Patents

Literature

213results about How to "Consumes less energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

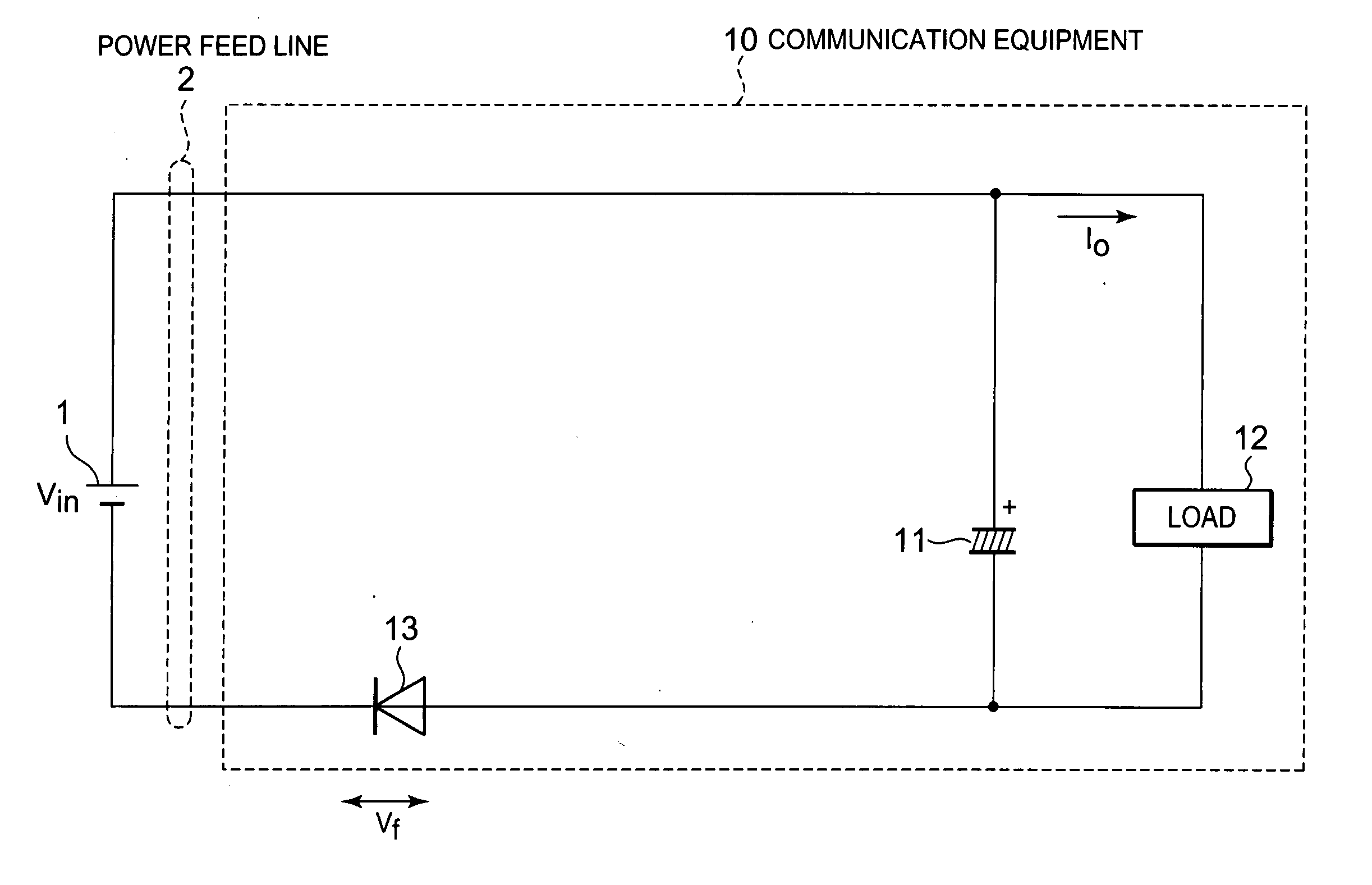

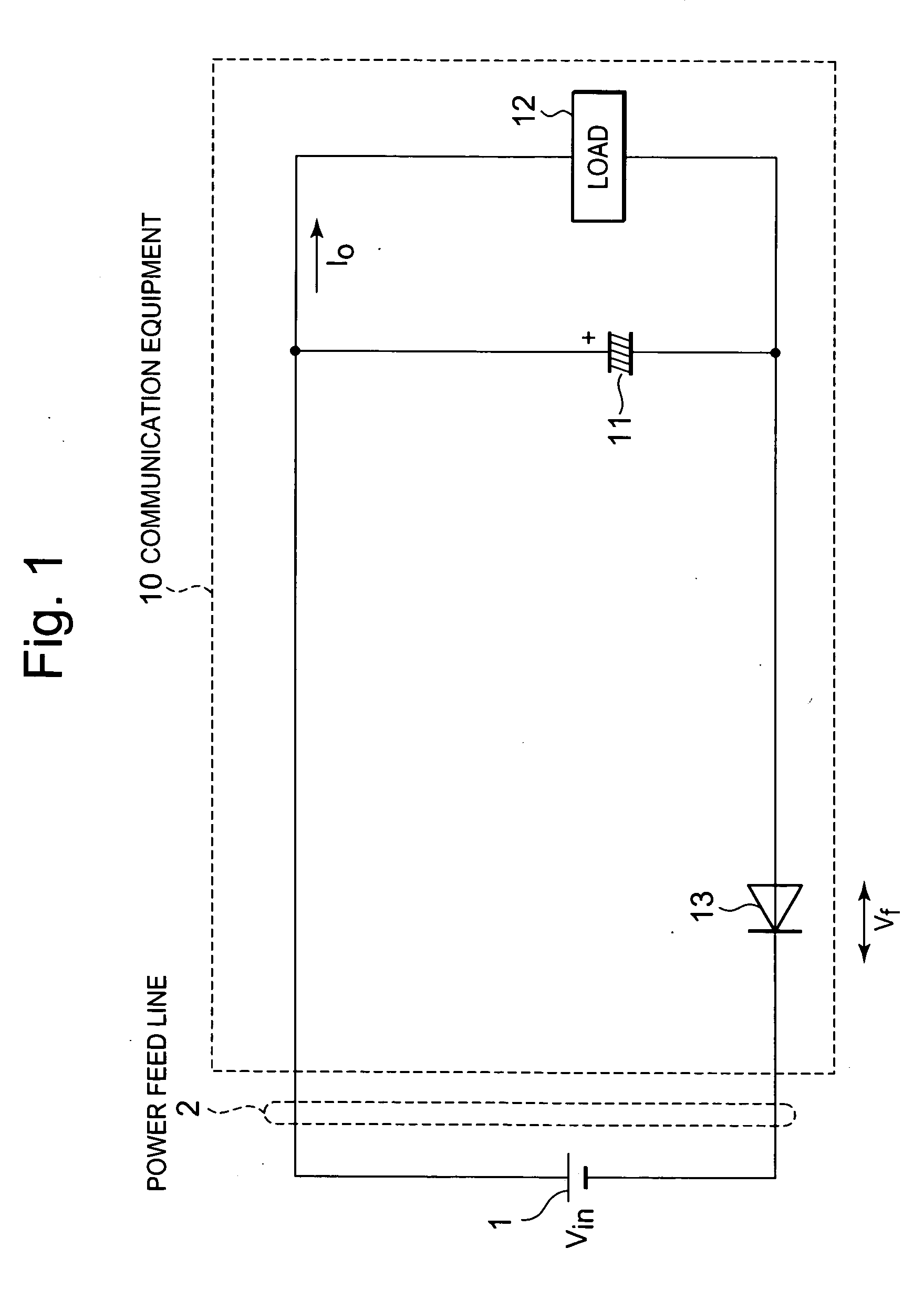

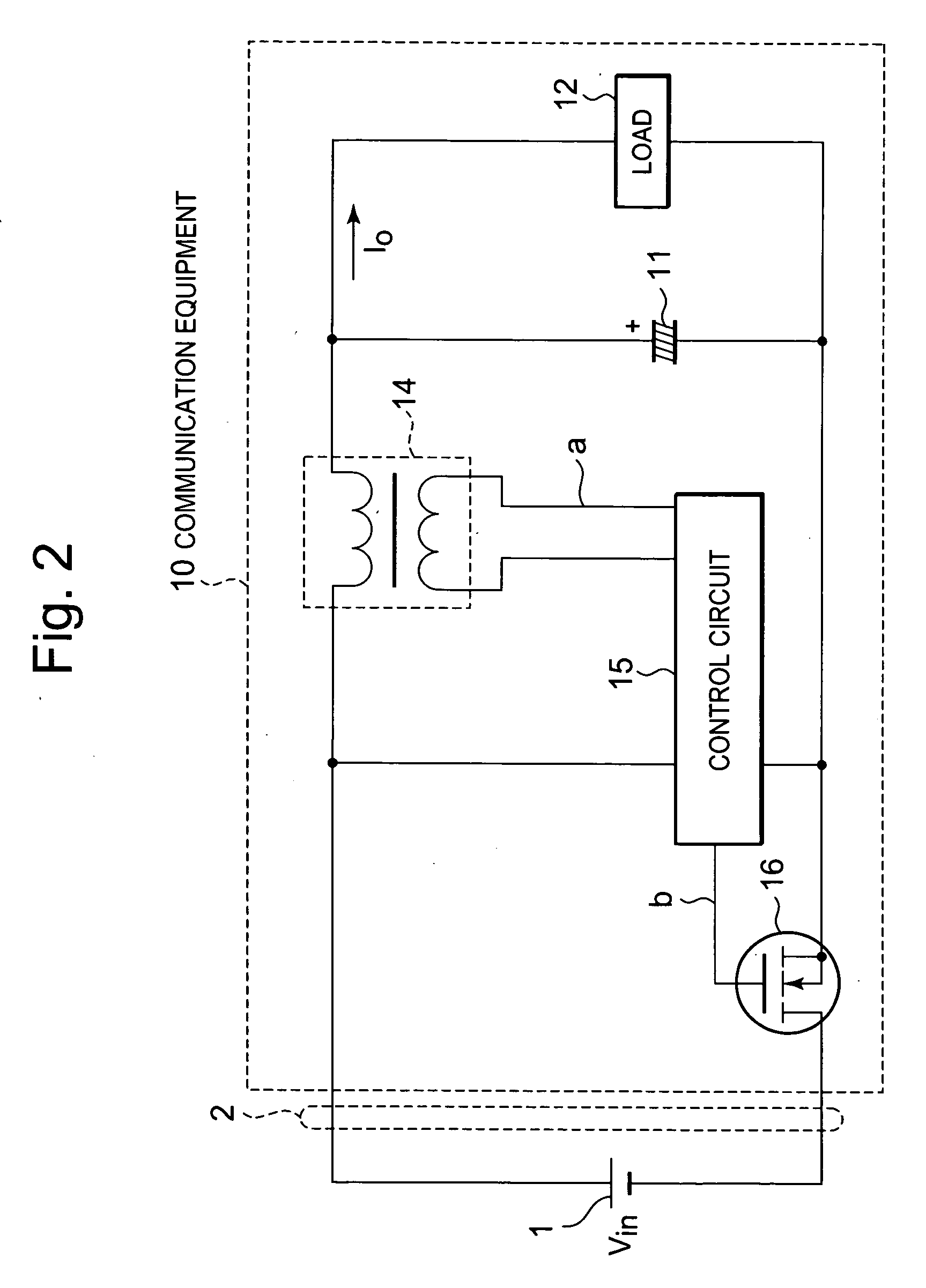

Discharge prevention circuit and electronic equipment provided with the discharge prevention circuit

ActiveUS20060261751A1Consumes less energyDc network circuit arrangementsBoards/switchyards circuit arrangementsCharge currentEngineering

A discharge prevention circuit and electronic equipment with the discharge prevention circuit are provided. The discharging prevention circuit includes a first power line, a second power line, a capacitor, a current detector and a switch. The first and second power lines directly or indirectly connect a power feed line to a load. The capacitor and the current detector are directly or indirectly connected in series between the first and second power lines. The switch is disposed in the first or second power line. The current detector detects at least charging current to the capacitor and discharging current from the capacitor. And if the current detector detects discharging current from the capacitor, the switch acts to stop current flow between the capacitor and the power feed line through the switch.

Owner:NEC CORP

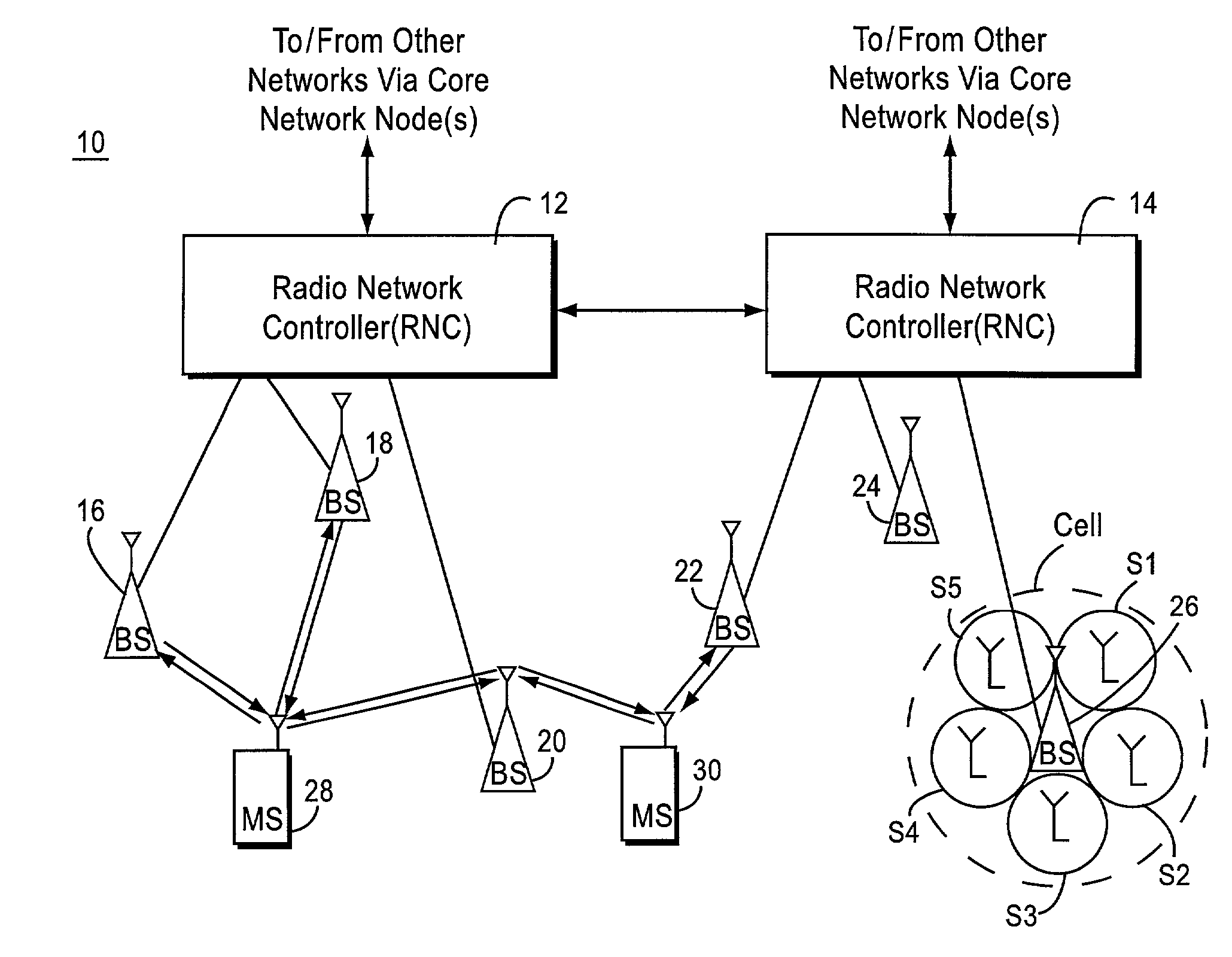

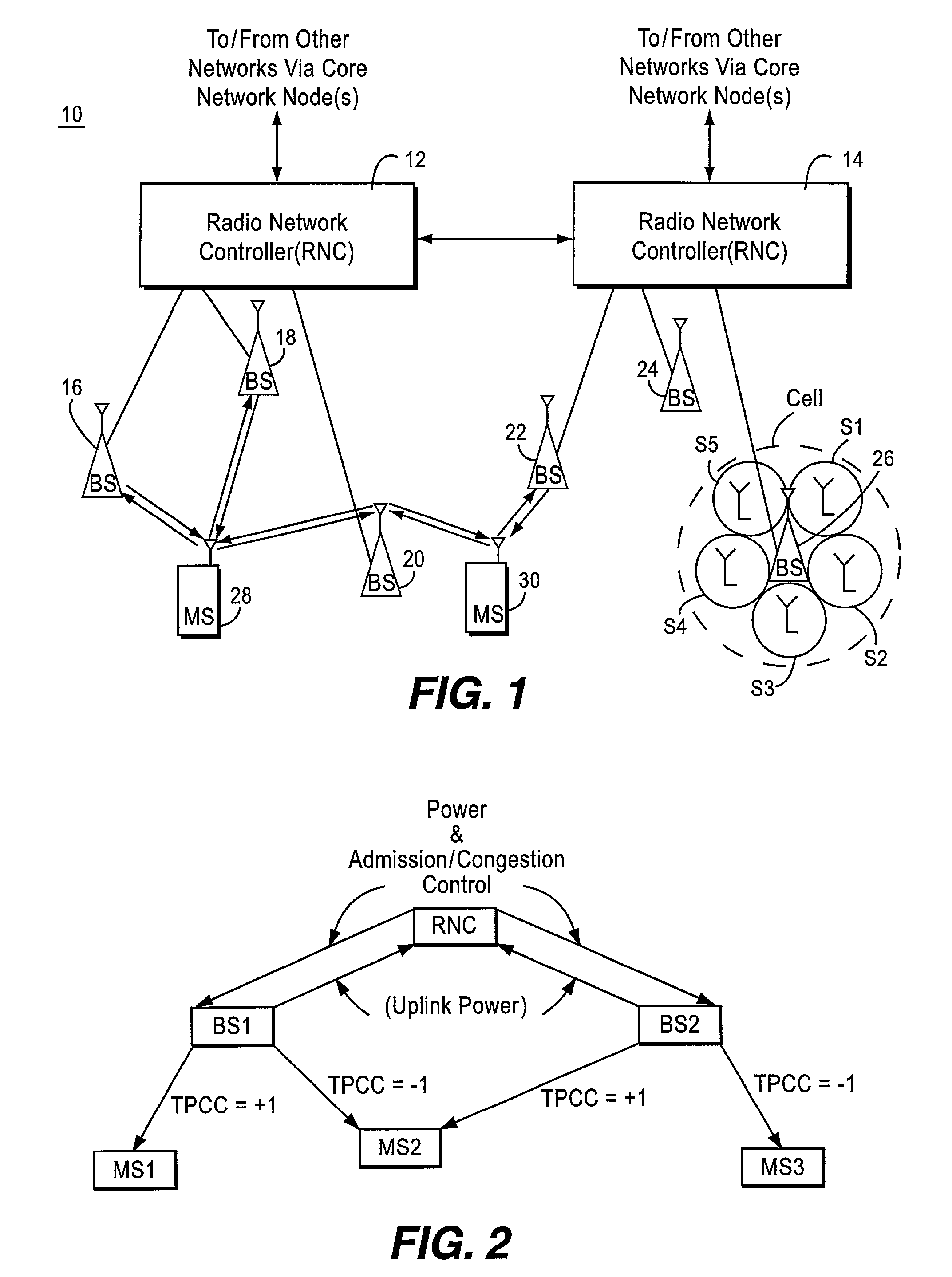

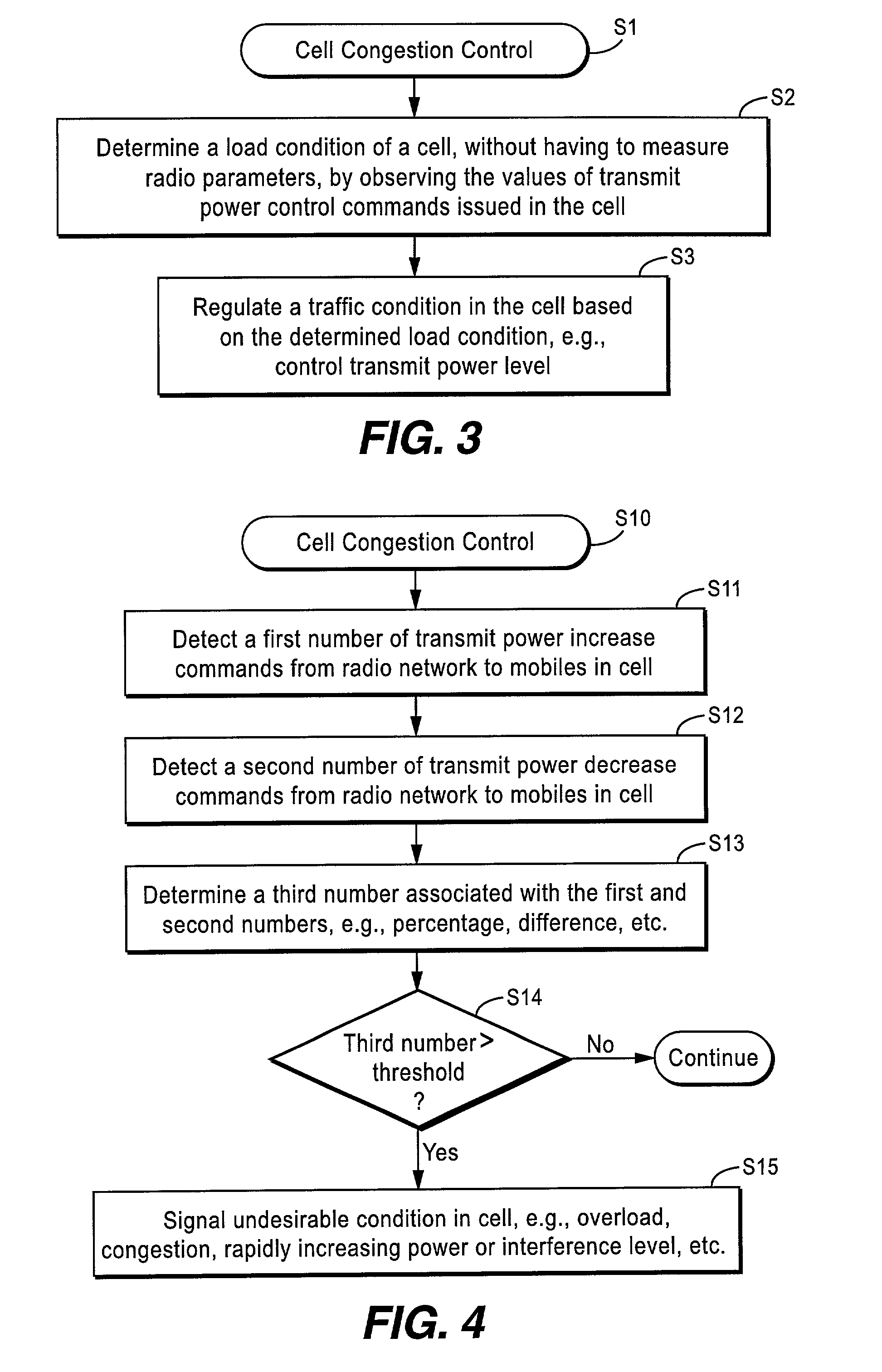

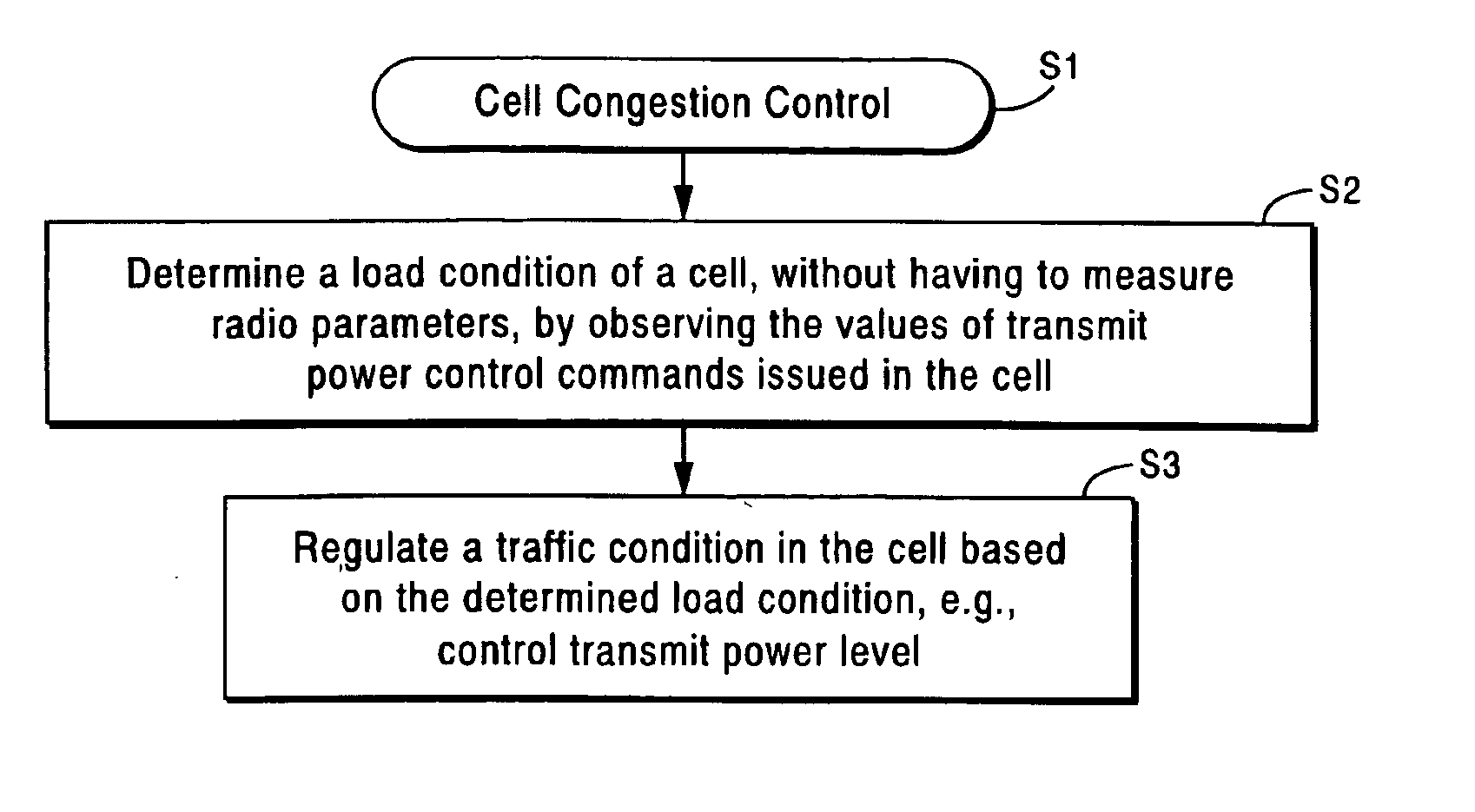

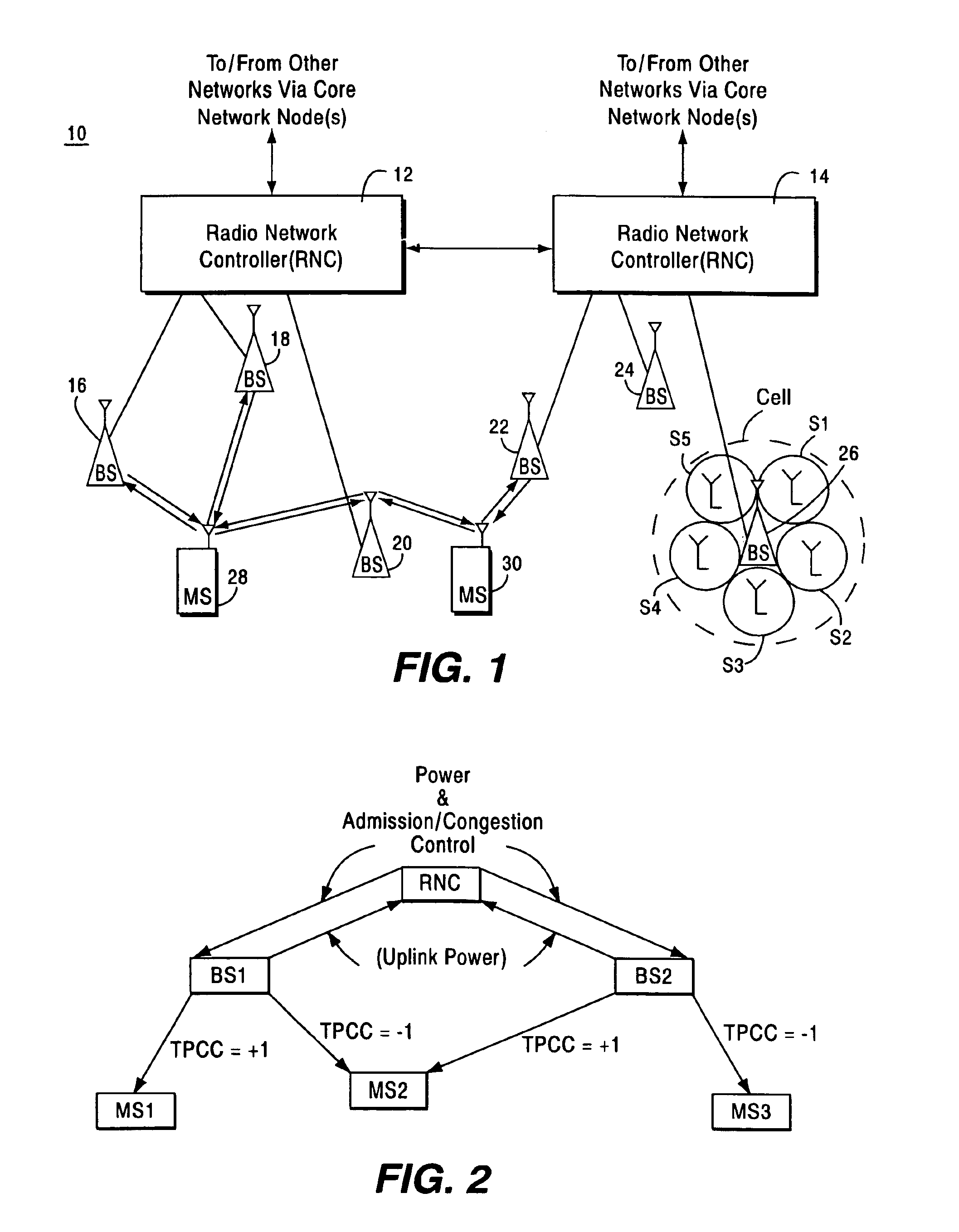

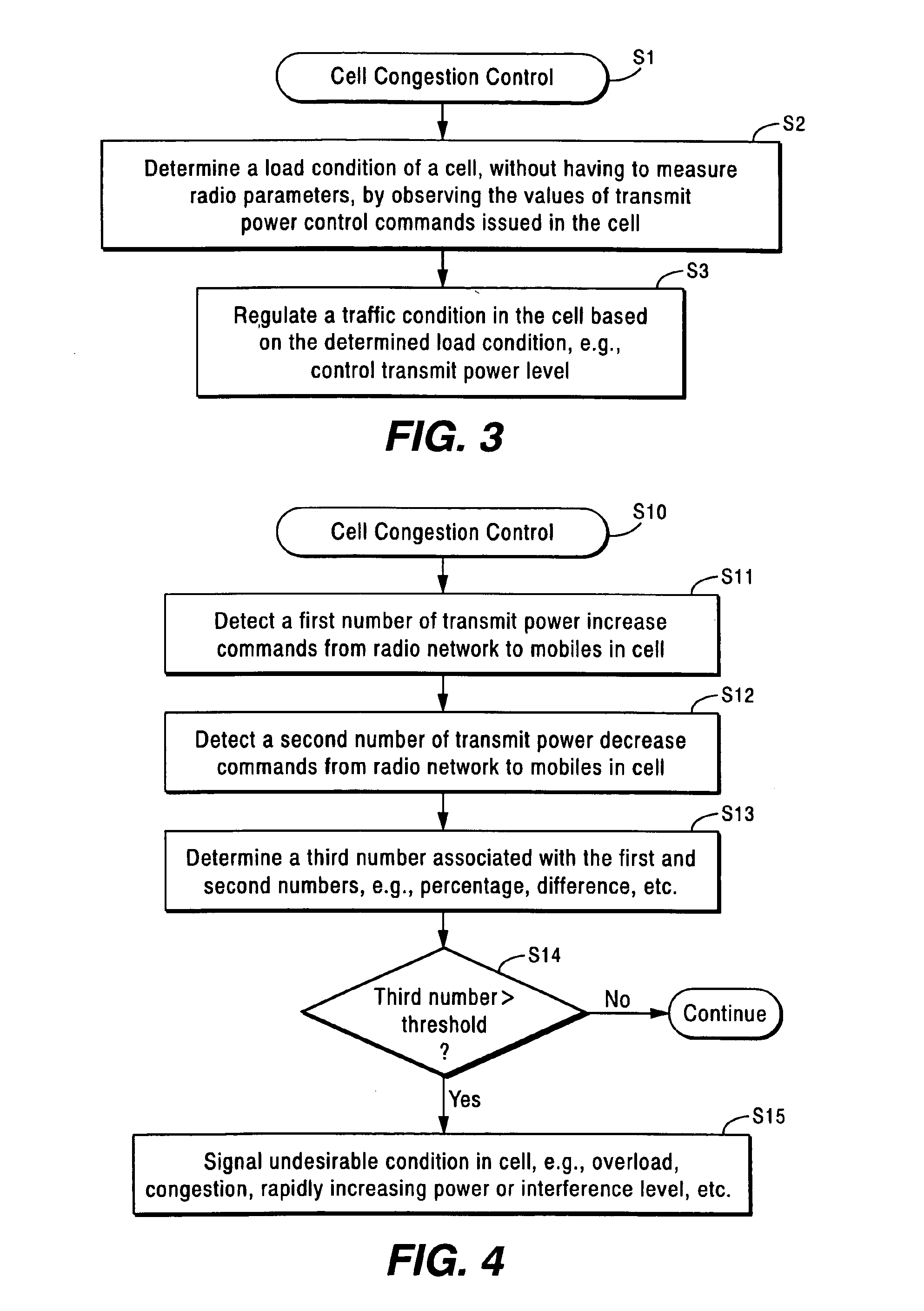

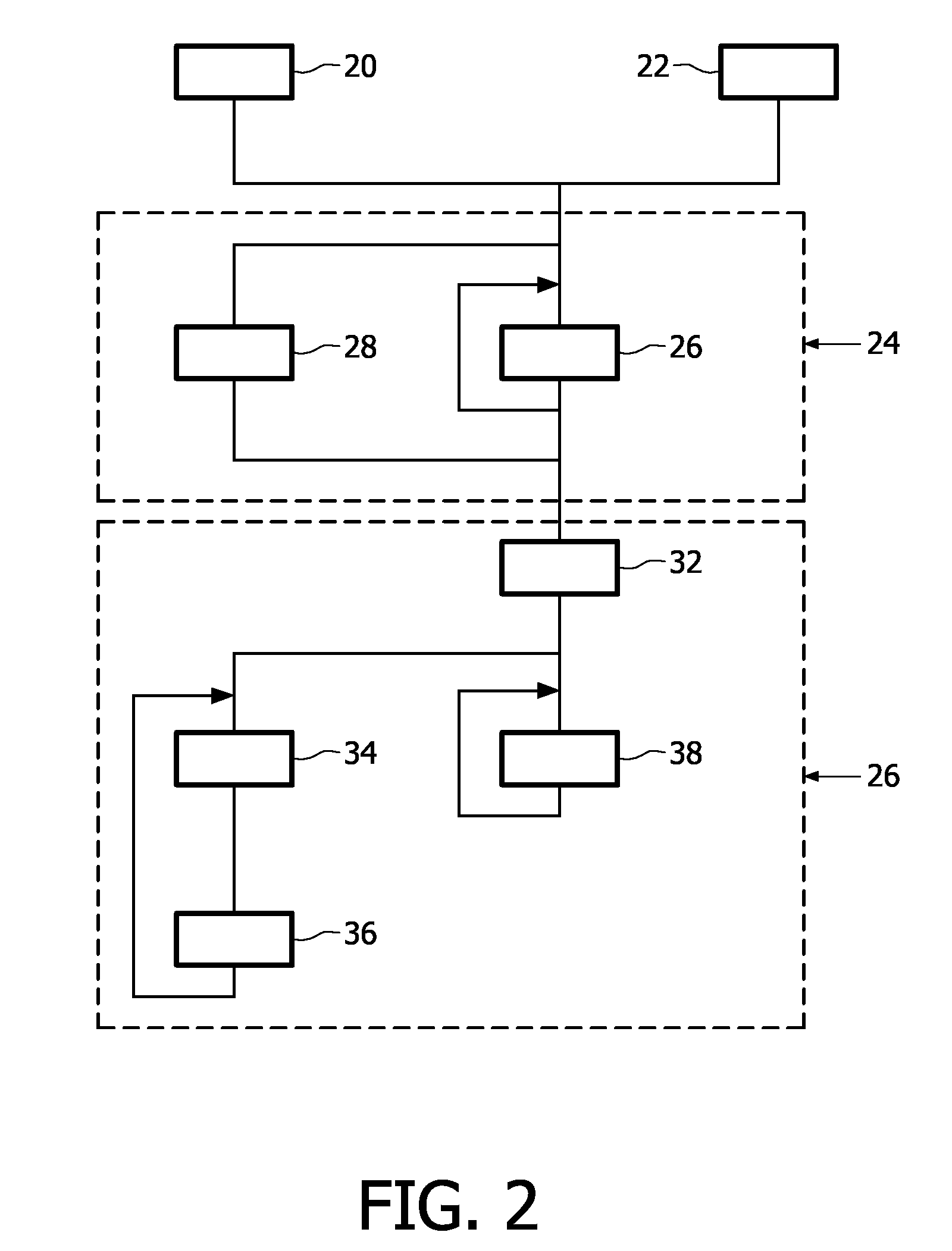

Congestion control in a CDMA-based mobile radio communications system

InactiveUS7016686B2Consumes less energyLight weightPower managementEnergy efficient ICTCommunications systemTransmitted power

A load condition of a cell is determined without having to measure one or more radio parameters pertaining to the cell load, e.g., interference level. Based upon that determined load condition, a traffic condition of the cell may then be regulated, e.g., admission and / or congestion control, transmit power control, etc. The load condition is determined simply and accurately by observing the value (absolute or weighted) of transmit power control commands issued in the cell over a particular time period. To identify potential “false alarms” of increased cell loads, a radio parameter associated with another frequency band in another cellular system that impacts the load condition of the cell in the current cellular system is measured. A traffic condition in that cell is regulated based upon the determined load condition in the cell taking into account the measured radio parameter.

