Method for preparing modified wood by compounding heat treatment based on alkali lignin

A composite heat treatment and alkali lignin technology, which is applied in the field of modified wood based on alkali lignin composite heat treatment, can solve the problems of low activity and limitation of alkali lignin, and achieve the effects of increasing added value, low cost and slowing down water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

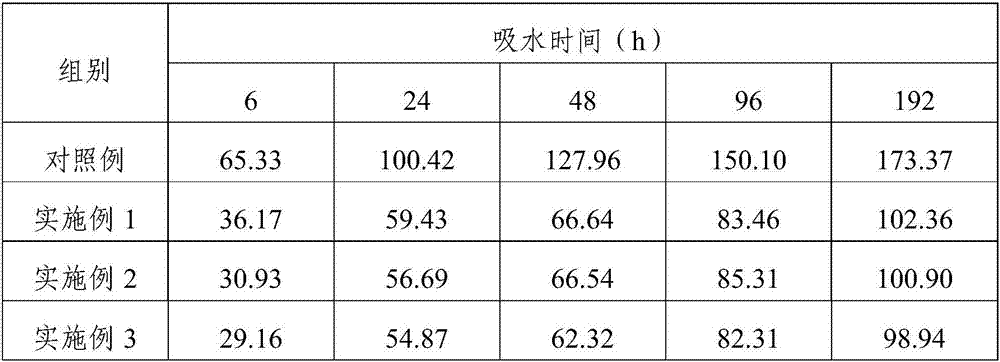

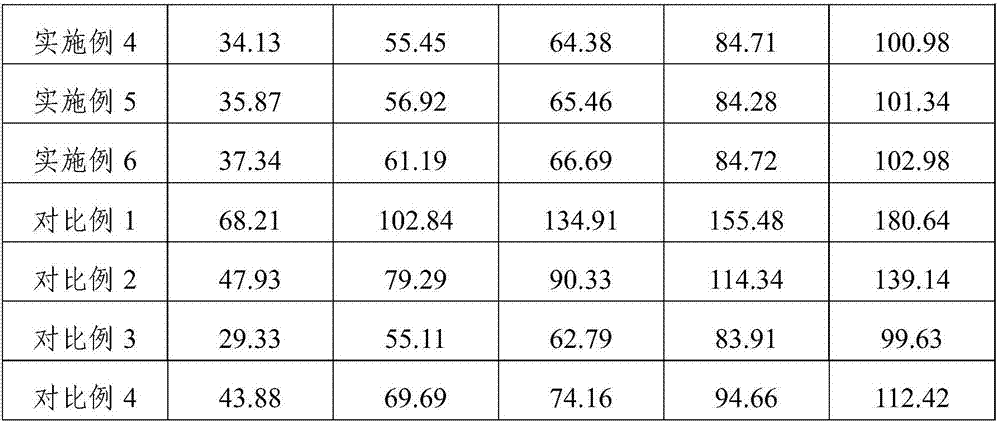

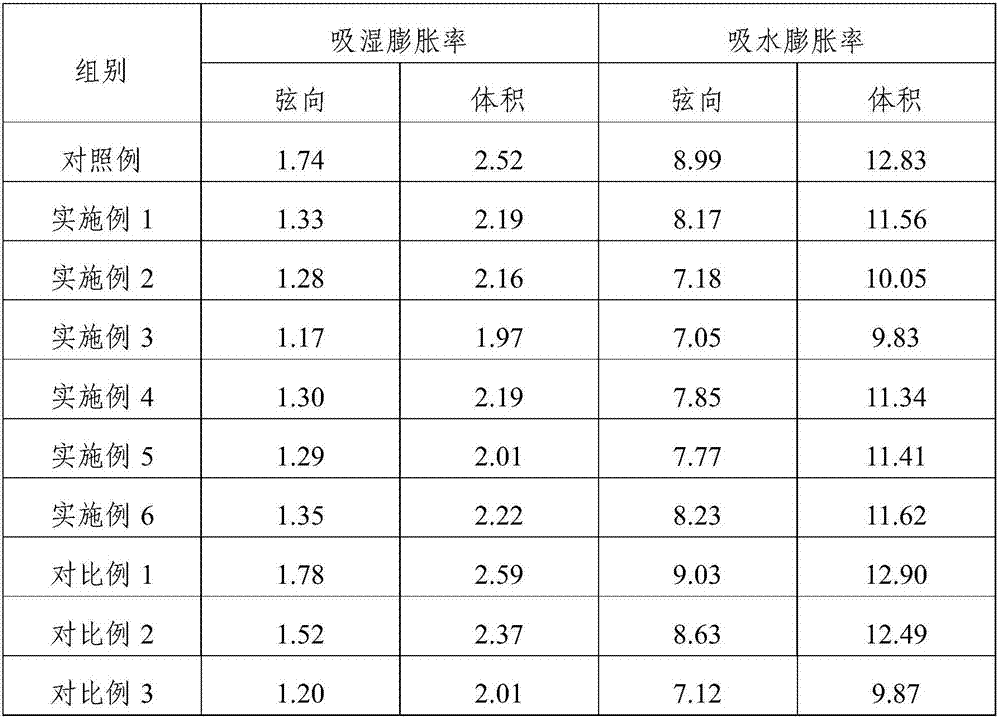

Examples

Embodiment 1

[0037] This embodiment provides a method based on alkali lignin composite heat treatment modified wood, the processing material is poplar, a fast-growing wood, cut into 20*20*20mm 3 , including the following steps:

[0038] 1) Dissolve 30 parts of alkali lignin in 500 parts of 1,4-dioxane solution, and stir for 2 hours with a magnetic stirrer to obtain an alkali lignin solution; filter the alkali lignin solution to remove excess Alkali lignin and impurities to obtain filtered alkali lignin solution;

[0039] 2) Put the poplar in the impregnation tank, under the condition of vacuum degree of -0.9MPa, after vacuum treatment for 30min, stop the vacuum, and add 1,4-dioxane of alkali lignin into the impregnation tank solution, adjust the pressure to 0.4MPa, and keep the pressure for 60min;

[0040] 3) Take out the soaked poplar, dry it naturally for 1 day until it is air-dried, then put it in a drying oven, and dry it at 100°C until it is absolutely dry; then place it at 140°C an...

Embodiment 2

[0042] This embodiment provides a method based on alkali lignin composite heat treatment modified wood, the processing material is poplar, a fast-growing wood, cut into 20*20*20mm 3 , including the following steps:

