Patents

Literature

44results about How to "Even oil supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

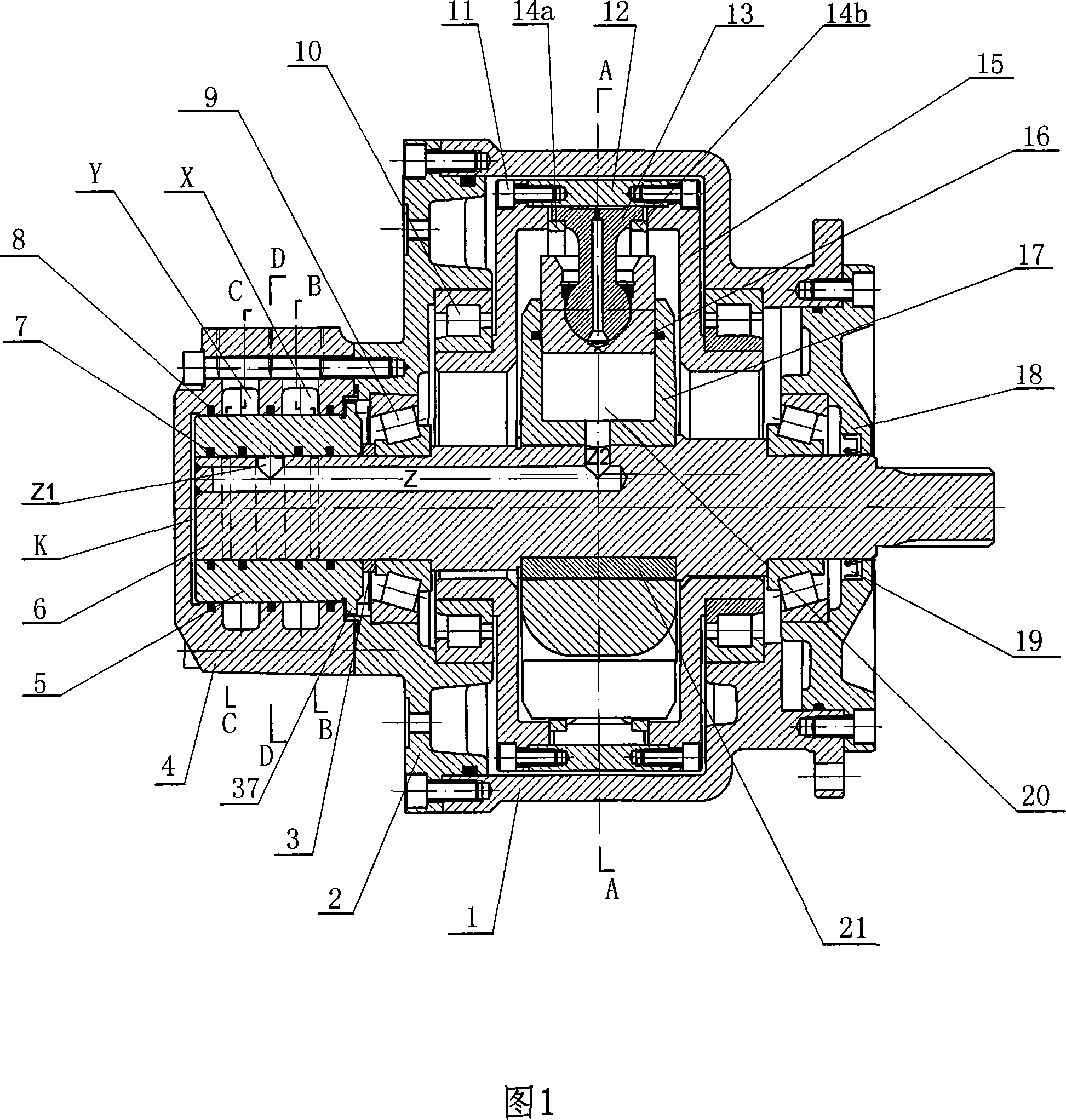

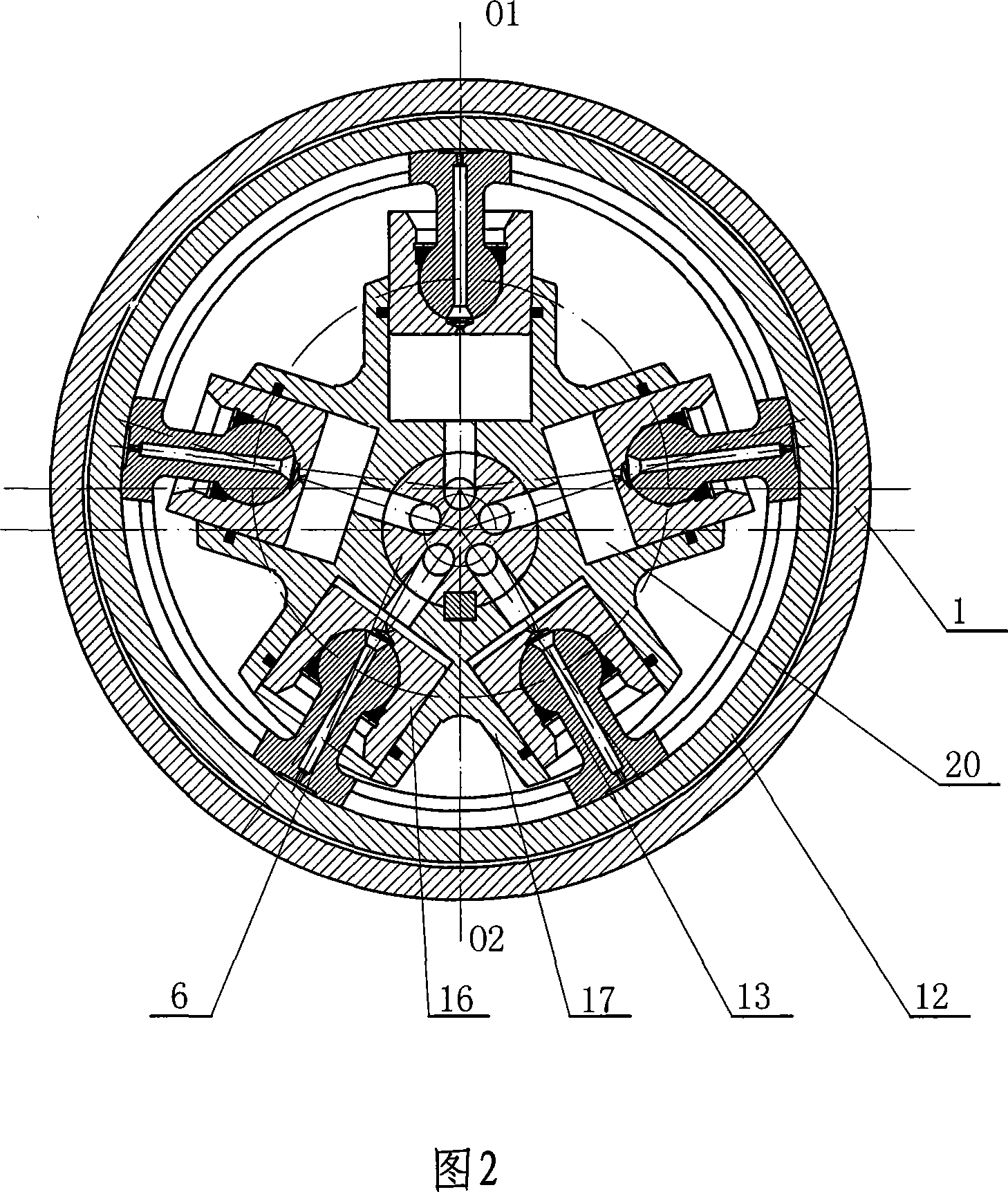

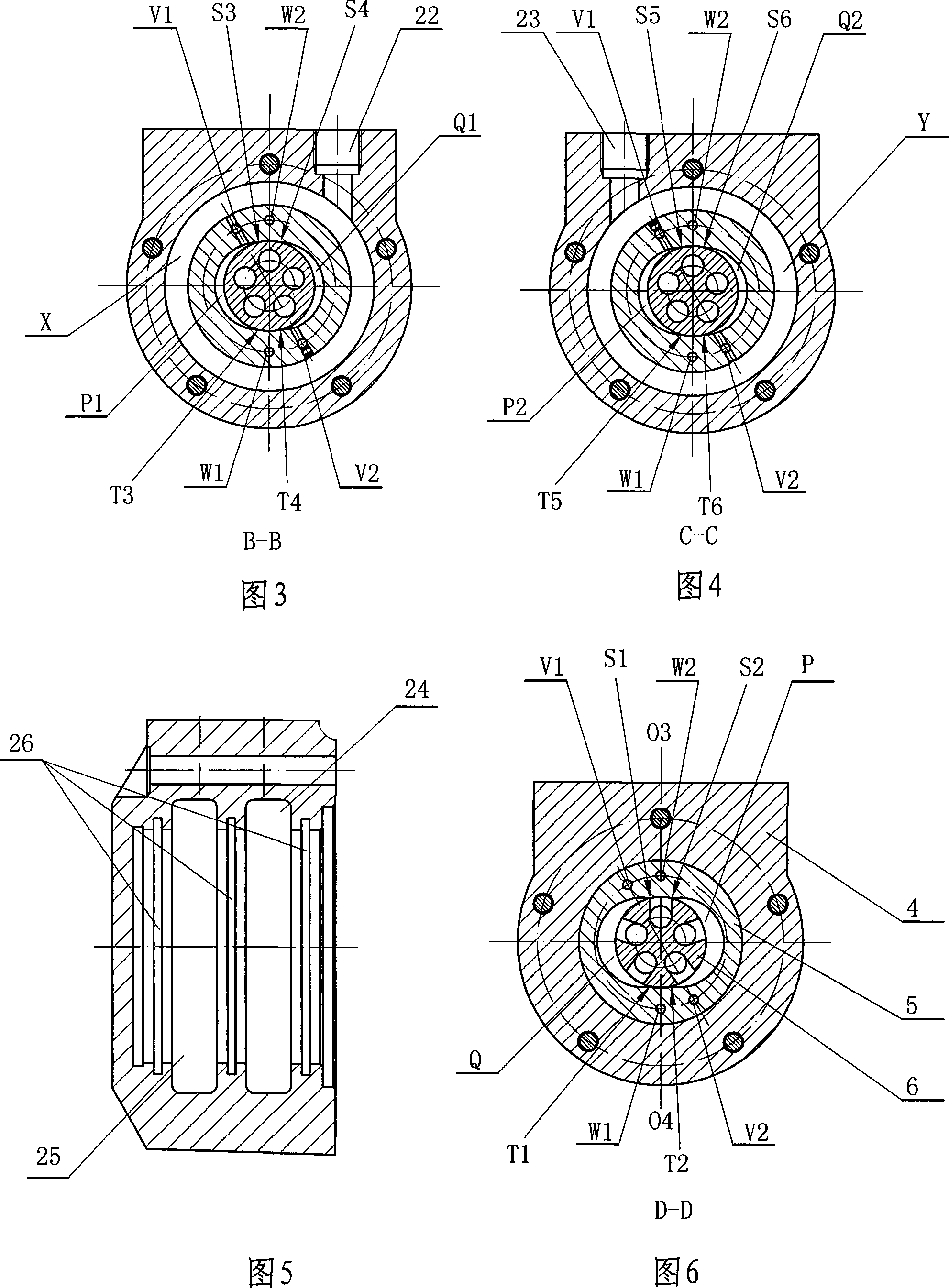

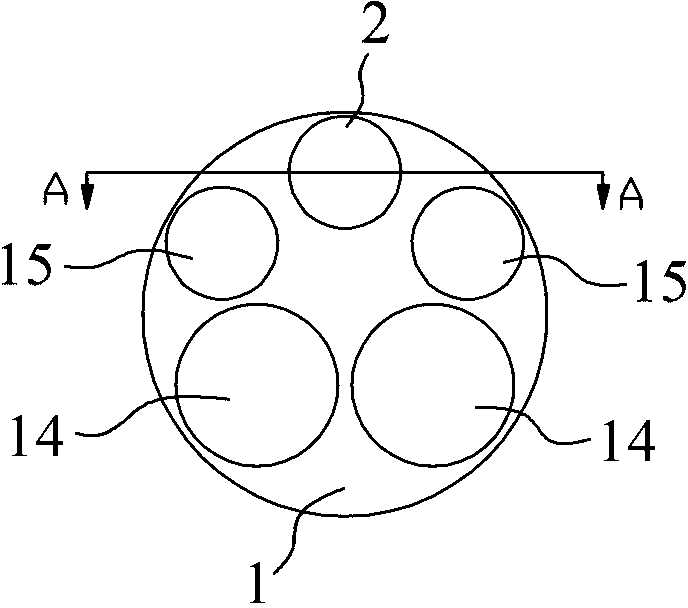

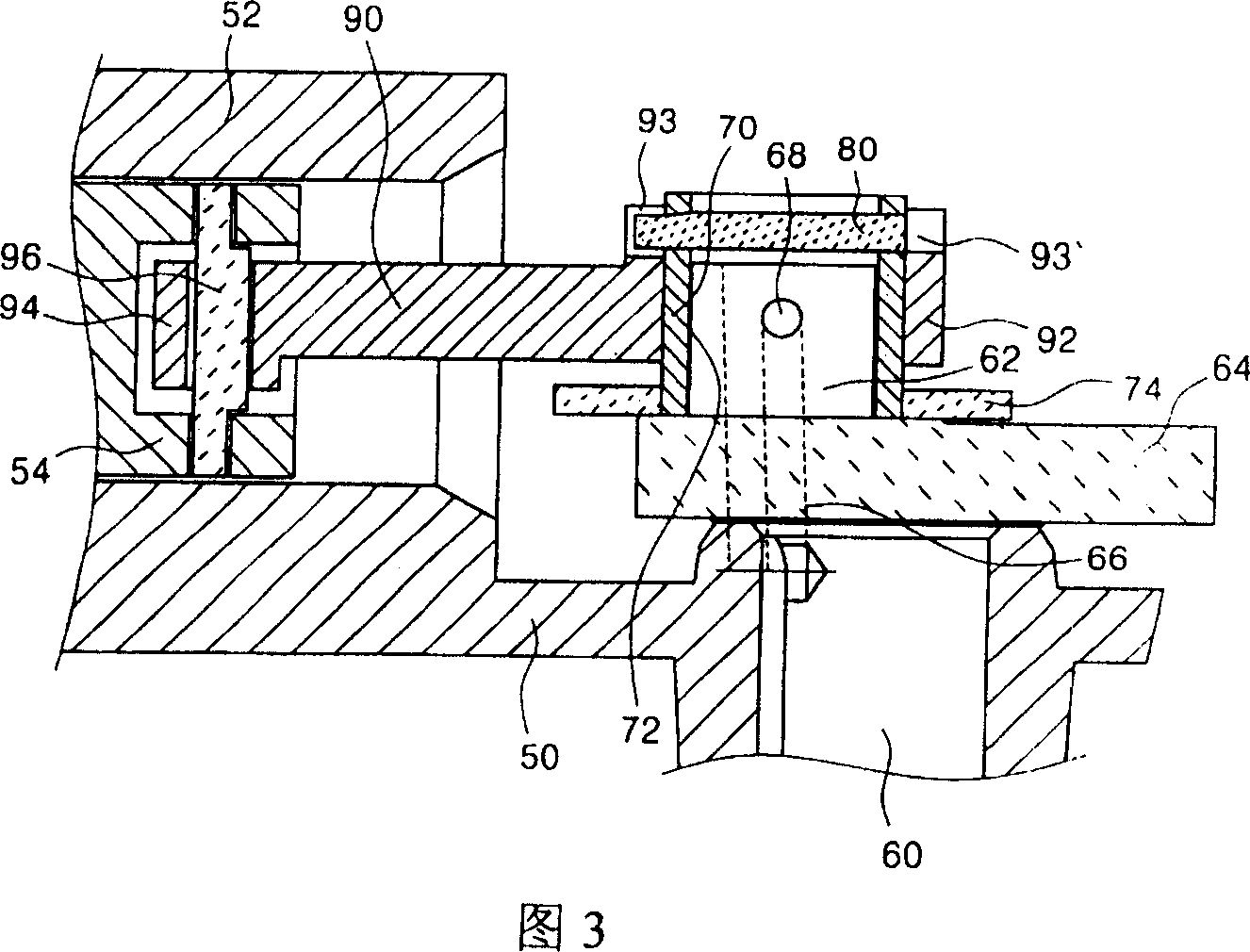

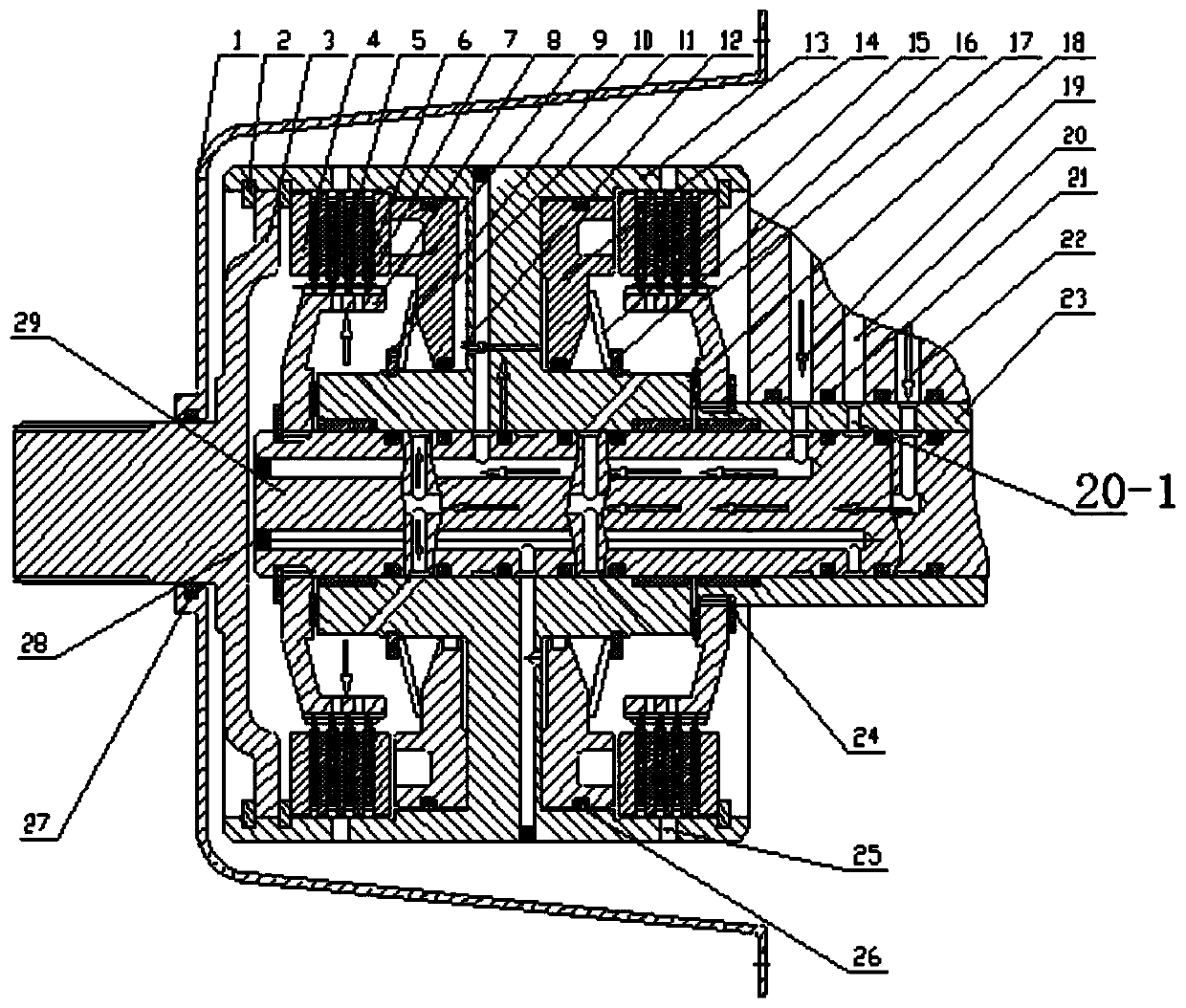

Oil distribution axle linkage rod type hydraulic motor

InactiveCN101117938AReduce axial sizeShaft oil distribution is compactReciprocating piston enginesPistonLinkage concept

A shaft-distribution-oil link-type oil hydraulic motor is improved on the basis of the original shell, the shaft-distribution-oil configuration, the rotating shaft, and the plunger piston-link assembly, etc., namely that the shaft-distribution-oil configuration consists of an oil-through disk and an oil distribution jacket. No.1 and No.2 hydraulic fluid ports are opened on the oil-through disk, and No.1 and No.2 ring grooves are opened on one of the interfaces of the oil-through disk and the oil distribution jacket to airproof and form No.1 and No.2 oil reservoirs; at the same time, No.1 and No.2 under cut slots which are separated by the contact crown faces are symmetrically opened on the same ring face of the inner wall of the oil-through jacket. The No.1 and No.2 under cut slots are arranged between the No.1 and No.2 oil reservoirs to airproof and form the No.1 and No.2 main oil reservoirs. A plurality of flow passages corresponding to the main oil reservoirs and connected with the plunger piston are arranged on the rotating shaft. The adopted structure forms the oil-through configuration and the oil distribution configuration into adjacency configurations, approximately distributing in the same orientation to greatly decrease the axial size of the oil distributor, and make the structure of the oil hydraulic motor closer and more reasonable.

