Patents

Literature

723results about How to "Automate cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

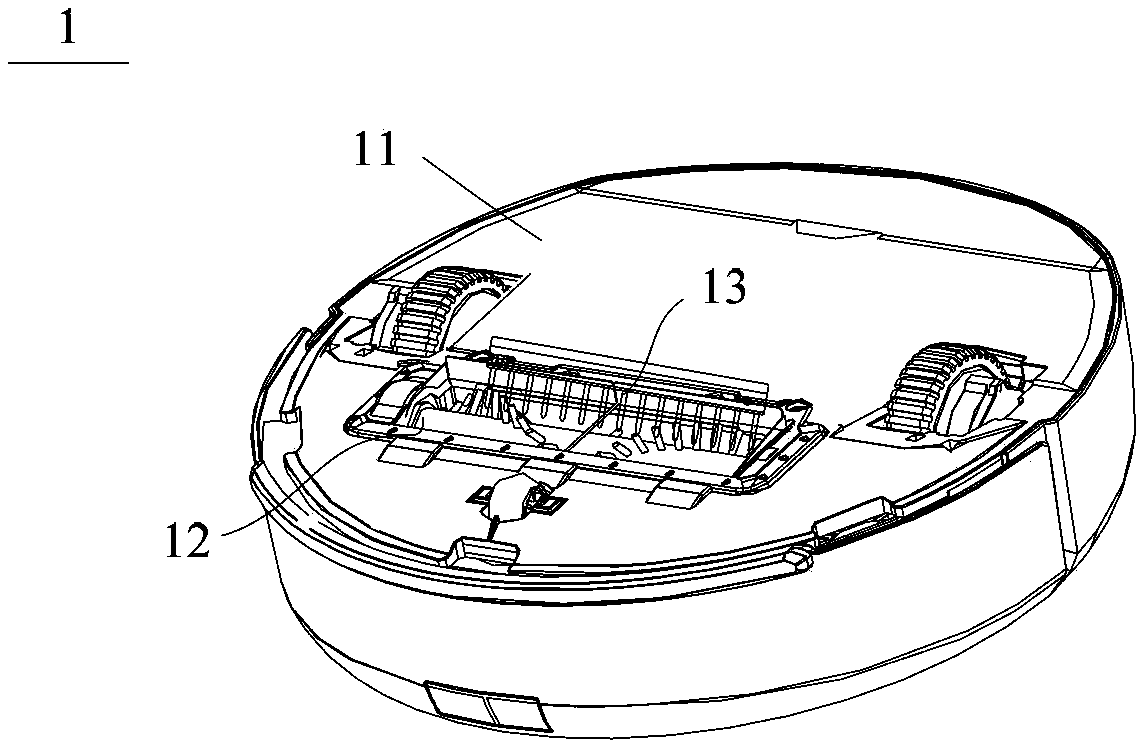

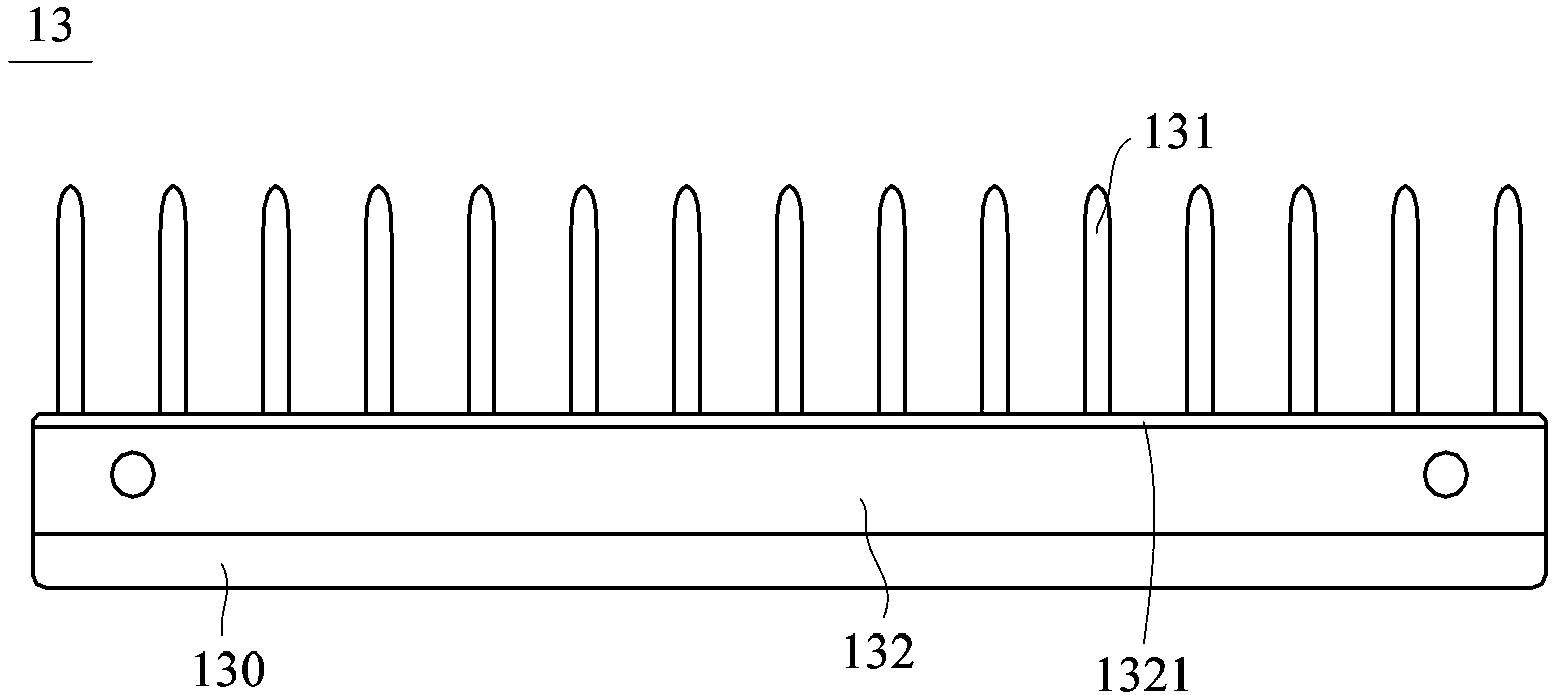

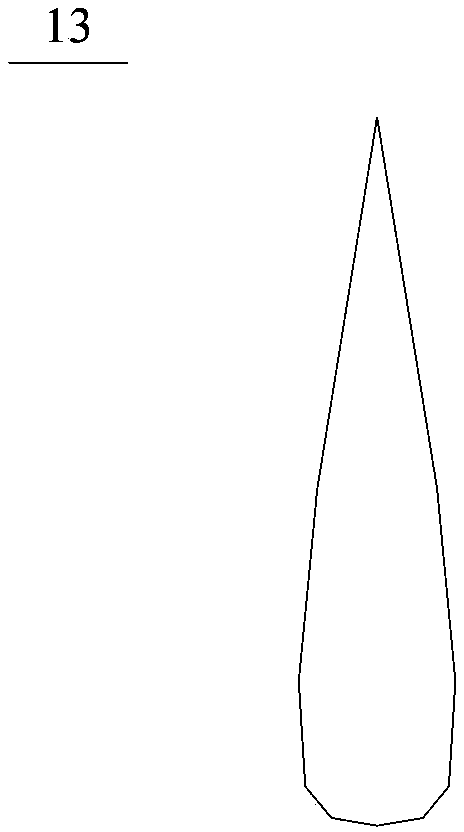

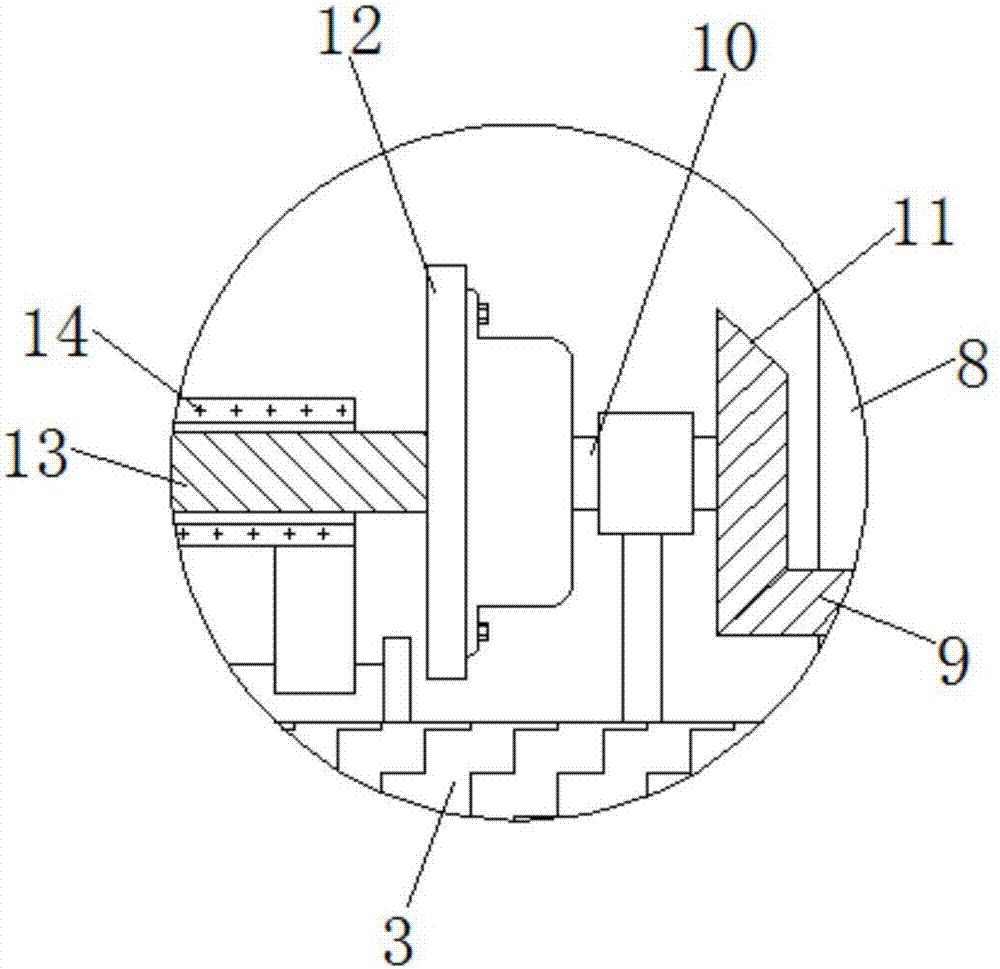

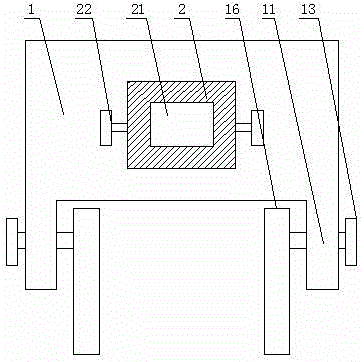

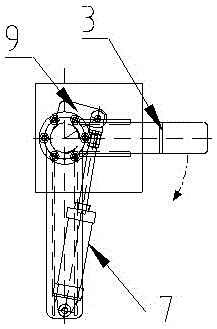

Cleaning device, rolling brush cleaning cabin and cleaning system

ActiveCN104248397AAutomate cleaningImprove intelligenceMachine detailsMechanical engineeringEngineering

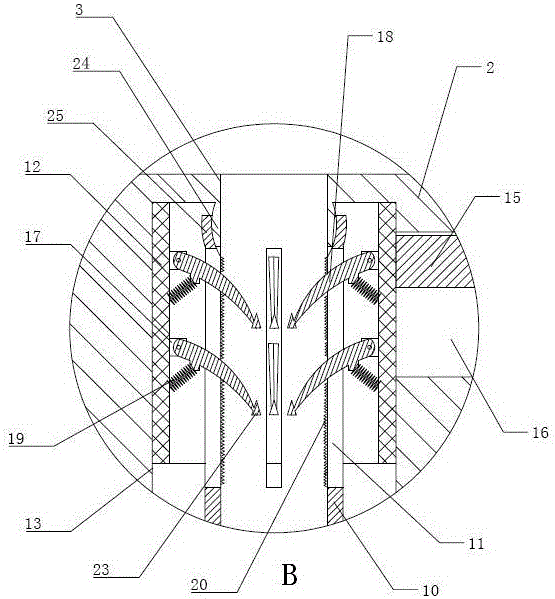

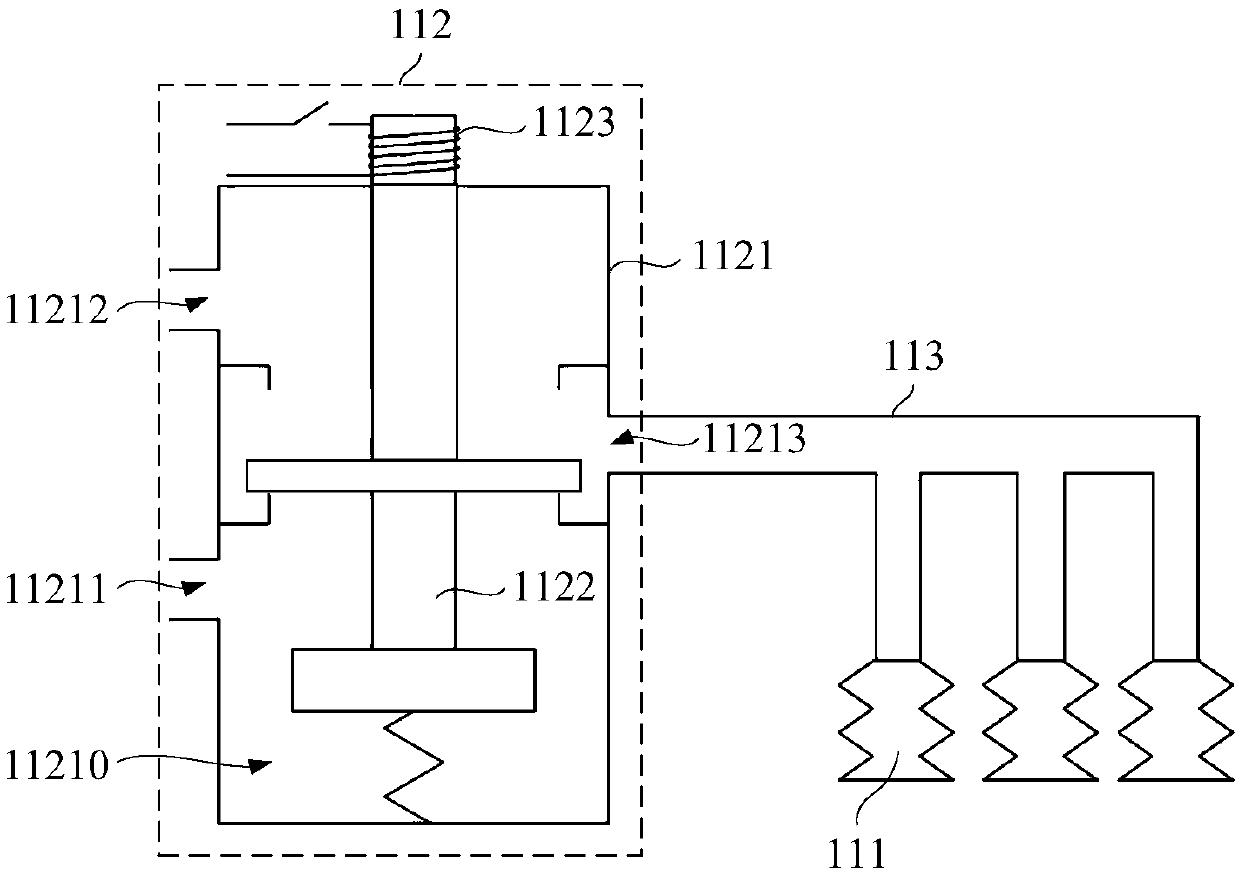

The invention discloses a cleaning device (1), a rolling brush cleaning cabin (2) and a cleaning system. A cleaning comb (13, 22) is arranged on each of the cleaning device, the rolling brush cleaning cabin and the cleaning system, wherein a main body (130), a blade (132) and more than two comb teeth (131) which are arranged on the main body are arranged on a first cleaning comb; the blade is arranged in the manner of corresponding to the rear section of a part of or all the comb teeth. When the first cleaning comb is used for cleaning a rolling brush (12), with the rotation of the rolling brush, the front sections of the comb teeth can be inserted into hair (121) of the rolling brush, the blade gets out of the hair of the rolling brush, and a cutting edge (1321) of the blade is close to the outer edge of the hair of the rolling brush. According to the cleaning device, the rolling brush cleaning cabin and the cleaning system, due to the fact that the first cleaning comb cleans the rolling brush, wound hair wound on the rolling brush can be easy to treat, the action of the rolling brush is also not affected, the rolling brush is also not damaged, and the cleaning device, the rolling brush cleaning cabin and the cleaning system are very simple and effective.

Owner:ECOVACS ROBOTICS CO LTD SUZHOU CITY

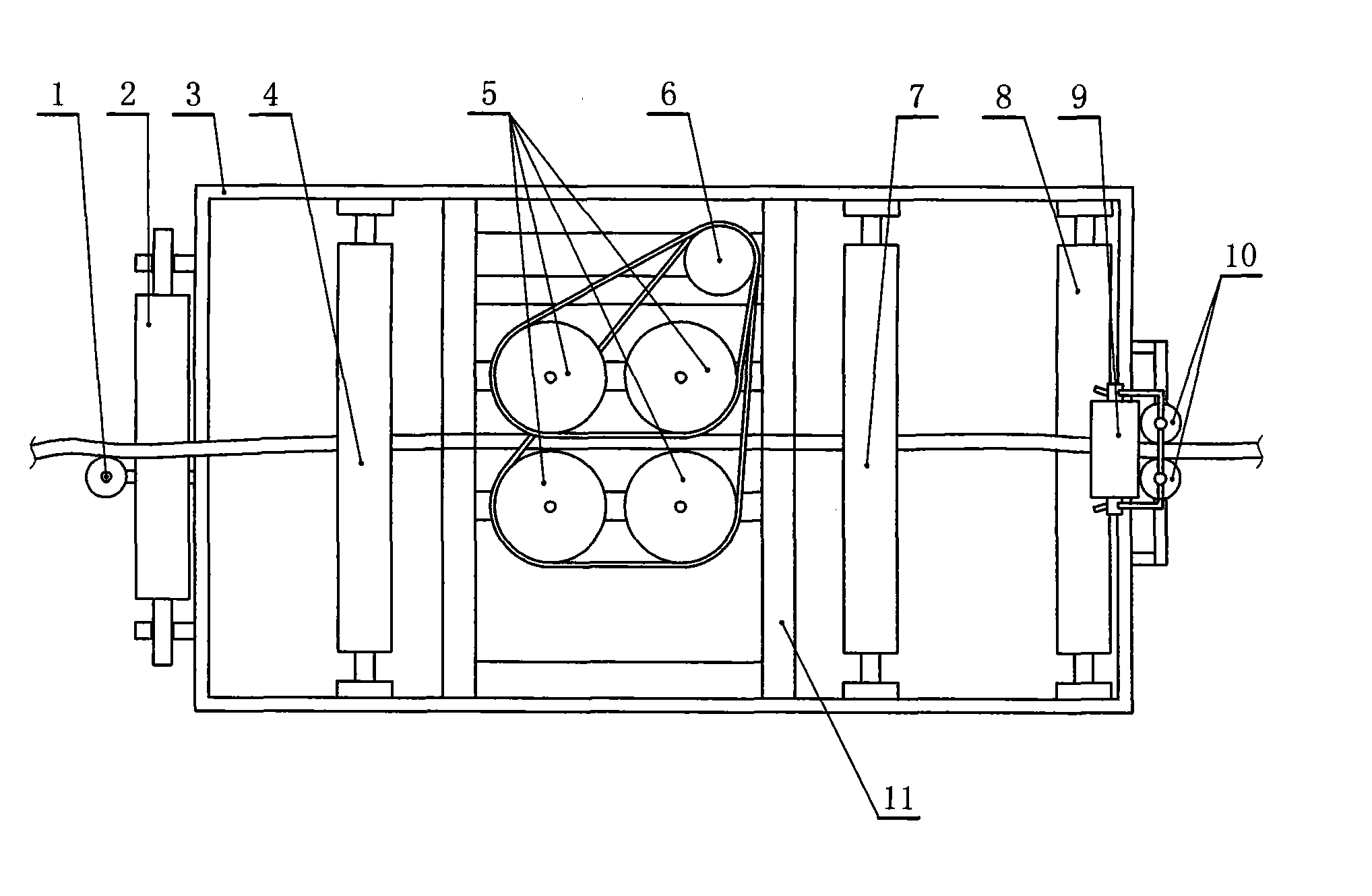

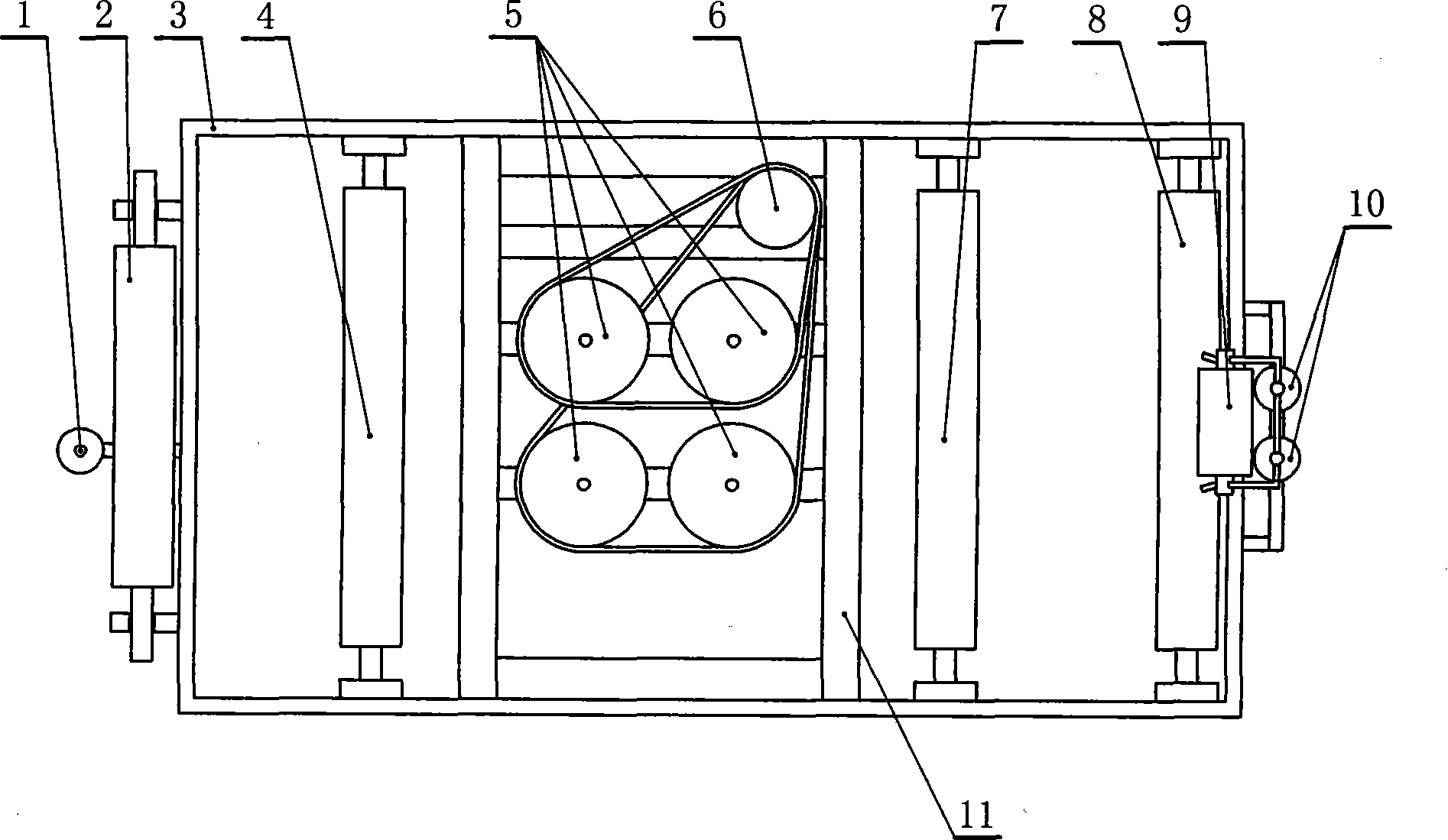

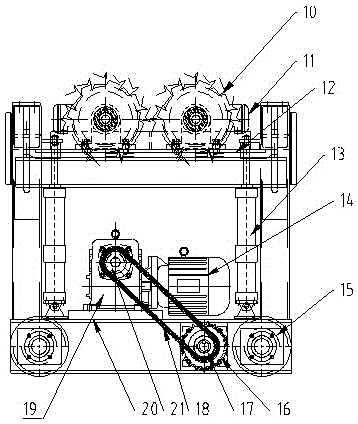

Electrical cable washer

InactiveCN101249496AReduce labor intensityAutomate cleaningFilament handlingCleaning using toolsElectric machineryEngineering

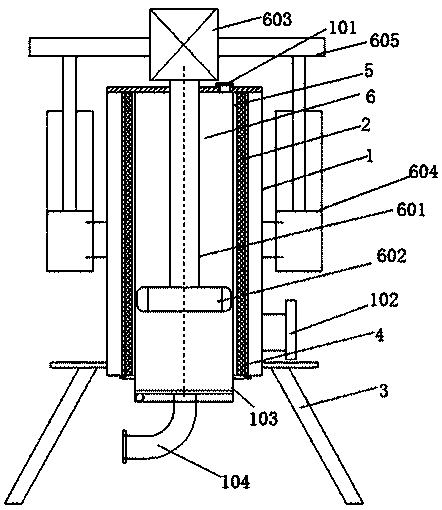

A cable cleaning machine capable of cleaning coal dust and mud as a substitute for manual operation belongs to mine machinery, and comprises a cleaning box, lead-in rollers relatively rotatably arranged on the left upper edge of the cleaning box, a lead-in compression roller and a lead-out compression roller relatively rotatably arranged on the corresponding left and the right sides in the cleaning box, and lead-out rollers relatively rotatably arranged on the right upper edge of the cleaning box, wherein the lowest point of the lead-in compression roller is lower than the highest point of the lead-in compression roller; the highest point of the lead-out roller is higher than the lowest point of the lead-out compression roller; a cleaning support is fixedly arranged in the cleaning box; a motor and a cleaning wheel are fixedly arranged on the cleaning support; brushes are arranged on the cleaning wheel; the motor is transmissively connected with the cleaning wheel; and the orthographic projection of the connection line of the lowest point of the lead-out compression roller and the lowest point of the lead-out compression roller intersects the cleaning wheel. The cable cleaning machine can substitute for manual operation for cleaning mine cables taken back under the well and achieve automatic cleaning with high efficiency and good cleaning effect, thereby lowing labor intensity.

Owner:枣庄矿业(集团)有限责任公司柴里煤矿

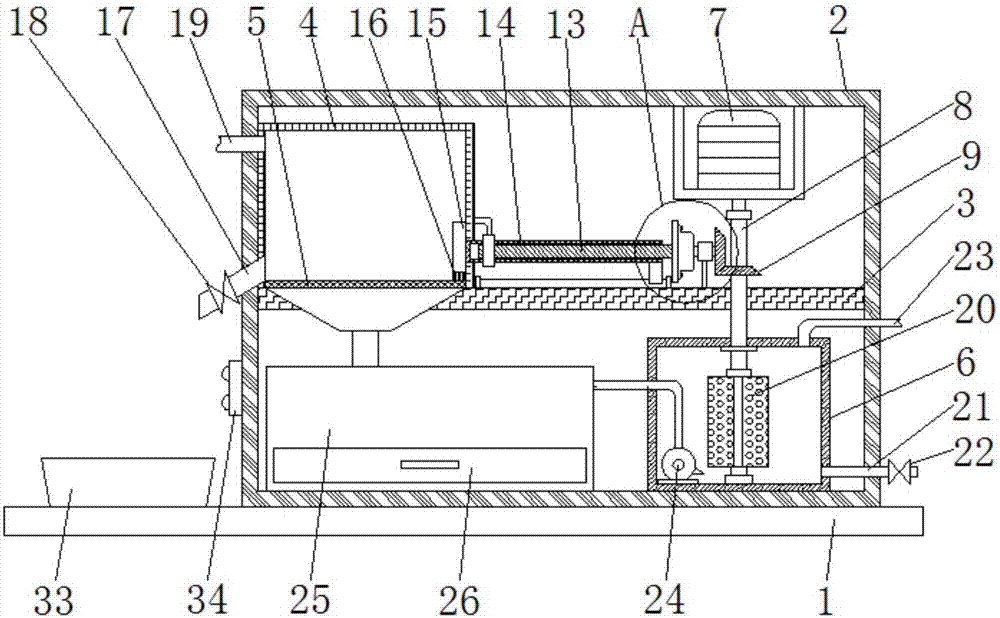

Culturing farm sewage treatment device with environmental protection function

ActiveCN107381938ASave time at workReduce workloadSpecific water treatment objectivesWaste water treatment from animal husbandryWork periodEngineering

The invention discloses a culturing farm sewage treatment device with environmental protection function. The device includes a pedestal, the top of the pedestal is fixedly connected to a case, a partition plate is fixedly connected between two sides of the case inner wall, one side at the top of the partition plate is fixedly connected to a filter tank, the bottom of the filter tank inner wall is fixedly connected to a filter net, one side at the bottom of the case inner wall is fixedly connected to a disinfection tank, and one side at the top of the case inner wall is fixedly connected to a motor through a mounting rack. The invention relates to the technical field of culturing farm sewage treatment equipment. The culturing farm sewage treatment device with environmental protection function provided by the invention has no need for manual cleaning of the filtered filter residue and precipitated sludge by culture staff, saves a lot of working time for the culture staff, alleviates the workload of culture staff, and realizes fast and thorough automatic cleaning of filter residue and precipitated sludge, thus greatly facilitating the sewage treatment work of the culture staff.