[0043] 1) Dissolve 35 parts of alkali lignin in 550 parts of 1,4-dioxane solution, and stir for 3 hours with a magnetic stirrer to obtain an alkali lignin solution; filter the alkali lignin solution to remove excess Alkali lignin and impurities to obtain filtered alkali lignin solution;

[0044] 2) Put the poplar in the impregnation tank, under the condition of vacuum degree of -0.9MPa, after vacuum treatment for 35 minutes, stop the vacuum, and add 1,4-dioxane of alkali lignin into the impregnation tank solution, adjust the pressure to 0.5MPa, and keep the pressure for 70min;

[0045] 3) Take out the soaked poplar wood, dry it naturally for 2 days to air-dry state, then put it into a drying box, and dry it to a dry state at a temperature of 103°C; then place it...

Embodiment 3

[0047] This embodiment provides a method based on alkali lignin composite heat treatment modified wood, the processing material is poplar, a fast-growing wood, cut into 20*20*20mm 3 , including the following steps:

[0048] 1) Dissolve 40 parts of alkali lignin in 550 parts of 1,4-dioxane solution and stir for 3 hours with a magnetic stirrer to obtain an alkali lignin solution; filter the alkali lignin solution to remove excess Alkali lignin and impurities to obtain filtered alkali lignin solution;

[0049] 2) Put the poplar in the impregnation tank, under the condition of vacuum degree of -1.0MPa, after vacuum treatment for 35min, stop the vacuum, and add 1,4-dioxane of alkali lignin into the impregnation tank solution, adjust the pressure to 0.5MPa, and keep the pressure for 60min;

[0050] 3) Take out the soaked poplar wood, dry it naturally for 2 days until it is air-dried, then put it in a drying oven, and dry it until it is absolutely dry at a temperature of 105°C; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com