Owner:宁波欧易液压有限公司

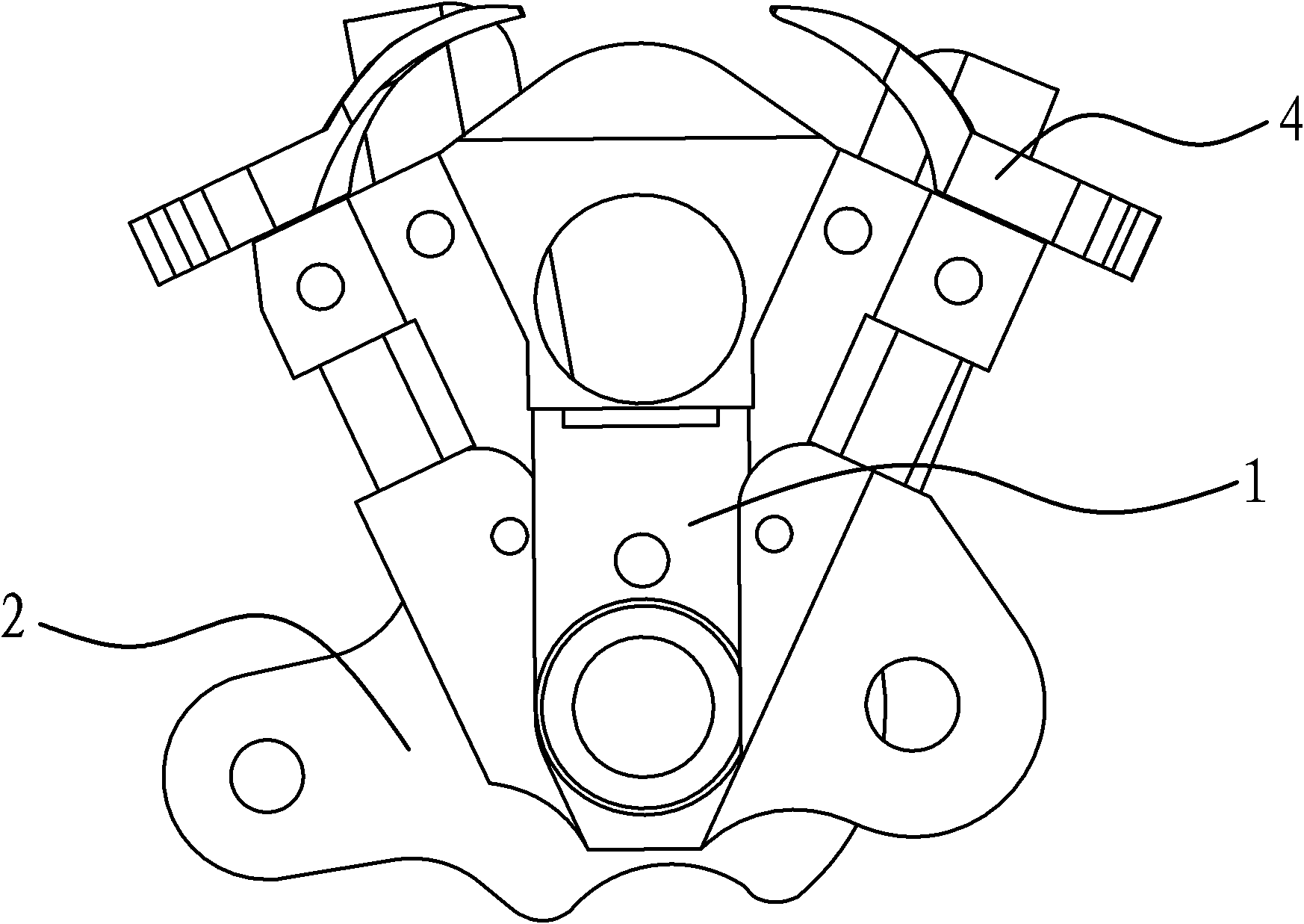

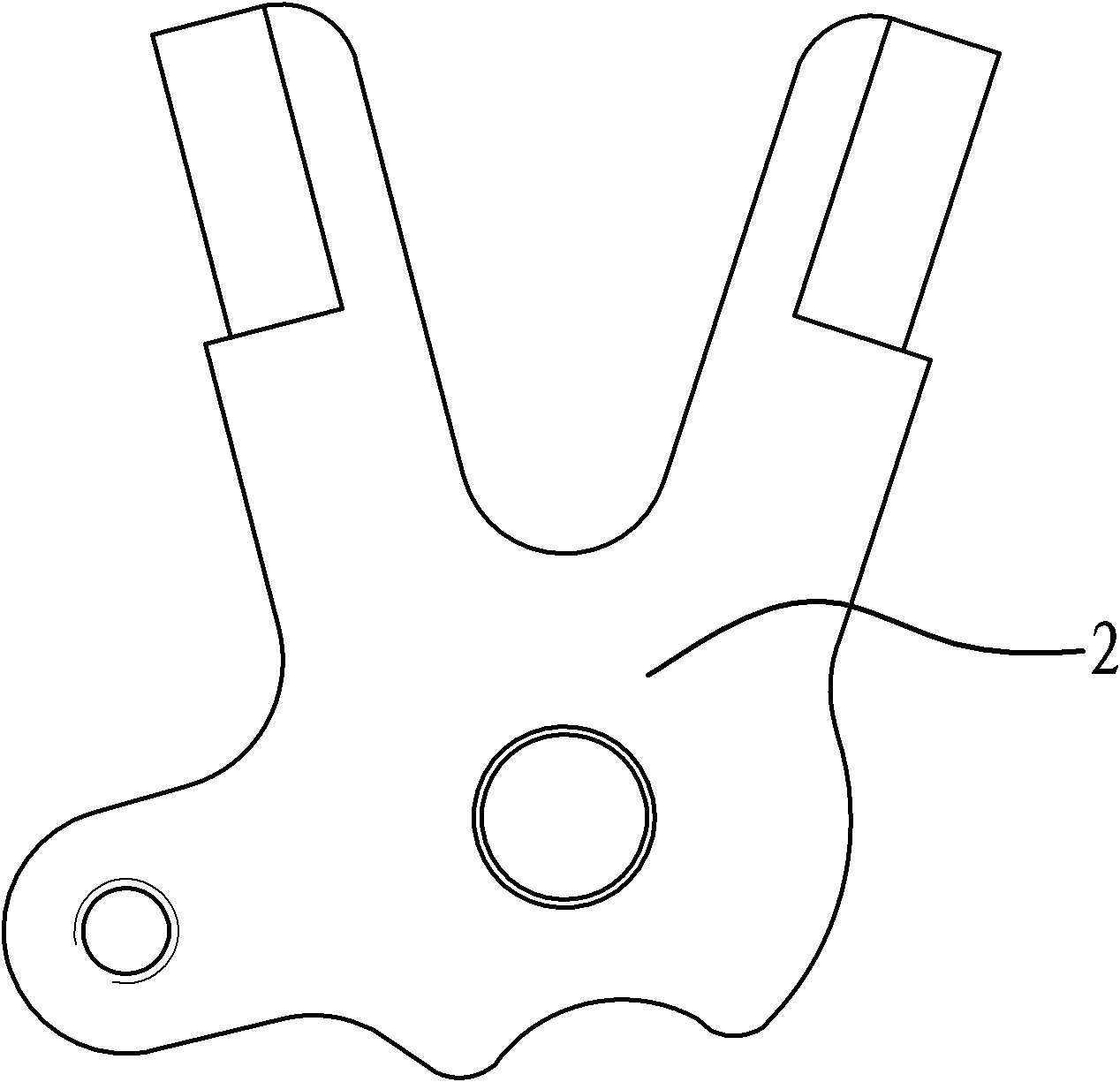

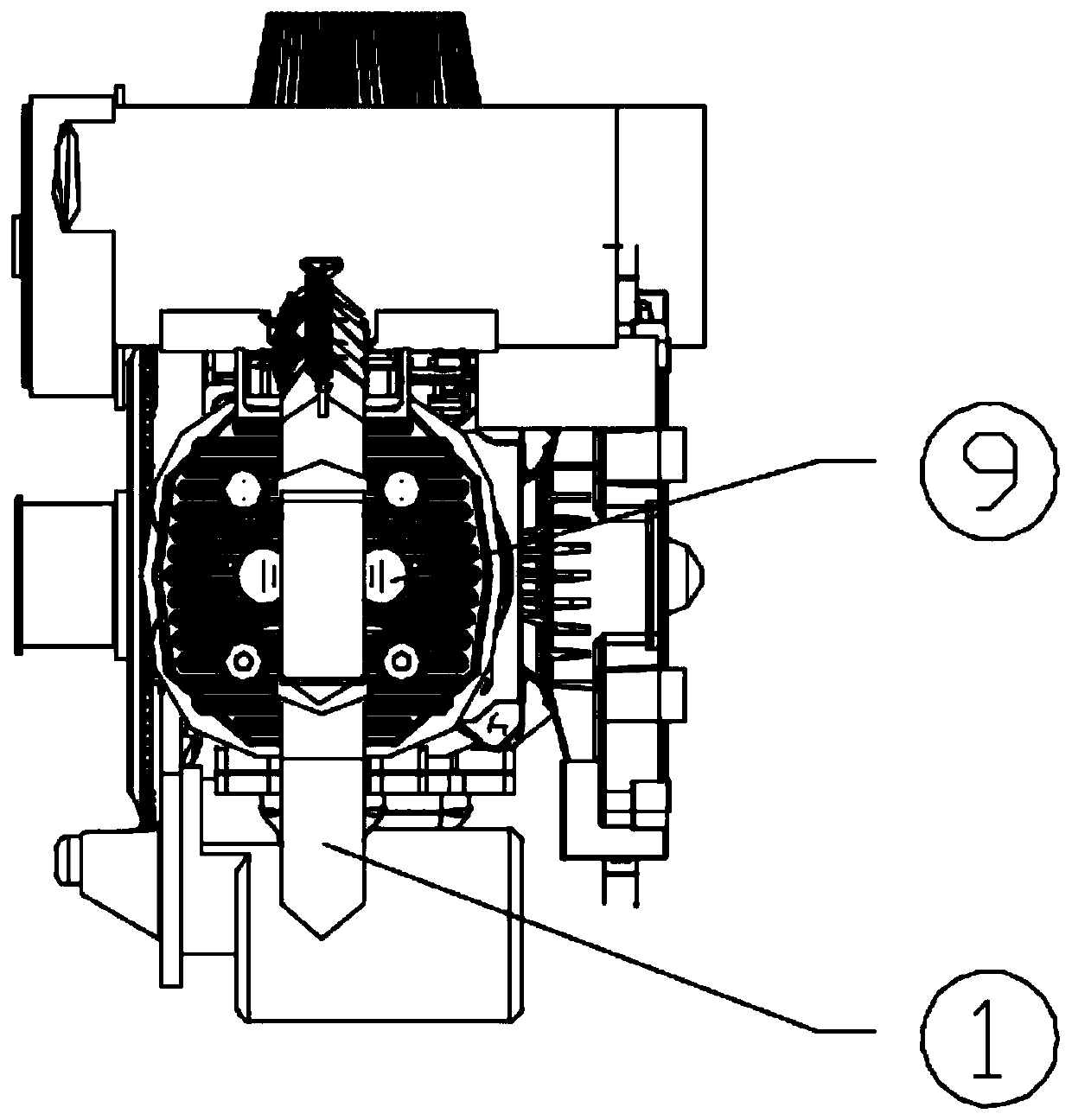

Variable-compression-ratio mechanism of engine

InactiveCN102937052AGuaranteed safe operationVolume changeEngine controllersMachines/enginesHydraulic cylinderCombustion chamber

The invention relates to an engine assembly, and in particular relates to a variable-compression-ratio mechanism of an engine. The variable-compression-ratio mechanism comprises a cylinder cover, wherein a hydraulic cylinder communicated with a combustion chamber of the cylinder is arranged on the cylinder cover; and a variable-pressure piston which can slide in the hydraulic cylinder under drive of a hydraulic device is arranged in the hydraulic cylinder. The variable-pressure piston is driven to move in the hydraulic cylinder through the hydraulic device, and the volume of a part at which the hydraulic cylinder is communicated with the combustion chamber can be changed, so that the total size of the combustion chamber is changed, the aim of changing the compression ratio of the engine is fulfilled, and the structures of a crankshaft and a connecting rod are not required to be changed.

