Patents

Literature

83 results about "Sulfur Acids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inorganic or organic acids that contain sulfur as an integral part of the molecule.

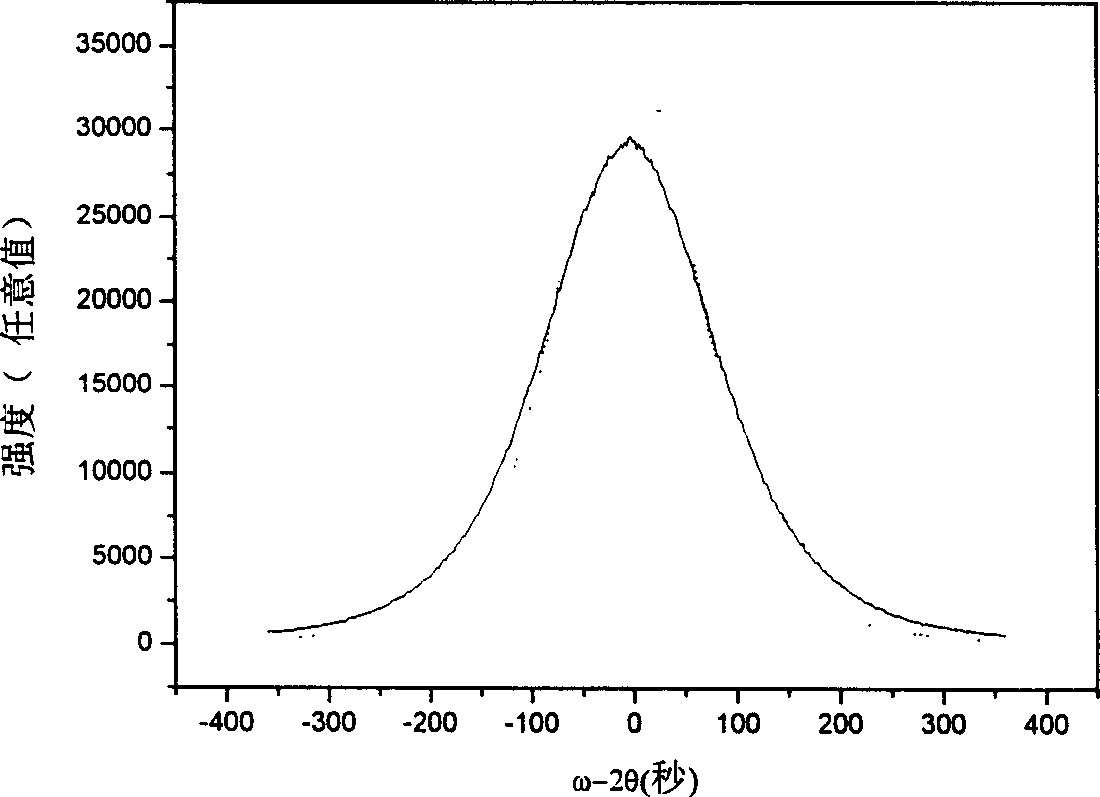

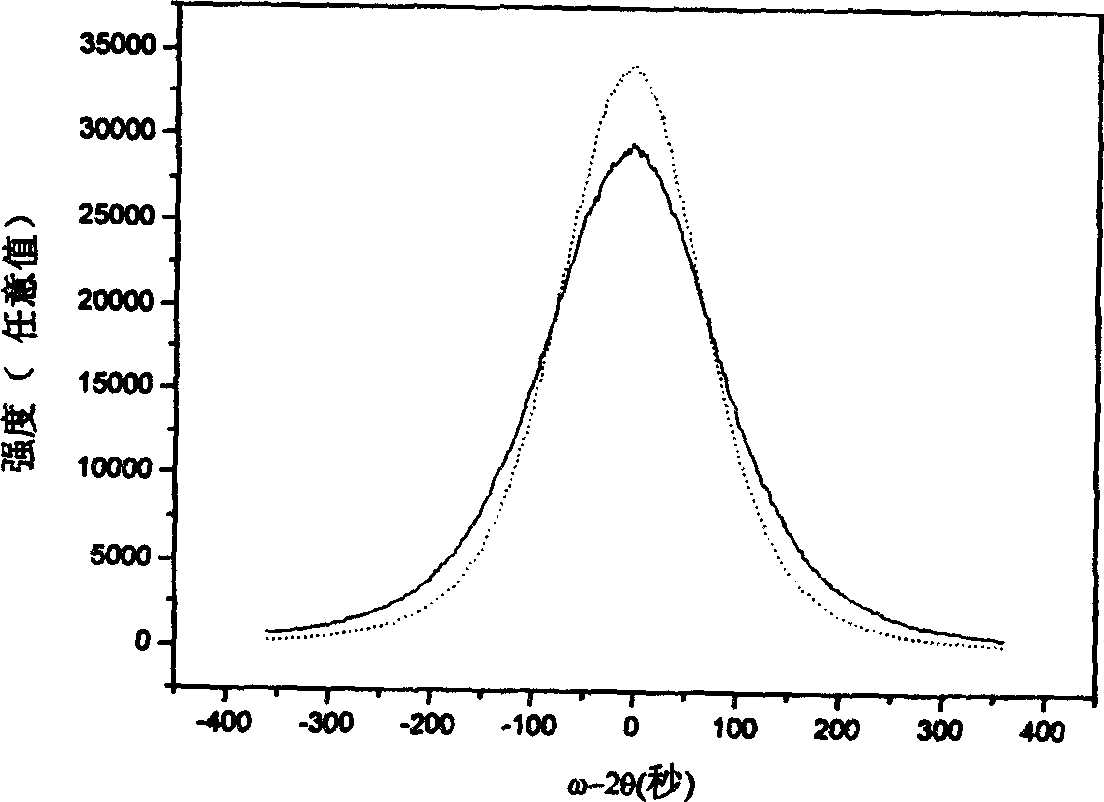

A method for corroding sapphire graphic substrate by wet-process

ActiveCN1700449ALow densityImprove crystal qualityLaser detailsFinal product manufactureHydrofluoric acidPhosphorus acid

This invention relates to humid erosion sapphire pattern underlay method, which comprises the following steps: adopting general C surface sapphire silicon dioxide mask layer coated; using technique of etching technique to the silicon dioxide mask pattern along [1100] or [1120] direction; using sulfur acid or mixture liquid of sulfur and phosphorus acids as erosion liquid underlay; finally using the rare hydrofluoric acid liquid to erode the mask layer to get the sapphire round underlay.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Method for rapidly determining total iron in sulfur acid residue

InactiveCN101609078AAchieve complete decompositionReduce labor intensityAnalysis using chemical indicatorsChemical analysis using titrationTest sampleHigh energy

The invention provides a method for rapidly determining total iron in sulfur acid residue, which is as follows: reagent is used for analyzing in public and in a blank way volume difference of potassium dichromate standard titrimetric solution which is consumed by front and back titration, wherein the volume difference is blank valve (V0=V1-V2); milliliter quantity obtained by V1-V0 is used for calculating mass friction of total iron in sulfur acid residue test sample. The method overcomes shortcomings that the existing analytic method has poor accuracy, and a method of recycling and resolving sulfur acid residue test sample by alkali fusion or acid soluble is fussy, and has high energy consumption and the like. The method determining total iron in sulfur acid residue has the advantages of economy, environmental protection, simplicity, rapidness and accuracy.

Owner:WUHAN IRON & STEEL (GROUP) CORP

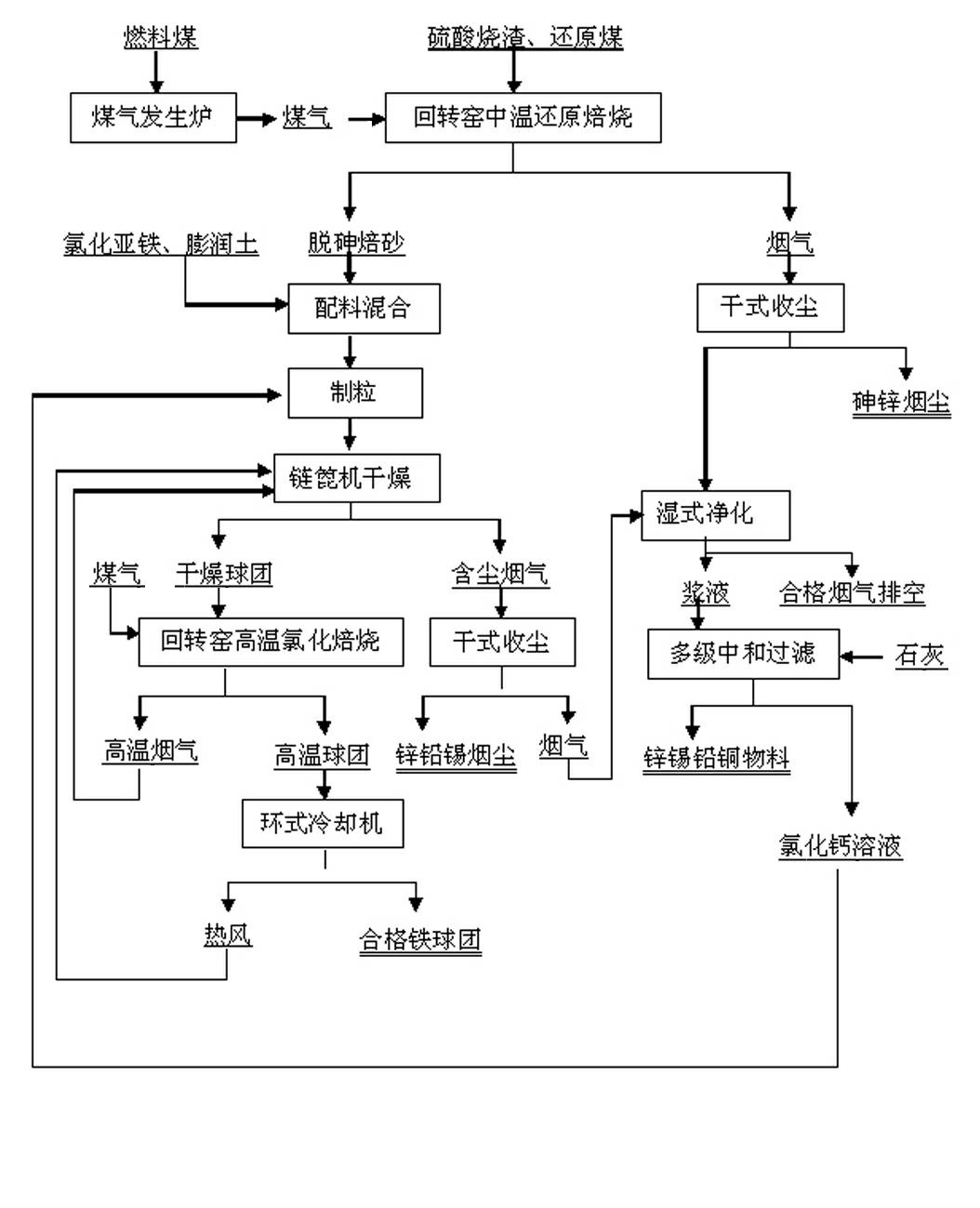

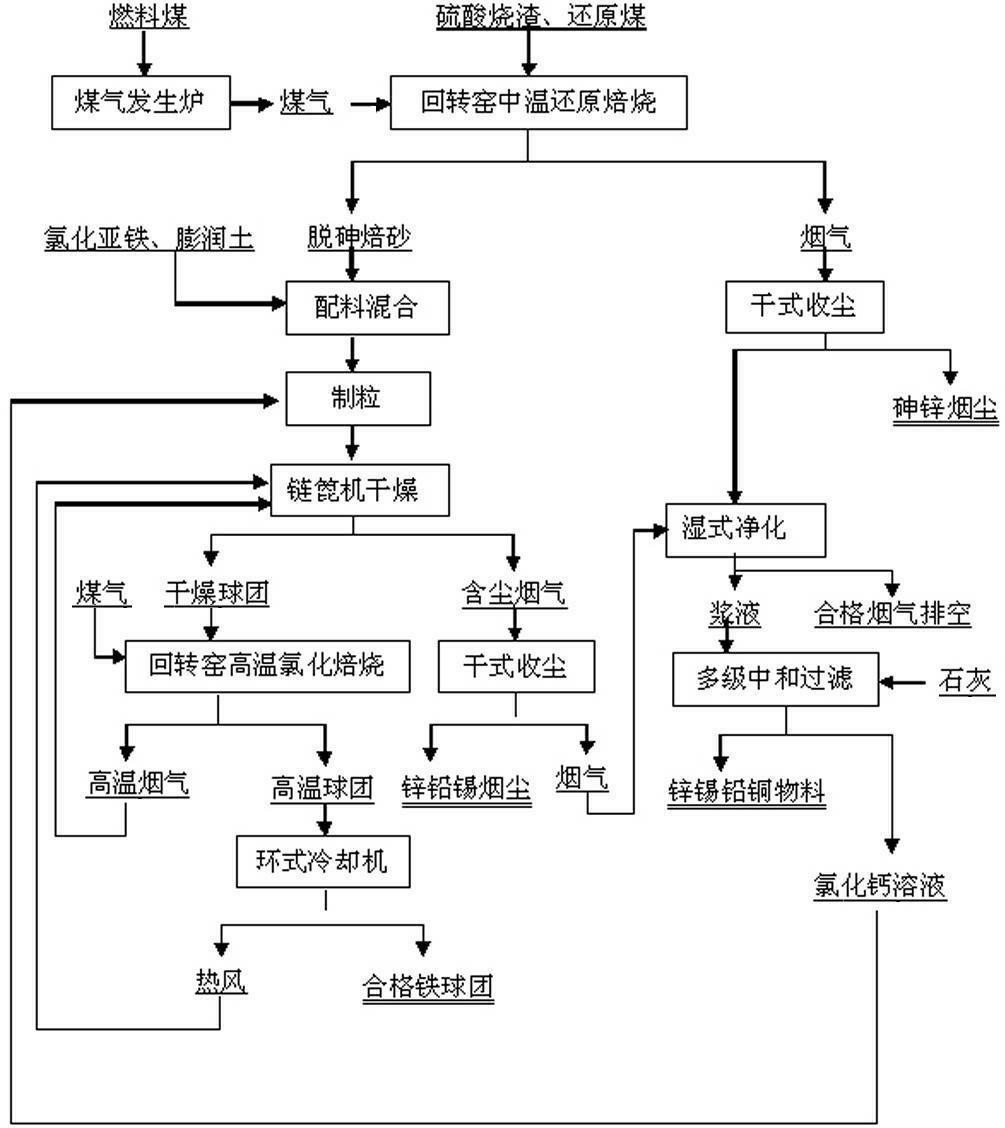

Method for producing iron pellet with sulfur acid residue containing large contents of impurities and enriching valuable metal

InactiveCN102534188AEmission complianceHigh recovery rateProcess efficiency improvementAdhesiveEmission standard

The invention discloses a method for producing iron pellets with sulfur acid residue containing large contents of impurities and enriching valuable metal. The method comprises the following steps: reducing and calcining under a moderate temperature, preparing the iron pellets, chlorinating and calcining under a high temperature, reducing the temperature of the iron pellets while recycling heat energy, collecting dust in flue gas and purifying the flue gas, adding a reducing agent of which the weight is 6 to 9 percent that of the sulfur acid residue on the condition that the kiln head temperature ranges from 750 to 900 DEG C, the kiln tail temperature ranges from 350 to 500 DEG C, and the reducing and calcining step lasts for 70 to 100 min; calcining sand in a high temperature on the condition that 3 to 5 percent of ferrous chloride, 2 to 3 percent of adhesive, and 2 to 3 percent of lignite and / or coke powder are added; pelletizing; carrying out the high-temperature chlorinating and calcining step after dry pre-heating; and recycling heat energy, collecting dust, and purifying the flue gas to achieve the emission standard. According to the invention, two sections of a rotary kiln are adopted for fulfilling the reducing and calcining step and the high-temperature chlorinating and calcining step respectively, wherein a large quantity of arsenic is extracted, part of zinc is reduced and volatilized, the chlorination calcining ensures the reduction and the volatilization of residual arsenic, zinc, tin, lead and copper are chlorinated and volatilized, and sulphur is oxidized into sulfur dioxide and enters the flue gas, so as to obtain qualified the iron pellets. The method has the advantages that the iron recovery rate is 92 to 95; the arsenic extraction rate is larger than 95 percent; the desulfuration rate is equal to or larger than 90 percent; the volatilization rates of the lead, tin and zinc are 60 to 70 percent; and the volatilization rate of copper is about 30 percent.