Owner:阳信亿利源清真肉类有限公司

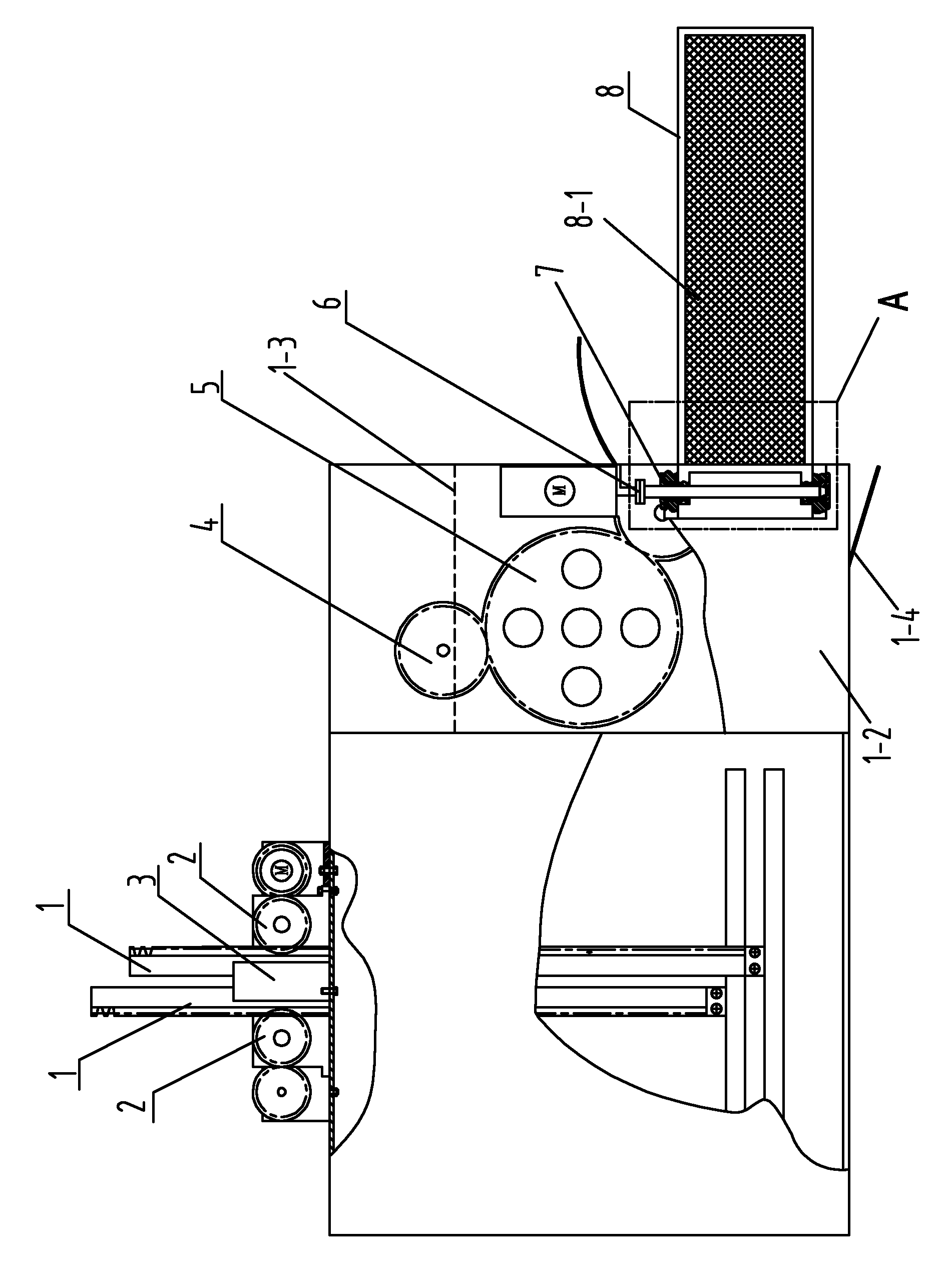

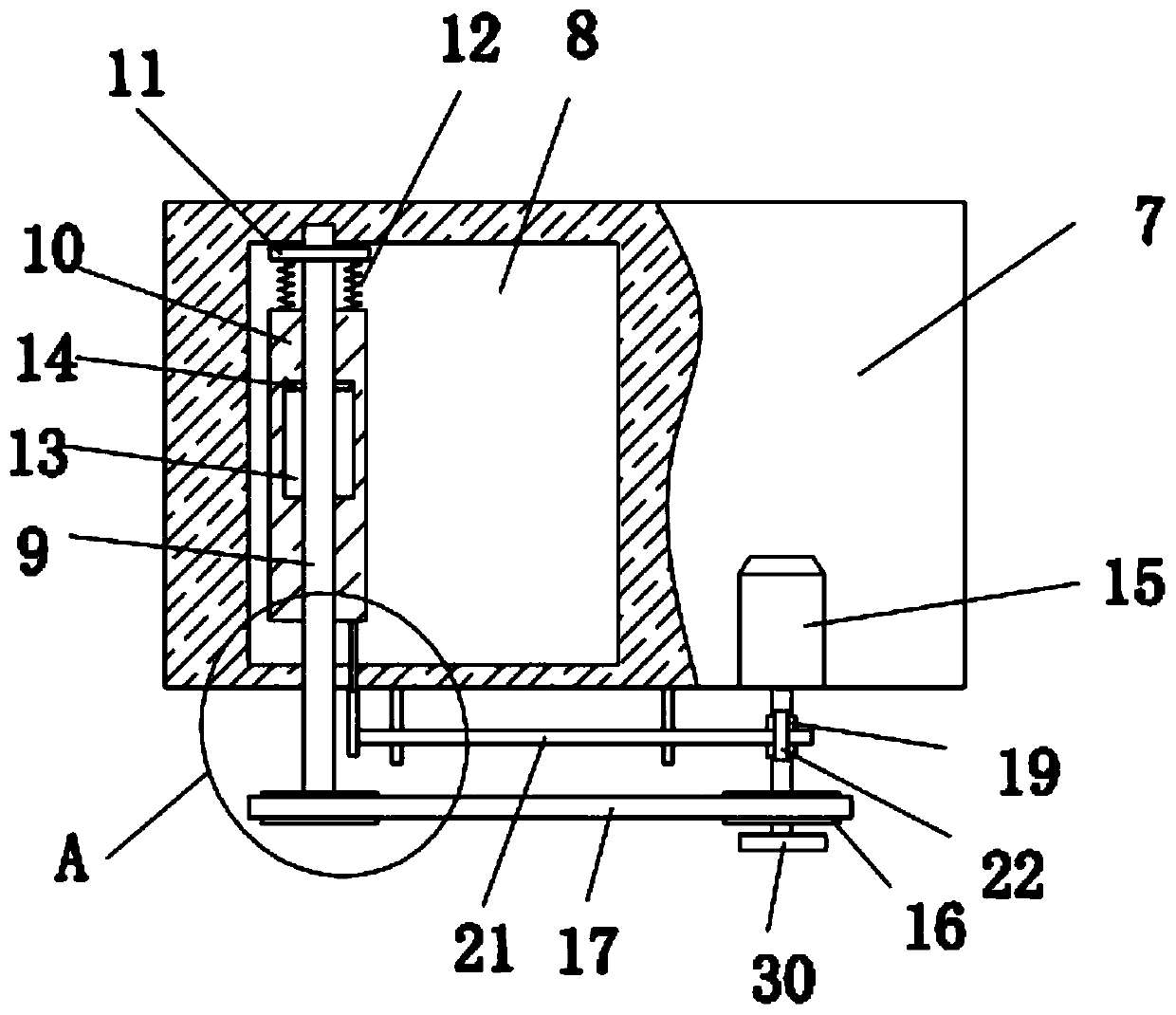

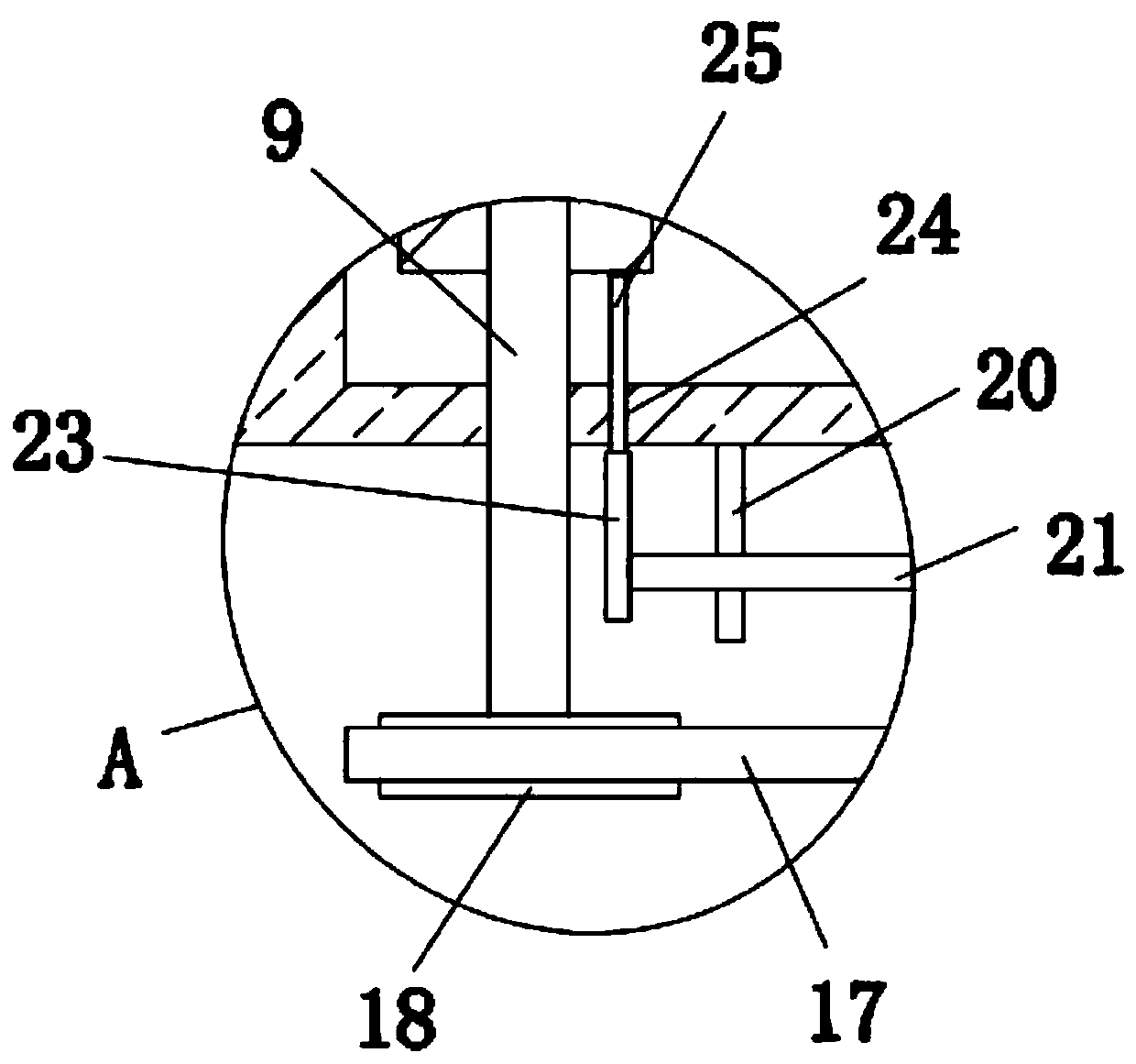

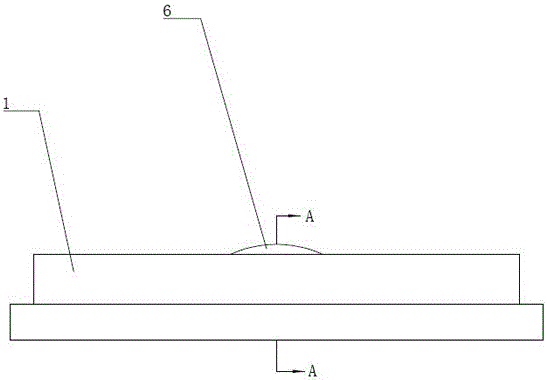

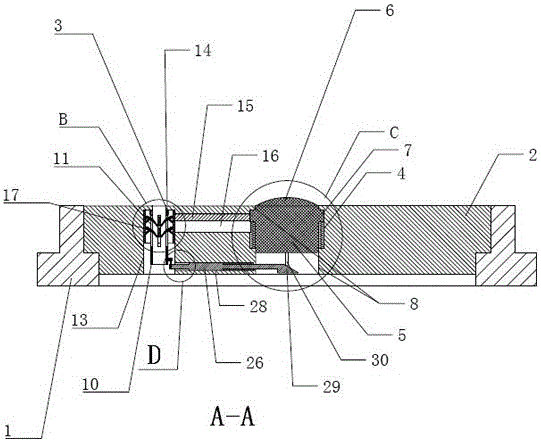

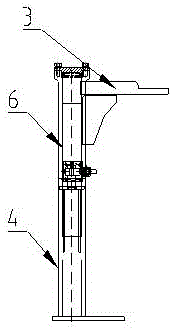

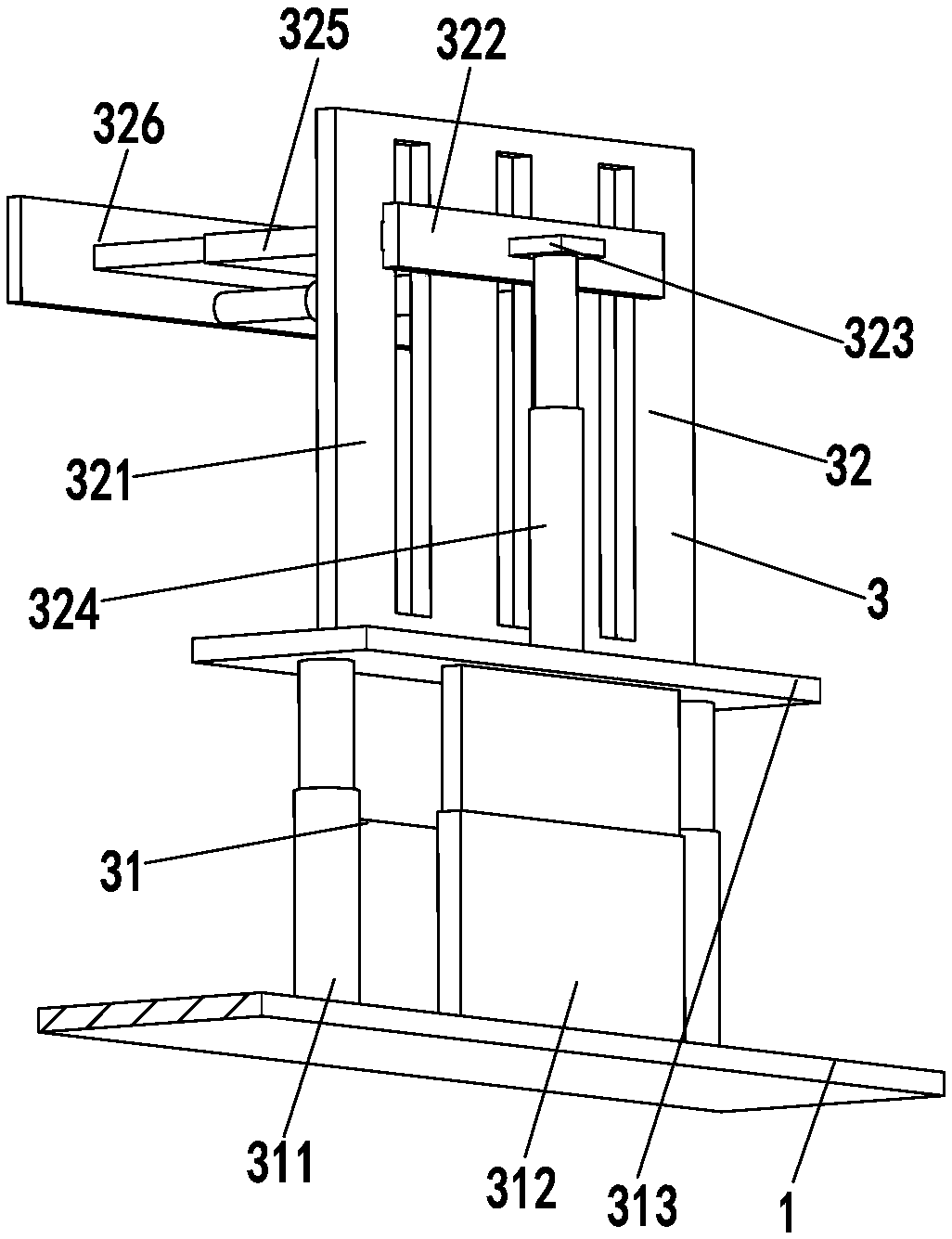

Rail cleaning device for solar cell panel

The invention discloses a rail cleaning device for a solar cell panel. The rail cleaning device is erected above the solar cell panel and comprises a support, a longitudinal moving mechanism erected on the support, a lifting mechanism and a cleaning mechanism. The longitudinal moving mechanism comprises a lead screw and a balance rod set. One end of the lead screw is directly connected with a transmission direct-current motor, and the other end of the lead screw penetrates through a lead screw sliding block. The lead screw is in engaged transmission with the lead screw sliding block. The balance rod set penetrates through a balance sliding block set. The lead screw is parallel to the balance rod set. The lead screw sliding block is fixed to the lifting mechanism. The lifting mechanism comprises a fixed plate connected with the lead screw sliding block, and a movable plate. Sliding grooves are formed in the two sides of the fixed plate. Sliding columns are arranged on the two sides of the movable plate. The sliding columns stretch out of the sliding grooves to make the movable plate slide relative to the sliding grooves. The cleaning mechanism is mounted at the lower end of the movable plate and comprises an electric brush and a sponge. The rail cleaning device has the advantages of automatic cleaning and high cleaning efficiency.

Owner:QINGHAI UNIVERSITY

Sweeper anti-winding device

ActiveCN108245084ASmooth rotationAutomate cleaningCarpet cleanersFloor cleanersMechanical engineering

The invention relates to a sweeper anti-winding device which comprises a support seat, telescopic rods, a driver and a cutting device. The driver and the cutting device are connected on the support seat through the telescopic rods, the cutting device comprises a pair of opposite matched cutting strips, the two cutting strips include a driving strip and a driven strip, the driven strip is fixedly connected with the ends of the telescopic rods, the driving strip is slidably connected with the ends of the telescopic rods, the driving strip can reciprocate and translate on the axis of the drivingstrip under driving of the driver, the axes of the two cutting strips are parallel to the axis of a rolling brush, cutting teeth are axially and equidistantly arranged on the cutting strips, and the telescopic rods, the driver and the cutting device are electrically connected with a computer chip in a body. The sweeper anti-winding device is novel and unique in structure, impurities such as hair and thread ends wound on the rolling brush can be efficiently removed, the sweeping effect of a sweeper is ensured, the impurities wound on the rolling brush can be cut off, and the rolling brush is effectively protected.

Owner:ZHEJIANG LANYU INTELLIGENT TECH CO LTD

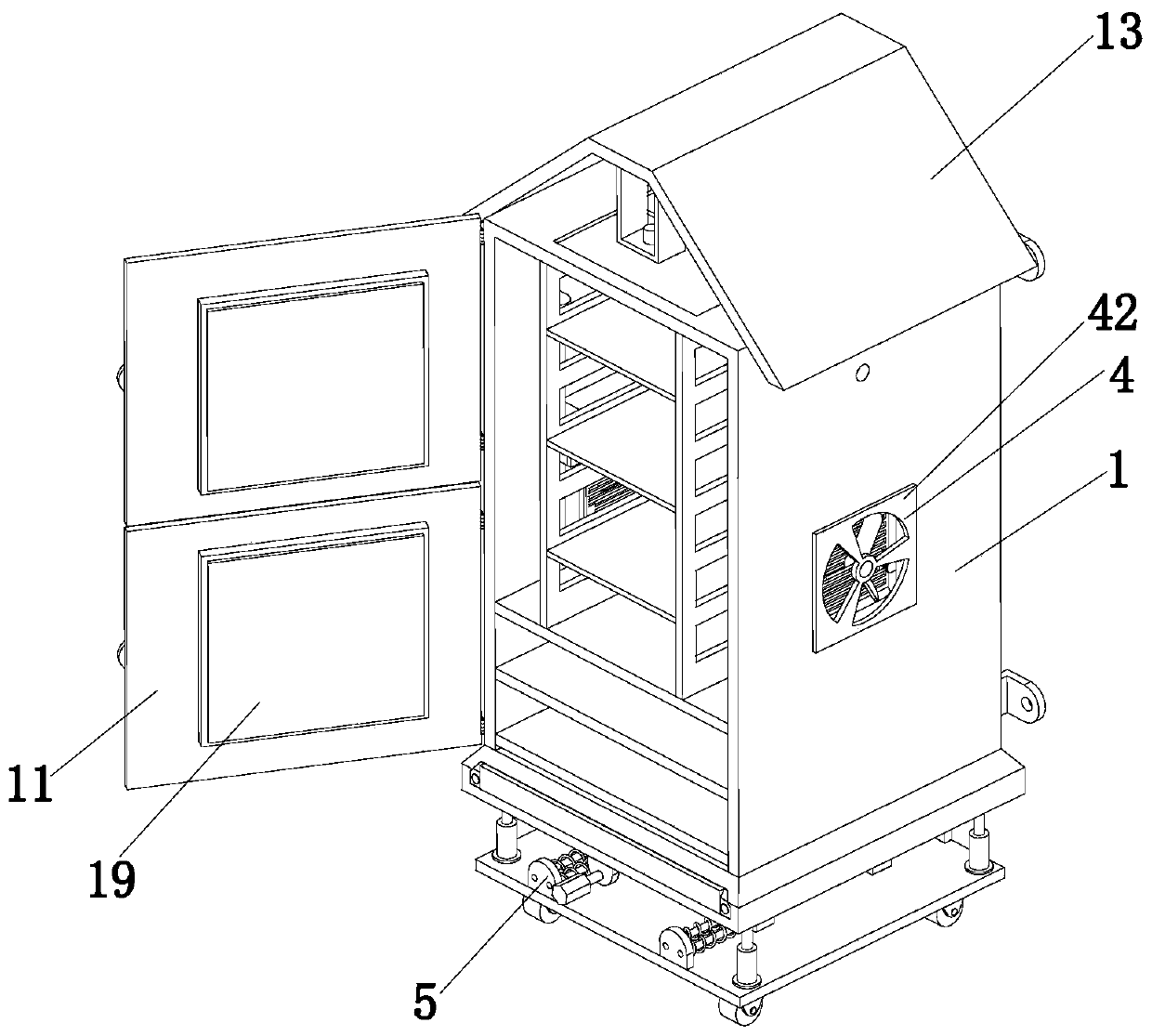

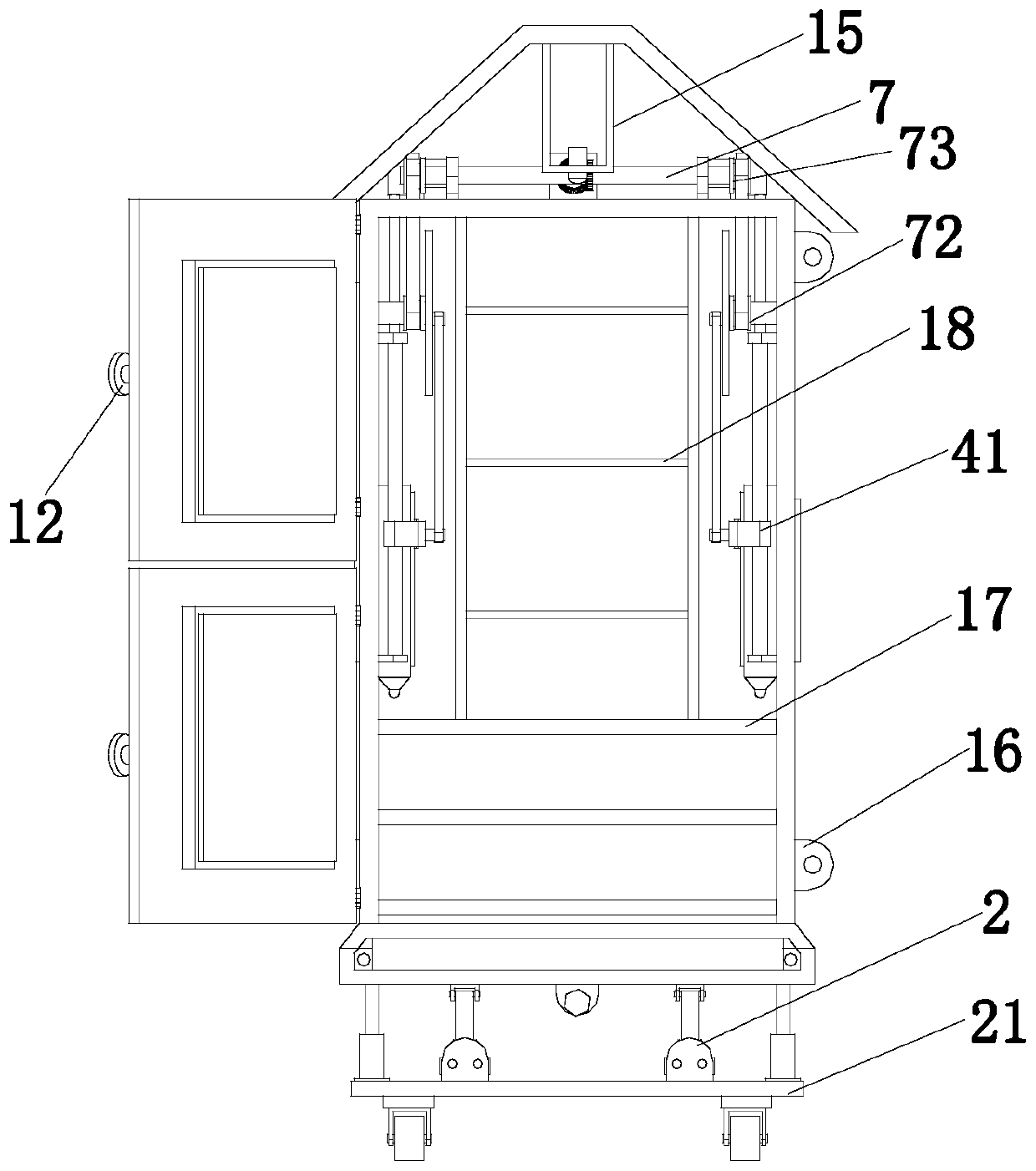

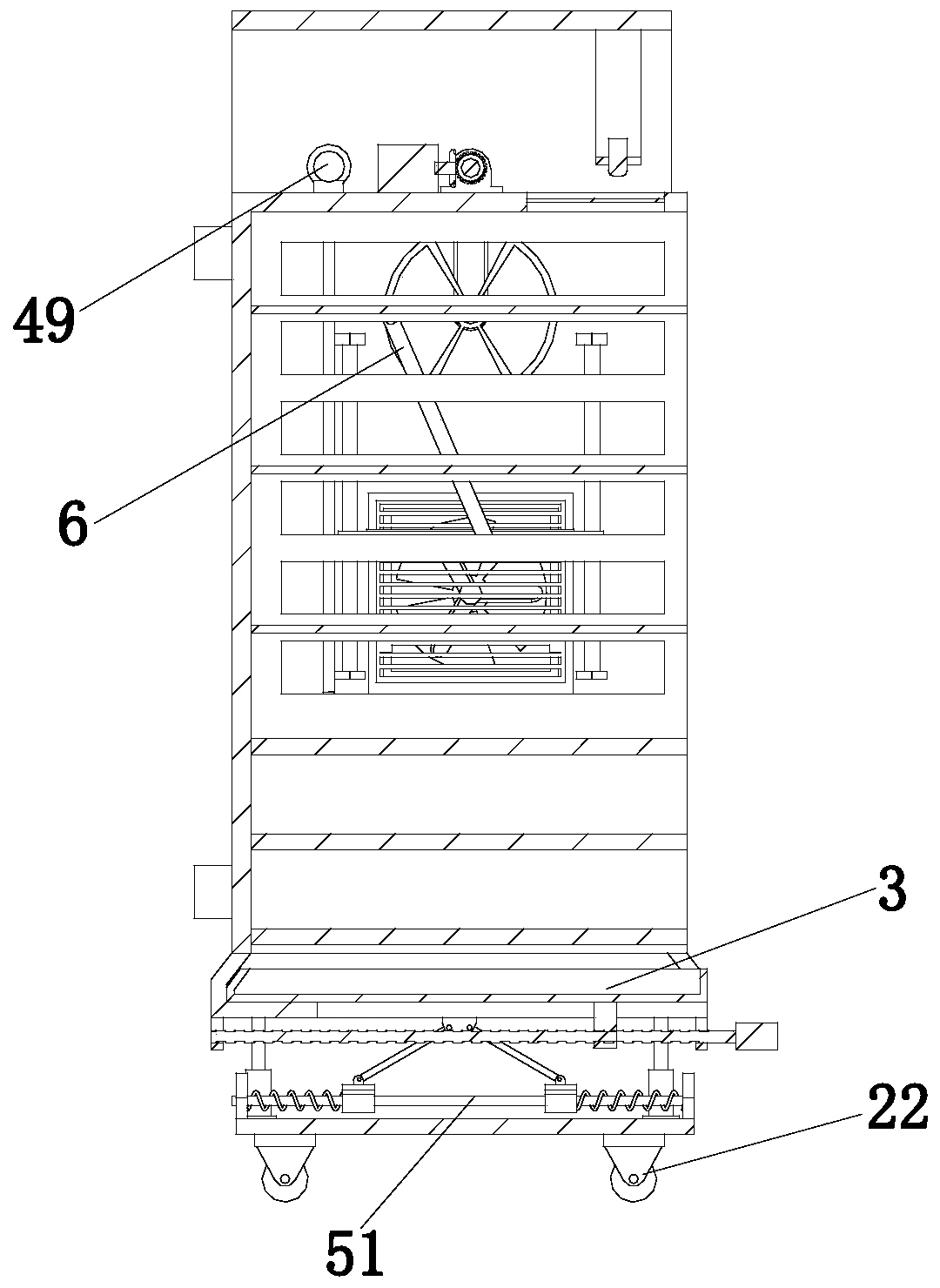

Electrical control cabinet

InactiveCN110707566AEasy to maintainAvoid damageSubstation/switching arrangement casingsAnti-seismic devicesElectrical controlStructural engineering

The invention discloses an electrical control cabinet. The invention belongs to the technical field of electrical equipment, the cabinet comprises a control cabinet, a shock absorption and bumping prevention mechanism, a dehumidification and water absorption mechanism and a dust prevention and accumulation mechanism, two opening and closing doors hinged to the control cabinet are arranged on the front portion of the control cabinet, a rain-proof shed and an observation window are arranged on the top of the control cabinet, an extension frame is arranged on the rain-proof shed, an illuminatinglamp is arranged on the extension frame, the shock absorption and bumping prevention mechanism comprises a base and a shock absorption assembly, four self-locking universal wheels are arranged at thebottom of the base, and four supporting columns are arranged on the top of the base. The electrical control cabinet has the beneficial effects that the damping and anti-bumping effects on the controlcabinet can be achieved through the damping and anti-bumping mechanism, electrical elements in the electrical control cabinet are prevented from being damaged due to bumping, and the safety of the control cabinet is improved; and dust adhering to the dustproof net can be removed through the dustproof dust accumulation mechanism, and falling dust can be collected in a centralized mode under the action of the dust collection assembly.

Owner:汪浩添

Automatic collecting device for floating objects on water

The invention discloses an automatic collecting device for floating objects on water, and aims to provide the automatic collecting device, which can automatically clear the floating objects on water, is low in manufacturing cost, is convenient to use, and is suitable for common people to use, for the floating objects on water. The automatic collecting device comprises a lower barrel body, waterproof bags which are open in upper and lower ends and a water pump arranged in the lower barrel body. The upper end of the lower barrel body is open and the lower end of the lower barrel body is closed. A connecting through hole is formed in the outer side surface of the lower barrel body. A water inlet of the water pump communicates with an inner cavity of the lower barrel body, and a water outlet of the water pump is connected with the connecting through hole. The lower ends of waterproof bags are connected with the upper end of the lower barrel body, and limiting sleeve rings are arranged on upper-edge open edges of the waterproof bags. Garbage filter mesh bags are arranged in the waterproof bags, and a plurality of self-adaptive anti-escape floating mechanisms are arranged on the limiting sleeve rings. Each self-adaptive anti-escape floating mechanism comprises a vertical guide hole which is formed in the limiting sleeve ring, a vertical guide rod which is arranged in the vertical guide hole in a sliding mode, and a floating block.

