Patents

Literature

101results about How to "Avoid air lock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

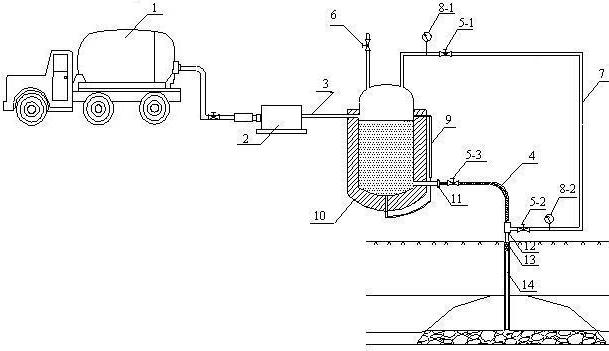

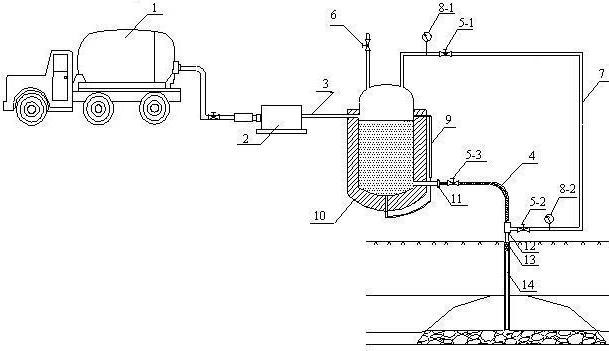

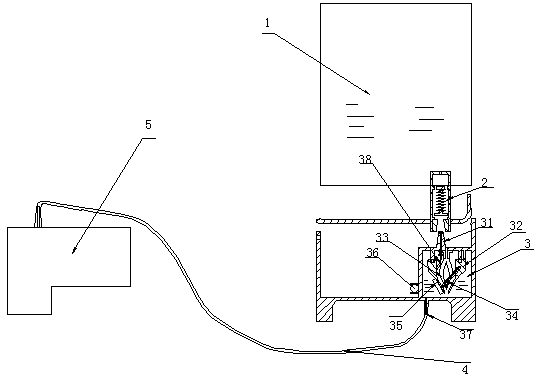

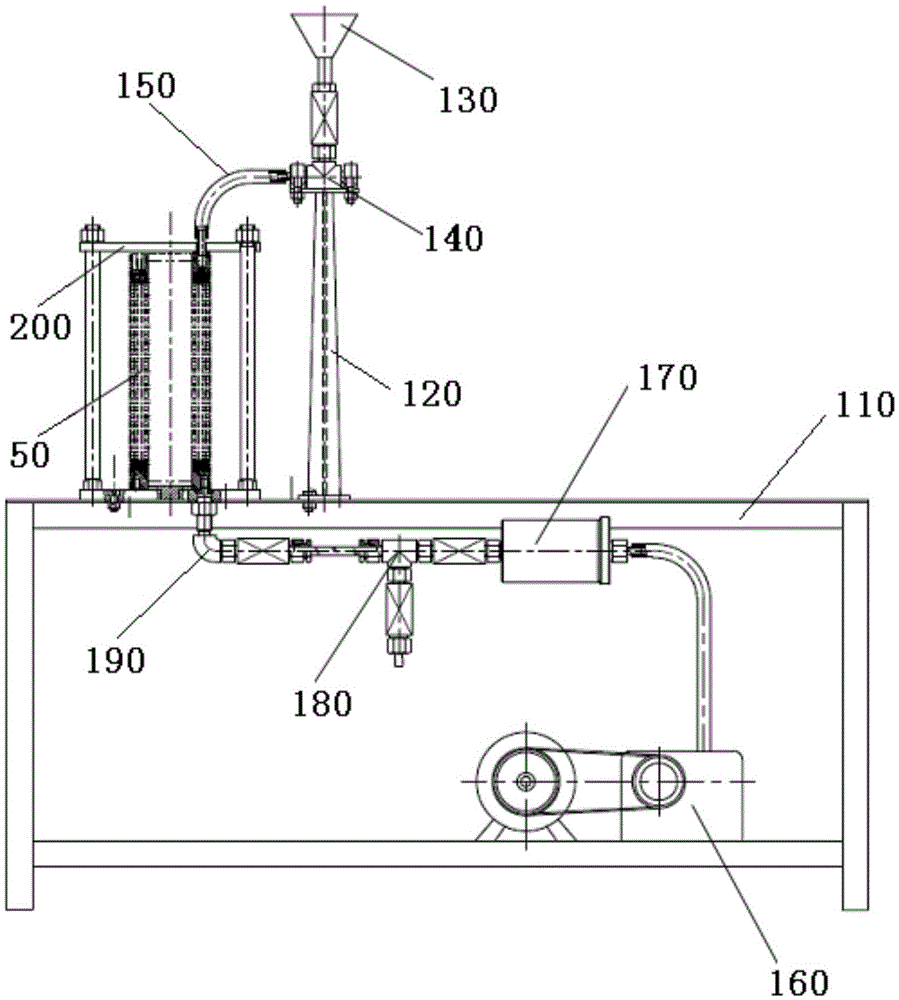

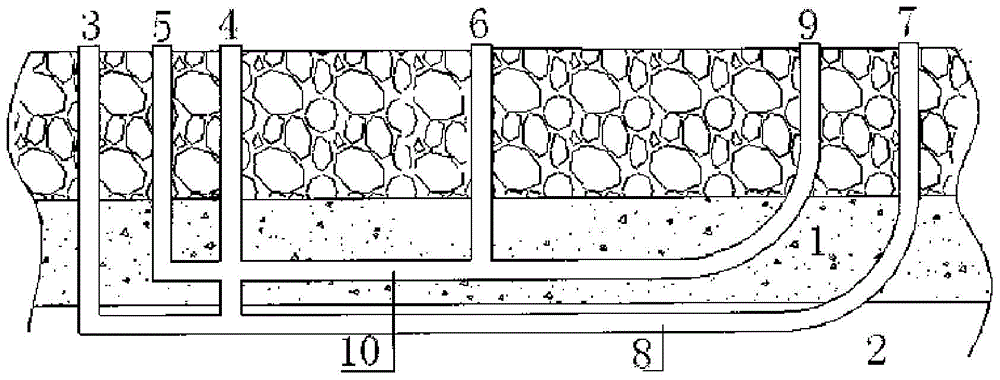

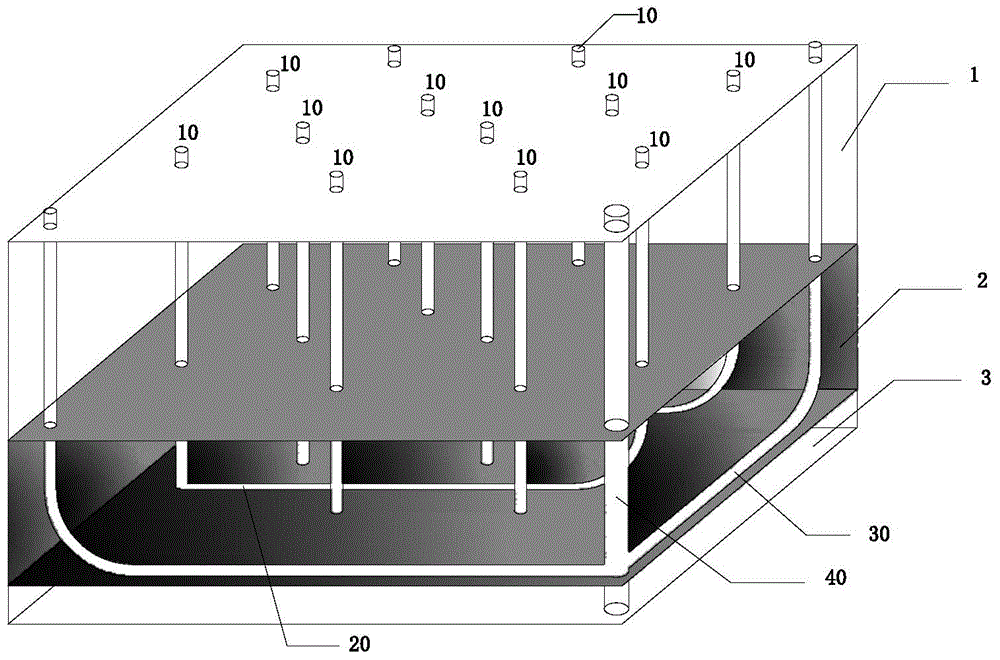

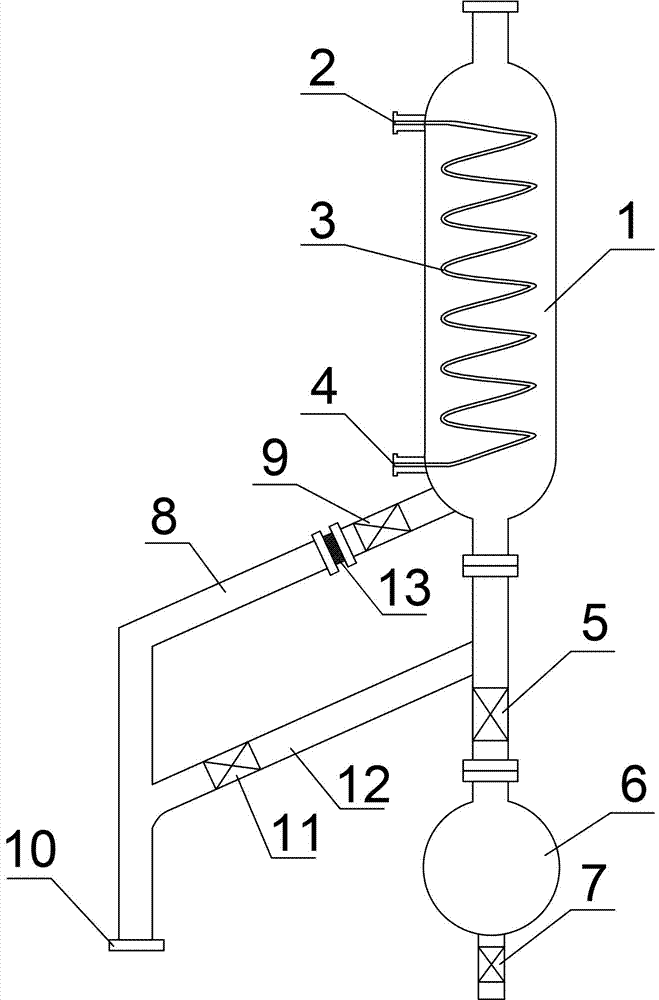

Ground direct injection type liquid nitrogen fire preventing and extinguishing system

The invention discloses a ground direct injection type liquid nitrogen fire preventing and extinguishing system. An outlet of a liquid nitrogen tank truck of the system is connected with an inlet of a reciprocating type low-temperature liquid pump, an outlet of the reciprocating type low-temperature liquid pump is connected with a liquid inlet of the upper portion of a buffering tank, a liquid outlet of the lower portion of the buffering tank is connected with a vacuum low-temperature heat insulation tube, the vacuum low-temperature heat insulation tube is connected with a nitrogen injection tube and a nitrogen gas delivery tube, a gas exhaust opening at the upper end of the buffering tank is connected with the nitrogen gas delivery tube, the upper portion of the buffering tank is a single-layered shell, and the upper end of the buffering tank is connected with a decompression valve. Key technical problems that gas phase and liquid phase are separated after liquid nitrogen is vaporized and the nitrogen injection tube is blocked are avoided. The ground direct injection type liquid nitrogen fire preventing and extinguishing system is simple in structure and convenient in installation, is safe and reliable, and effectively avoids problems of gas blockage, intermittent spring and the like in a liquid nitrogen injection process, and liquid nitrogen filling efficiency is improved by 20% at least as compared with traditional direct liquid nitrogen filling process. The ground direct injection type liquid nitrogen fire preventing and extinguishing system is particularly applicable to preventing and extinguishing fire of hidden fire sources of shallow-buried deep coal mine underground worked out sections.

Owner:CHINA UNIV OF MINING & TECH

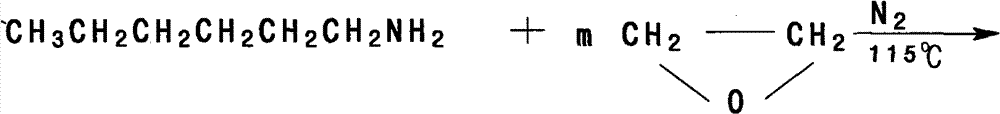

Co-solvent composition for compounding methanol gasoline

InactiveCN1740283APromote mutual solubilityHigh calorific valueLiquid carbonaceous fuelsAntioxidantMethyl carbonate

The co-solvent composition for compounding methanol gasoline consists of methyl tert-amyl ether 0-61 weight portions, dimethyl carbonate 0-52 weight portions, methyl tert-butyl ether 0-47 weight portions, allcyl polyoxyethylene ether 0.1-10 weight portions, isopropyl ether 0-10 weight portions, ethyl ether 0-30 wt%, tert-butanol 0-45 weight portions, iso-butanol 0-25 weight portions, isopropanol 0-15 weight portions, antioxidant í‹501íŒ 0-8 weight portions, xylene 0-20 weight portions, urotropin 0-7 weight portions, butanone 0-36 weight portions and acetone 0-20 weight portions. It is added while compounding methanol gasoline to raise the intersolubility between methanol and gasoline and raise the relevant physical and chemical performances of methanol gasoline.

Owner:翟雁萍

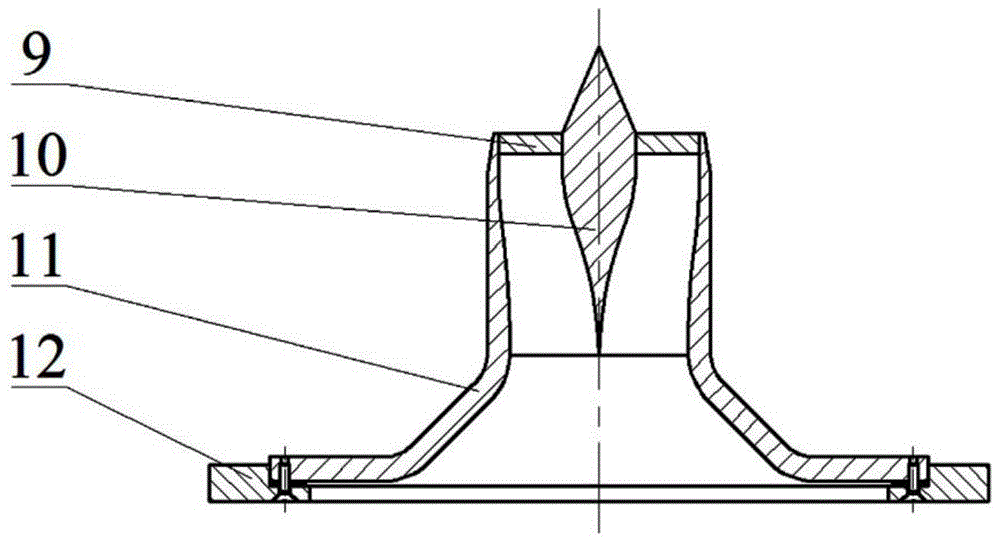

Method for preparing hydrogen peroxide

ActiveCN104418309AImprove hydrogen efficiencyAvoid air lockPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHydrogen peroxide breakdownHydrogen

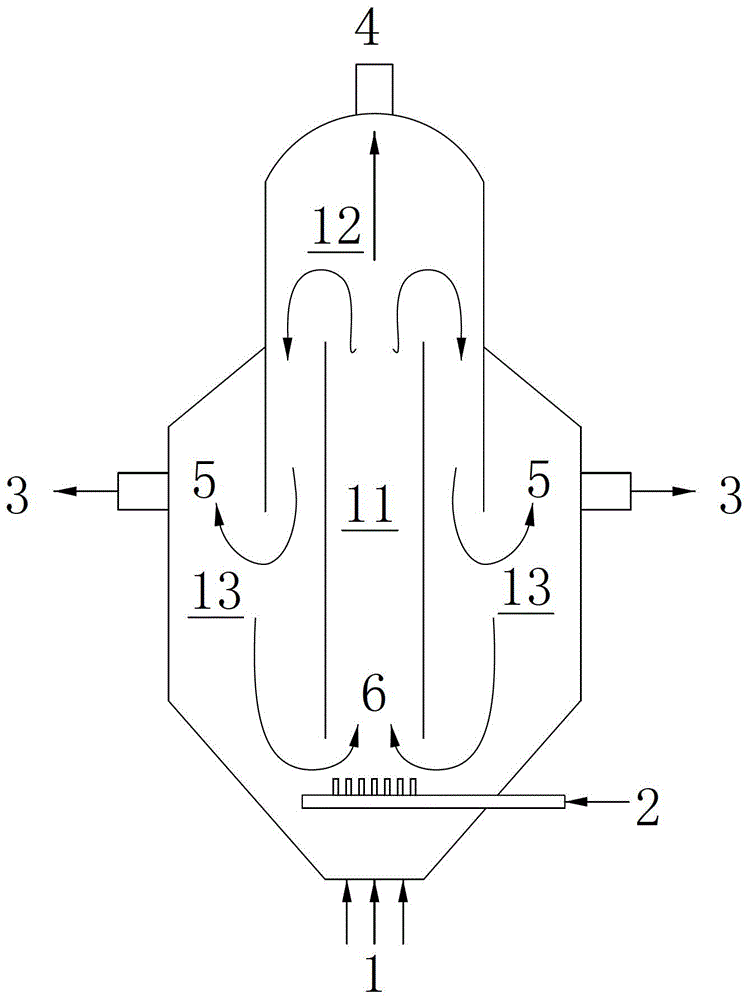

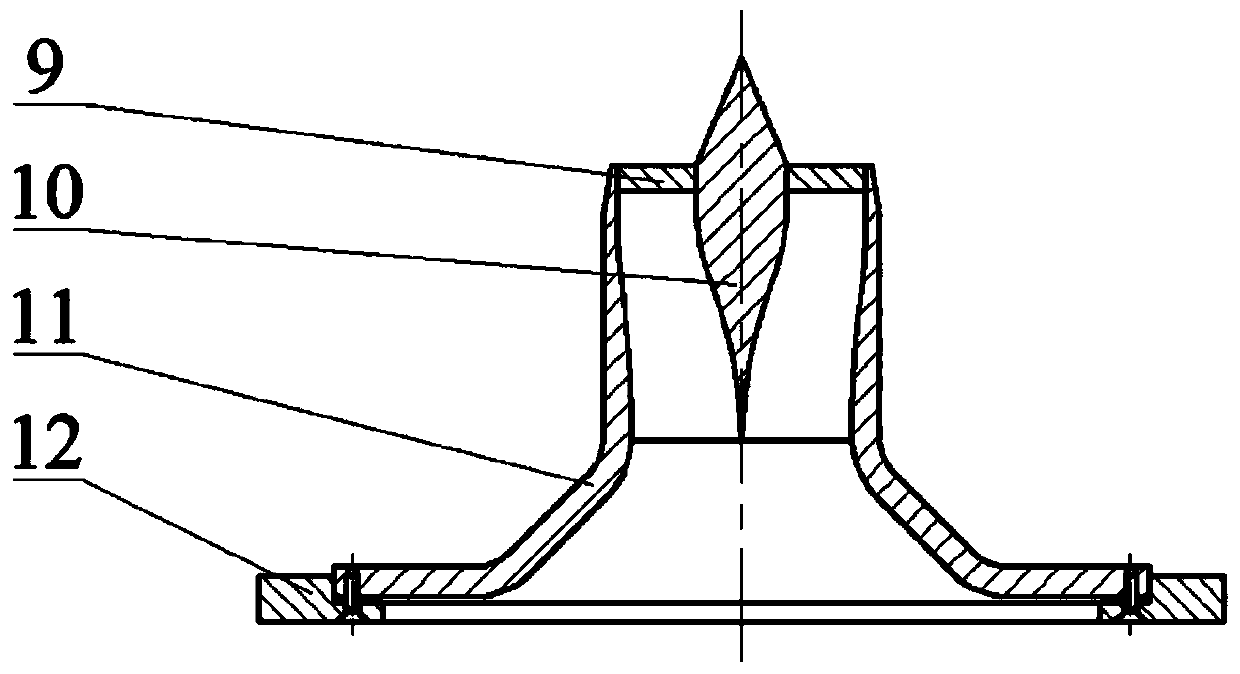

The invention discloses a method for preparing hydrogen peroxide. A working liquid and a hydrogen-containing gas are introduced into a slurry bed reactor; a hydrogenated liquid is obtained by reaction in the existence of a catalyst; the hydrogenated liquid reacts with oxygen to obtain the hydrogenated liquid containing hydrogen peroxide in an oxidation reactor; oxidized liquid is extracted and separated from an extraction tower to obtain a hydrogen peroxide solution and working liquid; the slurry bed reactor comprises a cap (12), an expanding section (13) and a draft tube (11); the expanding section (13) is positioned at the lower part of the cap (12); the pipe diameter of the expanding section (13) is greater than that of the cap; the draft tube (11) is arranged in the expanding section (13); the pipe diameter of the draft tube (11) is smaller than that of the cap (12); a bottom opening of the cap (12) extends into the expanding section (13); the outer wall of the cap (12) is connected with the top of the expanding section (13); an upper opening of the draft tube (11) extends into the cap (12); and an opening is formed in the lower part of the draft tube (11). The method disclosed by the invention is stable to operate, and easy for realization of industrial enlargement; no alkali is introduced in the process of preparing hydrogen peroxide; and the risk of explosion caused by hydrogen peroxide decomposition is avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

