Patents

Literature

50results about How to "Save on transportation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

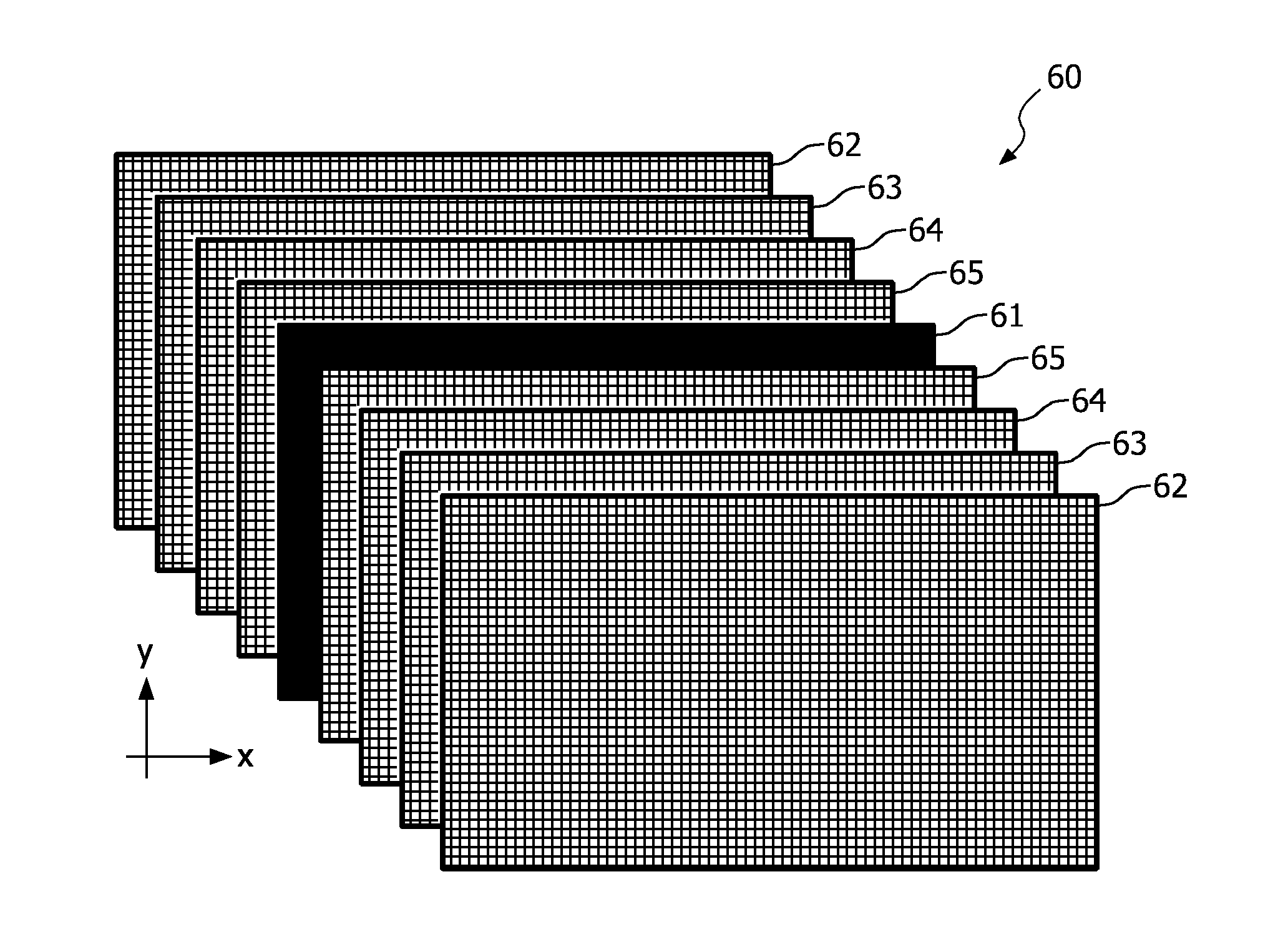

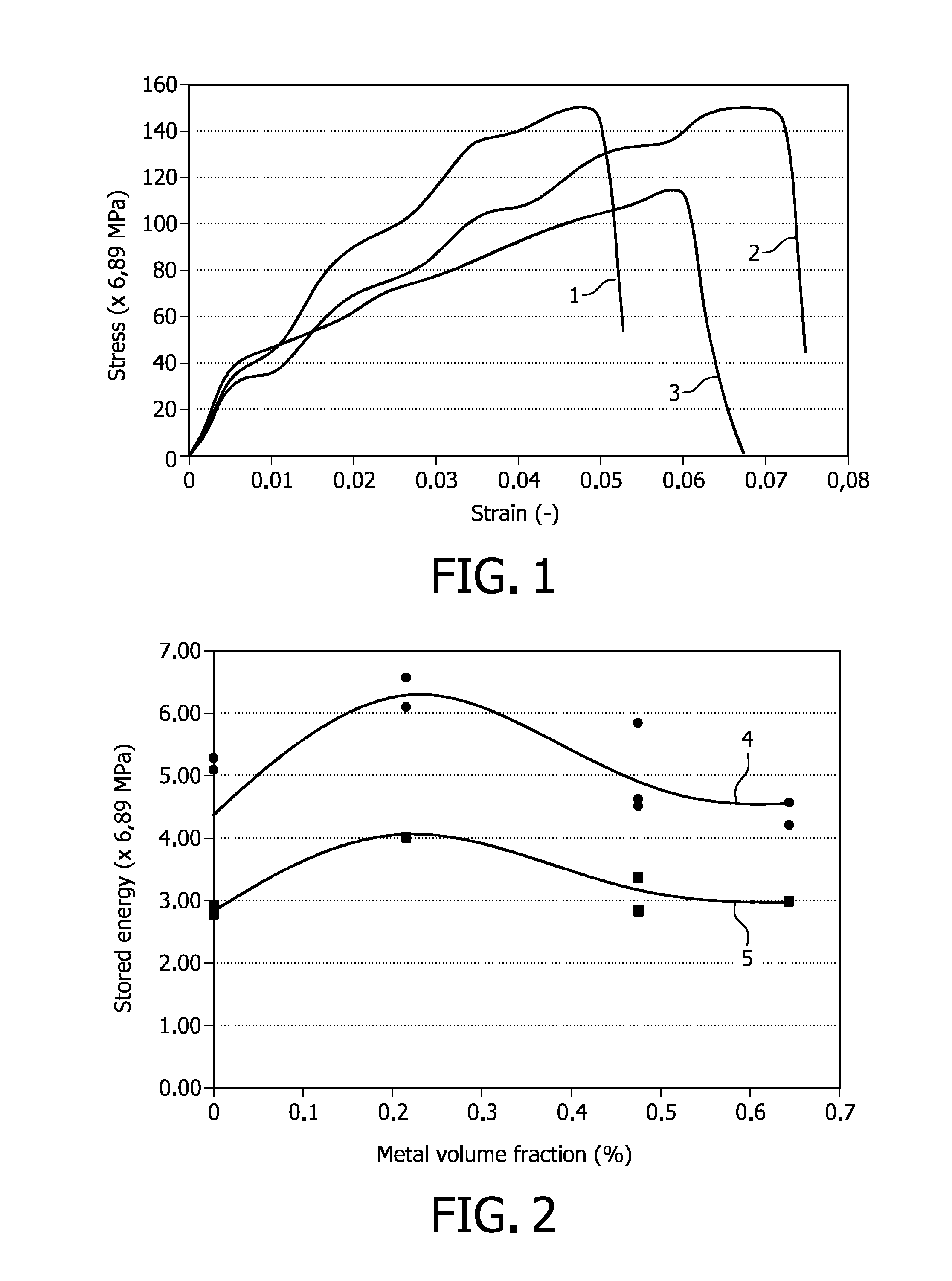

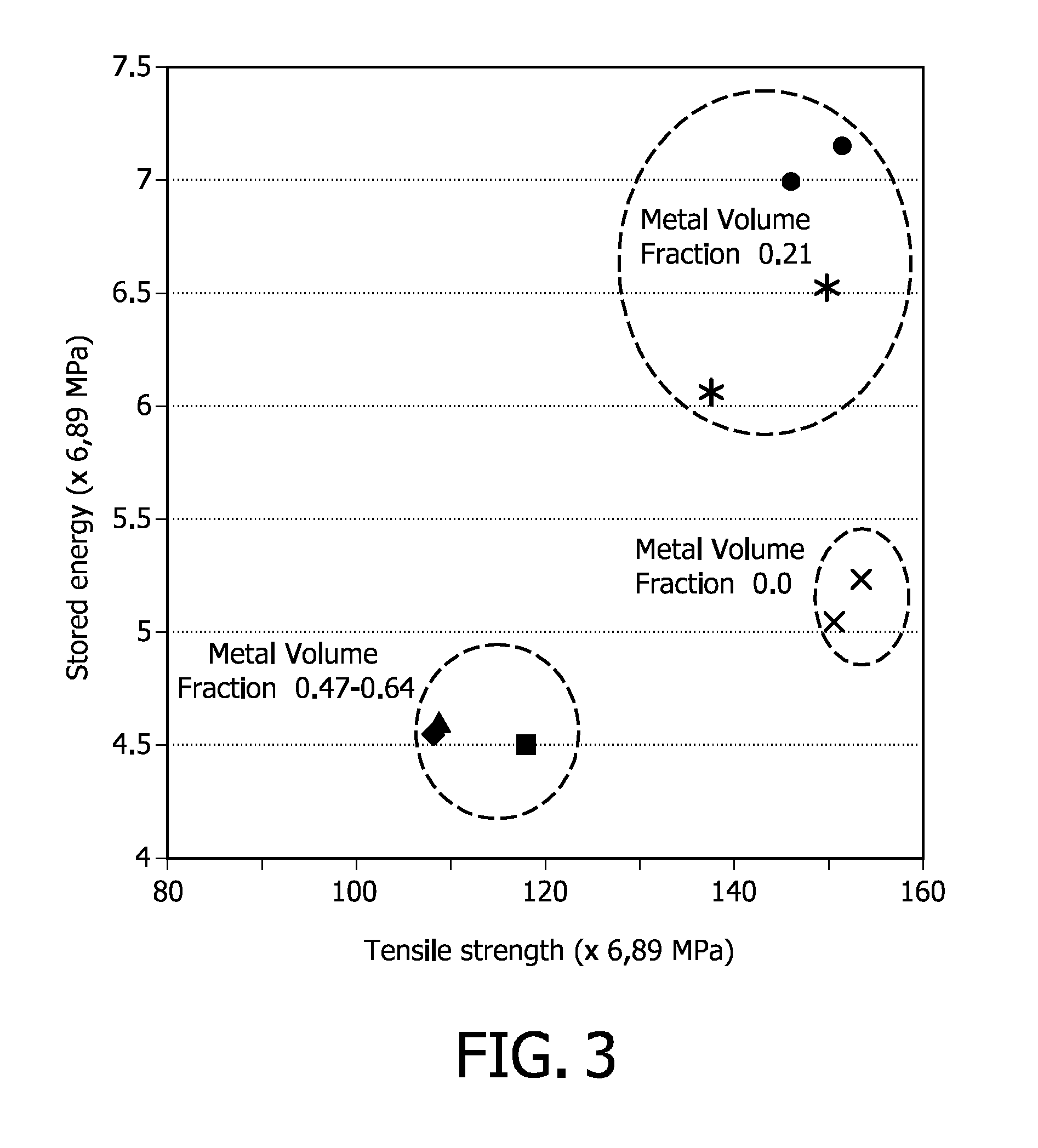

High toughness fiber-metal laminate

InactiveUS20110052910A1Good explosion resistanceReduce weightFilm/foil adhesivesAnimal housingThin metalLeading edge

The invention relates to a fiber-metallaminate comprising fiber-reinforced composite layers and thin metal sheets, wherein the total metal volume fraction of the laminate is between 0 vol. % and 47 vol. %. The fiber-metal laminate according to the invention shows an unprecedented combination of toughness and tensile strength. The laminate is advantageously used in constructing impact resistant objects, such as explosion resistant aircraft luggage containers and wing leading edges.

Owner:GTM HLDG +1

Concentrated sanitizing compositions for cleaning food and food contact surfaces

InactiveUS6617290B2Avoid damageIncreasing keeping quality of foodInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsFood additiveGram

The invention teaches the preparation of concentrated sanitizing and cleaning preparation. The preparation has dual use for cleaning and sanitizing food surfaces as well as food contact and non-food contact surfaces. The composition of the invention shows rapid microbicidal properties against representative gram positive and gram-negative bacteria. The invention uses GRAS, food additive ingredients and / or ingredients that are approved by the USFDA for use on food.