Owner:个旧市富祥工贸有限责任公司

Method for preparing active carbon materials SO#-[2] absorbent by medicament activation method

InactiveCN1593744AWide variety of sourcesLow priceOther chemical processesDispersed particle separationActivation methodSorbent

The invention relates to a kind of activated carbon basal material, a sulfur dioxide absorption agent, which manufactured by the way of medicine activation. The specificity of the invention is the steps as follows: put the material containing carbon into the water solution of chemical agent, then proceed the chemical modification with pressurization and hydro heating in high pressure reactor caldron, and finally, it can be manufactured by the way of drying activation. The medicine agents that mentioned above are: oxydol (H2O2), sulfur acid (H2SO4), nitrided hydrogen (HNO3), hydrogen fluoride (HF), sodium hydroxide (NaOH), potassium hydroxide (KOH), KMnO4 and so on. The source of the carbon basal material such as carbocoal is wide and the cost of it is low; the manufactured absorption agent can be used as the boiler fuel, and has no secondary pollution; and what mentioned above are the feature of the invention. Furthermore, the invention can be used widely for environmental protection of the stack gases desulfurization and purifying in coal-burning power station, coal fired boiler, and coal fired kiln.

Owner:OCEAN UNIV OF CHINA

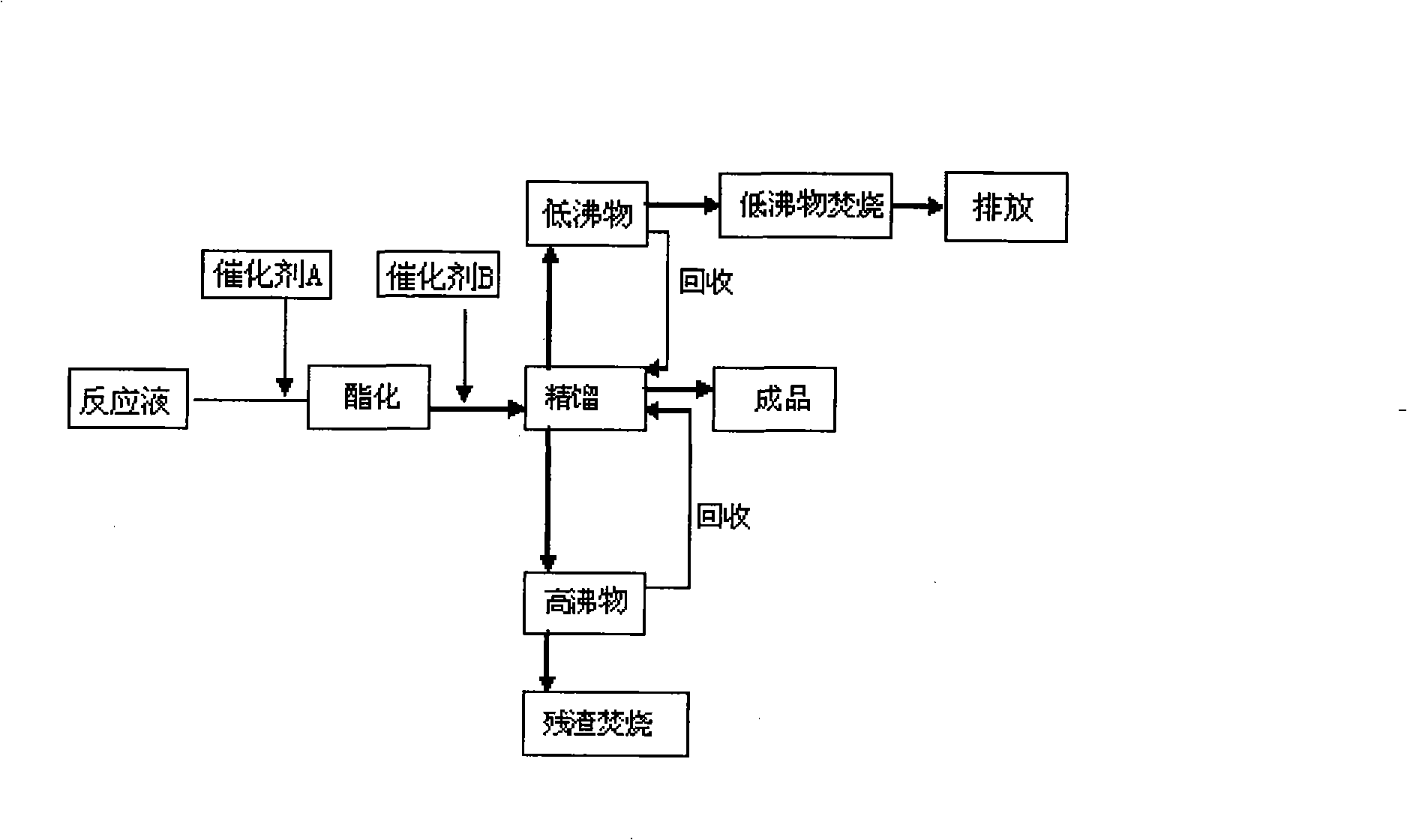

Method for preparing methyl acetoacetate by using novel composite catalyst

ActiveCN101337890AReduce energy consumptionIncrease production capacityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidBoiling point

The invention discloses a method for preparing methyl acetoacetate by using complex catalyst, which comprises the following steps: carrying out esterification reaction of methanol and diketene to generate crude methyl acetoacetate, wherein two different catalysts are added in the different stages of the esterification reaction; triethylenediamine catalyst is added before the esterification reaction; and diketene can be added directly dropwise without being heated by vapor, thereby overcoming the disadvantage that diketene is added dropwise after heating methanol to the boiling point in the conventional process and reducing the energy consumption; and cooling the generated liquid to 40 DEG C after the reaction, adding concentrated sulfur acid catalyst, keeping the temperature for half an hour, filtering, continuously rectifying the filtrate, and separating to obtain fine methyl acetoacetate with the content larger than 99%. Compared with the conventional intermittent rectification method, the continuous rectification method has greatly improved throughput and more convenient operation.

Owner:安徽天成新材料有限公司

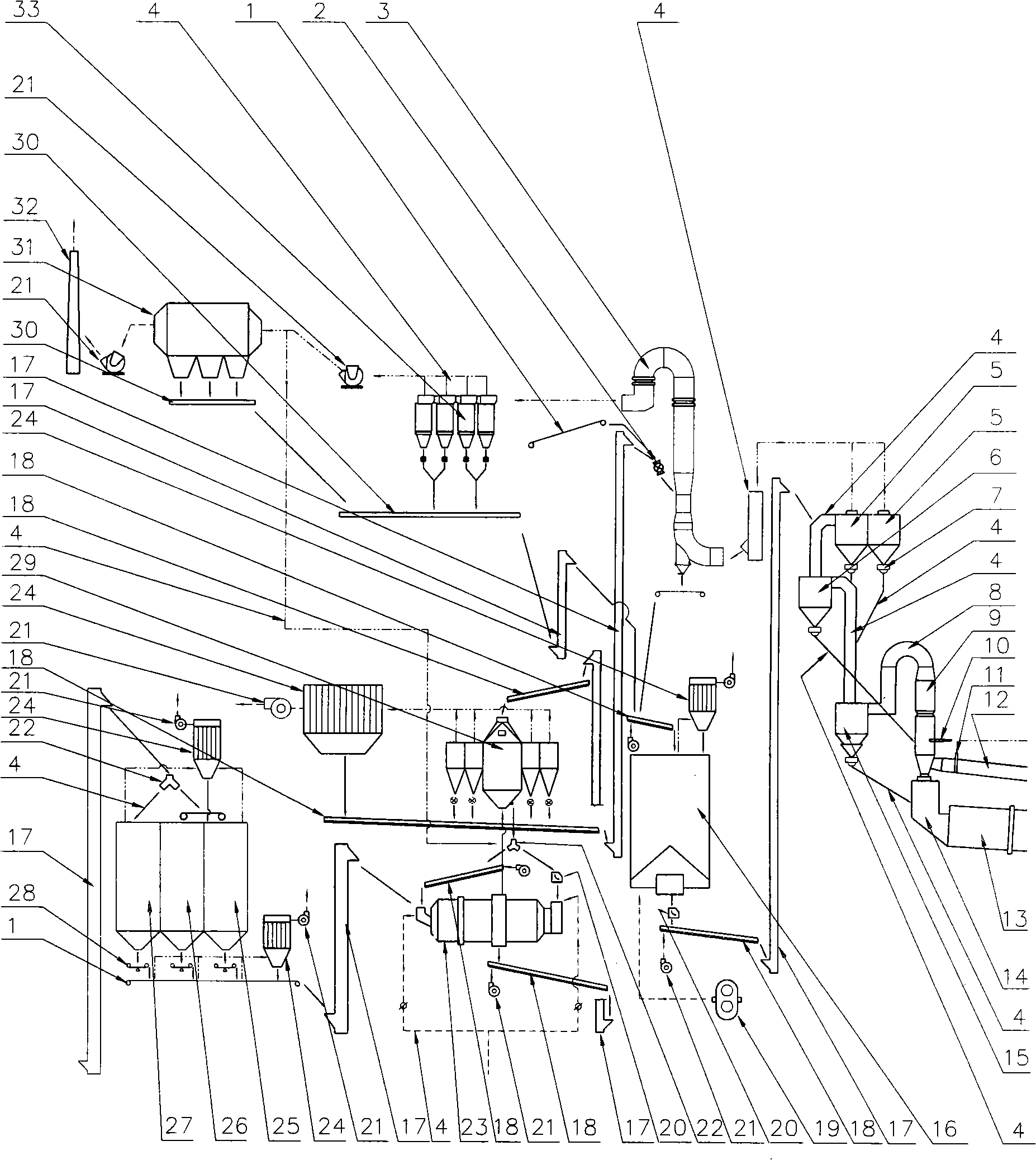

Technique for using dry discharging carbide slag to completely substitute natural calcareous raw material for producing cement chamotte

ActiveCN101265041ASolve the problem of environmental pollution that is difficult to deal withSolve pollutionCement productionCycloneSlag

The invention discloses a method for producing cement clinkers from dried carbide slag completely instead of natural limy materials, which relates to the field of building materials. Firstly, three auxiliary materials (including sand rock, coal ash and sulfur acid residue) are compounded, pulverized and sieved, and the fine powder is fed into a dryer. Then, the carbide slag with a water content less than or equal to 12% is fed into the dryer, and undergoes intensive heat exchange with the hot flue gas at the charge side, realizing complete drying and mixture. The crude material powder is fed into first-stage, second-stage and third-stage cyclone cylinders to undergo multiple suspension heat exchange with the hot flue gas, and then enter a rotary kiln for calcination. The hot flue gas inside the klin undergoes the heat exchange in a pipeline calciner and a wind pipe and then reversely flows into the third-stage, second-stage and first-stage third-stage cyclone cylinders, the dryer, a cyclone dust collector, a system fan and an airbox pulse bag-shaped dust collector sequentially, and the purified gas is discharged into the external atmosphere. The coal powder jets into the calciner at the charge side for further combustion, and the crude material powder undergoes decomposition reactions: Ca(OH)2-H2O+CaO. The clinker burned in the rotary kiln is cooled by a grate cooler and then delivered to a clinker storage room. In the invention, the waste carbide slag is completely dried by using the exhaust gas at the discharge side, and the heat consumption for clinker combustion is reduced by about 25%, thereby realizing energy conservation and exhaust reduction.

Owner:新疆凯盛建材设计研究院(有限公司)

