Method of preparing transparent ultraviolet absorption membrane material from enzymatic hydrolysis lignin

A technology of enzymatically decomposing lignin and external absorption, which is applied in the field of membrane materials, can solve the problems of membrane loss of transparency and limit the scope of application, and achieve the effect of excellent hardness and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) In a dry 250mL four-neck flask, add 6.0g LiCl and 98.0g DMAc (dimethylacetamide), and then add 3.0g of dry enzymatic lignin (Songyuan Bairui Biopolyol Co., Ltd.), Stir and dissolve at 70°C to a homogeneous solution; add catalyst triethylamine 1.2g and polymerization inhibitor hydroquinone 0.0450g to the above homogeneous system, and pass nitrogen protection at the same time; add acryloyl chloride 2.4g to the above solution, 50°C React for 3 hours; when the reaction is complete, pour the reaction solution into 1000 mL of distilled water, stir and centrifuge to collect the precipitate, wash with water several times until neutral, and dry at 50°C to constant weight to obtain a lignin-based macromer.

[0023] (2) Add 0.6g of lignin-based macromer, 4g of butyl methacrylate and 92mg of AIBN (azobisisobutylcyanide) into 30 mL of dioxane, and transfer the solvent to a 100mL eggplant-shaped reaction bottle During the process, nitrogen bubbles were used to remove oxygen for 1...

