Refuse collecting ship

A garbage collection and garbage technology, which is applied in water conservancy projects, cleaning of open water surfaces, construction, etc., can solve the problems of narrow water area, inability to guarantee the efficiency and effect of garbage cleaning, and inability to guarantee the safety of operators, so as to achieve low energy consumption of the device , Garbage collection and storage capacity increase, the effect of improving work efficiency

Inactive Publication Date: 2011-05-04

浙江机电职业技术学院

View PDF6 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the cleaning of garbage in water basically adopts the method of manual fishing. However, manual cleaning can neither guarantee the efficiency and effect of cleaning garbage, nor can it guarantee the safety of operators; The water area is narrow, and only garbage in the area touched by its tool can be fished

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

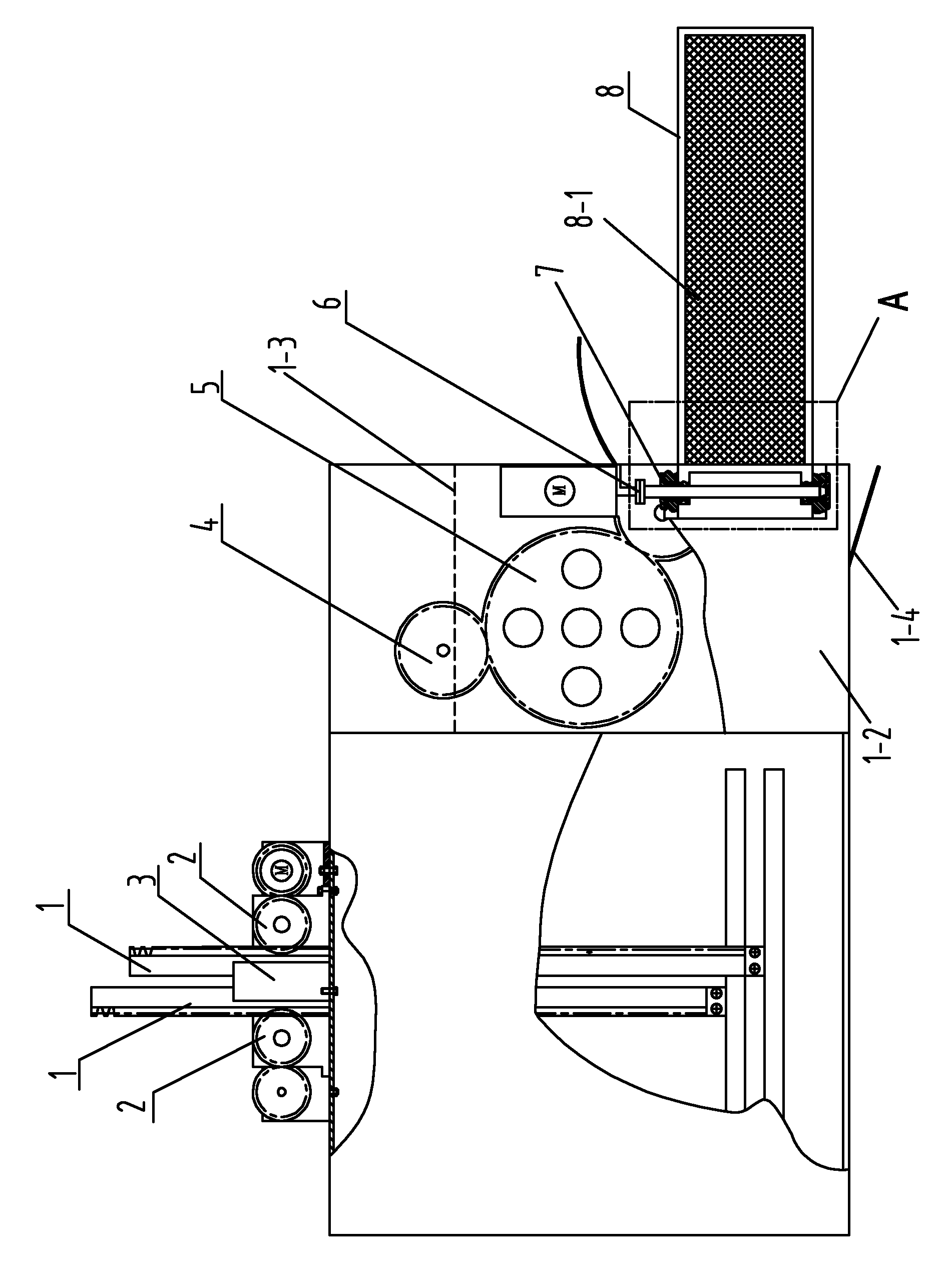

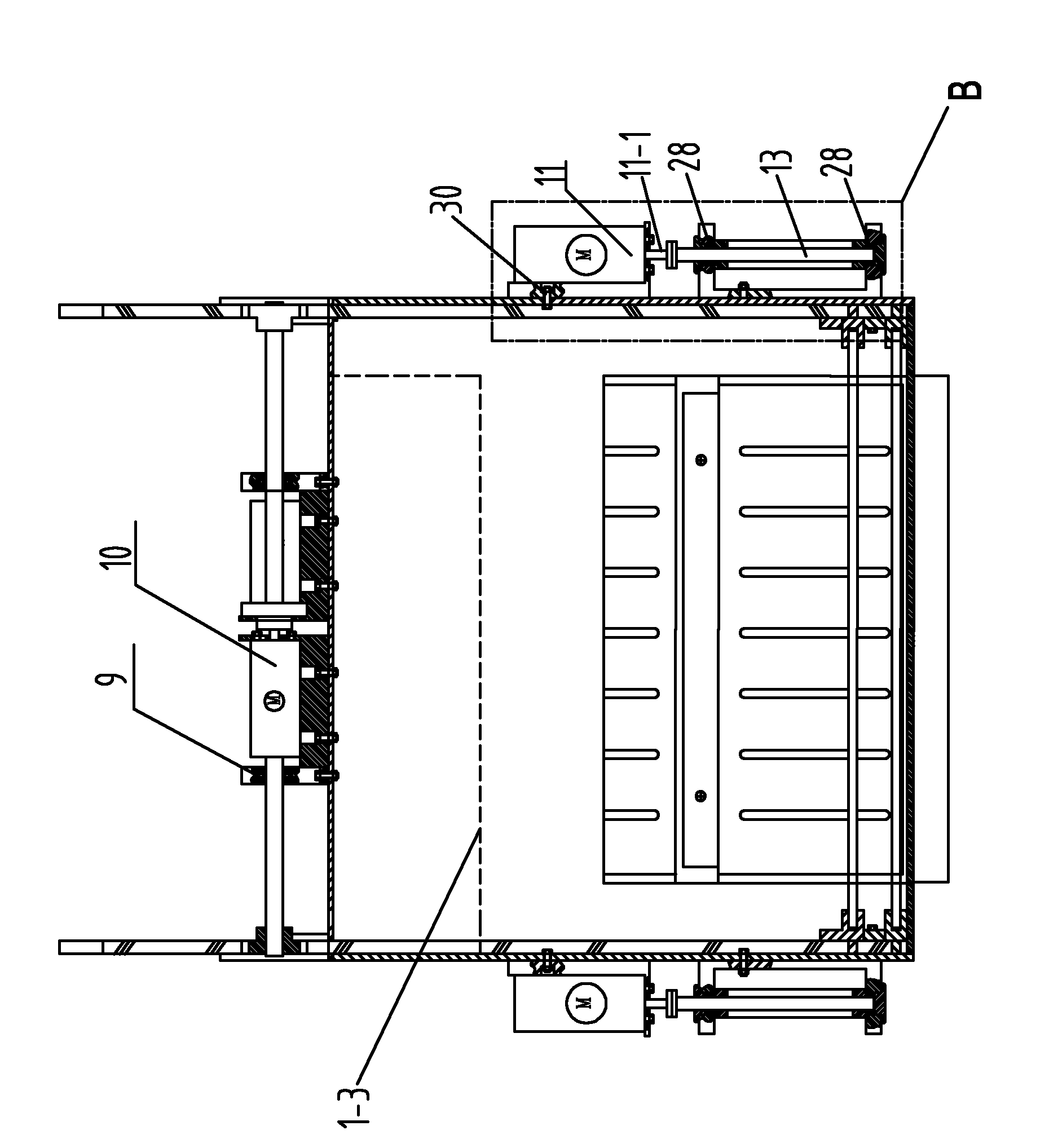

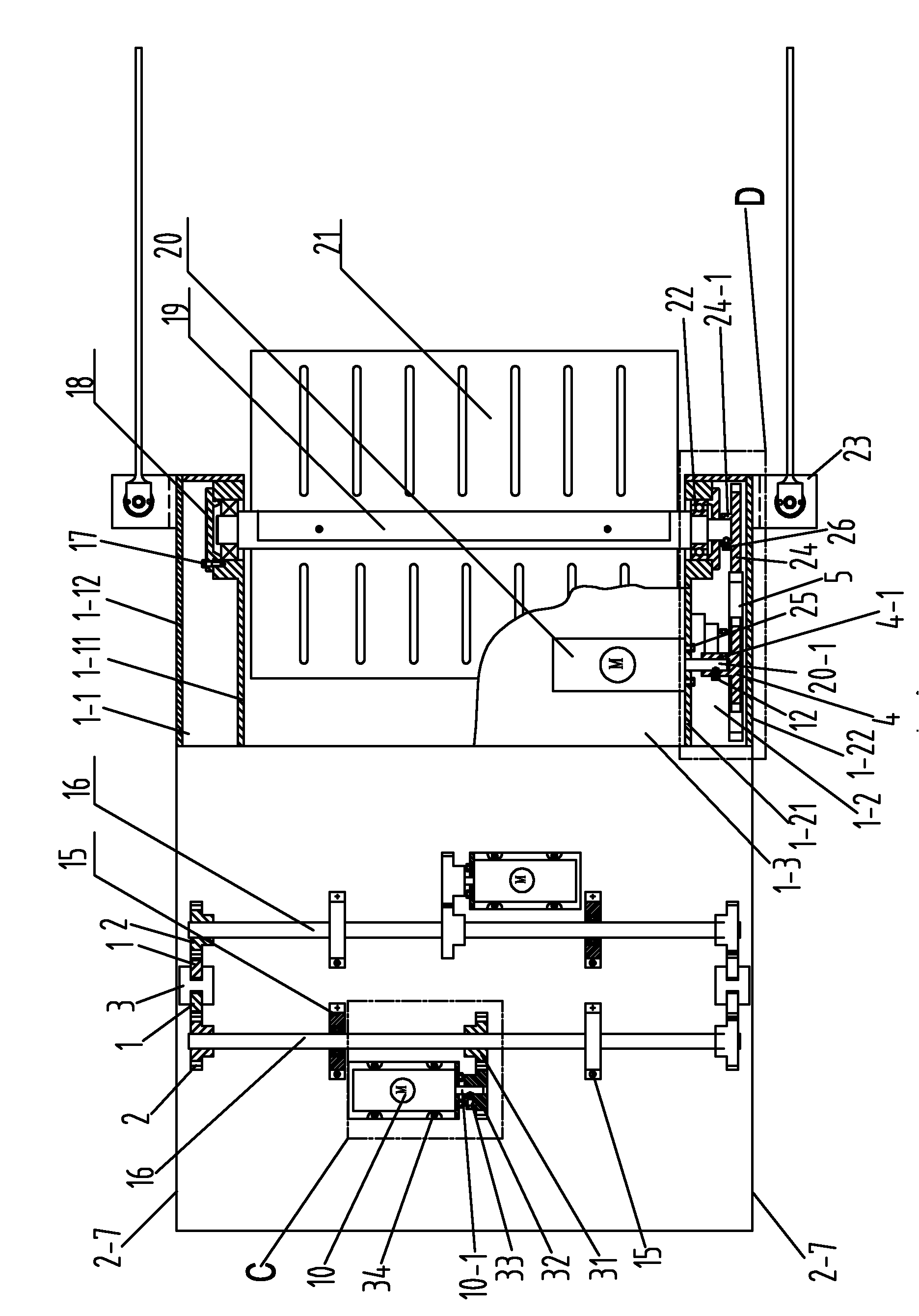