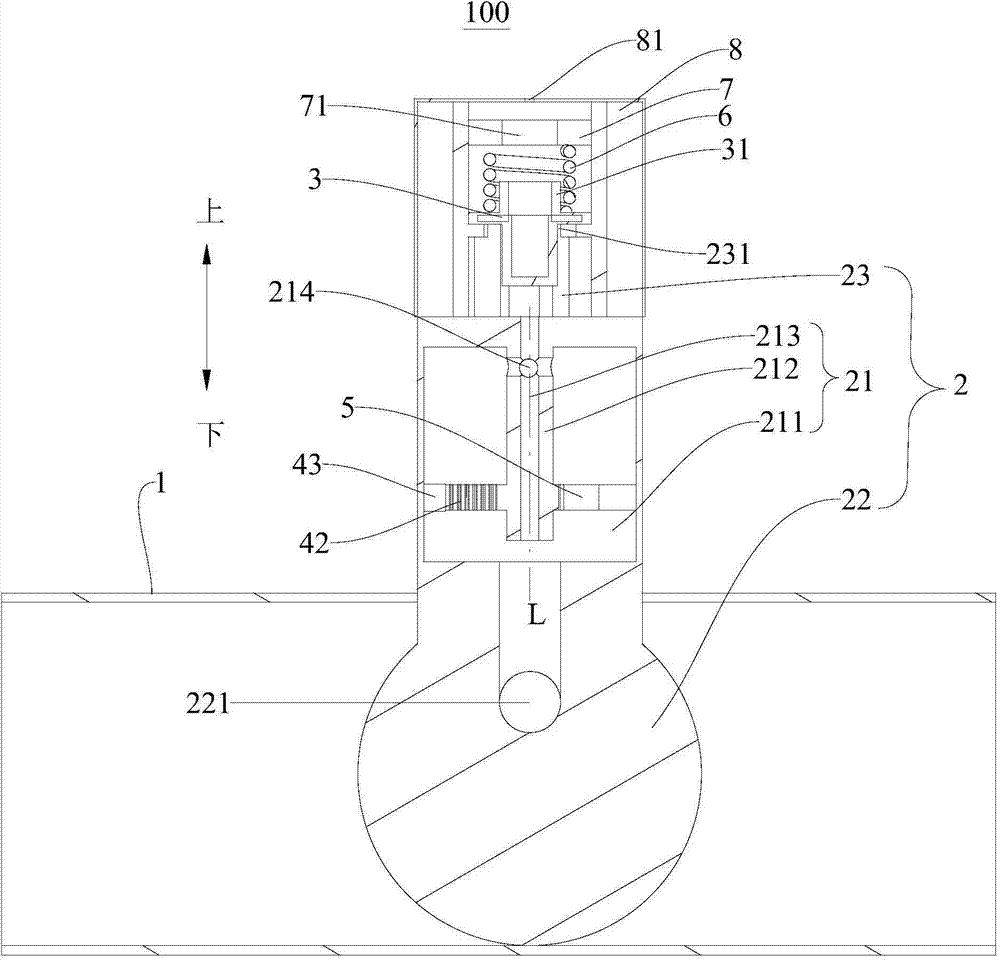

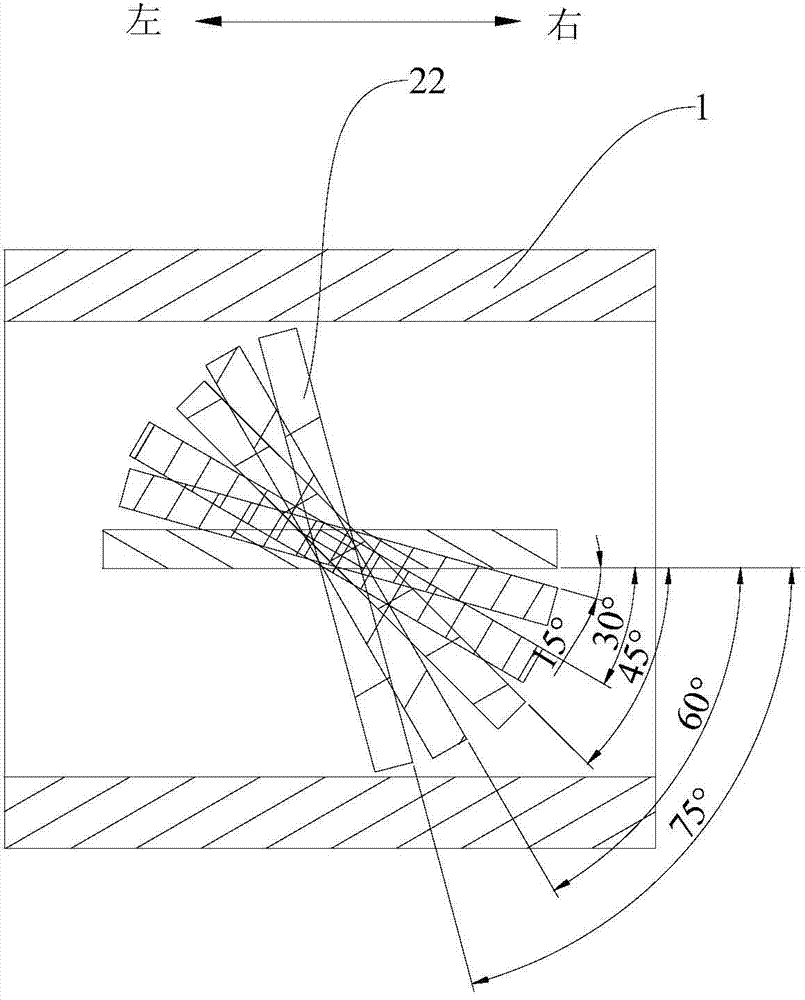

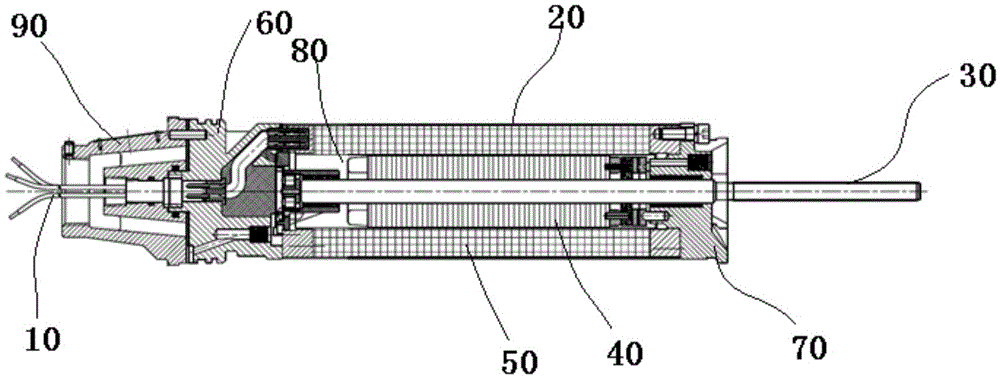

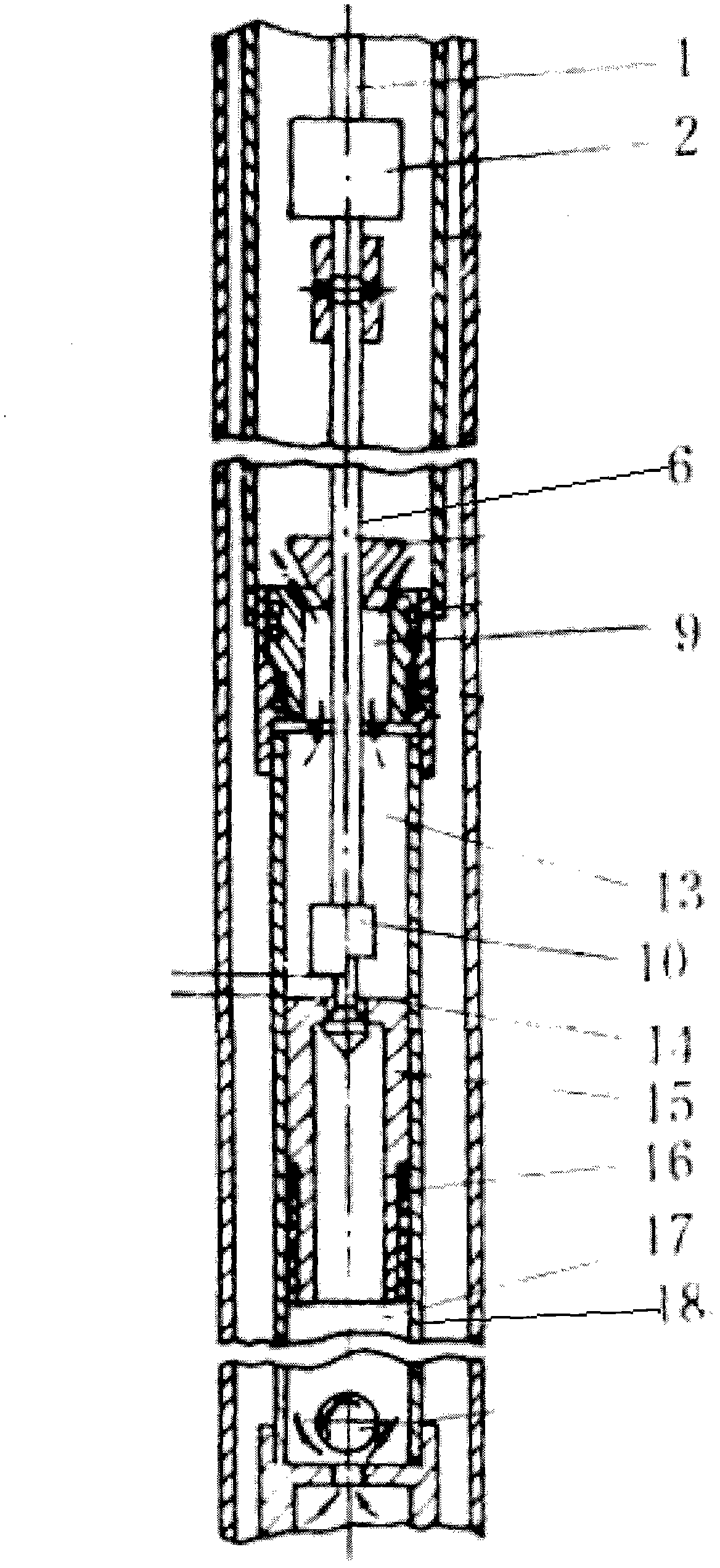

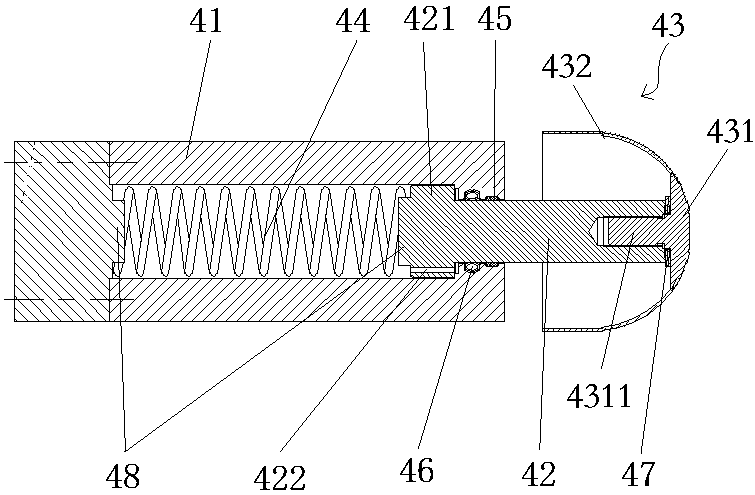

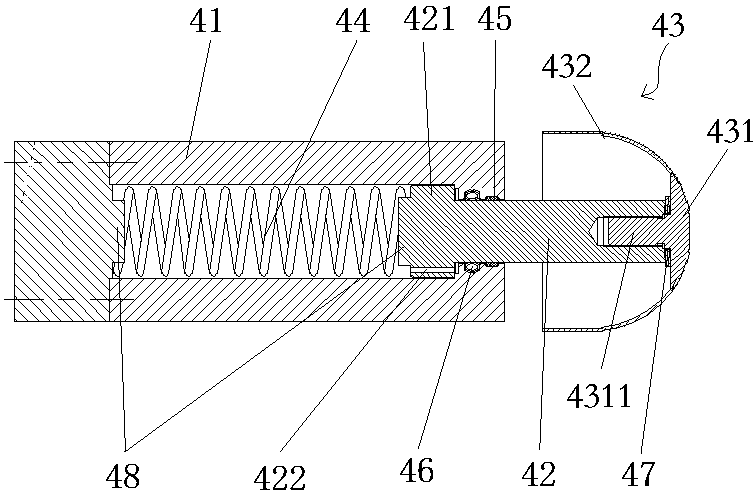

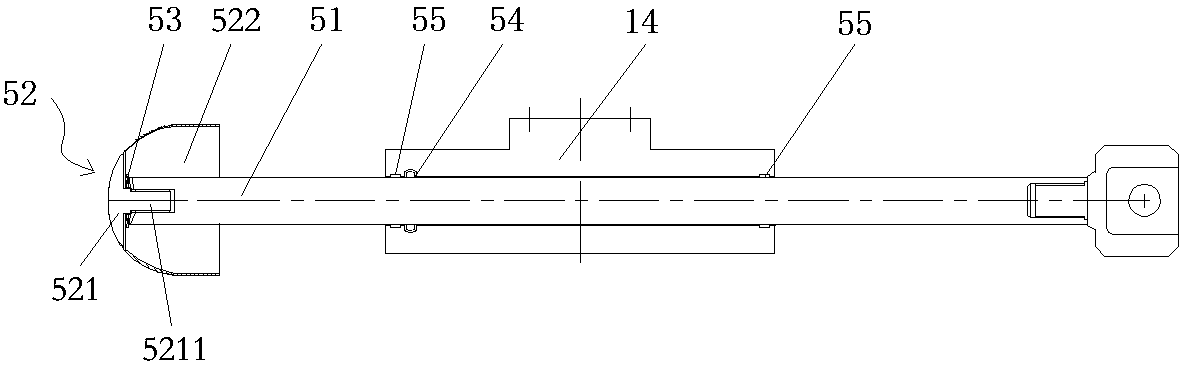

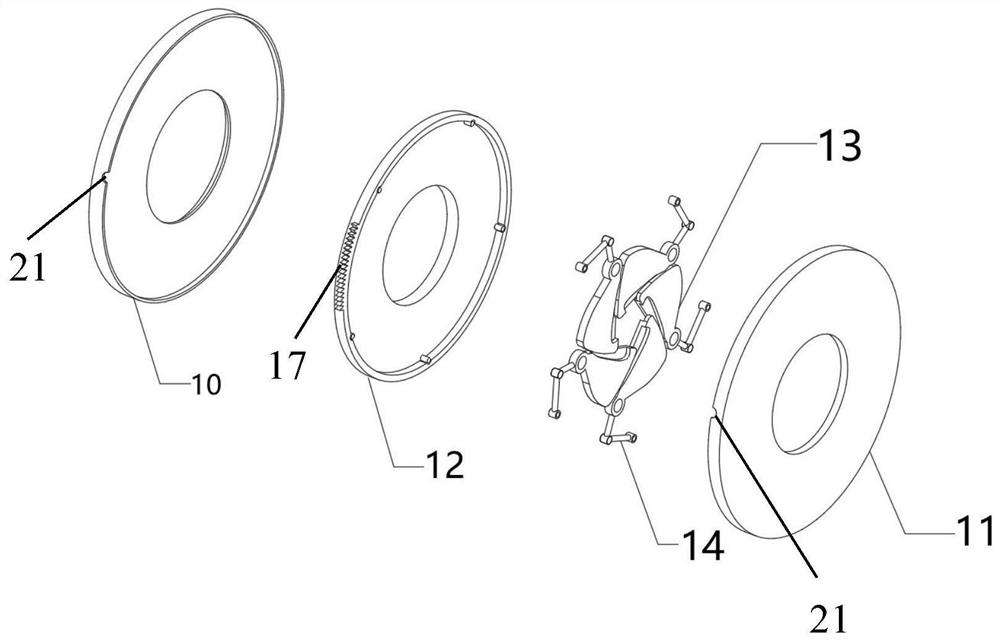

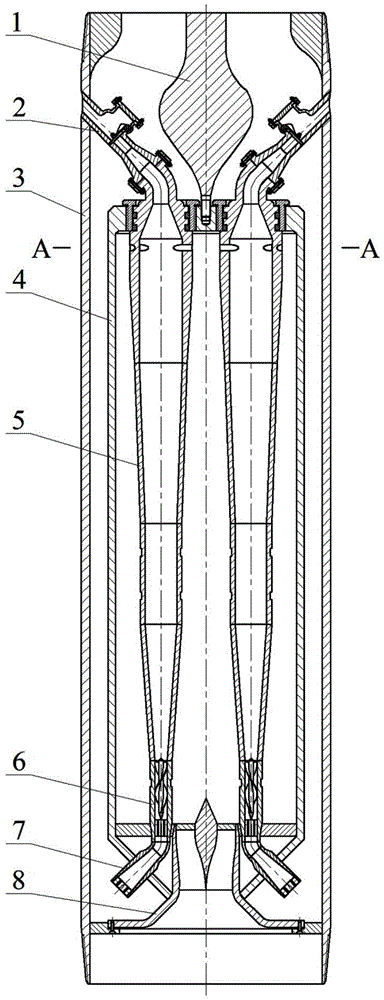

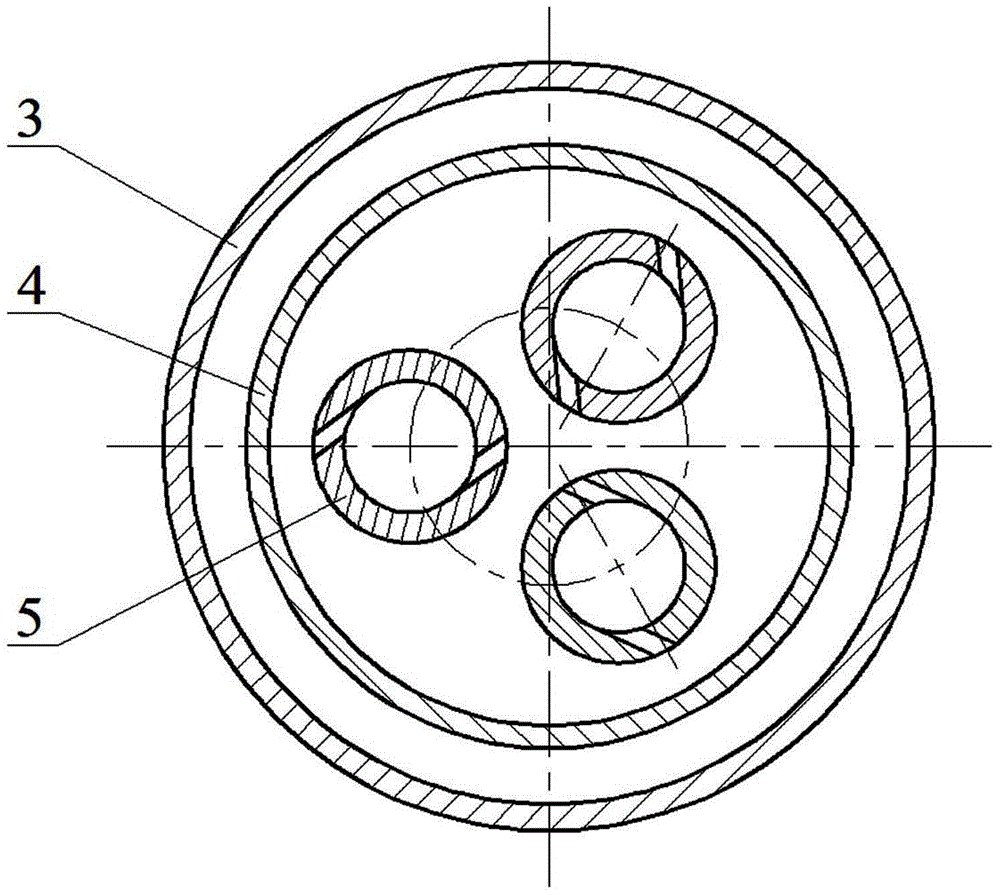

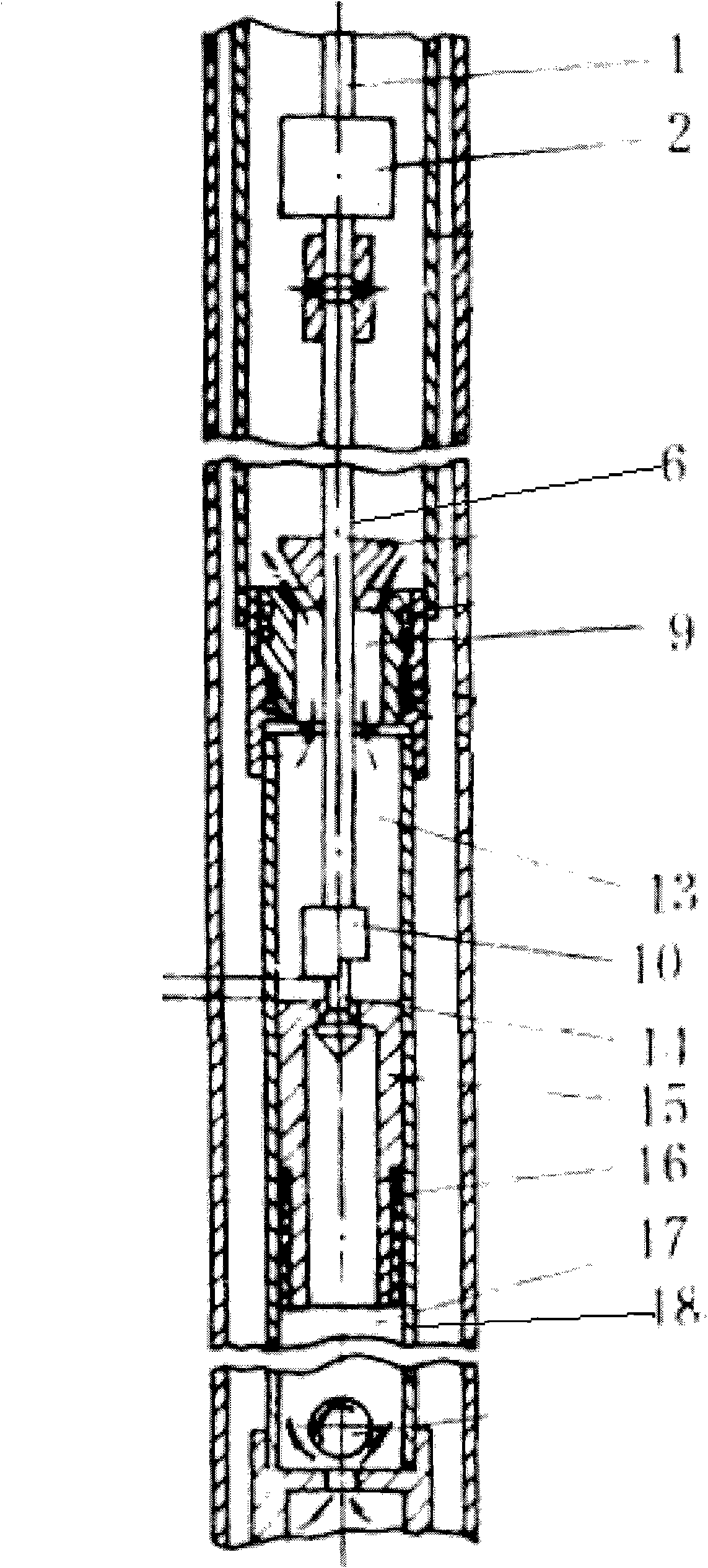

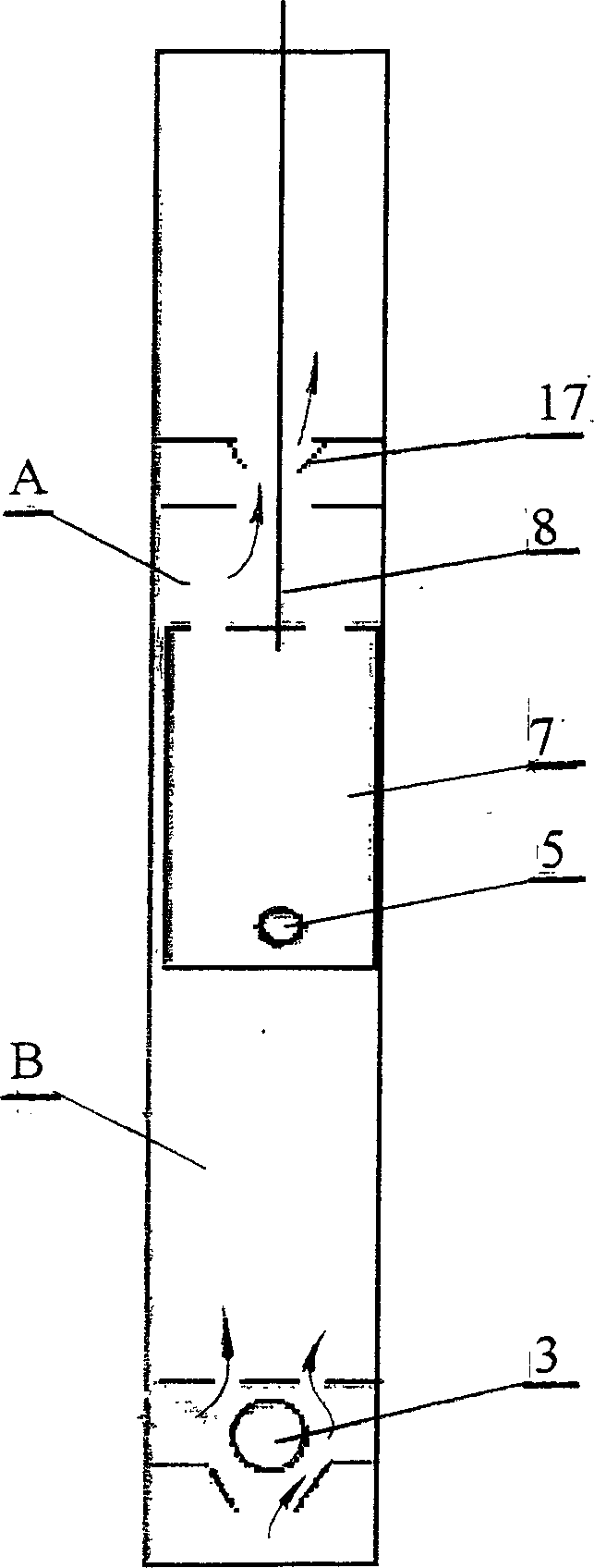

Double-barrel type two-stage axial flow downhole degassing device

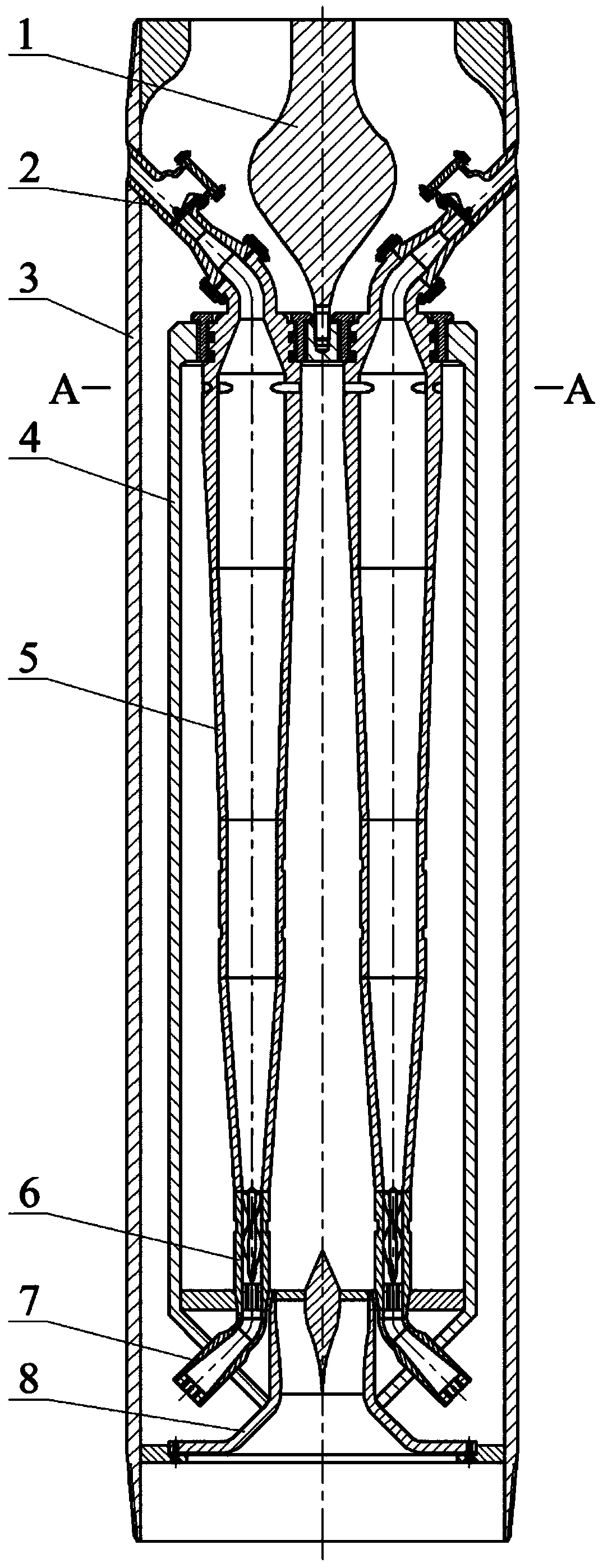

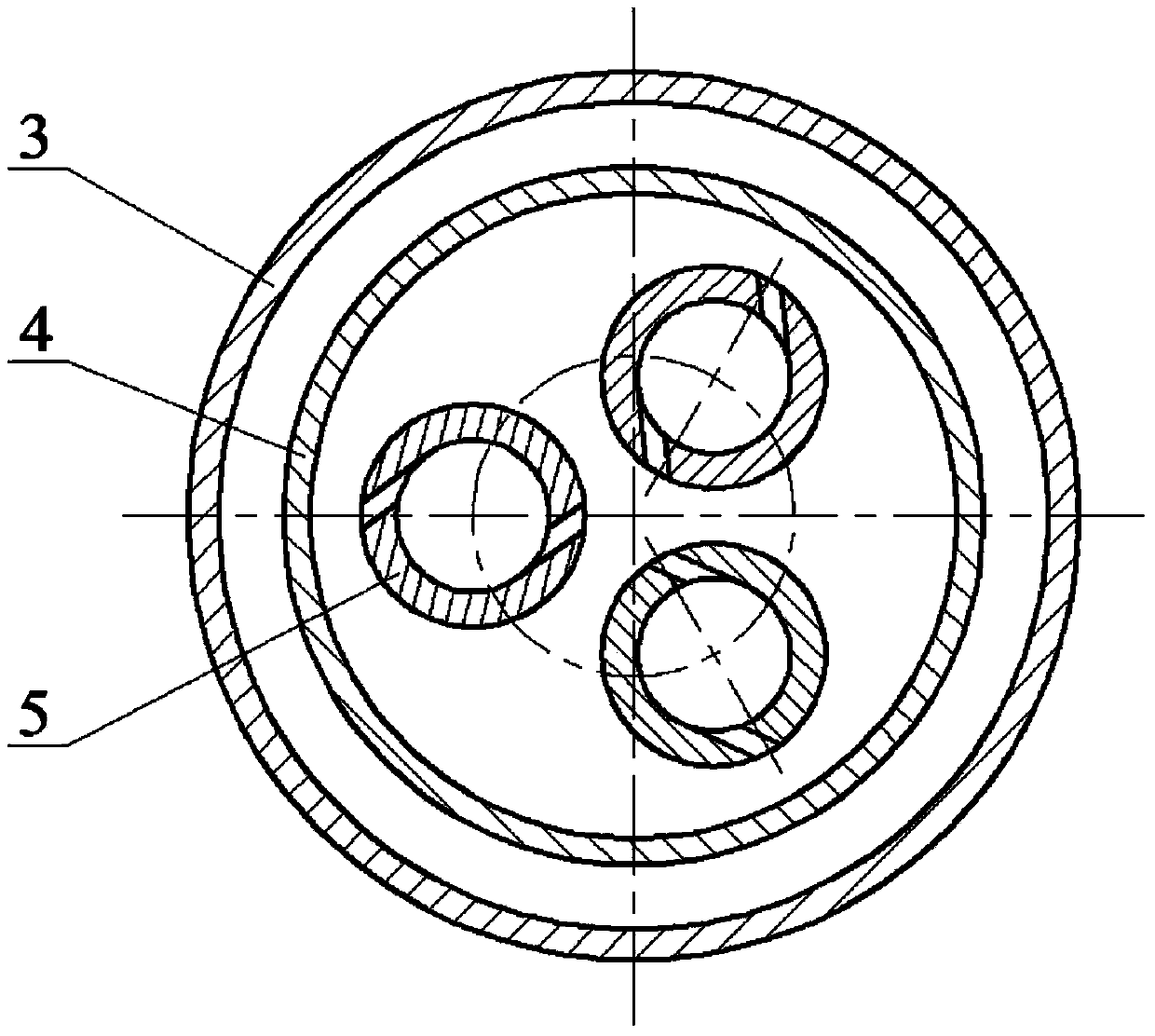

The invention provides a double-barrel type two-stage axial flow downhole degassing device which is mounted between an oil pump and a sieve pipe and which is used for gas-liquid phase separation before the oil and gas well output fluid enters the pump for the first time. According to the degassing device, by means of the special double barrel type structure and the two stage axial flow technology, the output fluid gas-liquid phase separation is implemented, and the mechanical recovery system efficiency is improved; the sieve tube is communicated with an inner fluid barrel through a fluid feeding device, and the speed of the fluid being outputted by pumping is increased; an axial flow pipe assembly adopts two stage axial flow gas-liquid separation, axial flow pipes are designed in standardized and modular manners, and the output fluid can be degassed efficiently and thoroughly; the output fluid can be ejected into the axial flow pipes in the high initial velocity through the inner fluid barrel, the double-barrel annular space is formed by the inner fluid barrel and an outer fluid barrel and is used for delivering the fluid in the axial flow pipes after degassing; the degassed fluid is adjusted reversely to form the stabilized flow through a rectifier, is discharged into the outer fluid barrel and is delivered to the oil pump after being accelerated through a fluid director, and the gas is slowed and pressurized through an exhauster before being exhausted into the wellhole.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

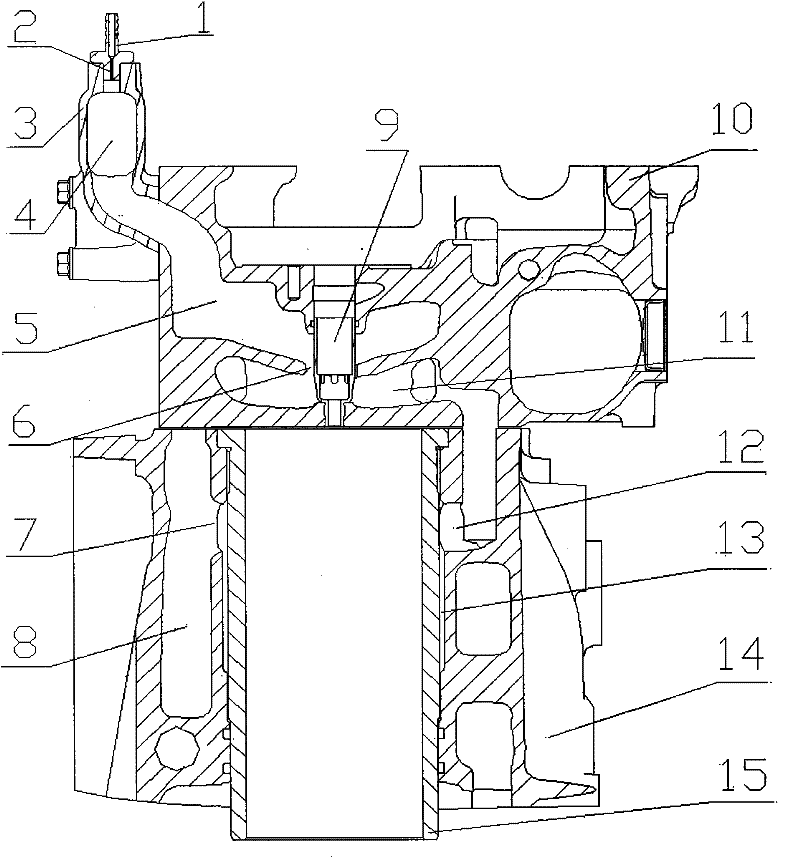

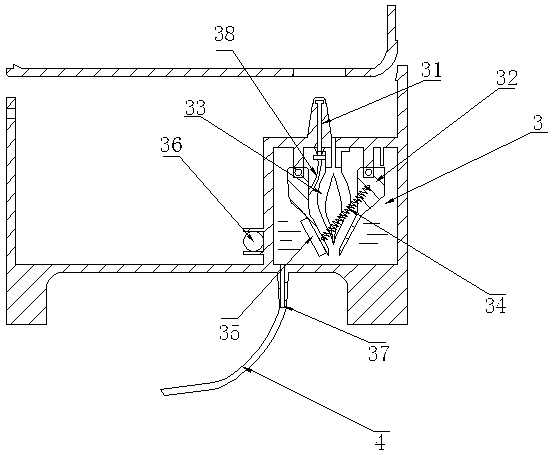

Water valve structure for automobile and automobile with same

InactiveCN104500826AStructural advantageRealize automatic adjustmentAir-treating devicesOperating means/releasing devices for valvesExhaust valveEngineering

