Patents

Literature

199results about "Special leather manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Engineered leather and methods of manufacture thereof

InactiveUS20160097109A1Increase heightEliminate needConnective tissue peptidesTanning treatmentAnimal skinBiology

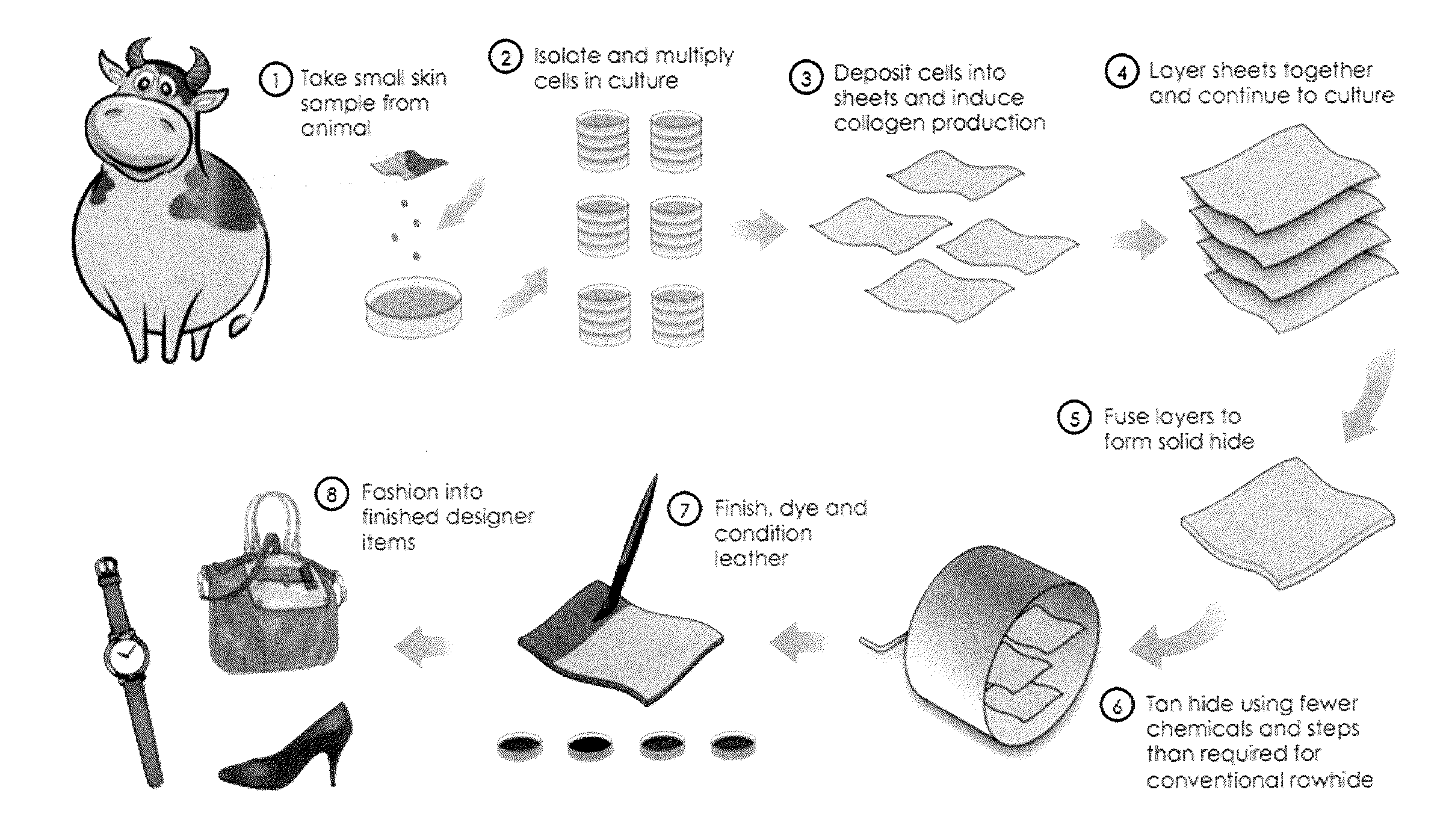

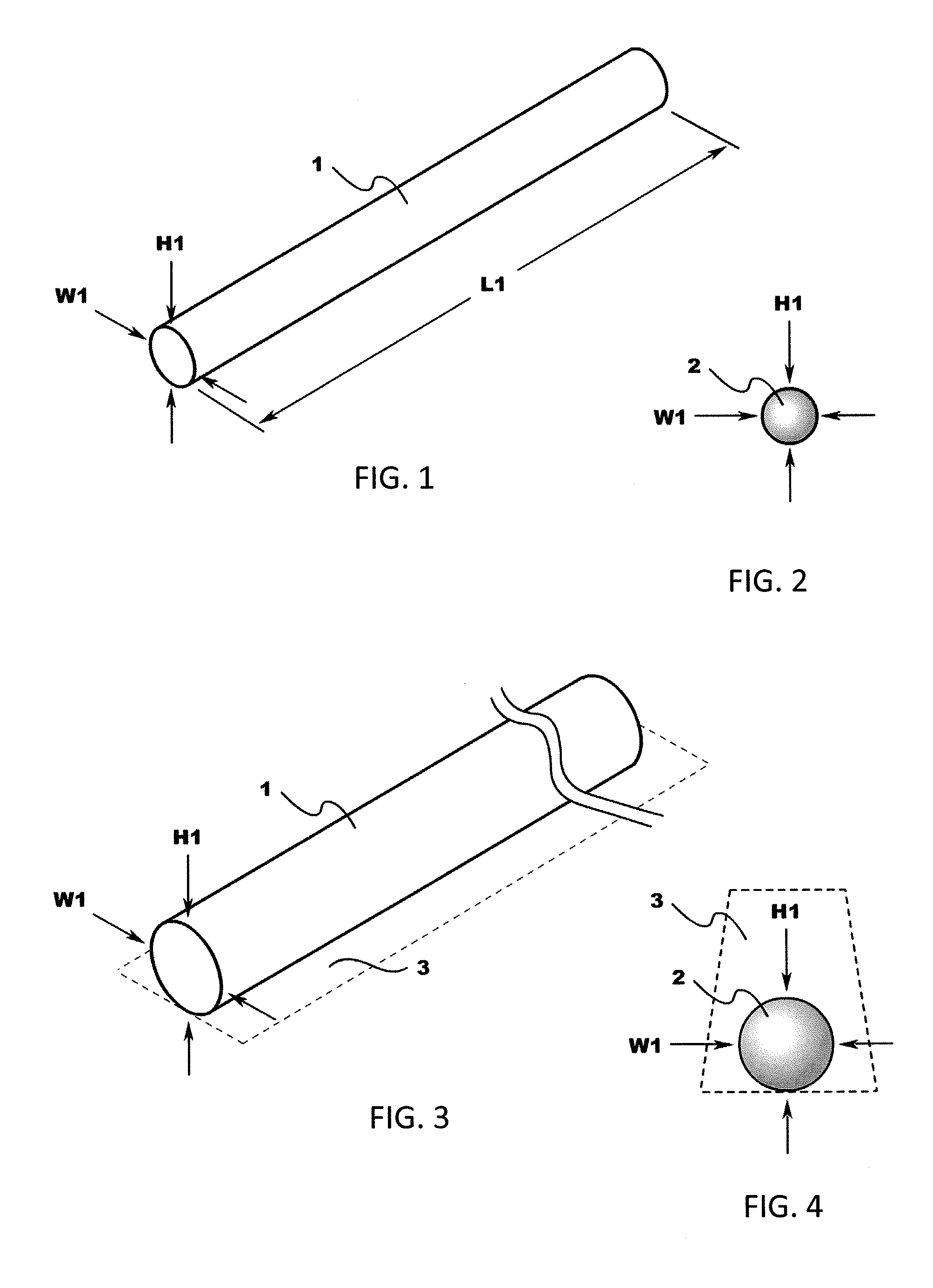

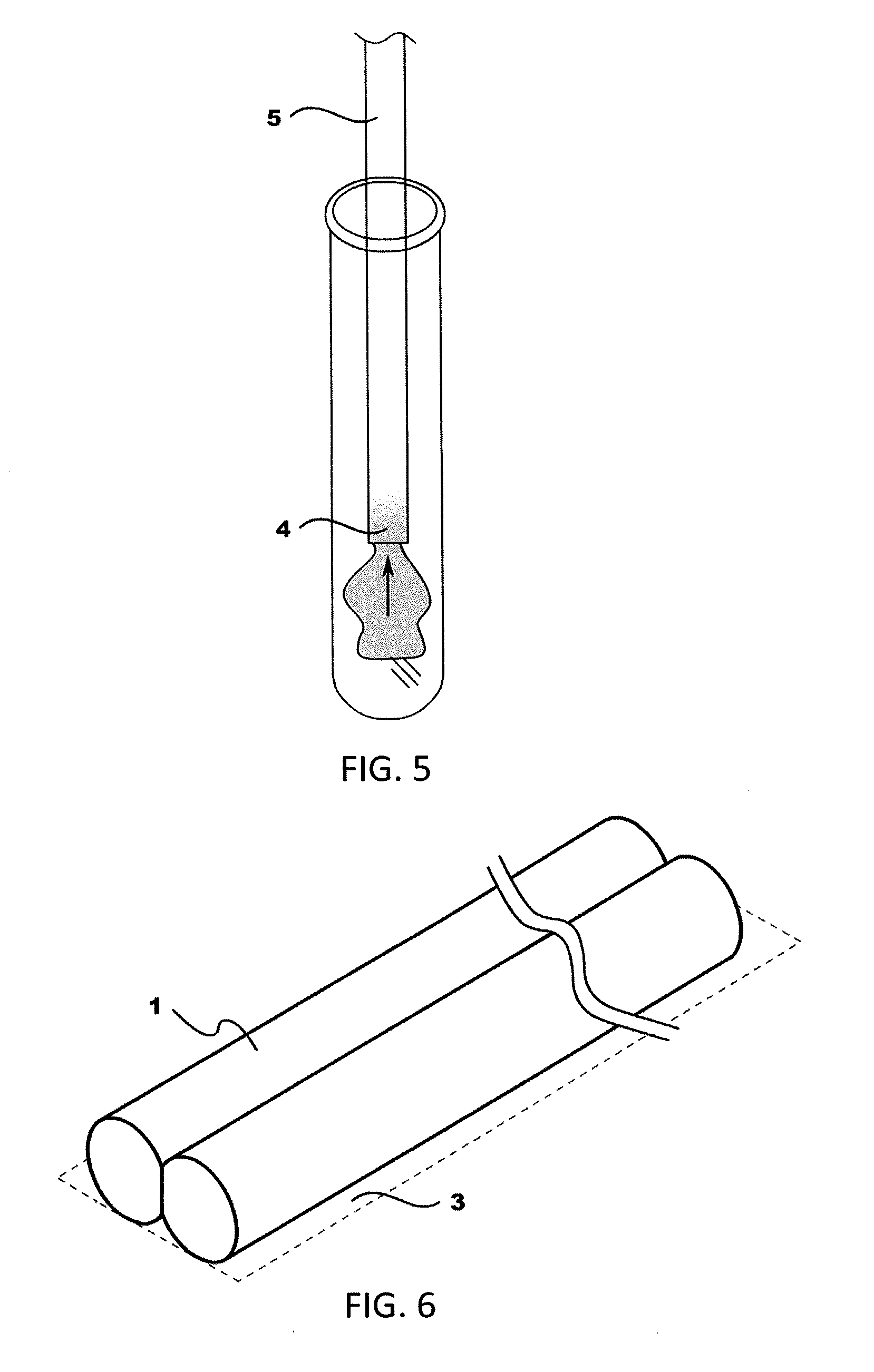

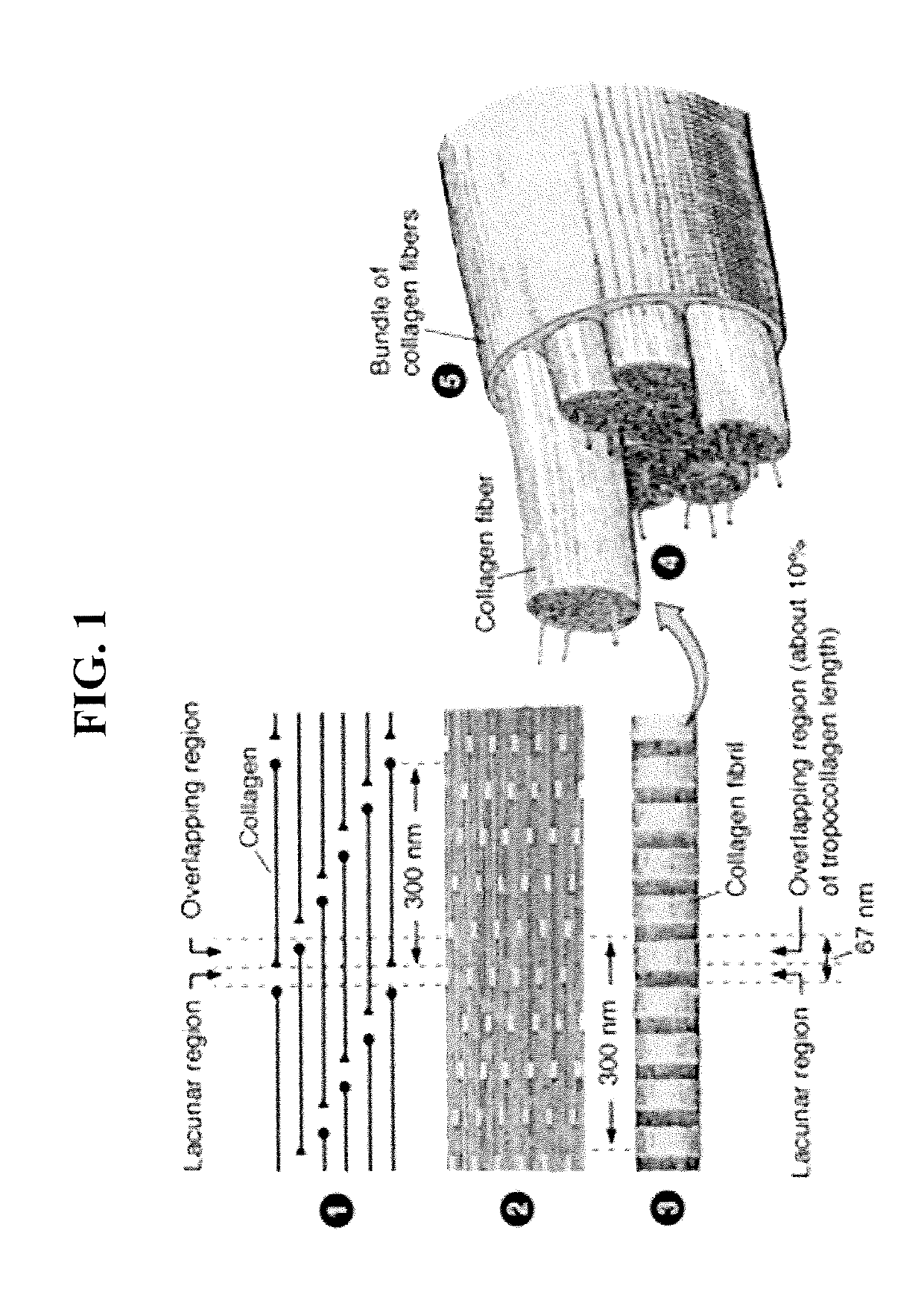

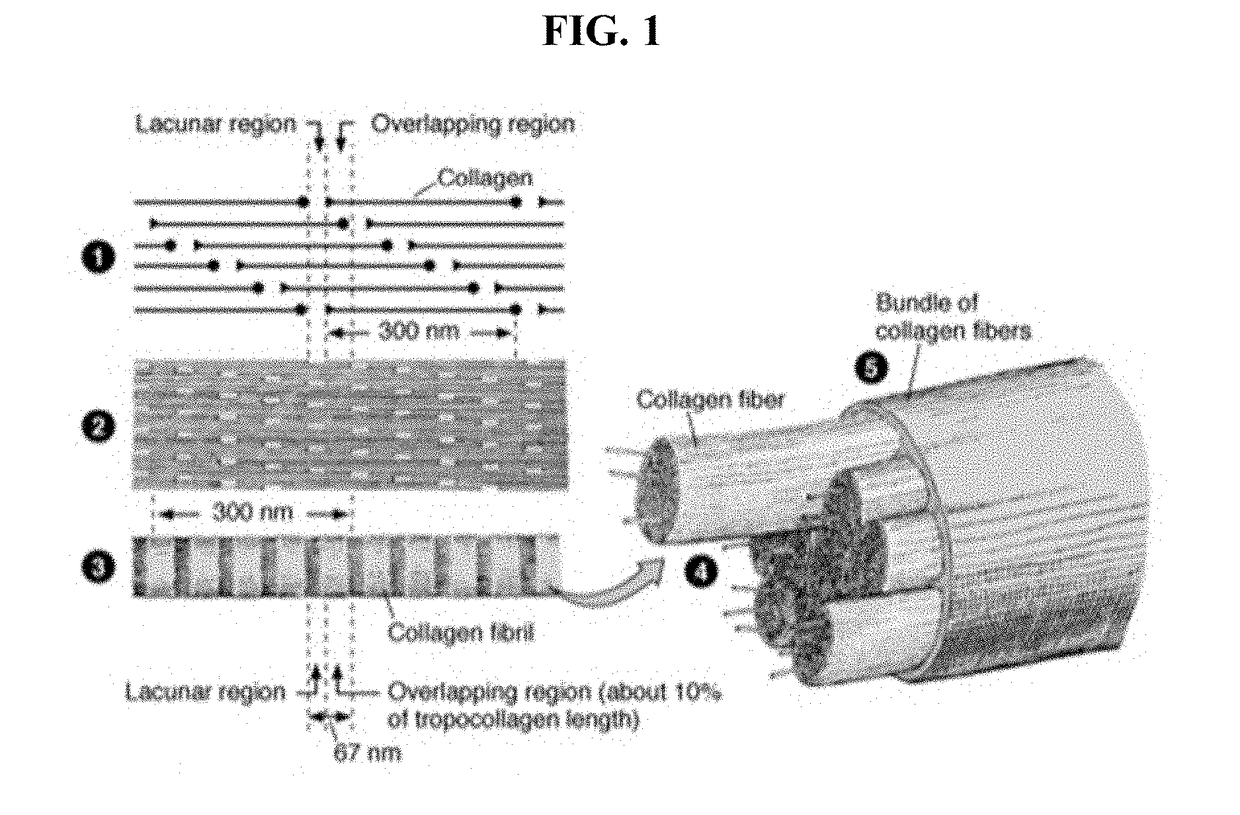

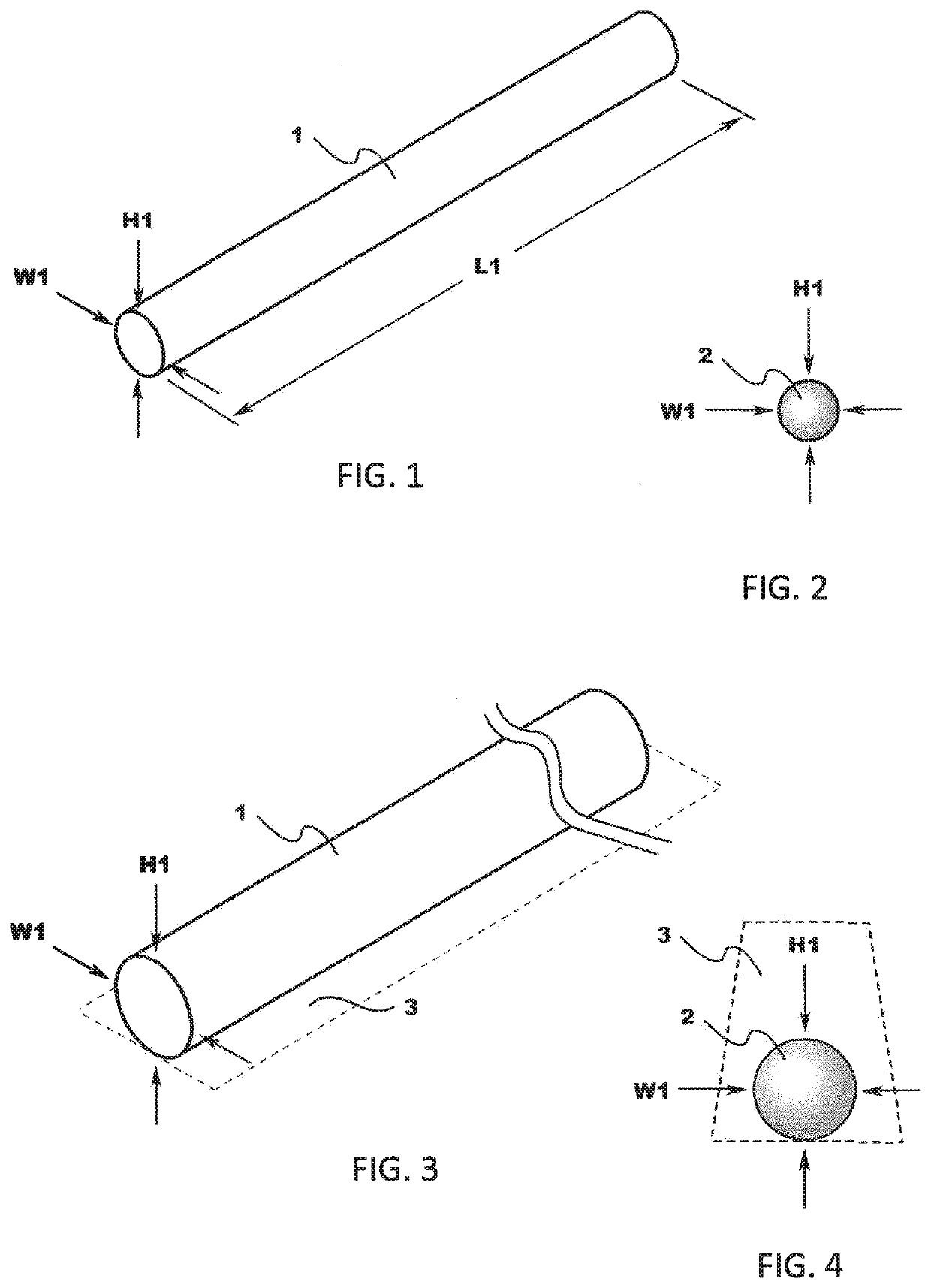

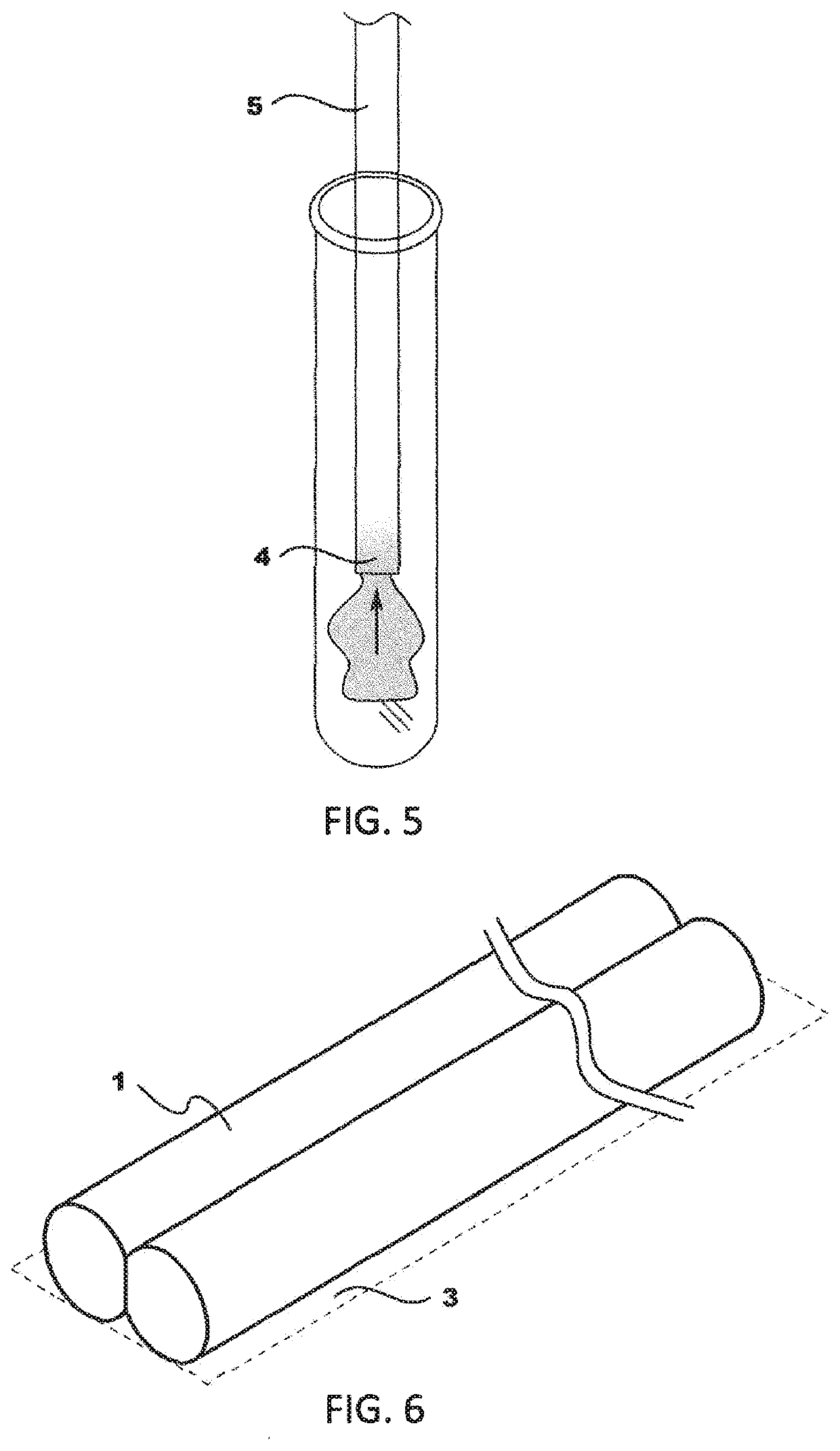

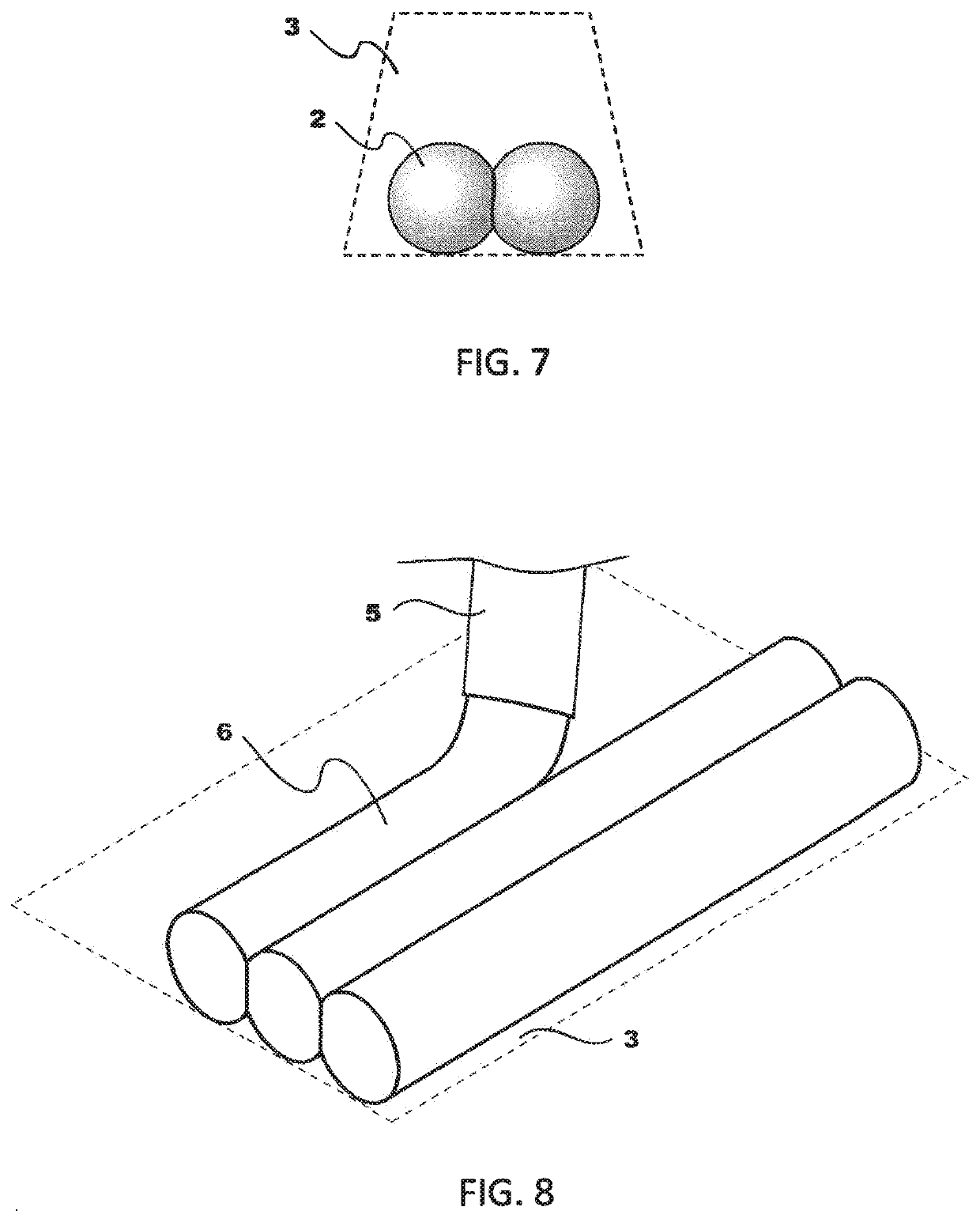

Engineered animal skin, hide, and leather comprising a plurality of layers of collagen formed by cultured animal collagen-producing (e.g., skin) cells. Layers may be formed by elongate multicellular bodies comprising a plurality of cultured animal cells that are adhered and / or cohered to one another; wherein the elongate multicellular bodies are arranged to form a substantially planar layer for use in formation of engineered animal skin, hide, and leather. Further described herein are methods of forming engineered animal skin, hide, and leather utilizing said layers of animal collagen-producing cells.

Owner:MODERN MEADOW INC

Biofabricated leather articles, and methods thereof

Owner:MODERN MEADOW INC

Production process for leather for painting

InactiveCN102796832AReduce pollutionIncreased complexitySpecial leather manufacturePulp and paper industryRemoving hair

The invention relates to a production process for leather for painting. The modern leather picture does not adopt the advanced production process for leather products, has a poor manufacturing method, a complex manufacturing process and single style, has no storage stability, and has high possibility of fading. The leather for painting is prepared by the steps of soaking in water, removing meat, degreasing, liming and removing hair, removing lime, softening, soaking in acid, tanning, extracting alkali after tanning, drying, painting, coating, shaping, mounting and obtaining the finished product, so that the leather has storage stability and is not damaged by worms when being placed for a long time. Painting adopts different painting methods of Chinese painting and oil painting, so that different styles are shown. The leather subjected to painting is treated, so the leather is anti-oxidant and is not faded along with the time. Chromium is not used in the tanning process, so environmental pollution is little.

