, chlorinated benzene and concentrated sulfuric acid are added into a nitration reaction kettle, the chlorinated benzene is reclaimed and purified by reduced pressure distillation and water boiling, and 5-nitryl benzimidazolone is obtained by drying the mixture; the reduction process is as follows: the 5-nitryl benzimidazolone, iron powder, hydrochloric acid and water are added into a reduction reaction kettle, the mixture is subject to suction filtering, cooling, crystallization and drying after the reaction for producing the 5-amino benzimidazolone; and the acetylization process is as follows: the 5- amino benzimidazolone, Diketene, phosphoric acid, caustic soda liquid and water are added into an acetylization kettle, the pressure inside the kettle is discharged in the temperature rising process, and the mixture is subject to suction filtering and drying to produce the 5-acetyl amido benzimidazolone. The process has the total yield coefficient up to 75 percent, purity quotient more than 99 percent and the product quality which meets the international standards of the same products at home and abroad.

Owner:DONGYING TIANZHENG CHEM

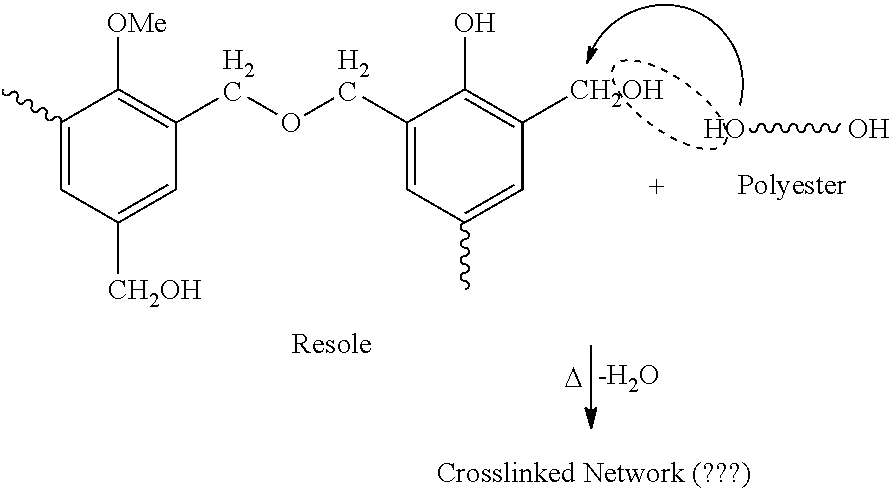

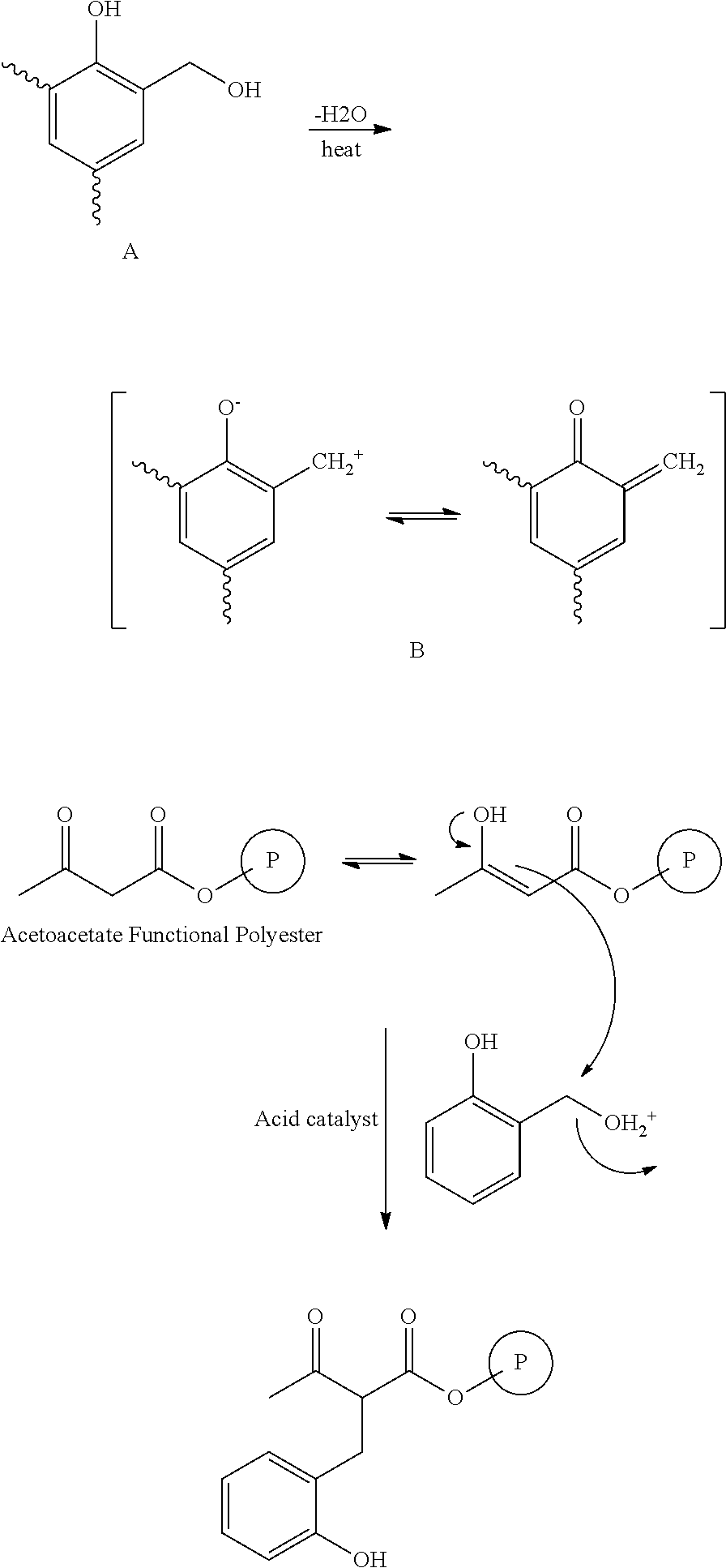

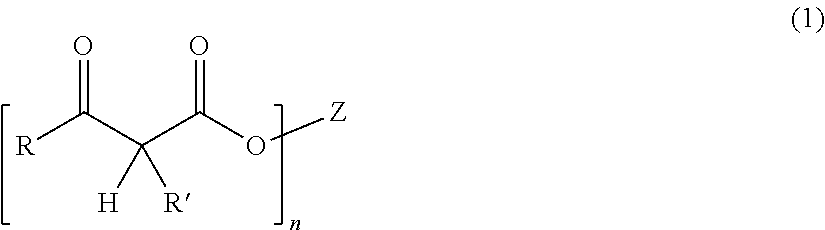

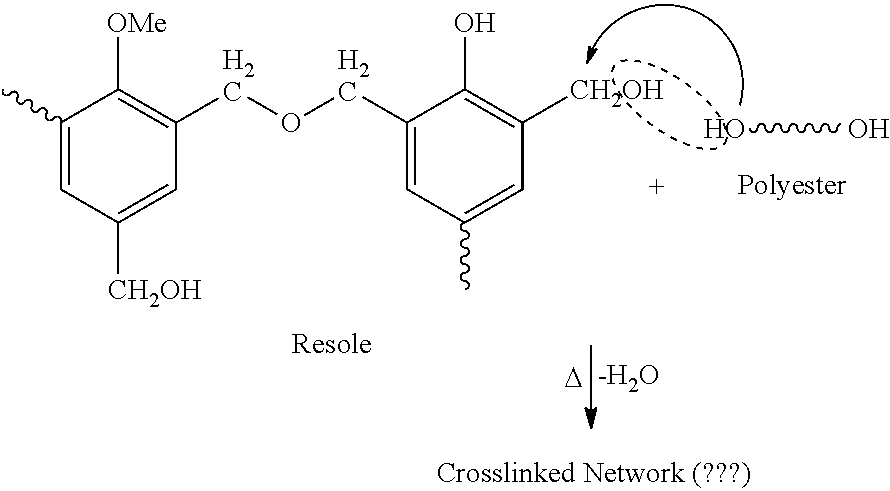

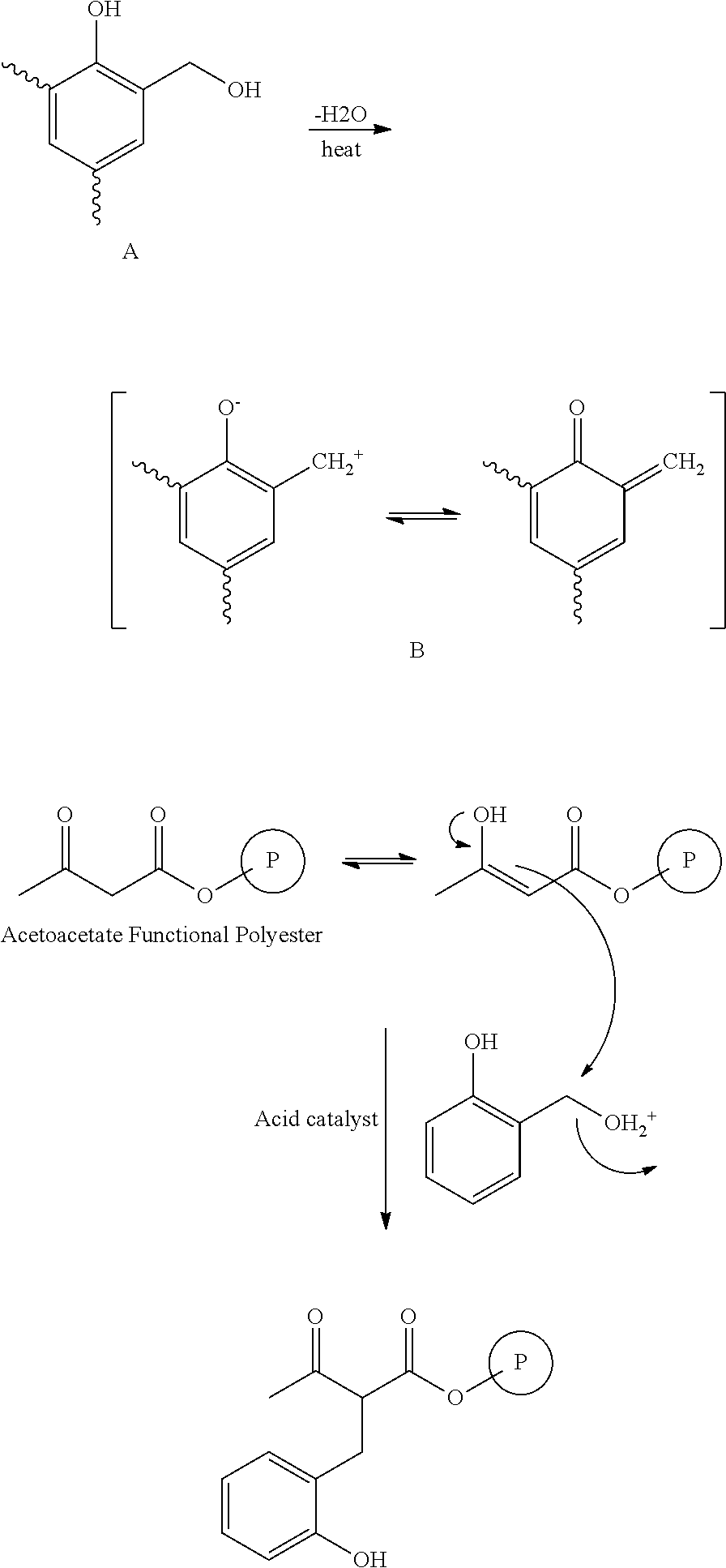

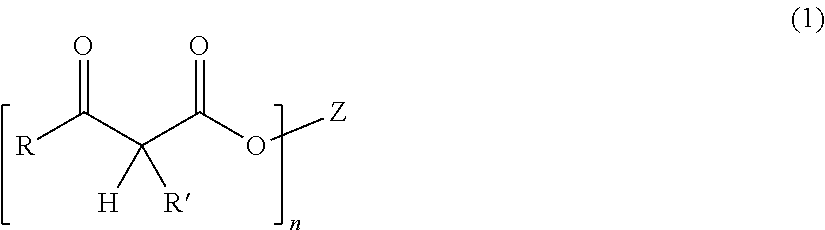

Thermosetting compositions based on phenolic resins and curable poleyester resins made with diketene or beta-ketoacetate containing compounds

ActiveUS20160137877A1Good solvent resistanceEffective cross-linkingPretreated surfacesPolyester coatingsCompound aPolymer science

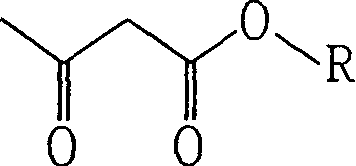

A thermosetting composition having:I. a curable polyester resin containing beta-ketoacetate moieties without vinyl unsaturations; andII. a phenolic resin having at least one methylol group.The curable polyester resin can be made by reacting a polyester resin with a compound containing a beta-ketoacetate moiety that does not contain a vinyl unsaturation such as alkyl acetoacetate compounds or diketene compounds.The curable polyester resin can be dispersed in water or dissolved in a solvent and is suitable for waterborne or solventborne coating compositions. Phenolic based crosslinking coating compositions that contain these curable polyester resins cure well with phenolic resin crosslinking compounds.