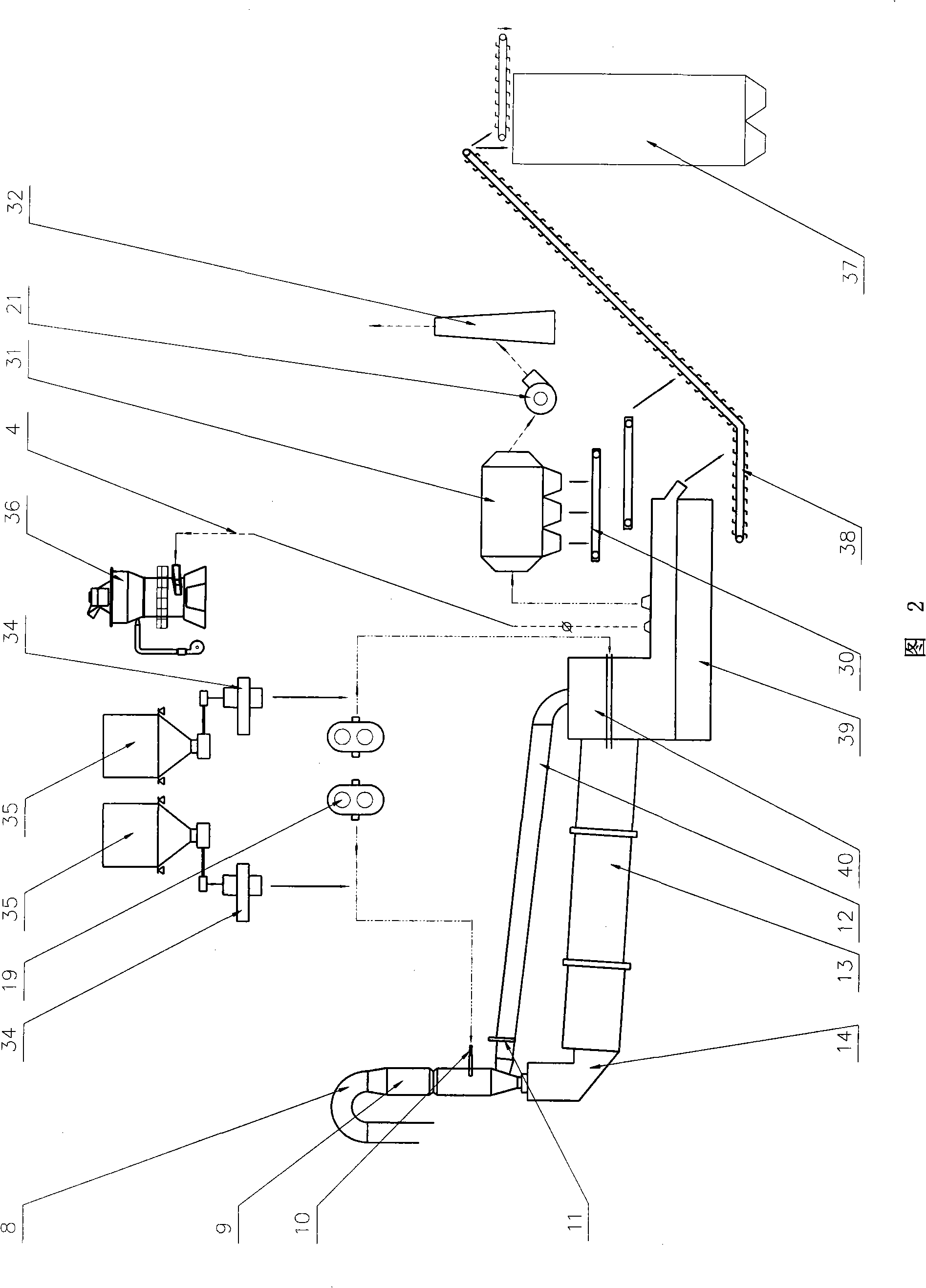

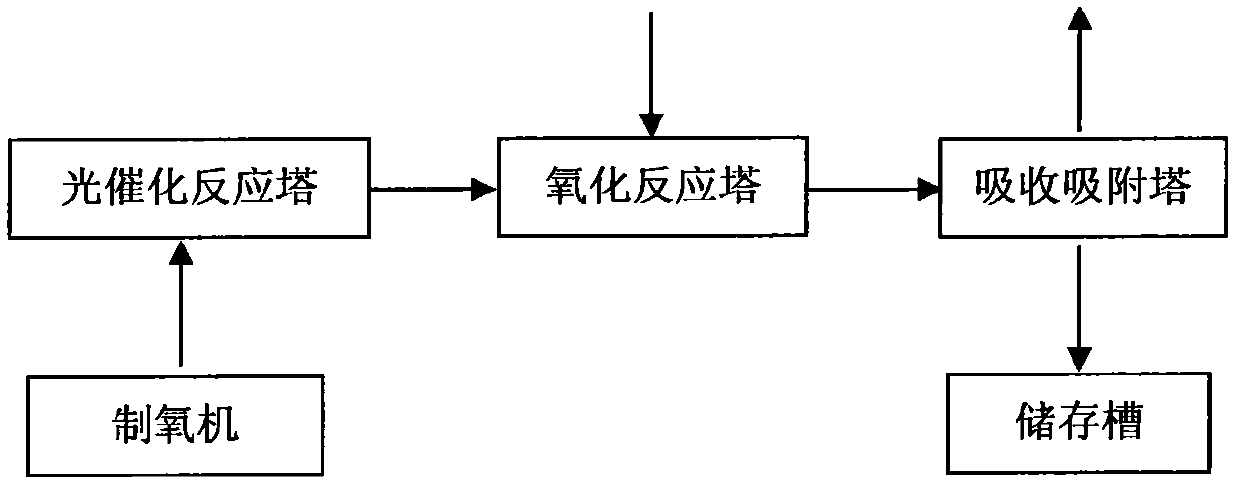

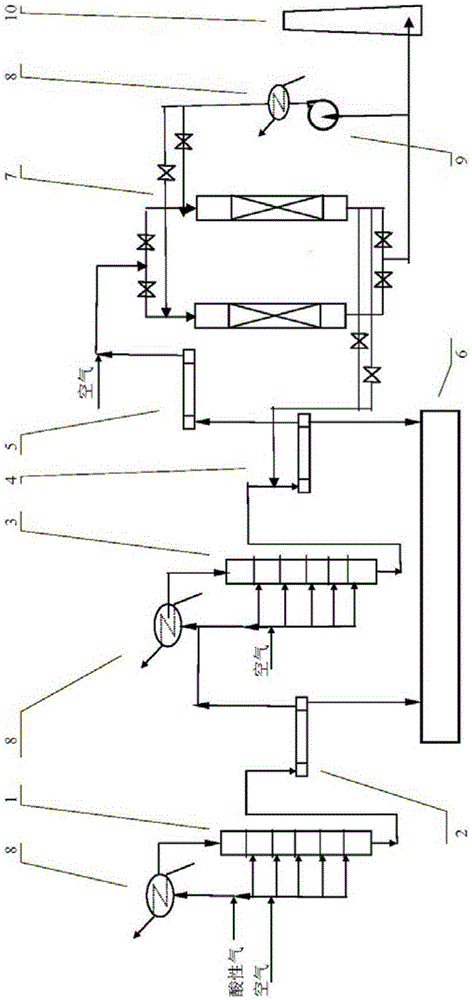

Photocatalytic oxidation flue gas desulfurization and denitration system of coal-fired power plant

InactiveCN102000503ASmall footprintSimple operation and maintenanceDispersed particle separationAir quality improvementPhotocatalytic reactionCatalytic oxidation

The invention relates to a photocatalytic oxidation flue gas desulfurization and denitration system of a coal-fired power plant, which belongs to the cross field of energy source engineering and environmental engineering, and is applied to simultaneous flue gas desulfurization and denitration of the coal-fired power plant. The process route of the system comprises the following steps of: preparing oxygen with more than 90% of purity by using an oxygenator, and introducing the prepared oxygen into a photo-catalyzing reaction tower for fully reacting to produce an oxidizing material as a main component; simultaneously introducing the oxidizing material and flue gas (after dust extraction) into an oxidizing reaction tower, oxidizing SO2 in the flue gas by the oxidizing material into a final product SO3, and oxidizing NO and NO2 by the oxidizing material into a final product NO3; absorbing SO3 and NO3 in the flue gas after oxidizing reaction when passing through an absorption tower; and completing the simultaneous flue gas desulfurization and denitration process. During desorbing, the obtained by-product, namely nitrate-sulfur acid is collected by a storage tank and is an industrial chemical with wide uses. The system simultaneously realizes desulfurization and denitration in one set of device (complete equipment) and has high removal efficiency and no secondary pollution.

Owner:武汉慧邦环境工程技术有限公司

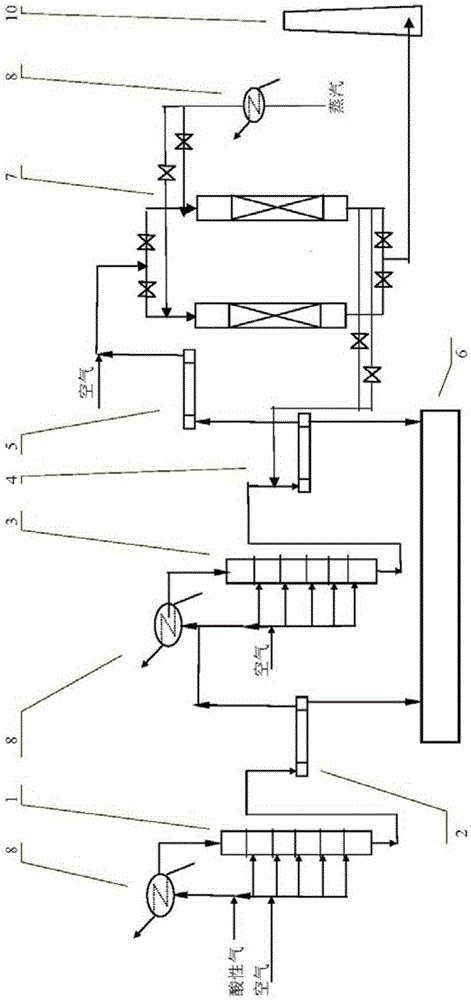

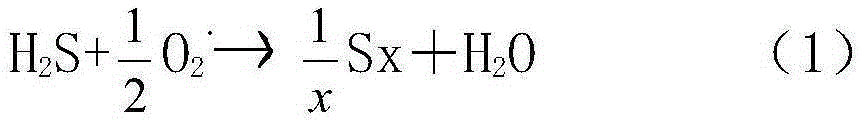

Low-sulfur discharging and sulfur recycling process of intermediate concentration acid gas

ActiveCN105314607ALow sulfur concentrationHigh desulfurization precisionEnergy inputSulfur preparation/purificationCatalytic oxidationCooling coil

The invention provides a low-sulfur discharging and sulfur recycling process of intermediate concentration acid gas. A purpose of desulphurizing low-concentration acid gas with H2S content of 5 to 20 percent can be achieved by treating the low-sulfur acid gas by virtue of a direct oxidation reactor, a selective oxidation reactor and two adsorption desulphurization towers which can be connected in series and parallel; the direct oxidation reactor is filled with a TiO2 sulfur recycling catalyst, the selective oxidation reactor is filled with a H2S selective oxidation catalyst, catalysts in the direct oxidation reactor and selective oxidation reactor are packed in multiple layers, an air inlet and a cooling coil pipe are respectively arranged between two layers, and the adsorption desulphurization tower is filled with a thermally-renewable catalytic oxidation adsorption desulphurization agent; by selecting the appropriate catalyst and desulphurization agent and precisely controlling the process condition of each step, the total sulfur contained in the process discharged gas is that SO2 content is less than or equal to 10mg / m<3>. By virtue of thermal regeneration, the service life of the catalytic oxidation adsorption desulphurization agent is greatly prolonged, and the desulphurization amount of the catalytic oxidation adsorption desulphurization agent is greatly increased. The process has the advantages of low sulfur emission, high sulfur recycling rate (approximate to 100 percent), long service life and large desulphurization amount of the desulphurization agent, fewer replacement times, less expense, good desulphurization agent removal and scrapping condition, safety and the like.

Owner:山东迅达化工集团有限公司

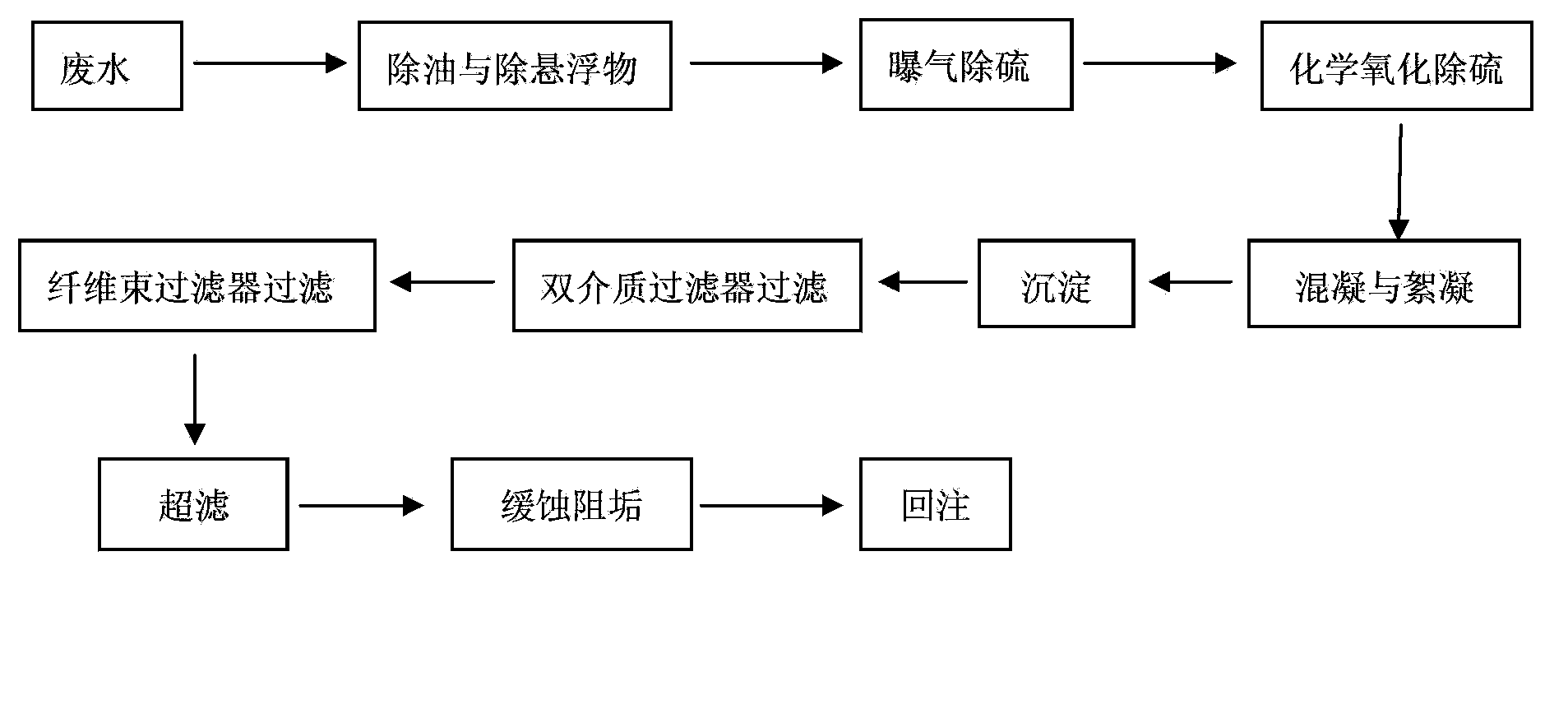

Rejection processing technology for gas production wastewater in sulfur acid containing gas field

ActiveCN103880202AEasy to handleEnsure normal dischargeWaste water treatment from quariesMultistage water/sewage treatmentUltrafiltrationWater quality

The invention discloses a rejection processing technology for gas production wastewater in sulfur acid containing gas field. The rejection processing technology for gas production wastewater in sulfur acid containing gas field comprises the following steps: enabling the sulfur acid containing gas field gas production wastewater to be successively subjected to suspension and oil removal processing, aeration sulfur removal, chemical oxidation sulfur removal, coagulation and flocculation processing, settlement, sterilization, double-medium filter filtering, fiber bundle filter filtering, ultrafiltration, and corrosion and scale inhibition. The invention also provides a corrosion and scale inhibition agent which comprises hydroxyethylidene diphosphonic acid, sodium sulfonate and benzotriazole. The gas production wastewater rejection processing technology is simple in flow, relatively low in operation cost and simple in management, and is capable of effectively processing sulfur acid containing gas field gas production wastewater, and discharged water reaches A3 standard in Recommended Index for the Injection Water Quality for Clastic Reservoir in People's Republic of China petroleum and Natural Gas Industry Standards SY / T5329 / 94.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

Method for recycling copper from acid waste etching solution

InactiveCN104962742AHigh purityLow oxygen contentPhotography auxillary processesProcess efficiency improvementEtchingCu2 ions

The invention discloses a method for recycling copper from an acid waste etching solution. The method is characterized by comprising the following steps that firstly, an organic phase and the acid waste etching solution are subjected to 1-5 levels of extraction according to the volume ratio of 1-30:1, and copper is extracted; secondly, the load organic phase obtained in the first step and purified water are subjected to 1-5 levels of washing according to the volume ratio of 0.1-10:1; thirdly, the load organic phase washed in the second step and a copper sulphate solution including sulfur acid of 130-250 g / L and copper ions of 1-50 g / L are subjected to 1-3 levels of back extraction according to the volume ratio of 1-10:1, the organic phase obtained through back extraction is returned to the first step to be repeatedly used, and a water phase is a copper sulphate solution; fourthly, metal stainless steel 304 or stainless steel 316 or metal titanium is used as a cathode, the copper sulphate solution obtained in the third step is electroplated under the current density of 50-400 A / m<2>, electroplated copper is obtained, and the copper sulphate solution obtained after the copper is electroplated is returned to the third step to be repeatedly used. According to the method for recycling copper from the acid waste etching solution, the copper can be separated selectively from the acid waste etching solution, the technology is simple, and the separation effect is good.