The invention discloses a refuse collecting ship, which comprises a refuse collecting device and a refuse storing device, wherein the refuse collecting device comprises a tank body of which the middle is provided with a through hole; a motor is arranged above the tank body, the output shaft of the motor is linked with an impeller shaft, and the impeller shaft is arranged in the tank body and traverses the tank body; a plurality of blades are fixedly arranged on the outer circumference of the impeller shaft; an accommodating area is formed in the refuse storing device and is provided with a refuse inlet; a refuse compressing mechanism is arranged in the refuse storing device and drives a compressing plate to act; the refuse storing device is fixedly connected with the refuse collecting device; and the refuse inlet of the refuse storing device corresponds to an outlet of the through hole in the middle of the tan body. When used, the refuse collecting ship can be arranged on the conventional ship, and the conventional ship drives the refuse collecting ship to move in water so as to clean refuse in the water; and the refuse collecting ship also can work independently and is provided with a floating device to float on water surface and clean the refuse in the water simultaneously.

Description

technical field [0001] The invention belongs to the technical field of manufacturing garbage cleaning devices in water, and in particular relates to a garbage collection ship. Background technique [0002] Due to the lack of awareness of environmental protection of some people, they throw garbage into the water at will and a large amount of floating garbage on the water surface produced by the natural environment, resulting in more and more garbage in the water, and the water pollution is becoming more and more serious. Because the water body can flow, when the polluted water flows to other places, the pollutants will be taken to other places. It can be said that the harm of water body pollution is greater than that of ground pollution. Therefore, it is more urgent and important to clean up the garbage on the water than to clean up the garbage on the land. At present, the cleaning of garbage in water basically adopts the method of manual fishing. However, manual cleaning ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E02B15/10

Inventor 陈晓英颜关祥施程适闻绍华倪寅乾陈铭铭

Owner 浙江机电职业技术学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com