Owner:TELEFON AB LM ERICSSON (PUBL)

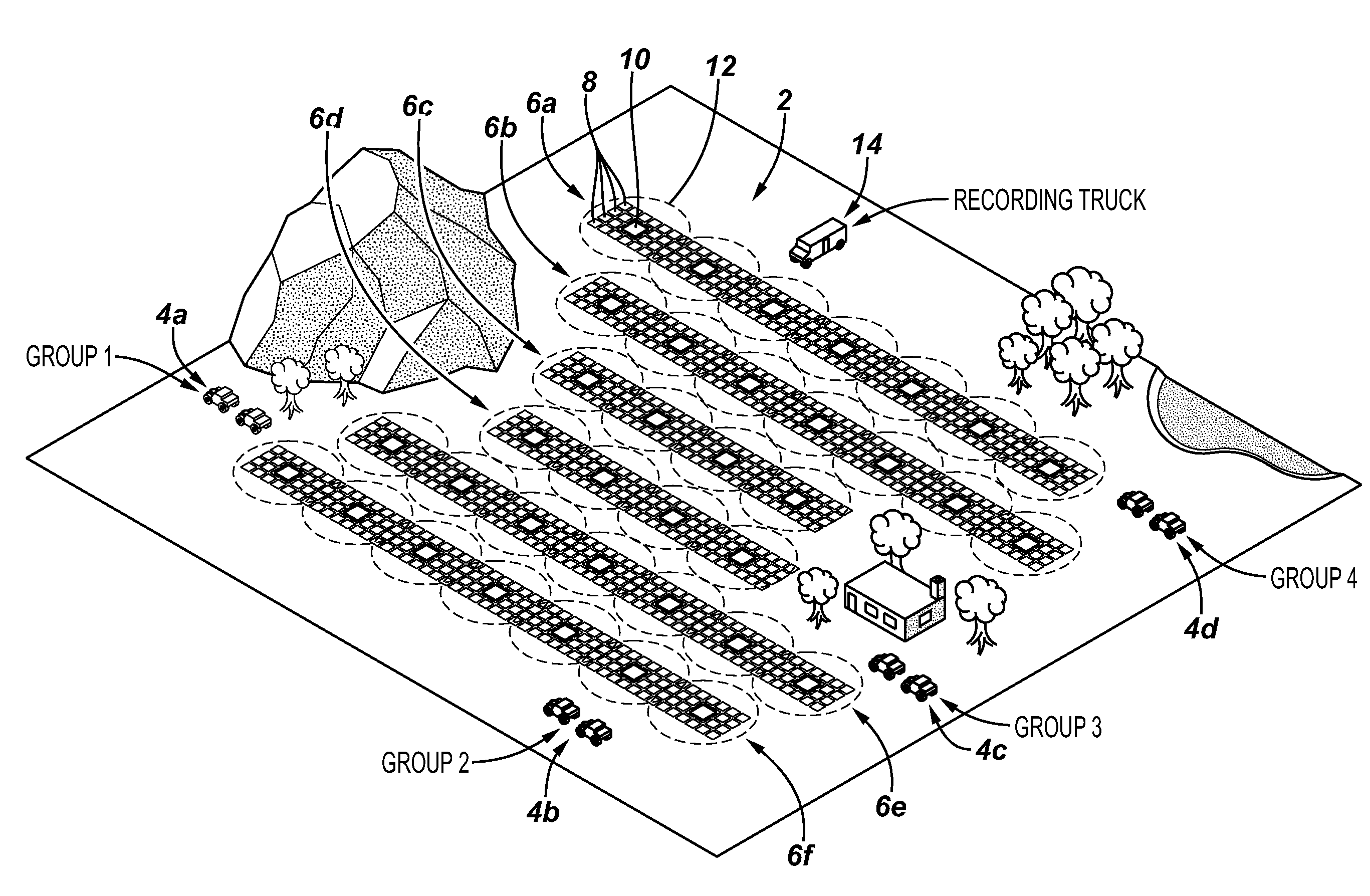

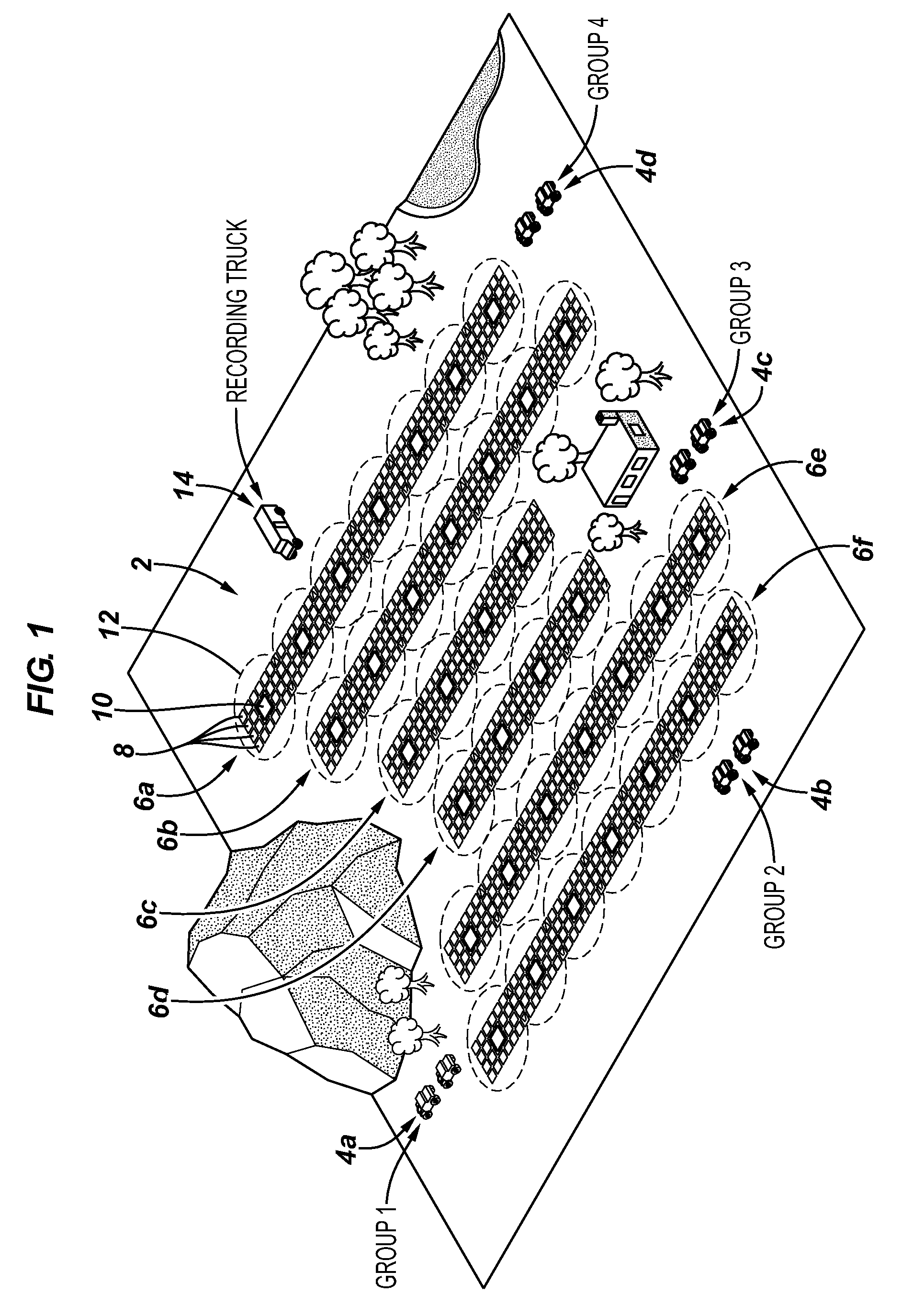

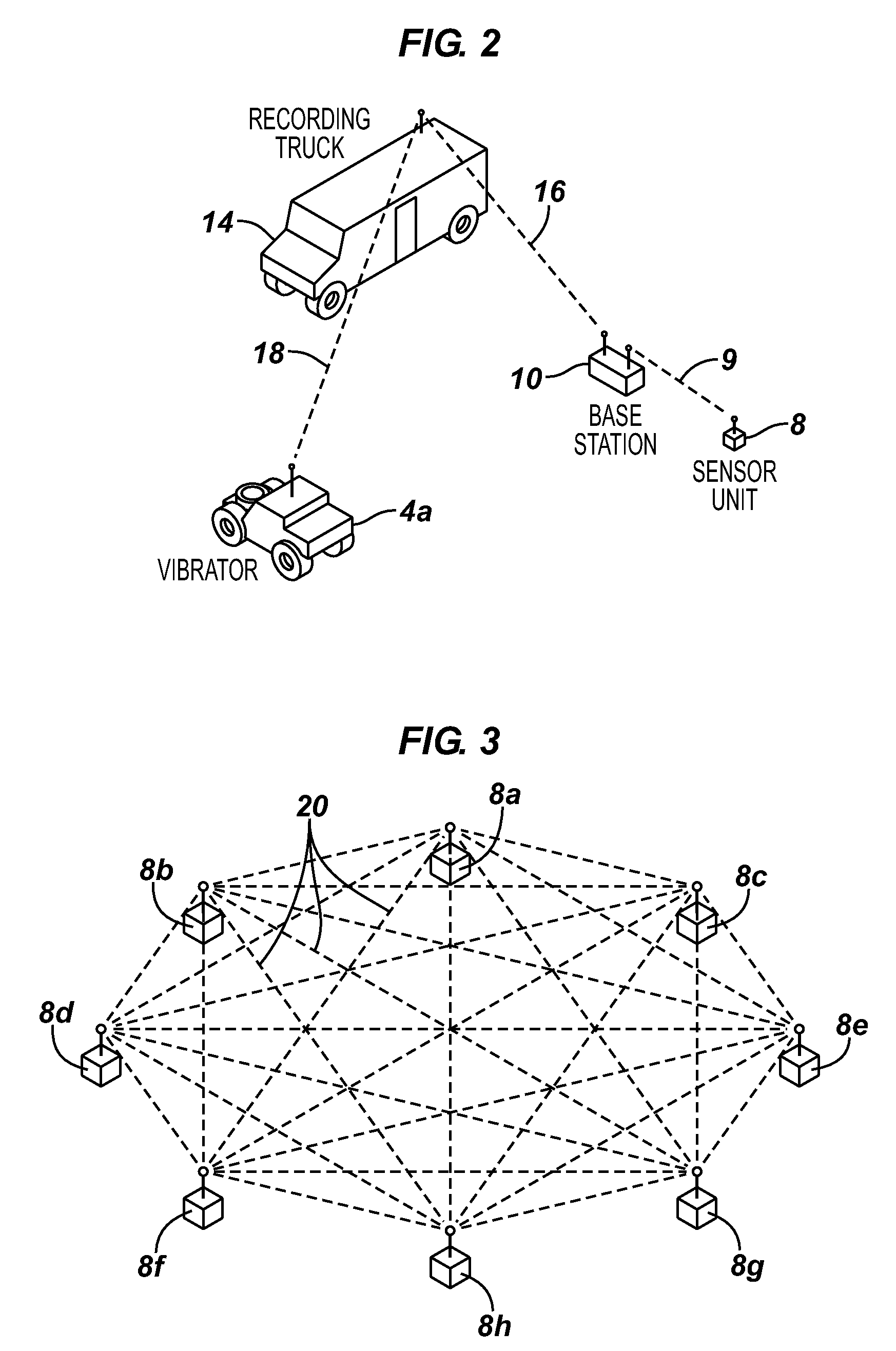

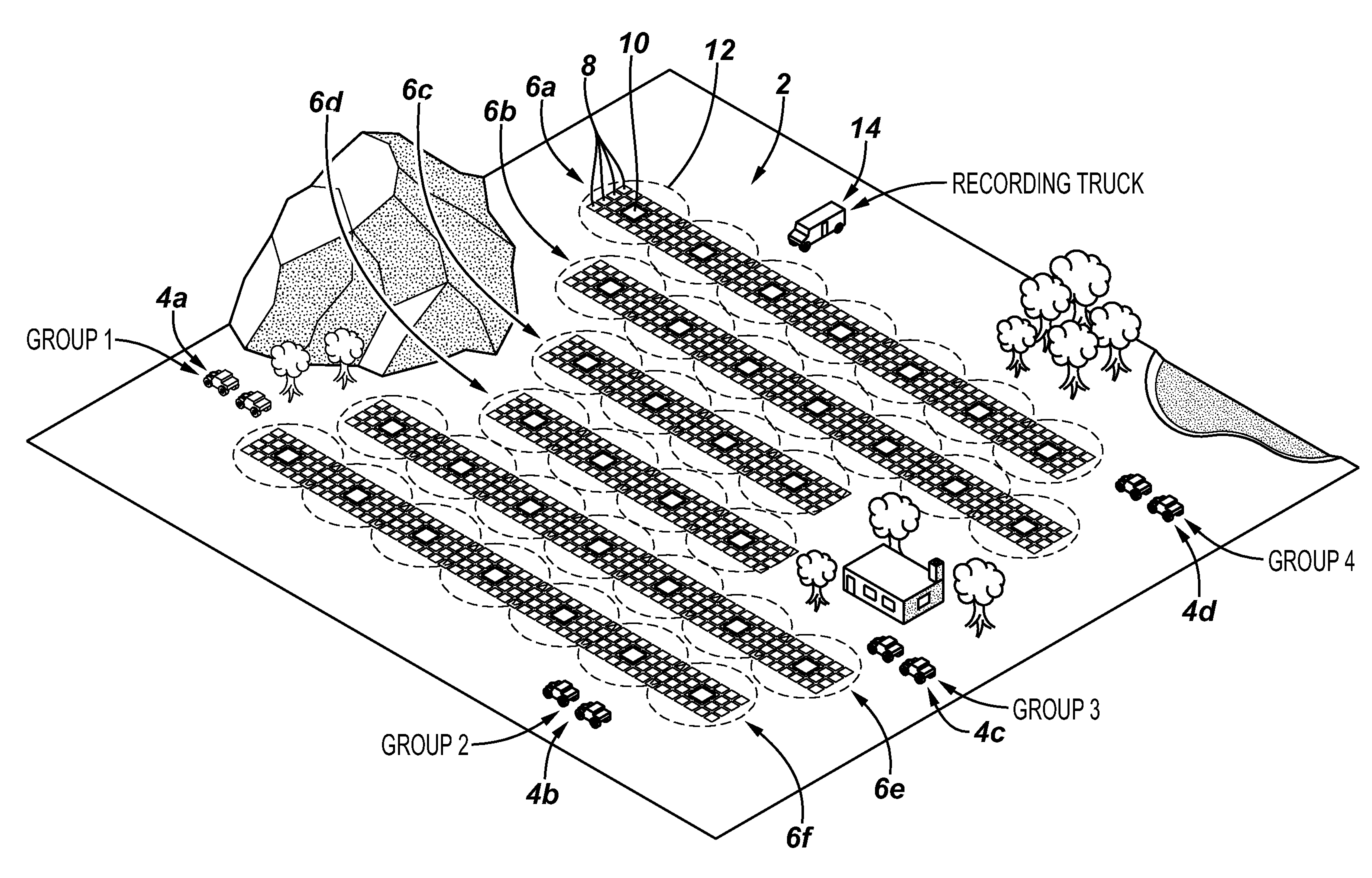

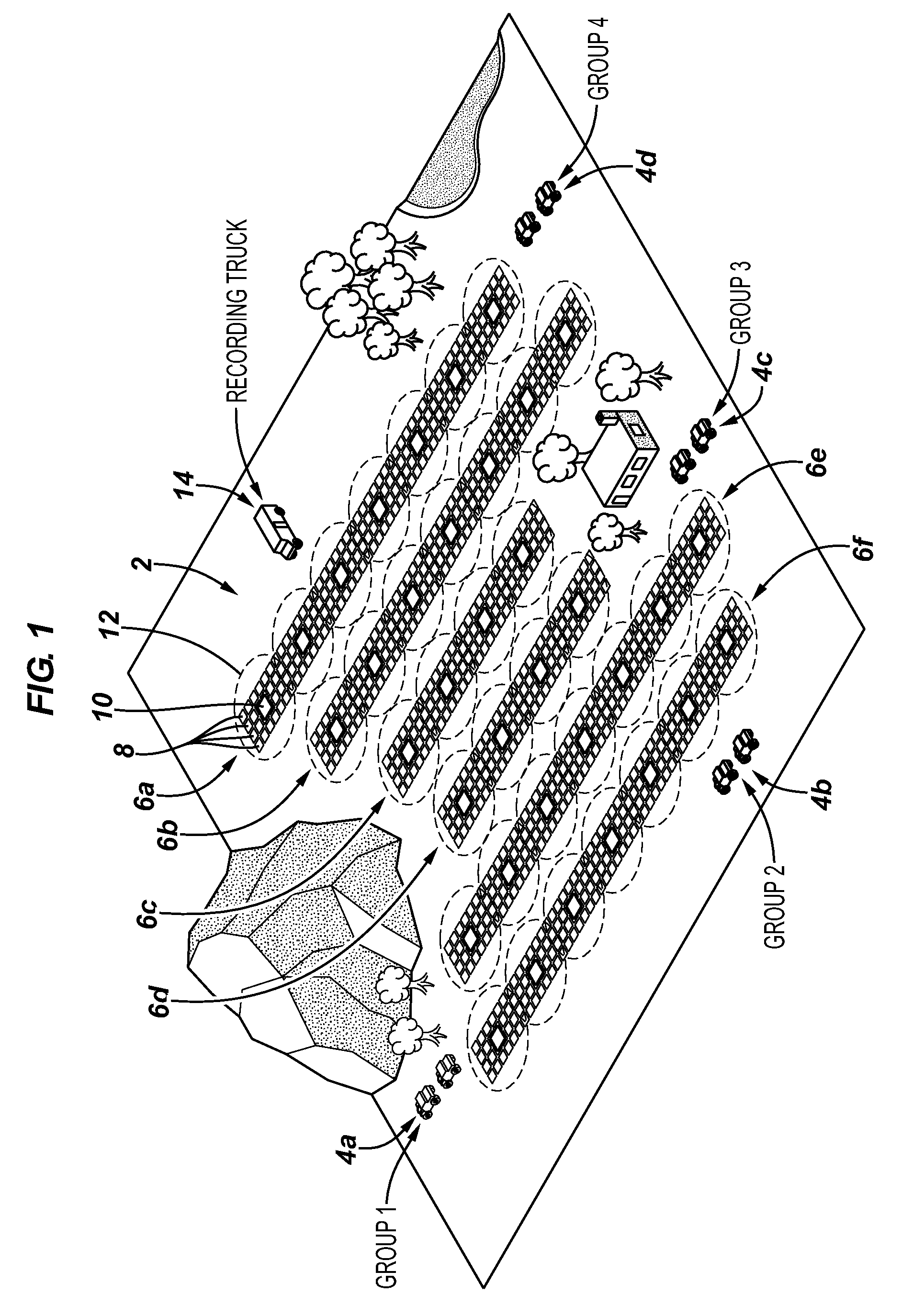

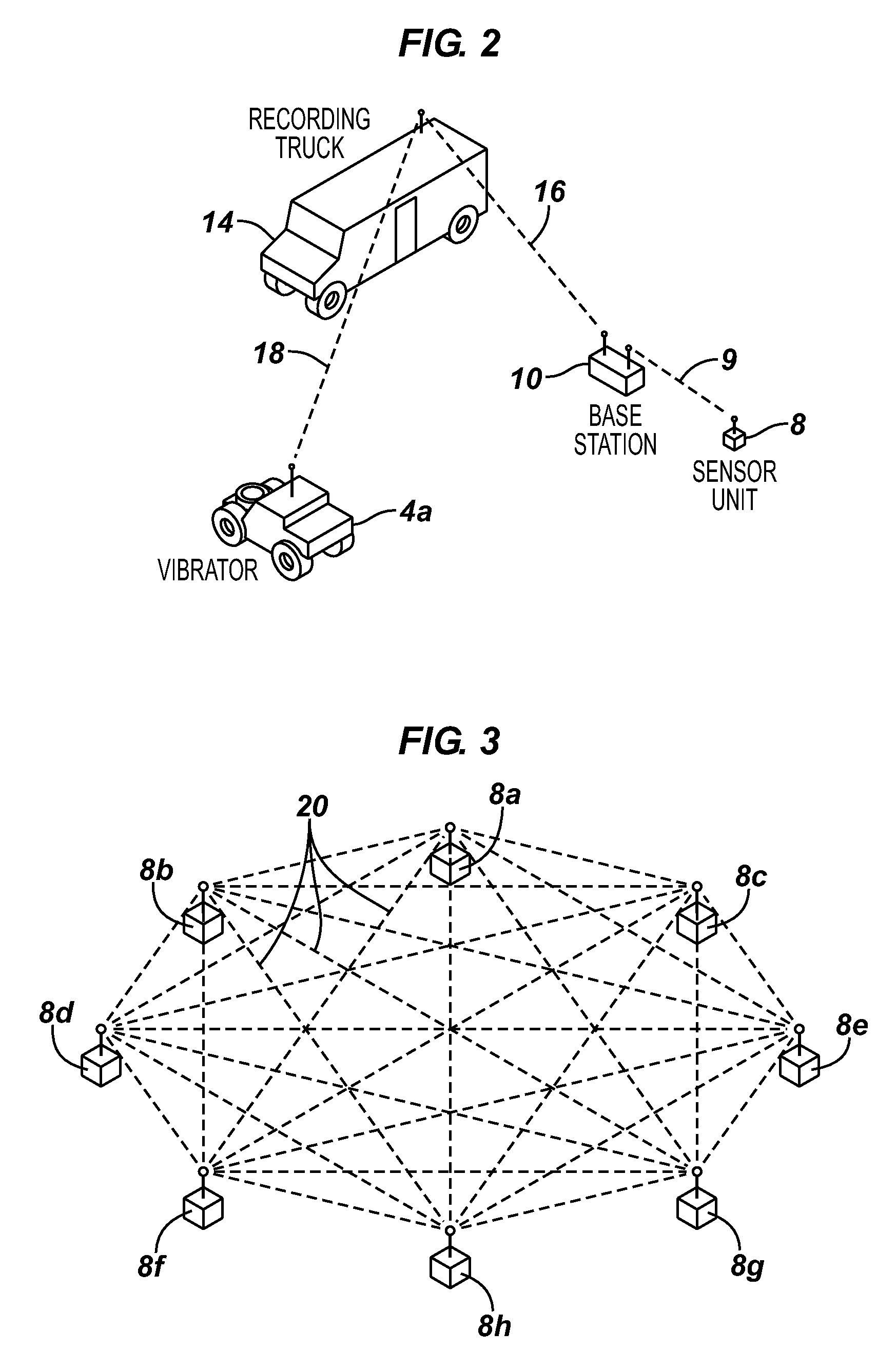

Systems and Methods for Seismic Data Acquisition Employing Asynchronous, Decoupled Data Sampling and Transmission

InactiveUS20080219094A1Eliminate costlyEliminate inflexibleSeismic signal transmissionSeismic signal processingData acquisitionSubject matter

Systems and methods for asynchronously acquiring seismic data are described, one system comprising one or more seismic sources, a plurality of sensor modules each comprising a seismic sensor, an A / D converter for generating digitized seismic data, a digital signal processor (DSP), and a sensor module clock; a seismic data recording station; and a seismic data transmission sub-system comprising a high precision clock, the sub-system allowing transmission of at least some of the digitized seismic data to the recording station, wherein each sensor module is configured to periodically receive from the sub-system an amount of the drift of its clock relative to the high precision clock. This abstract is provided to comply with rules requiring an abstract to ascertain the subject matter of the disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:WESTERNGECO LLC

