Method for preparing methyl acetoacetate by using novel composite catalyst

A technology of methyl acetoacetate and composite catalyst, which is applied in the direction of chemical instruments and methods, preparation of organic compounds, organic compound/hydride/coordination complex catalysts, etc., and can solve the problem of low product yield and crude methyl acetoacetate Low content and other problems, to achieve the effect of reducing energy consumption, easy operation, and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0008] Add 1.2 tons of methanol with a purity of 99.9% to a 5000L enamel kettle, add 1.5 kg of triethylene diamine under stirring, and dropwise add 3.0 tons of diketene with a content of ≥ 97.5%. After holding at 110-120°C for 1 hour, the temperature is lowered to 40°C. Add 3 kg of concentrated sulfuric acid with a content of ≥98% as a catalyst, keep it for half an hour, and filter the resulting solution to obtain crude diethyl methyl ester.

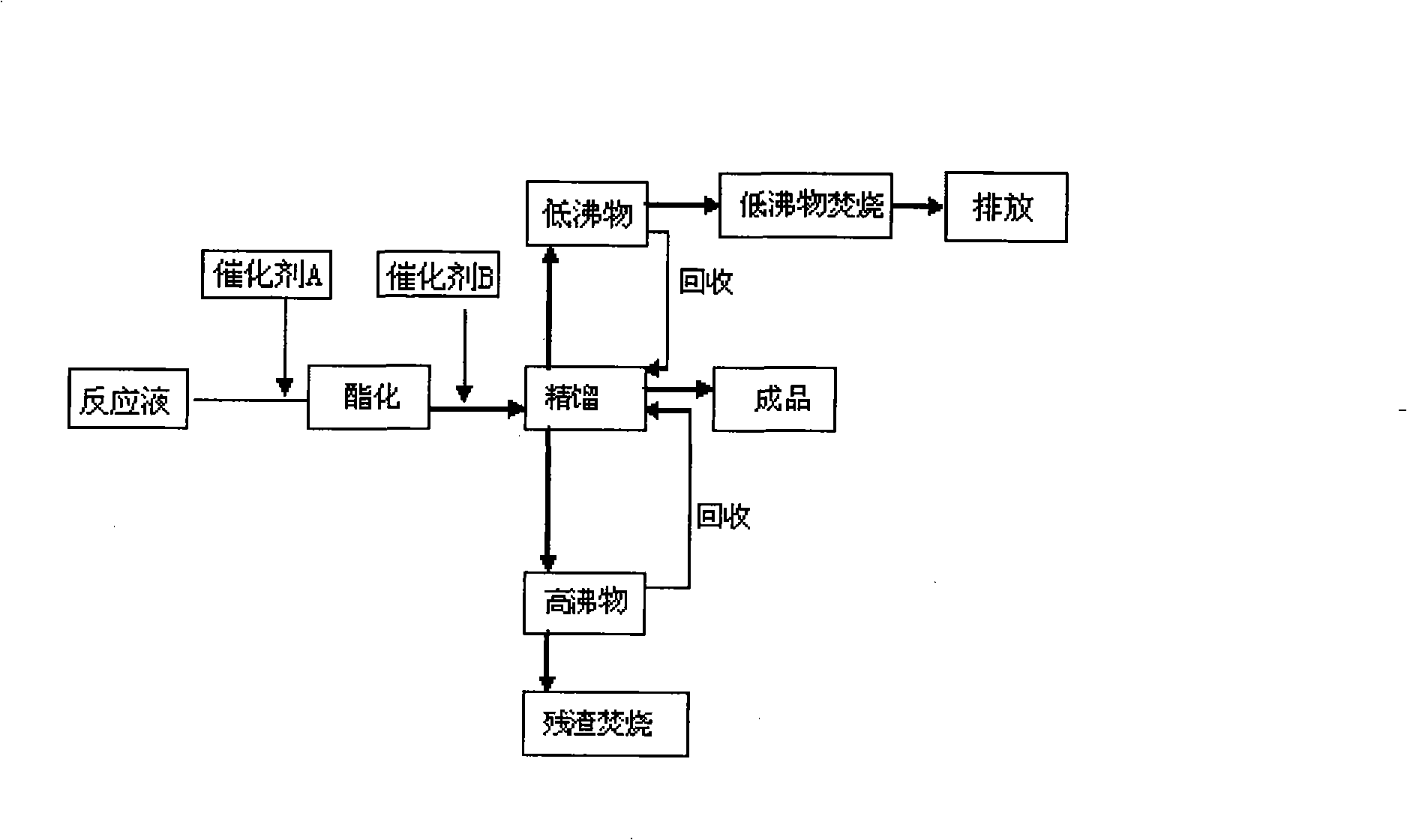

[0009] The crude diethyl methyl ester is preheated by the diethyl methyl ester steam of the high boiling tower and then enters the low boiling tower to remove the low boilers. About 70% of the methyl acetoacetate in the low boilers is recovered into the rectification tower, where acetic acid, After methanol and other substances are incinerated, carbon dioxide and water are generated, which is pollution-free. The reaction liquid from which low boilers are removed flows by itself into the high boiling tower, the rectification residue is discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com