Owner:EASTMAN CHEM CO

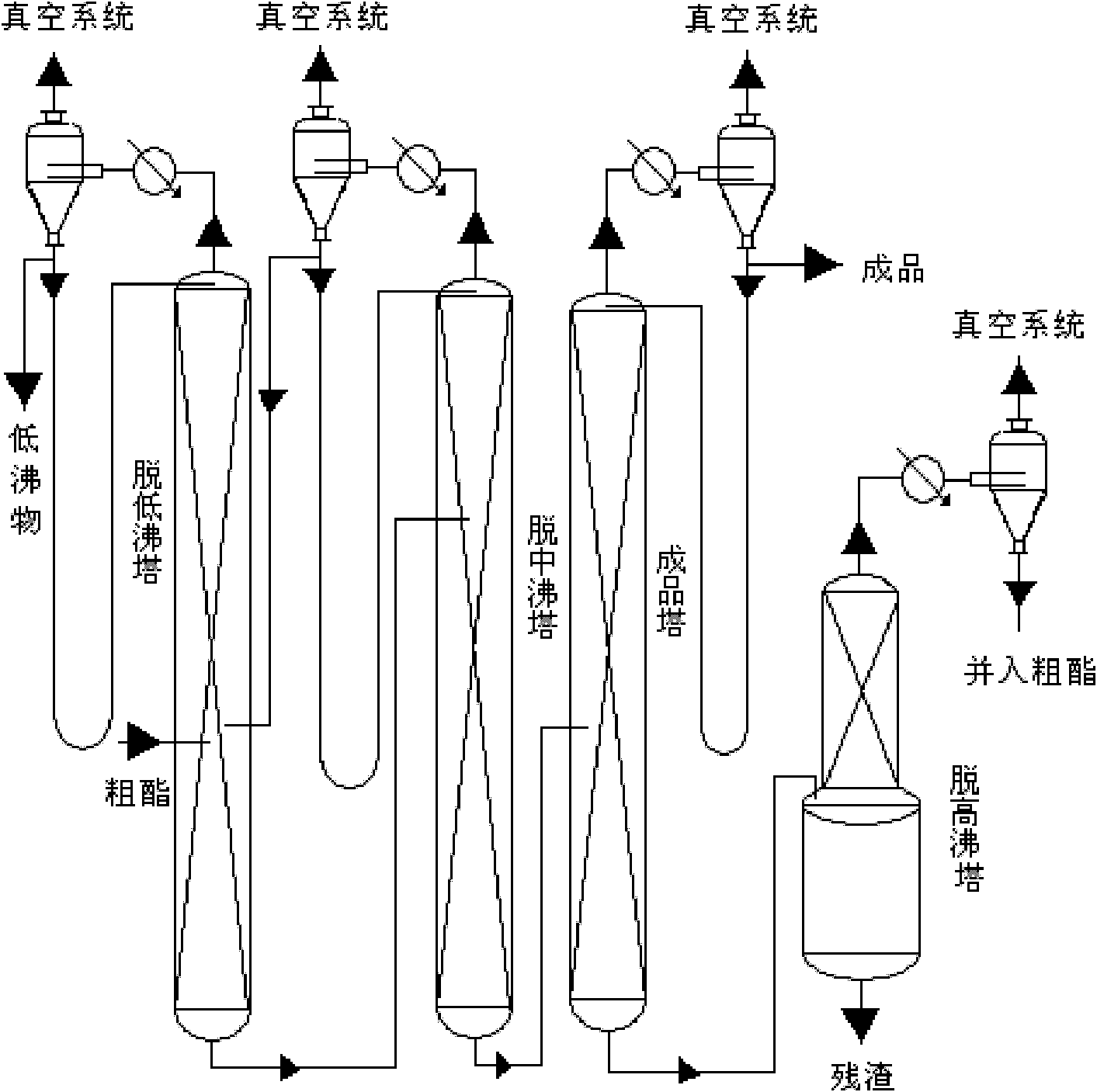

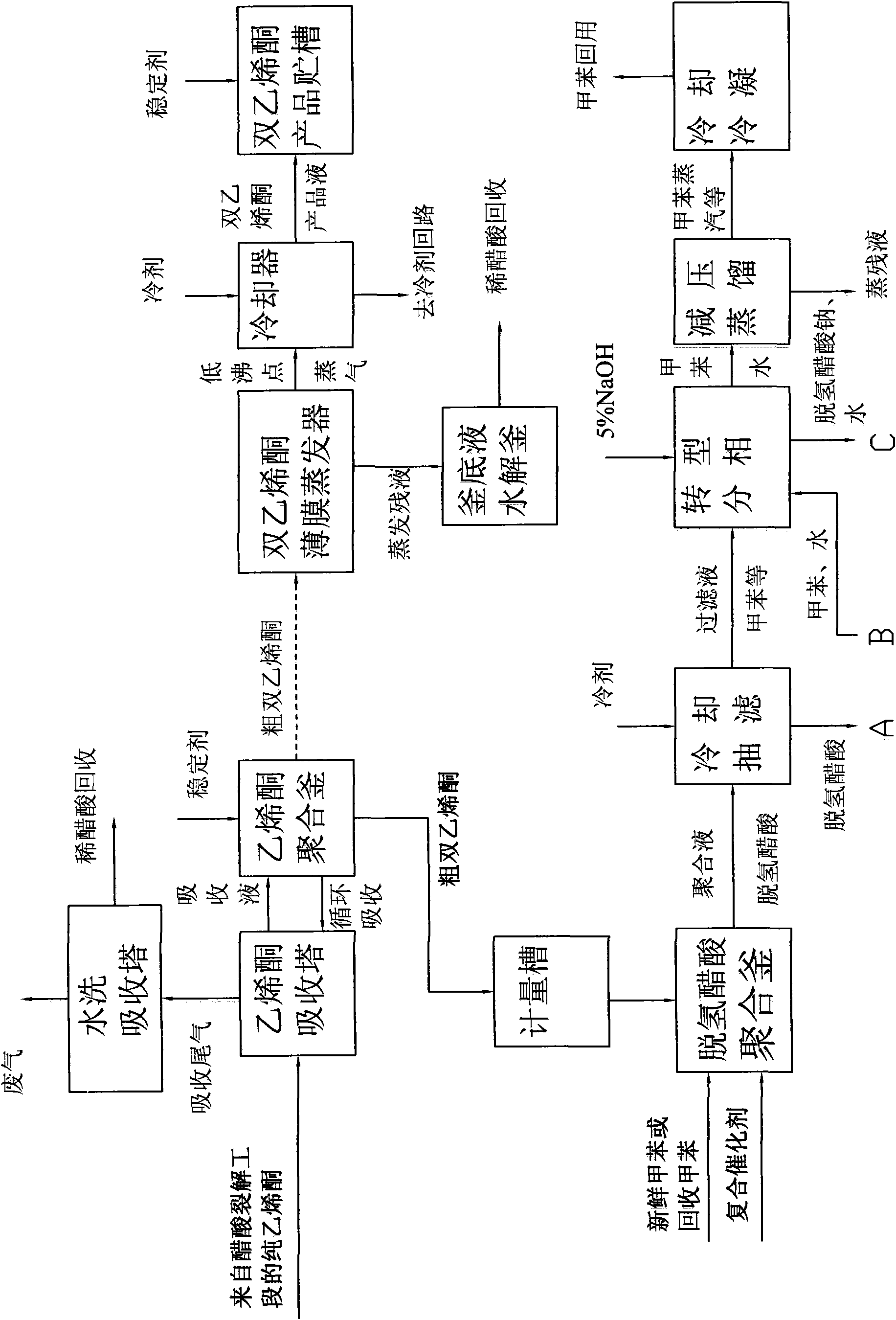

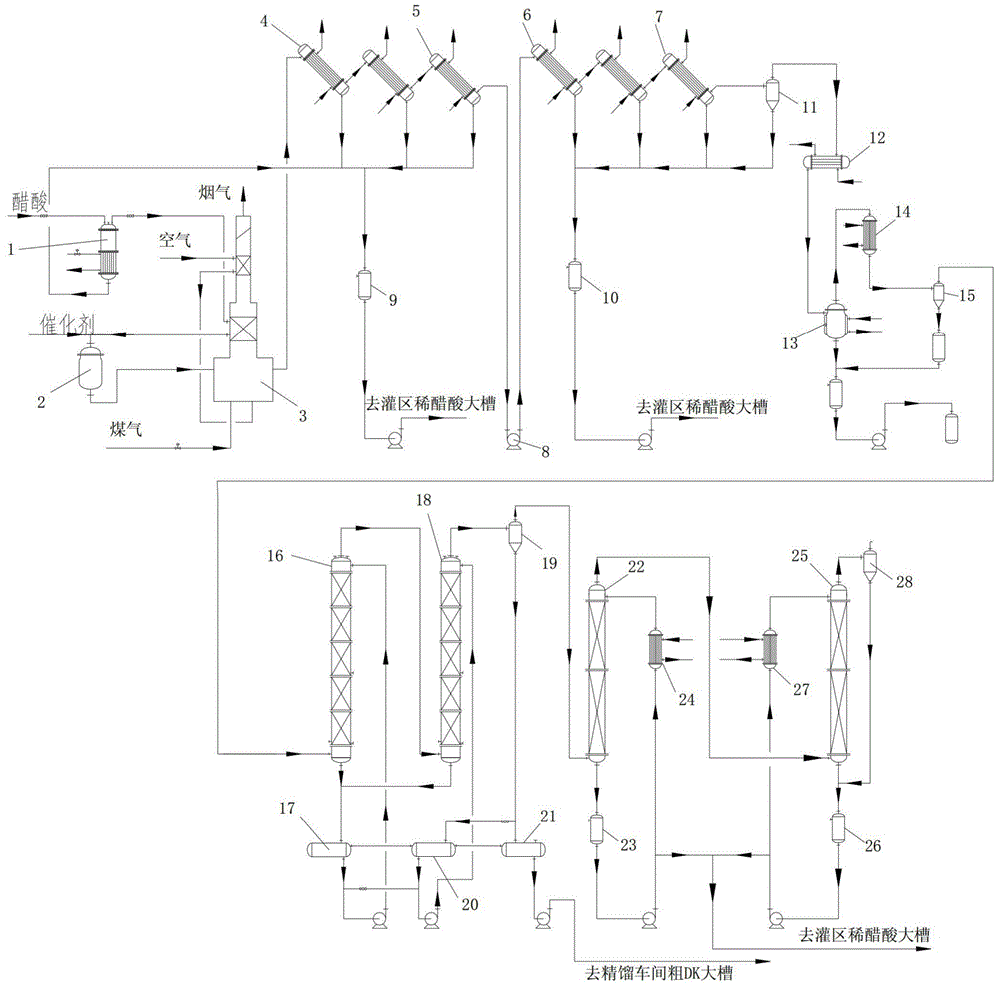

Process for preparing high-purity diketene

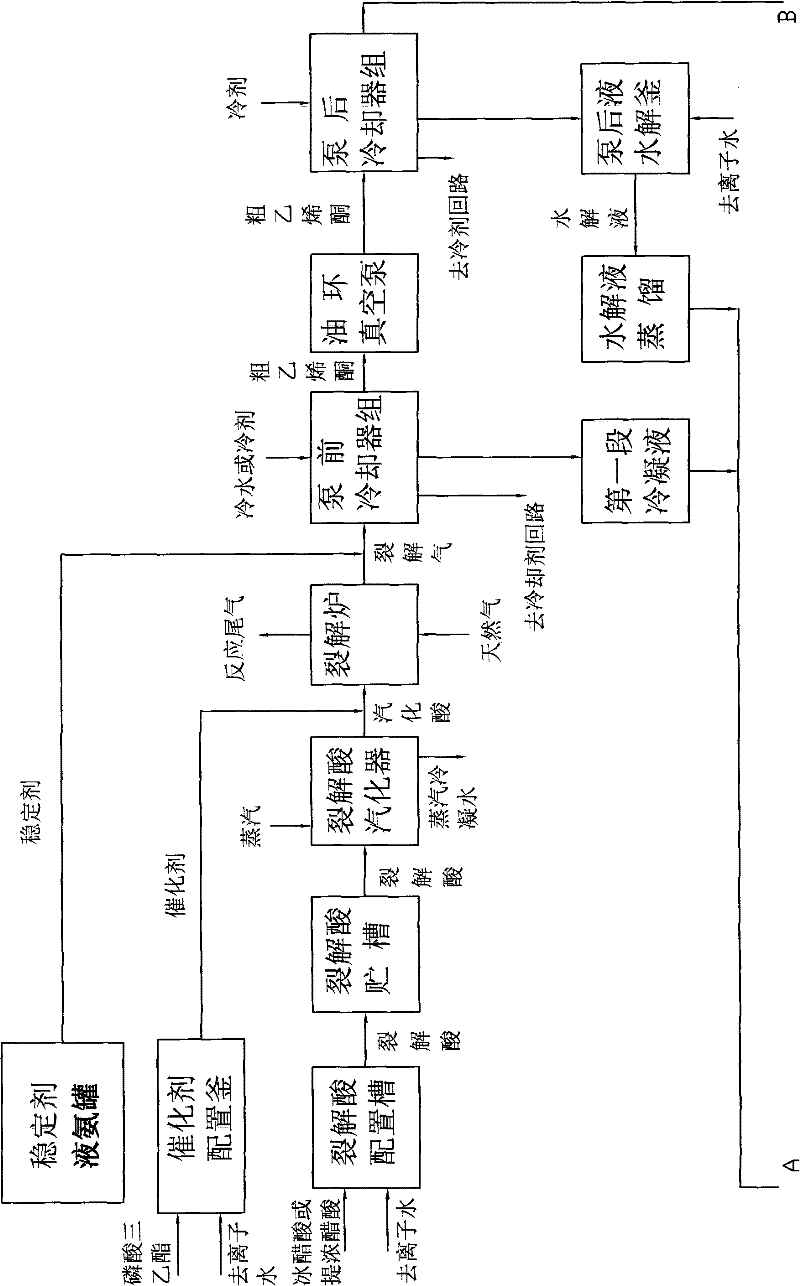

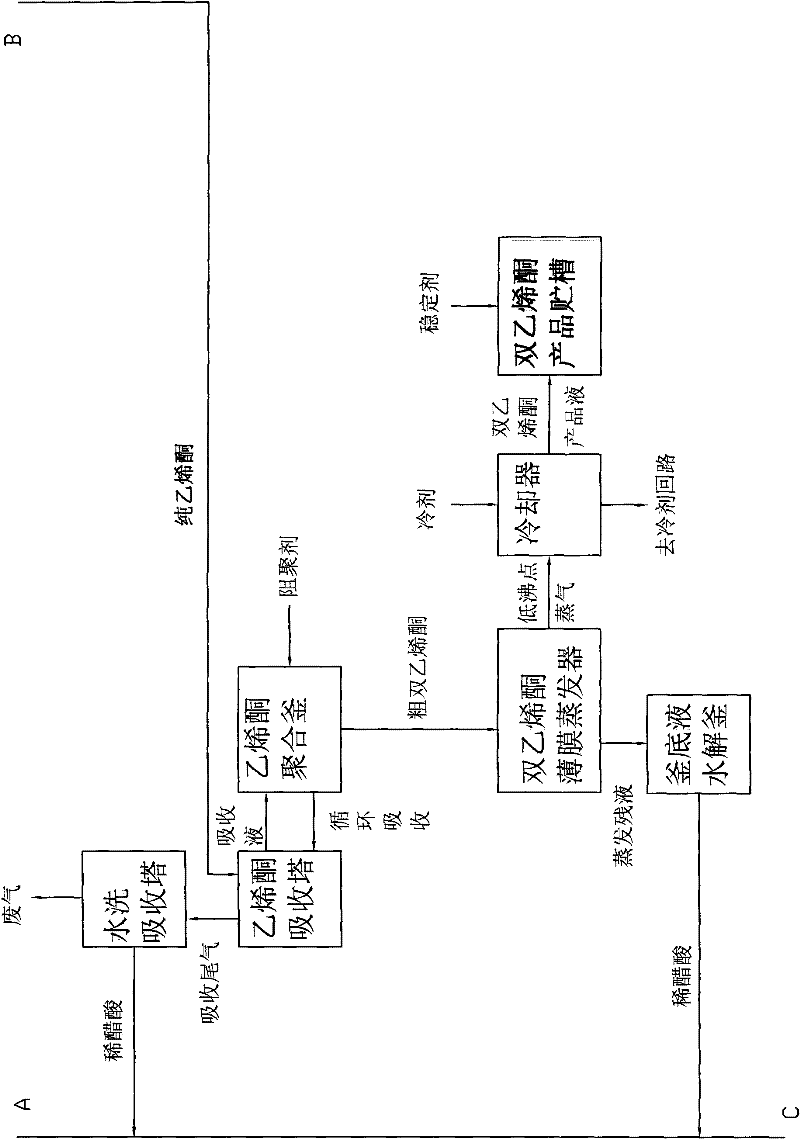

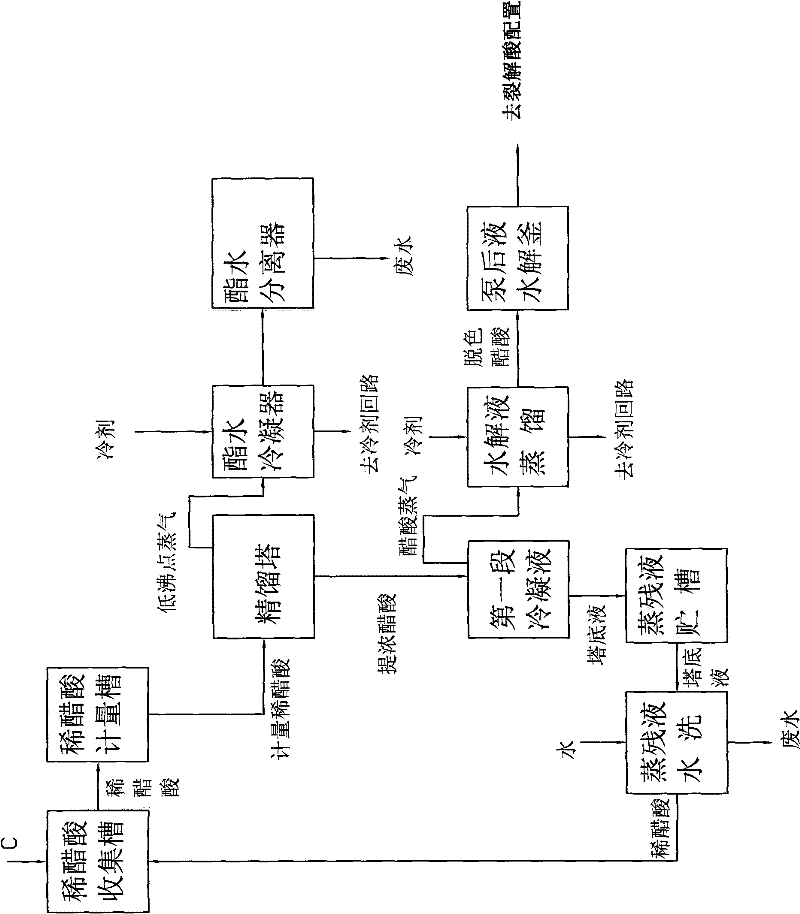

The invention relates to a process for preparing high-purity diketene, which overcomes the defects of low purity of ketene, low purity and poor safety of diketene products formed by absorbing and polymerizing ketene, as well as complex process, high cost and high acetic acid content of raffinate in the concentration recovery of dilute acetic acid. The process for preparing high-purity diketene is suitable for absorbing and polymerizing ketene dimer at low temperature on the basis of adopting stable acetic acid cracking conditions and deep refrigeration to remove impurities from cracking gas and generate pure ketene gas, adopting a film evaporator to further purify diketene products at low temperature under low pressure, and adding stabilizers after introducing polymerization inhibitor and diketene for refining during the absorption and polymerization of ketene in order to improve synthesis safety and the stability of products in storage tanks. Meanwhile, the dilute acetic acid produced in the process reasonably matches the temperature of each point of a stripping section through a sensitive plate technique, improves the water-carrying capability of butyl acetate, and greatly reduces the concentration of acetic acid in concentrated raffinate.

Owner:NINGBO WANGLONG TECH

Method for preparing methyl acetoacetate by using novel composite catalyst

ActiveCN101337890AReduce energy consumptionIncrease production capacityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidBoiling point

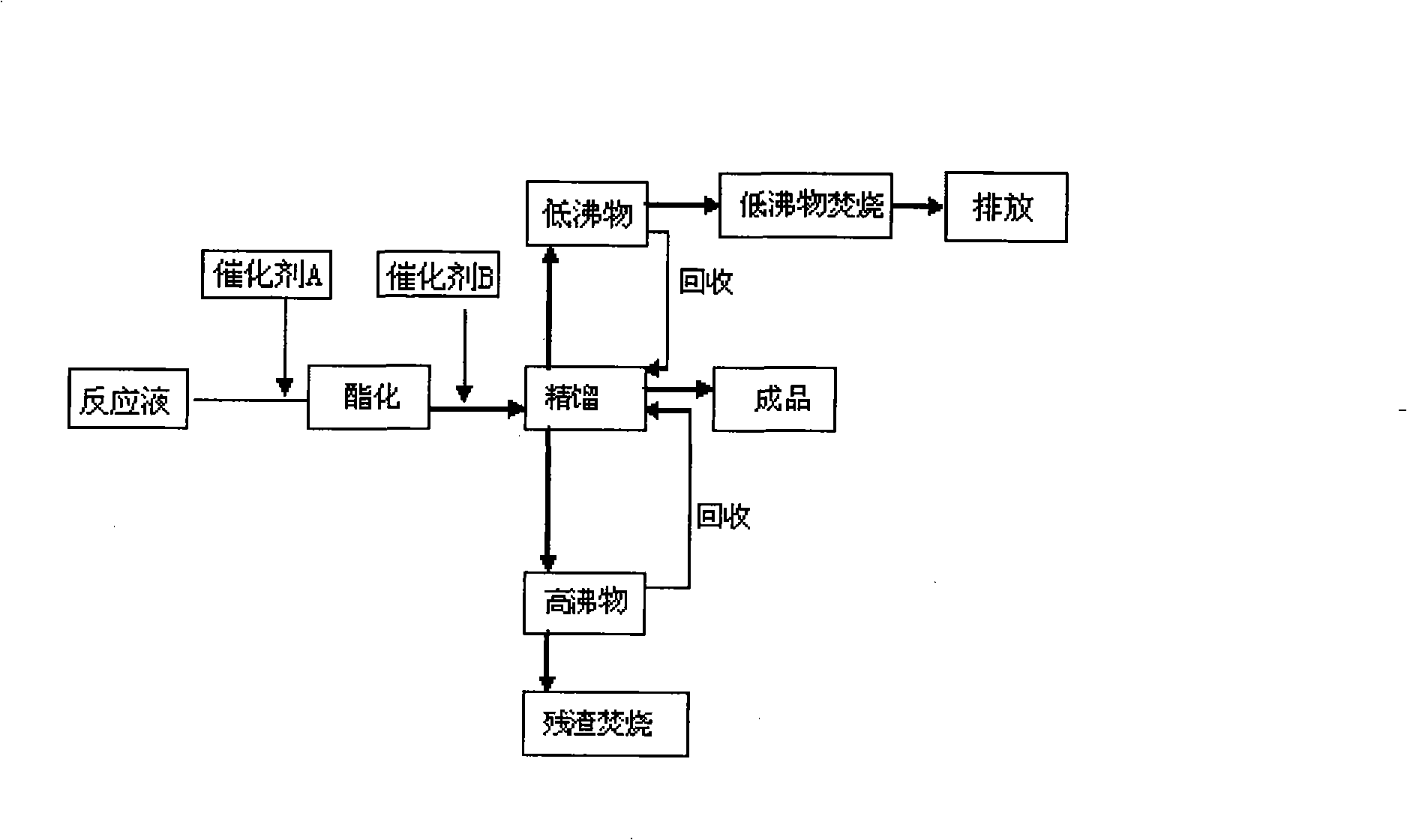

The invention discloses a method for preparing methyl acetoacetate by using complex catalyst, which comprises the following steps: carrying out esterification reaction of methanol and diketene to generate crude methyl acetoacetate, wherein two different catalysts are added in the different stages of the esterification reaction; triethylenediamine catalyst is added before the esterification reaction; and diketene can be added directly dropwise without being heated by vapor, thereby overcoming the disadvantage that diketene is added dropwise after heating methanol to the boiling point in the conventional process and reducing the energy consumption; and cooling the generated liquid to 40 DEG C after the reaction, adding concentrated sulfur acid catalyst, keeping the temperature for half an hour, filtering, continuously rectifying the filtrate, and separating to obtain fine methyl acetoacetate with the content larger than 99%. Compared with the conventional intermittent rectification method, the continuous rectification method has greatly improved throughput and more convenient operation.