Owner:MICROCIDE

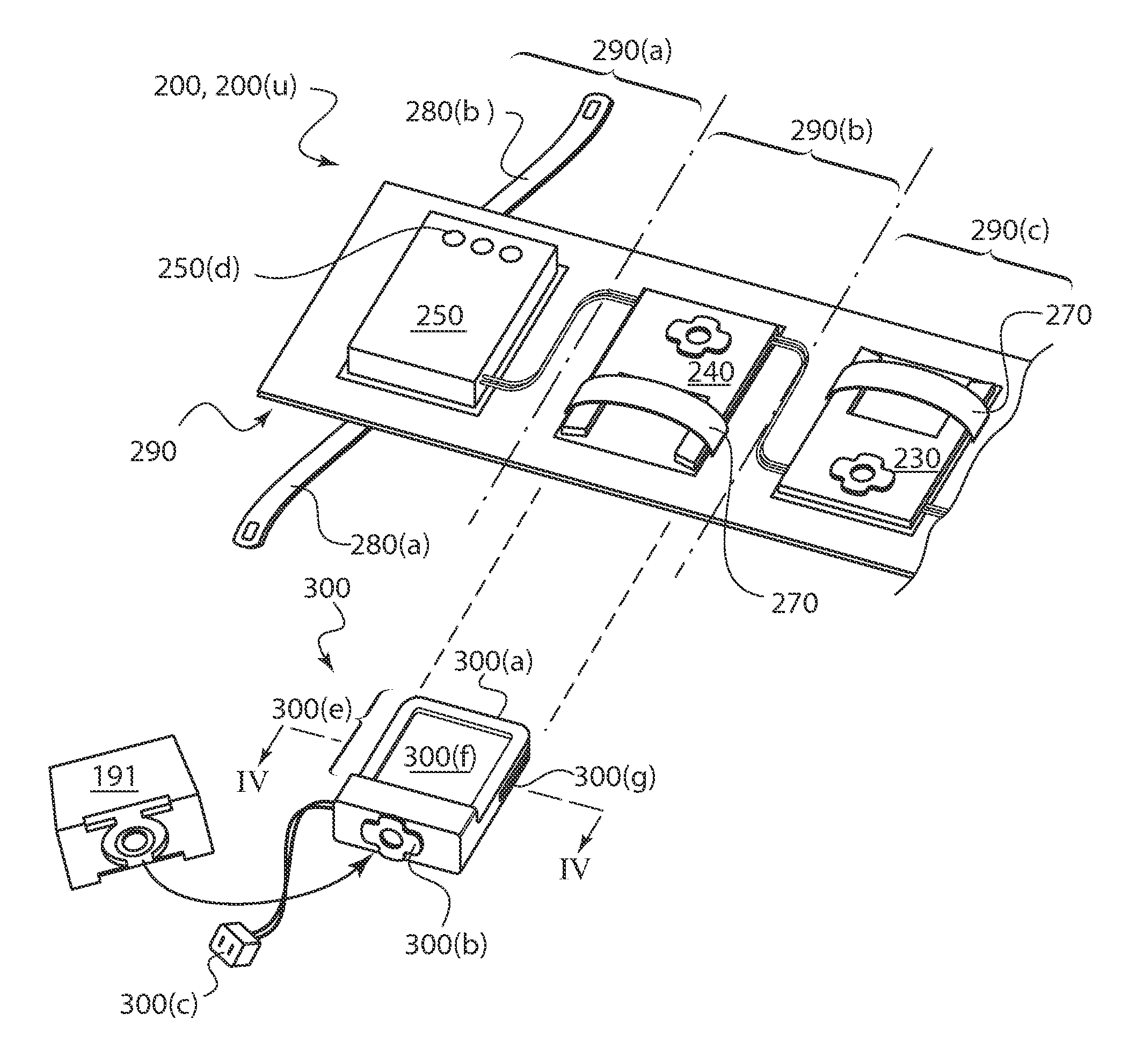

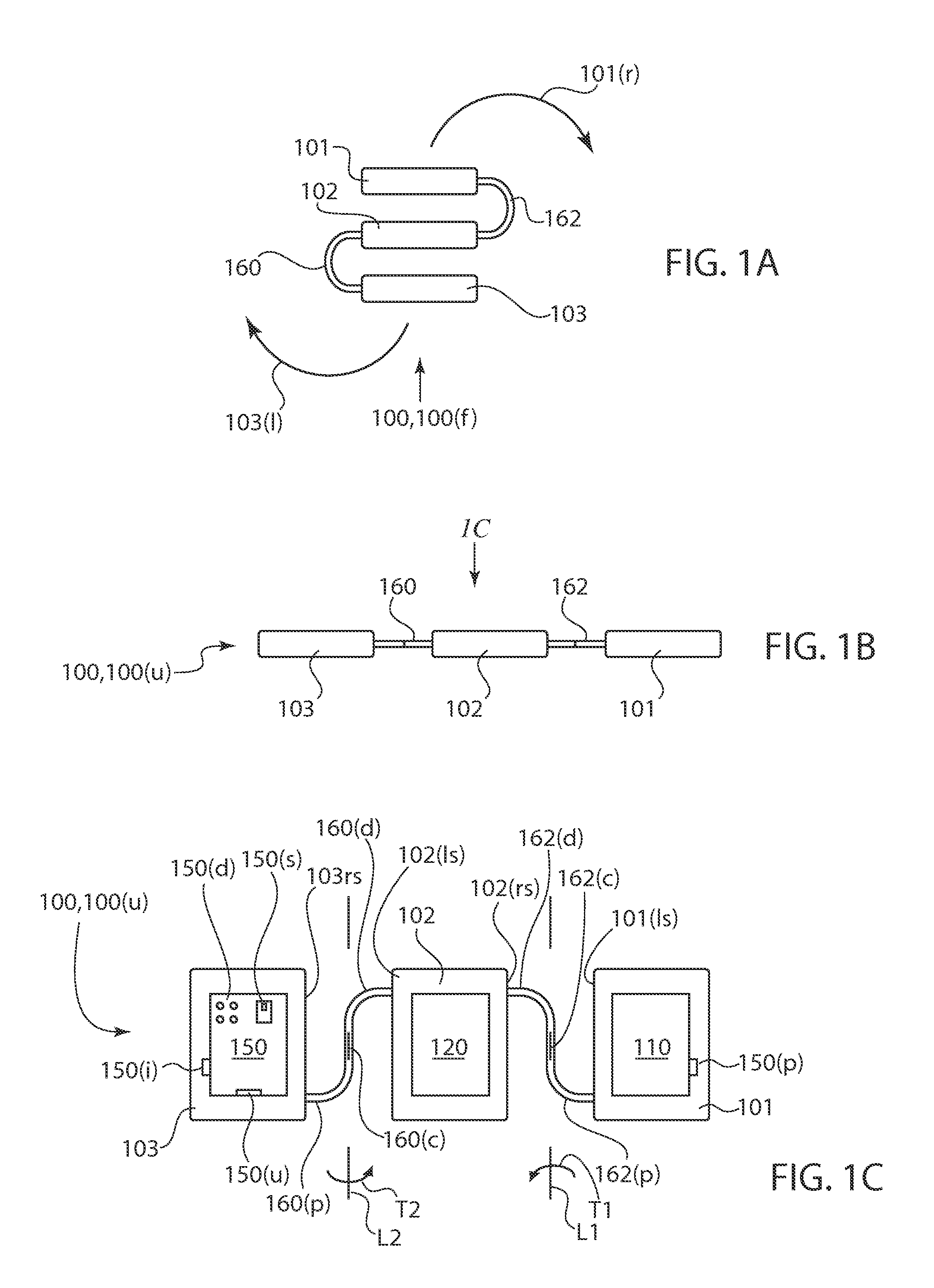

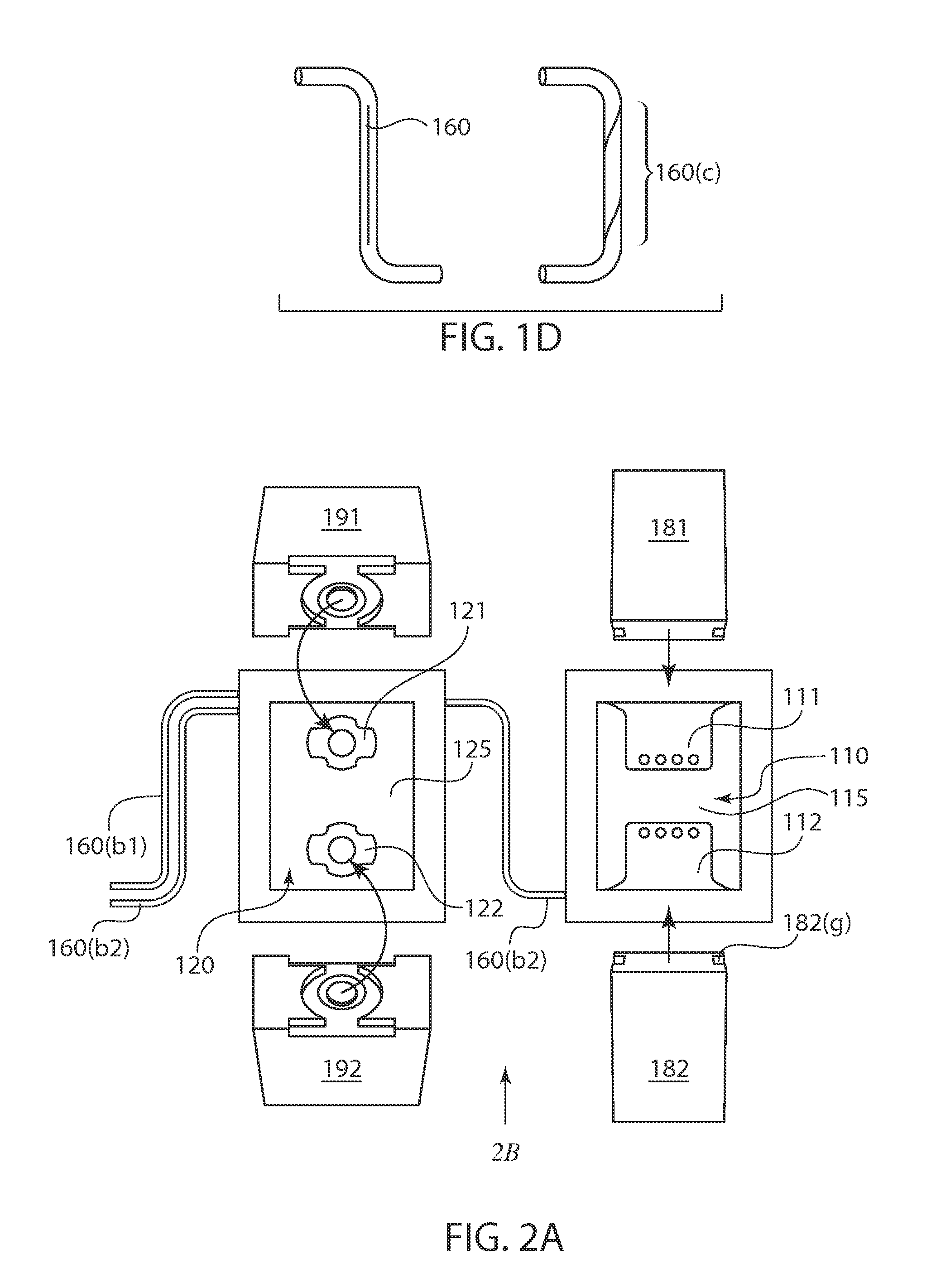

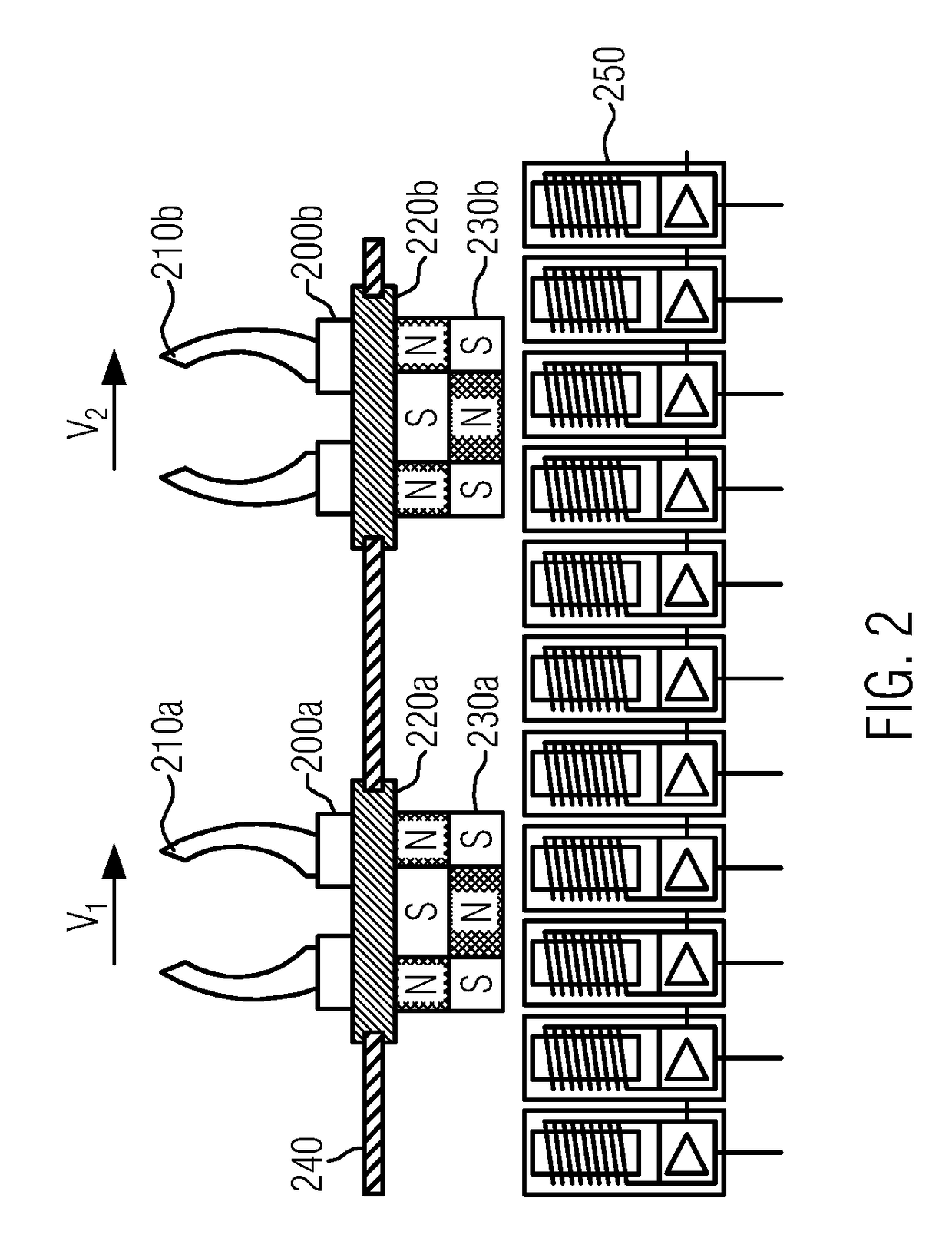

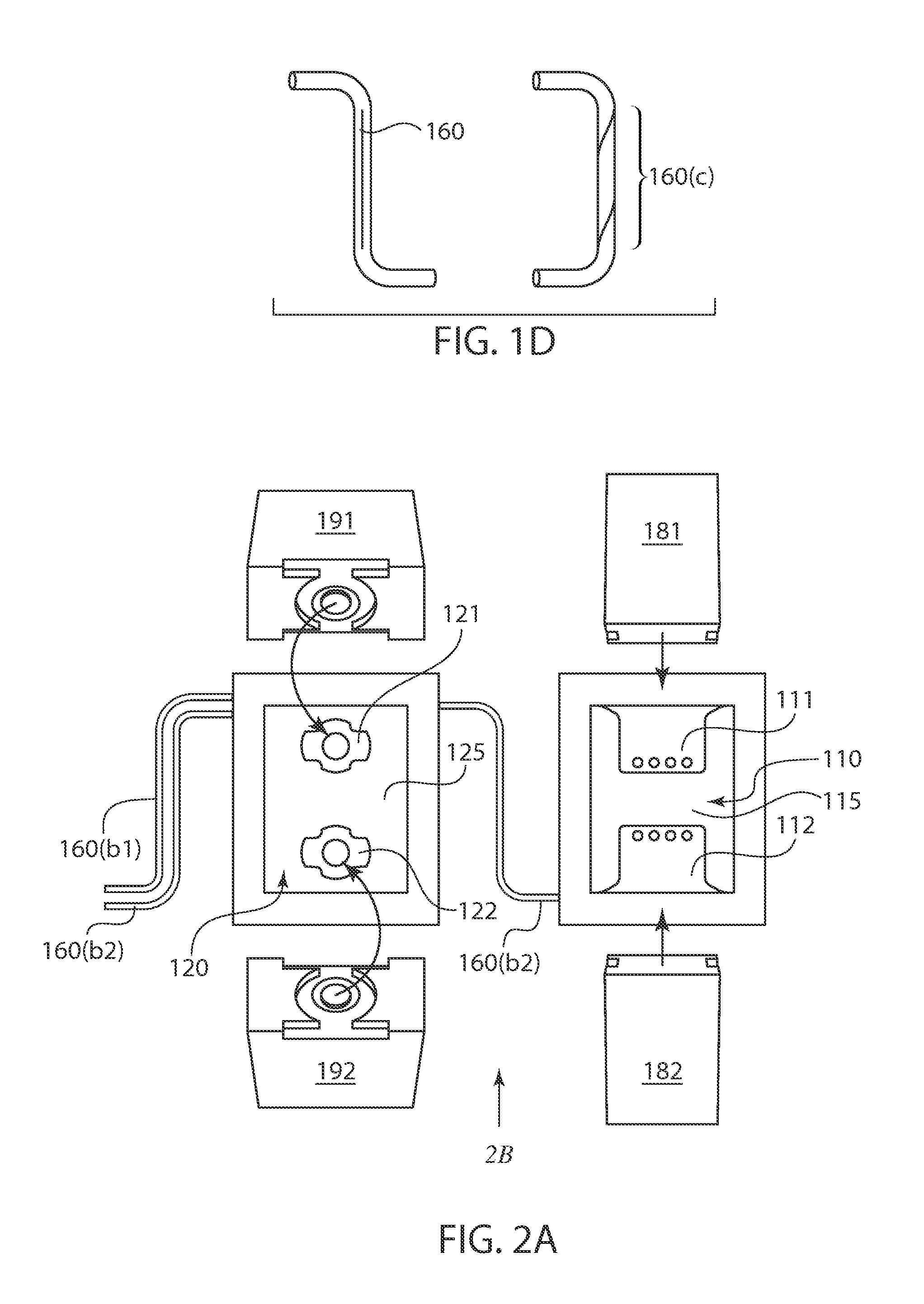

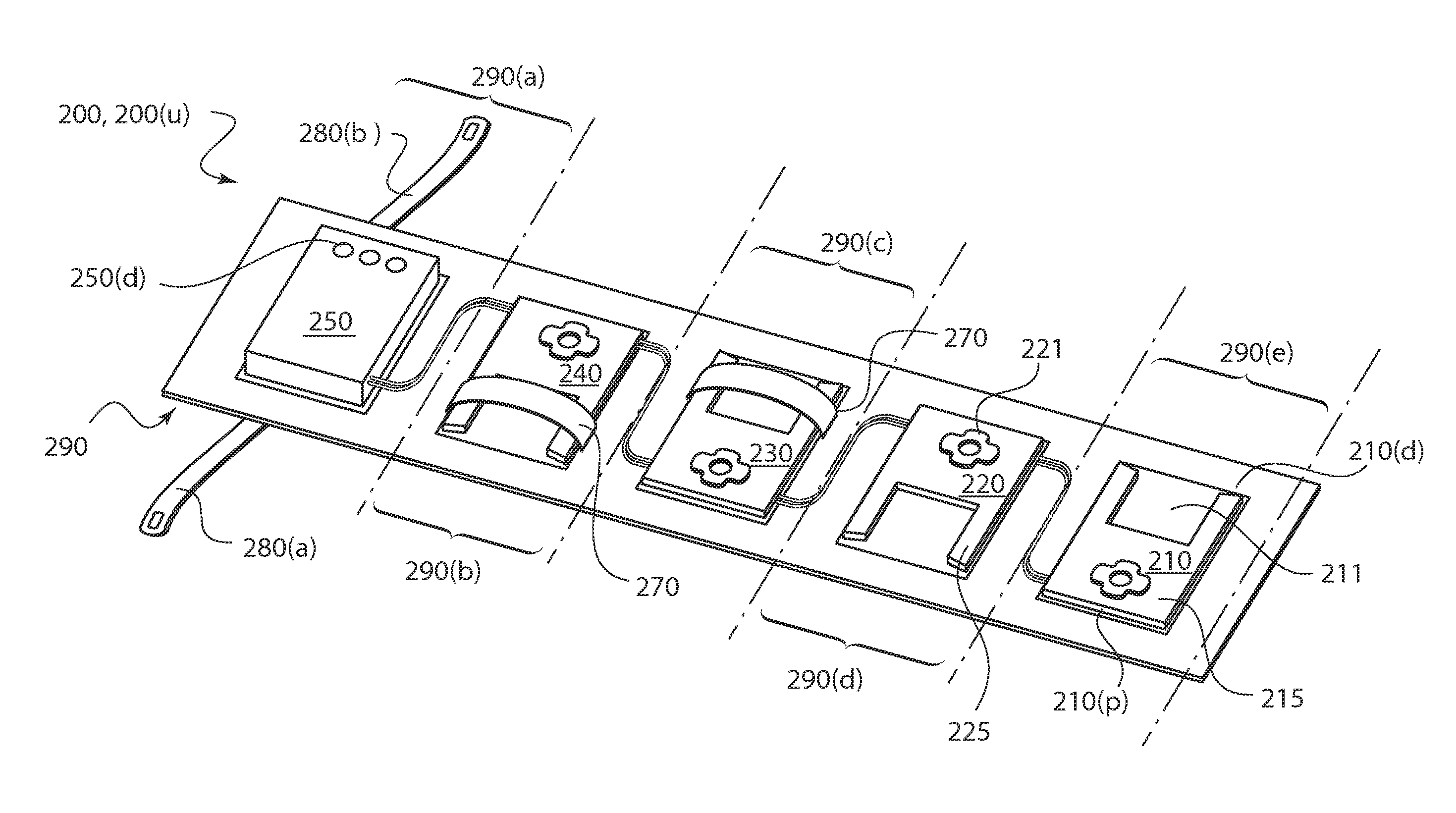

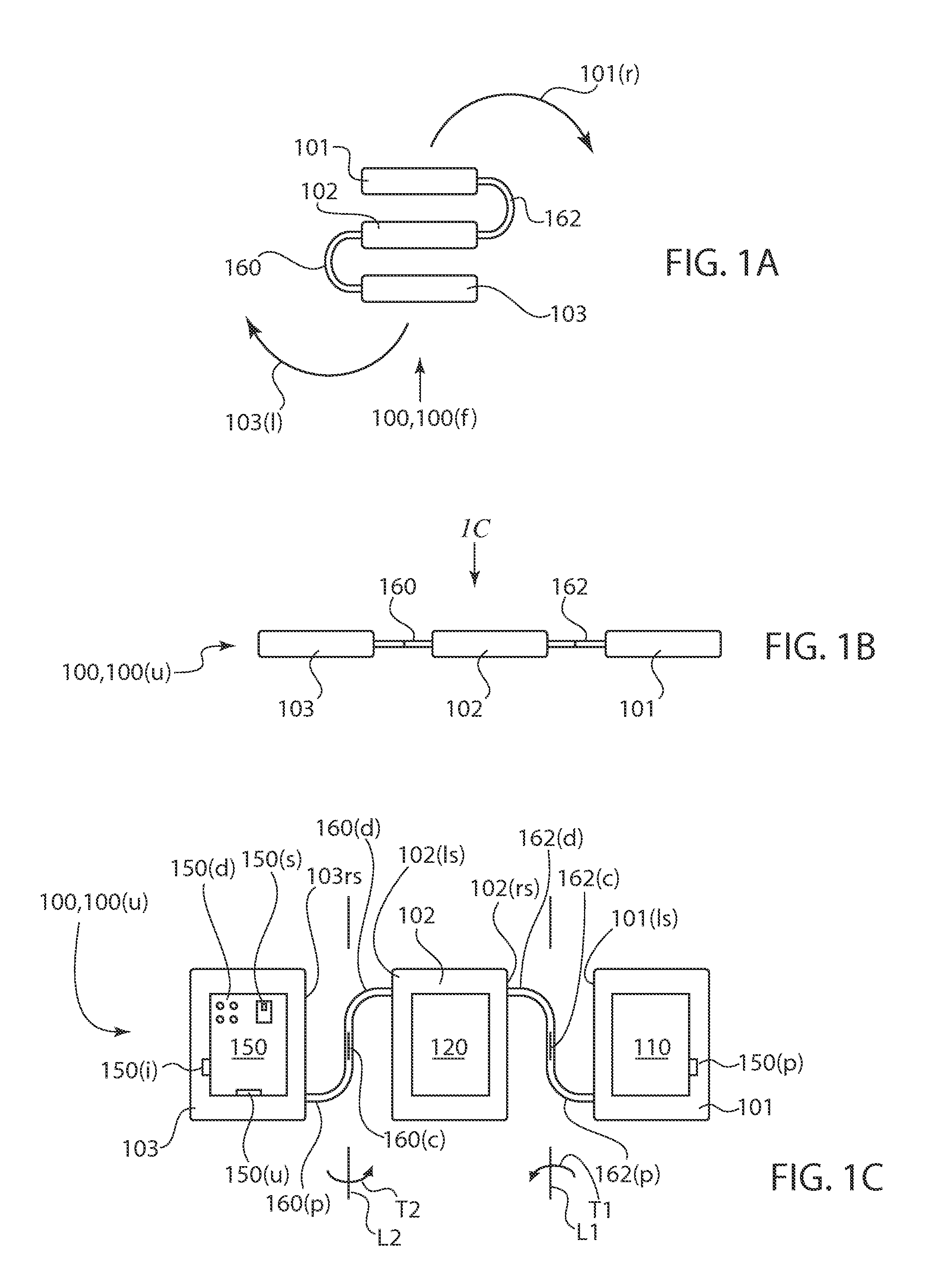

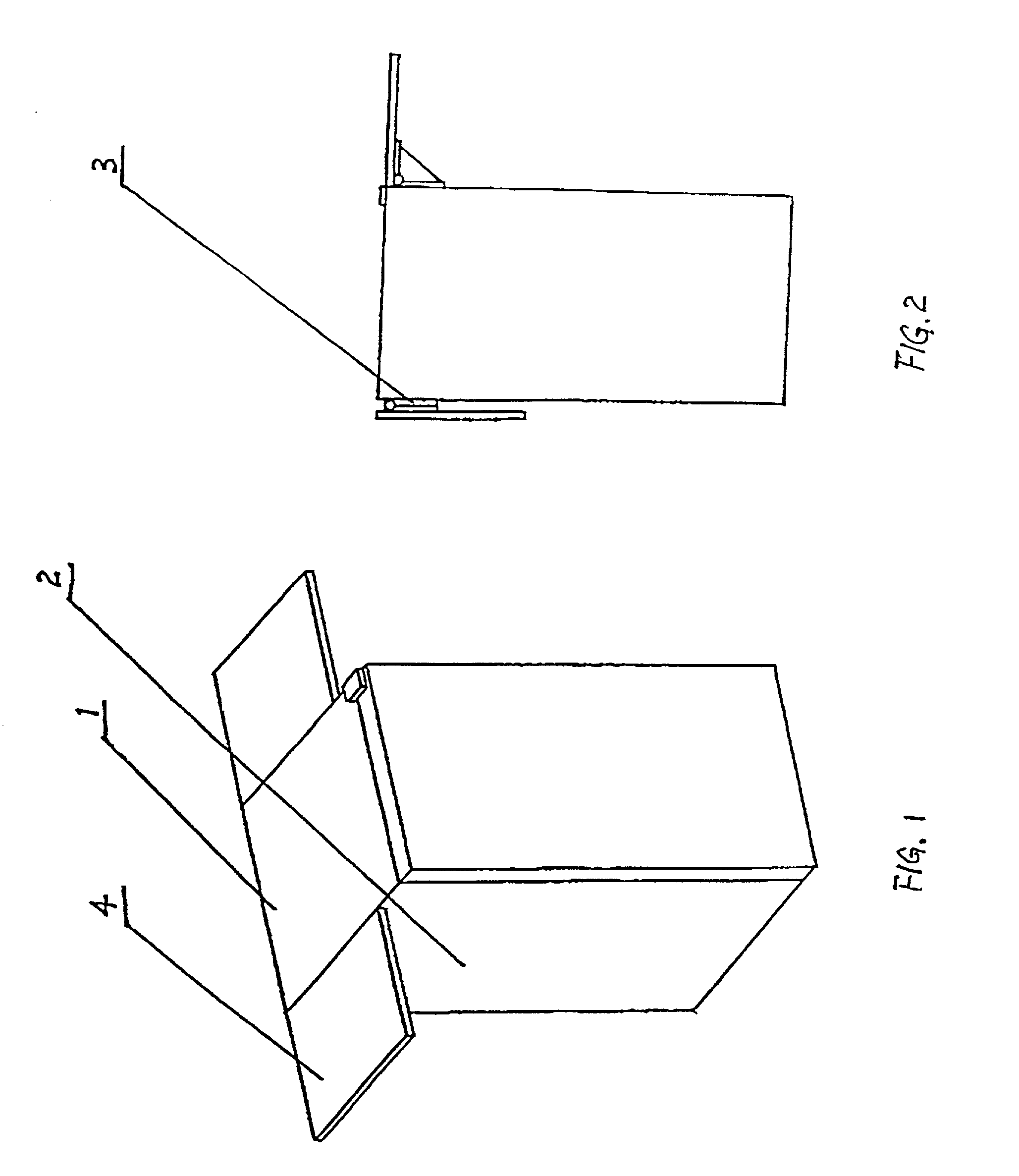

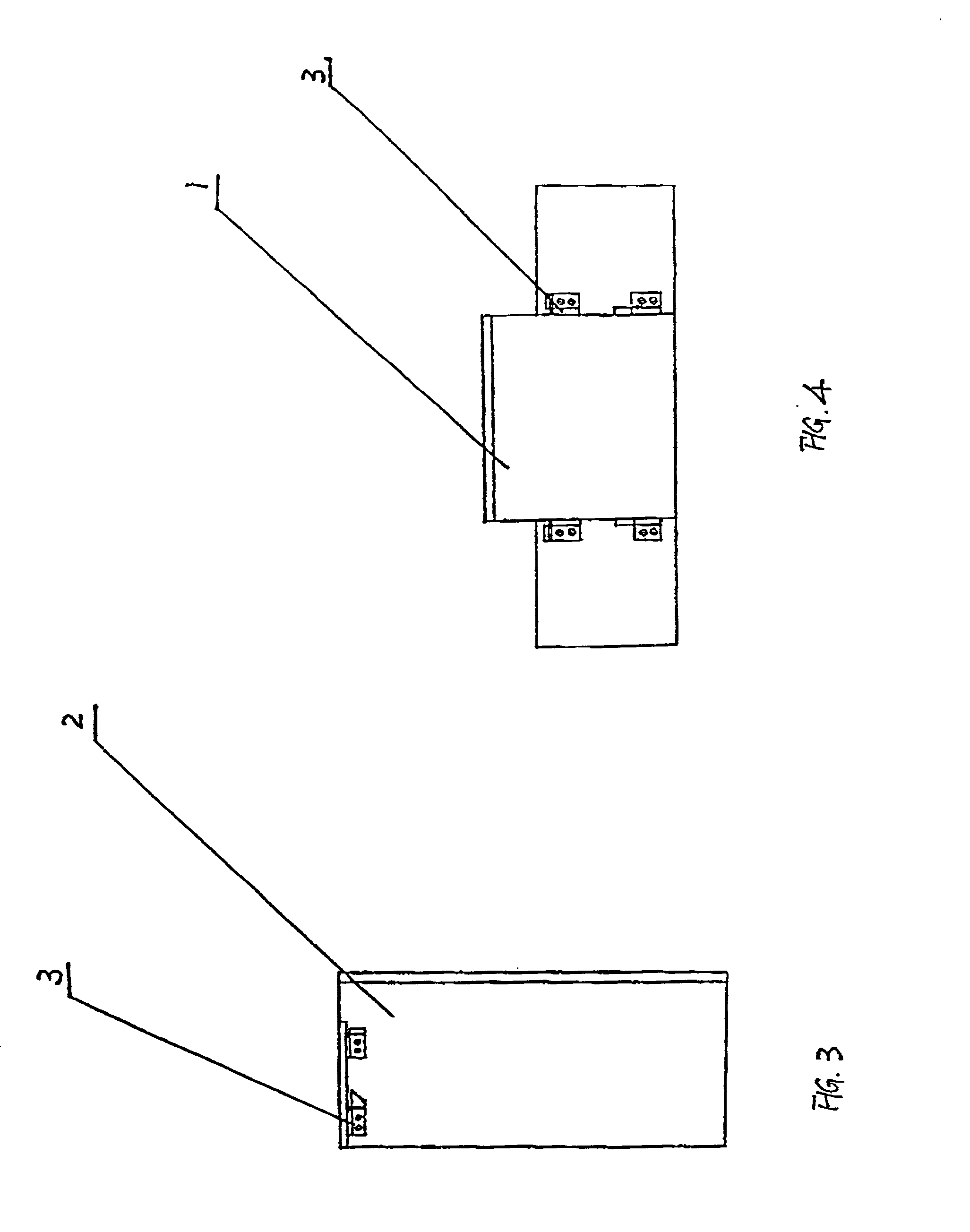

Adapter for foldable battery charger

ActiveUS20140132205A1Improve protectionIncreased durabilityBatteries circuit arrangementsElectric powerBattery chargeElectrical battery

An adapter for a portable battery charging apparatus having two or more battery charging interfaces on separate panels. Wires electrically couple the battery charging apparatuses to a charger unit. The wires are routed for flexibility to fold and unfold the panels. The adapter is configured to nest between two panels of the battery charging apparatus when the panels are stacked together in a compact folded state.