Owner:SHAANXI UNIV OF SCI & TECH

Production method of negative oxygen ion multifunctional automotive trim leather

ActiveCN107312895AIncrease the fragranceFeel goodTanning treatmentPre-tanning chemical treatmentLiquid ratioKnurling

The invention relates to a production method of a negative oxygen ion multifunctional automotive trim leather. The production method comprises fleshing, liming, deliming, softening, pickling, tanning, retanning, neutralization, dyeing, fat liquoring, drying, softening, bottom coating, middle coating, knurling and top coating; in the pickling and tanning steps, salt is added for pickling, and aldehyde is added for tanning; the pickling by adding the salt is as follows: the leather is washed by softening water; the liquid ratio is 50%; by 100 mass parts of the leather, 50 parts of water are added; the temperature is controlled at 20+-2 DEG C; 7 parts of sodium chloride are added for reaction by 15 minutes; then, 0.5 part of 10 wt% of dilute formic acid is added for reaction by 30 minutes; then, 0.5 part of 10 wt% of dilute formic acid is added for reaction by 30 minutes; 0.35 part of 5 wt% of dilute sulfuric acid is added for reaction by 30 minutes; sulfuric acid is added again by the same mode for reaction by 90 minutes; after dilute sulfuric acid is added, the pH value is controlled within 2.8+-0.1; and the reaction is performed by 60 minutes. The production method has the functions of constant release of negative oxygen ions, sterilization and bacteria resistance, achieves the effect of efficiently absorbing, decomposing and degrading such harmful gas as formaldehyde, and achieves softness and excellent shaping property.

Owner:HAINING SENDE LEATHER

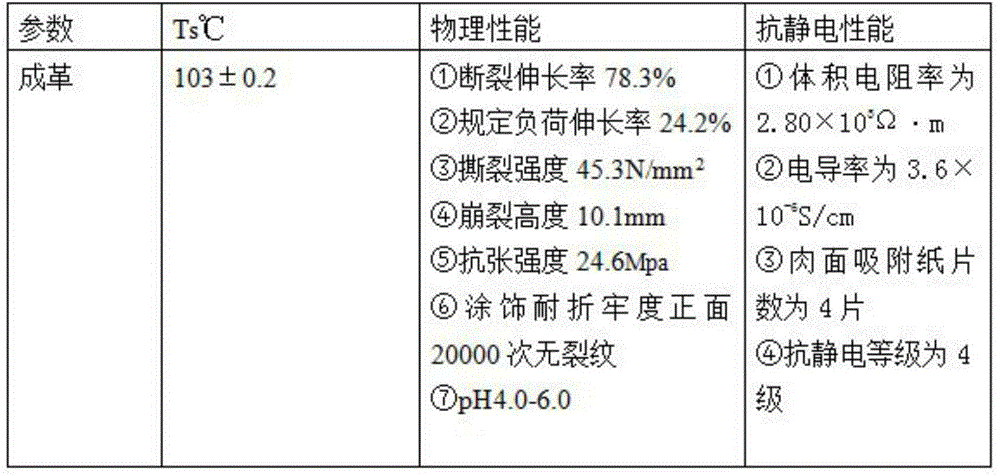

Method for making a biofabricated material containing collagen fibrils

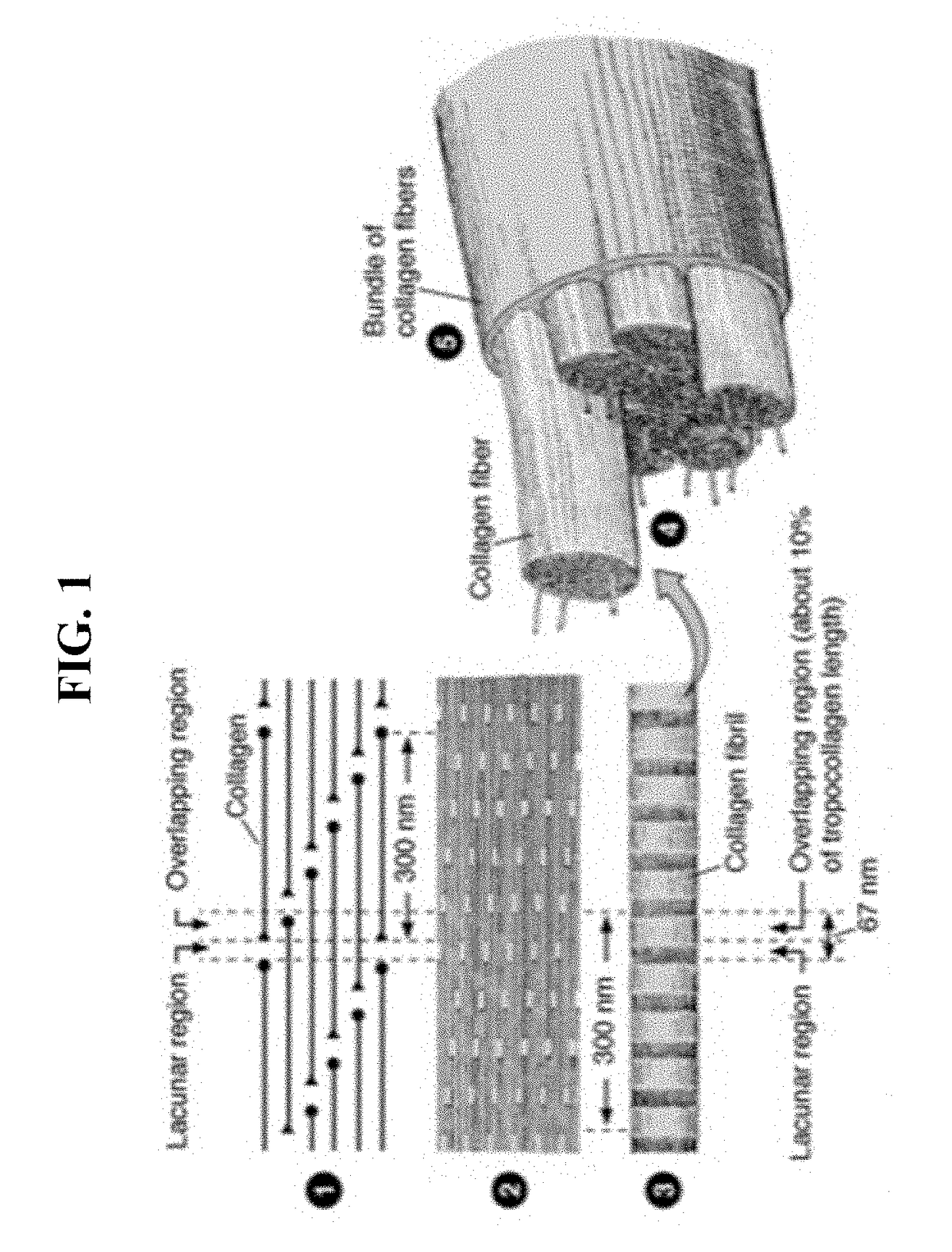

ActiveUS20170233834A1Facilitates uniform uptakeSame elasticityMonocomponent protein artificial filamentDomestic upholsteryFiberChemical synthesis