Owner:陈飙

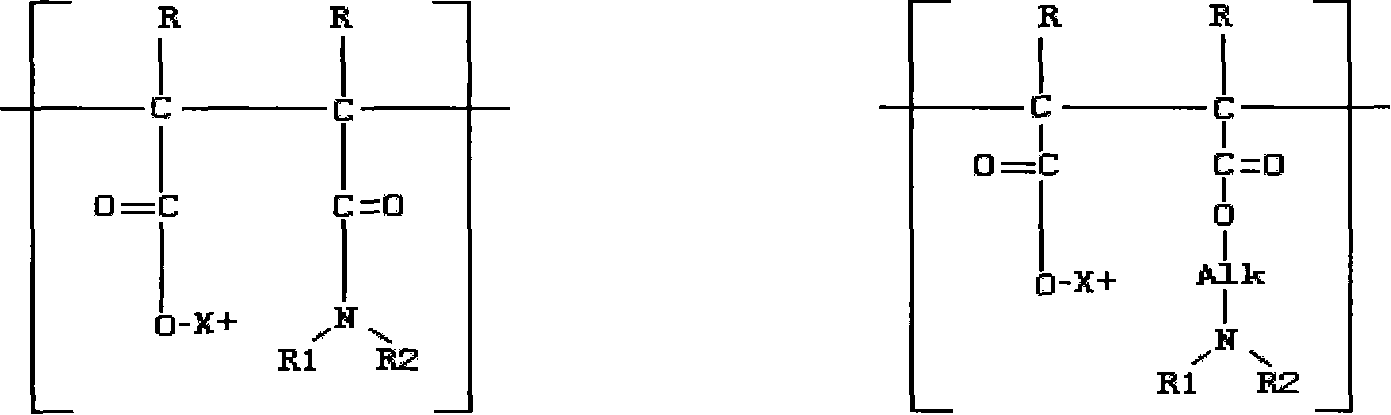

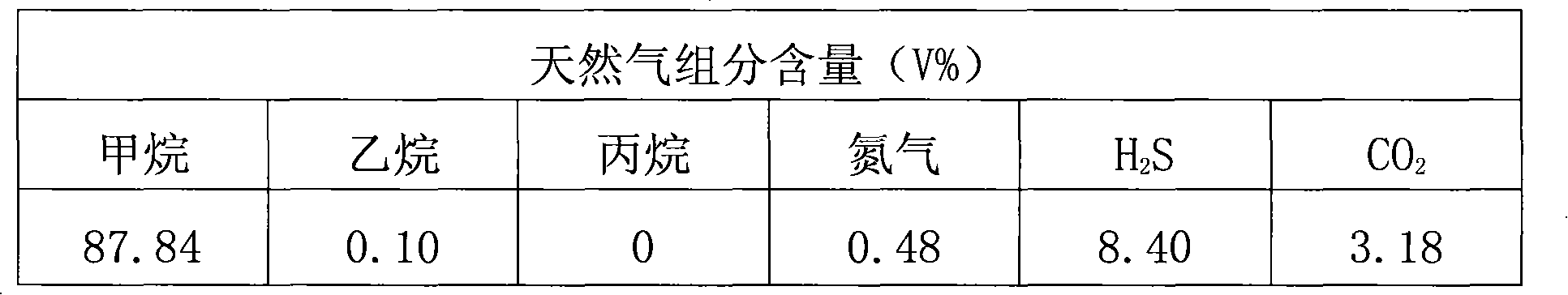

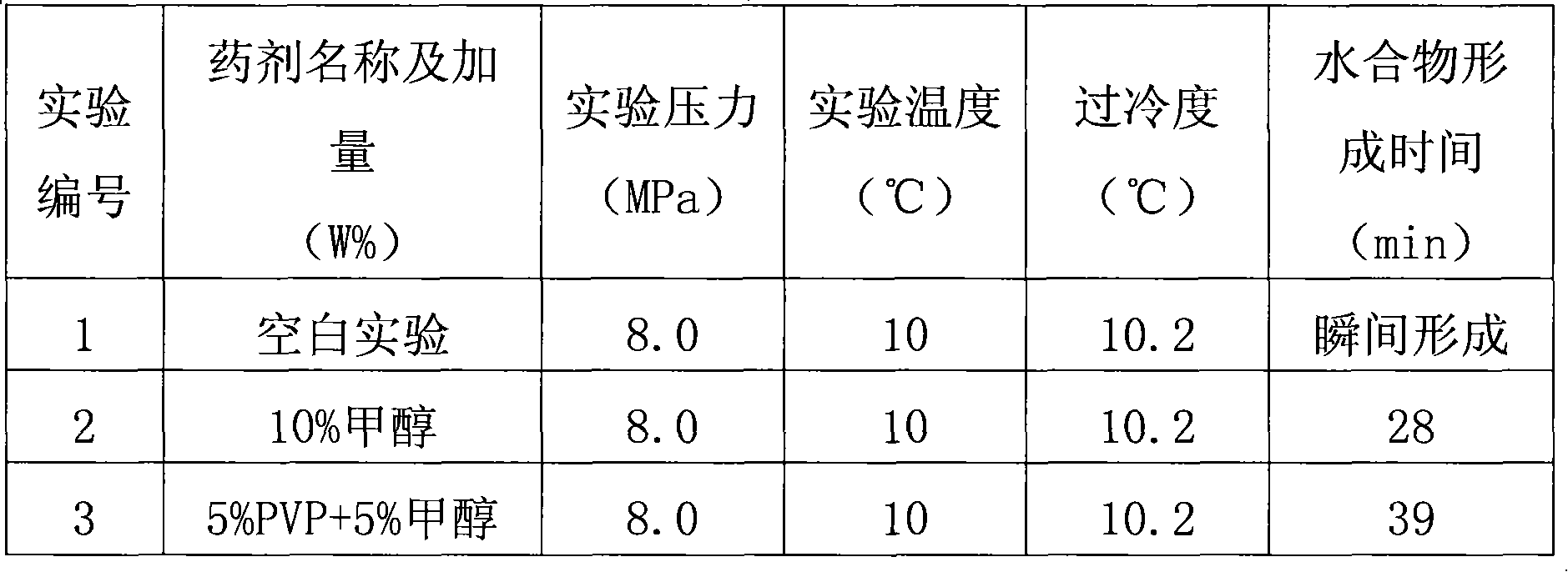

Inhibitor for preventing the formation of natural gas hydrates of high-sulfur acid gas fields

ActiveCN101608118APrevent anti-corrosion effectNot easy to aggregateGaseous fuelsFluid removalBiopolymerCO2 content

The invention relates to an inhibitor for preventing the formation of natural gas hydrate of high-sulfur acid gas fields, which comprises the following components in percentage by weight: 5 to 30 percent of biopolymer, which has the weight average molecular weight of between 3,000 and 10,000, of vinyl pyrrolidone and vinyl caprolactam or terpolymer, which has the weight average molecular weight of between 65,000 and 100,000,of the vinyl pyrrolidone, the vinyl caprolactam and N, N-(dimethylamino)ethyl methacrylate, 5 to 30 percent of amido group-containing and lipid group-containing polyesteramide or amidation product which is formed by polymerizing maleic anhydride, a derivative thereof and alkyl alcohol amine and has the number average molecular weight of between 1,000 and 15,000, 10 to 15 percent of surfactant and defoaming agent, and 50 to 70 percent of mixture of methanol or ethanol and glycol. The inhibitor has better inhibition effect on acid natural gas hydrate which has the H2S content between 0 and 8 percent, the CO2 content between 0 and 5 percent, and no hydrocarbon components above C2.

Owner:PETROCHINA CO LTD

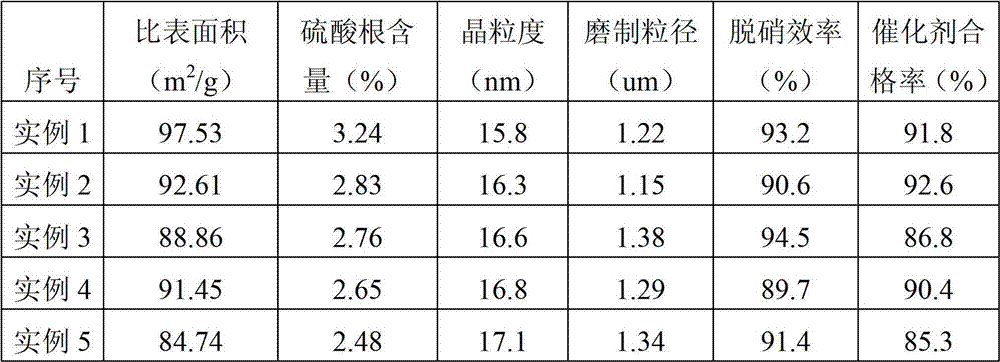

Preparation method of nanometer titanium dioxide

InactiveCN102765751AChoose from a wide range of sourcesLow priceMaterial nanotechnologyTitanium dioxideInorganic ChemicalSulfur Acids

The invention provides a preparation method of nanometer titanium dioxide, and relates to the preparation field of inorganic chemical materials. In the method, metatitanic acid intermediate from titanium dioxide preparation by a sulfur acid process is used as a raw material, and nanometer titanium dioxide is prepared through technical processes of pulping, dispersing, filter pressing, calcining and crushing. Compared with a prior art, the preparation method provided by the invention has the beneficial effects as follows: a selective catalytic reduction (SCR) denitration catalyst made of nanometer titanium dioxide provided by the invention is more applicable to coal characteristics and smoke conditions of domestic coal-fired power plants, beneficial to controlling the production of various raw materials in catalyst production companies and effectively reducing the production cost of the catalyst; and the catalyst made of the product provided by the invention is better adapted to smoke characteristics of the domestic coal-fired power plants and achieves higher denitration efficiency.

Owner:CHONGQING PUYUAN CHEM IND

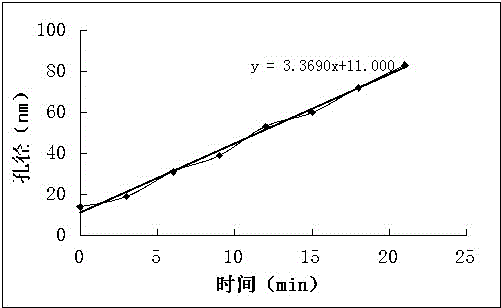

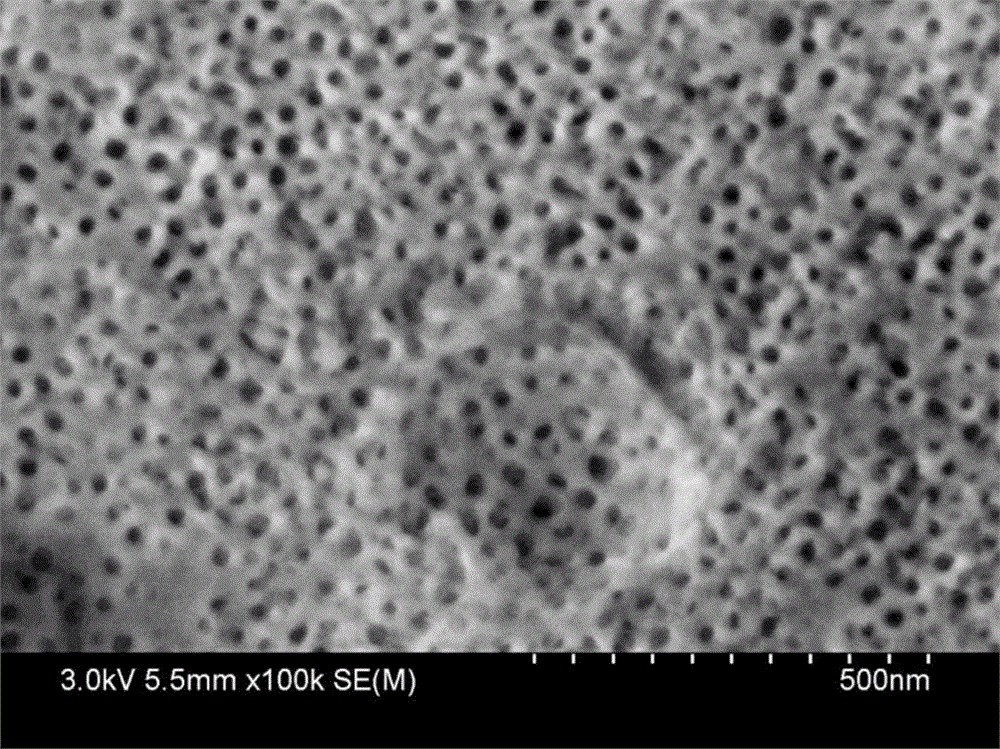

Method for microporous treatment of metal surface

ActiveCN104593786AImprove orderSolve the problem of low bonding strengthPhosphoric acidPhosphate anion

The invention belongs to the technical field of material treatment and particularly relates to a method for microporous treatment of a metal surface. The method comprises the following steps: (1) performing anodic oxidation on a preprocessed metal base material to obtain a metal base material provided with an anodic oxide film layer on the surface; (2) soaking the metal base material obtained in the step (1) in etching liquor for treatment; (3) putting the metal base material obtained in the step (2) into an anodic oxidation groove with sulfur acid and ammonium chloride for modification treatment; (4) soaking the metal base material obtained in the step (3) in a phosphate anion solution, washing with water, soaking in a washing regulating agent at a room temperature, washing with water, and baking for 0.5-1 hour. The purpose of pore size expansion is achieved in a condition-controllable AAO (anodic aluminum oxide) film production mode, a problem that a conventional pore-forming method cannot obtain ordered controllable micropores is solved, and strict requirements on various aspects of product size, structure and the like are avoided from a macroscopic perspective.