Owner:ZHEJIANG PROVINCE INST OF ARCHITECTURAL DESIGN & RES

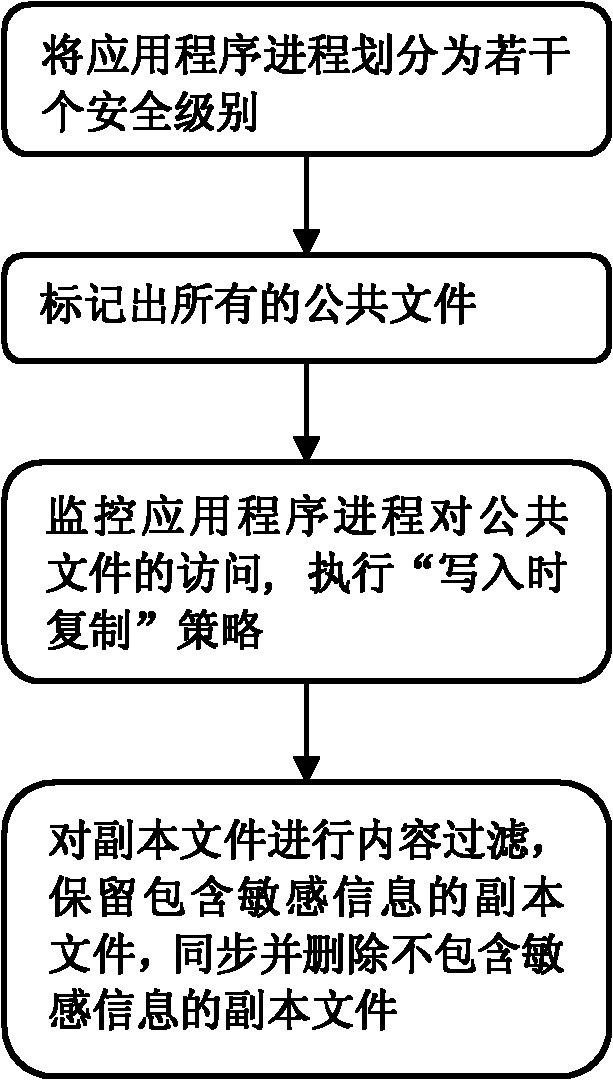

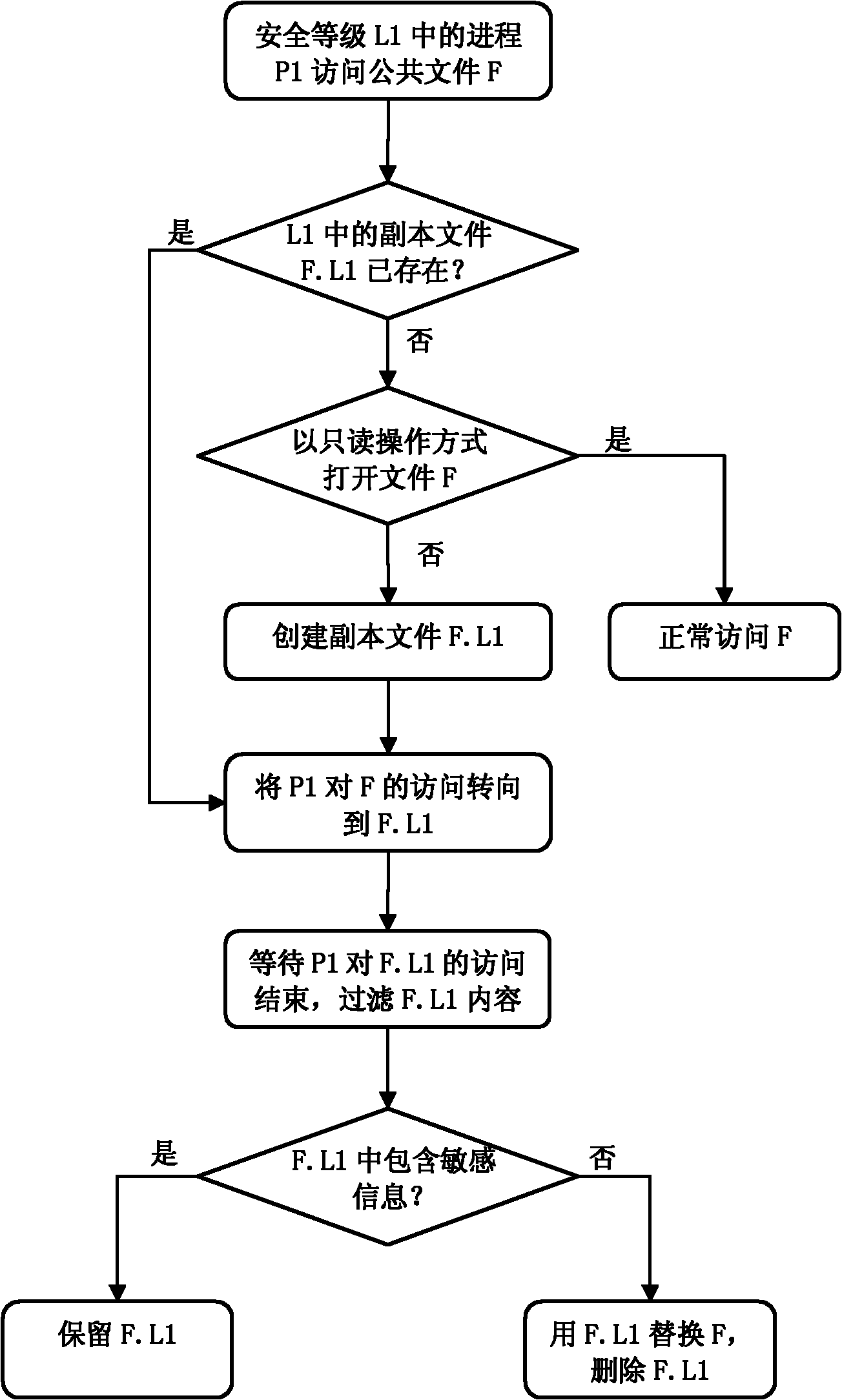

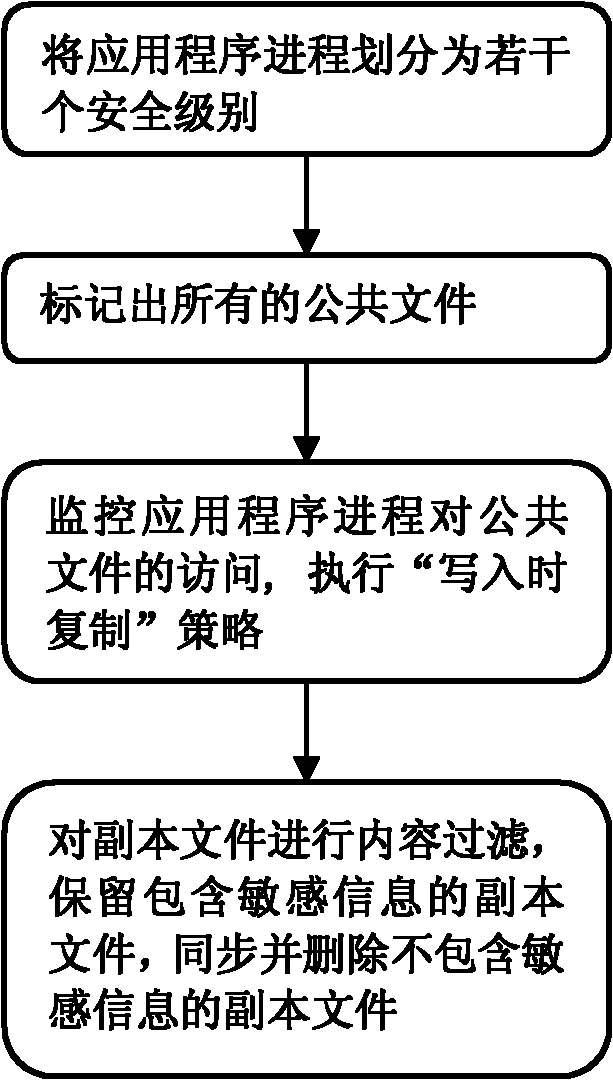

Access quarantine method of public file in data divulgence protection system

InactiveCN102043920AResolve application common filesReliable and efficient data isolationDigital data protectionApplication softwareCopy-on-write

The invention provides an access quarantine method of a public file in a data divulgence protection system. The method comprises the following steps: application process is divided into different security levels; a public file is marked; and when the application process accesses the public file, the strategy of copy-on-write is implemented. In the access quarantine method in the data divulgence protection system, a first copy file is set in the first security level; when the application process accesses the public file, the access to the public file is redirected to the first copy file; and the copy file redirecting technology is utilized to perform safe quarantine on the public file, thus the access quarantine of the public file can be realized and the problem of the application program public file in the data divulgence protection system can be solved.

Owner:BEIJING SENSELOCK SOFTWARE TECH CO LTD

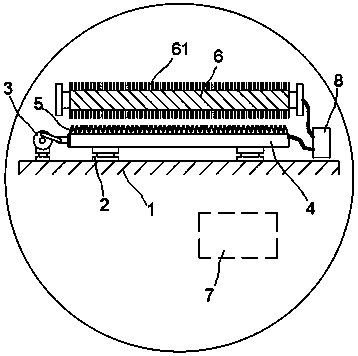

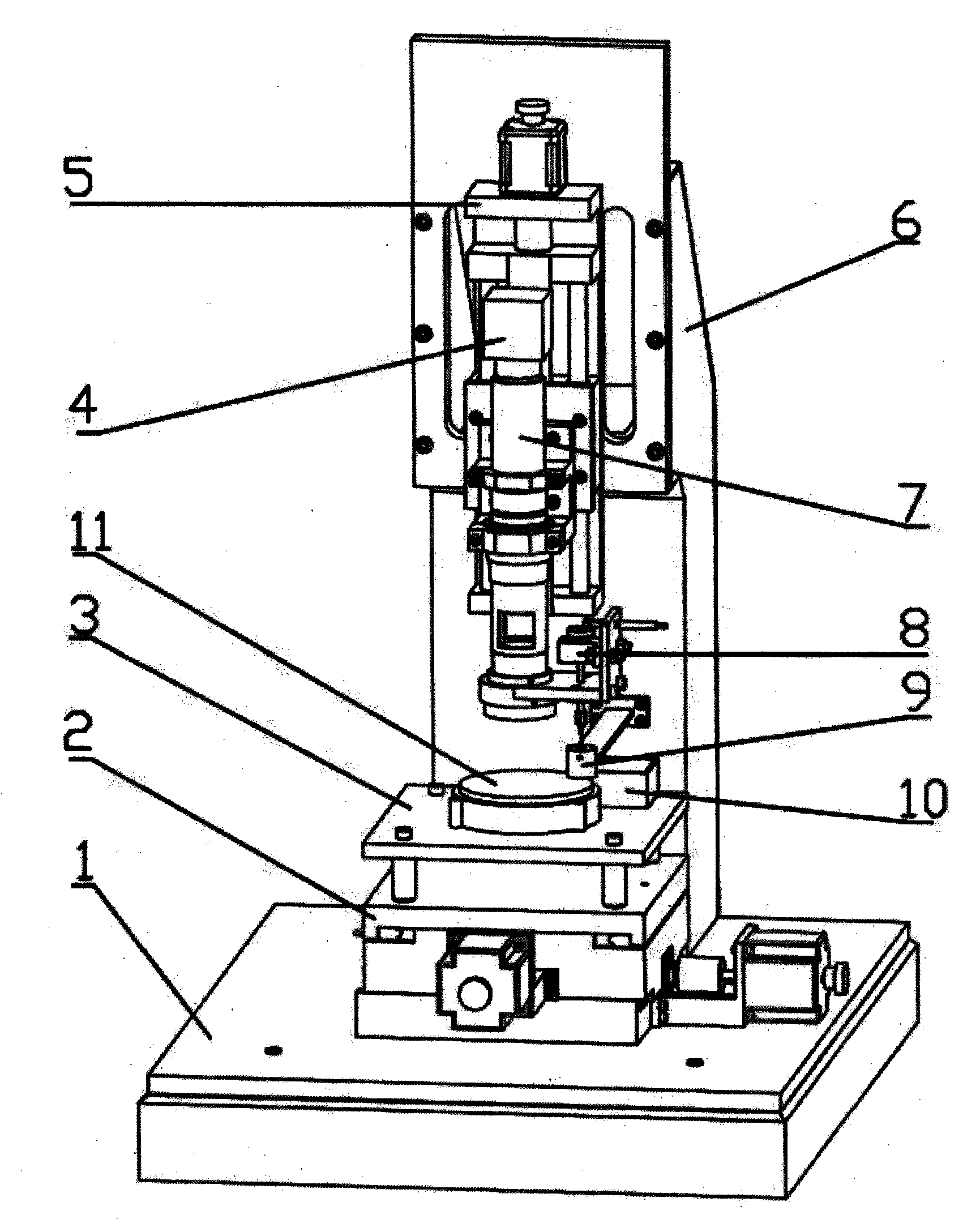

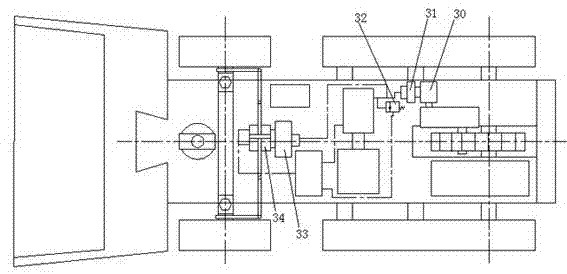

Fully-automatic cleaning device and method for spinneret plate micro-holes

The invention relates to a fully-automatic cleaning device for spinneret plate micro-holes. The device is characterized in that an XY precision moving platform which can move forward, backward, left and right in a horizontal direction is arranged on a base; a spinneret plate clamp used for accommodating a to-be-checked spinneret plate is arranged on the XY precision moving platform; a supporting arm fixedly connected with the base is arranged on a side edge of the XY precision moving platform; a Z-axis precision electronic control stand is fixed on the supporting arm; the Z-axis precision electronic control stand drives a cleaning part to move up and down in a vertical direction; a cleaning needle is arranged at the bottom of the cleaning part; the cleaning part drives the cleaning needle to rotate around an axis of the cleaning part; and a standard guide hole is formed below the cleaning needle. Manual cleaning of original pinneret plate micro-holes can be replaced with the device, so that impurities of the spinneret plate micro-holes can be cleaned away automatically, the operation efficiency for spinneret plates in chemical fiber production can be substantially increased, and at the same time, the production efficiency of an enterprise can be substantially improved.

Owner:DONGHUA UNIV

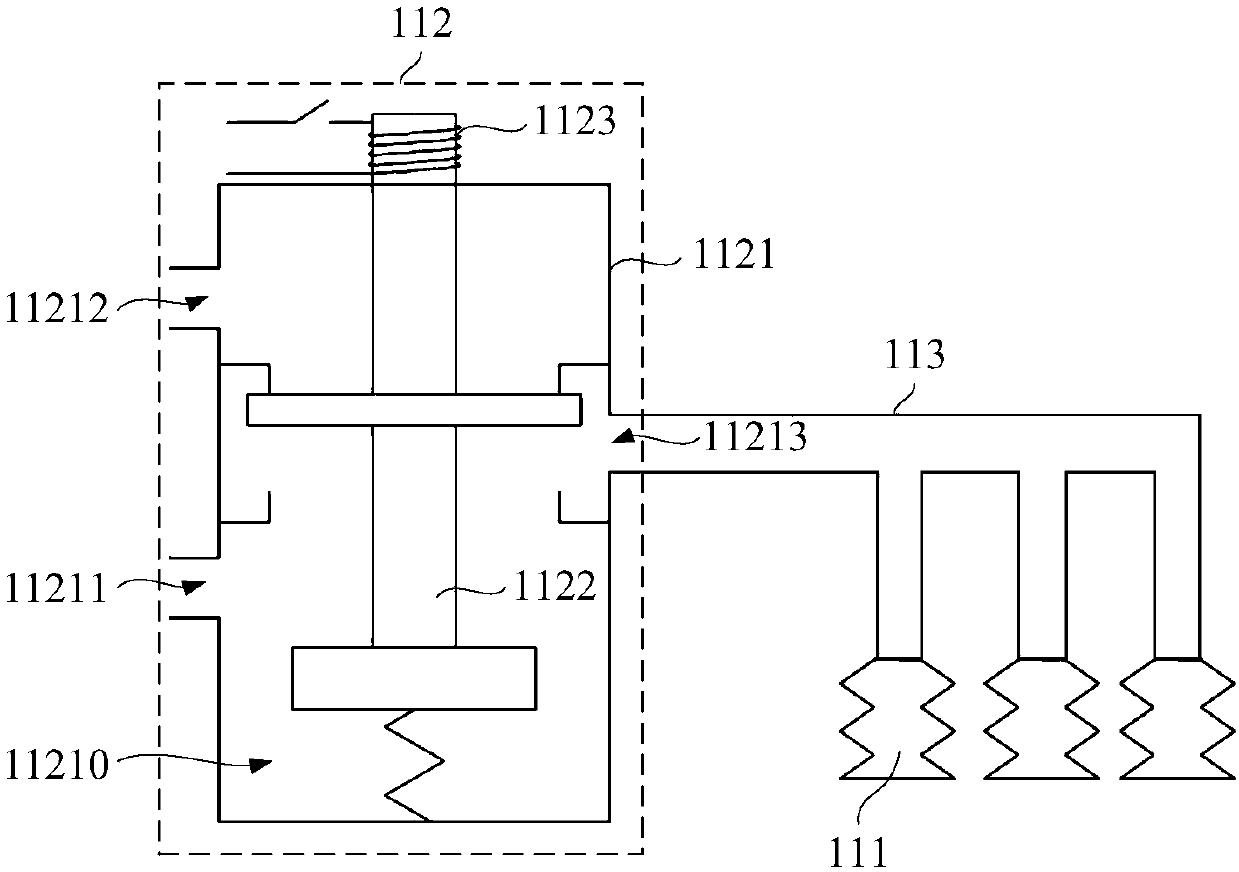

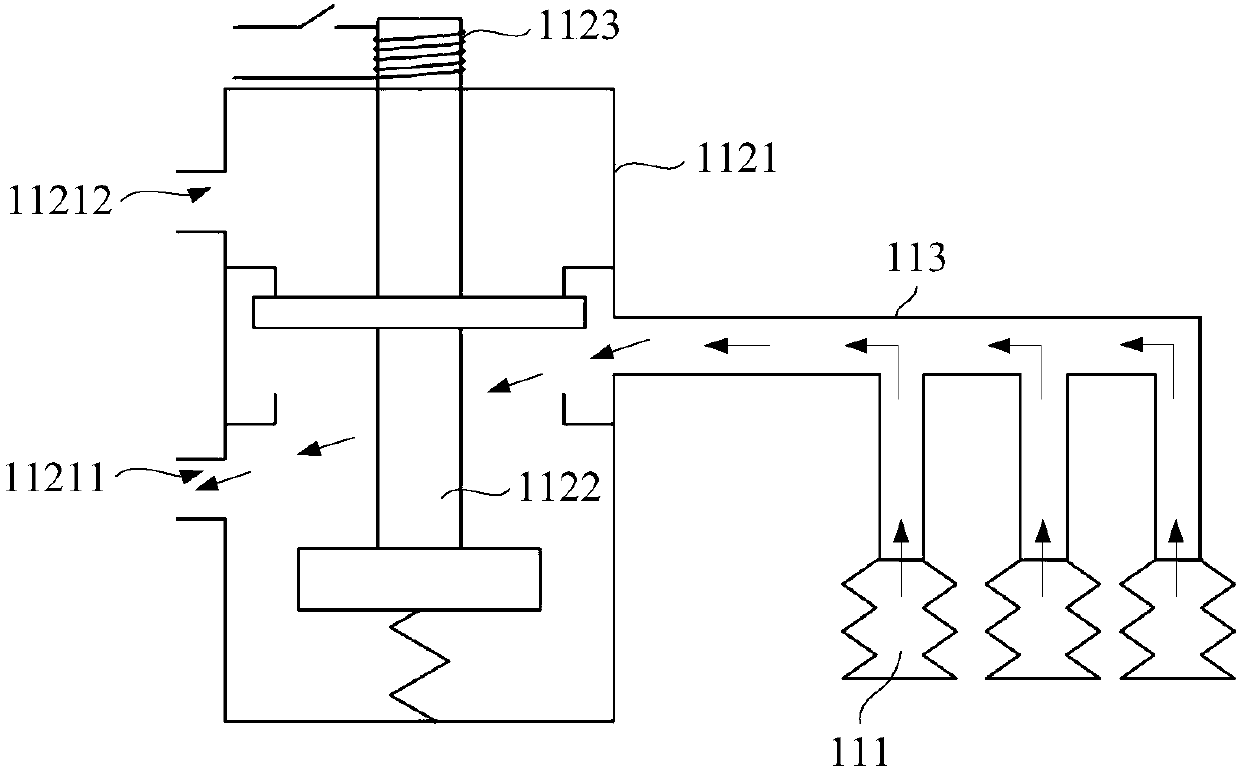

Full hydraulic automatic dung cleaning robot

InactiveCN102893875AChieve progressImplement backClimate change adaptationAnimal housingDiseaseElectronic speed control

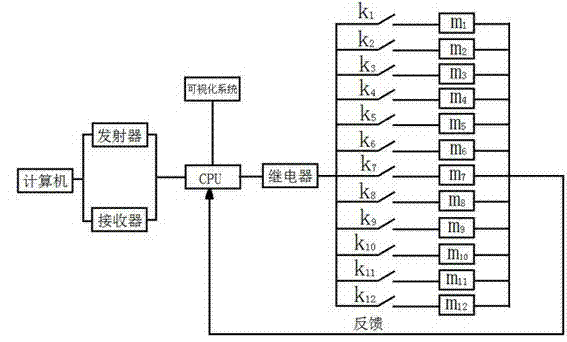

The invention discloses a full hydraulic automatic dung cleaning robot, and belongs to the technical field of dung cleaning mechanical equipment. According to the full hydraulic automatic dung cleaning robot, a front wheel is provided with a steering gear; the back of a base plate is connected with a crawler-type back wheel; the crawler-type back wheel is connected to a driving system and is driven by the driving system; the front end of the base plate is provided with a concave dung scraper; the dung scraper is provided with a hydraulic control system for controlling vertical movement; the front end on the upper part of the base plate is provided with a visualization system; the steering gear, the driving system, the hydraulic control system and the visualization system are connected to an electronic control system; and the electronic control system is in wireless signal transmission connection with a computer to realize remote control and monitoring within 200 meters. The full hydraulic automatic dung cleaning robot can remotely control to clean dung and monitor livestock in 24 hours, working conditions of livestock breeding managers are improved, a good environment for the growth of the livestock is created, diseases are reduced, the meat quality of the livestock is improved and the like.

