Preparation method of special titanium-tungsten powder for SCR (selective catalytic reduction) denitrification catalyst

A technology of denitrification catalyst and titanium tungsten powder, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems that restrict the development of denitrification environmental protection industry, the catalyst is not acclimatized, and the coal quality is uneven, so as to promote the industry. The effects of upgrading, broadening the industrial chain, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

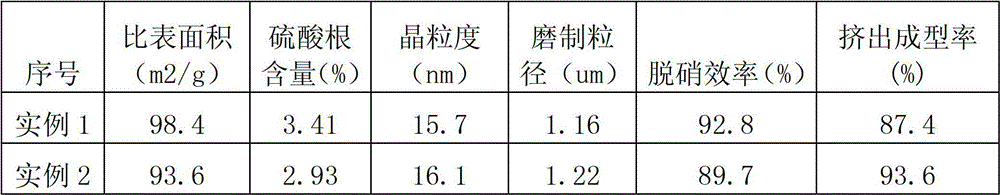

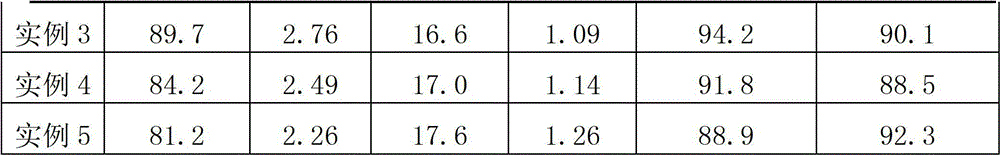

Embodiment 1

[0027] Weigh 10kg metatitanic acid (equivalent to TiO 2 In total, the raw material TiO 2 The content is about 28%), placed in a reactor equipped with a stirrer, and about 31kg of deionized water was added to make the slurry TiO 2 The content is about 15%, stir for 1 hour; add ammonia water to the slurry to adjust the pH value to 6, heat the slurry to 80°C with steam, keep warm and stir for 2 hours, and add ammonia water in an appropriate amount to maintain the pH of the slurry at 6; weigh 0.58kg Ammonium metatungstate (WO in ammonium metatungstate 3 content of about 91%) was dissolved in 5kg of hot deionized water at a temperature of 80°C, and stirred for 1 hour with a stirrer; the prepared ammonium metatungstate solution was added to the aforementioned metatitanic acid slurry with a pH value of 6 and fully dispersed, Stir for 1 hour; press filter the slurry to a massive filter cake with a solid content of about 40%; chop the filter cake into small pieces and calcinate it fo...

Embodiment 2

[0029] Weigh 10kg metatitanic acid (equivalent to TiO 2 In total, the raw material TiO 2 The content is about 28%), placed in a reactor equipped with a stirrer, and about 65kg of deionized water was added to make the slurry TiO 2 The content is about 10%, stir for 1 hour; add ammonia water to the slurry to adjust the pH value to 7, heat the slurry to 85°C with steam, keep warm and stir for 2 hours, and add ammonia water in an appropriate amount to maintain the pH value of the slurry at 7; weigh 0.58kg Ammonium metatungstate (WO in ammonium metatungstate 3 content of about 91%) was dissolved in 5 kg of hot deionized water at a temperature of 80°C, and stirred for 1 hour with a stirrer; the prepared ammonium metatungstate solution was added to the aforementioned metatitanic acid slurry with a pH value of 7 and fully dispersed, Stir for 1 hour; press filter the slurry to a cake with a solid content of about 45%; chop the filter cake into small pieces and calcinate it for 2 hour...

Embodiment 3

[0031] Weigh 10kg metatitanic acid (equivalent to TiO 2 In total, the raw material TiO 2 The content is about 28%), placed in a reactor equipped with a stirrer, and about 65kg of deionized water was added to make the slurry TiO 2 The content is about 10%, stir for 1 hour; add ammonium bicarbonate to the slurry to adjust the pH value to 7, heat the slurry to 80°C with steam, keep it warm and stir for 2 hours, and at the same time add an appropriate amount of ammonium bicarbonate to maintain the pH of the slurry at 7; Weigh 0.58kg ammonium metatungstate (WO in ammonium metatungstate 3 content of about 91%) was dissolved in 5kg of hot deionized water at a temperature of 85°C, and stirred for 1 hour with a stirrer; the prepared ammonium metatungstate solution was added to the aforementioned metatitanic acid slurry with a pH value of 7 and fully dispersed, Stir for 1 hour; press filter the slurry to a massive filter cake with a solid content of about 45%; chop the filter cake int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com