Ream-crushing device of death pig harmless treatment system

A technology for harmless treatment of sick and dead pigs, applied in grain treatment, chemical instruments and methods, cleaning methods using tools, etc., can solve problems such as inability to complete crushing work, easy burnout of motors, and jamming on toothed blades, etc. , to achieve the effect of avoiding human and animal contact, good sealing, and controlling the spread of germs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

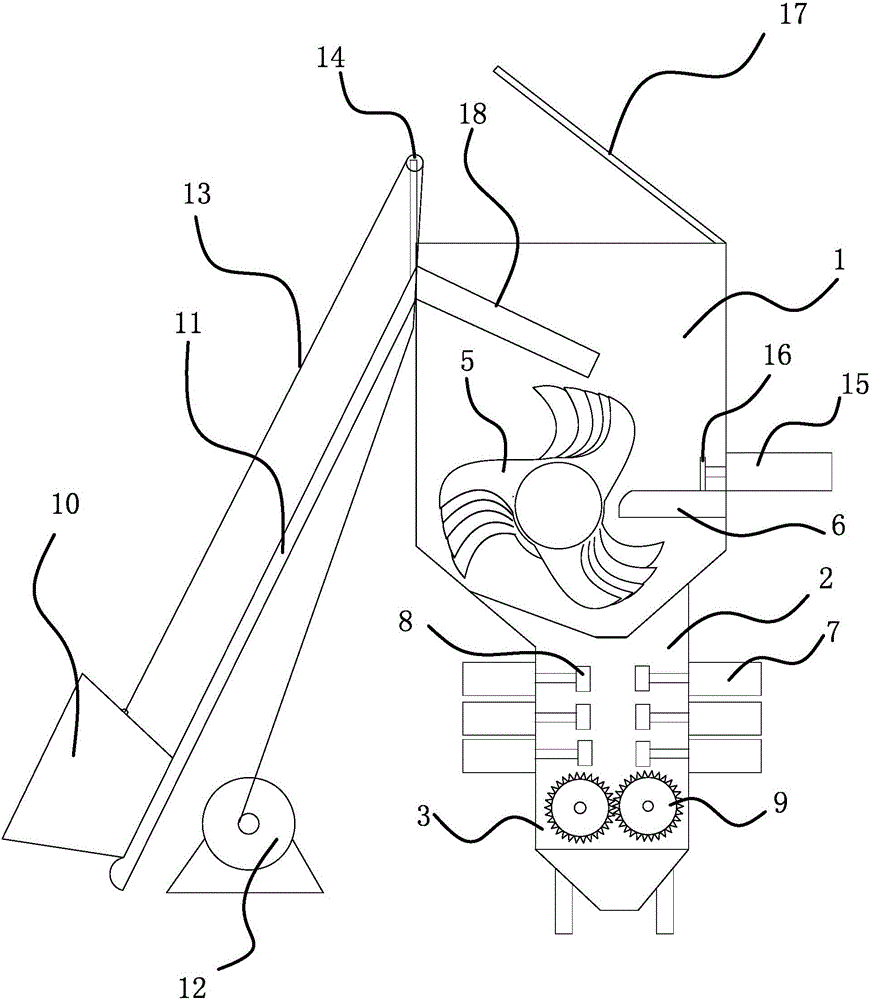

[0025] Such as figure 1 As shown, the crushing device of the harmless treatment system for sick and dead pigs includes a feeding mechanism, a hinged cutting chamber 1, a hammer crushing chamber 2 and a crushing chamber 3, and the hinged cutting chamber 1, hammer crushing chamber 2 and crushing chamber 3 are all located in one In the vertical cylinder and distributed in order from high to low. An openable cover plate 17 is hinged above the hinge cutting bin 1 . The cover plate 17 can be closed after the sick and dead pigs are put into the reaming and cutting bin 1 to prevent debris from being thrown out during the reaming and cutting.