Owner:SICHUAN AGRI UNIV

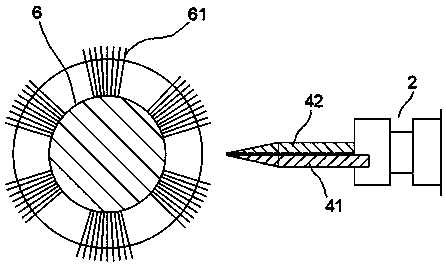

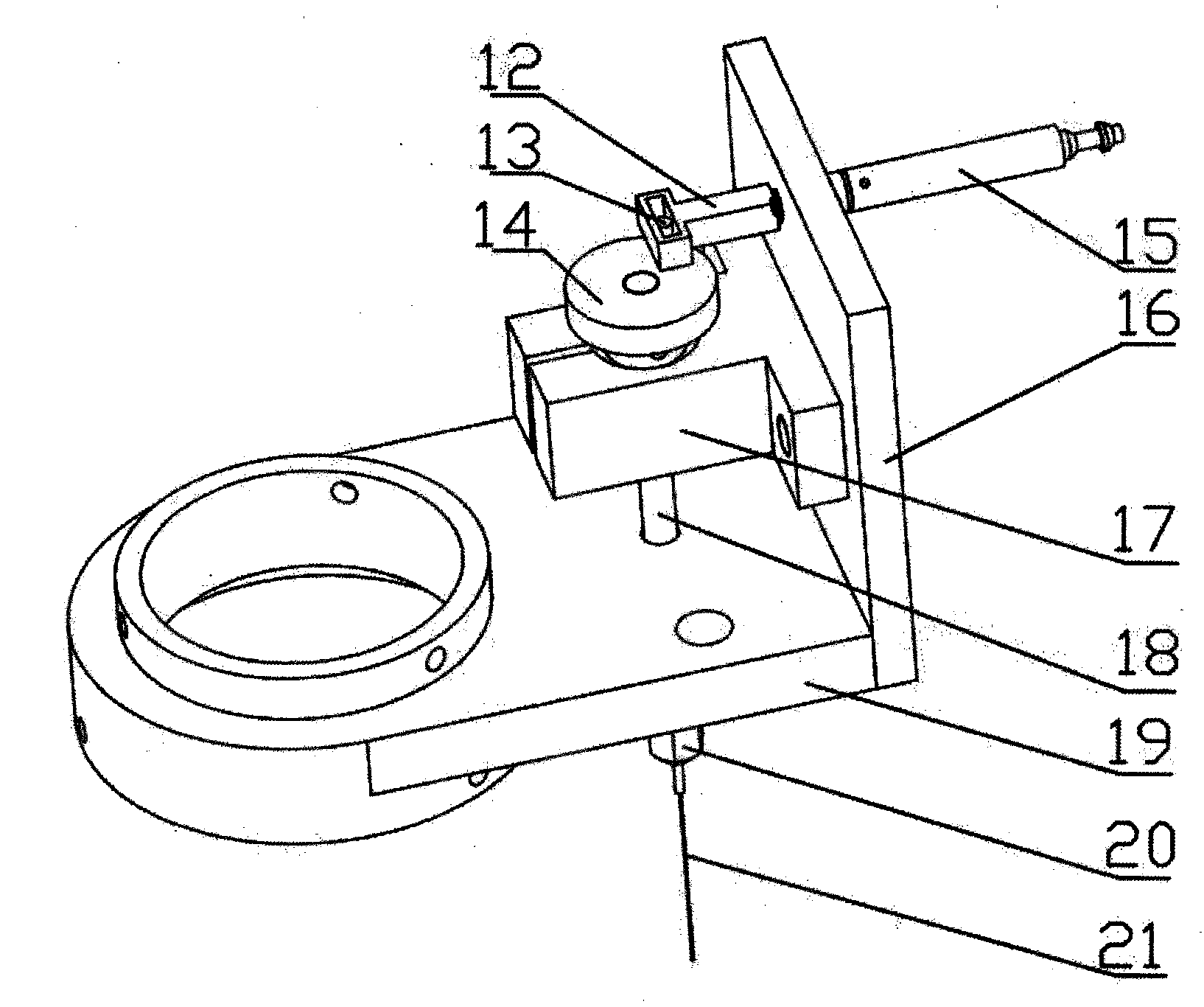

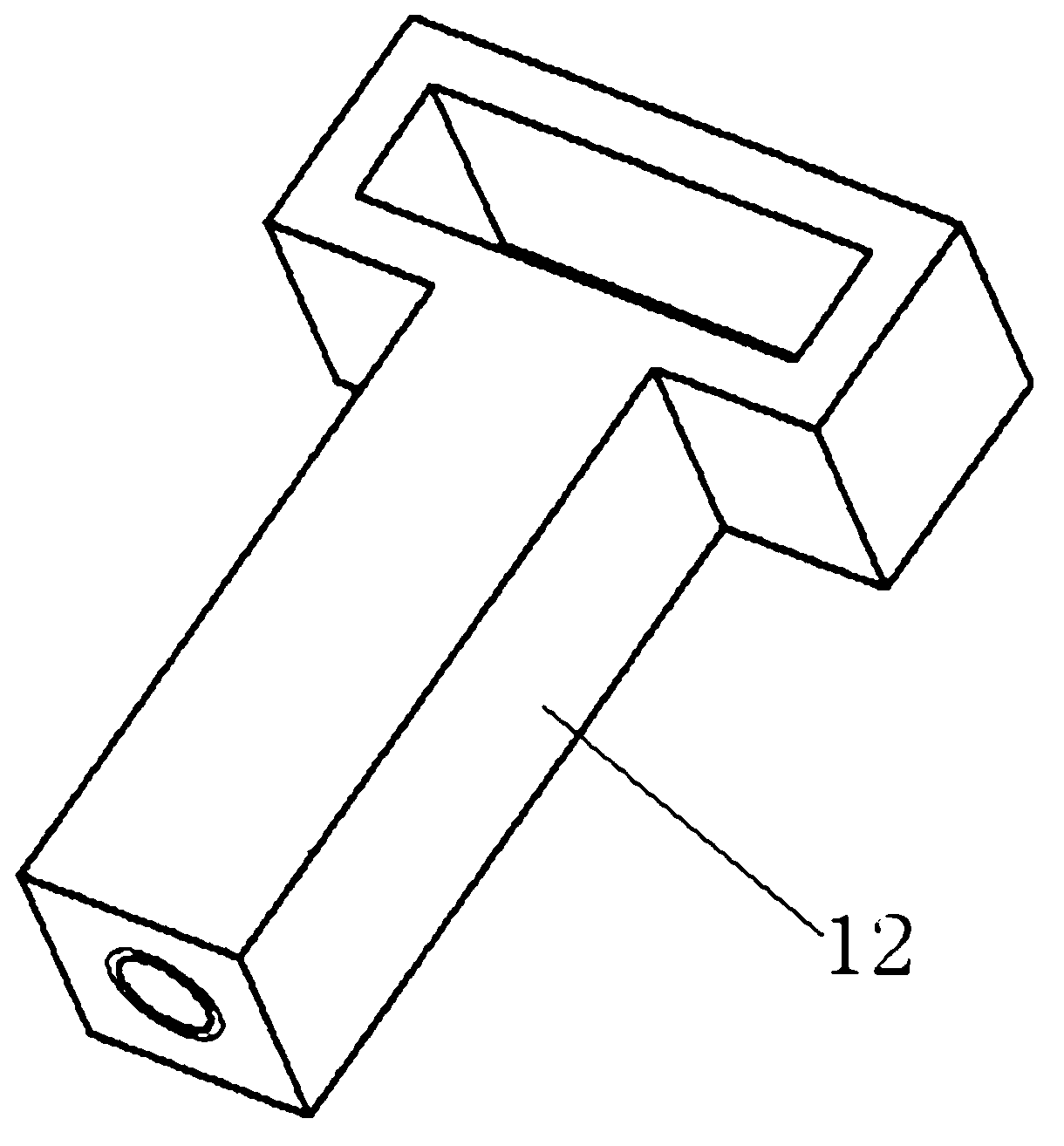

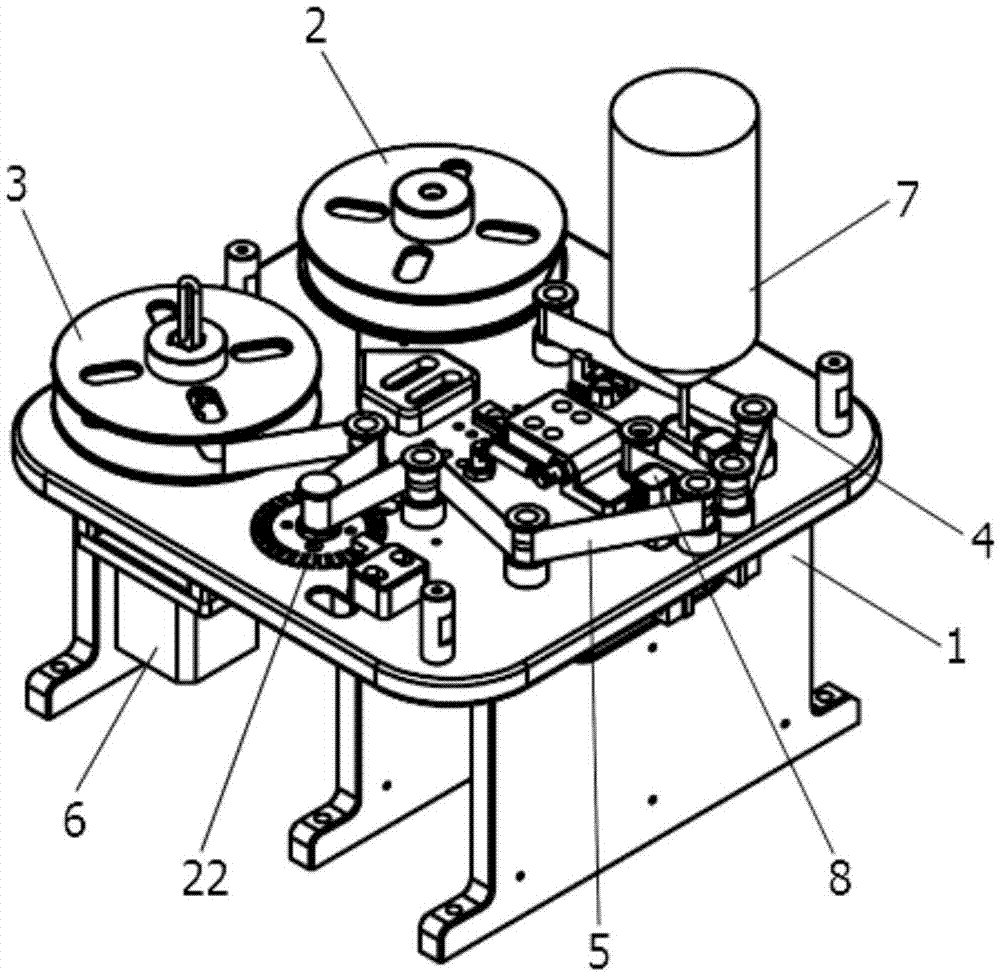

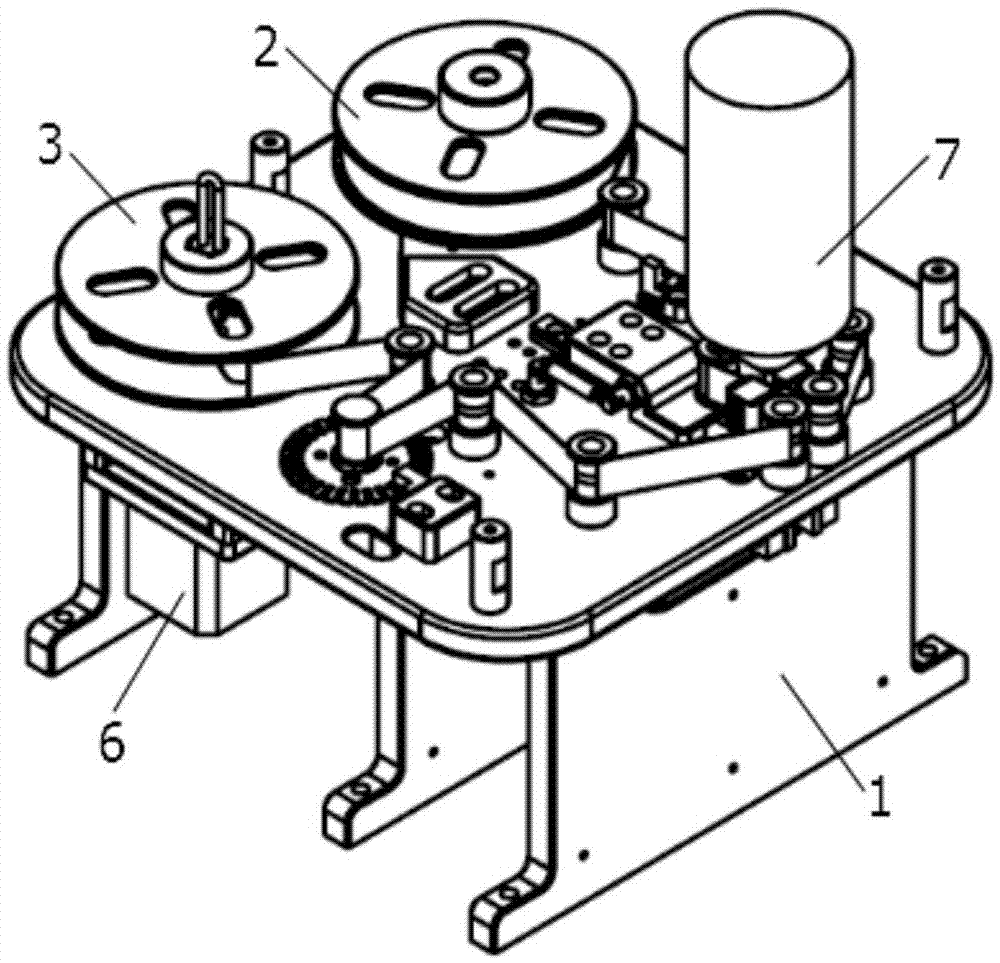

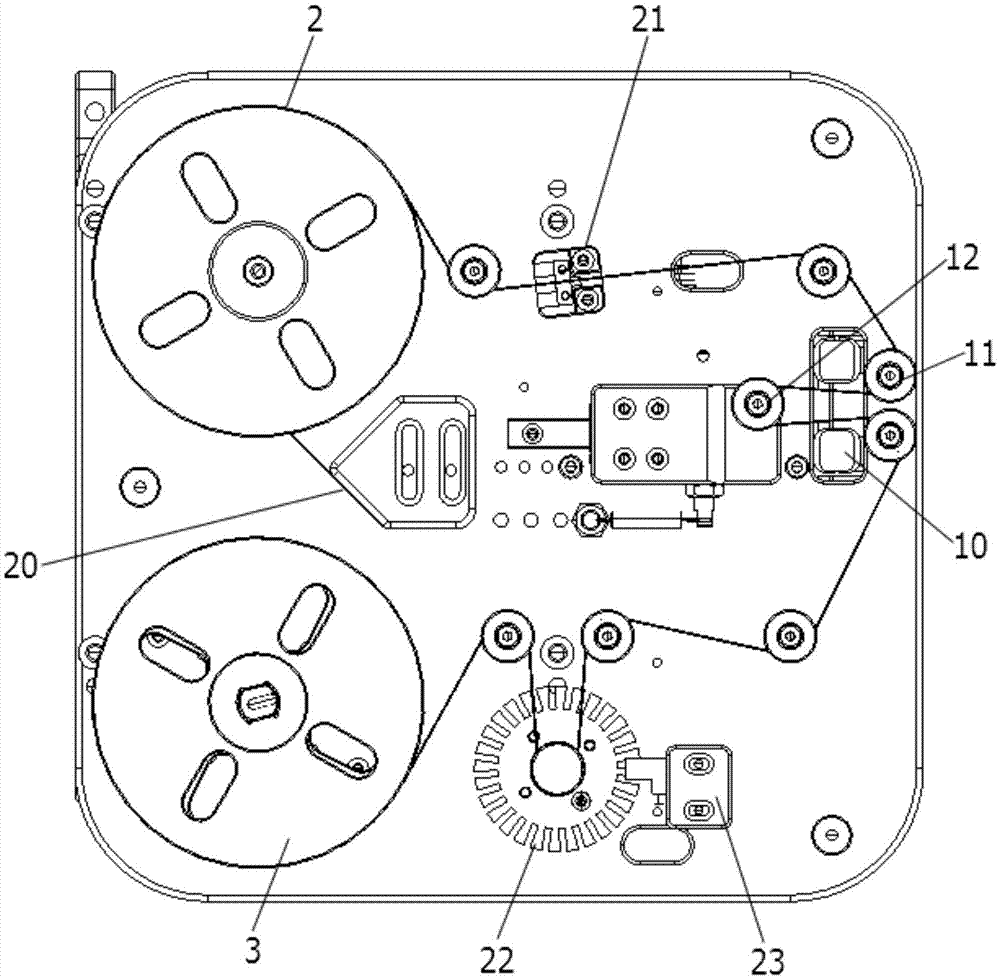

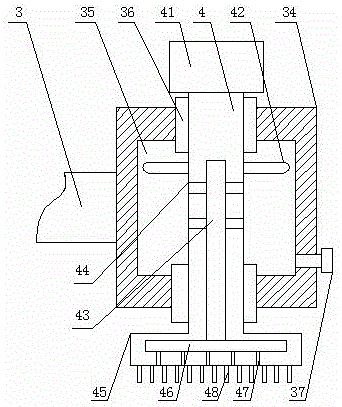

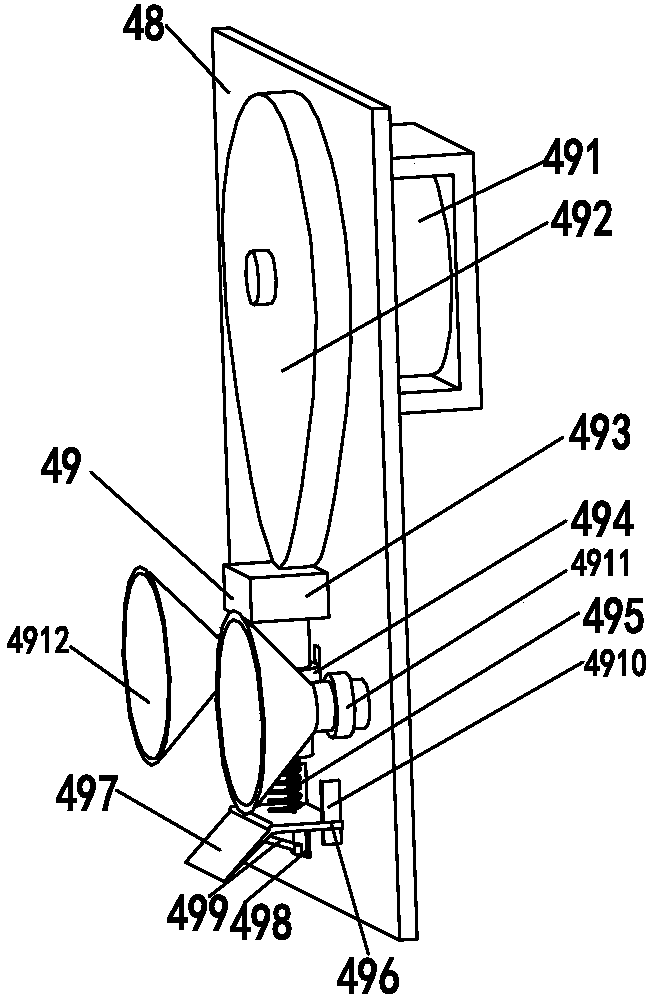

Needle glue removing mechanism and dispenser

ActiveCN105436037AAutomate cleaningImprove cleanlinessLiquid surface applicatorsSpraying apparatusMotor driveWorking environment

The invention discloses a needle glue removing mechanism which comprises a cabinet, wherein a material tray, a material receiving tray and a pulley block are fixed on the cabinet; a material band is rolled in the material tray, and one end of the material band is led out from the material tray and then sequentially passes each pulley of the pulley block to be connected with the material receiving tray; the bottom of the material receiving tray is connected with a stepping motor, and the stepping motor drives the material receiving tray to rotate, so that the material band is rolled into the material receiving tray; and at least three pulleys in the pulley block fold the material band into U shape, the middle of the U-shaped material band is used for insertion of a to-be-cleaned dispenser needle, and two sides of the U-shaped material band are respectively provided with a chuck which is used for clamping the material band and the needle. According to the invention, the stepping motor is used for driving the material receiving tray and the material band to move, and due to clamping friction of the material band and the needle, residual glue on the needle can be cleaned up, thus overcoming inconvenience of manual operation, realizing automatic cleaning of the needle, and greatly improving the working quality; and since a material rolling form is adopted, used material band can be recycled in rolls, pollution of the field due to production of rubbish can be avoided, and the cleanness of the working environment can be improved.

Owner:SUZHOU SECOTE PRECISION ELECTRONICS CO LTD

Building cement waste breaking and cleaning device

InactiveCN107930834AEasy to break and clean upAchieve double crushingSievingScreeningArchitectural engineeringEngineering

The invention discloses a building cement waste breaking and cleaning device, and relates to the technical field of building facilities. The device comprises a bottom plate, a breaking box is fixedlyconnected to the top of the bottom plate, a partition plate, a mounting plate and a supporting plate are fixedly connected between the two sides of the inner wall of the breaking box from top to bottom in sequence, a separation plate is arranged between the top of the partition plate and the inner wall of the breaking box, a separation plate is arranged between the bottom of the partition plate and the top of the mounting plate, and a separation plate is arranged between the bottom of the mounting plate and the top of the supporting plate. According to the building cement waste breaking and cleaning device, the breaking effect is greatly enhanced, the breaking efficiency is well improved, building cement can be sufficiently broken, one breaking device can automatically carry out two-time breaking, people do not need to waste a large amount of time for building cement block breaking, work burdens of the people are reduced, and the building cement blocks can be rapidly and efficiently broken.

Owner:HUANGHE S & T COLLEGE

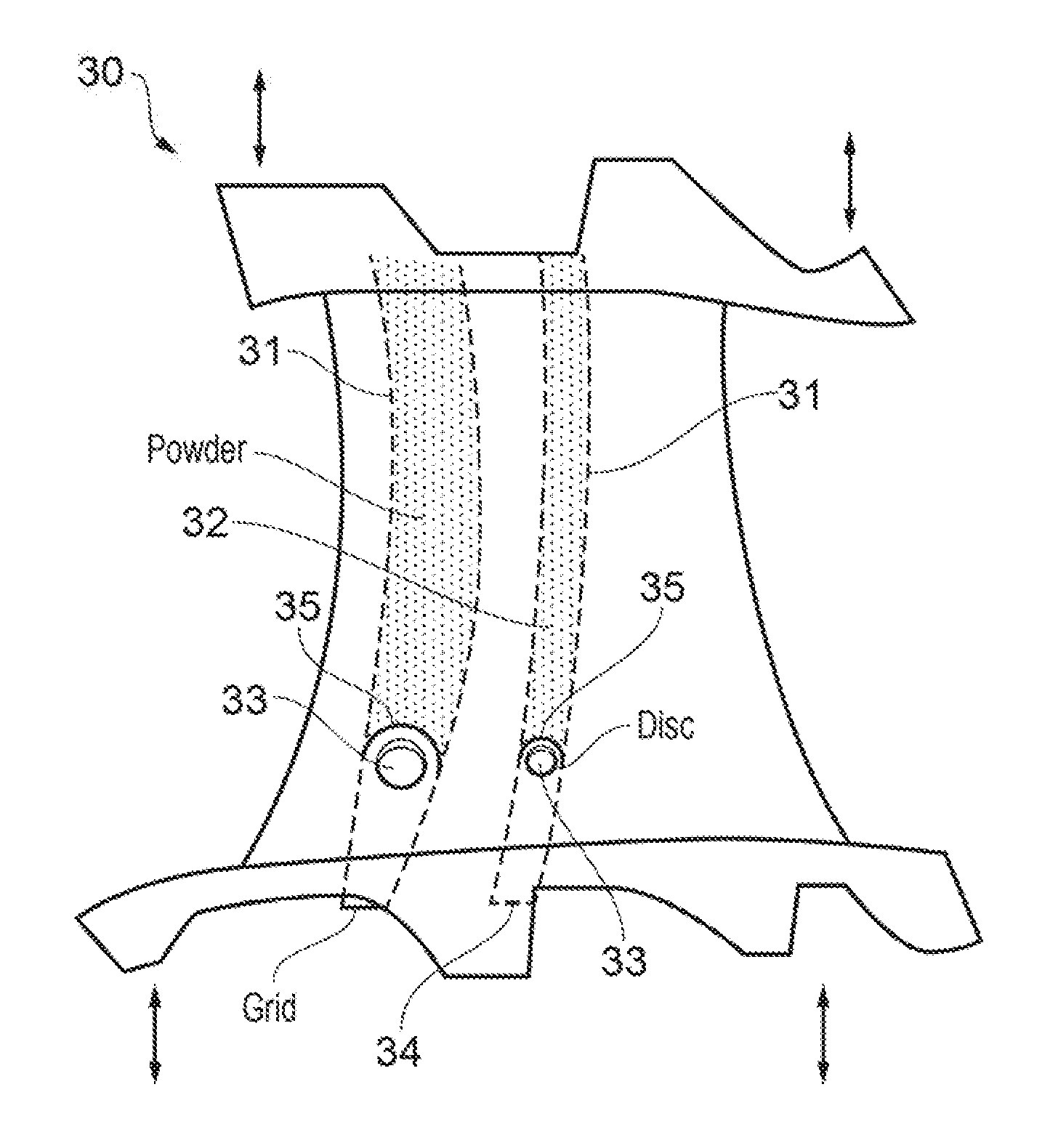

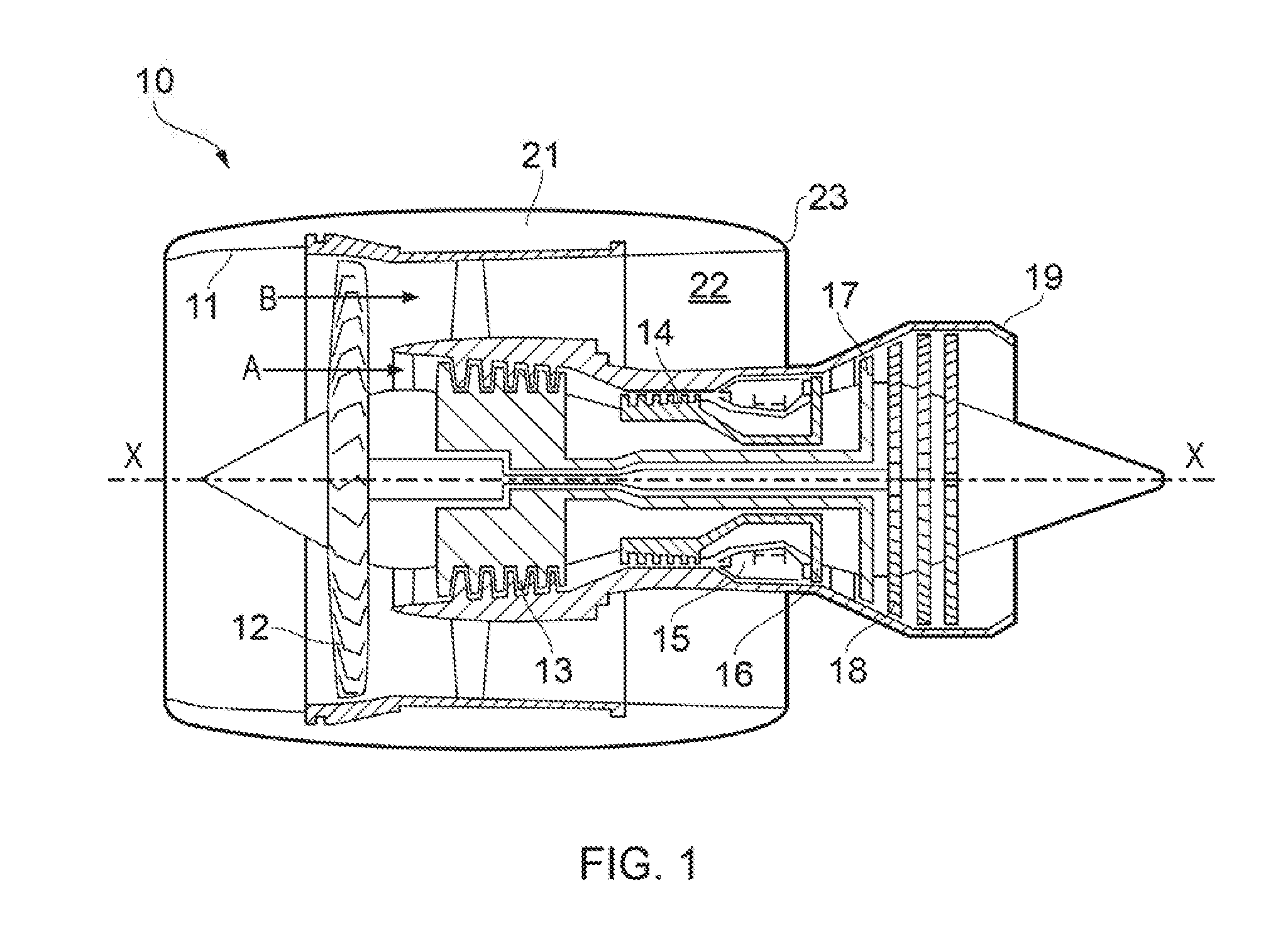

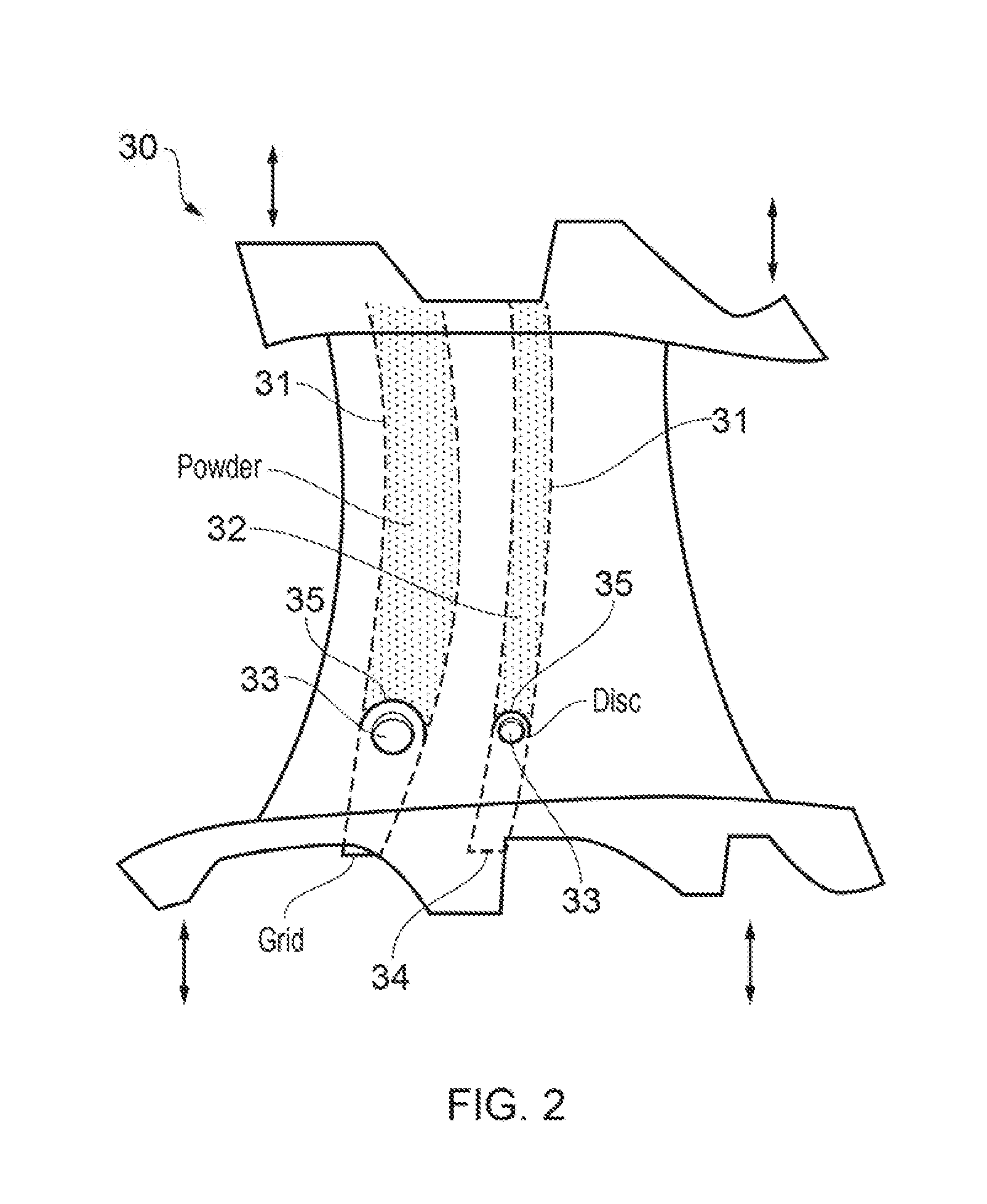

Methods of manufacturing and cleaning

ActiveUS20160228929A1Avoid contaminationAvoid damageAdditive manufacturing apparatusStatorsEngineeringGas turbines

Methods of cleaning internal portions of additively manufactured components are provided, together with an apparatus for carrying out the cleaning. The methods use an impacting element which is contained within the internal portion and the component is vibrated to clean material from the component and leave one or more hollow portions. Various embodiments for retaining the impacting element are set out, which preferably use a grid which allows loosened powder to fall out of the component and, optionally, be recycled for use in further manufacturing processes. The methods are described in relation to components for gas turbine engines but have wider application in relation to any additively manufactured component in which it is desired to have a hollow internal portion.

Owner:ROLLS ROYCE PLC

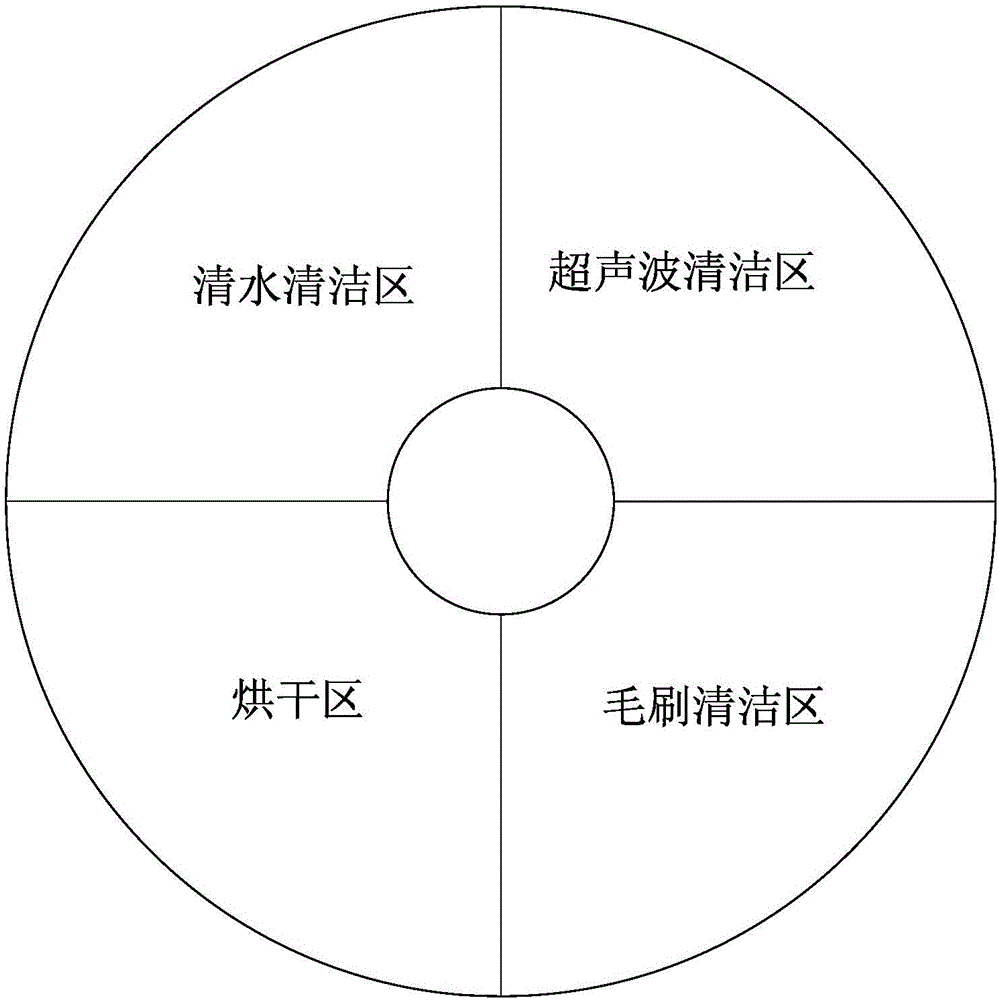

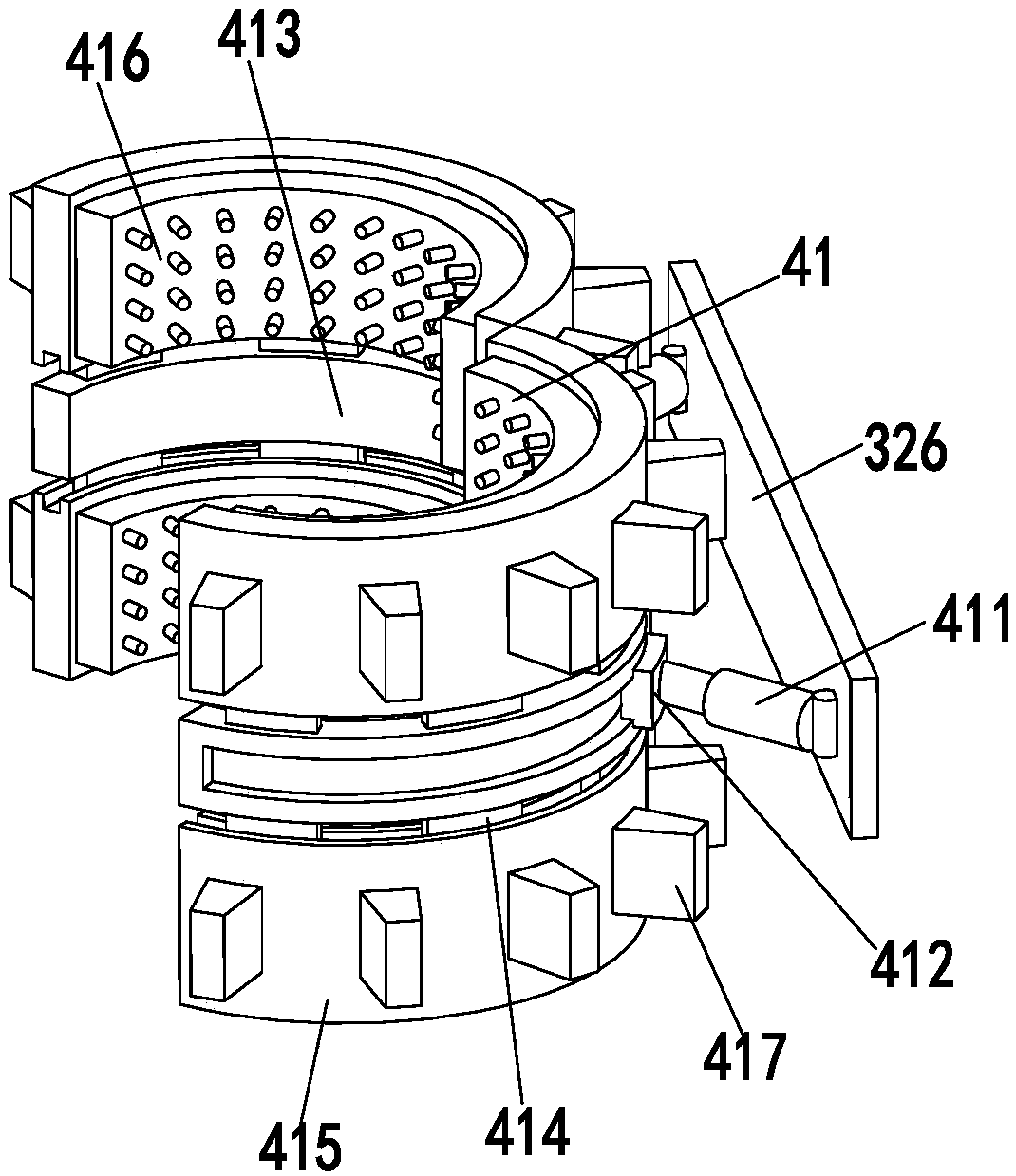

Automatic cleaning device for culture dishes

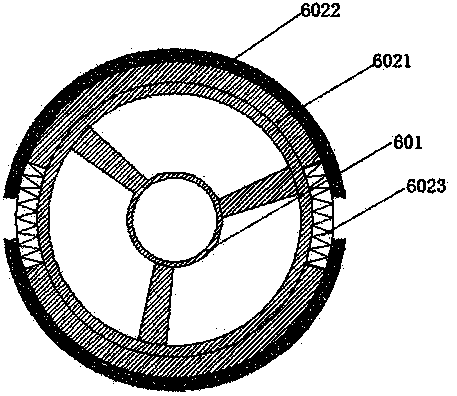

InactiveCN104138872AEasy to cleanUniform cleaning effectDrying solid materials with heatHollow article cleaningSpray nozzleThrough transmission

The invention provides an automatic cleaning device for culture dishes. The automatic cleaning device comprises a base and a rotary disc. A brush cleaning region, an ultrasonic cleaning region, a clear water cleaning region and a drying region are uniformly arranged on the base circumferentially, rotatable brushes are installed in the brush cleaning region, an ultrasonic generator is installed in the ultrasonic cleaning region, and a groove of the ultrasonic cleaning region is filled with an ultrasonic cleaning medium. Multiple high-pressure nozzles for spraying water to the culture dishes are installed in the clear water cleaning region, and water outlets are formed in a groove where the clear water cleaning region is located. An infrared generator is installed in the drying region. The rotary disc comprises a tray, a rotating shaft and a climbing mechanism. The hollowed-out tray is installed on the top of the rotating shaft through a turning arm, and the rotating shaft is driven by a driving motor and through transmission of a gear at the bottom end to rotate by 90 degrees every time. The automatic cleaning device has four stations, operation from cleaning to drying can be achieved in the device, basic functions of cleaning and washing can be achieved, the washing effect is better than a traditional manual washing effect, and the culture dishes are washed and cleaned more uniformly.

Owner:MAIZE RES INST SHANDONG ACAD OF AGRI SCI

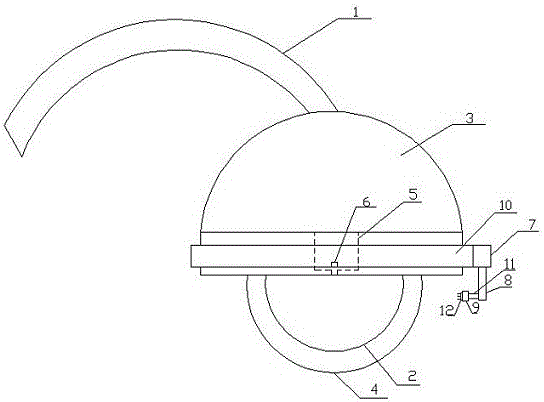

Circular surveillance camera with cleaning device

InactiveCN106534640ASimple structureEasy to operateTelevision system detailsColor television detailsGlass coverSurveillance camera

The invention discloses a circular surveillance camera with a cleaning device. The circular surveillance camera comprises a support. The end portion of the support is provided with a camera base; a camera is arranged under the camera base; the outer side of the camera is provided with a transparent protection cover; the camera base is hemispherical; the transparent protection cover is arranged on the camera base; the camera base is internally provided with a water storage cavity; the water storage cavity is internally provided with a water pipe leading to the transparent glass cover; the camera base is equipped with a cleaning base; the cleaning base is provided with a lift pole; the lift pole is provided with a hairbrush; and the hairbrush is driven to move so as to clean the transparent protection cover through the water storage cavity and the cleaning base. The circular surveillance camera is simple in structure, convenient to operate and capable of carrying out cleaning automatically.