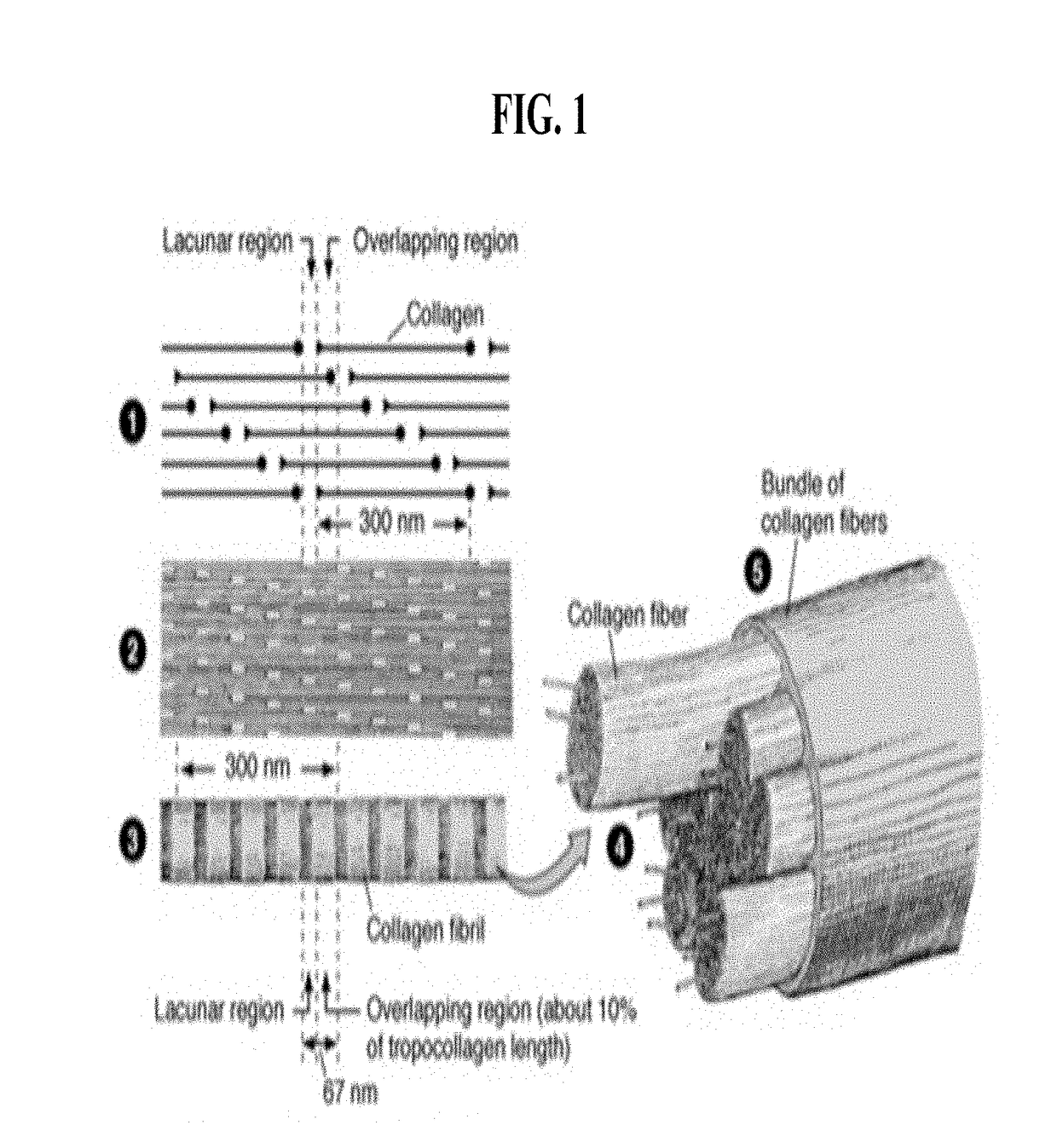

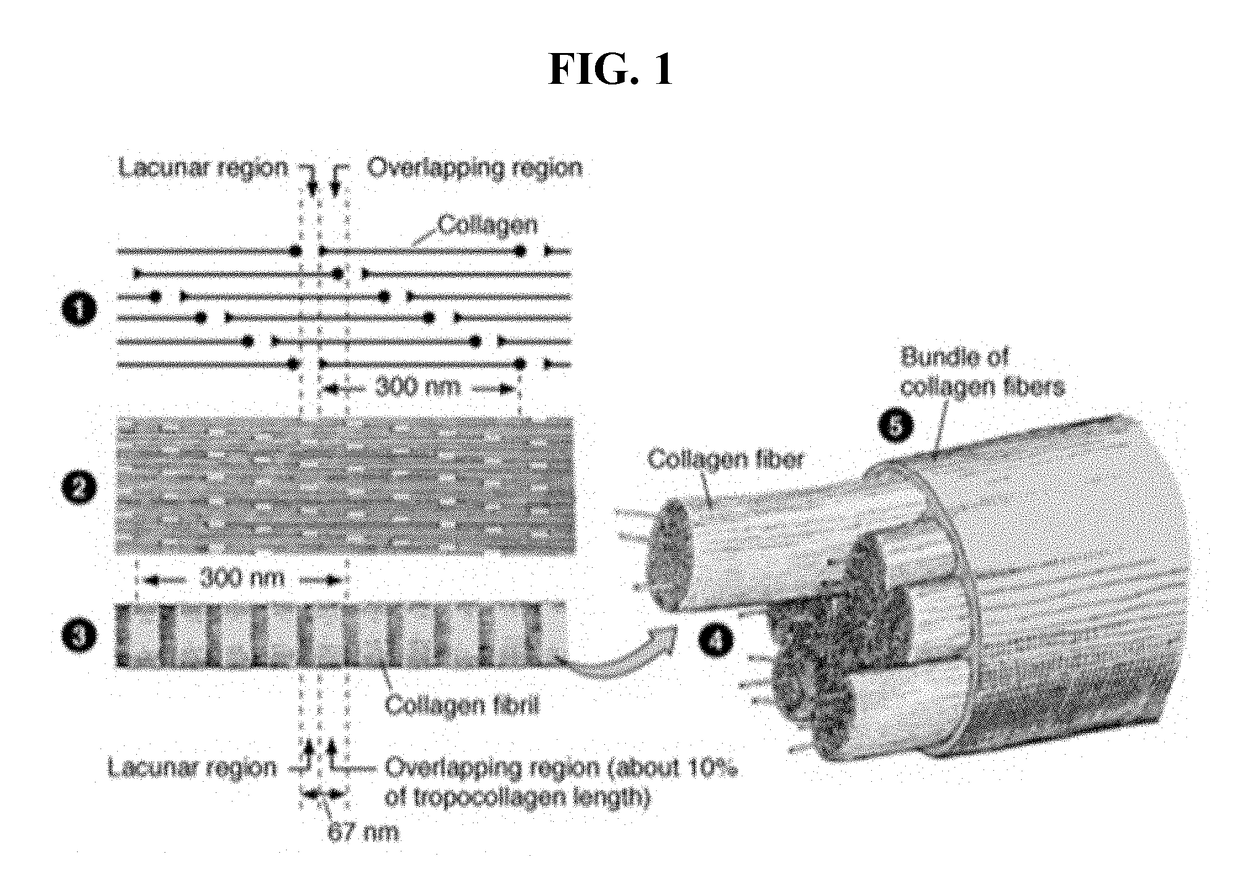

Described herein is a method for producing a biofabricated material from collagen or collagen-like proteins which are recombinantly produced and which contain substantially no 3-hydroxyproline. The collagen or collagen-like proteins are isolated from animal sources, or produced by recombinant DNA techniques or by chemical synthesis. The collagen or collagen-like proteins are fibrillated, crosslinked, dehydrated and lubricated thus forming the biofabricated material having a substantially uniform network of collagen fibrils.

Owner:MODERN MEADOW INC

Method for biofabricating composite material

ActiveUS20170233945A1Facilitates uniform uptakeSame elasticityMonocomponent protein artificial filamentDomestic upholsteryFiberSecondary component

The invention is directed to a method for producing a composite material comprising a biofabricated material and a secondary component. The secondary component may be a porous material, such as a sheet of paper, cellulose, or fabric that has been coated or otherwise contacted with the biofabricated material. The biofabricated material comprises a uniform network of crosslinked collagen fibrils and provides strength, elasticity and an aesthetic appearance to the composite material.

Owner:MODERN MEADOW INC

Tanning method for fish skin and after finishing method for fish skin leather

InactiveCN1492057AFeel goodImprove tensile propertiesTanning treatmentSpecial leather manufactureFiberNitrocellulose

The fish skin leather processing method includes painting acrylic resin onto tanned fish skin, the first ironing and shaping in leather ironing machine after drying, spraying the mixture of polyurethane and acrylic resin onto the fish skin, the second ironing and shaping in leather ironing machine after drying, spraying the mixture of nitrocellulose brightener and slip agent onto the fish skin, the third ironing and shaping in leather ironing machine after drying, and spraying the mixture of feeling agent and waterproof agent onto the fish skin. The advantages include good feeling, high tensile strength, cold resistance, water proofing, no delaminating, high penetrating and beautiful grain of the processed fish leather; low processing cost, less pollution, etc. The skin leather is suitable for making various leather products.

