Shield electric motor for oil-submerged pump and preparation method therefor

A technology for shielded motors and submersible pumps, applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of poor sealing, complex structure of shielded motors, and short service life, and achieve long service life, good insulation, High safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

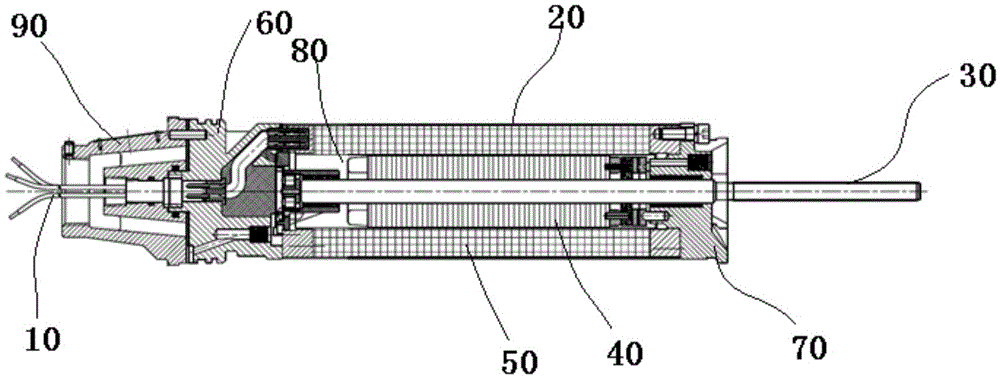

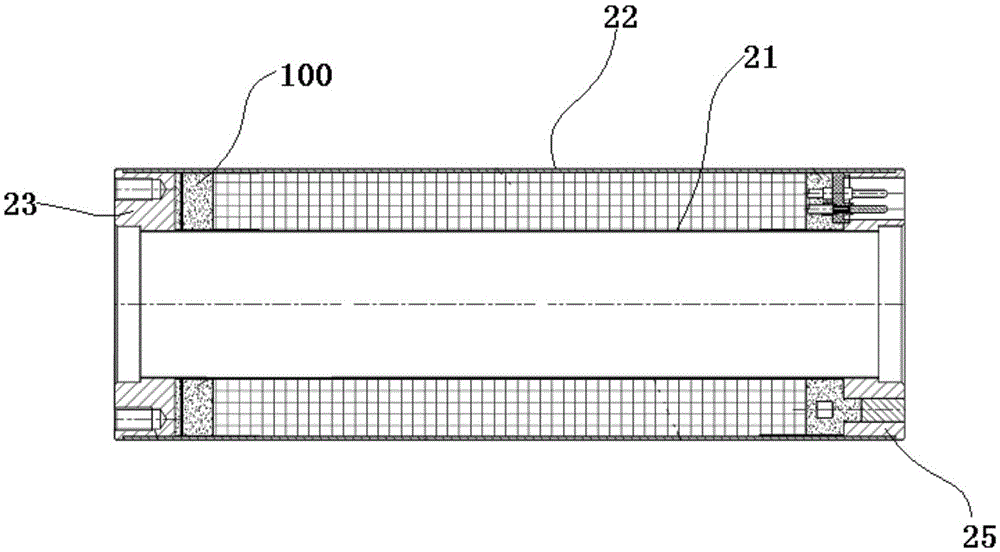

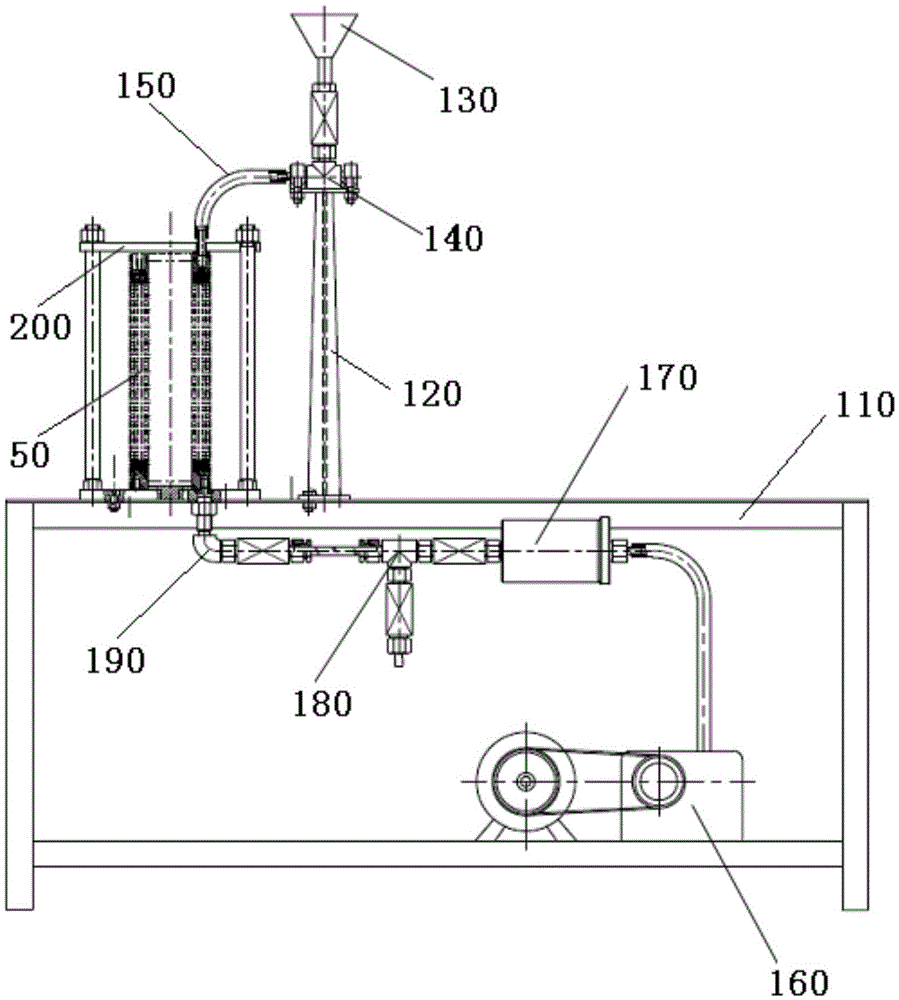

[0033] see figure 1 and figure 2 As shown, the present invention discloses a shielded motor for a submersible oil pump. The shielded motor includes a vacuum pump housing, a cable assembly 10, a stator assembly installed in the vacuum pump housing, a cylinder sleeve 20, a driving shaft 30, and a motor mounted on the driving shaft 30. The rotor assembly 40, the stator assembly 50 arranged in the stator assembly installation cylinder liner 20, the upper end support body assembly 60 and the lower bearing seat assembly 70; the upper end support body assembly 60 and the lower bearing seat assembly 70 are arranged in the stator assembly installation cylinder liner 20 two ends, and form an airtight cavity 80 inside, the rotor assembly 40 is located in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com