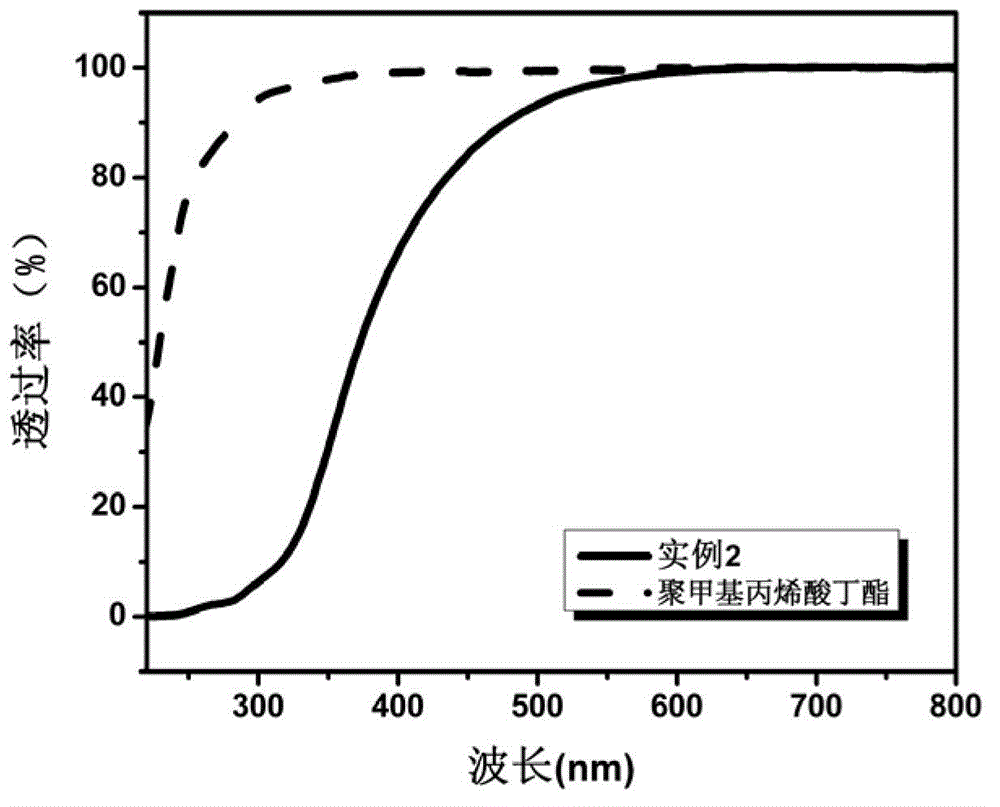

Embodiment 2

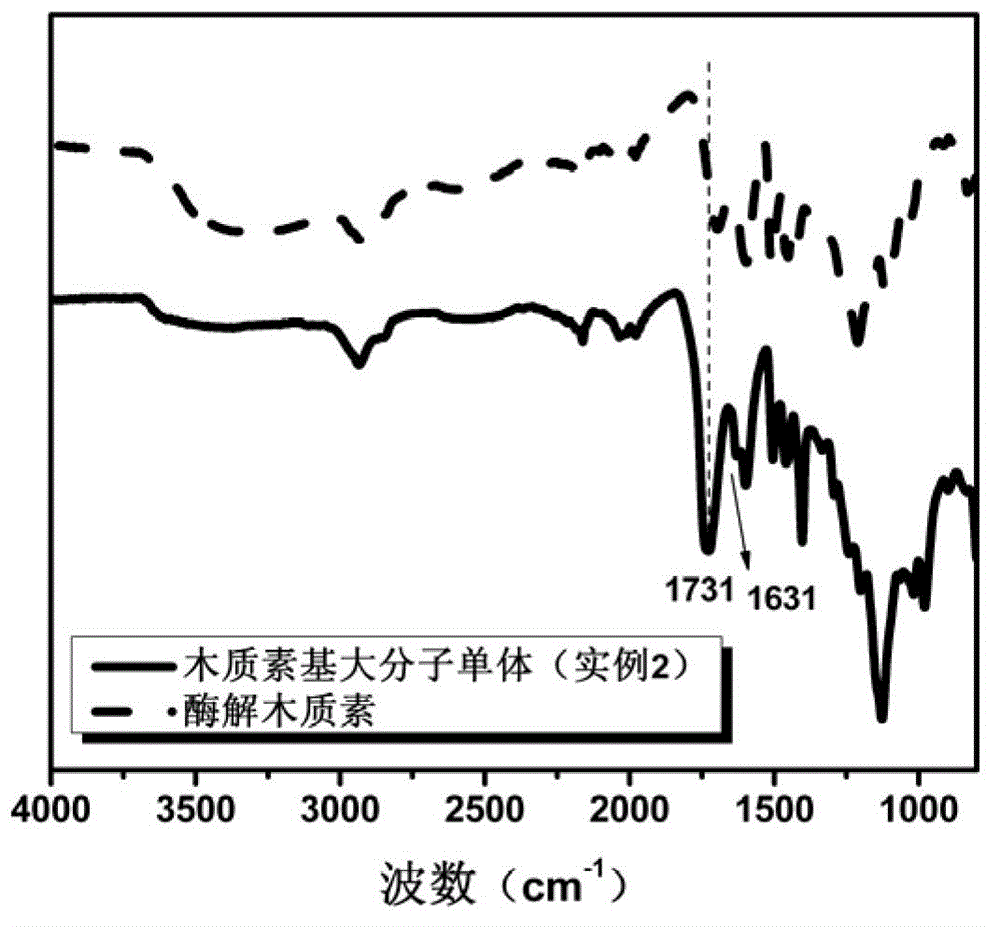

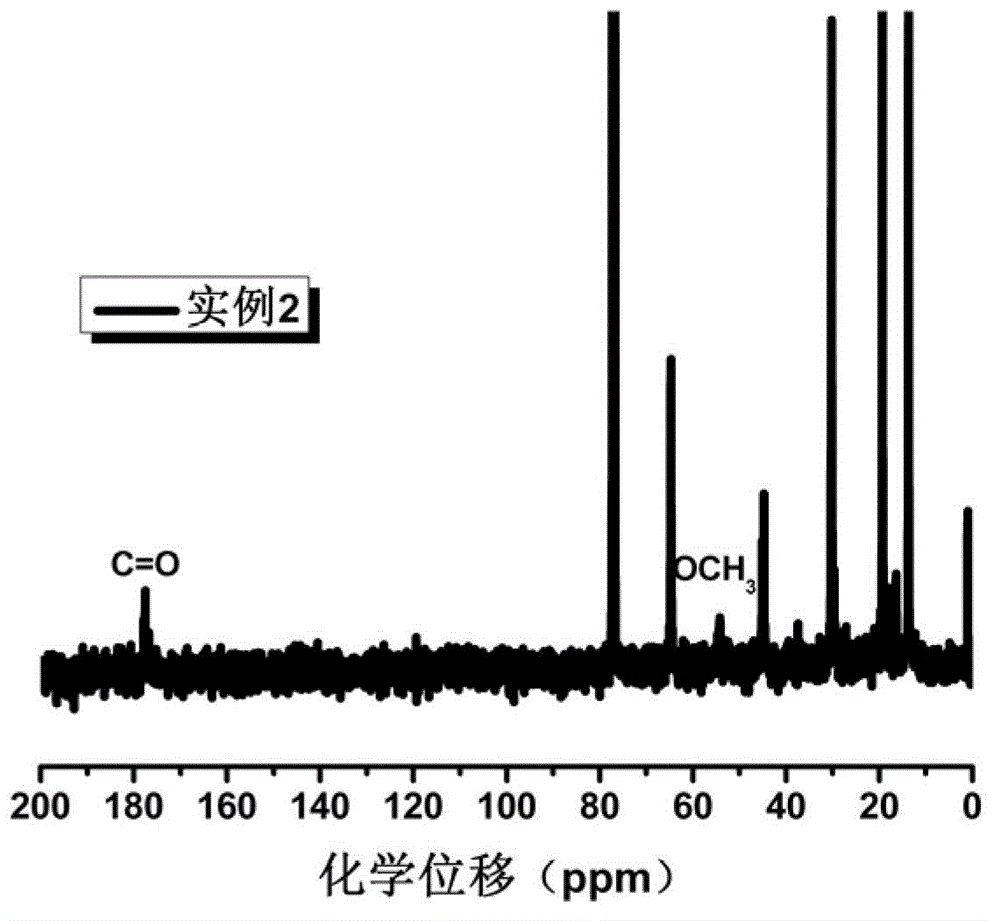

[0025] (1) In a dry 250mL four-neck flask, add 8.0g LiCl and 98.0g DMAc, then add 3.0g of dry enzymatic lignin (Songyuan Bairui Biopolyol Co., Ltd.), stir and dissolve at 70°C until homogeneous solution; add catalyst triethylamine 1.2g and polymerization inhibitor hydroquinone 0.0450g to the above homogeneous system, and pass through nitrogen protection at the same time; add acryloyl chloride 2.4g to the above solution, and react at 50°C for 3h; The reaction solution was poured into 1000 mL of distilled water, stirred and centrifuged to collect the precipitate, washed with water several times until neutral, and dried at 50°C to constant weight to obtain a lignin-based macromer.

[0026] (2) Add 0.6g of lignin-based macromer, 3g of butyl methacrylate and 72mg of AIBN (azobisisobutylcyanide) into 30mL of tetrahydrofuran, transfer the solvent to a 100mL eggplant-type reaction flask, blow with nitrogen Soak for deoxygenation for 10 minutes. Then heat up to 70°C and react for 10 h...

Embodiment 3

[0028] (1) In a dry 250mL four-neck flask, add 2.0g LiCl and 98.0g DMAc, then add 3.0g of dry enzymatic lignin, stir at 20°C for 5h to dissolve into a homogeneous solution; add catalyst to the above homogeneous system Triethylamine 1.2g and polymerization inhibitor hydroquinone 0.0450g, nitrogen protection at the same time; add acryloyl chloride 2.4g to the above solution, and react at 40°C for 5h; after the reaction, pour the reaction solution into 1000mL distilled water, stir and centrifuge The precipitate was collected, washed with water several times until neutral, and dried at 50°C to constant weight to obtain a lignin-based macromer.

[0029] (2) Add 0.6g of lignin-based macromer, 2.4g of butyl methacrylate and 60mg of AIBN (azobisisobutylcyanide) into 30mL of tetrahydrofuran, transfer the solvent to a 100mL eggplant type reaction flask, and nitrogen Deoxygenate by bubbling for 10 minutes. Then heat up to 70°C and react for 10 hours to obtain a polymer. The conversion r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com