Owner:沈玉良

Device for leather processing

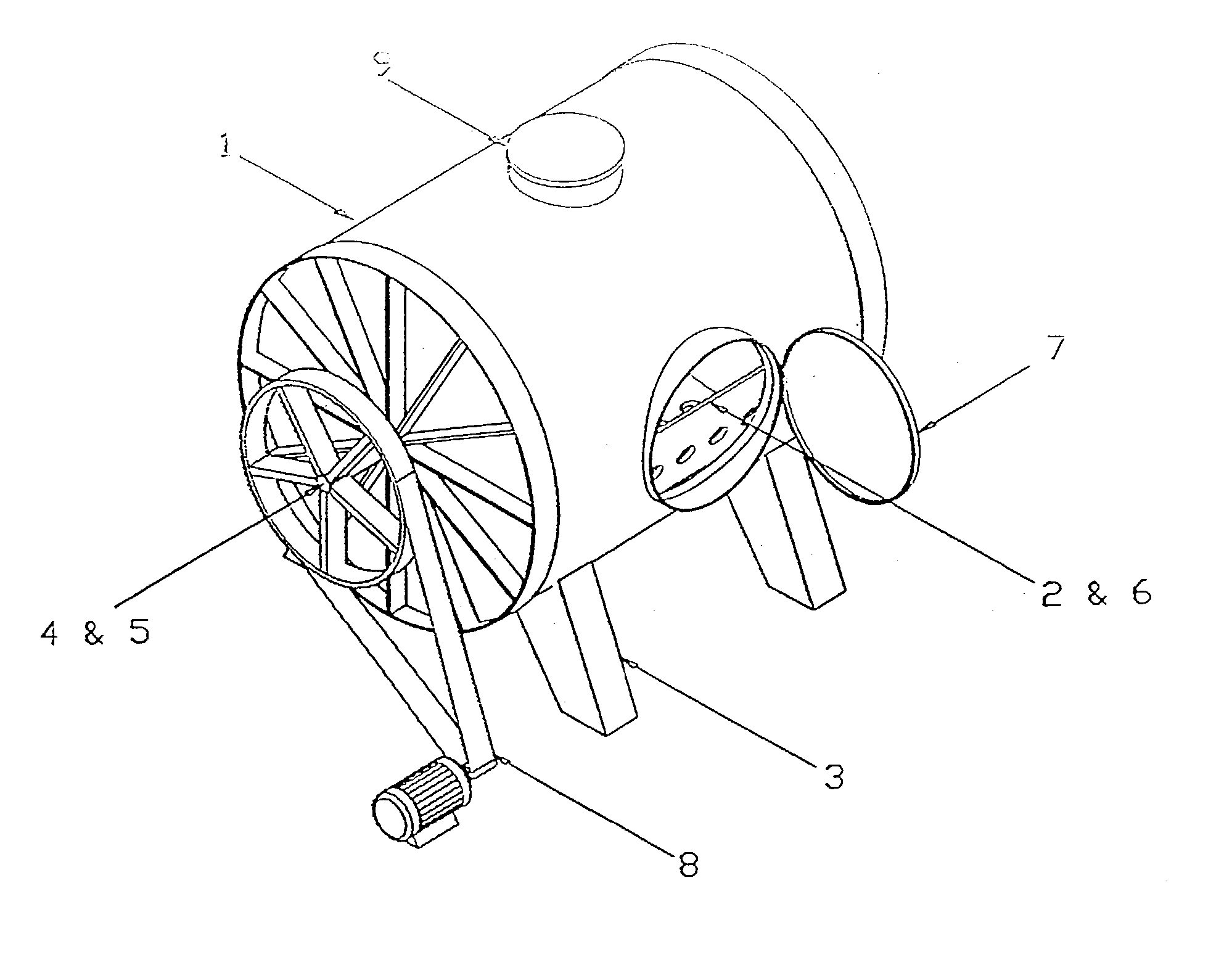

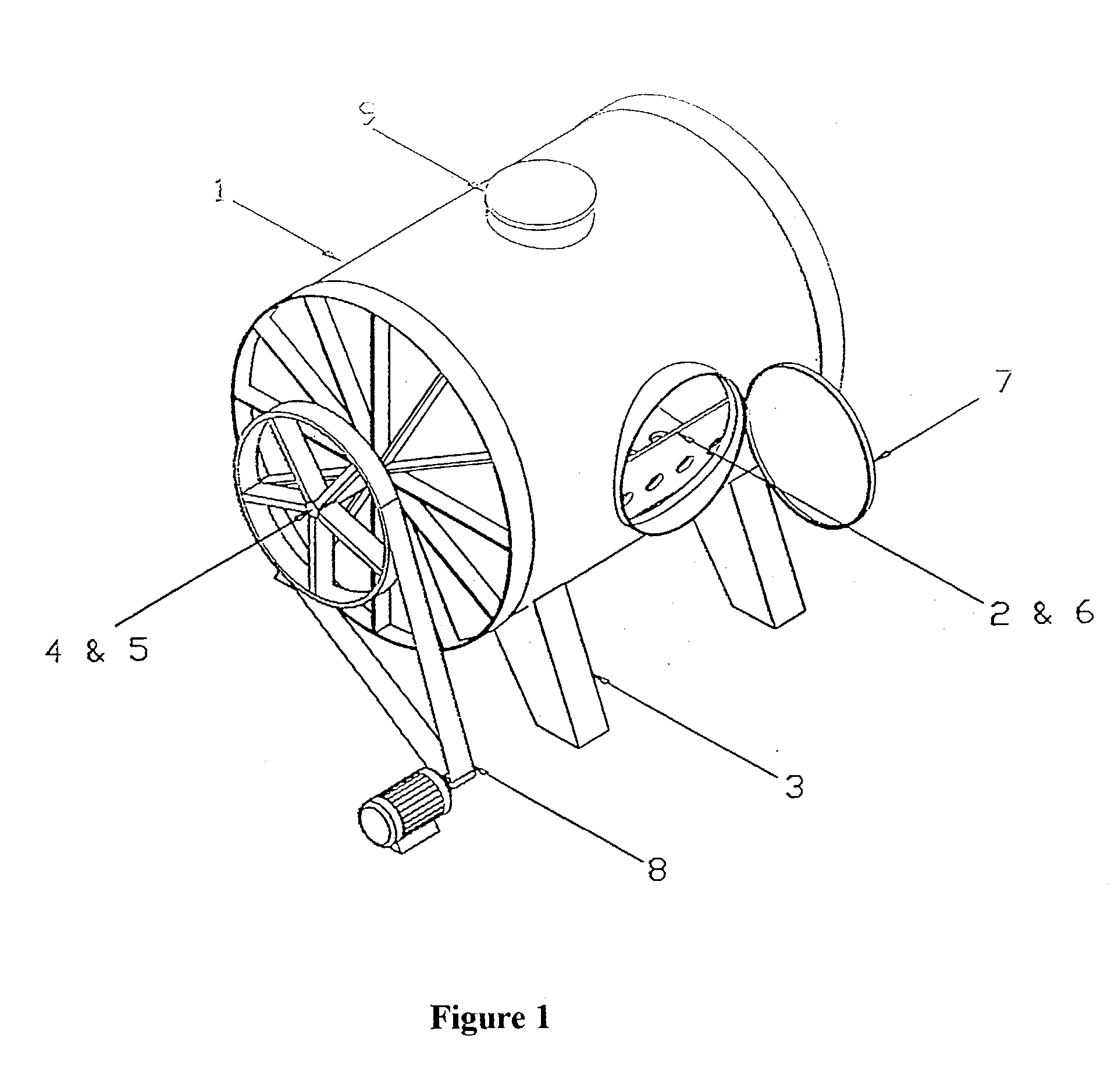

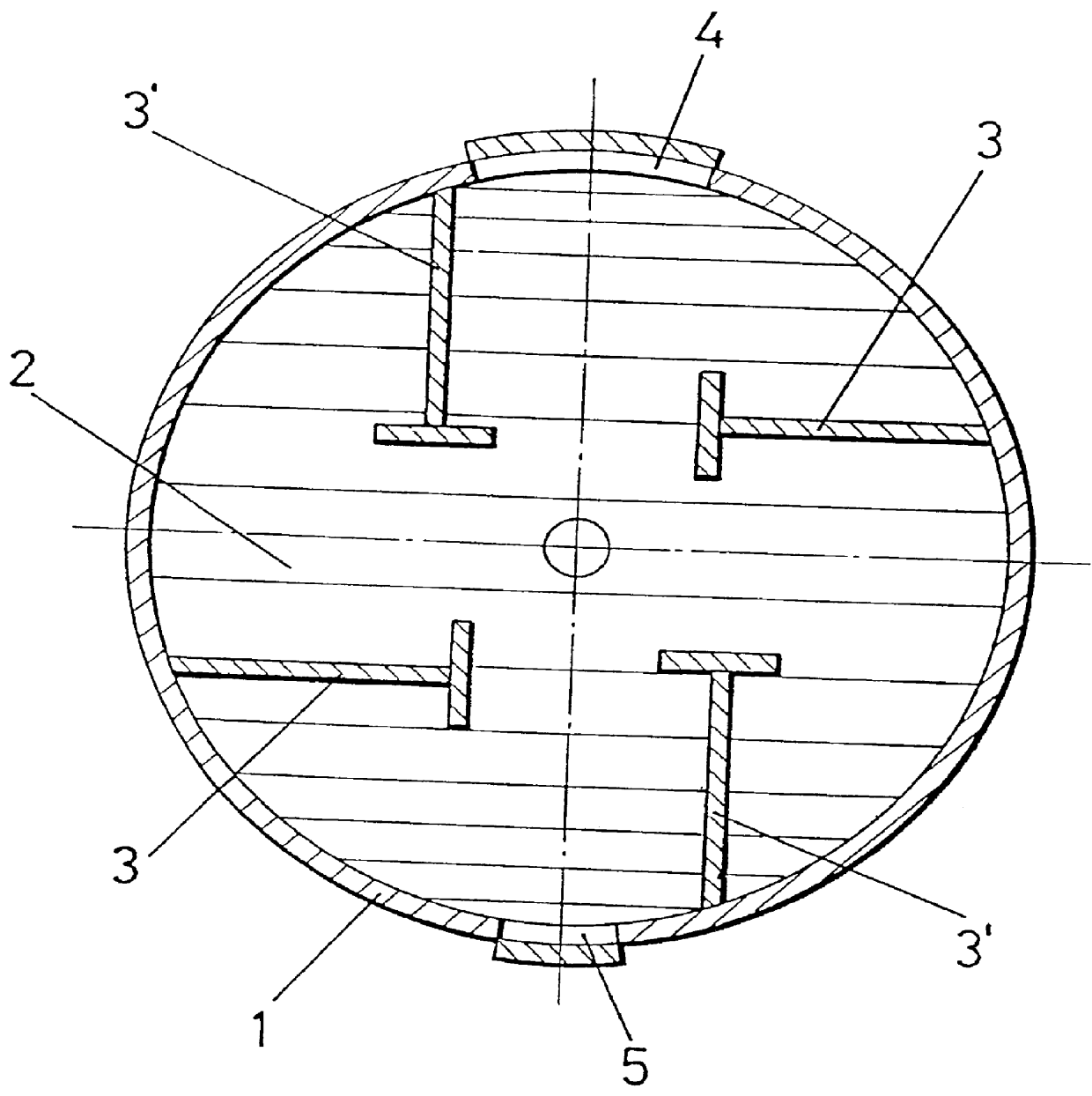

InactiveUS20040182118A1Consumes less energyReduce noisePre-tanning chemical treatmentLeather/skins/hides/pelt chemical treatment apparatusChemical solutionPressure generation

An improved device for leather processing comprising a vessel containing perforated dummy doors and compartments with pegs as well as friction disk fixed along the exterior periphery of the vessel. The leathers to be wet processed are subjected to mechanical action in terms of both rocking action as well as rotational movement simultaneously. The perpetual motion of the device help to create pressure generation for quickening the process and for addition of chemical solution continuously. The processing takes place under pressure generated inside the vessel and with the support of multiple mechanical actions, resulting in higher exhaustion of bath with less processing time and energy requirement and higher capacity utilization to produce good quality leather.

Owner:COUNCIL OF SCI & IND RES

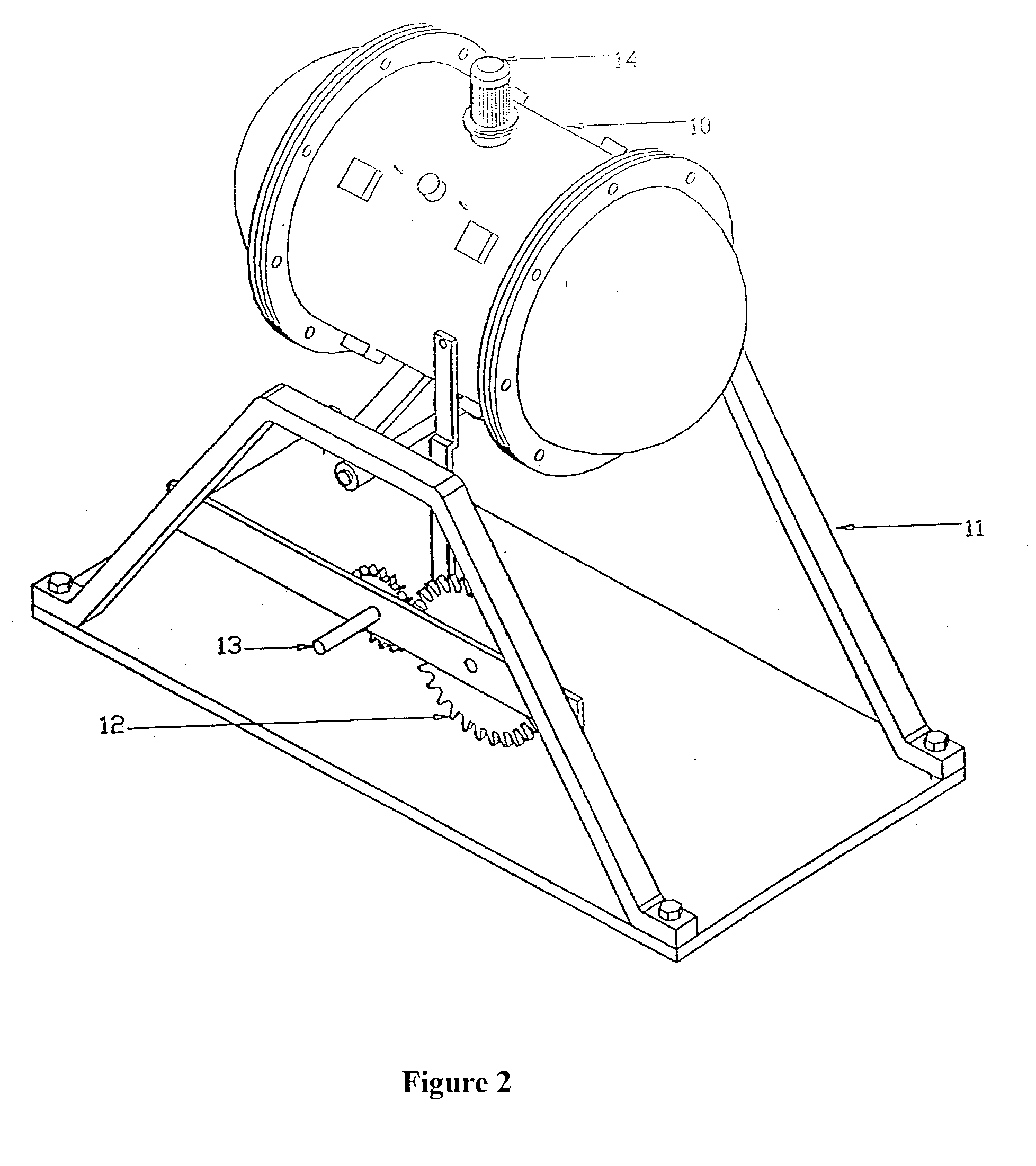

Drum for treating leather, fur and similar products

InactiveUS6151932AImproved performance and efficiencyRotating receptacle mixersPre-tanning chemical treatmentMicrochiropteraEngineering

Owner:MOLTO CONCEPCION JULIA +1

Transparent leather and manufacturing method thereof

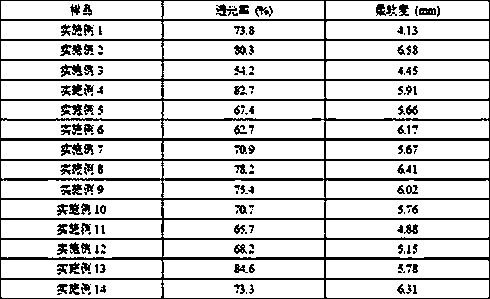

The invention discloses transparent leather which is characterized by the light transmittance being 50-85%, the thickness being 0.5-1.5 mm, the softness being 4.0-8.0, the moisture content being 8-20%, and the shrinkage temperature being 50-70 DEG C. The transparent leather takes delimed and softened pelts as raw materials, the pelts are immersed in an aqueous solution for 0.5-4 h through an expansion agent with the mass accounting for 0.3-2.5% of the mass of the delimed and softened pelts, the expanded pelts are aired, then the aired pelts are immersed in a transparent liquid for 1-6 h, wherein the mass of the transparent liquid accounts for 50-200% of the mass of the delimed and softened pelts, the transparent liquid is composed of, by mass, 40-90% of water, 10-60% of polyhydric alcohols, 0.01-0.1% of nano-silver, and 0.01-0.1% of curing agent, and finally the leather treated by the transparent liquid is aired, and thus the transparent leather is obtained. The prepared transparent leather has the similar softness, fullness, flexural resistance and other sensory properties and service properties with traditional leather, but has the transparency which is not possessed by the traditional leather, and is a brand new type of leather. According to a transparent leather manufacturing method, materials in use have a wide source range, the manufacturing process is easy to operate, and practicality is high.

Owner:SICHUAN UNIV

Method for making a biofabricated material containing collagen fibrils

ActiveUS20170233536A1Facilitates uniform uptakeSame elasticityMonocomponent protein artificial filamentDomestic upholsteryChemical synthesisFiber

Described herein is a method for producing a biofabricated material from collagen or collagen-like proteins. The collagen or collagen-like proteins are isolated from animal sources or produced by recombinant DNA techniques or by chemical synthesis. The collagen or collagen-like proteins are fibrillated, crosslinked, dehydrated and lubricated thus forming the biofabricated material having a substantially uniform network of collagen fibrils.