Owner:东莞市慧泽凌化工科技有限公司 +1

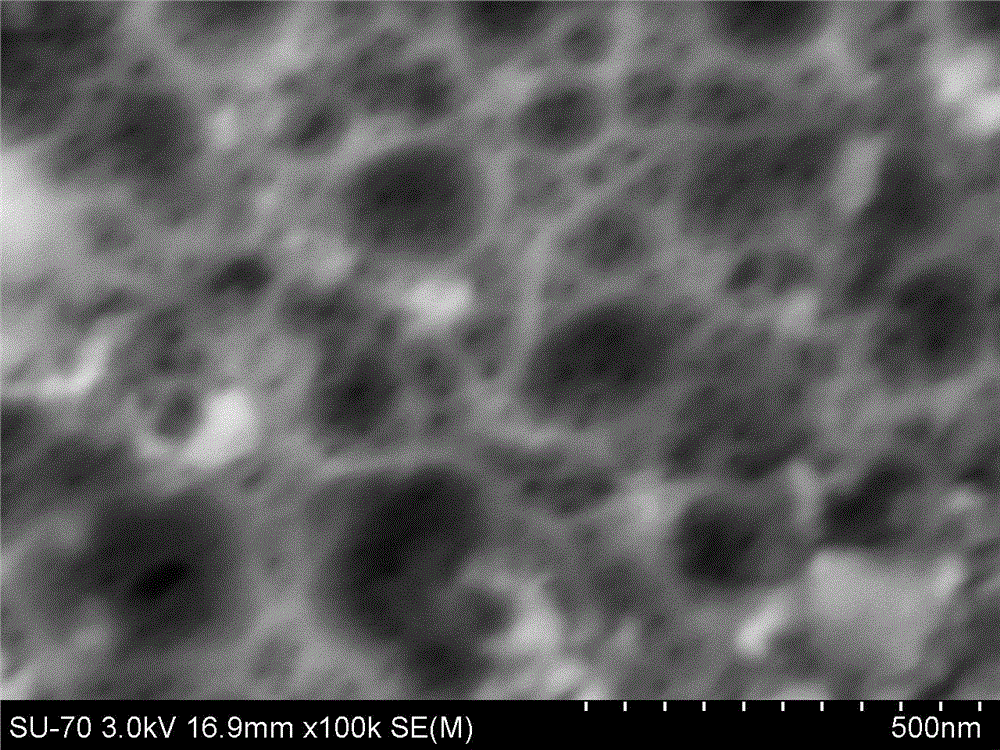

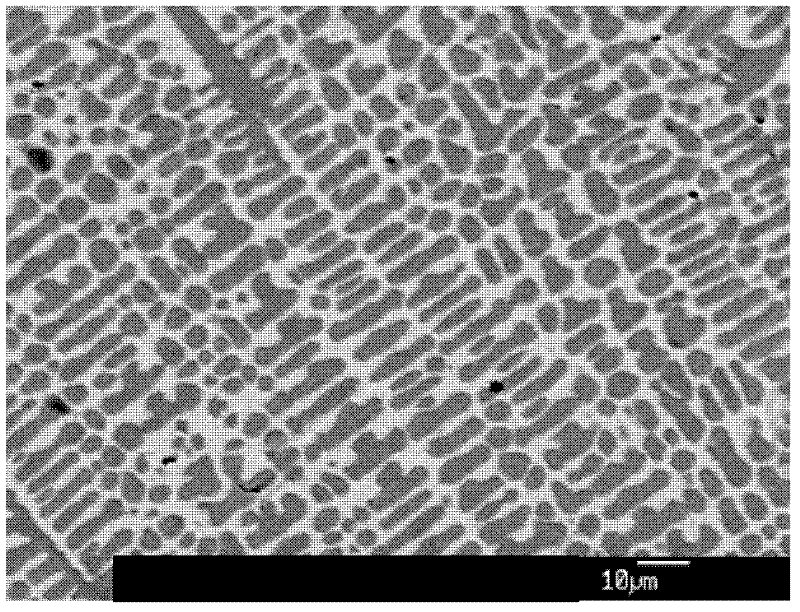

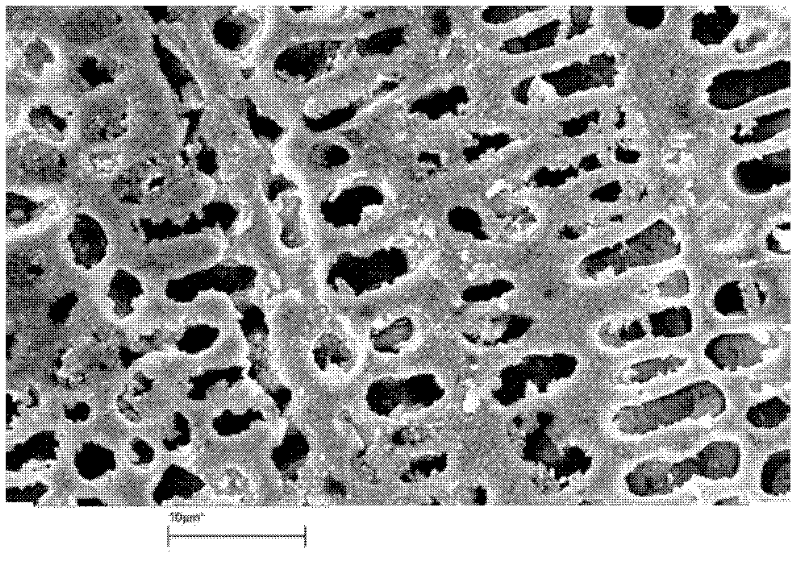

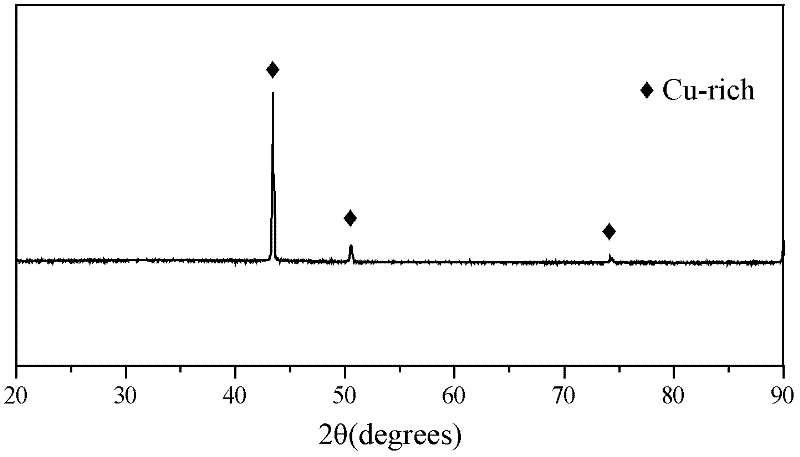

Highly-ordered single-piece copper-based porous material and preparation method thereof

The invention provides a highly-ordered single-piece copper-based porous material and a preparation method thereof and relates to a single-piece copper-based porous material. The preparation method comprises the following steps: preparing the raw materials of the single-piece copper-based porous material according to the atom ratios of Cu50Fe[50-x]Cox, Cu50Fe[50-x]Nix and Cu50Fe[50-x]Mnx, wherein x is 1-20at.%; smelting prepared alloys, starting a magnetic stirring button, and cooling after uniformly smelting; cutting a smelted Cu-Fe-X system alloy into slices by adopting a line cutting machine, carrying out thermal treatment after polishing, and quenching, wherein X is Co, Ni or Mn; pretreating a sample subjected to thermal treatment in a hydrochloric acid solution and then placing in an electrochemical workstation for electrochemical corrosion, wherein the alloy is connected with a positive electrode of a power supply, pure copper is connected with a negative electrode, and a sulfur acid solution is used as an electrolyte and placed in an electrochemical device; and cleaning the alloy subjected to electrochemical corrosion, and blow-drying so as to obtain a product. The single-piece copper-based porous material has the advantages of high order degree and controllable pore diameter size and distribution.

Owner:XIAMEN UNIV

Cement clinker produced by using various industrial waste residues

The invention relates to cement clinker produced by using various industrial waste residues, which is characterized in that: metal magnesium reducing slag, lime mud or calcium carbide mud or dicyandiamide slag, mountain flour, fly ash or coal gangue and sulfur acid residue are compounded and optimally mixed to produce a raw material; and the raw material is calcined by a calcining process to produce the cement clinker. The cement clinker is characterized in that: various industrial waste residues are comprehensively used to produce the cement clinker, a large amount of waste residues are used, a large amount of natural resources and energy is saved, and standard coal consumption is saved by more than 20 percent in the calcining process of the waste residues which are compounded and optimally mixed, the emission of CO2 and other harmful gases in a large amount is reduced at the same time, the calcining speed of the clinker is increased, and the energy-saving, emission-reducing, consumption-reducing and environmental-protection effects are obvious; and experiments prove that single-machine output and production efficiency are improved and that after 28 days, the pressure strength of the clinker is improved by more than 5MPa compared with that of the clinker produced by the traditional method.

Owner:宁夏建筑材料研究院(有限公司)

Anti-125 DEG C-level low smoke halogen free-flame retardant single-core cable insulation rubber for railway locomotive

ActiveCN101851368AGuaranteed performanceCost controlPlastic/resin/waxes insulatorsCross-linkPolyolefin

The invention discloses anti-125 DEG C-level low smoke halogen free-flame retardant single-core cable insulation rubber for a railway locomotive. The insulation rubber formulation comprises the following ingredients in parts by weight: 100 parts of cross-linked polyolefin, 2-5 parts of organic peroxide vulcanizer, 1 to 4 parts of sulfur-acid agent and 1 to 4 parts of stabilizer, wherein the cross-linked polyolefin is preferably selected from ethylene-vinyl acetate copolymer EVA-40L-03 produced by DuPont, the organic peroxide vulcanizer is preferably selected from dicumyl peroxide (DCP), the sulfur-acid agent is triallyl isocyanurate (TAIC), and the stabilizer is preferably selected from dibasic lead phosphate. The invention not only has excellent insulation property, but also has excellent weather resistance, ozone resistance, heat-proof aging, acid-base resistance, fuel oil resistance, low smoke zero halogen flame retardant, environment protection, safety and long service life.

Owner:JIANGSU JUYE CABLE

TFT (Thin Film Transistor) glass thinning pretreatment method

The invention provides a TFT (Thin Film Transistor) glass thinning pretreatment method, which comprises the following steps: injecting mixed acid liquor of concentrated sulfur acid, concentrated hydrochloric acid and hydrofluoric acid into an airtight container; heating the mixed acid liquor to 28-30DEG C and bubbling and evenly mixing; injecting the mixed acid liquor into etching equipment, continuously bubbling and mixing for 30-60 minutes until mixing evenly; soaking TFT glass to be-thinned in the mixed solution for 15-60 minutes, so as to remove the double layers of a glass surface by 50-80micrometers; washing and moisturizing the TFT glass, and thinning in the hydrofluoric acid etching solution. Pits in the surface of a pretreated TFT glass panel are reduced, the depths of the pits are shallower and size is obviously reduced in comparison with pits of the glass which is not treated or etched, and indirectly the polishing time can be shortened by 50-80% through the same machine platform under the same conditions, even the effect of no need of polishing can be achieved.

Owner:SUZHOU CRANE OPTOELECTRONICS TECH

A method for corroding sapphire graphic substrate by wet-process

ActiveCN1294649CLow densityImprove crystal qualityLaser detailsFinal product manufactureHydrofluoric acidPhosphorus acid

This invention relates to humid erosion sapphire pattern underlay method, which comprises the following steps: adopting general C surface sapphire silicon dioxide mask layer coated; using technique of etching technique to the silicon dioxide mask pattern along [1100] or [1120] direction; using sulfur acid or mixture liquid of sulfur and phosphorus acids as erosion liquid underlay; finally using the rare hydrofluoric acid liquid to erode the mask layer to get the sapphire round underlay.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

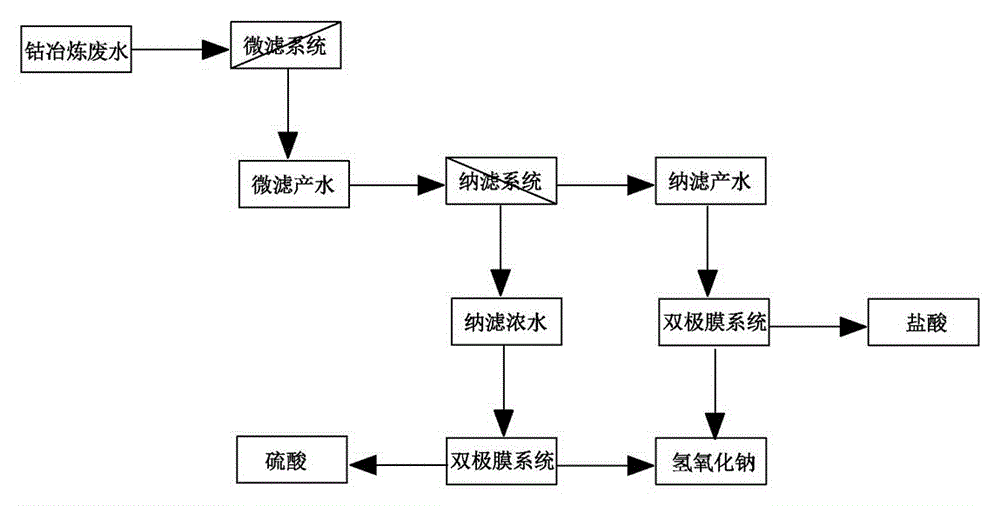

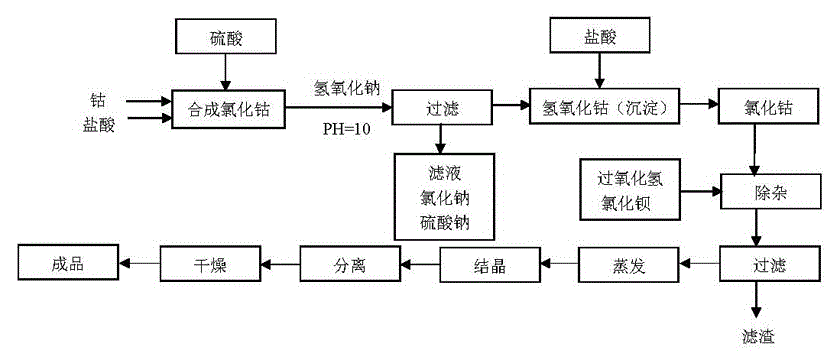

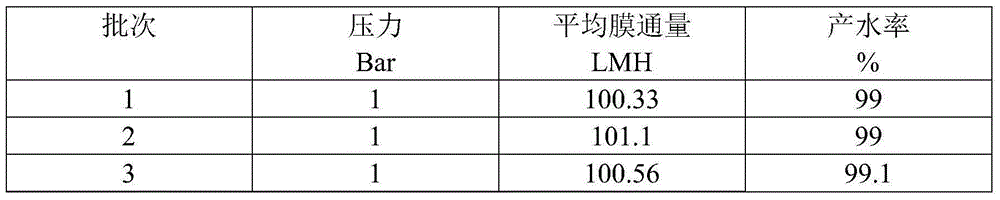

Process for preparing strong acid and strong alkali by separating cobalt smelting wastewater

InactiveCN105060405AAchieve zero emissionsChlorine/hydrogen-chlorideWaste water treatment from metallurgical processFiltrationStrong acids

The invention discloses a process for preparing strong acid and strong alkali by separating cobalt smelting wastewater. The process is characterized by comprising the following steps: S1, filtration by microfiltration: using a microfiltration system to treat cobalt smelting wastewater to remove a lot of suspended soils and particles and controlling the SS value being less than 1 to obtain microfiltration contributing water; S2, nanofiltration separation: feeding the treated microfiltration contributing water to a nanofiltration system to separate two types of salt to obtain nanofiltration concentrated water and nanofiltration contributing water, wherein the nanofiltration concentrated water is sodium sulfate and the nanofiltration contributing water is sodium chloride; S3, nanofiltration concentrated water treatment: feeding the nanofiltration concentrated water into a bipolar membrane system to be treated to prepare sodium hydroxide and sulfur acid; and S4, nanofiltration contributing water treatment: feeding the nanofiltration contributing water into the bipolar membrane system to be treated to obtain sodium hydroxide and hydrochloric acid. The process for preparing strong acid and strong alkali by separating cobalt smelting wastewater disclosed by the invention abandons high cost caused by evaporation, so that salt in the wastewater can be recycled in the process, and zero discharge of wastewater is achieved.

