Patents

Literature

32results about How to "Choose from a wide range of sources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

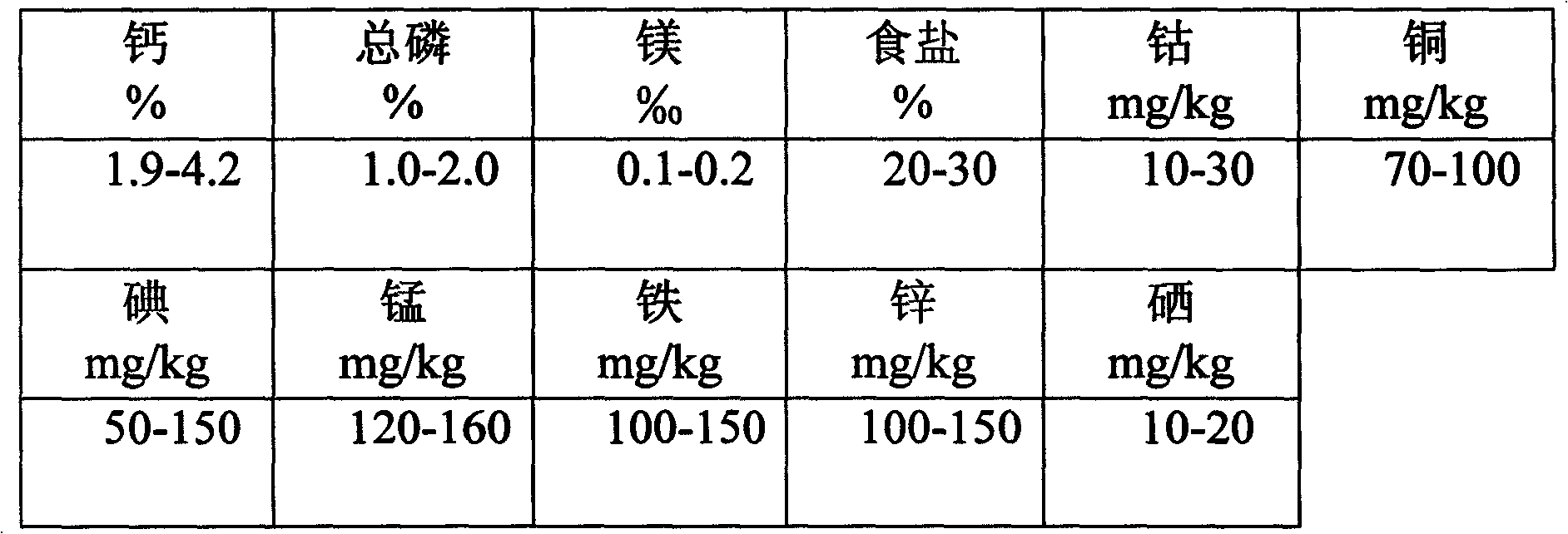

Nutrient-balance composite licking brick for cattle and sheep and its preparing process

InactiveCN1709129AChoose from a wide range of sourcesLow priceFood processingAnimal feeding stuffNutrientCobaltous chloride

The present invention provides a nutrient balance compound type licking brick for cattle and sheep and its preparation process. Every kg of licking brick contains 0.5-0.3g of zinc sulfate, 0.1-0.2g of copper sulfate, 0.2-0.3g of manganese sulfate, 0.01-0.02g of sodium selenite, 0.01-0.3g of potassium iodide, 0.03-0.06g of cobaltous chloride, 0.1-0.3g of magnesium oxide, 0.02-0.04g of nano zinc sulfate and copper sulfate mixture, 30-150g of sodium sulfate, 40-80g of calcium hydrogen phosphate, 0.2-1g of chromium nicotinate, 50-200g of carrier, 150-300g of edible sale, 200-300g of solidifying agent, 20-80g of freacle, 50-200g of urea, 20-80g of puffed corn flour, 20-80g of physiological regulating and controlling agent and 10-60g of vitamin premixed material.

Owner:NINGXIA ACAD OF AGRI & FORESTRY SCI RES INST OF ANIM

Mineral substance composite licking brick for cattle and sheep and its preparing process

The present invention provides a mineral compound type licking brick for cattle and sheep and its preparation method. Every kg of licking brick contains 0.15-0.3g of ferrous sulfate, 0.15-0.3g of zinc sulfate, 0.1-0.2g of copper sulfate, 0.2-0.3g of manganese sulfate, 0.01-0.02g of sodium selenite, 0.05-0.3g of potassium iodide, 0.03-0.08g of cobaltous chloride, 0.1-0.3g of magnesium oxide, 0.02-0.03g of nano zinc oxide and copper sulfate mixture, 6-10g of chromium nicotinate, 30-150g of sodium sulfate, 40-100g of calcium hydrogen phosphate, 200-400g of edible salt, 200-400g of solidifying agent, 50-200g of carrier and 30-70g of treacle.

Owner:NINGXIA ACAD OF AGRI & FORESTRY SCI RES INST OF ANIM

High-energy composite licking brick for cattle and sheep and its preparing process

The present invention provides a high-energy compound type licking brick for cattle and sheep and its preparation process. Every kg of licking brick contains 0.15-0.3g of ferrous sulfate, 0.15-0.3g of zinc sulfate, 0.1-0.2g of copper sulfate, 0.2-0.3g of manganese sulfate, 0.01-0.02g of sodium selenite, 0.05-0.3g of potassium iodide, 0.03-0.08g of cobaltous chloride, 0.1-0.3g of magnesium oxide, 0.03-0.03g of nano zinc oxide and copper sulfate mixture, 30-120g of sodium sulfate, 40-80g of calcium hydrogen phosphate, 50-200g of carrier, 150-300g of edible salt, 200-300g of solidifying agent, 80-150g of treacle and 150-300g of high-energy lipoid powder.

Owner:NINGXIA ACAD OF AGRI & FORESTRY SCI RES INST OF ANIM

Cattle and sheep fattening barbary wolfberry fruit and licorice root health-care licking brick and preparation method thereof

InactiveCN101606640AChoose from a wide range of sourcesLow priceFood processingAnimal feeding stuffSodium BentoniteBrick

The invention relates to a cattle and sheep fattening barbary wolfberry fruit and licorice root health-care licking brick and a preparation method thereof, and the licking brick is characterized in that each kg of the licking brick comprises the following raw materials: 0.21-0.35g of ferrous sulfate, 0.21-0.35g of zinc sulfate, 0.14-0.21g of copper sulfate, 0.24-0.35g of manganese sulfate, 0.01-0.02g of sodium selenite, 0.07-0.35g of potassium iodide, 0.03-0.07g of cobalt chloride, 0.14-0.35g of magnesium oxide, 6.0224-8.038g of chromium nicotinate, 30-150g of sodium sulfate, 200-300g of common salt, 200-300g of bentonite, 30-60g of molasses, 190-285g of barbary wolfberry fruit and 50-100g of licorice root. The preparation method combines the chemical coagulation technology and the mechanical pressing technology, simultaneously targets the characteristics of cattle and sheep fattening and develops the nutrition licking brick which adds the barbary wolfberry fruit and the licorice root and supplements cattle and sheep complex nutrition, thereby fully playing good properties of cattle and sheep. The licking brick is characterized by a wide range of sources for selecting a curing agent, low cost, more comprehensive nutrition, greater density, reasonable feed intake, sustained release of elements, health care, safety, environmental protection and the like, thereby being suitable for raising levels with different feeding methods.