The invention provides a water valve structure for an automobile and the automobile with the same. The water valve structure comprises a water tube, a water valve, exhaust valve blocks and a driving component, wherein the water valve penetrates through the water tube and can rotate relative to the water tube; the water valve comprise a body part and a valve block part; the valve block part is at least partially positioned inside the water tube; the body part is at least partially positioned outside the water tube; a cavity, which is internally communicated with the water tube, is defined inside the body part; the body part is internally provided with a rotating shaft part which is fixed with the body part; a shaft hole, which is communicated with the cavity, is formed inside the rotating shaft part; a water-gas separation cavity is also formed in the end, relatively far away from the valve block part, of the body part; the water-gas separation cavity is communicated with the shaft hole; exhaust holes are formed in the water-gas separation cavity; the exhaust valve blocks can be used for opening or closing the exhaust holes; the driving component is arranged to drive the rotating shaft part to rotate around the axis of the rotating shaft part. By adopting the water valve structure for the automobile, functions of automatically adjusting the liquid flow and automatically exhausting gases are achieved simultaneously.

Owner:TIANJIN BOXIN AUTOMOBILE PARTS

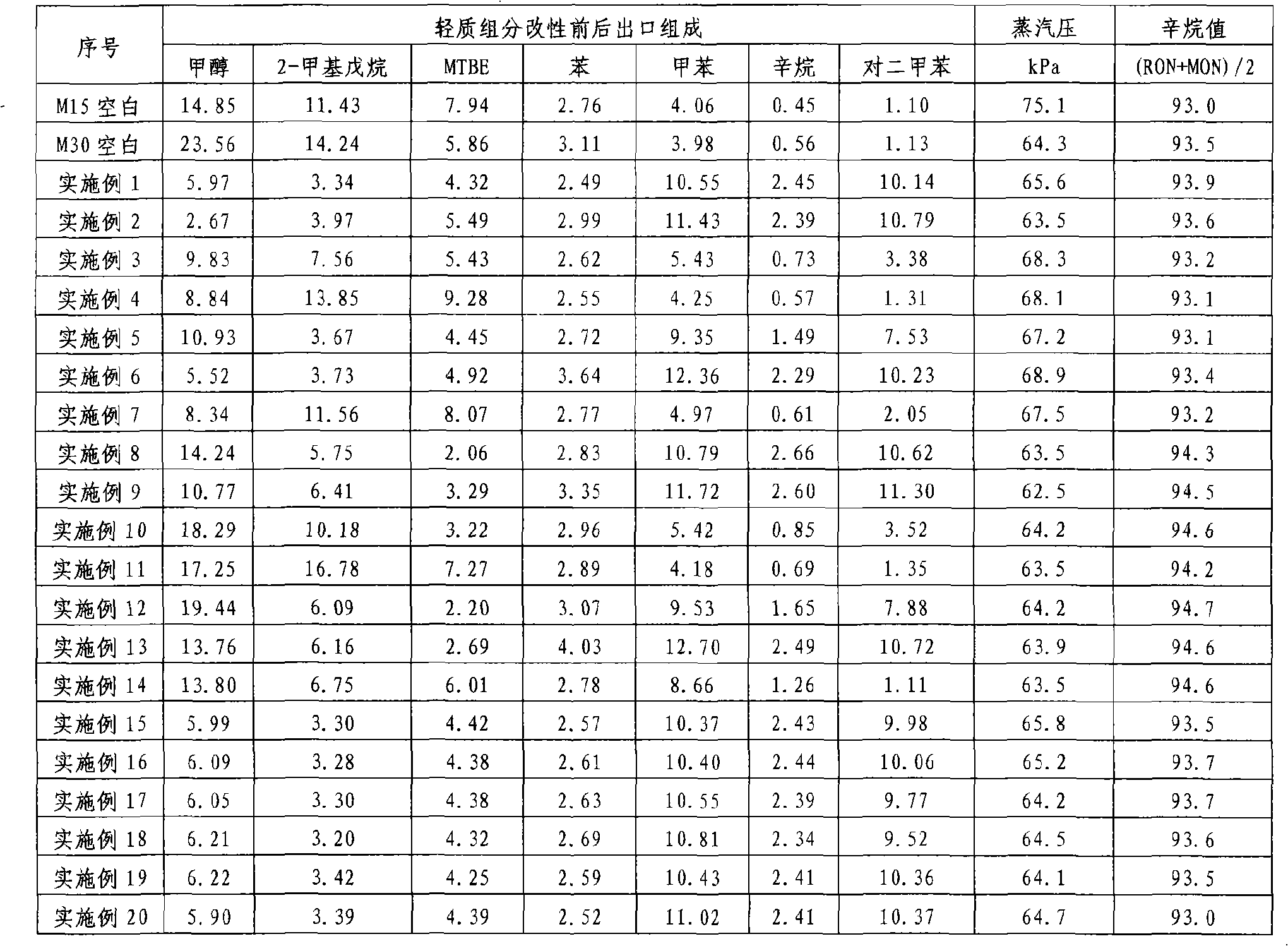

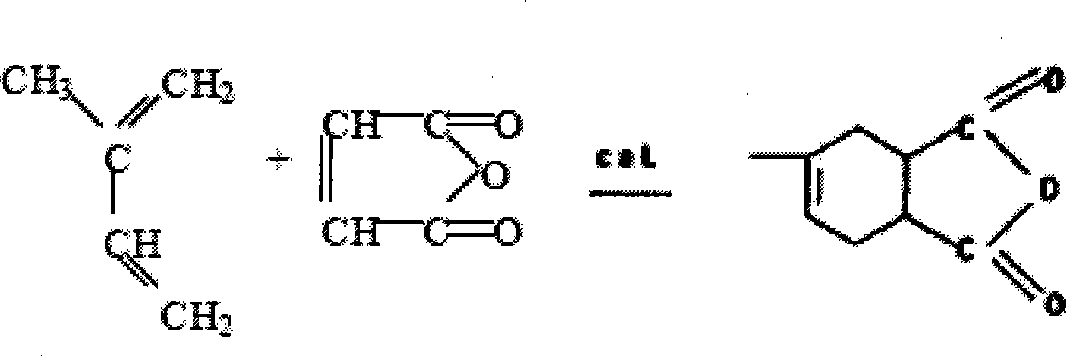

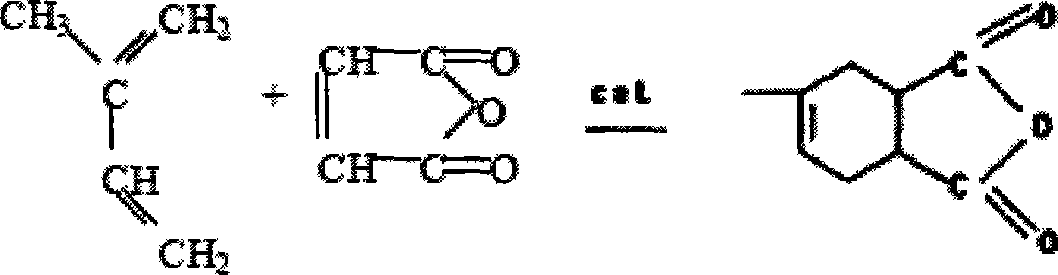

Composite catalyst for catalytic modification of methanol gasoline, method for preparing same and application thereof

InactiveCN101537370AReduce volatile componentsAvoid air lockMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystMetallurgy

The invention provides a composite catalyst for catalytic modification of methanol gasoline. Oxides, and / or phosphides, and / or silicides, and / or borides of one or more of Cr, W, Mo, Co, Ni, Zn, Cd, Cu, Pt, Sn, Sb, Zr and Sr elements are taken as active components to be loaded on a porous carrier to prepare the catalyst. According to elements, the active components account for 0.5 to 3 percent of the weight of the catalyst carrier. The catalyst can also load an auxiliary catalyst which is oxides of one or more of K, Mg and Mn, and according to elements, the auxiliary catalyst accounts for 0.2 to 1.5 percent of the weight of the catalyst carrier. The catalyst is prepared by the isometric immersion method, and mainly applied to low-proportion methanol gasoline, optimally the catalytic modification of two types of methanol gasoline of M15 and M30.