Owner:MODERN MEADOW INC

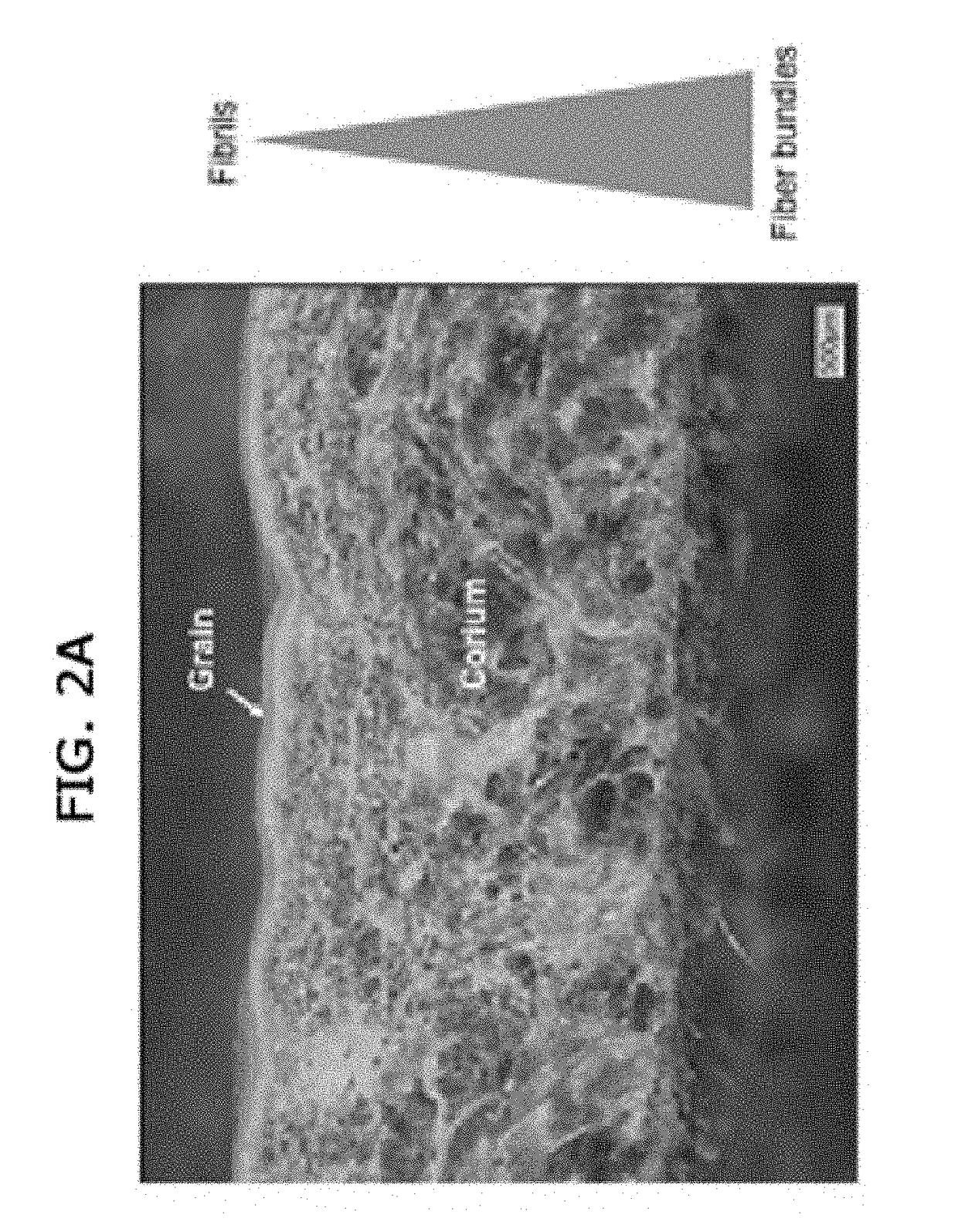

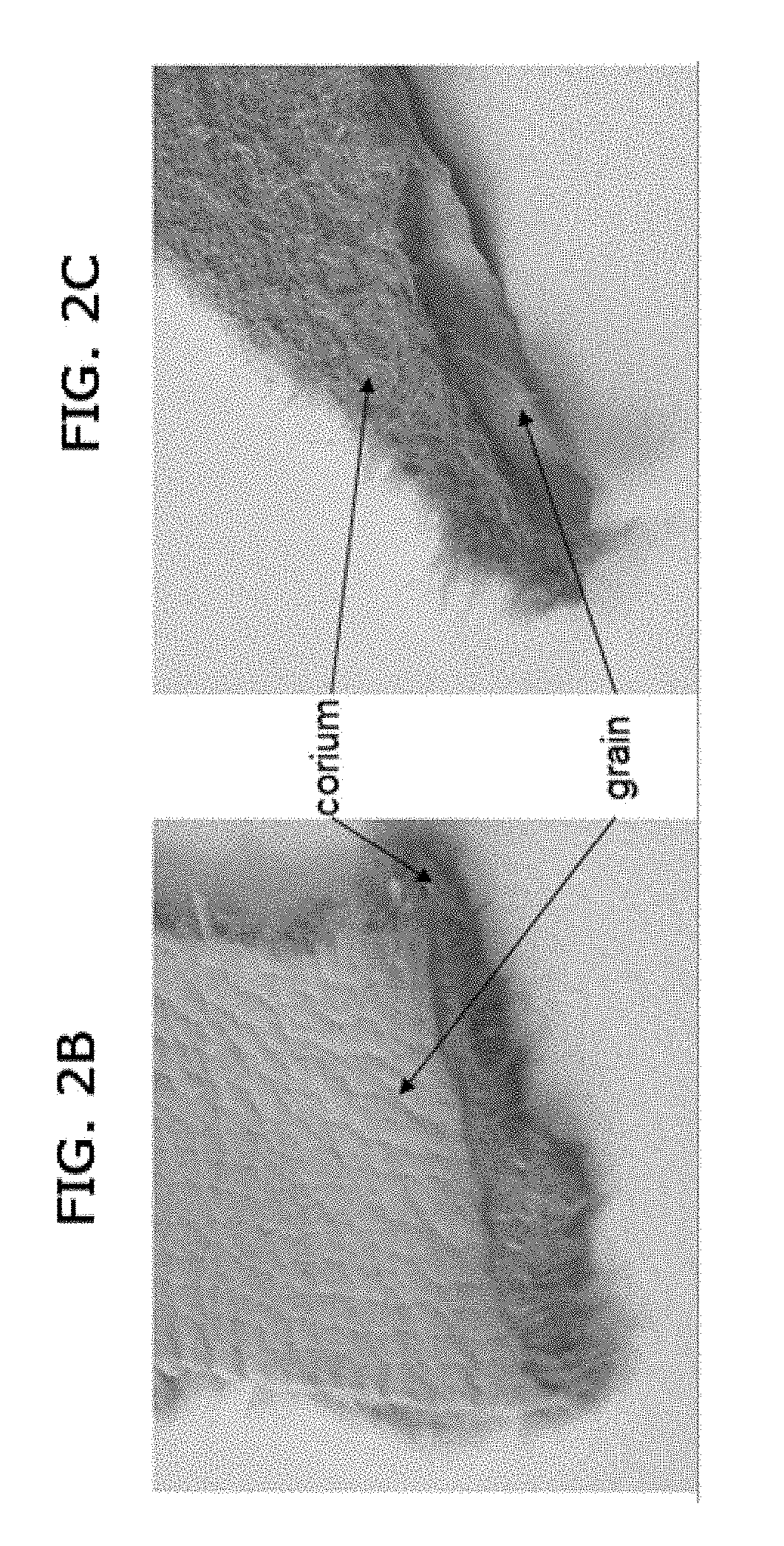

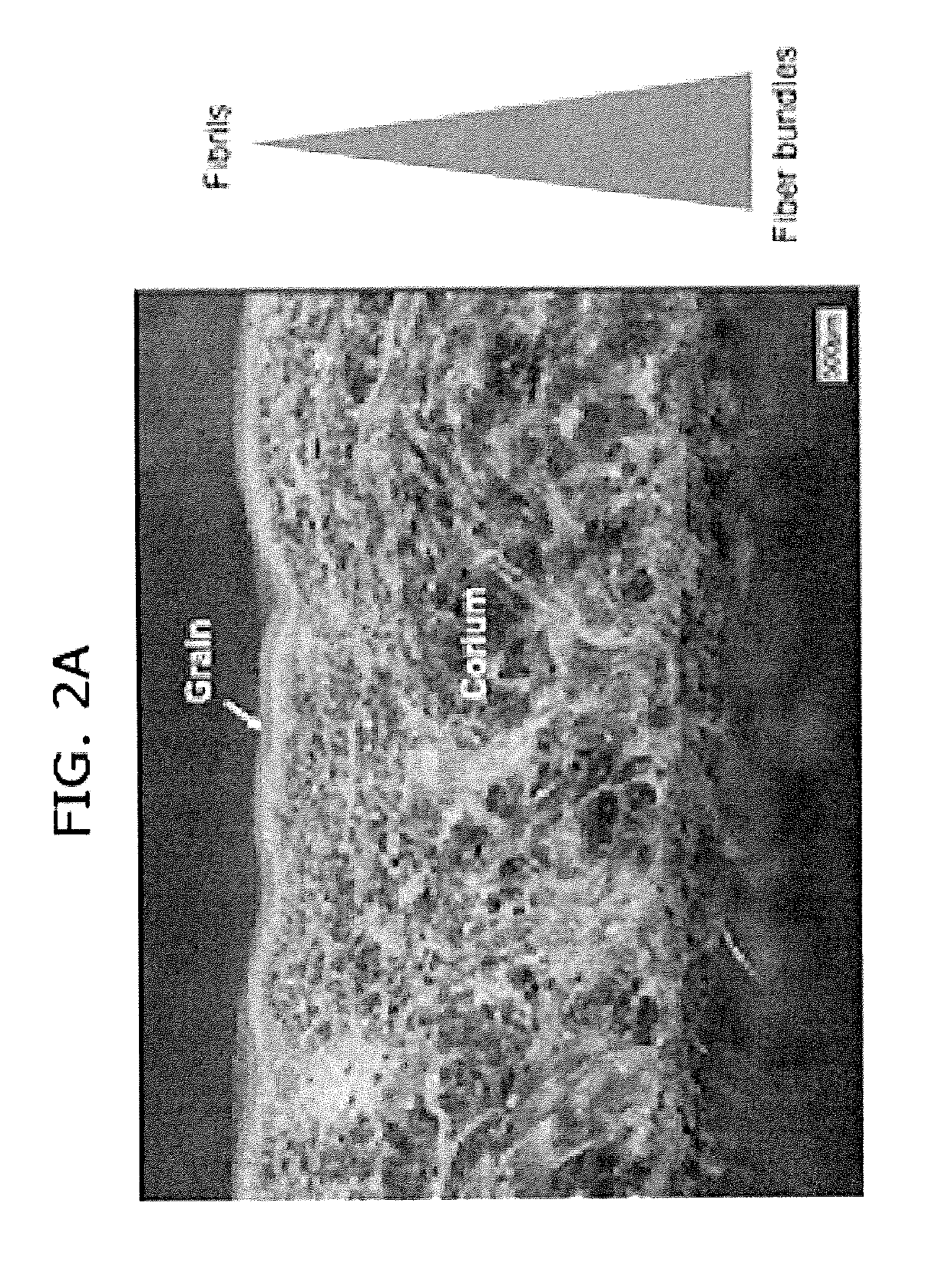

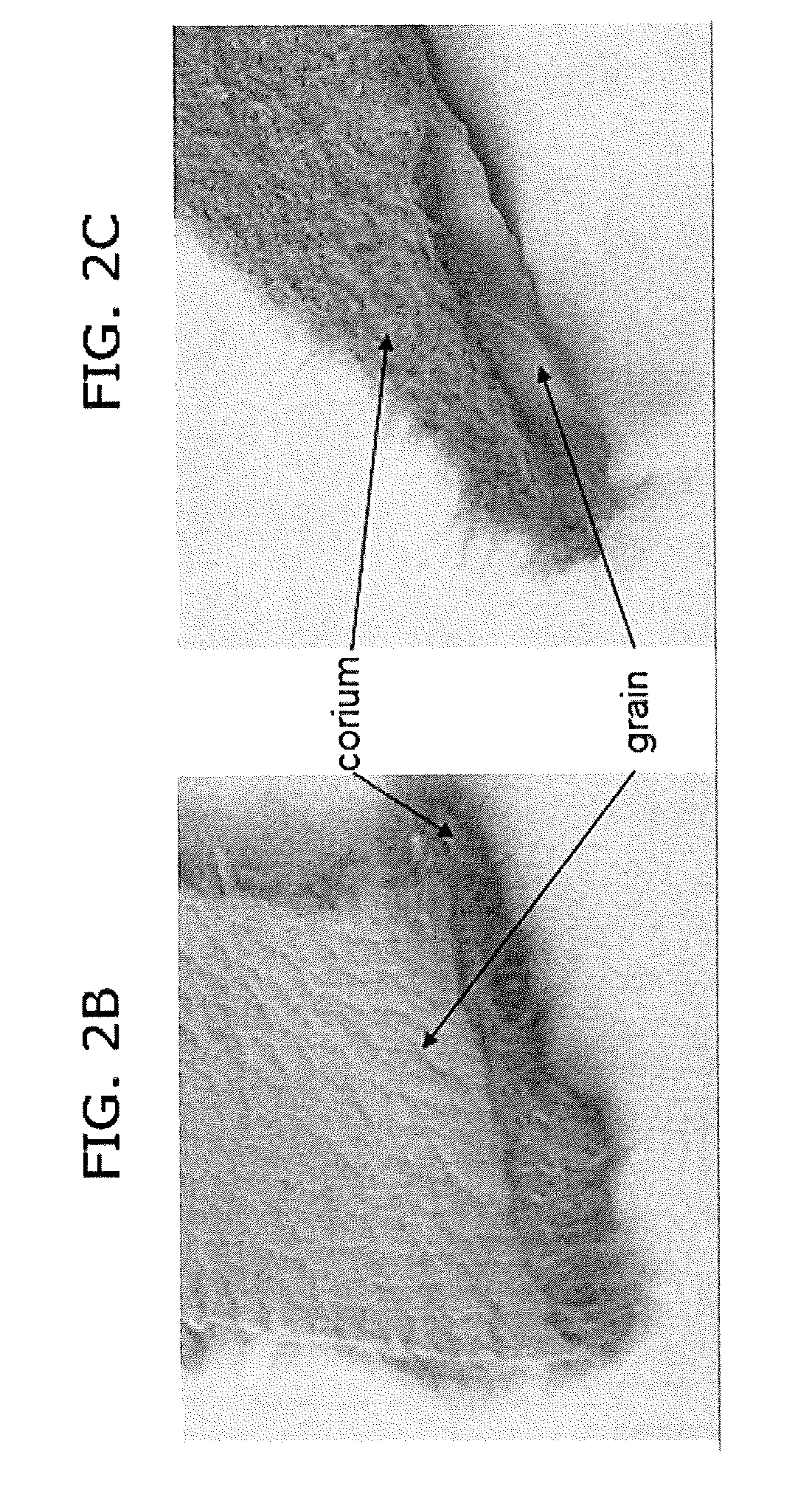

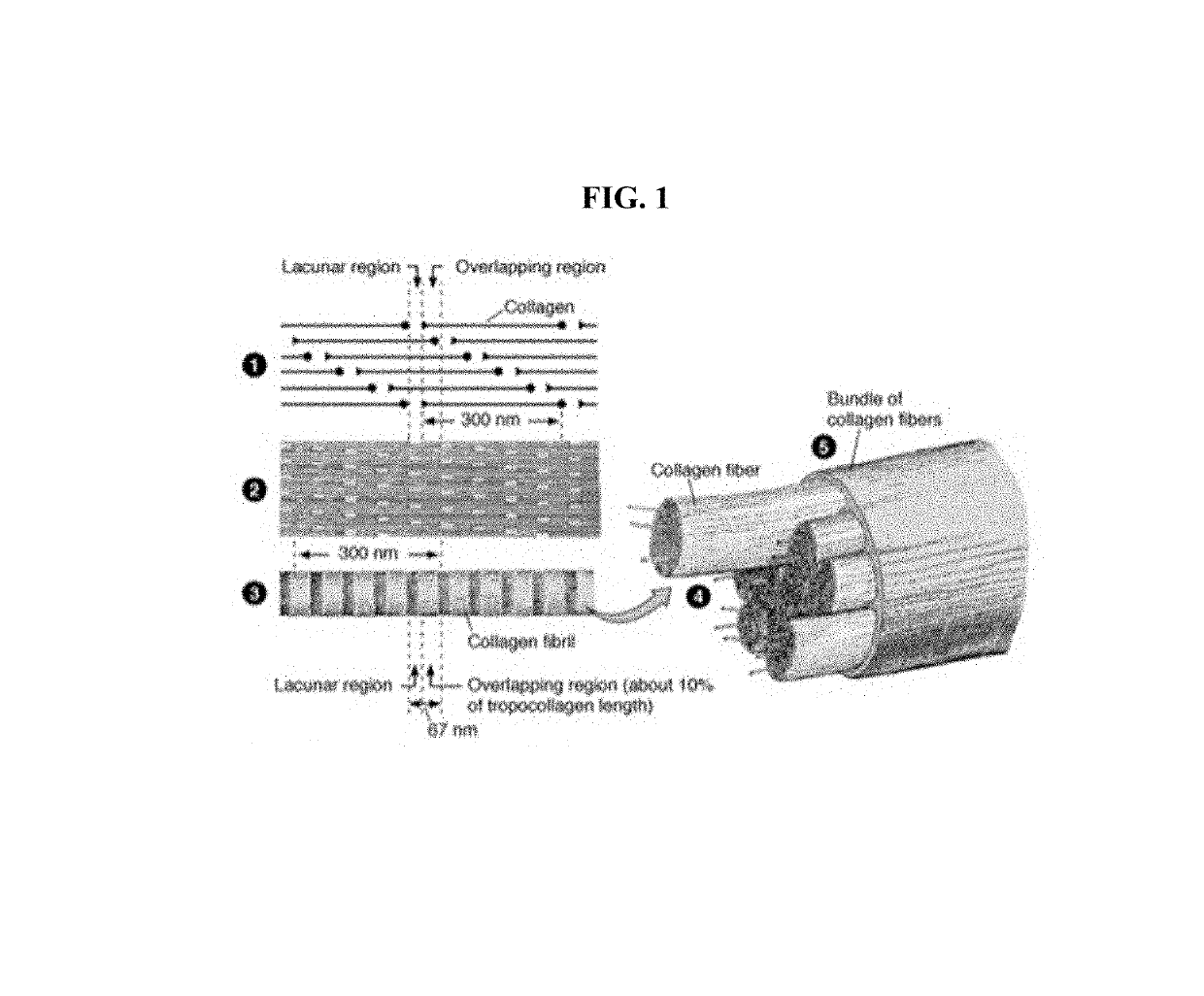

Biofabricated material containing collagen fibrils

ActiveUS20170233838A1Facilitates uniform uptakeSame elasticityMonocomponent protein artificial filamentDomestic upholsteryFiberFibril