Owner:NINGXIA ACAD OF AGRI & FORESTRY SCI RES INST OF ANIM

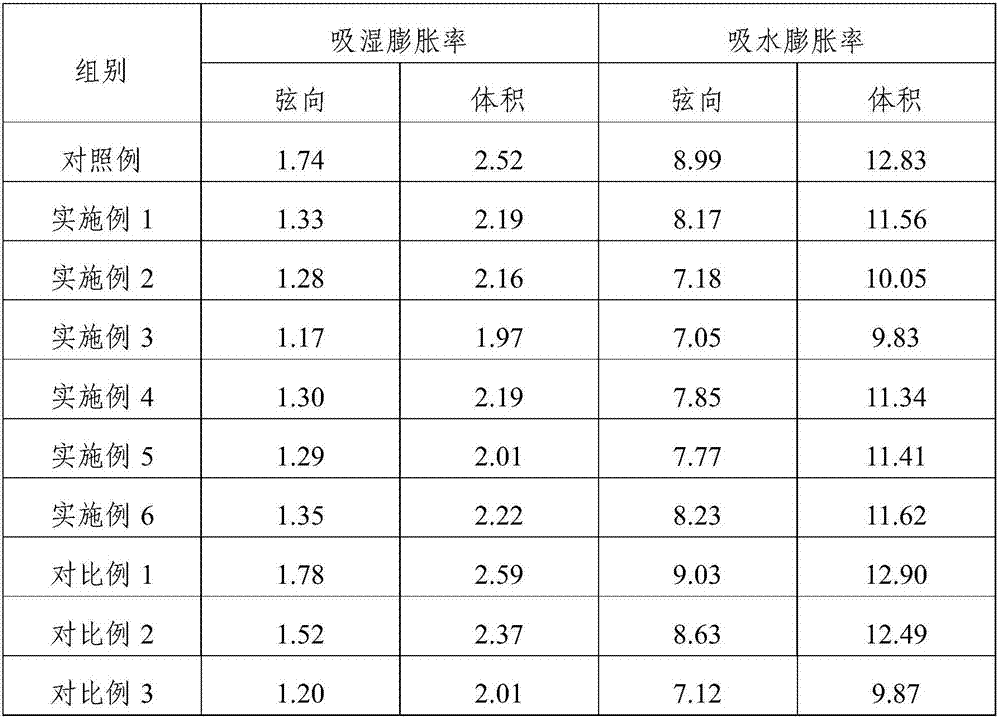

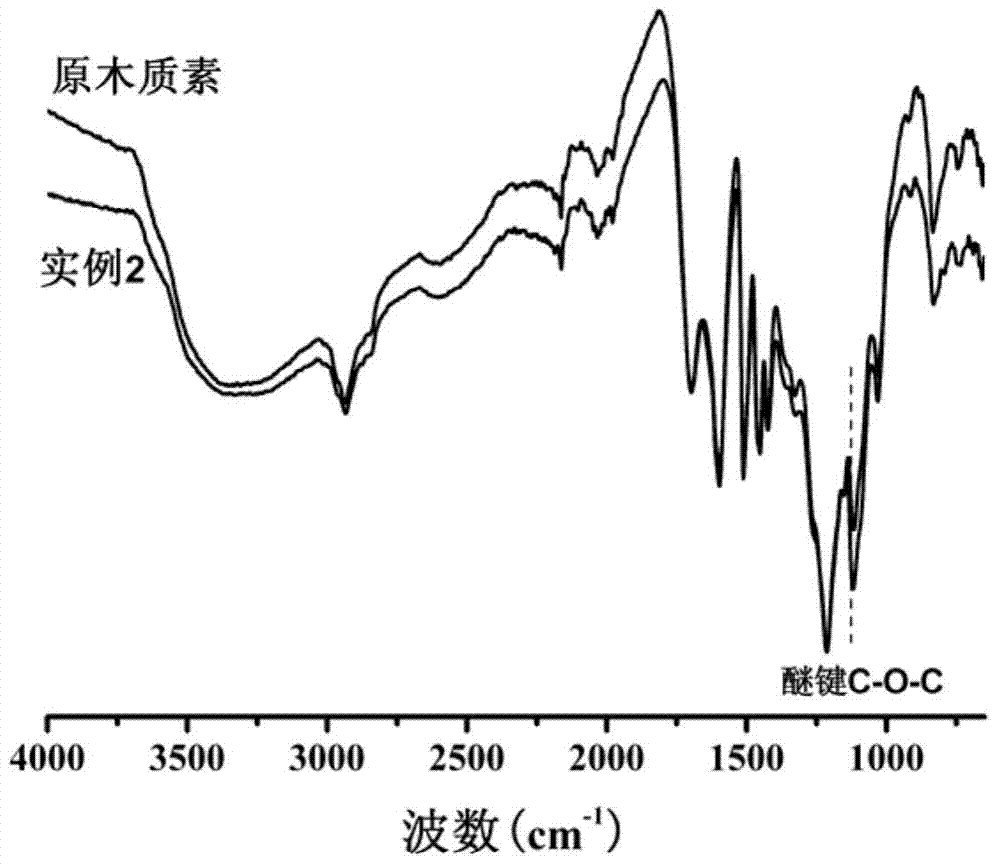

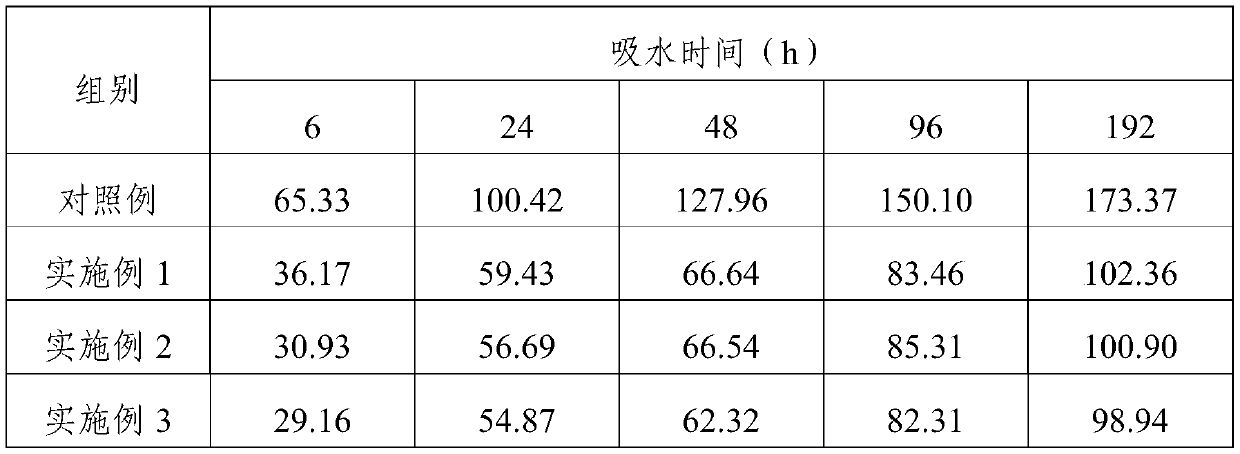

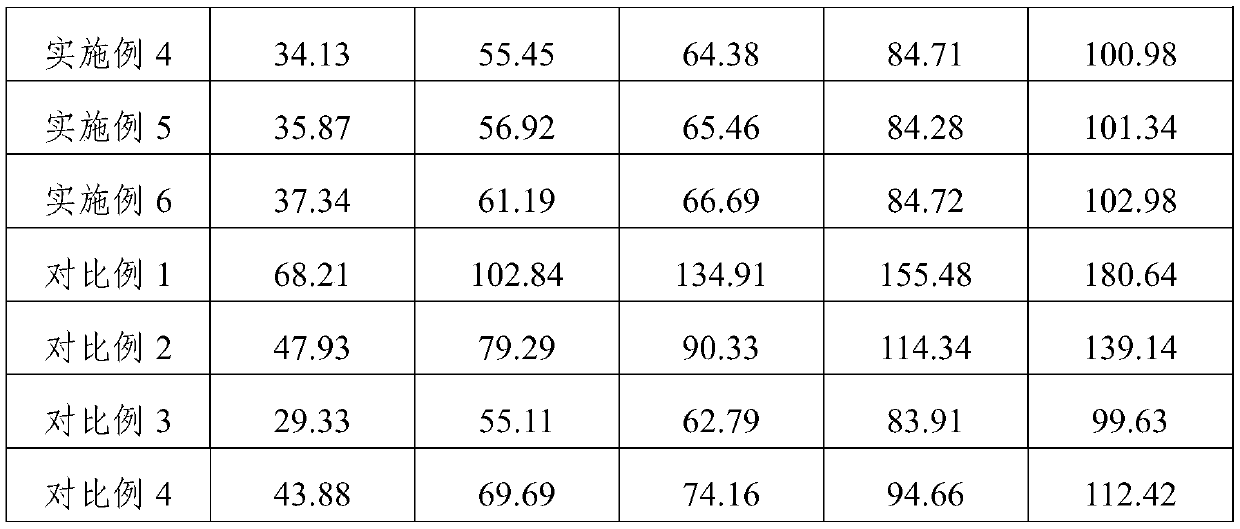

Method for preparing modified wood by compounding heat treatment based on alkali lignin

InactiveCN107972144AImprove waterproof performanceOvercome crackingWood treatment detailsThermal wood treatmentCompound aHeat treated

The invention relates to a method for preparing modified wood by compounding heat treatment based on alkali lignin. The method comprises the following steps: (1) soaking the wood treated in vacuum ina 1,4-dioxane solution with alkali lignin, adjusting the pressure to 0.2-0.8MPa and retaining the pressure for 50-90 minutes; and (2) taking the wood soaked in the step (1) out, drying the wood, putting the wood under the condition at the temperature of 120-200 DEG C, and carrying out heat treatment for 1.5-4 hours to obtain the modified wood. The method is used as a non-toxic and long-acting woodmodification manner with low cost and simple process; the modified wood with high water resistance and high size stability is prepared by compounding a heat treatment method; the defects of high possibility of cracking and high possibility of deformation of the fast-growing wood can be effectively overcome; the bottleneck problem of utilization of the fast-growing wood at present can be solved.

Owner:BEIJING FORESTRY UNIVERSITY

Production method of transparent leather

ActiveCN111455118AEasy to operateChoose from a wide range of sourcesPre-tanning chemical treatmentSpecial leather manufacturePolymer scienceActive agent

The invention discloses a production method of transparent leather. The production method of the transparent leather disclosed by the invention comprises the following four steps: 1, fully washing deashed and softened pelt with water until a total ash content is less than 0.5%, then taking the pelt out of a drum, carrying out stacking and standing for 30 minutes, and weighing the pelt, wherein theweight of the pelt is used as a reference for materials used in subsequent operation; 2, dissolving a surfactant or a polyfunctional amphiphilic substance such as a fatting agent for leather by usinga proper amount of water, adding the dissolved substance into a rotary drum, and then feeding the leather and carrying out rotating for at least 30 minutes; 3, dissolving or diluting acid or alkali with a proper amount of water, adding the dissolved or diluted acid or alkali into the rotary drum in batches, rotating the rotary drum for at least 10 minutes after each time of addition, continuing to rotate for at least 15 minutes after all the acid or alkali is added, and controlling the pH value of a bath solution to be 3.5-5.5 or 9.5-11.5; and 4, carrying out toggling and drying at a temperature not higher than 35 DEG C to finish the production of the transparent leather. Equipment and materials used in the method are widely used by leather making enterprises, and the types and the usingamounts of the materials and processing technological parameters can be adjusted according to product requirements, so practicability is high. Meanwhile, the pelt does not undergo violent expansion any more in the production process, so the production accident of breakage of the pelt is avoided, operation is easy, and risks are low.

Owner:SICHUAN UNIV

High-protein composite licking brick for cattle and sheep and its preparing process

InactiveCN1709131AChoose from a wide range of sourcesLow priceAnimal feeding stuffAccessory food factorsBrickManganese

The present invention provides a high protein compound type licking brick for cattle and sheep and its preparation method. Every kg of licking brick contains 0.21-0.35g of ferrous sulfate, 0.21-0.35g of zinc sulfate, 0.14-0.21g of copper sulfate, 0.24-0.35g of manganese sulfate, 0.01-0.02g of sodium selenite, 0.07-0.35g of potassium iodide, 0.03-0.07g of cobaltous chloride, 0.14-0.35g of magnesium oxide, 0.24-0.38g of nano zinc oxide and copper sulfate mixture, 6-8g of chromium nicotinate, 30-150g of sodium sulfate, 50-100g of calcium hydrogen phosphate, 50-200g of carrier, 200-300g of edible salt, 200-300g of solidifying agent, 30-60g of treacle, 100-150g of urea, 30-60g of urea phosphate and 3-7g of physiological regulating and controlling agent.