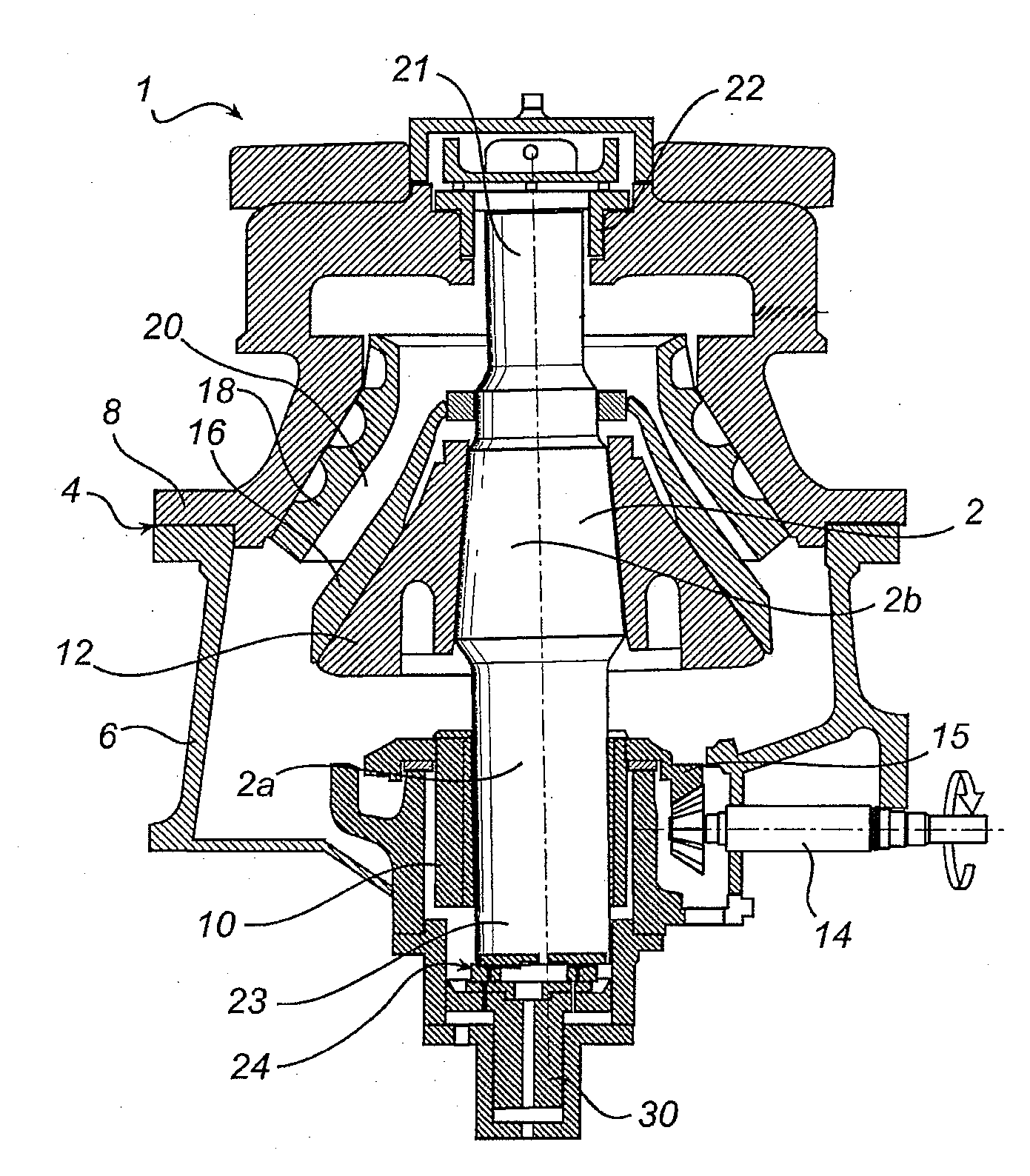

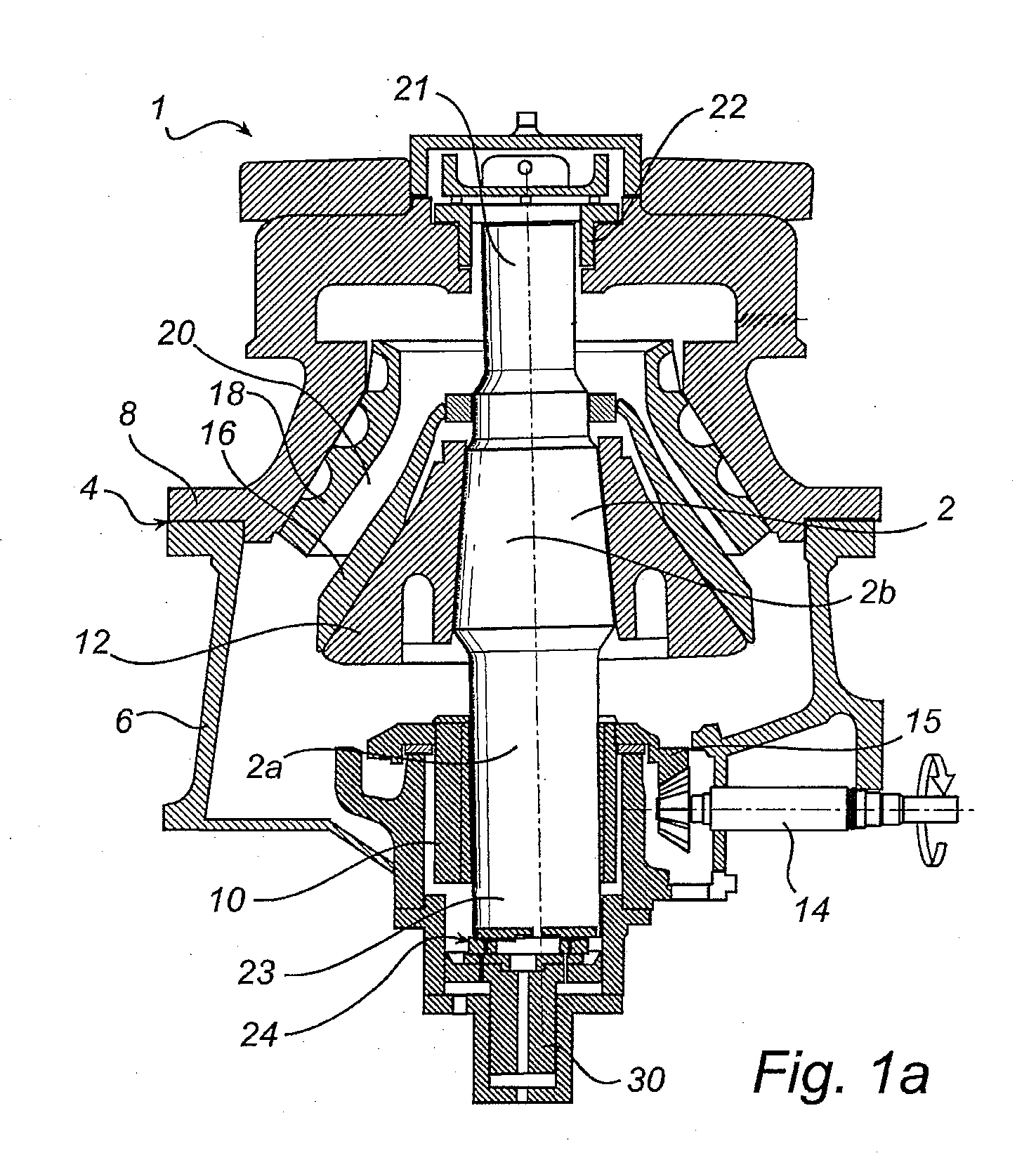

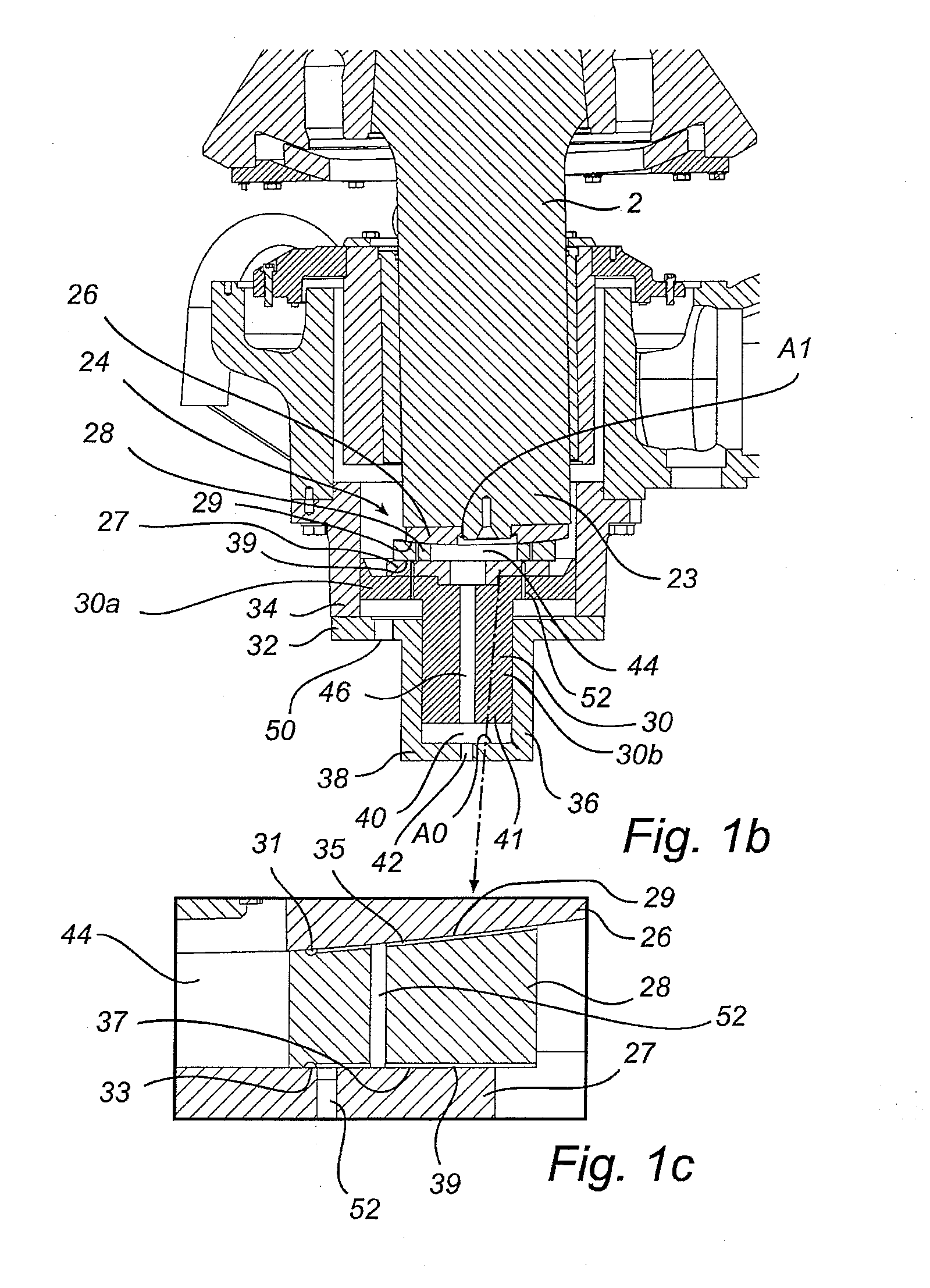

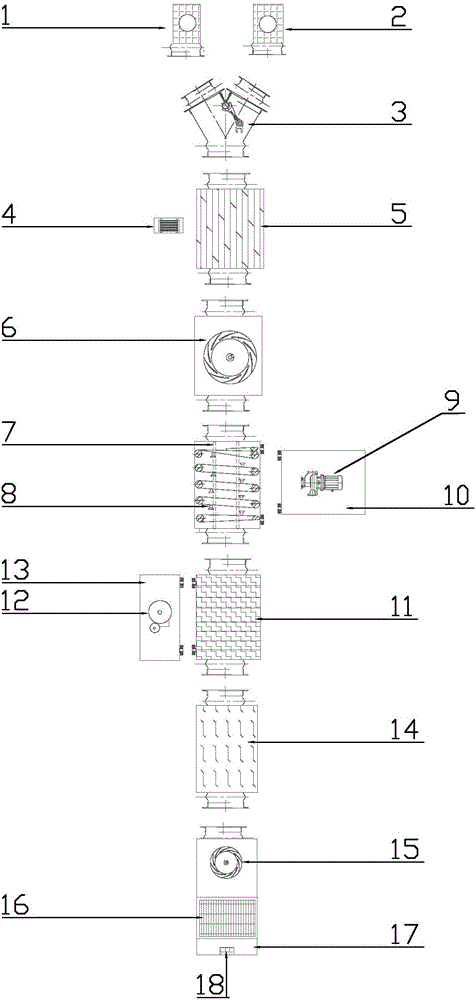

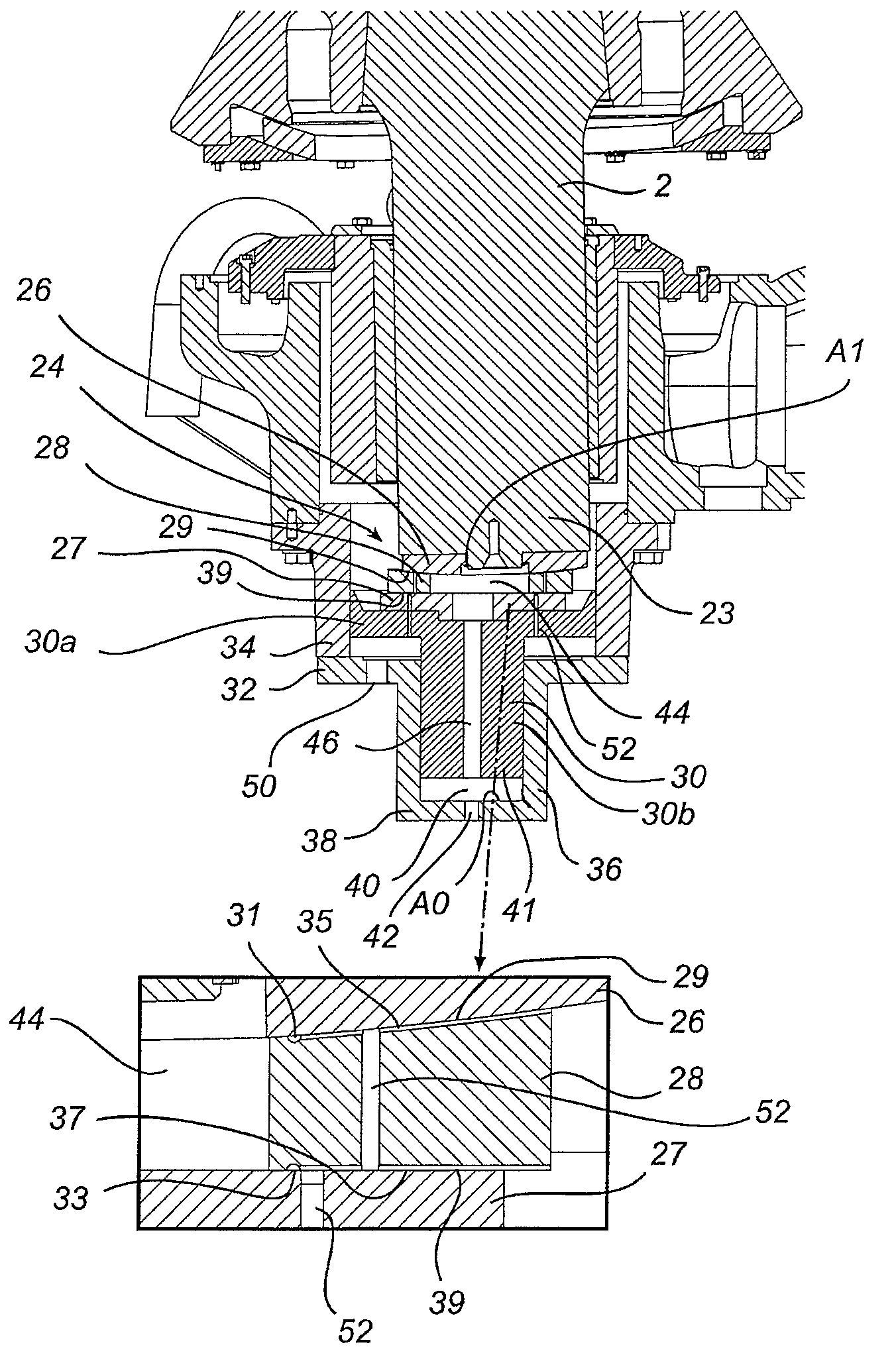

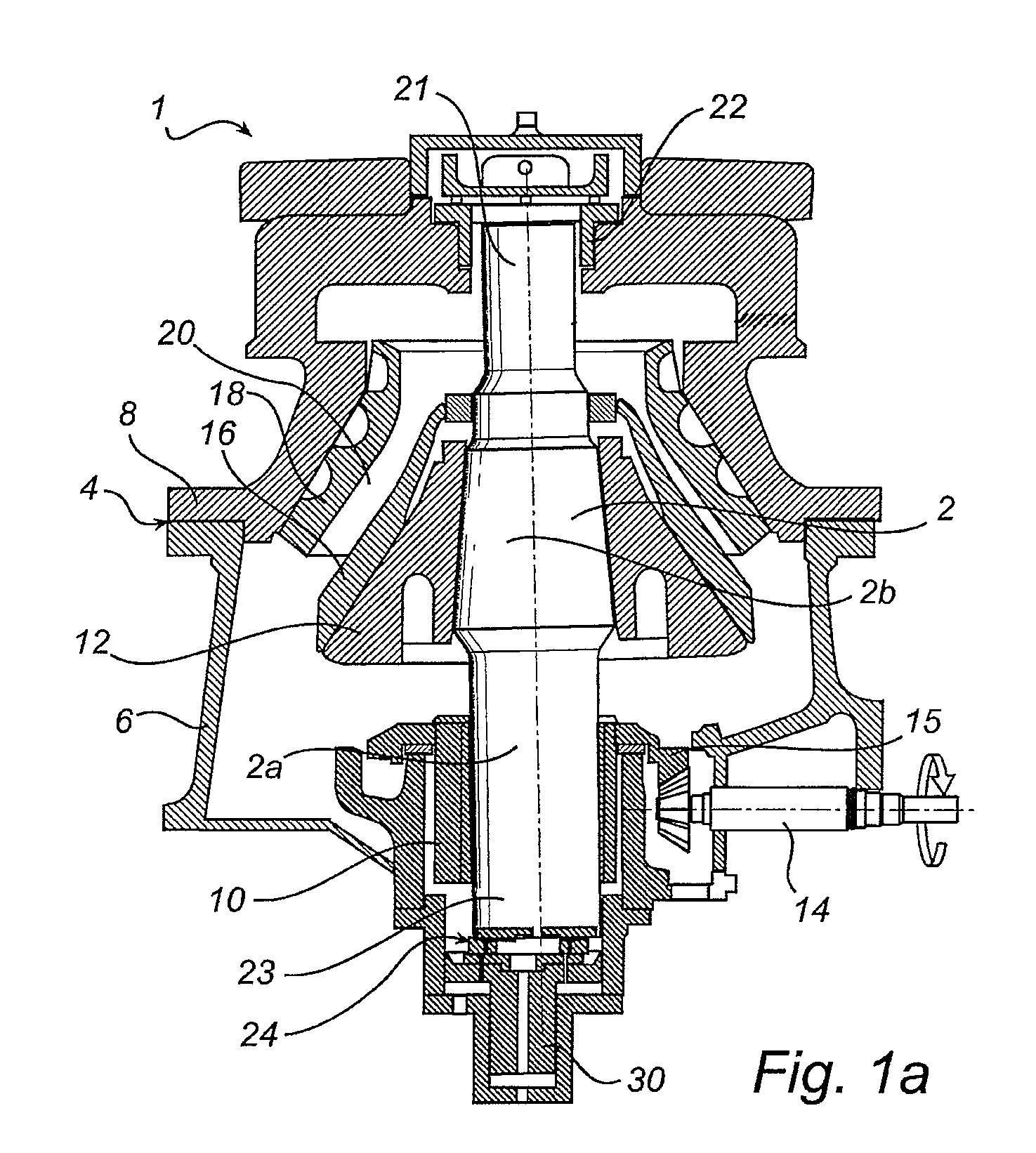

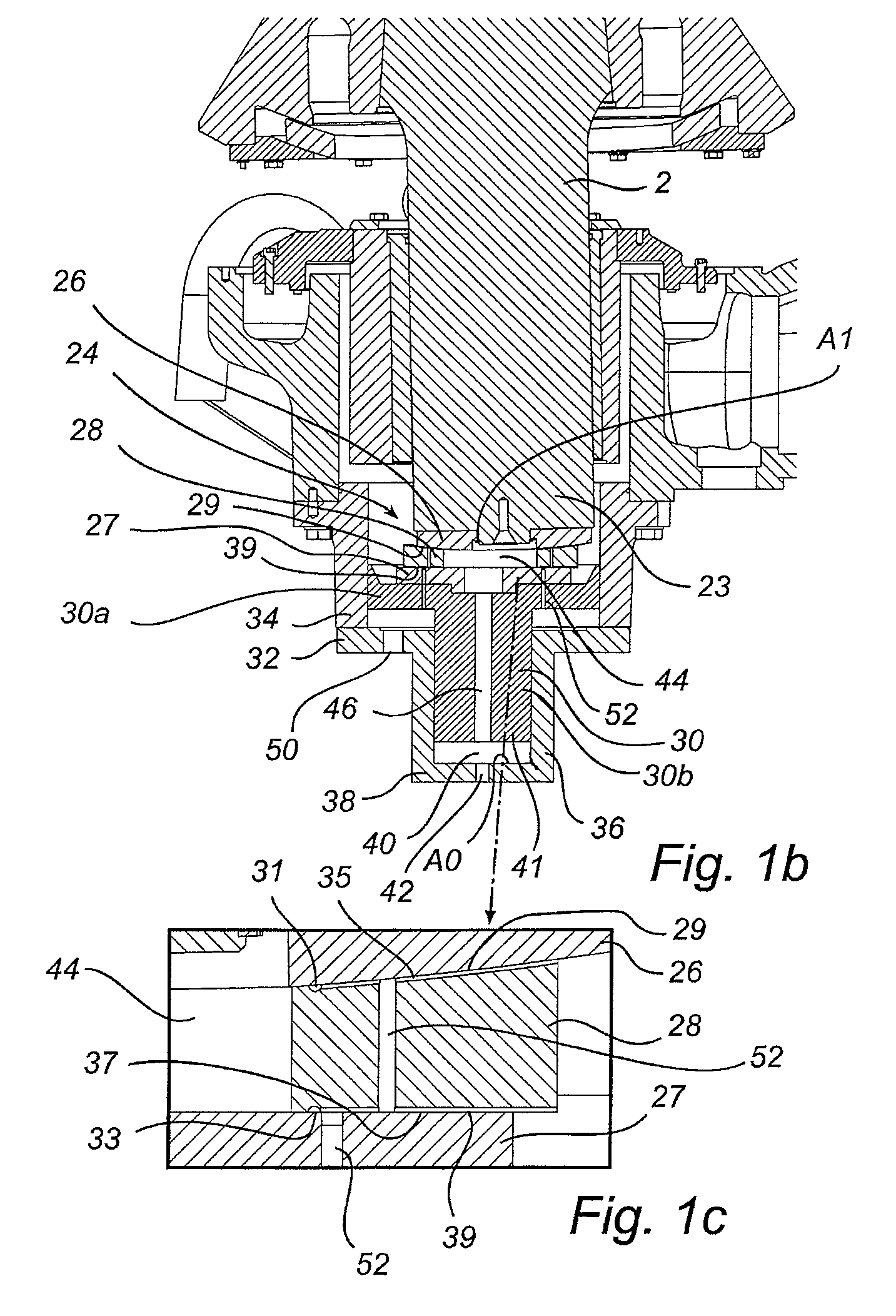

Thrust bearing for a gyratory crusher and method of supporting a vertical shaft in such a crusher

InactiveUS20100155512A1Reduce maintenance costsReduce mechanical wearSliding contact bearingsHydrostatic bearingsThrust bearingEngineering

A gyratory crusher includes a crushing head on which a first crushing shell is mounted, and a frame on which a second crushing shell is mounted. The crusher has a thrust bearing which is made up of horizontal bearing plates and which is located between a vertical shaft and a piston arranged vertically below the vertical shaft. The crusher further has a first space, which is adapted to receive a variable amount of pressurized liquid, the first space being defined by the piston and a piston housing formed in the frame, and a second space which is adapted to receive, by way of a duct, pressurized liquid from the first space, the second space being located between the vertical shaft and the piston and at least partly accommodated in an opening in at least one of the bearing plates. The first space and the second space are adapted, by the liquid, to transmit forces from the crushing head to the piston housing, in order that the load on the thrust bearing is relieved.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

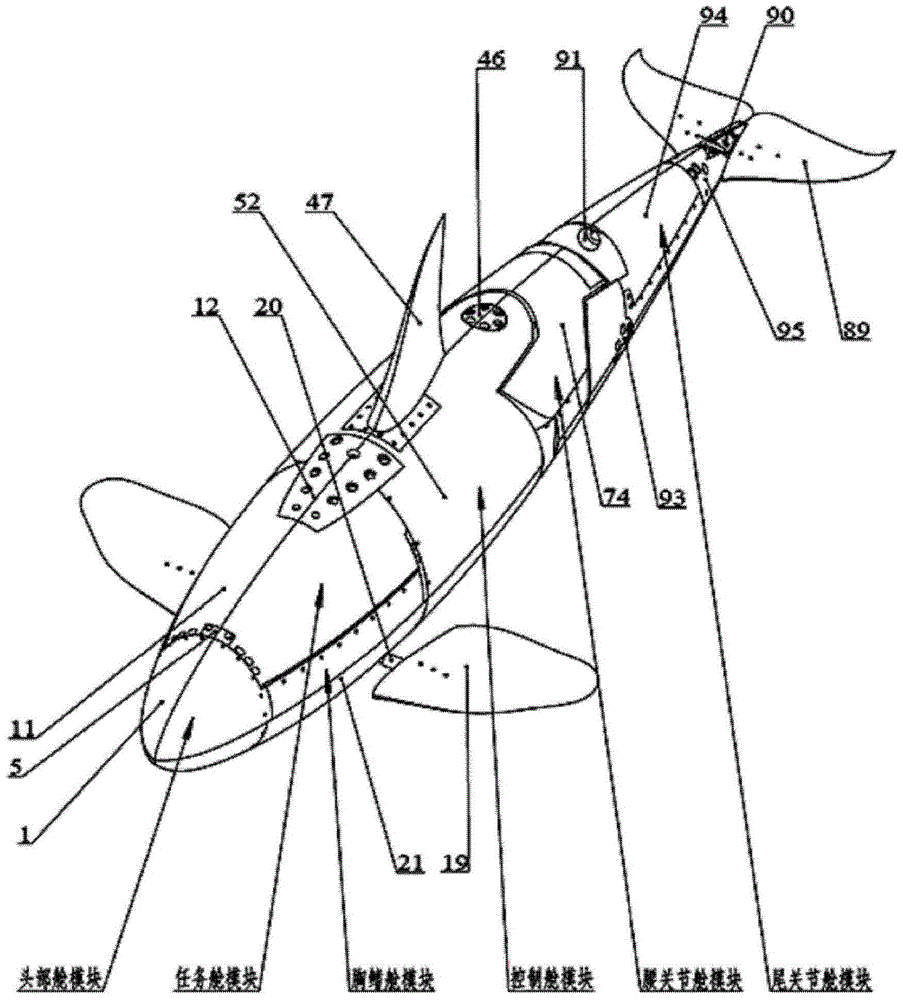

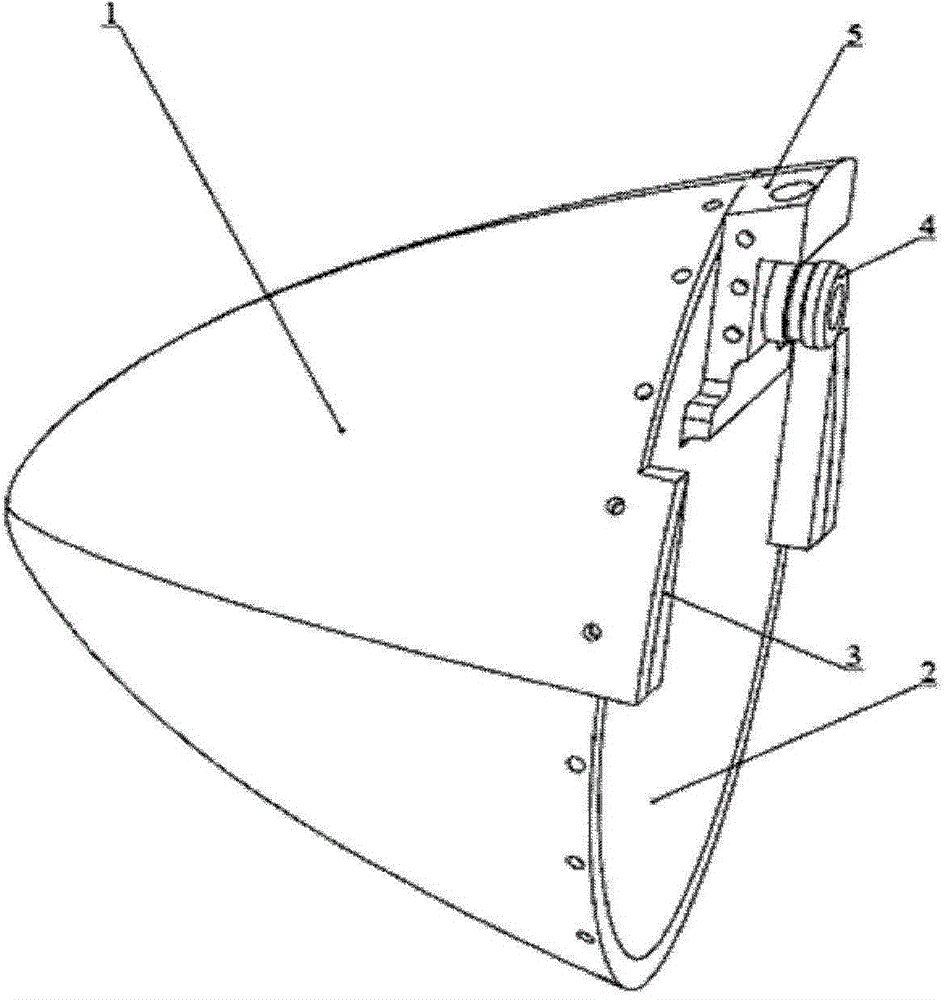

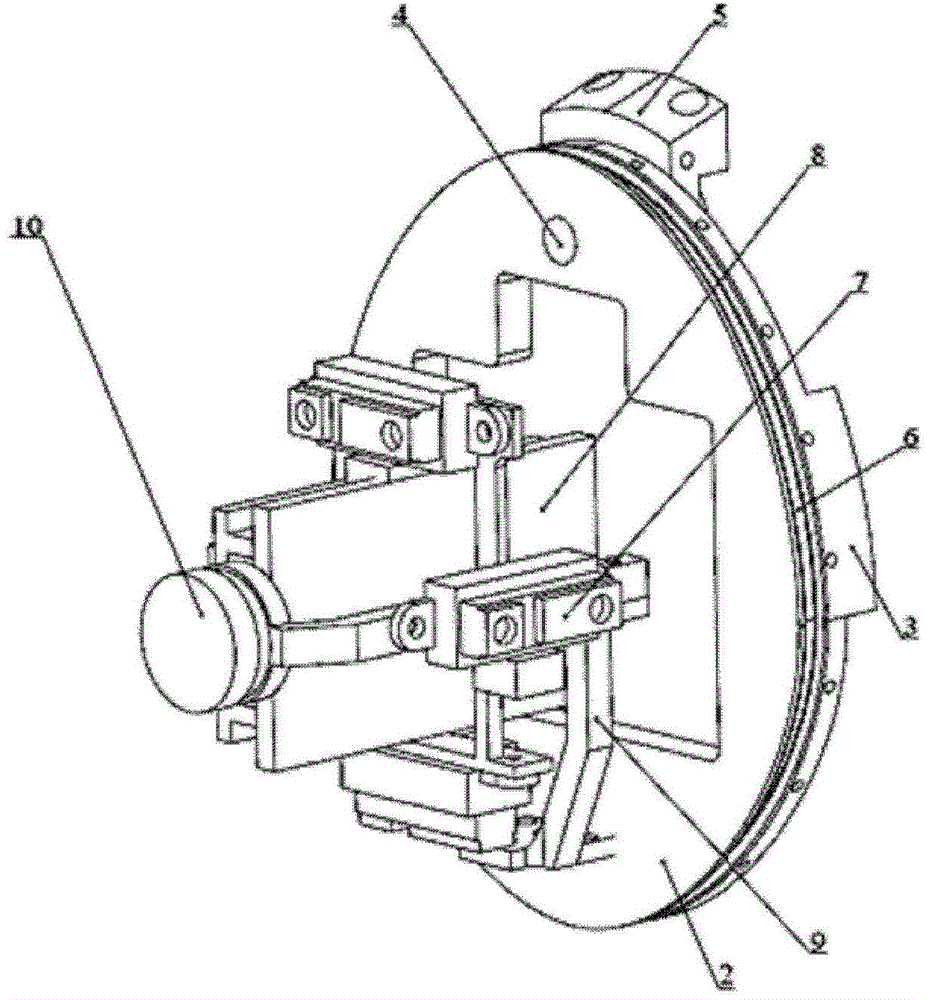

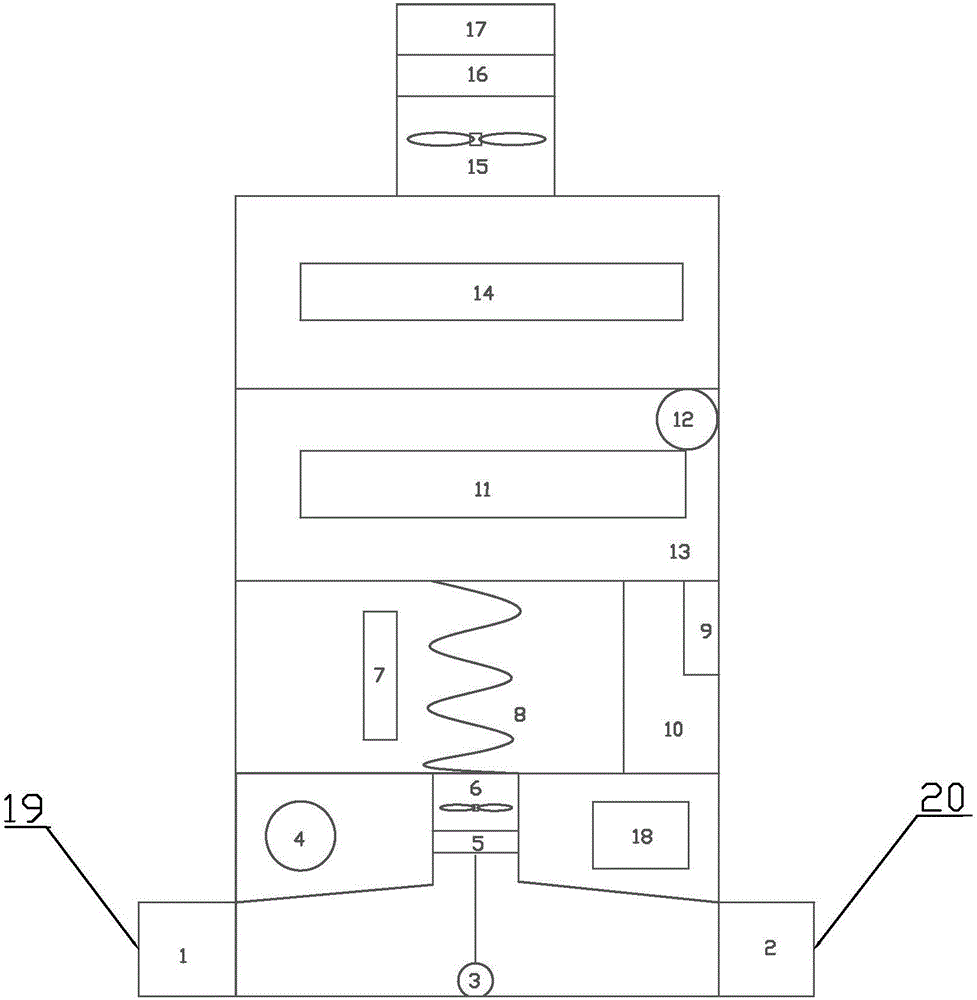

Gliding machine dolphin

ActiveCN104627342AConsume less energyStrong battery lifePropulsive elements of non-rotary typeRolling angleBuoyancy

The invention discloses a gliding machine dolphin. The gliding machine dolphin is composed of a head cabin module, a task cabin module, a pectoral fin cabin module, a control cabinet module, a waist joint cabin module and a tail joint cabin module. A pectoral fin driving mechanism, a water sucking-draining mechanism and a cabin body throwing carrying mechanism are arranged in the pectoral fin cabin module. A gravity center adjustment mechanism is arranged in the control cabin module. A yawing driving mechanism and a tail driving mechanism are arranged in the waist joint cabin module. A tail fin driving mechanism is arranged in the tail joint cabin module. According to the gliding machine dolphin, two joints at the tail are driven by the tail driving mechanism and the tail fin driving mechanism to vertically swing, and back-abdomen type propelling is achieved; the whole net buoyancy is adjusted through the water sucking-draining mechanism, and buoyancy driving propelling is achieved; the pitching angle and the roll angle during movement can be adjusted through a pectoral fin, and the yawing angle can be adjusted through a yawing driving mechanism. The gliding machine dolphin has the advantages of being high in speed, high in maneuverability and high in of underground gliding machine cruising at the same time; in addition, the modular design is adopted, and installation and assembling are easy.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Admission and congestion control in a CDMA-based mobile radio communications system

InactiveUS6985739B2Consumes less energyLight weightEnergy efficient ICTPower managementCommunications systemTransmitted power

A load condition of a cell is determined without having to measure one or more radio parameters pertaining to the cell load, e.g., interference level. Based upon that determined load condition, a traffic condition of the cell may then be regulated, e.g., admission and / or congestion control, transmit power control, etc. The load condition is determined simply and accurately by observing the value (absolute or weighted) of transmit power control commands issued in the cell over a particular time period. In one example implementation, the number of increase transmit power commands issued in a cell over a particular time period is determined relative to a total number of transmit power commands, (i.e., both increase and decrease), issued in the cell for that same time period. If the number of increase transmit power commands relative to the total number of transmit power commands exceeds a threshold, an overload condition may be indicated. When an overload is indicated, an action may be taken that reduces the number of increase transmit power commands issued in the cell. Alternatively, a difference between the number of increase and decrease transmit power commands may be used.

Owner:TELEFON AB LM ERICSSON (PUBL)

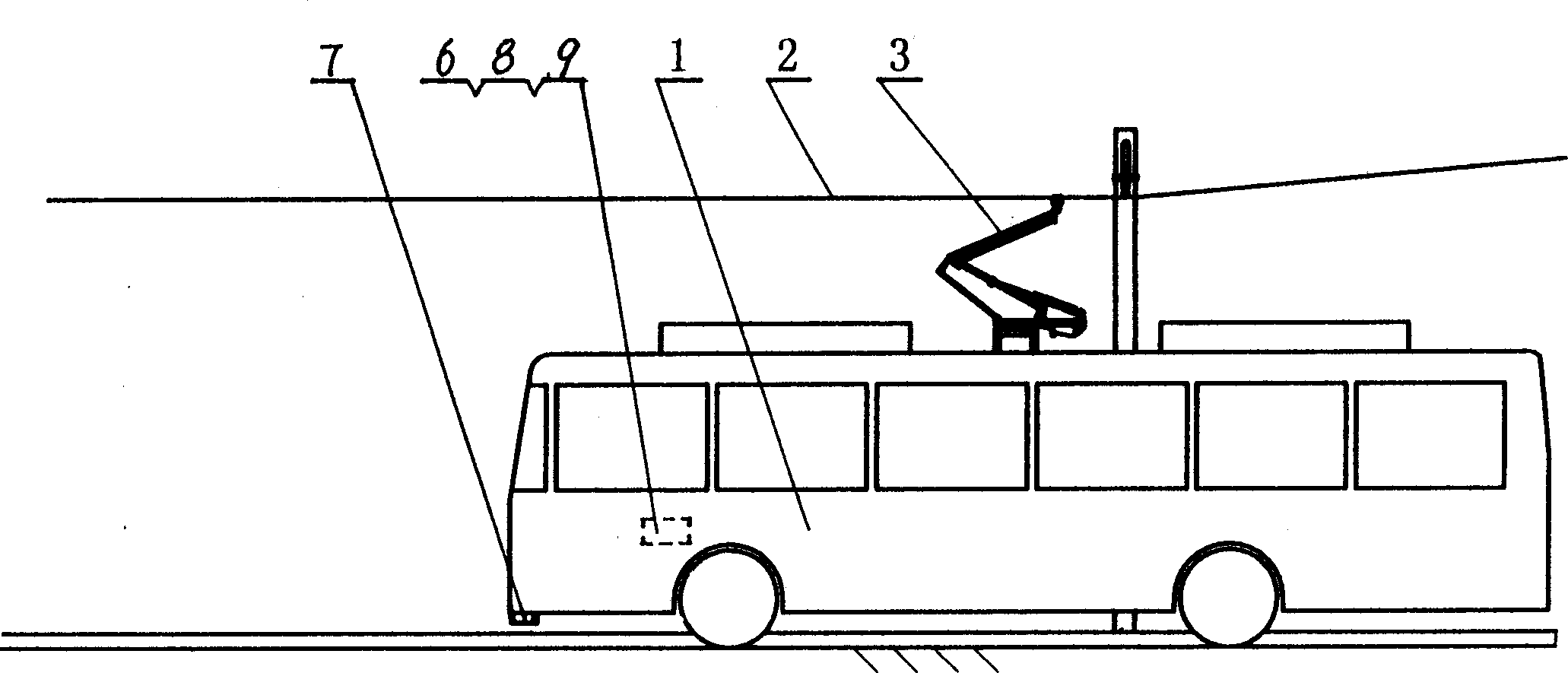

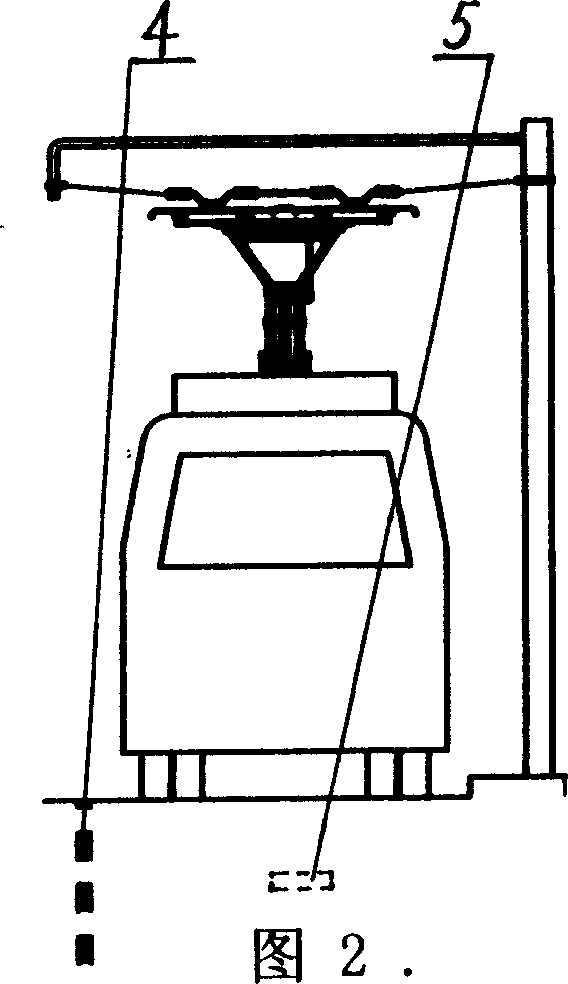

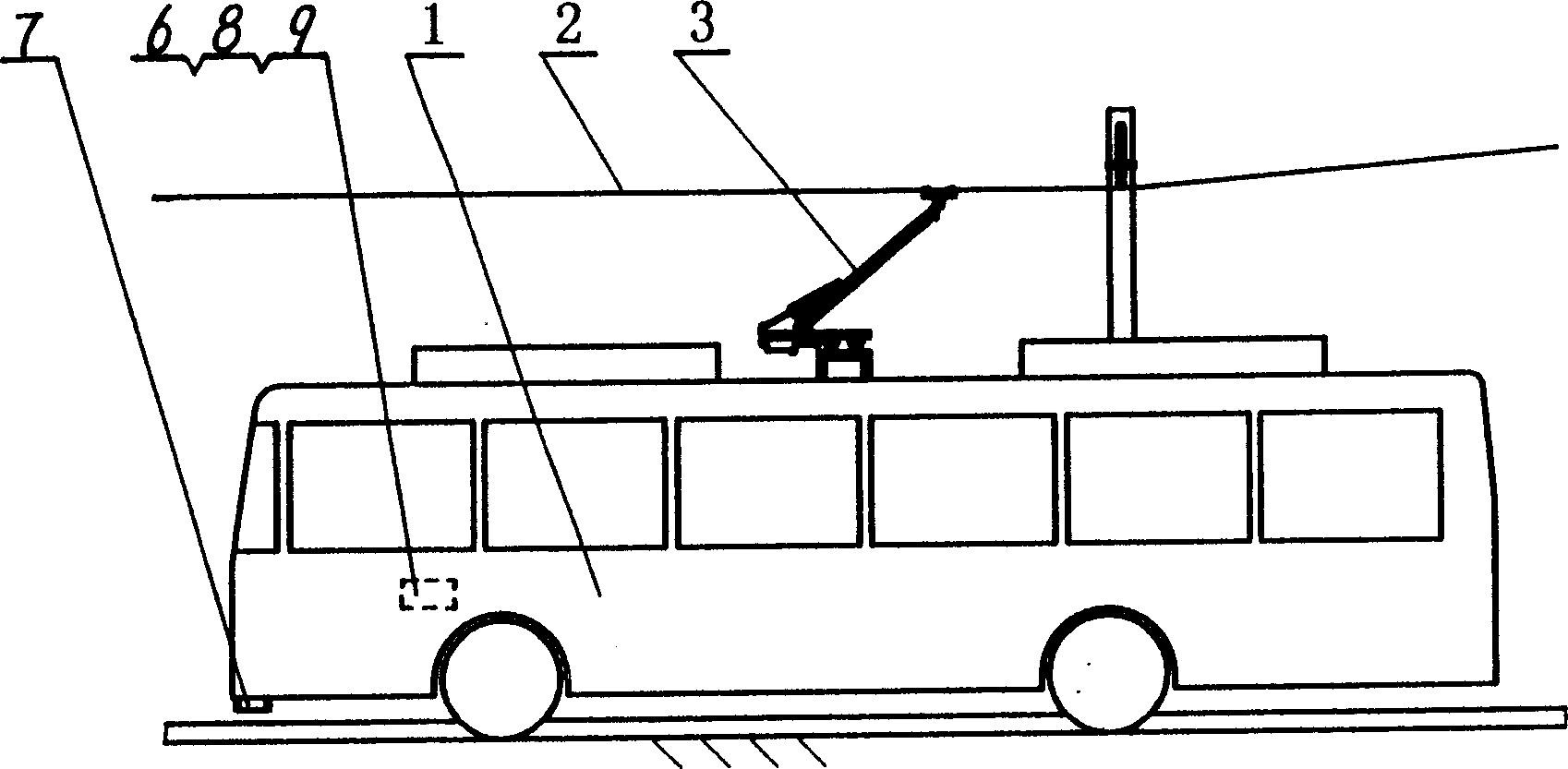

Station-charging trollybus system

InactiveCN1486886AImprove mobilityDoes not affect normal drivingPower current collectorsElectricityContact network

The station-charging trolleybus system for city public traffic includes trolleybus, contact network, double-wire current collecting pantograph, station ground road mark, sensing source and current collecting switch device. The connection mode includes setting the double-wire current collecting pantograph in the top of the trolleybus, contacting the double-wire current collecting pantograph to the contact network in the charging station, setting the current collecting switch device inside the trolleybus, and embedding passive metal parts on the ground of station entrance as the sensing source corresponding to the suspended section of the network access. The present invention has reasonable system constitution, network-free running of the trolleybus, low cost of the trolleybus and attached equipment, safe and reliable operation and simple implementation.