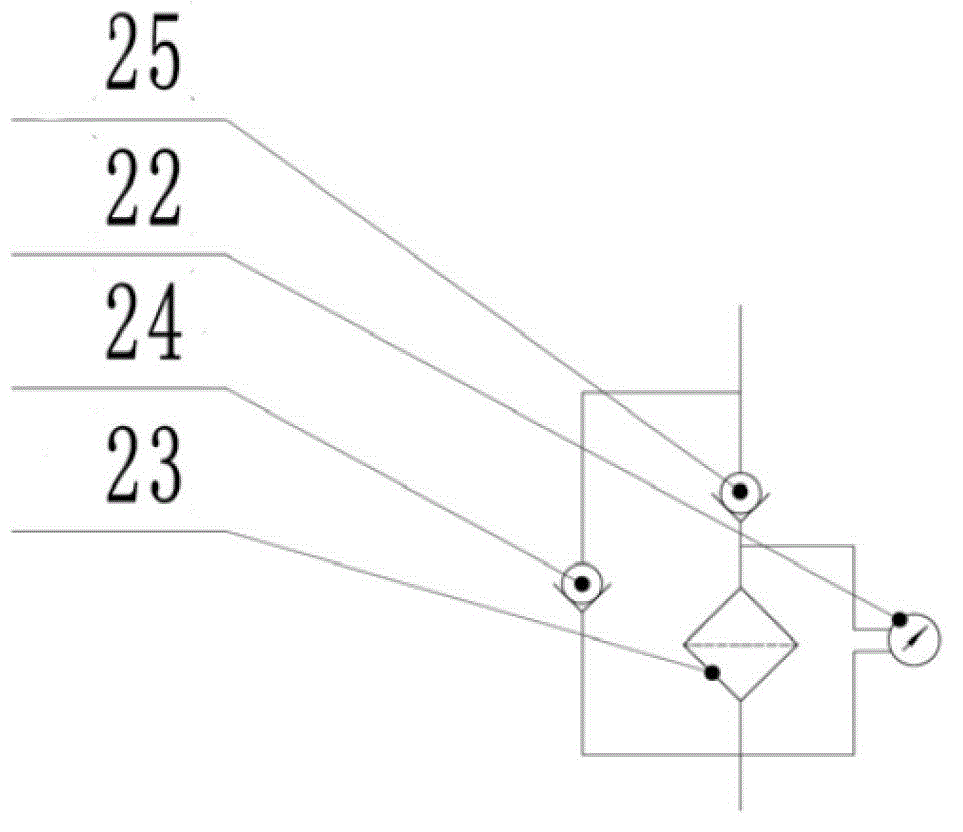

Owner:GREAT WALL MOTOR CO LTD

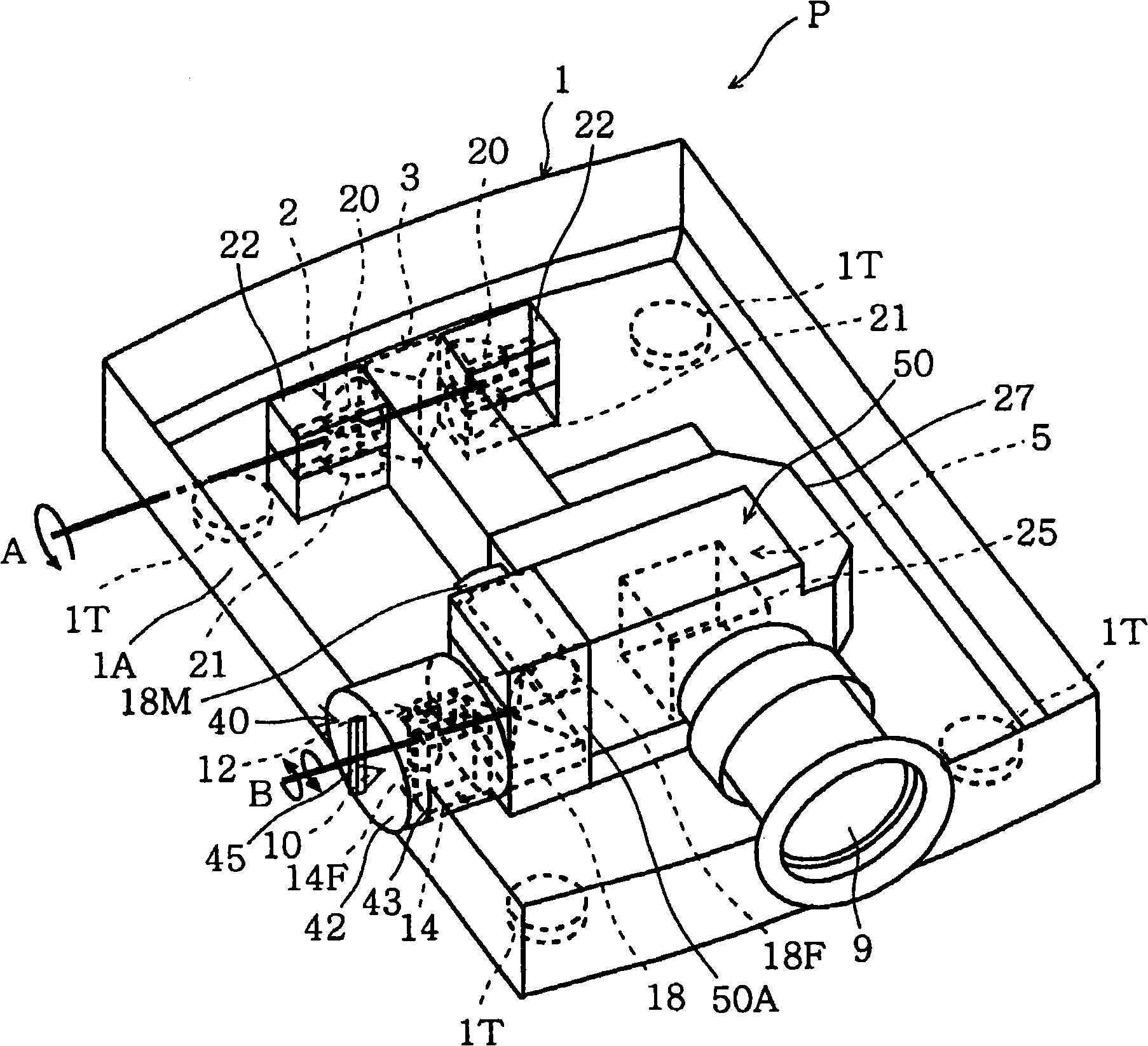

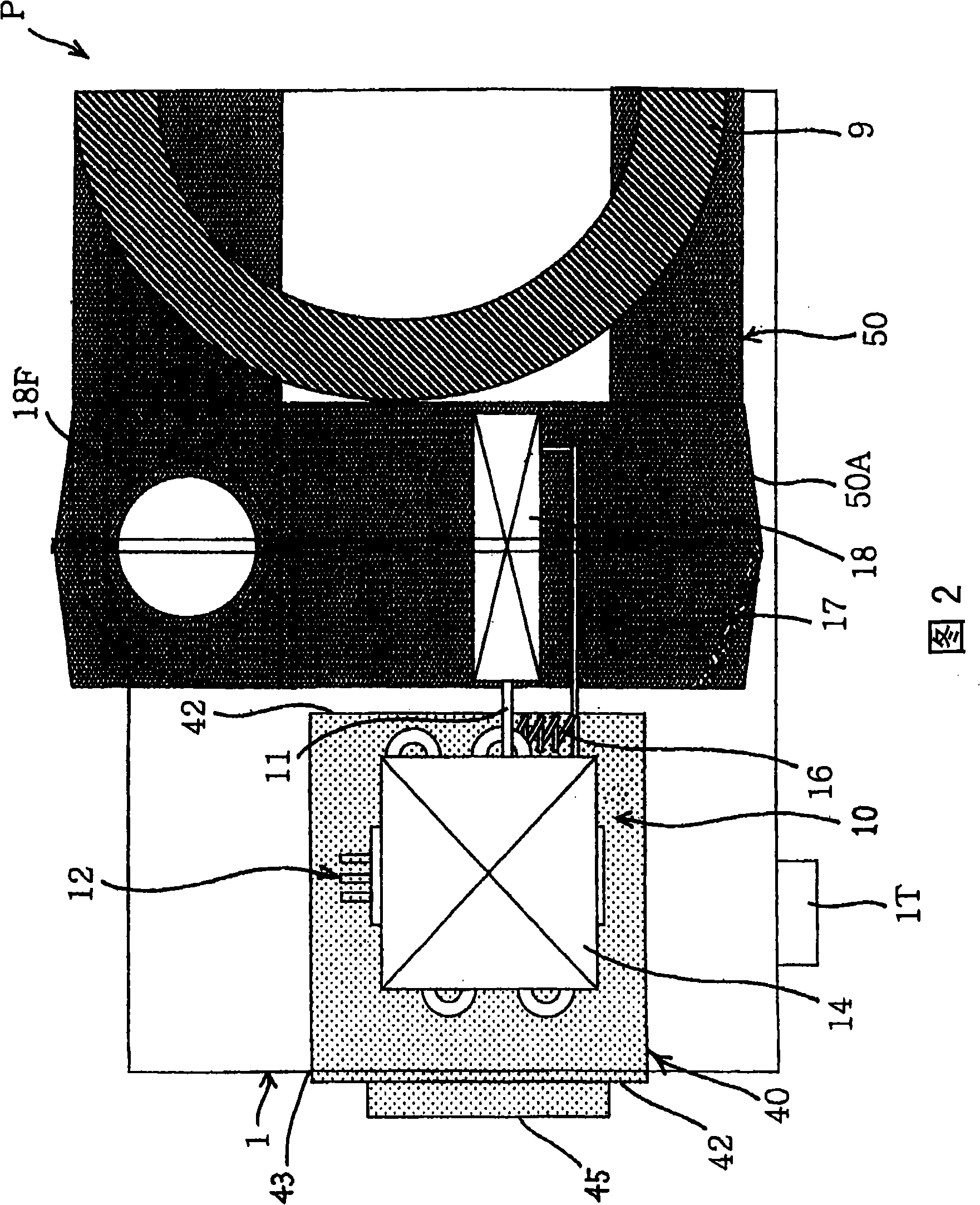

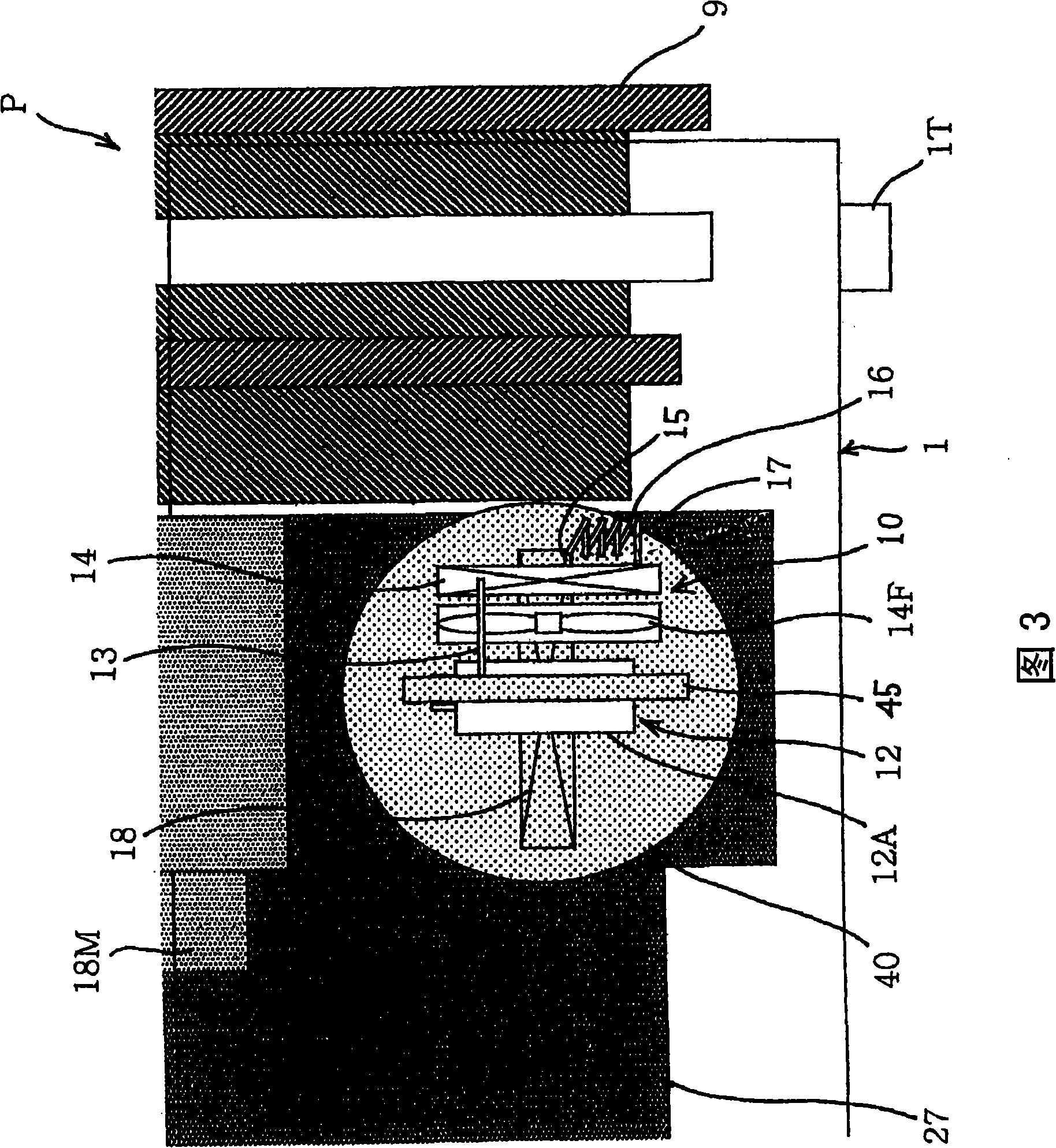

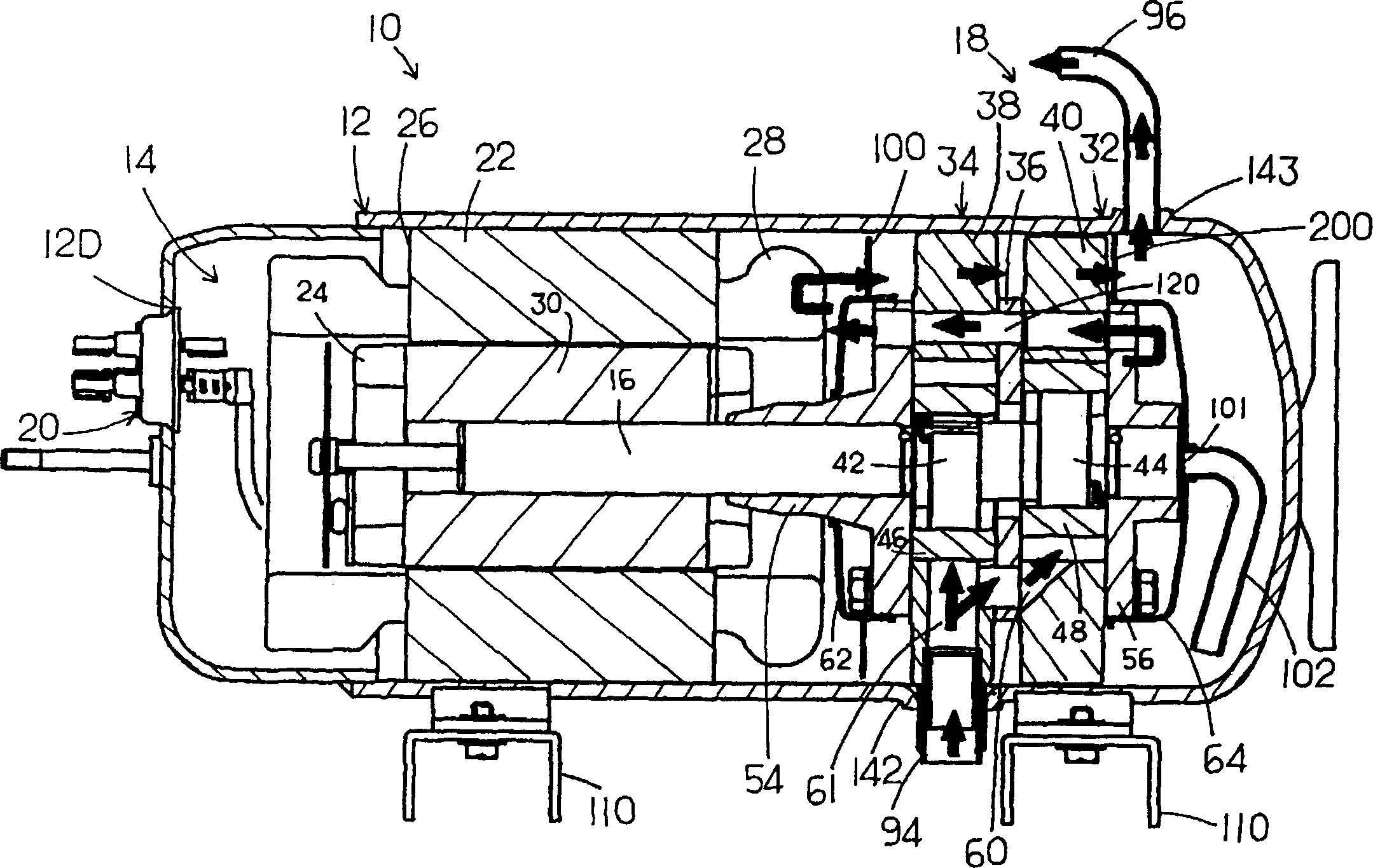

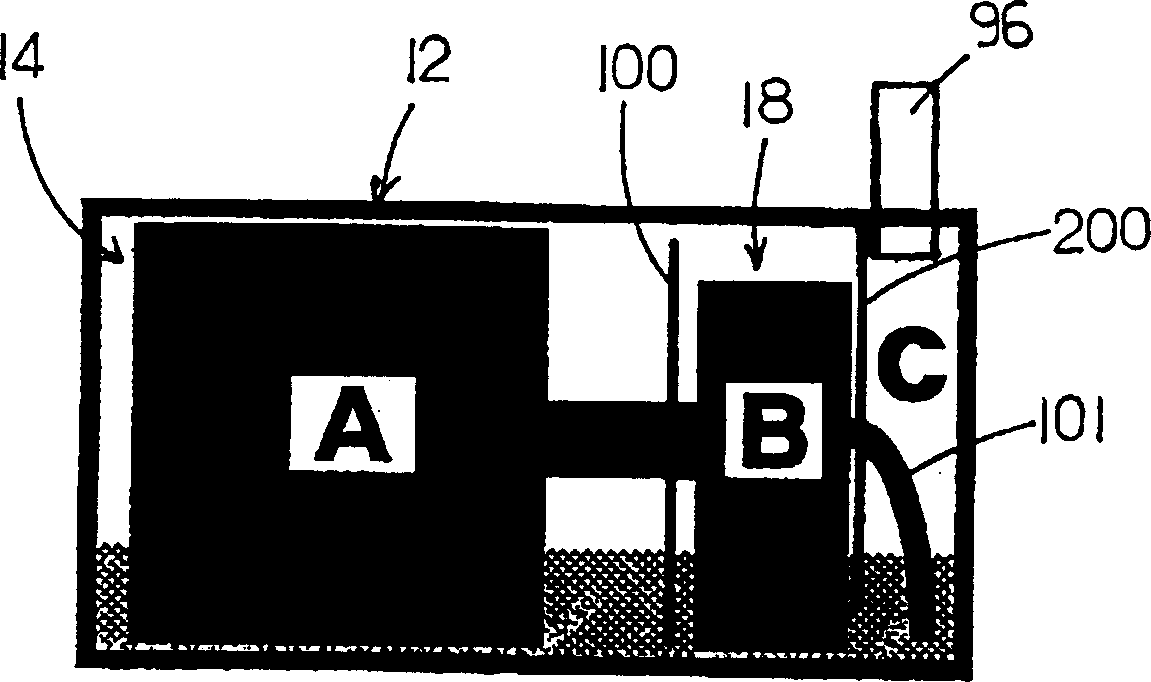

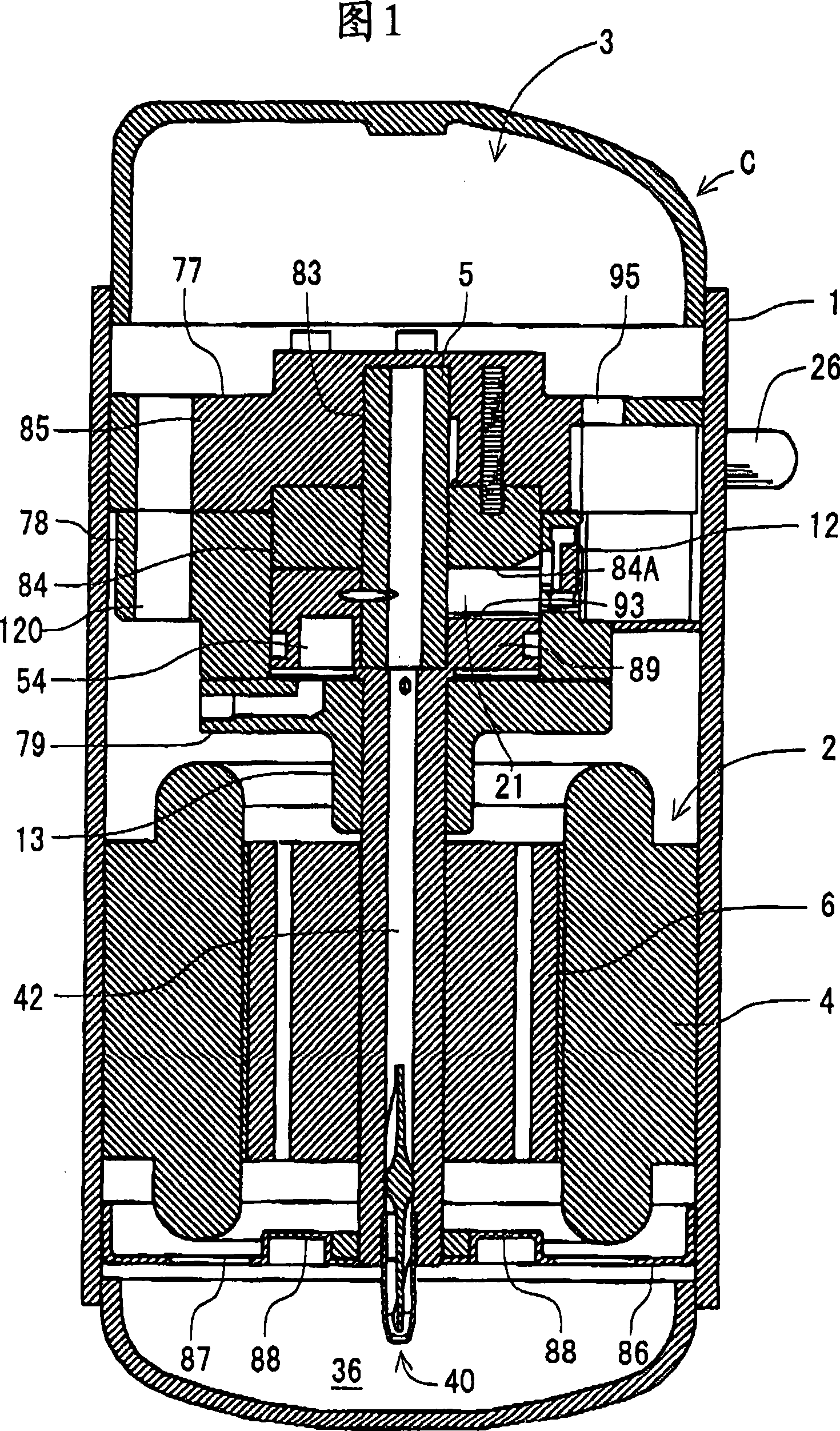

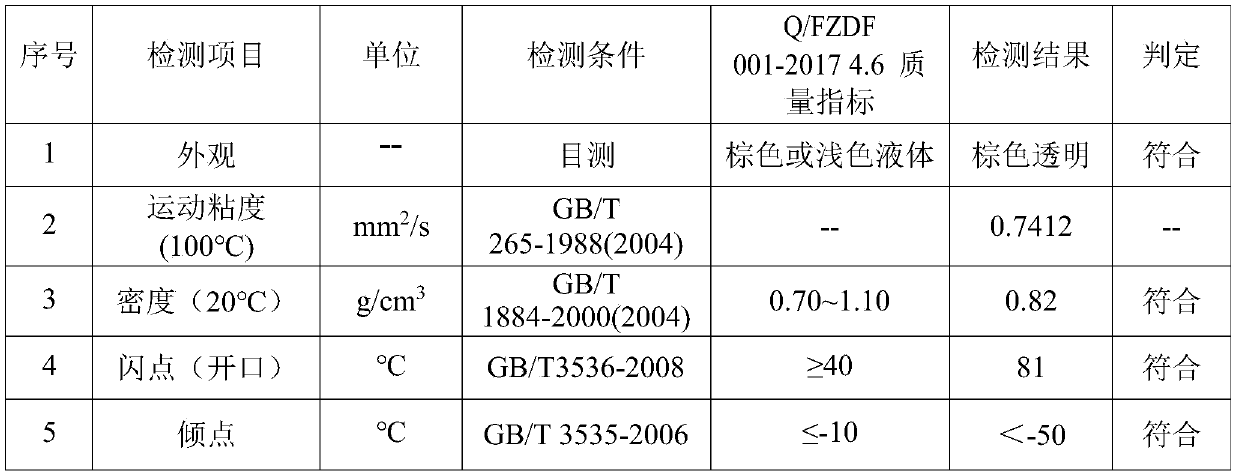

Apparatus including freezing unit and projector including freezing unit

InactiveCN101275787AUnhindered operationGuaranteed lubrication effectCompressorCompression machines with non-reversible cycleLiquid-crystal displayOptical axis

Owner:SANYO ELECTRIC CO LTD

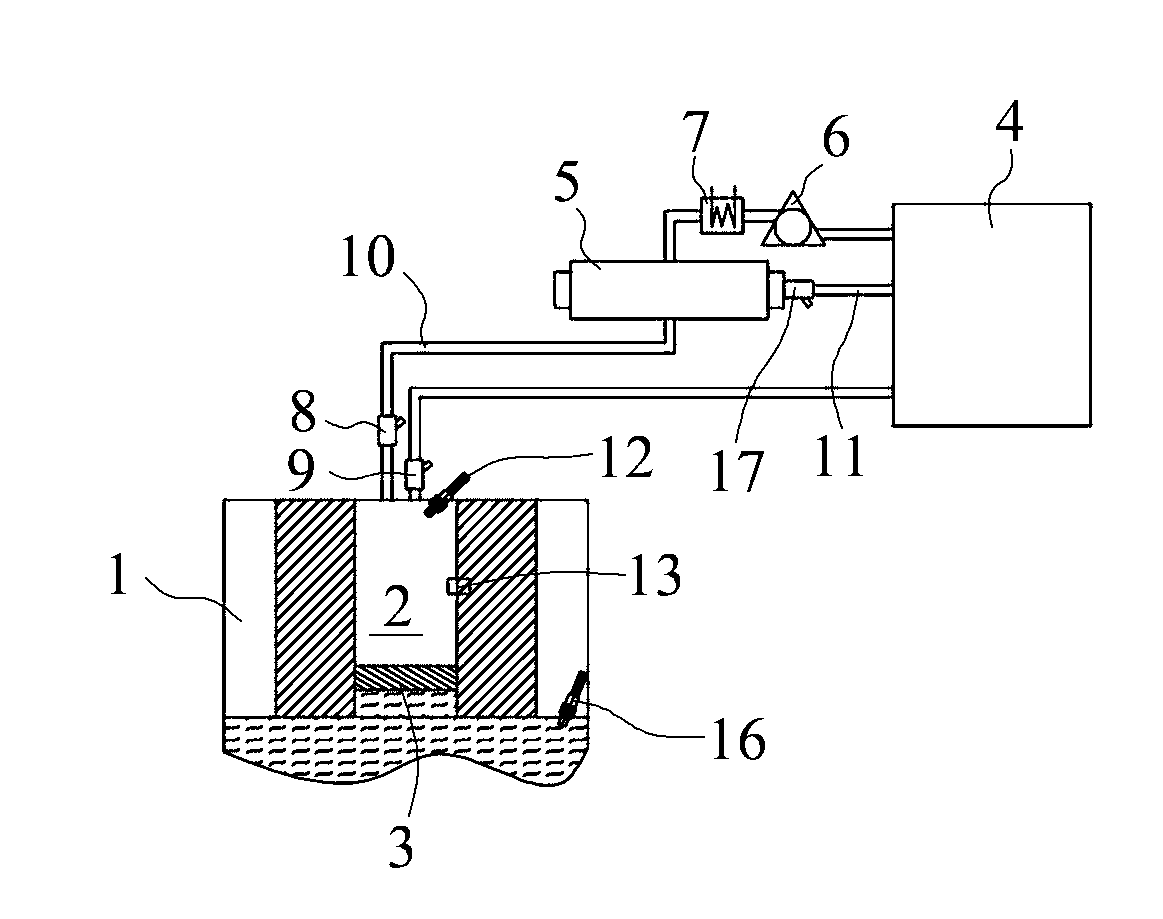

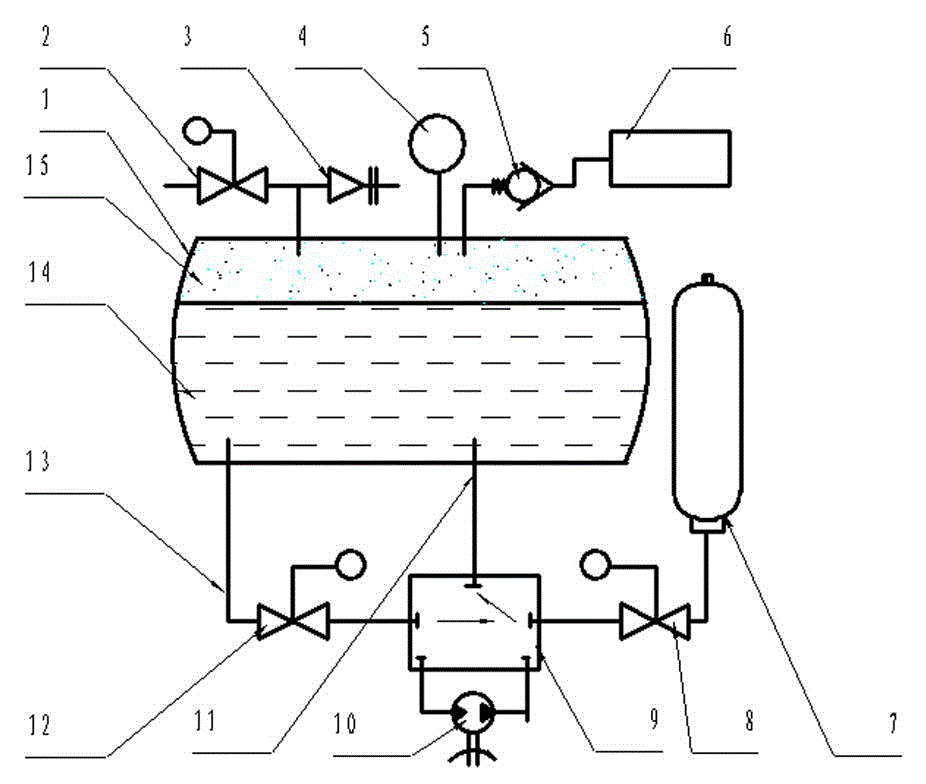

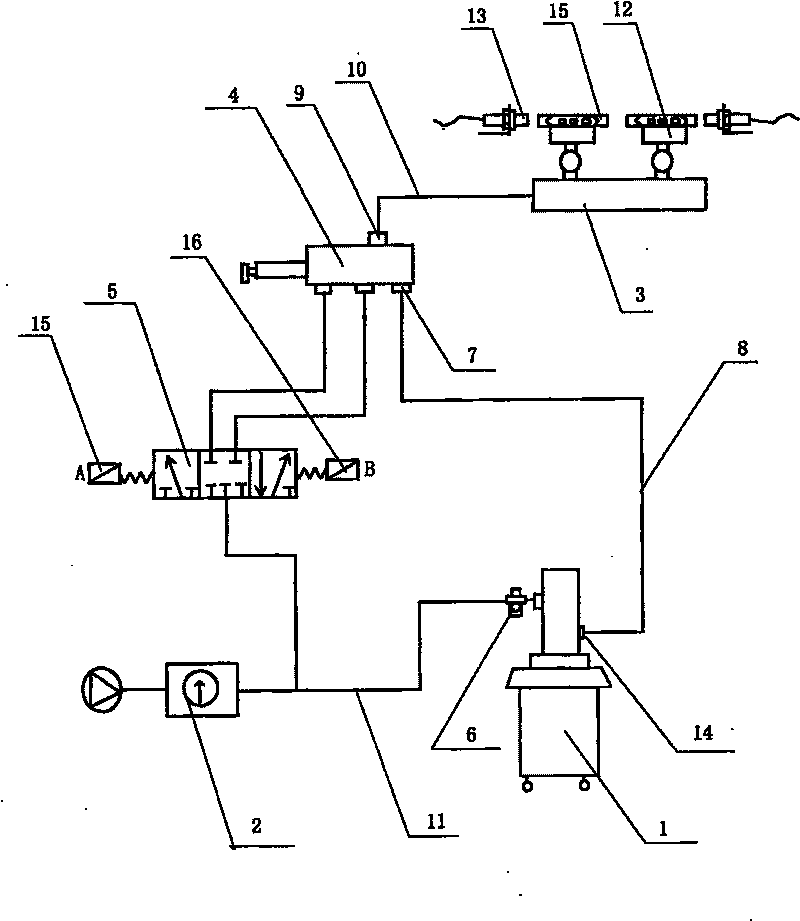

Hydraulic oil tank for air power starting system (hydraulic hybrid power system)

InactiveCN105020185AReduce hydraulic noiseImprove energy storage efficiencyFluid-pressure actuator safetyAccumulator installationsHydraulic hybrid vehicleBall valve

The invention relates to a hydraulic oil tank for an air power starting system (hydraulic hybrid power system). The hydraulic oil tank is arranged on a hydraulic hybrid power vehicle or an air power energy-saving vehicle, and compressed air is pumped into the hydraulic oil tank through an air tank. Therefore, certain minimum pressure is kept in an air chamber above the hydraulic oil level in the hydraulic oil tank, and oil supply backpressure of a hydraulic pump under the energy storage working condition is formed; oil supply smoothness of the hydraulic oil tank is guaranteed, hydraulic noise in the work process is reduced, and energy storage efficiency is improved. The hydraulic oil tank is composed of a hydraulic oil tank body, a pressure indicator, an energy accumulator, an energy accumulator ball valve, a combined type hydraulic valve, a hydraulic motor / pump, an oil tank oil return pipe, an oil tank oil outlet pipe and an oil tank oil outlet pipe ball valve, and is characterized by further comprising an exhaust valve, a safety valve, a pressure limiting check valve and the air tank. The hydraulic oil tank belongs to automobile parts.

Owner:SHANGHAI SHENZHOU VEHICLE ENERGY SAVING & ENVIRONMENTAL PROTECTION

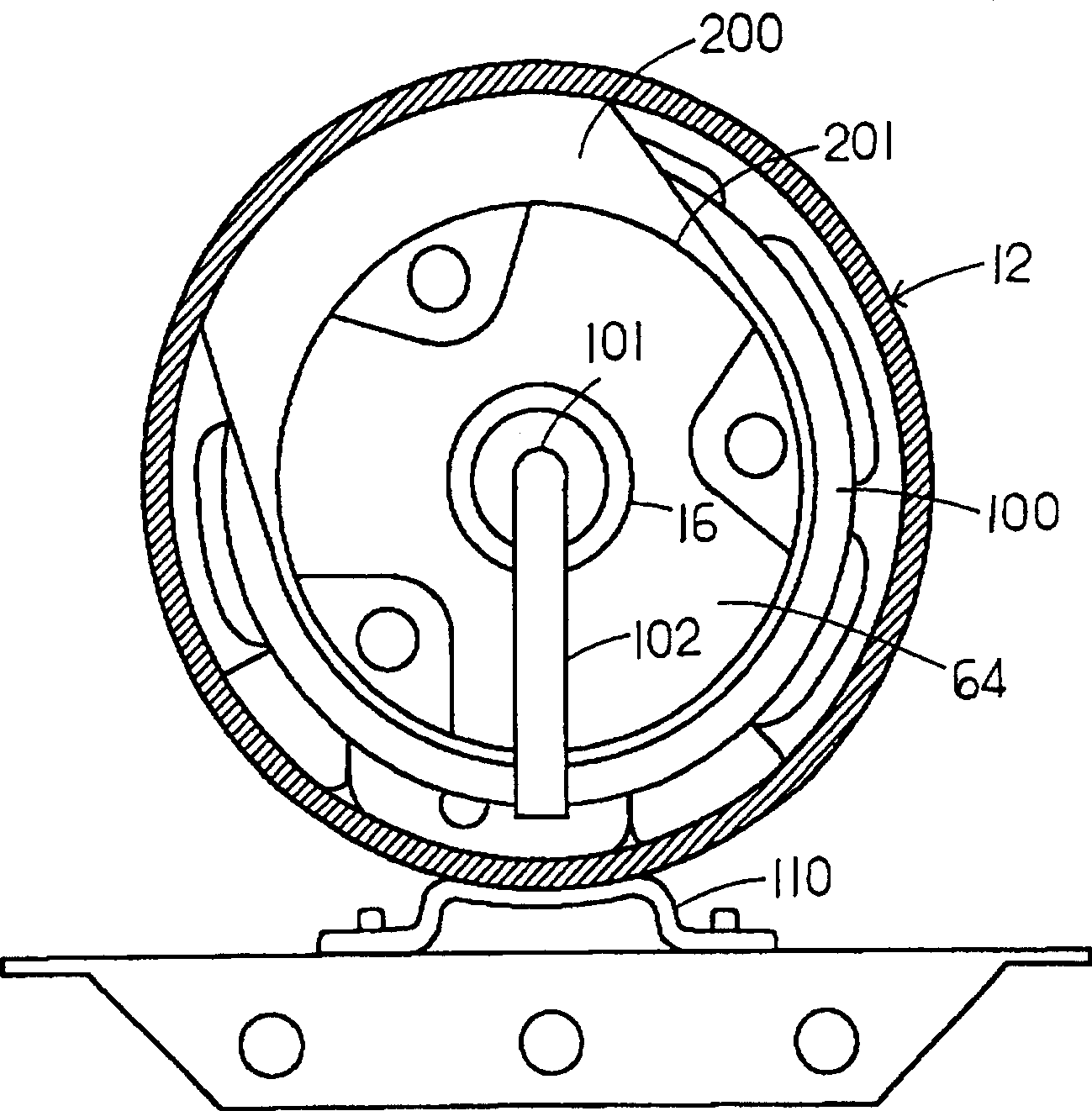

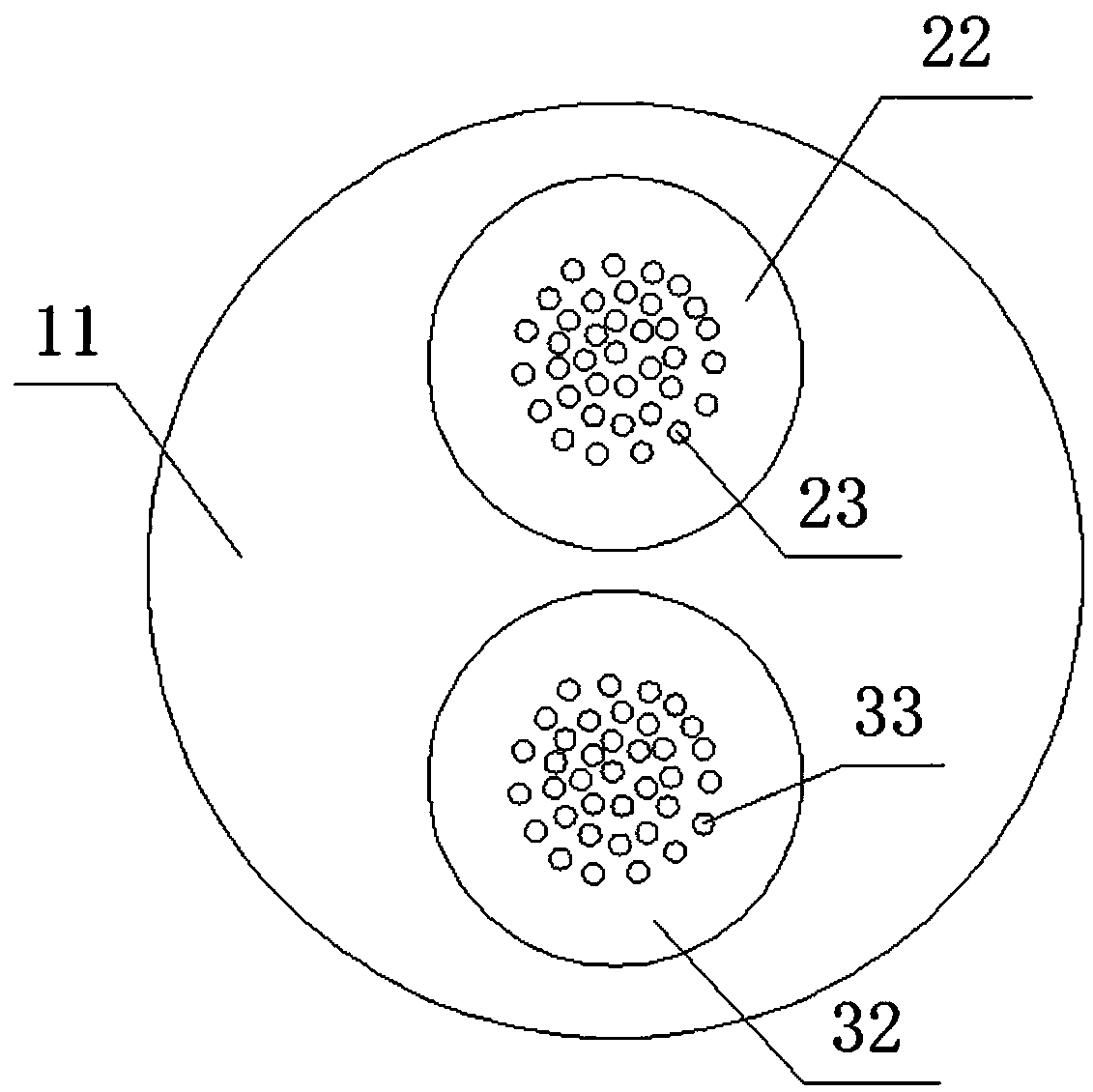

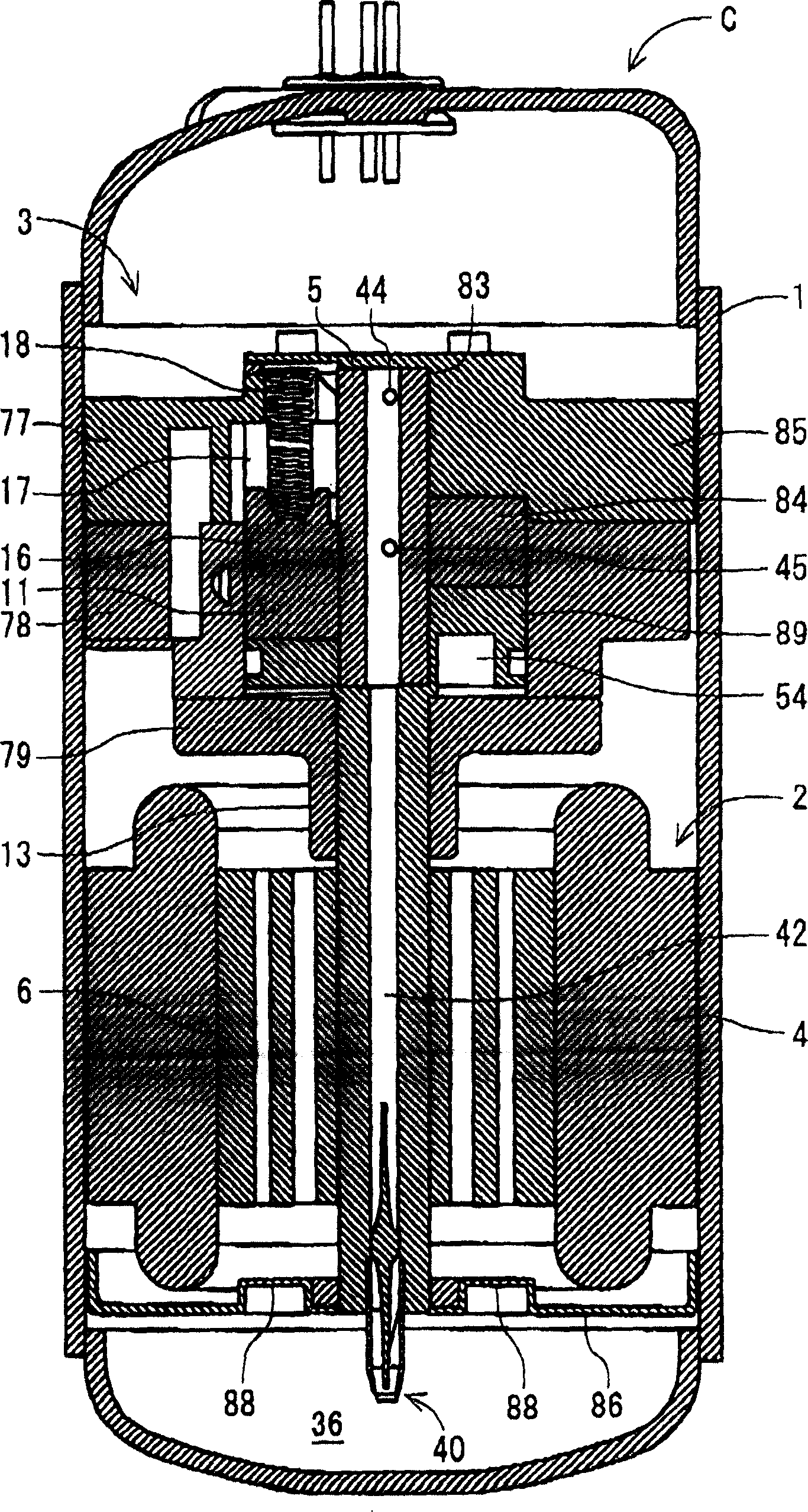

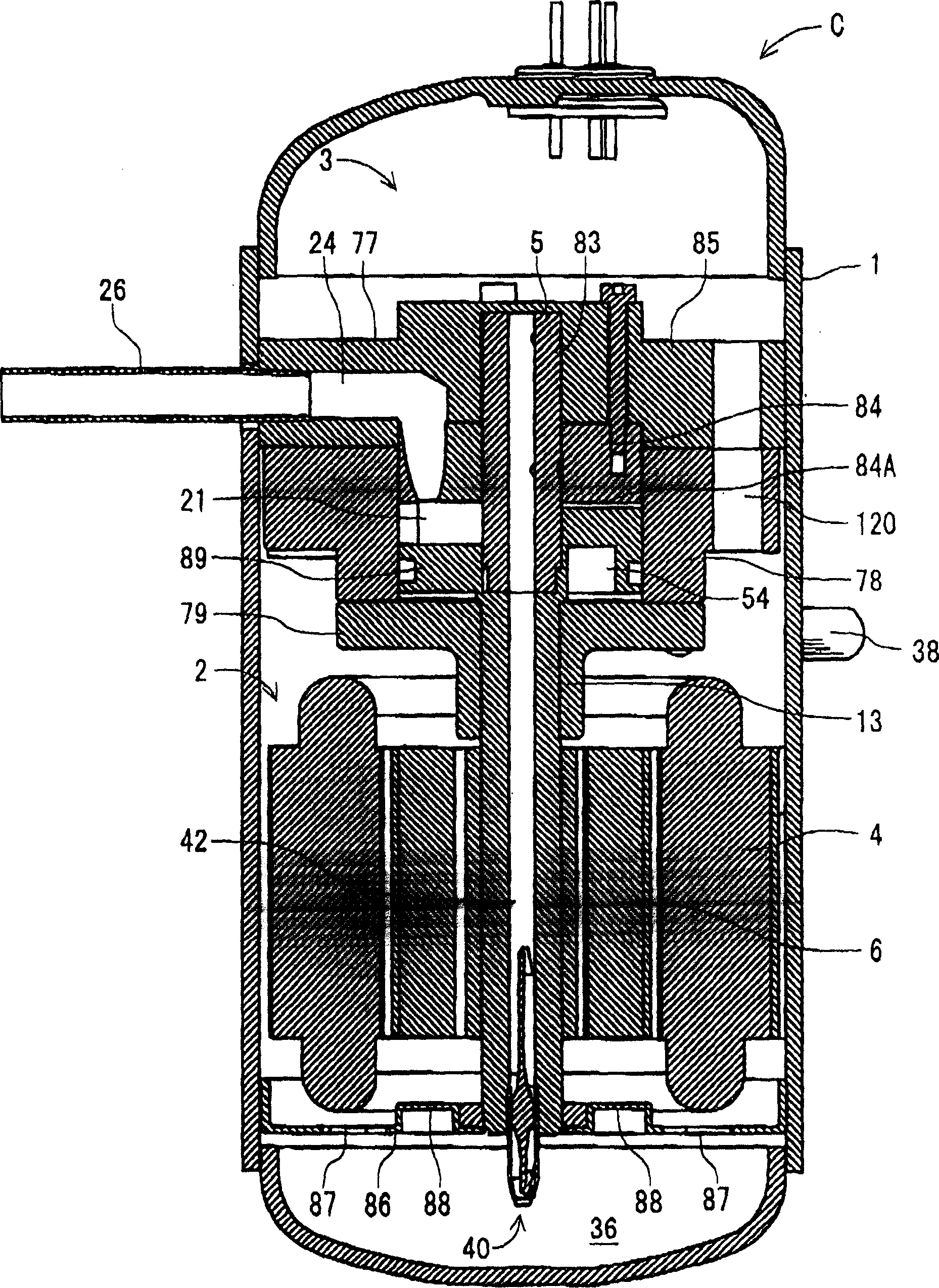

Horizontal rotary compressor

InactiveCN1445460AEven oil supplyEliminate problems that create barriers to circulationRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringMotronic

Owner:SANYO ELECTRIC CO LTD

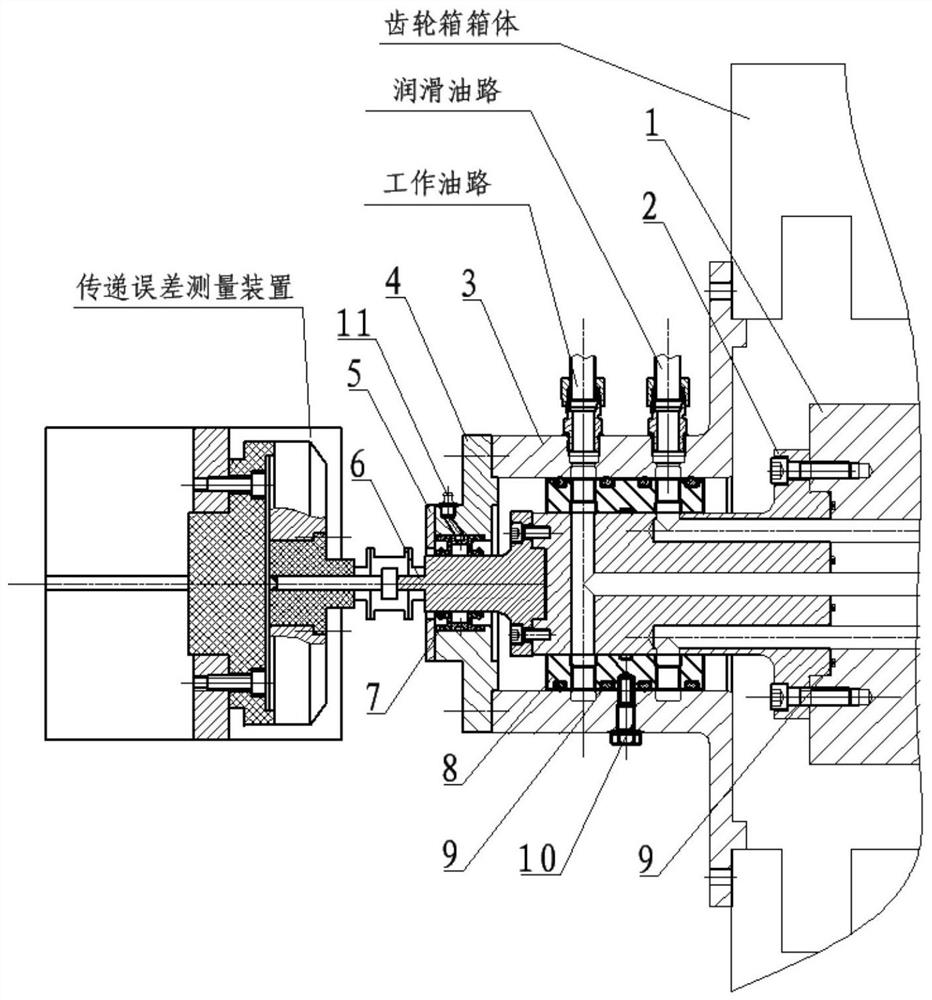

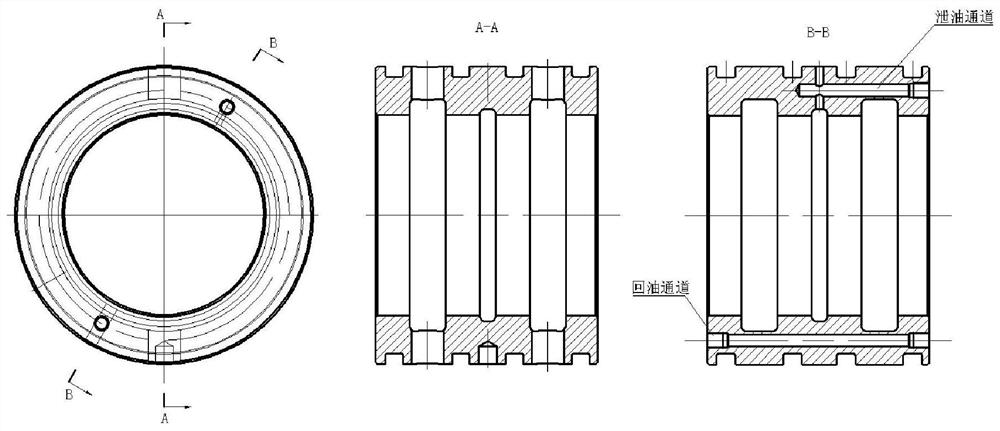

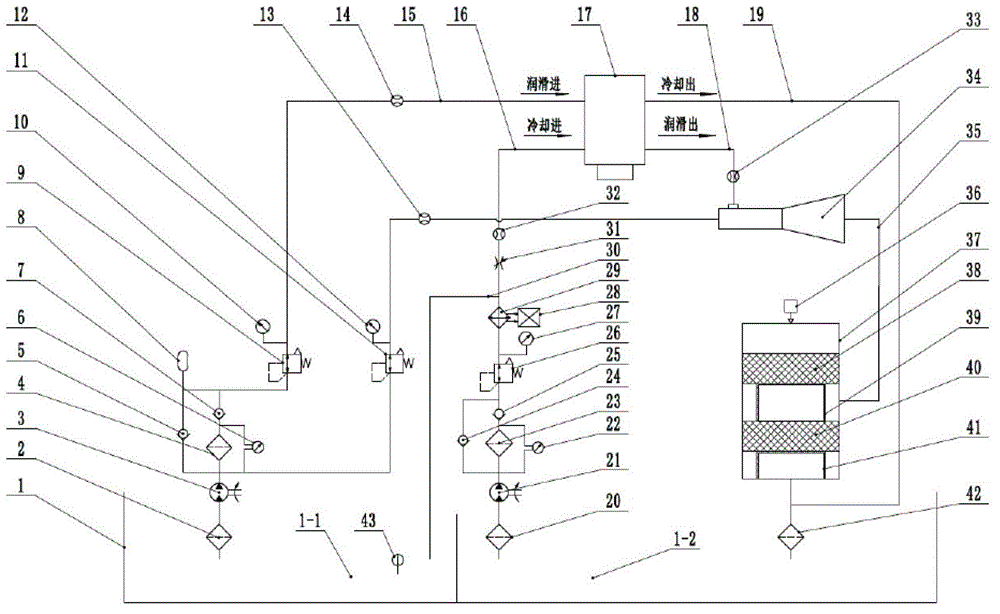

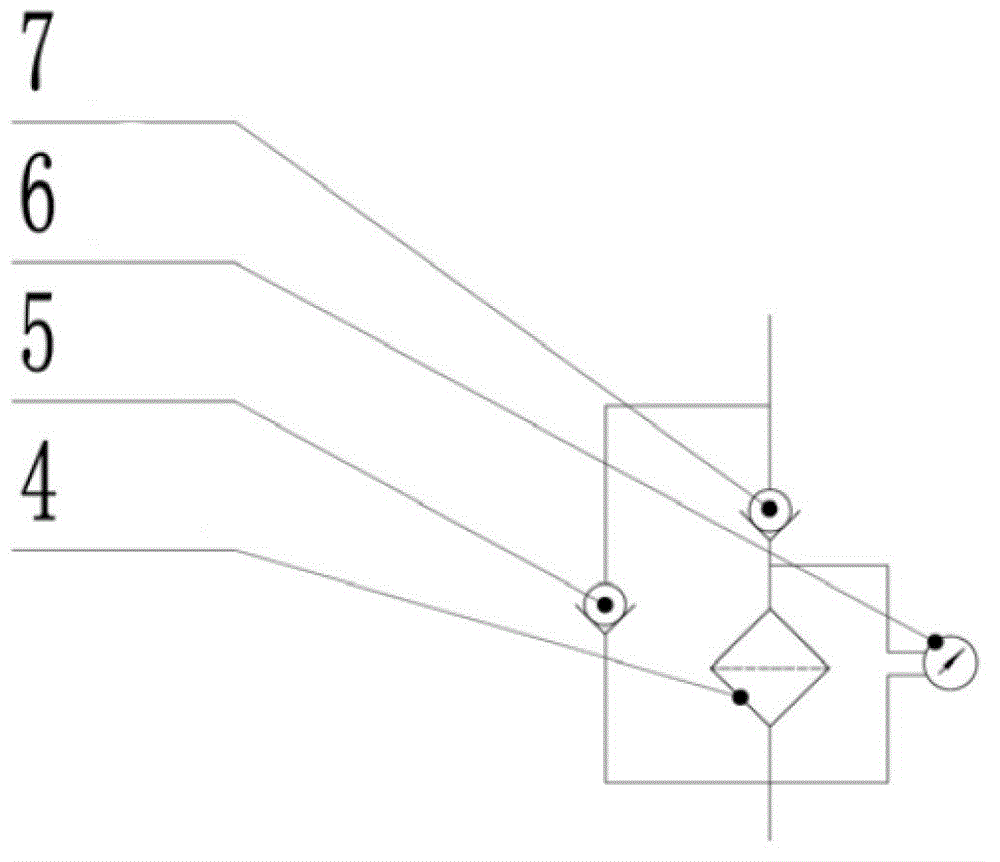

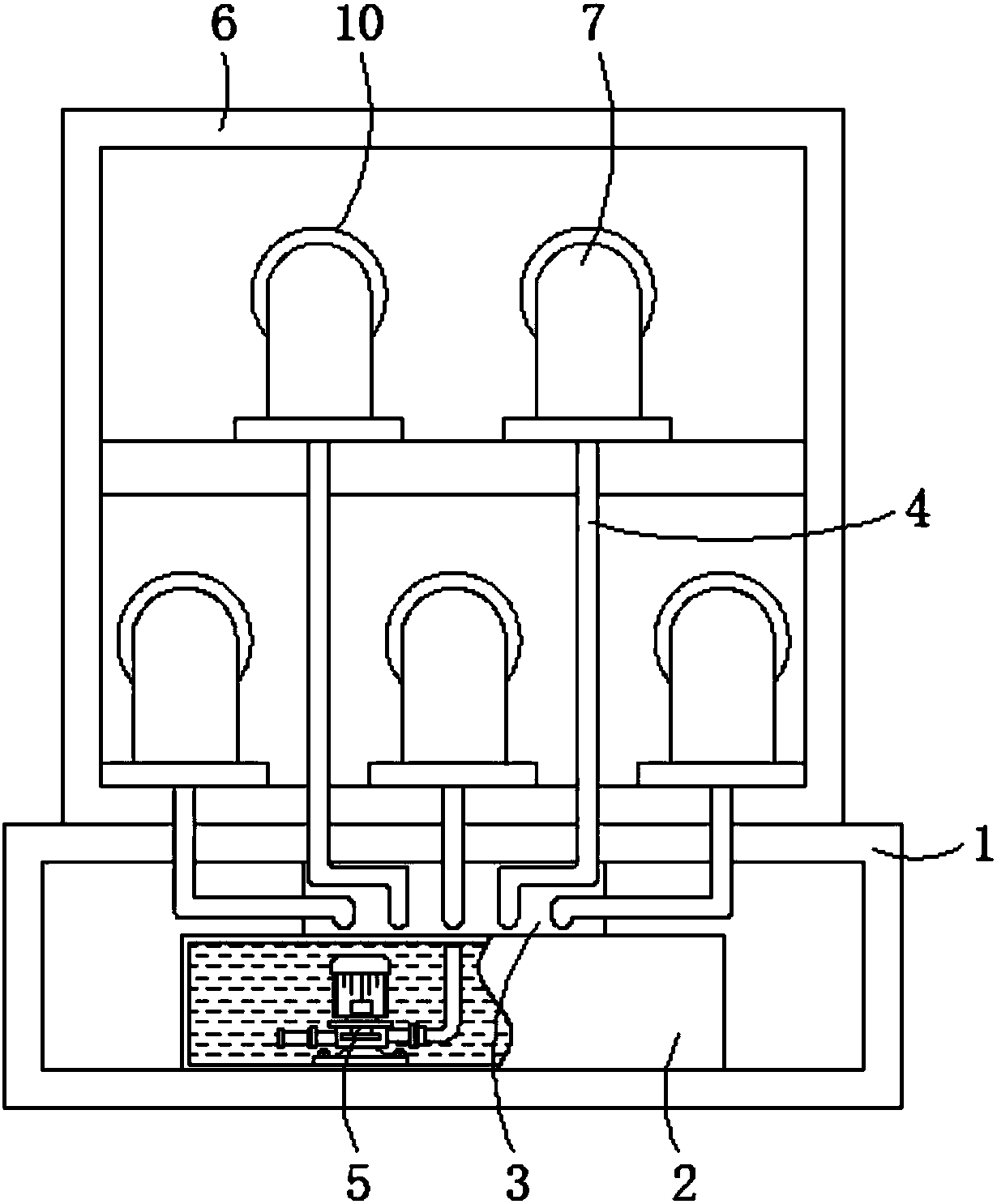

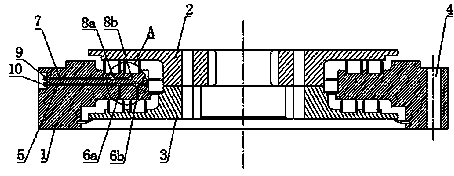

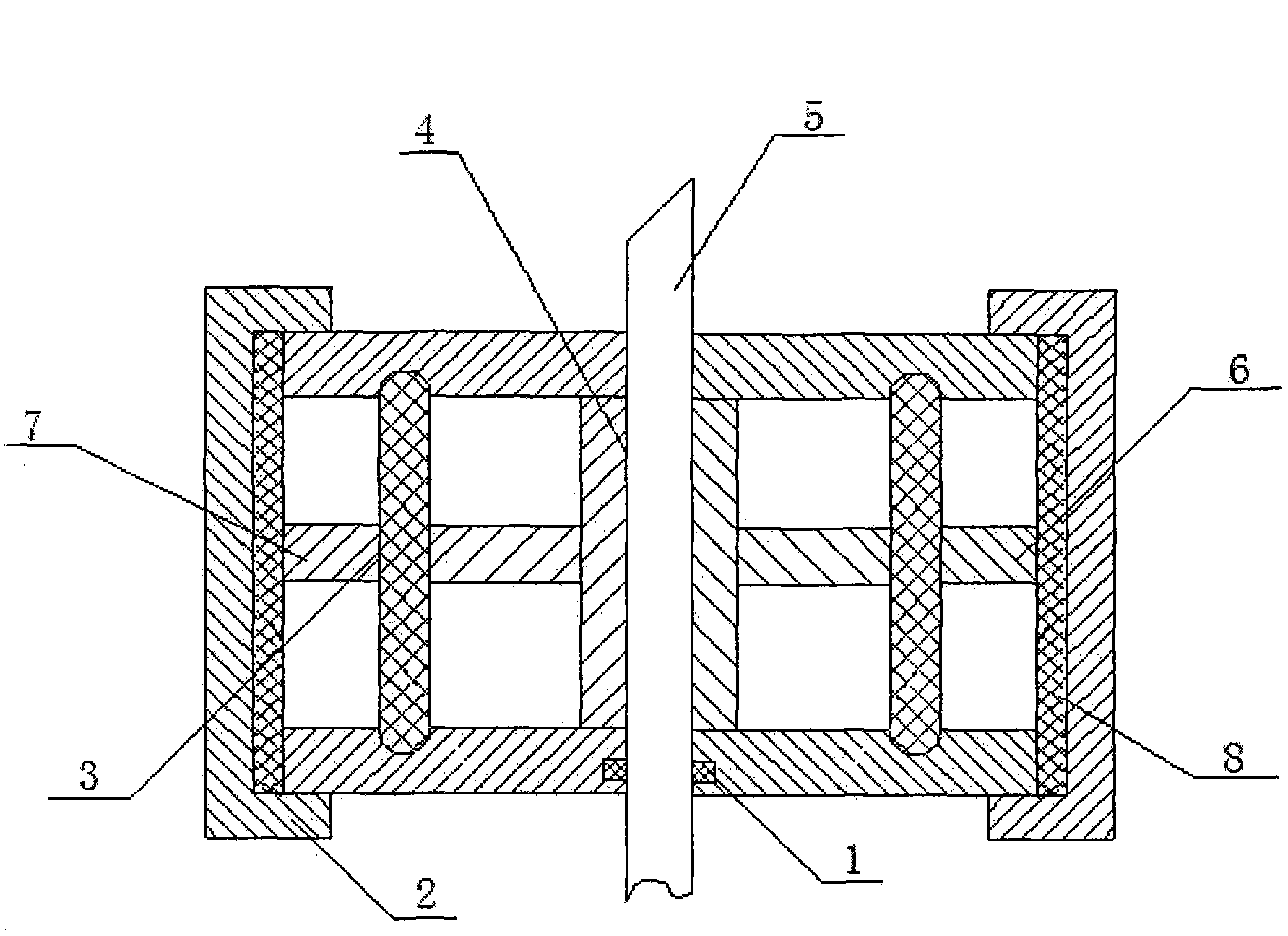

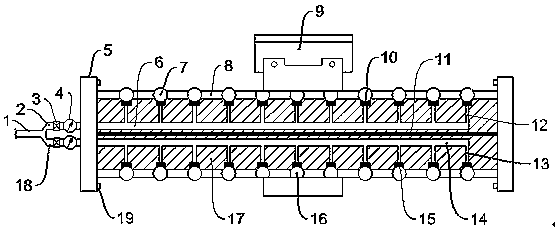

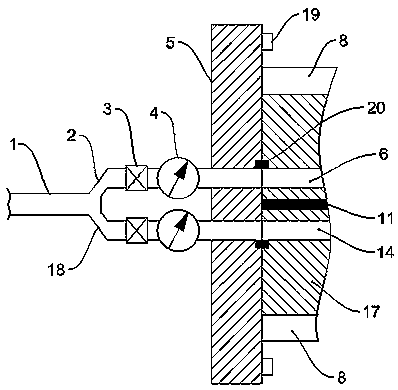

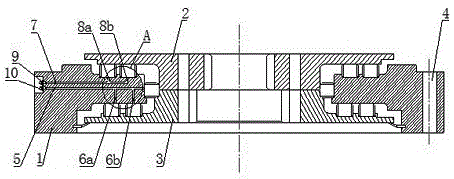

Friction plate clutch oil supply device of double-speed gear box transmission error test bed

ActiveCN112696487AEven oil supplyPrevent leakageGear lubrication/coolingFriction clutchesControl engineeringWasher

The invention provides a friction plate clutch oil supply device of a double-speed gear box transmission error test bed. The oil supply device is mainly composed of a gear shaft, an oil supply shaft section, an oil supply end cover, a shaft seal seat, a baffle, a coupling shaft section, a lip-shaped seal ring, a rotary joint, an O-shaped seal washer, a threaded pin and an oil cup. Working oil and lubricating oil for a clutch are connected to the oil supply end cover through a pipe joint, the oil supply end cover conveys oil for the clutch to an internal oil path of the gear shaft through the rotary joint and the oil supply shaft section and finally enters a tooth web type friction plate clutch, and the lip-shaped seal ring is arranged at the shaft seal seat to prevent high-pressure oil from leaking out of a gear box. According to the friction plate clutch oil supply device of the double-speed gear box transmission error test bed, the working oil and the lubricating oil of the friction plate clutch can be smoothly supplied while a transmission error measurer is smoothly connected, and the leakage of the internal oil and the pollution of external pollutants to the lubricating oil in the gear box can be avoided while the transmission error measurer is smoothly connected.

Owner:中国船舶重工集团公司第七0三研究所

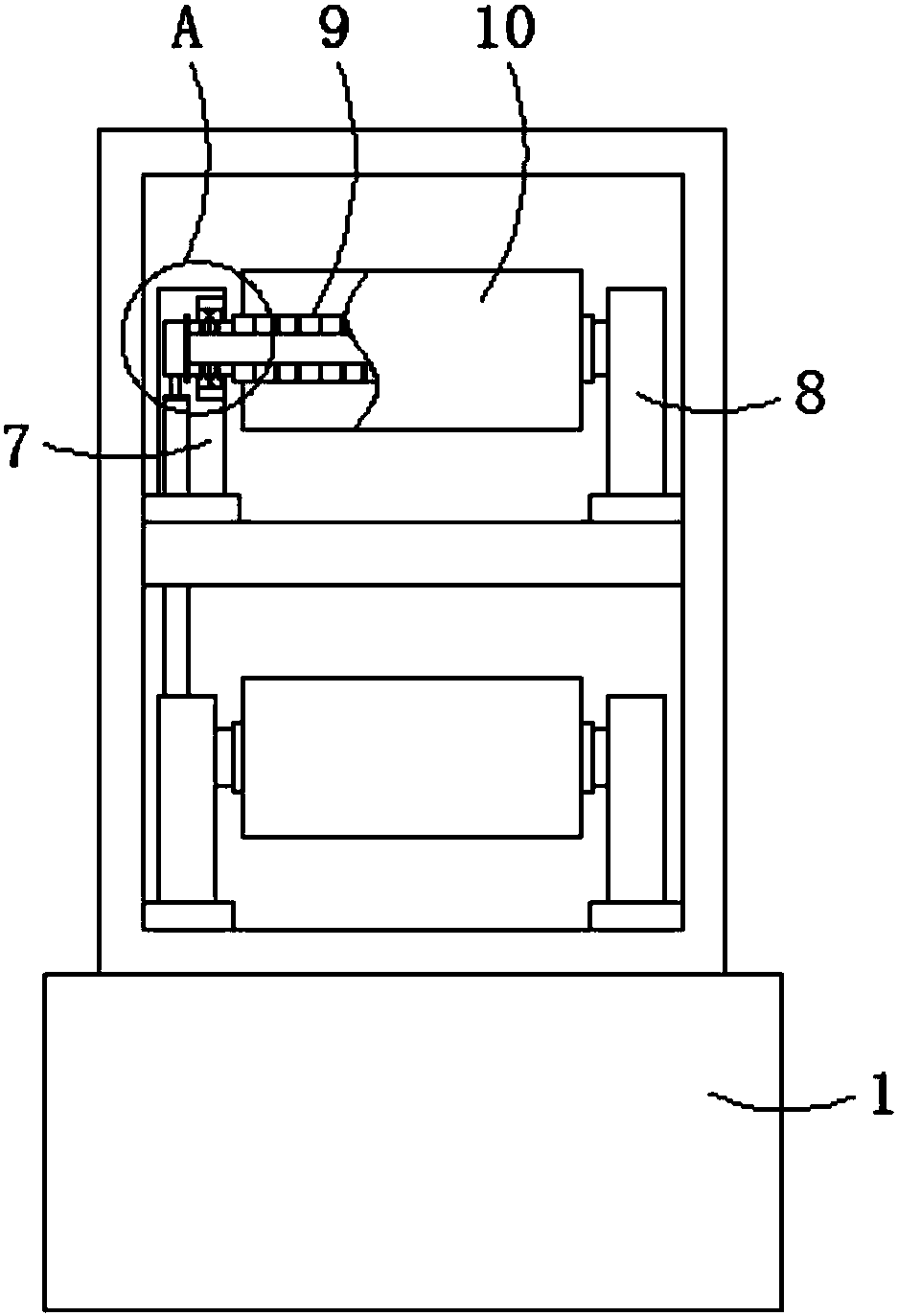

Intelligent hydraulic station

The invention discloses an intelligent hydraulic station, which comprises a lubricating oil feeding subsystem, a cooling oil feeding subsystem, a lubricating oil return subsystem and a cooling oil return subsystem. The intelligent hydraulic station is characterized in that the lubricating oil feeding subsystem and the cooling oil feeding subsystem respectively comprise a precision filter assembly, the precision filter assemblies comprise a precise filter, two one-way valves and a differential pressure sensor, the lubricating oil return subsystem comprises a jet device, a lubricating oil return channel of an electric spindle is connected with a negative pressure chamber interface of the jet device, and oil is sprayed out through the ejection port of the jet device. Defects of failure in oil supply and non-prompt lubricating oil return in case of filter blockage in the prior art can be overcome, smoothness of pressure lubricating oil supply and return can be ensured, bubbles generated in oil return process can be removed, the real-time monitoring of the oil feeding quantity and oil return quantity of the electric spindle lubricating system can be realized, and the intelligent hydraulic station can be widely applied in lubricating oil circulation systems for electric spindles and other hydrodynamic and hydrostatic functional components.

