Negative pressure oil-well pump

An oil well pump and negative pressure technology, which is applied in the field of oil well pump development, can solve the problems of low oil production efficiency, achieve the effects of improving oil production efficiency, reducing uplink load, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

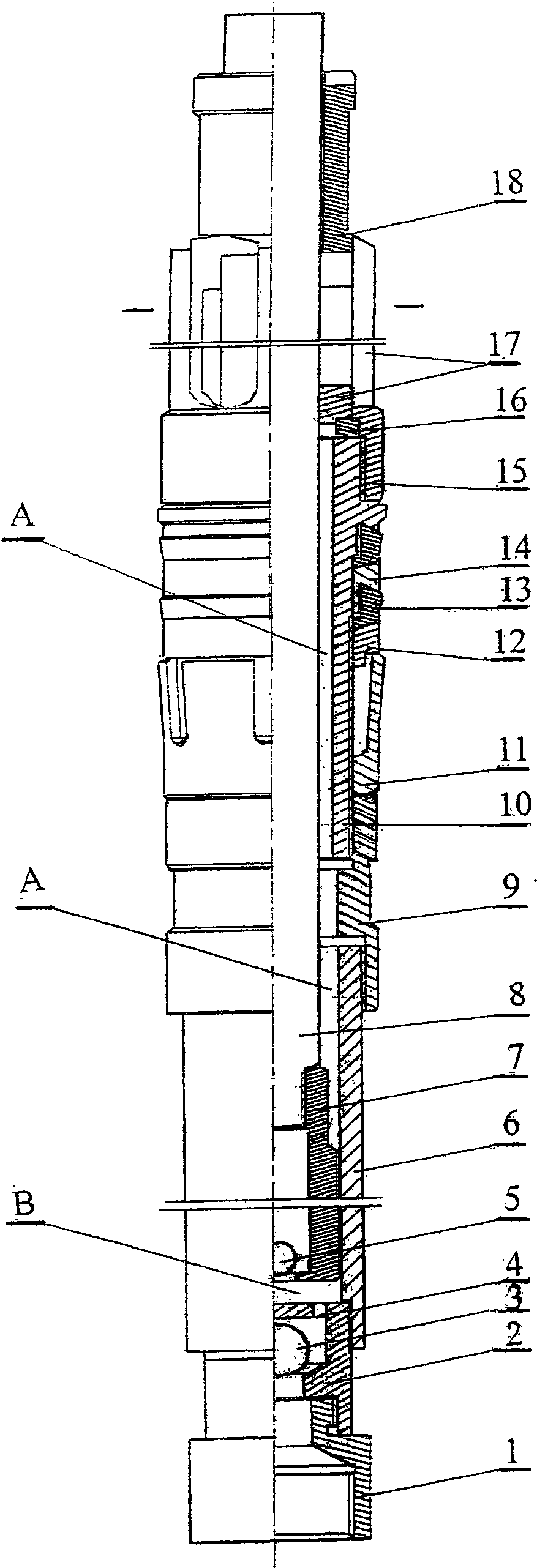

[0014] Embodiment 1: see attached image 3 . The lower fixed valves all adopt the prior art, and are not described in detail. The lower fixed valve includes a lower fixed valve joint (1), a lower fixed valve seat (2), a lower fixed valve ball (3) and a lower fixed valve cover (4). Fix the upper end of the valve and connect the pump barrel (6) with threads. Pump cylinder (6) internal diameter is 80 millimeters, and length is 3500 millimeters. Piston (7) is arranged in the pump cylinder (6), and piston (7) outer diameter is 80 millimeters, and slide fits between piston (7) and pump cylinder (6). Swimming valve (5) is arranged in the piston (7). The upper end of the piston (7) is connected with the plunger (8). The plunger (8) profile is cylindrical, with a diameter of 50 millimeters and a length of 4000 millimeters. The top of the pump barrel (6) is connected to the central pipe (10) by a connecting sleeve (9) with threads at both ends. The lower end of the connecting sle...

Embodiment 2

[0015] Embodiment 2: see attached image 3 . Substantially the same as embodiment 1, the difference is: the annular fixed valve (17) is an annular one-way ball valve. That is, there are 2-6 ball valves distributed on the inner circumference of the ring-shaped fixed all (17). Present embodiment 2 adopts 4 ball valves.

[0016] A brief description of the working process of the negative pressure oil well pump of the present invention is helpful for understanding the present invention.

