Integrated arrangement structure of decanter centrifuge and hydraulic station

A decanter centrifuge and configuration structure technology, which is applied in the field of machinery, can solve problems such as inconvenient operation, long pipelines, and large space occupation, and achieve smooth oil return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

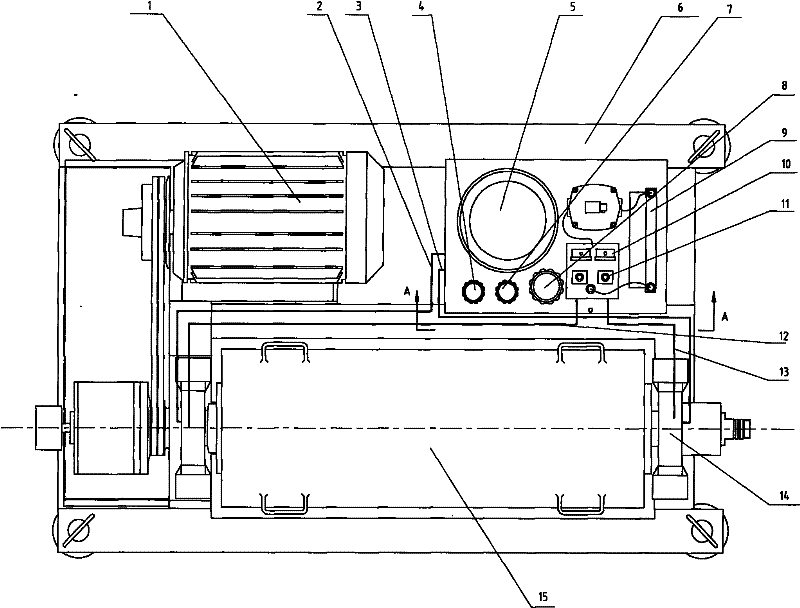

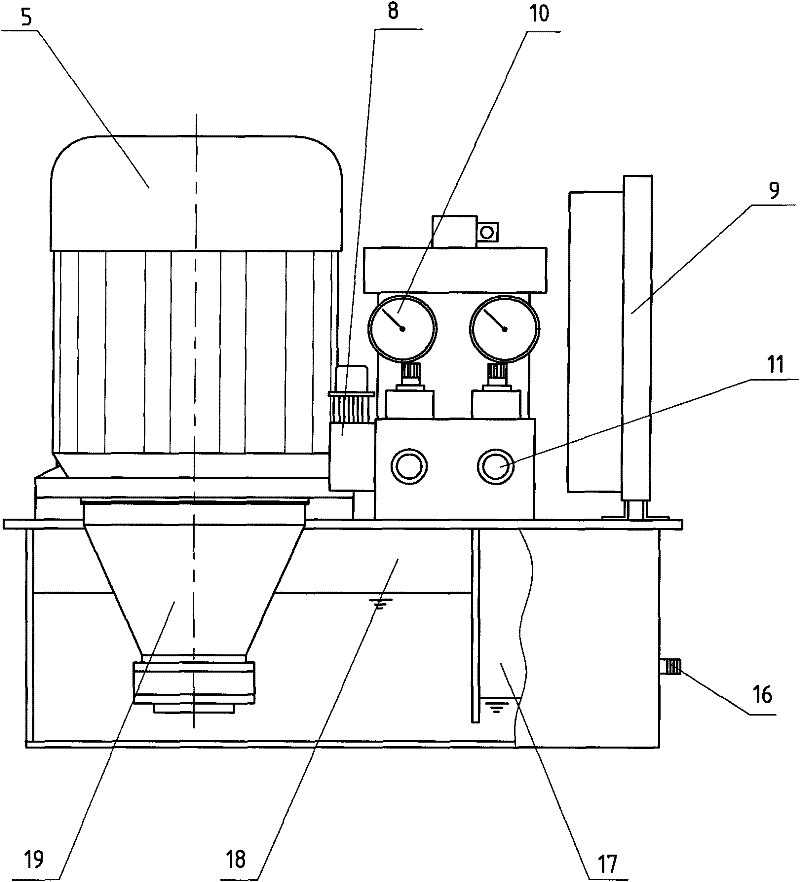

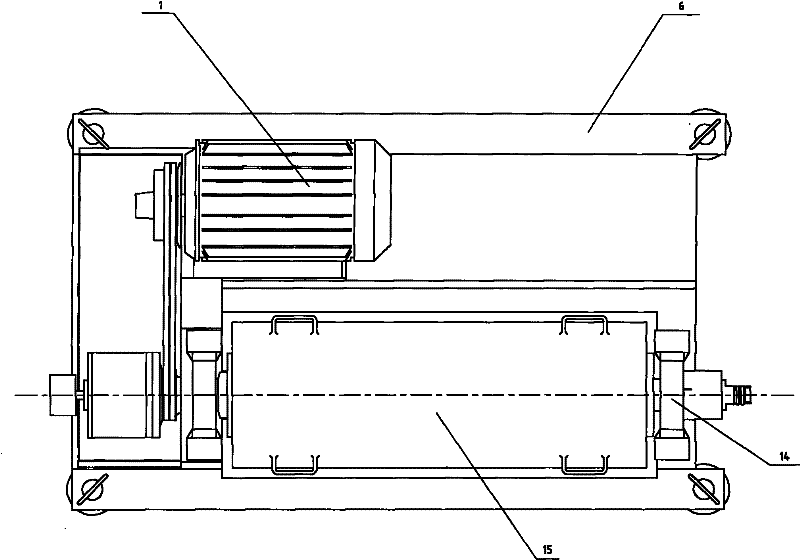

[0025] The structure of the present invention will be described in further detail below in conjunction with the drawings.

[0026] The integrated configuration structure of the decanter centrifuge and the hydraulic station. In the rectangular frame 6, one side is a horizontally arranged decanter centrifuge cylinder 15, and the other end is equipped with a motor 1, which is sent to the centrifuge through a belt The input shaft end of the barrel 15 is equipped with a hydraulic station in the rear space of the electric motor 1.

[0027] The hydraulic station is a vertically arranged rectangular body. The oil pump motor 5 drives the oil pump 19, and the oil pump 19 is connected to the two sides of the centrifuge cylinder 15 by the front and rear oil inlet pipes 12 and 13 through the two oil inlet speed regulating valves 11. At the end, the oil supply tank 18 and the oil return tank 17 are arranged side by side at the lower part, and the lower parts of the two oil tanks are communicated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com