Owner:SHANGHAI JIAO TONG UNIV

Method for producing bricks from silt and sludge

InactiveCN101830687AWon't breakSolve processing problemsCeramic materials productionClaywaresBrickLand resources

The invention discloses a method for producing bricks from silt and sludge, which comprises the following steps of: stacking silt and sludge of which the water content is 80-85% in a parking field to enable the water content of the silt and the sludge to be less than or equal to 60% for standby; conveying the silt and the sludge of which the water content is less than or equal to 60% to a primary stirrer through a feeding box for stirring together with fly ash, rice chaffs or wood flour, coal slag and black sand to enable the water content of the mixture to be less than or equal to 30%; putting the mixture in an aging field for aging to enable the water content of the mixture to be less than or equal to 22%; conveying the mixture to a secondary stirrer through the feeding box, and adding water or fly ash according to the degree of dryness and wetness to obtain a blank preparing material of which the water content is less than or equal to 20%; preparing the blank preparing material into a wet blank of which the water content is 17.8-18.8% through extruding and cutting devices; and roasting to obtain a finished product brick. In the method of the invention, silt and sludge are used as main raw materials for producing bricks; on one hand, clay does not need to be used, and the cultivated land can not be destroyed; and on the other hand, the invention solves the problem of treatment of silt and sludge, saves land resources and has obvious effect of environmental protection.

Owner:常州市振东新型节能建筑材料厂

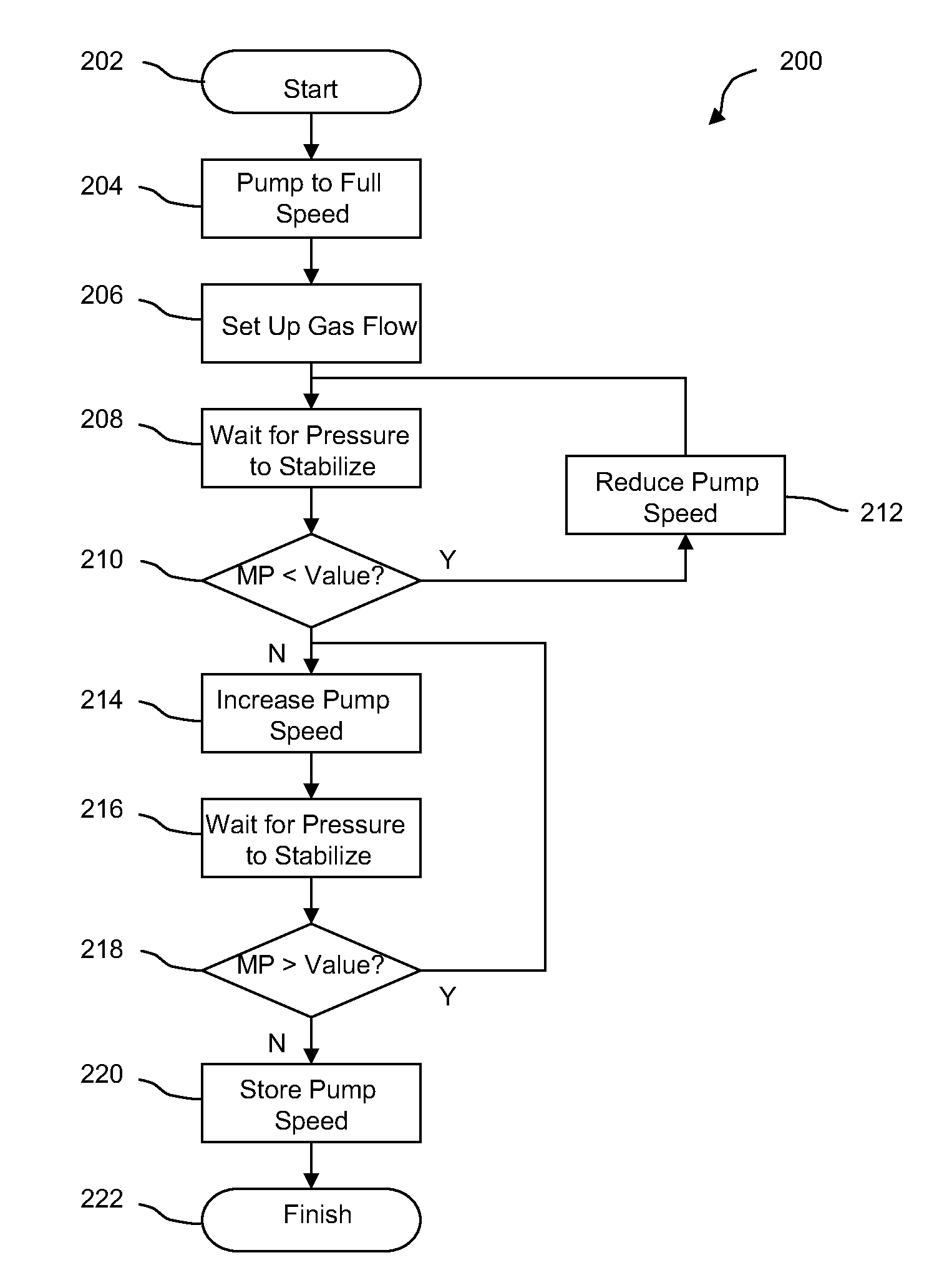

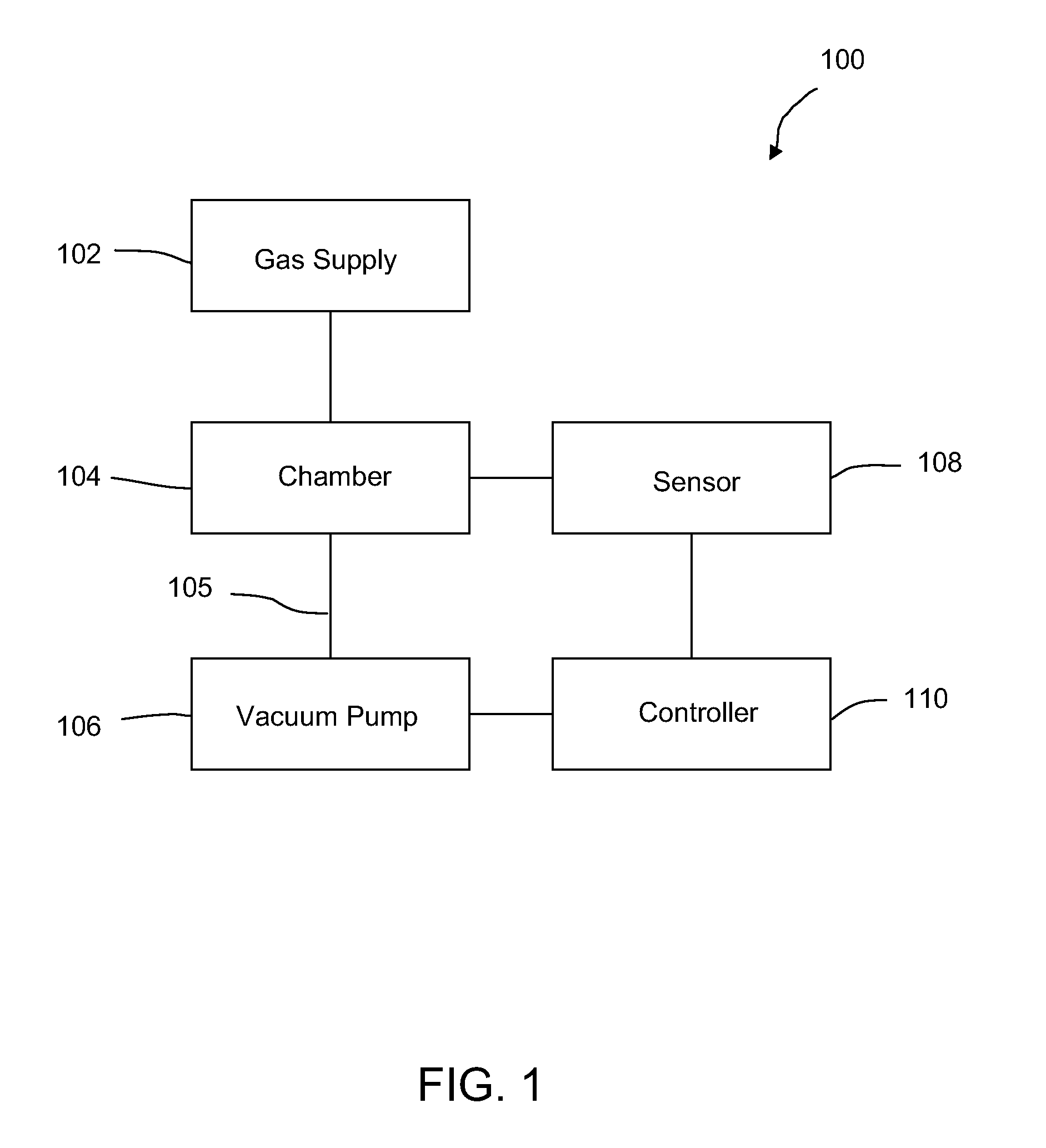

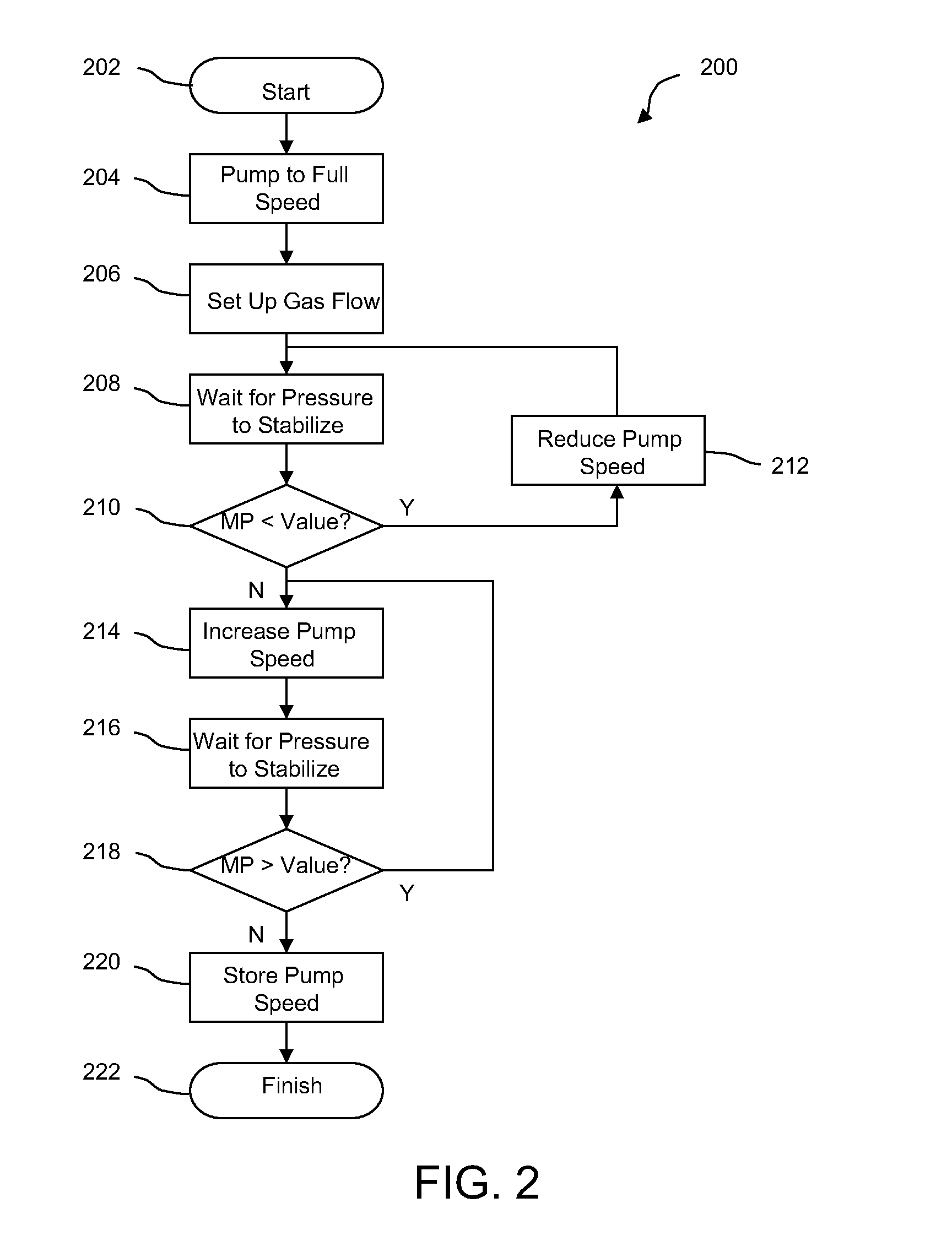

Apparatus and method for tuning pump speed

ActiveUS20110200450A1Consumes less energyEliminate spaceExternal parameterWorking fluid for enginesEngineeringVacuum pump

An apparatus for tuning pump speed at an optimal or desired speed using an automated method is disclosed. The apparatus includes a vacuum pump connected to a chamber for evacuating gas from the chamber. A sensor measures one or more characteristics, such as pressure, of the gas in the chamber. The measured characteristic is compared to a predetermined value. The speed of vacuum pump is adjusted based on the comparison until it falls in a desired range.

Owner:EDWARDS LTD

Systems and methods for seismic data acquisition employing asynchronous, decoupled data sampling and transmission

InactiveUS7660203B2Reduce and overcome short-comingsEliminate costlySeismic signal transmissionSeismology for water-covered areasData acquisitionData recording

Systems and methods for asynchronously acquiring seismic data are described, one system comprising one or more seismic sources, a plurality of sensor modules each comprising a seismic sensor, an A / D converter for generating digitized seismic data, a digital signal processor (DSP), and a sensor module clock; a seismic data recording station; and a seismic data transmission sub-system comprising a high precision clock, the sub-system allowing transmission of at least some of the digitized seismic data to the recording station, wherein each sensor module is configured to periodically receive from the sub-system an amount of the drift of its clock relative to the high precision clock.

Owner:WESTERNGECO LLC

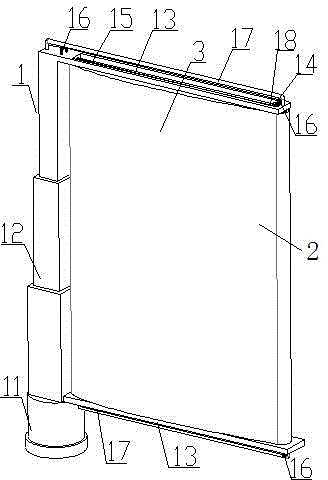

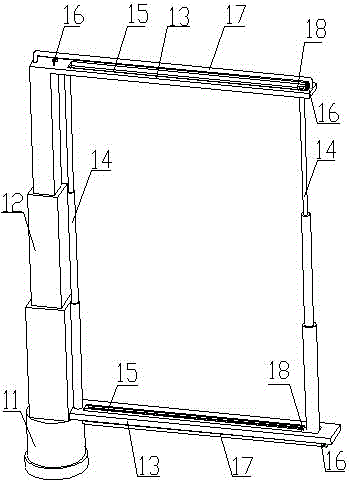

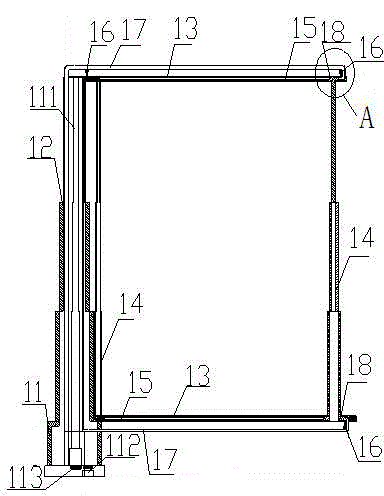

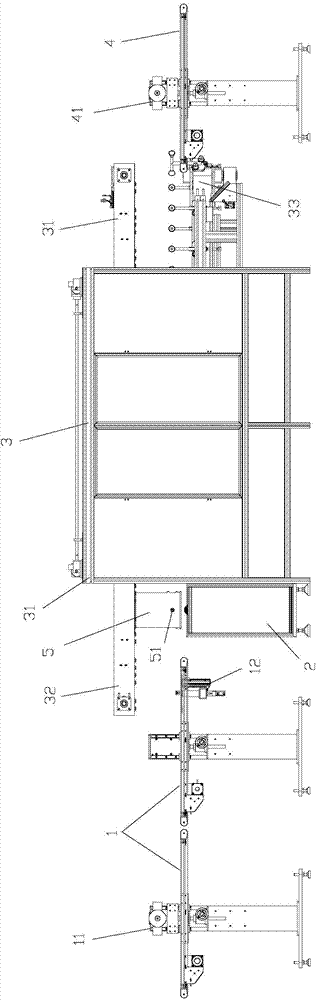

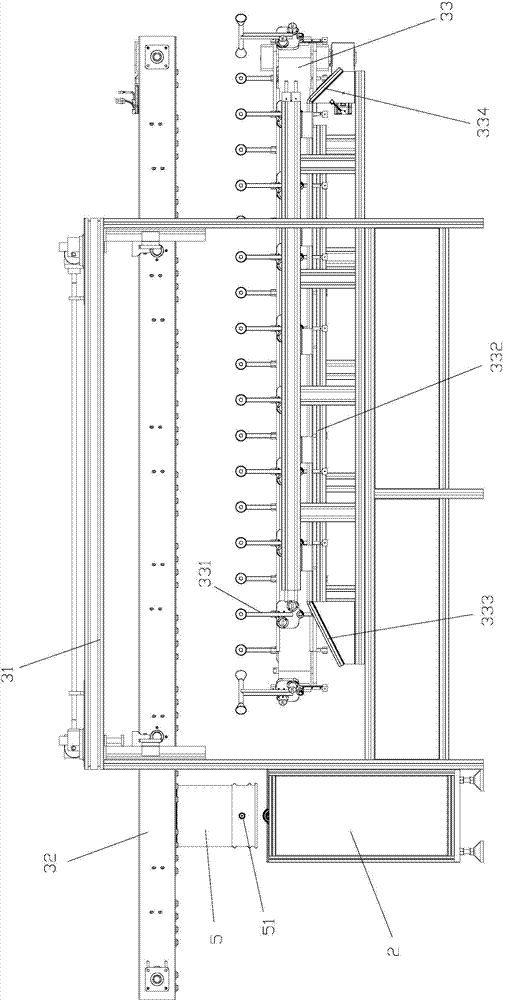

Multifunctional gypsum block die

InactiveCN101249668ALow priceReduce manufacturing costMould separation apparatusMouldsEngineeringGypsum block

The invention relates to a multi-functional gypsum block mold. A rail is provided with a mold box carriage, the base of which is connected via a first hinge with a front side mold plate and a back side mold plate parallel to each other. A cavity formed by the front side mold plate and back side mold plate is divided into small cavities by diaphragms arranged in parallel. The left and the right heads of the small cavities are sealed by an end mold plate, which is connected with an upper mold and a bottom mold through the concave and convex surfaces of the end mold plate. The upper end of the front side mold plate and the back side mold plate are connected by a locking device. The base is equipped symmetrically with a strip hole along the vertical center line of the base. The lower end of the hinge is fixed on the base through the bolt of the strip hole. The end mold plate is fixed with a positioning pin, which is inserted into the pin slot of the diaphragm or the front side mold plate or back side mold plate. The mold can produce the gypsum block with different types and specifications through replacing the end mold plate, the bottom mold and the upper mold, achieves multiple functions for one machine, and saves production cost.

Owner:胡云模

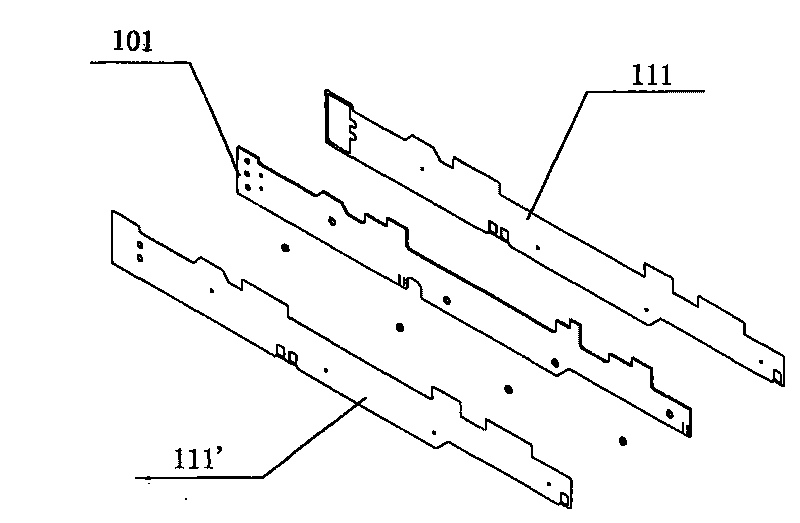

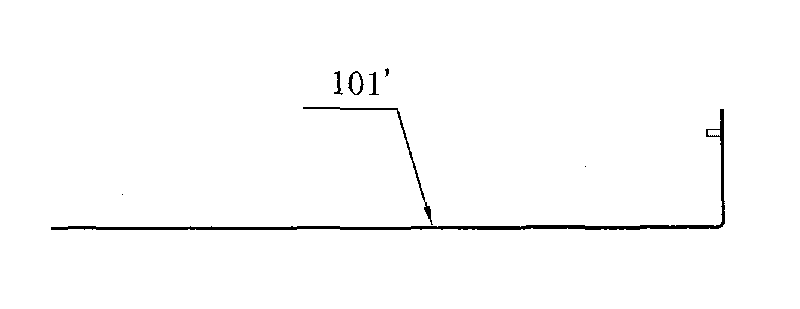

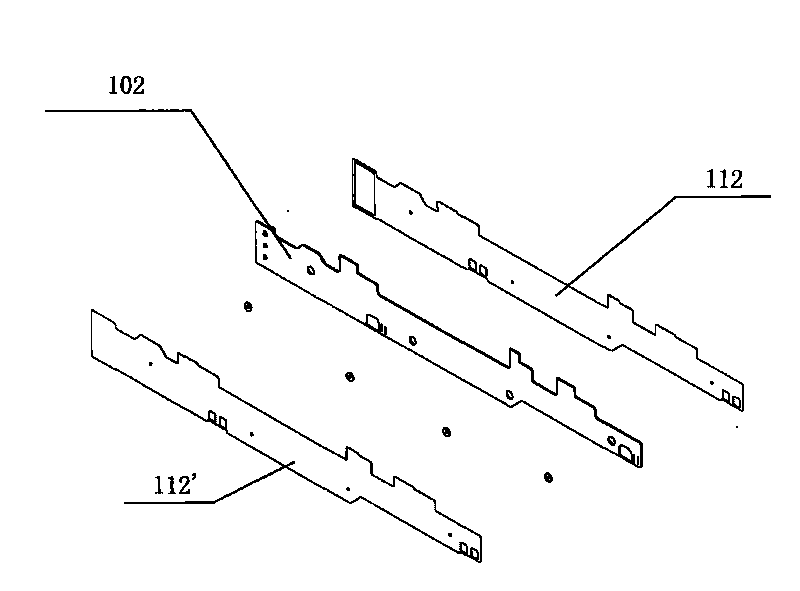

Method for manufacturing laminated busbar and laminated busbar manufactured by the method

InactiveCN101728026AReduce capacitanceImprove reliabilityInsulated cablesInsulated conductorsBusbarEngineering

The invention discloses a method for manufacturing a laminated busbar, which comprises the following steps: machining conducting panels and insulating panels of each layer; spraying insulating powder on the surfaces of the conducting panels of each layer; and alternately stacking the conducting panels coated with the insulating powder and the insulating panels in a laminating die, and then laminating the conducting panels and the insulating panels into a whole by a laminating machine. Through spraying technology, the method makes insulativity of the conducting panels of each layer more easily realized, can realize multidimensional insulativity of more complex parts and has the advantages of low cost of insulating treatment, low energy consumption, few laminating times and high production efficiency. In addition, by adopting a laminating method with the laminating die, the method effectively reduces the volume of the laminated busbar and has high safety. The invention also provides the laminated busbar manufactured by the method.