Owner:BREN TRONICS INC

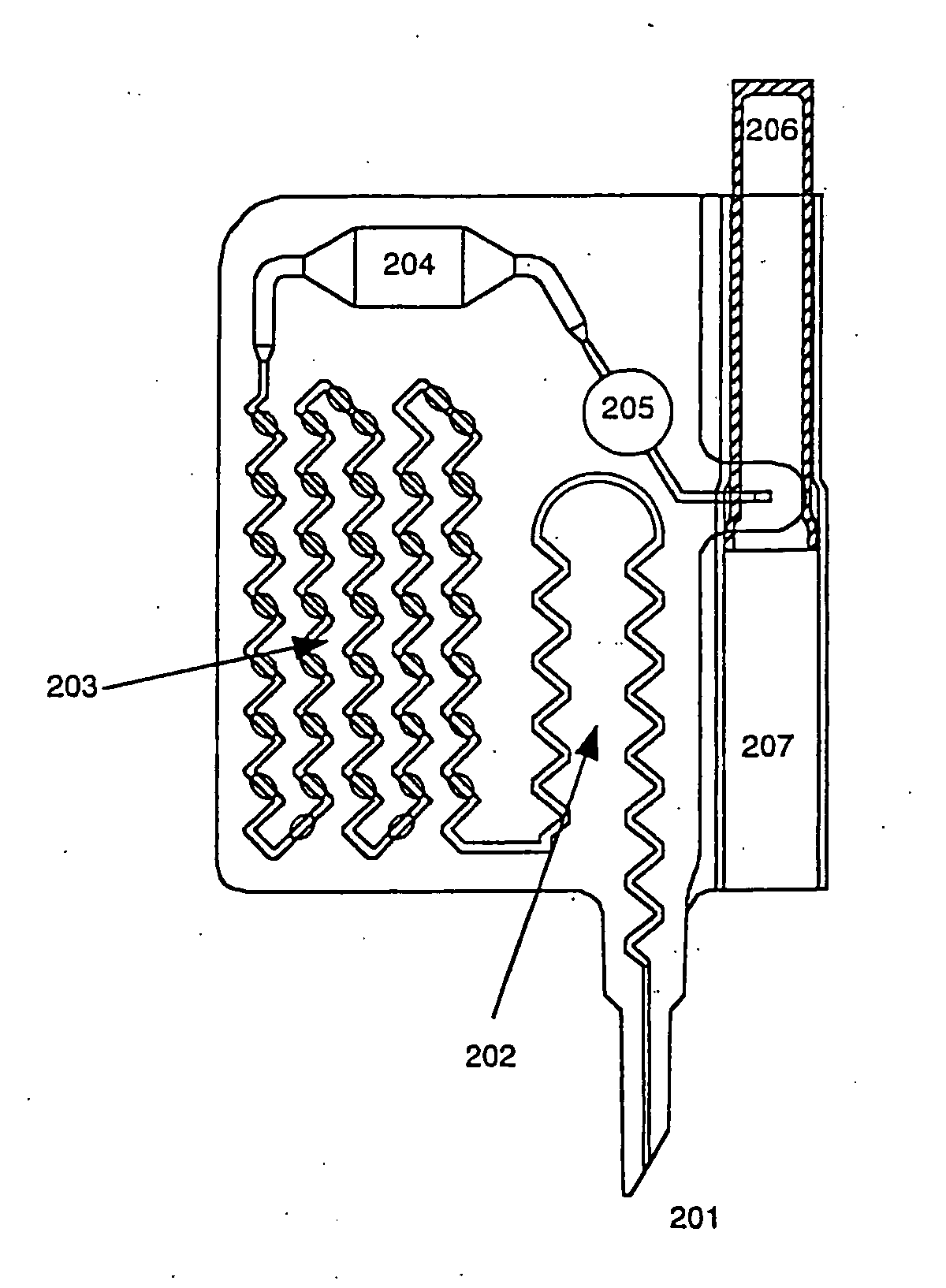

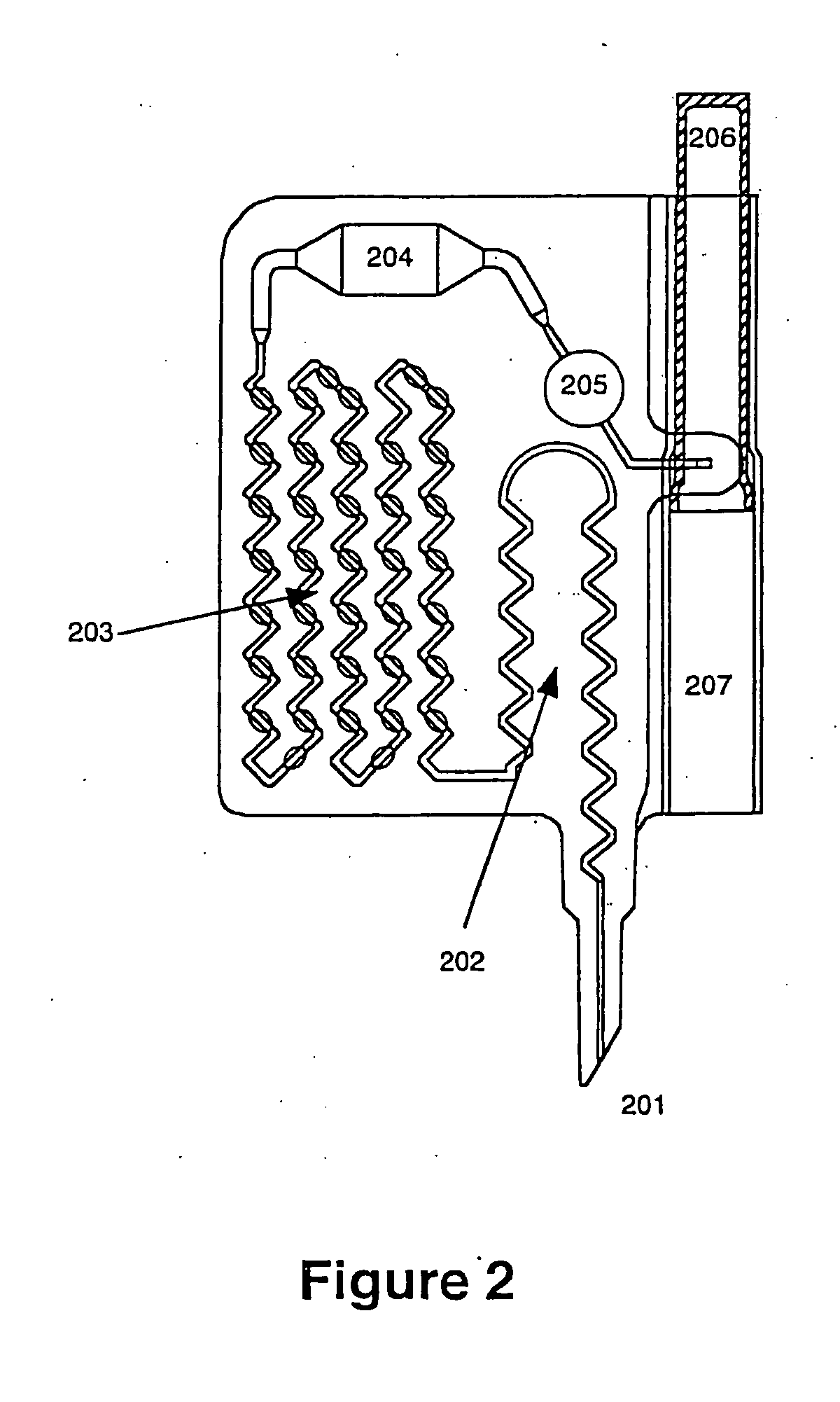

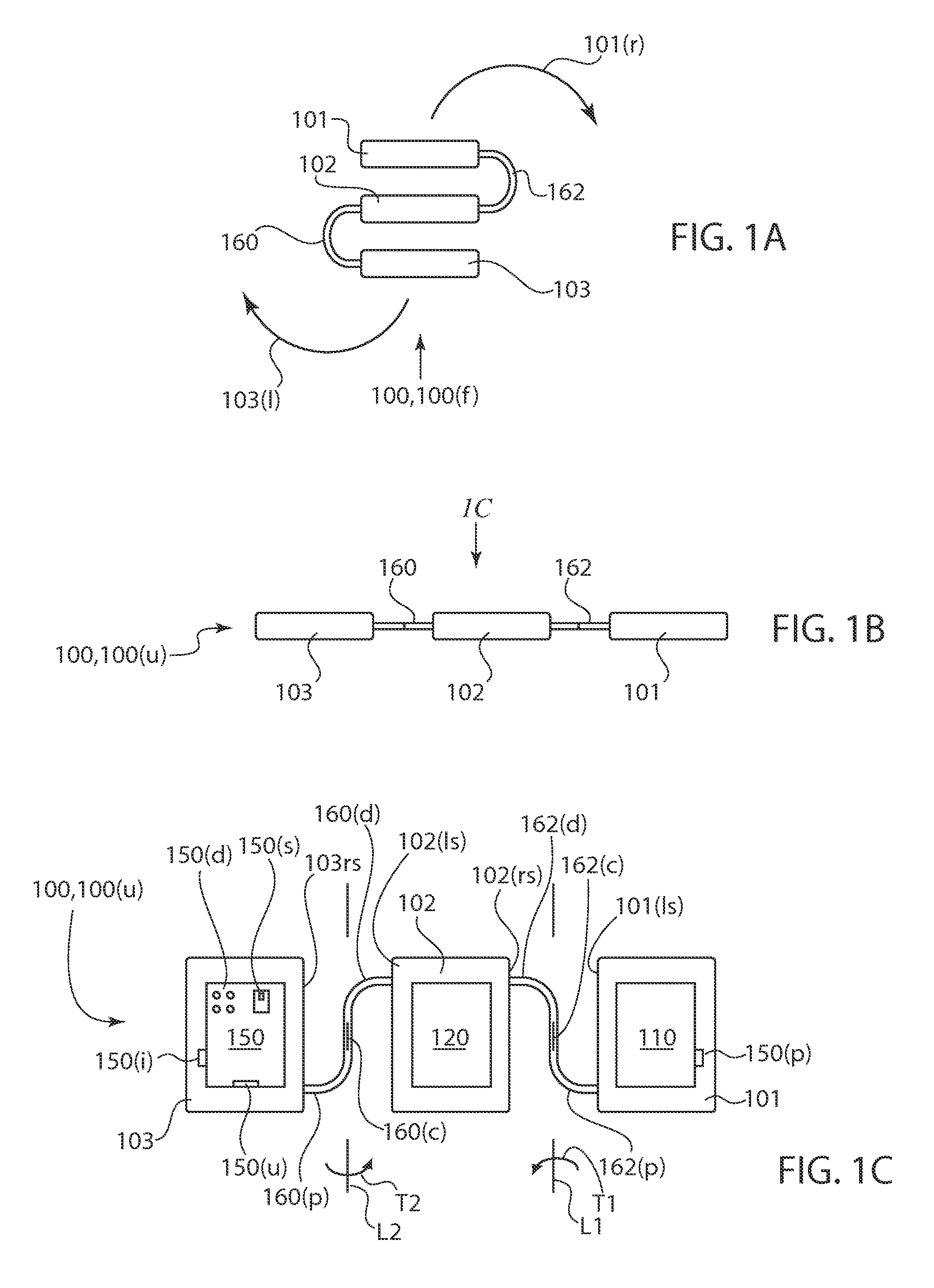

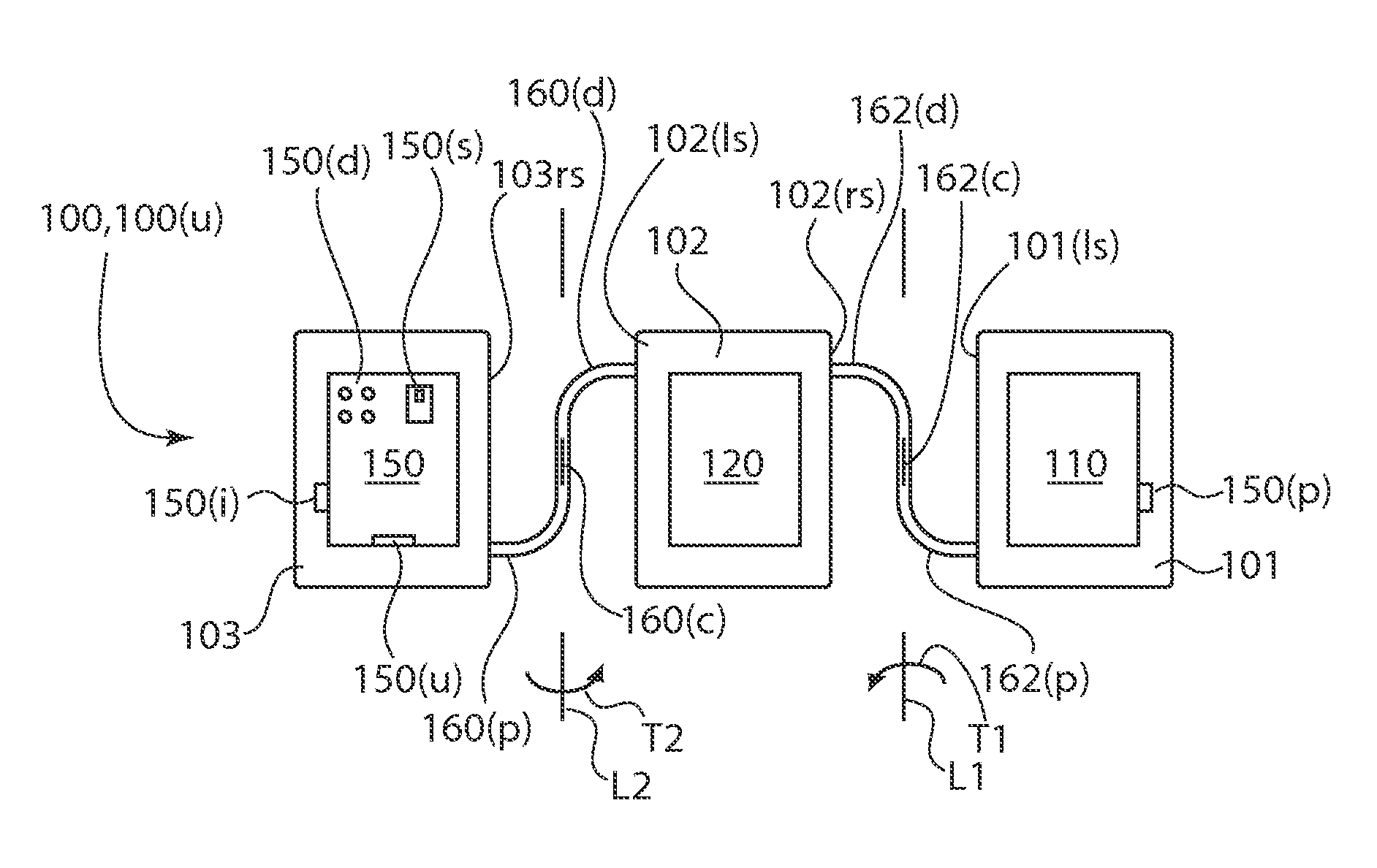

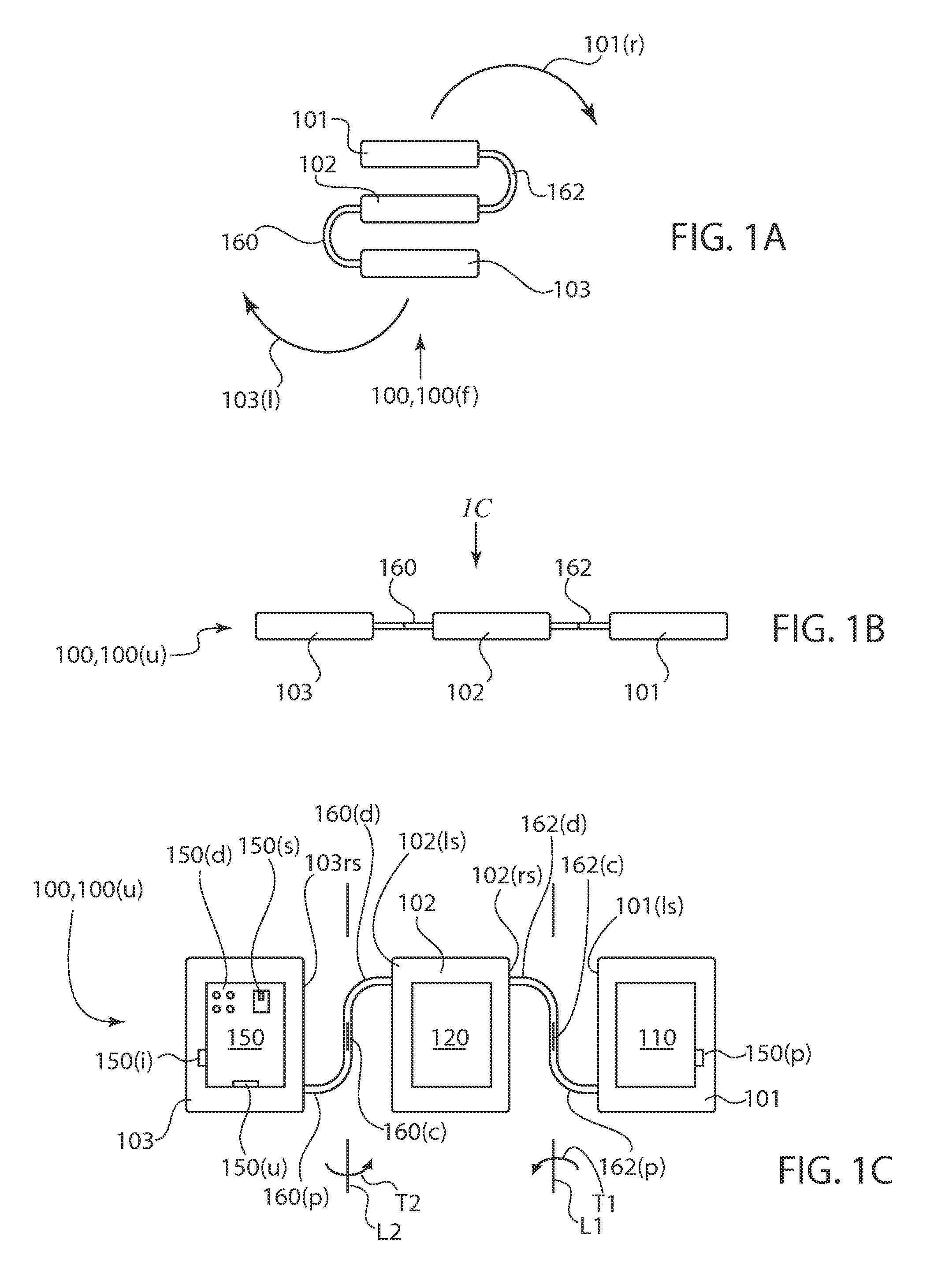

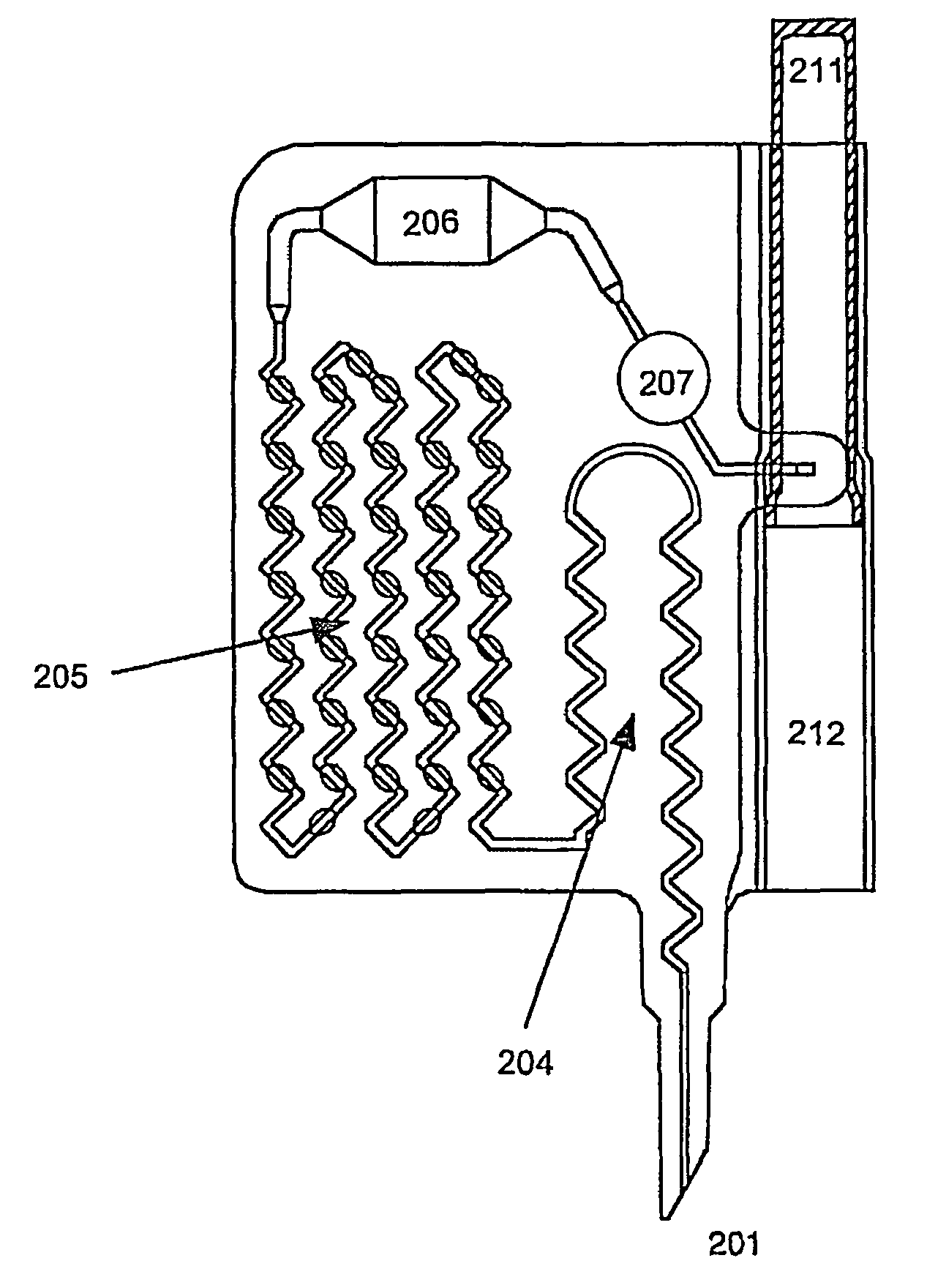

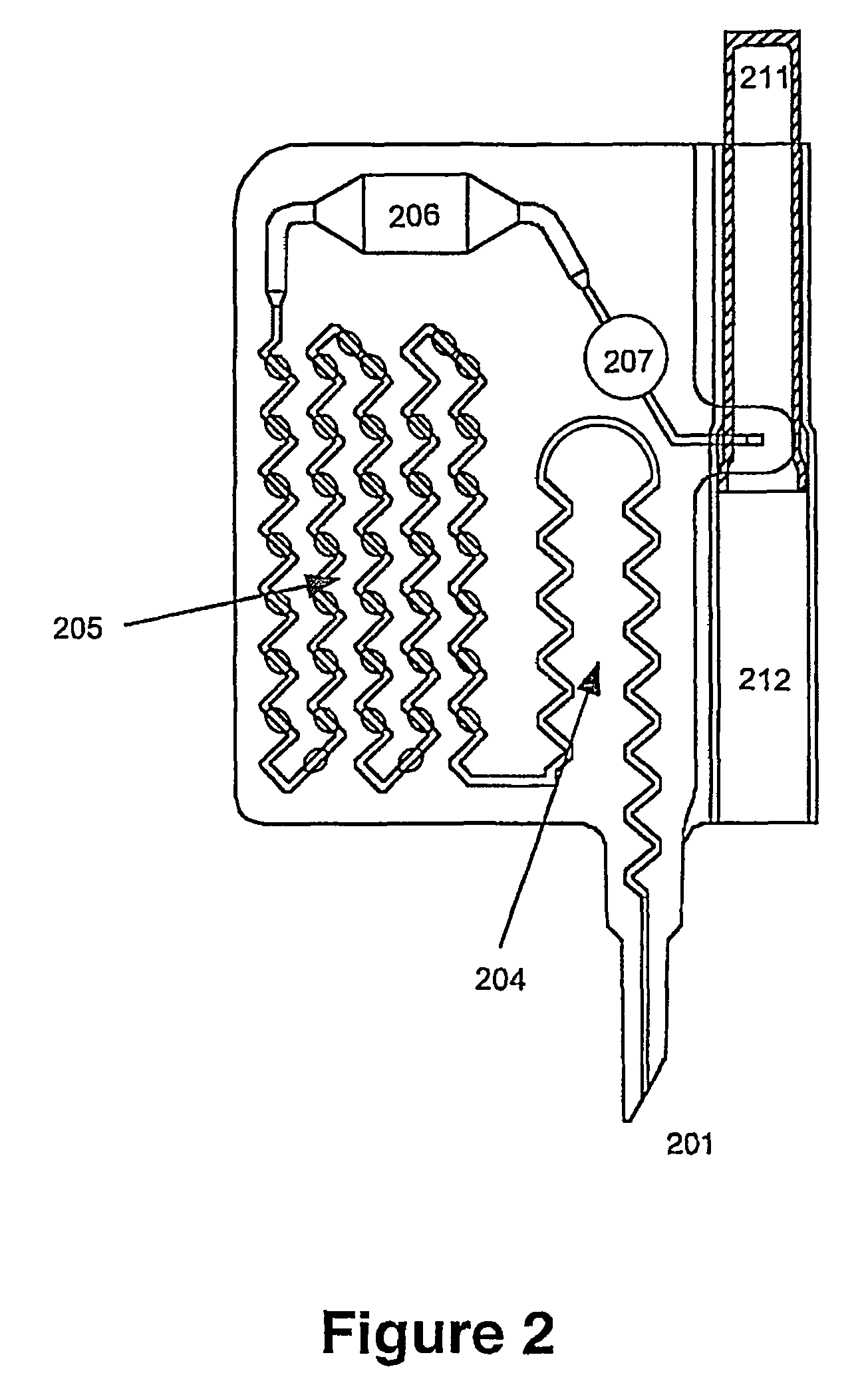

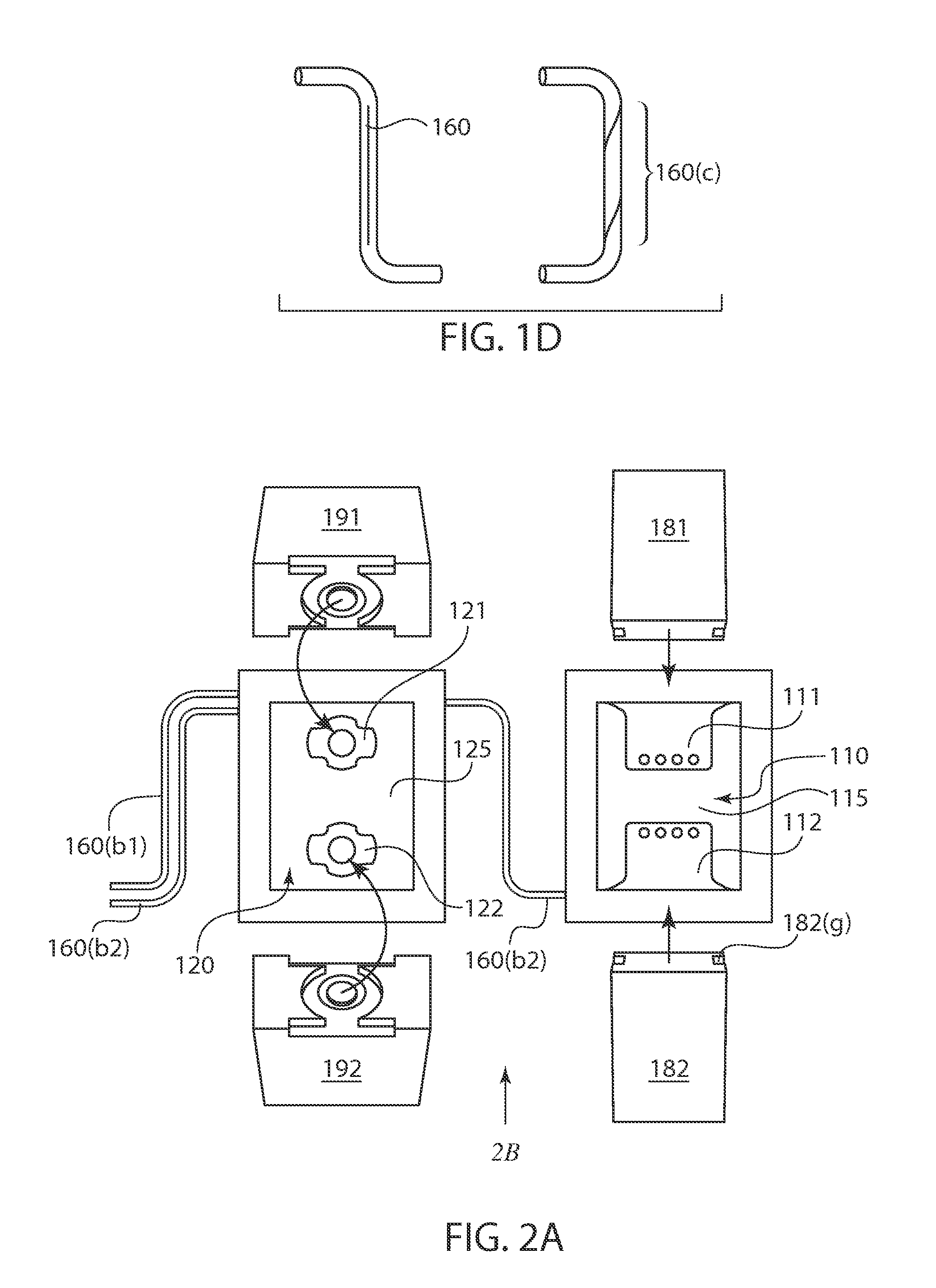

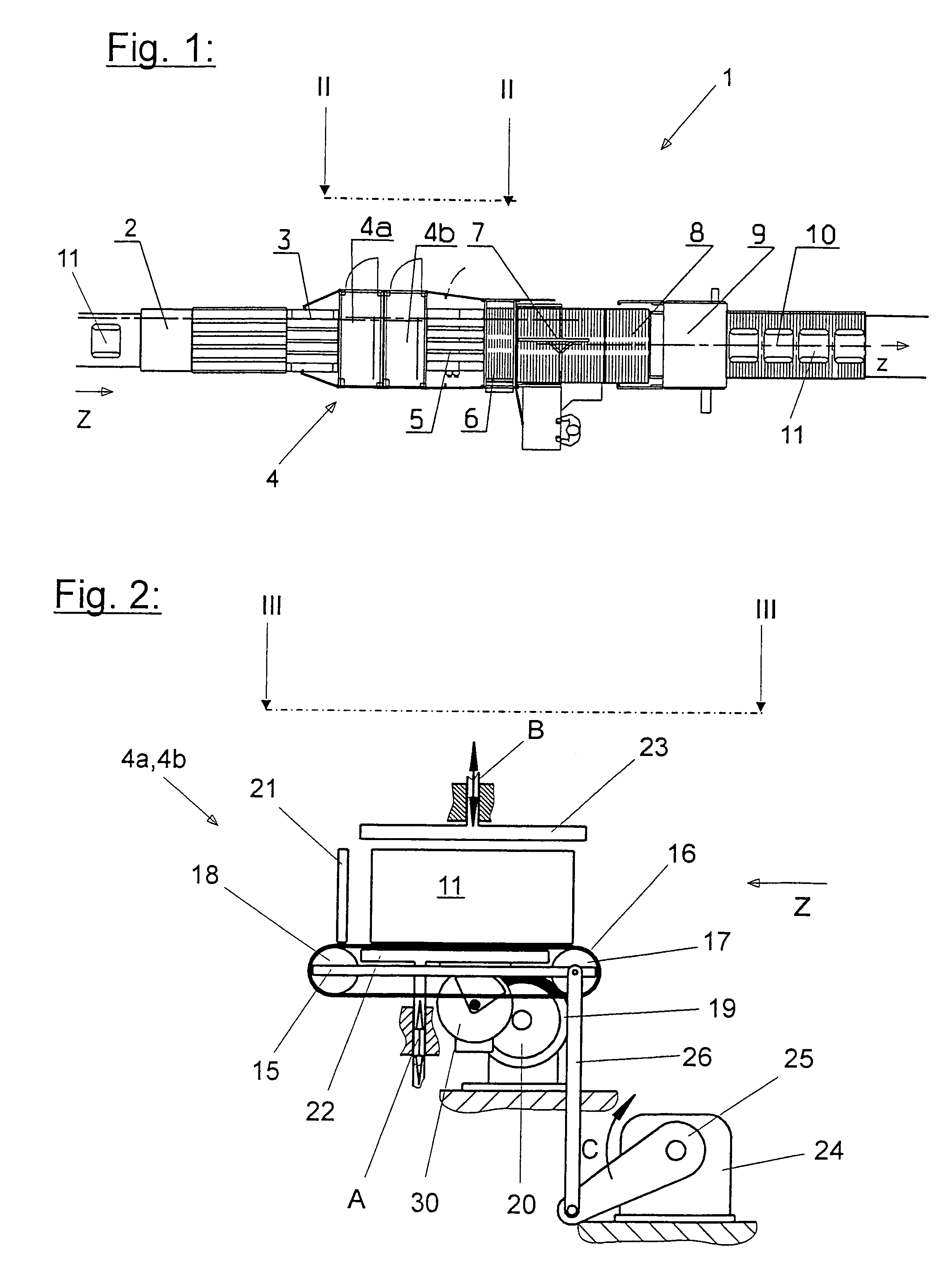

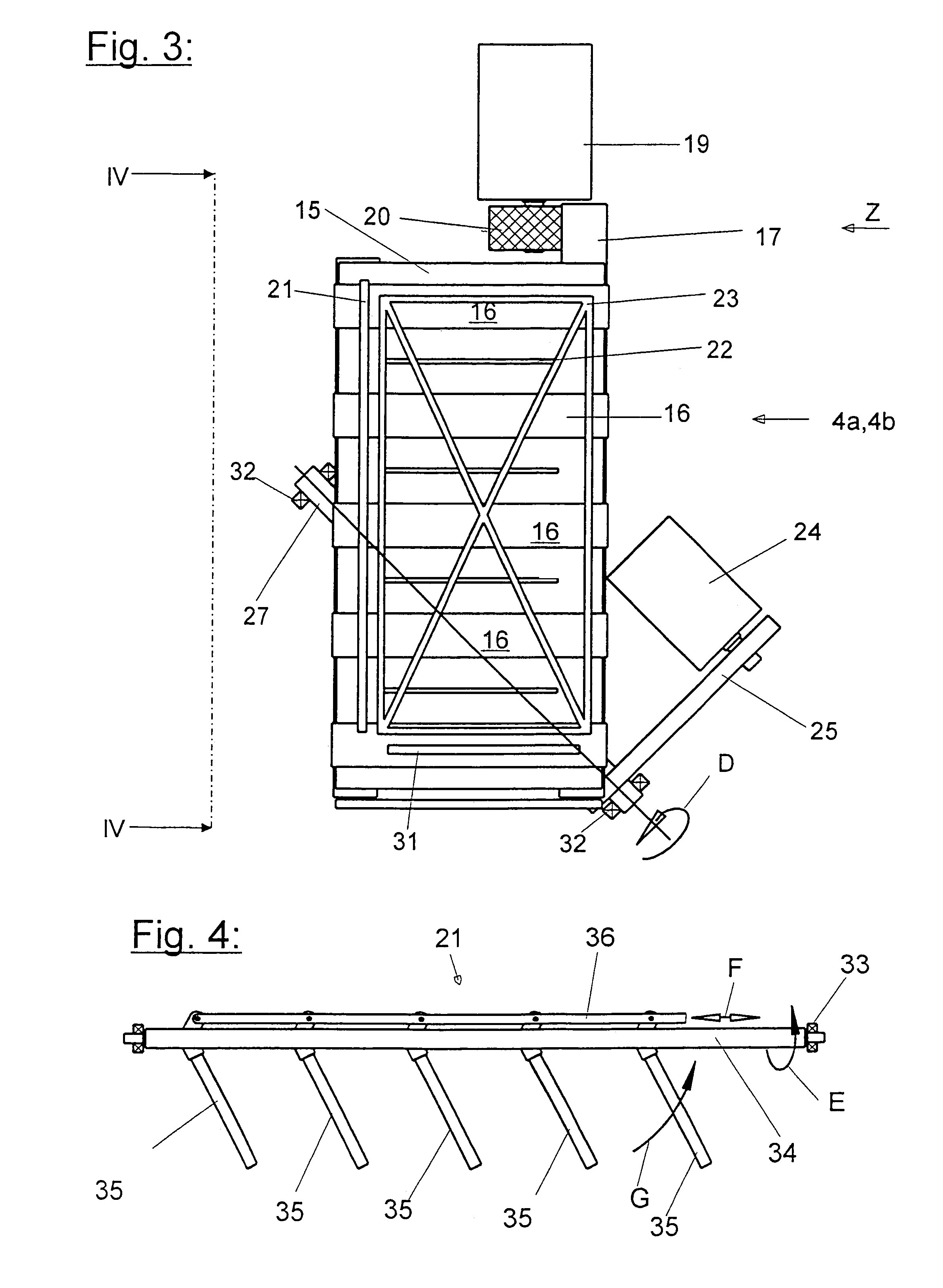

Method for the assessment of particles and a system and device for use in the method

ActiveUS20070207551A1Small amountSave on transportationExhaust apparatusElement comparisonSingle-Use DeviceImage presentation

The present invention relates to a method and a device for the assessment of at least one parameter of particles in a liquid analyte material, comprising providing a device comprising a sample compartment comprising an exposing domain, an inlet through which a volume of a liquid sample representing the analyte material can be introduced, and a flow system comprising at least a channel allowing at least a portion of the volume of the liquid sample to flow within the device. A volume of the liquid sample is introduced in the device through the inlet of the disposable device, passing at least a portion of the volume of the liquid sample through the flow system of the device into the exposing domain of the sample compartment, arranging the device in relation to detection device comprising a detection means for quantitatively detecting spatial image data and processing means for processing the detected image presentation detecting electromagnetic signals from the sample in the exposing domain of the device in the detection device forming, in the detection device, a spatial image representation of the exposing domain, and processing the detected image presentation obtaining the assessment of the at least one parameter.