Owner:安徽天成新材料有限公司

A kind of production method of methyl acetoacetate

ActiveCN102276464AHigh purityThe four-column continuous negative pressure rectification of the high boiling column obtains a high purity with a content of 99.7%Preparation from ketenes/polyketenesAcetic acidEsterification reaction

The invention relates to a method for producing methyl acetoacetate. The method is characterized by comprising the following steps of: (1) performing esterification reaction of crude diketene and methanol at the temperature of between 20 and 150 DEG C, wherein in the esterification reaction, one of tertiary amine, an ethylidene-amine-containing compound or an alkaline compound is used as a catalyst; and (2) rectifying a product generated in the esterification reaction in the step (1) continuously in four towers under negative pressure to prepare methyl acetoacetate. In the method, the esterification reaction of the crude diketene is adopted, and the diketene is not needed to be rectified and purified, so energy consumption is low, the yield is high, the catalyst is easy to obtain, reaction conditions are mild, the process is safe and a product has high content and the yield of the product is high, and the method is suitable for large-scale industrial production.

Owner:NANTONG ACETIC ACID CHEM

Preparation method for 5-acetoacetlamino benzimdazolone

The invention provides a preparation method for 5-acetoacetlamino benzimdazolone. The method comprises the following step of enabling 5-aminobenzimidazolone, diketene, alcohol and water to react in the presence of an acid catalyst to obtain the 5-acetoacetlamino benzimdazolone, wherein the alcohol is one or more of methanol, ethanol and propanol. According to the preparation method, the reaction temperature of an acetylation process in a production process of the 5-acetoacetlamino benzimdazolone is lowered, so that requirements on equipment are lowered, the danger coefficient during actual production is also lowered, reaction conditions are mild, and the method is easy to operate.

Owner:QINGDAO DOUBLE PEACH SPECIALTY CHEM GRP

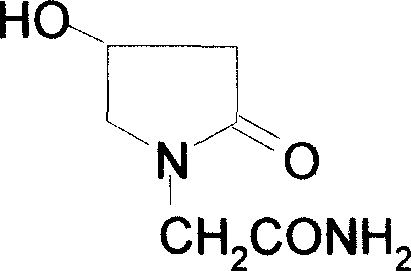

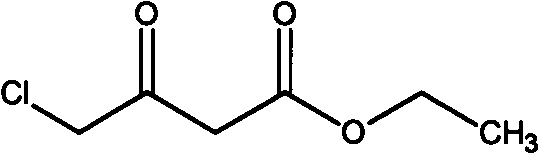

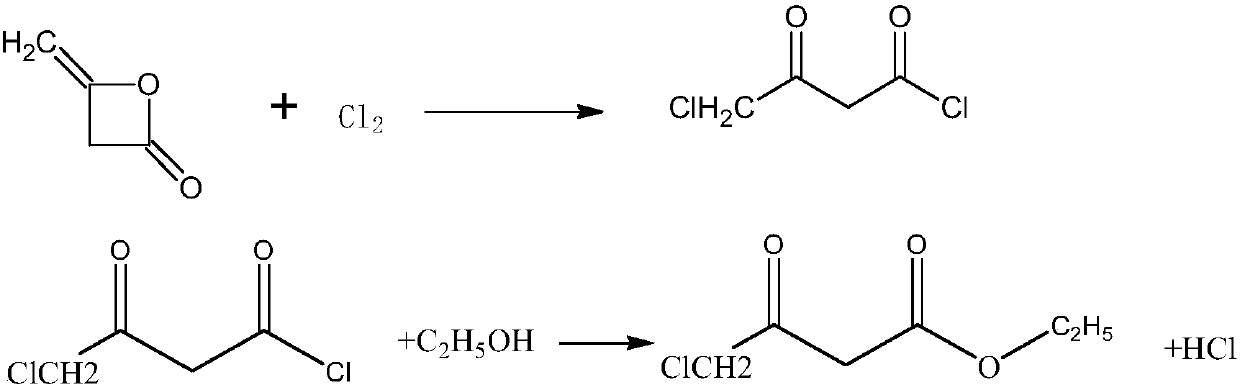

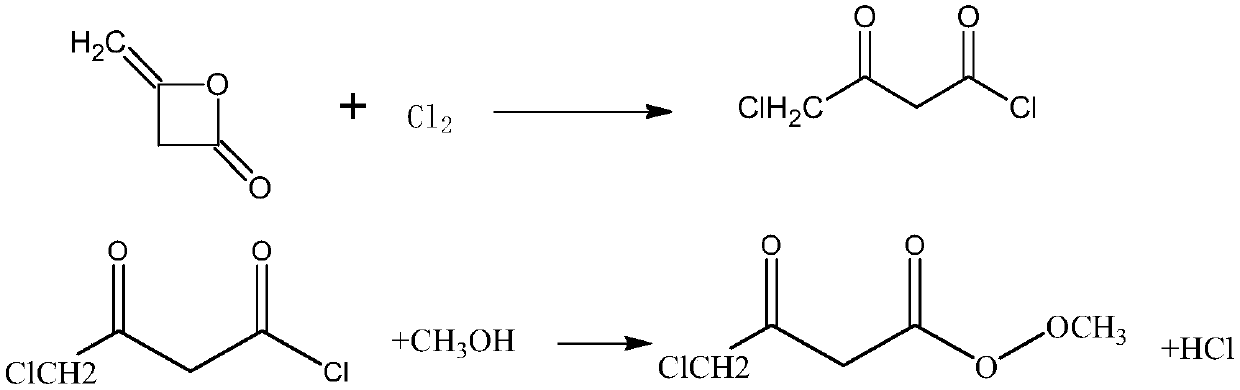

Method of preparing 4-hydroxy pyrrolidone-2-acetylamine

InactiveCN1948285ARaw materials are cheap and easy to getLow costOrganic chemistryState of artChloride