Owner:SHENZHEN ZHENQIN ELECTRONICS TECH

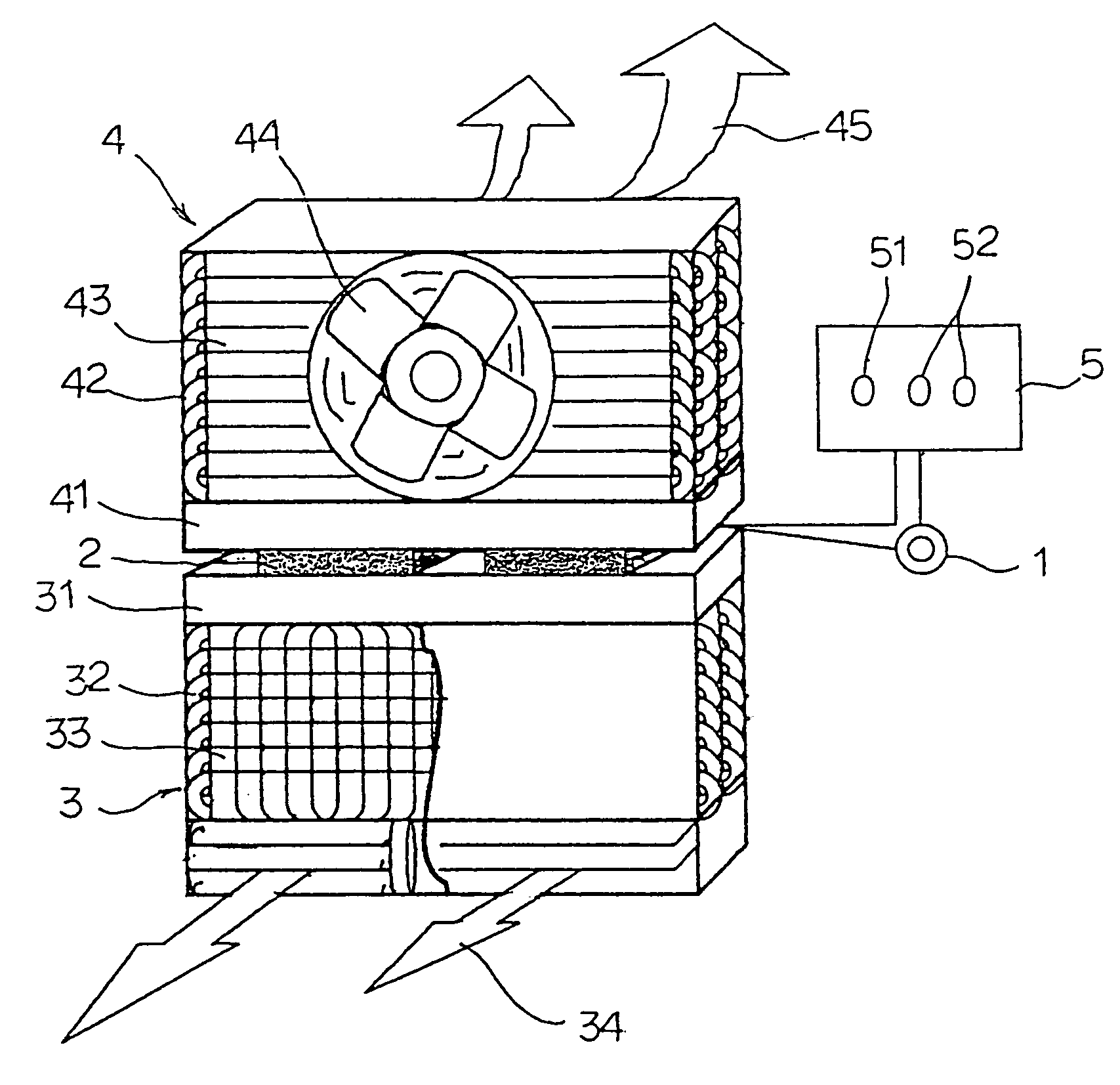

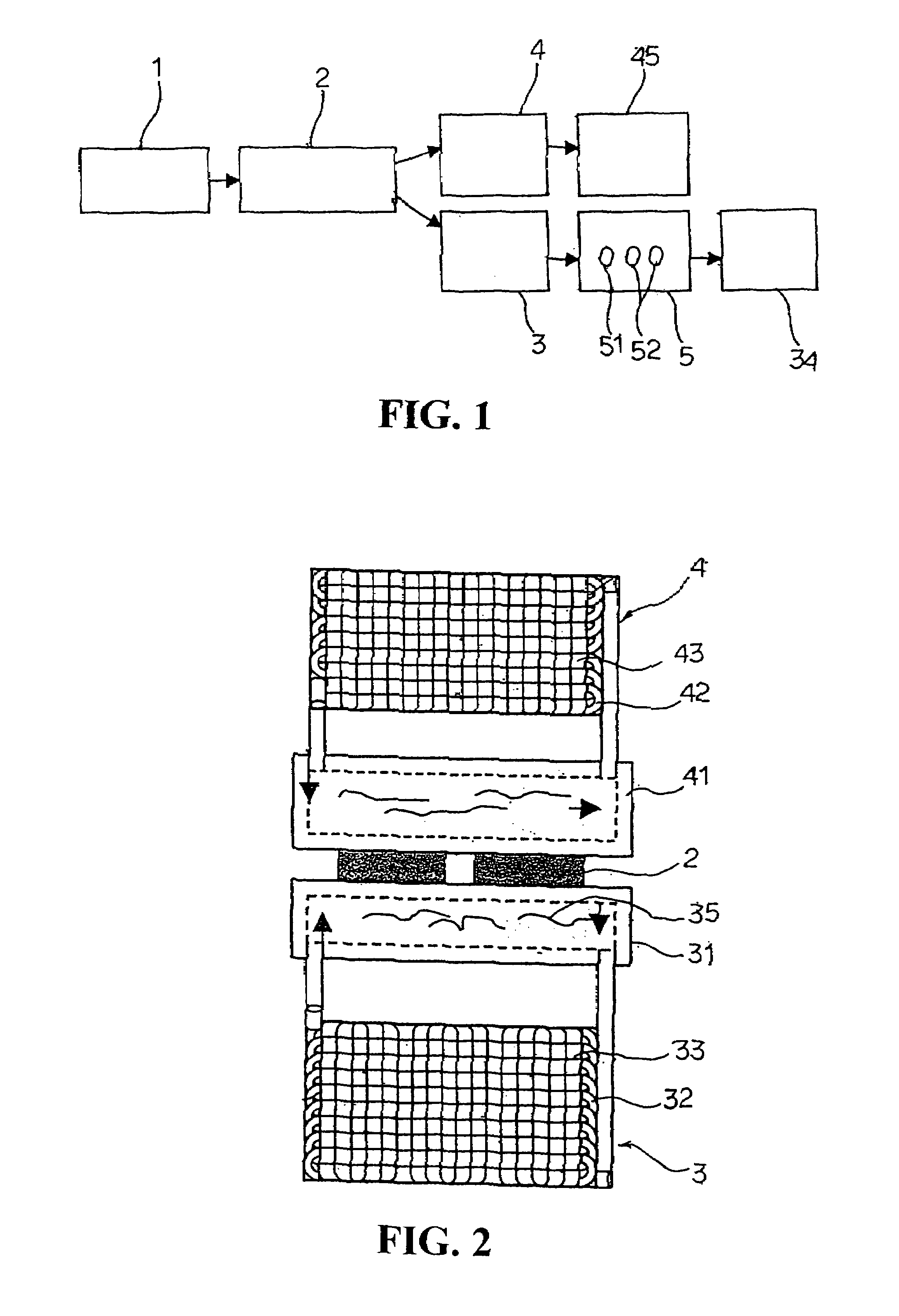

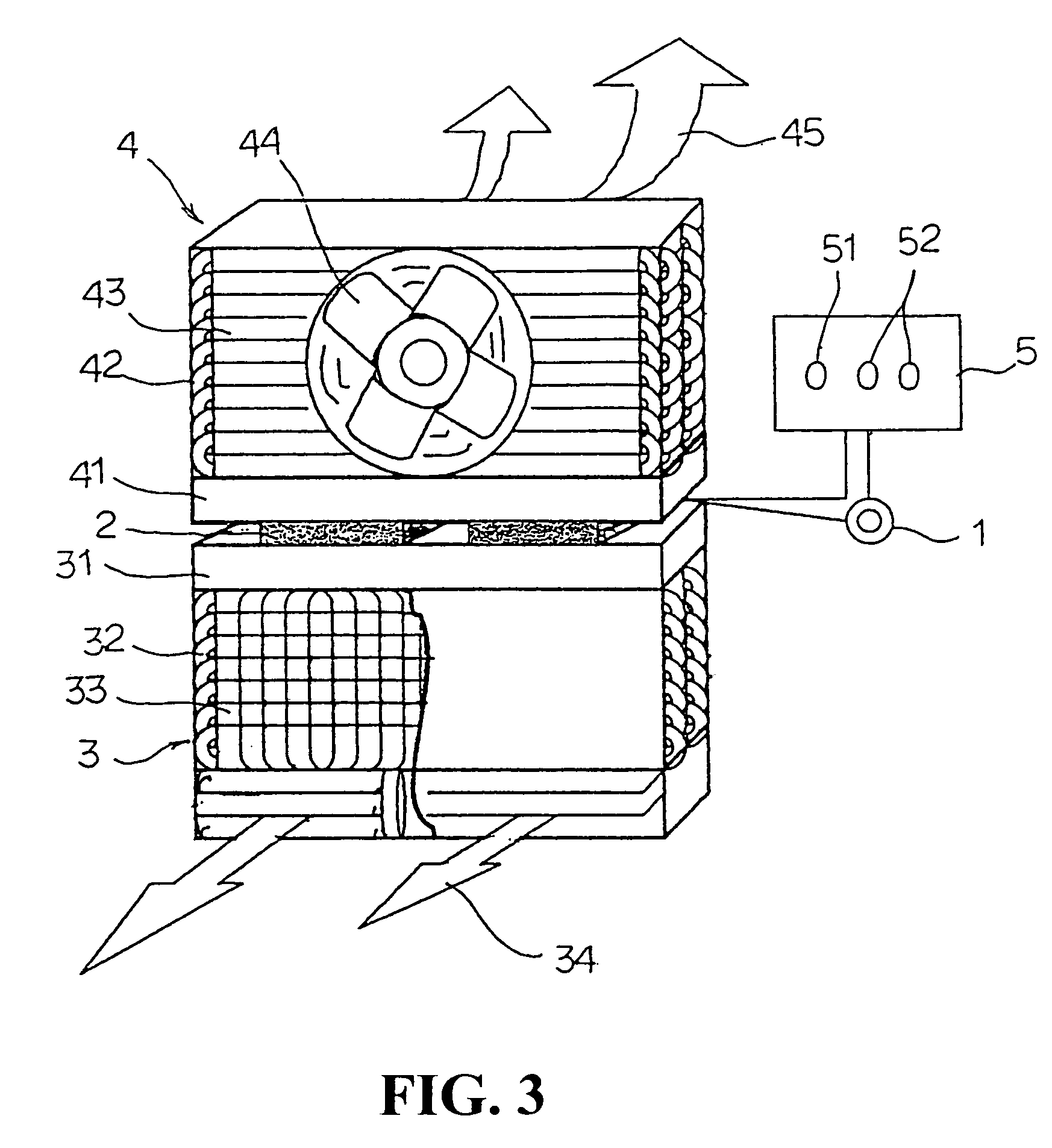

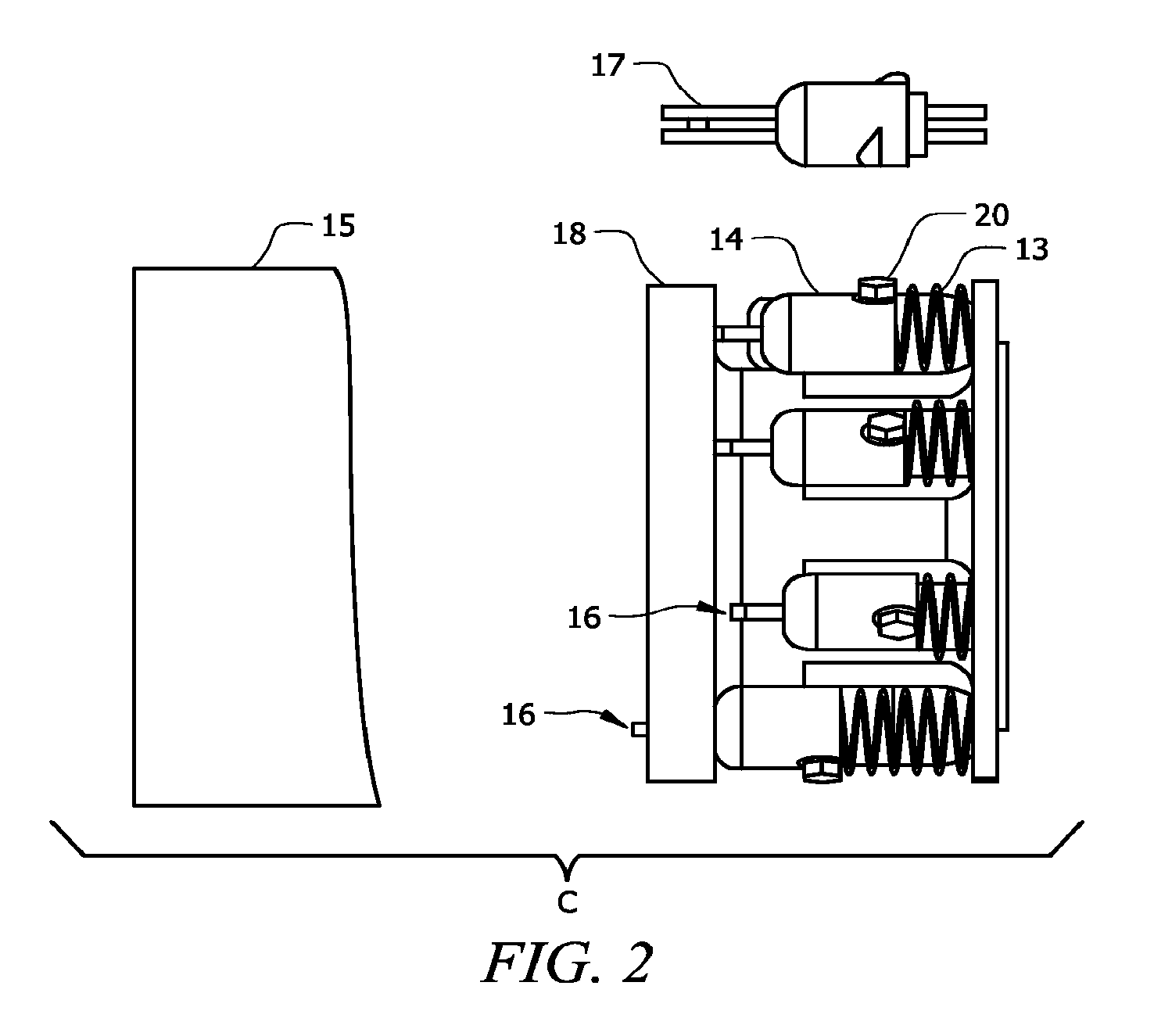

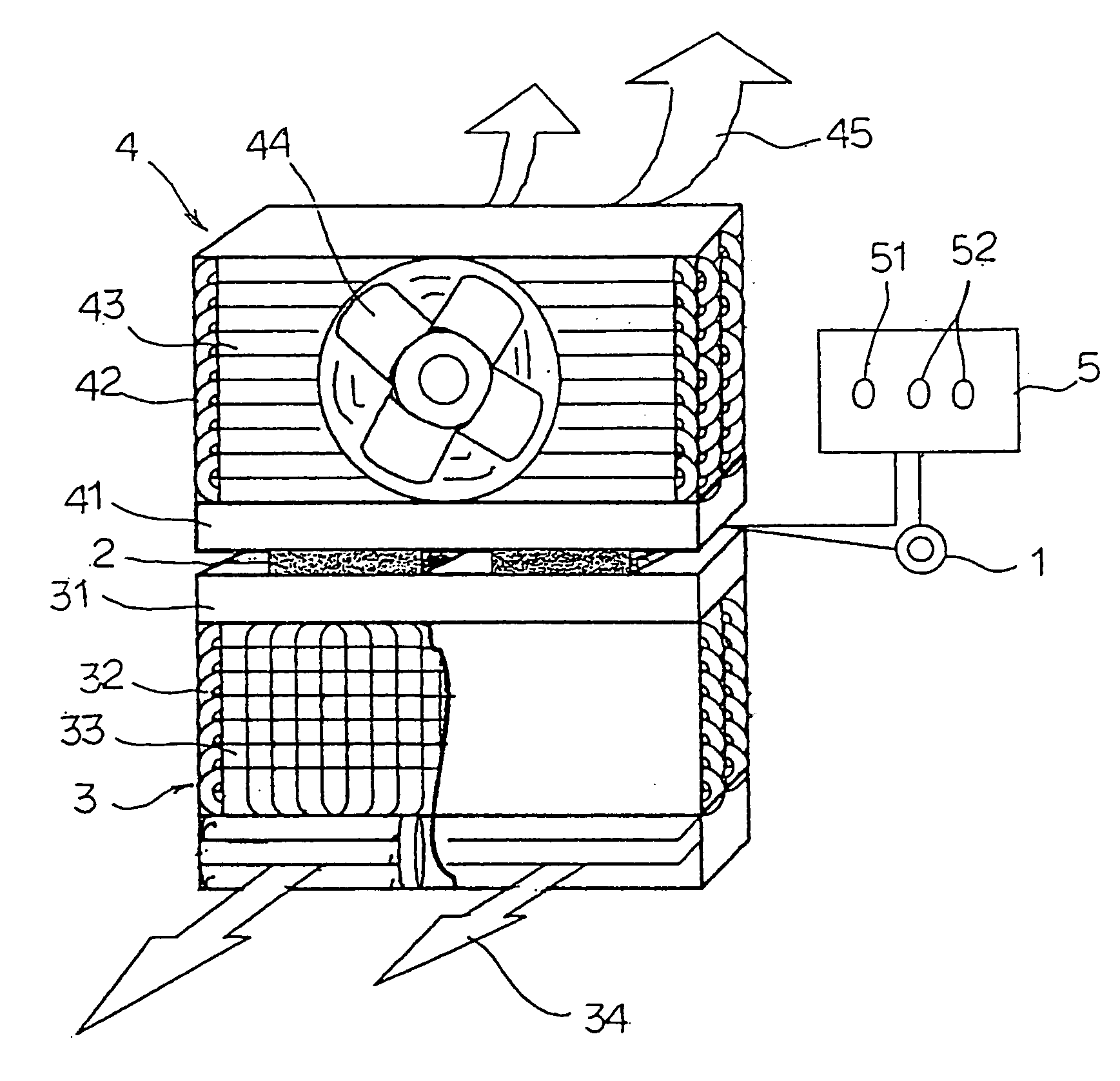

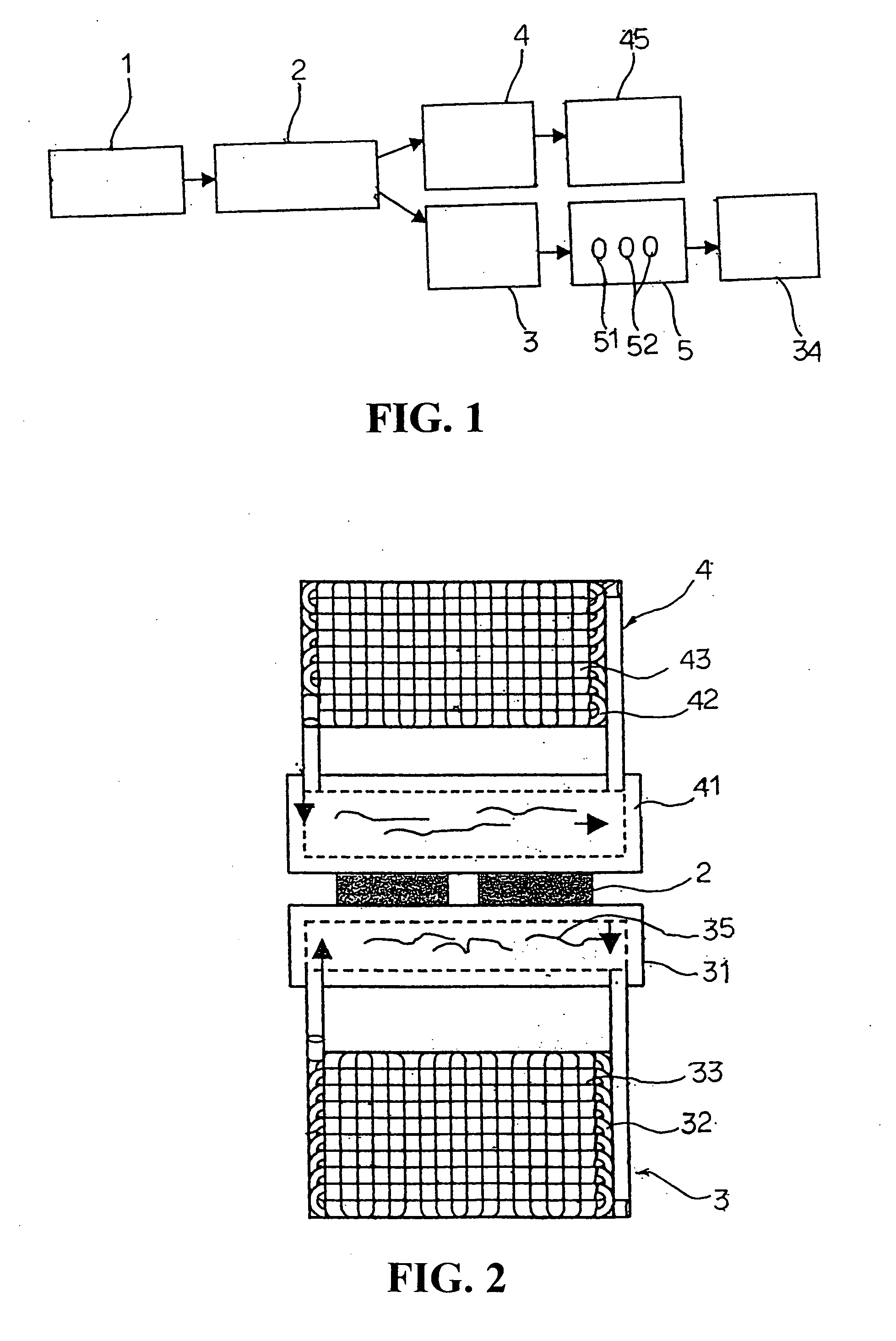

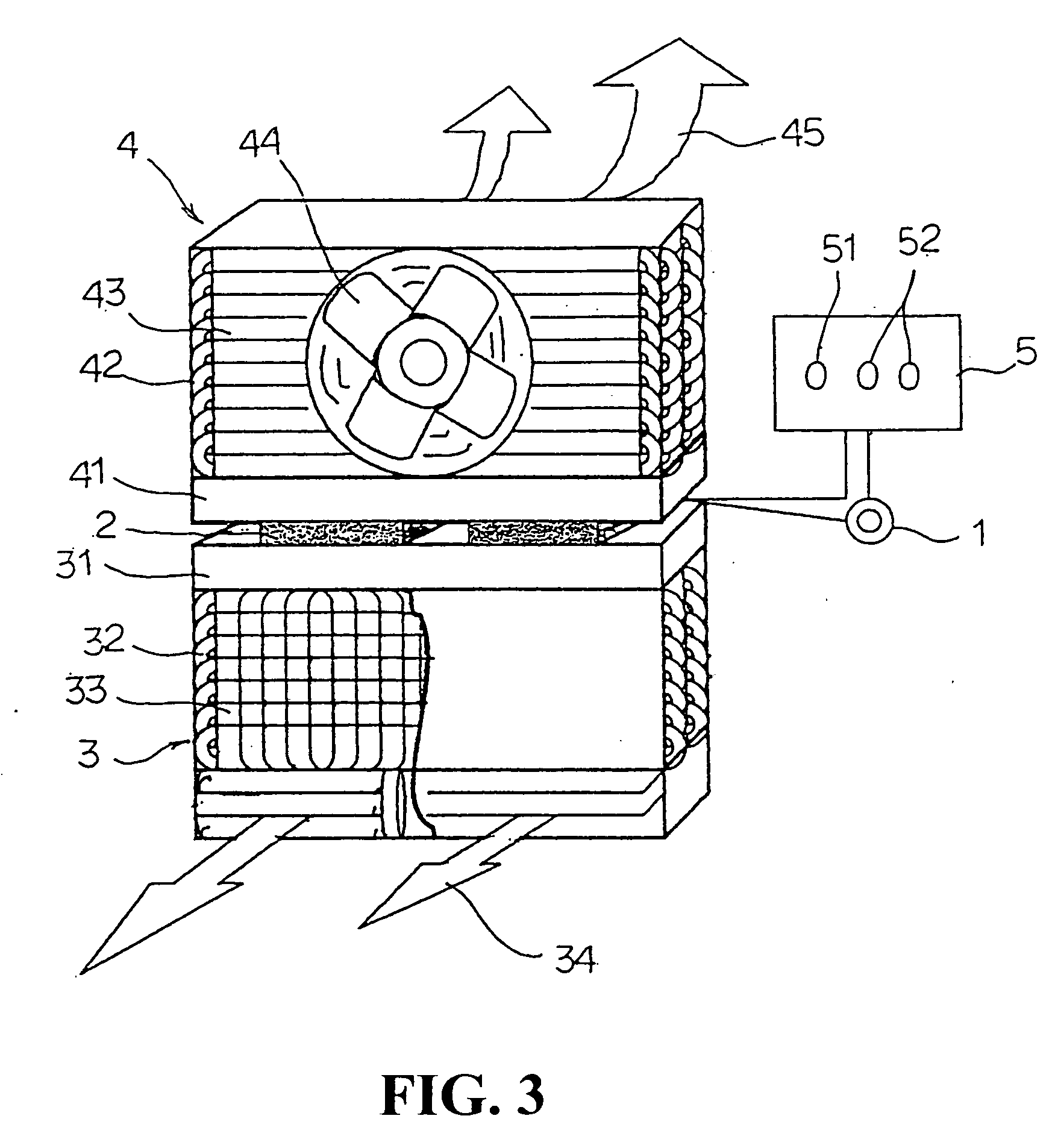

Semiconductor based air conditioning device

ActiveUS7251943B2Consumes less energyProducing coldnessInternal combustion piston enginesDomestic cooling apparatusTemperature controlThermoelectric cooling

The present invention mainly utilizes a specialized semiconductor ship, the so-called thermoelectric cooling chip, for producing the coldness. A cooling circulating member and a heat dissipating member are configured at the two sides of the thermoelectric cooling chip. The coldness produced by the thermoelectric cooling chip is delivered by a cold conduction plate and cooling pipes, and is stored in fins of the cooling circulating member. A temperature controller determines a desired temperature and the coldness stored in the fins are blown out as cool air by a fan. Similarly, the heat produced by the chip is dissipated by the heat dissipating member. As such, the present invention could reach the desired temperature within a short period of time without the conventional compressor. The present invention therefore is easier to install and transport, consumes less power, and produces almost no noise and pollution to the environment.

Owner:CHEN CHUAN SHENG

Cross foldable automatic retracting and spreading wing type sail

ActiveCN104890845AReduce areaDoes not affect stabilityVessel superstructuresVessel mastsEngineeringPulley

The invention discloses a cross foldable automatic retracting and spreading wing type sail. A first fixed pulley is fixed at the upper end of a multi-section main mast, a second fixed pulley is fixed at the right end of a top frame cross rod, and a third fixed pulley is fixed at the right end of a bottom frame cross rod. The left ends of an upper spring telescopic rod and a lower spring telescopic rod are fixedly connected with one corresponding frame cross rod respectively, and the right ends are fixedly connected with one corresponding sliding block in snap grooves respectively. A first sail body fixing mast is arranged close to the right of the multi-section main mast, the upper end of a second sail body fixing mast is fixedly connected with a first sliding block at the top, and the lower end of the second sail body fixing mast is fixedly connected with a second sliding block at the bottom. One end of a first pulling cable is fixedly connected with the lower end of the inside of a base, and the other end is fixedly connected with the first sliding block. One end of a second pulling cable is fixedly connected with the upper end of the inside of the multi-section main mast, and the other end is fixedly connected with the second sliding block. By means of the sail, the sail is driven to be spread and retracted automatically by using hydraulic lifting rods as power, and accordingly, the wind energy utilization rate is improved.

Owner:JIANGSU UNIV OF SCI & TECH

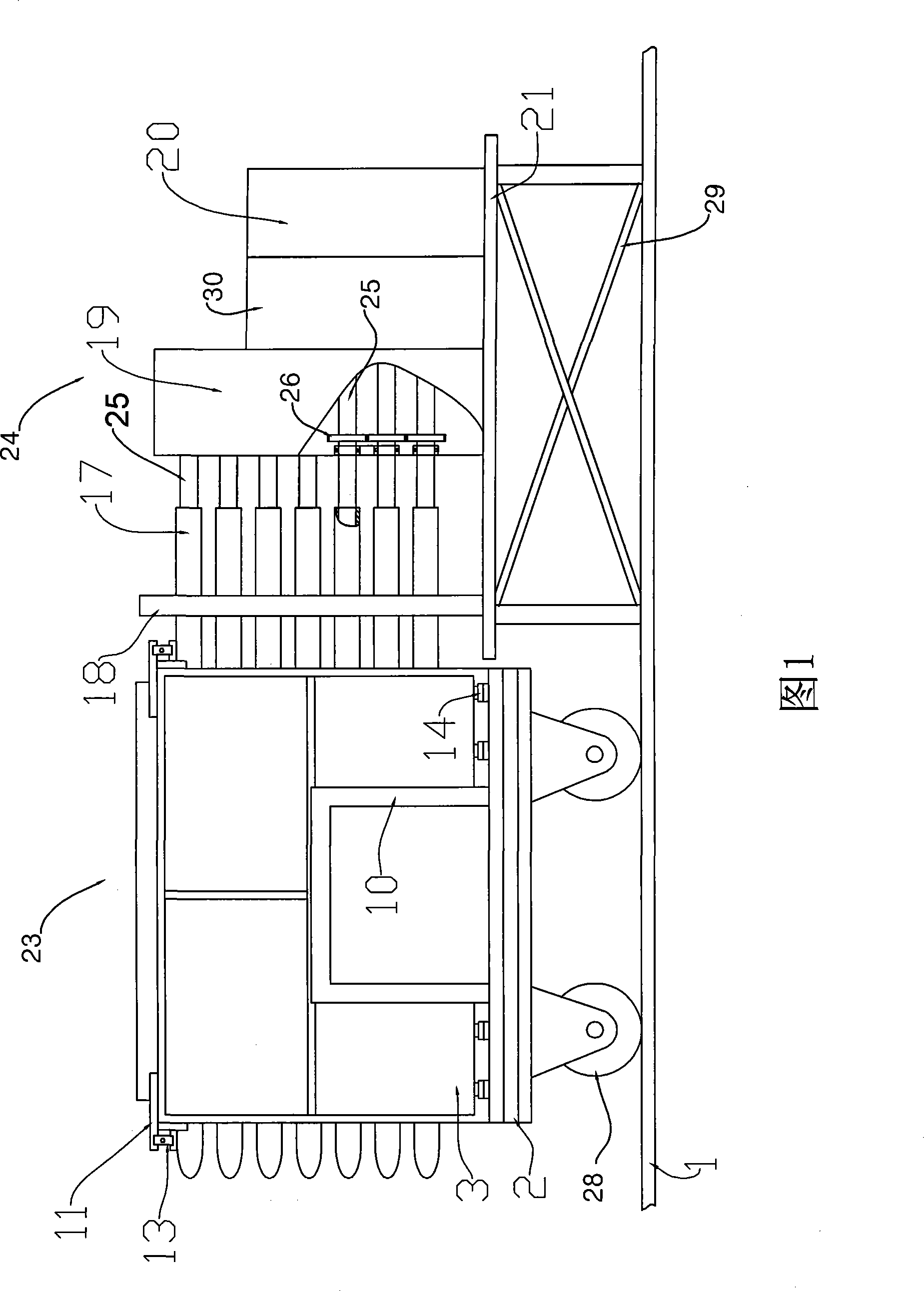

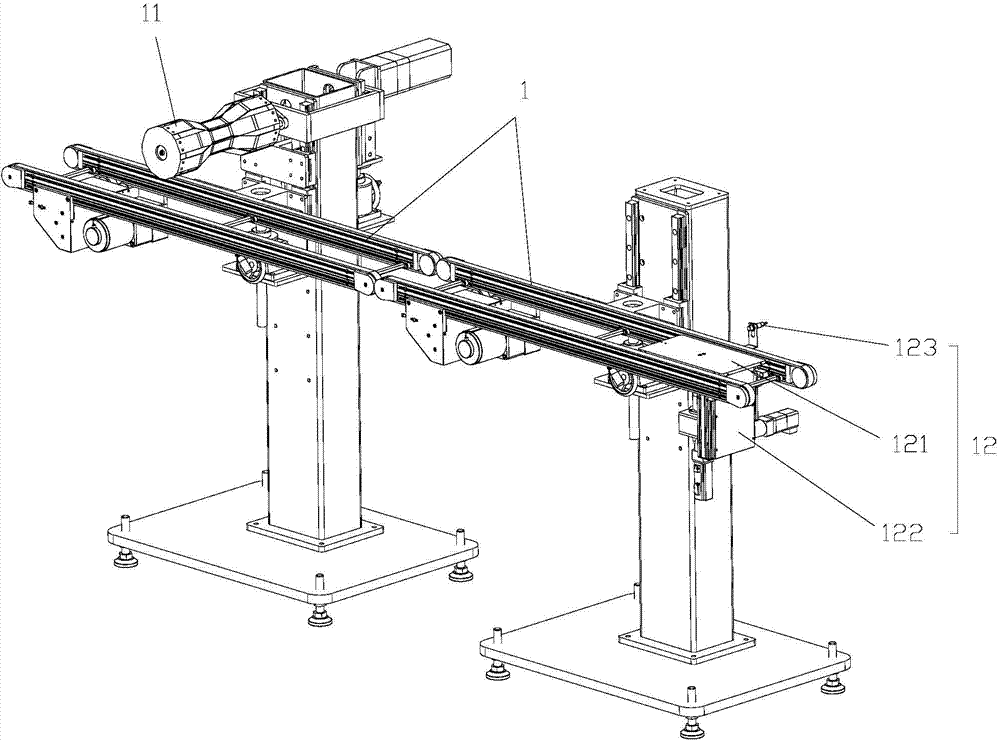

Powder spraying curing system

ActiveCN104841596AImprove curing effectEfficient use ofLiquid spraying plantsLiquid surface applicatorsSpray nozzleEngineering

The invention discloses a powder spraying curing system which comprises a first conveying belt, a powder sprayer and a heating oven. The first conveying belt is used for conveying workpieces; the powder sprayer comprises a spray head, the spray head comprises a spray head body and a spray sleeve, one end of the spray head body is a spray nozzle used for power spraying, the spray sleeve is arranged at the position of the spray nozzle, and a suction channel is arranged in the spray head body and is communicated with the spray channel; the heating oven comprises an oven body and a second conveying belt used for conveying the workpieces, the second conveying belt penetrates the oven body, a heating conveying belt is arranged in the oven body, the heating conveying belt corresponds to the second conveying belt and is cooperatively operated with the second conveying belt, a plurality of heating units are arranged on the heating conveying belt, and each heating unit corresponds to one workpiece; the workpieces pass through the first conveying belt, the powder sprayer and the heating oven in sequence. The powder spraying curing system has the advantages that spraying areas can be strictly controlled, spraying materials can be utilized efficiently, energy consumption is low, and curing effect is good.

Owner:广州卓迅包装机械有限公司

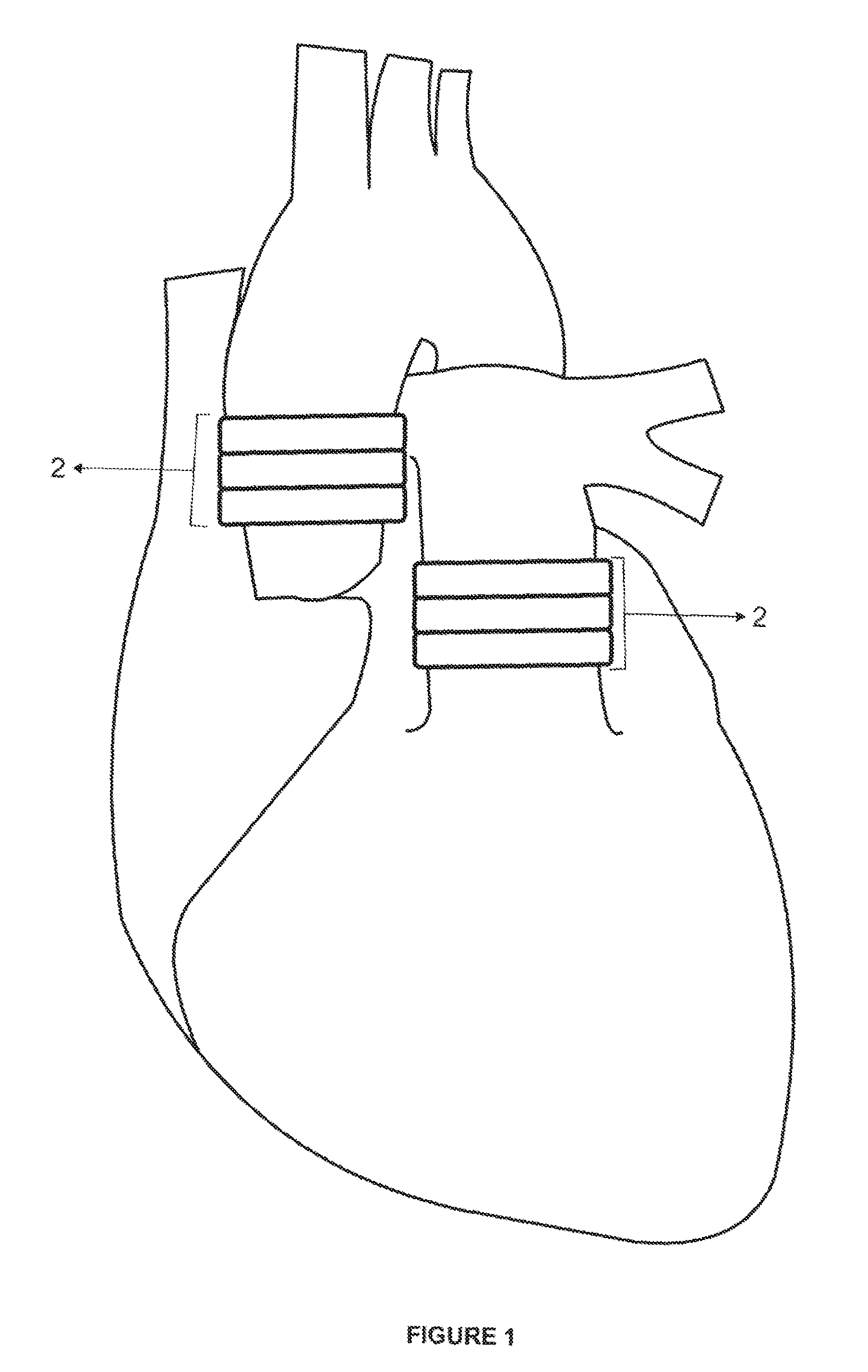

Endovascular heart assist device

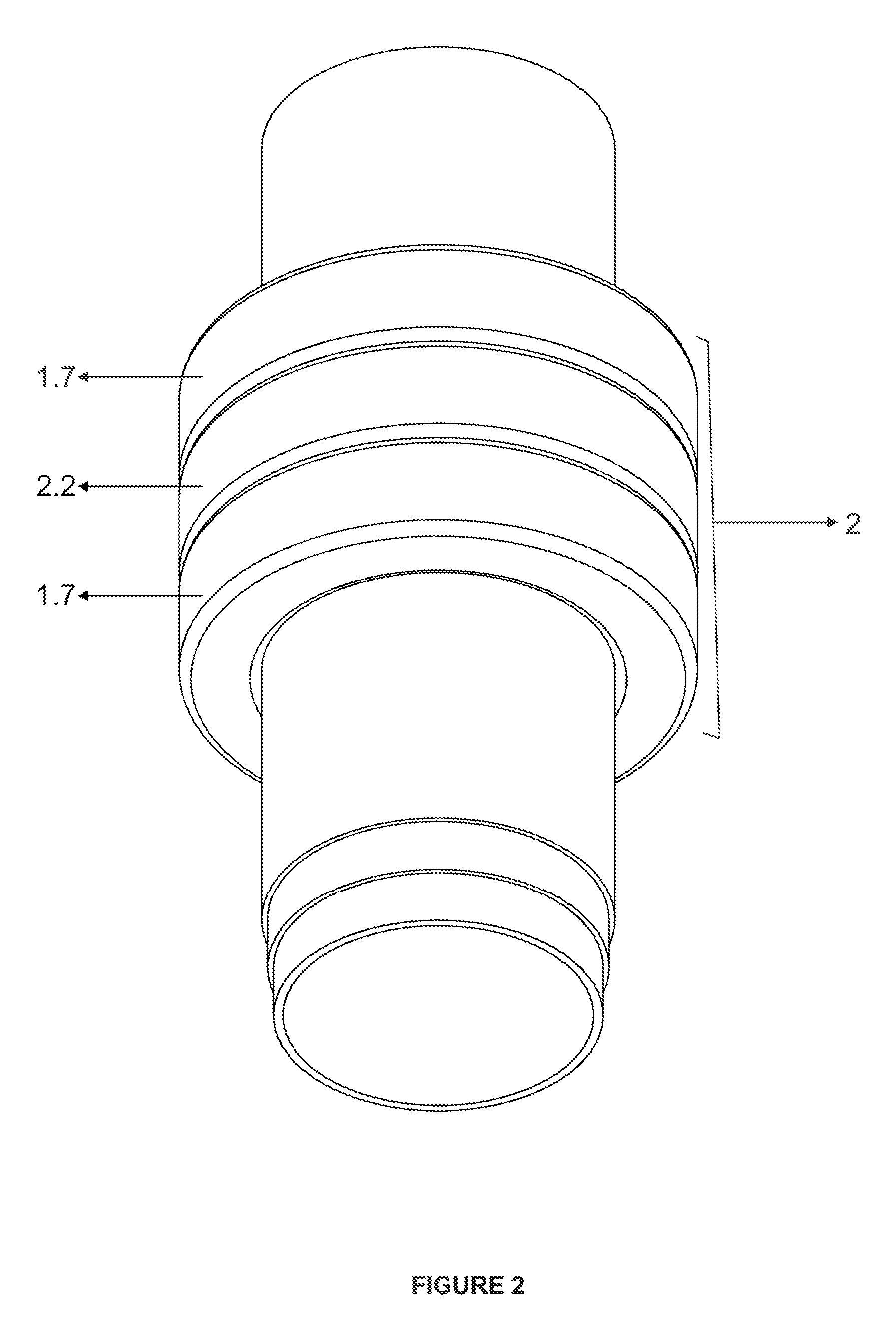

ActiveUS9555175B2Maintain blood circulationConsumes less energyElectrocardiographyControl devicesCellular componentThrombus

The invention is a next generation miniature heart assist device developed in order to maintain the blood circulation in patients with severe heart failure, and is applied endovascularly to the large arteries. This device is technically a kind of synchronous servo electric motor using “direct drive technology”. It provides longer battery life and high blood flow. Small volume and very low energy consumption provide a much longer battery life and a high blood flow. As the outer surface of the parts placed into the blood vessel will be completely covered with the endothelial cells and the intima layer of the arteries in time, there will be no foreign surface contacting directly with blood. As a result, no thromboembolic event or any negative effect on the cellular components of blood is expected.

Owner:BULENT ORAN +2

Refuse collecting ship

InactiveCN102041803AImprove collection and storage capacityReduce consumptionWater cleaningImpellerRefuse collection

The invention discloses a refuse collecting ship, which comprises a refuse collecting device and a refuse storing device, wherein the refuse collecting device comprises a tank body of which the middle is provided with a through hole; a motor is arranged above the tank body, the output shaft of the motor is linked with an impeller shaft, and the impeller shaft is arranged in the tank body and traverses the tank body; a plurality of blades are fixedly arranged on the outer circumference of the impeller shaft; an accommodating area is formed in the refuse storing device and is provided with a refuse inlet; a refuse compressing mechanism is arranged in the refuse storing device and drives a compressing plate to act; the refuse storing device is fixedly connected with the refuse collecting device; and the refuse inlet of the refuse storing device corresponds to an outlet of the through hole in the middle of the tan body. When used, the refuse collecting ship can be arranged on the conventional ship, and the conventional ship drives the refuse collecting ship to move in water so as to clean refuse in the water; and the refuse collecting ship also can work independently and is provided with a floating device to float on water surface and clean the refuse in the water simultaneously.