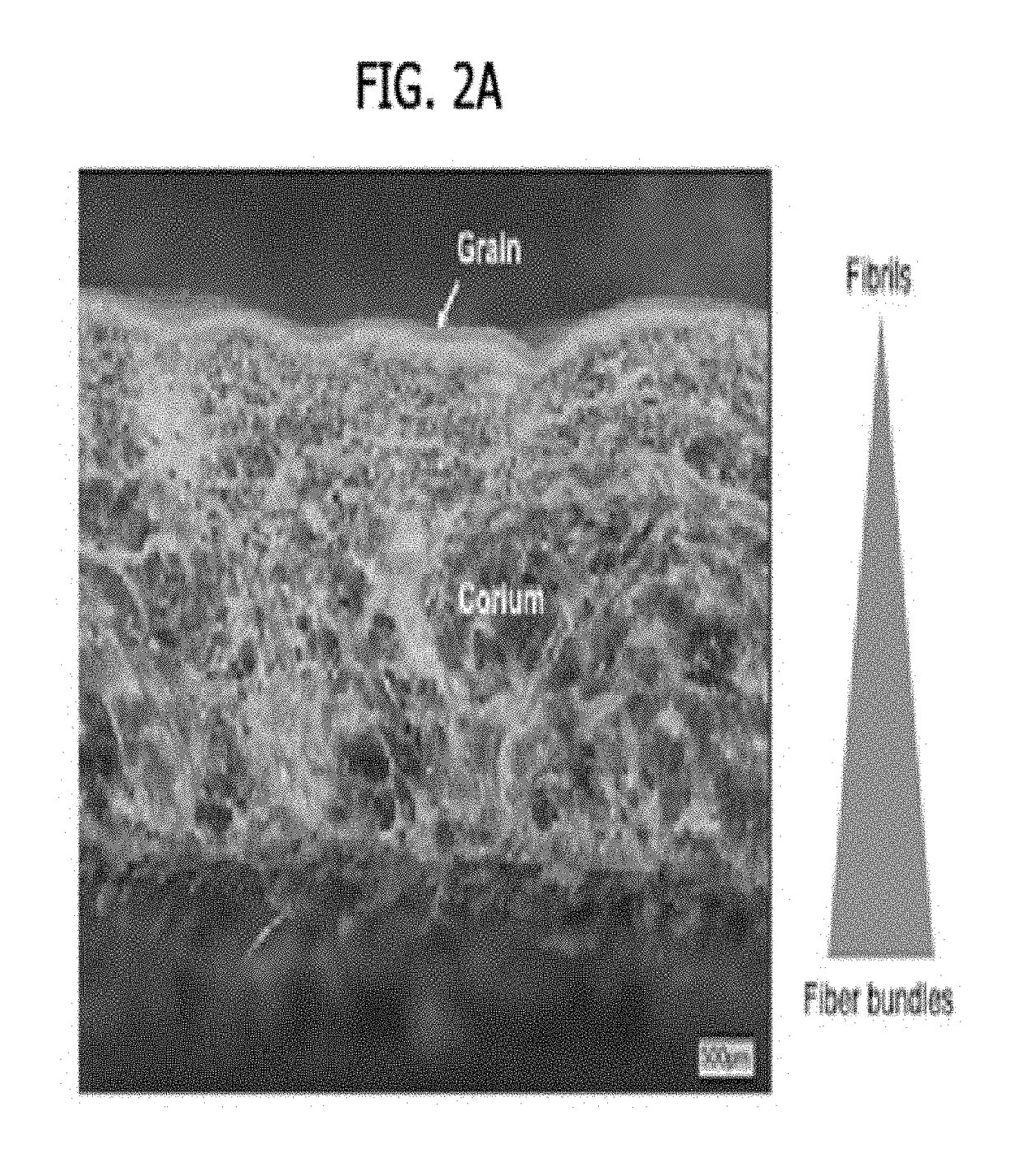

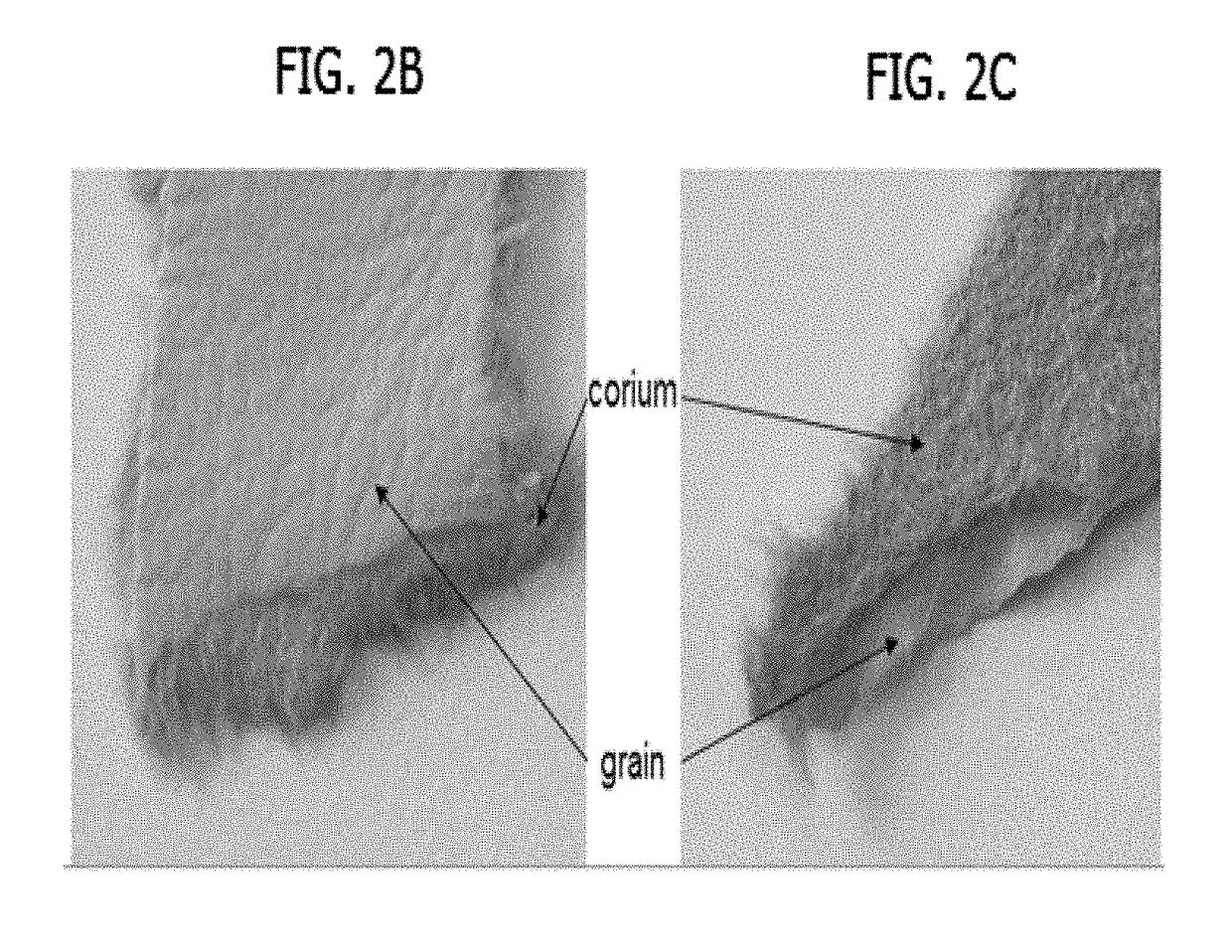

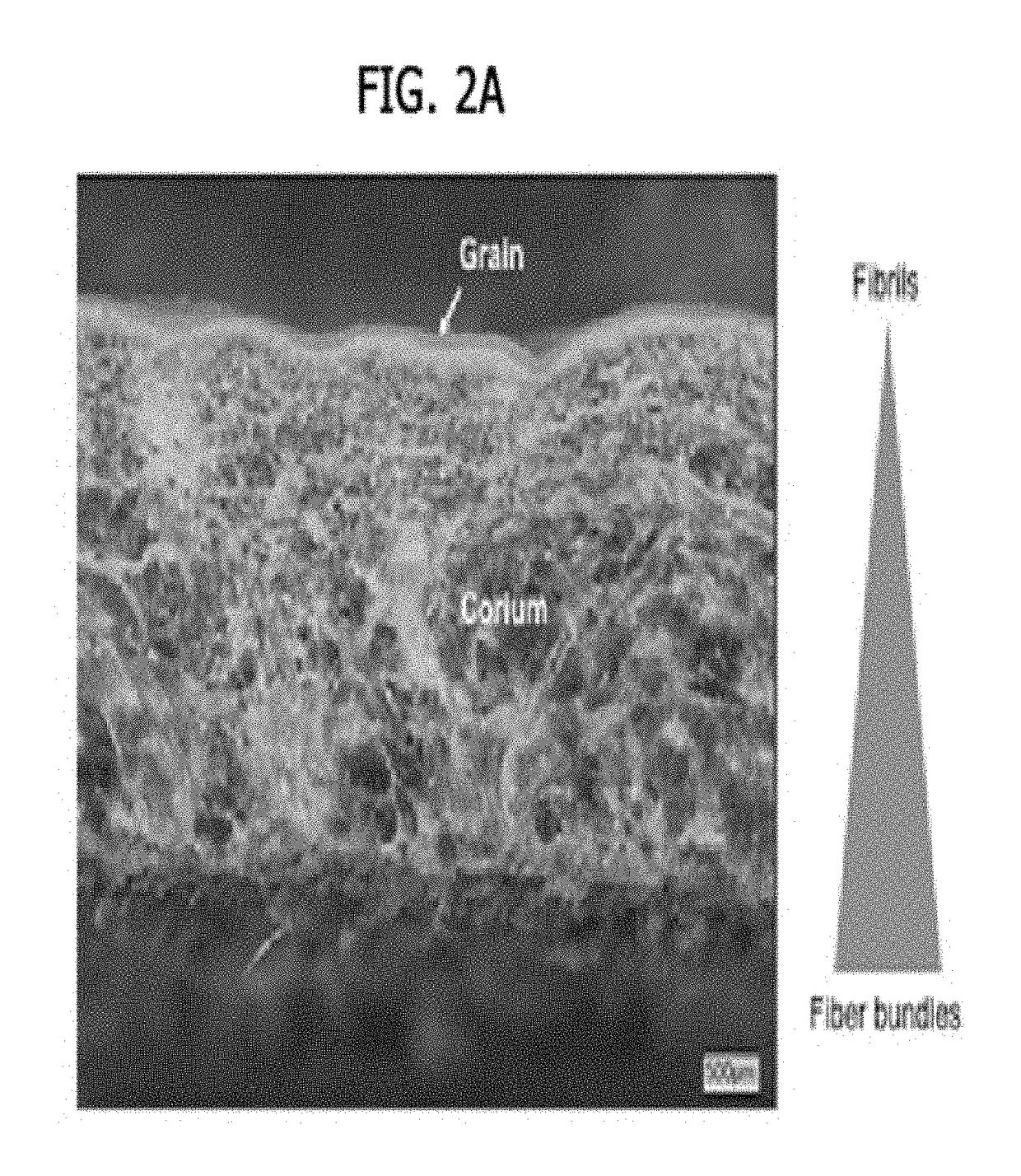

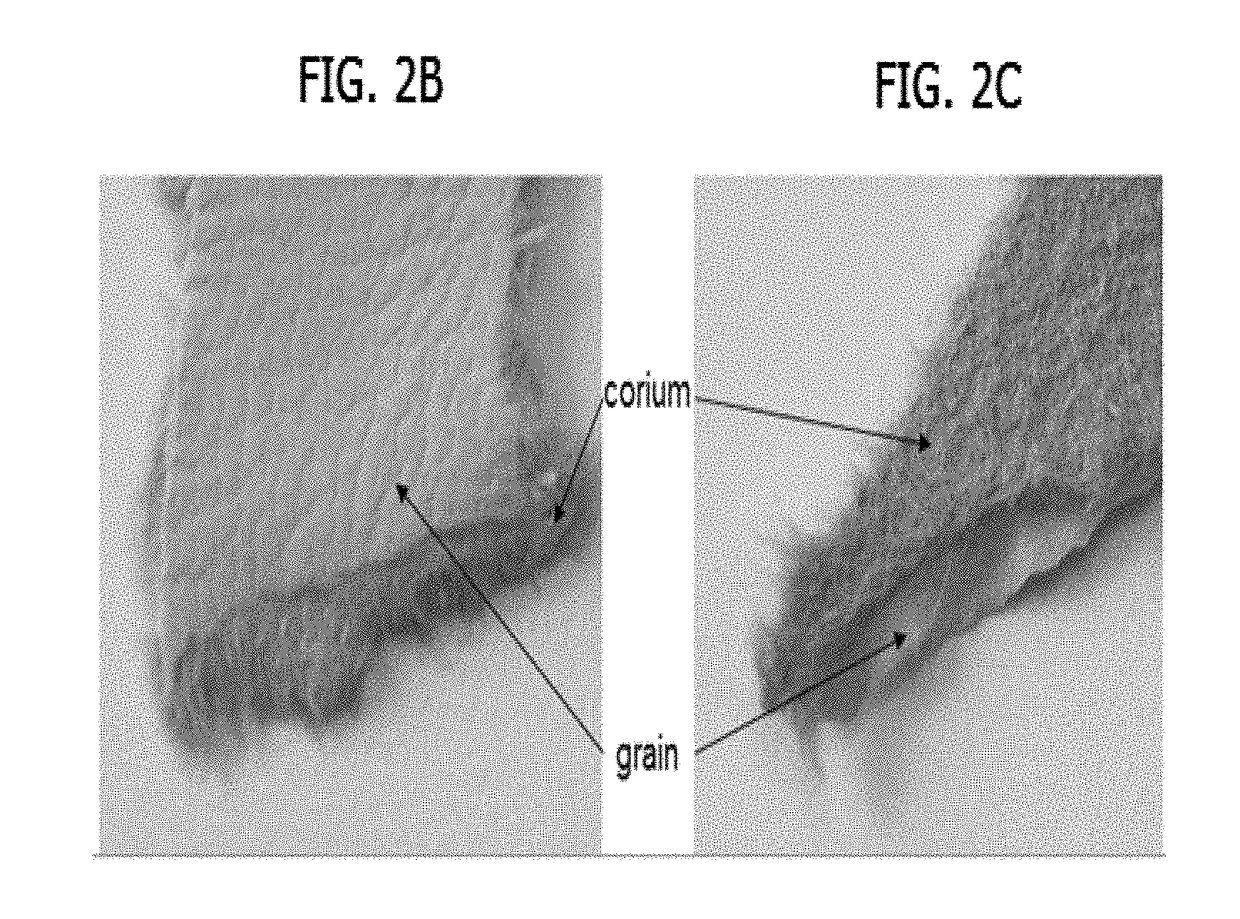

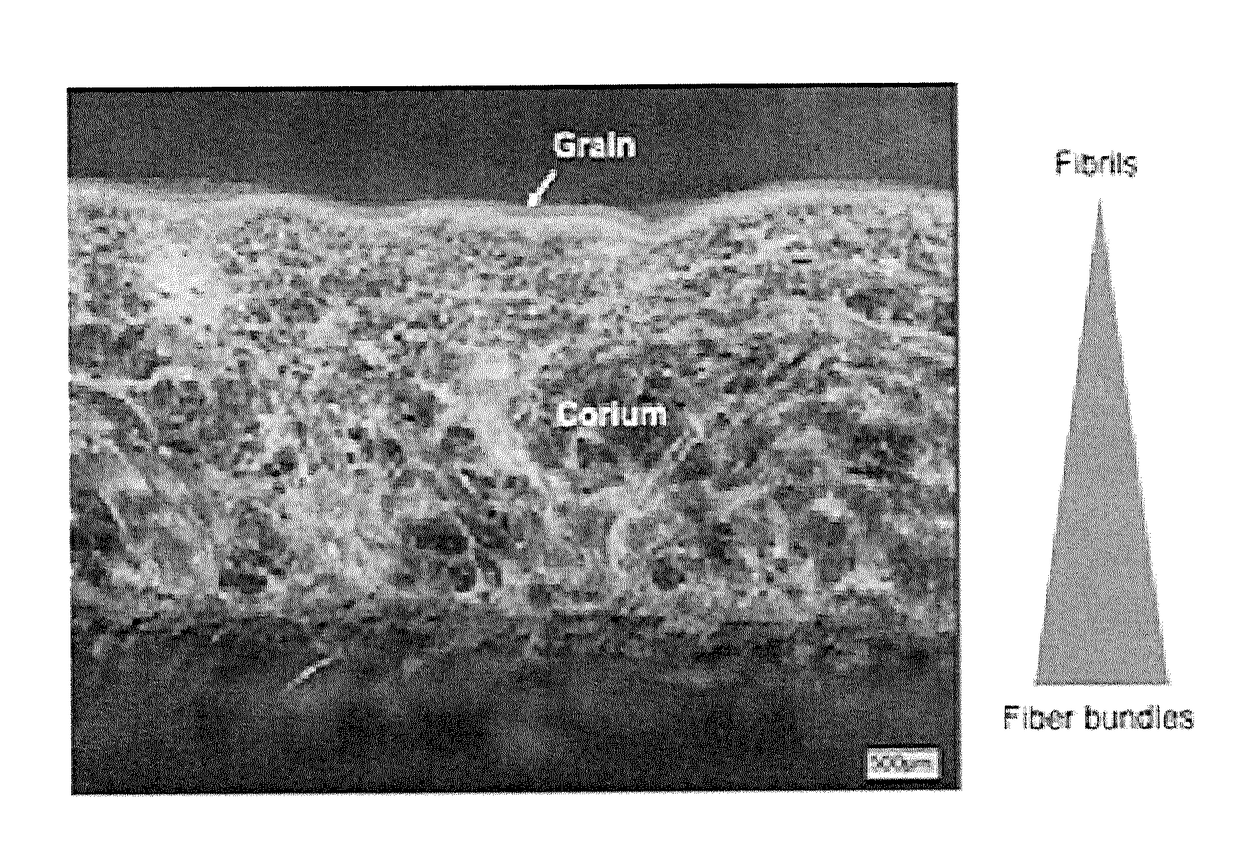

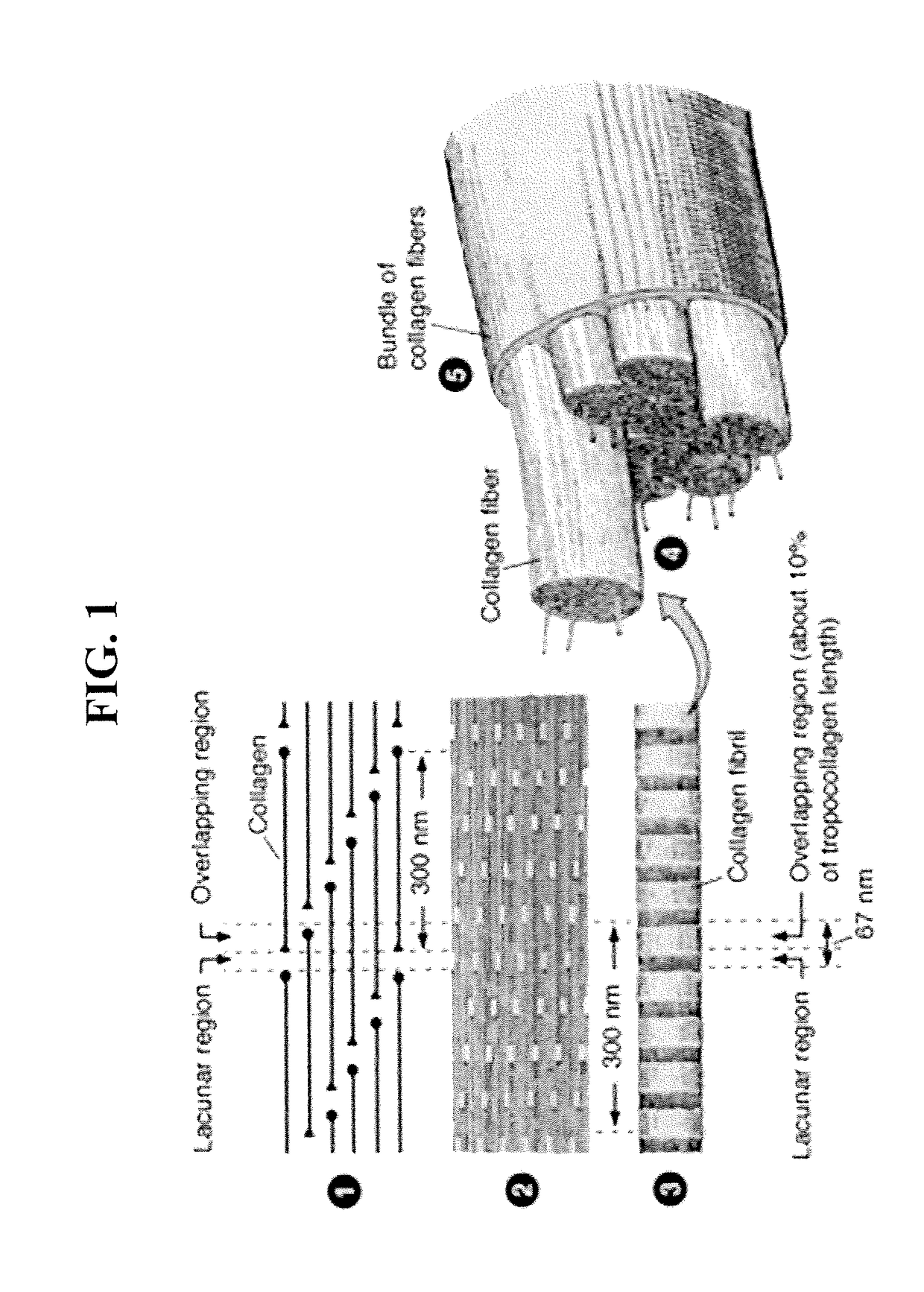

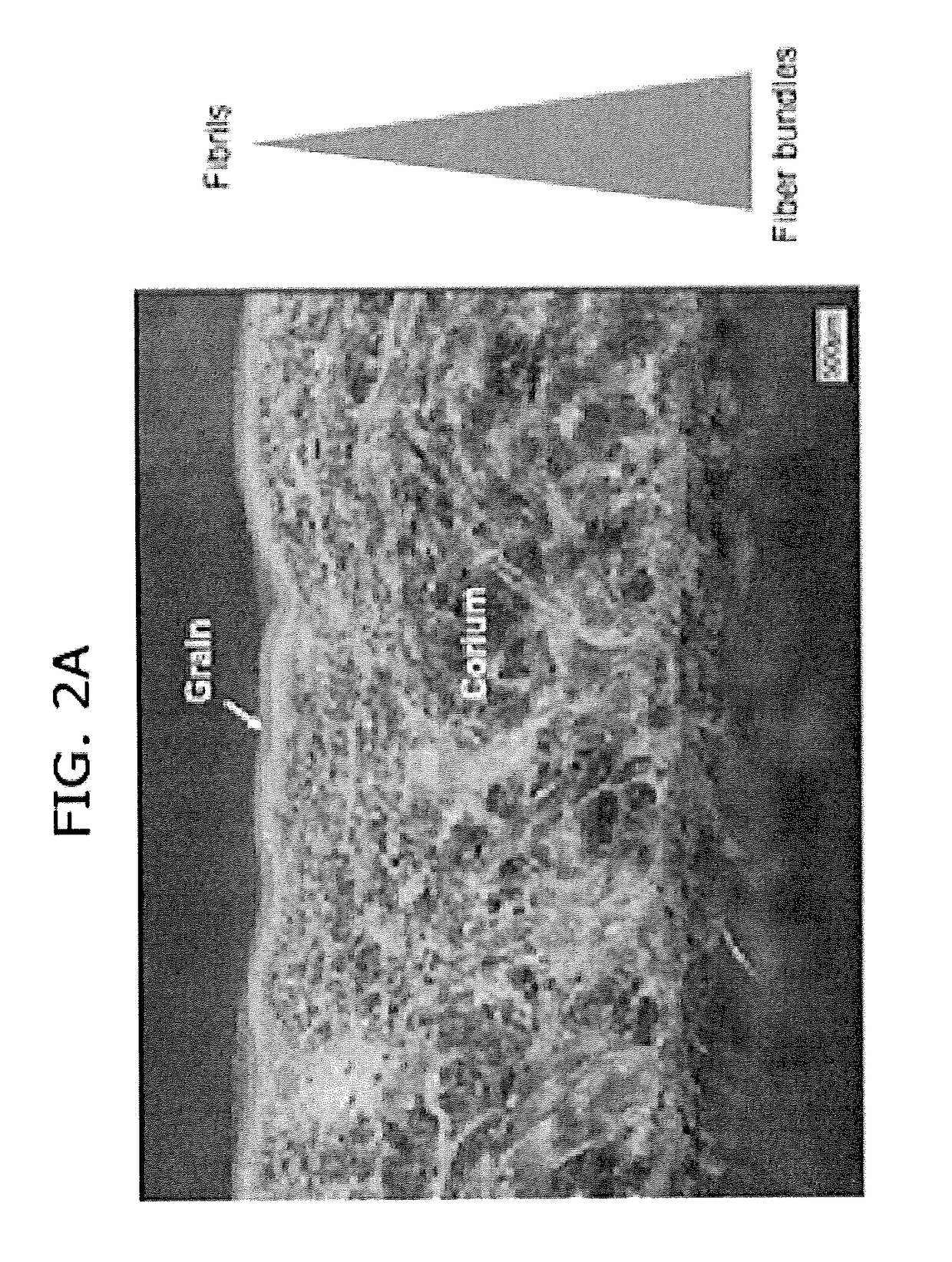

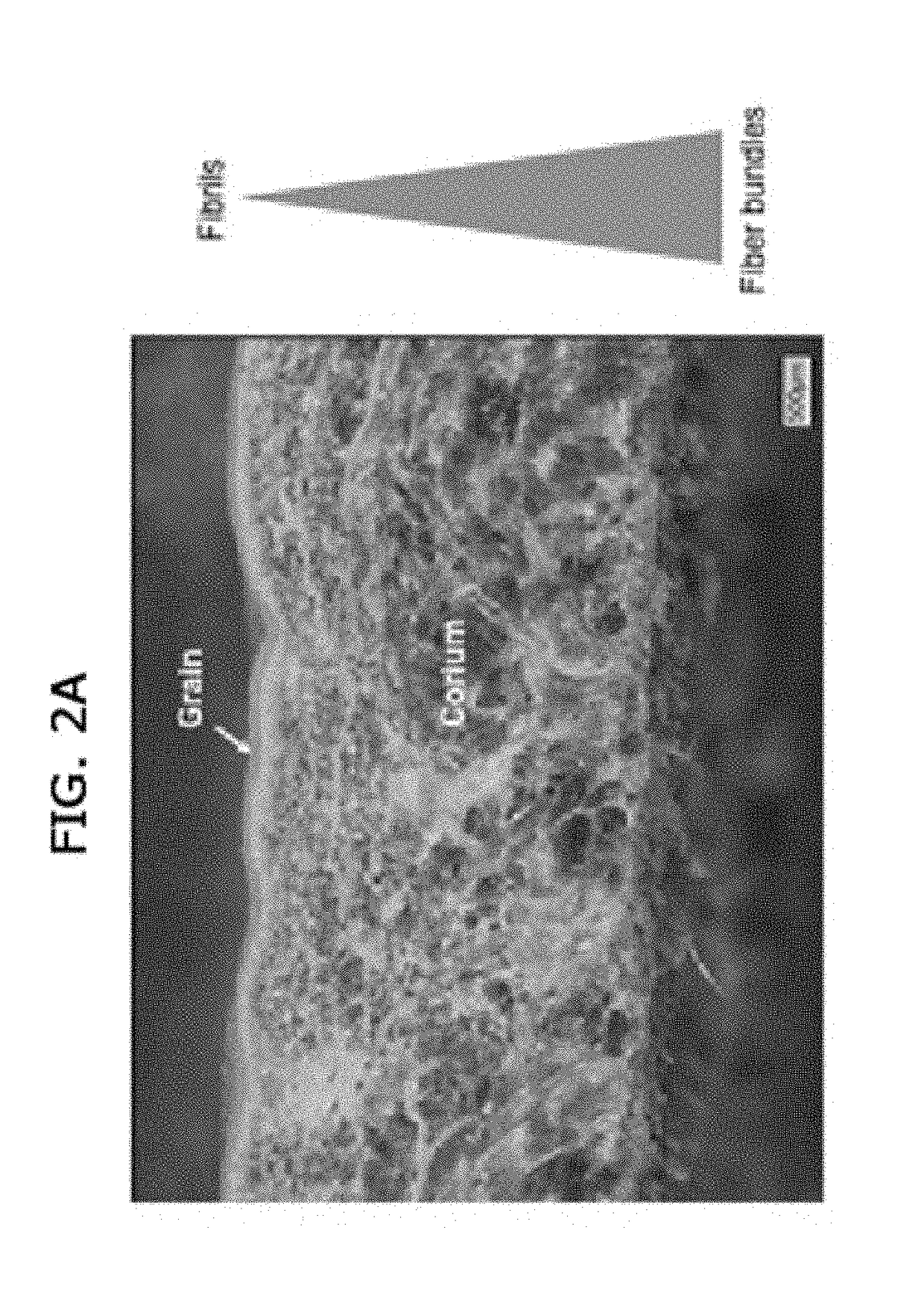

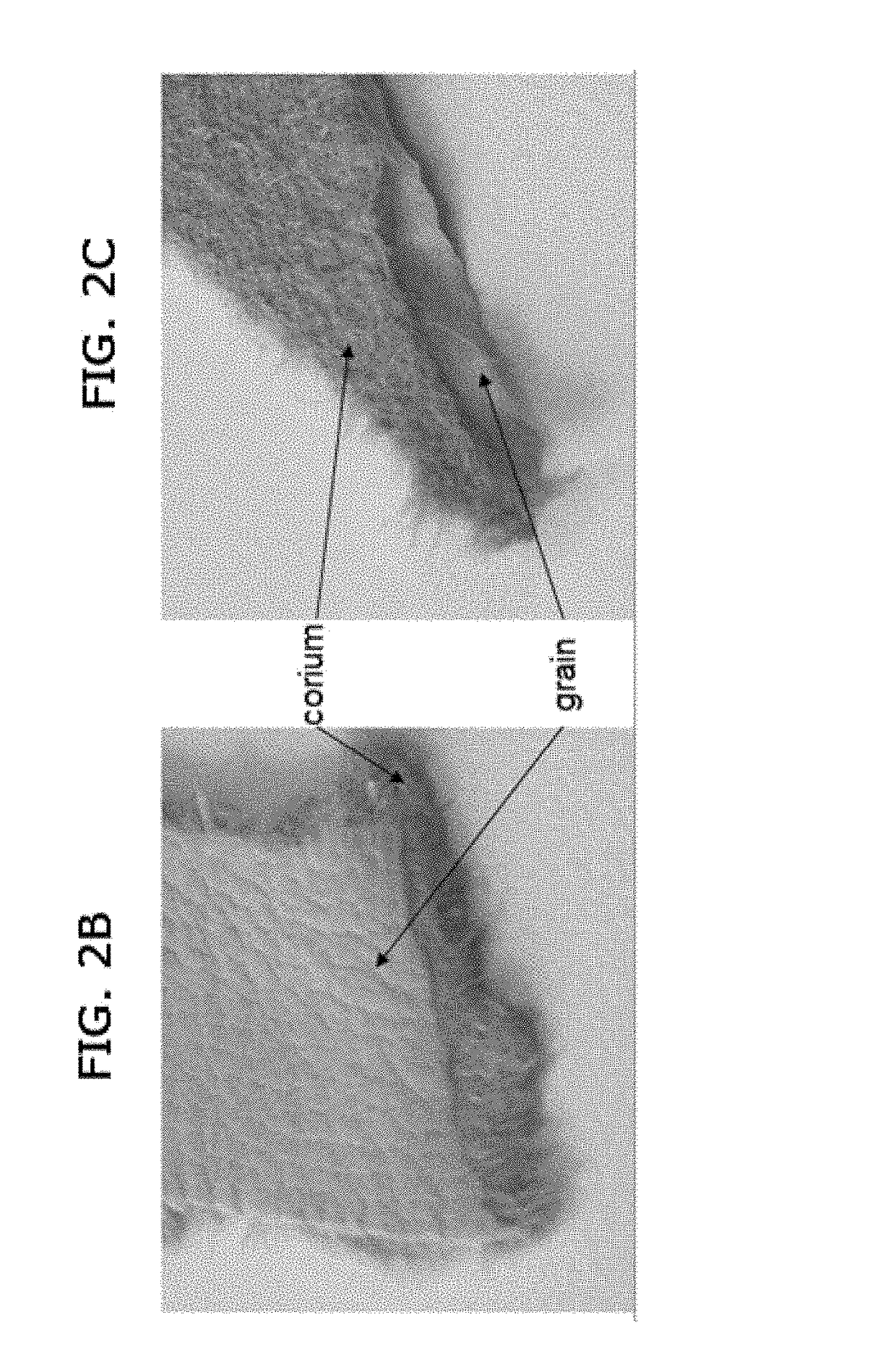

A biofabricated material containing a network of crosslinked collagen fibrils is disclosed. This material is composed of collagen which is also a major component of natural leather and is produced by a process of fibrillation of collagen molecules into fibrils, crosslinking the fibrils and lubricating the crosslinked fibrils. Unlike natural leathers, this biofabricated material exhibits non-anisotropic (not directionally dependent) physical properties, for example, a sheet of biofabricated material can have substantially the same elasticity or tensile strength when stretched or stressed in different directions. Unlike natural leather, it has a uniform texture that facilitates uniform uptake of dyes and coatings. Aesthetically, it produces a uniform and consistent grain for ease of manufacturability. It can have substantially identical grain, texture and other aesthetic properties on both sides distinct from natural leather where the grain increases from one side (e.g., distal surface) to the other (proximal inner layers).

Owner:MODERN MEADOW INC

Production method of transparent leather

ActiveCN111455118AEasy to operateChoose from a wide range of sourcesPre-tanning chemical treatmentSpecial leather manufacturePolymer scienceActive agent

The invention discloses a production method of transparent leather. The production method of the transparent leather disclosed by the invention comprises the following four steps: 1, fully washing deashed and softened pelt with water until a total ash content is less than 0.5%, then taking the pelt out of a drum, carrying out stacking and standing for 30 minutes, and weighing the pelt, wherein theweight of the pelt is used as a reference for materials used in subsequent operation; 2, dissolving a surfactant or a polyfunctional amphiphilic substance such as a fatting agent for leather by usinga proper amount of water, adding the dissolved substance into a rotary drum, and then feeding the leather and carrying out rotating for at least 30 minutes; 3, dissolving or diluting acid or alkali with a proper amount of water, adding the dissolved or diluted acid or alkali into the rotary drum in batches, rotating the rotary drum for at least 10 minutes after each time of addition, continuing to rotate for at least 15 minutes after all the acid or alkali is added, and controlling the pH value of a bath solution to be 3.5-5.5 or 9.5-11.5; and 4, carrying out toggling and drying at a temperature not higher than 35 DEG C to finish the production of the transparent leather. Equipment and materials used in the method are widely used by leather making enterprises, and the types and the usingamounts of the materials and processing technological parameters can be adjusted according to product requirements, so practicability is high. Meanwhile, the pelt does not undergo violent expansion any more in the production process, so the production accident of breakage of the pelt is avoided, operation is easy, and risks are low.

Owner:SICHUAN UNIV

Manufacturing method of highly tear resistant ultrathin boot leather

InactiveCN102943138AHigh tear strengthGood expansion strengthTanning treatmentSpecial leather manufactureMoisture regainDyeing

The invention relates to the technical field of leather manufacturing method, and provides a manufacturing method of highly tear resistant ultrathin boot leather. The boot leather prepared by the method has high tear strength and high cutting rate, and is thin and soft. The method comprises the following steps: routine wringing of leather felt, stretching, shaving, retanning and dyeing, removal out of drum and ageing for overnight, stretching, vacuumizing, hanging, drying, moisture regain, mill, toggling and finishing.

Owner:XINGYE LEATHER TECH CO LTD

Manufacturing method of tanned shrunk grain top layer leather

ActiveCN104762422AUnique shapeCan be used in a wide rangeTanning treatmentPre-tanning chemical treatmentTanninEngineering

The invention provides a manufacturing method of tanned shrunk grain top layer leather. In the method, crust leather is successively subjected to following processes: degreasing, re-tanning, neutralization, filling, dyeing, fat-liquoring, stacking, vibration-softening, leather grinding, painting-decoration and roll-burnishing. In the re-tanning process, by means of addition of sodium carbonate, the pH value of liquid in a drum machine is regulated to be 8-10 and meanwhile the temperature of the liquid is adjusted to be 33-35 DEG C, and then the crust leather is added with a shrunk grain agent to generate patterns on the crust leather, and finally when the processes are finished, the liquid in the drum machine is drained completely. In the invention, the shrunk grain agent is added at special pH value and temperature for generate bull-shoulder pattern on the crust leather, so that the tanned shrunk grain top layer leather is unique in appearance and is wider in available range when compared with a tanned leather prepared through a conventional technology. Meanwhile, by means of addition of a tannin extract in a special manner and at a special proportion during the filling process, the bull-shoulder pattern on the crust leather can be shaped to form a pattern shrinking effect.