The present invention discloses a preparation method of oxiracetam (4-hydroxypyrrolidone-2-acetylamine) which can be used as cerebral function improving agent. Said method uses diketene as initial raw material, and includes the following steps: firstly, making the diketene be reacted with chlorine gas to obtain chloroacetoacetyl chloride, then making the chloroacetoacetyl chloride undergo the processes of substitution, hydrogenation and cyclopolymerization, etc. so as to obtain the invented product.

Owner:SUZHOU HOPE TECH

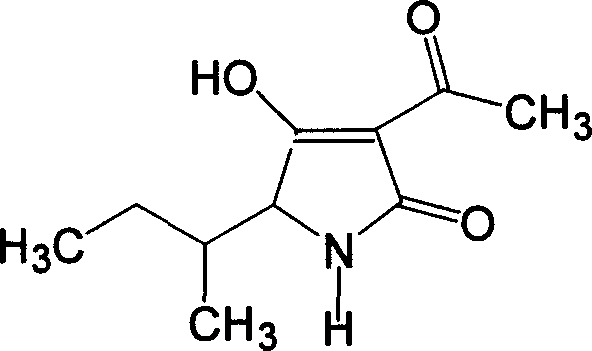

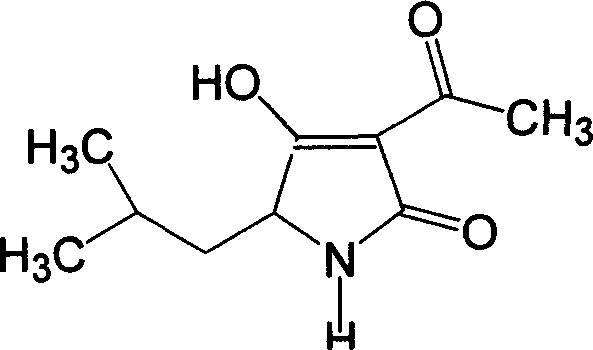

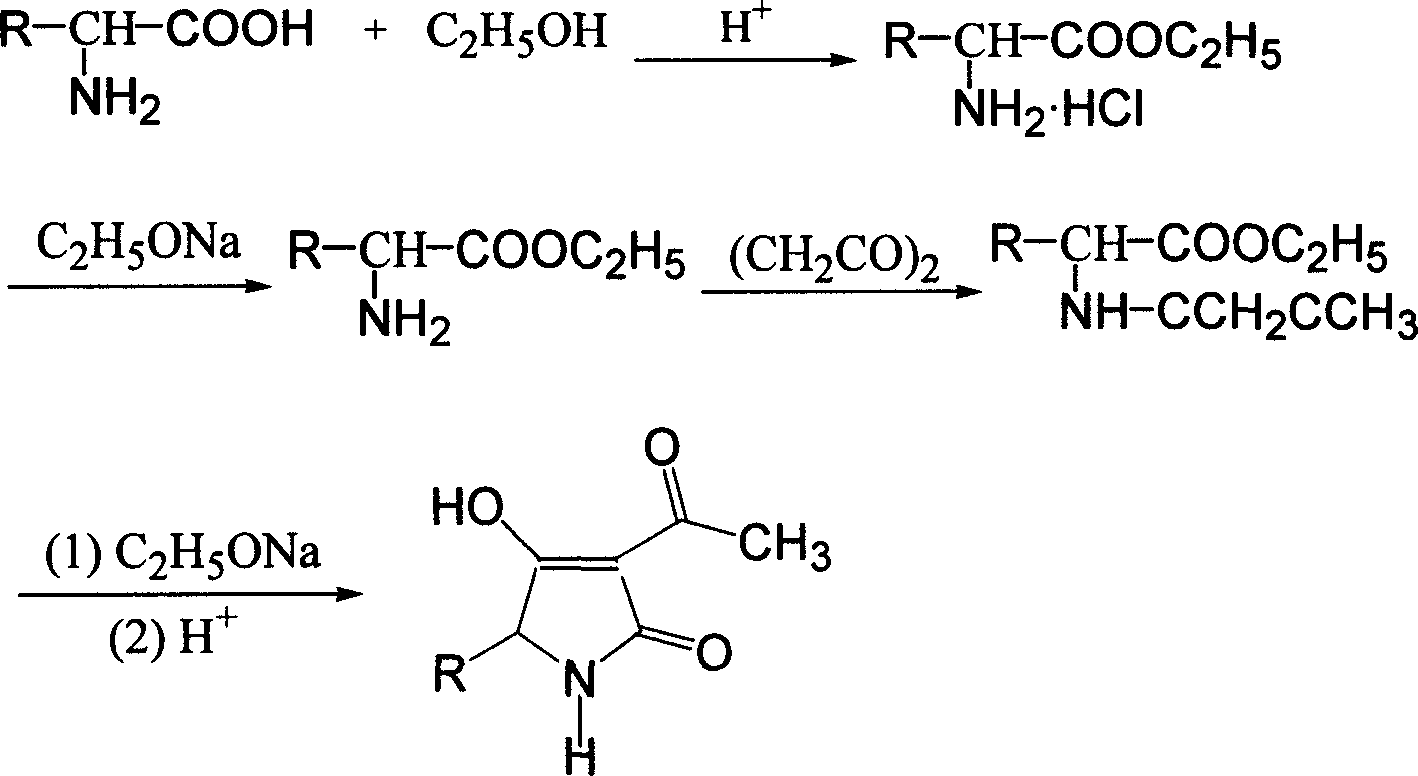

Synthesis of tenuazonic acid and iso-tenuazonic acid

InactiveCN1817859AProduction equipment requirements are simpleSimple and fast operationOrganic chemistryAlcoholTenuazonic acid

Synthesis of tenuazonic acid and isotenuazonic acid is carried out by taking amino acid as initial material, esterifying by alcohol, neutralizing by sodium alcoholate, acidylating by diketene, cyclizing and acidifying under the existence of sodium alcoholate to obtain final product. It is simple, safe and cheap, has more yield and better quality.