Owner:NINGXIA ACAD OF AGRI & FORESTRY SCI RES INST OF ANIM

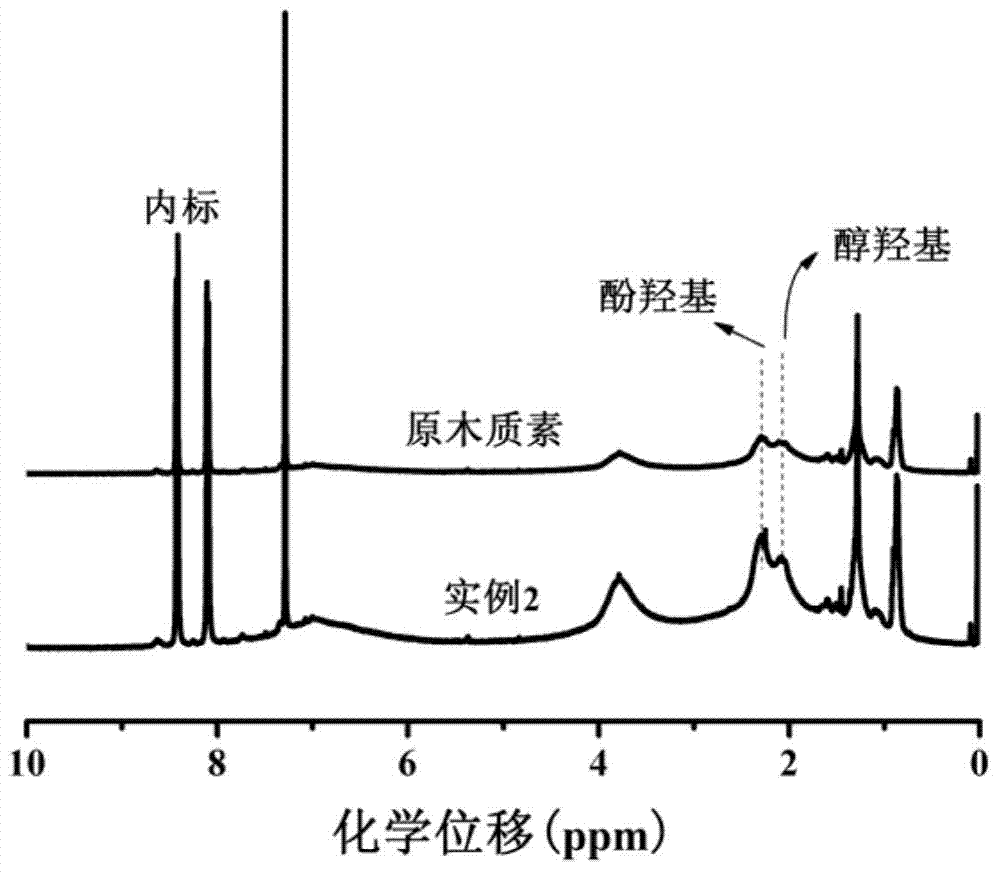

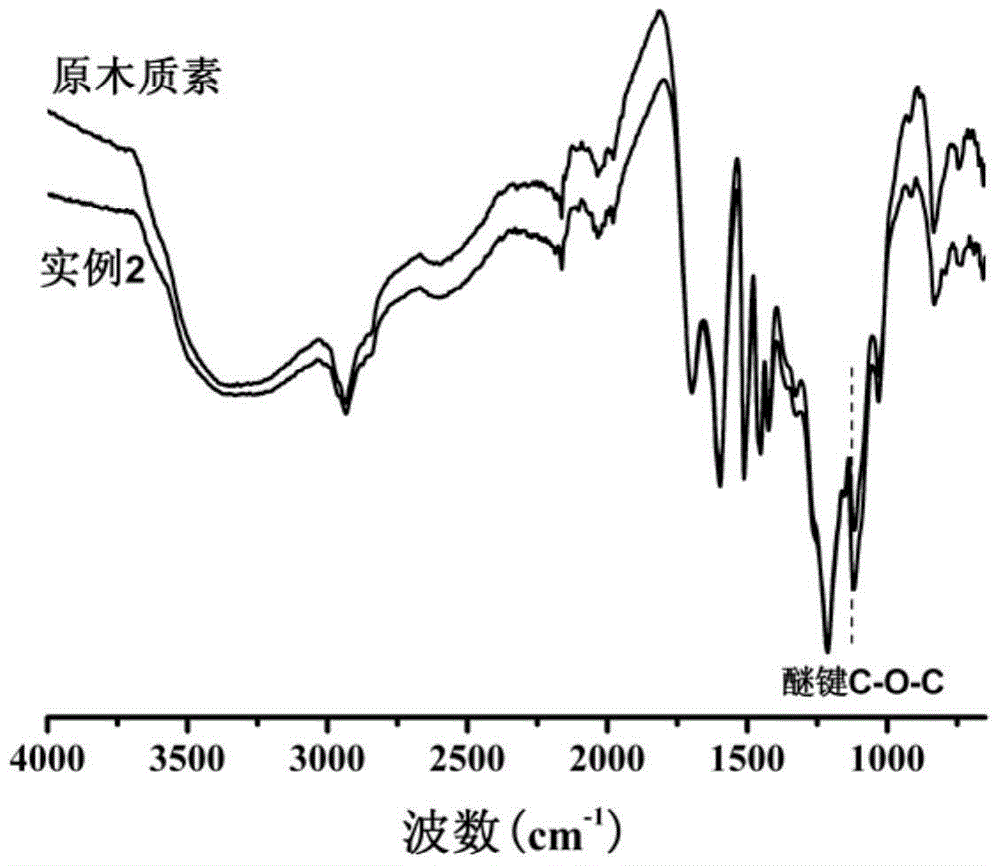

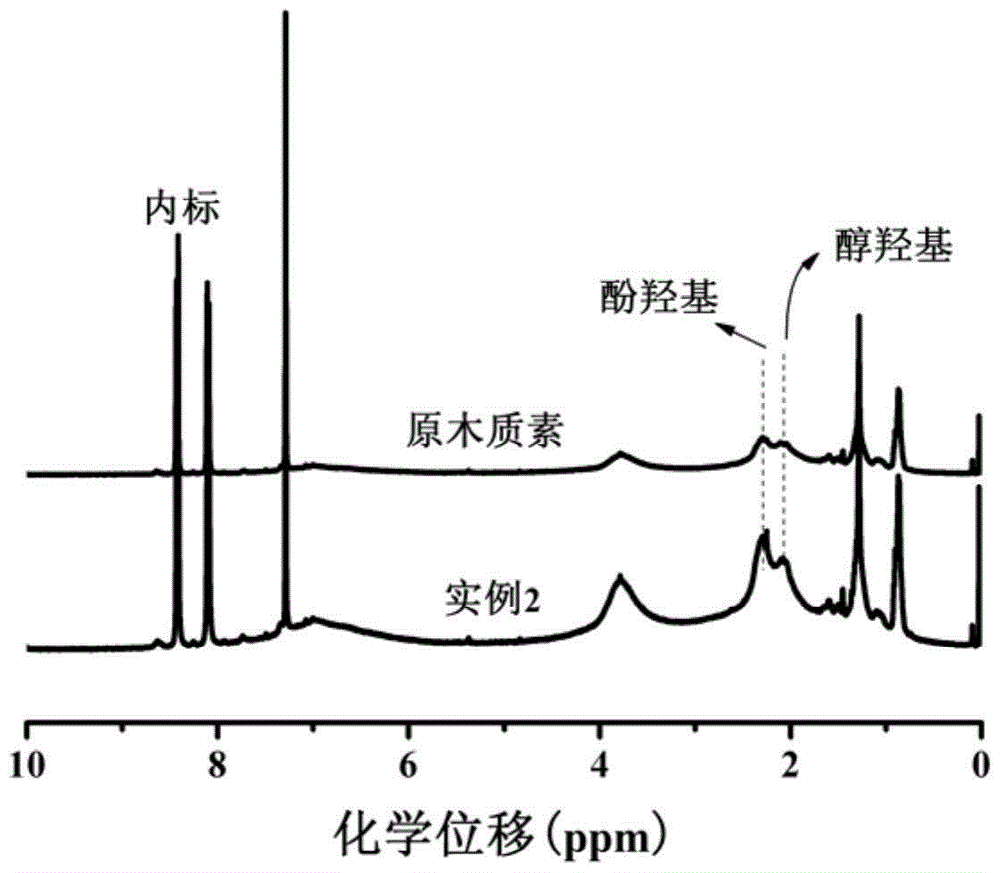

Method for modifying enzymatic hydrolysis lignin by alkali activation

The invention relates to a method for modifying enzymatic hydrolysis lignin by alkali activation. The method comprises the following steps: fully dissolving lignin in alkaline liquor according to mass ratio of enzymatic hydrolysis lignin to a base catalyst to distilled water of1.0:(0.1-2.0):(5.0-10.0); then, pouring the mixture into a hydrothermal reaction kettle; after reaction, adjusting the pH to 1.0 by HCl; and settling, filtering, washing and drying to obtain pure activated enzymatic hydrolysis lignin. According to the method provided by the invention, biomass-refined lignin, namely enzymatic hydrolysis lignin which is wide in source and low in price is selected as the raw material to carry out modification by alkaline activation on the lignin. More active functional groups such as phenolic hydroxyl groups are exposed for the activated lignin, so that the water solubility of the lignin is increased, and meanwhile, the molecular weight is reduced, thereby improving the reaction activity with formaldehyde and replacing phenol in a higher proportion. The method is significant for realizing development and utilization of the lignin which is a huge renewable resource.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

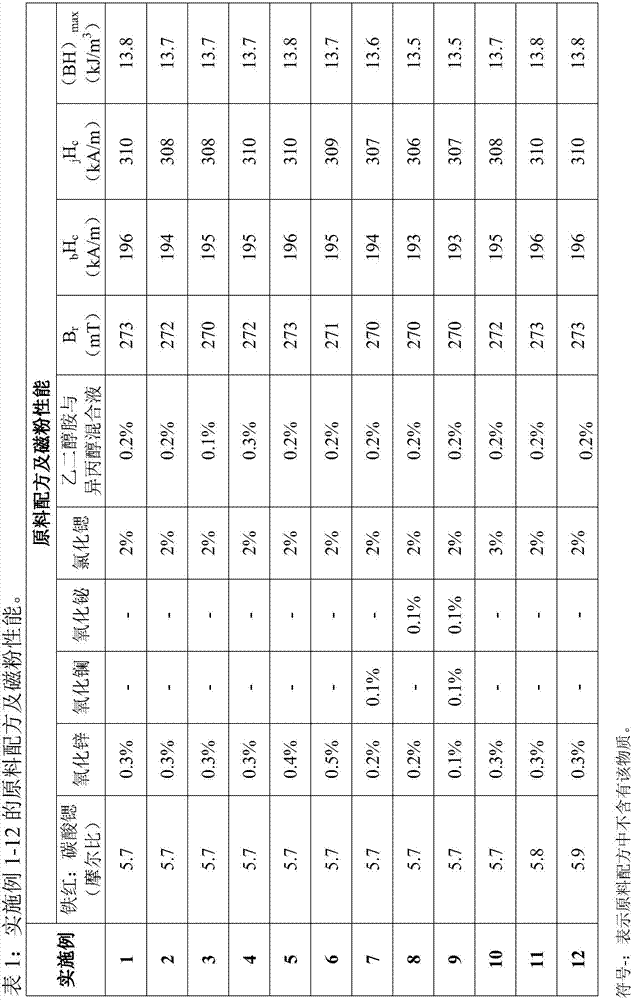

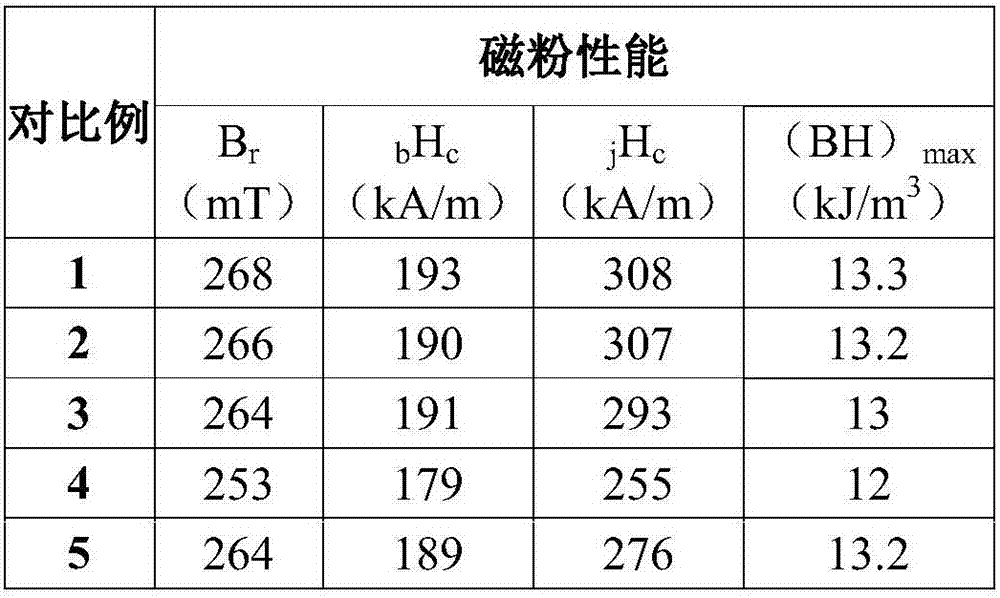

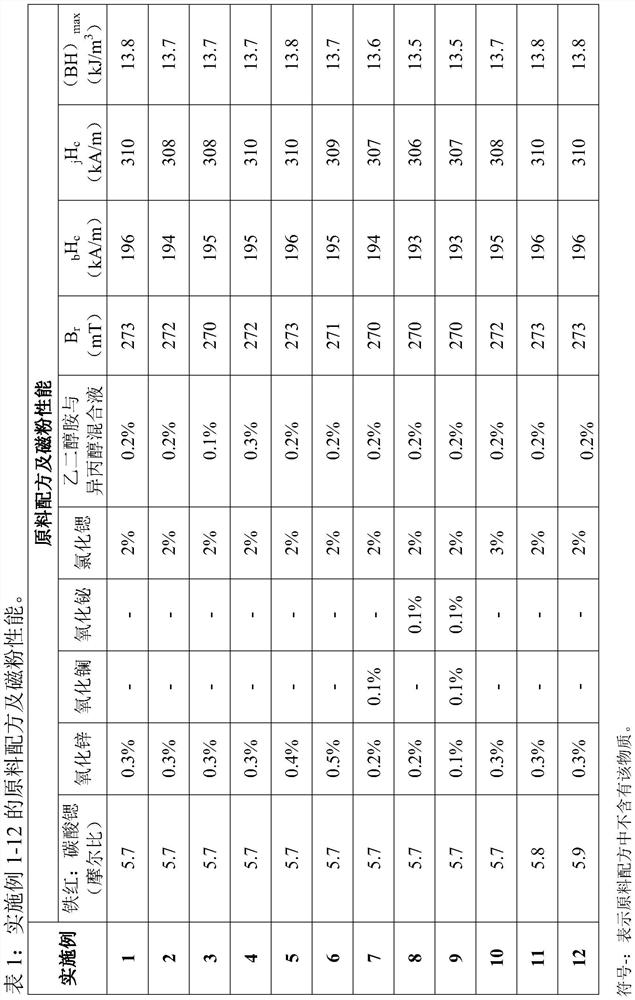

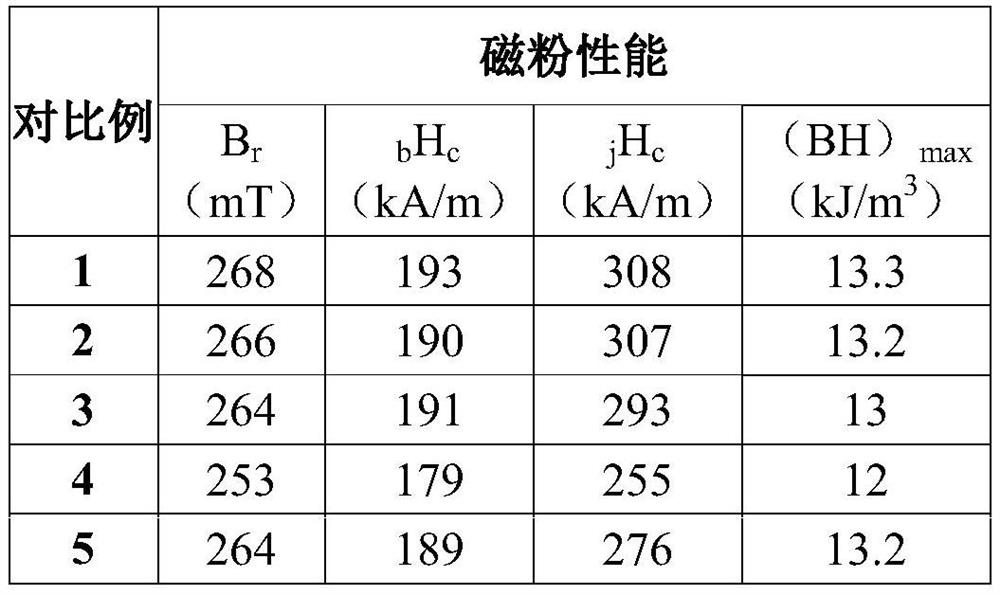

Method for preparing adhesive ferrite magnetic powder

ActiveCN107399964AReduce control difficultyLow raw material costInductances/transformers/magnets manufactureMagnetic materialsIron oxideMagnetic flux

The invention relates to a method for preparing adhesive ferrite magnetic powder. The method comprises the following steps: mixing a strontium-containing compound and / or a barium-containing compound with iron oxide red so as to obtain a mixed material, sintering the mixed material so as to obtain a sintered material, crushing the obtained sintered material, screening with a screening net so as to obtain crude powder, finely grinding the crude powder into slurry so as to obtain fine powder, further uniformly mixing the fine powder with an alcamines mixture so as to obtain ferrite magnetic powder, and finally annealing the obtained ferrite magnetic powder, thereby obtaining the adhesive ferrite magnetic powder. By adopting the method, a process route is shortened (without acid pickling), the purity of raw materials is lowly required (particularly the content of chlorine), the raw materials are relatively widely selected, the production process is low in control difficulty, and the cost is greatly reduced. The adhesive ferrite magnetic powder prepared by using the method is high in magnetism, the residual magnetic flux density of the powder is as high as 273mT, the intrinsic coercive force of the powder is as high as 310kA / m, and the maximum magnetic energy product of the powder is as high as 13.8kJ / m<3>.

Owner:北矿磁材科技有限公司

Tan sheep fattening lamb special nutrition licking brick and preparation method thereof

InactiveCN101606641AChoose from a wide range of sourcesLow priceFood processingAnimal feeding stuffBrickSodium Bentonite

The invention relates to a Tan sheep fattening lamb special nutrition licking brick and a preparation method thereof, and the licking brick is characterized in that each kg of the licking brick comprises the following raw materials: 0.10-0.15g of ferrous sulfate, 0.10-0.15g of zinc sulfate, 0.07-0.10g of copper sulfate, 0.12-0.16g of manganese sulfate, 0.01-0.02g of sodium selenite, 0.05-0.15g of potassium iodide, 0.01-0.03g of cobalt chloride, 0.05-0.15g of magnesium oxide, 2-5g of chromium nicotinate, 30-150g of sodium sulfate, 50-100g of calcium hydrophosphate, 50-250g of extruded corn seed powder, 200-300g of common salt, 200-300g of bentonite and 60-100g of molasses. The preparation method combines the chemical coagulation technology and the mechanical pressing technology, simultaneously targets the characteristics of Tan sheep fattening and develops the nutrition licking brick which supplements mineral nutrition for Tan sheep, thereby fully playing good properties of the Tan sheep. The licking brick is characterized by a wide range of sources for selecting a curing agent, low cost, more comprehensive nutrition, greater density, reasonable feed intake, sustained release of elements, health care, safety, environmental protection and the like, thereby being suitable for raising levels with different feeding methods.