Owner:FENGAN LEATHER

Method for preparing antibacterial silver-plating leather

InactiveCN101608246AImprove thermal conductivityHas broad-spectrum antibacterial propertiesSpecial leather manufactureLeather surface finishingAlloyRadio frequency sputtering

The invention discloses a method for preparing antibacterial silver-plating leather. The method is characterized in that the adopted sputtering method is magnetron sputtering and / or radio-frequency sputtering method and comprises the following steps of: removing spots on the surface of a leather material; and then putting the leather material as a substrate into a sputtering room, taking metal silver or silver alloy material as a sputtering target material, carrying out sputtering coating by adjusting technique parameters such as the temperature of the substrate and the temperature of the silver target material in the sputtering technique, and obtaining the antibacterial silver-plating leather. The method for preparing antibacterial silver-plating leather has no pollution, does not changethe performance of the raw leather materials and has high antibacterial efficiency.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Biofabricated material containing collagen fibrils

ActiveUS10301440B2Facilitates uniform uptakeSame elasticityMonocomponent protein artificial filamentDomestic upholsteryFiberFibril

A biofabricated material containing a network of crosslinked collagen fibrils is disclosed. This material is composed of collagen which is also a major component of natural leather and is produced by a process of fibrillation of collagen molecules into fibrils, crosslinking the fibrils and lubricating the crosslinked fibrils. Unlike natural leathers, this biofabricated material exhibits non-anisotropic (not directionally dependent) physical properties, for example, a sheet of biofabricated material can have substantially the same elasticity or tensile strength when stretched or stressed in different directions. Unlike natural leather, it has a uniform texture that facilitates uniform uptake of dyes and coatings. Aesthetically, it produces a uniform and consistent grain for ease of manufacturability. It can have substantially identical grain, texture and other aesthetic properties on both sides distinct from natural leather where the grain increases from one side (e.g., distal surface) to the other (proximal inner layers).

Owner:MODERN MEADOW INC

Method for making biofabricated composite

ActiveUS20170233837A1Facilitates uniform uptakeSame elasticityMonocomponent protein artificial filamentDomestic upholsteryFiberSecondary component

The invention is directed to a composite material comprising a biofabricated material and a secondary component. The secondary component may be a porous material, such as a sheet of paper, cellulose, or fabric that has been coated or otherwise contacted with the biofabricated material. The biofabricated material comprises a uniform network of crosslinked collagen fibrils and provides strength, elasticity and an aesthetic appearance to the composite material.

Owner:MODERN MEADOW INC

Preparation method of wear-resistant ultrahydrophobic flame-retarding leather

ActiveCN108441588AGuaranteed persistenceHigh mechanical strengthSpecial leather manufactureLeather surface finishingFiberFiltration

The invention discloses a preparation method of wear-resistant ultrahydrophobic flame-retarding leather. The method includes the steps of: performing suction filtration to an anhydrous ethanol dispersion liquid of a carbon material, a solution containing vegetable tannin, and a solution containing a metal compound in certain order onto leather which has been washed and dried, then soaking the leather having a micron-nano rough structure in a solution containing a low surface energy substance to modify the leather. According to the method, through the suction filtration, the vegetable tannin and metal ions, which are adhered to outside the carbon material on leather collagen fiber, are subjected to in-situ complexing reaction to form a binder, so that the carbon material stably coats and isfixed to the surface of the leather collagen fiber. The leather material has excellent surface mechanical strength; under wearing by external force, the leather collagen fiber is effectively coated and protected by the carbon material, so that the leather has wear-resistant and ultrahydrophobic performance and is further improved in flame retarding property. The method is simple in process, is short in preparation period, is low in energy consumption and is easy to carry out in large scale industrial production.

