Preparation method of nanometer titanium dioxide

A technology of nano-titanium dioxide and metatitanic acid, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems that restrict the development of denitrification environmental protection industry, the catalyst is not acclimatized, and the coal quality is uneven, so as to promote the industry Upgrading, broadening the industrial chain, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

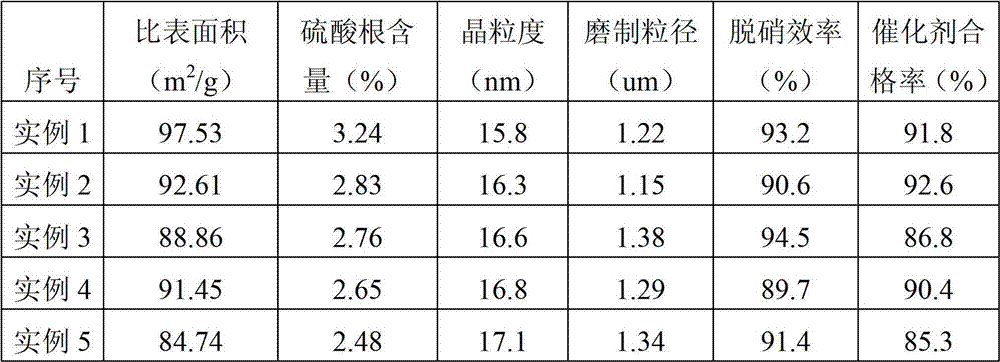

Embodiment 1

[0025] Weigh 25kg metatitanic acid (equivalent to TiO 2 In total, the raw material TiO 2 The content is about 28%), placed in a reactor equipped with a stirrer, and about 223kg of deionized water was added to make the slurry TiO 2 The content is about 8%, stir for 0.5h; add ammonia water to the slurry to adjust the pH value to 6, heat the slurry to 70°C with steam, keep warm and stir for 2.0h, and at the same time add an appropriate amount of ammonia water to maintain the pH of the slurry at 6; Add 0.125kg of ammonium citrate to the mixture and stir for 1 hour; press filter the slurry to a block filter cake with a solid content of about 40%; calcinate the filter cake for 2 hours at 150°C, 2 hours at 250°C, 2 hours at 350°C, 480°C Calcined at ℃ for 3 hours; the calcined solid was pulverized by a powder mill to a particle size D50 of 1.22um to obtain a nano-titanium dioxide product.

Embodiment 2

[0027] Weigh 25kg metatitanic acid (equivalent to TiO 2 In total, the raw material TiO 2 The content is about 28%), put it in a reaction kettle equipped with a stirrer, add about 223kg deionized water to make the slurry TiO2 content about 8%, stir for 0.8h; add ammonia water to the slurry to adjust the pH value to 7, use steam Heat the slurry to 70°C, keep warm and stir for 2.5 hours, and at the same time add an appropriate amount of ammonia water to maintain the pH of the slurry at 7; add 0.125kg of ammonium citrate to the slurry and stir for 1 hour; press filter the slurry until the solid content is about 50% Block filter cake; calcining the filter cake, including calcination at 180°C for 2 hours, calcination at 300°C for 2 hours, calcination at 400°C for 2 hours, and calcination at 490°C for 3 hours; the calcined solid was pulverized by a powder machine until the particle size D50 was 1.15um to obtain nano Titanium dioxide products.

Embodiment 3

[0029] Weigh 25kg metatitanic acid (equivalent to TiO 2 In total, the raw material TiO 2 The content is about 28%), put it in a reactor equipped with a stirrer, add about 188kg deionized water to make the slurry TiO2 content about 9%, stir for 1h; add ammonium carbonate to the slurry to a pH value of 7, and use steam to Heat the slurry to 75°C, keep it warm and stir for 2.5 hours, and at the same time add an appropriate amount of ammonium carbonate to maintain the pH of the slurry at 7; add 0.125kg of pentadecylsulfanthamine to the slurry, and stir for 1 hour; press filter the slurry until the solid content is about It is a 45% block filter cake; the filter cake is calcined at 150°C for 2h, at 300°C for 2h, at 390°C for 2h, and at 520°C for 3h; the calcined solid is pulverized by a powder machine until the particle size D50 is 1.38 um, to obtain nano-titanium dioxide products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com