Owner:NANJING AGRICULTURAL UNIVERSITY

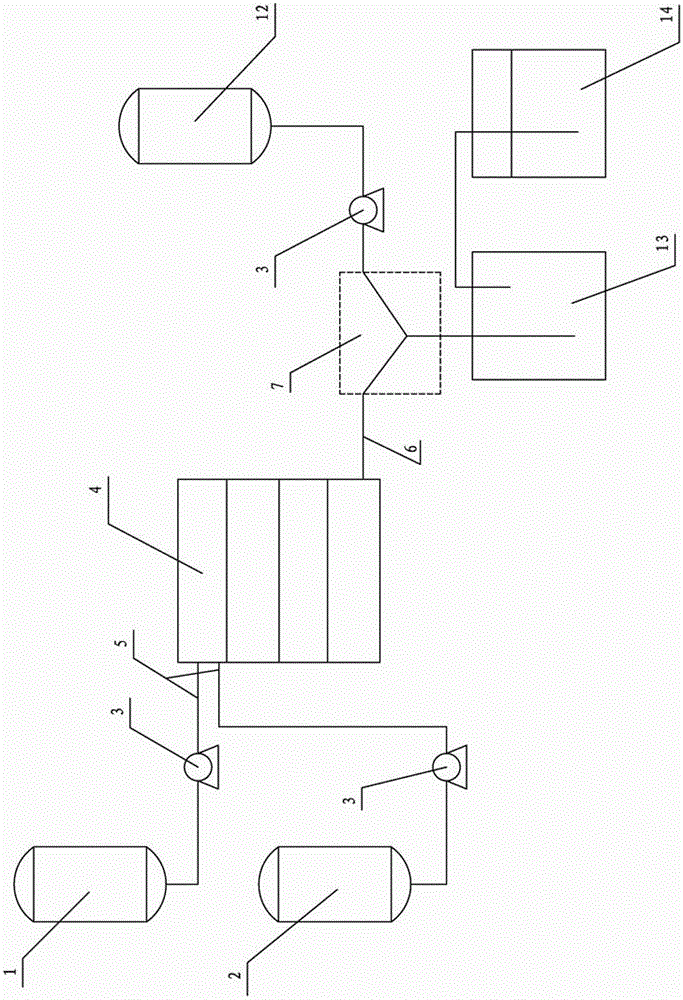

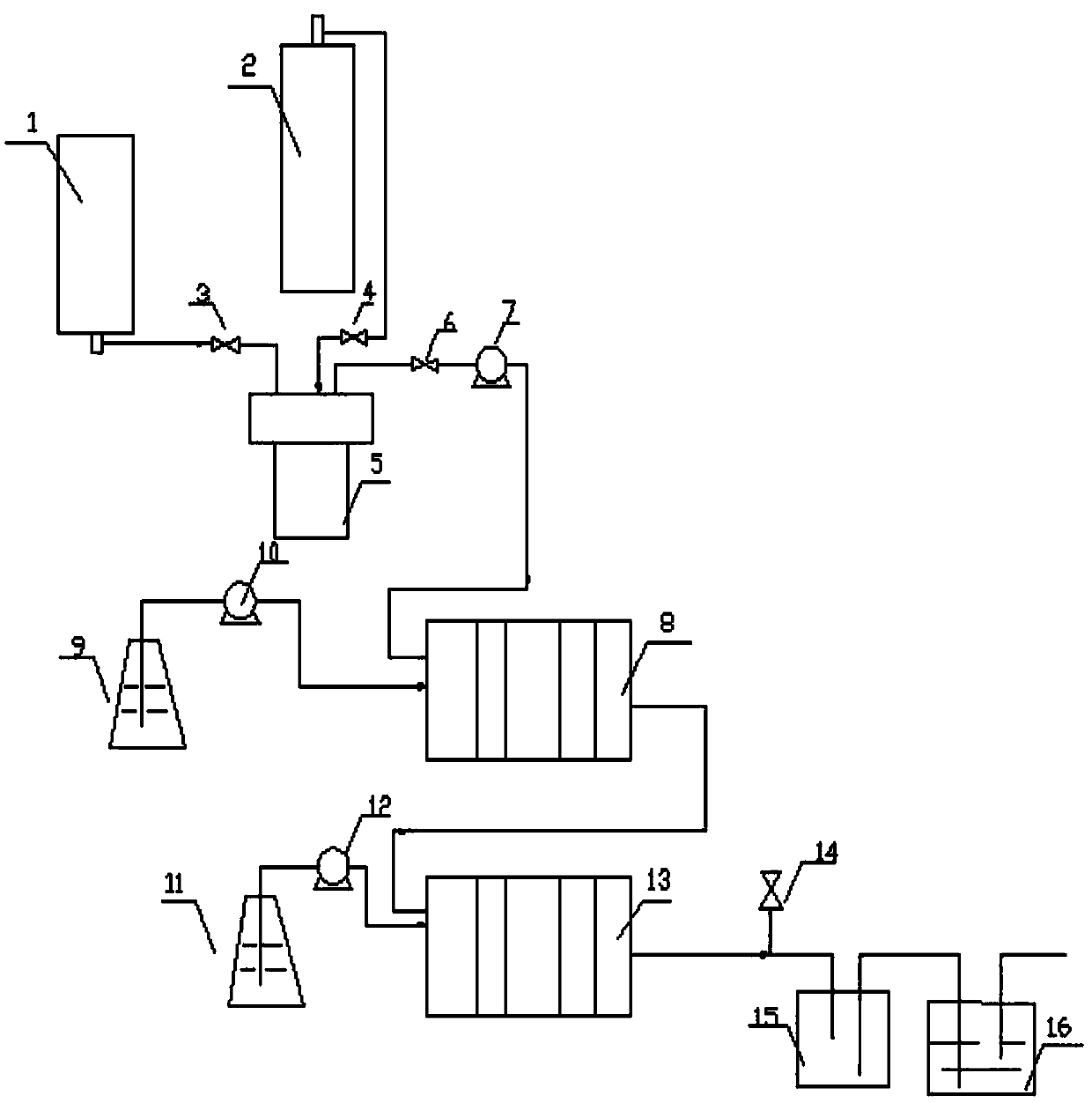

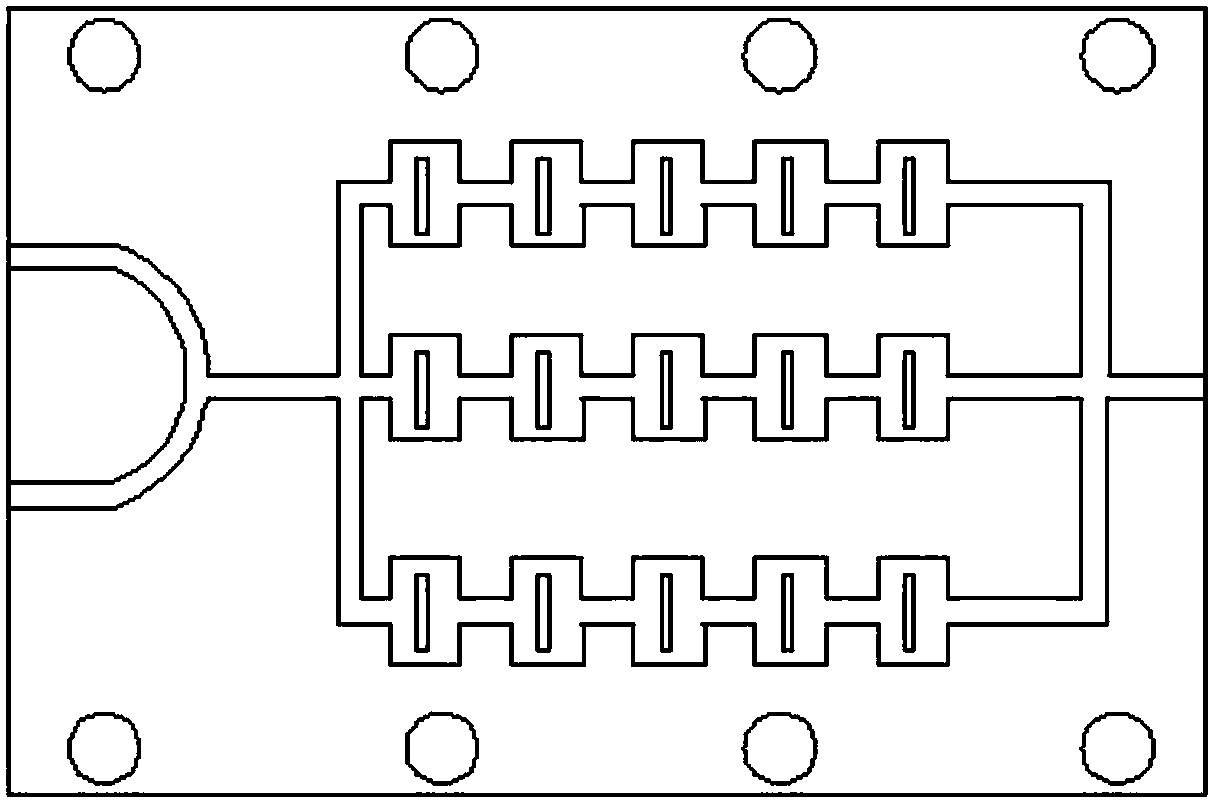

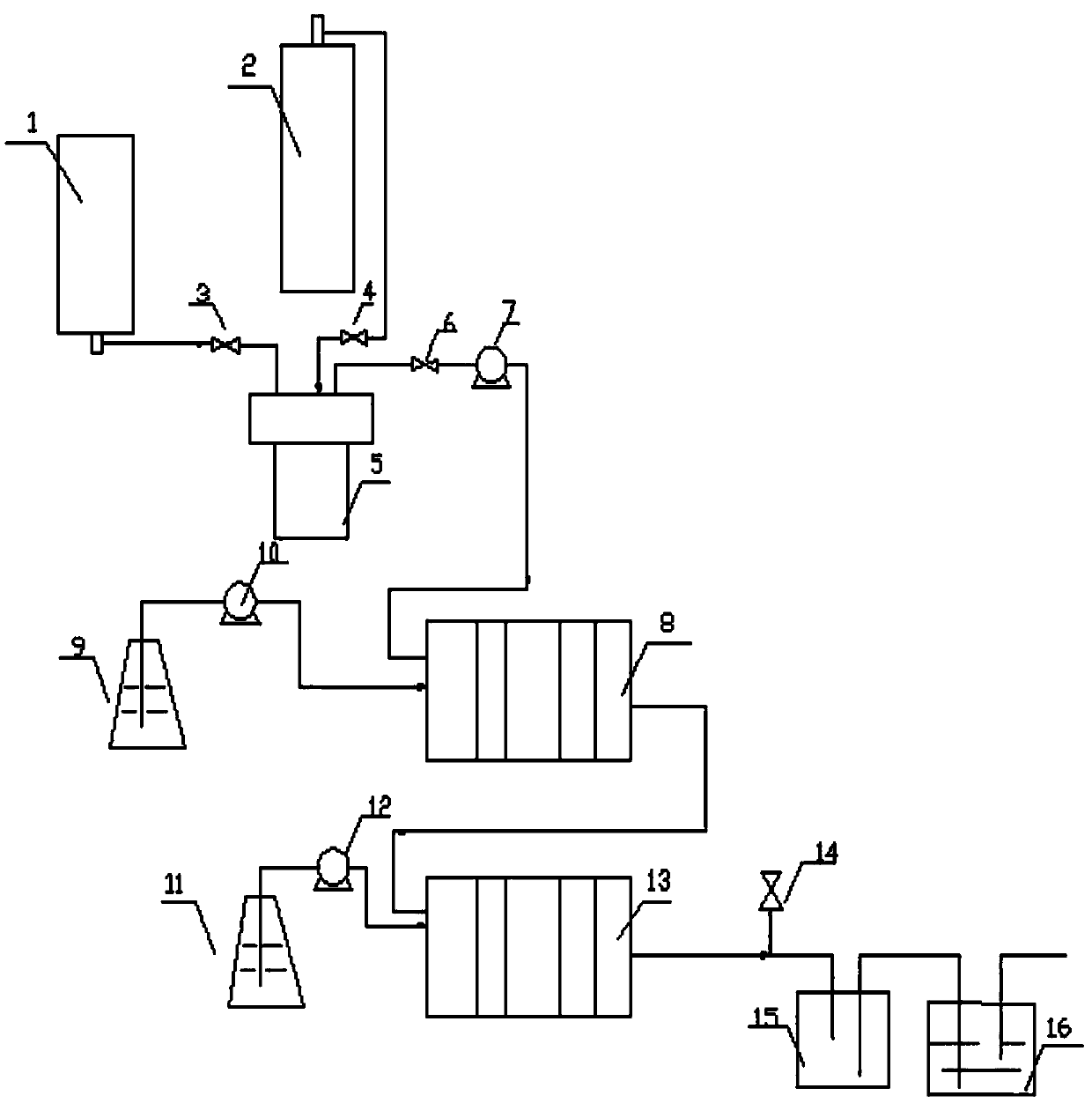

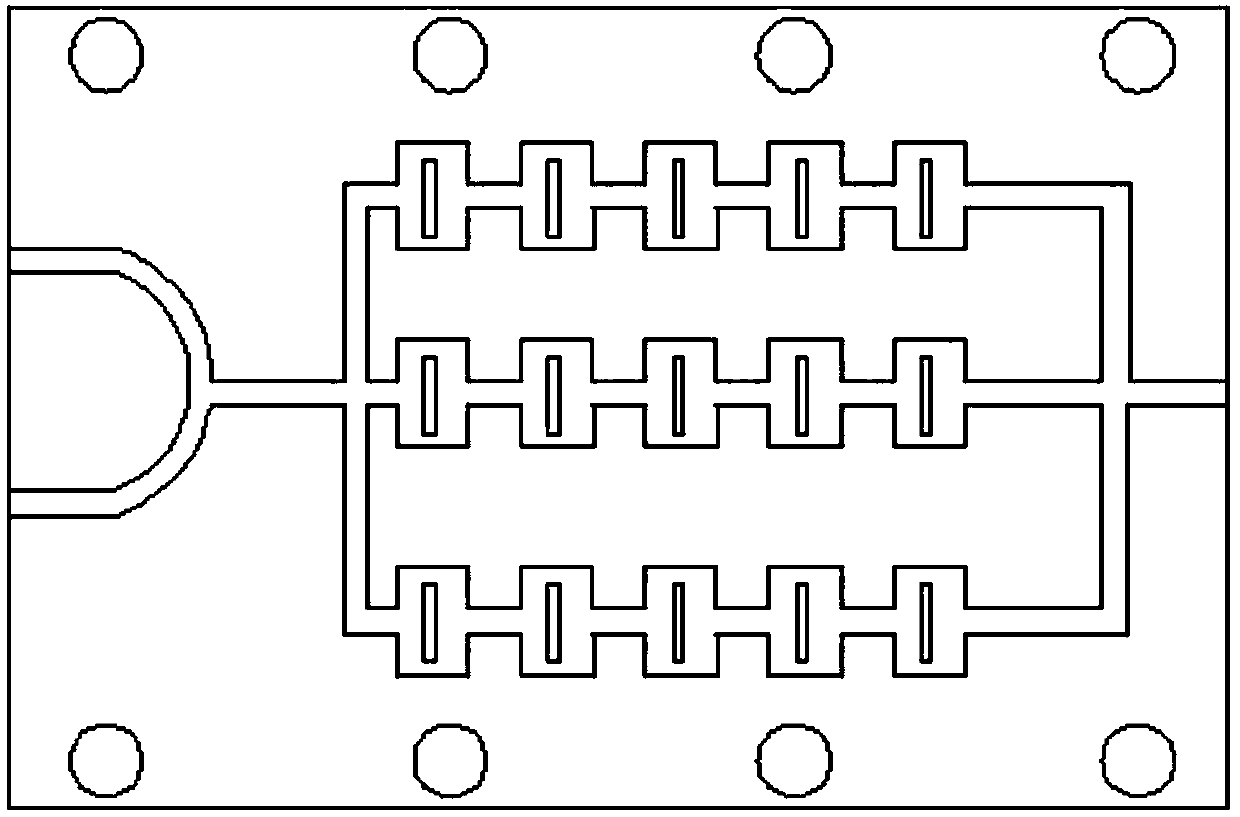

Continuous synthesis system and method of ethyl 4-chloroacetoacetate

InactiveCN106748764AHigh selectivityReduce manufacturing costPreparation from carboxylic acid halidesCarboxylic acid halides preparationEthyl acetateDiketene

The invention relates to a continuous synthesis system and method of ethyl 4-chloroacetoacetate. The method comprises the steps of adopting diketene, chlorine and ethyl alcohol as raw materials and inputting the raw materials into a micro-channel reactor through a metering pump; and carrying out chlorination and esterification and then synthesizing the ethyl 4-chloroacetoacetate. The reaction time is greatly shortened, and the produced product is high in content, low in cost, small in pollution and high in security and meets the requirements of industrial production.