Owner:XIAMEN STARMEM TECH

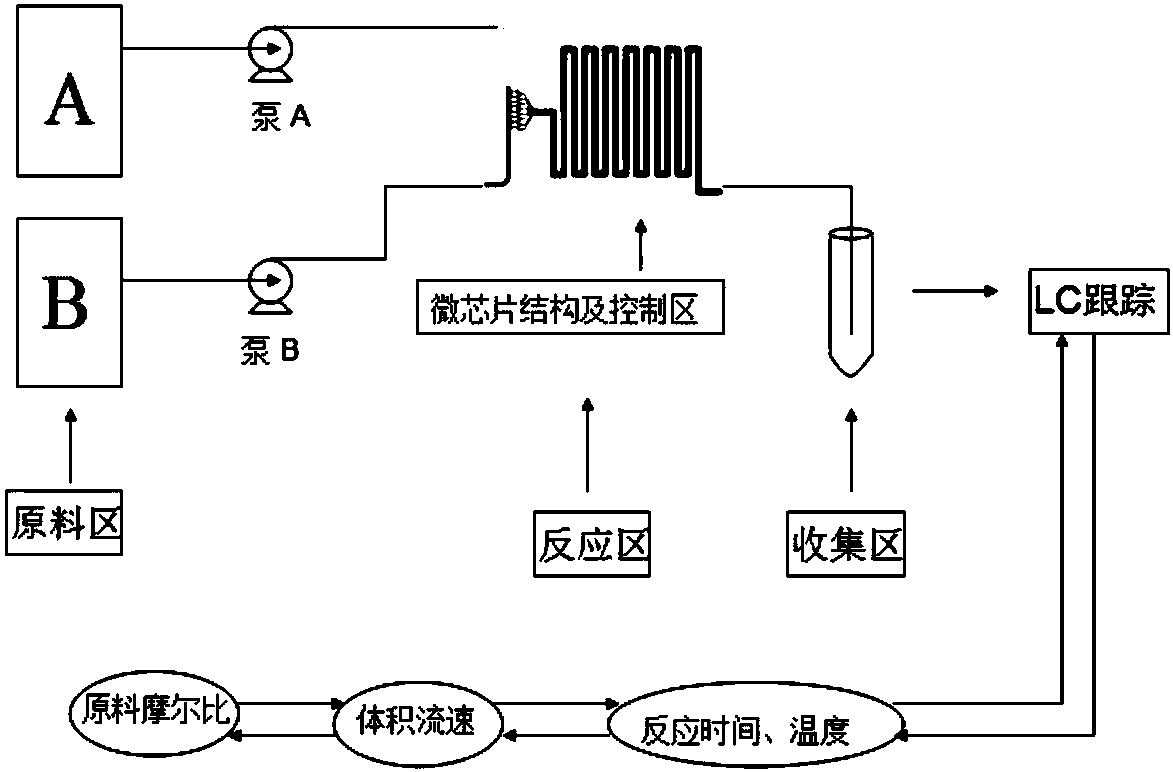

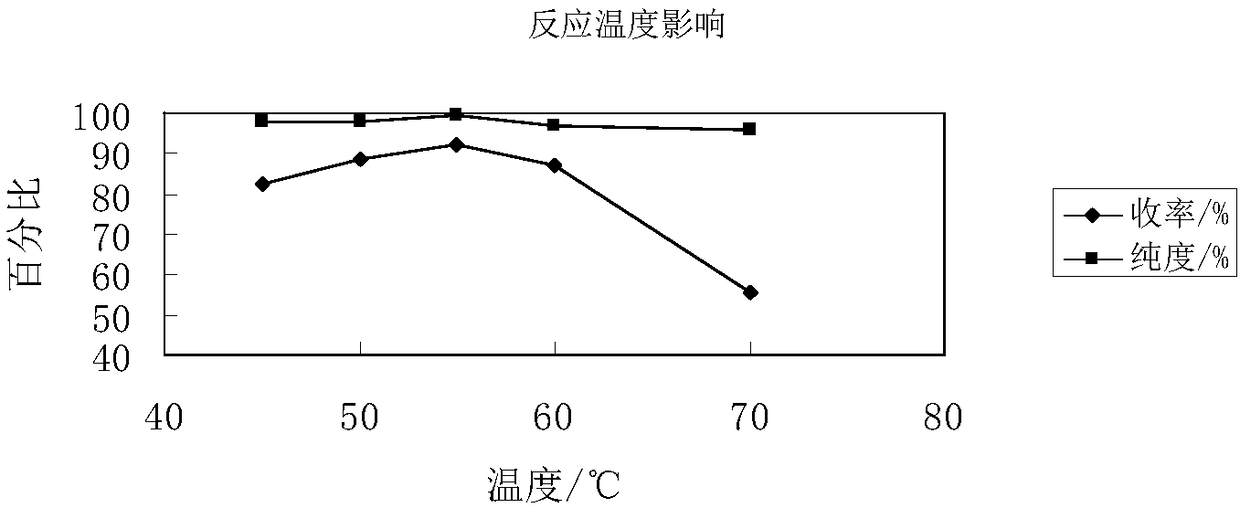

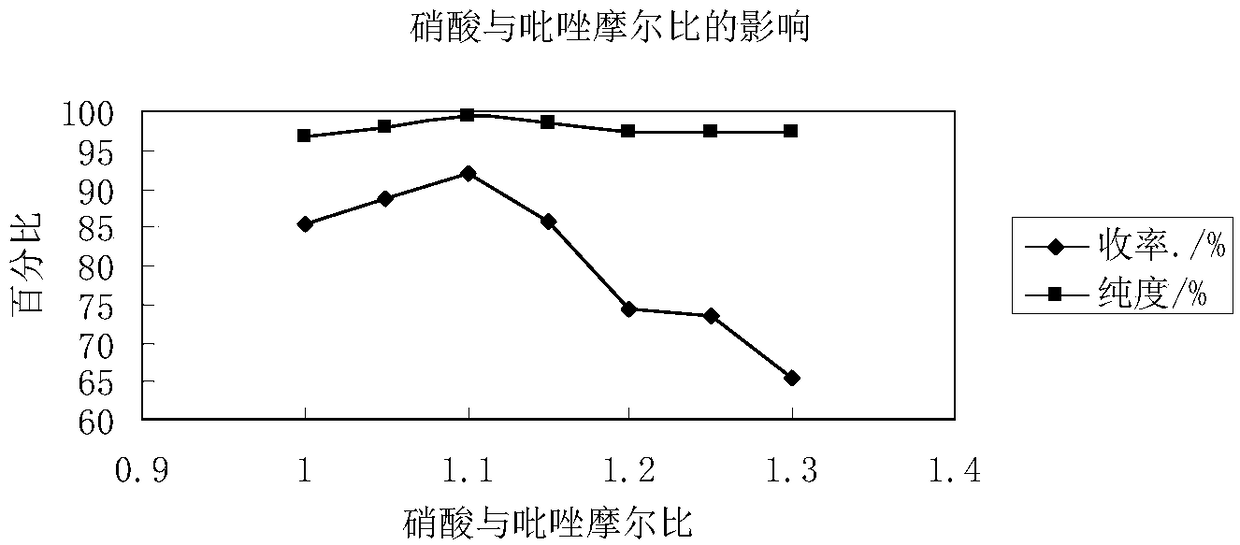

Method for synthesizing 3,4-dinitropyrazole by using micro-channel reactor

ActiveCN108570010AReduce usageReduce energy consumptionOrganic chemistryChemical/physical/physico-chemical microreactorsAcetic anhydrideNitration

The invention discloses a method for synthesizing 3,4-dinitropyrazole by using a micro-channel reactor. The method comprises the following steps: with pyrazole as a raw material, subjecting pyrazole and a nitric-acetic anhydride system to nitration in the micro-channel reactor so as to synthesize N-nitropyrazole; then with N-nitropyrazole as a raw material, carrying out thermal rearrangement so asto synthesize 3-nitropyrazole; and finally, with 3-nitropyrazole as a raw material, synthesizing 3,4-dinitropyrazole in virtue of a nitric acid-sulfur acid mixed acid system in the micro-channel reactor. According to the invention, the micro-channel reactor is employed, so the adverse outcomes of hardly controllable process, proneness to local overheating which leads to dangers, easy generation of side reactions and the like of convetional tank reactors are avoided, rapid reaction is realized, and direct enlargement can be realized through increase of the number of parallel micro-channel reactors. With the method, the yield of the synthesized 3,4-dinitropyrazole reaches 87.5%, and the purity of the synthesized 3,4-dinitropyrazole reaches 99.8%.

Owner:NANJING UNIV OF SCI & TECH

Method for biological desulfurization by catalytic oxidation of pyrite residue and associated non-ferrous metal leach

InactiveCN1594610AReduce pollutionLow investment costSolid waste disposalProcess efficiency improvementMetal leachingElectrolysis

This invention has publicized one kind of sulfur acid residue biologically catalyzed oxidation desulphurization and the associated non-ferrous metal leaching method, it uses Fe # + [3+] containing bacterium for spray-wet method desulfurization of burnt ore of non- immerse type, the immerse type, the pile-soaking type, the shallow layer pile-soaking type, stir- soaking type, the granularity of which is the 25-50mm,at same time leaching non-ferrous metal. when leaching, it may be aerated or not aerated. The inventive method uses the hydrometallurgy, chemical extract, chemical precipitation, the electrolysis, the ion floats washes, ionic exchange and so on for recycling non-ferrous metals, the leaching temperature is 10 DEG C- 70 DEG C, and the pH value is 1.0-8.5. Burnt ore comprehensive utilization has provided a quick method for desulfurization and associated non-ferrous metal leaching method , in which investment is low, the energy consumption is low, the environmental pollution is little.

Owner:徐晓军

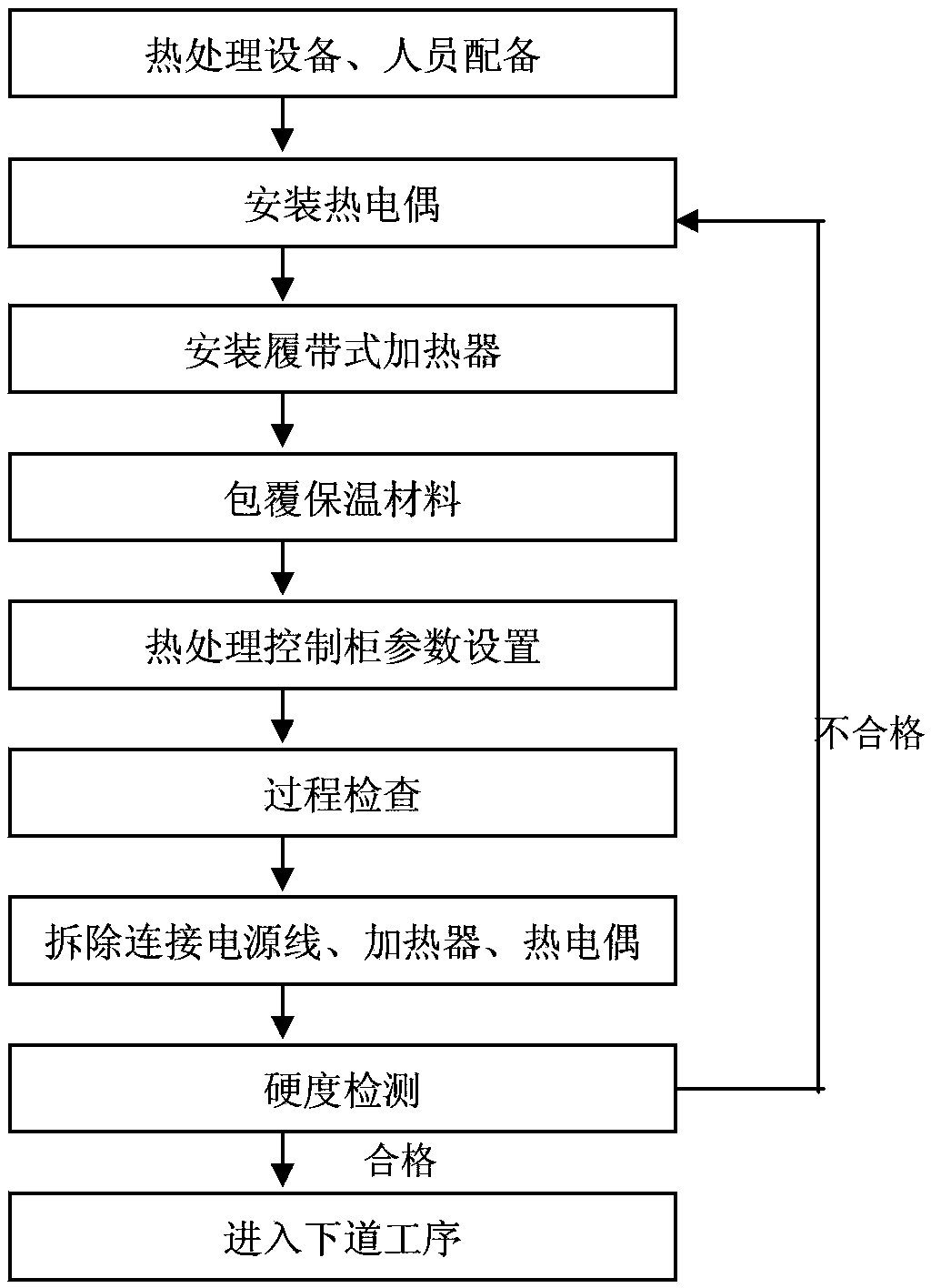

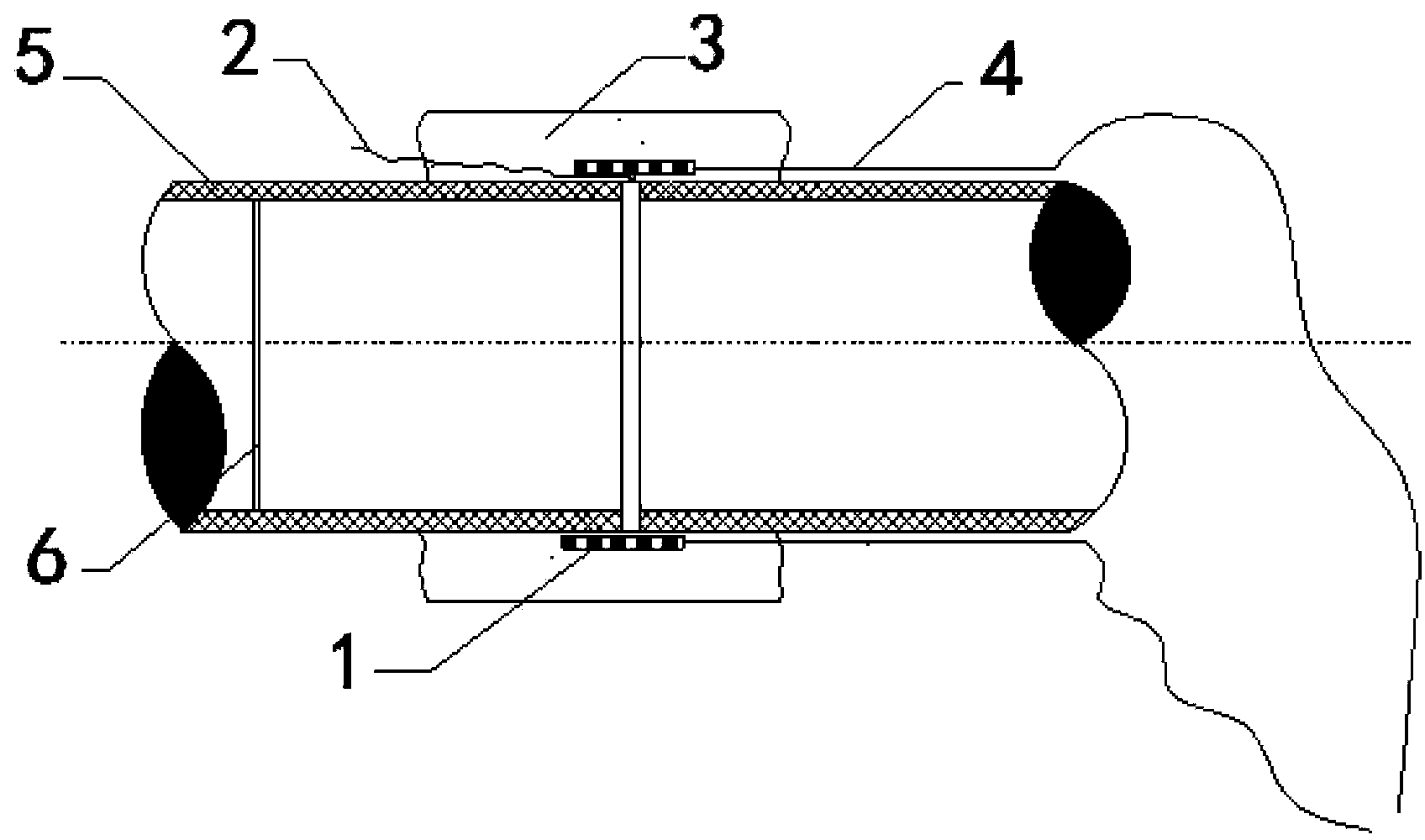

Anti-sulfur acid-resistant long conveying pipeline heat treatment process

ActiveCN104212966AEasy to operateImprove ergonomicsFurnace typesHeat treatment furnacesTemperature controlInfrared

The invention relates to an anti-sulfur acid-resistant long conveying pipeline heat treatment process, which belongs to the technical field of a pipe-line system. According to the invention, Jiangsu Yineng heat treatment equipment is selected, an infrared ray high-temperature ceramic crawler type electric heater is employed, a set of complete heat treatment equipment comprises a lorry (transportation), a generator with 200KW, two temperature control cabinets (six crossings can be simultaneously controlled by each temperature control cabinet, each technical curve parameter can be respectively set, and each temperature control cabinet can be independently operated) and a corresponding secondary power line; a forklift is specially equipped for the heat treatment, temporary road can be build, and heat treatment equipment can be ensured to reach the assigned field. The heat treatment process has the advantages of strong operationality, high work efficiency and simple process. The heat treatment construction problem of the non fixed place pipeline weld can be effectively solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Copper-covered circuit board etching technology

ActiveCN103781282ANo problems with bridging connectionsHigh precisionConductive material chemical/electrolytical removalEtchingCopper wire

The invention relates to a copper-covered circuit board etching technology which is low in cost and high in etching precision. The copper-covered circuit board etching technology comprises the steps that a copper-covered board after development of a front working procedure is washed through RO water to neutral, polishing is carried out on the copper-covered plate after water washing by using a needle brushing type scrubbing machine, and micro-etching liquid is evenly sprayed on the surface of the copper-covered plate, wherein the micro-etching liquid is a water solution containing sulfur acid and hydrogen peroxide; the copper-covered plate after the micro-etching is washed into the neutral through the RO water again; the copper-covered plate after the washing is immerged into etching liquid for 1-2min, and then the copper-covered plate is washed to neutral by using the RO water again. Compared with the prior art, micro copper wire bridging connection problems cannot emerge on etched circuit boards, production cost is low, special etching liquid does not need to be prepared, micro etching process is carried out on the copper-covered plate by adopting the mode of combining physic micro etching of a pin type plate brushing machine and chemical micro etching, the precision of etching process is improved greatly, and etched micro copper wires with the wire width less than 0.2mm are neat in edge.