Owner:芜湖赋兴光电有限公司

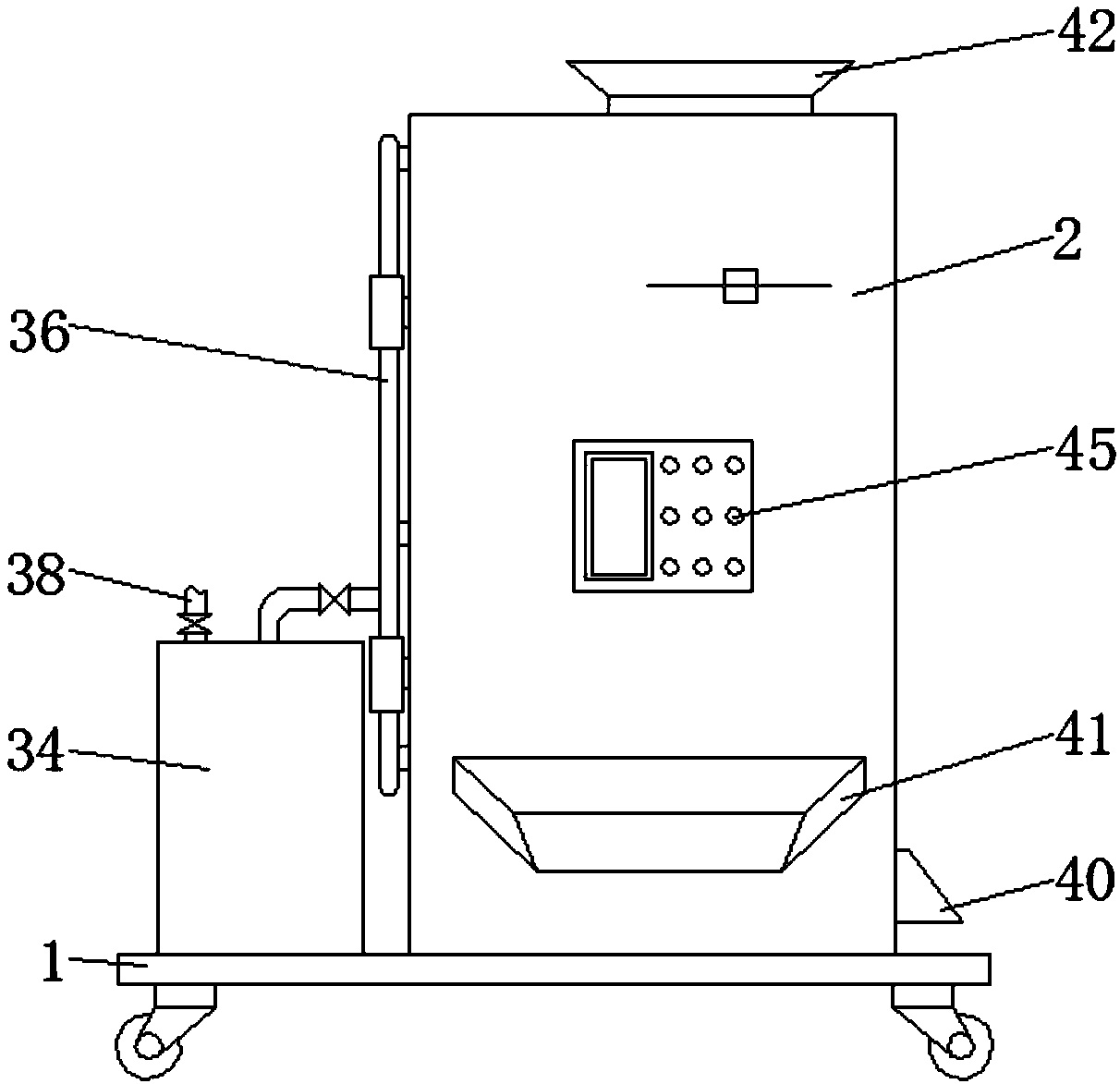

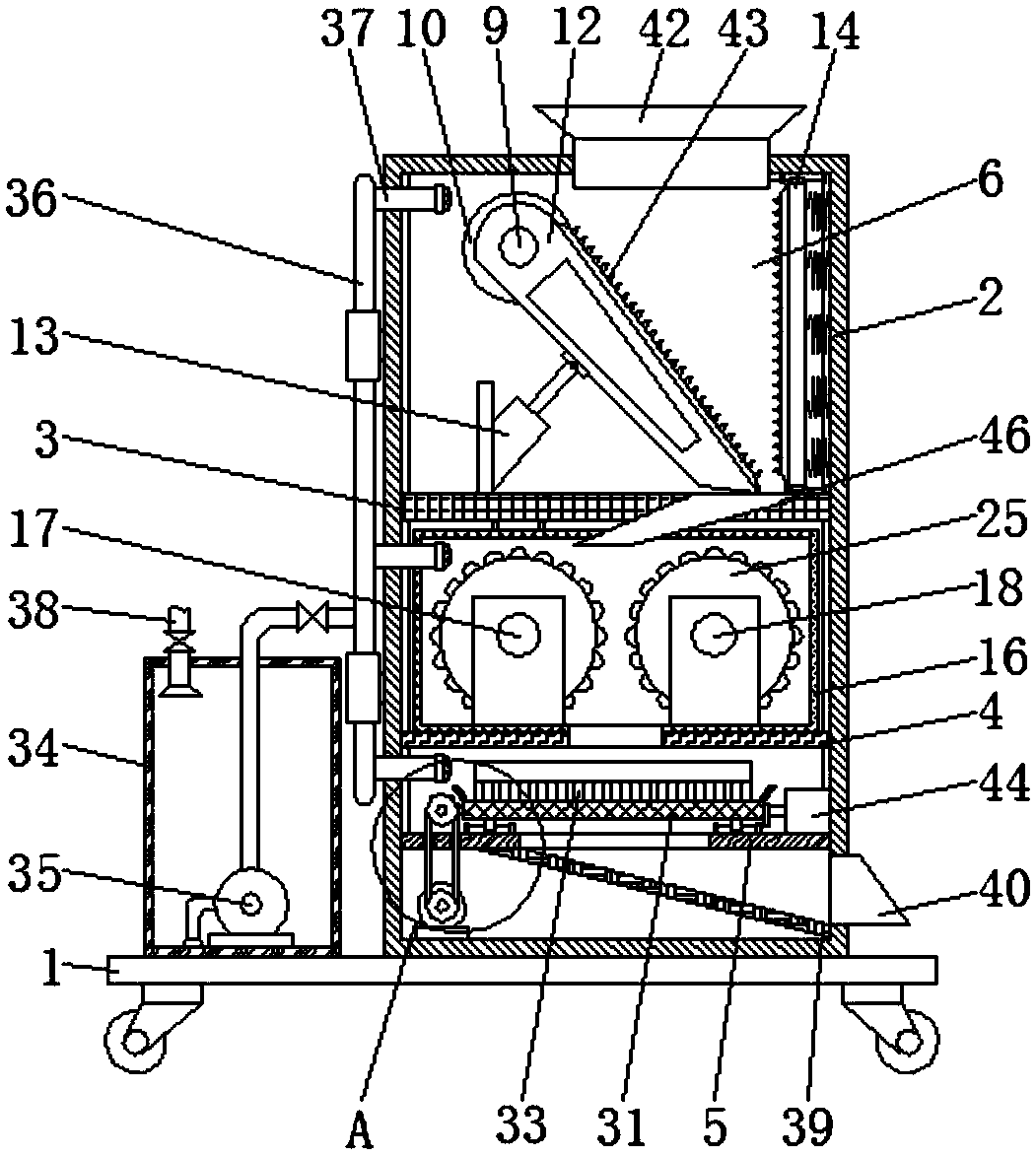

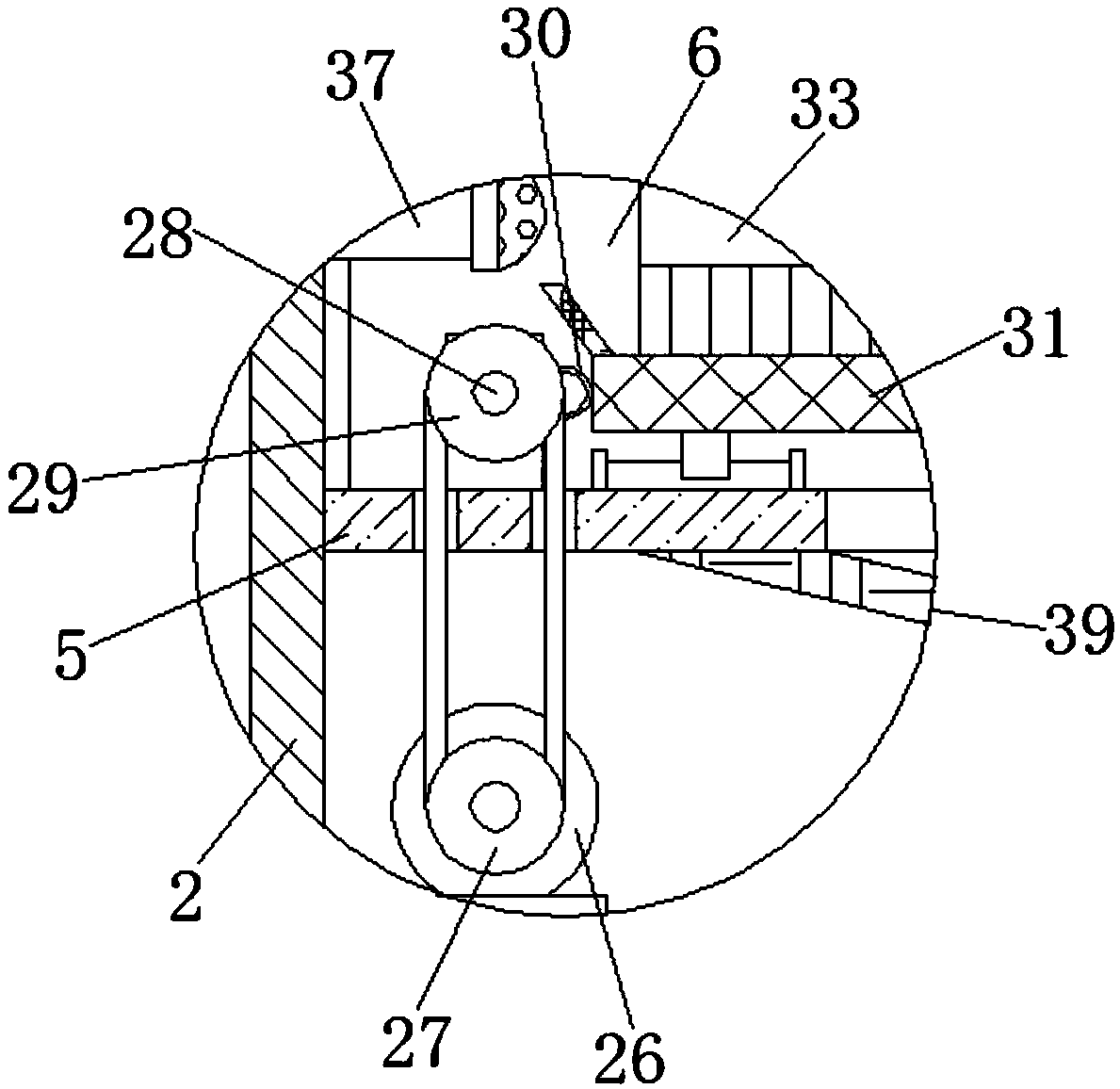

Ream-crushing device of death pig harmless treatment system

InactiveCN105833973AControl spreadGood sealingCleaning using toolsGrain treatmentsMechanical engineeringImpact hammer

The invention provides a ream-crushing device of a death pig harmless treatment system. The ream-crushing device of the death pig harmless treatment system comprises a feeding mechanism, a ream-cutting bin, a hammer-crushing bin and a crushing bin, wherein a cylindrical cutting disc is arranged in the ream-cutting bin; cutting blades are equidistantly arranged on the cutting disc in the axial direction; a fixed blade assembly is fixed on a side wall of the ream-cutting bin and is provided with a plurality of steel blades which are arranged equidistantly at intervals; the steel blades and the cutting blades are staggered; a discharging opening of the ream-cutting bin is connected with a feeding opening of the hammer-crushing bin in a communication manner; hammering cylinders are fixed on the outer side of the hammer-crushing bin; two rows of impacting hammers are horizontally arranged in the hammer-crushing bin; push rods of the hammering cylinders are connected with the impacting hammers and drive the impacting hammers to be close to one another; a discharging opening of the hammer-crushing bin is connected with a feeding opening of the crushing bin in a communication manner; two crushing rolls which are engaged with each other are arranged in the crushing bin; and a plurality of crushing teeth are uniformly distributed on each crushing roll. Three working procedures including ream-cutting, hammer-crushing and crushing are integrated, thorough crushing is implemented, a spindle of a motor cannot be jammed easily, and the crushing efficiency is high.

Owner:嘉兴星创科技有限公司

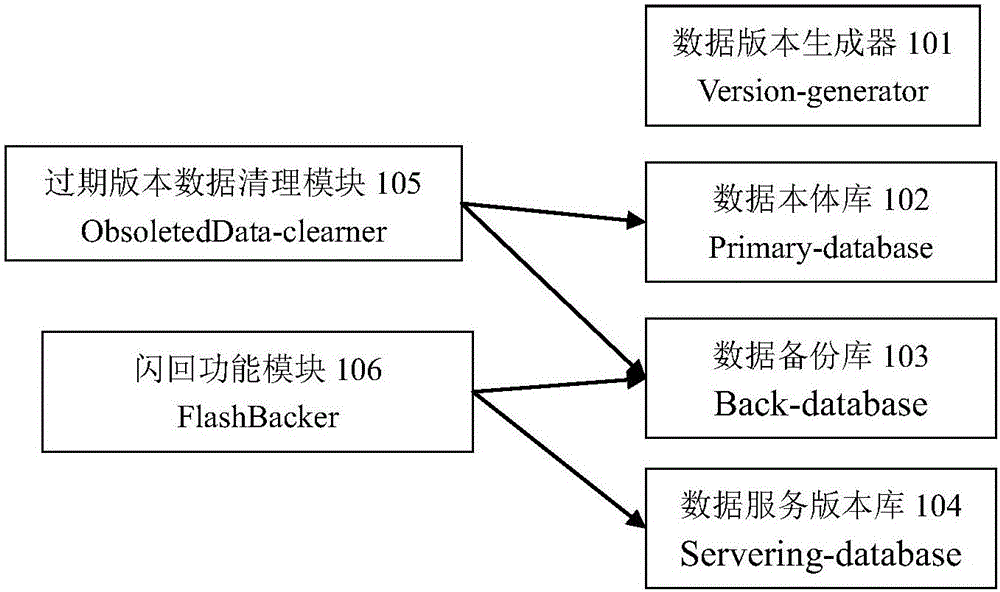

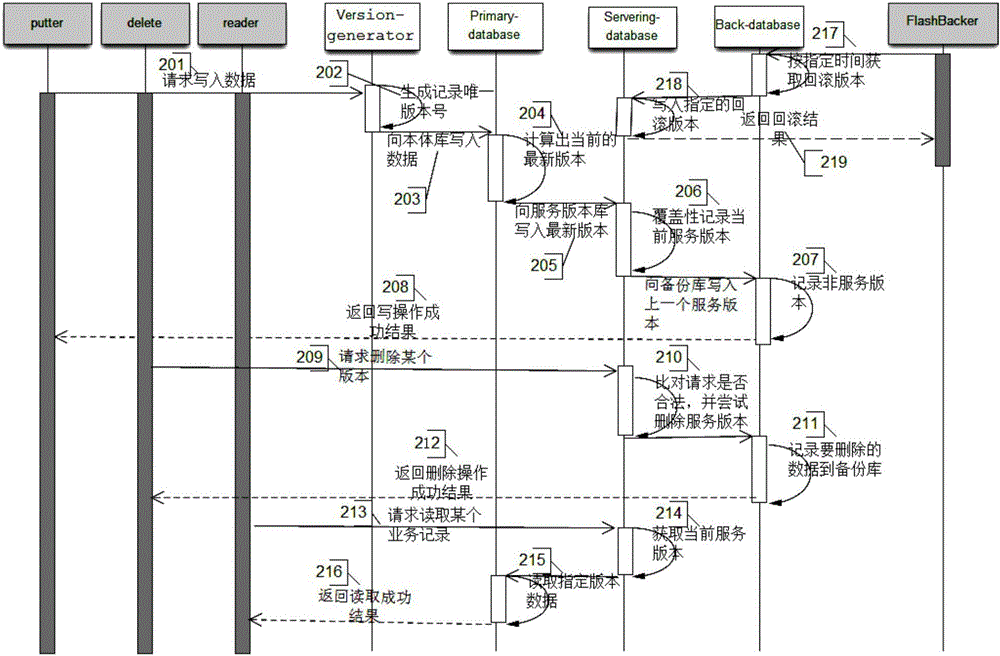

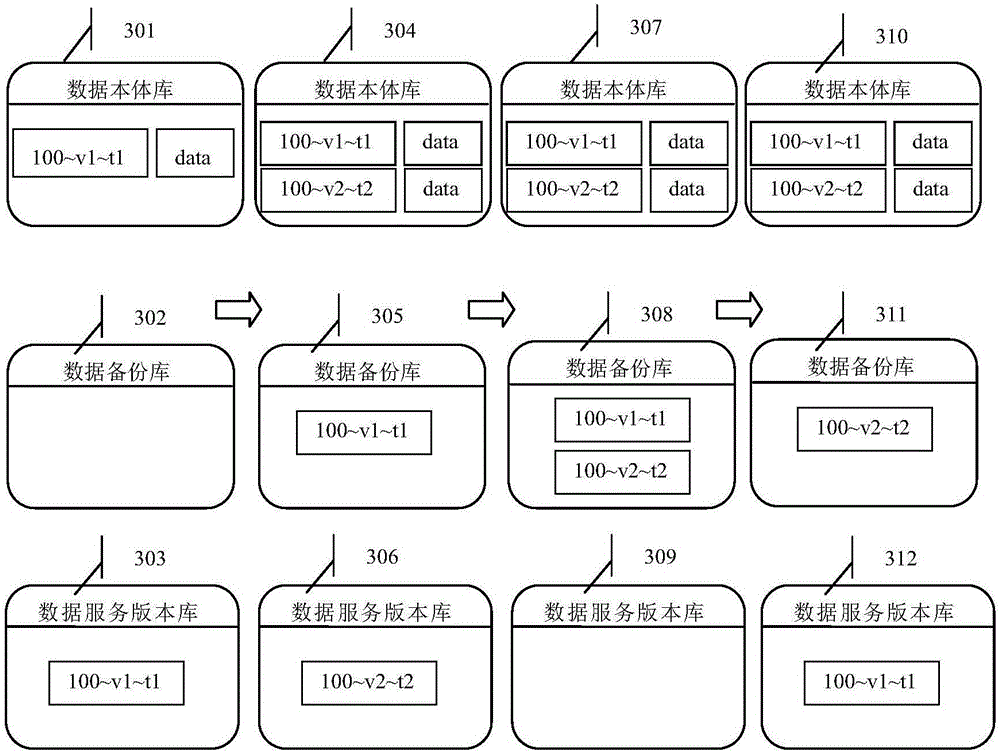

Flashback method and device of distributed object-based storage system

ActiveCN106484906AReversibleReduce complexitySpecial data processing applicationsData setData operations

A flashback method of a distributed object-based storage system is characterized by comprising the following steps: performing writing and reading of data of the distributed object-based storage system, data deleting data flashing bac, and deleting of outdated version data; constructing three data storing units, namely, a primary database, a back database and a servering database, based on a storage engine of a key-value data model; and performing data writing and reading, data deleting, data flashing back and deleting of outdated version data based on the three data storage units when a storage system receives a data operation request. With the adoption of the flashback method, the system complexity, increased by the flashback property, of the data can be greatly reduced, and a user can avoid the problems of additional data mirror server, serializing and deserializing of mirror files; a record-level previous version recovery mode is treated as the flashback mechanism, so that the data flashback process is only performed on a specified data set, and as a result, mis-operation can be avoided.

Owner:FOCUS TECH

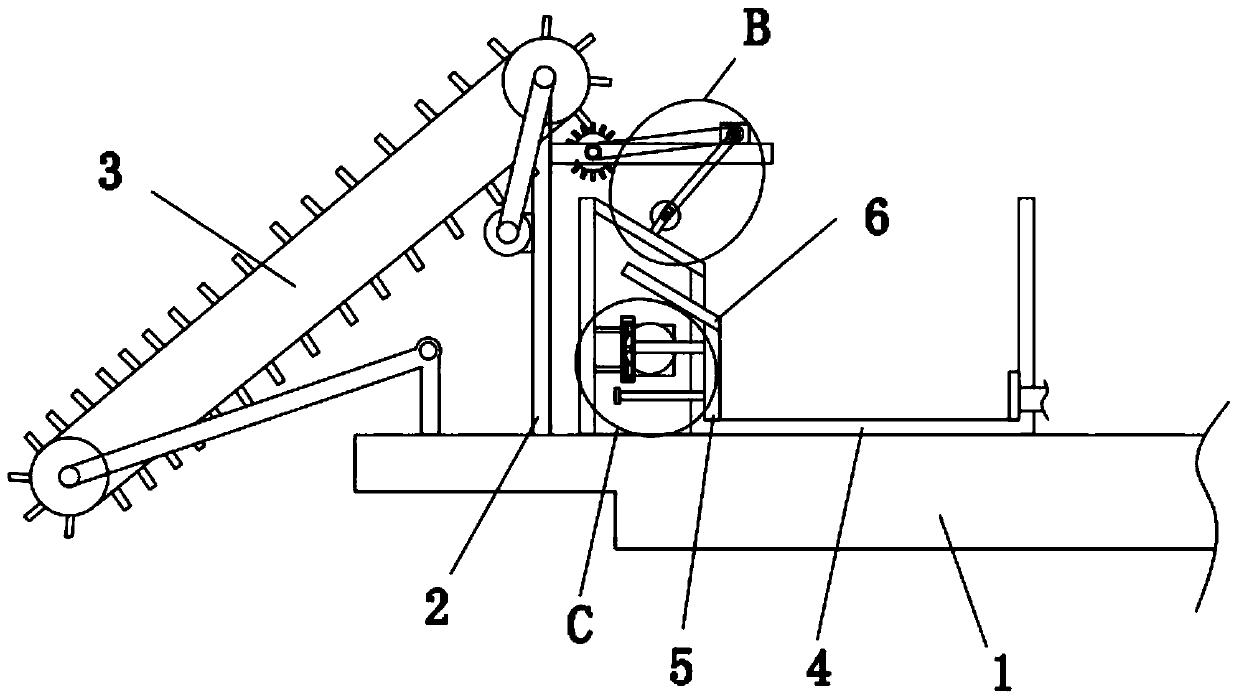

Refuse collecting ship

InactiveCN102041803AImprove collection and storage capacityReduce consumptionWater cleaningImpellerRefuse collection

The invention discloses a refuse collecting ship, which comprises a refuse collecting device and a refuse storing device, wherein the refuse collecting device comprises a tank body of which the middle is provided with a through hole; a motor is arranged above the tank body, the output shaft of the motor is linked with an impeller shaft, and the impeller shaft is arranged in the tank body and traverses the tank body; a plurality of blades are fixedly arranged on the outer circumference of the impeller shaft; an accommodating area is formed in the refuse storing device and is provided with a refuse inlet; a refuse compressing mechanism is arranged in the refuse storing device and drives a compressing plate to act; the refuse storing device is fixedly connected with the refuse collecting device; and the refuse inlet of the refuse storing device corresponds to an outlet of the through hole in the middle of the tan body. When used, the refuse collecting ship can be arranged on the conventional ship, and the conventional ship drives the refuse collecting ship to move in water so as to clean refuse in the water; and the refuse collecting ship also can work independently and is provided with a floating device to float on water surface and clean the refuse in the water simultaneously.

Owner:浙江机电职业技术学院

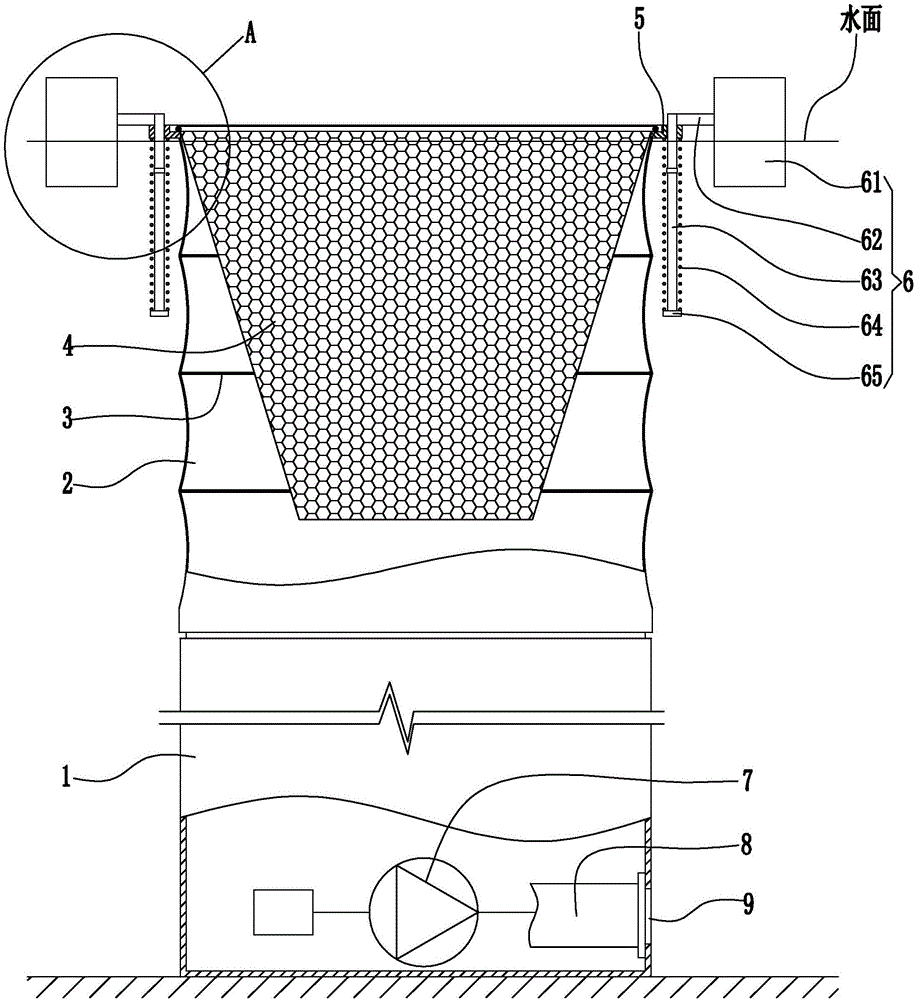

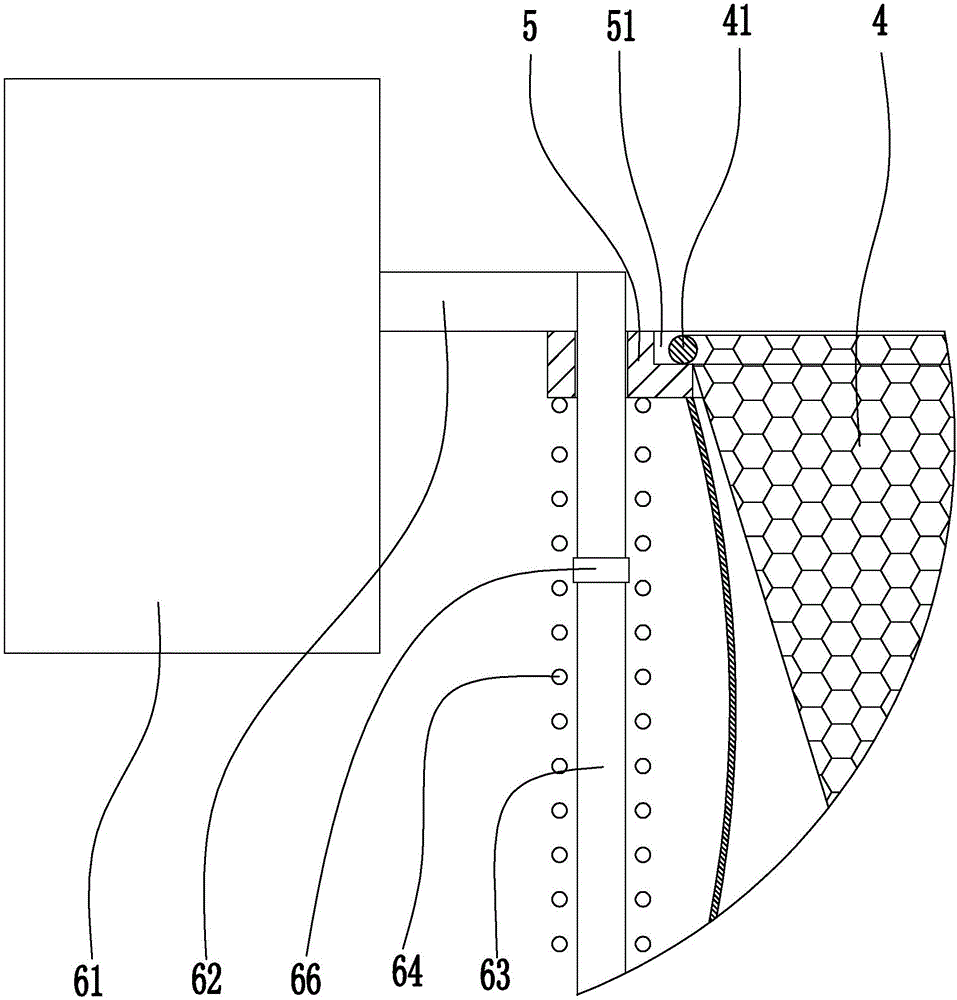

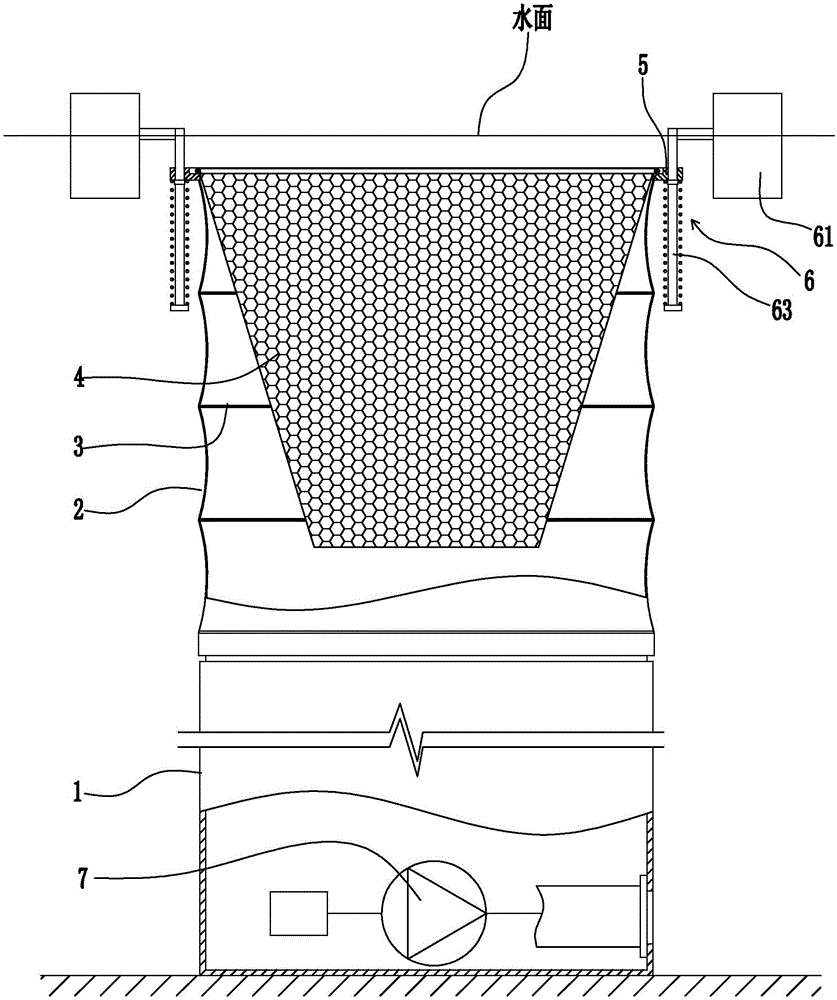

Suspended removal cleaning device for hydraulic engineering

InactiveCN111516815AReasonable designPrevent garbage from stickingWater cleaningWaterborne vesselsLeather beltStructural engineering

The invention belongs to the field of cleaning equipment, and especially relates to a suspended garbage removal device for hydraulic engineering. The device aims at the problem that an existing cleaning device is inconvenient to clean a belt conveying assembly, garbage is inconvenient to extrude, so that the collection amount is increased. The device comprises a hull, an installation frame is fixedly mounted at the top of the hull, a belt conveying assembly is fixedly installed on the installation frame, a collecting box is placed at the top of the hull, a push plate is slidably installed at the bottom of the collecting box, an inclined plate is fixedly installed at the top of the push plate and penetrates through the collecting box, a connecting plate is fixedly installed on one side of the installation frame, a first hole is formed in the connecting plate, and rotating rods are rotatably installed on the inner walls of the two sides of the first hole. The device is reasonable in design, garbage can be prevented from adhering to the belt conveying assembly through rotation and movement of a brush roller, the garbage can be extruded through rotation of a pressing roller, and the collection amount is increased.