Owner:JIANGSU CHENGXIN PHARMA

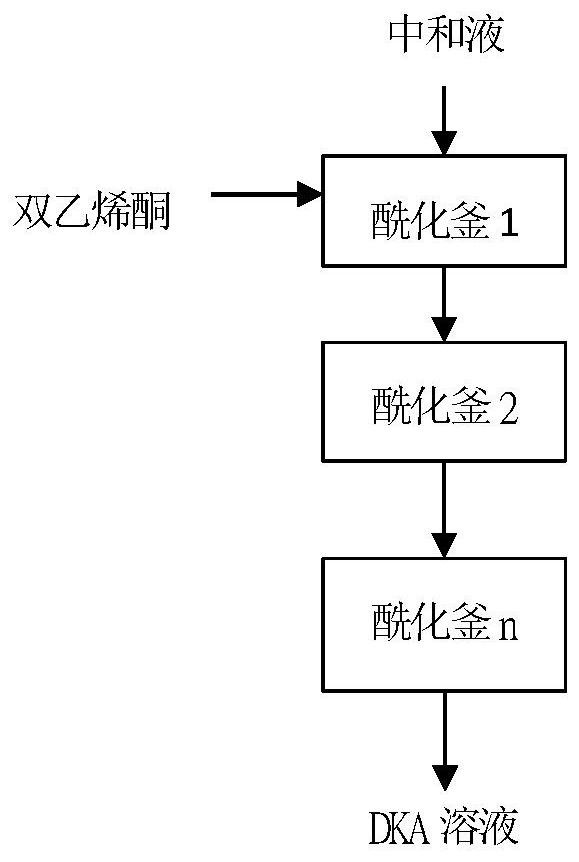

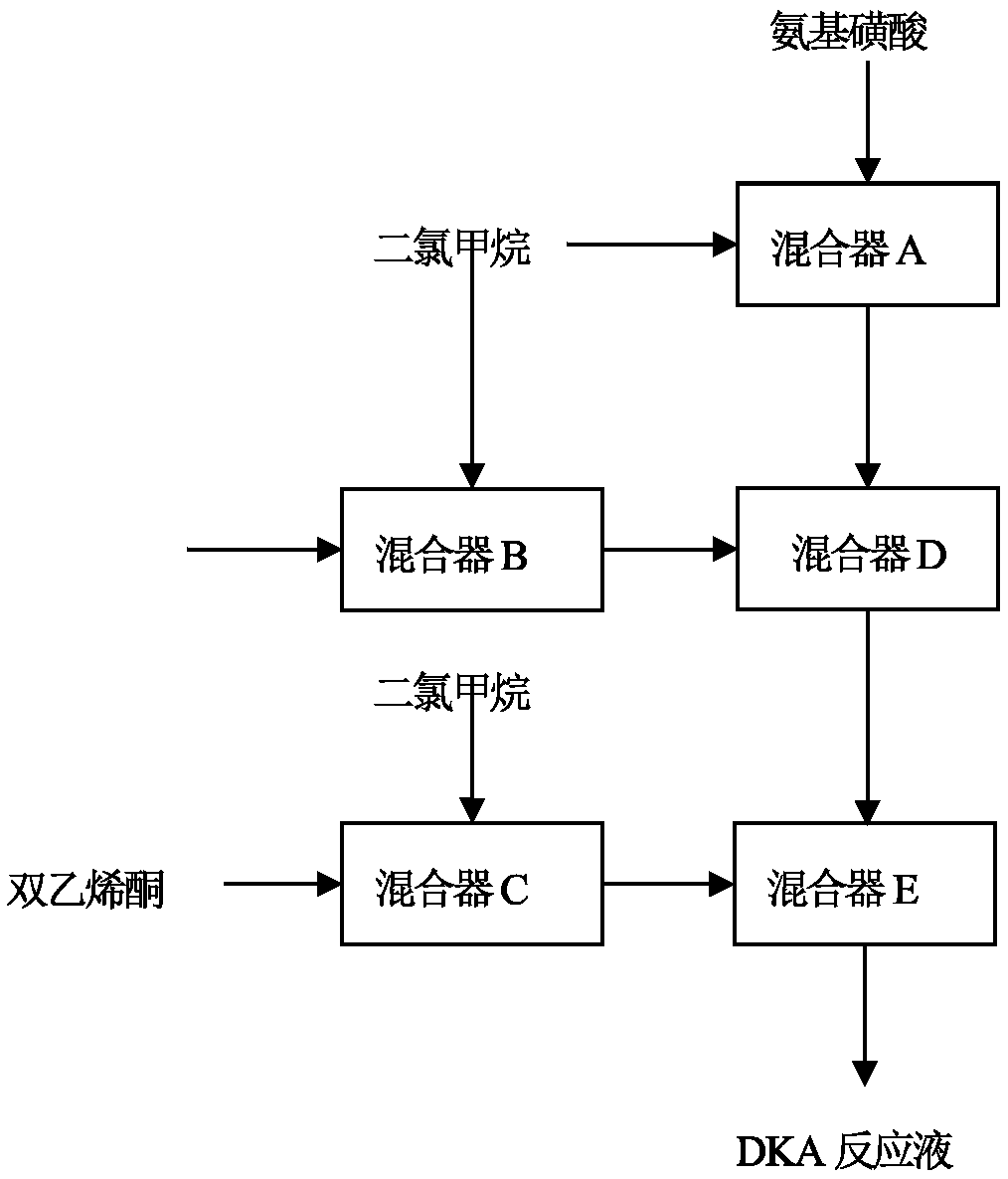

Continuous acylation synthesis method in acesulfame potassium synthesis

The invention belongs to the field of chemical production, and particularly relates to a continuous acylation synthesis method in acesulfame potassium synthesis, wherein the method comprises the following steps: partially paving a synthesis material of sulfamic acid and triethylamine, namely a neutralization reaction solution, dropwisely adding a certain amount of diketene, reacting to obtain a preparation solution, continuously feeding the neutralization reaction solution and diketene into a reactor, and carrying out continuous acylation reaction to obtain a DKA reaction solution. Compared with traditional single-kettle intermittent dropwise adding of diketene, the method has the advantages that the heat exchange speed is increased, the production period is shortened, the production efficiency is improved, and meanwhile, the problems of unstable quality, potential safety hazards and the like caused by manual operation are solved.

Owner:NANTONG ACETIC ACID CHEM +1

Method for preparing 4-chloroacetoacetic acid ethyl ester

InactiveCN102746151AImprove recycling ratesLow costOrganic compound preparationCarboxylic acid esters preparationAcetic acidOrganic solvent

The invention relates to a method for preparing 4-chloroacetoacetic acid ethyl ester. The method comprises the following steps of: (1), putting an organic solvent into a container, cooling to 30 DEG C below zero-0 DEG C; (2) adding diketene, uniformly stirring, and controlling the reaction temperature at 30 DEG C below zero-0 DEG C; (3) controlling the temperature of a reaction liquid at 30 DEG C below zero-10 DEG C while stirring, and introducing chlorine gas; (4) keeping the temperature of the reaction liquid at 30 DEG C below zero-10 DEG C while stirring, and dropwise adding ethanol; (5) heating the reaction liquid to 0-30 DEG C while stirring; (6) distilling the reaction liquid, and recovering the organic solvent till no fraction flows out; and (7) refining oily matters, and collecting a colorless or slightly-yellow transparent liquid to obtain a target product, i.e., 4-chloroacetoacetic acid ethyl ester. The yield of the 4-chloroacetoacetic acid ethyl ester prepared with a process method is 75-88 percent.

Owner:JIANGSU CHENGXIN PHARMA

Thermosetting compositions based on phenolic resins and curable poleyester resins made with diketene or beta-ketoacetate containing compounds

ActiveUS9598602B2Good solvent resistanceEffective cross-linkingPolyester coatingsCompound aCompound (substance)

Owner:EASTMAN CHEM CO

Method for preparation of EHATA

The invention discloses a new method for preparing ethyl 2-(2-aminothiazole-4-yl)-2-hydroxyimino acetate. The method for preparing ethyl 2-(2-aminothiazole-4-yl)-2-hydroxyimino acetate comprises following steps: taking diketene as raw material and producing intermediate product 4-chloracetyl acetidin through chlorination and esterification, and preparing final product through nitrosation and cyclization reaction. The invention is characterized in that it employs cheaper raw material and phase transition catalysis technology, which simplifies operation process, reduces reaction phase transition, decreases production cost and three- waste pollution, and its industry application value is great.

Owner:SHANDONG HUIHAI PHARMA & CHEM

Preparation method for N-acetyl acetanilide

ActiveCN103224455APrevent mutual condensationReduce the amount of waterOrganic compound preparationCarboxylic acid amide separation/purificationBiotechnologyEthenone

The invention relates to a preparation method for N-acetyl acetanilide. The method comprises the following steps of adding N-acetyl acetanilide crystal seeds and an emulsifying agent to deionized water at a temperature of 0-10 DEG C to carry out a reaction; then dropwise adding diketene and aniline simultaneously under the control of a certain temperature; keeping the reaction at the temperature; cooling to a temperature of 0 DEG C; filtering and drying to obtain the N-acetyl acetanilide. The method has the advantages of effectively preventing product caking, improving product appearance and performance, increasing product yield and greatly reducing wastewater quantity.

Owner:NANTONG ACETIC ACID CHEM

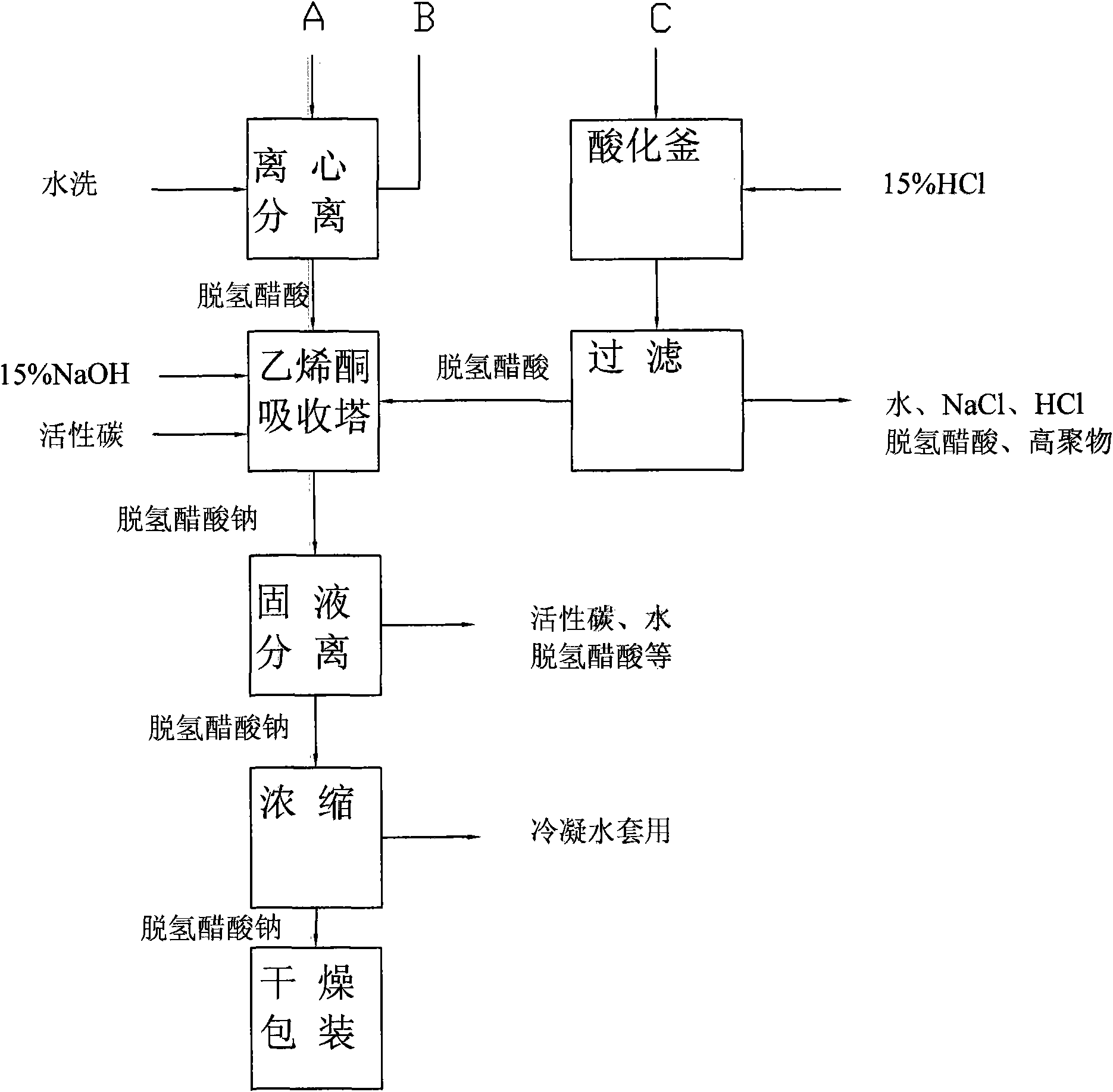

Process for preparing sodium dehydroacetate

ActiveCN101885716AInhibition formationShort processOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsDehydroacetic acidMaterial consumption

The invention relates to a process for preparing sodium dehydroacetate. The process comprises preparation of diketene, polymerization of dehydroacetic acid, separation of the dehydroacetic acid, preparation of the sodium dehydroacetate and the like. The dehydroacetic acid is polymerized by adopting crude diketene finished product of the diketene as a raw material; the adopted screened good composite catalyst is mixed solution of triethylamine and ethylene glycol, so good catalytic polymerization effect can be achieved, and the formation of high polymer can be inhibited; and the pure sodium dehydroacetate is synthesized by adopting an initial dehydroacetic acid product which is not decolorized or refined as a raw material. Therefore, the preparation process simplifies the production process, shortens the flow, and reduces energy consumption and material consumption required in the traditional process at the same time.

Owner:NINGBO WANGLONG TECH

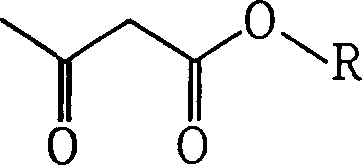

Acetacetic acid alkyl ester metal chelate coating drier and production thereof

A drier of acetacetic acid alkyl ester metal chelate paint and its production are disclosed. The procedure is carried out by reacting alkyl alcohol with diketene to obtain acetacetic acid alkyl ester chelant, and synthesizing the chelant with inorganic metal salt to obtain drier of acetacetic acid alkyl ester metal chelate. Its advantages include solid storage, light color, non-toxic, various raw material resources, simple process and more output.

Owner:上海市涂料研究所有限公司

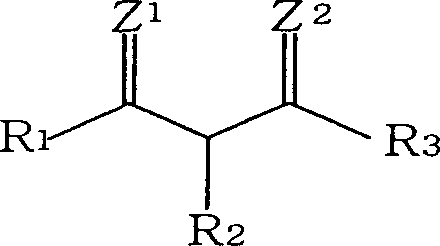

Wax-like β-ketocarbonyl-functional organosilicon compounds

Long chain β-ketocarbonyl-functional organosilicon waxes are easily synthesized from organosilicon compounds bearing a reactive hydrogen bonded to N, O, or S, with a diketene. The products remain silicone-like despite being waxy, and can be used to gel low viscosity silicones to creamy formulations useful in cosmetics.

Owner:WACKER CHEM GMBH

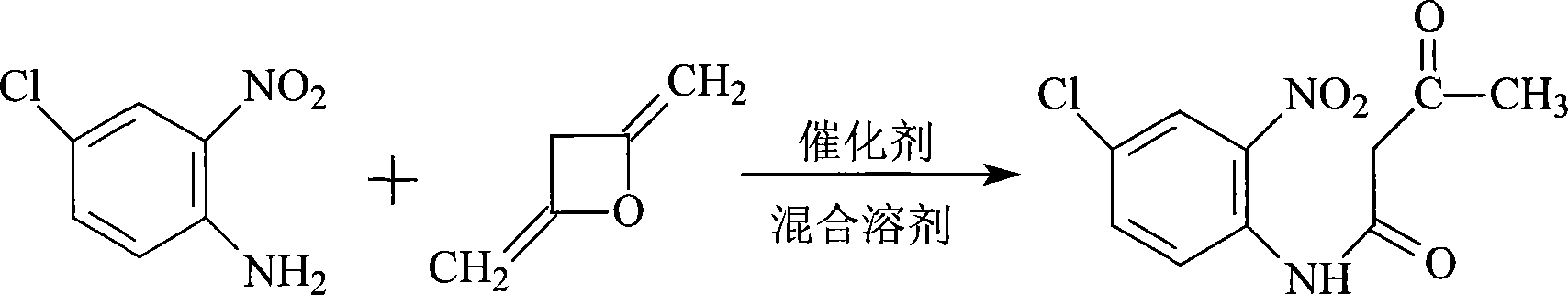

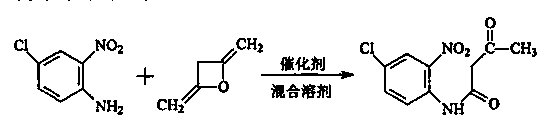

Method for preparing high-purity p-chloro-m-nitroacetoacetanilide

ActiveCN101177404AImprove solubilityHigh purityOrganic compound preparationCarboxylic acid amides preparationEthyl acetateDiketene

The invention discloses a method for preparing high-purity p-chloro-m-nitroacetoacetanilide, in which adopts the technical proposal that p-chloro-o-nitroaniline and catalyst are added in mixed solvent at 15 to 100 DEG C, and then diketene is dripped within 0.5 to 4 hours for reaction for 0.5 to 6 hours to prepare the p-chloro-m-nitroacetoacetanilide, wherein the mixed solvent can be either the solvent composed of two or more materials among water, acetone, tetrahydrofuran, acetonitrile, ethanol, toluene, benzene, isopropyl alcohol, chloroform, dichloromethane, ethyl acetate, butyl acetate and methyl acetate or circulating mother liquor. The circulating mother liquor can be recycled for as many as 10 times and extra catalyst is not needed with the purity of products exceeding 99% and the yield reaching 97%. The invention has the advantages of simple and controllable process, no need of recrystallization and high purity.

