Finished product collecting device for additive printer and printer thereof

A finished product collection and printer technology, applied in additive processing, additive manufacturing, 3D object support structure, etc., can solve the problem of low storage efficiency of finished products, and achieve the effect of avoiding pollution, improving collection efficiency, and improving collection and storage effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

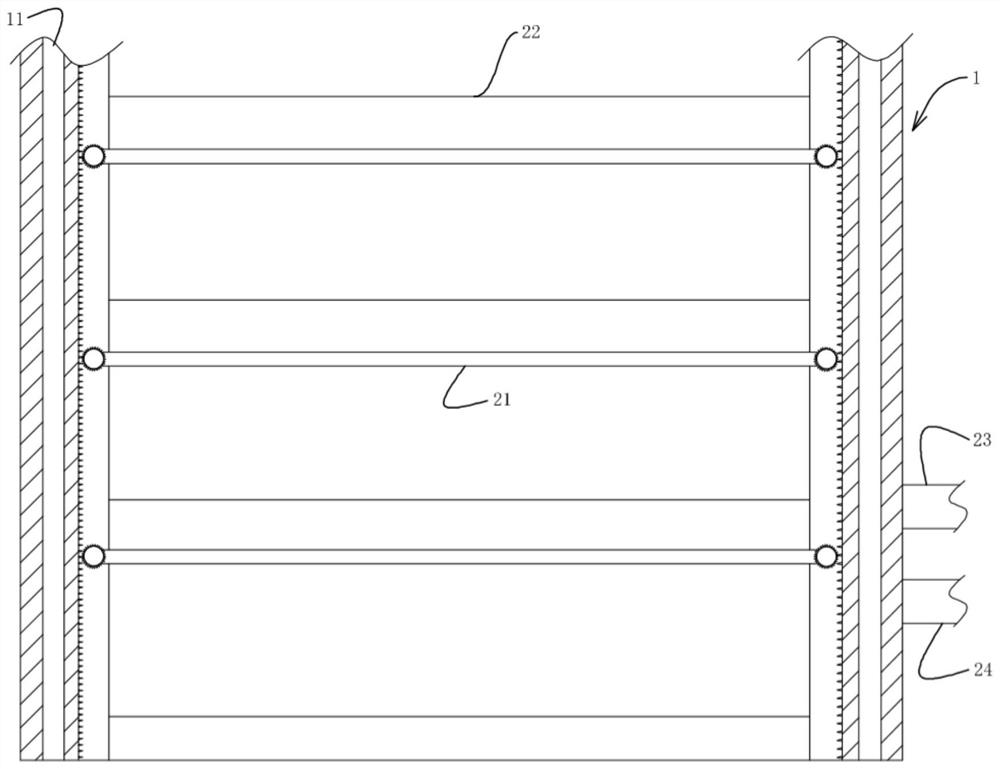

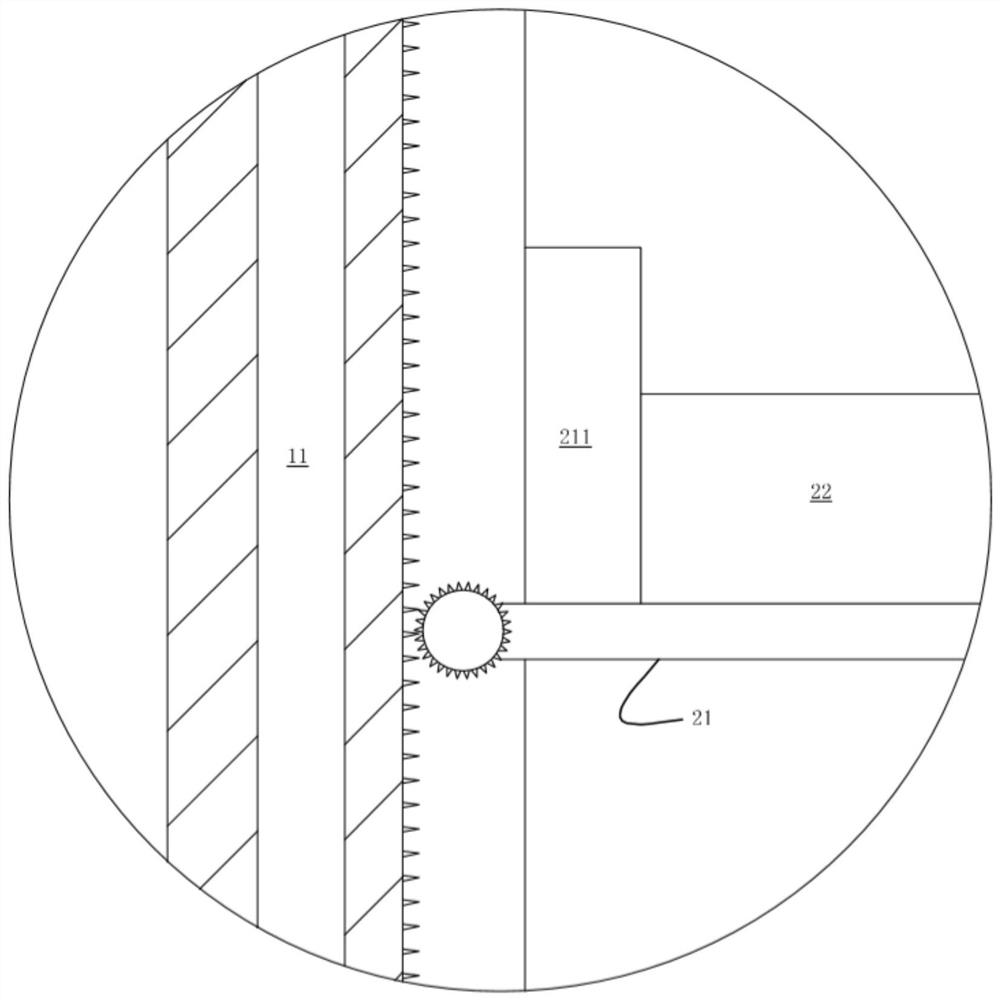

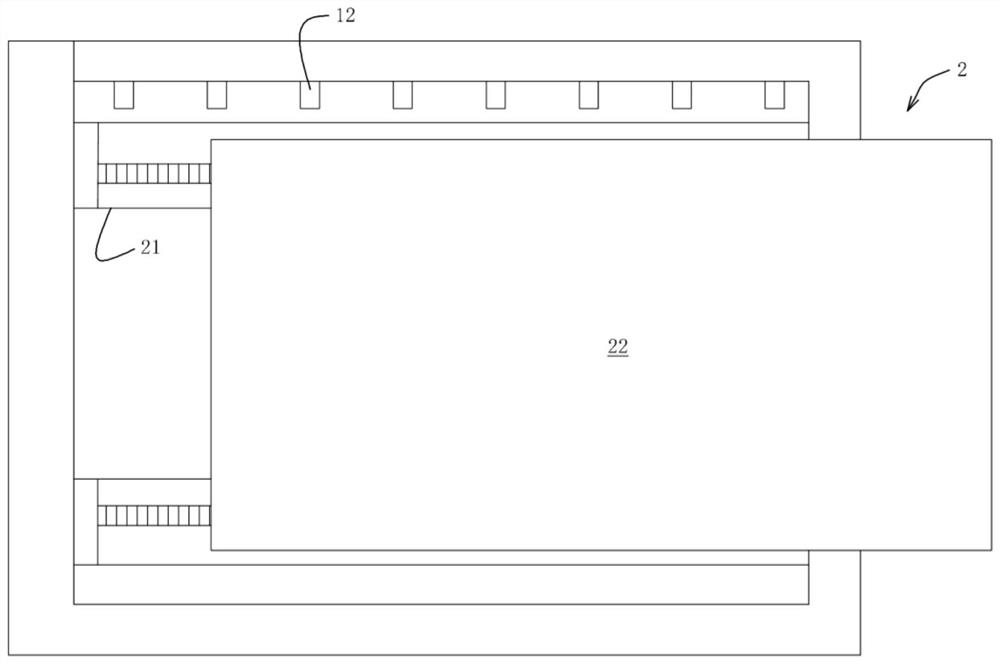

[0022] A finished product collection device for an additive printer, comprising a collection box body 1 and a finished product placement device movably arranged in the collection box body 1, the finished product placement device 2 includes a number of finished product carriers vertically slidably arranged in the collection box body 1 The frame 21 and the auxiliary printing flat plate 22 horizontally slidably arranged on the finished product carrier 21 are provided with an opening for the auxiliary printing flat plate 22 to pass through near the right end of the collection box body 1. After the printing is completed, the printing flat plate located in the additive printer The auxiliary printing plate 22 on the top slides onto the finished product carrier 21 and conflicts with the limit plate 211 located at the left end of the finished product carrier 21. The collection box body 1 is provided with a gas circulation channel 11 for gas circulation, located in the collection box body...

Embodiment 2

[0025] An additive printer, including the finished product collection device for the additive printer described in Embodiment 1, and also includes an auxiliary collection box body 3 for switching and printing the auxiliary printing plate 22, and there are several auxiliary collection box bodies 3 The auxiliary carrier frame III31 for placing the auxiliary printing plate 22, and the auxiliary carrier frame III31 is vertically slid in the auxiliary collection box body 3, wherein the other end of the auxiliary carrier frame II24 is in sliding contact with the auxiliary collection box body 3 , the auxiliary printing plate 22 slides to the auxiliary carrier III 31 through the auxiliary carrier II 24 , and through the conveying action of the auxiliary carrier III, the auxiliary printing plate 22 slides to the printing plate of the additive printer, and the printing is collected and printed in sequence.

[0026] The principle of use of the present invention: specifically, in the initi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com