Owner:RES INST OF XIAN JIAOTONG UNIV & SUZHOU

Electronic cigarette cartridge with fluid one-way valve structure and application thereof

PendingCN112450490ASolve the problem of high altitude negative pressure oil leakageEven oil supplyTobaccoEngineeringElectronic cigarette

The invention discloses an electronic cigarette cartridge with a fluid one-way valve structure and application of the electronic cigarette cartridge. The electronic cigarette cartridge comprises a smoke cartridge shell; a one-way valve structural body connected with the smoke cartridge shell; a porous metal atomization element connected with the one-way valve structure body; and a base is connected with the porous metal atomization element. According to the electronic cigarette cartridge with the fluid one-way valve structure, different resistances are exerted on fluid flowing in the forward direction and the reverse direction of the Tesla valve, air guiding and no oil guiding can be achieved by reasonably designing the size of a Tesla valve pipe body, the air pressure of an oil bin can beadjusted in real time along with forward breakover of suction, and the smooth oil supply is guaranteed; and the problem of high-altitude negative-pressure oil leakage of the electronic cigarette cartridge can be solved by utilizing reverse resistance and consuming pressure difference.

Owner:SHENZHEN REELLY TECH CO LTD

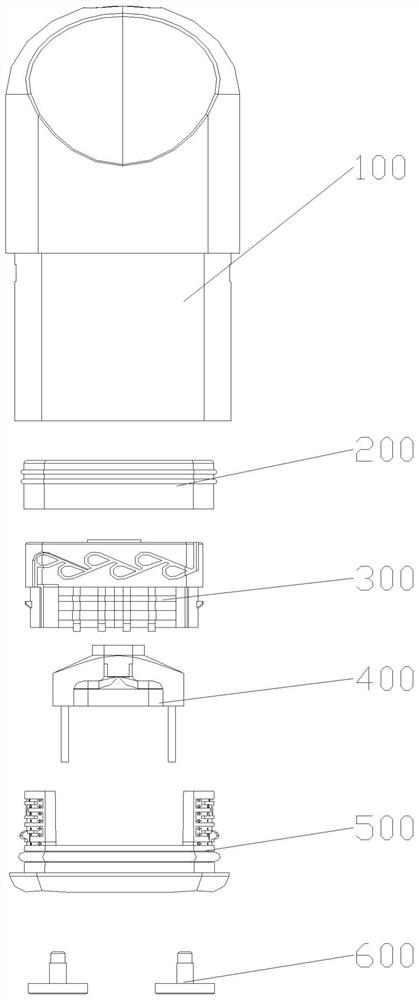

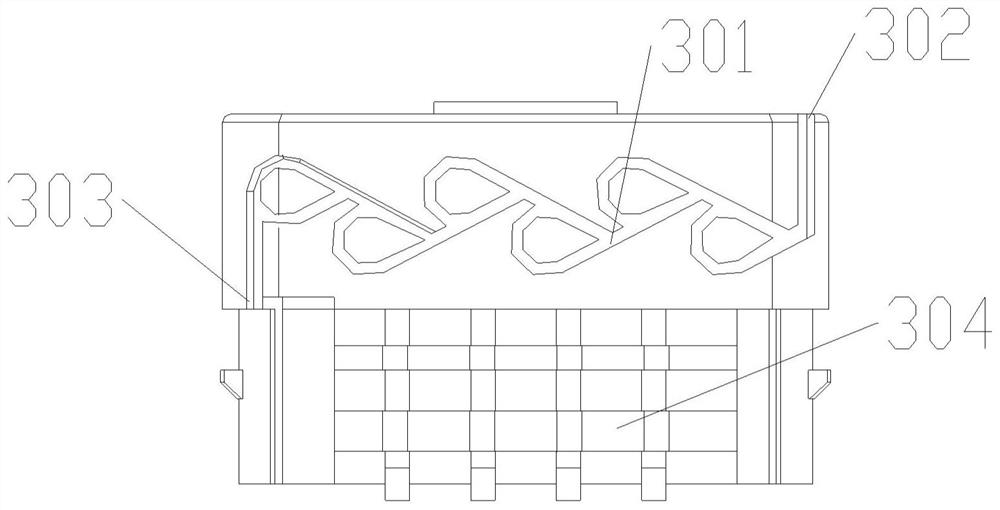

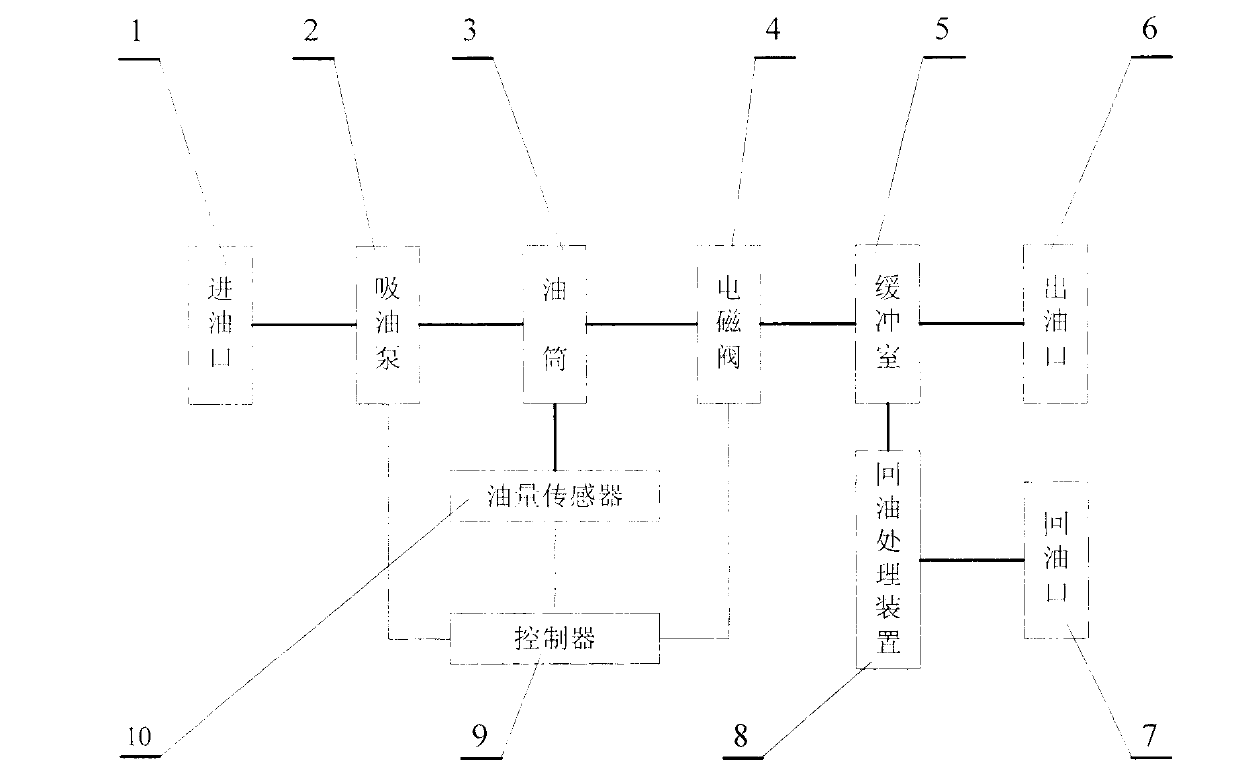

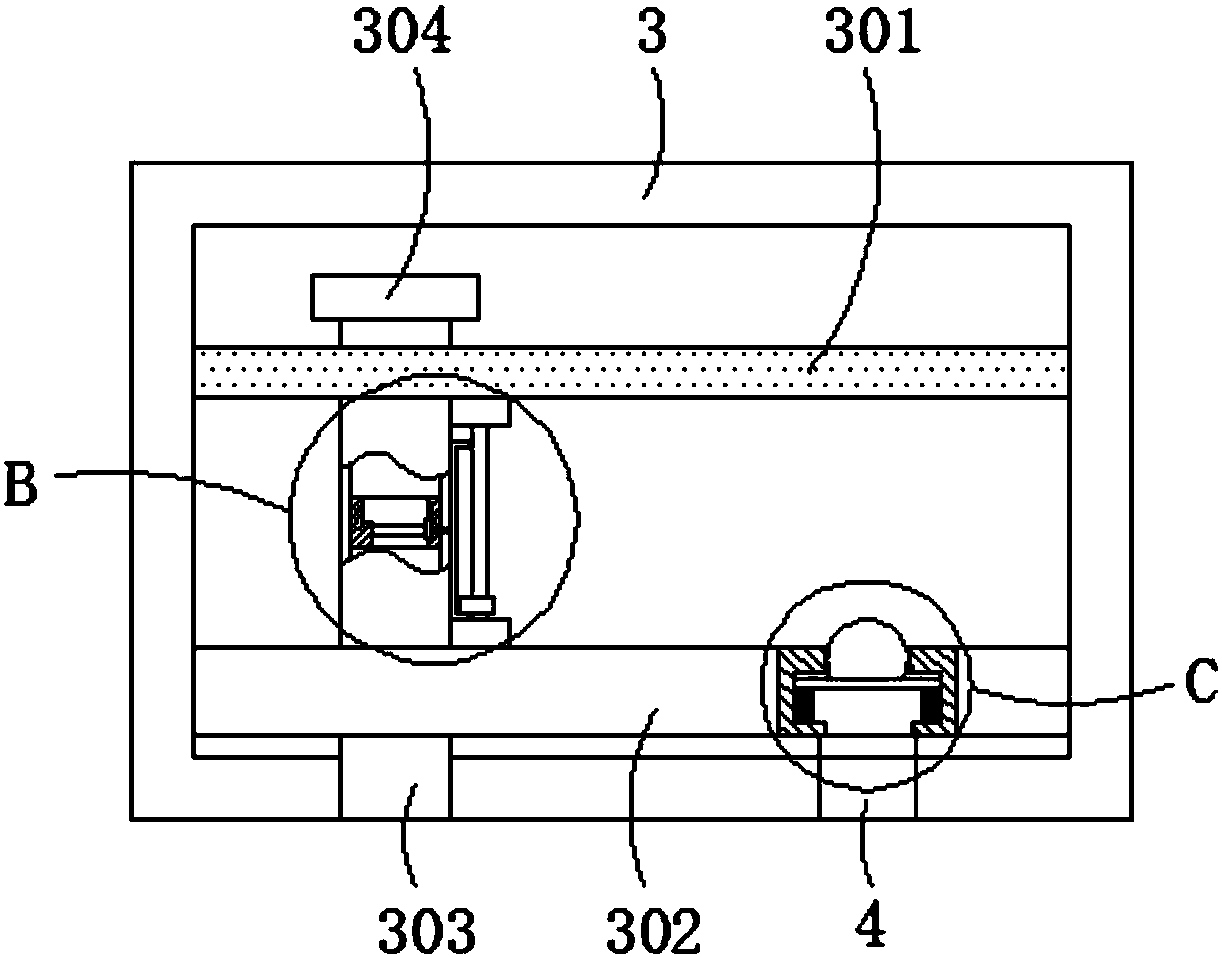

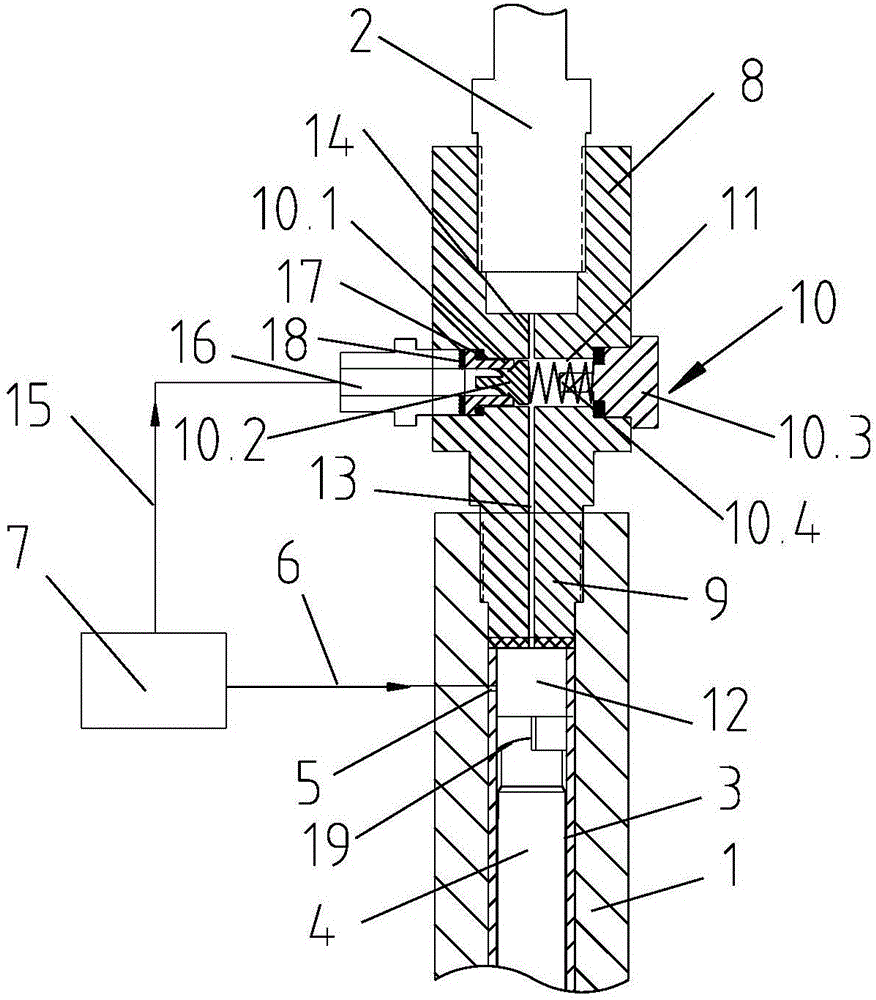

Device and method for detecting real-time oil consumption of engine

InactiveCN103292850AEliminate high frequency pulsationUle out high frequency pulsationRelative volume flow measurementsOil processingSolenoid valve

The invention discloses a device and a method for detecting the real-time oil consumption of an engine. The device comprises an oil inlet 1, an oil outlet 6, an oil return port 7, an oil suction pump 2, an oil tube 3, an oil measurement sensor 10, a solenoid valve 4, a buffer room 5, a return oil processing device 8 and a controller 9, and can detect the real-time oil consumption of the engine, the oil consumption accumulated in the operation zone, the oil consumption accumulated in the historical time period and the total accumulated oil consumption.

Owner:易年川 +1

Automatic oiling device used in filament sizing machine

InactiveCN108426158ASame split velocityGuaranteed oil supplyProportioning devicesTextile treatmentFuel tankSizing

The invention discloses an automatic oiling device for a filament sizing machine, which comprises a base, wherein an oil tank is arranged in the base; a flow equalizer is arranged on the top end of the oil tank; a filter plate, a sealing partition and a main flow pipe are arranged in the flow equalizer; the main flow pipe penetrates through the filter plate and the sealing partition and one end ofthe main flow pipe is provided with a spray head. The filter plate is arranged above the sealing partition. A sealing ball valve is arranged on one side of the main flow pipe. According to the invention, a flow equalizer, a filter plate, a sealing partition, a sealing ball valve and a flow divider pipe are arranged. The lubricating oil in the oil tank is led into the flow equalizer by an oil pumpduring operation. The lubricating oil is filtered by the filter plate in the flow equalizer. The filtered lubricating oil flows into a uniform flow cavity formed between the filter plate and the sealing partition. A sealing ball valve is arranged on the sealing partition. The more the content of the lubricating oil in the uniform flow cavity is, the greater the pressure of the sealing ball in thesealing ball valve is.

Owner:CHANGXING JUFENG SILK WEAVING FACTORY

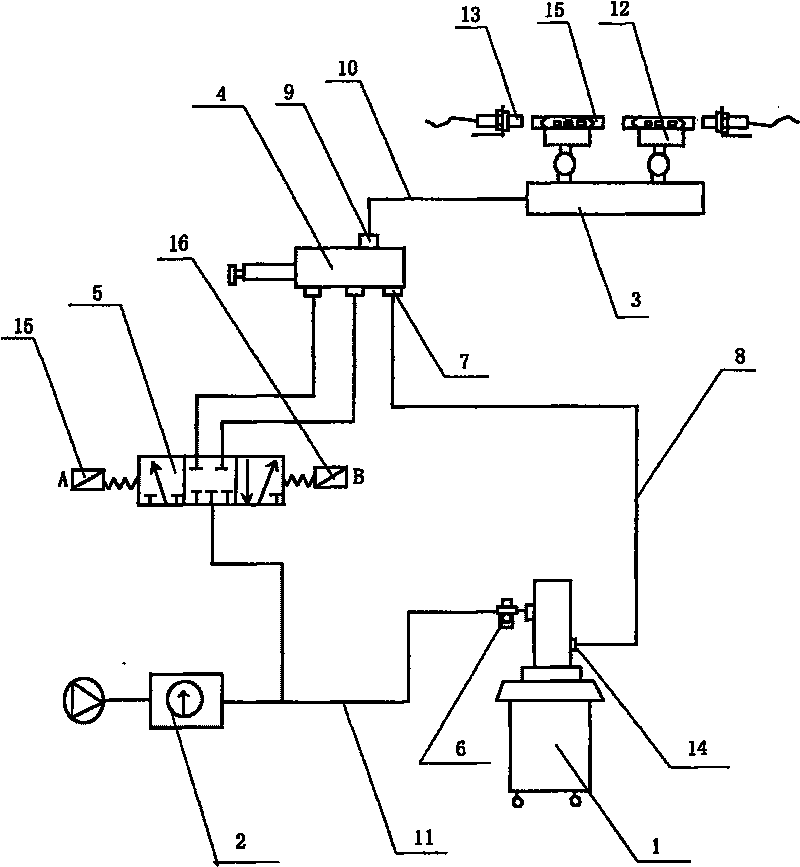

Oil or grease coating machine

ActiveCN101234371BImprove mobilityImprove accuracyLiquid surface applicatorsCoatingsOil and greaseInput control

The invention discloses an oil coating machine and is characterized in that an output end of a water oil separator (2) is connected with a reducing valve (6) of a consistent lubricant injection machine (1); an oil outlet (14) of the consistent lubricant injection machine (1) is communicated with an oil inlet (7) of a proportion valve (4) by a high-pressure oil tube I (8); an oil outlet I (9) of the proportion valve (4) is communicated with a greasing clamp (3) by a high-pressure oil tube II; a pipe (11) is arranged between the water oil separator (2) and the reducing valve (6) of a consistentlubricant injection machine (1) and is connected with an input end of a electromagnetic valve (5), the output end of which is connected with an input controlling end of the proportion valve (4); the monitoring plant is adjacent to an oil outlet II (12) in the upper part of the greasing clamp (3) and is corresponding to the electromagnetic valve (5).

Owner:雅马哈动力机械(江苏)有限公司

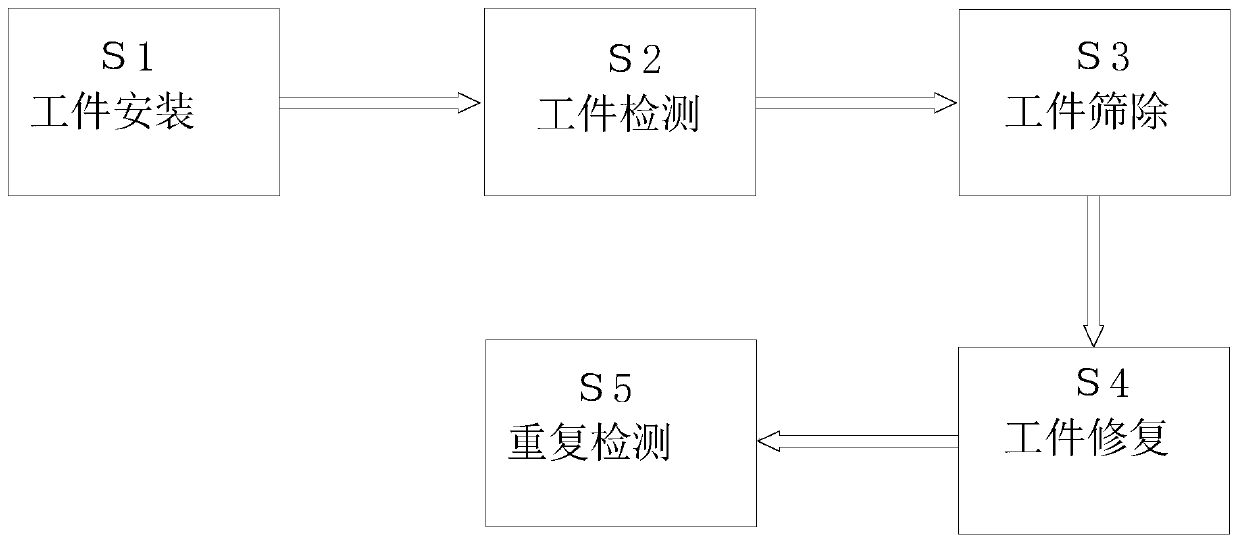

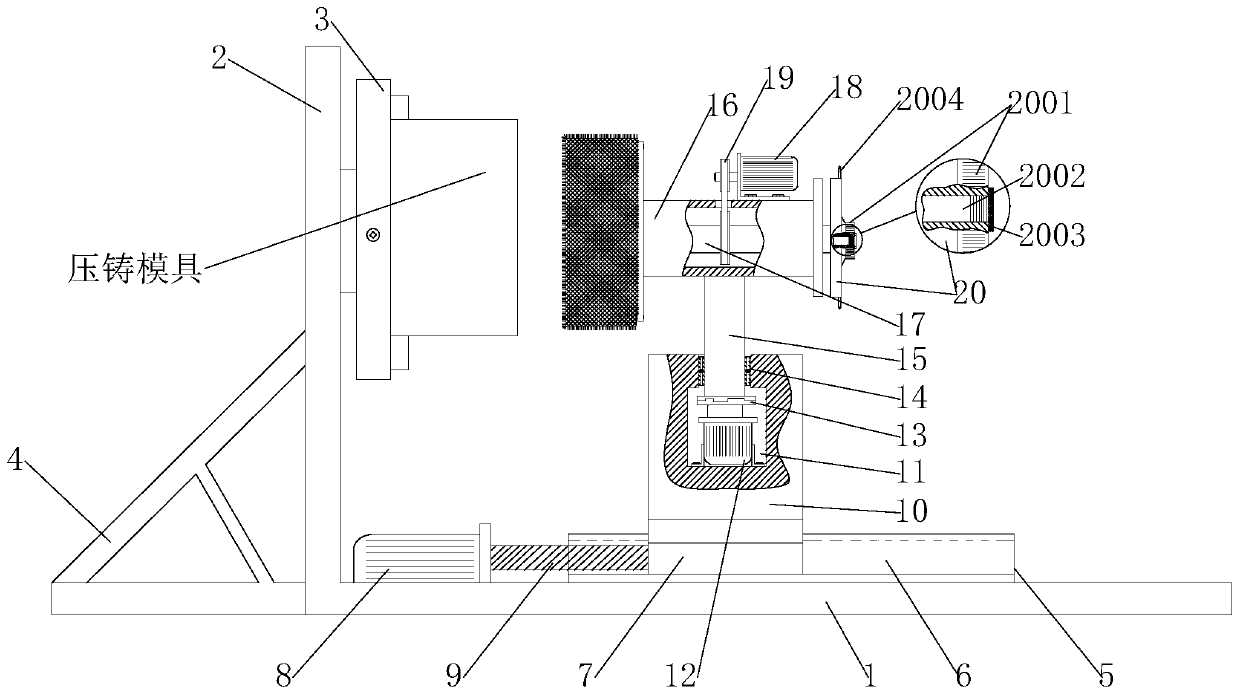

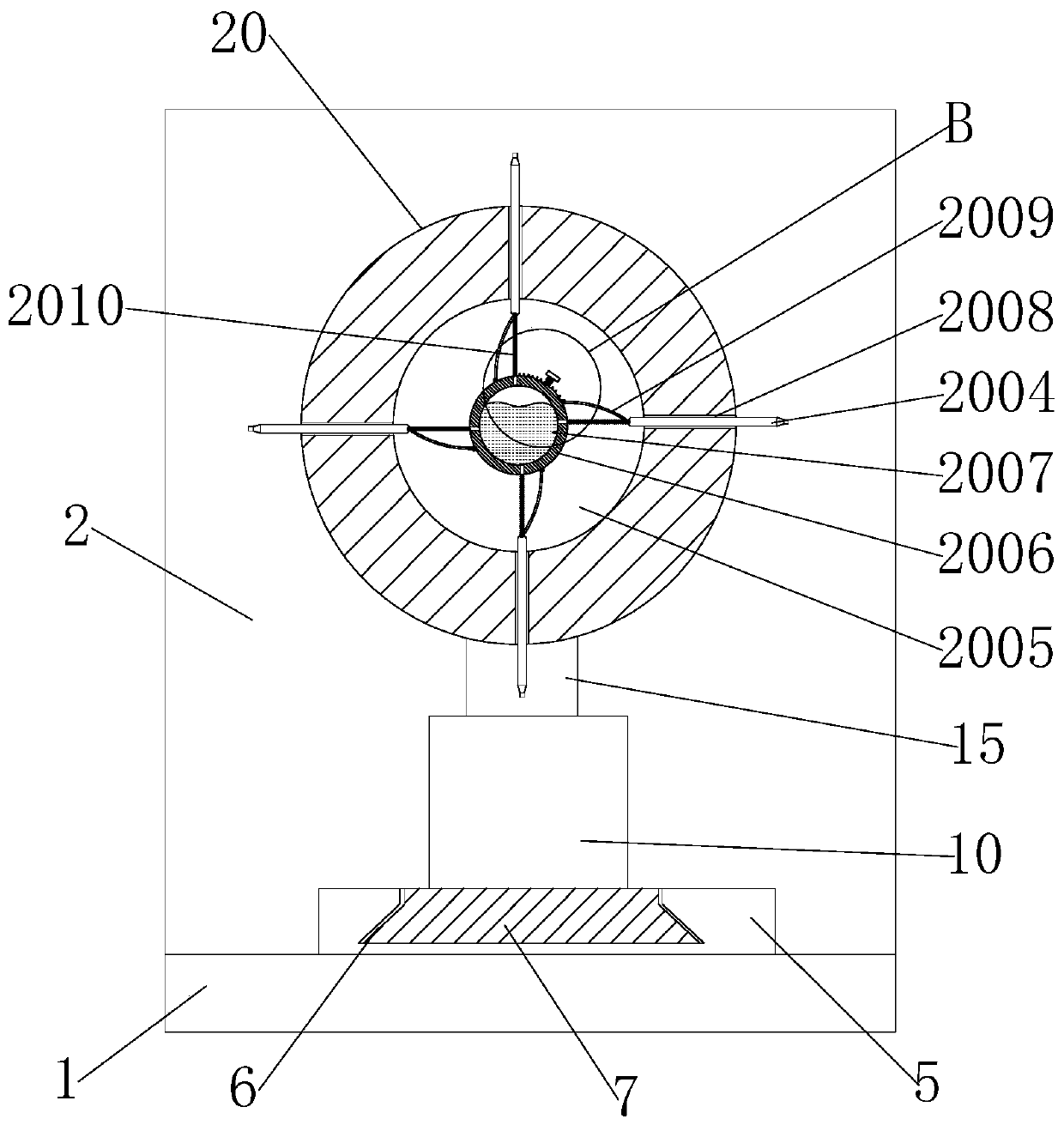

Method for improving precision pressure casting mold product accuracy

ActiveCN111300215AUniform speed operationEven oil supplyGrinding drivesGrinding feed controlPressure castingManufacturing engineering

