Cleaning system of steel dies for tubular pile production

A steel mold and pipe pile technology, which is applied in the field of steel mold cleaning system for pipe pile production, can solve the problems of large labor consumption and low work efficiency, and achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

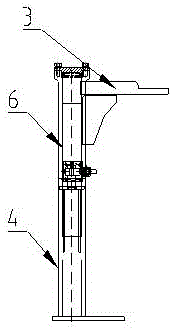

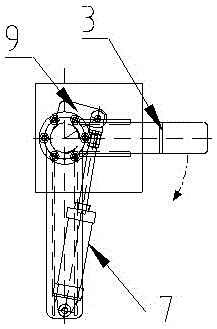

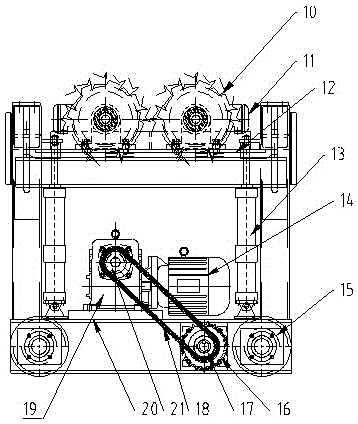

[0018] Such as Figure 1-Figure 5 From the schematic diagram shown, it can be known that the steel mold cleaning system for pipe pile production of the present invention includes a steel mold support mechanism, a cleaning mechanism and a driving mechanism.

[0019] The steel mold support mechanism includes a lower mold support mechanism for supporting the lower mold 2 and an upper mold support mechanism for supporting the upper mold 1. The cleaning mechanism is located between the upper mold 1 and the lower mold 2 and can be driven by the driving mechanism A The reciprocating movement in the horizontal direction is carried out along the long axis direction of the upper mold 1 and the lower mold 2 .

[0020] The supporting mechanism of the lower mold includes several supporting blocks 5 arranged side by side along the long axis of the lower mold 2 , and the upper end section of the supporting blocks 5 is V-shaped.

[0021] Such as figure 2 , image 3 and Figure 4 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com