Owner:山西华顿实业有限公司

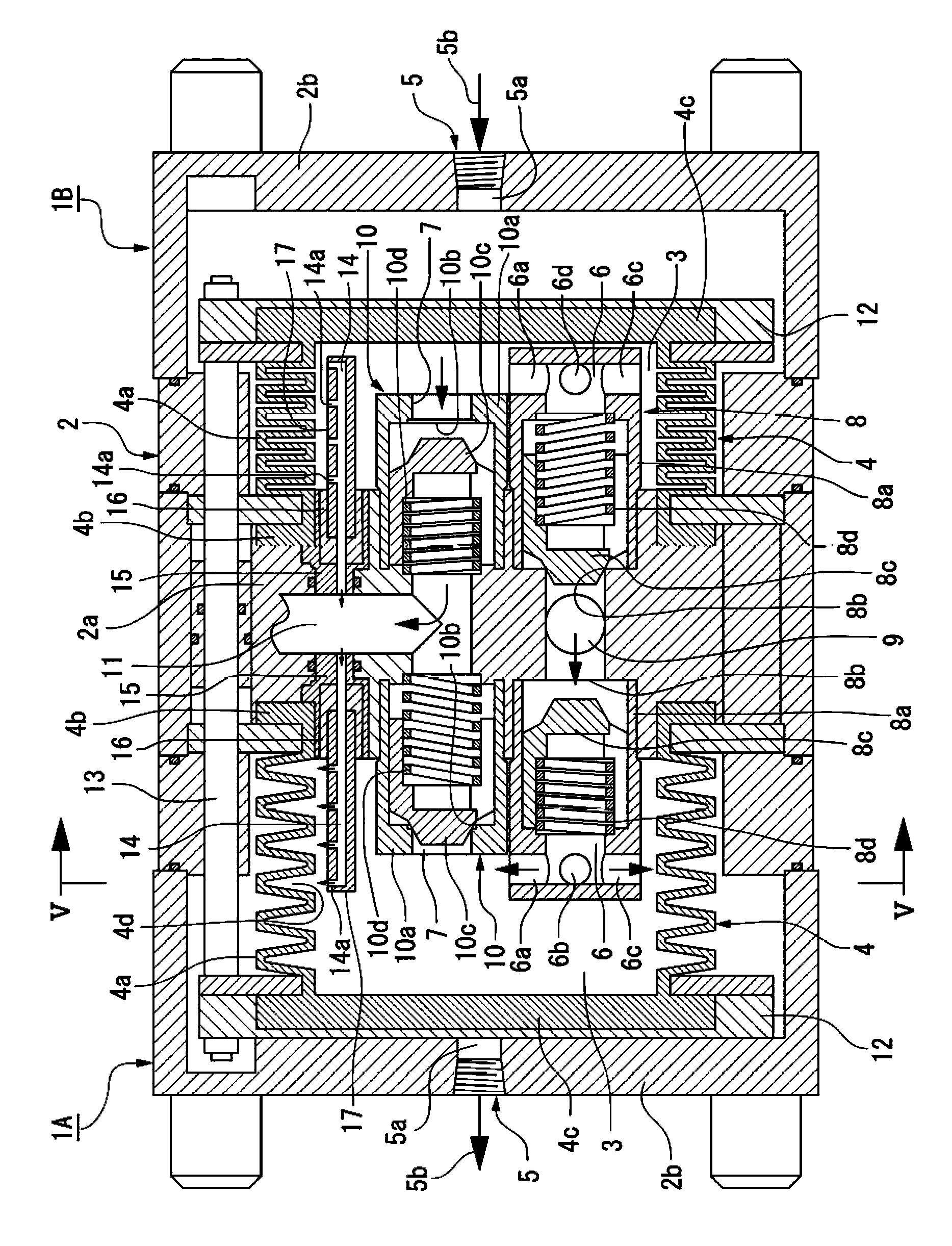

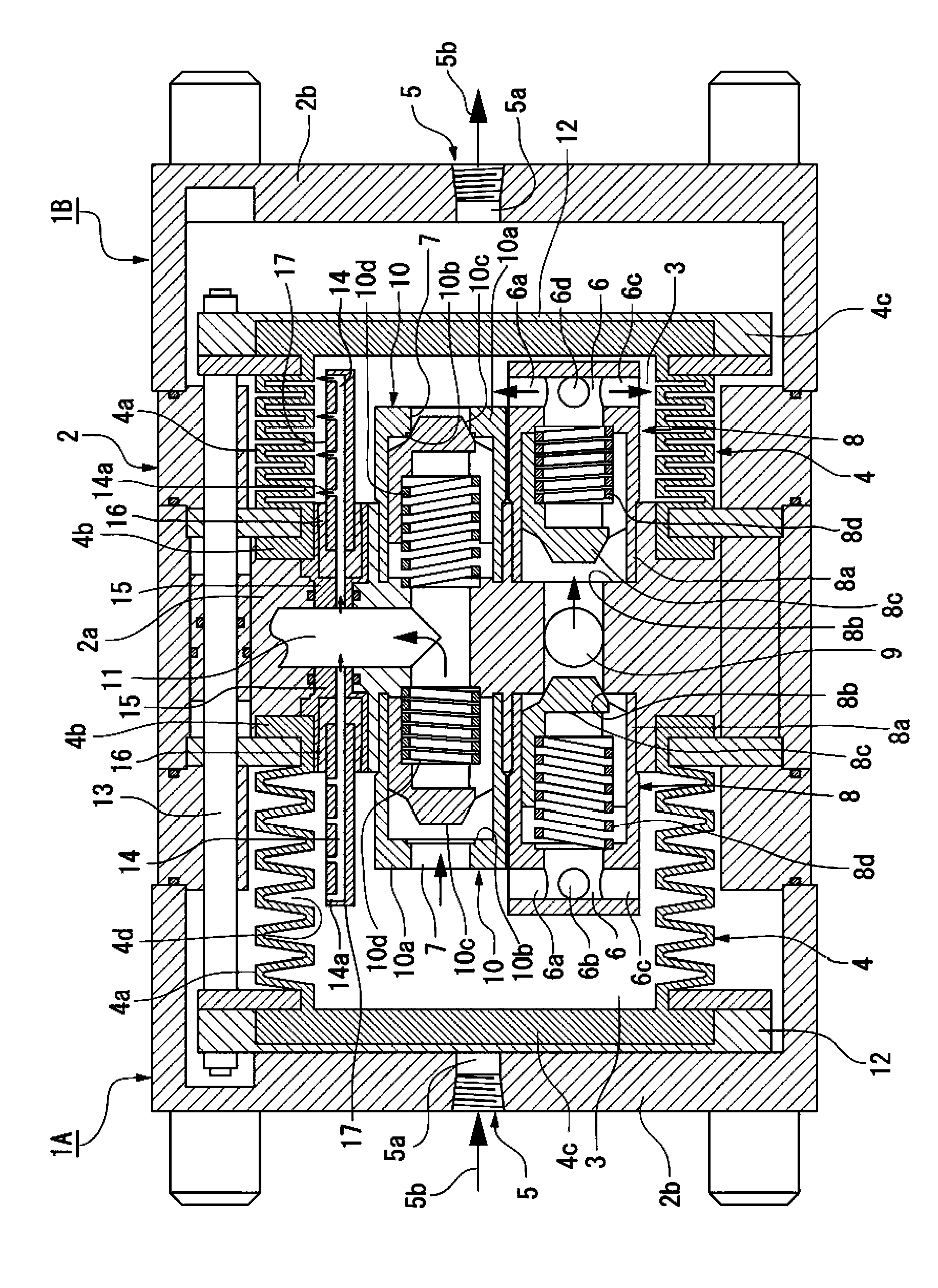

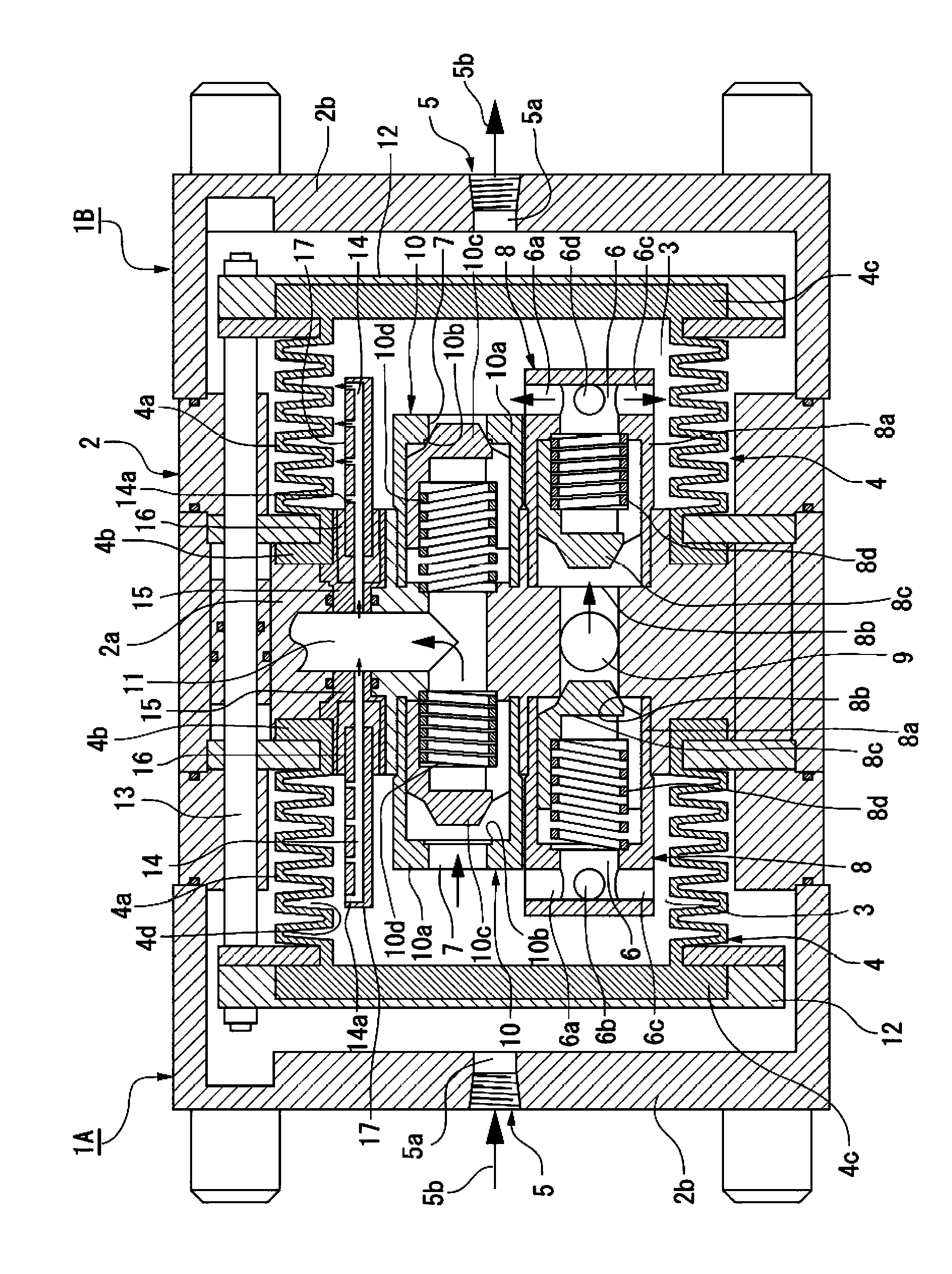

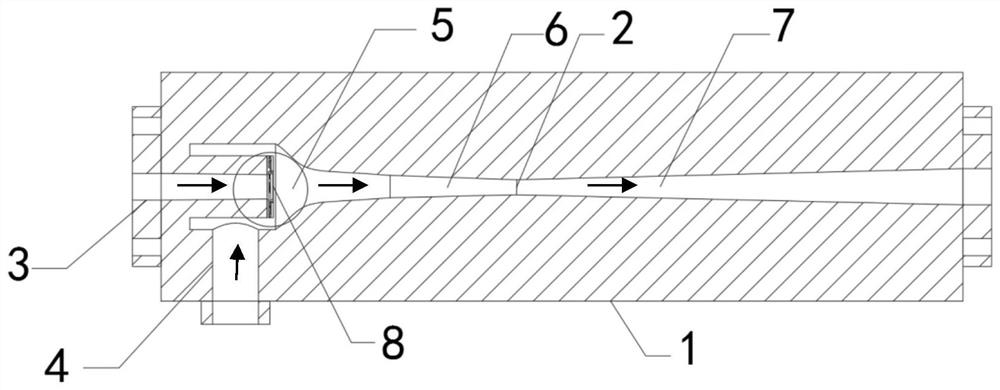

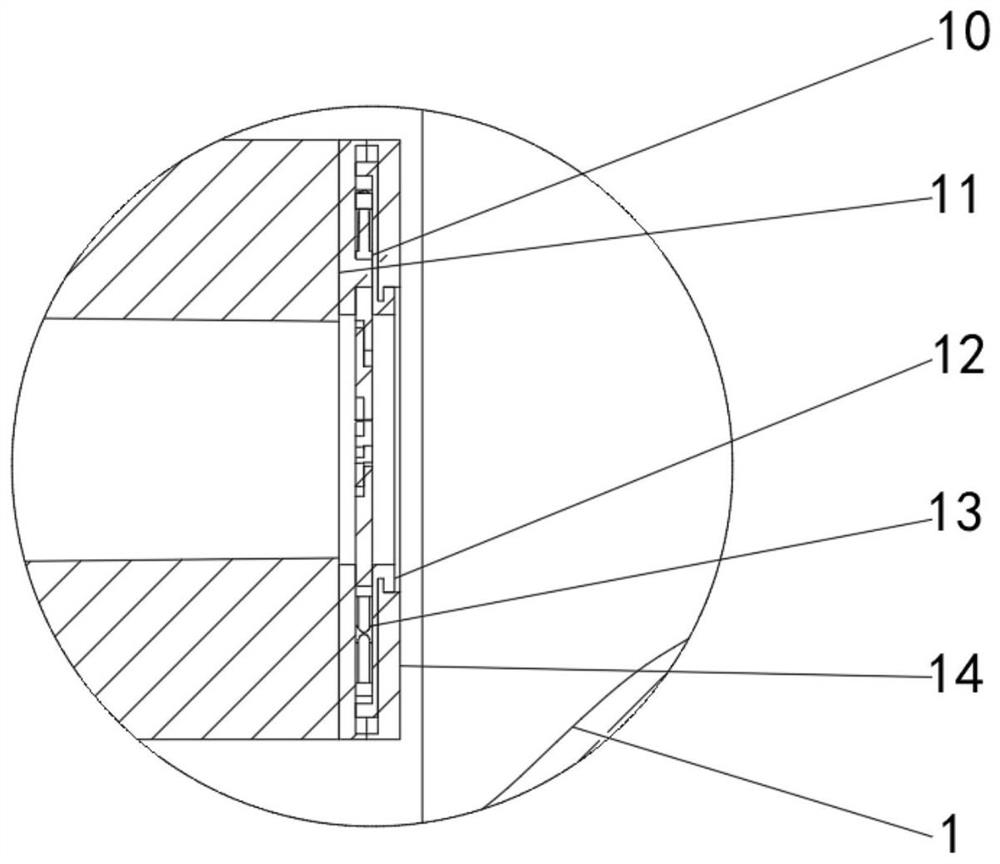

Volume pump for liquid

InactiveCN103388577APracticalAvoid air lockFlexible member pumpsPositive-displacement liquid enginesPump chamberEngineering

The invention discloses a volume pump for liquid. In the invention, the volume pump for liquid is formed in a mode of alternately and continuously carrying out a suction process of supplying the liquid to a pump chamber (3) from a suction passage (9) through a check valve (8) at the suction side and a suction port (6) by enlarging the volume of the pump chamber (3) and a discharge process of feeding the liquid to a discharge passage (9) from the pump chamber (3) through a discharge port (7) and a check valve (10) at the discharge side by reducing the volume of the pump chamber (3); and in a pump for processing the liquid which generates bubbles in the pump chamber (3), the volume pump for liquid is formed in a mode that an upper region of the pump chamber (3) is directly communicated and connected with the discharge passage (9) by a pore passage (14) and the liquid in the pump chamber (3) is enabled to slightly flow towards the discharge passage (9) from the pore passage (14) in the discharge process so as to remove the bubbles in the pump chamber (3) and enable the check valves (8, 10) not to generate the gas locking phenomenon.

Owner:NIPPON PILLAR PACKING CO LTD +1

A kind of degassing method of diesel engine cooling system

InactiveCN102269040AAvoid air lockAvoid Coolant LossLiquid coolingMachines/enginesEngineeringCylinder block

The invention relates to a method for degassing the cooling system of a diesel engine. The cooling system includes a degassing joint, a water inlet main pipe, a water jacket on the cylinder head, a water jacket under the cylinder head, a water jacket on the cylinder block and a water collection main pipe on the cylinder block; the degassing joint is installed on At the highest position above the water inlet pipe, the coolant of the diesel engine enters the upper water jacket of the cylinder head, the lower water jacket of the cylinder head, the water jacket of the cylinder block and the water collection pipe of the cylinder block from the water inlet pipe in sequence; The water jacket enters the lower water jacket of the cylinder head and the upper water jacket of the cylinder head in turn, collects the air bubbles generated by the coolant in the lower water jacket of the cylinder head and the upper water jacket of the cylinder head, enters the water inlet main pipe, and is discharged through the degassing joint. The coolant of the diesel engine cooling system and the air bubbles generated by the coolant during the operation of the diesel engine move in the opposite direction to ensure that the air bubbles generated by the coolant are discharged at any time during the operation of the diesel engine, so as to avoid air resistance in the cooling system, resulting in a decrease in the flow of the coolant, and finally the occurrence of diesel engine coolant. The phenomenon of boiling the pot.