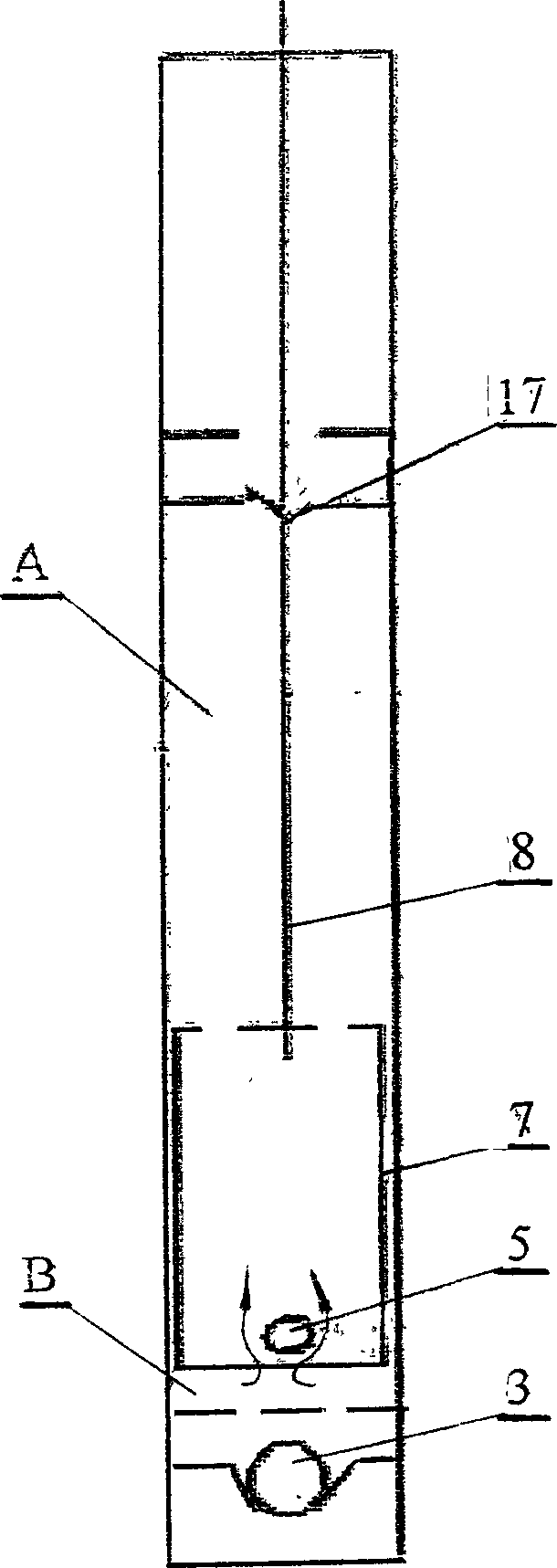

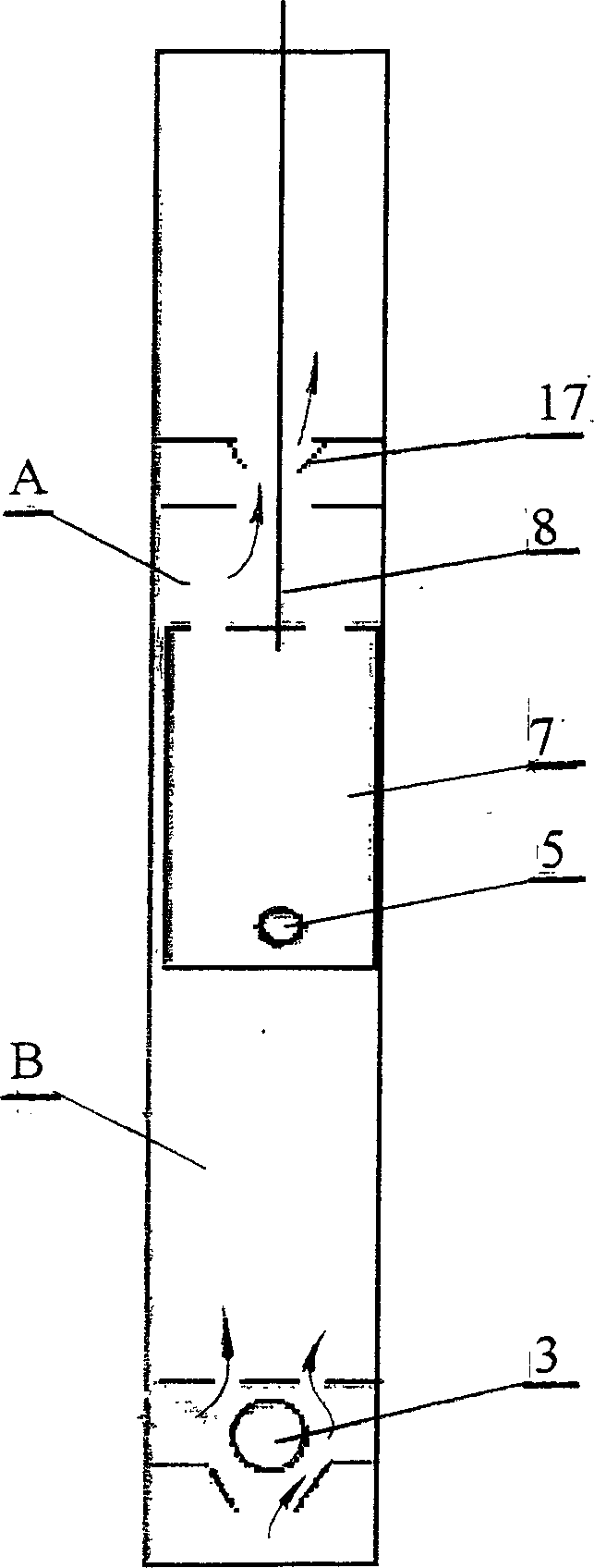

[0017] See attached figure 2 . During the upstroke, the plunger (8) and the piston (7) move upward simultaneously. The ring-shaped fixed valve (17) is opened under the action of the liquid pressure and the friction of the plunger (8), the channel of the ring-shaped fixed valve (17) is opened, and the liquid between the piston (7) and the ring-shaped fixed valve (17) enters the ring Above the fixed valve (17); at the same time, a negative pressure zone is formed between the piston (7) and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com