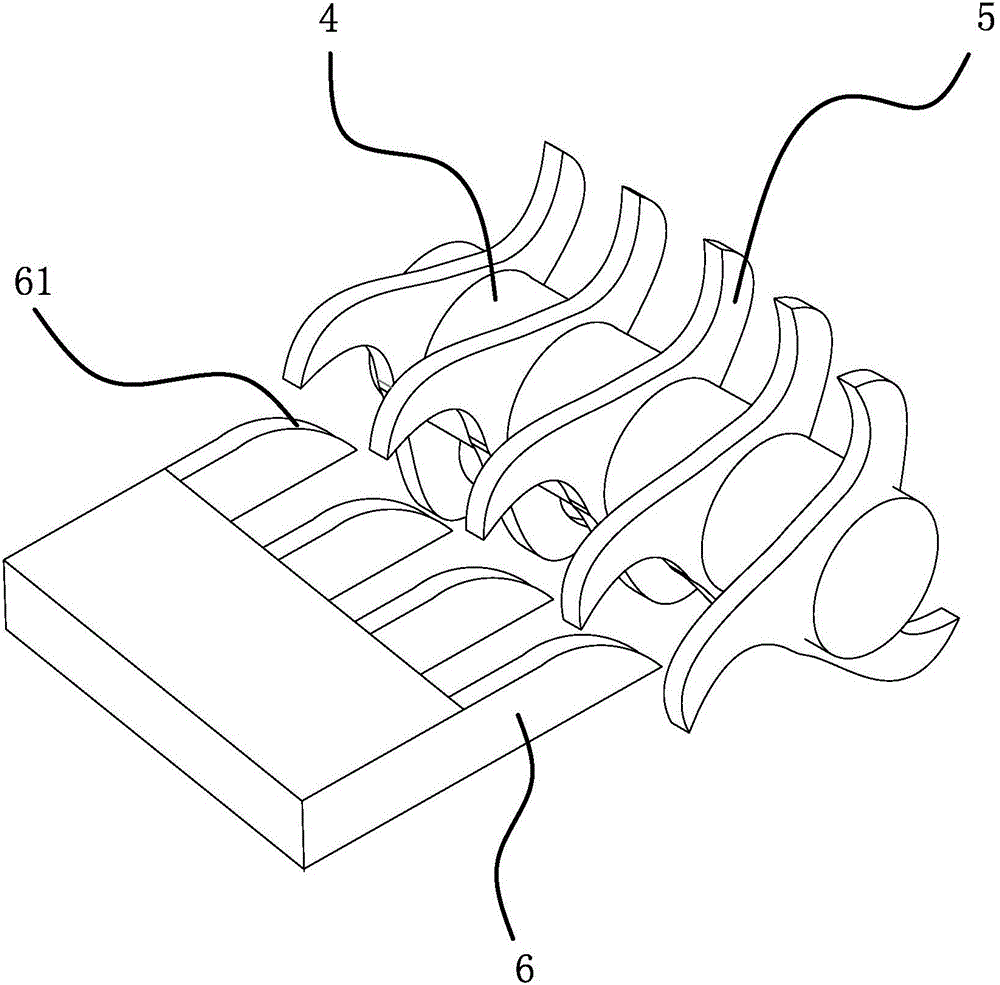

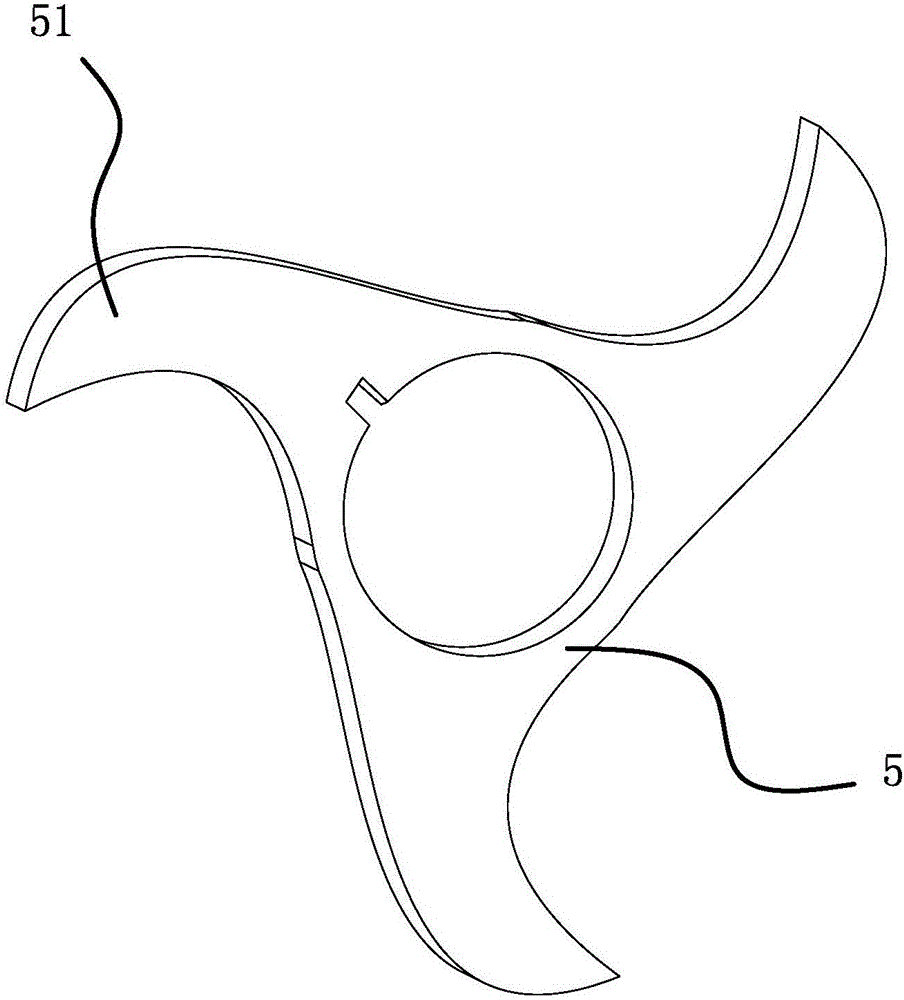

[0026] Such as figure 2 As shown, the reaming chamber 1 is provided with a cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com