Owner:NINGXIA ACAD OF AGRI & FORESTRY SCI RES INST OF ANIM

Cattle and sheep fattening sustained-release protein licking brick and preparation method thereof

InactiveCN101606642AIncrease proteinEasy to useFood processingAnimal feeding stuffSodium BentoniteBrick

The invention relates to a cattle and sheep fattening sustained-release protein licking brick and a preparation method thereof, and the licking brick is characterized in that each kg of the licking brick comprises the following raw materials: 0.21-0.35g of ferrous sulfate, 0.21-0.35g of zinc sulfate, 0.14-0.21g of copper sulfate, 0.24-0.35g of manganese sulfate, 0.01-0.02g of sodium selenite, 0.07-0.35g of potassium iodide, 0.03-0.07g of cobalt chloride, 1.14-3.35g of magnesium oxide, 35-160g of sodium sulfate, 50-100g of calcium hydrophosphate, 130-310g of extruded corn seed powder, 200-300g of common salt, 200-300g of bentonite, 30-60g of molasses, 50-100g of extruded urea and 3-7g of acetoxy oxolinic acid. The preparation method combines the chemical coagulation technology and the mechanical pressing technology and simultaneously grants the extruded urea, the acetoxy oxolinic acid and other substances in the formula raw materials, so that the licking brick has the advantages of a wide range of sources for selecting a curing agent, low cost, more comprehensive nutrition, greater density, reasonable feed intake, sustained release of elements, health care, safety and environmental protection, thereby being suitable for raising levels with different feeding methods.

Owner:NINGXIA ACAD OF AGRI & FORESTRY SCI RES INST OF ANIM

Compound yak blocks for balancing minerals in warm seasons and preparation process thereof

InactiveCN102669430AAchieving Balanced SupplyChoose from a wide range of sourcesAnimal feeding stuffSodium BentoniteBrick

The invention discloses compound yak blocks for balancing minerals in warm seasons. Each kg of blocks are formed by the following raw materials: 0.3-0..9g of zinc sulfate, 0.3-0.6g of copper sulfate, 0.01-0.02g of sodium selenite, 0.07-0.2g of potassium iodide, 0.04-0.08g of cobalt chloride, 20-40g of magnesium oxide, 3-6g of chromium nicotinate, 50-100g of calcium hydrophosphate, 300-500g of salt, 200-400g of bentonite, 30-60g of cement, 20-100g of limestone and 30-60g of molasses. The invention simultaneously provides a preparation process of the compound yak blocks. The blocks and the preparation process have the following advantages: according to the seasonal characteristics of yak production and seasonal variations of contents and compositions of mineral elements in grass, in combination with compositions and quantities of mineral elements in soil ingested by the yaks, the yak block mineral formula is optimized in real time to realize balanced supply of the mineral elements to the yaks; the chemocoagulation process and the mechanical compaction process are optimally combined; and the products have high density and reasonable feed intake and are suitable for yak mineral element supply in warm seasons.

Owner:NINGXIA UNIVERSITY

Cattle and sheep ultrafine particle feed licking brick and preparation method thereof

InactiveCN101606643AIncrease the areaImprove adsorption capacityFood processingAnimal feeding stuffSodium BentoniteBrick

The invention relates to a cattle and sheep ultrafine particle feed licking brick and a preparation method thereof, and the licking brick is characterized in that each kg of the licking brick comprises the following raw materials: 0.10-0.15g of ferrous sulfate, 0.10-0.15g of zinc sulfate, 0.07-0.10g of copper sulfate, 0.12-0.16g of manganese sulfate, 0.01-0.02g of sodium selenite, 0.05-0.15g of potassium iodide, 0.01-0.03g of cobalt chloride, 0.05-0.15g of magnesium oxide, 2-5g of chromium nicotinate, 30-150g of sodium sulfate, 50-100g of calcium hydrophosphate, 50-250g of extruded corn seed powder, 200-300g of common salt, 200-300g of bentonite and 60-100g of molasses. The substances adopt ultrafine smashing. The preparation method combines the chemical coagulation technology and the mechanical pressing technology and simultaneously carries out the ultrafine smashing treatment on the formula raw materials, so that the licking brick has the advantages of a wide range of sources for selecting a curing agent, low cost, more comprehensive nutrition, greater density, reasonable feed intake, sustained release of elements, health care, safety and environmental protection, thereby being suitable for raising levels with different feeding methods.

Owner:NINGXIA ACAD OF AGRI & FORESTRY SCI RES INST OF ANIM

Method of producing organization engineered cartilage with inner support

InactiveCN101134118AChoose from a wide range of sourcesEasy to get materialsBone implantBiocompatibility TestingTgf beta1

The present invention relates to medical tissue engineering, and is process of preparing tissue engineering cartilage with inner support for use as permanent prosthesis clinically. The process includes the following steps: making inner support with nondegradable stable medical porous high-density polyethylene MEDPOR, coating the inner support with nonwoven net of degradable polyglycolic acid (PGA) with high biocompatibility to form compound MEDPOR-PGA rack, dropping prepared autologous marrow matrix stem cell suspension to the nonwoven PGA net, in vitro culturing to the inducing solution with DMEM cartilage connecting TGF-beta1,IGF-I and insulin for certain time, and implanting to under skin for 4-6 weeks to constitute the tissue engineering cartilage. The present invention makes it possible to prepare clinically essential permanent implant.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

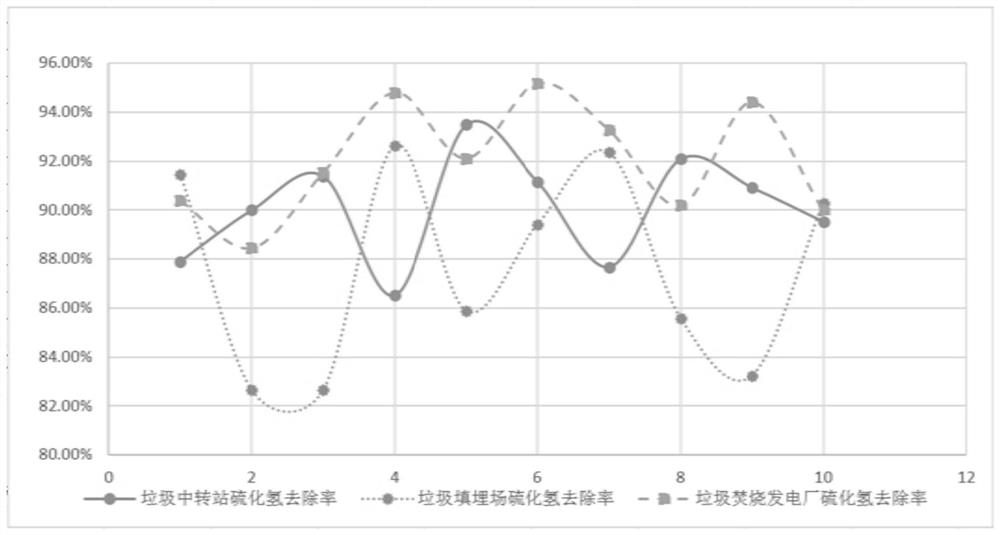

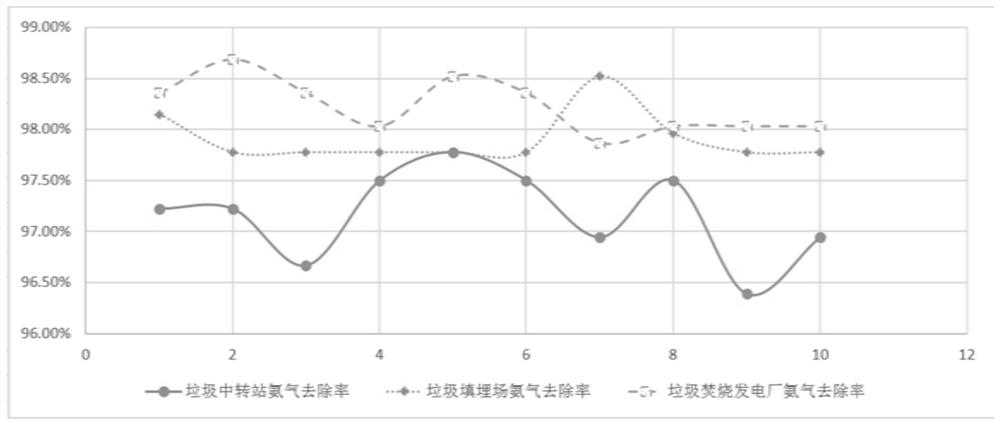

Garbage deodorant and preparation method thereof

InactiveCN111821841ASimple preparation processGood workmanshipSolid waste disposalDispersed particle separationMeth-Active agent

The invention belongs to the technical field of chemical deodorants and preparation thereof, and discloses a garbage deodorant and a preparation method thereof. The garbage deodorant is a colorless and odorless preparation prepared from dimethylolbutyric acid, a sterilizing agent, a surfactant, hydrogenated castor oil, an adsorbent, oleylamine polyoxyethylene ether, lauryl methacrylate and cyclodextrin. Lauryl methacrylate in the preparation has an extremely strong removal effect on hydrogen sulfide and ammonia gas; the sterilizing agent can effectively prevent breeding of harmful microorganisms in the garbage; cyclodextrin can efficiently block volatilization of garbage stink, secondary stink pollution is effectively avoided in the using process, meanwhile, drug stains are prevented fromremaining, the stink source environment is improved, and the stink removing efficiency is improved. The preparation process is simple, the process is convenient, and the synergistic interaction amongvarious raw materials is realized while the effect of each raw material is exerted to a greater extent. The finished product is simple to prepare and wide in raw material selection source.