Owner:GUANGXI YUCHAI MASCH CO LTD

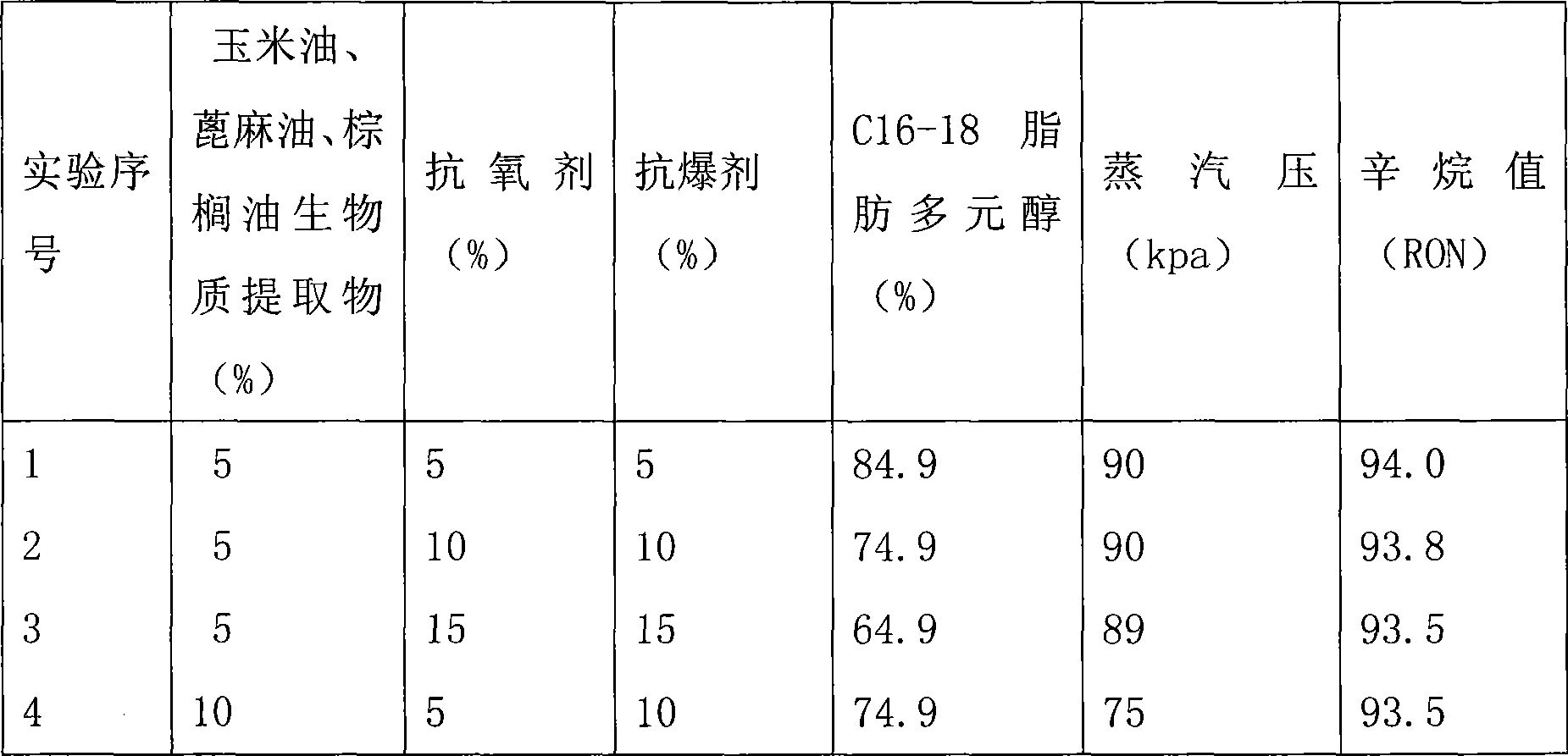

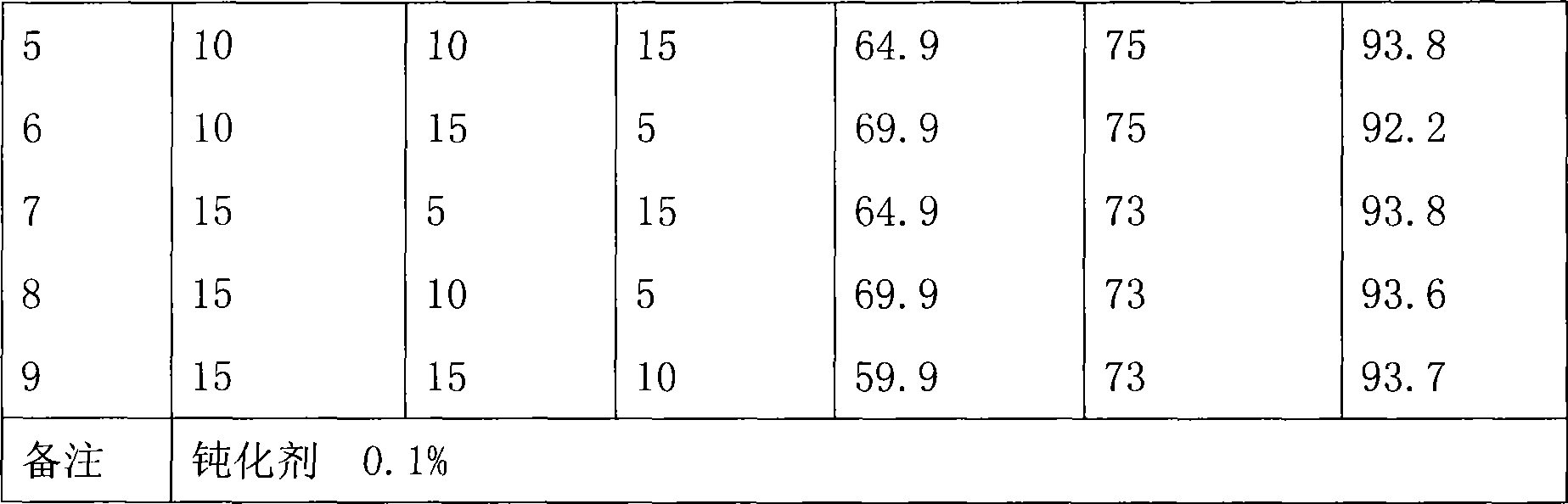

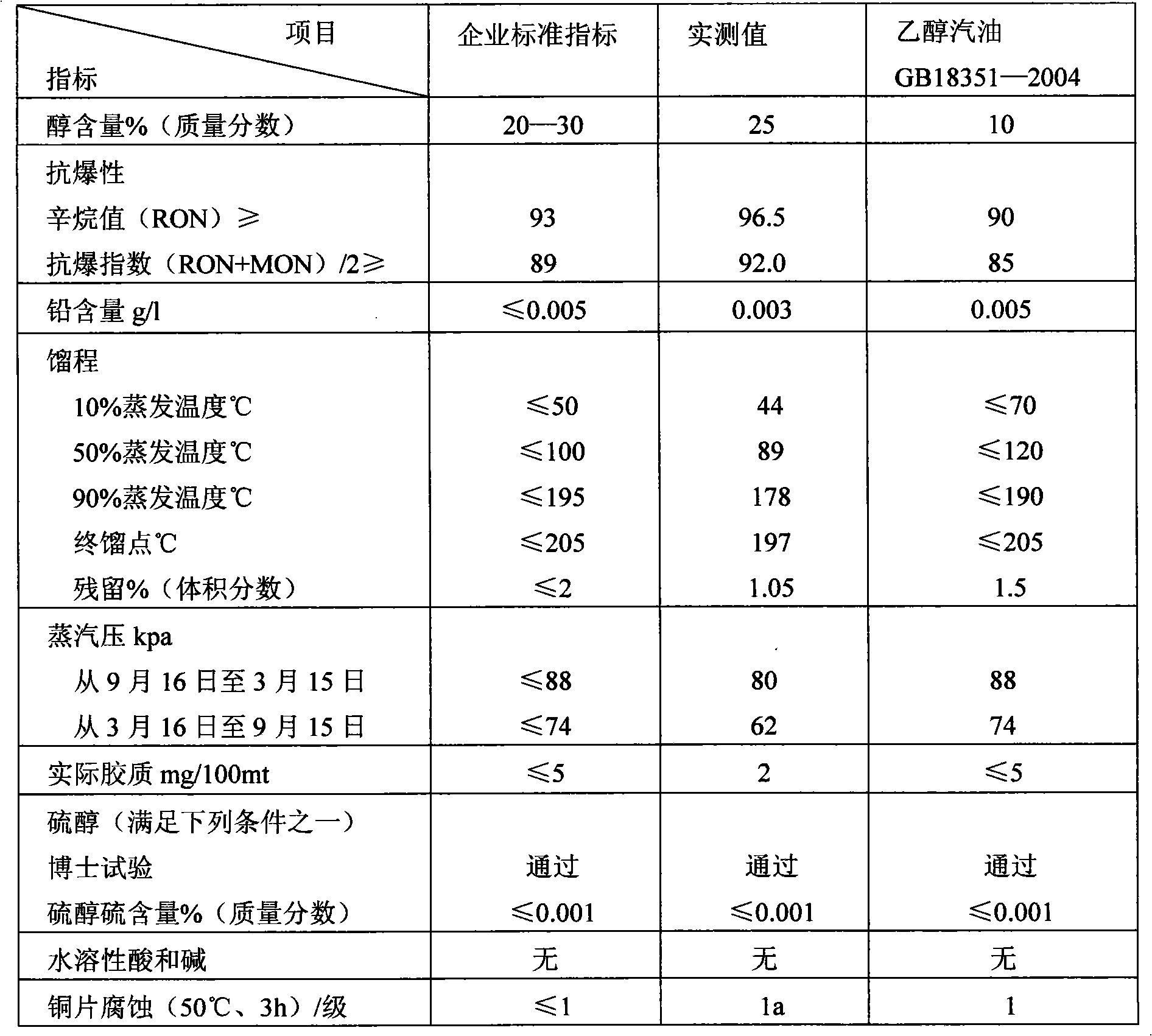

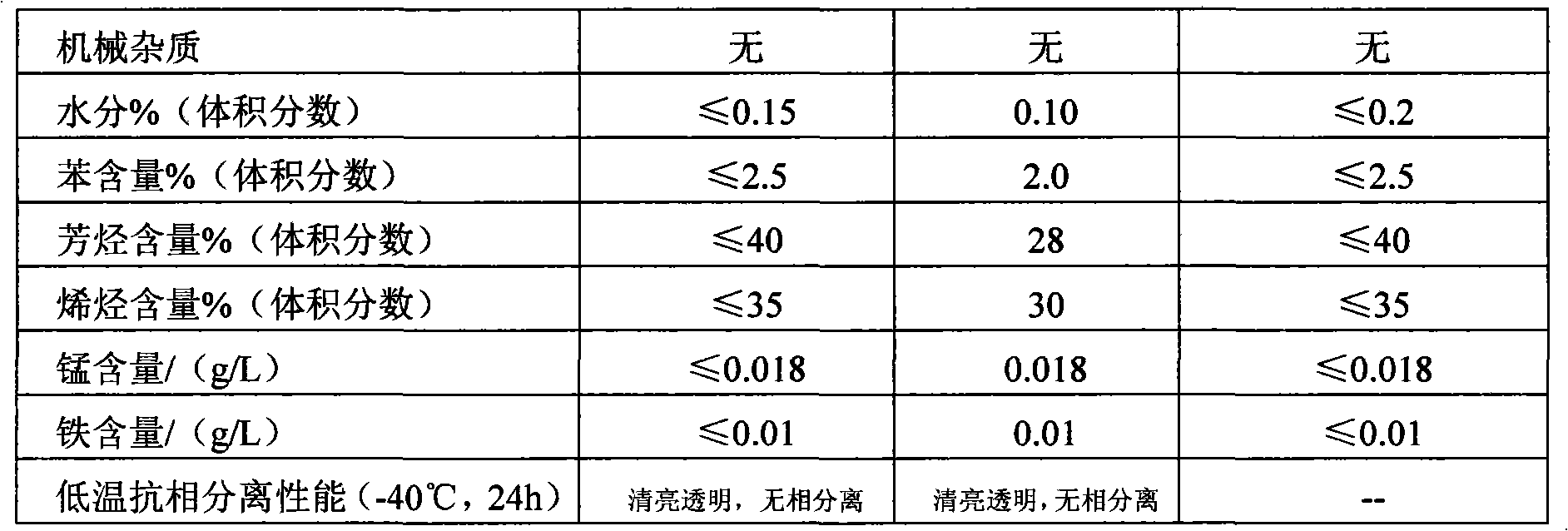

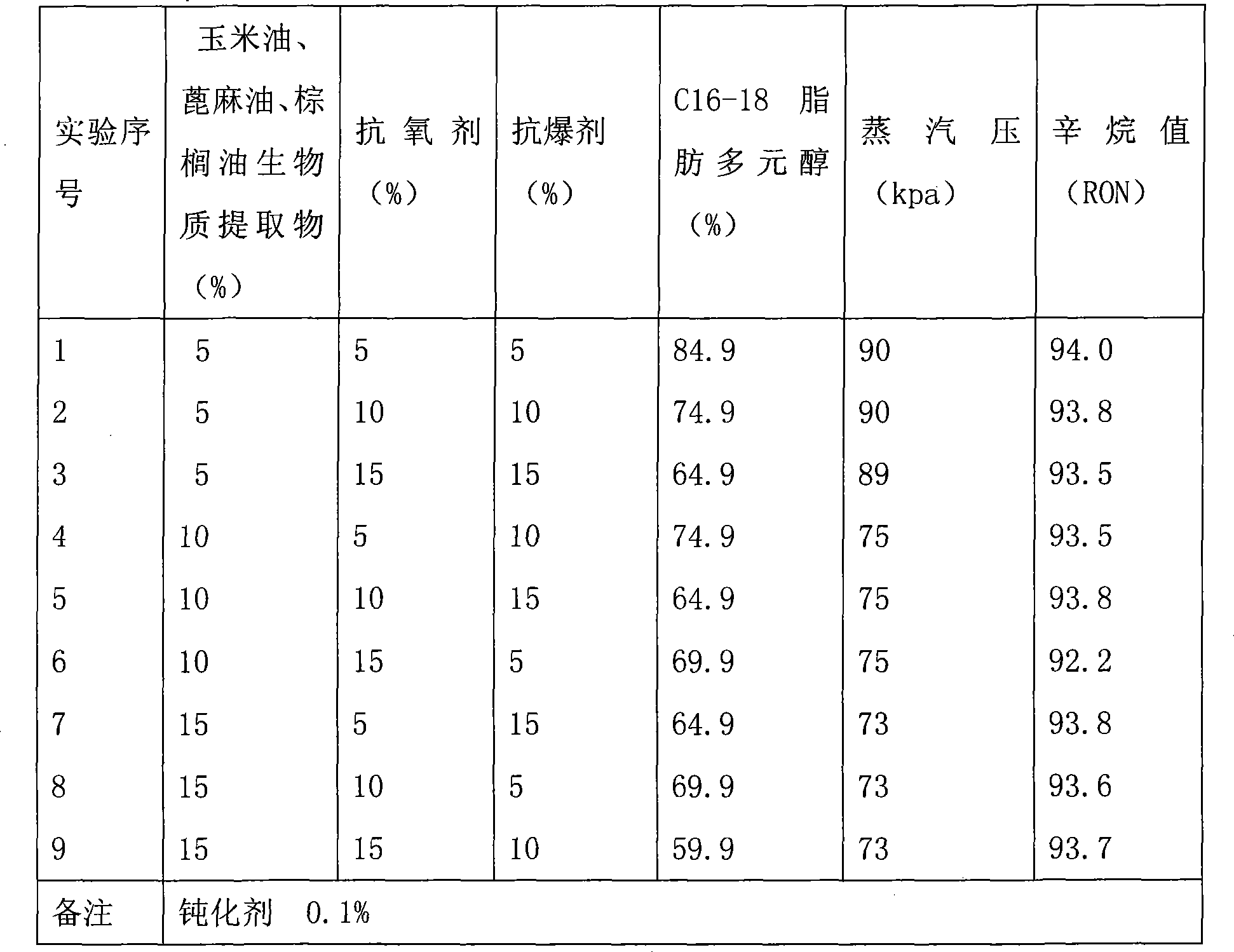

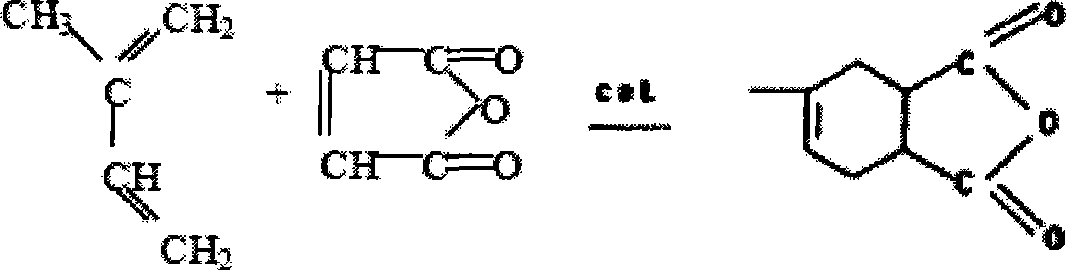

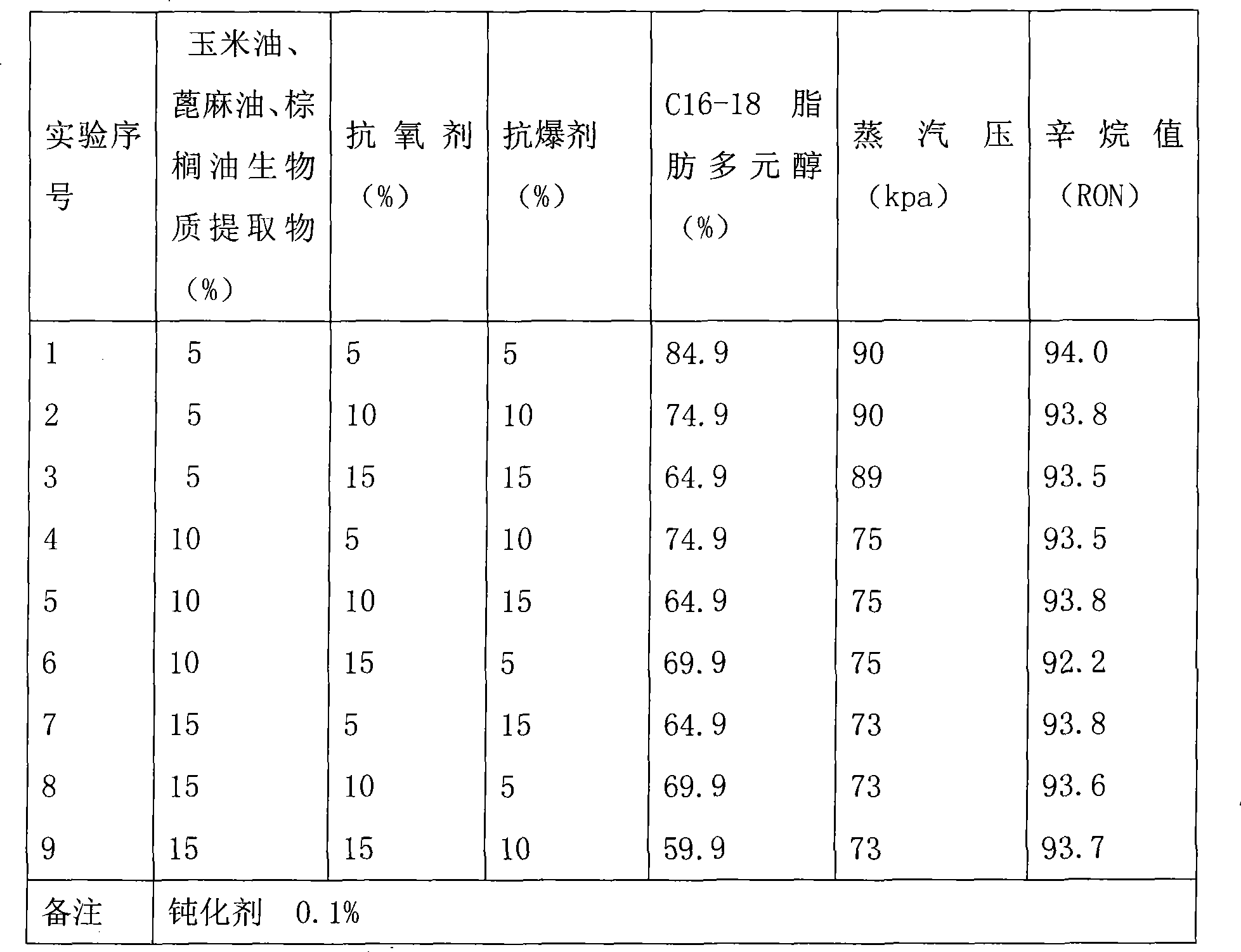

Automobile composite fuel

InactiveCN101386798ASolve cokingSolve the problem of carbon accumulationLiquid carbonaceous fuelsGasoline fuelAntioxidant

The invention discloses a composite fuel oil for automobiles, which belongs to the technical field of automobile fuel oil. The fuel oil product of the automobiles is compounded by a fuel oil additive and gasoline, wherein the fuel oil additive is prepared by mixing a mixture of extractives of biomass such as corn oils, castor oils and palm oils, fatty polyol, antioxidants, antiknock agents, passivation agents and modified C5 according to certain proportion. The composite fuel oil product can partly substitute gasoline as well as improve gasoline performance so as to combust gasoline more fully and reduce coking and carbon deposition in an engine and emission of harmful substances in automobile tail gas. Through inspection of Chinese Ethanol Gasoline Quality Supervision and Testing Center, the product reaches national standard.

