Disintegrating slag afterheat utilizing system

A technology of waste heat and slag, applied in the direction of improving process efficiency, etc., can solve the problems of ineffective use of heat, many impurities in slag water, and inability to recycle slag water, etc., to achieve protection from corrosion and uniform heat transfer effect , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

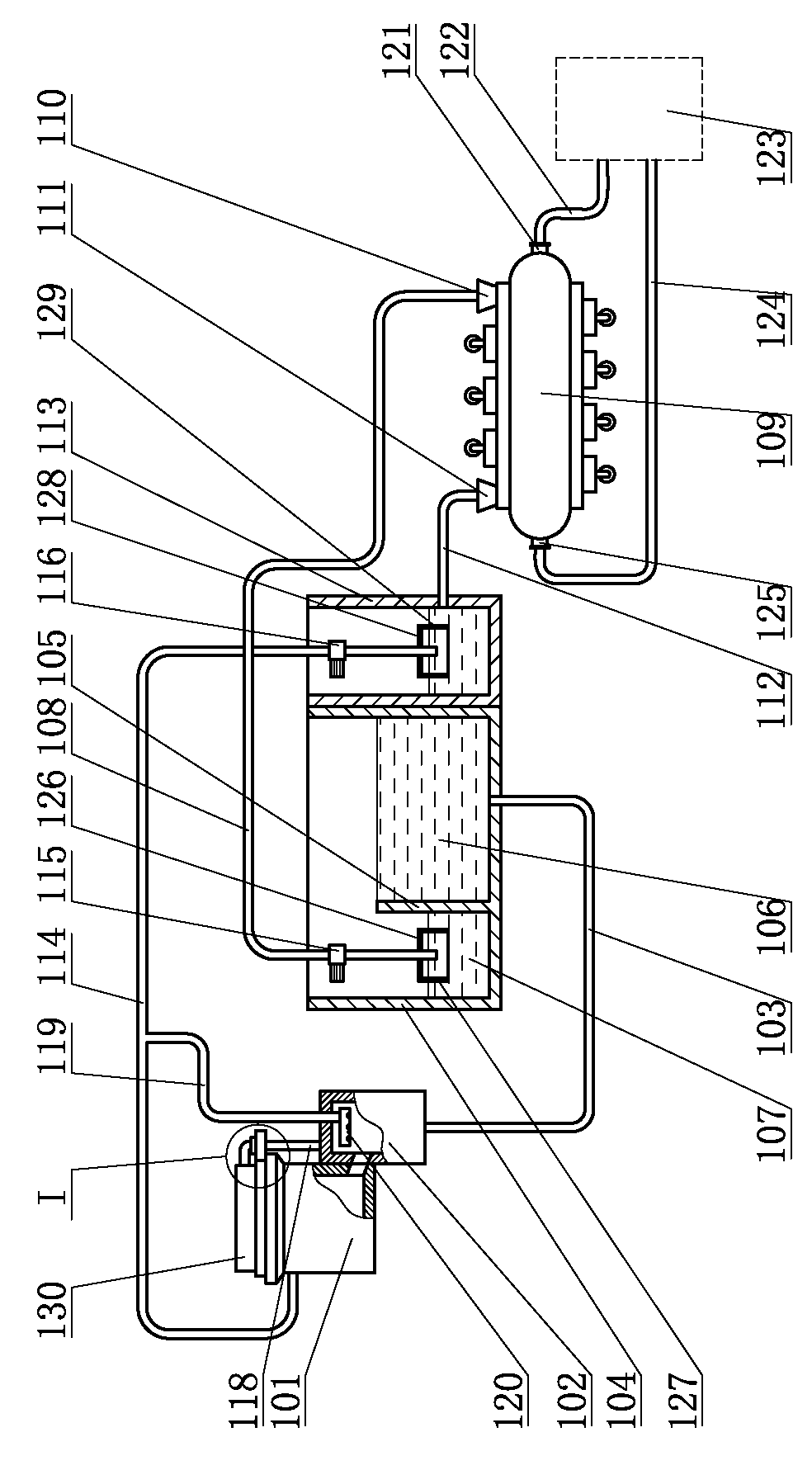

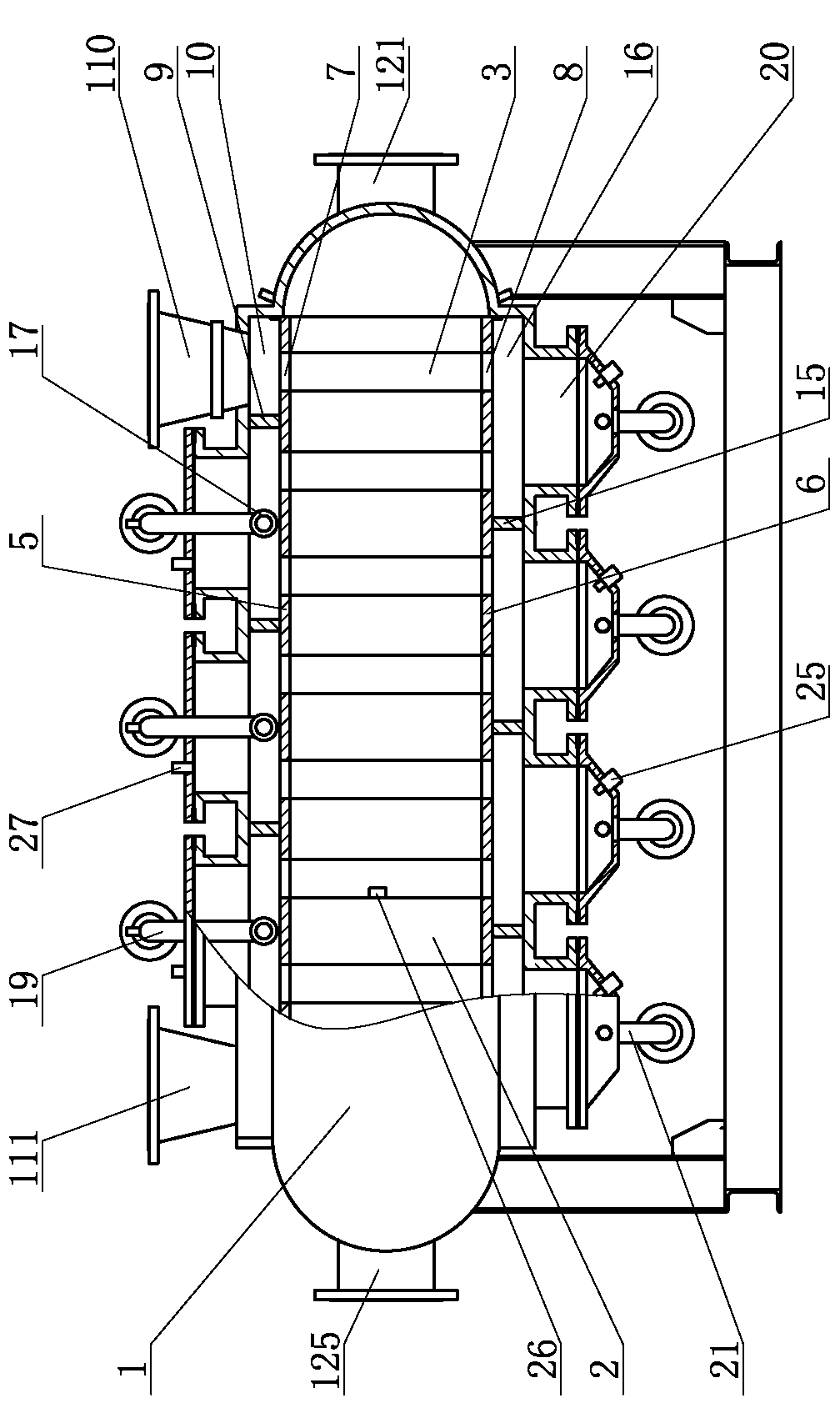

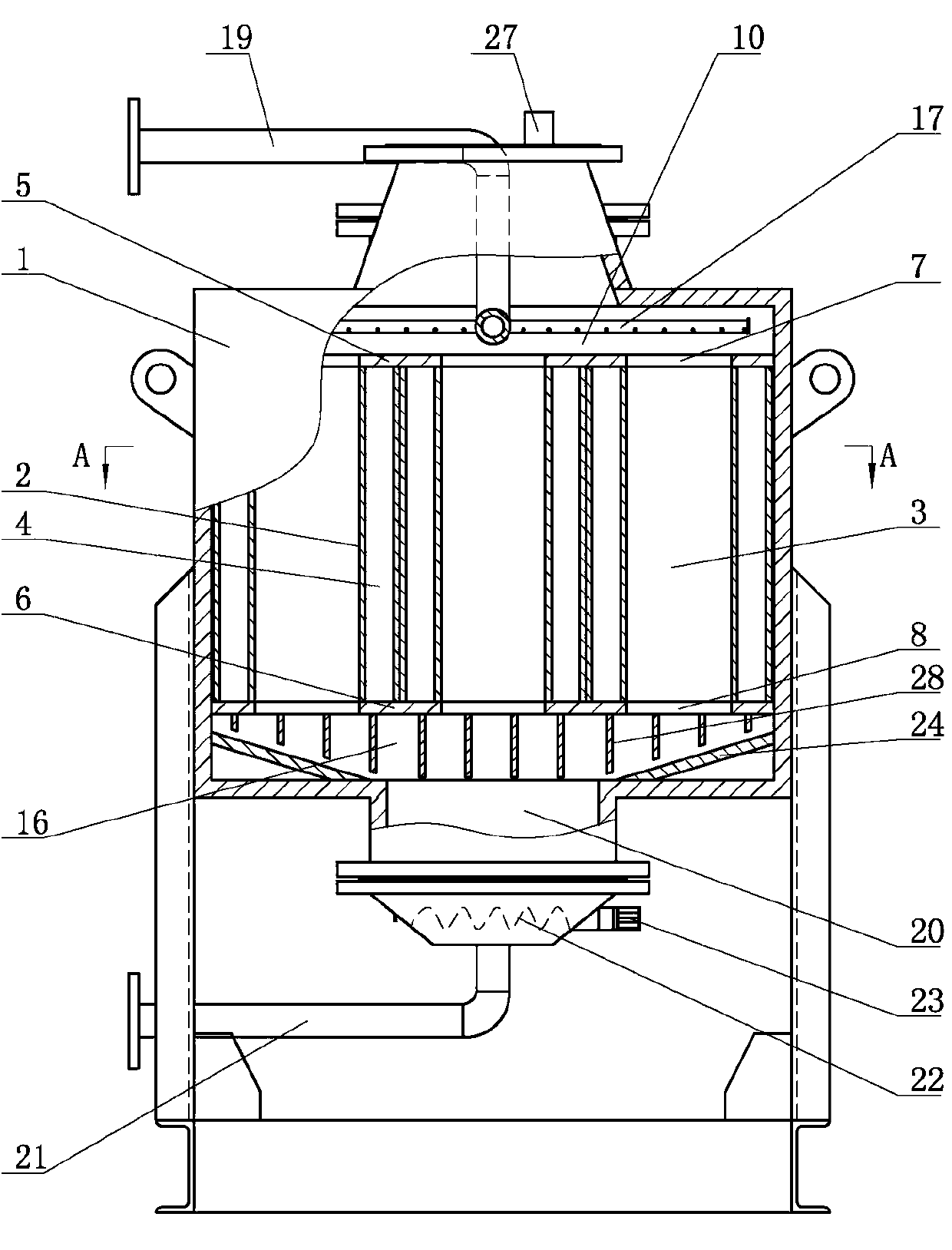

[0011] The slag waste heat utilization system of the present invention comprises a slag tank 101, the slag outlet at the bottom of the slag tank 101 communicates with the slag flushing ditch 102, the slag tank 101 communicates with the top of the slag flushing ditch 102 through a steam discharge pipe 118, and The bottom of the slag ditch 102 communicates with the sedimentation tank 104 through the drain pipe 103. An overflow partition 105 is arranged in the sedimentation tank 104. The overflow partition 105 divides the lower part of the sedimentation tank 104 into a sedimentation chamber 106 and a clean water chamber 107. The drain pipe 103 is located at On one side of the sedimentation chamber 106 of the sedimentation tank 104, a hot water supply pipe 108 is arranged in the clean water chamber 107, and a hot water circulation pump 115 is installed on the hot water supply pipe 108, and one end of the hot water supply pipe 108 is located inside the clean water chamber 107 The ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com