Owner:耿纪鲜

Drainage manhole cover

ActiveCN106703171APrevent slipping outEasy to crushSewerage structuresSewer cleaningDraining tubeEngineering

The invention discloses a drainage manhole cover. The technical scheme mainly includes that according to the drainage manhole cover, when a vehicle passes the manhole cover, a drive column positioned in the center of the manhole cover is driven to generate vertical displacement, a blockage clearing sleeve generates vertical displacement through a fixed connection rod, and a blockage clearing knife is arranged on the inner side of the blockage clearing sleeve and extends into the inner side of a drainage pipe through a blockage clearing groove in the drainage pipe to move vertically, so that debris in the drainage pipe can be pulverized; since the blockage clearing knife is arranged and can move in the drainage pipe conveniently, excellent pulverizing effects are achieved; a shaking mechanism enables the drainage pipe to swing horizontally, so that the debris can be pulverized more easily and blockage prevention is achieved. The drainage manhole cover solves the problem that an existing manhole cover drainage hole needs to be cleaned manually when being blocked and can achieve automatic cleaning, so that water can be drained more quickly in rainy seasons.

Owner:台州四野园林工程有限公司

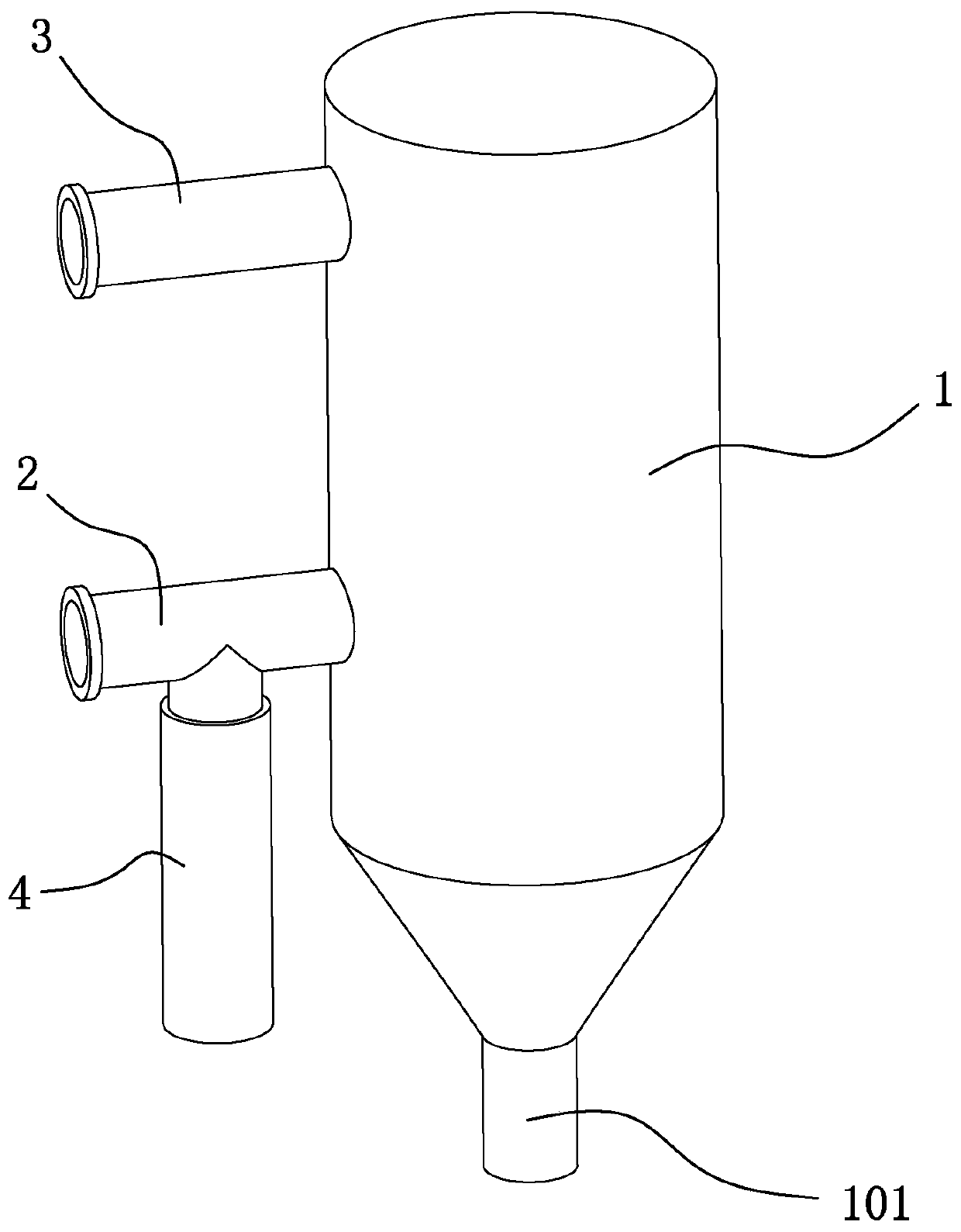

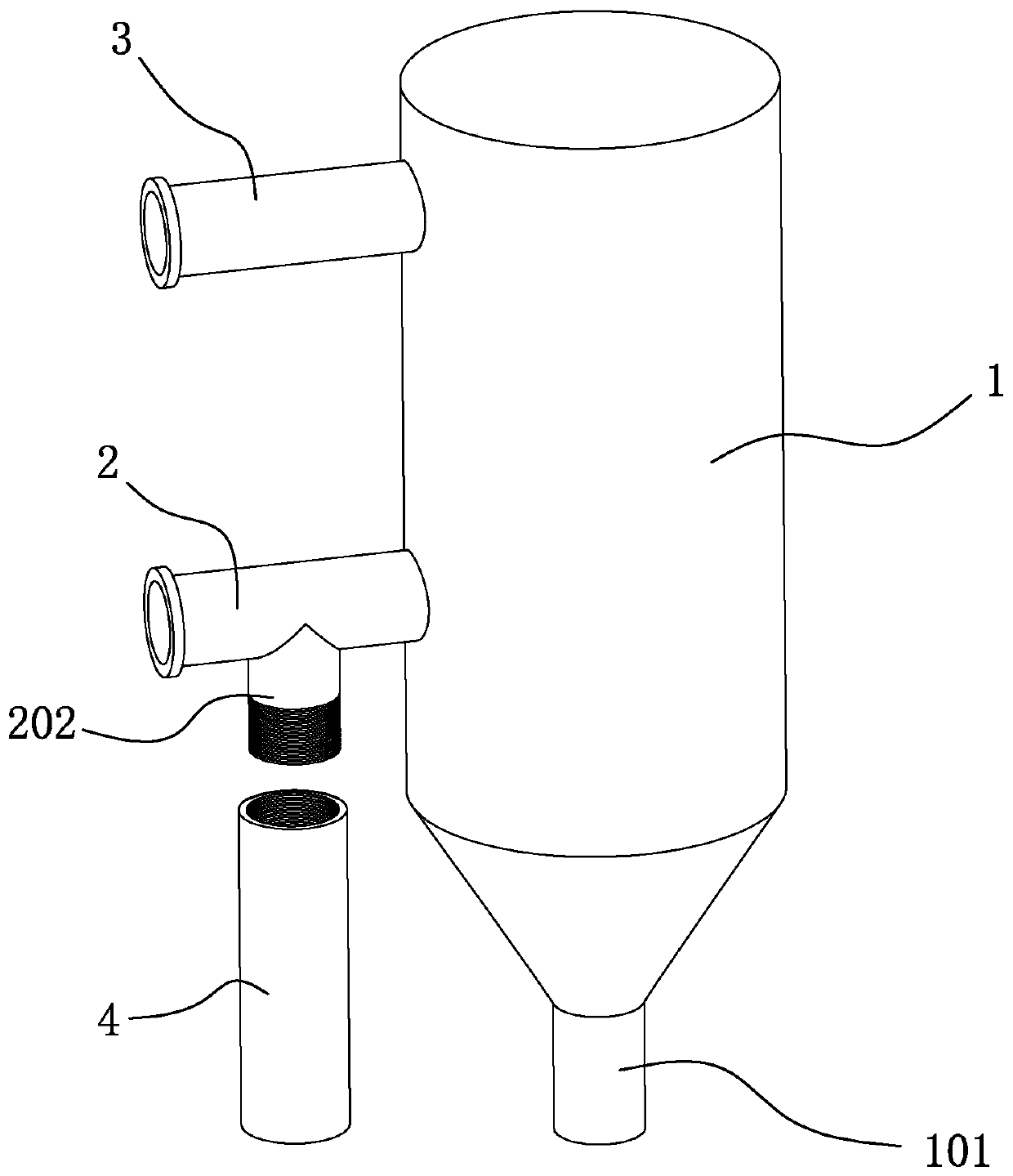

Liquid core-type filter

InactiveCN104162302AAutomate cleaningReduce lossesStationary filtering element filtersLiquid coreSlag

The invention discloses a liquid core-type filter comprising a cylinder body and a filter screen; the filter screen is arranged in the cylinder body; the upper end of the cylinder body is provided with a feed port, the lower end of the cylinder body is provided with a discharge port, and the lower end of the cylinder body is provided with a triangular supporting frame for supporting the cylinder body on the ground; the outer side of the filter screen is provided with an annular supporting cylinder, and the wall of the supporting cylinder is provided with a plurality of uniform-distribution liquid flowing holes; the filter screen is close to the inner wall of the supporting cylinder, a plurality of fixing bars are arranged on the inner side of the filter screen and tightly press the filter screen on the inner wall of the supporting cylinder, and the filter screen is internally provided with a rotary cleaning scraping plate mechanism. The liquid core-type filter overcomes the defects of the prior art, and is reasonable in design and compact in structure; the cylinder body interior is subjected to a special structural design, and the filter screen is fixed at the middle of the cylinder body and is provided with the rotary scraping plate mechanism, so that automatic cleaning and slag scraping can be achieved, online operation is achieved, liquid loss is less, and the production efficiency is improved.

Owner:安徽融创化工科技股份有限公司

Dust-extraction device special for electric control cabinet

InactiveCN106493104AAutomate cleaningAvoid secondary fallsDirt cleaningCleaning using toolsEngineeringElectric control

The invention discloses a dust-extraction device special for an electric control cabinet. The dust-extraction device comprises a foundation, wherein an adjusting base is fixedly connected to the center of the upper surface of the foundation, an adjusting groove is formed in the inner part of the adjusting base, an adjusting rod is slidably connected to the inner part of the adjusting groove, a movable base is fixedly connected to the upper surface of the adjusting rod, a movable groove is formed in the inner part of the movable base, a movable rod is slidably connected to the inner part of the movable groove, a sweeping base is fixedly connected to the surface of a rear end of the movable rod, a cleaning hole is formed in the outer surface of the sweeping base, a cavity is formed in the inner part of the sweeping base, bearing pedestals are fixedly arranged on both the upper surface and the lower surface of the cavity, and a sweeping head is fixedly connected to the lower surface of a rotating shaft. According to the dust-extraction device special for the electric control cabinet, the foundation can be fixed on the electric control cabinet through clamping blocks connected by threads, not only efficiency and an adaptive surface of cleaning can be greatly improved, but also safety can be effectively guaranteed.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO LONGKOU POWER SUPPLY CO

Mechanical arm and mechanical arm system

The invention relates to the technical field of mechanical arms, in particular to a mechanical arm and a mechanical arm system. The mechanical arm comprises at least one suction cup and further comprises an air channel conversion mechanism; the air channel conversion mechanism comprises a shell internally provided with a cavity and a switch assembly installed in the cavity; the shell is further provided with a first air vent, a second air vent and a third air vent, wherein the first air vent, the second air vent and the third air vent are communicated with the cavity, the first air vent is communicated with the third air vent to form a first air flow channel, the second air vent is communicated with the third air vent to form a second air flow channel, and the third air vent is communicated with each suction cup through a connecting pipe. The mechanical arm can automatically clean foreign matter in a connecting air pipe and the suction cup.

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

Wall surface clearing robot special for building decoration material cement fiber boards

InactiveCN107811589ASolve labor intensitySolve the costCarpet cleanersCleaning action controlFiberBrush device

The invention relates to a special wall cleaning robot for cement fiberboard, a building decoration material, which includes a lifting platform, a bottom plate, a filling device, a leveling device and a brushing device. A leveling device is installed, and a brushing device is installed at the rear end of the bottom plate. The number of filling devices is three, and the three filling devices are evenly installed at the front end of the bottom plate. Each filling device includes a placing frame, a fixing plate, a pushing cylinder, a sliding plate, and a dividing frame , fixed frame, adjusting cylinder, electric slide table, lifting cylinder, lifting frame, traction electric push rod, sliding frame and spray gun. The invention can solve the problems of high labor intensity, high labor cost, potential safety hazards, complicated operation, uneven filling and low work efficiency existing in the existing cement fiberboard wall surface cleaning technology, and can realize cleaning of the cement limit board wall surface. Automatic cleaning function.

Owner:储田生

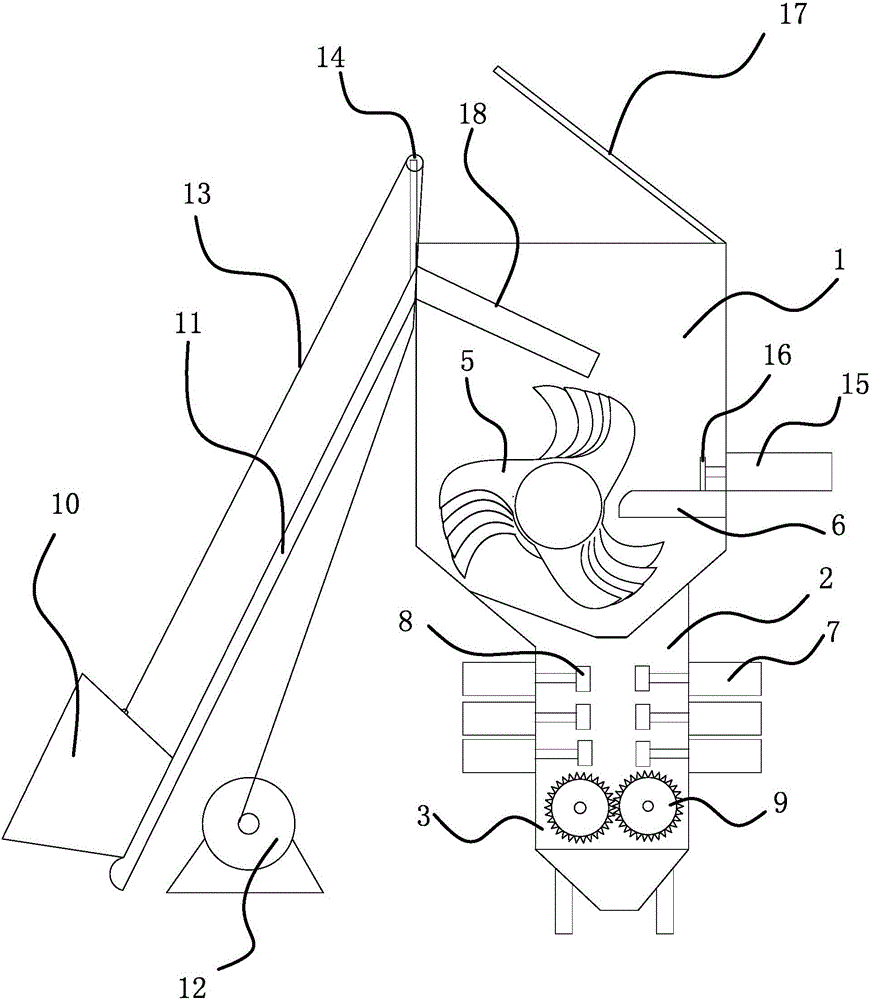

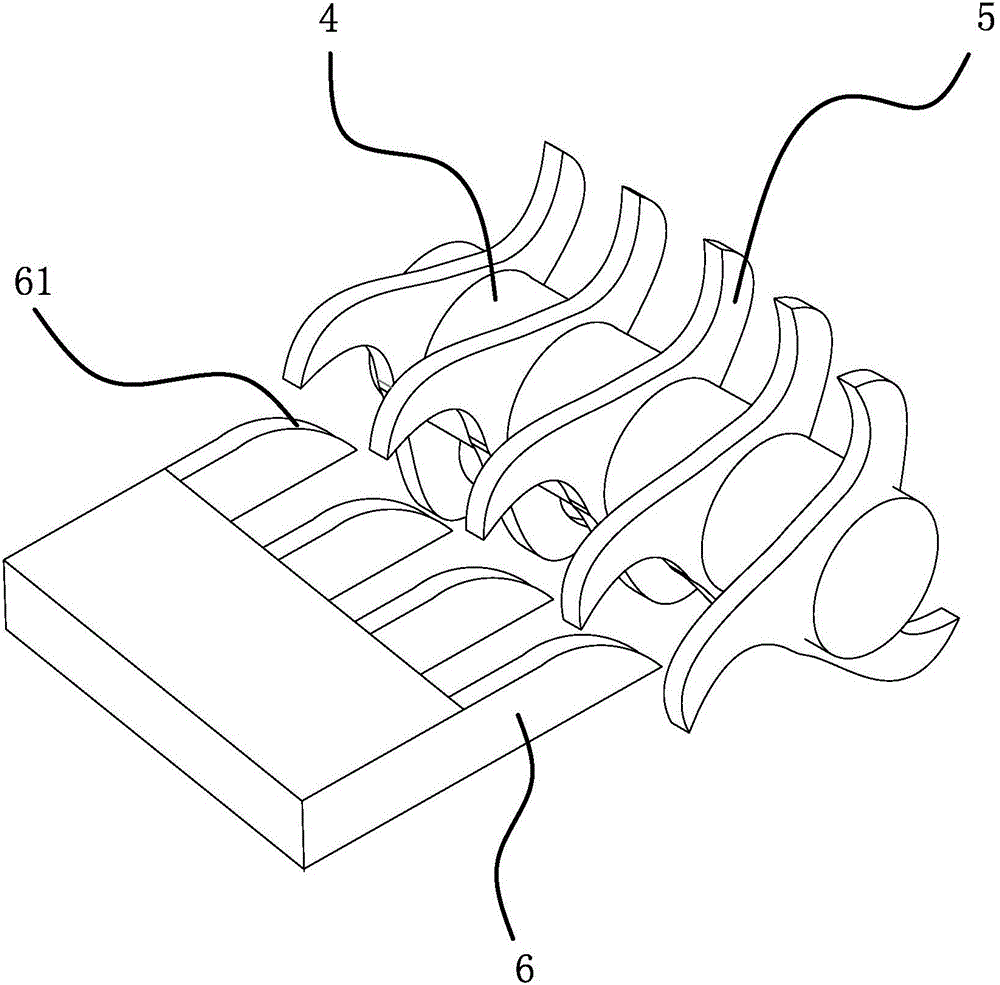

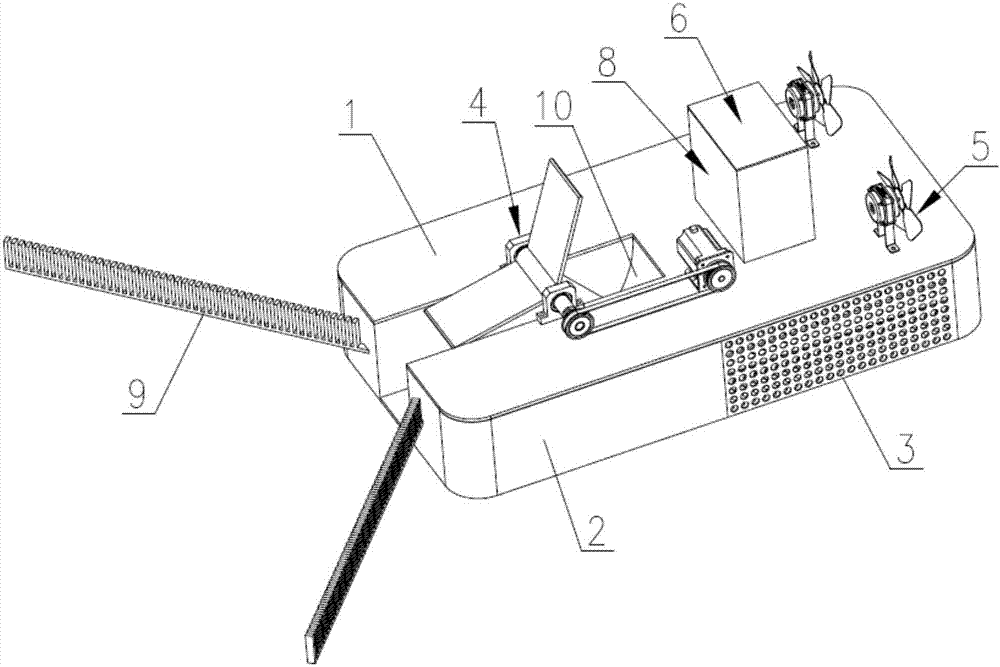

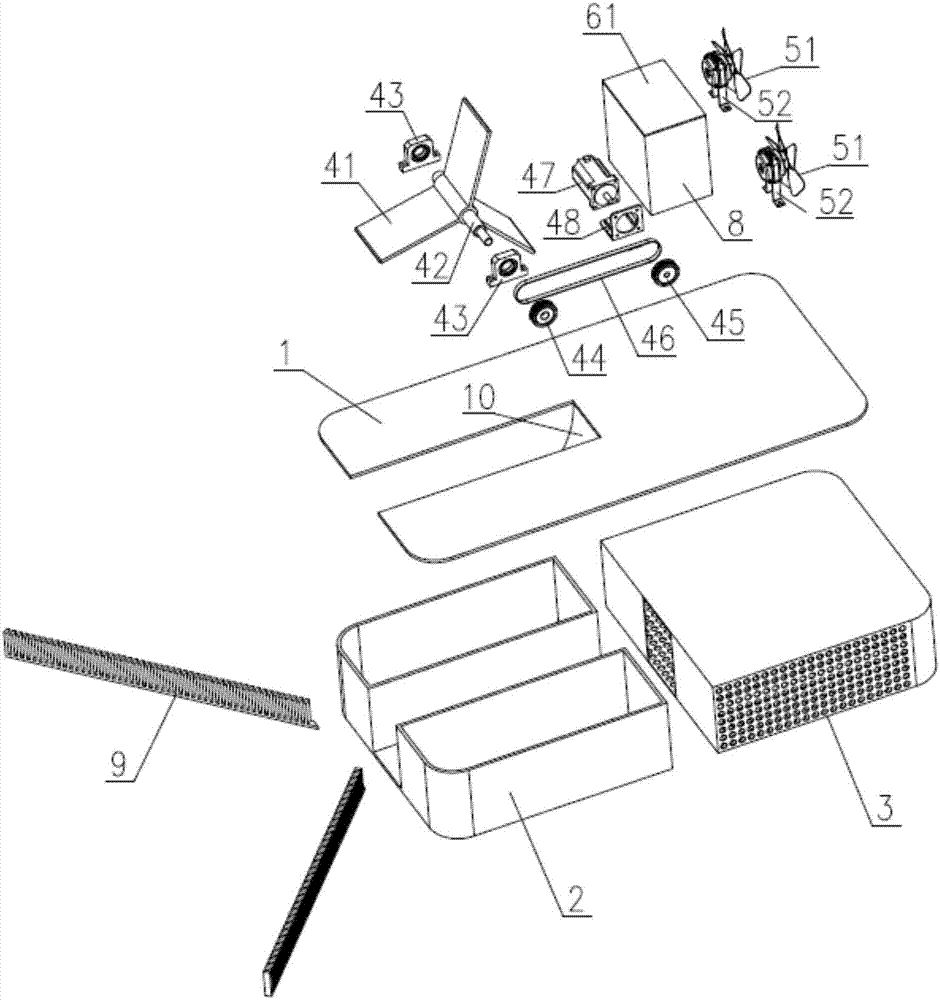

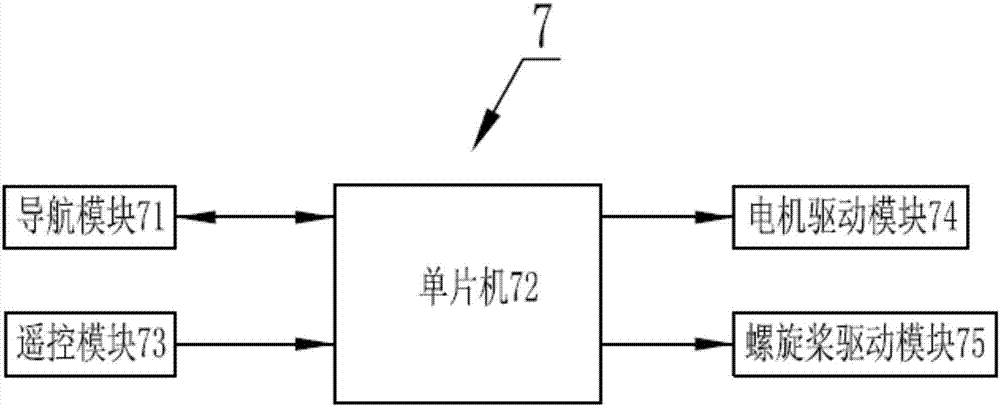

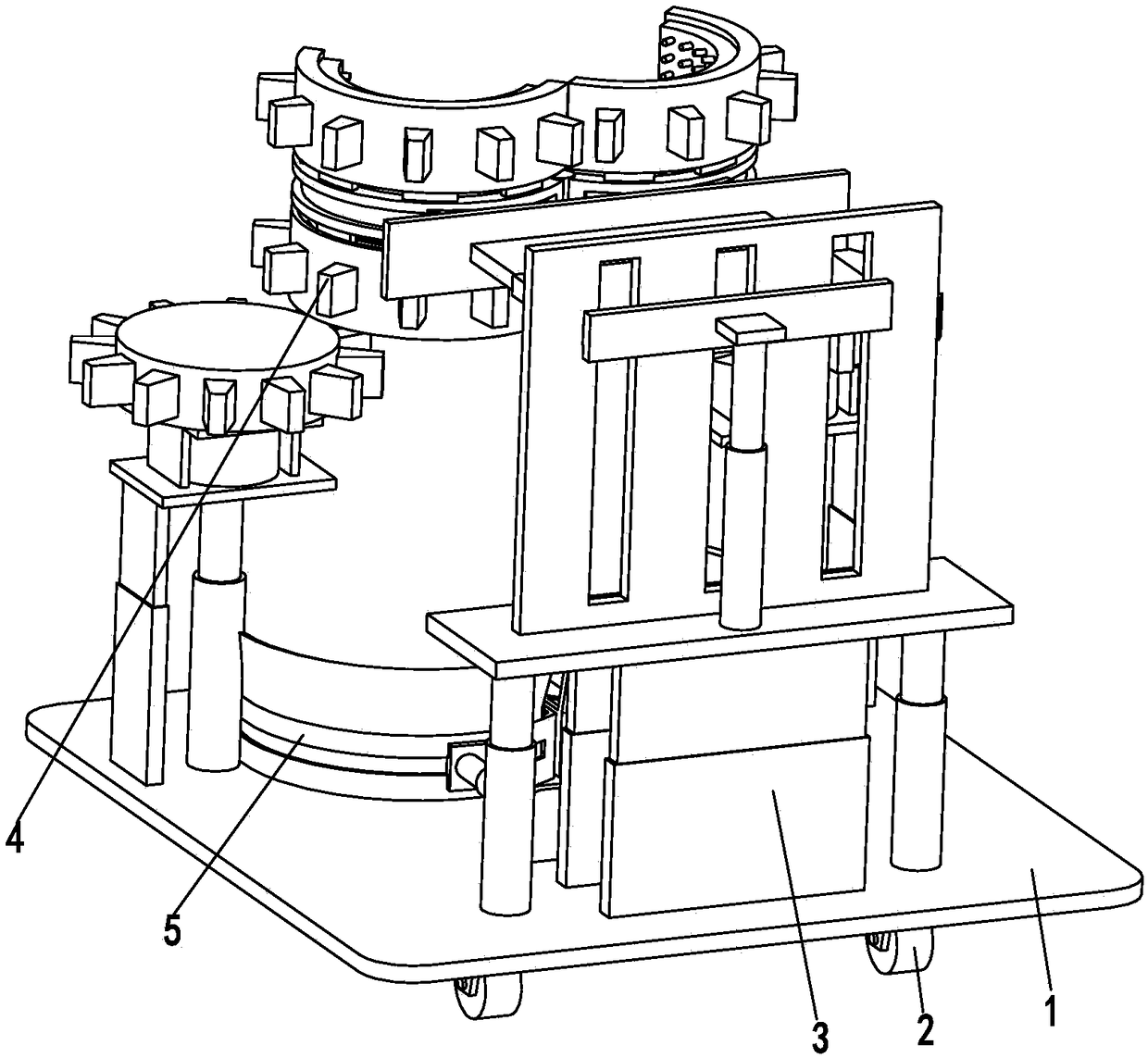

Water surface floating garbage collecting device and method

PendingCN107985519ASimple structureLow costWater cleaningAir acting propulsive elementsElectric energyMaterial resources

The invention provides a water surface floating garbage collecting device. The water surface floating garbage collecting device comprises a panel (1), a float box (2), a garbage storage box (3), a garbage collecting mechanism (4), a power driving mechanism (5), an electric energy supply module (6) and a central processing module (7). The float box (2) is mounted at the front bottom of the panel (1), the garbage storage box (3) is mounted at the rear bottom of the panel (1), the garbage collecting mechanism (4) is mounted on the front upper surface of the panel (1), the power driving mechanism(5) is mounted on the rear upper surface of the panel (1), and the electric energy supply module (6) and the central processing module (7) are mounted on the panel (1). The electric energy supply module (6) is used for supplying power to the garbage collecting mechanism (4), the power driving mechanism (5) and the electric energy supply module (6), and the central processing module (7) is used fortransceiving signals and controlling operations of the garbage collecting mechanism (4) and the power driving mechanism (5). The invention further provides a water surface floating garbage collectingmethod. The water surface floating garbage collecting device and the water surface floating garbage collecting device have advantages of structural simplicity, low cost, automation in clearing and saving of manpower and material resources.