Owner:武汉世纪瑞科环保科技有限公司

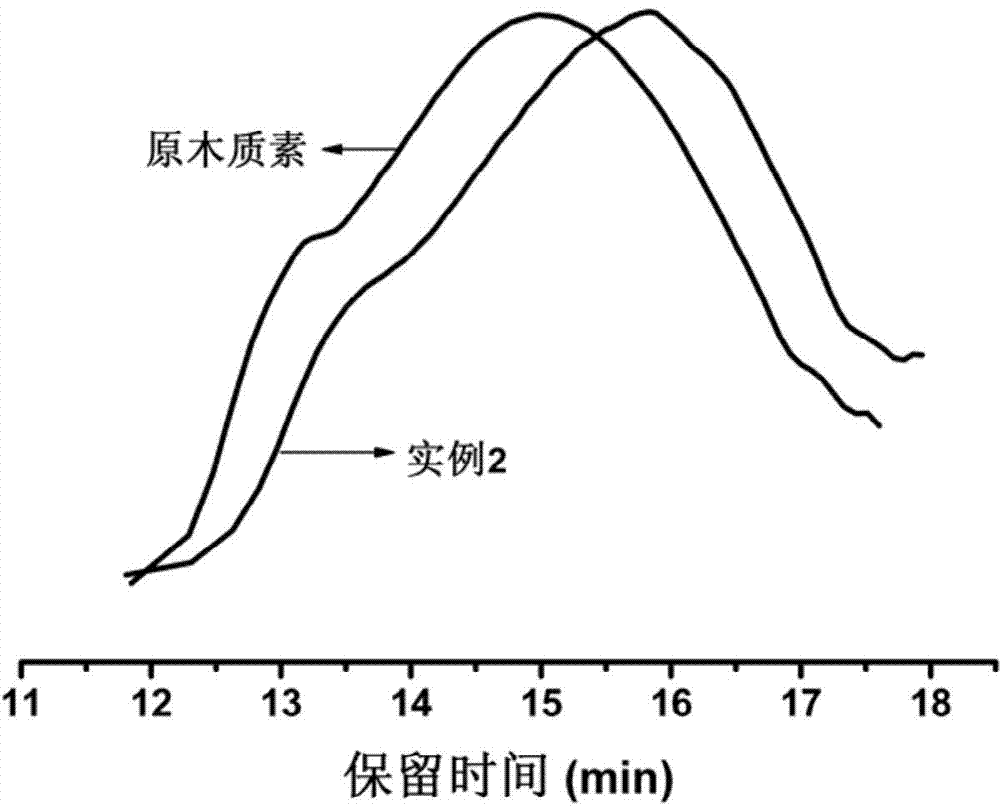

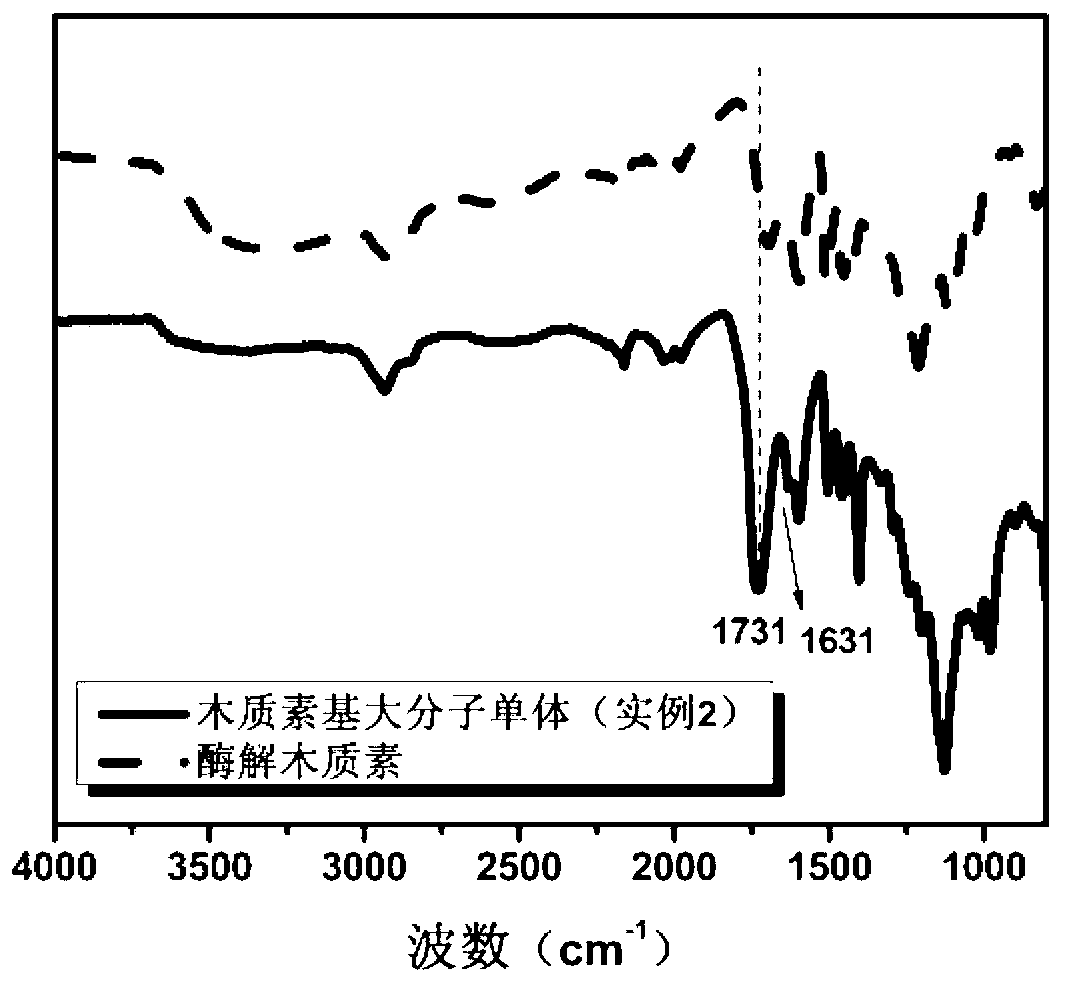

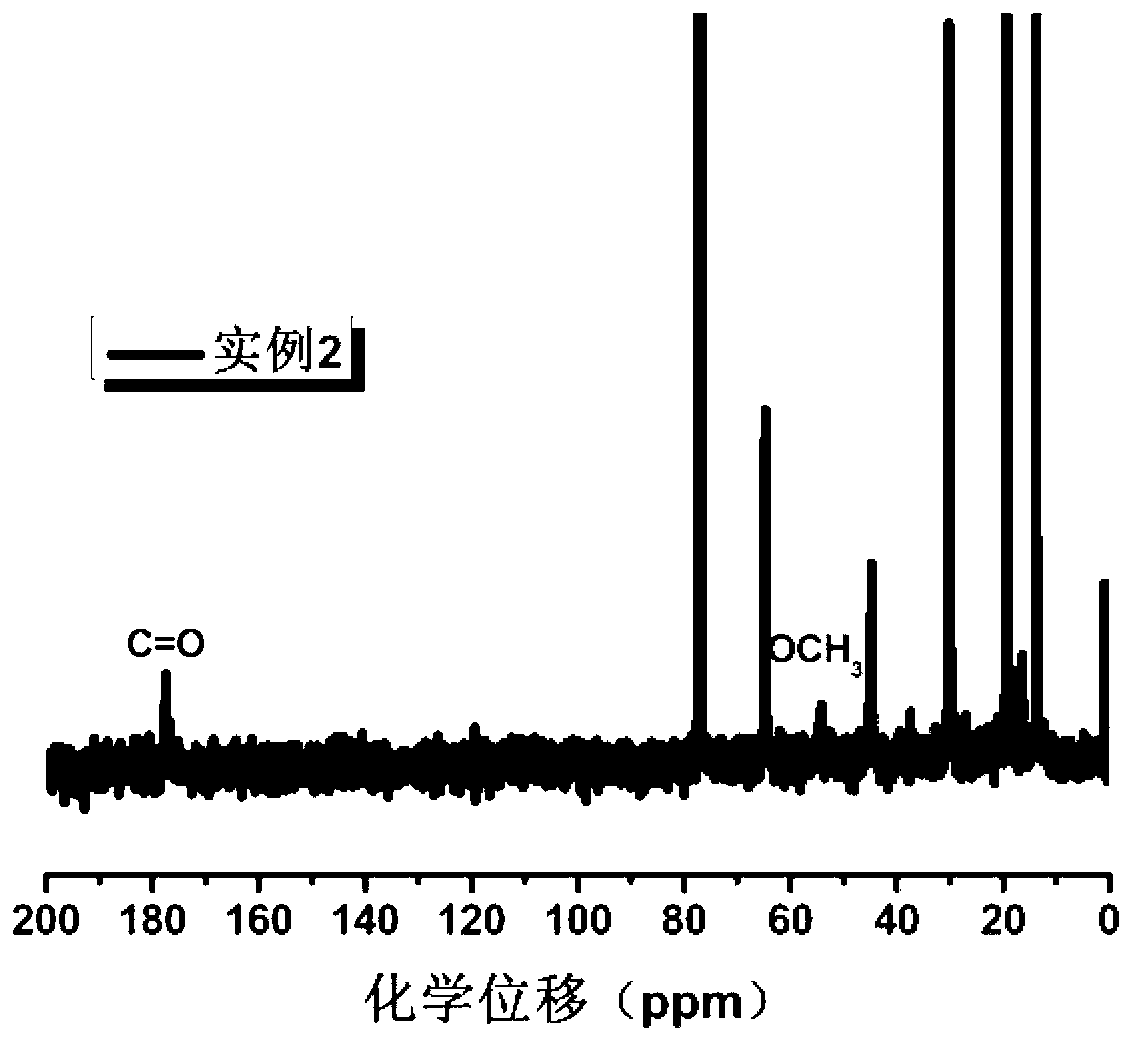

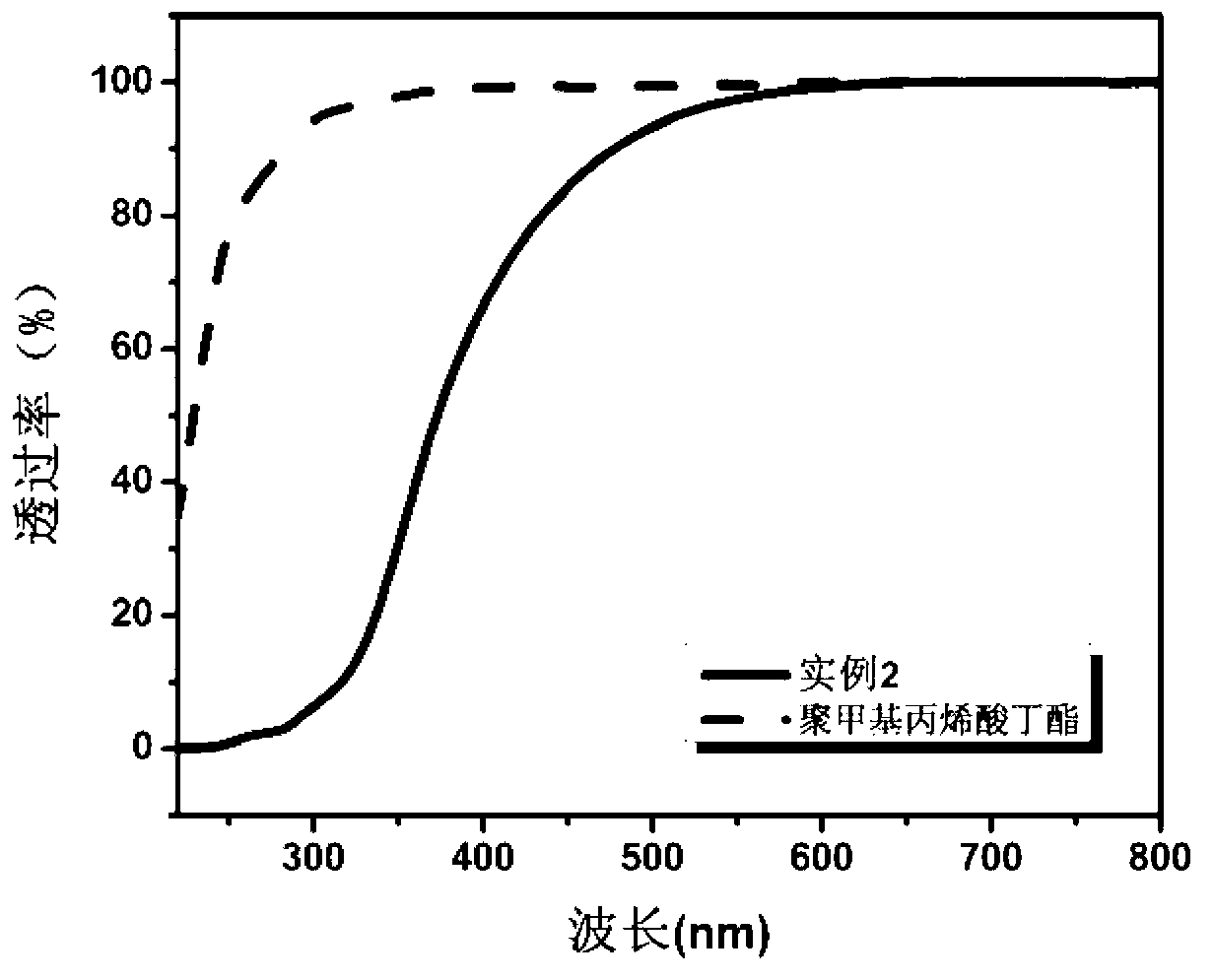

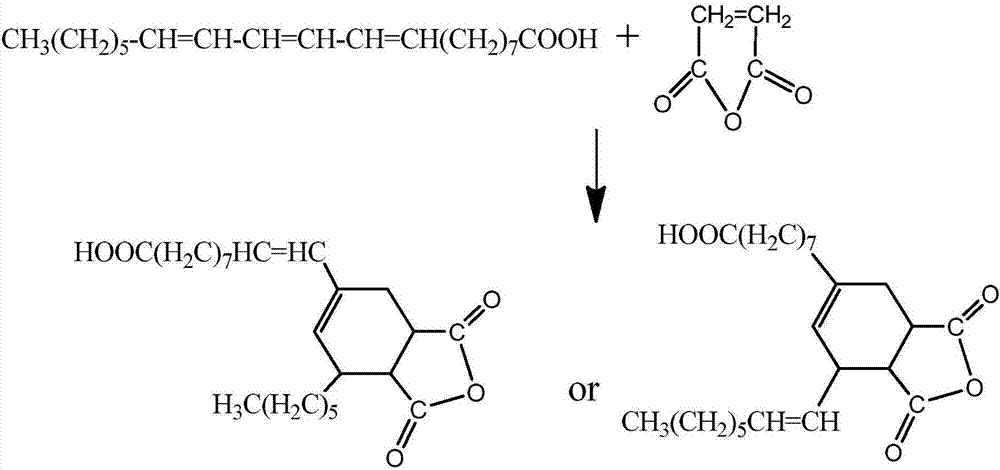

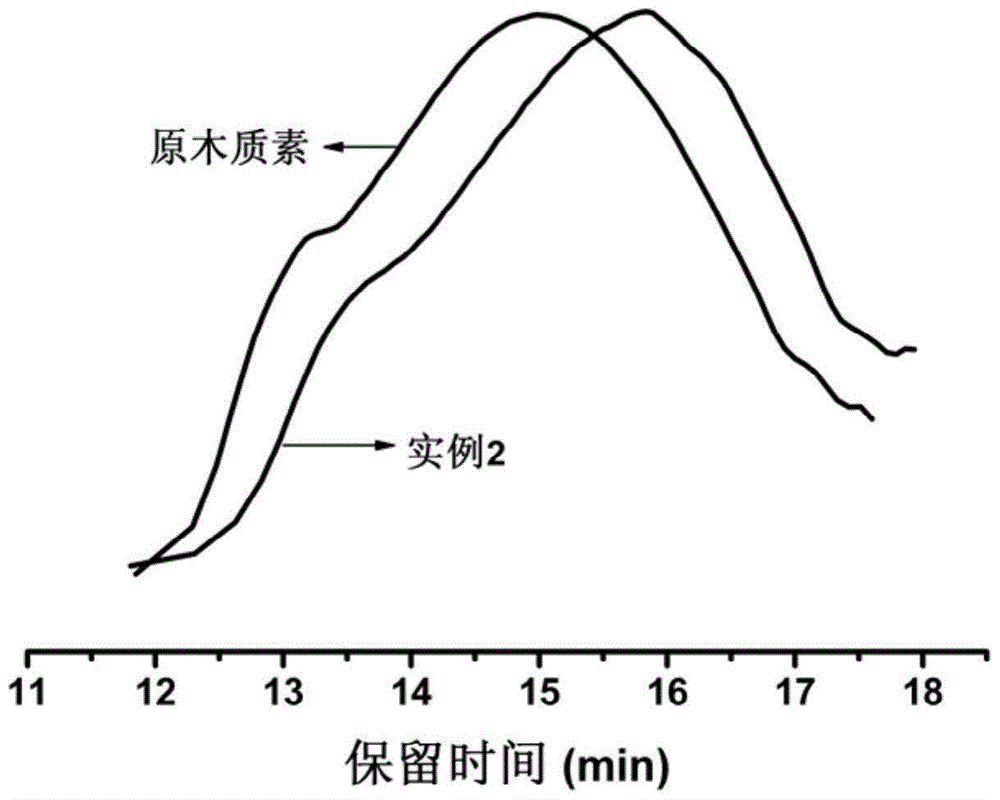

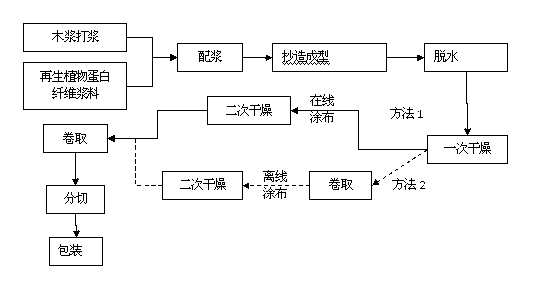

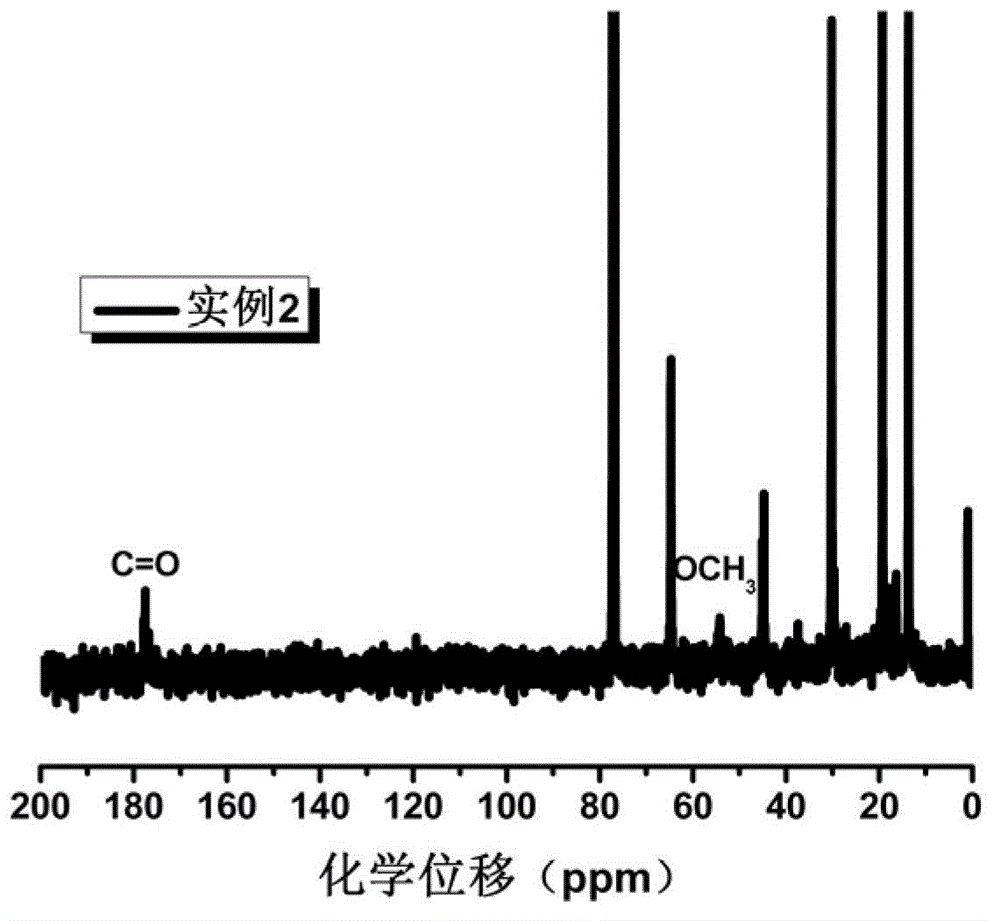

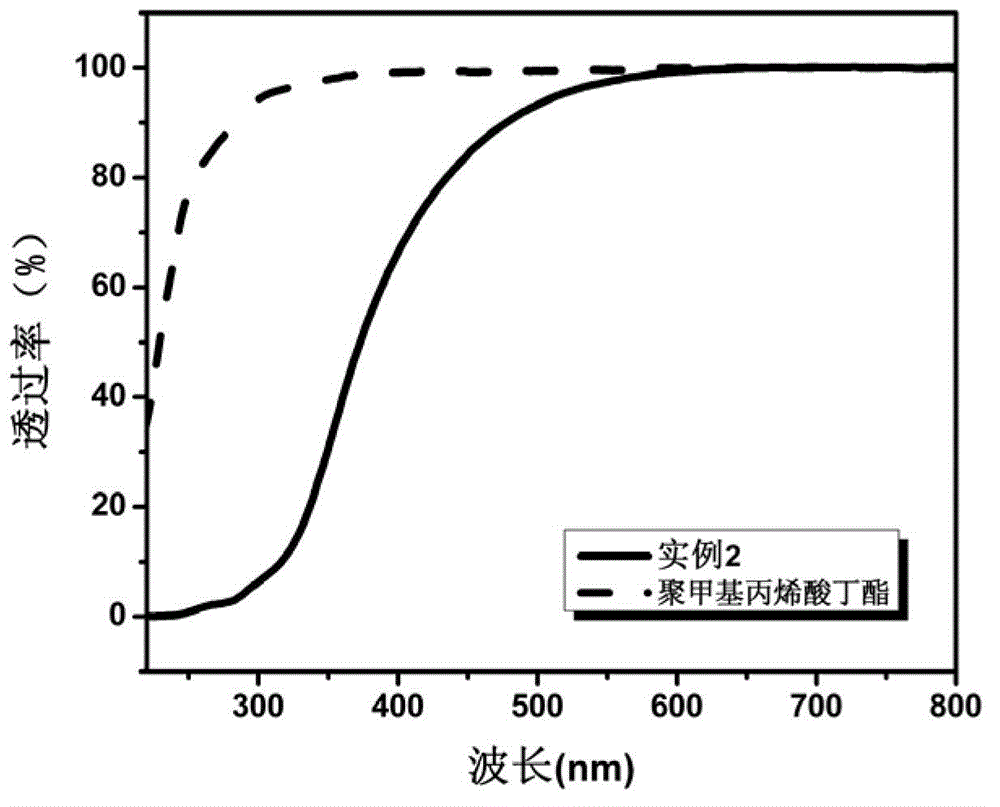

Method of preparing transparent ultraviolet absorption membrane material from enzymatic hydrolysis lignin

The invention relates to a method of preparing a transparent ultraviolet absorption membrane material from enzymatic hydrolysis lignin. The method comprises the following steps: subjecting lignin to graft modification so as to obtain a lignin-based macro-monomer; dissolving the lignin-based macro-monomer, an acrylic acid monomer and an initiator for free radical polymerization in an organic solvent, introducing nitrogen to remove oxygen and carrying out a reaction at a temperature of 50 to 100 DEG C for 6 to 24 h; and subjecting a polymer to precipitation in n-hexane with a temperature of 30 to 60 DEG C and carrying out filtering and drying so as to obtain the ultraviolet absorption membrane material. According to the invention, a lignin aromatic ring structure is genuinely introduced into a polymer structure, and the synthesized polymer lignin-based membrane material has the advantages of high transparency, excellent hardness, thermal stability and ultraviolet light absorption performance and can be widely applied in fields like functional uvioresistant paints.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Three-dimensional net rack bamboo filament wall

The invention provides a three-dimensional net rack bamboo filament wall, which is formed by a base material and a three-dimensional net rack buried in the base material, wherein the base material is prepared from the following materials in parts by weight: 10 to 15 parts of bamboo filaments, 4 to 6 parts of cements, 1 to 3 parts of perlites, 0.01 to 0.03 part of adhesion agent and 0.2 to 0.6 part of functional auxiliary material. The three-dimensional net rack bamboo filament wall provided by the invention adopts the bamboo filaments with wide sources, long fibers, good flexibility and small decomposing possibility as a main raw material, and utilizes the characteristic that the bamboo filament fibers are uniformly dispersed to interweave a spider web, so that the compactness of the wall can be improved; in addition, various functional components are matched, so that under the regulation of a three-dimensional net rack structure, the prepared wall has the excellent characteristics of heat insulation, fire and water resistance, shock and crack resistance, corrosion resistance and sound insulation, striking resistance, wear resistance, ageing resistance, high strength and light weight.