Owner:浙江机电职业技术学院

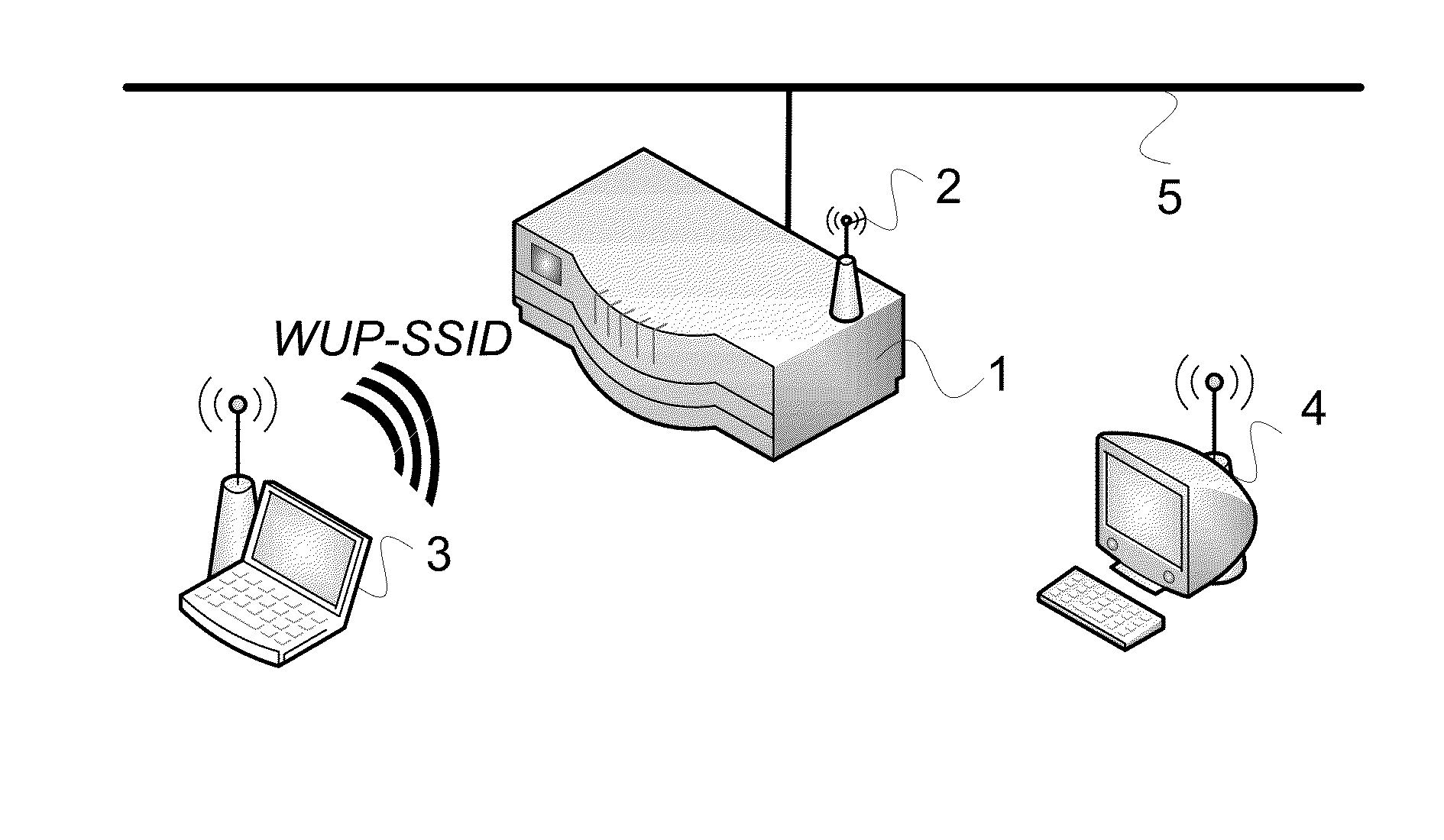

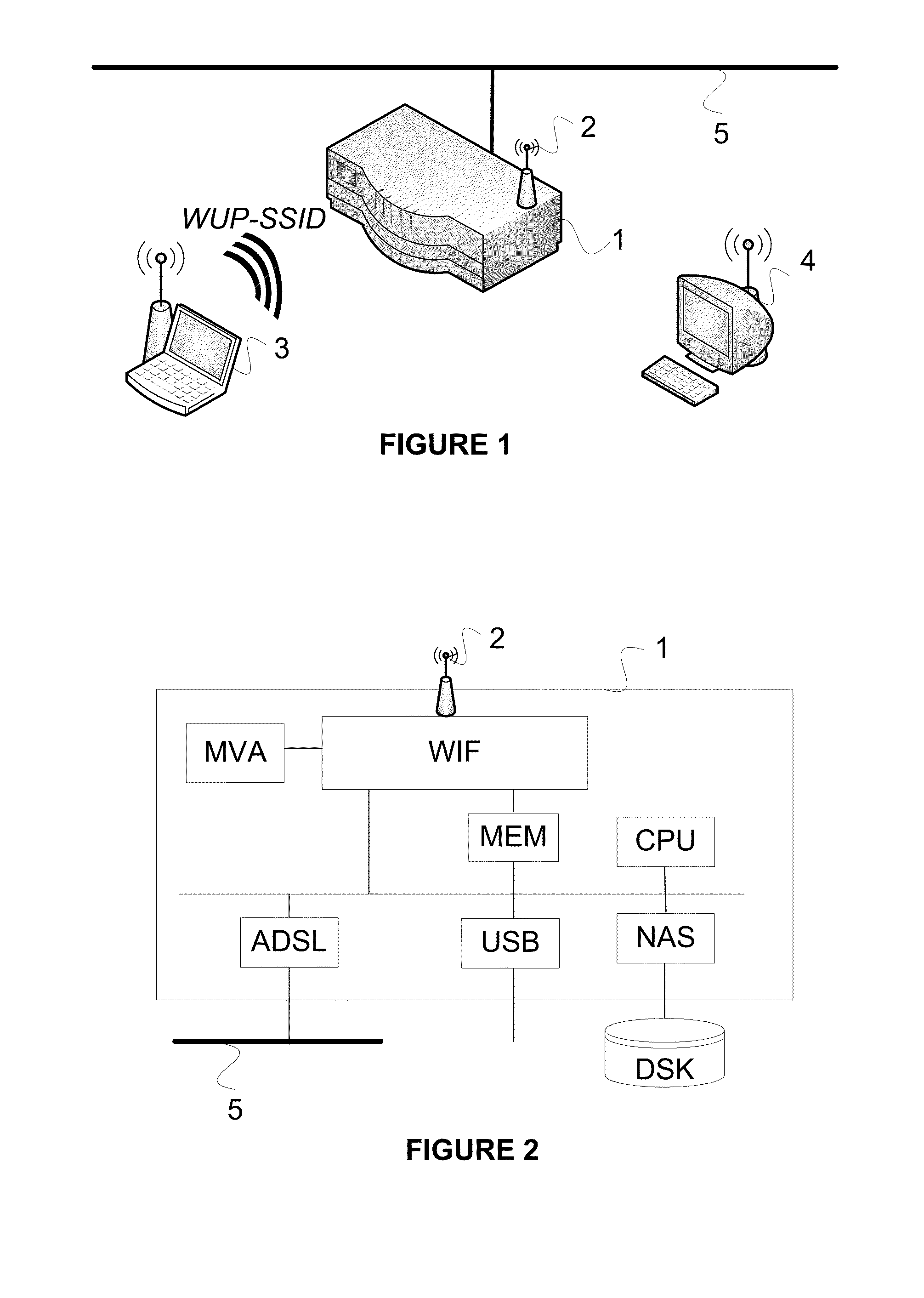

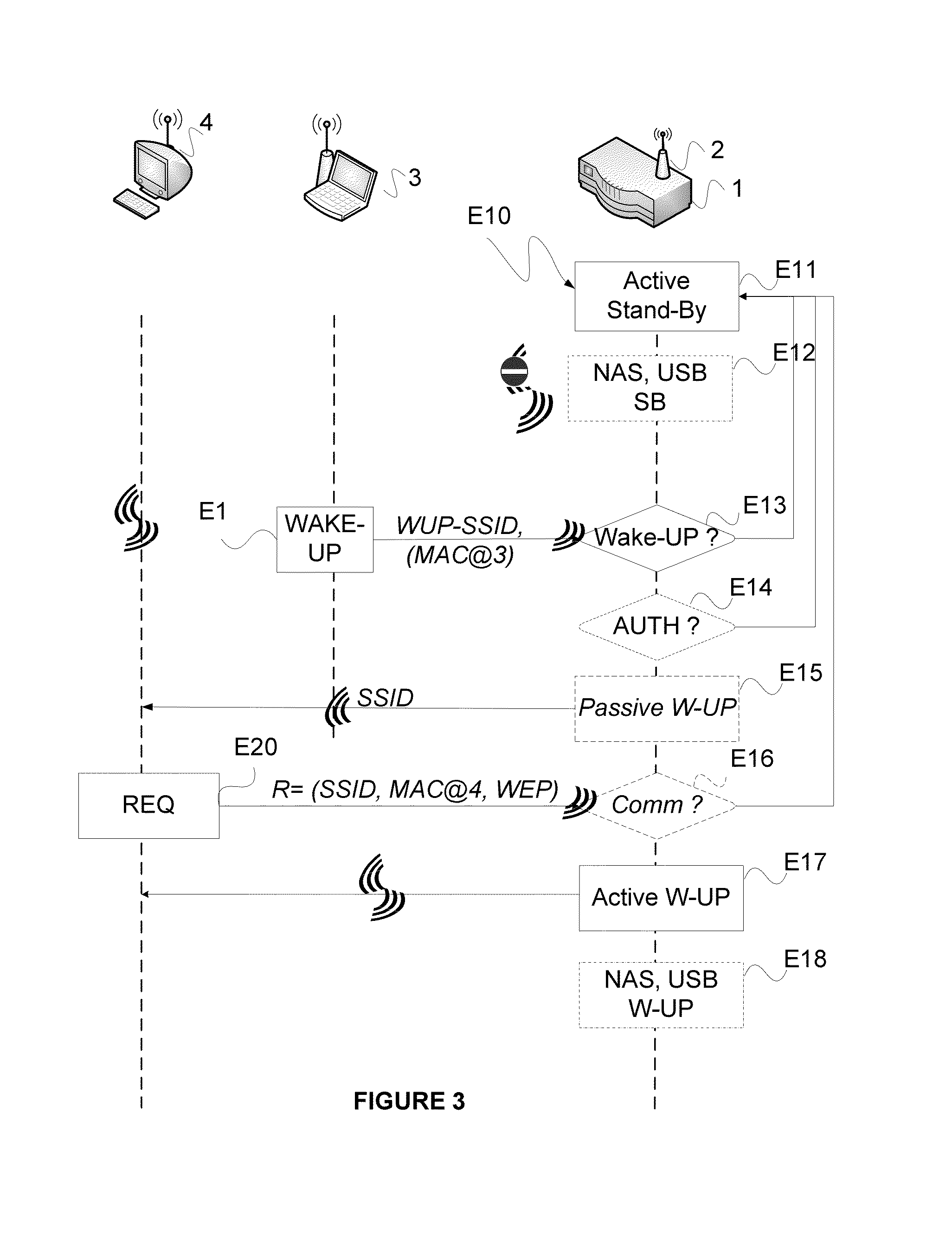

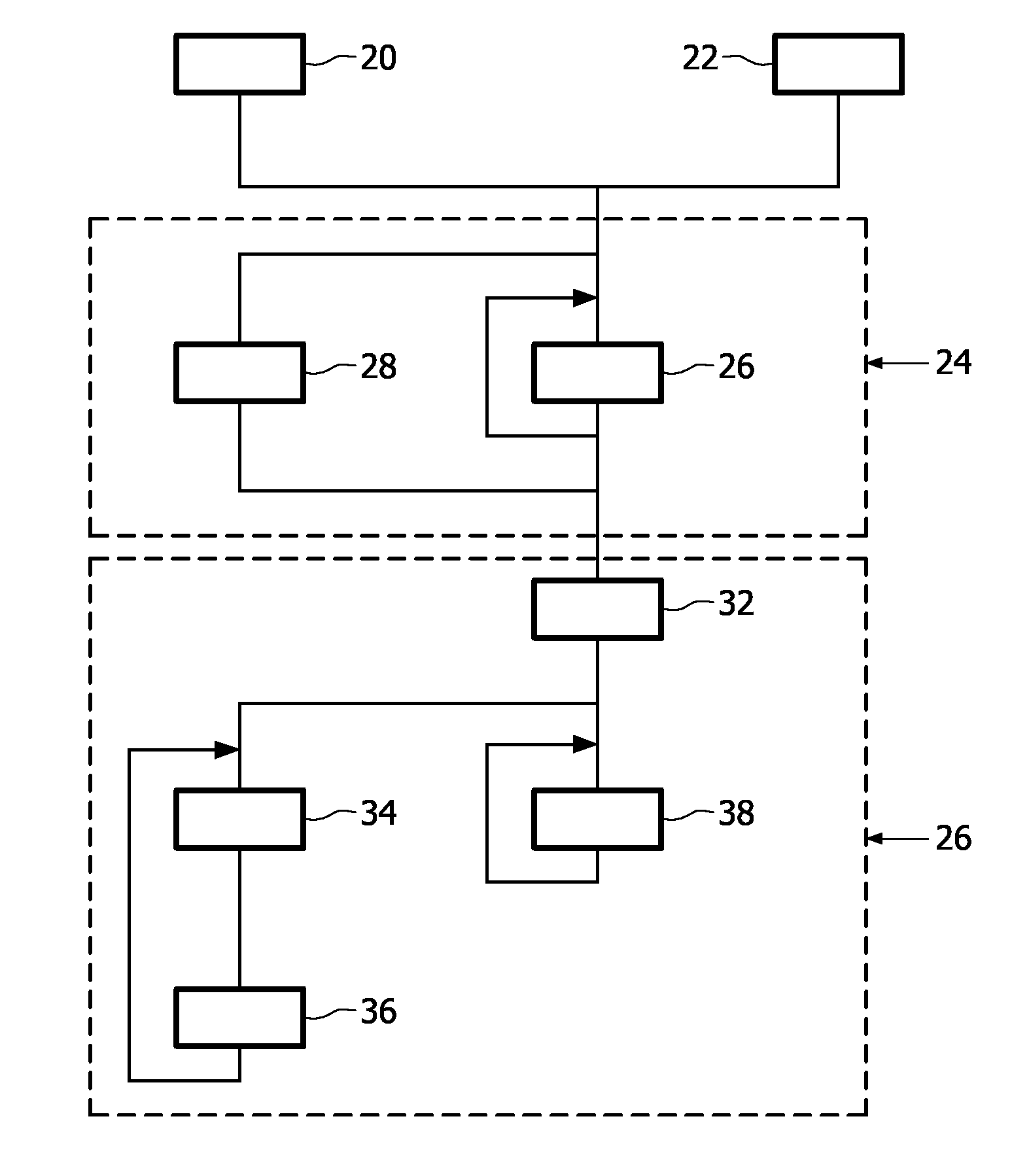

Method of remotely waking up wireless router equipment

ActiveUS20150237658A1Consumes less energyReduce power consumptionPower managementTransmission systemsWireless routerFamily network

Owner:ORANGE SA (FR)

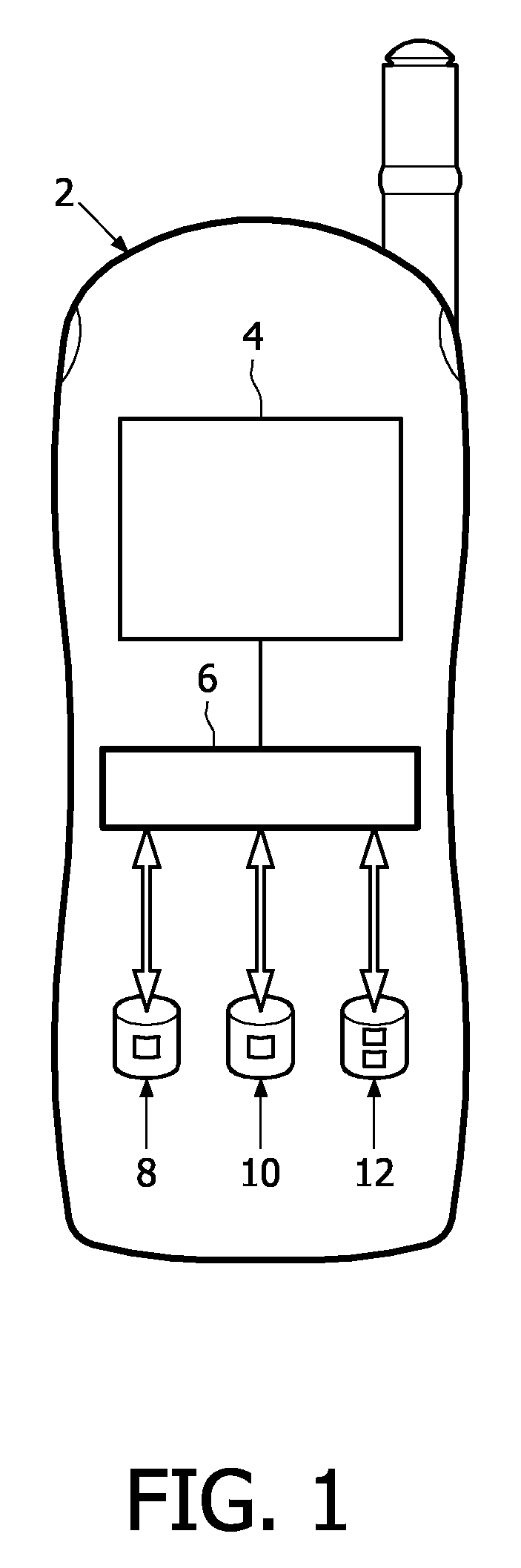

Portable electronic terminal and method therefor

InactiveUS20100017637A1Reduce energy consumptionReduce amount of data storePower managementPower supply for data processingCalculatorElectronics

A portable electronic terminal capable of changing to an idle or sleep mode during which selective powering of portions of the electronics of the terminal takes place to save energy, the terminal comprising:—at least one memory storing, when in the idle or sleep mode, a program code of a background task and data necessary for the execution of the background task,—a calculator (6) adapted to execute the program code directly from said at least one memory when the terminal is in the idle or sleep mode, wherein said at least one memory includes a NVRAM (Non-Volatile Random Access Memory) (12) which consumes no power to retain and access stored information, the NVRAM storing the program code and / or the data.

Owner:NXP BV

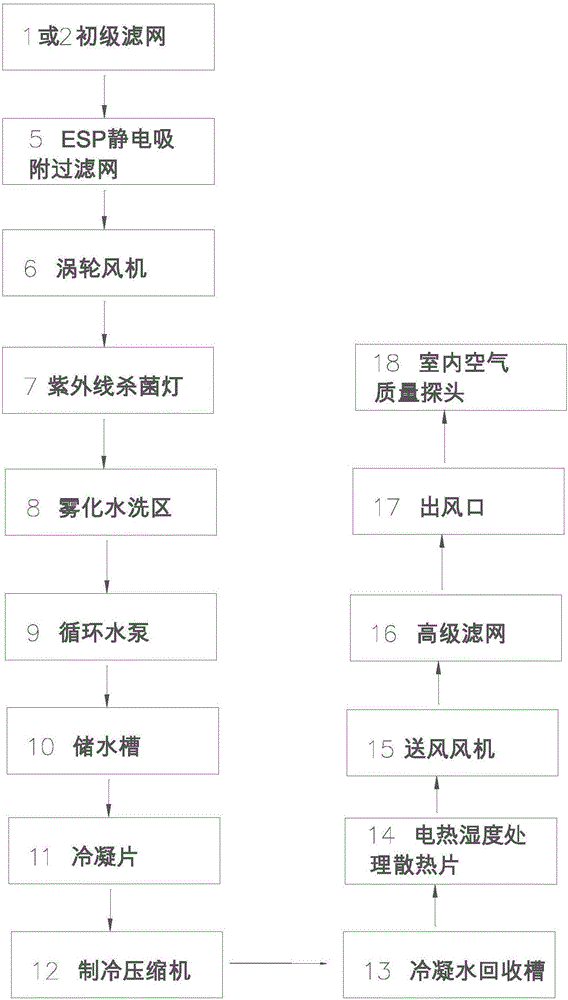

Energy saving type air water washing system

PendingCN106839142ASimple and fast operationHigh degree of automationMechanical apparatusSpace heating and ventilation safety systemsRefrigeration compressorParticulates

The invention discloses an energy saving type air water washing system. The energy saving type air water washing system comprises an air feeding section, an electrostatic precipitation section, an atomization and water washing region, a condensation section, a humidity adjusting section and an efficient filtering section, wherein indoor and outdoor primary filter screens are arranged in indoor and outdoor air inlets; indoor and outdoor air is input through a steering air door; the steering air door is communicated with an electrostatic precipitation filter screen and a turbine air blower; the atomization and water washing region is internally provided with an ultraviolet sterilization lamp, a water storage groove and a circulating water pump; an air outlet is internally provided with a high-grade filter screen and an air supplying air blower; the condensation section is internally provided with a condensed water recycling groove, a condensation sheet and a refrigeration compressor; the humidity adjusting section is internally provided with an electric heating heat dissipation sheet; and a transformer and an air detection probe are arranged at the lateral side of the electrostatic precipitation section and air purification treatment of a whole machine is controlled through a controller. The energy saving type air water washing system is used for monitoring air in real time and is operated automatically; PM2.5 (Particulate Matter 2.5) in the air is effectively removed; meanwhile, pollutants can be effectively removed, and sterilization and humidity adjustment are realized synchronously; and the energy saving type air water washing system has the advantages of energy saving and environment friendliness, low maintenance cost and good air purification effect.

Owner:阚剑锋

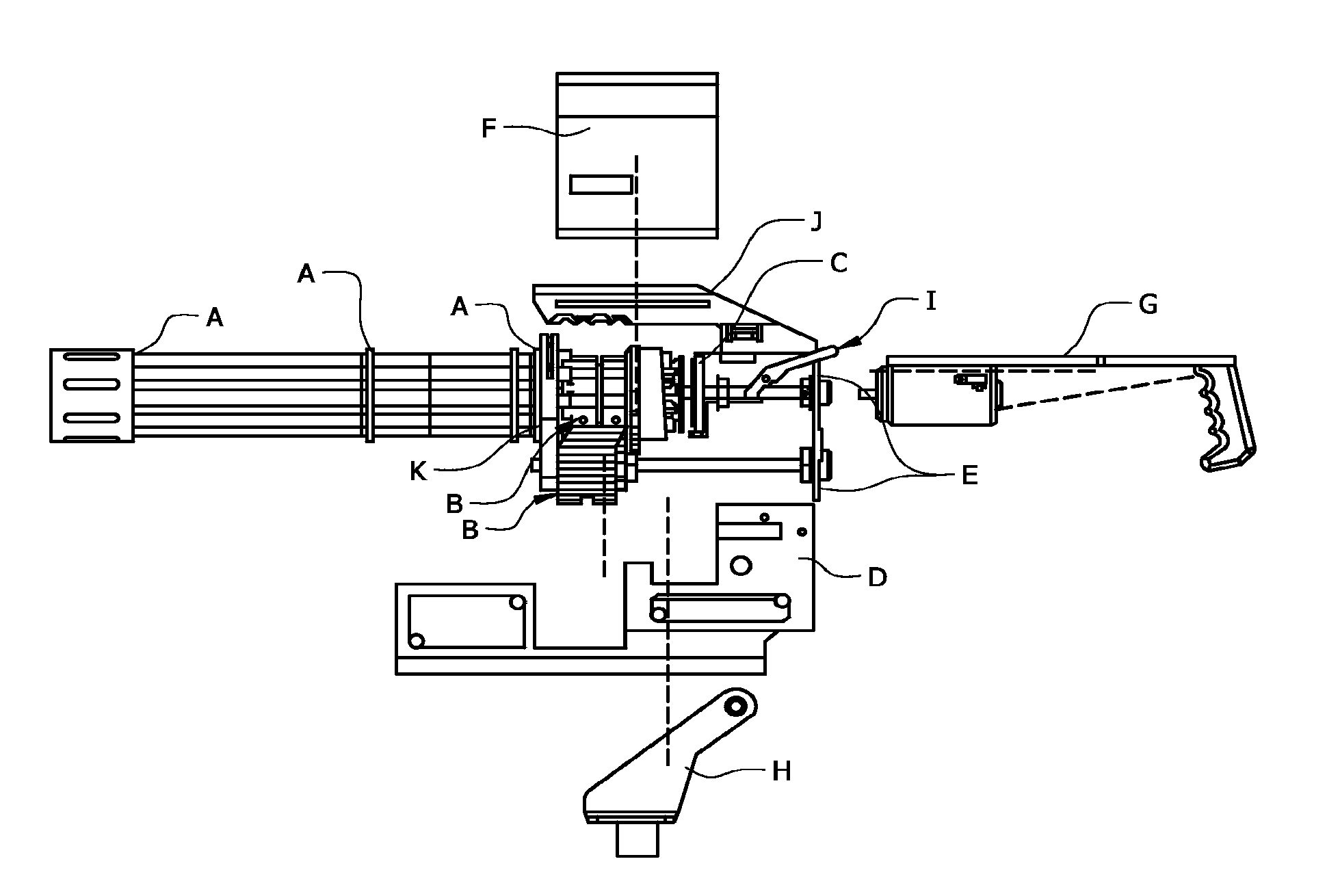

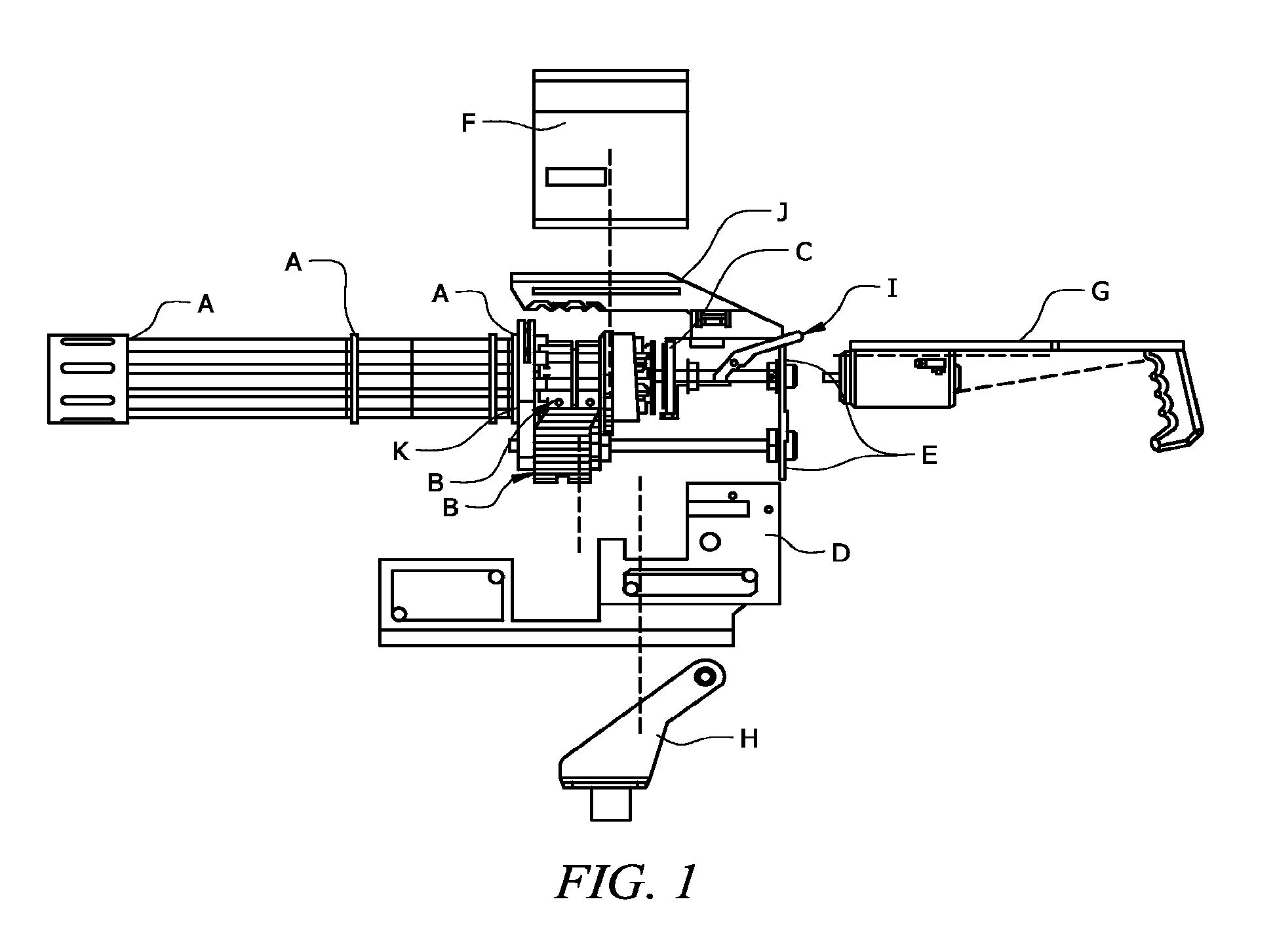

High attrition, rapid dispersal x 8 (h.a.r.d. 8) extreme rate of fire weapon system

ActiveUS20120118132A1Optimize and simplify designLower energy requirementsAmmunition storageAmmunition loadingEngineeringRate of fire

An weapon system comprising: a plurality of barrels, wherein the barrels are disposed coaxially around a main shaft and wherein the barrels are held in place by at least one barrel rack; and a plurality of intermeshing, counter rotating cylinders, wherein the cylinders include a central hole for the main shaft or a lower shaft and a plurality of coaxial half-holes disposed around the central hole at the edge of the cylindrical shape to form a chamber when the cylinders mesh. An ammunition belt comprising: a first and second ammunition case, wherein each ammunition case comprises: a casing having a first and second end, wherein the first end is adapted to receive and hold a primer and the second end is adapted to receive and hold propellant and a projectile, wherein the first ammunition case is attached to the second ammunition case.