Owner:太仓万利达精密模具有限公司

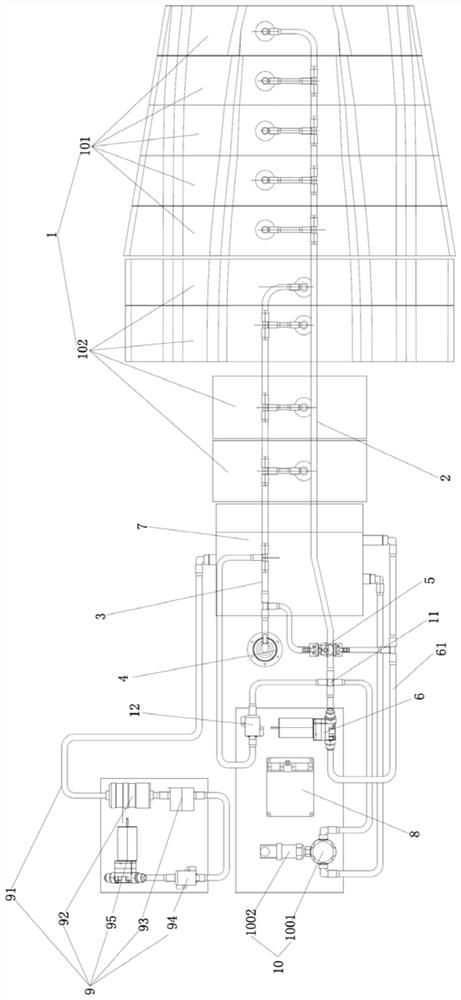

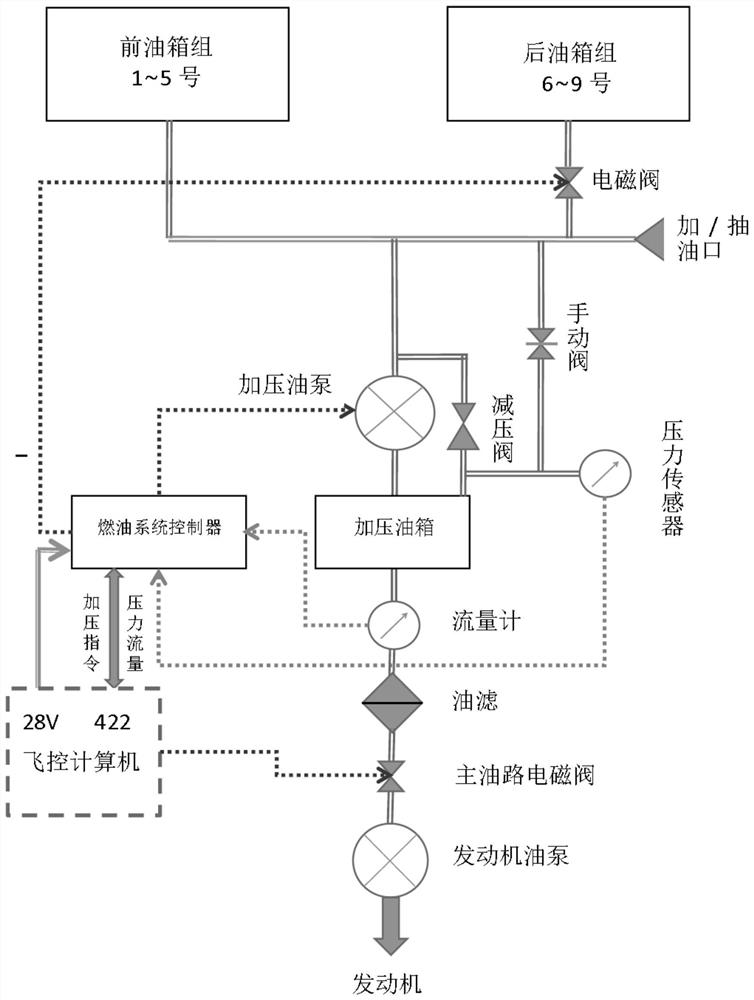

Unmanned aerial vehicle fuel oil supply system and oil supply and refueling control methods

The invention discloses an unmanned aerial vehicle fuel oil supply system and oil supply and refueling control methods. In the system, one part of an oil tank set is connected with a pressurizing oil pump through a first pipeline; the pressurizing oil pump is connected with a pressurizing oil tank through a third pipeline; the other part of the oil tank set is connected with an oil filling port through a second pipeline; the pressurizing oil tank is connected with the engine through an oil supply assembly. A four-way joint is arranged between the pressurizing oil pump and the first pipeline, and one end of the four-way joint is connected with the second pipeline through a fuel sequence control valve; the controller is connected with the pressurizing oil pump, the oil supply assembly and the fuel oil sequence control valve. The controller is further connected with a flight control computer and used for receiving the pressurization instruction and sending the oil pressure and the flow value. By means of the oil supply system, the oil supply system has the relative pressure ranging from 25 kpa to 50 kpa within the height range from 0m to 20,000 m under the condition that the use overload ranges from 1 g to 6 g to guarantee that oil is smoothly supplied to an engine.

Owner:西安九天航空科技有限公司

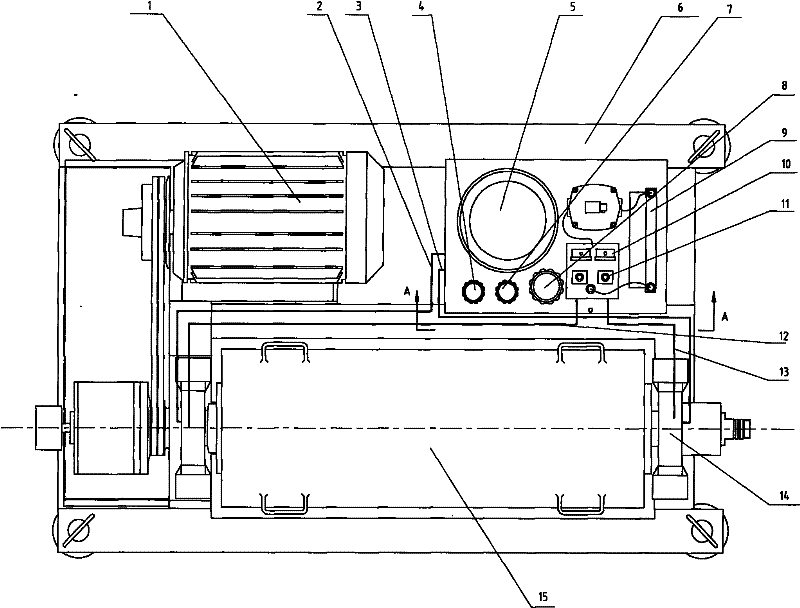

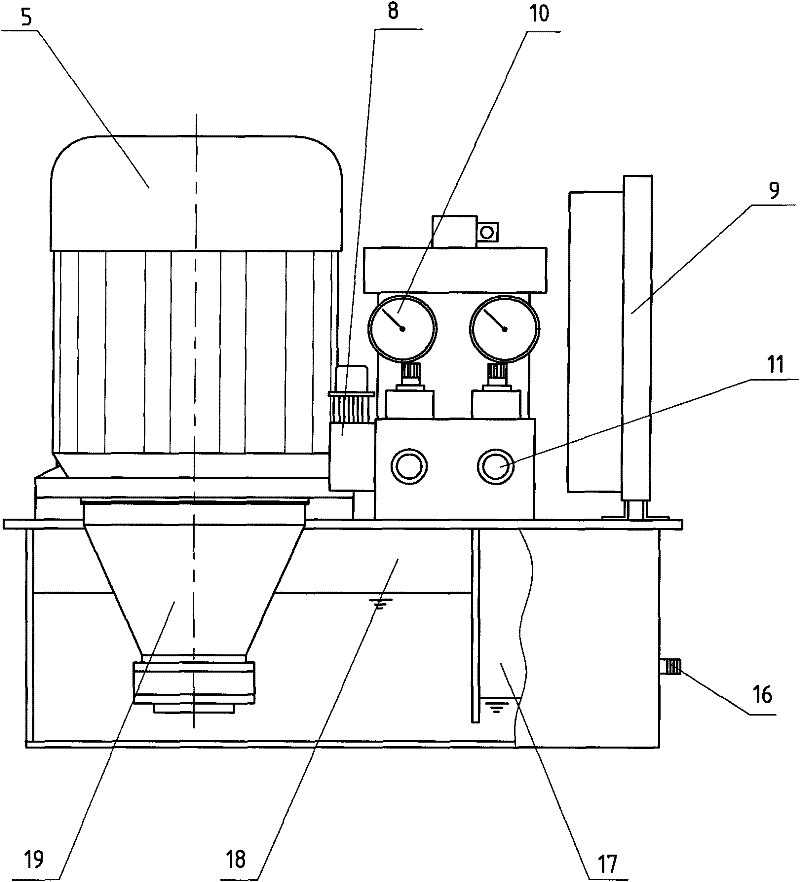

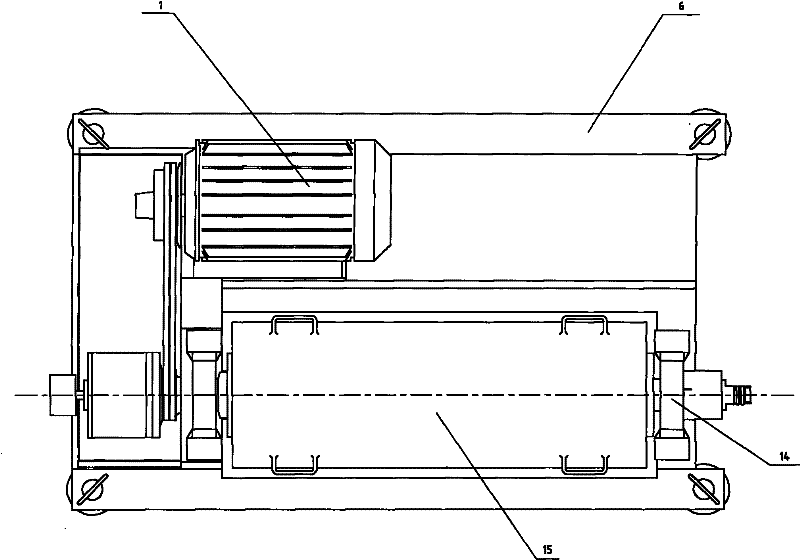

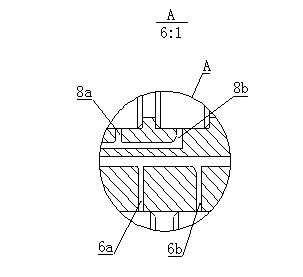

Integrated arrangement structure of decanter centrifuge and hydraulic station

The invention relates to a centrifuge structure in the field of machines, in particular to an integrated arrangement structure of a decanter centrifuge and a hydraulic station. In a rectangular frame (6), one side is provided with an accumbent decanter centrifuge barrel (15), the end of the other side is provided with a motor (1), and power is transmitted to the input shaft end of the centrifuge barrel (15) through a belt. The structure is characterized in that: the hydraulic station is arranged in a rear space of the motor (1) and is a vertically arranged rectangular body; an oil pump motor (5) drives an oil pump (19); the oil pump (19) is respectively connected to the two ends of the centrifuge barrel (15) by front and rear oil inlet pipes (12 and 13) through two oil inlet speed regulating valves (11); an oil supply box (18) and an oil return box (17) are parallelly arranged on the lower part; the lower parts of the two oil boxes are communicated with each other; and the upper part of the oil supply box (18) is connected with a vacuum pump (8). Through the technical scheme, the residual space on the frame (6) is fully utilized, so that the space of a factory building is saved, the problem of transportation and installation inconvenience of a split structure is solved, engineering progress is accelerated, and efficiency is improved.

Owner:SHANGHAI CENTRIFUGE INST

Oil supply mechanism of curved needle seat in sewing machine

The invention provides an oil supply mechanism of a curved needle seat in a sewing machine, which belongs to the technical field of machinery. The invention solves the problem that the traditional oil supply mechanism needs to process an oil guide structure at a curved needle seat and an actuating cam plate and can not supply oil to a curved needle. In the oil supply mechanism of the curved needle seat in the sewing machine, the curved needle seat comprises a support seat platform and an actuating cam plate, wherein the support seat platform and the actuating cam plate are mutually abutted together, and the actuating cam plate is articulated on the support seat platform by a connecting shaft; a curved needle hole capable of installing a curved needle is arranged on the support seat platform; an oil supply hole is arranged on the support seat platform; and an oil guide structure which can guide oil in the oil supply hole into the curved needle hole is arranged between the support seat platform and the actuating cam plate. The oil supply mechanism of the invention supplies oil to the contact surface of the support seat platform and the actuating cam plate and the curved needle, and the oil in the oil supply hole permeates into the contact surface of the support seat platform and the actuating cam plate by an oil guide structure and is supplied to the contact surface of the support seat platform and the actuating cam plate; meanwhile, the oil can also flow into the curved needle hole and is supplied to the curved needle.

Owner:ZHEJIANG ZOJE SEWING MACHINE

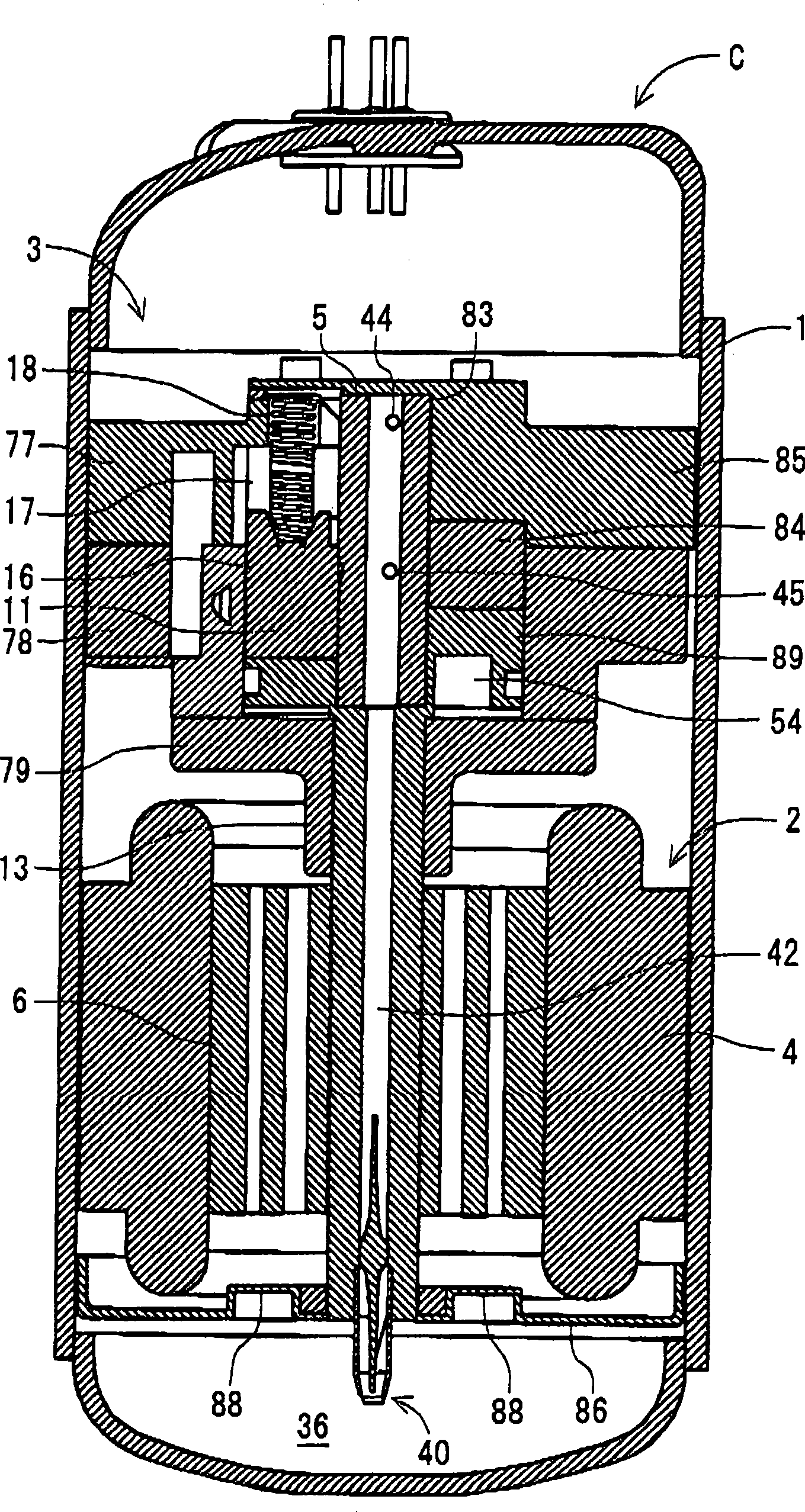

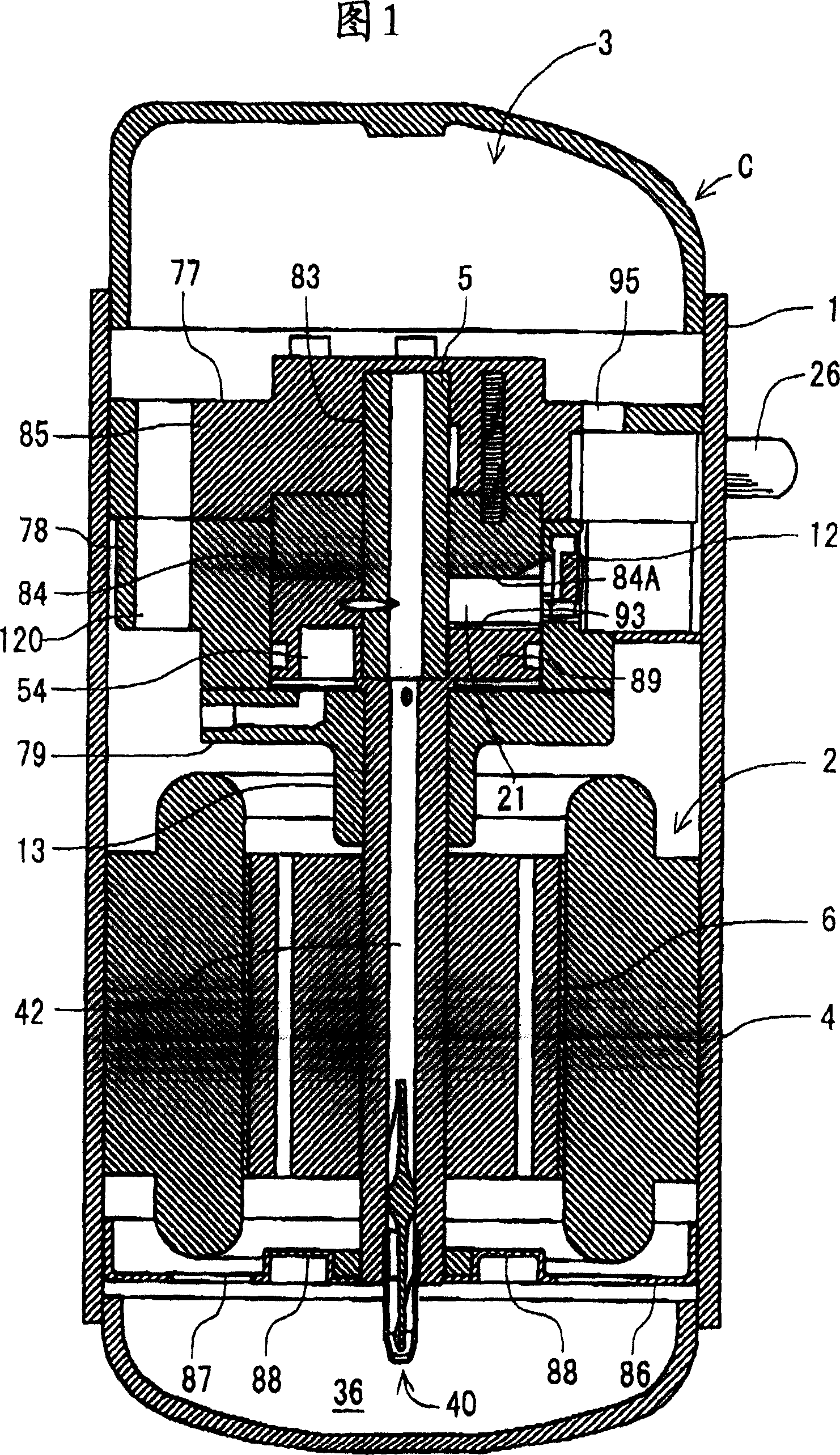

Compressor

InactiveCN101372965APrevent bad situationIncrease pressureRotary piston pumpsRotary piston liquid enginesTop dead centerEngineering

An object is to inhibit a refrigerant leakage and enhance a performance of a compressor. The compressor comprises a driving element stored in a sealed container of the compressor, and a compression element driven by a rotary shaft of the driving element. This compression element comprises a cylinder in which a compression space is constituted; a suction port and a discharge port which communicate with the compression space in the cylinder; a compression member whose one surface crossing an axial direction of the rotary shaft is inclined continuously between a top dead center and a bottom dead center and which is rotatably disposed in the cylinder and which compresses a fluid (refrigerant) sucked from the suction port to discharge the fluid via the discharge port; and a vane which is disposed between the suction port and the discharge port to abut on an upper surface as one surface of the compression member and which partitions the compression space in the cylinder into a low pressure chamber and a high pressure chamber, and one surface of the compression member is disposed on a side opposite to the driving element.

Owner:SANYO ELECTRIC CO LTD

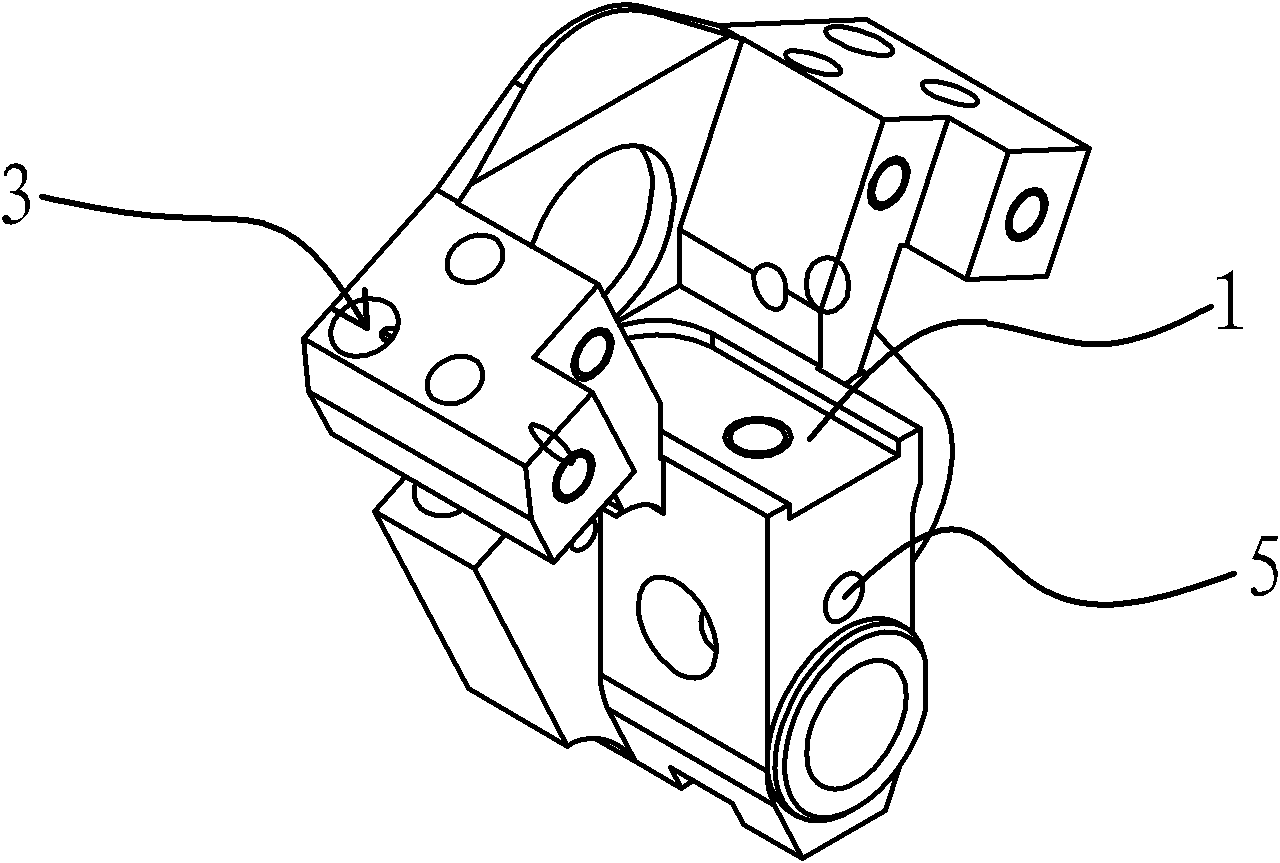

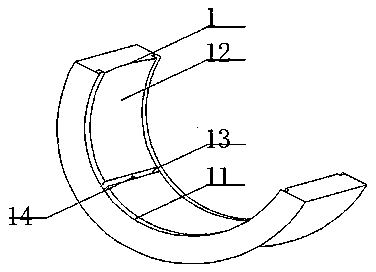

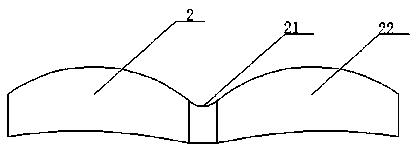

Bypass one-way valve of double-fuel supply system of DME/diesel engine

The invention discloses a bypass one-way valve of a double-fuel supply system of a DME / diesel engine. The bypass one-way valve comprises an upper valve body and a lower valve body, wherein the upper valve body and the lower valve body are integrally shaped, and a valve cavity allowing a one-way valve assembly to be mounted is formed between the upper valve body and the lower valve body; the top of the upper valve body is connected with an oil outlet valve through threads, and the bottom of the lower valve body is connected with a pump body through threads; the bottom end of the lower valve body, the top end of a plunger piston and the inner wall of a plunger piston sleeve surround to form a pump cavity allowing fuel oil to be stored. Through the adoption of the bypass one-way valve disclosed by the invention, the problems that the pressure of a high-pressure oil circuit fluctuates fiercely and the oil supply quantity is in serious shortage caused by phase changes of DME in the fuel oil pump cavity in the oil supply process can be effectively solved, and an air resistance phenomenon caused by aerification of DME fuel in the high-pressure pump cavity is avoided.