Owner:HENAN ACAD OF SCI

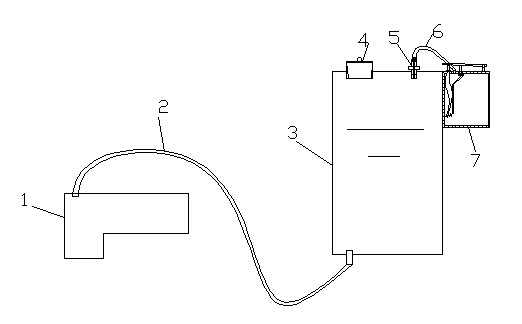

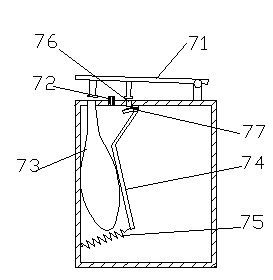

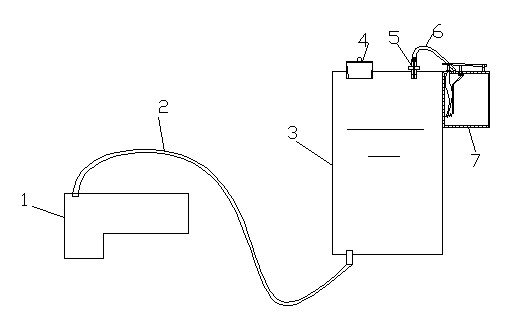

Pressure dynamic compensation device and continuous ink supply system using pressure dynamic compensation

The invention relates to a pressure dynamic compensation device and a continuous ink supply system using pressure dynamic compensation. The pressure dynamic compensation device comprises a pressure dynamic compensation container (7) and an elastic air bag (73), wherein the elastic air bag (73) is arranged inside the pressure dynamic compensation container (7), an opening of the elastic air bag (73) is in sealed connection with a connector of the container and communicated with the atmosphere, a compensation port (72) and an air inlet (76) are arranged on the pressure dynamic compensation container (7), an air inlet inner cover which corresponds to the position of the air inlet (76) is connected with the bag body of the elastic air bag (73) directly or indirectly. According to the pressure dynamic compensation device and the continuous ink supply system using pressure dynamic compensation, the chance that ink contacts with the outside air is reduced effectively, also the probabilities of oxidation, evaporation and crystallization of ink are reduced so that a phenomenon that heads are blocked is reduced; small bubbles of the ink disappear gradually due to discontinuous negative pressure of an ink storage barrel so as to solve phenomenon that air is blocked; and the problem that the ink flows out of an ink box and flows back to the ink box is solved.

Owner:抚州市新智铨科技有限公司

Built-in sealed continuous ink supply system with pressure dynamic compensation function

The invention relates to a built-in sealed continuous ink supply system with a pressure dynamic compensation function. The built-in sealed continuous ink supply system comprises an ink soft bag (1), a pressure dynamic compensation device and a printing head (5). The ink soft bag (1) is positioned above the pressure dynamic compensation device and is connected with an ink inlet (31) of the pressure dynamic compensation device by a soft bag connecting tube (2), an elastic air bag (33) is arranged in the pressure dynamic compensation device, an ink outlet (37) on the lower side of the pressure dynamic compensation device is connected with the printing head (5) by an ink supply tube (4), and the pressure dynamic compensation device is in a sealed state when ink is supplied by the ink inlet (31) and the ink outlet (37). The built-in sealed continuous ink supply system has the advantages that the ink is completely prevented from being in contact with external air, the probability of oxidation, evaporation and crystallization of the ink is reduced, and a phenomenon of head blockage is decreased; problems of air resistance, backflow, misting, overflow and the like can be effectively solved, and the built-in sealed continuous ink supply system is provided with a warning device with functions of ink deficiency voice prompting, corresponding indicator lamp prompting and the like.

Owner:抚州市新智铨科技有限公司

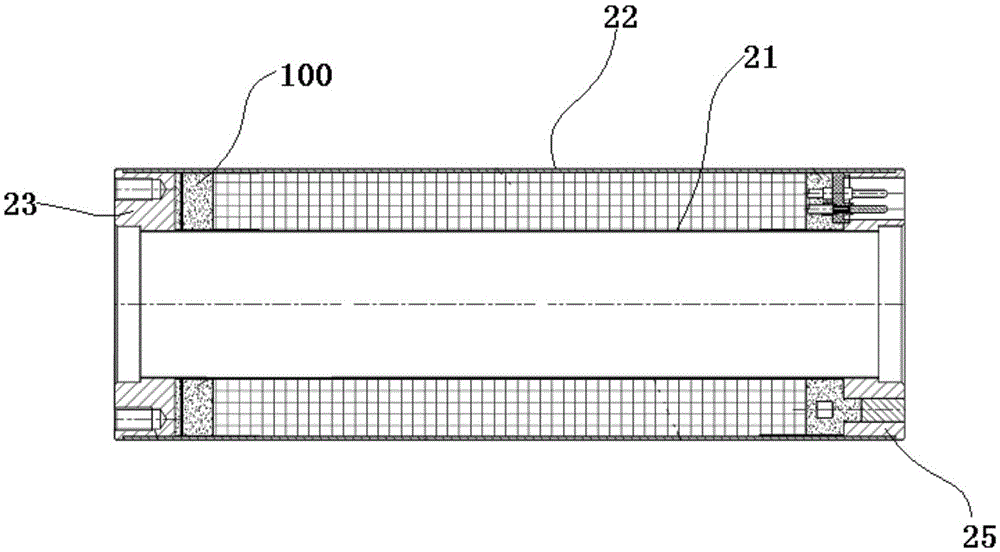

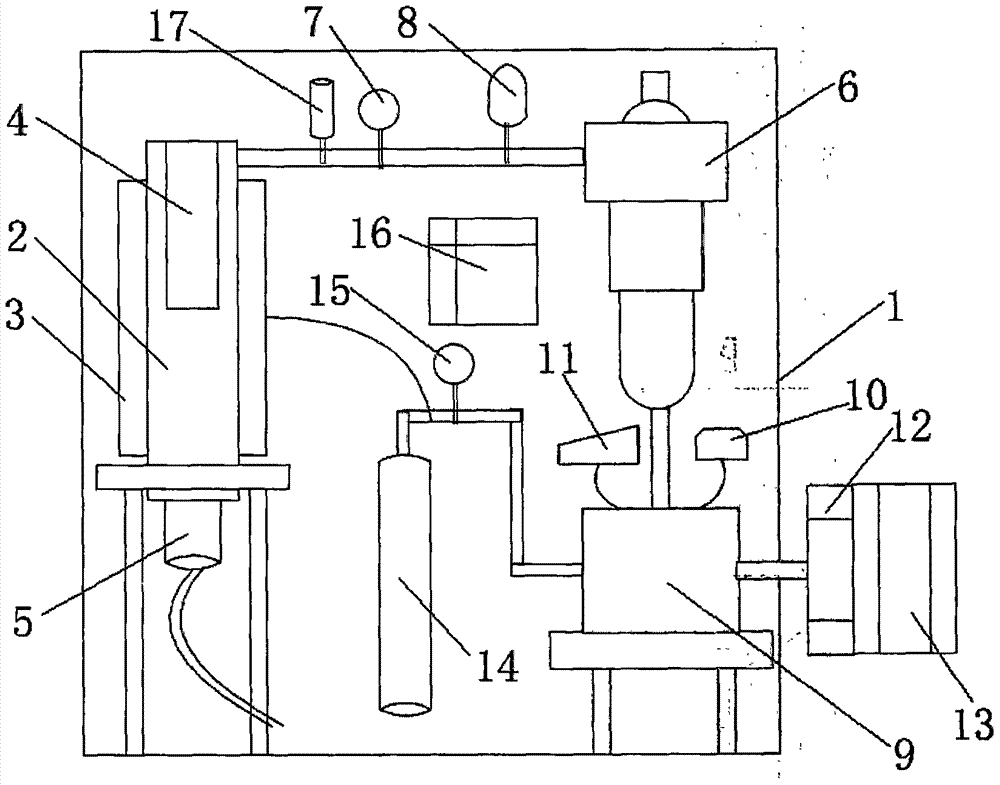

Shield electric motor for oil-submerged pump and preparation method therefor

ActiveCN105634183AImprove insulation performanceImprove securityMagnetic circuit stationary partsManufacturing dynamo-electric machinesDrive shaftEngineering

The invention discloses a shield electric motor for an oil-submerged pump and a preparation method therefor. The shield electric motor comprises a vacuum pump shell, a cable assembly, a stator assembly mounting cylinder sleeve arranged in the vacuum pump shell, a driving shaft, a rotor assembly mounted on the driving shaft, a stator assembly arranged in the stator assembly mounting cylinder sleeve, an upper end supporting base body assembly and a lower bearing base assembly, wherein the upper end supporting base body assembly and the lower bearing base assembly are arranged at the two ends of the stator assembly mounting cylinder sleeve, and a sealed cavity is formed in the stator assembly mounting cylinder sleeve; the rotor assembly is positioned in the sealed cavity; the stator assembly mounting cylinder sleeve comprises an inner cylinder sleeve, an outer cylinder sleeve, and a left end cover and a right end cover for fixing the inner cylinder sleeve and the outer cylinder sleeve together; the stator assembly in the stator assembly mounting cylinder sleeve is poured and sealed with epoxy resin; and the epoxy resin is poured and sealed through a resin pouring and sealing working table. The shield electric motor is simple in structure, high in insulation, high in safety, capable of eliminating an air-resisting phenomenon, long in service life, and convenient to process.

Owner:ZHEJIANG JIASONG TECH CO LTD

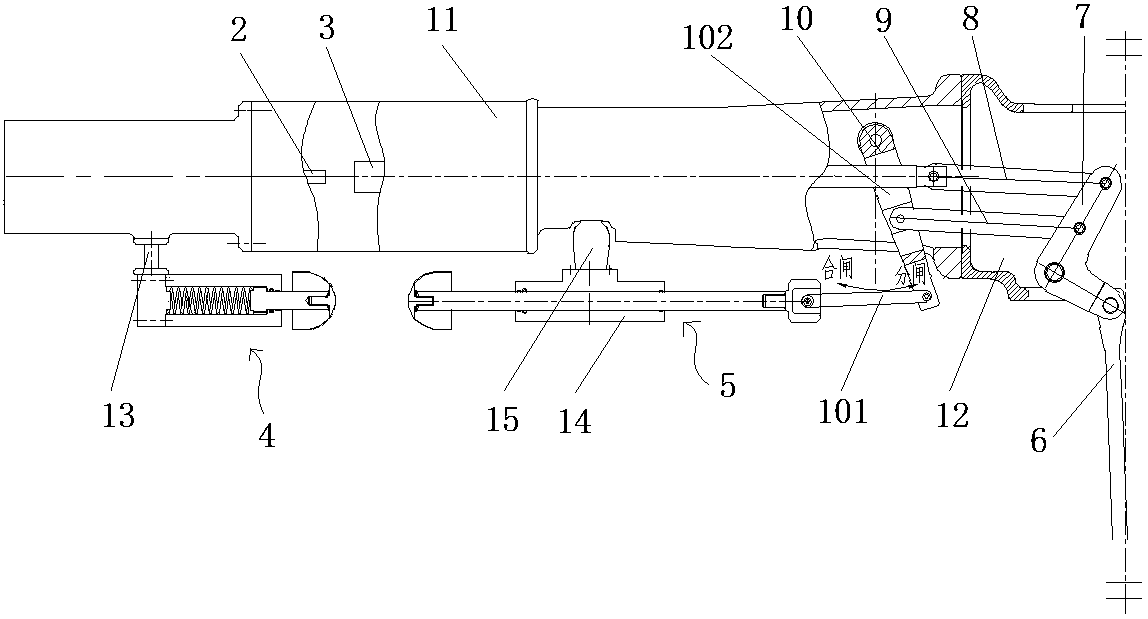

Oil pumping technique based on mechanical open-and-close valve oil well pump

InactiveCN103133309AAvoid "air lock"Positive displacement pump componentsFlexible member pumpsInlet valvePlunger

The invention discloses an oil pumping technique based on a mechanical open-and-close valve oil well pump. The technique includes an upstroke and a downstroke. The upstroke includes: an oil pumping rod is elevated to enable a plunger oil outlet valve to be closed, a plunger is driven to move upward, and an oil inlet valve is opened to for oil in-taking; and the pressure of an upper cavity is increased, oil and gas in the upper cavity are exhausted into an oil pipe in advance, and the airlock phenomenon is effectively prevented from occurring. The downstroke includes: the oil pumping rod moves downward to open the plunger oil outlet valve and the upper cavity and a lower cavity to be communicated; when the oil pumping rod moves downward, the plunger is driven to move downward, oil and gas in the lower cavity enter the upper cavity; and during the period of time when the plunger approaches a bottom death center and then leaves the bottom death center, the upper cavity and the lower cavity of the plunger oil outlet valve are communicated by a gas outlet hole to complete gas exhausting and ensure that the plunger oil outlet valve is opened timely in the upstroke. A push block and the gas outlet hole are designed on a valve rod, and when the plunger whether approaches the bottom death center or moves upward for a small distance in a reversing direction, the upper cavity and the lower cavity of the plunger oil outlet valve can be communicated to discharge oil and gas in the upper cavity into the oil pipe in advance, so that the airlock phenomenon is effectively prevented from occurring.

Owner:严欢

Low-carbon denatured alcohol gasoline and application

InactiveCN101597523ALow costSave resourcesLiquid carbonaceous fuelsFuel additivesDenatured alcoholMethanol fuel

The invention discloses a low-carbon denatured alcohol gasoline and application. The low-carbon denatured alcohol gasoline comprises the following components in percentage by weight: 60-80% of alcohol, 5-15% of fuel ethanol and 5-26% of additive, wherein the additive is composed of the following components in percentage by weight: 45-55% of ortho-nitrotoluene, 20-37% of dimethoxymethane, 5-8% of dimethyl malenate, 0.4-.06% of corrosion inhibitor for metal and 0.4% of antiswelling inhibitor for rubber. The low-carbon denatured alcohol gasoline is added into the national standard gasoline in percentage by weight of 20-85% to be applied. The low-carbon denatured alcohol gasoline is a motor gasoline with better cleanability, lower gasoline consumption rate, larger mixing amount and lower raw material cost; the cost of the motor gasoline is obviously lowered, resource is saved, and engine emission is further improved; at the same time, the motor gasoline solves the problems of high gasoline consumption, low-temperature layering, and the like, lowers saturation vapour pressure and prevents the air blocking phenomenon.

Owner:莫春福

High-voltage switch and fracture structure

ActiveCN111105954AAchieve shieldingEasy to processHigh-tension/heavy-dress switchesAir-break switchesCrankElectric power system

The invention relates to a high-voltage switch and a fracture structure. The high-voltage switch comprises a support cylinder, and a horizontal cylinder body is arranged at the upper end of the supporting cylinder; a transmission rod is arranged in the supporting cylinder; a pull rod connected with a moving contact of an arc extinguishing chamber is arranged in the horizontal cylinder body; the transmission rod is connected with the pull rod through a crank arm; a resistor moving contact and a resistor static contact are arranged on the horizontal cylinder body; a swing arm is hinged to the horizontal cylinder body, the swing arm is connected with the crank arm through a connecting rod and drives the resistor moving contact to move in the same direction as the arc extinguishing chamber moving contact when the crank arm rotates; and the resistor moving contact and the resistor static contact are switched on before the arc extinguishing chamber moving contact and the arc extinguishing chamber static contact are switched on when the swing arm swings. Before the moving contact and the static contact of the arc extinguishing chamber are switched on, the resistor moving contact and the resistor static contact are switched on firstly, the closing resistor is connected into an electric power system earlier than a main loop, large current generated by closing directly acts on the closing resistor and is dissipated in the form of heat, and then, the main loop is closed, so that the moving contact and the static contact of the arc extinguishing chamber are protected.

Owner:PINGGAO GRP +2

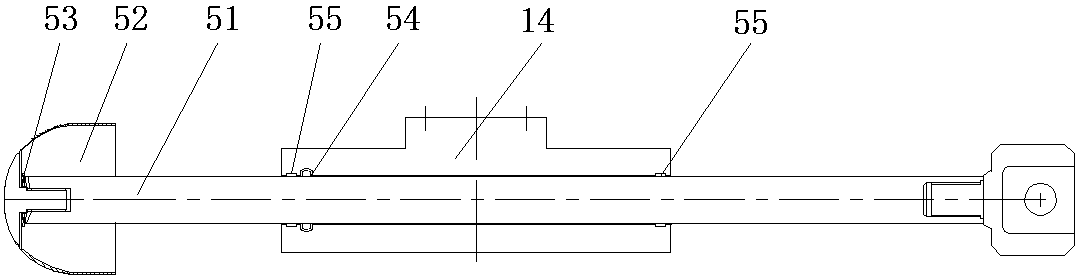

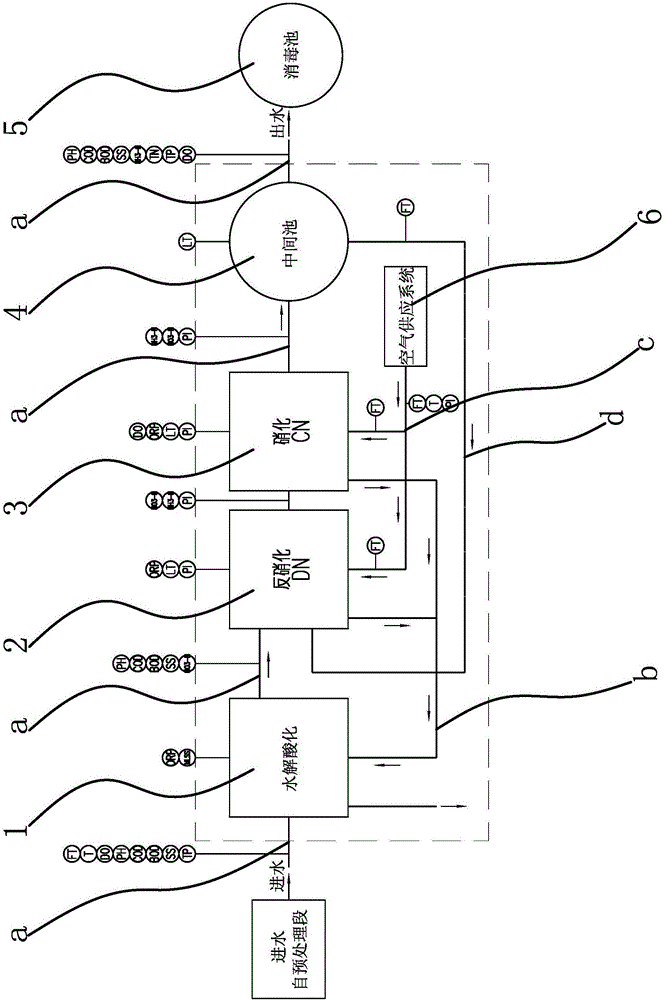

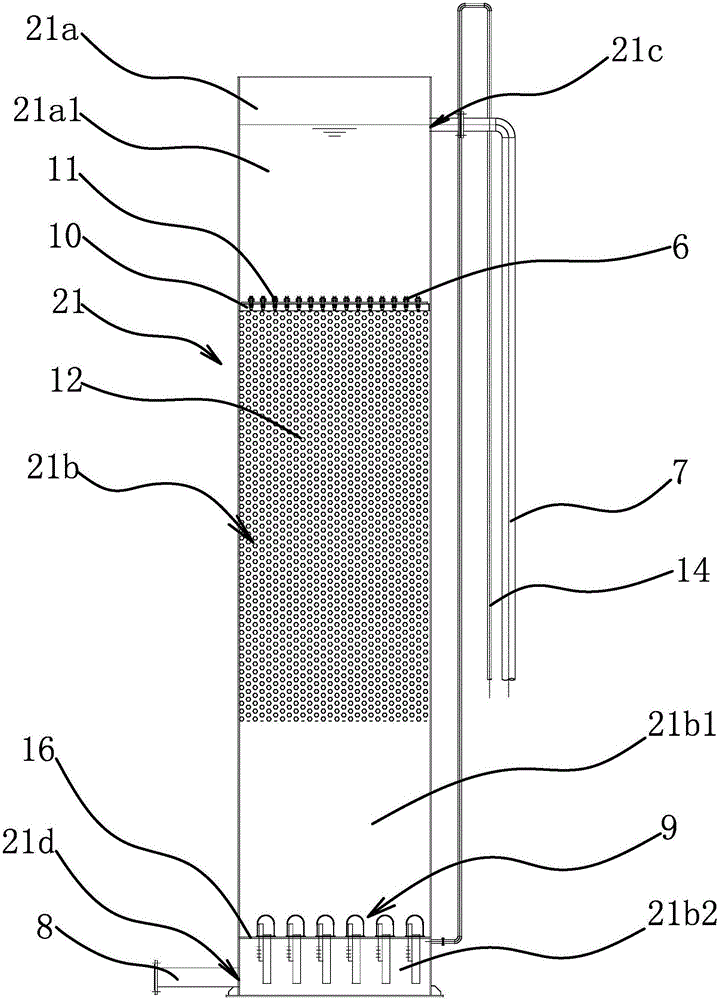

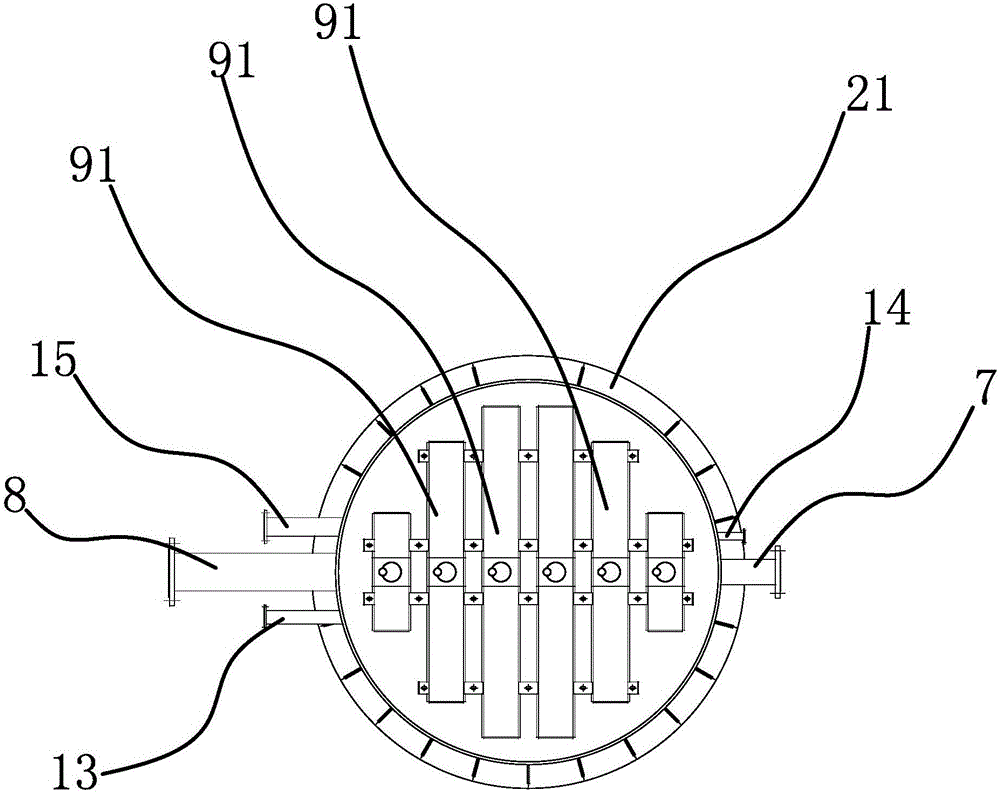

Integrated modularization sewage treatment plant

PendingCN106630423AStructure simplification and improvementEfficient removalSpecific water treatment objectivesTreatment with anaerobic digestion processesWater dischargeSewage treatment

The invention provides an integrated modularization sewage treatment plant, belongs to the technical field of sewage treatment, and solves the problems that the structure of a denitrification pool cannot be simplified and operation cost in a sewage treatment process is high. The treatment plant comprises a hydrolysis acidification pool, a denitrification pool, a nitrification pool, a middle pool and a disinfection pool, wherein the denitrification pool comprises a pool body, a water outlet pipe communicated with a process water pipeline, a washing water discharge pipe communicated with a water discharge pipeline, a water and gas distribution device, a filter plate and a filter head; the filter plate is fixedly arranged on the upper part of the pool body and divides the inner cavity of the pool body into an upper chamber and a lower chamber; a water outlet communicated with the water outlet pipe is formed in the upper chamber; a gravity type washing water chamber is formed between the water outlet and the filter plate; a suspension material filtering layer is arranged in the lower chamber; a water discharging hole communicated with the washing water discharge pipe is formed in the lower chamber below the suspension material filtering layer. Through the above design, operation cost including manufacture cost, daily maintenance cost, ton water treatment power consumption cost and the like of the treatment plant can be greatly lowered.