Owner:HUNAN UNIV OF SCI & TECH

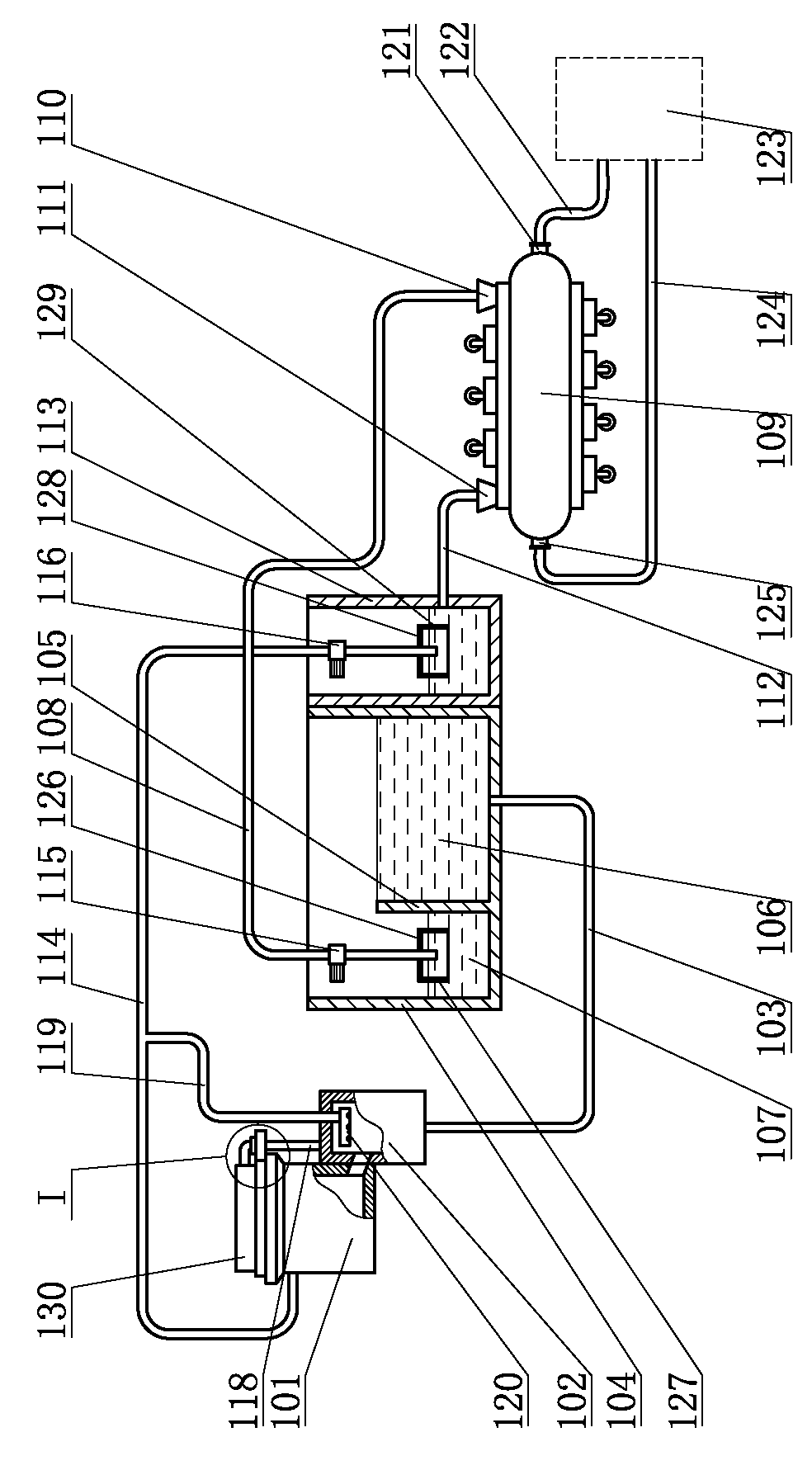

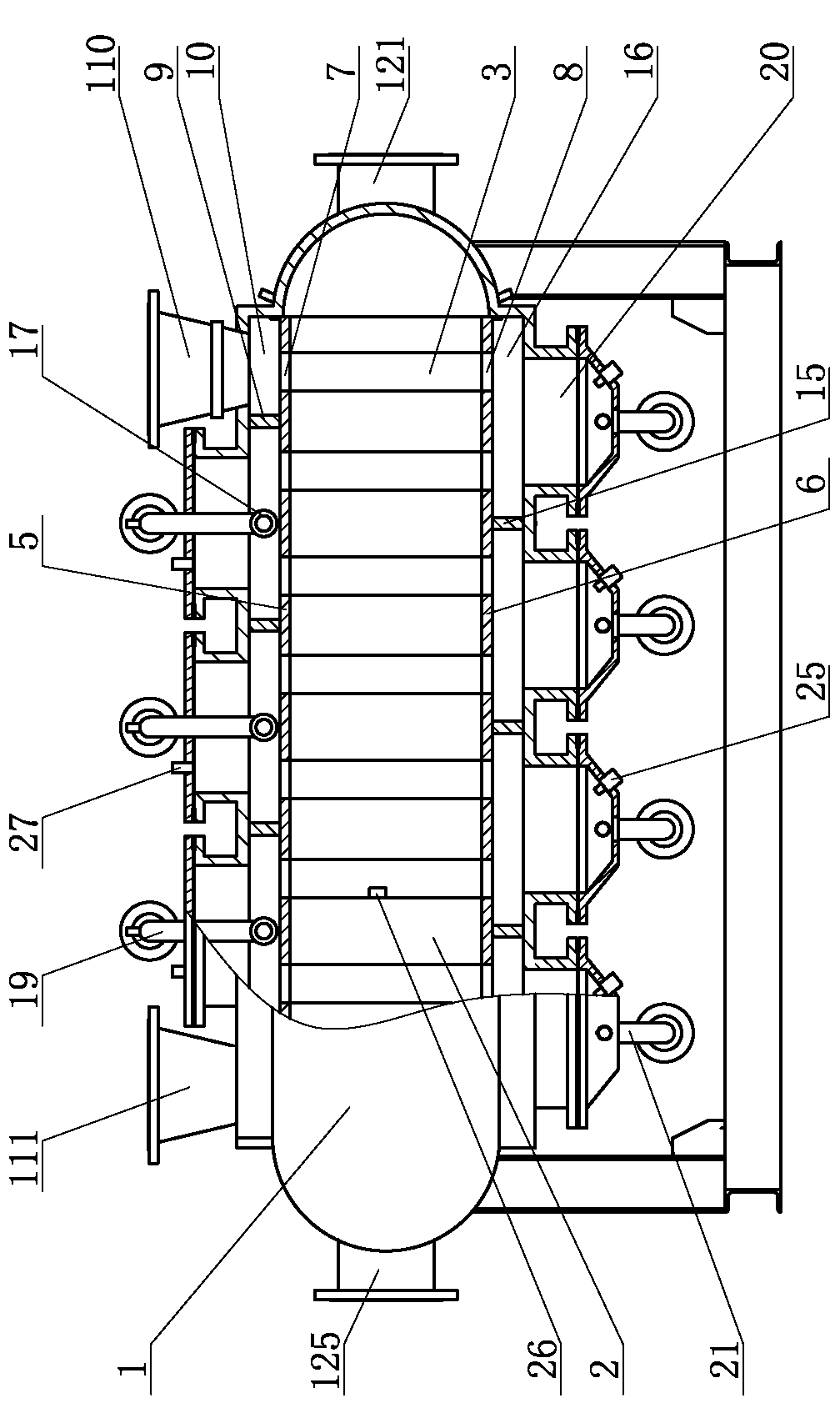

Disintegrating slag afterheat utilizing system

The invention discloses a disintegrating slag afterheat utilizing system. The disintegrating slag afterheat utilizing system comprises a disintegrating slag tank, wherein a deslagging port at the bottom of the disintegrating slag tank is communicated with a slag sluice, the disintegrating slag tank is communicated with the top of the slag sluice through a steam discharge pipe, the slag sluice is communicated with a sedimentation tank, an overflow baffle plate is arranged in the sedimentation tank, a hot water supplying and feeding pipe is arranged in the sedimentation tank and is connected with a heating water heat exchange device which is communicated with a cold water pond, a cold water supplying and feeding pipe is arranged in the cold water pond and is connected with the disintegrating slag tank, a spraying branch pipe is arranged on the cold water supplying and feeding pipe and is connected with a spraying pipe in the slag sluice, and the heating water heat exchange device is connected with a heating unit. The disintegrating slag afterheat utilizing system has the advantages of being free of influence of impurities in disintegrating slag water, being capable of recycling heat in disintegrating slag water, being contributed to saving of energy sources, reducing the pollution of iron and steel enterprises to environments, and recycling heat for heating so that the heating expenses of enterprises are saved.

Owner:JIGANG INT ENG & TECH CO LTD

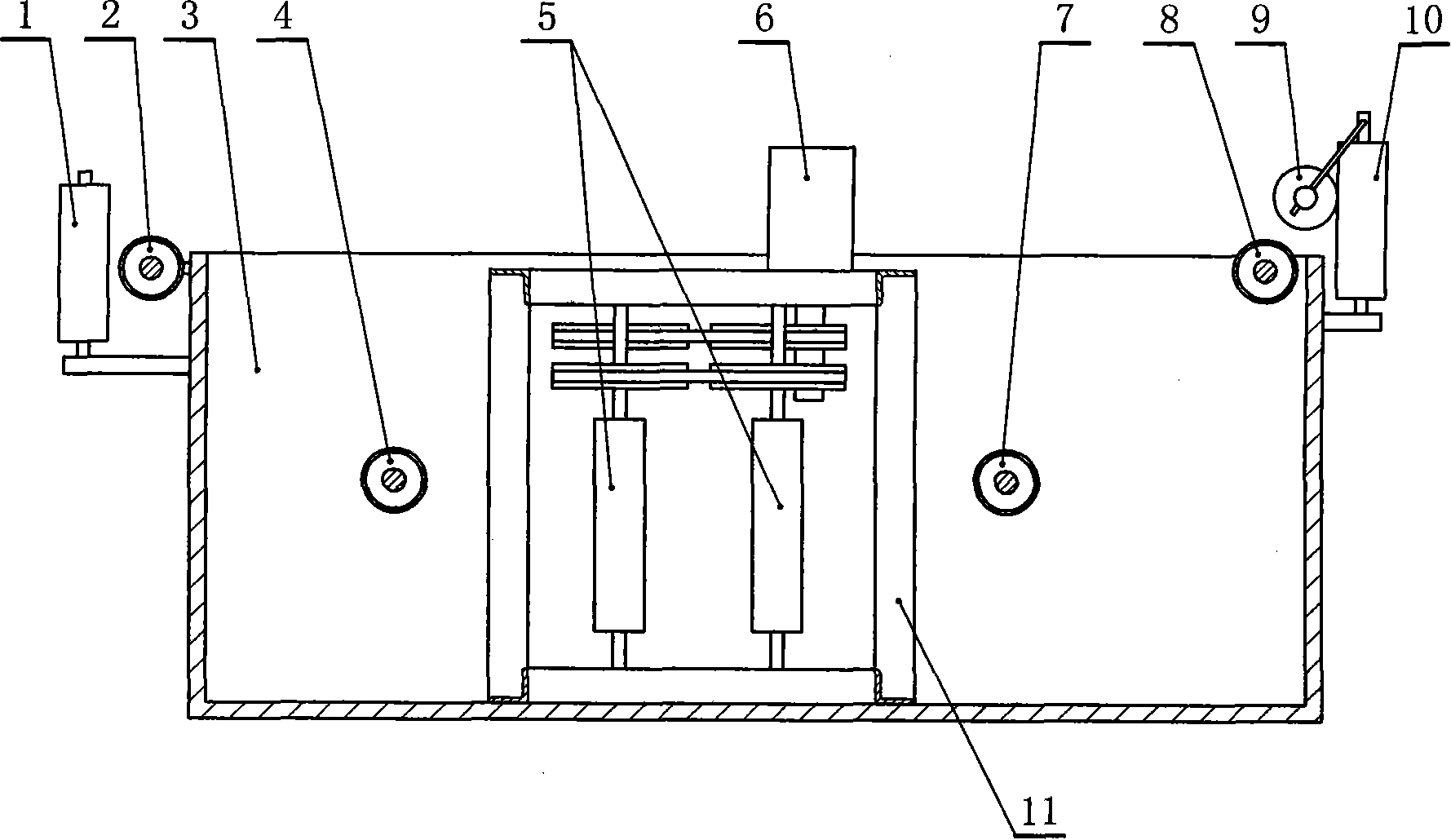

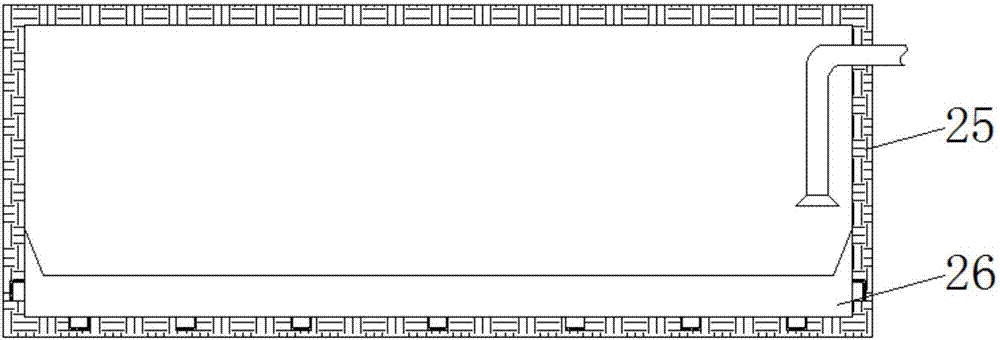

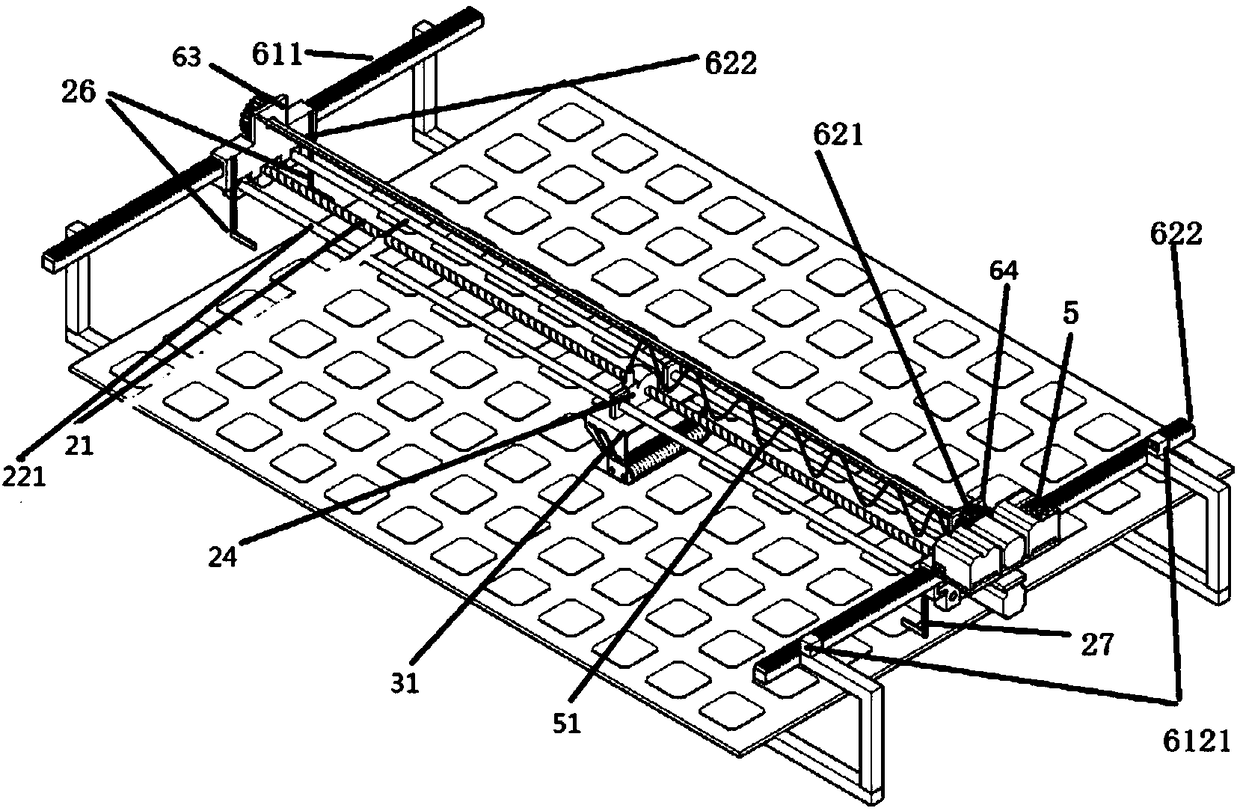

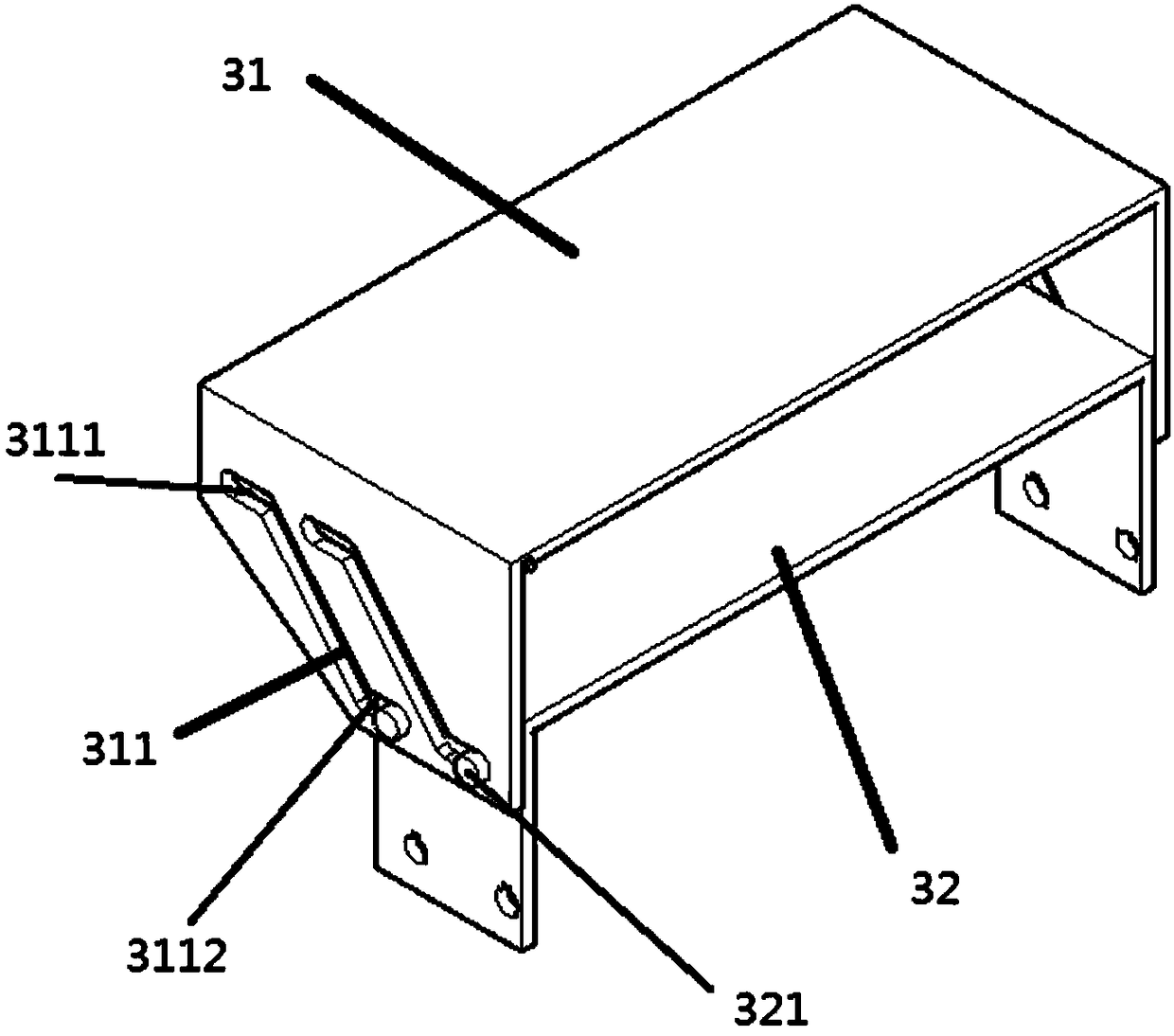

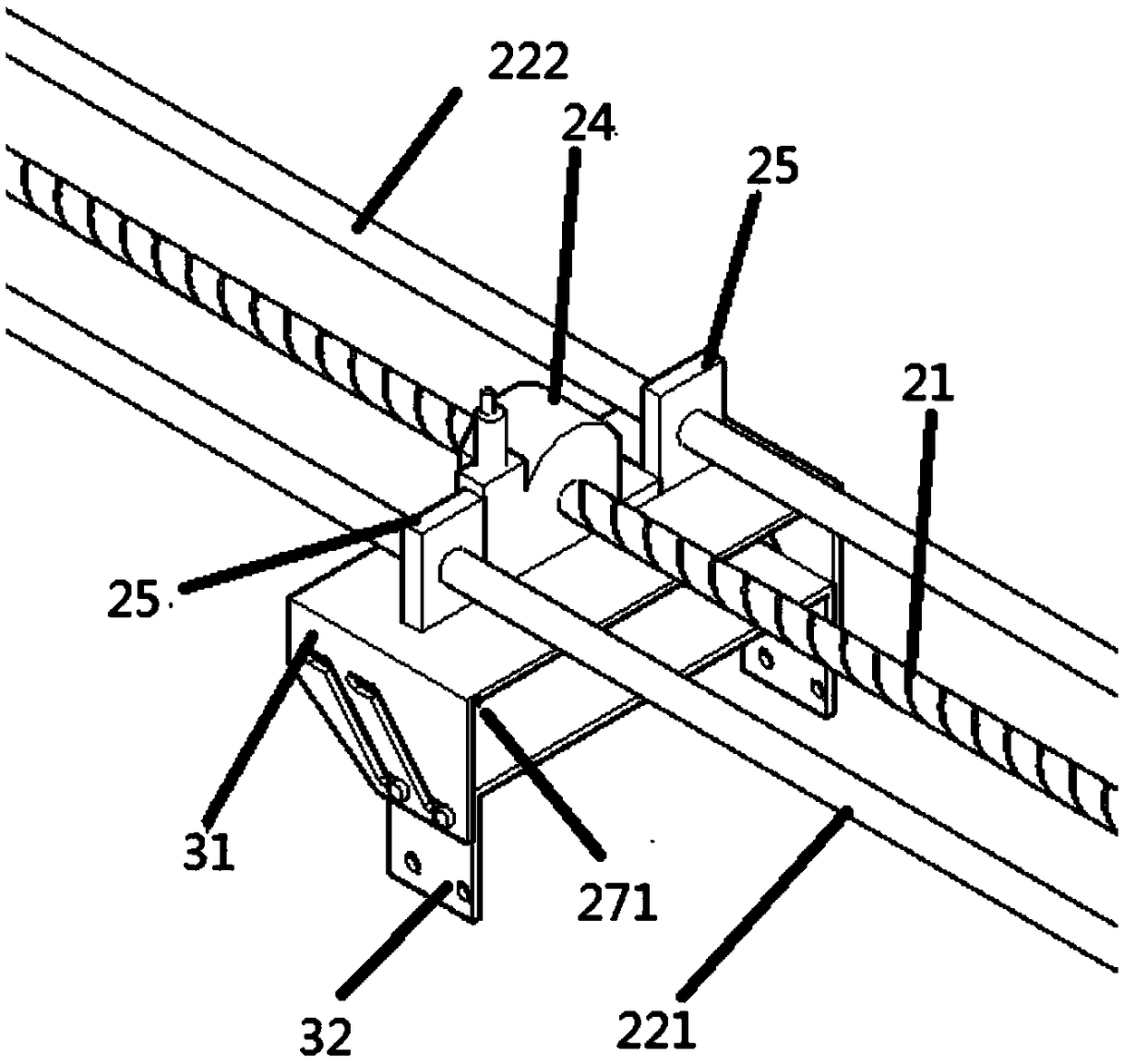

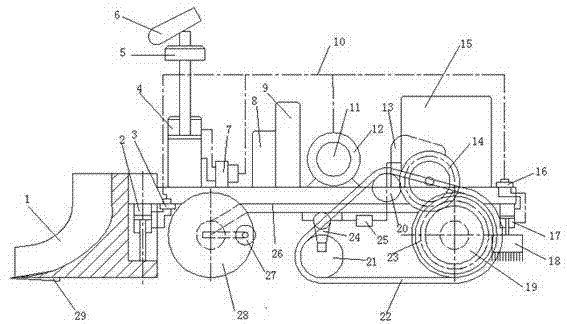

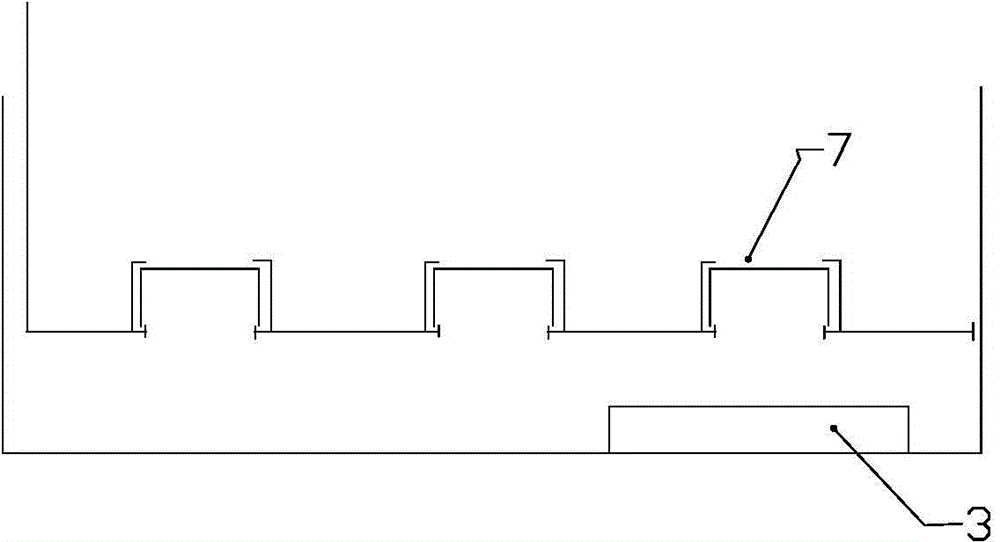

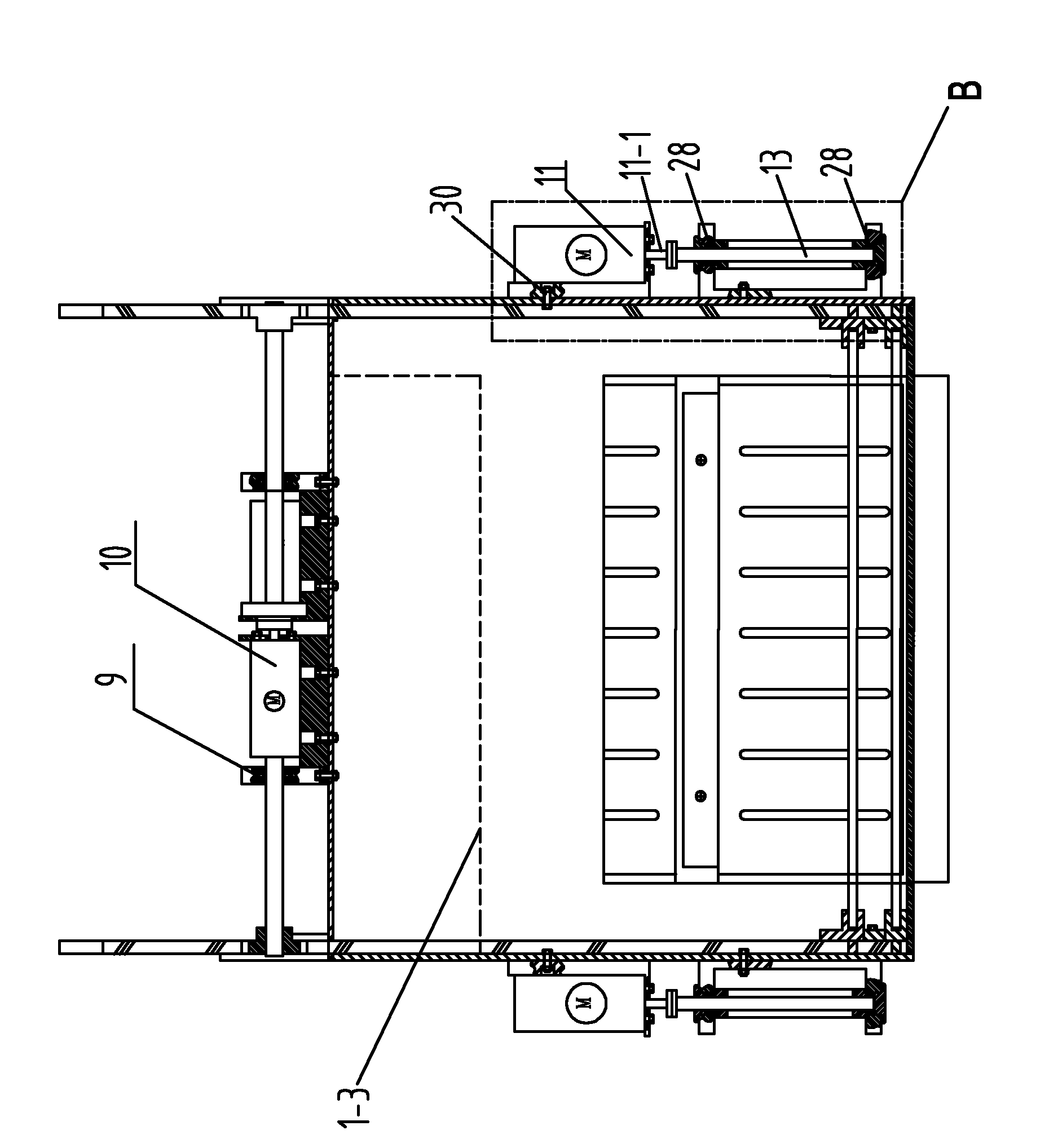

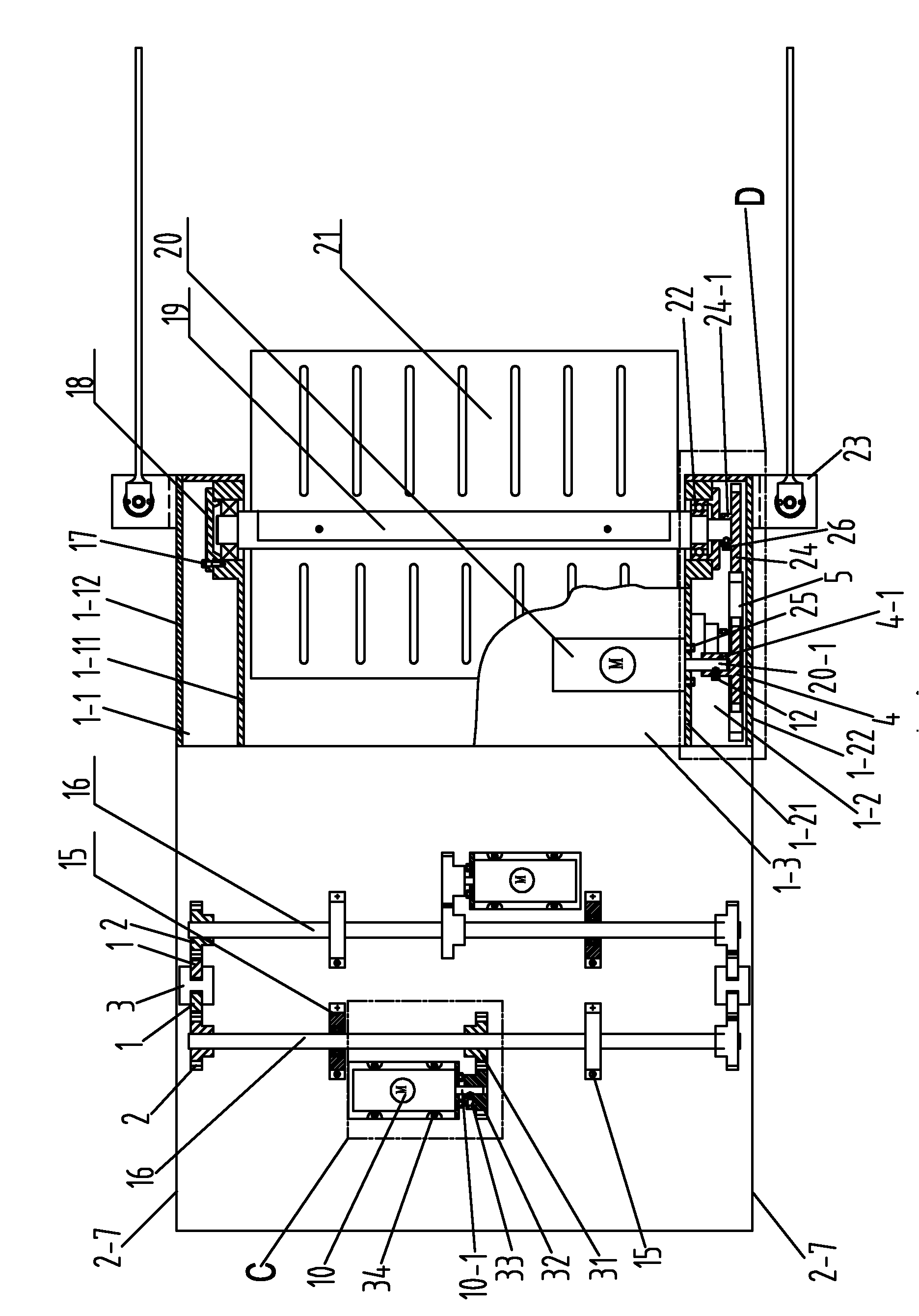

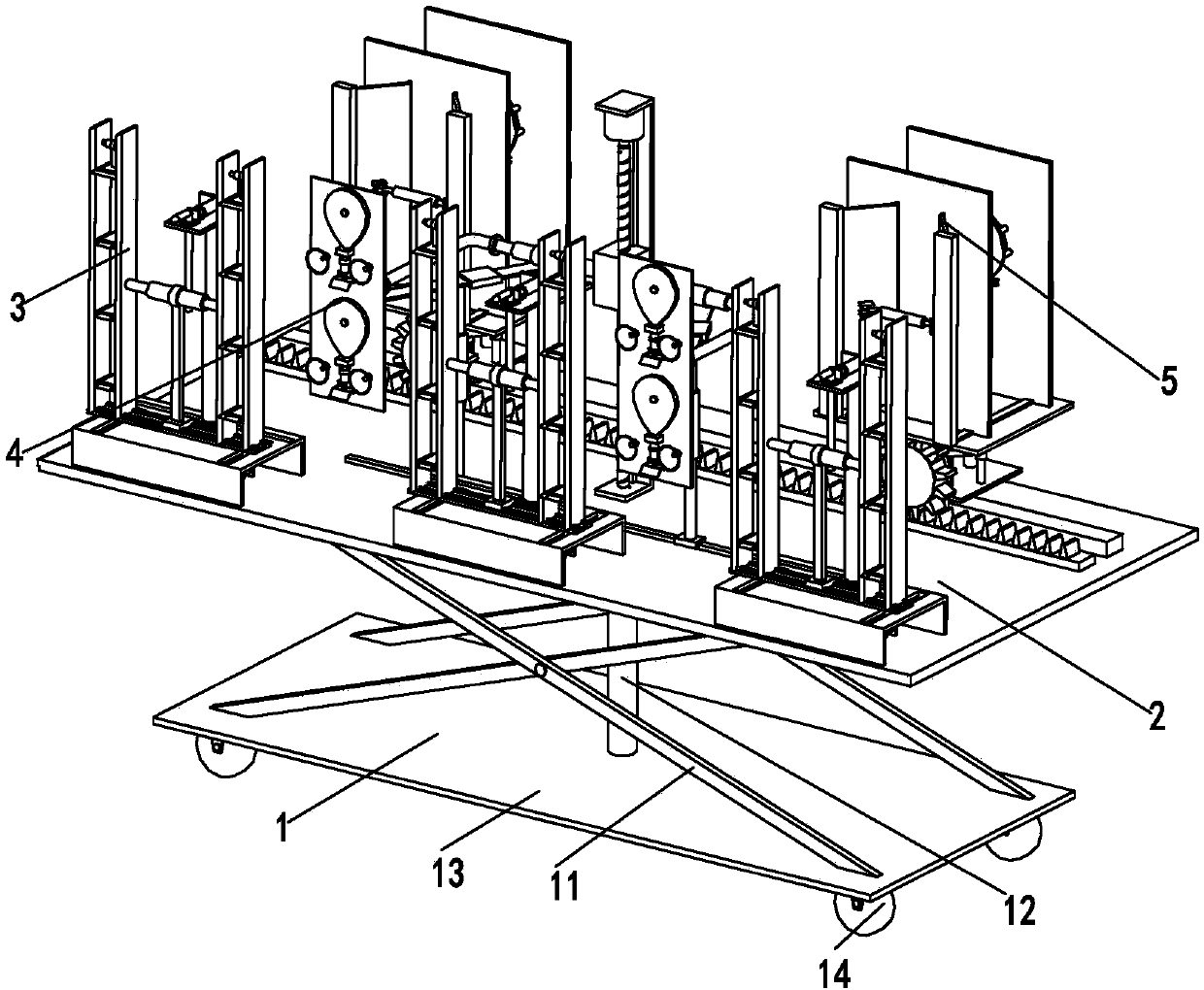

Cleaning system of steel dies for tubular pile production

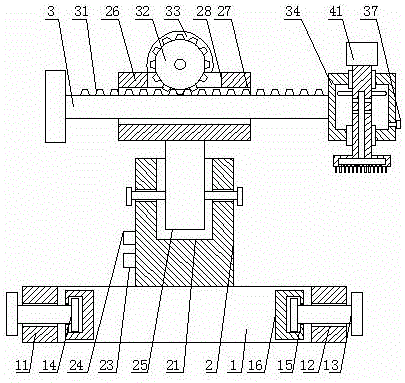

InactiveCN104999550AEasy to placeAutomate cleaningCeramic shaping apparatusReciprocating motionEngineering

The invention relates to a cleaning system of steel dies for tubular pipe production. The cleaning system comprises a steel-die supporting mechanism, a cleaning mechanism and driving mechanisms, wherein the steel-die supporting mechanism comprises a lower-die supporting mechanism for supporting a lower die and an upper-die supporting mechanism for supporting an upper die; and the cleaning mechanism is located between the upper die and the lower die and can be driven by the driving mechanism A to reciprocate in the macro-axis direction of the upper die and the lower die. The cleaning system has the advantages that the upper steel die and the lower steel die can be automatically cleaned, and manual cleaning is not needed, so that the labor intensity of workers is reduced and the working efficiency is improved.