Owner:WUHAN UNIV OF TECH

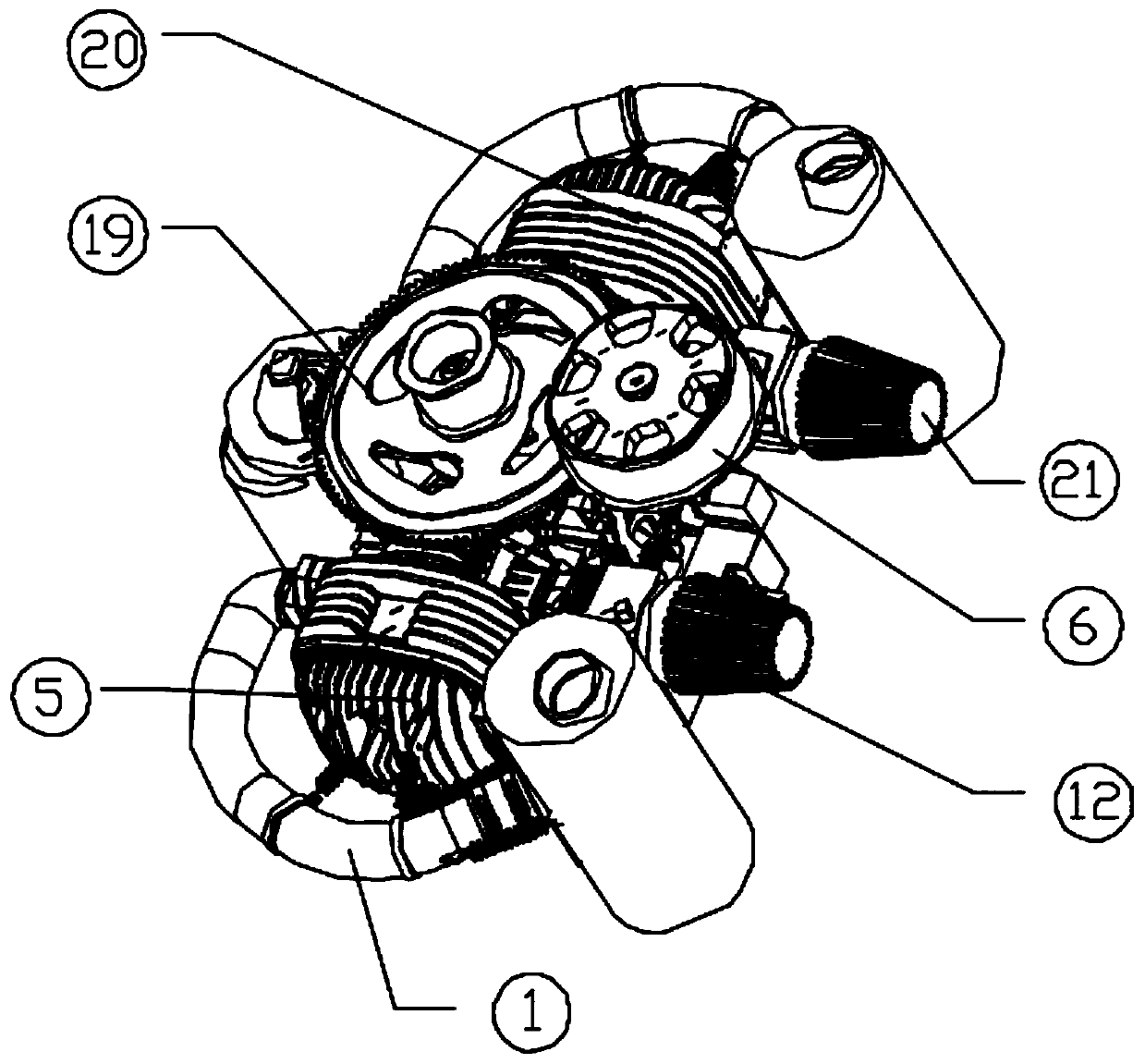

Light horizontal opposed engine

PendingCN109944691ALower the altitudeShorten the lengthMachines/enginesCarburettorsCombustion chamberCylinder block

The invention provides a light horizontal opposed engine, and belongs to the field of engines. The light horizontal opposed engine comprises a starting motor, a gear disc, a crankshaft, a first cylinder body, a second cylinder body, a first piston and a second piston, wherein the starting motor is connected with the gear disc, the gear disc is connected with the crankshaft, the gear disc drives the crankshaft to rotate through the starting motor, the first cylinder body and the second cylinder body are horizontally and oppositely arranged and are arranged on the two sides of the crankshaft, and the volume ratio of a combustion chamber to a cylinder body of the first cylinder body and the volume ratio of a combustion chamber to a cylinder body are both 9:1-11:1. The light horizontal opposedengine has the advantages of being small in size, light in weight, high in power, high in torque and good in thermal effect.

Owner:天津德盛镁汽车部件有限公司

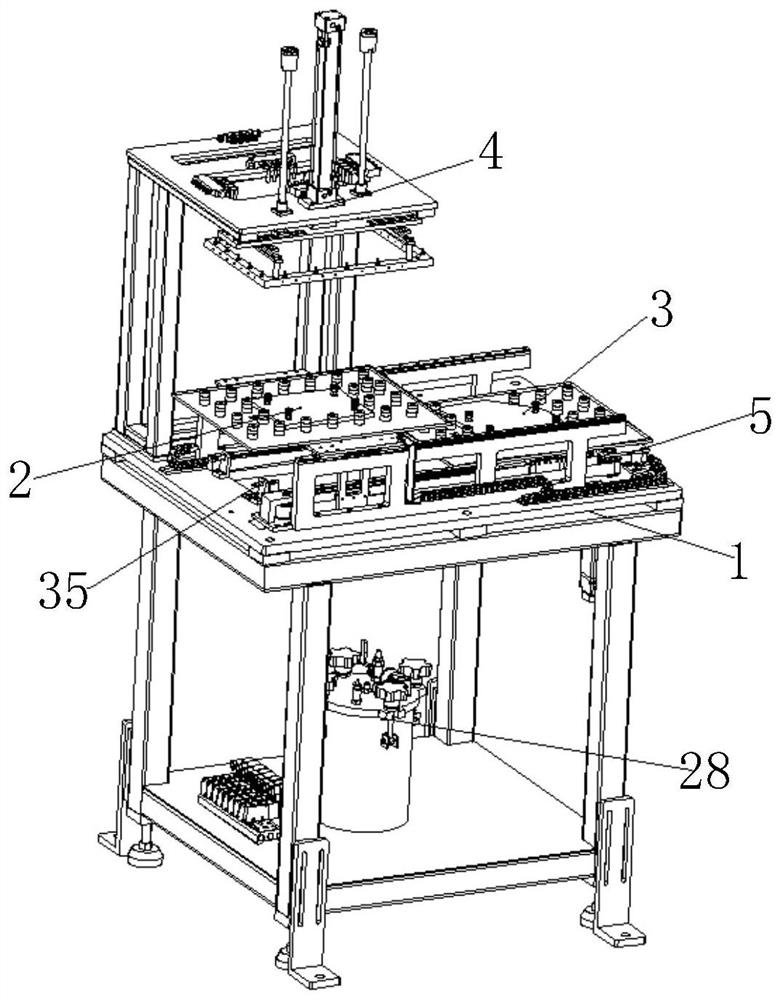

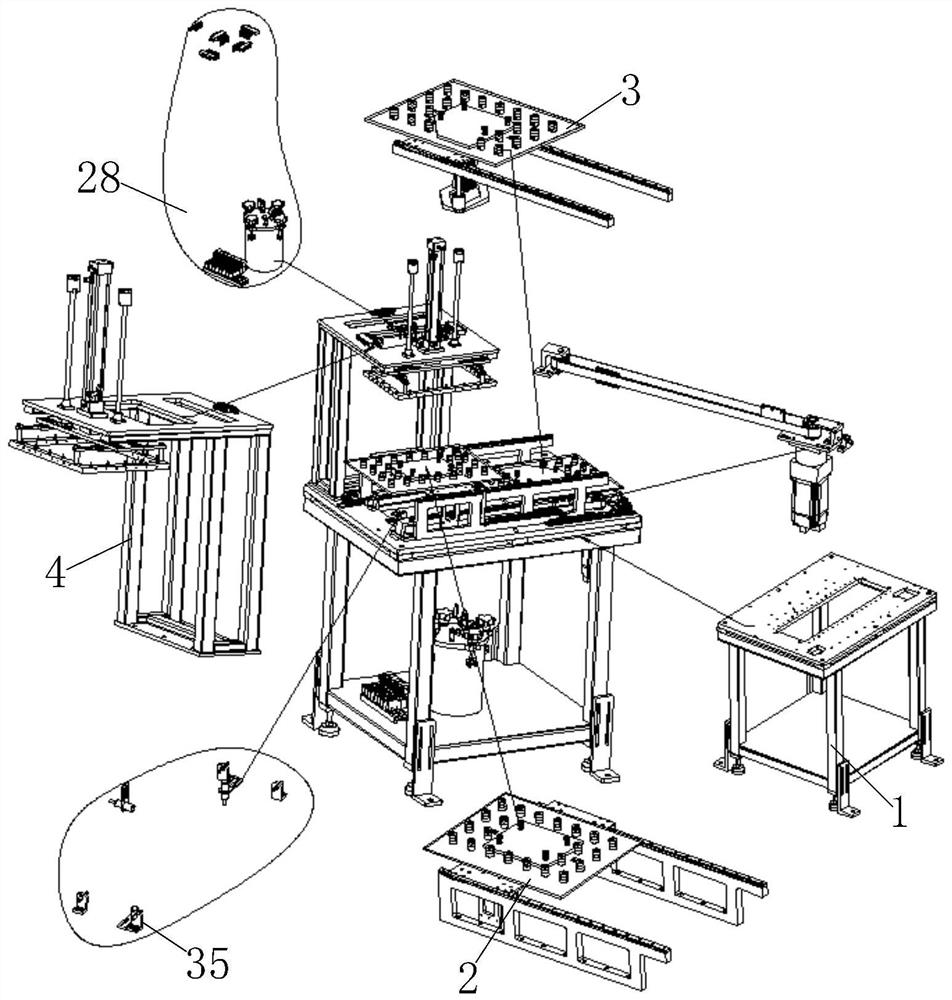

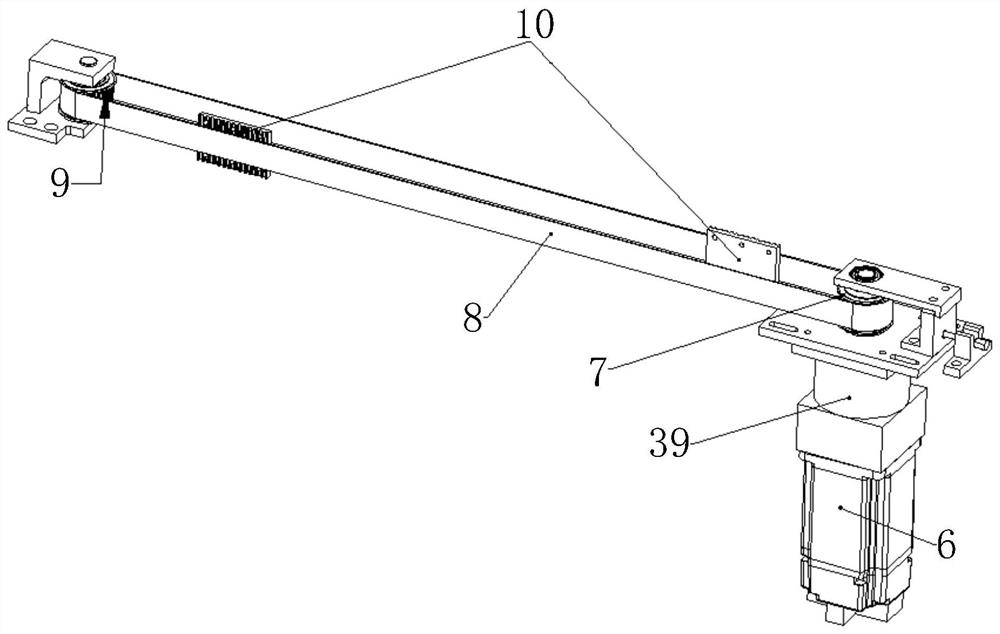

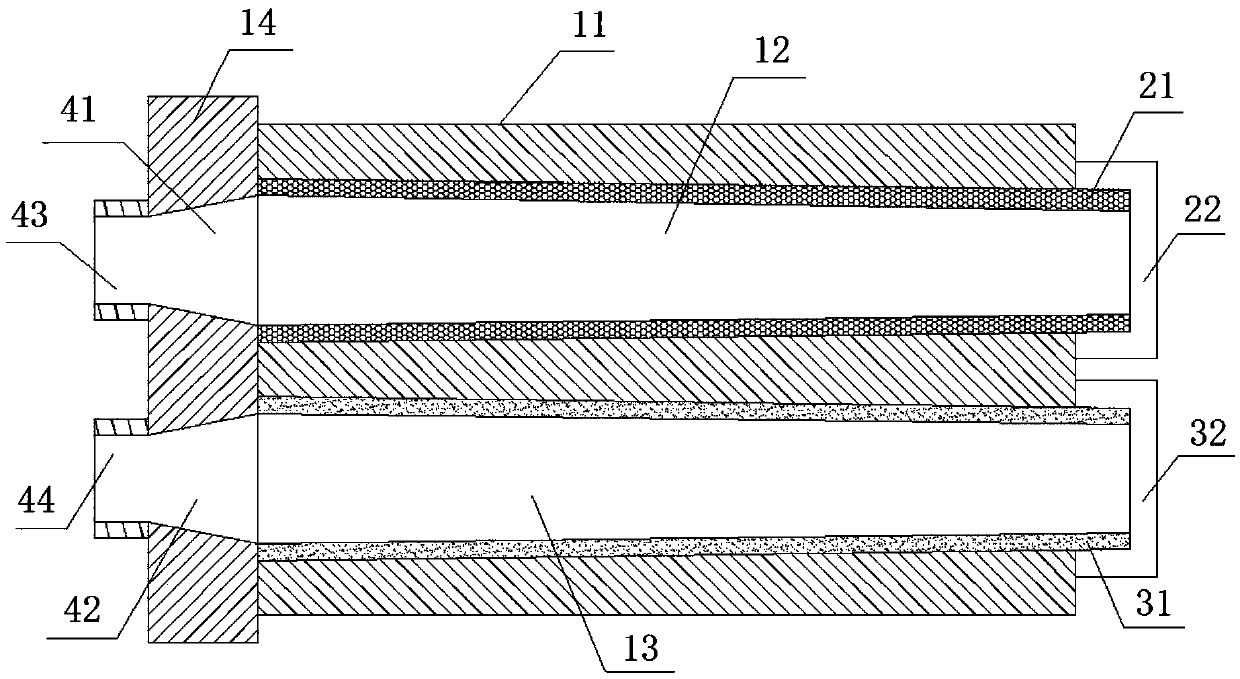

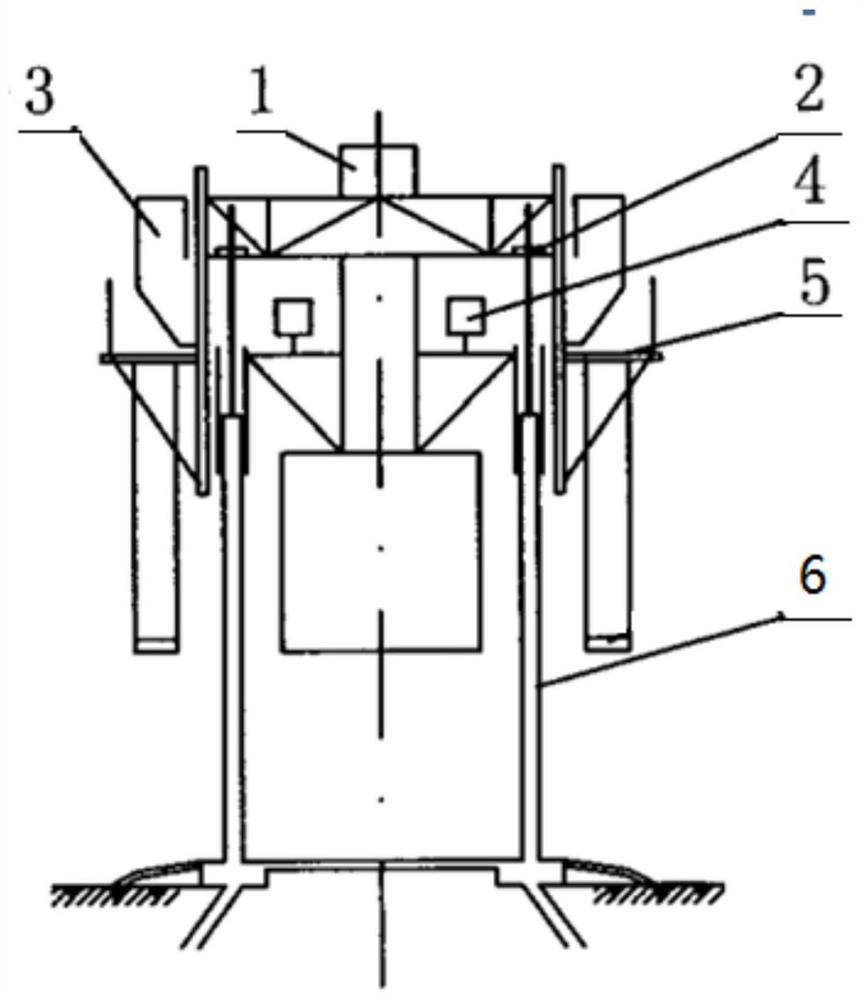

Double-station automatic oiling equipment

PendingCN111957531AImprove automationReduce labor intensityLiquid surface applicatorsConveyorsAgricultural scienceAgricultural engineering

The invention provides double-station automatic oiling equipment which comprises a support, a first transplanting mechanism, a second transplanting mechanism, an oiling mechanism and a power mechanism. The first transplanting mechanism and the second transplanting mechanism are movably arranged at the top end of the support, the oiling mechanism is arranged above the support, the first transplanting mechanism is arranged above the second transplanting mechanism, the oiling mechanism is arranged above the first transplanting mechanism and the second transplanting mechanism, the output end of the oiling mechanism corresponds to notebook metal shells on the first transplanting mechanism and the second transplanting mechanism, the bottom of the power mechanism is arranged on the right side ofthe top end of the support, the power mechanism is positioned below the first transplanting mechanism and the second transplanting mechanism, and the top of the power mechanism is respectively in transmission connection with the first transplanting mechanism and the second transplanting mechanism.

Owner:CHONQING HUASHU ROBOT CO LTD

Novel automobile fuel injection nozzle

InactiveCN111365155AGood atomization effectFully contactedFuel injection apparatusMachines/enginesInjector nozzleGasoline

The invention discloses a novel automobile fuel injection nozzle, which comprises a cylindrical fuel injection nozzle main body; two ends of the fuel injection nozzle body are penetrated and fixedly embedded with a gasoline pipe and an air pipe which are mutually parallel; the same ends of the gasoline pipe and the air pipe extend from the fuel injection nozzle main body respectively to form a gasoline nozzle and an air nozzle; the gasoline nozzle and the air nozzle are fixedly and respectively provided with a gasoline cap and an air cap; a plurality of atomizing holes and shunts holes are evenly and respectively formed in the gasoline cap and the air cap; one end of the fuel injection nozzle main body away from the gasoline nozzle and the air nozzle is provided with a base; and an oil inlet and an air inlet, an oil inlet socket pipe and an air inlet socket pipe are arranged on the base. The novel automobile fuel injection nozzle has the advantages of simple structure, smooth fuel supply, and good gasoline atomization and combustion effects.

Owner:BORUN HONGDA (TIANJIN) TECH DEV CO LTD

Lubricating structure for slewing bearing for construction machinery

ActiveCN103410866AEven oil supplyGuaranteed uptimeRolling contact bearingsShaftsEngineeringSlewing bearing

The invention relates to a lubricating structure for a slewing bearing of construction machinery. The lubricating structure comprises a seat ring, an upper shaft ring, a lower shaft ring and cylindrical rolling bodies, wherein two upper rolling paths, two lower rolling paths and a side rolling path are arranged on the seat ring and are respectively and internally provided with cylindrical rolling bodies. The innovative point is that the lubricating structure further comprises a lower main runner, a lower branch runner, an upper main runner and an upper branch runner, wherein the upper and the lower main runners are respectively used for supplying oil to the upper and the lower rolling path through the upper and the lower branch runner; guiding angles are respectively arranged at the junctions of the upper and the lower branch runner and the upper and the lower main runner. The lubricating structure has the advantages that the upper main runner and the upper branch runner work together to supply oil for the upper rolling path, and the lower main runner and the lower branch runner work together to supply oil for the lower rolling paths and the side rolling path, and meanwhile, the branch runners at the rear side adopt a large-guiding angle structure, so that oil supply amounts of the branch runners on the front sides and the rear sides of the main runners are nearly the same, and accordingly, the oil supply of the lubricating structure is relatively uniform so as to ensure normal operation of the bearing.

Owner:RUGAO NONSTANDARD BEARING

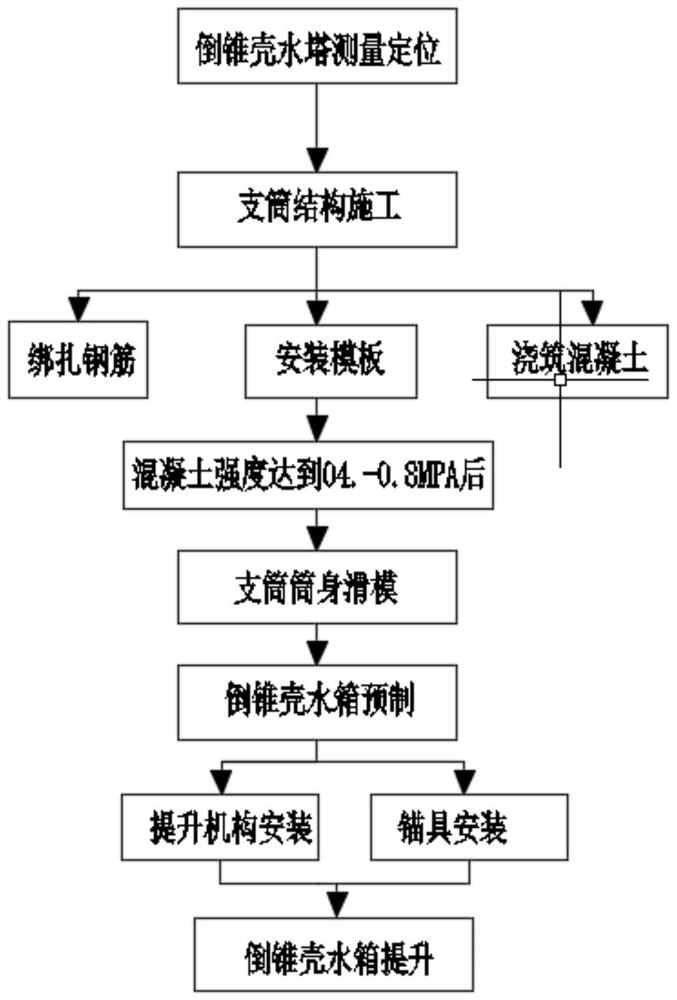

Inverted conical shell water tower construction process

PendingCN114319990ALess cutting workReduce transport workForms/shuttering/falseworksTowersArchitectural engineeringJackscrew

The invention relates to the technical field of building construction, in particular to an inverted conical shell water tower construction technology which comprises the following steps that firstly, an inverted conical shell water tower is measured and positioned; secondly, a supporting cylinder structure is constructed; and thirdly, the inverted conical shell water tank structure is constructed. The method has the advantages that the suspender adopts a steel strand, one-time investment and repeated use are achieved, a hydraulic jack is adopted for lifting, mechanical operation is adopted for oil supply and oil return, the number of constructors used in an old process is only 1 / 2, meanwhile, cutting and transporting work of the suspender of the high steel ring beam is reduced, and potential safety hazards of construction are reduced; besides, according to the slip form technology, the center hole jack ascends and resets to the height of the next stroke, oil supply is balanced, a plummet does not need to be adopted for centering, alignment and alignment in each stroke, time is saved for next-step construction, the construction period can be shortened, and the construction period of an old technology can be shortened by 1 / 3 through supporting cylinder construction.

Owner:CHINA THIRD METALLURGICAL GRP

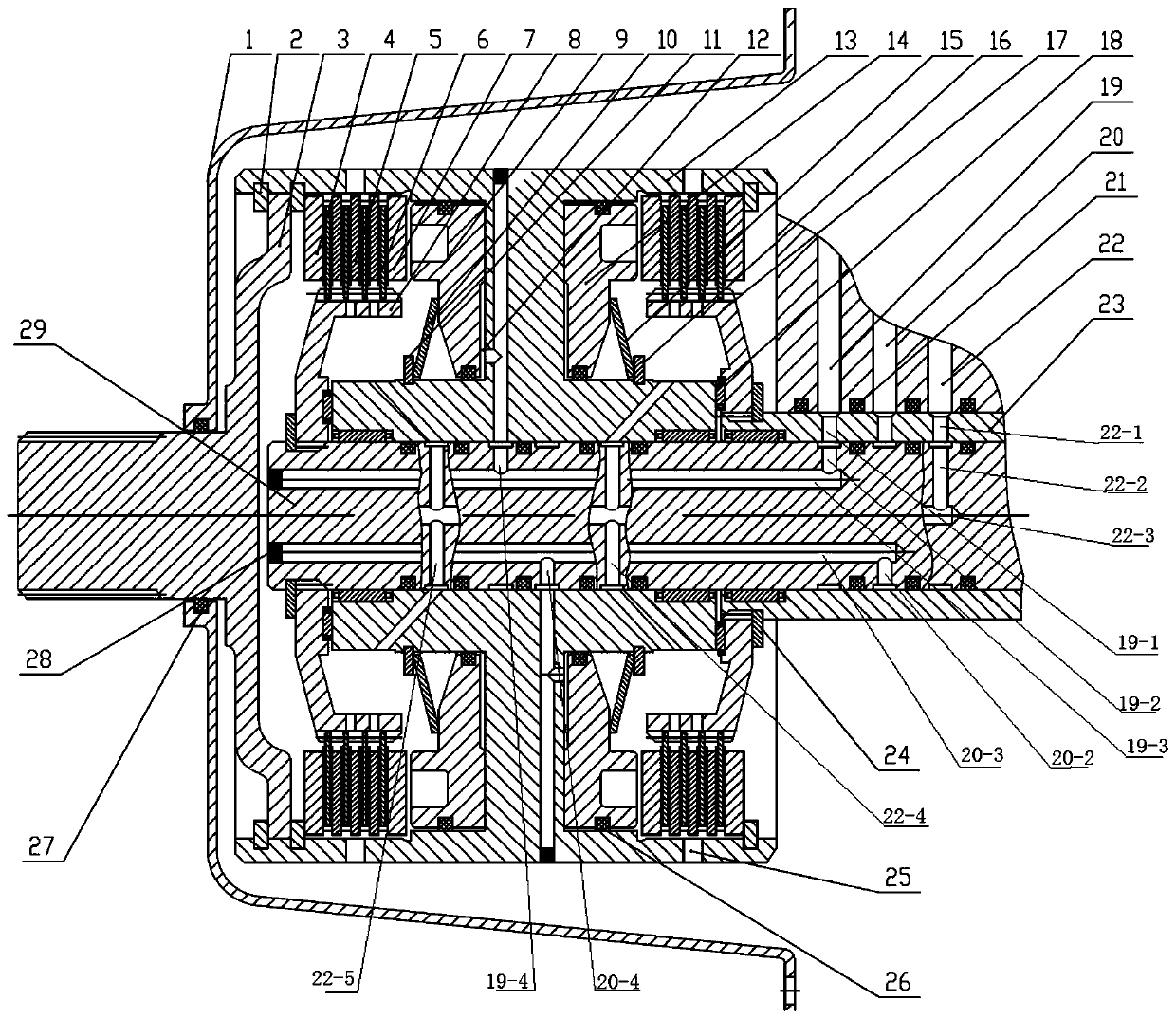

Novel piston rod mechanism of forging and pressing machinery

InactiveCN103418723ASufficient lubricityImprove the lubrication effectForging press drivesCopperLubrication

Disclosed is a novel piston rod mechanism of forging and pressing machinery. The novel piston rod mechanism is characterized in that sealing rings are mounted on two sides of a bearing seat, a piston rod is mounted in the middle of the bearing seat, oil supply grooves are formed in the left side and the right side of the piston rod, an oil seal is arranged on each oil supply groove, and a double-fixing copper sleeve is mounted on the outer side of each oil supply groove and on the inner side of the corresponding sealing ring and mounted on the bearing seat through an own hole; oil inlets and oil return ports are arranged on the bearing seat and the double-fixing copper sleeve, so that lubricating oil is stored in the oil supply grooves after entering the double-fixing copper sleeves and flows out from the double-fixing copper sleeve through the oil return ports of the bearing seat after the oil supply grooves are filled with the lubricating oil to form good circulatory lubrication.