Owner:SHANDONG JINCHENG PHARMACEUTICAL GROUP CO LTD

Green synthesis process for p-chloro-o-nitroacetoanilide

InactiveCN103408452AImprove solubilityNo need to crystallize againOrganic compound preparationCarboxylic acid amides preparationSolubilityDiketene

The invention discloses a green synthesis process for p-chloro-o-nitroacetoanilide. The process comprises the following steps of mixing a novel mixed catalyst system and p-chloro-o-nitroaniline, and enabling the novel mixed catalyst system and the p-chloro-o-nitroaniline to dissolve, wherein the mole ratio of the p-chloro-o-nitroaniline to diketene is 1: (1.05-1.5); finishing the dropwise adding operation of the diketene within 3h; and continuing to react at the temperature of 90 DEG C for 4h to obtain the p-chloro-o-nitroacetoanilide. The solubility of the p-chloro-o-nitroaniline in a solvent is improved, the yield of products is high, the reaction time is shortened, the solvent dosage is reduced, and no solid wastes are generated.

Owner:JIANGSU LONGCHANG CHEM

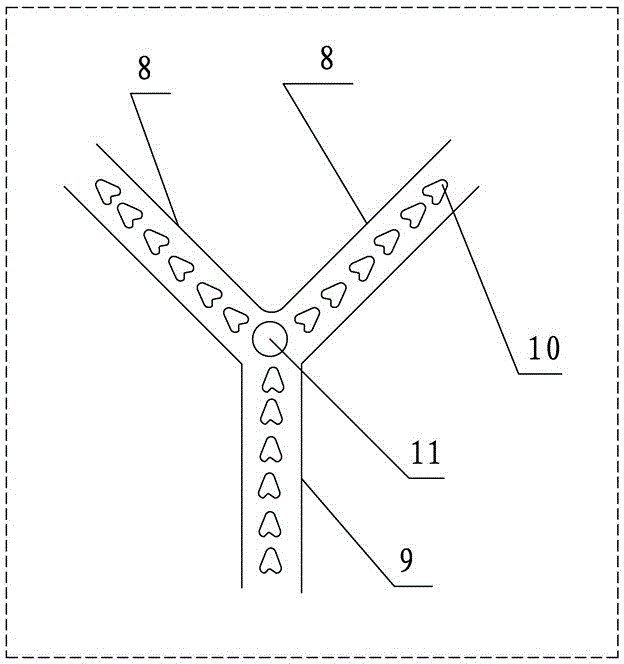

Continuous flow synthesizing method and system for 4-chloro-3-oxo-ethyl butyrate without solvent

InactiveCN107915622AProcess environmental protectionReduce manufacturing costPreparation from carboxylic acid halidesOrganic compound preparationAlcoholContinuous flow

The invention belongs to the field of chemical engineering, and particularly relates to a continuous flow synthesizing method and a system for 4-chloro-3-oxo-ethyl butyrate without solvent. The methodcomprises the following steps of in the reaction process, firstly, performing chlorination reaction on diketene and liquid chloride through a micro-channel reactor module 8, and then performing esterification reaction on the chlorinating liquid and ethyl alcohol through a reaction module 13, so as to obtain a crude product of the 4-chloro-3-oxo-ethyl butyrate; performing pressure-relief rectification on the crude product, so as to obtain a finished product of the 4-chloro-3-oxo-ethyl butyrate. The method can solve the problem that because the micro-channel reactor has certain drag, the liquidchloride cannot be fed by a conventional feeding device; in the micro-channel reactor, the mixing effect of gas and liquid reaction is poorer than the mixing effect of liquid and liquid reaction, themetering accuracy of gas is poor, the amount of reaction byproducts is increased, the yield rate is reduced, and the like.

Owner:NANTONG ACETIC ACID CHEM +1

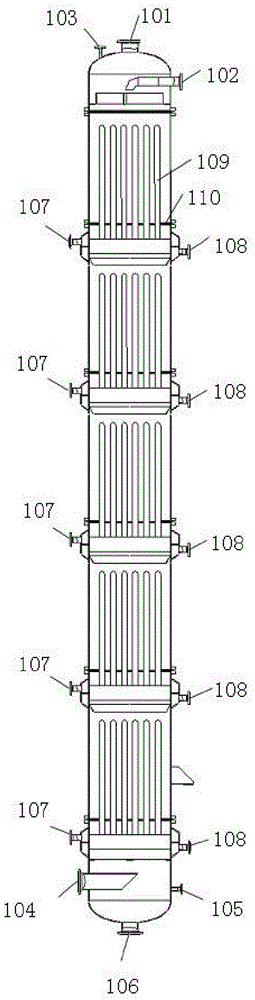

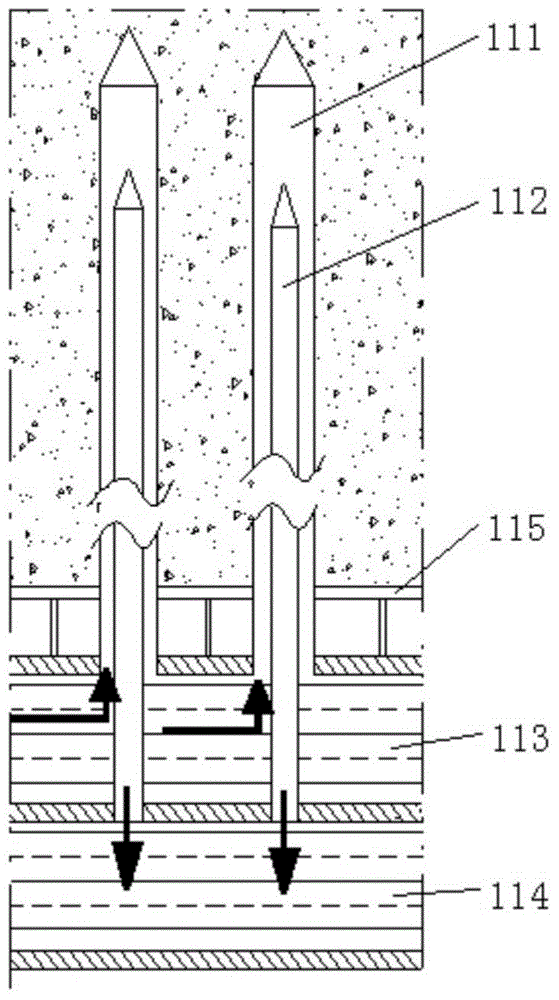

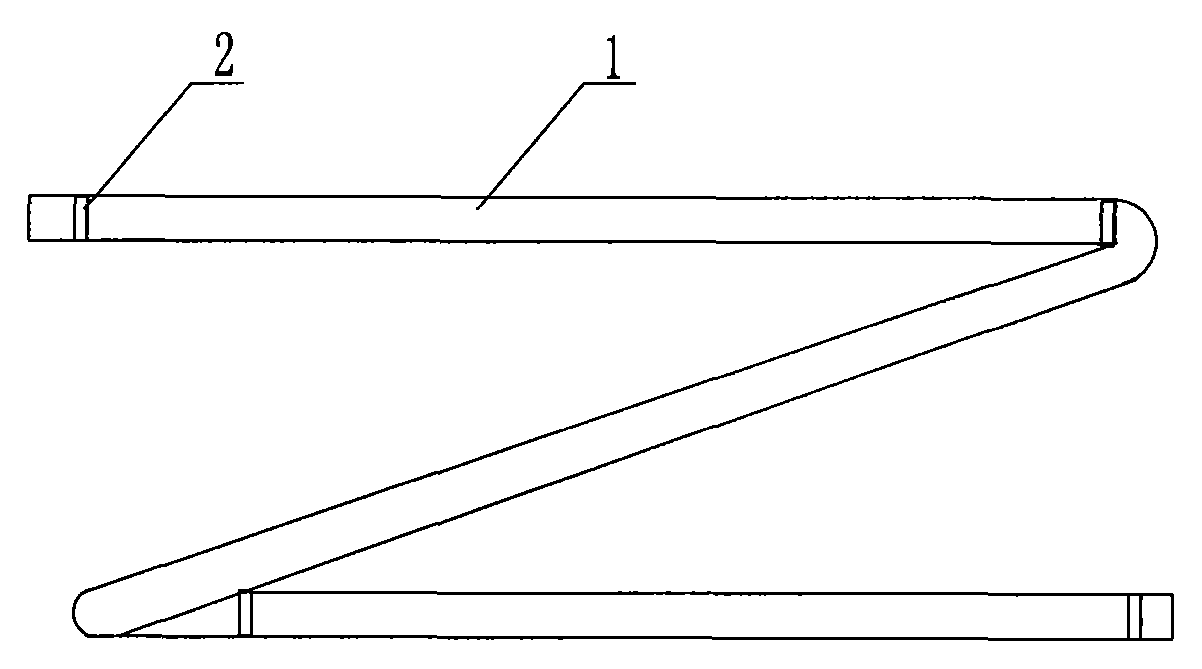

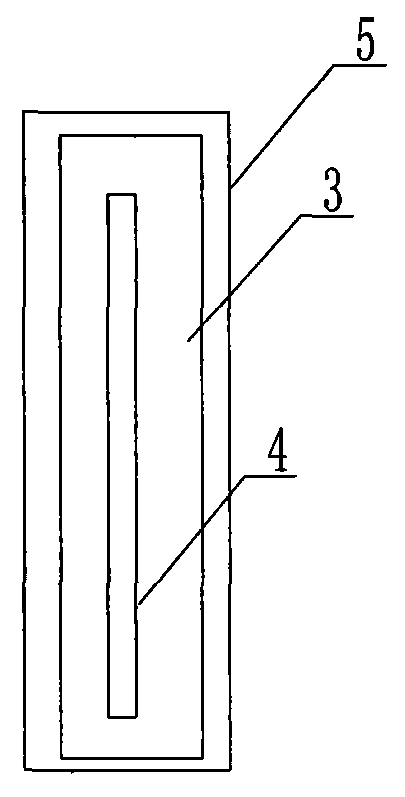

Diketene preparation device and diketene preparation method

ActiveCN104592172AEasy to condense and separateDowngradeOrganic chemistryAcetic acidAcetic anhydride

The invention relates to a diketene preparation device and a diketene preparation method. The diketene preparation device comprises an acetic acid evaporator, a mixer, a cracking furnace, a quenching condenser and an absorption tower. The outlets of the acetic acid evaporator and the mixer are connected with the cracking furnace; the cracking furnace is then connected with the multi-level quenching condenser; the quenching condenser is then connected with the absorption tower; one branch of the absorption tower is connected with a polymerization tank, and the other branch of the absorption tower is connected with a water absorption tower; and the outlet of the third-level quenching condenser is connected with the quenching condenser behind through a liquid ring pump. The diketene preparation device and diketene preparation method provided by the invention have the beneficial effects that when the cracked gas is pressurized, the impurities such as acetic acid, water and acetic anhydride in the cracked gas can be condensed out more sufficiently, and thus the quality of the cracked gas before entering the absorption tower is improved while the freezing level is lowered; and compared with the traditional technology in which the energy consumption accounts for 45% of the total cost of diketene, the device and method provided by the invention have the advantage that the energy consumption only accounts for 25% of the total cost of diketene through improvement.

Owner:QINGDAO UNIV OF SCI & TECH

Treatment process of diketene distillation residues

InactiveCN104031943ALimit overflowHigh purityBio-organic fraction processingClimate change adaptationThermal energyDistillation

The invention relates to the field of chemical engineering, and provides a treatment process of diketene distillation residues, and the treatment process is used for solving the problems in waste liquids of the diketene distillation residues in the prior art that the extraction rate of acetone is low, the acetone purity is low, the whole process is long in time and low in efficiency, and the discharged liquid residues and the like after the treatment are not thoroughly treated. According to the method provided by the invention, the fermentation treatment is carried out after the reduced pressure distillation is carried out; hazardous substances are decomposed by utilizing biological bacteria, so that the method is simple in process, high in production efficiency and thorough in treatment of wastewater and waste residues, wherein marsh gas during the production can be used for heating a distillation retort and can also be used for providing heat energy or power for other process procedures in the production. Thus, the energy recycling is realized, i.e., the energy conservation and the environment friendliness are realized. As a result, the treatment process provided by the invention is suitable for popularization applications.

Owner:NINGBO WANGLONG TECH

Continuous flow synthesizing method and system for methyl 4-chloroacetoacetate without solvent

InactiveCN107915623AProcess environmental protectionReduce manufacturing costPreparation from carboxylic acid halidesOrganic compound preparationAcetic acidAlcohol

The invention belongs to the field of chemical engineering, and particularly relates to a continuous flow synthesizing method and a system for methyl 4-chloroacetoacetate without solvent. The method comprises the following steps of in the reaction process, firstly, performing chlorination reaction on diketene and liquid chloride through a micro-channel reactor module 8, and then performing esterification reaction on the chlorinating liquid and methyl alcohol through a reaction module 13, so as to obtain a crude product of the methyl 4-chloroacetoacetate; performing pressure-relief rectification on the crude product, so as to obtain a finished product of the methyl 4-chloroacetoacetate. The method can solve the problem that because the micro-channel reactor has certain drag, the liquid chloride cannot be fed by a conventional feeding device; in the micro-channel reactor, the mixing effect of gas and liquid reaction is poorer than the mixing effect of liquid and liquid reaction, the metering accuracy of gas is poor, the amount of reaction byproducts is increased, the yield rate is reduced, and the like.