Owner:CHEMOMETEC AS

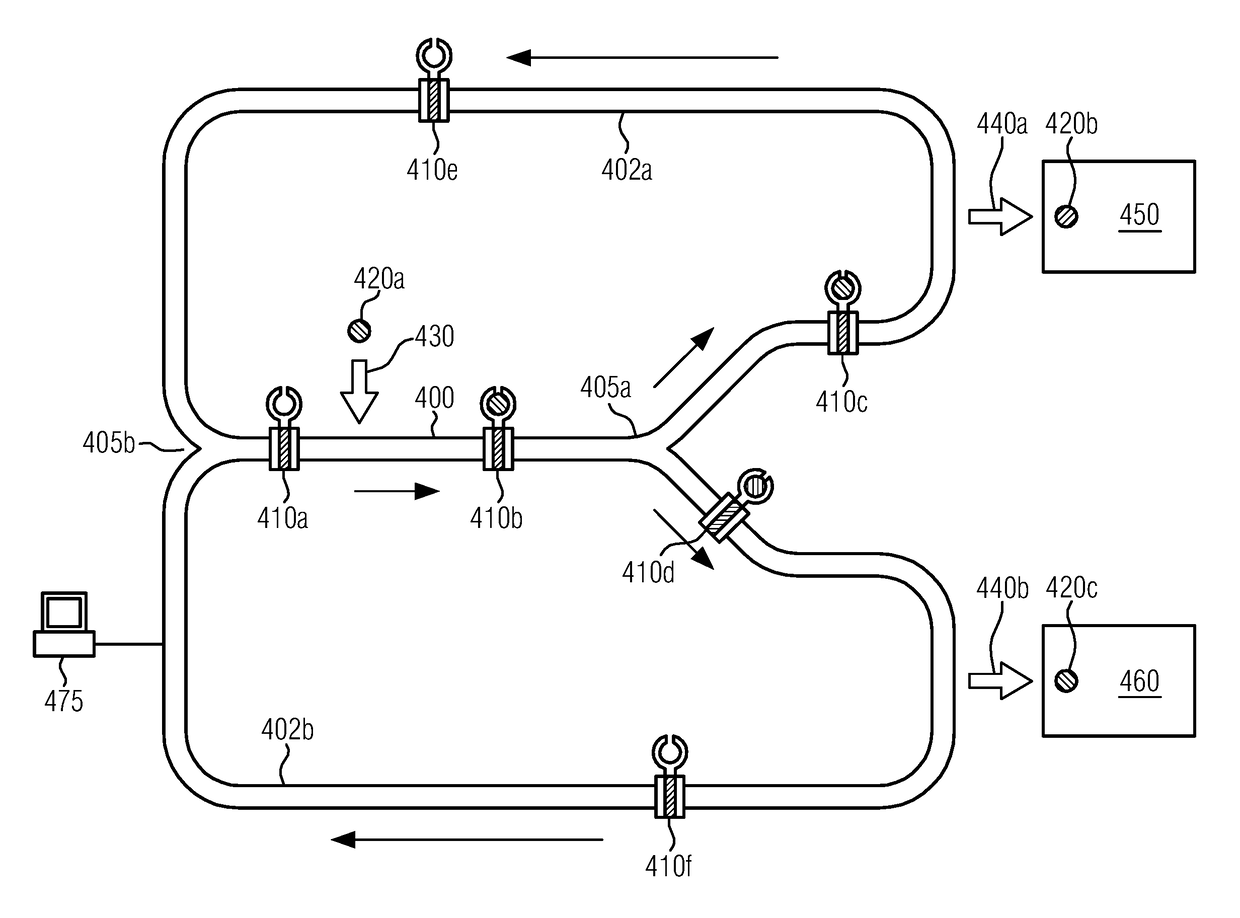

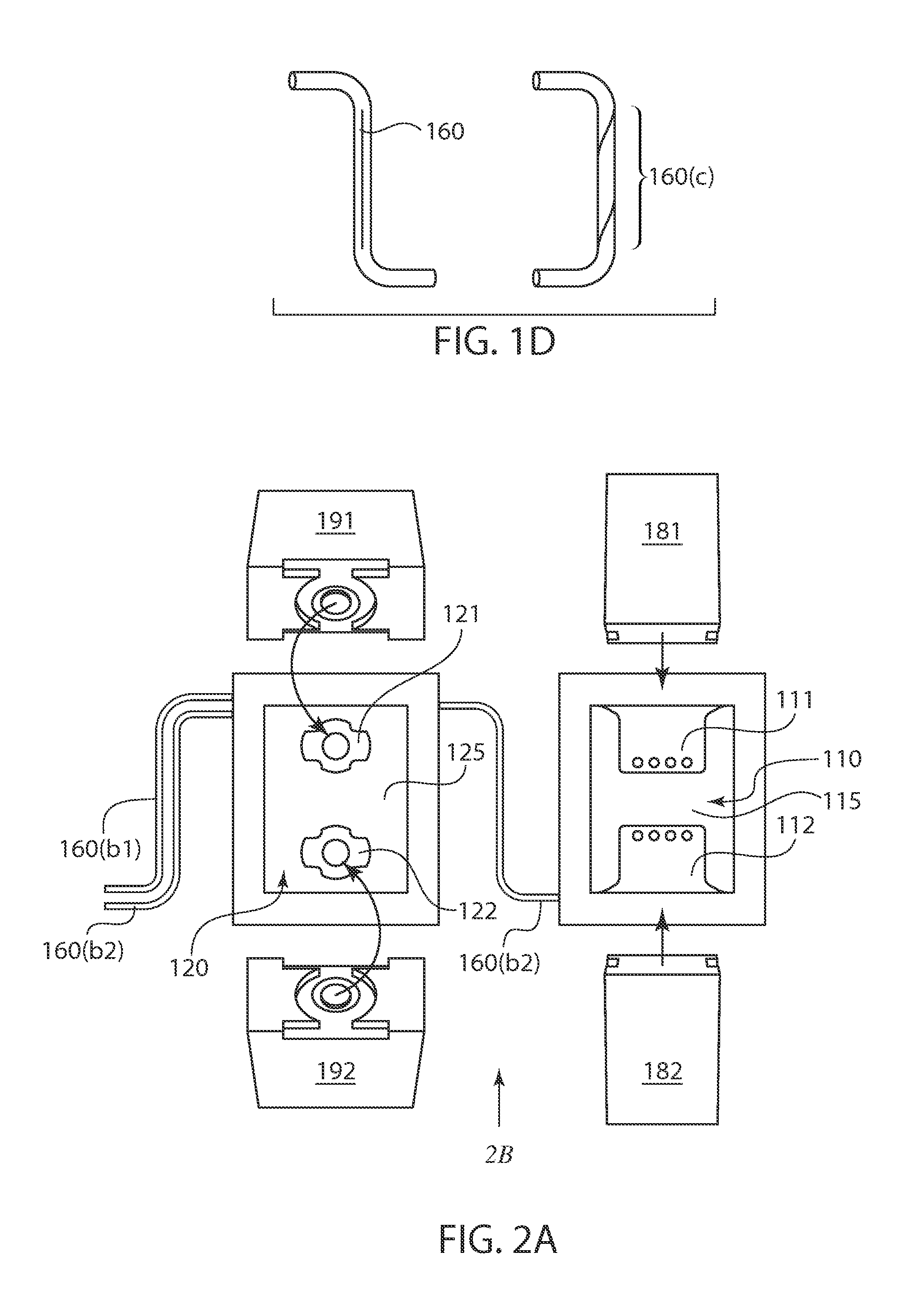

Device and method for transporting containers in a container treatment system

ActiveUS9809392B2Minimize production downtimeImprove utilizationSynchronising machinesControl devices for conveyorsTransport engineeringTreatment system

A transport device for transporting containers in a container treatment system which has a first container treatment unit for a process step and a second container treatment unit for the process step, the transport device having at least one receiving point for the containers, at least one delivery point for the containers, a transport track which connects the at least one receiving point, the at least one delivery point, the first container treatment unit, and the second container treatment unit, and at least one transport element for transporting a container, the transport element being movably arranged on the transport track. The transport track and the at least one transport element are designed such that the at least one transport element can be guided from a receiving point to a delivery point in an individually controllable manner.