Owner:甘宜侠

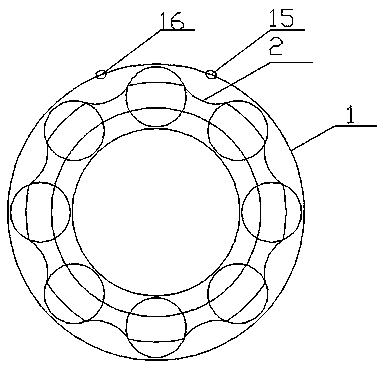

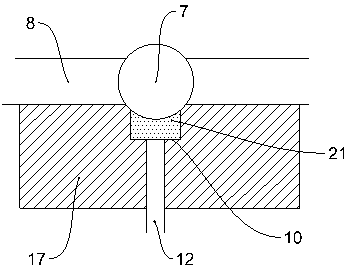

High-speed ultra-wide roller oil supply bearing

The invention relates to an oil supply bearing, in particular to a large high-speed ultra-wide roller oil supply bearing which comprises an inner ring, an outer ring and a roller, wherein the outer ring is sleeved on the inner ring, and the roller is arranged between the two rings. The oil supply bearing is characterized in that a runner for oil to pass is arranged on the inner wall of the outer ring; an oil inlet hole and an oil outlet hole are respectively formed at the upper part of the outer ring; sealing covers are arranged at two ends of the outer ring and the inner ring; and a chip removal hole is formed at the bottommost part of the outer ring. The high-speed ultra-wide roller oil supply bearing can solve the problems of the prior art that oil supply is non-uniform and chip removal is unsmooth and not thorough. The invention provides the high-speed ultra-wide roller oil supply bearing which can solve the problem of chip removal no matter in a working state or a halt state.

Owner:RUGAO NONSTANDARD BEARING

A long-lasting lubricating guide rail for industrial robots

The invention discloses a permanent lubricating guide rail for an industrial robot. The permanent lubricating guide rail comprises an air inlet main pipe, limiting stop blocks, an executing mechanismand a base, wherein the limiting stop blocks are mounted on the two ends of the base; clamp slots are formed in both upper and lower side surfaces of the base; a plurality of upper roll balls are uniformly mounted on the upper side of the base through a retainer I in a rolling manner, and a plurality of lower roll balls are uniformly mounted on the lower side of the base through a retainer II in arolling manner; the executing mechanism and the clamp slots are buckled one another and attached to the upper roll balls and the lower roll balls; a heating plate is arranged in the middle of the inner side of the base; a first oil passage and a second oil passage are formed in the upper side and the lower side of the heating plate respectively; upper grooves are formed in the lower sides of theupper roll balls; lower grooves are formed in the upper sides of the lower roll balls; the upper grooves and the lower grooves are filled with sponges; the oil inlet main pipe is arranged on the leftsides of the limiting stop blocks. The permanent lubricating guide rail has better lubricating effect on the roll balls, is higher in uniformity, and can effectively reduce waste of a lubricant, automatic lubrication is realized, and production efficiency is improved.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

Emission-reduction gasoline and diesel additive and preparation method thereof

PendingCN110396438AImprove efficiencySave fuelLiquid carbonaceous fuelsFuel additivesFuel oilCorrosion

The invention discloses an emission-reduction gasoline and diesel oil additive and a preparation method thereof. The gasoline and diesel oil additive comprises the following components in percentage by weight: 1-10% of graphene / zinc oxide blended powder, 10-20% of bio-oil, 5-10% of a dispersing agent, 0.1-0.3% of ferrocene, 1-5% of an antirust agent, 0.1-0.5% of a demulsifying agent and the balance of a diluent. The gasoline and diesel oil additive can improve the efficiency of fuel oil, so that the fuel oil is saved by 15-30% and the cost is reduced; the gasoline and diesel oil additive can eliminate carbon deposition inside an engine cylinder and a piston, prolong the service life of an engine, and reduce corrosion of fuel oil to an oil supply pipeline, thereby reducing tail gas emission. The additive has the effects of wear resistance and noise reduction, ensures smooth oil supply of a fuel oil supply system, maintains an oil nozzle, and prolongs the service life of precision partssuch as the oil nozzle. The additive can solve the problems of difficult starting, slow acceleration, idling jitter, gasp and the like of an automobile.

Owner:鸿源新能源科技(广州)有限公司

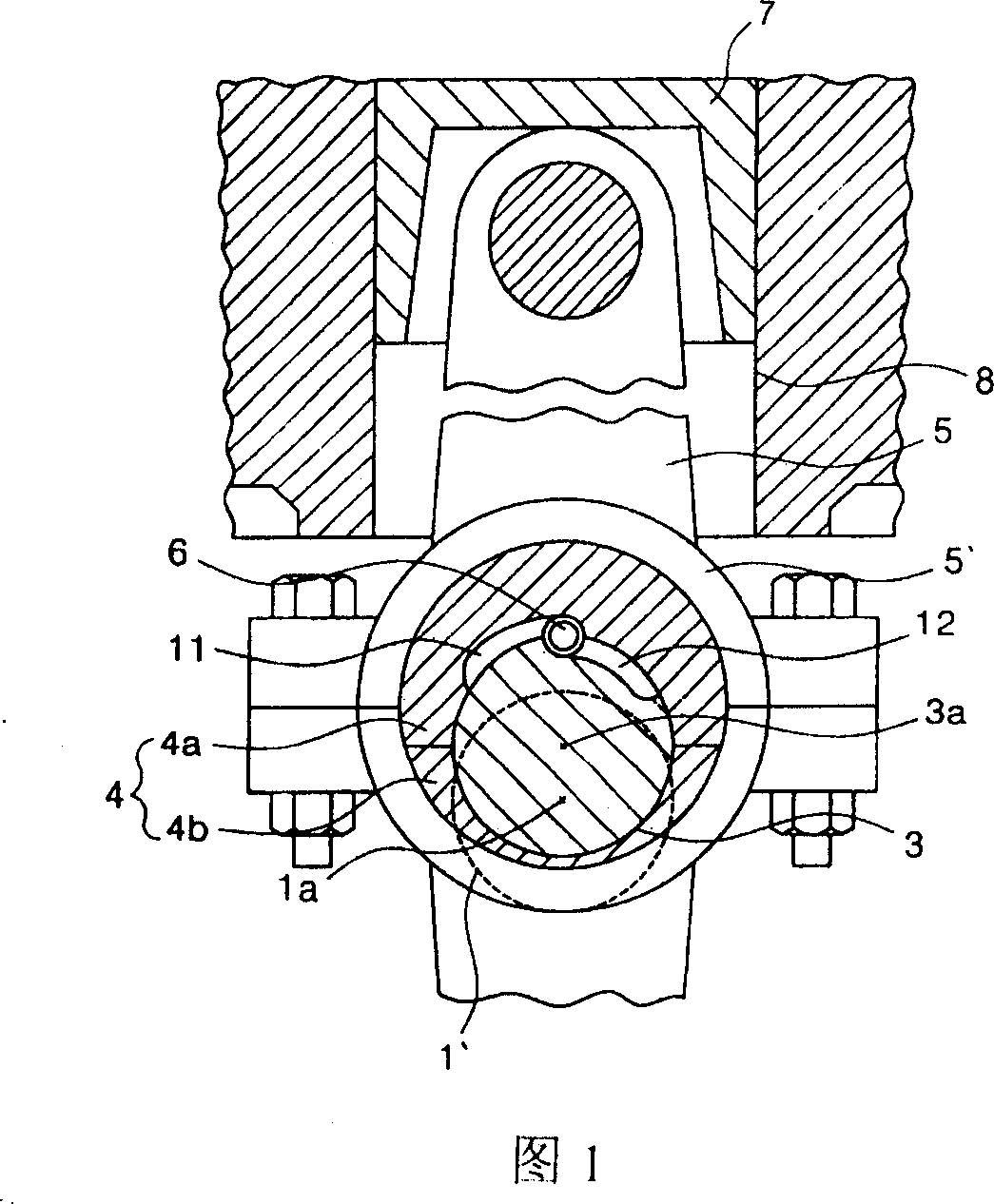

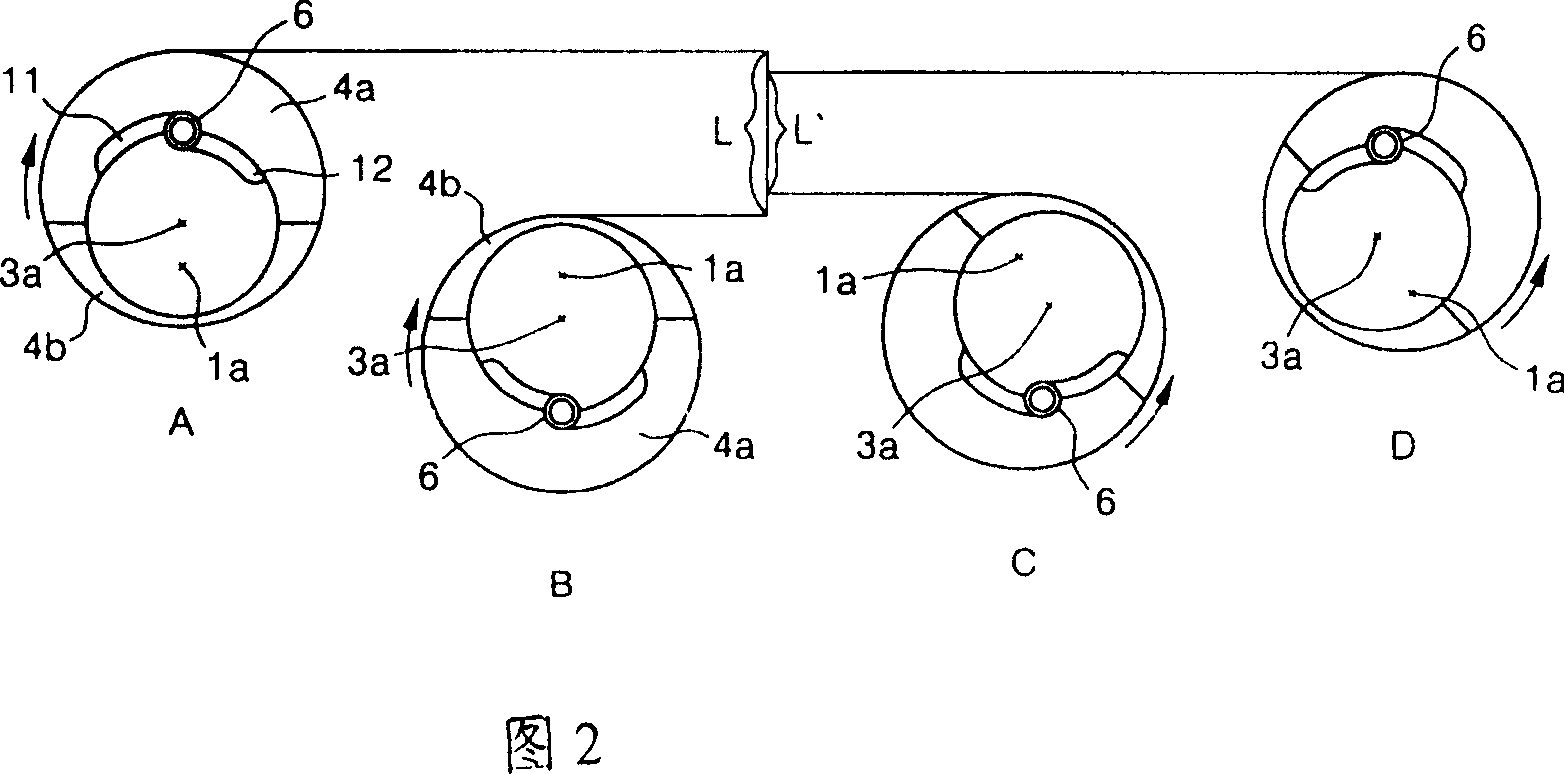

Compressor

InactiveCN1755118APrevent bad situationIncrease pressureRotary piston pumpsRotary piston liquid enginesEngineeringHigh pressure chamber

The invention provides a compressor, which has the function of improving the cooling medium leakage and realize the performance of the compressor to be increased. The compressor has a driving factor contained in a sealed container of the compressor and a compression factor driven by a rotating shaft of the driving factor. The compression factor has a cylinder, a suction port, an exhaust port, a compression component and blades; wherein, the cylinder forms a compression space in the interior, the suction port and the exhaust port are communicated with the compression space of the cylinder, the compression component and an surface which is axially crossed with the rotating shaft are slant between an upper dead center and a lower dead center in a continuous way, at the same time, the compression component is arranged in the cylinder and is driven by the rotating shaft to rotate, liquid (cooling medium) sucked in from the suction port is compressed and discharged from the exhaust port, and the blades which divide the compression space in the cylinder into a low pressure chamber and a high pressure chamber are arranged between the suction port and the exhaust port, and are contacted with the top of one surface of the compression component. The compressor arranges one surface of the compression component at the opposite side of the driving factor.

Owner:SANYO ELECTRIC CO LTD

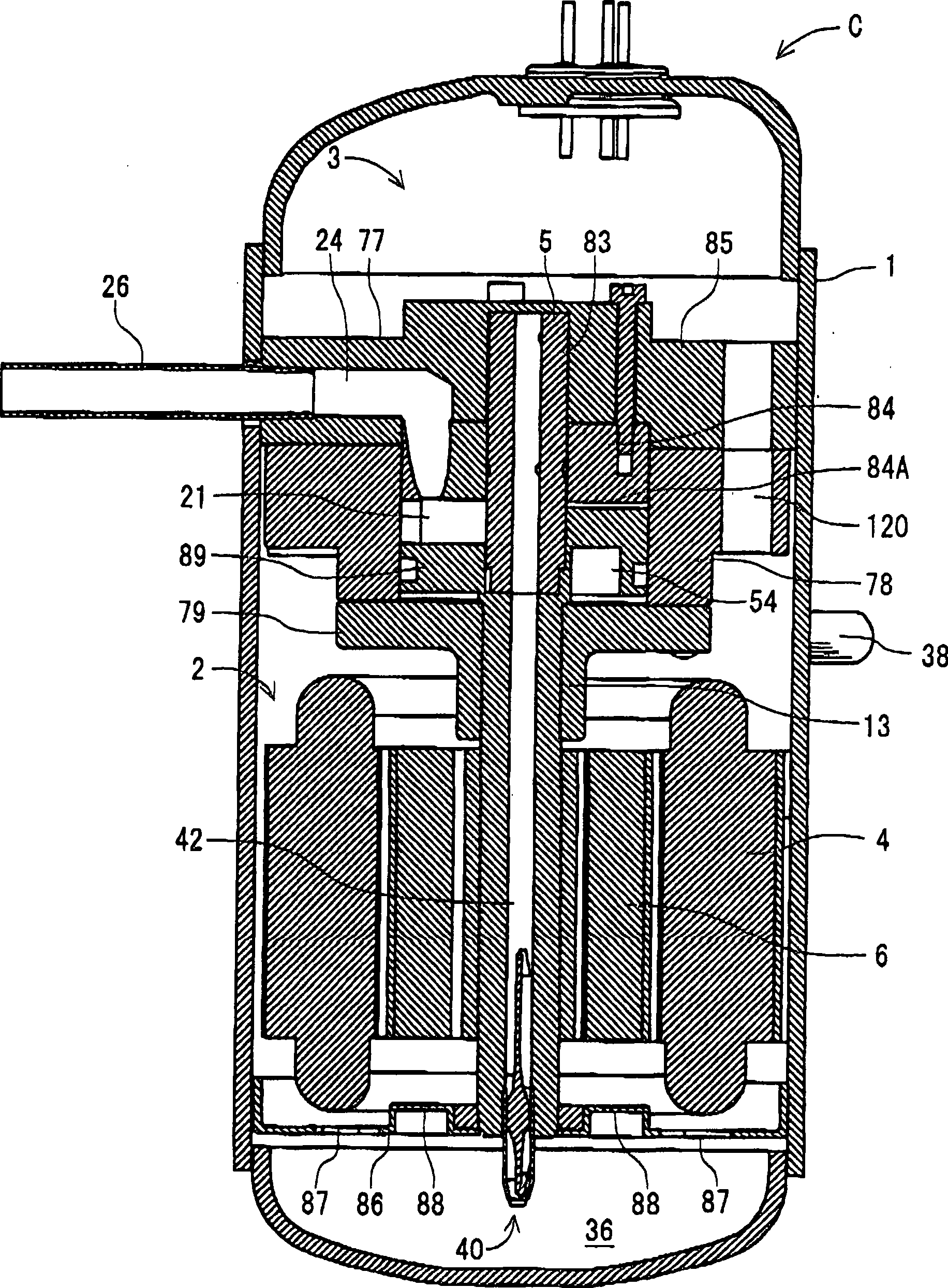

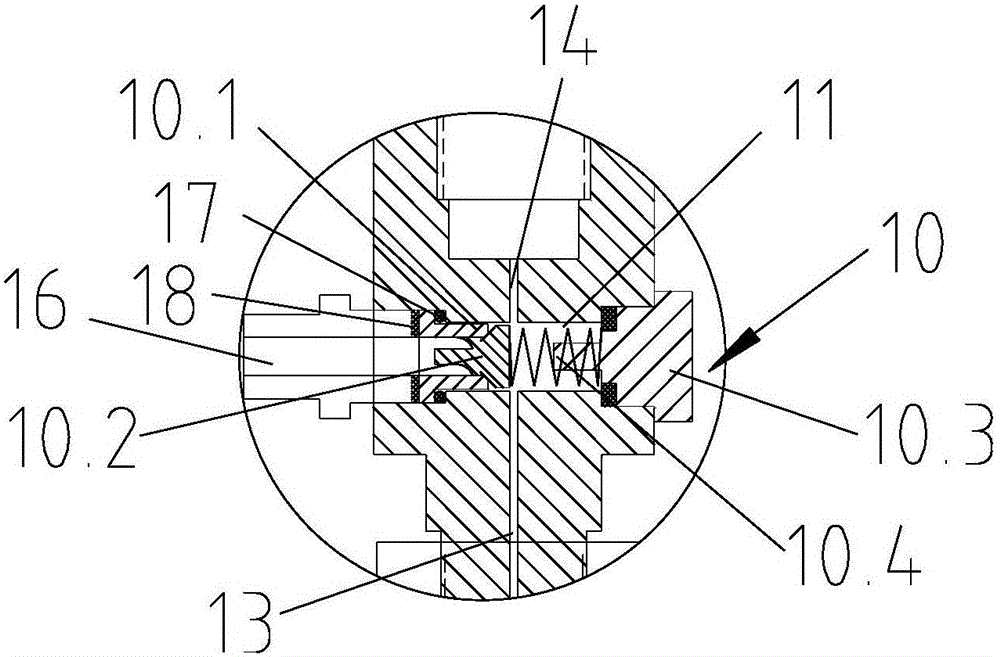

Locking device for dual capacity compressor

InactiveCN100344873CIncreased durabilityFunction increasePositive displacement pump componentsCranksEngineeringMechanical engineering

The invention is about a double capacity compressor. In the invention, a friction surface is formed between the periphery of the crankshaft eccentric part and the inside of the eccentric shaft sleeve. A through hole mounted with eccentric part is positioned on the eccentric shaft sleeve a little bit deflect from the center. on the top end of the eccentric shaft sleeve, a latch is arranged preventing the eccentric shaft sleeve rotating randomly. The latch must be mounted with one end convex to outside of the eccentric shaft sleeve. The eccentric shaft sleeve is placed on the center, on the eccentric part, the big port of the connecting lever is linked, and the big port must be kept rotatable. On the big port, a hook capable of hanging the latch is arranged. On bottom end of the eccentric shaft sleeve, a latch pendant is arranged. The invention can make the oil supply more smoothly and reduce the relative length of the connecting lever.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Lubricating structure for slewing bearing for engineering machinery

ActiveCN103410866BEven oil supplyGuaranteed uptimeRolling contact bearingsShaftsEngineeringSlewing bearing

The invention relates to a lubricating structure for a slewing bearing of construction machinery. The lubricating structure comprises a seat ring, an upper shaft ring, a lower shaft ring and cylindrical rolling bodies, wherein two upper rolling paths, two lower rolling paths and a side rolling path are arranged on the seat ring and are respectively and internally provided with cylindrical rolling bodies. The innovative point is that the lubricating structure further comprises a lower main runner, a lower branch runner, an upper main runner and an upper branch runner, wherein the upper and the lower main runners are respectively used for supplying oil to the upper and the lower rolling path through the upper and the lower branch runner; guiding angles are respectively arranged at the junctions of the upper and the lower branch runner and the upper and the lower main runner. The lubricating structure has the advantages that the upper main runner and the upper branch runner work together to supply oil for the upper rolling path, and the lower main runner and the lower branch runner work together to supply oil for the lower rolling paths and the side rolling path, and meanwhile, the branch runners at the rear side adopt a large-guiding angle structure, so that oil supply amounts of the branch runners on the front sides and the rear sides of the main runners are nearly the same, and accordingly, the oil supply of the lubricating structure is relatively uniform so as to ensure normal operation of the bearing.

Owner:RUGAO NONSTANDARD BEARING

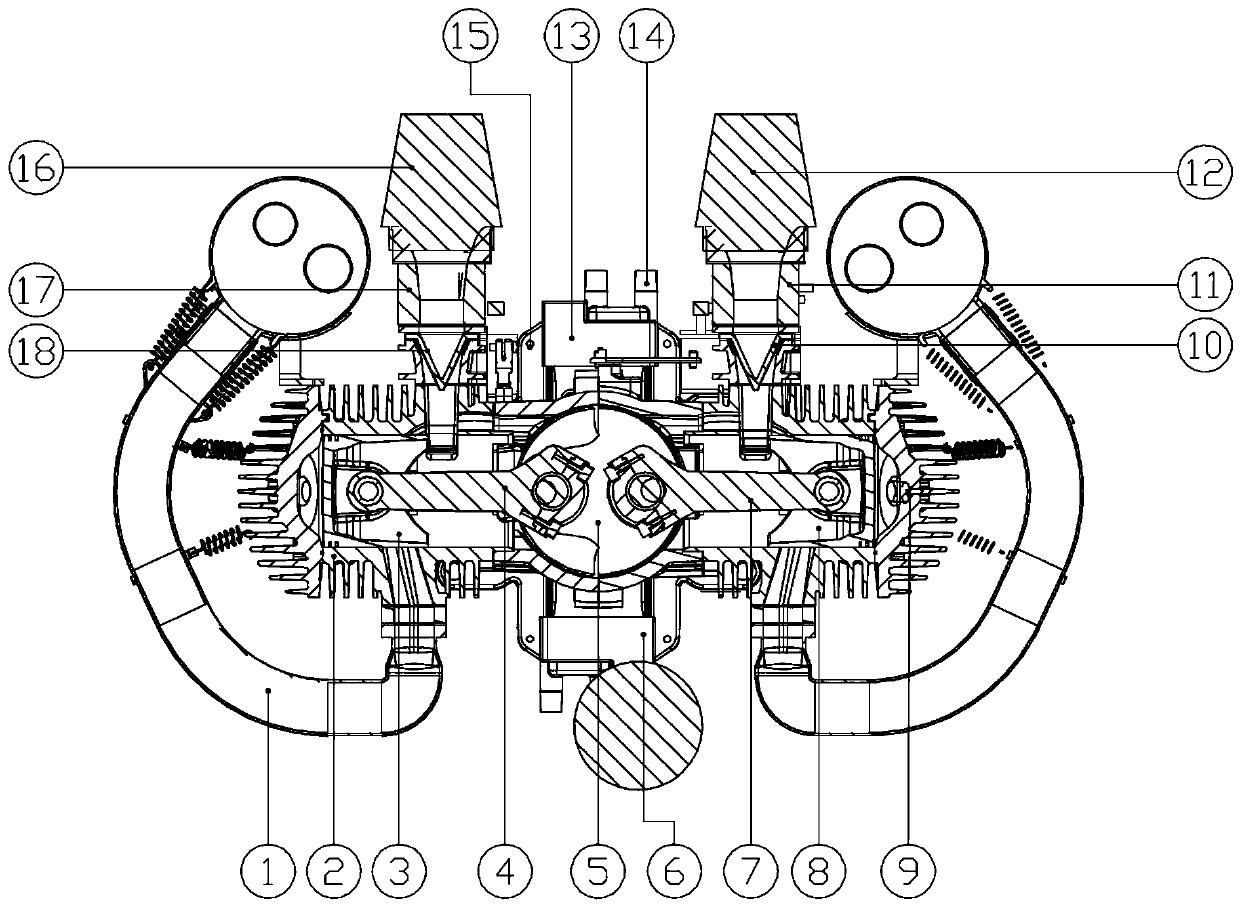

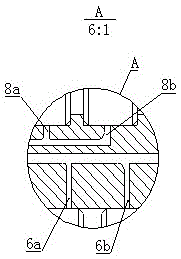

A wet dual clutch

The invention provides a wet double clutch, which includes a clutch outer hub, the same left and right clutch units arranged in the clutch outer hub, the left clutch unit includes a left clutch output shaft and a left clutch coaxially fixed on the left clutch output shaft Output hub, the right clutch unit includes the right clutch output shaft and the right clutch output hub coaxially fixed on the right clutch output shaft, the right clutch output shaft is in the shape of a sleeve, and one end of the left clutch output shaft is rotatably installed on the right output In the shaft and sealed, the clutch outer hub is rotatably installed on the output shaft of the left clutch, the left clutch unit and the right clutch unit are respectively controlled through the left clutch control oil passage and the right clutch control oil passage, and both pass through the lubricating oil passage Enter lube. The present invention can respectively control different executive components through the output shaft of the right clutch and the output shaft of the left clutch, realize fast switching, and enhance the stability and high efficiency of the transmission system.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com