Owner:XRF USA LLC

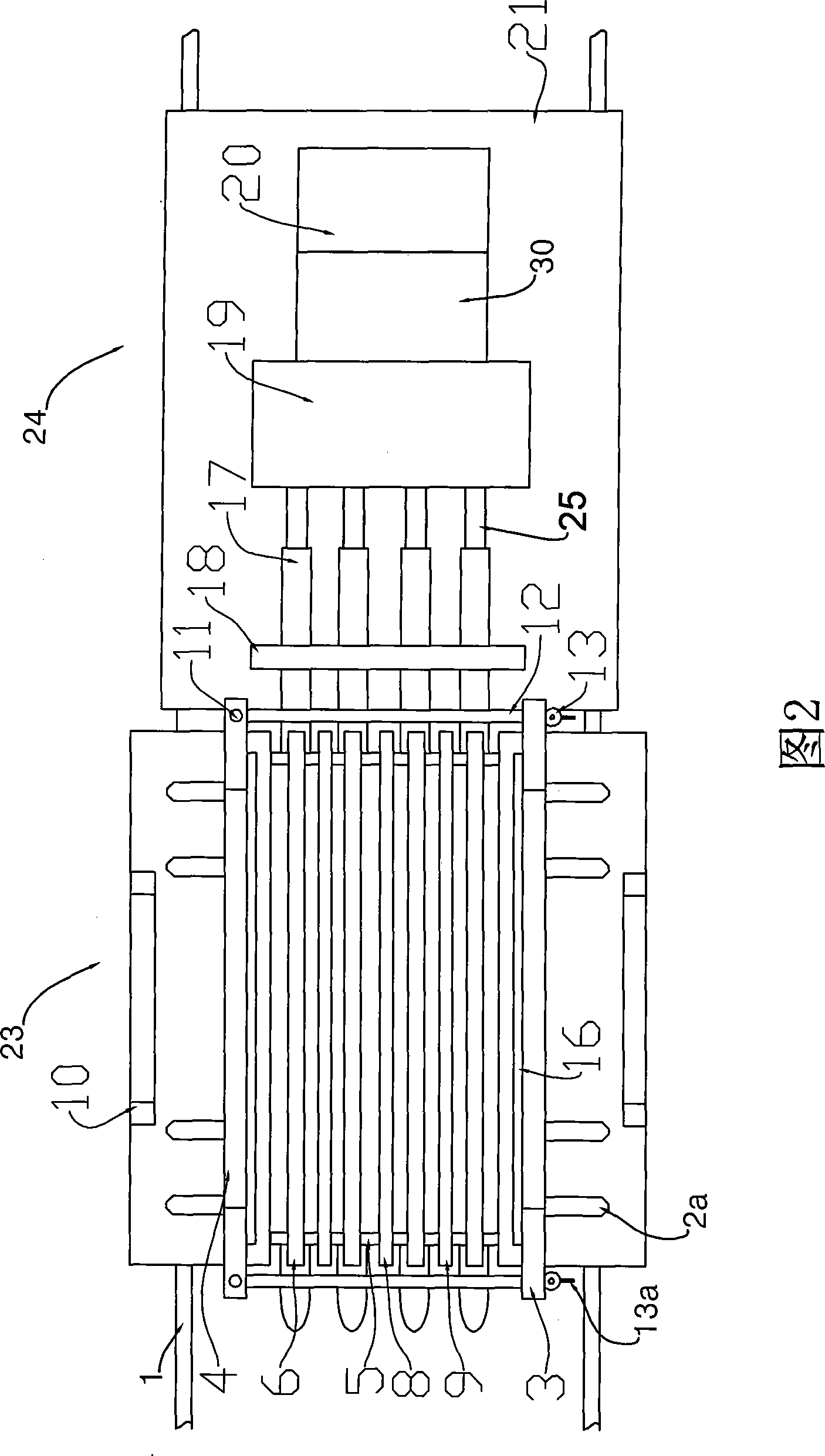

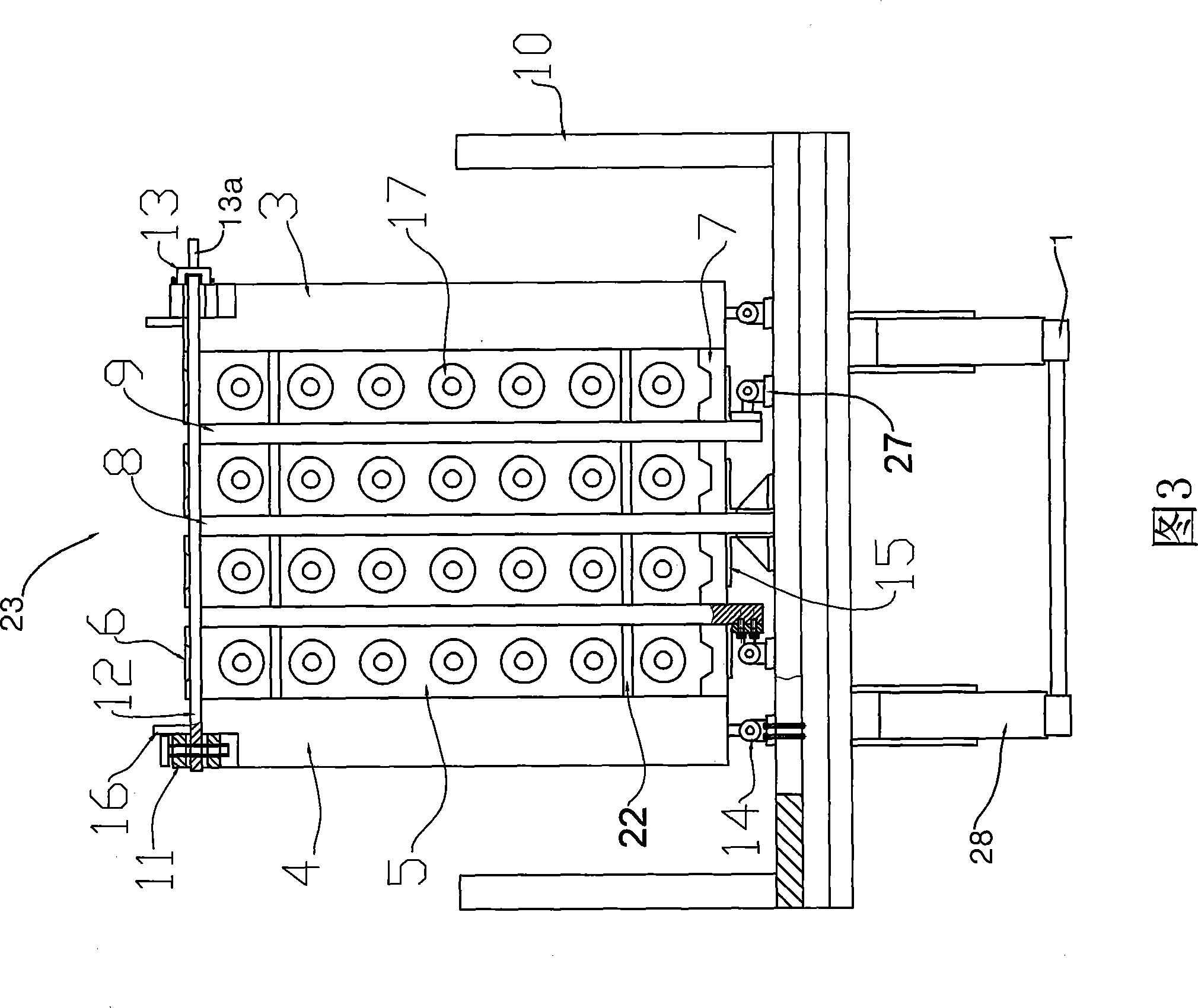

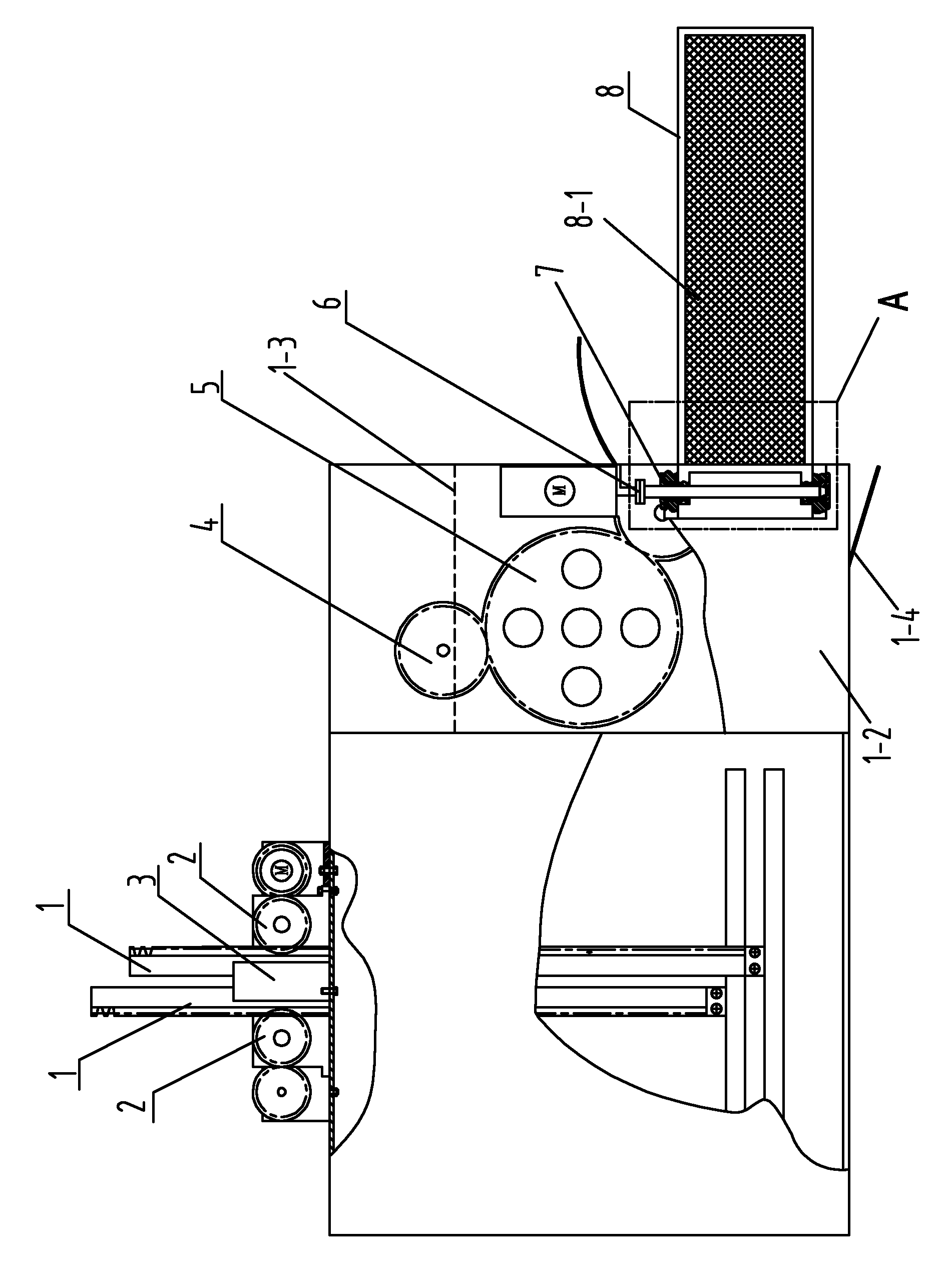

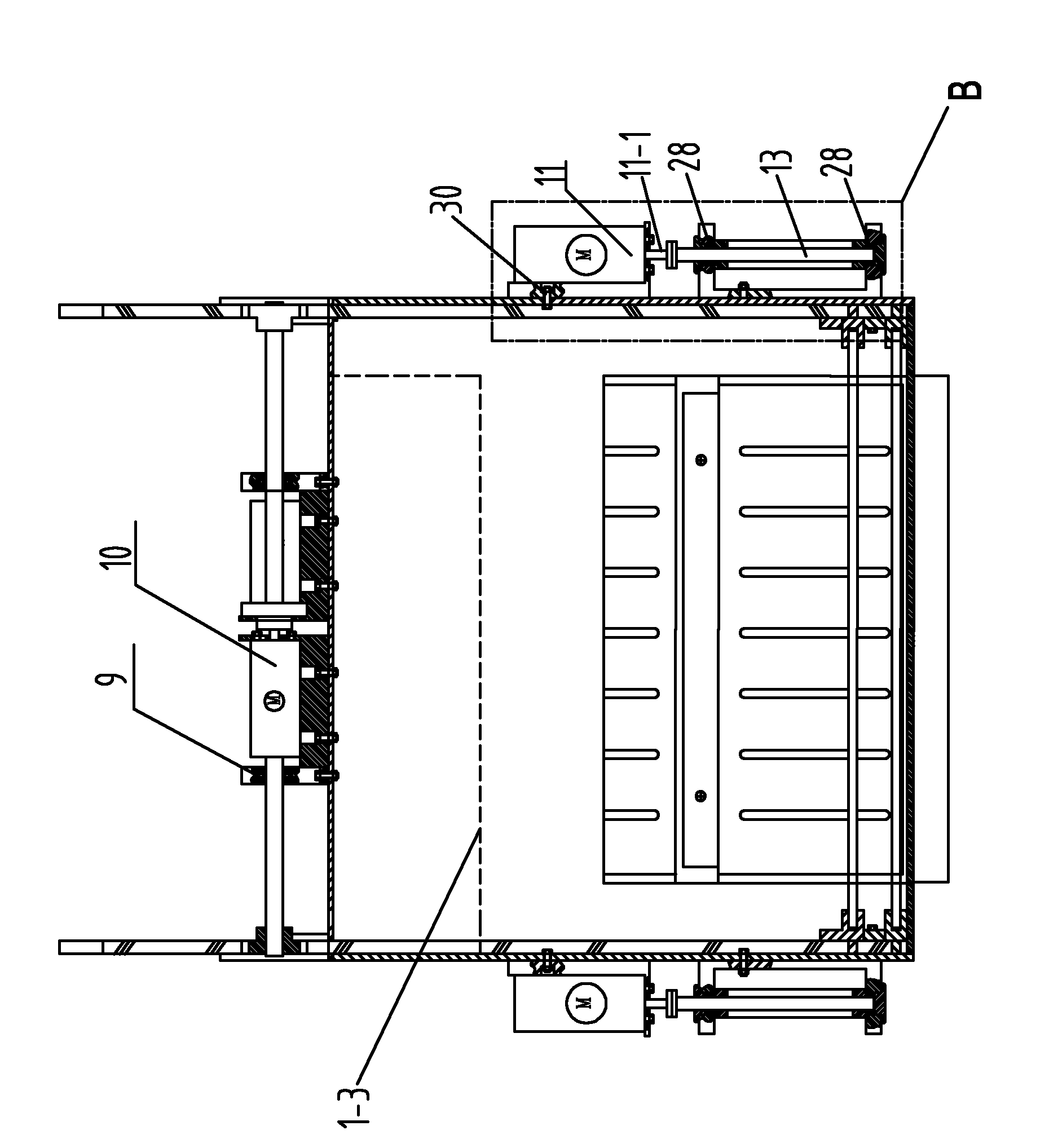

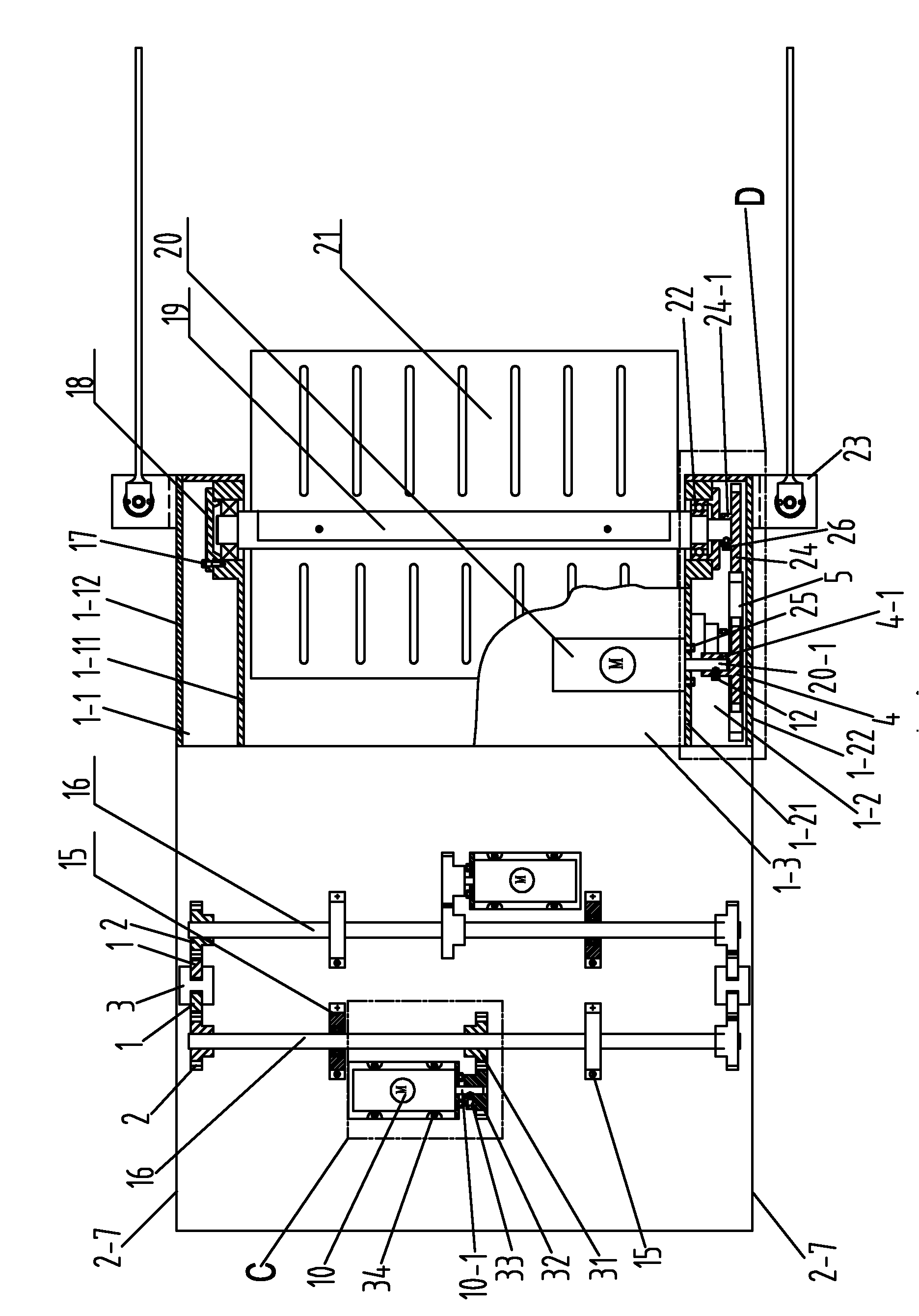

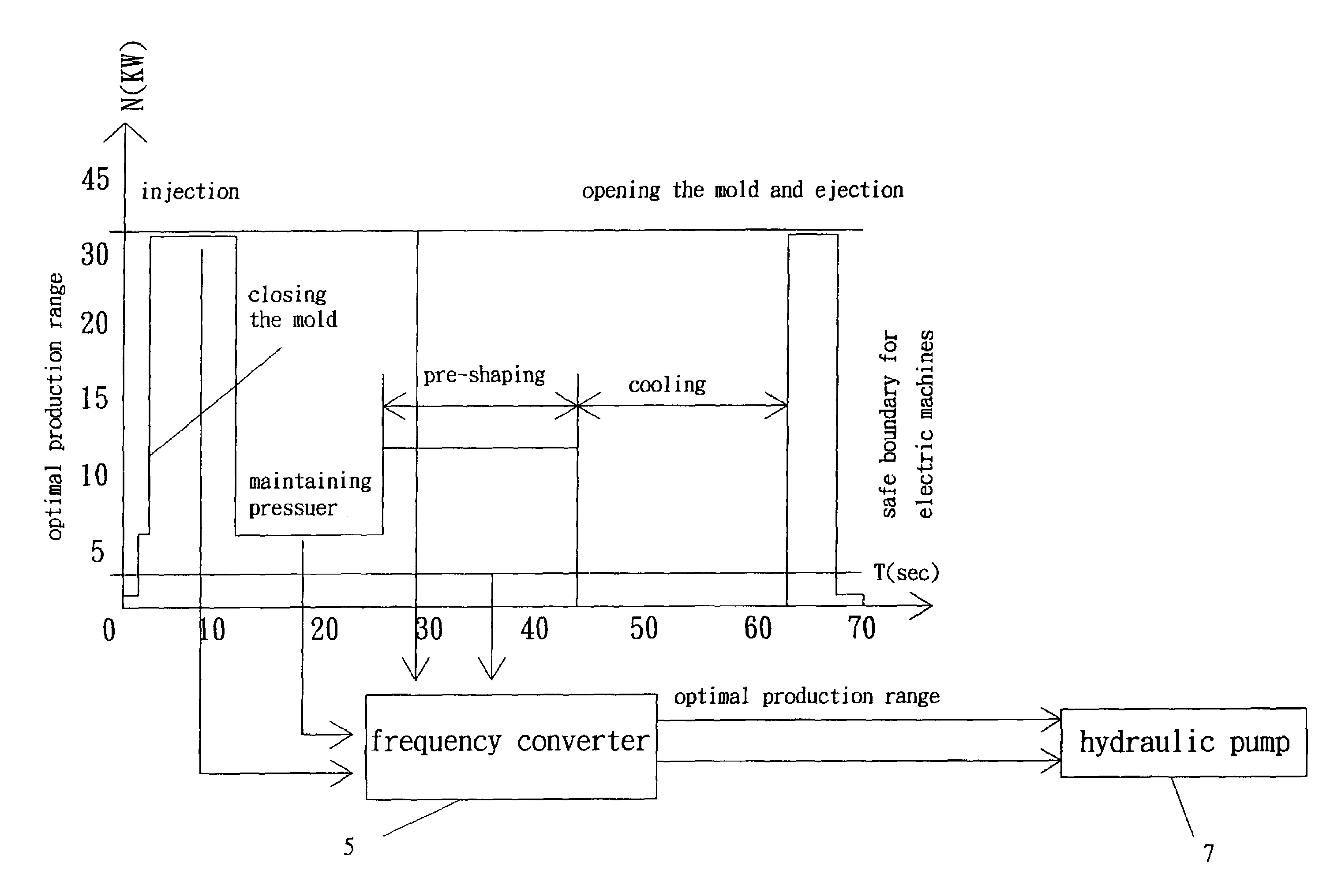

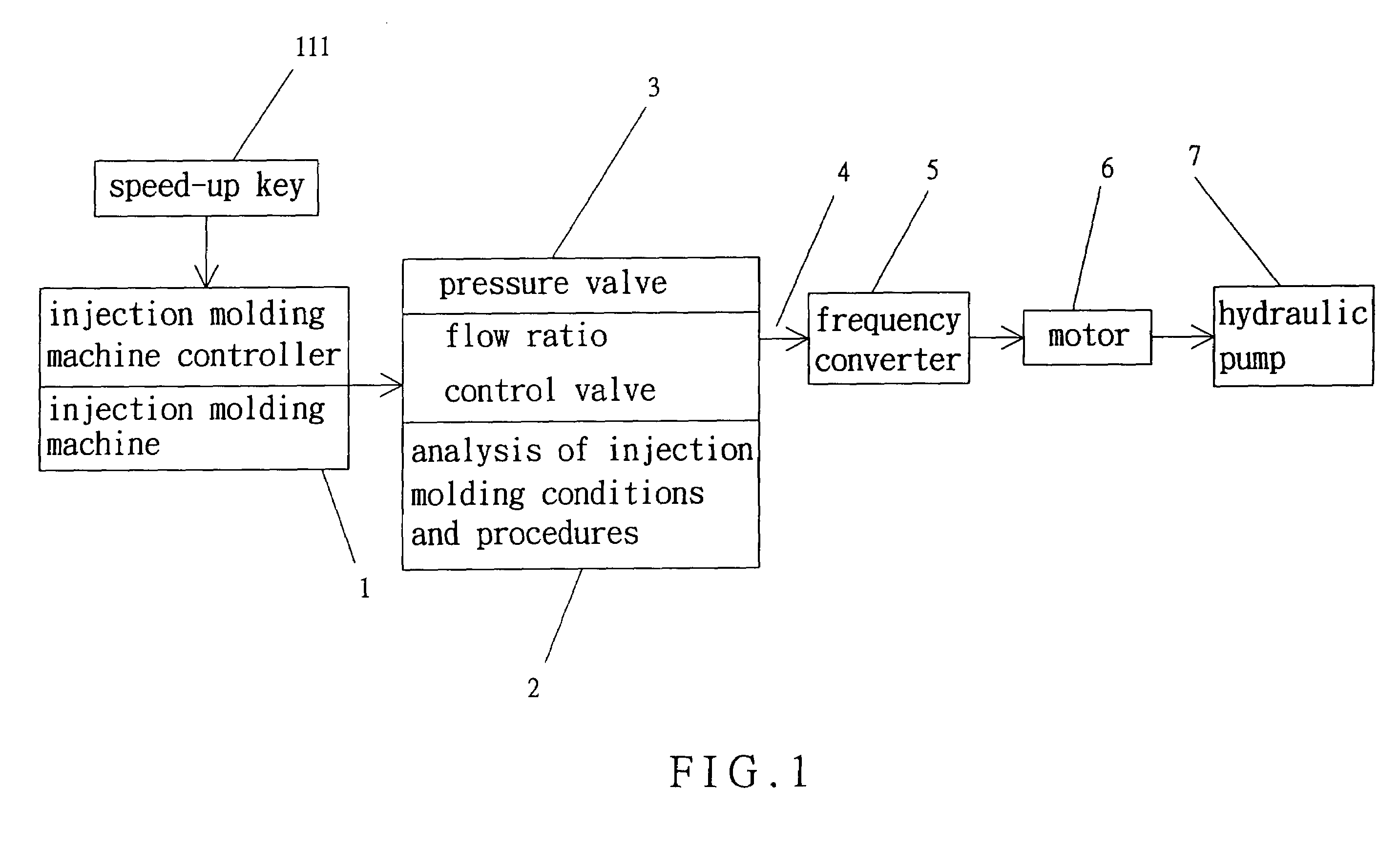

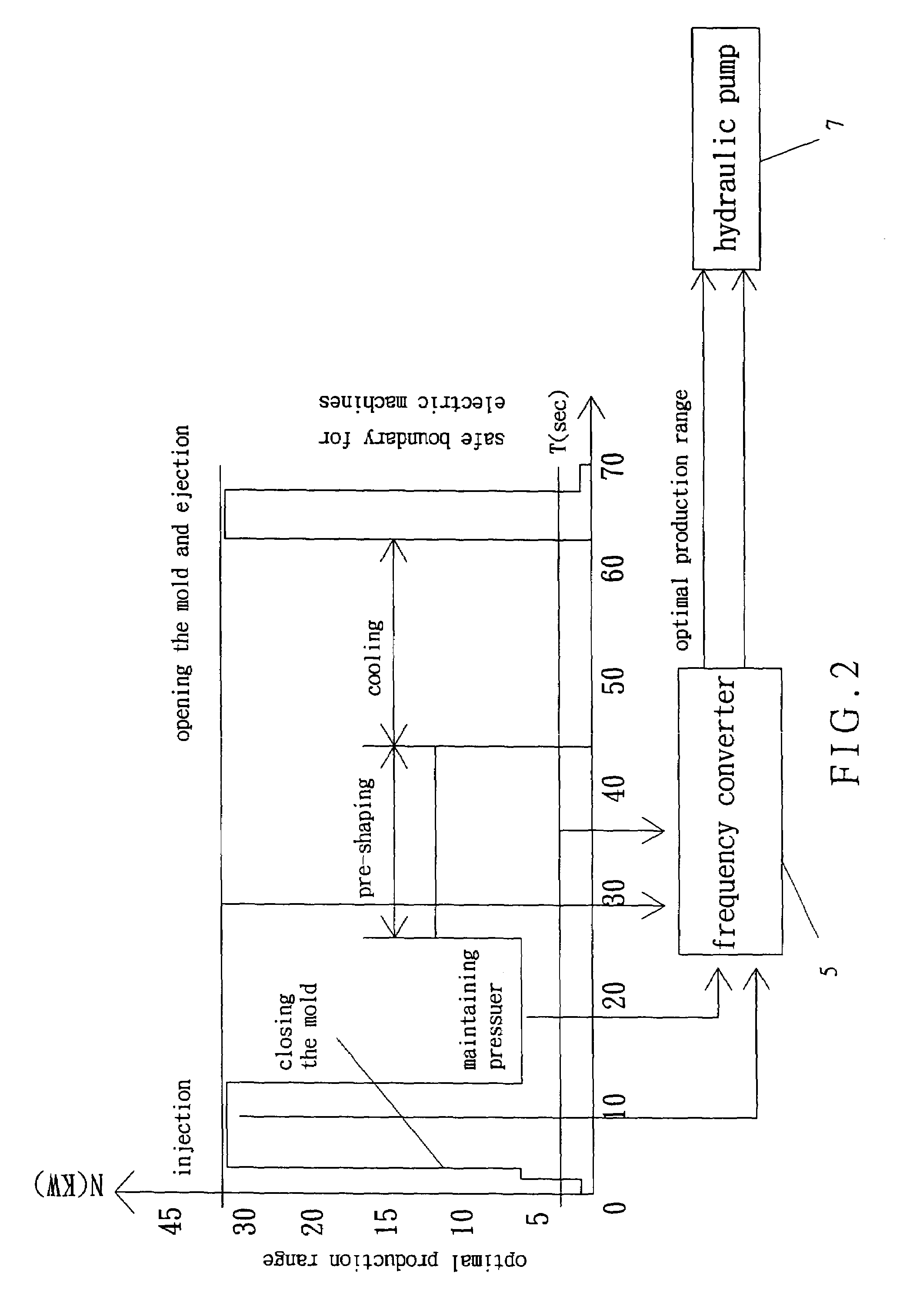

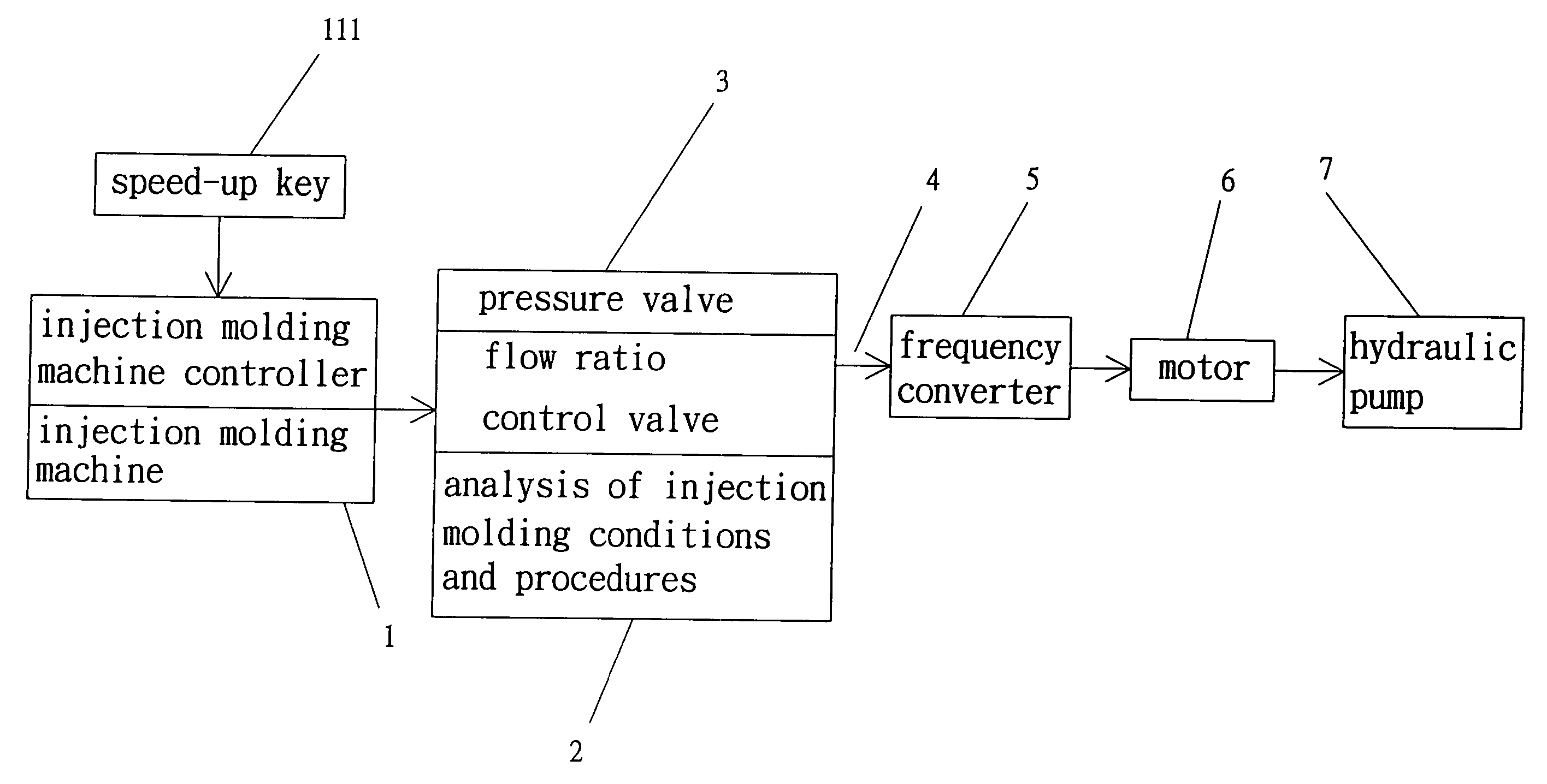

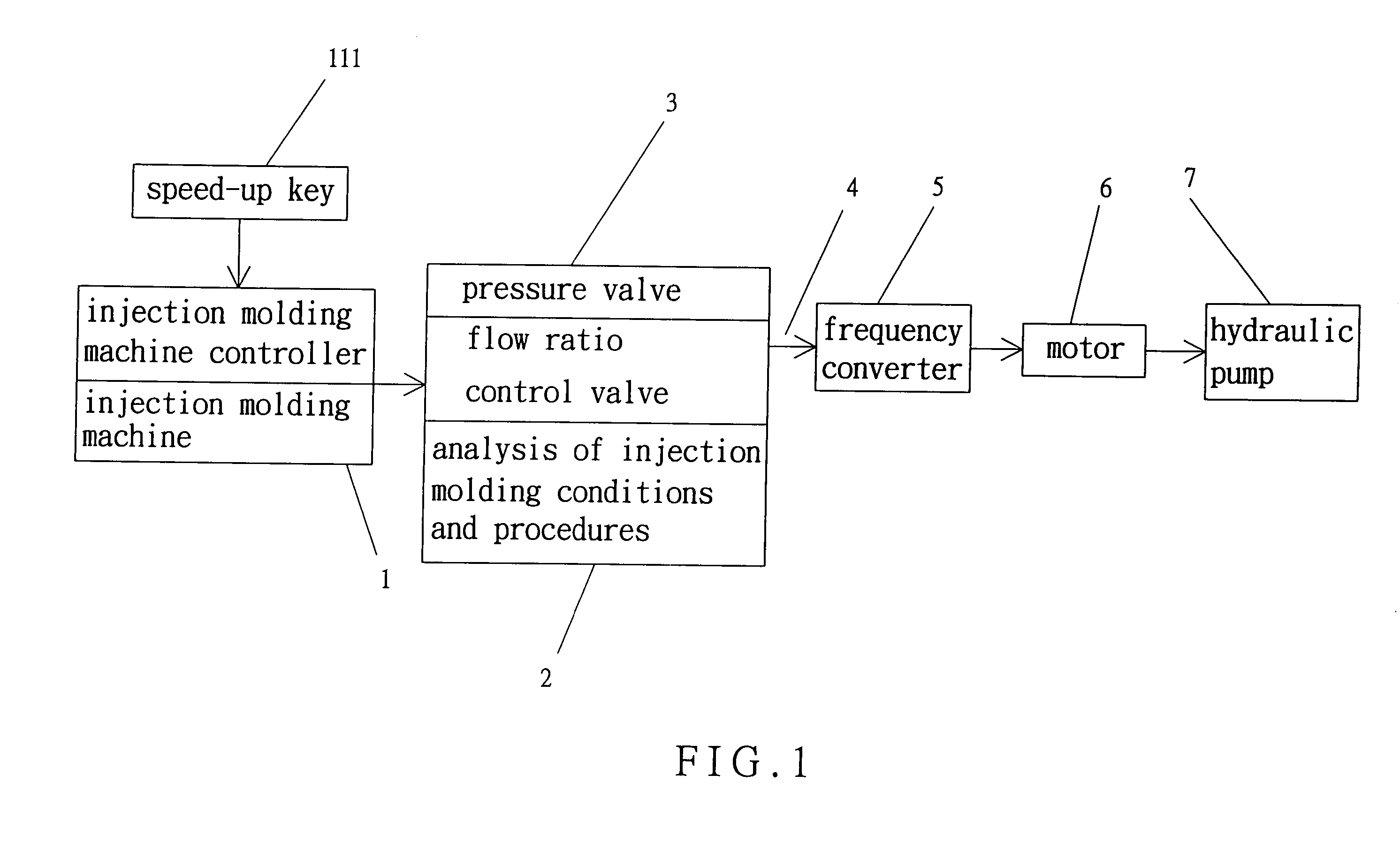

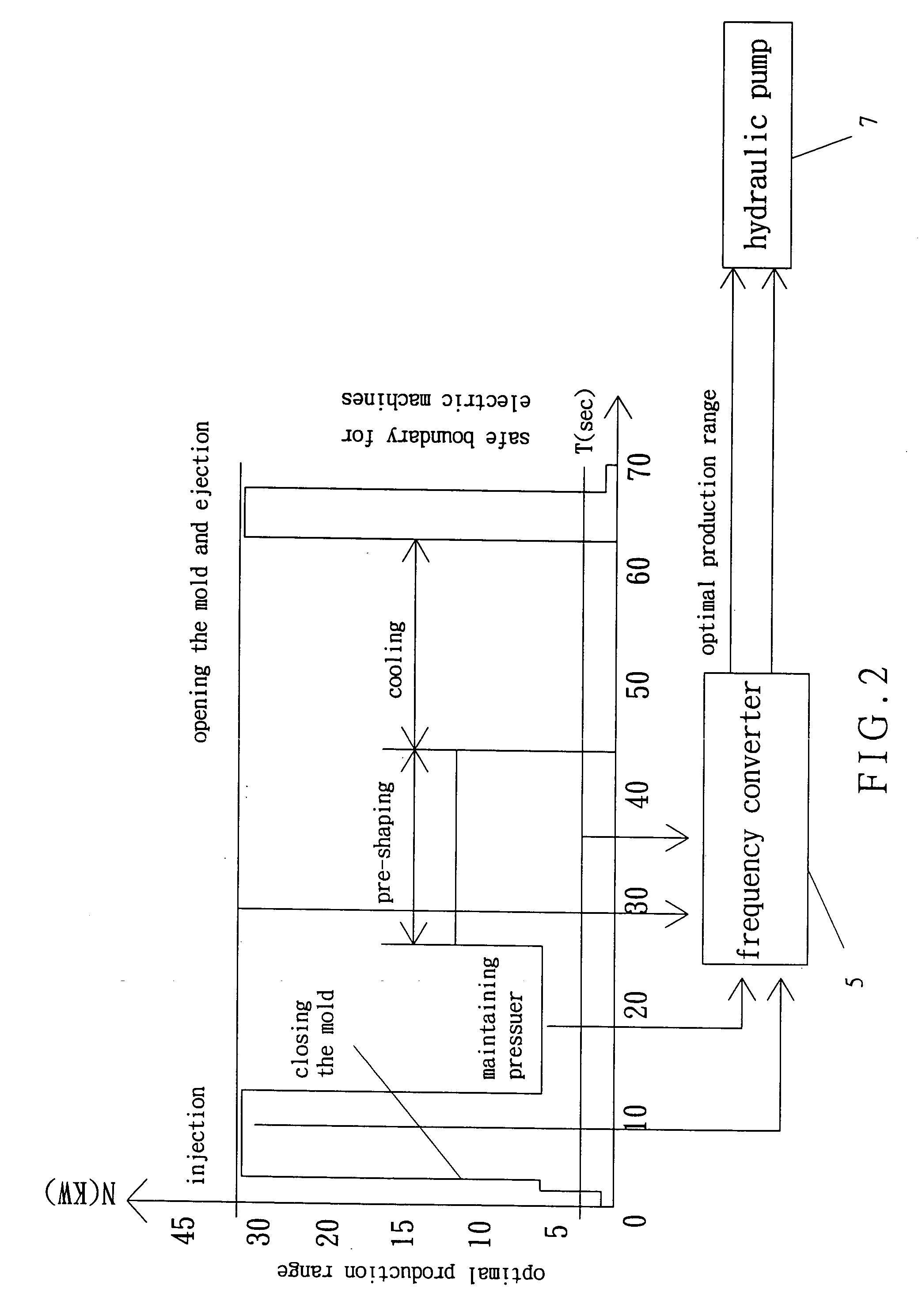

Injection molding system

InactiveUS7281918B2Consumes less energyImprove productivityAuxillary shaping apparatusFrequency changerHydraulic pump

An injection molding system includes an injection molding machine, a pressure valve, a flow ratio control valve, a frequency converter, and the flow ratio control valve, a motor controlled by the frequency converter, a hydraulic pump connected to the motor, and an injection molding machine controller for controlling the injection molding machine and the frequency converter. Injection molding conditions and procedures for controlling operation of the pressure valve and the flow ratio control valve are analyzed. The injection molding machine controller sets a maximum output frequency for the frequency converter and a maximum flow for the hydraulic pump, preventing inappropriate operation of a user and avoiding waste of energy. The injection molding machine controller further sets a maximum speed and a minimum speed of the motor and sets a maximum speed and a minimum speed of the hydraulic pump.