Owner:广东晶盈环保建材实业有限公司

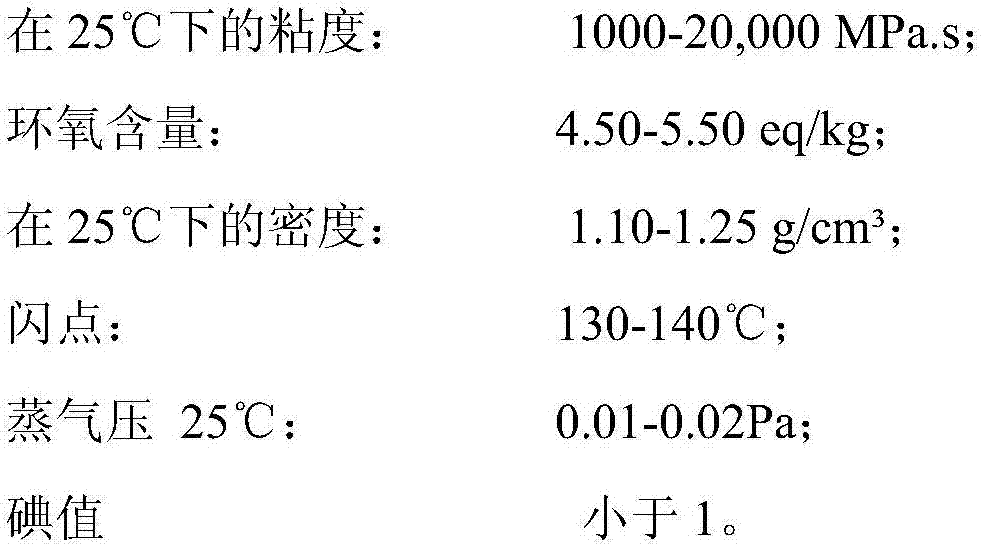

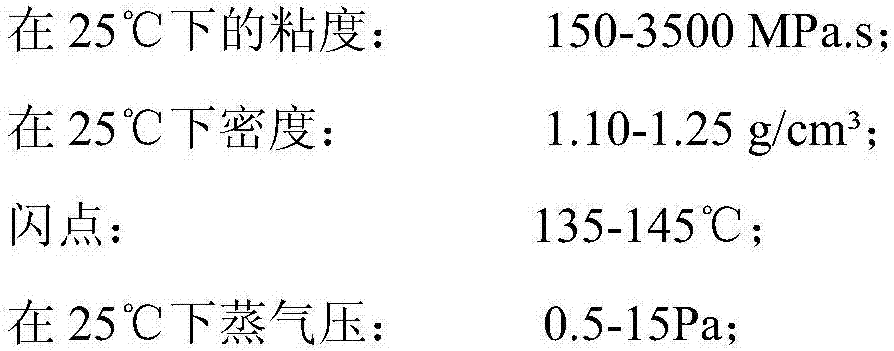

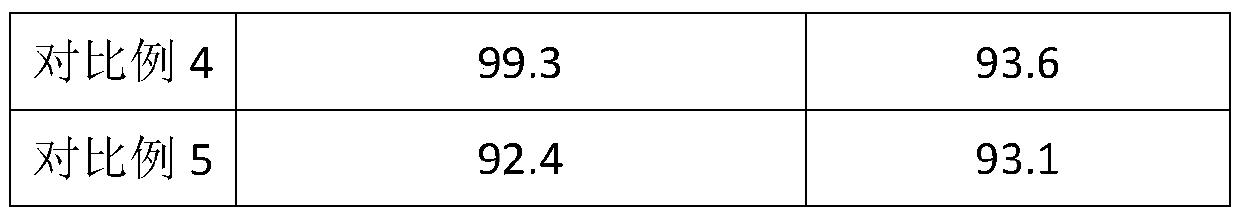

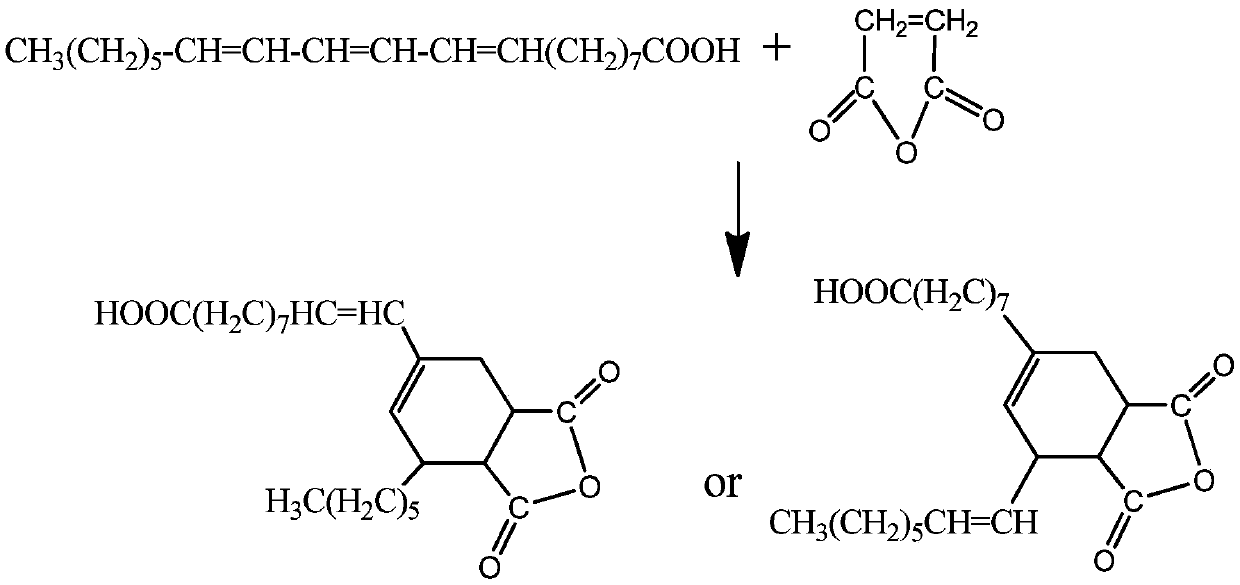

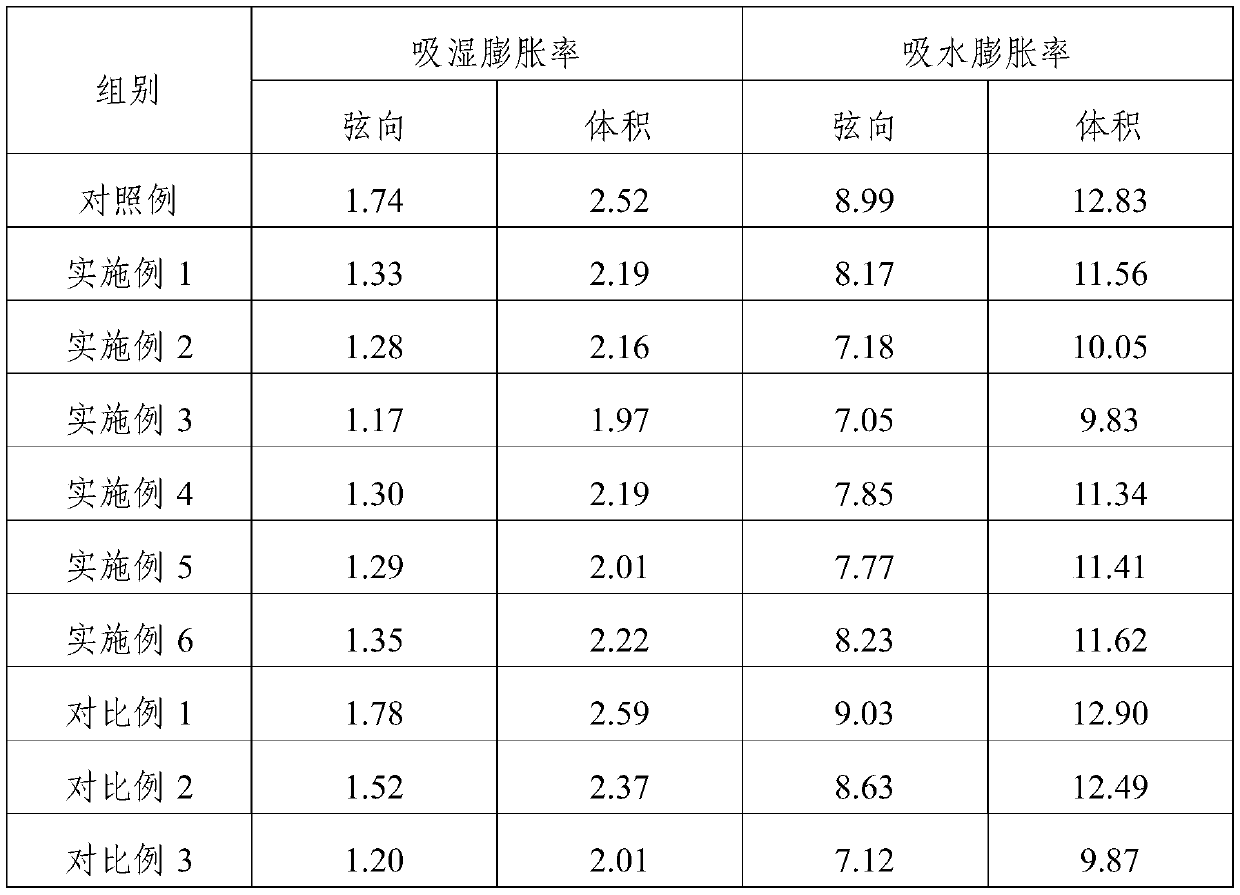

Epoxy system for bio-based electric insulation and preparation method of epoxy system

The invention discloses an epoxy system for bio-based electric insulation and a preparation method of the epoxy system. Vegetable oil modified epoxy resin and an anhydride curing agent containing one or more groups of an epoxy group, a hydroxyl group, a carboxyl group and a phenolic hydroxyl group are used respectively to prepare the epoxy system for bio-based electric insulation with low cost, good product stability, wide application range, simple technology, no pollution, no wastewater, excellent mechanical properties, improved glass transition temperature and good crack resistance.

Owner:广州仑利奇合成树脂有限公司

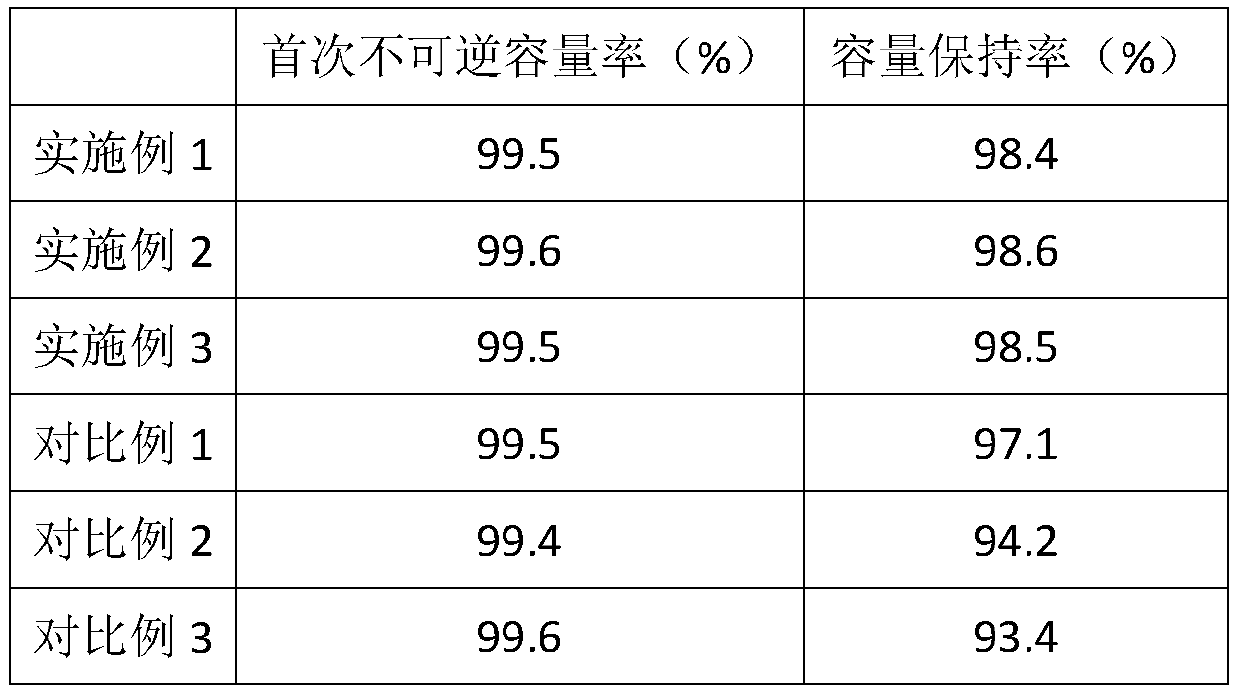

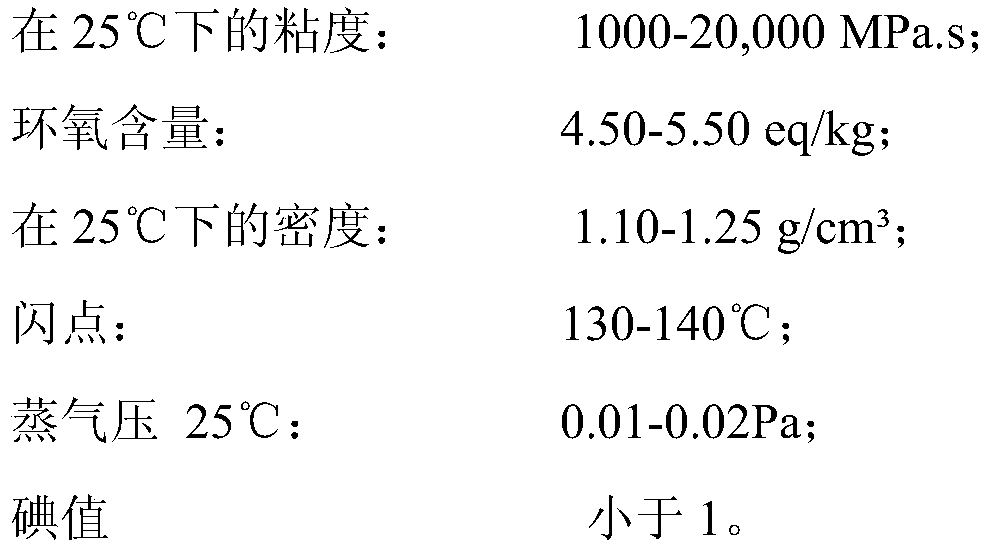

Preparation method of lithium secondary battery

InactiveCN111370771AImprove cycle performanceReduce manufacturing costFinal product manufactureElectrolyte accumulators manufactureElectrolytic agentLithium sulphate

The invention provides a preparation method of a lithium secondary battery. The lithium secondary battery comprises a positive electrode and a negative electrode; an active substance of the positive electrode is LiNi < 0.15 > Co < 0.35 > Mn < 0.5 > O < 2 >; an active substance of the negative electrode is carbon-coated silicon particles, the preparation method comprises the following steps: placing the positive electrode and the negative electrode in a first electrolyte for pre-formation, wherein the first electrolyte contains saturated lithium carbonate and saturated lithium sulfite as additives; obtaining the battery. According to the invention, an SEI film is formed on the surface of an electrode through a pre-formation process; the electrolyte used in the pre-formation is not the electrolyte of the finished battery; therefore, the influence of the additive on the later performance of the battery does not need to be considered, the selection source of the additive is wider, and lithium ions are not obtained from the battery electrolyte when the SEI film is formed, so that the irreversible capacity is not reduced, the obtained battery has better cycle performance, and the production cost is lower.

Owner:朱虎

A kind of epoxy system for bio-based electrical insulation and preparation method thereof

The invention discloses an epoxy system for bio-based electric insulation and a preparation method of the epoxy system. Vegetable oil modified epoxy resin and an anhydride curing agent containing one or more groups of an epoxy group, a hydroxyl group, a carboxyl group and a phenolic hydroxyl group are used respectively to prepare the epoxy system for bio-based electric insulation with low cost, good product stability, wide application range, simple technology, no pollution, no wastewater, excellent mechanical properties, improved glass transition temperature and good crack resistance.

Owner:广州仑利奇合成树脂有限公司

A method for modifying wood based on alkali lignin composite heat treatment

InactiveCN107972144BChoose from a wide range of sourcesWide variety of sourcesWood treatment detailsThermal wood treatmentPulp and paper industryHeat treating

The invention relates to a method for preparing modified wood by compounding heat treatment based on alkali lignin. The method comprises the following steps: (1) soaking the wood treated in vacuum ina 1,4-dioxane solution with alkali lignin, adjusting the pressure to 0.2-0.8MPa and retaining the pressure for 50-90 minutes; and (2) taking the wood soaked in the step (1) out, drying the wood, putting the wood under the condition at the temperature of 120-200 DEG C, and carrying out heat treatment for 1.5-4 hours to obtain the modified wood. The method is used as a non-toxic and long-acting woodmodification manner with low cost and simple process; the modified wood with high water resistance and high size stability is prepared by compounding a heat treatment method; the defects of high possibility of cracking and high possibility of deformation of the fast-growing wood can be effectively overcome; the bottleneck problem of utilization of the fast-growing wood at present can be solved.

Owner:BEIJING FORESTRY UNIVERSITY

A kind of production method of transparent leather

ActiveCN111455118BEasy to operateChoose from a wide range of sourcesPre-tanning chemical treatmentSpecial leather manufactureActive agentSurface-active agents

The production process of the transparent leather disclosed by the present invention is divided into four steps: 1. The bare leather after deliming and softening is fully washed with water until the total ash content is less than 0.5%, and then drummed for 30 minutes, and weighed as the following operation material reference; 2. Dissolve multifunctional amphiphilic substances such as surfactant or leather fatliquoring agent with appropriate amount of water and add them to the drum, then cast the skin and rotate for at least 30 minutes; 3. Dissolve or dilute the acid or alkali with appropriate amount of water and add to the drum gradually , rotate the drum for at least 10 minutes after each addition, and continue to rotate for at least 15 minutes after adding all acids or alkalis, and control the pH value of the bath solution to 3.5‑5.5 or 9.5‑11.5; 4. Stretch the plate when it is not higher than 35 °C After drying, the production of transparent leather is completed. The equipment and materials used in the method disclosed by the invention are widely used by tanning enterprises, and the material type, dosage and processing parameters can be adjusted according to product requirements, and the method has strong practicability. At the same time, during the production process, the bare leather no longer undergoes violent expansion, and there will be no production accidents of rotten leather. The operation is simple and the risk is small.