Owner:YUHUAN JINGHUA GROUP

Polluted gas filter

The invention provides a polluted gas filter. The polluted gas filter comprises an air inlet, an inner filter tank, an outer filter tank and an exhaust opening; the air inlet is respectively connected with one end of a first gas conveying pipeline and one end of a second gas conveying pipeline through a tee pipe, the other end of the first gas conveying pipeline is communicated with the inner filter tank, and the other end of the second gas conveying pipeline is communicated with the outer filter tank; the exhaust opening is respectively connected with one end of a first exhaust pipeline and one end of a second exhaust pipeline through a tee pipe, the other end of the first exhaust pipeline is communicated with the top of the outer filter tank, and the other end of the second exhaust pipeline is communicated with the top of the inner filter tank; the middle parts of the inner filter tank and the outer filter are respectively provided with filter aggregates. The polluted gas filter has beneficial effects that the polluted gas produced after combustion is filtered through the filter, so that the gas is discharged into the air after reaching the national high-quality gas discharging standard, and the environment pollution can be prevented.

Owner:江苏宇宏纺织品印花有限公司

Oil well casing gas pressurizing and collecting device

The invention relates to an oil well casing gas pressurizing and collecting device. The oil well casing gas pressurizing and collecting device comprises a shell internally provided with a gas-liquid automatic separation pipe; the gas-liquid automatic separation pipe is sleeved with an antifreezing constant-temperature diversion pipe; a filter element is arranged inside the gas-liquid automatic separation pipe, the lower end of the gas-liquid automatic separation pipe is connected with an automatic separation drainage device, and the upper end of the gas-liquid automatic separation pipe is connected with an inlet of a second-level pressure stabilizing separator; a casing pressure transmitter, a first vibration-resisting pressure gauge and a meter are arranged between the gas-liquid automatic separation pipe and the second-level pressure stabilizing separator; an outlet of the pressure stabilizing separator is connected with a compressor; the compressor is provided with an overpressure safety valve and a thermoswitch; an input shaft is connected with a belt wheel through a clutch; a gas outlet is connected with an oil collecting mains, and a second vibration-resisting pressure gauge is arranged between the gas outlet and the oil collecting mains; the gas outlet is connected with the interior of the antifreezing constant-temperature diversion pipe; a controller is arranged inside the shell; and the casing pressure transmitter, the thermoswitch and the clutch are all connected with the controller. The device is not provided with a motor, installed in front of an oil well reduction gearbox and driven by left power of a motor of a pumping unit, and is small in size, easy to install and high in safety; and operation cost is avoided, oil gas is recycled thoroughly, energy waste is avoided, the environment is protected, and pollution is completely eradicated.

Owner:东营玺诺石油科技有限公司

High-voltage switch and resistor static contact thereof

ActiveCN111105951AAvoid air lockAffectHigh-tension/heavy-dress switchesAir-break switchesElectrical resistance and conductanceEngineering

The invention relates to a high-voltage switch and a resistor static contact thereof. The high-voltage switch comprises a fracture structure. A resistor static contact is arranged at the fracture structure; and the resistor static contact comprises a conductive cylinder and a static conductive rod installed in the conductive cylinder in a guiding mode. The front end of the static conductive rod extends out of the conductive cylinder and is provided with a static contact part which is used for being in pressing fit with a corresponding resistor moving contact; the static contact part comprisesa conductive matching part and a shielding cover, wherein the conductive matching part is used for being in conductive matching with the resistor moving contact, the shielding cover is in a hemispherical cover shape with a backward opening, and the diameter of the opening in the rear end of the shielding cover is larger than the outer diameter of the conductive cylinder so as to wrap the conductive cylinder or wrap the conductive cylinder in the retreating process, and thus shielding of the conductive cylinder is achieved. Through one shielding cover structure, shielding of the conductive matching part and shielding of the conductive cylinder are realized at the same time, the structure is simple, and processing and manufacturing of the whole resistor static contact are facilitated.

Owner:PINGGAO GRP +2

Ejector device with adjustable nozzle cross-sectional area

InactiveCN112145485AEfficient recyclingSolving Recycling ProblemsJet pumpsFluid removalGear wheelGear tooth

The invention provides an ejector device with an adjustable nozzle cross-sectional area. The ejector device comprises an ejector shell, wherein a drainage channel formed by a liquid inlet section, a variable cross-sectional area nozzle, a receiving chamber, a mixing chamber and a diffusion chamber which are sequentially connected is arranged in the ejector shell; a gas inlet section communicatingwith the receiving chamber is arranged on the ejector shell; the variable cross-sectional area nozzle comprises an annular nozzle shell I, an annular nozzle shell II, a gear ring and adjusting valves;the gear ring is arranged between the nozzle shell I and the nozzle shell II; the adjusting valves are arranged on the nozzle shell II; a plurality of adjusting valves are sequentially embedded in anend-to-end manner to form an annular structure; the annular structure is positioned in the drainage channel; each adjusting valve is fixedly connected with a linkage rod piece; the adjusting valves are connected with the gear ring through the linkage rod pieces; an adjusting knob is arranged outside the ejector shell; and the adjusting knob is connected with gear teeth of the gear ring through atoothed bar. According to the ejector device disclosed by the invention, the nozzle aperture of the ejector can be changed, so that the ejector can efficiently recover casing gas under different working conditions.

Owner:YANGTZE UNIVERSITY

Double-tube two-stage axial flow downhole degassing device

ActiveCN104196516BEfficient and thorough degassingEfficient miningFluid removalVapor–liquid separatorEngineering

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

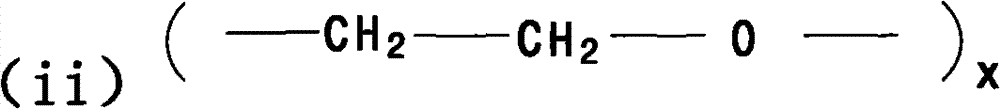

Application of modified C5 in gasoline additives

InactiveCN101381635ASolve cokingSolve the problem of carbon accumulationLiquid carbonaceous fuelsHazardous substanceGasoline fuel

The invention provides application of modified carbon-5 in a gasoline additive, which belongs to the technical field of recycling gasoline side products and particularly discloses a method for treating light hydrocarbons taking carbon-5 as a main composition and application of the treated carbon-5 in the gasoline additive. When the modified carbon-5 is used, 50 to 80 percent of the additive according to the weight percentage is added in gasoline to produce composite gasoline, thereby not only partially replacing the gasoline fuel with tension in supply, but also improving the performance of the gasoline, ensuring that the gasoline is fully burnt and reducing the coking and carbon deposition in an engine and the emission of harmful matters; moreover, according to the inspection by the National Ethanol Gasoline Quality Surveillance Inspection Center, the composite gasoline meets the national standard.

Owner:HENAN ACAD OF SCI

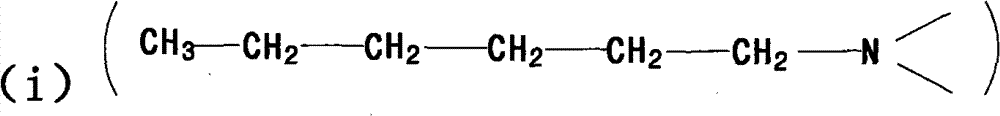

Polyether amine, production method thereof and application of polyether amine in methanol gasoline

InactiveCN101948396BNot easy to failGreat ability to maintain solubilizing effectOrganic compound preparationLiquid carbonaceous fuelsEthylene oxideGasoline

Owner:张延涵 +3

Automobile fuel oil additive

InactiveCN101381642ASolve cokingSolve the problem of carbon accumulationLiquid carbonaceous fuelsHazardous substanceModified carbon

The invention provides an automobile fuel additive, which belongs to the technical field of fuel additive. The automobile fuel additive is formed by mixing the mixture of biomass extracts of corn oil, castor oil, palm oil and the like, fat polyhydric alcohol, an antioxidant, an antiknock agent, modified carbon-5 and the like according to certain ratio; when the automobile fuel additive is used, according to the weight percentage, 50 percent of additive is added in gasoline, thereby not only partially replacing the gasoline with tension in supply, but also improving the performance of the gasoline, ensuring that the gasoline is fully burnt and reducing the coking and carbon deposition in an engine and the emission of harmful matters; moreover, according to the inspection by the National Ethanol Gasoline Quality Surveillance Inspection Center, the automobile fuel additive meets the national standard.

Owner:HENAN ACAD OF SCI

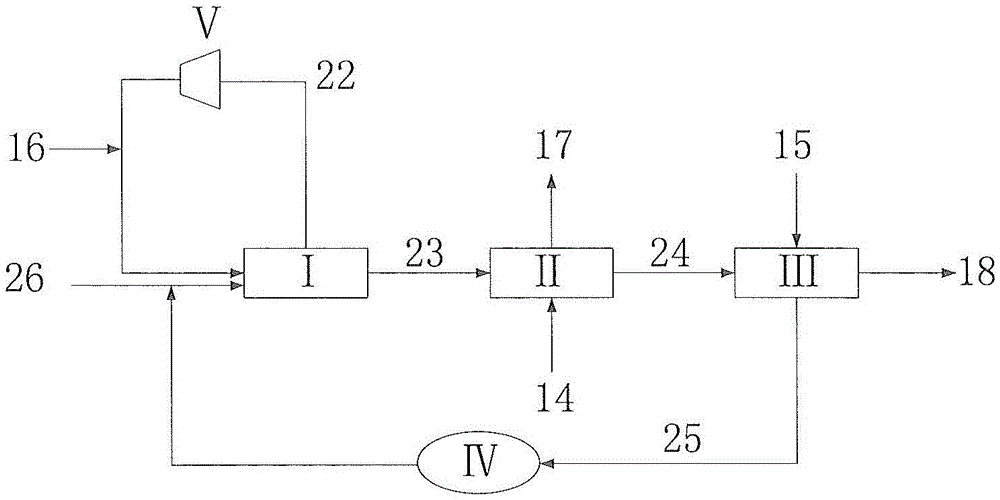

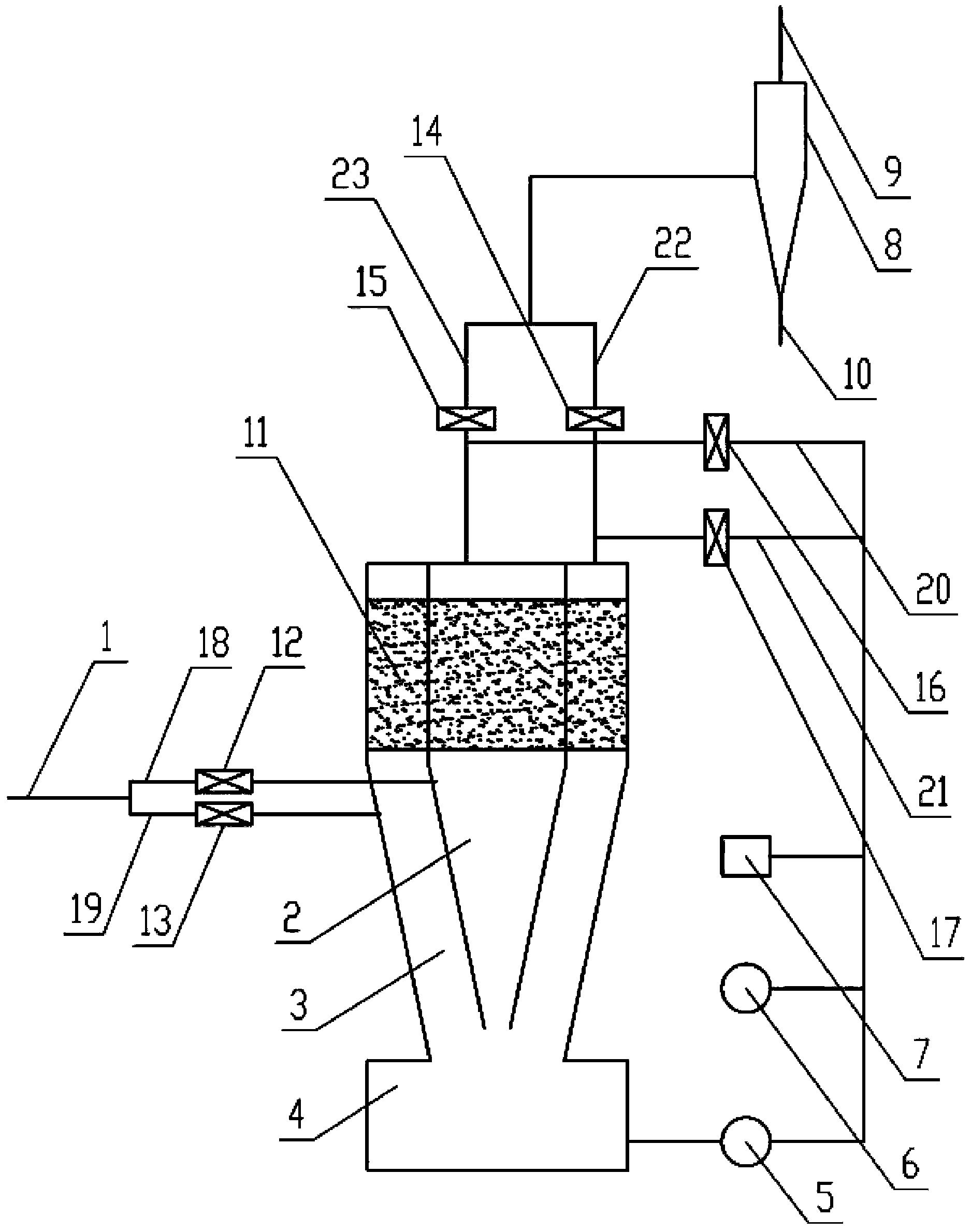

Water control system and method for coal underground gasifier

ActiveCN104453830ALess chance of crosstalkAvoid air lockConstructionsCoal gasificationControl systemEngineering

The invention provides a water control system and method for a coal underground gasifier. The water control system for the coal underground gasifier comprises a plurality of drainage channels communicated with one another and at least one vertical drainage well. The drainage channels are communicated with the vertical drainage wells. The drainage channels are arranged on the periphery and at the bottom of the coal underground gasifier. The coal underground gasifier is provided with a gasification channel. The drainage channels are communicated with the gasification channel of the coal underground gasifier through coal bed cracks. The water control method includes the step that water in the gasification channel is guided into the drainage channels through the coal bed cracks. The water control system and method for the coal underground gasifier can effectively control the water amount of a gasification coal bed, the gasification reaction is facilitated, gas and water crossing is avoided, and the drainage channels are prevented from being blocked.

Owner:ENN SCI & TECH DEV

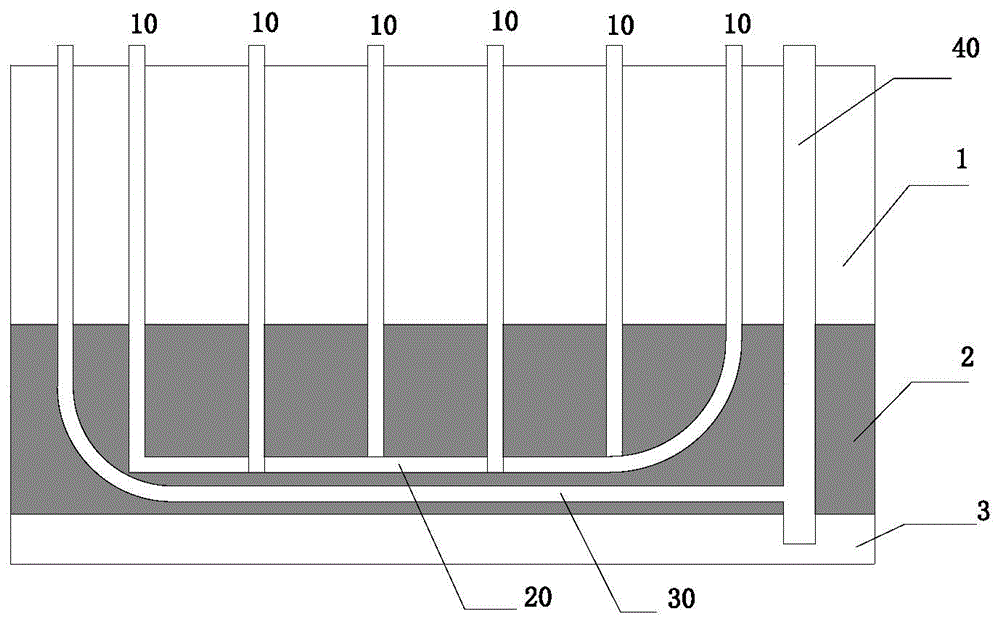

Oil-gas mixed convey pumping set for oil field

InactiveCN101007621AIncrease inhalationAvoid air lockLiquid transferring devicesSocial benefitsLiquid ratio

The invention provides an oil field gas mixing delivery pump units. It mainly includes mixing delivery pump, reduction motor, oil gas voltage stabilizing tank and out transmission mixing delivery tank; the tank body of the oil gas voltage stabilizing tank and the out transmission mixing delivery tank both are equipped with input and output mouth, and the input and output mouth of the oil gas voltage stabilizing tank is installed along the tangent direction of the tank body, its input mouth is higher than output mouth. The input mouth of the out transmission mixing delivery tank is lower than its output mouth. The input and output mouth of the mixing delivery pump is connected with output mouth of oil gas voltage stabilizing tank and the input mouth of out transmission mixing delivery tank through oil pipes. The transported polyphase media collected from each oil wells is vortex stabilized its pressure through oil gas voltage stabilizing tank, then enters mixing delivery pump, improves the sucking condition of gas mixing delivery pump, and the out transmission mixing delivery tank can prevent the excavating cavity and sucking cavity of mixing delivery pump generate air-resistance effectively, meets the requirement of polyphase media can be transported in any operating mode condition with different gas-liquid ratio. Thus, the invention improves the efficiency of oil gas mixing delivery and the safe performance, reduces pollution, and it has good economic and social benefits.