Owner:CHONGQING HANGLING PCB

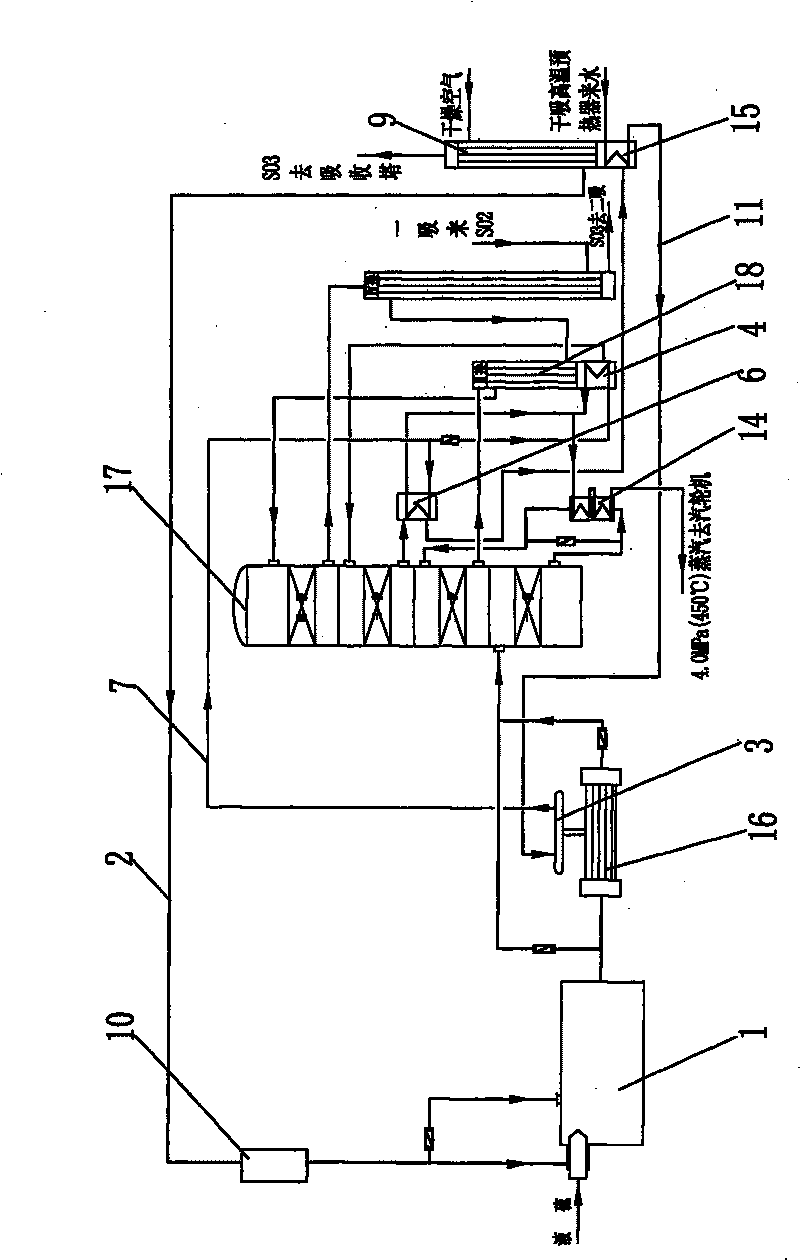

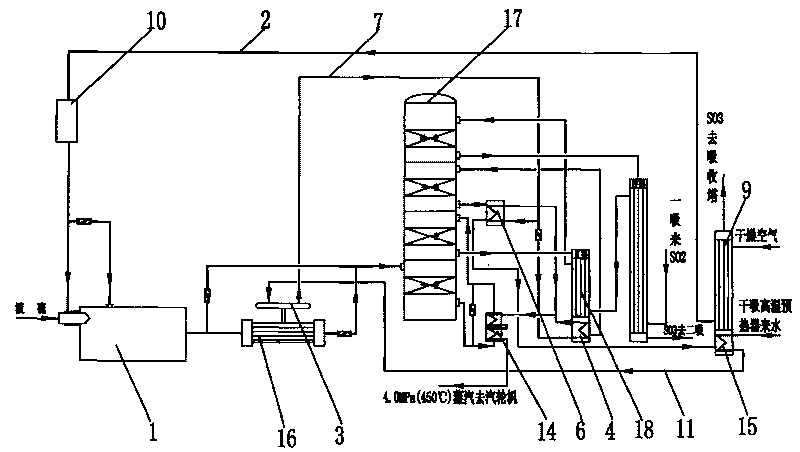

Method for recovering acid making waste heat

InactiveCN101706095AHigh recovery rateIncrease profitSulfur compoundsEnergy inputAir preheaterThermal energy

The invention discloses a method for recovering acid making waste heat of sulfur acid making or smelting acid making. The method comprises the following steps of: recovering partial heat carried by SO3 gas discharged from a first-section outlet, a second-section outlet and a third-section outlet of a converter in the production process of making acid; recovering heat generated by high temperature of a dry absorption system; and transferring partial heat carried by acid of a dry absorption heat recovering system to boiler water feed by using a heat exchanger on a boil water feed channel of an outlet of a reacting furnace. The scheme uses heat absorbed by dry absorption high temperature to preheat the boiler water feed of an outlet of a sulfur burner and converts the partial heat into medium pressure overheat steam. Therefore, the method can save investment, reduces requirements for soft water quality, and improves generating efficiency above all. The method appropriately modifies a heat recovering system of a converting system at the same time. The method saves a coal economizer, increases a superheater and is additionally provided with an air preheater. For smelting fume acid making, the method can provide a high temperature absorption system on the dry absorption part, and the generated heat can preheat the boiler water feed in the smelting part.

Owner:陈祥明

Production method for zinc sulfate

The invention provides a production method for zinc sulfate. The production method comprises the following steps: grinding and crushing zinc concentrate into powder with a particle size of 50 to 80 meshes and adding the powder into a hermetic container; adding ferrous sulfate accounting for 1 to 3 wt% of the zinc concentrate powder into the container as a catalyst and adding a sulfur acid solution at the same time; starting an electric mixer, carrying out heating to 80 to 90 DEG C and maintaining the temperature for 3 to 5 h; successively carrying out filtering, cooling and pumping filtration so as to obtain leachate and leaching residues; and separating the leachate by using a solvent extraction method and subjecting the leachate to acidity adjustment, concentration, evaporation, crystallization, centrifugation and drying so as to obtain zinc sulfate. The production method provided by the invention can guarantee the purity of the zinc sulfate product and enables resources to be maximally utilized.

Owner:HENGYANG YISHUN CHEM CO LTD

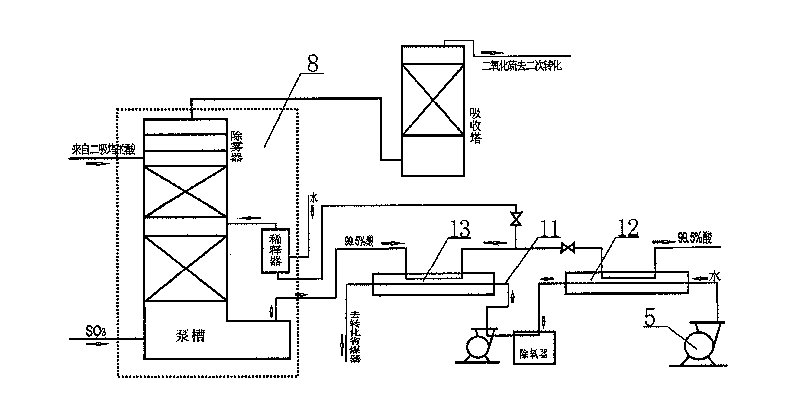

Application method of fine desulfurization in sulfuric acid exhaust absorption

The invention discloses an application method of fine desulfurization in sulfuric acid exhaust absorption, and relates to a technical scheme of the application of fine desulfurization in sulfuric acid exhaust absorption, in particular to a method for discharging SO2 exhaust. The method comprises the following steps of: A, introducing sulfur-containing exhaust into an absorption tower; and B, spraying ammonium sulfite-ammonium hydrogen sulfite solution serving as a fine desulfurization solution with the pH value of 5.6 to 6.1 from the top of the tower to absorb SO2 and SO3 in the sulfur-containing exhaust, and regulating the gas-liquid ratio to be (350-370): 1, wherein according to the concentration of aqueous ammonia in step B, the absorption mother solution refluxes to a mother solution circulating tank from the bottom of the absorption tower, and 10.3 to 10.6 mass percent of diluted aqueous ammonia is added, so that the ratio of (NH4)2SO3 to NH4HSO3 in the absorption solution is unchanged in an optimal range of the ammonium sulfite-ammonium hydrogen sulfite solution serving as the fine desulfurization solution; and the temperature of the mother solution in step B is between 25 and 30 DEG C. After the sulfur-containing exhaust is treated, the conversion rate of a sulfur acid device is more than or equal to 99.5 percent, and 60mg / Nm<3> of SO2 exhaust is discharged; and by substituting the expensive imported accelerant for the cheap domestic accelerant, the national emission standard can also be achieved, and the cost is reduced.

Owner:云南云天化云峰化工有限公司

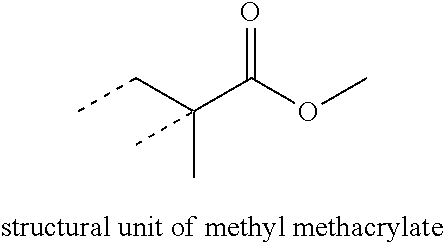

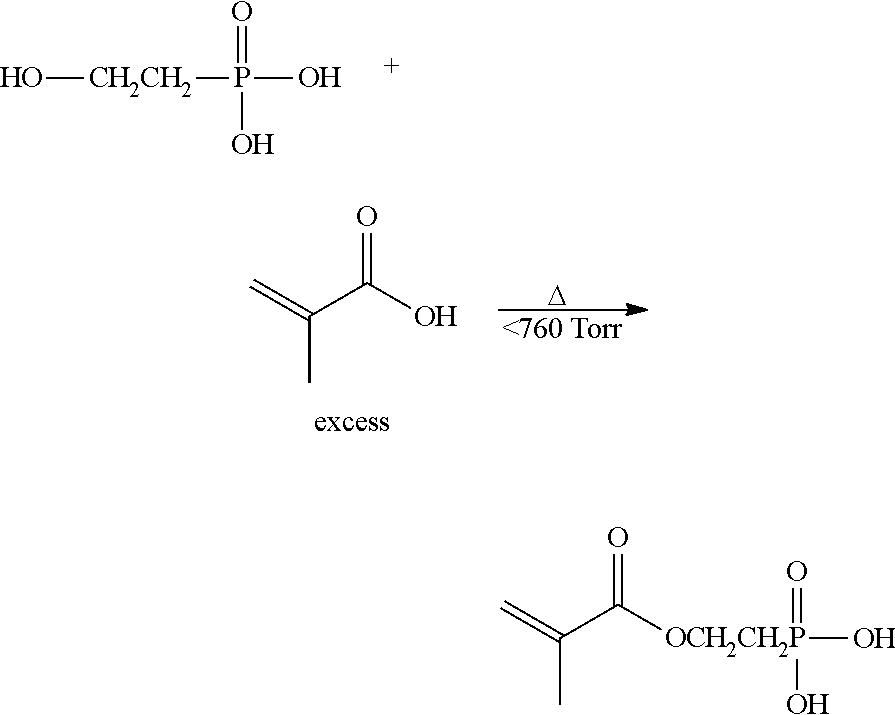

Stable aqueous dispersion of particle polymers containing structural units of 2-(methacryloyloxy)ethyl phosphonic acid and composites thereof

The present invention is a composition comprising a stable aqueous dispersion of polymer particles comprising structural units of a nonionic monoethylenically unsaturated monomer; 2-(methacryloyloxy)ethyl phosphonic acid (MEP) or a salt thereof; and a sulfur acid monomer or carboxylic acid monomer or a combination thereof or a salt thereof, as well as a composite comprising the polymer particles adsorbed to the surface of a pigment particle such as TiO2. The composition and composite are prepared using the phosphorus acid monomer MEP, which can be prepared in high purity with low residual non-polymerizable phosphorus acid, thereby reducing the load of neutralizing agent required to achieve the targeted pH as compared with phophoethyl methacrylate (PEM).