Owner:SICHUAN UNIV

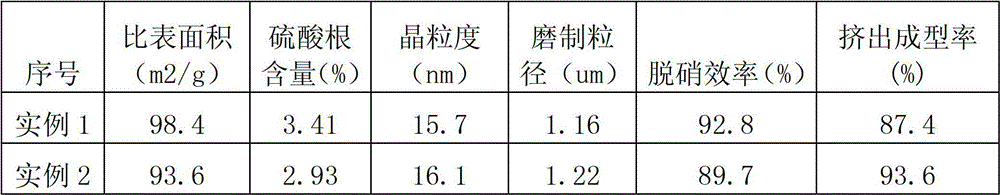

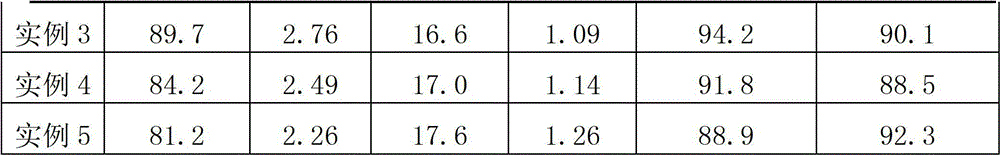

Preparation method of special titanium-tungsten powder for SCR (selective catalytic reduction) denitrification catalyst

InactiveCN102764662BChoose from a wide range of sourcesLow pricePhysical/chemical process catalystsDispersed particle separationInorganic ChemicalFiltration

The invention provides a preparation method of special titanium-tungsten powder for an SCR (selective catalytic reduction) denitrification catalyst, and relates to the field of the preparation of an inorganic chemical material. The preparation method comprises the following process steps: by using intermediate metatitanic acid in the preparation of titanium white through a sulfuric acid method as the raw material, beating, dispersing, performing pressure filtration, dicing, calcining, and crushing to obtain the high-quality nano titanium-tungsten powder. Compared with the prior art, the invention has the following beneficial effects: an SCR denitrification catalyst prepared from the titanium-tungsten powder is more suitable for strict flue gas conditions in China; and for flue gas characteristics of thermal power plants in China, the SCR denitrification catalyst has higher applicability and higher denitrification efficiency. Meanwhile, the titanium-tungsten powder production process is reliable, the product quality is stable, the cost is relatively low, and the manufacturing cost of the denitrification catalyst is greatly reduced.

Owner:CHONGQING PUYUAN CHEM IND

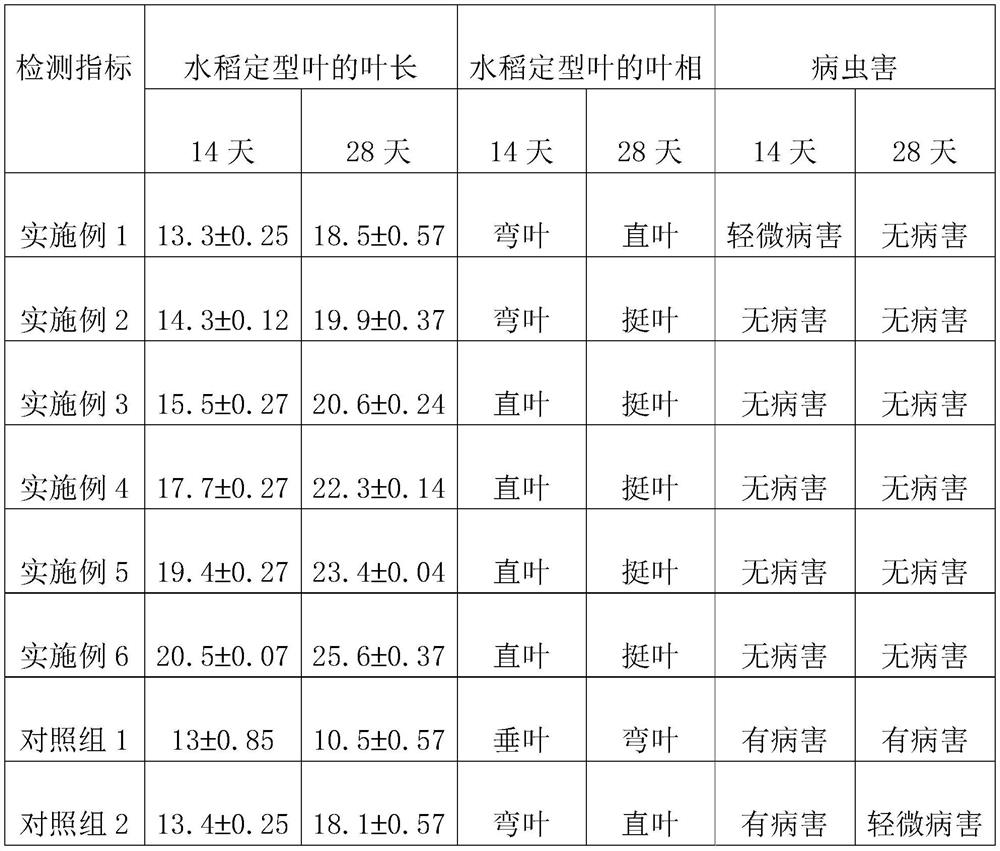

Pest-resistant traditional Chinese medicine preparation and preparation method thereof

InactiveCN111820247ASimple processEasy source selectionBiocidePest repellentsBiotechnologyInsect pest

The invention belongs to the technical field of traditional Chinese medicine inhibitors and preparation thereof, and discloses a traditional Chinese medicine preparation for resisting diseases and insect pests and a preparation method thereof. According to the traditional Chinese medicine preparation, artemisia apiacea, nerium oleander, pinellia ternate, rhizoma alismatis, celastrus angulatus, castor oil plants, ailanthus altissima leaves, purslane, prunella vulgaris, cortex dictamni, ligusticum wallichii, golden cypress, Chinese pulsatilla roots, dandelions, duchesnea indica, rumex japonicus,sanguisorba officinalis roots, hairyvein agrimony, pine needles, sargentgloryvine stems, xanthium sibiricum, camellia oleifera, achyranthes roots, aster, basil, cassia seeds and garden balsam stems are selected to prepare the traditional Chinese medicine preparation. The invention ensures that the nutrient components among the raw materials are more comprehensive and satisfies the requirements ofcrops for the diversity of nutrient elements; various nutrient elements contained in the traditional Chinese medicine preparation can also be quickly absorbed and utilized by crops, so that the growth is accelerated, and the damage is reduced; and the synergistic effect of the effective components has a good inhibition effect on diseases and insect pests. The preparation method is simple in process, convenient in process, simple in configuration, wide in raw material selection source, free of by-products, economical and environment-friendly, and maximization of raw material utilization is realized.

Owner:安徽朗宜百草生物工程有限公司

A kind of preparation method of bonded ferrite magnetic powder

ActiveCN107399964BLow purity requirementNo high chlorine content requirementInductances/transformers/magnets manufactureMagnetic materialsAlcoholStrontium

Owner:北矿磁材科技有限公司

A method for alkali-activated modified enzymatic lignin

InactiveCN103483597BChoose from a wide range of sourcesGood water solubilityPtru catalystDistilled water

A method for alkali-activated modified enzymatic lignin, according to the mass ratio of enzymatic lignin: alkali catalyst: distilled water is 1.0: (0.1-2.0): (5.0-10.0), lignin is completely dissolved in alkaline solution, and then pour it into a hydrothermal reaction kettle. After the reaction is completed, adjust the pH to 1.0 with HCl, precipitate, filter, wash and dry to obtain pure activated enzymatic lignin. The present invention selects biomass refined lignin with low price, i.e. enzymatic lignin, as a raw material, and performs alkali activation modification on it, and the activated lignin will expose more active functional groups such as phenolic hydroxyl groups, increasing its water solubility. sex. At the same time, the molecular weight is reduced, which is conducive to improving the reactivity with formaldehyde and replacing phenol with a higher proportion. It is of great significance to realize the development and utilization of lignin, a huge renewable resource.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

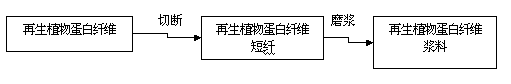

Specialty paper containing regenerated plant protein fiber for filling filter rod of cigarette

ActiveCN102154950BChoose from a wide range of sourcesWide variety of sourcesNon-fibrous pulp additionSpecial paperFiberPapermaking

The invention discloses a cigarette filter stick filling specific paper containing regenerative protein based fiber and a preparation method thereof. The specialty paper contains 10-100% of regenerative protein based fiber, 0-60% of hard wood pulp fiber, and 0-90% of soft wood pulp fiber. The preparation method of the specialty paper comprises the following steps: cutting the regenerative protein based fiber into 0.5-5.0mm, and grinding into pulp to obtain the pulp of the regenerative protein based fiber; evenly mixing and blending the pulp of the regenerative protein based fiber with one or several of the regenerative protein based fiber and the soft wood pulp fiber which are respectively prepared in a pulp blending pool; papermaking and shaping by a paper machine; after dehydration and one-time drying, coating the functional accessory ingredient on the paper surface according to 1.0-10wt% of dry paper; and obtaining the specialty paper containing regenerative protein based fiber after secondary drying. The functional accessory ingredient is one or more of a macromolecule material of a water-soluble derivate or a tobacco leaf extract or tobacco sweet. According to the invention, the use ratio of fiber material is improved, paper quality is improved, influence on the taste of cigarettes is lightened, and the specialty paper is easy to degrade.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

High-energy composite licking brick for cattle and sheep and its preparing process

InactiveCN1290430CChoose from a wide range of sourcesLow priceAnimal feeding stuffBiotechnologyAnimal science

The present invention provides a high-energy compound type licking brick for cattle and sheep and its preparation process. Every kg of licking brick contains 0.15-0.3g of ferrous sulfate, 0.15-0.3g of zinc sulfate, 0.1-0.2g of copper sulfate, 0.2-0.3g of manganese sulfate, 0.01-0.02g of sodium selenite, 0.05-0.3g of potassium iodide, 0.03-0.08g of cobaltous chloride, 0.1-0.3g of magnesium oxide, 0.03-0.03g of nano zinc oxide and copper sulfate mixture, 30-120g of sodium sulfate, 40-80g of calcium hydrogen phosphate, 50-200g of carrier, 150-300g of edible salt, 200-300g of solidifying agent, 80-150g of treacle and 150-300g of high-energy lipoid powder.

Owner:NINGXIA ACAD OF AGRI & FORESTRY SCI RES INST OF ANIM

Method of preparing transparent ultraviolet absorption membrane material from enzymatic hydrolysis lignin

The invention relates to a method of preparing a transparent ultraviolet absorption membrane material from enzymatic hydrolysis lignin. The method comprises the following steps: subjecting lignin to graft modification so as to obtain a lignin-based macro-monomer; dissolving the lignin-based macro-monomer, an acrylic acid monomer and an initiator for free radical polymerization in an organic solvent, introducing nitrogen to remove oxygen and carrying out a reaction at a temperature of 50 to 100 DEG C for 6 to 24 h; and subjecting a polymer to precipitation in n-hexane with a temperature of 30 to 60 DEG C and carrying out filtering and drying so as to obtain the ultraviolet absorption membrane material. According to the invention, a lignin aromatic ring structure is genuinely introduced into a polymer structure, and the synthesized polymer lignin-based membrane material has the advantages of high transparency, excellent hardness, thermal stability and ultraviolet light absorption performance and can be widely applied in fields like functional uvioresistant paints.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

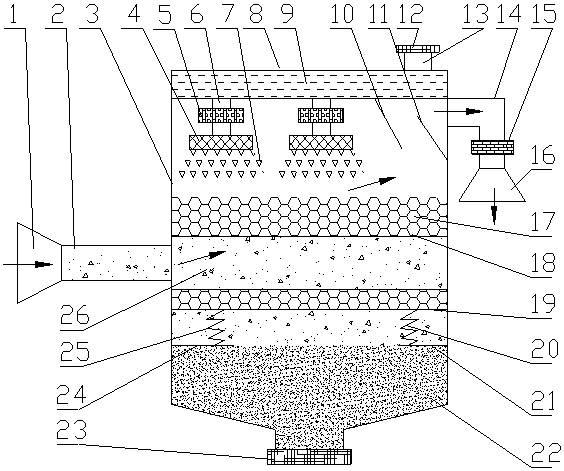

Automobile exhaust purification treatment emission device

ActiveCN105909346BChoose from a wide range of sourcesWide variety of sourcesExhaust apparatusSilencing apparatusElectric controlPollution

The invention discloses an automobile exhaust purification and emission device. The automobile exhaust purification and emission device comprises a shell, an intake pipe and a vent pipe, wherein the intake pipe and the vent pipe are arranged at two ends of the shell; a purification particle is arranged above the intake pipe in the shell; a ventilation pipeline is embedded in the purification particle; a treating fluid containing cavity is formed in the top end of the shell; the lower end of the treating fluid containing cavity is connected with a spray head which is controlled by an electric control component; the electric control component is connected with a sensor in the shell; a solid waste containing cavity is formed in the inner lower end of the shell. The automobile exhaust purification and emission device is simple in structure, good in purification effect, easy to produce, low in production cost and convenient to mount and maintain, and has the effects of decreasing the influences, caused by the automobile exhaust emissions, on the air, collecting the generated waste so as to avoid secondary pollution, not causing influences to the normal running of automobiles, and conveniently mounting and reforming the produced and used automobiles.

Owner:山东泰克生态环境有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com