Owner:江苏恒源泵业制造有限公司

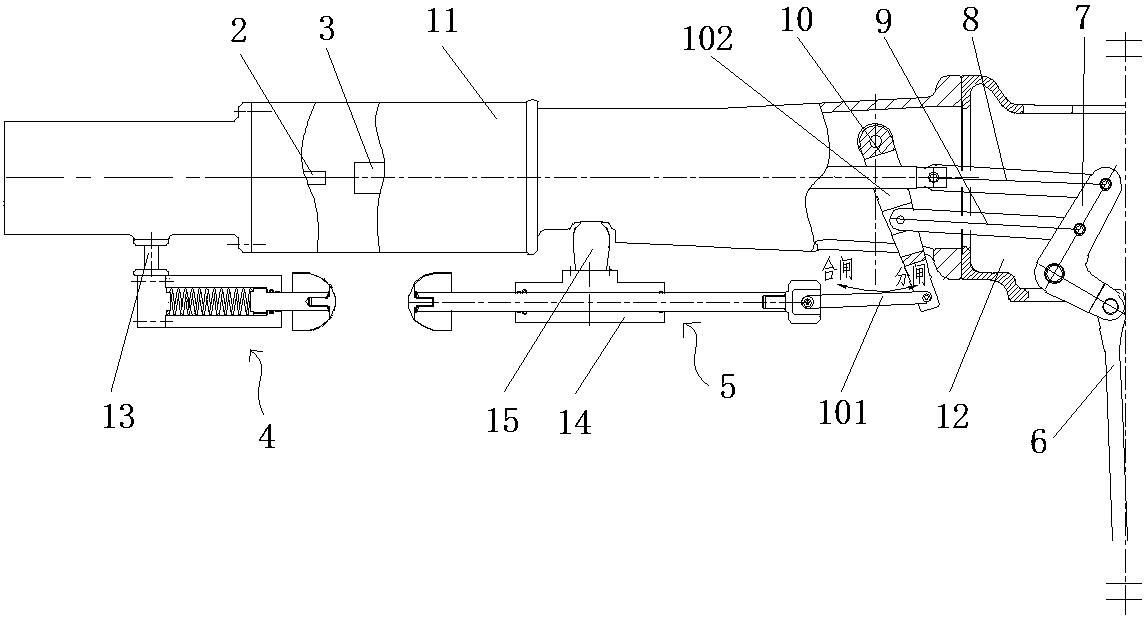

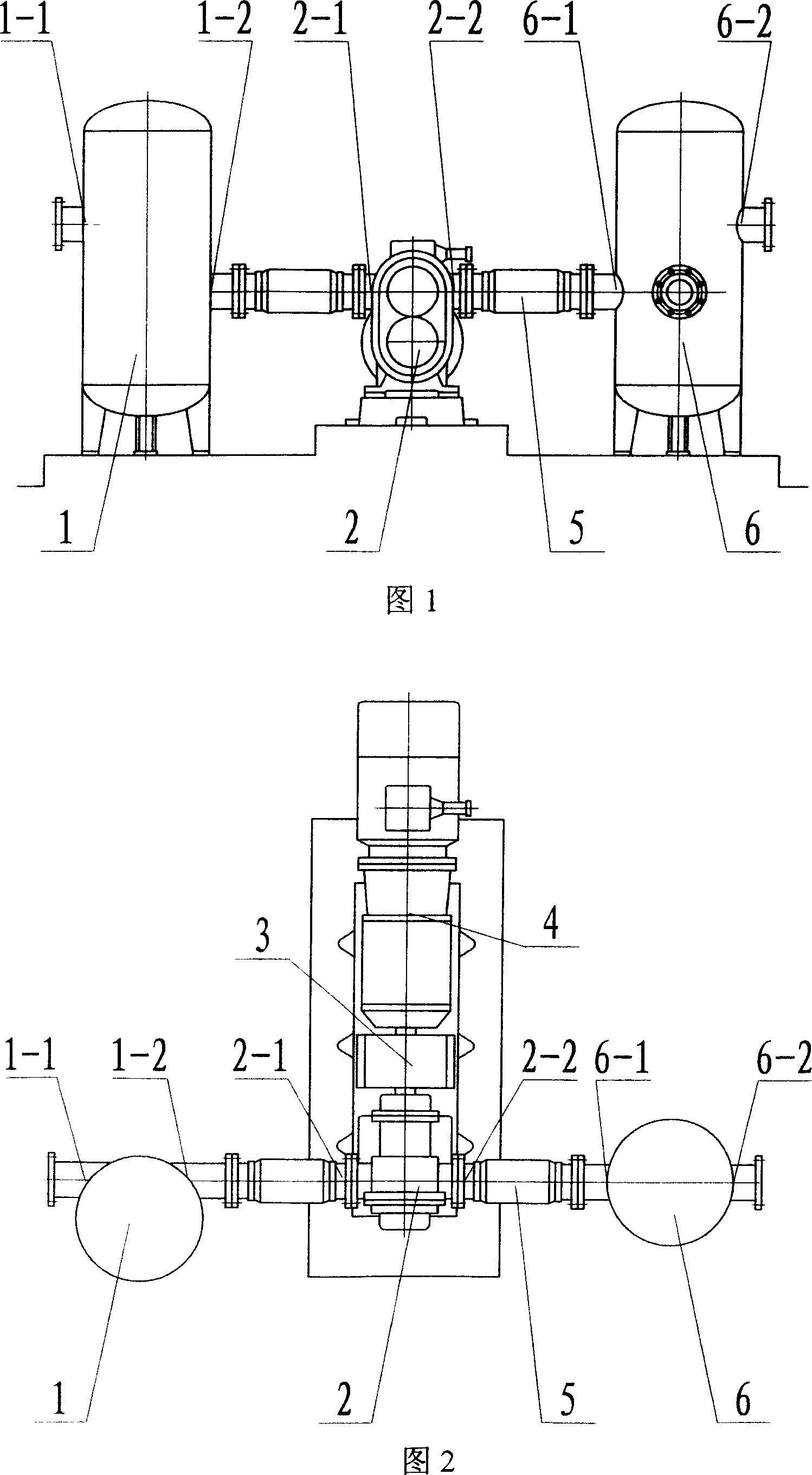

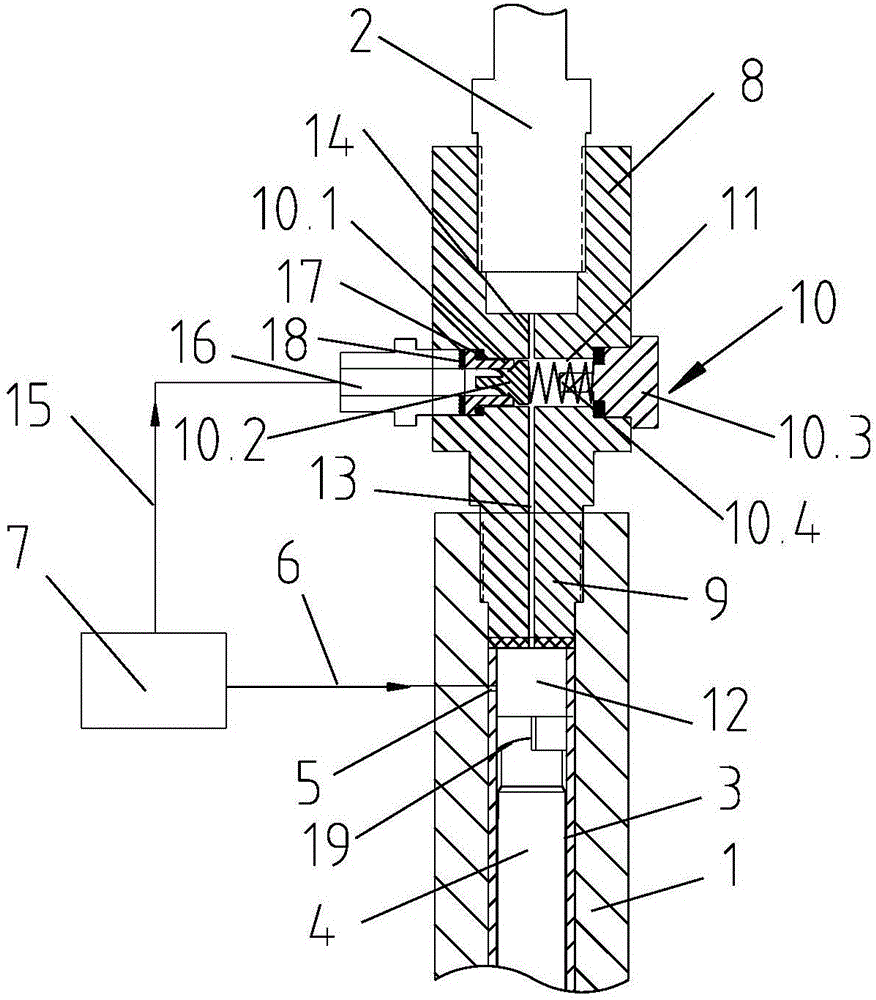

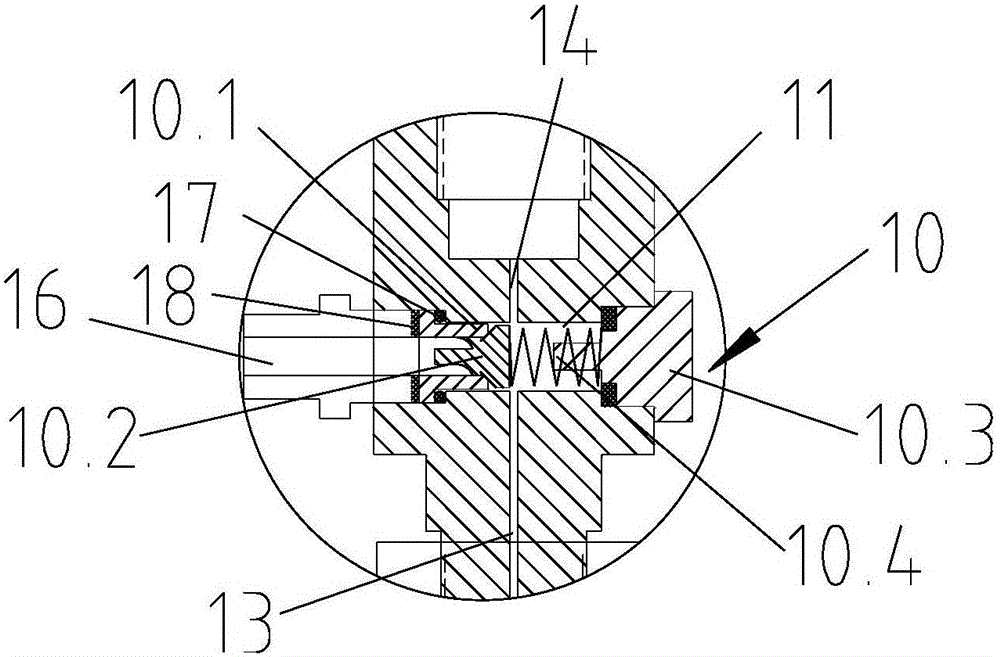

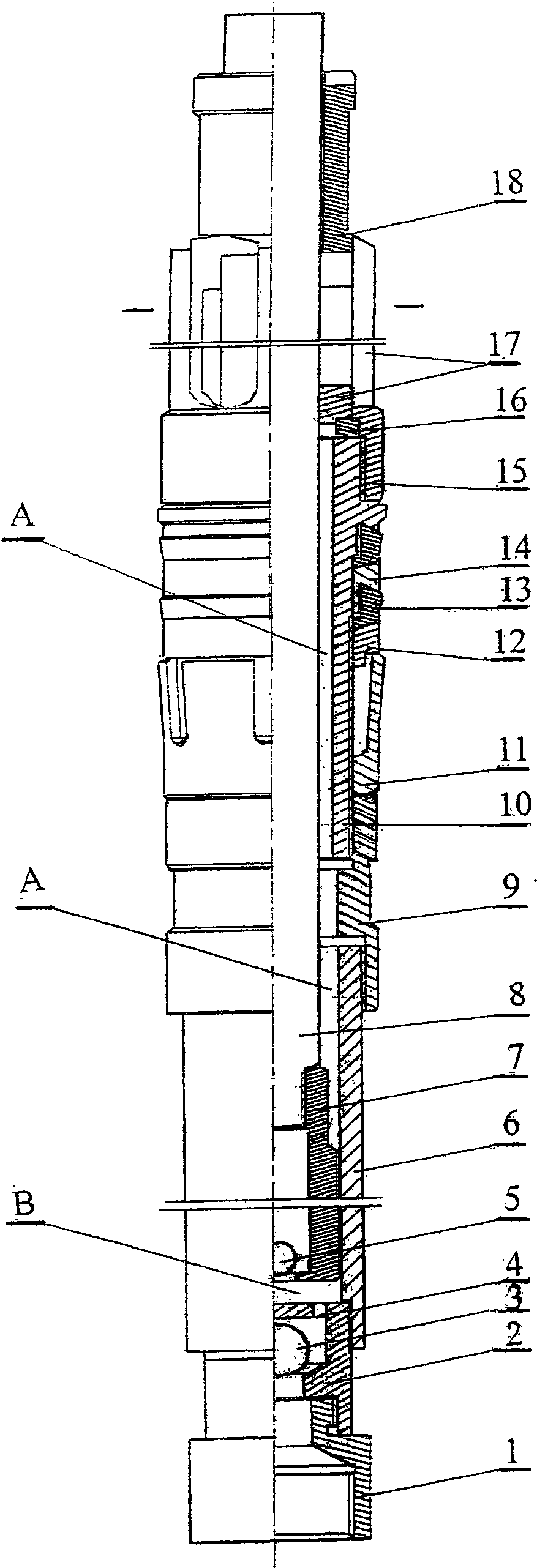

Mechanical switch valve oil-well pump and oil pumping technology thereof

InactiveCN103133316AAvoid "air lock"Positive displacement pump componentsFlexible member pumpsEngineeringPlunger

The invention discloses a mechanical switch valve oil-well pump which is mainly composed of a pump cylinder (18), a valve rod (9) arranged in the pump cylinder (18), and a plunger arranged at the lower end of the valve rod (9). The plunger partitions the interior of the pump cylinder (18) into an upper cavity chamber (13) and a lower cavity chamber (17). The invention further discloses an oil pumping technology based on the mechanical switch valve oil-well pump. A pushing block and an air-bleed hole are arranged on the valve rod, a plunger delivery valve upper cavity and a plunger delivery valve lower cavity can be communicated when the plunger is close to a bottom dead center and reverses to ascend for a small section of distance, oil gas in the upper cavity chamber is exhausted into an oil tube in advance, and therefore 'airlock' is effectively prevented from happening.

Owner:严欢

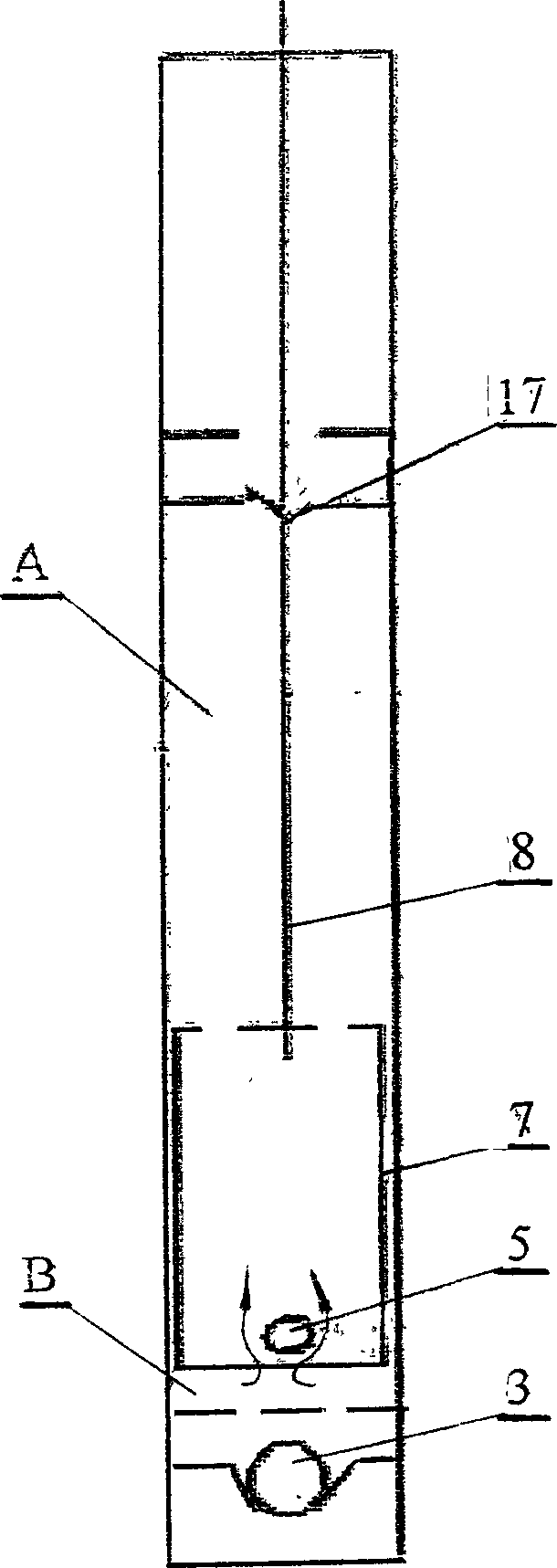

Distillation condensing refluxing device

InactiveCN107510950AAvoid air lockImprove production efficiencyDistillation in pipe stillsDistillationEngineering

The invention discloses a distillation condensing refluxing device. A refluxing condenser comprises a distillation port (10), a distillation pipe (8), a condenser (1), a receiver (6), a receiver upper valve (5), a receiver lower valve (7) and a refluxing pipe (12). The condenser is internally provided with a snakelike condensing pipe (3), the lower end of the condensing pipe is a condensate water inlet (4) and the upper end is a condensate water outlet (2). The distillation pipe (8) is a right-angled elbow pipe, the lower end of the distillation pipe is connected with the distillation port and the upper end is connected with the lower end of the condenser, a distillation pipe valve (9) is arranged at the middle of the distillation pipe, and a demister (13) is arranged behind the valve. The refluxing pipe (12) is a straight pipe, the lower end of the refluxing pipe (12) is connected with the distillation pipe below the distillation pipe valve (9), and the upper end is connected with the straight pipe at the lower end of the condenser and is located below the distillation elbow pipe and above the receiver upper valve (5). The distillation condensing refluxing device has the advantages that the structure is simple, the distillation gas does not affect the refluxing of refluxing liquid, and the practicability is high.

Owner:营创三征(营口)精细化工有限公司

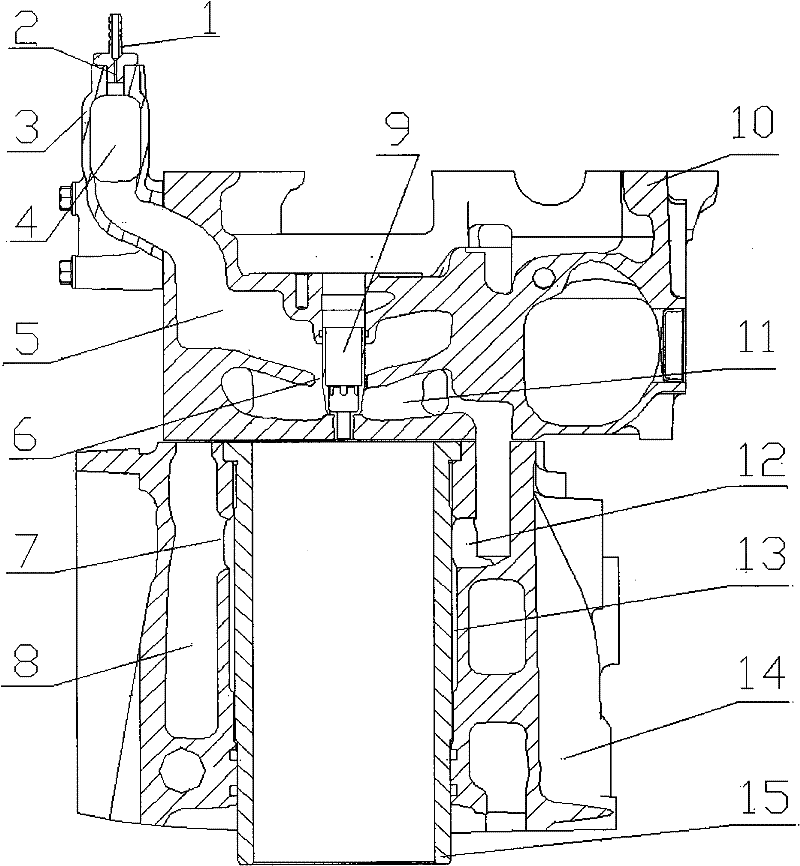

Bypass one-way valve of double-fuel supply system of DME/diesel engine

The invention discloses a bypass one-way valve of a double-fuel supply system of a DME / diesel engine. The bypass one-way valve comprises an upper valve body and a lower valve body, wherein the upper valve body and the lower valve body are integrally shaped, and a valve cavity allowing a one-way valve assembly to be mounted is formed between the upper valve body and the lower valve body; the top of the upper valve body is connected with an oil outlet valve through threads, and the bottom of the lower valve body is connected with a pump body through threads; the bottom end of the lower valve body, the top end of a plunger piston and the inner wall of a plunger piston sleeve surround to form a pump cavity allowing fuel oil to be stored. Through the adoption of the bypass one-way valve disclosed by the invention, the problems that the pressure of a high-pressure oil circuit fluctuates fiercely and the oil supply quantity is in serious shortage caused by phase changes of DME in the fuel oil pump cavity in the oil supply process can be effectively solved, and an air resistance phenomenon caused by aerification of DME fuel in the high-pressure pump cavity is avoided.

Owner:WUHAN UNIV OF TECH

Negative pressure oil-well pump

ActiveCN1730943AAvoid air lockReduce the pressure of the liquid columnFlexible member pumpsFluid removalPistonEngineering

The negative pressure oil well pump as one sucker rod pumping equipment consists of fixed valve, traveling valve and pump barrel, and features that the plunger has upper part penetrating the central hole of the annular fixed valve mounted and lower part connected to the piston with inside traveling valve and one negative pressure cavity is formed between the traveling valve and the annular fixed valve. The present invention has the positive effects of double negative pressure area oil pumping resulting in reduced effect of gap ratio on pump efficiency and raised oil pumping efficiency; lowered liquid column pressure the plunger bears and up load of the oil well pump; and increased production pressure difference. The present invention provides improved negative pressure oil well pump structure and introduces double negative pressure area concept for oil well pump.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com