Owner:LU HSIAO TING

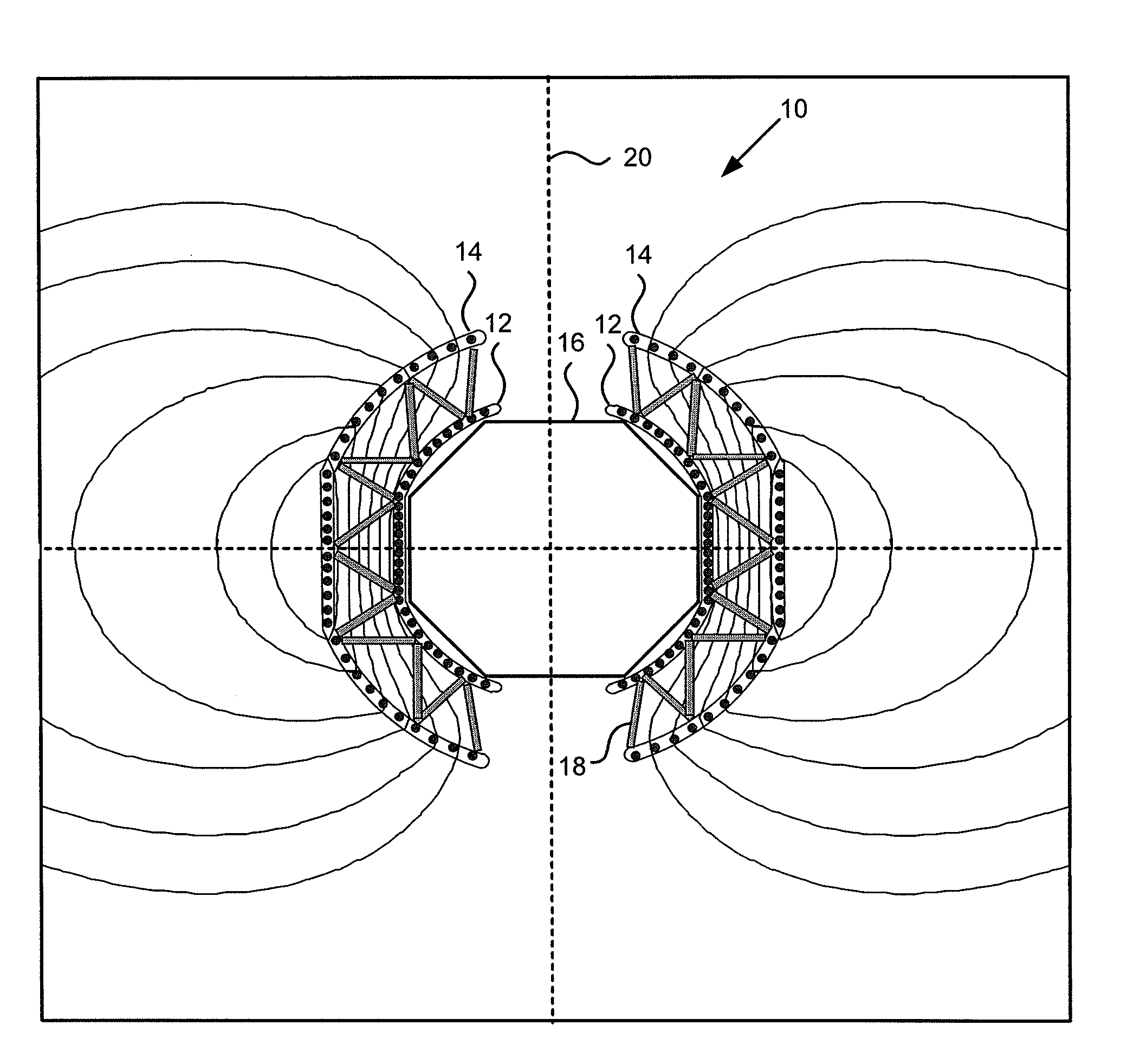

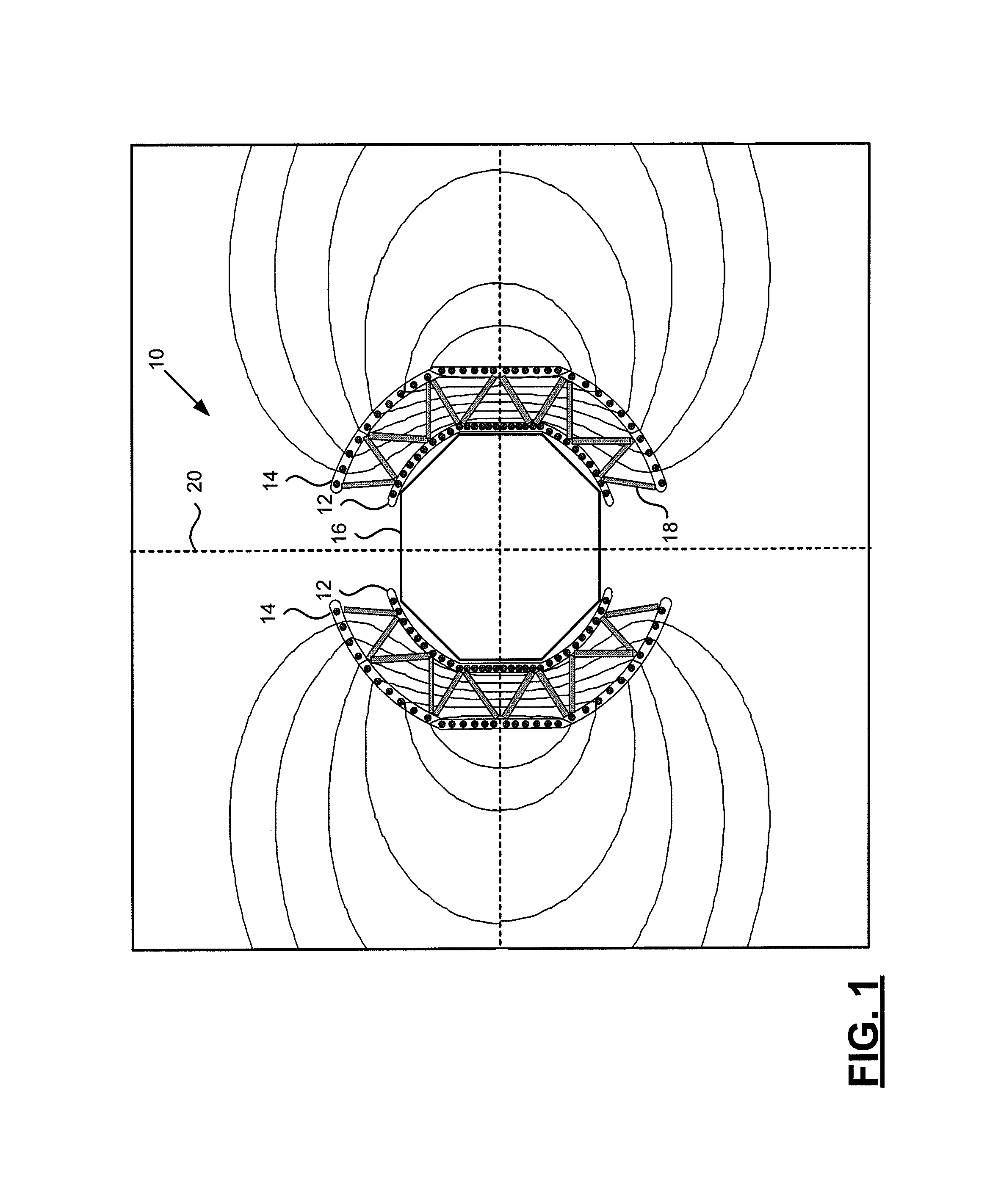

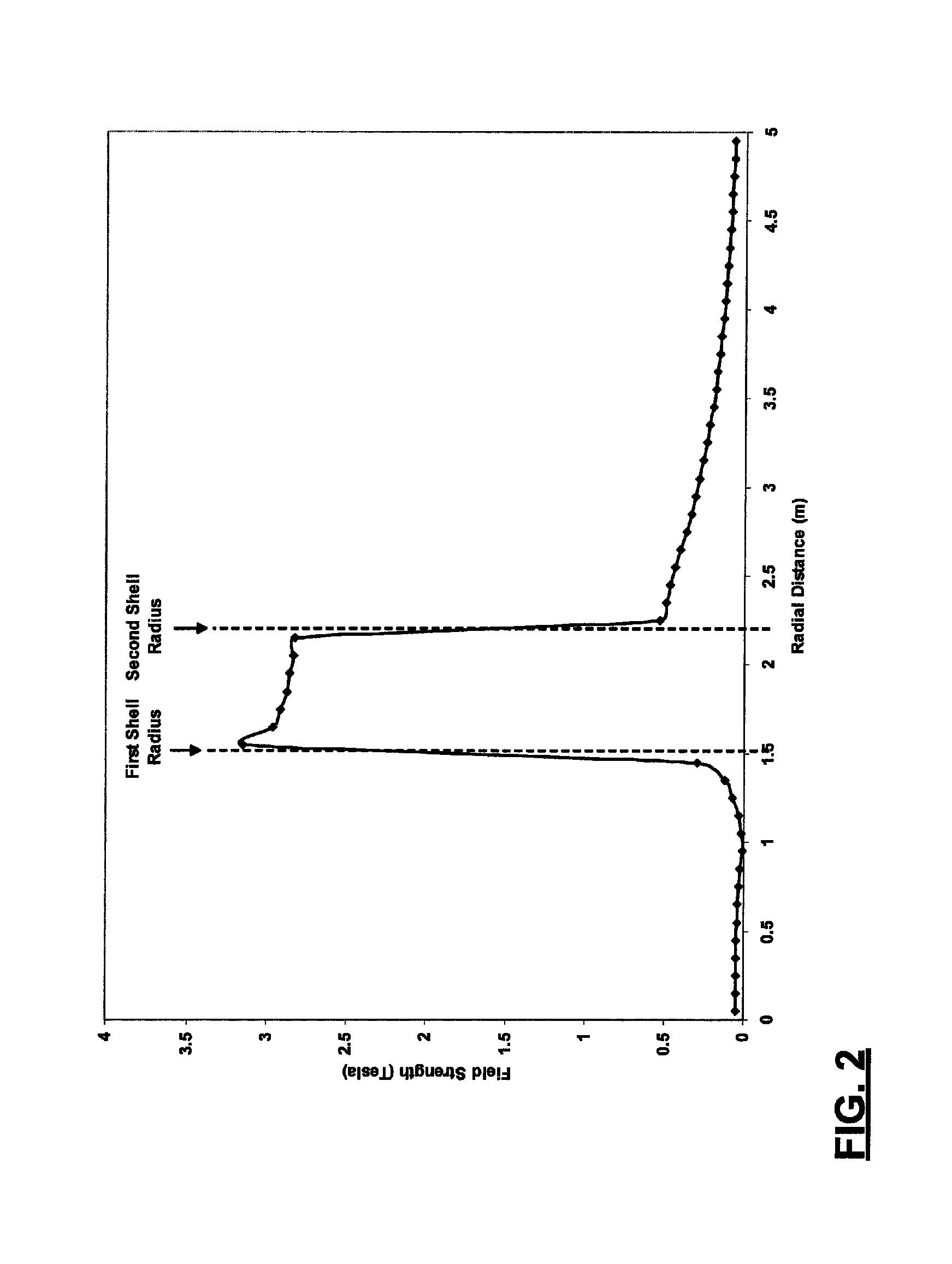

Radiation shield device and associated method

ActiveUS8575580B1Efficiently deflectedConsumes less energyCosmonautic radiation protectionShieldingRadiation shieldPhysics

A method and device of shielding an area from radiation are provided. A radiation shield device may include first and second shells at least partially surrounding the area with the second shell being spaced apart from and further away from the area than the first shell. Both the first and second shells include a plurality of coils that are arranged in paired coil groupings and that encircle the area to be shielded from radiation. The coil groupings of the first shell may be configured to support current flow in an opposite direction to that in which the paired coil groupings of the second shell are configured to support current flow. As such, each coil grouping of the first shell has north and south poles that are correspondingly oppositely positioned from the north and south poles of the paired coil grouping of the second shell.

Owner:THE BOEING CO

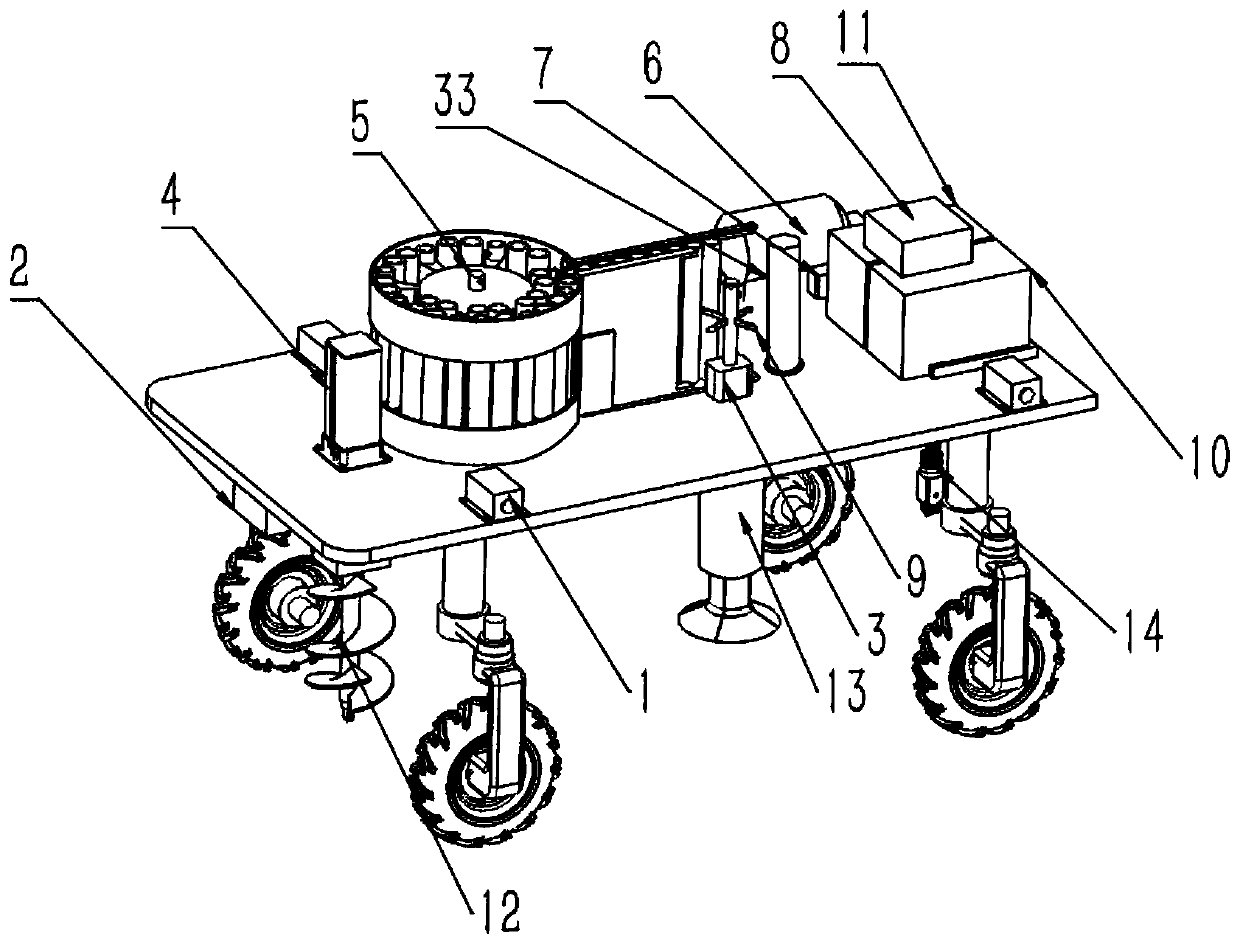

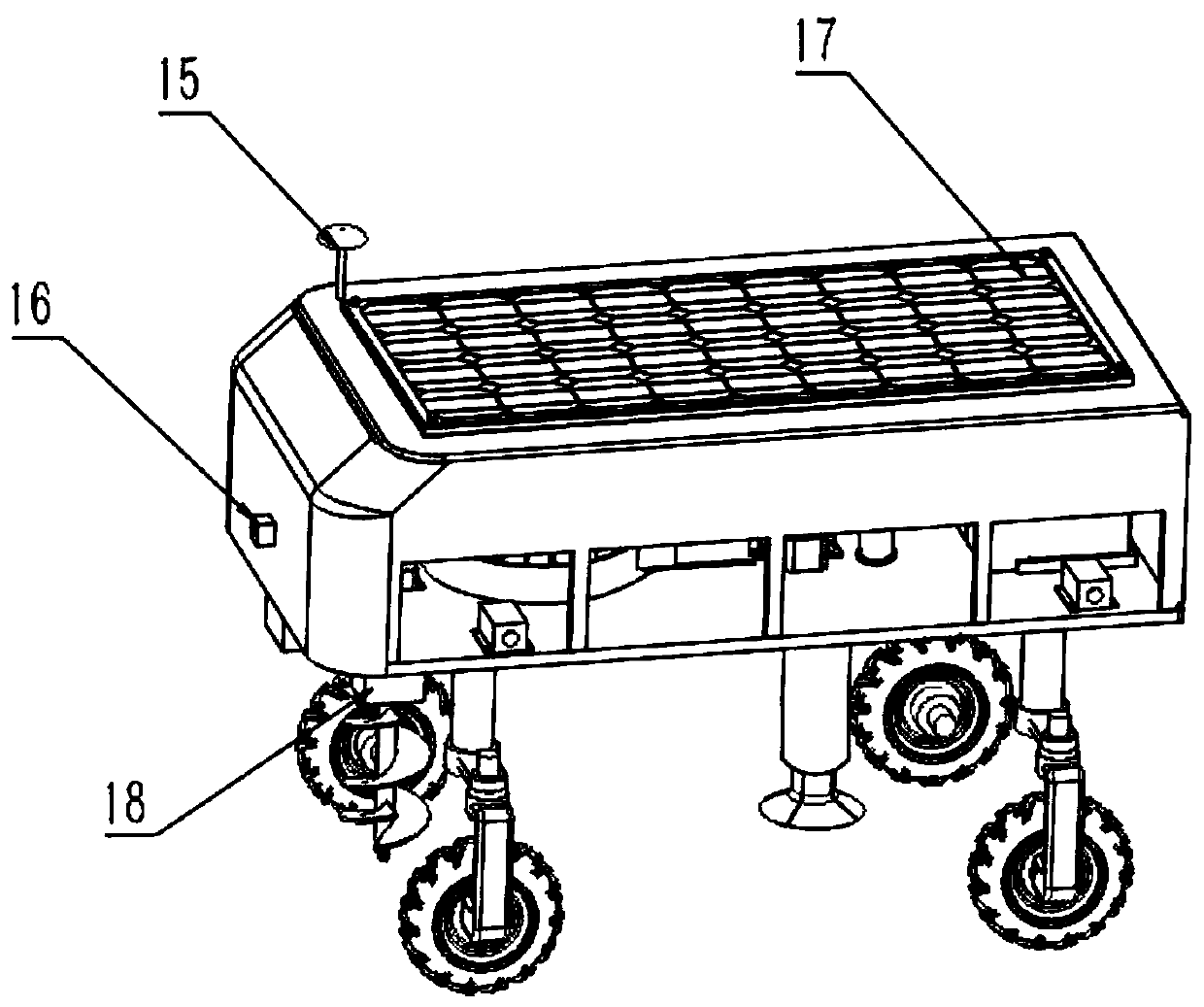

Autonomous sapling planting system and method

PendingCN109699432AIncrease the number ofThe overall structure is simple and reliablePlantingPressurised distribution of liquid fertiliserPersonal computerEngineering

The invention relates to an autonomous sapling planting system and method. The system comprises a trolley body, an automatic sapling feeding system, an automatic planting mechanism, a navigation module and a fertilization module. Saplings are carried through the vehicle body, an industrial personal computer controls the movement distance of a trolley, after a pit is dug, the trolley just moves toa sapling outlet to align at the pit, then the industrial personal computer sends an instruction to control a sampling pulling motor to work, the sapling is pulled into the sapling outlet until the sapling falls into the dug pit of a sapling planting mechanism, soil is compacted through an automatic planting mechanism, then pesticide is applied through an automatic pesticide applying device, the planting process is completed, the trolley is combined with the navigation module to walk through a planned route, and the planting process is efficient.

Owner:NANJING FORESTRY UNIV

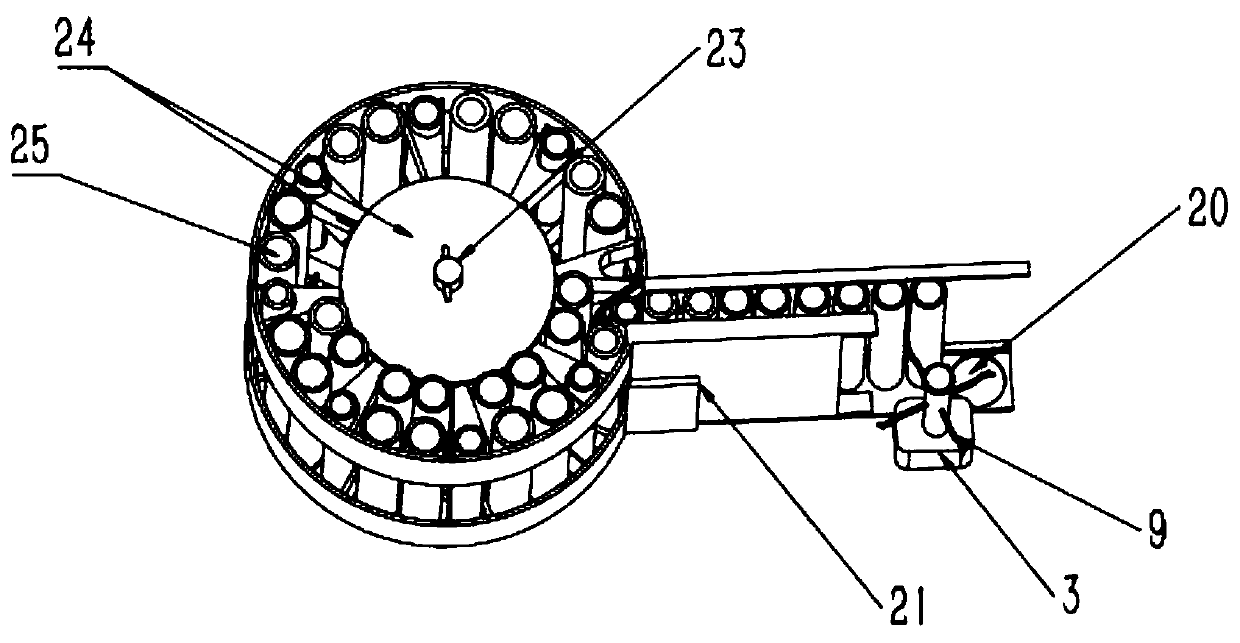

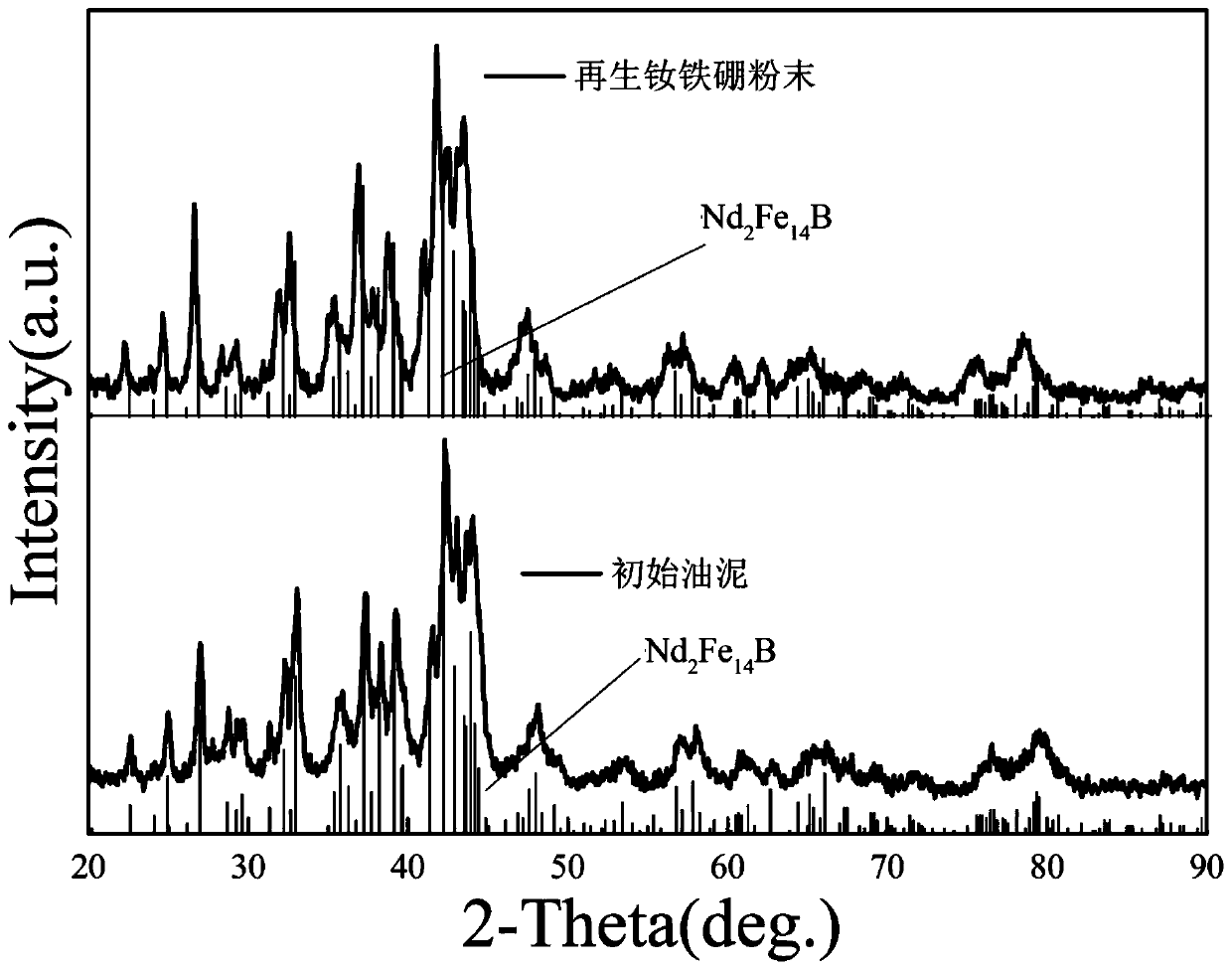

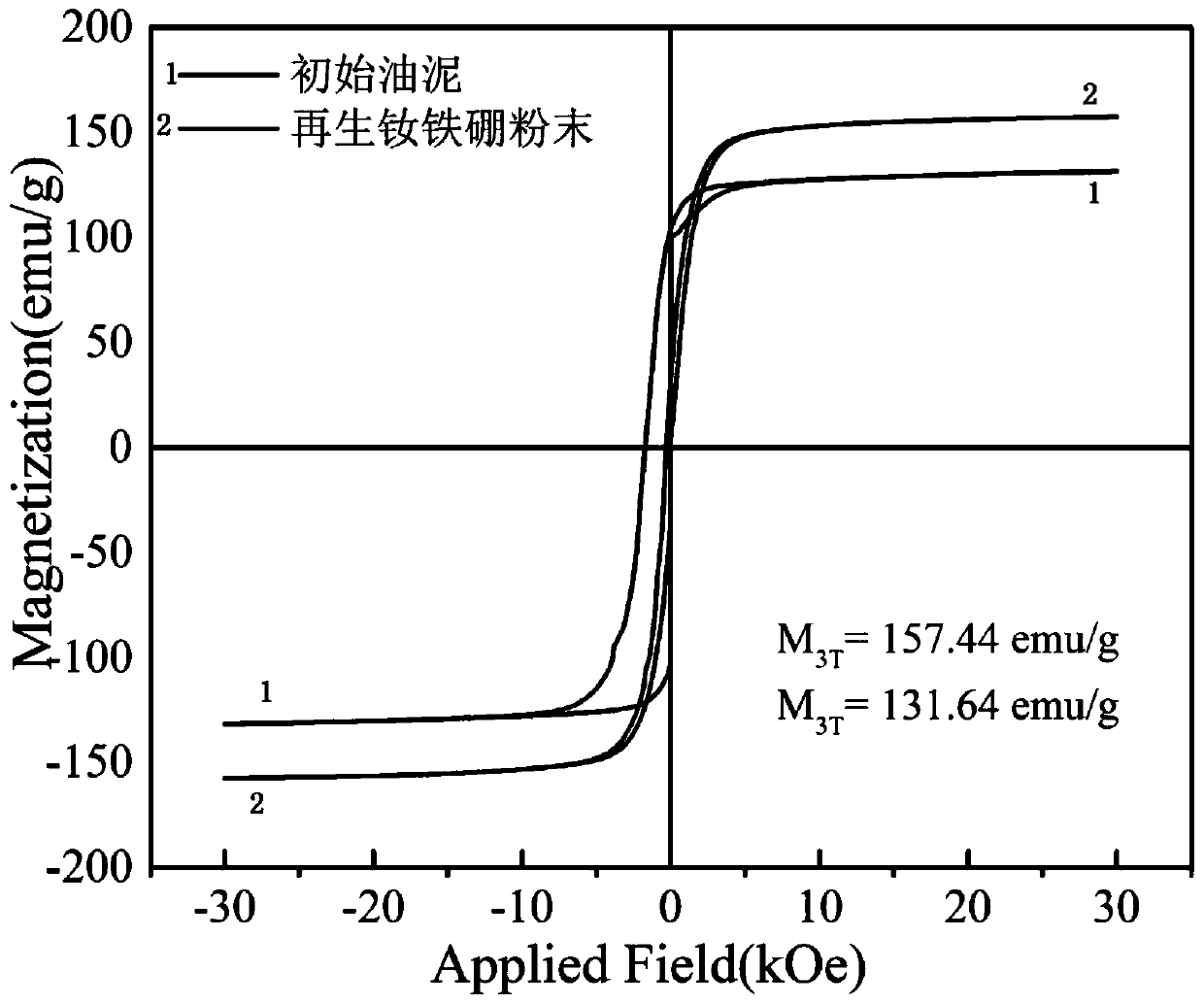

Impurity removal method of oil-based neodymium iron boron oil sludge waste

ActiveCN110218870AConsumes less energyImprove performanceInductances/transformers/magnets manufactureMagnetic materialsRare earthOil sludge

The invention discloses an impurity removal method of oil-based neodymium iron boron oil sludge wastes, and belongs to the technical field of recycling of rare earth permanent magnetic materials. Aiming at the problems of high content of carbon, hydrogen and oxygen, fine powders, extremely easy agglomeration of the powders and the like in oil-based slicing oil sludge wastes, an organic solvent, aninorganic solvent, a surfactant and an acid solution are used for cleaning the inorganic impurities oil sludge wastes, organic impurities, oxides and inorganic impurities in the oil sludge are removed by combining an ultrasonic and magnetic separation method, and regenerated neodymium iron boron powders which are low in carbon, hydrogen and oxygen content, good in performance and relatively highin purity are obtained. The method has the significant characteristics and advantages that, 1) the process is short, and the oil sludge is used as raw materials to directly obtain the regenerated neodymium iron boron powders; 2), the efficiency is high, and the performance of the regenerated powders is good, and the purity of the regenerated powders is relatively high; 3) the cost is low, and theconsumed energy in the process flow is less and the used raw materials and reagents are easy to obtain; and 4) the process is simple and easy to operate, and the repeatability is good.

Owner:BEIJING UNIV OF TECH

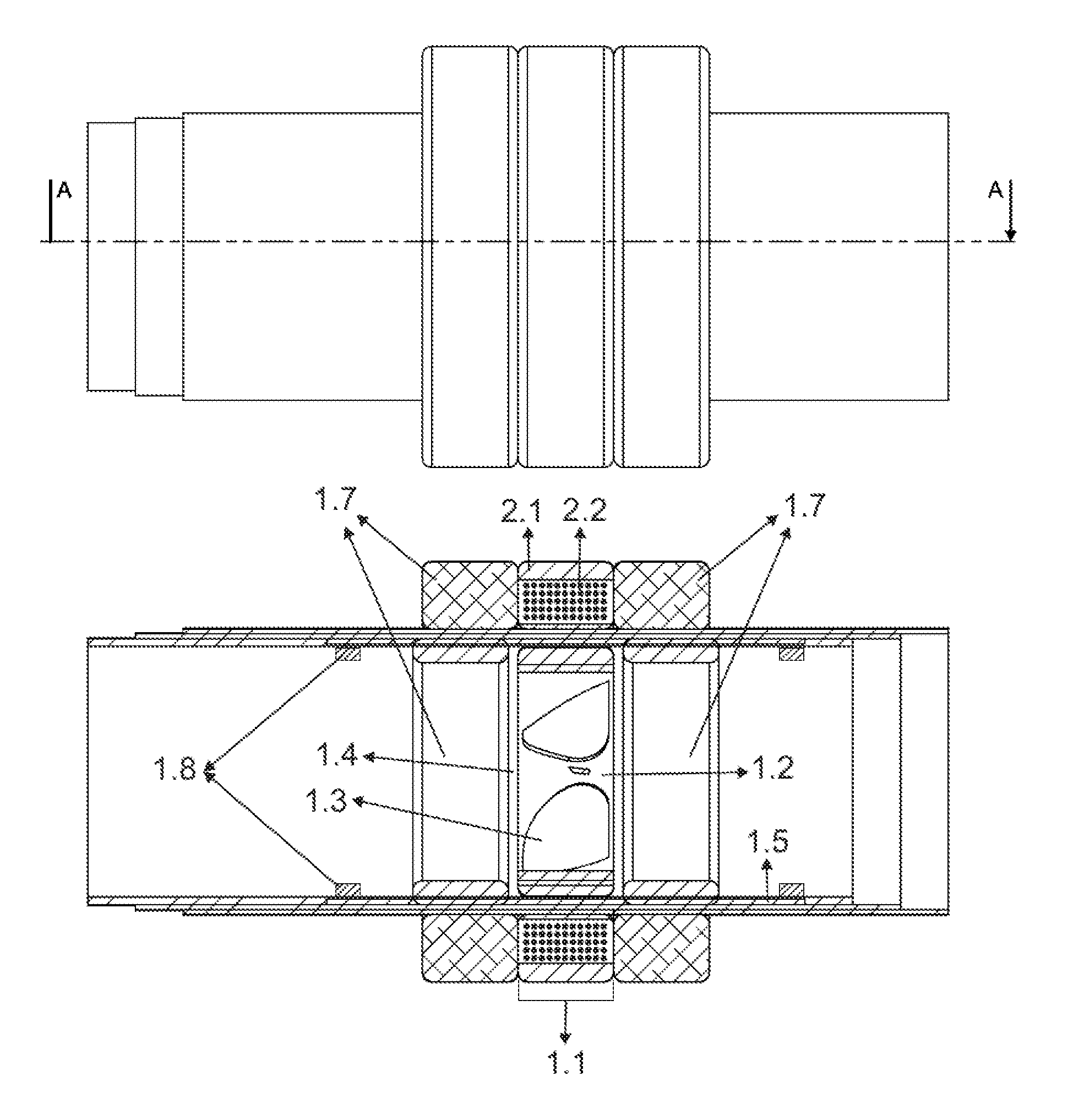

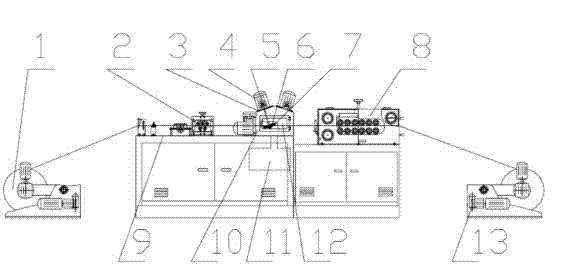

Electromagnetic wire insulating layer separation device and method

ActiveCN103795009ASuitable for separate useSimple structureApparatus for removing/armouring cablesEngineeringEnergy consumption

The invention discloses an electromagnetic wire insulating layer separation device and method. The electromagnetic wire insulating layer separation device comprises a paying-off mechanism, a stripping mechanism, a taking-up mechanism, a straightening device, a traction mechanism, a platform and a dust collection device. The platform is located between the paying-off mechanism and the taking-up mechanism. The straightening device, the stripping mechanism, the dust collection device and the traction mechanism are all arranged on the platform. The stripping mechanism comprises a stripping box, a guide rail, motors, a metal rod, stripping wheels and a transparent baffle. According to the electromagnetic wire insulating layer separation method, an electromagnetic wire is straightened, the guide rail is adjusted so that all the stripping wheels can be attached to the surface of the electromagnetic wire, and the motors rotate to drive the stripping wheels to rotate so that an insulating layer of the electromagnetic wire can be stripped off. The electromagnetic wire insulating layer separation device has the advantages of being simple in structure, reasonable in design, reliable in performance, capable of separating the electromagnetic wire insulating layer through the coordination effect of all components, free of increased power, low in energy consumption, not prone to environment pollution, and capable of meeting the requirement for recycling of metal wires of electromagnetic wires.

Owner:株洲兆源机电科技有限公司

Semiconductor based air conditioning device

ActiveUS20070012049A1Consumes less energyProducing coldnessInternal combustion piston enginesDomestic cooling apparatusThermoelectric coolingEngineering

The present invention mainly utilizes a specialized semiconductor ship, the so-called thermoelectric cooling chip, for producing the coldness. A cooling circulating member and a heat dissipating member are configured at the two sides of the thermoelectric cooling chip. The coldness produced by the thermoelectric cooling chip is delivered by a cold conduction plate and cooling pipes, and is stored in fins of the cooling circulating member. A temperature controller determines a desired temperature and the coldness stored in the fins are blown out as cool air by a fan. Similarly, the heat produced by the chip is dissipated by the heat dissipating member. As such, the present invention could reach the desired temperature within a short period of time without the conventional compressor. The present invention therefore is easier to install and transport, consumes less power, and produces almost no noise and pollution to the environment.

Owner:CHEN CHUAN SHENG

Method for making health care beverage by utilizing residues produced by juice making of fresh dendrobium

InactiveCN102090695AReduce manufacturing costConsume less energyFood preparationDendrobiumZero emission

The invention relates to a method for making a health care beverage by utilizing residues produced by juice making of fresh dendrobium, and the health care beverage containing a dendrobium active ingredient is made by adopting the technologies comprising re-dissolution of residual liquid with water, ultrasonic enhanced extraction, hydrolysis and saccharification through amylase, filtration by a diatomite filter, pasteurization and the like. In the production process, pure water for diluting the residues produced by juice making of the dendrobium is taken as water for drinking, starch-sugar conversion in the dendrobium can reduce the using amount of sugar in the beverage, and the production cost of the made beverage is low. The low-temperature treatment is adopted, less energy resources are consumed, the damages of high temperature to nutrition and functional components can be avoided, the color, luster, flavor, nutrition and functional components of the health care beverage can be kept to the maximum extent, and the produced health care beverage has the characteristics of pure color and luster and mellow taste. In the whole production process, not only can resources be effectively utilizd, but also the requirements of energy conservation and emission reduction are achieved, and zero emission is also really achieved.

Owner:杨军

Injection molding system

InactiveUS20060127520A1Less energyConsumes less energyAuxillary shaping apparatusFrequency changerHydraulic pump

An injection molding system includes an injection molding machine, a pressure valve, a flow ratio control valve, a frequency converter, and the flow ratio control valve, a motor controlled by the frequency converter, a hydraulic pump connected to the motor, and an injection molding machine controller for controlling the injection molding machine and the frequency converter. Injection molding conditions and procedures for controlling operation of the pressure valve and the flow ratio control valve are analyzed. The injection molding machine controller sets a maximum output frequency for the frequency converter and a maximum flow for the hydraulic pump, preventing inappropriate operation of a user and avoiding waste of energy. The injection molding machine controller further sets a maximum speed and a minimum speed of the motor and sets a maximum speed and a minimum speed of the hydraulic pump.

Owner:LU HSIAO TING

Thrust bearing for a gyratory crusher and method of supporting a vertical shaft in such a crusher

InactiveUS7922109B2Low costConsumes less energySliding contact bearingsHydrostatic bearingsThrust bearingCrusher

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com