Owner:SICHUAN UNIV

Production method for waterproof and flame-retardant shoe upper leather

ActiveCN107881269AImprove compactnessReduce usageTanning treatmentLeather/skins/hides/pelt chemical treatment apparatusManufacturing technologyAcrylic resin

The invention relates to the technical field of leather manufacturing technologies and provides a production method for waterproof and flame-retardant shoe upper leather. Chromium-zirconium-aluminum and zirconium-aluminum-titanium which have the flame-retardant property serve as a tanning agent and a retanning agent to conduct tanning and retanning; the retanning agent, a neutralizing agent and afatting agent which have the waterproof property are selected to enable the leather to have the waterproof property; an environment-friendly-type flame retardant is selected to enable the leather to have the flame-retardant property; and modified graphene-based acrylic resin and modified graphene-based polyurethane are added in filling and coating materials to serve as waterproof and flame-retardant enhancers to enable the leather to have the good waterproof and flame-retardant effects. According to the production method, under the precondition that natural leather has the excellent quality, the environment-friendly and flame-retardant effects of the leather can be achieved, the dosage of the flame retardant is reduced, the production cost is reduced, and the production method is suitablefor batch production and application.

Owner:XINGYE LEATHER TECH CO LTD

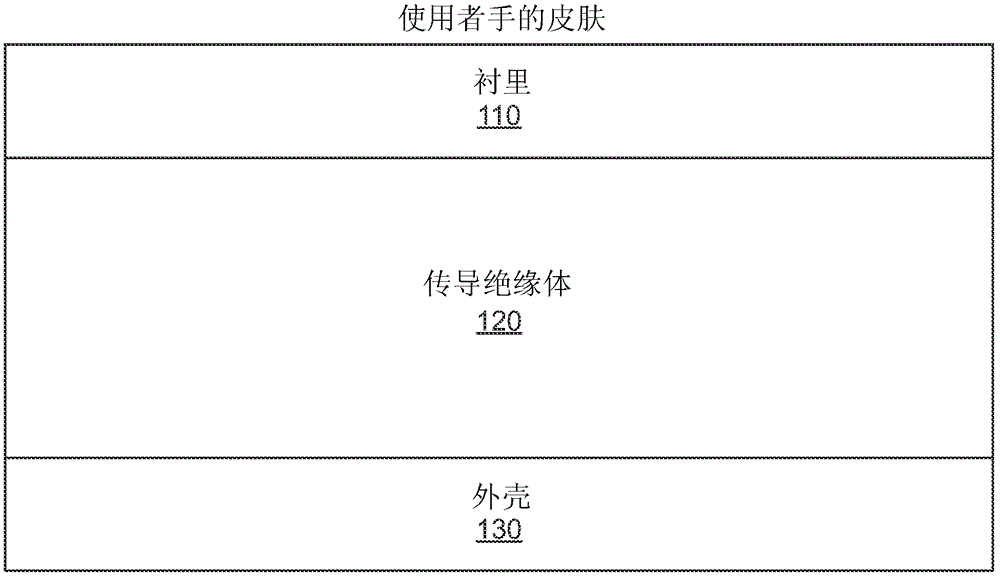

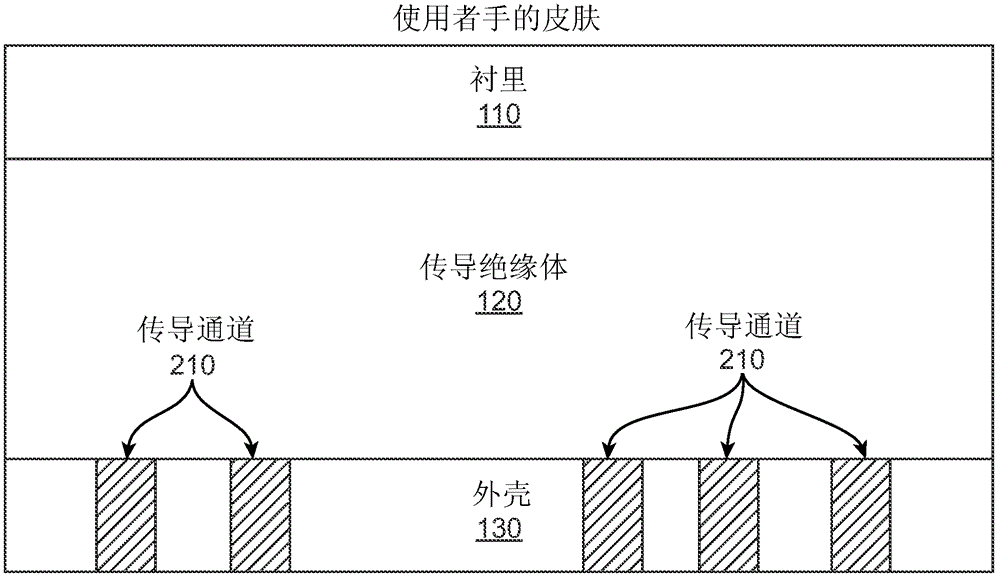

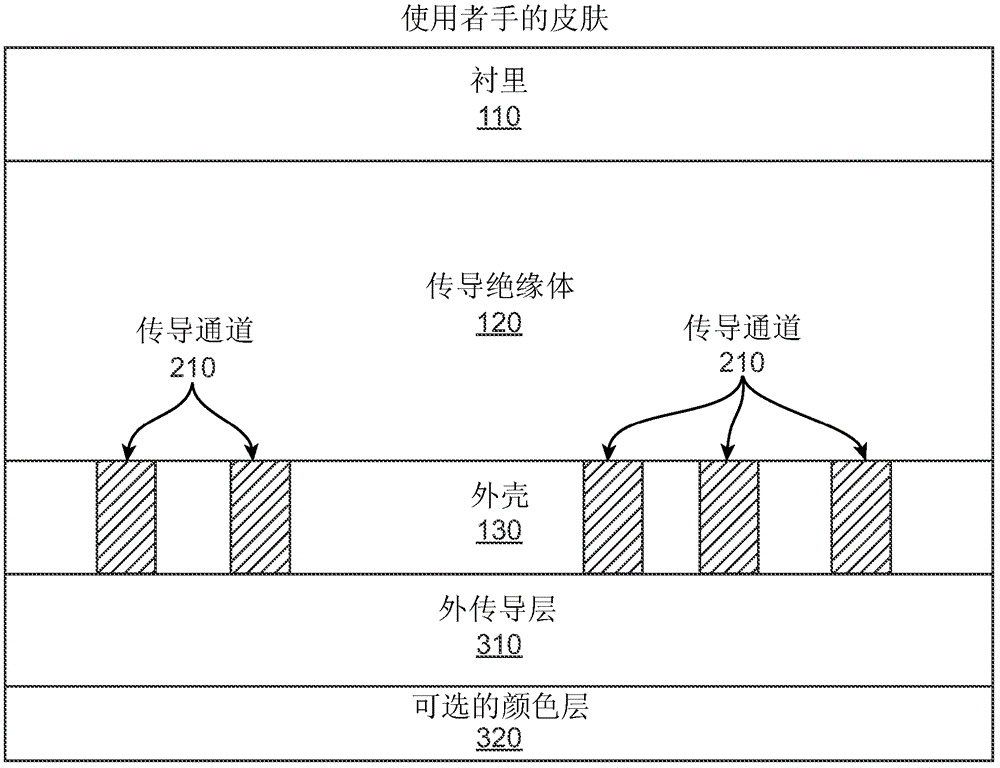

Material for use with a capacitive touch screen

Owner:GLT TECHNOVATIONS

Sturgeon leather production method and sturgeon leather produced using same

InactiveCN102154529AImprove wrinkle resistanceFeel goodSpecial leather manufactureEngineeringSturgeon

The invention provides a sturgeon leather production method and a sturgeon leather produced using same. The sturgeon leather production method comprises the following steps of: 1) pretreating a sturgeon leather raw material with a bone deck by means of cleaning, soaking and degreasing; 2) sequentially performing primary softening, pickle softening and tanning to the bone deck of the pretreated sturgeon leather by means of cleaning, soaking and degreasing, so that the bone deck is softened; and 3) treating the sturgeon leather with the softened bone deck by means of neutral retanning, dyeing, greasing and drying to obtain the sturgeon leather with the softened bone deck after the bone deck is treated by means of the primary softening, the pickle softening and the tanning. The sturgeon leather produced by the method is soft and ventilate, and has good tear-resistant performance and buckling-resistant performance, so that the special bone deck of the sturgeon is firmly adhered to the surface of the leather without falling off, the bone deck can be bended at 45-90 degrees without breaking off, and each bone deck is distinct in gradation, natural in decorative pattern, beautiful and fashionable.

Owner:李宏强

Method for producing shrunk grain leather from wet blue leather

The invention discloses a method for producing shrunk grain leather from wet blue leather. The method comprises the following steps: performing dechroming treatment on wet blue (cattle) leather, and removing toxic Cr <6+>, so that the product can be prepared into a non-toxic and environment-friendly product; softening the leather blank through an alkaline enzyme, so that the leather fiber is properly loosened and softened, and the leather blank is soft and comfortable; shrinking the grain in two steps, to be specific, shrinking the grain by using an aldehyde, and then shrinking the grain by a non-toxic and ecological vegetable tanning agent, so that the grain shrinking effect is enhanced; filling multiple materials, so that the leather grains are full and raised; enabling the leather surface to present uniform and regular grains through the mechanical action. The shrunk grain leather produced by the method is particularly suitable for manufacturing high-grade chrome-free furniture leather, sofa leather and package leather, and a novel way is provided for recycling the wet blue leather.

Owner:HUNAN LEAD LEATHER

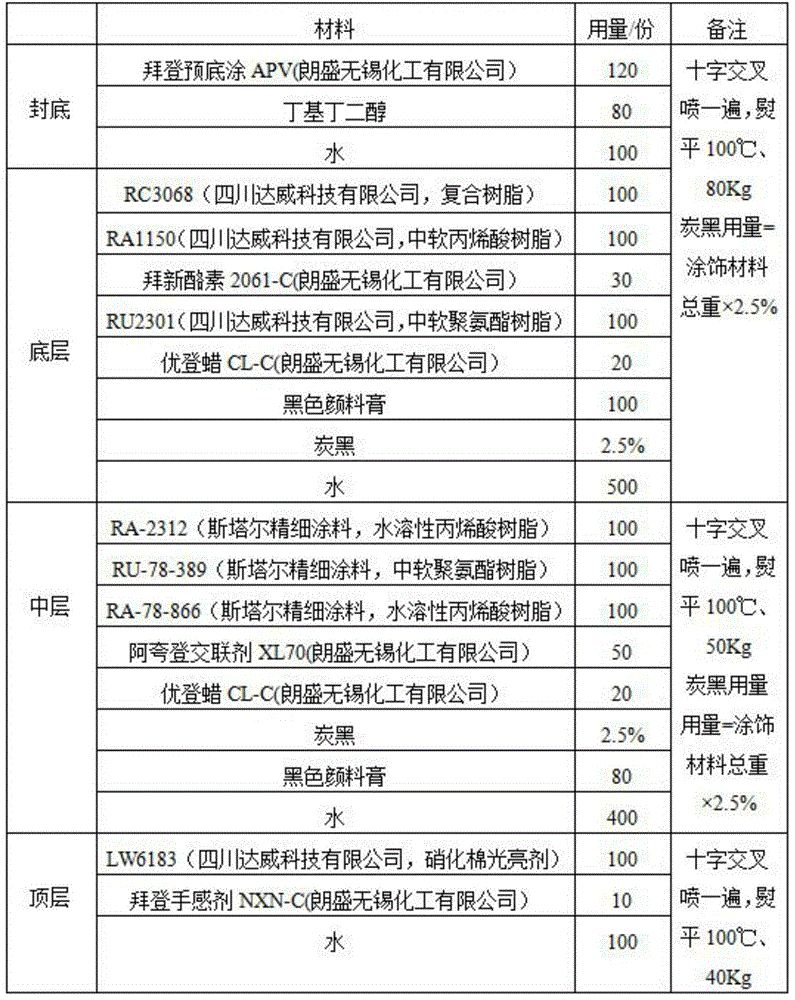

Anti-static cattle hide upper leather and preparation method thereof

The invention discloses anti-static cattle hide upper leather and a preparation method thereof. The process is conducted by the adoption of the combination method of wet dyeing and finishing anti-static treatment and dry finishing anti-static treatment; in the wet dyeing and finishing work section, 6.0% of anti-static agents are added for anti-static treatment after dyeing and fat-liquoring procedures, and a drum is stopped to stay the night; in the dry finishing coating procedure, conductive fillers are adopted to be doped in a coating material to conduct anti-static treatment on a coating. The physical and chemical property of the anti-static cattle hide upper leather manufactured through the technology can meet the national standard, the volume resistivity is 103 omega m, the number of flesh side adsorption paper pieces is four, and the anti-static grade is four.

Owner:SICHUAN UNIV +1

Akhal-teke horse posture specimen hide preparation method

InactiveCN103773910AElasticEasy to storeTanning treatmentPre-tanning chemical treatmentEngineeringProtective Agents

The invention discloses an Akhal-teke horse posture specimen hide preparation method. The Akhal-teke horse hide preparation method is divided into two stages, wherein the first stage is the wet finishing of the fresh hide of the Akhal-teke horse, including the processes of soaking at normal temperature, re-soaking at normal temperature, pickling, degreasing, softening, tanning and basification; the second stage is the dry finishing of the fresh hide, including repeated drum treatment for cleaning and drum treatment for bright fur to obtain a finished product. According to the method disclosed by the invention, the tanned Akhal-teke horse hide is light, thin, soft, elastic and easy to store and can be stored for a long time without using a protective agent; the prepared specimen does not deform easily and better reflects the form details of animals; the specimen fur is glossy, thus the prepared specimen is more realistic.

Owner:KUNMING INST OF ZOOLOGY CHINESE ACAD OF SCI

Method for tempering fur coat of goose down through strong fiber for fastening down hair

This invention relates to a tanning method for effectively increasing the intensity of downs of goose furs and intensity of the leather to realize strong goose down fur fibers and solid downs by the following steps: selecting goose-drawing feather while alive-curing the muscles-vein drainage-skinning-antiseptic-freezing-immersing in the water and softening-pressing the fat-immersing in the acid-pressing fat two times-pretanning-drying-degreasing in organic liquors-retanning and filling.

Owner:陈仲仁

Method for producing water-proof salmon leather

InactiveCN101240355ASimplified tanning processEasy to operateSpecial leather manufactureSurface patternFiber

The invention provides a production method for a waterproof salmon leather, which performs waterproof treatment to the leather during the tanning process with a specific waterproof tanning agent, the waterproof tanning agent is got by mainly mixing acrylic acid multi-chain alkyl ester, unsaturated anhydride ester and N-hydroxymethyl benzamide in weight proportion of 8-12: 5-7:6-10, emulsifying with water, and then dipping formic acid to adjust the pH value to about 1.4-1.6. After the leather is tanned by the waterproof tanning agent, water-repellent group forms between fibers, the waterproof ability of the leather and the final leather product has improved, and the contractibility of the leather and the structure stability of the fiber can also be increased. The production method of the invention also has special treatment to the surface pattern of the leather, which makes the leather both beautiful and waterproof.

Owner:李宏强

Biofabricated material containing collagen fibrils

ActiveUS20190203000A1Facilitates uniform uptakeSame elasticityMonocomponent protein artificial filamentDomestic upholsteryFiberFibril

A biofabricated material containing a network of crosslinked collagen fibrils is disclosed. This material is composed of collagen which is also a major component of natural leather and is produced by a process of fibrillation of collagen molecules into fibrils, crosslinking the fibrils and lubricating the crosslinked fibrils. Unlike natural leathers, this biofabricated material exhibits non-anisotropic (not directionally dependent) physical properties, for example, a sheet of biofabricated material can have substantially the same elasticity or tensile strength when stretched or stressed in different directions. Unlike natural leather, it has a uniform texture that facilitates uniform uptake of dyes and coatings. Aesthetically, it produces a uniform and consistent grain for ease of manufacturability. It can have substantially identical grain, texture and other aesthetic properties on both sides distinct from natural leather where the grain increases from one side (e.g., distal surface) to the other (proximal inner layers).

Owner:MODERN MEADOW INC

Washable leather with repellency

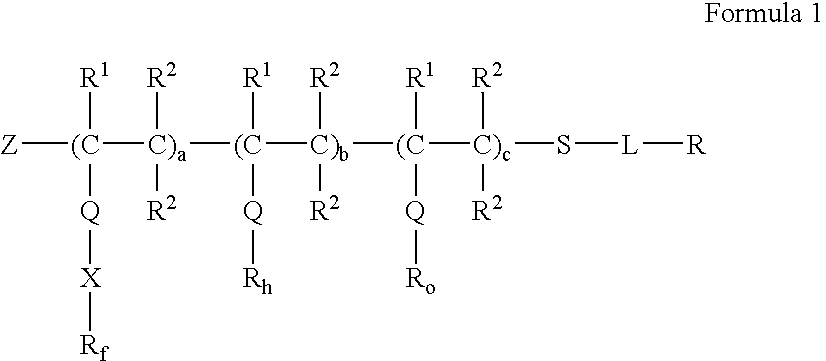

InactiveUS20060188729A1Durable oil repellencyReliable releaseSynthetic resin layered productsSpecial leather manufactureCITRATE ESTERPolymer science

A washable leather having durable oil repellency, durable stain release, and durable water repellency is disclosed and a method of its preparation comprising contacting the leather during tanning with a composition which comprises at least one fluorinated urethane; at least one fluorinated ester; a mixture thereof; or a mixture of at least one fluorinated citrate urethane with at least one fluorinated urethane, at least one fluorinated ester, or a mixture of fluorinated urethane and fluorinated ester.

Owner:SHEEN LEATHER +1

Engineered leather and methods of manufacture thereof

InactiveUS20200199695A1Eliminate needIncrease heightConnective tissue peptidesTanning treatmentCollagenanSkin cell

Engineered animal skin, hide, and leather comprising a plurality of layers of collagen formed by cultured animal collagen-producing (e.g., skin) cells. Layers may be formed by elongate multicellular bodies comprising a plurality of cultured animal cells that are adhered and / or cohered to one another; wherein the elongate multicellular bodies are arranged to form a substantially planar layer for use in formation of engineered animal skin, hide, and leather. Further described herein are methods of forming engineered animal skin, hide, and leather utilizing said layers of animal collagen-producing cells.

Owner:MODERN MEADOW INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com