Owner:NANTONG ACETIC ACID CHEM +1

Continuous preparation method of acetoacetamido triethylamine sulfonate

PendingCN111377834ASimple processLow costOrganic compound preparationSulfuric acid amide preparationReaction temperatureDiketene

The invention discloses a continuous preparation method of acetoacetamido triethylamine sulfonate, comprising the following steps of: continuously mixing and dissolving sulfamic acid and dichloromethane, continuously neutralizing with a triethylamine solution to obtain a neutralization reaction solution, introducing the neutralization reaction solution and diketene into a continuous reactor, and carrying out addition acylation reaction to obtain a DKA reaction solution; wherein the molar ratio of n (sulfamic acid) to n (dichloromethane) in the continuous mixing and dissolving process is 1: (1-20), and the temperature is 0-40 DEG C; in the continuous neutralization, the pH of the neutralization is equal to 7-9, and the neutralization temperature is 10-40 DEG C; in the addition acylation reaction, the molar ratio of n (sulfamic acid) to n (diketene) is 1: (0.5-1.5), the acylation reaction temperature is 0-30 DEG C, and the acylation retention time is 0.01 s to 30 min. The invention provides a process for continuously preparing a DKA solution. The process is simple, low in cost, continuous in the whole process and high in yield.

Owner:NANTONG ACETIC ACID CHEM +1

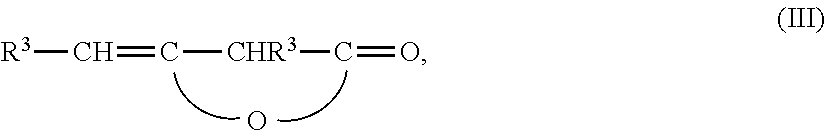

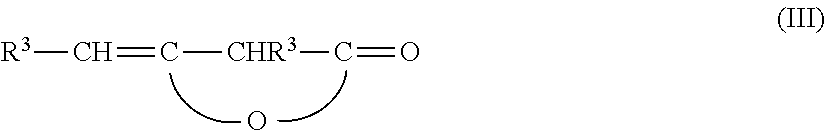

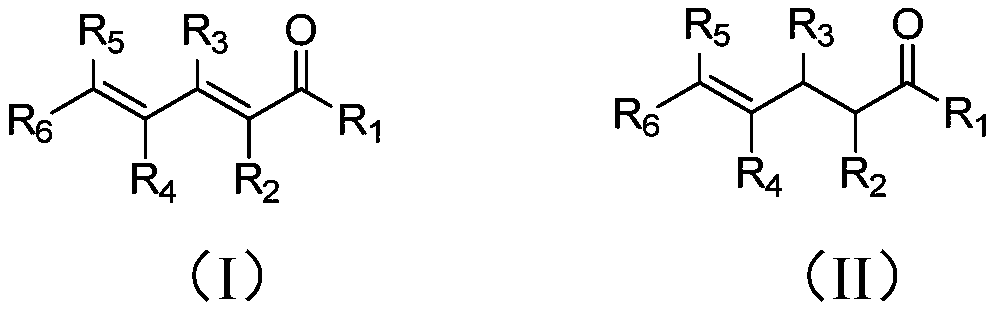

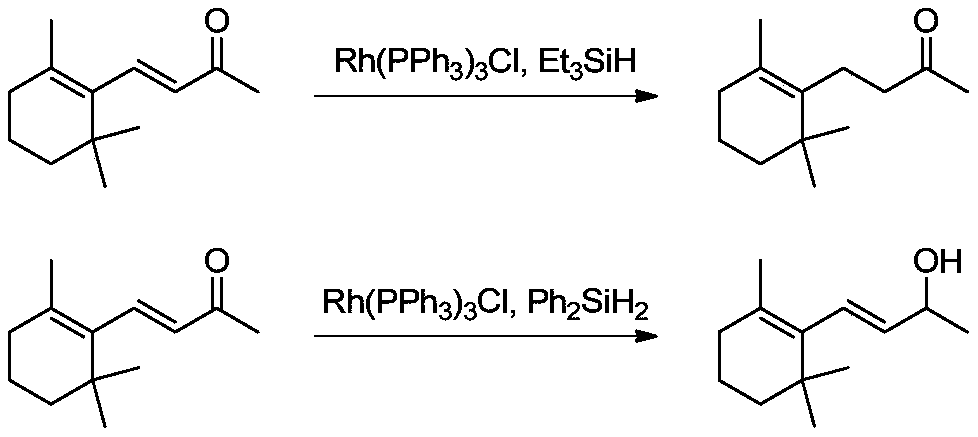

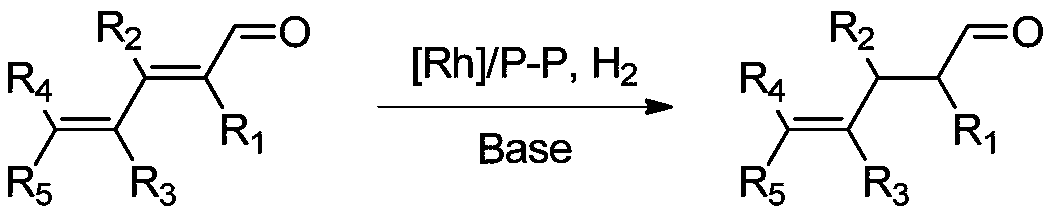

Method of preparing gamma-ketene from alpha, gamma-unsaturated diketene

ActiveCN110922321AReduce dosageHigh selectivityOrganic compound preparationCarbonyl compound preparationPtru catalystSilanes

The invention provides a method of preparing gamma-ketene from alpha, gamma-unsaturated diketene. According to the method, single hydrogen silane is used as a silicon hydrogen reducing agent, a palladium complex is used as a catalyst, a Lewis acid is used as an auxiliary agent, and alpha, gamma-unsaturated diketene are subjected to silicon hydrogen reduction reactions to obtain gamma-ketene through a one-step method. The method has the advantages of mild conditions, simple operation, high product selectivity and yield, cheap and easily available silicon hydrogen reducing agent, high catalystactivity, little using amount, and low cost, and has potential of industrial scale-up.

Owner:WANHUA CHEM GRP CO LTD

Process of continuously producing methyl acetoacetate

InactiveCN105384631AFast outputIncrease finished productOrganic compound preparationPreparation from ketenes/polyketenesAcetic acidNitrogen

The invention discloses a process of continuously producing methyl acetoacetate and relates to the technical field of production of chemical raw materials. The production process comprises the following steps of firstly, welding a separation board at the middle of an esterification reactor for separating the esterification reactor into a cooling bin and an insulating bin; secondly, adding a methyl acetoacetate finished product into the esterification reactor to serve as a bottom material in the reactor, and meanwhile, simultaneously dropping DK and methanol into the cooling bin; thirdly, realizing water cooling and air cooling in the cooling bin; after the cooling bin is cooled, realizing pressurization; after pressurization, enabling a product to overflow to the inside of the insulating bin through an overflow pipe; during overflowing, adding diketene on the overflow pipe; fourthly, when the product in the insulation bin reaches a certain amount, transferring the methyl acetoacetate to the inside of a rectifying tower through a transfer pump; fifthly, vacuumizing the inside of the rectifying tower for exhausting air, and meanwhile, inputting nitrogen, and rectifying the methyl acetoacetate in a reflux state to obtain a final product at the moment. According to the process disclosed by the invention, quick production can be realized, the finished product output is improved, the accuracy in control is realized, and the time and the cost are saved.

Owner:JIANGSU TIANCHENG BIOCHEM PROD

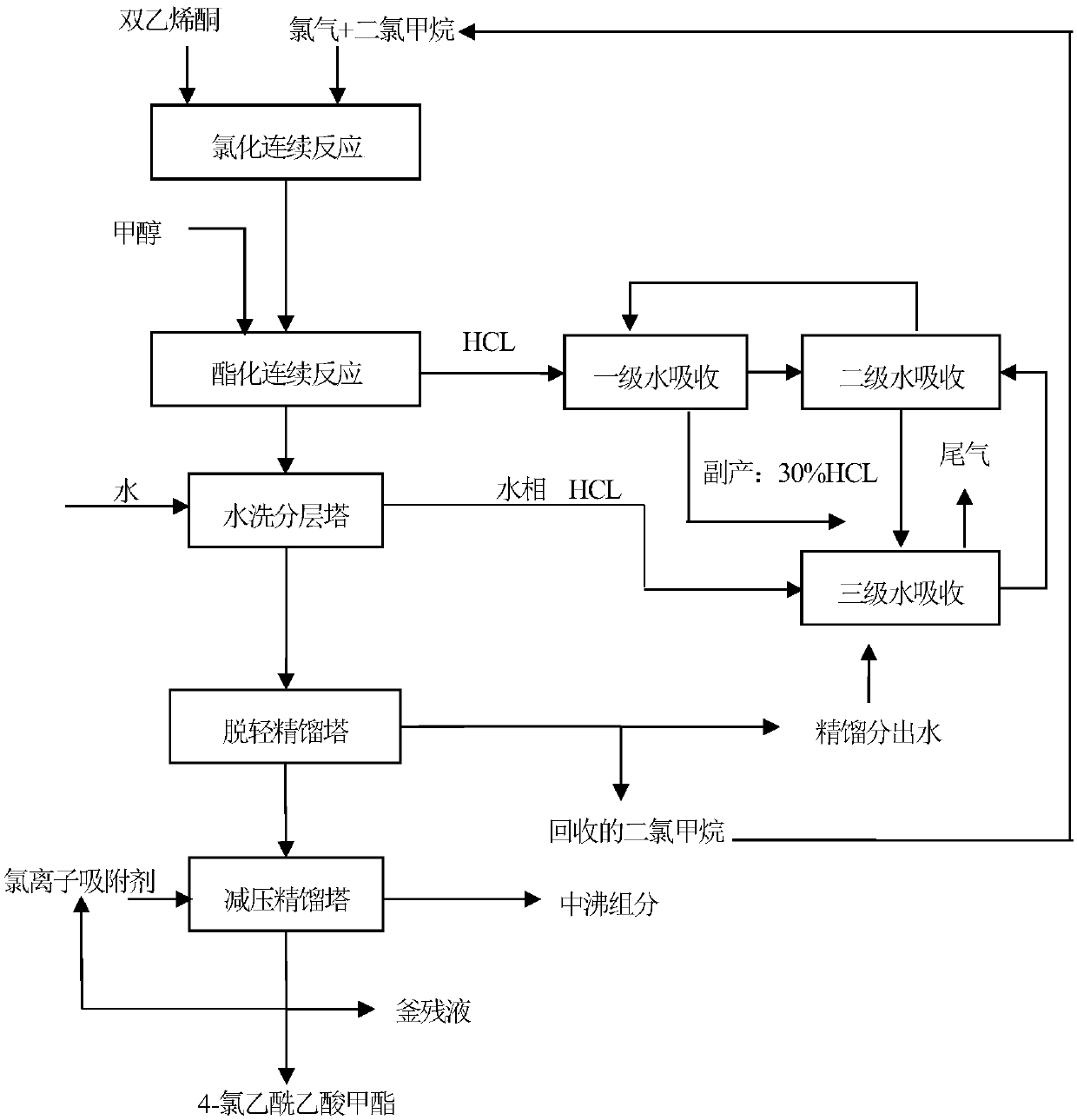

Post-treatment method for continuously synthesizing methyl 4-chloroacetoacetate

ActiveCN107915631AHigh purityNothing producedChlorine/hydrogen-chloride purificationOrganic compound preparationSeparation technologyDiketene

The invention belongs to the field of chemical engineering and in particular relates to a post-treatment method for continuously synthesizing methyl 4-chloroacetoacetate. The post-treatment method comprises the following steps: taking diketene, chlorine gas, dichloromethane and methanol as raw materials; inoculating HCl tail gas generated in a process of synthesizing the methyl 4-chloroacetoacetate into a three-grade HCl absorption system; carrying out esterification reaction to obtain a dichloromethane solution of the methyl 4-chloroacetoacetate; adding the dichloromethane solution into a water-washing layering tower; after carrying out water washing, removing the three-grade HCl absorption system from a water phase; after conveying an organic phase into a light component rectifying tower, continuously feeding the organic phase into a negative-pressure rectifying tower from a tower kettle through a feeding pump, so as to obtain a methyl 4-chloroacetoacetate finished product. A byproduct of the HCl absorption system is 25 to 30 percent industrial hydrochloric acid and can be used for selling. The light component rectifying tower and a decompression rectifying tower are used for continuously rectifying and separating a solvent and the product; the solvent can be recycled and applied; a separation technology is green and environmentally friendly and the rectifying efficiency is greatly improved.

Owner:NANTONG ACETIC ACID CHEM +1

Technology method capable of continuously carrying out methyl acetoacetate production

InactiveCN104262153AReduce energy consumptionIncrease contentOrganic compound preparationPreparation from ketenes/polyketenesThermal insulationSlag

The invention discloses a technology method capable of continuously carrying out methyl acetoacetate production, and relates to the technology field of chemical raw material production. The technology production comprises the following steps: adding a methyl acetate finished product into an esterification reactor as a reactor substrate, simultaneously dropwise adding DK and methanol into the reactor; cooling the sleeve of the esterification reactor; keeping on dropwise adding until the fluid in the esterification reactor starts to overflow to the thermal insulation reactor; adding diketene from the overflow pipe; when the fluid in the thermal insulation reactor reaches a certain amount, making the methyl acetoacetate in the thermal insulation reactor overflow to the thermal insulation transfer tank at a constant temperature; pumping the coarse methyl acetoacetate in the thermal insulation transfer tank to a rectifying tower; feeding the coarse product into the rectifying tower from the middle of the rectifying tower, increasing the vacuum degree, carrying out rectification under a certain reflux state so as to obtain finished products; and discharging light components from the tower top, finished products from the middle of the tower, and slag from the tower bottom. The provided technology method is capable of improving work efficiency, greatly increasing the production power, reducing part of steam energy consumption, and saving the equipment investment, can carry out rectification in one tower, and thus reduces the steam energy consumption, moreover the operation is easy to control, and products with a high content are more easily obtained.

Owner:JIANGSU TIANCHENG BIOCHEM PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com