Owner:ROHM & HAAS CO

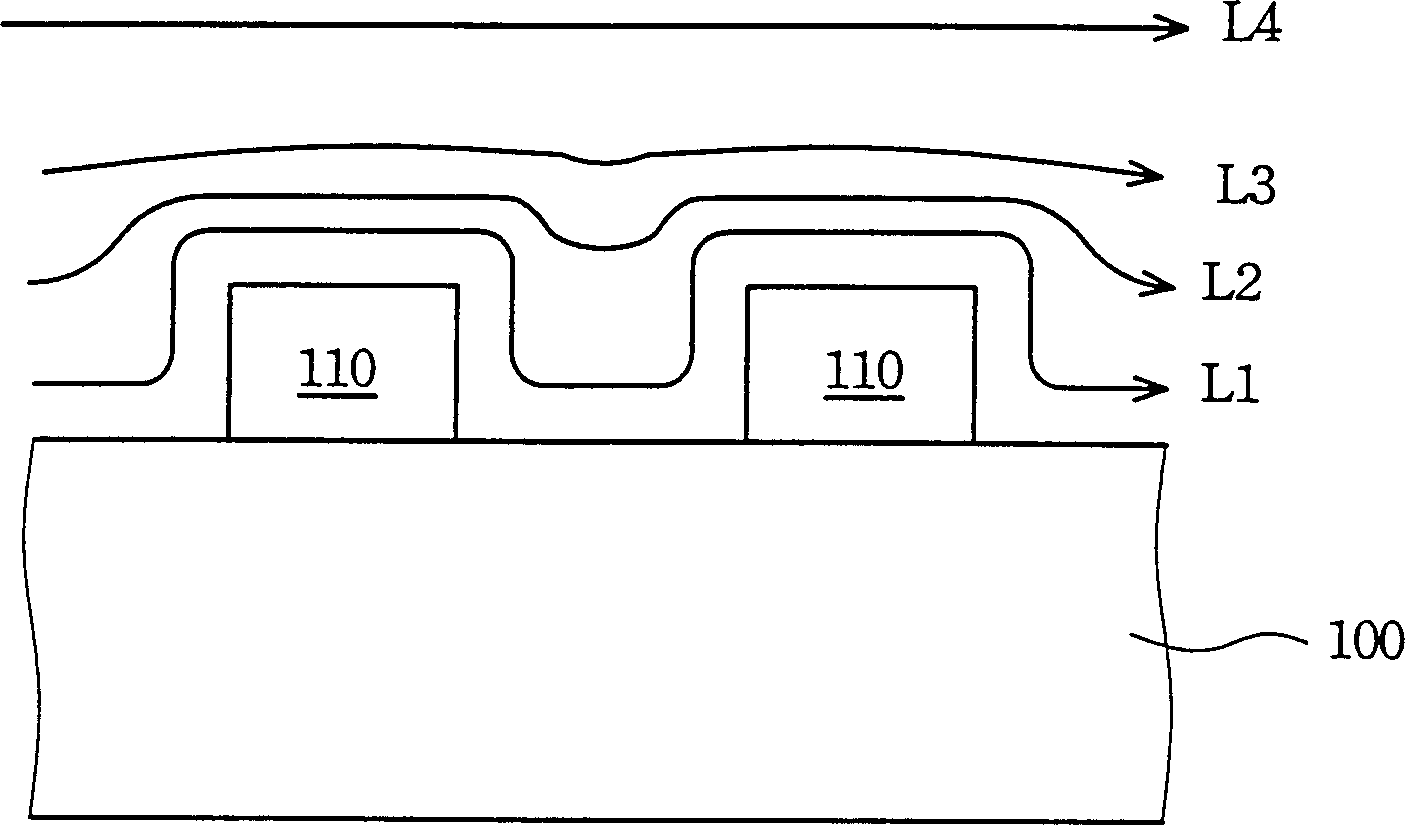

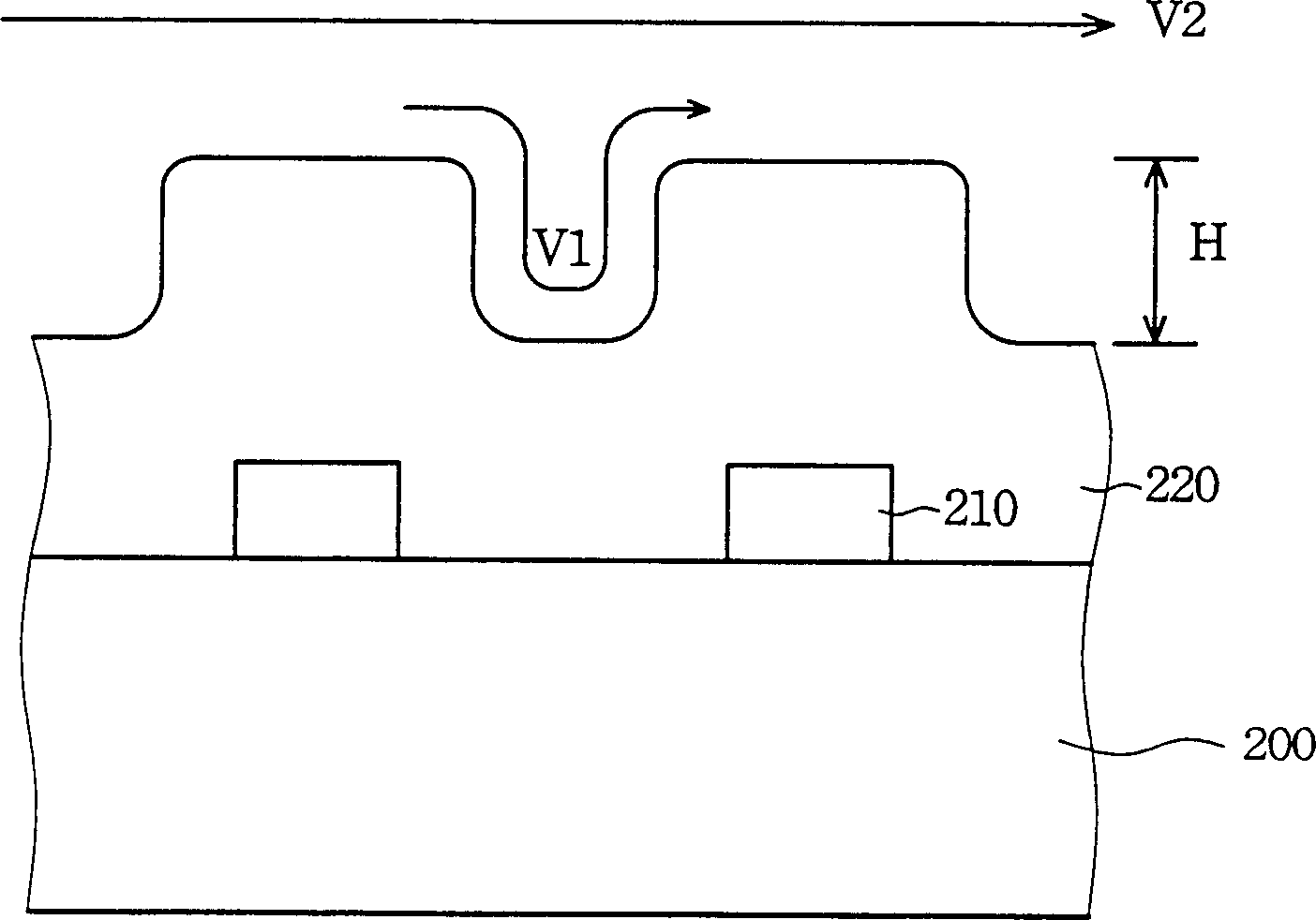

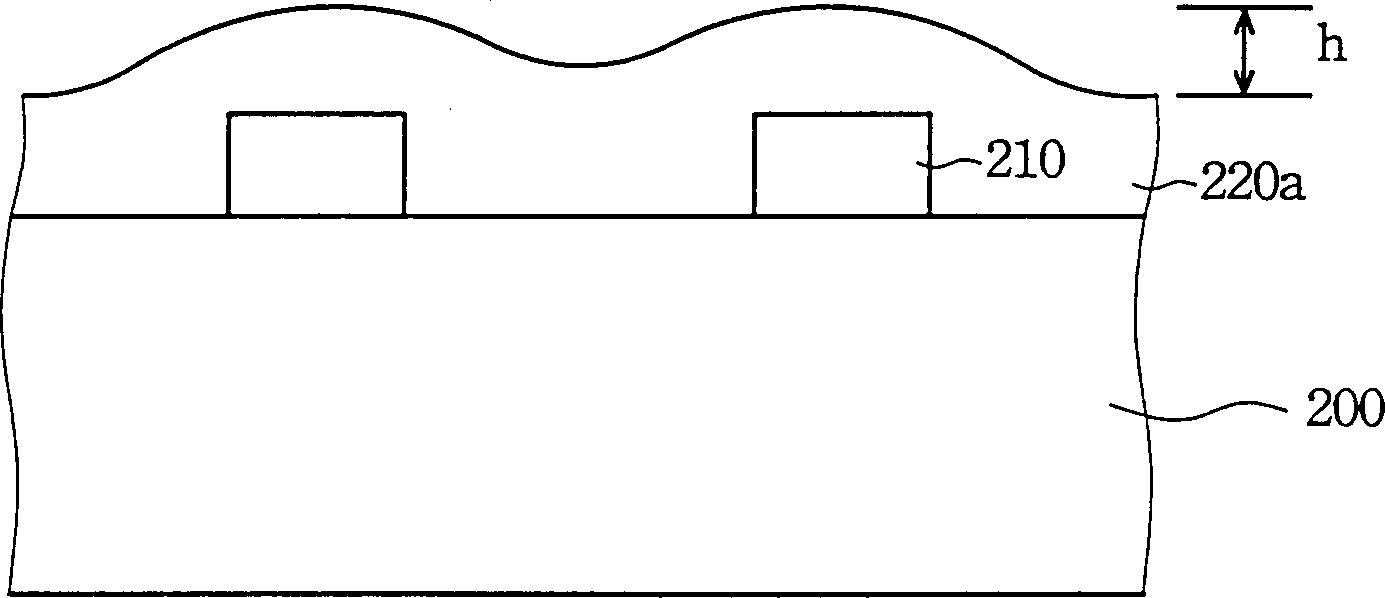

Method by using wet etching with non-equivalence in directions to carry out even process

InactiveCN1431685ATo achieve the goal of flatteningSemiconductor/solid-state device manufacturingHydrofluoric acidInsulation layer

Sulfur acid, phosphoric acid, hydrofluoric acid and water are mixed to form the etching solution. Then, the substrate is put into the etching solution. The etching solution flows across the insulation layer on the substrate with proper velocity of flow. The insulation layer possesses multiple channels. The different velocities of flow of the etching solution on the accidental surface of the insulation layer make different etching speeds. The etching speed at the bulging is higher than the speed at the dishing so as to reach the goal of evenness.

Owner:MACRONIX INT CO LTD

Method for preparing iron carbide from multi-metal sulfur acid residue

The invention discloses a method for preparing iron carbide from multi-metal sulfur acid residues. The method comprises the following steps that the multi-metal sulfur acid residues, a bonding agent and a chloridizing agent are uniformly mixed and are prepared into a pelletizing material; the pelletizing material are made into green balls; after drying, heating chlorination is performed; carburization is performed in CO+CO2+H2 or CH4+H2 gas, and cooling is performed in inert atmosphere; a ball group subjected to carburization is obtained; the ball group subjected to the carburization is subjected to wet ball milling; after ball milling, wet magnetic separation and drying are performed to obtain the iron carbide. The method provided by the invention has the advantages that the iron carbide preparation is efficient, fast and convient; the cost is low; the energy is saved and the environment is protected.

Owner:SUZHOU UNIV

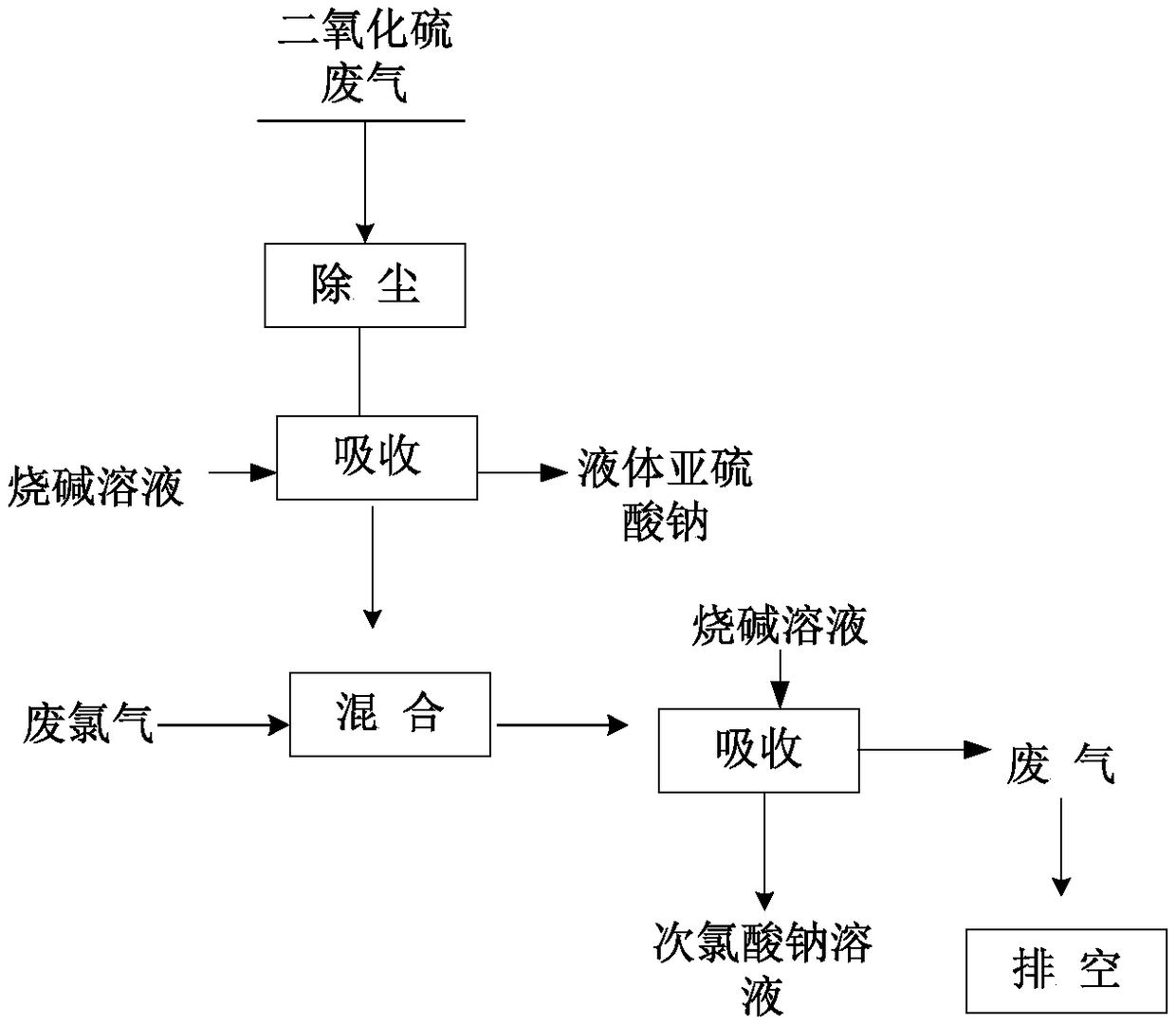

Comprehensive treatment method for sulfur dioxide exhaust gas

InactiveCN109485072ASolve the problem of impurities brought in by storage oxidationReduce the impactDispersed particle separationAlkali metal sulfite preparationSulfite saltSodium sulfite

The invention belongs to the technical field of sulfur dioxide exhaust gas treatment and in particular relates to a comprehensive treatment method for sulfur dioxide exhaust gas. The invention solvesthe technical problem that the sulfur dioxide content is high after sulfur dioxide exhaust gas treatment. The invention provides the comprehensive treatment method for sulfur dioxide exhaust gas. Themethod comprises the following steps: a, collecting sulfur dioxide exhaust gas of a sulfur acid plant, dedusting the sulfur dioxide exhaust gas and conveying the same to an adsorption tower, and absorbing the same with a 10-17% by mass of caustic soda solution to obtain a sodium sulfite solution and exhaust gas absorbed by alkali liquor; and b, introducing exhaust chlorine into the exhaust gas absorbed by the alkali liquor, absorbing the mixed gas with 10-17% by mass caustic soda solution, wherein the absorption end point is that the effective alkali content is smaller than 1%; and absorbing to obtain a sodium hypochlorite solution and residual exhaust gas, the content of sulfur dioxide of which is smaller than 50 ppm. By treating the sulfur dioxide exhaust gas by means of the method, thecontent of sulfur dioxide in the treated residual exhaust gas is smaller than 50 ppm.

Owner:PANZHIHUA STEEL ENTERPRISES XINYU CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com