Owner:国鼎(南通)管桩有限公司

Pipeline outer wall processing device and pipeline processing technology thereof

ActiveCN108723016AEnsure personal safetyImprove work efficiencyHollow article cleaningWorking environmentEngineering

The invention relates to a pipeline outer wall processing device and a pipeline processing technology thereof. The pipeline outer wall processing device comprises a bottom plate, walking wheels, a position adjusting device, a cleaning device and a collecting device. The walking wheels are mounted at the lower end of the bottom plate, and the position adjusting device is installed at the upper endof the bottom plate. The cleaning device is mounted on the side wall of the position adjusting device, the collecting device is disposed below the cleaning device, and the collecting device is mountedon the bottom plate. The pipeline outer wall processing device solves the difficult problems that in the existing cleaning process of an indoor vertical pipeline outer wall, the difficulty of cleaning is high, labor cost is high, potential safety hazard exists, the labor intensity is high, the work efficiency is low and the cleanness of the working environment is poor; and the function of automatic cleaning of the indoor vertical pipeline outer wall can be realized, and the pipeline outer wall processing device has the advantages of convenient cleaning, low labor cost, high safety degree, lowlabor intensity, high work efficiency, high cleanliness of the working environment and the like.

Owner:无锡市治宇百通投资管理有限公司

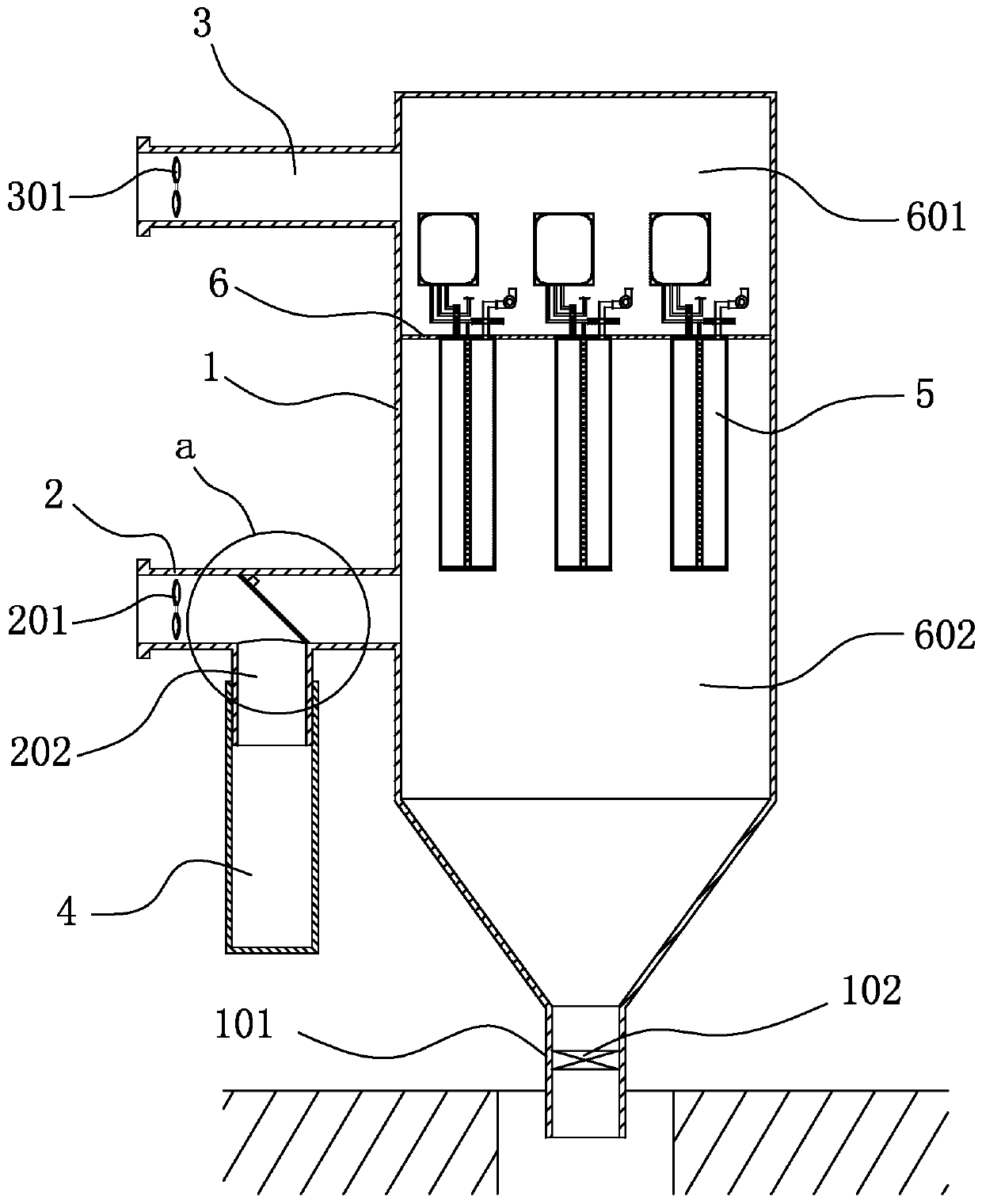

Industrial air purification device

ActiveCN109806686APriority filterEasy to cleanHuman health protectionDispersed particle filtrationExhaust valveFiltration

The invention discloses an industrial air purification device, relates to the technical field of dust removers. The device at least comprises a tank body, an air inlet pipe and an air outlet pipe, wherein the air inlet pipe and the air outlet pipe are fixed to the outer wall of the tank body and are communicated with the inner cavity of the tank body, an air intake fan is arranged in the air inletpipe, an exhaust fan is arranged in the air outlet pipe, the tank body is provided with a plurality of filter components, a second dust exhaust pipe is arranged at the lower end of the tank body, a dust exhaust valve is arranged in the second dust exhaust pipe, the air inlet pipe is provided with a first dust exhaust pipe, the first dust exhaust pipe is vertically arranged on the lower side of the air inlet pipe and is communicated with the air inlet pipe, an isolation filter screen is arranged in the hole of the air inlet pipe, and the lower end of the first dust exhaust pipe is butted witha detachable dust collecting cylinder. Aiming to solve the problems that only one-stage filtration exists, cloth bag is likely to accumulate ash and the cleaning and replacement are troublesome of anexisting industrial dust remover, the invention provides the industrial air purification device provided with two-stage filtration of which the service life of the cloth bag can be prolonged and the cloth bag is easy to clean.

Owner:山西蓝盛益通环保科技有限公司

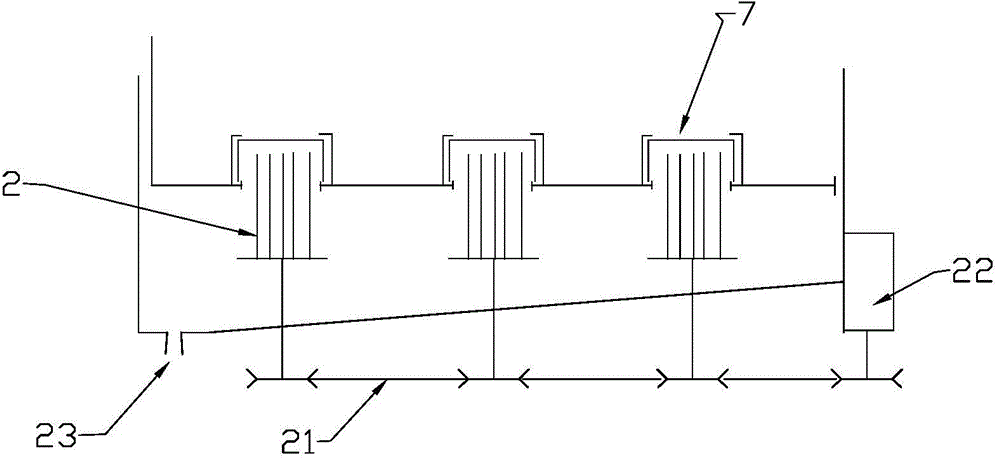

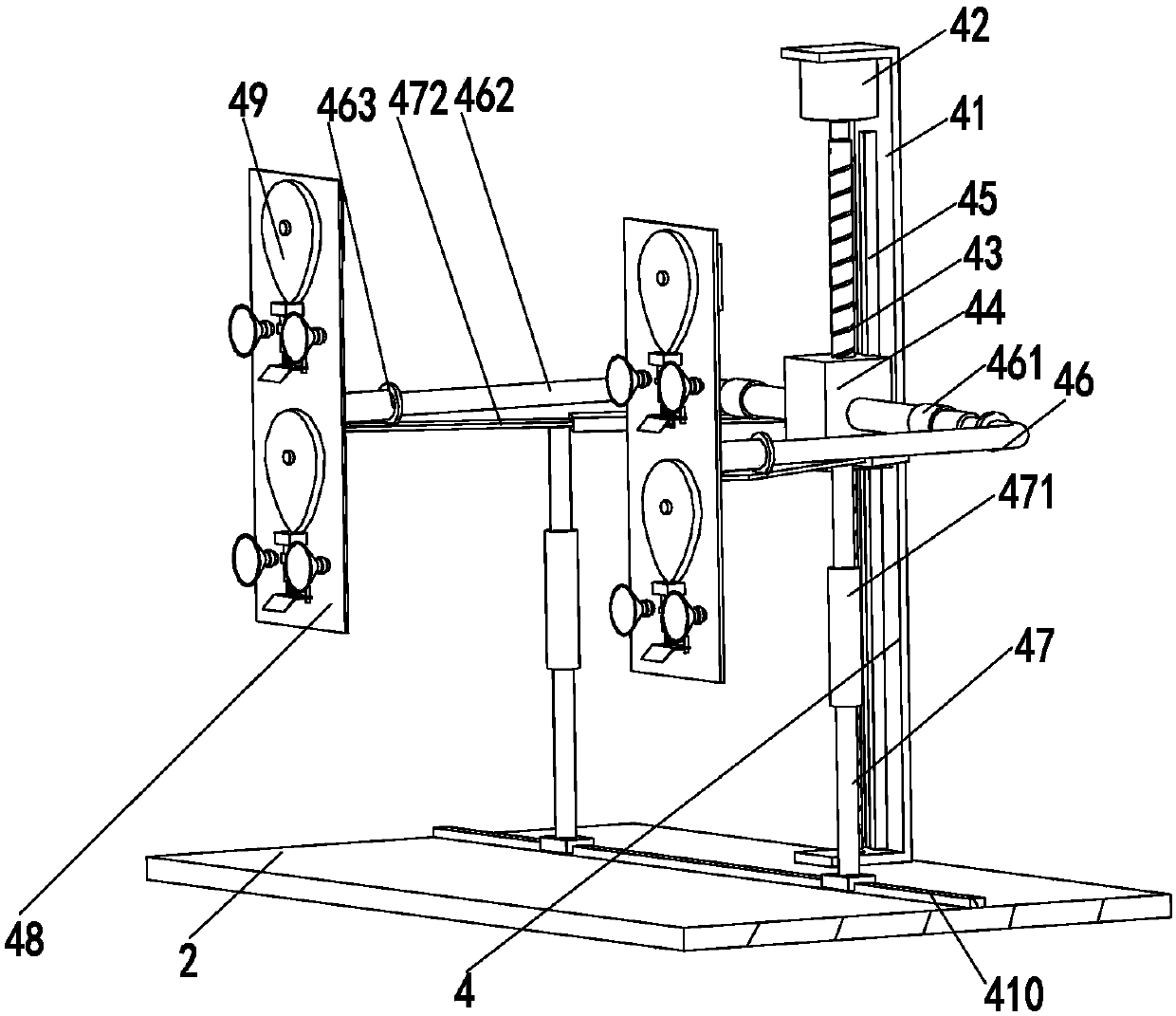

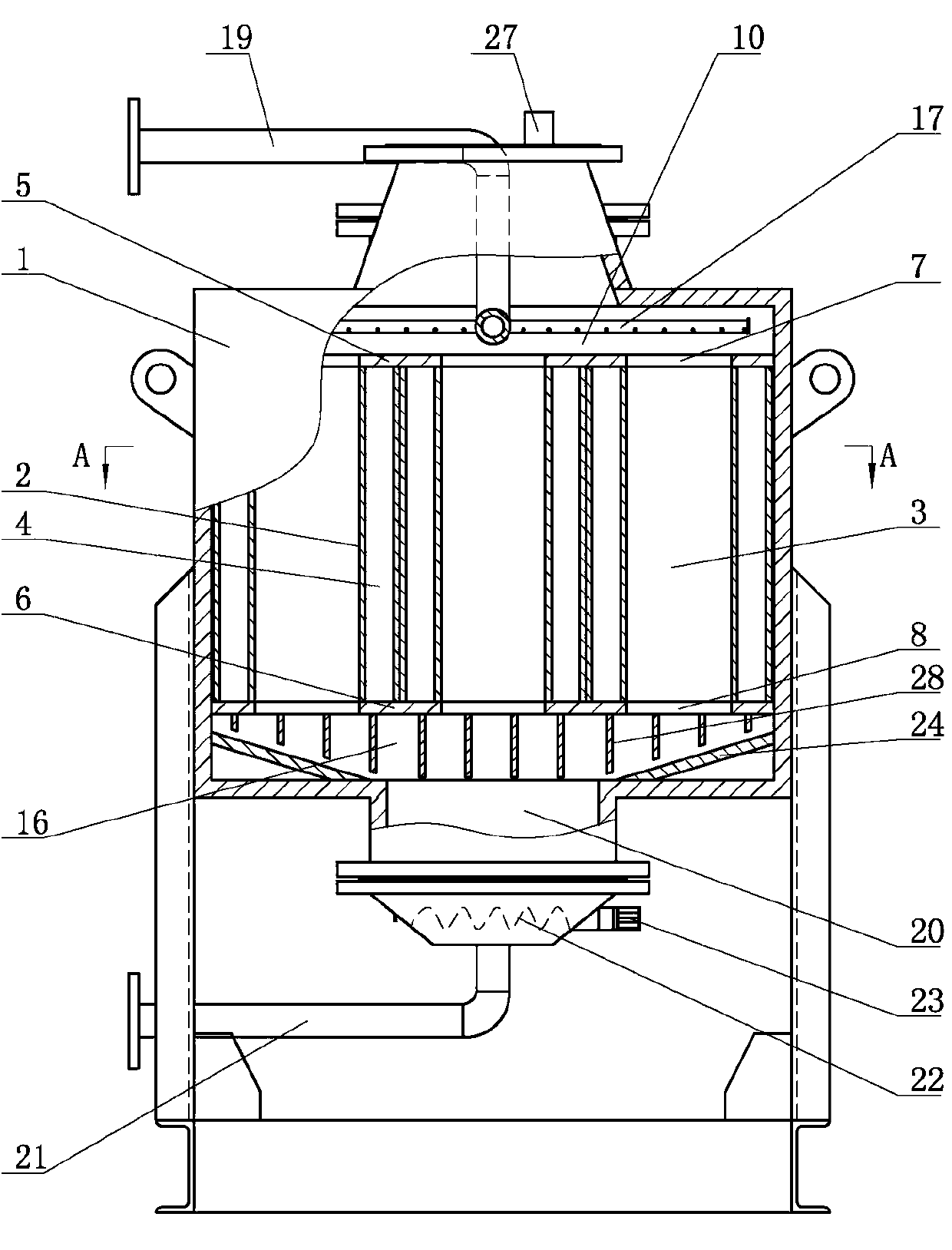

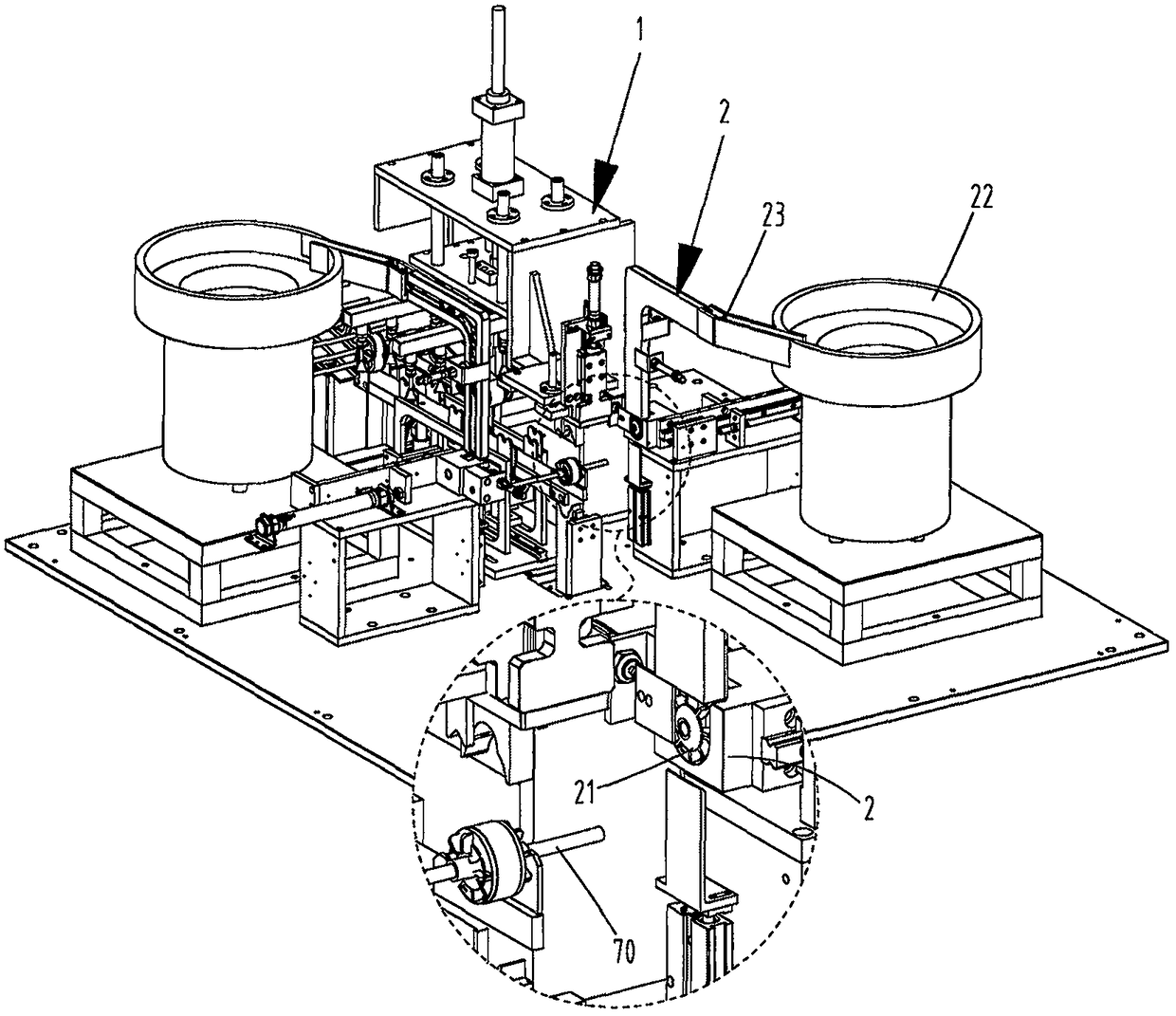

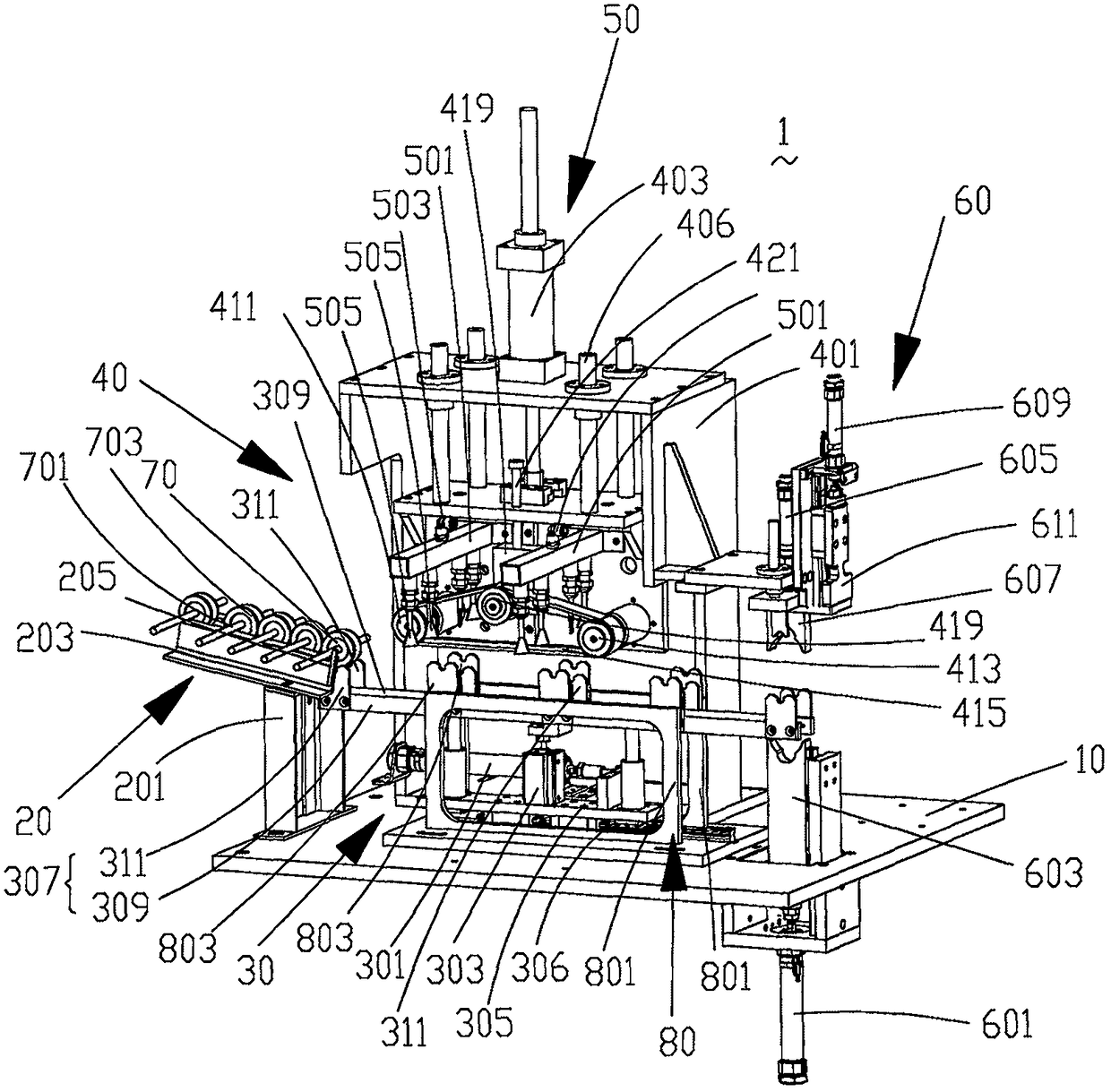

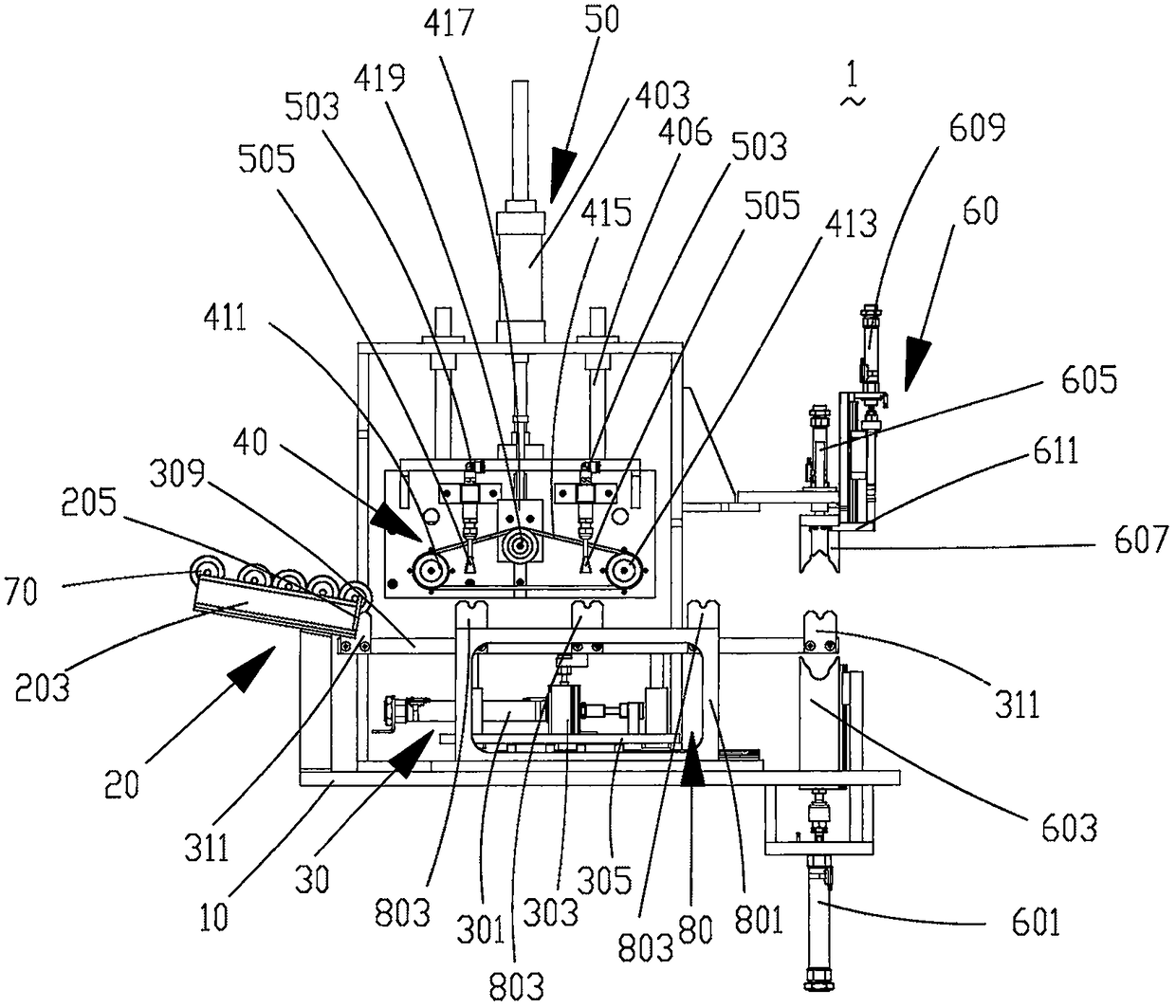

Cleaning and assembling multistation assembly line for motor rotor

InactiveCN108394707AAutomate cleaningImprove work efficiencyCleaning using toolsManufacturing stator/rotor bodiesEngineeringMicro motor

The invention relates to the field of machining and provides a cleaning and assembling multistation assembly line for a motor rotor. The cleaning and assembling multistation assembly line for the motor rotor comprises a micromotor rotor cleaning and conveying mechanism and a blade assembling mechanism, wherein the micromotor rotor cleaning and conveying mechanism comprises a table board, and a loading mechanism, a transfer mechanism, a supporting mechanism, a first cleaning mechanism, a second cleaning mechanism and an unloading mechanism arranged on the tableboard; the transfer mechanism is used for transferring the micromotor rotor to a cleaning position and an unloading position; the supporting mechanism is used for supporting the micromotor rotor in the cleaning position; the first cleaning mechanism is used for scrubbing and cleaning the micromotor rotor; and the second cleaning mechanism is used for flushing and cleaning the micromotor rotor. The cleaning and assembling multistation assembly line for the motor rotor can achieve automatic cleaning of the micromotor rotor, so that the operation efficiency is improved, the operation cost is lowered, and meanwhile, the cleaning effect can be also enhanced, and the cleaning and assembling multistation assembly line for the motor rotor is relatively high in cleaning degree, reliability and stable degree.

Owner:WENZHOU POLYTECHNIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com