Owner:KRONES AG

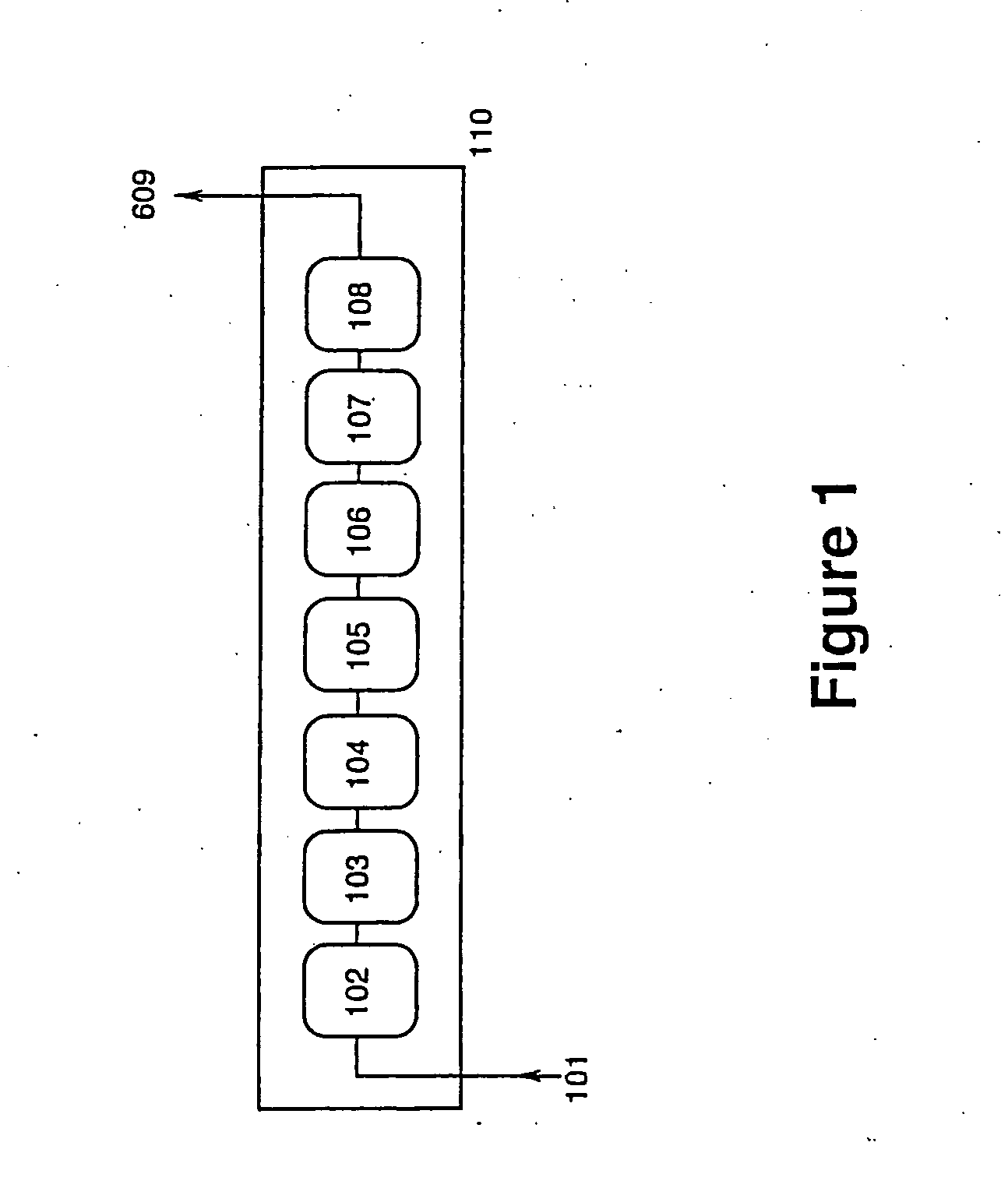

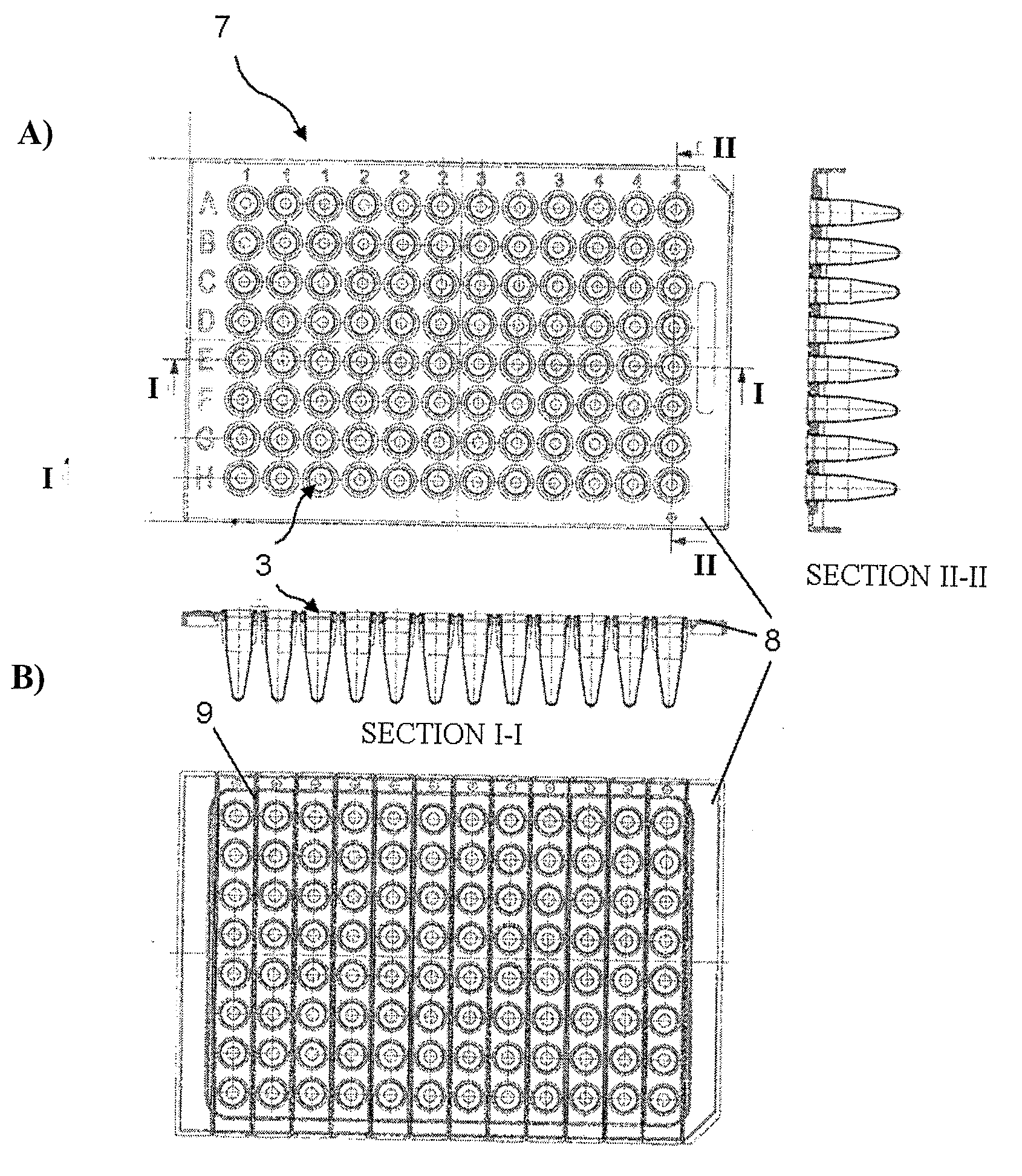

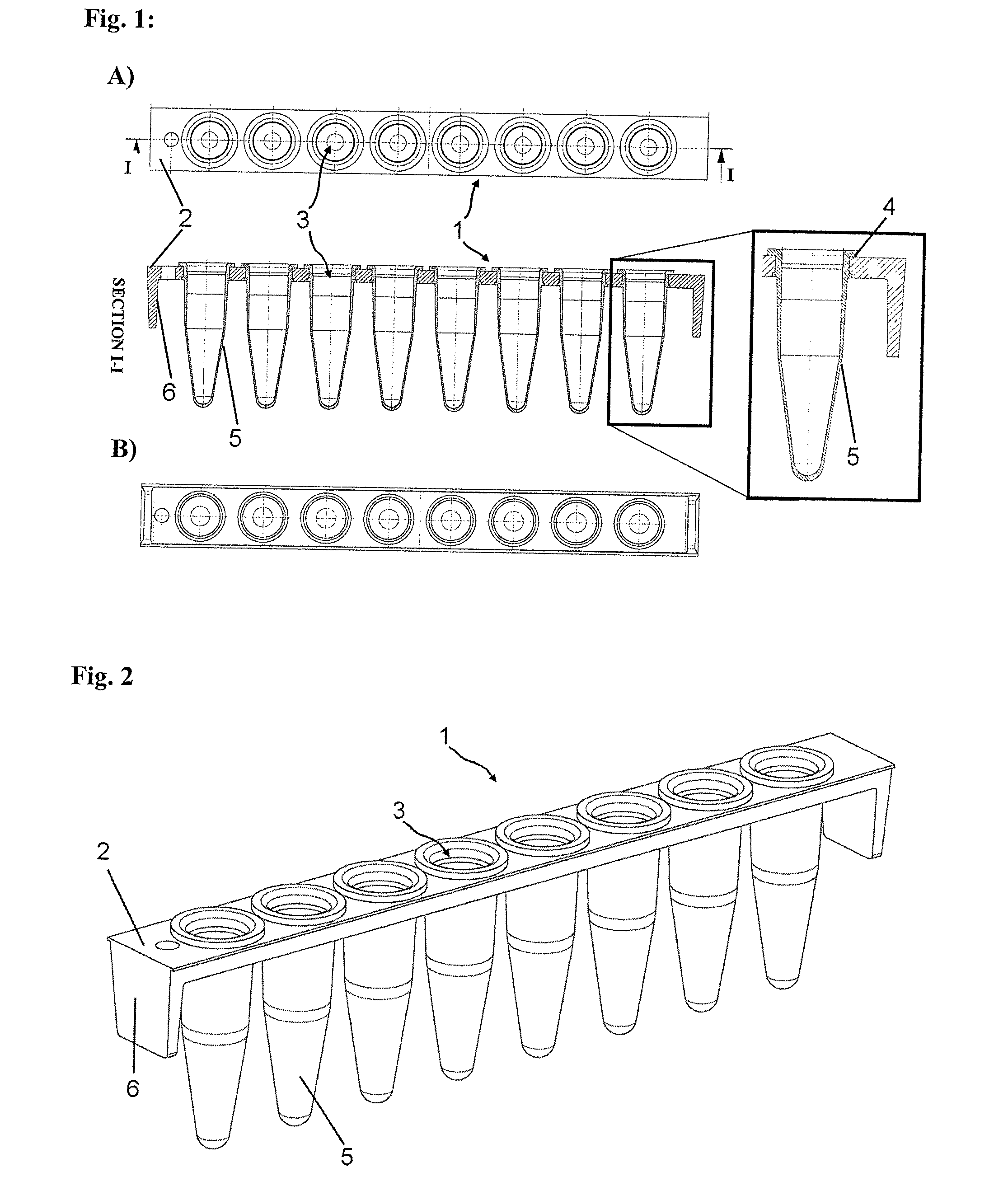

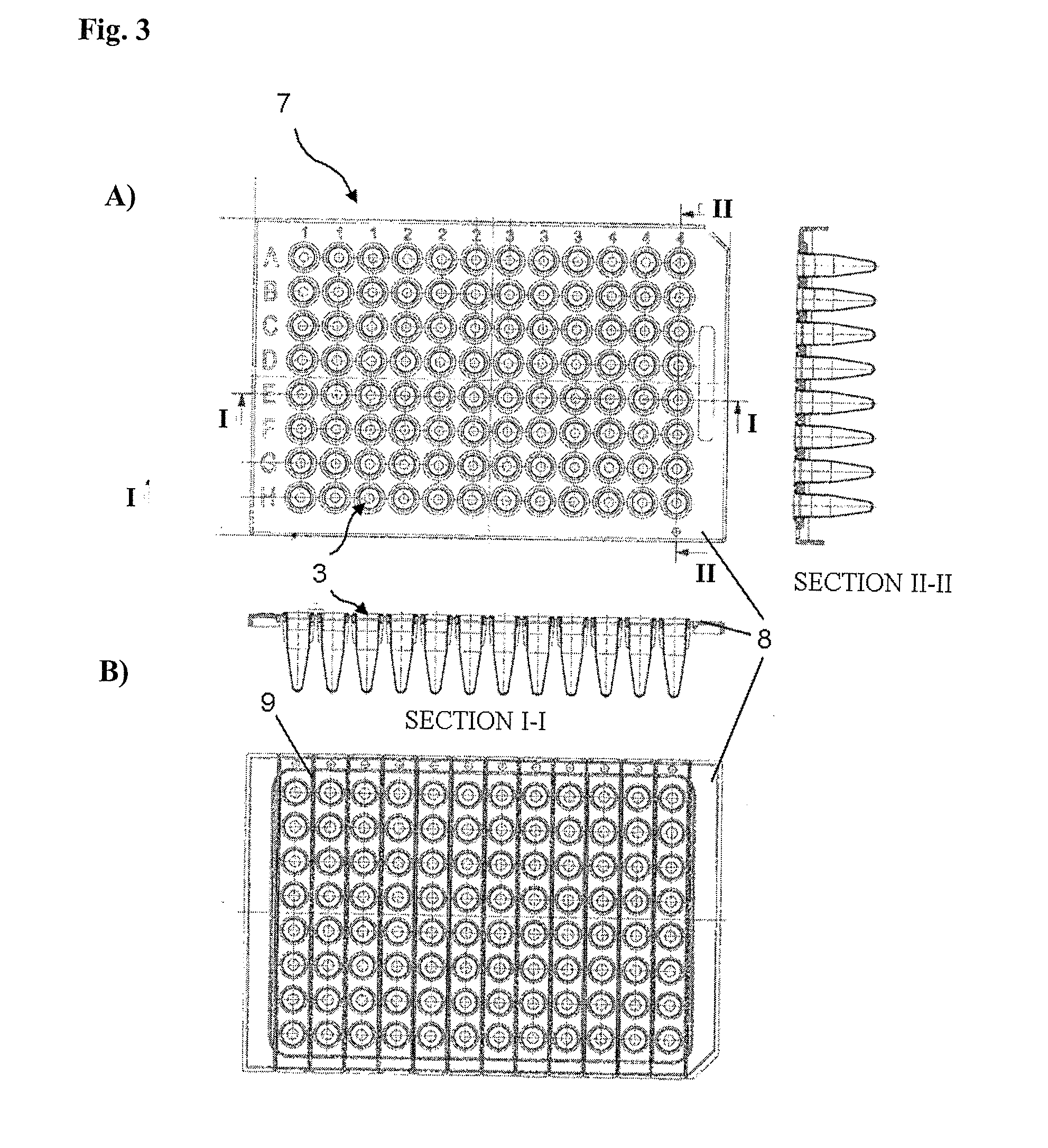

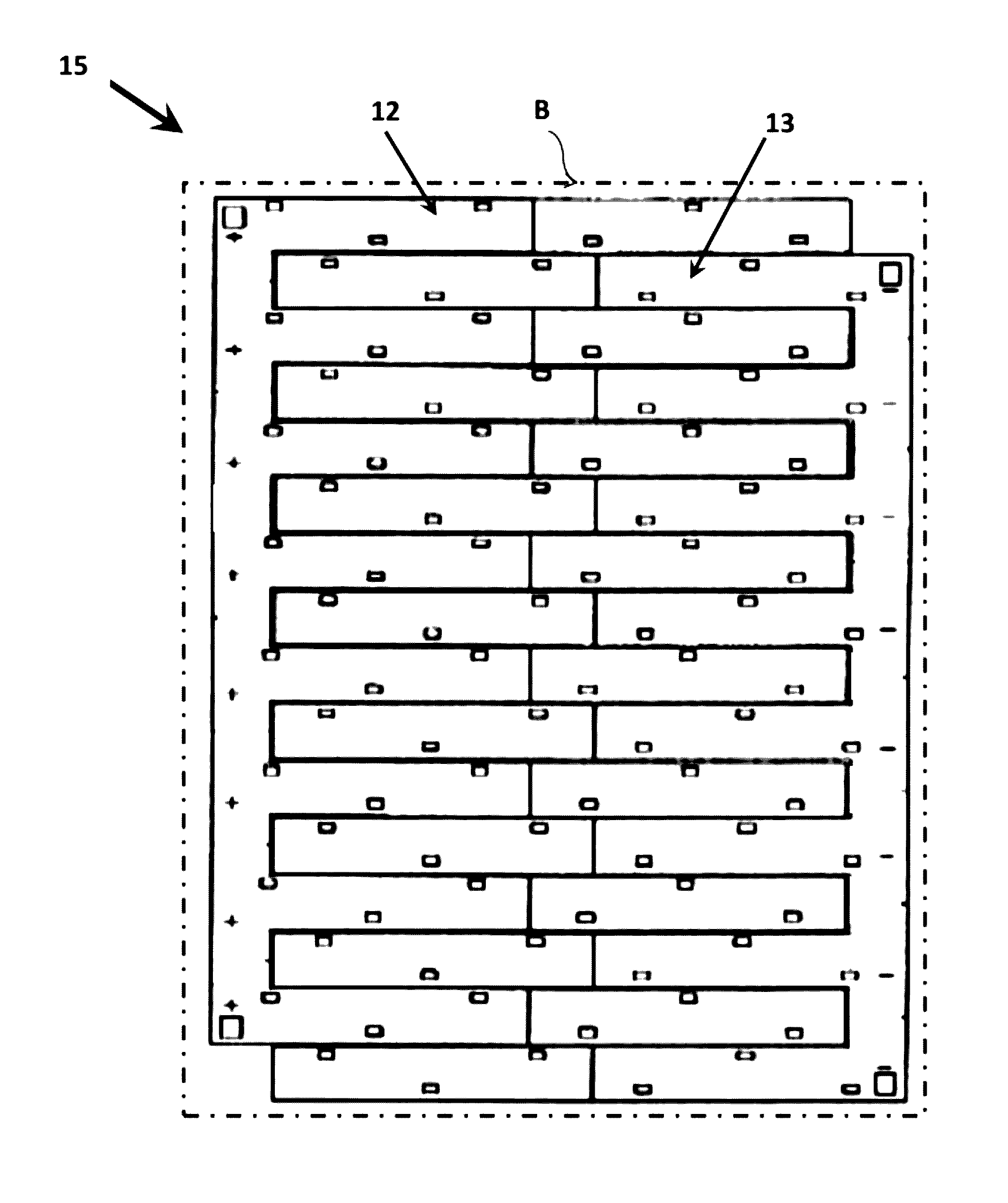

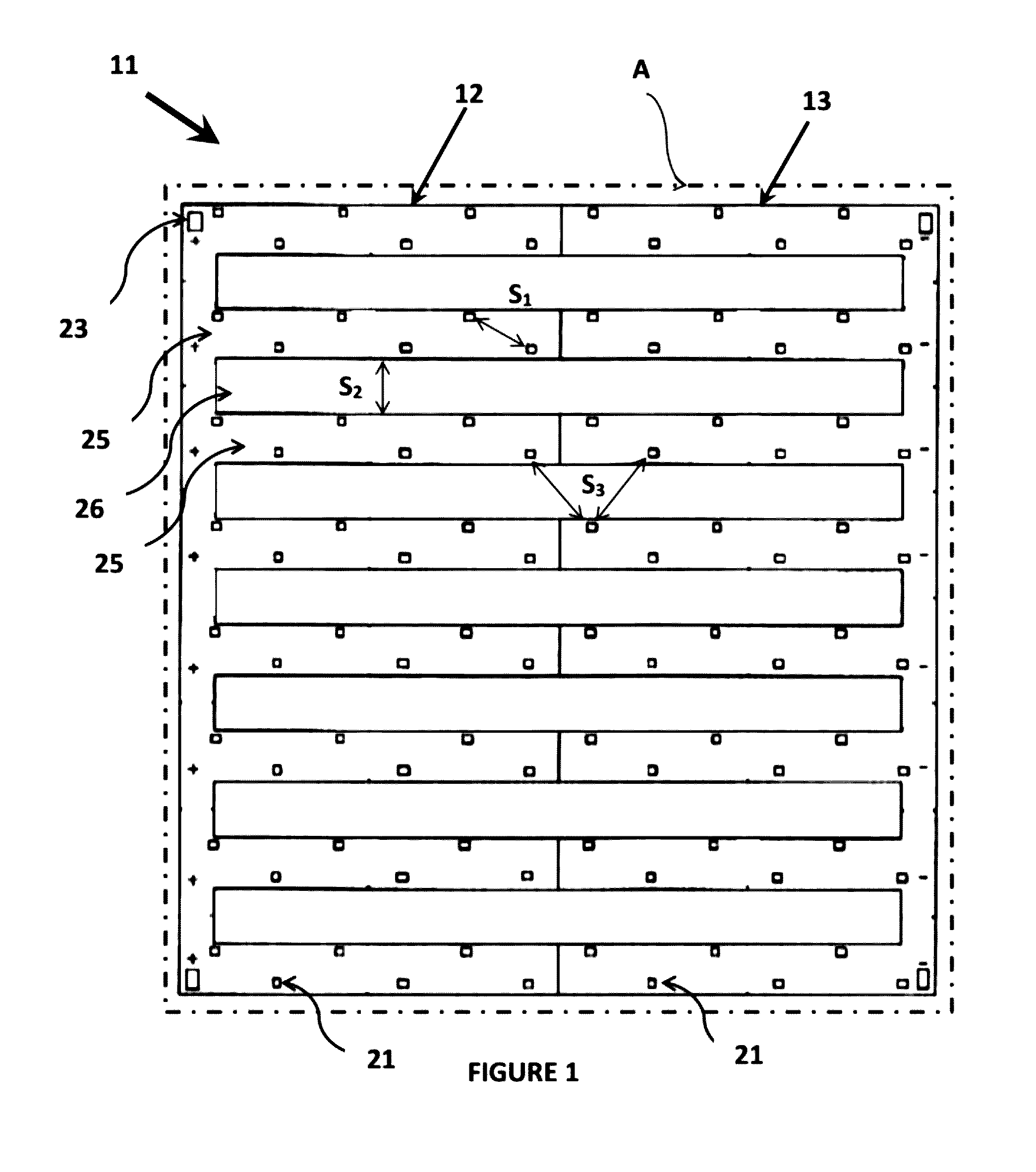

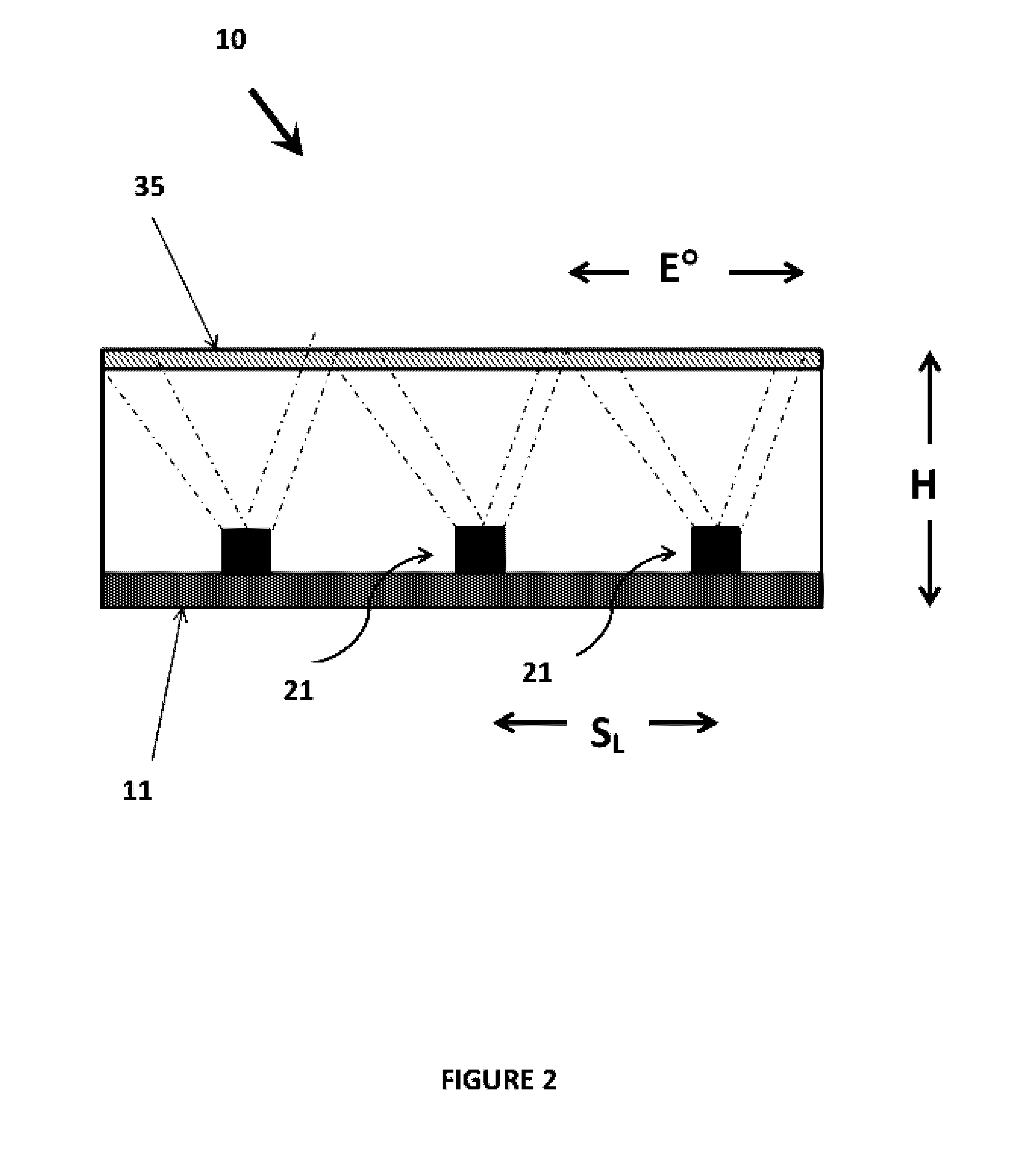

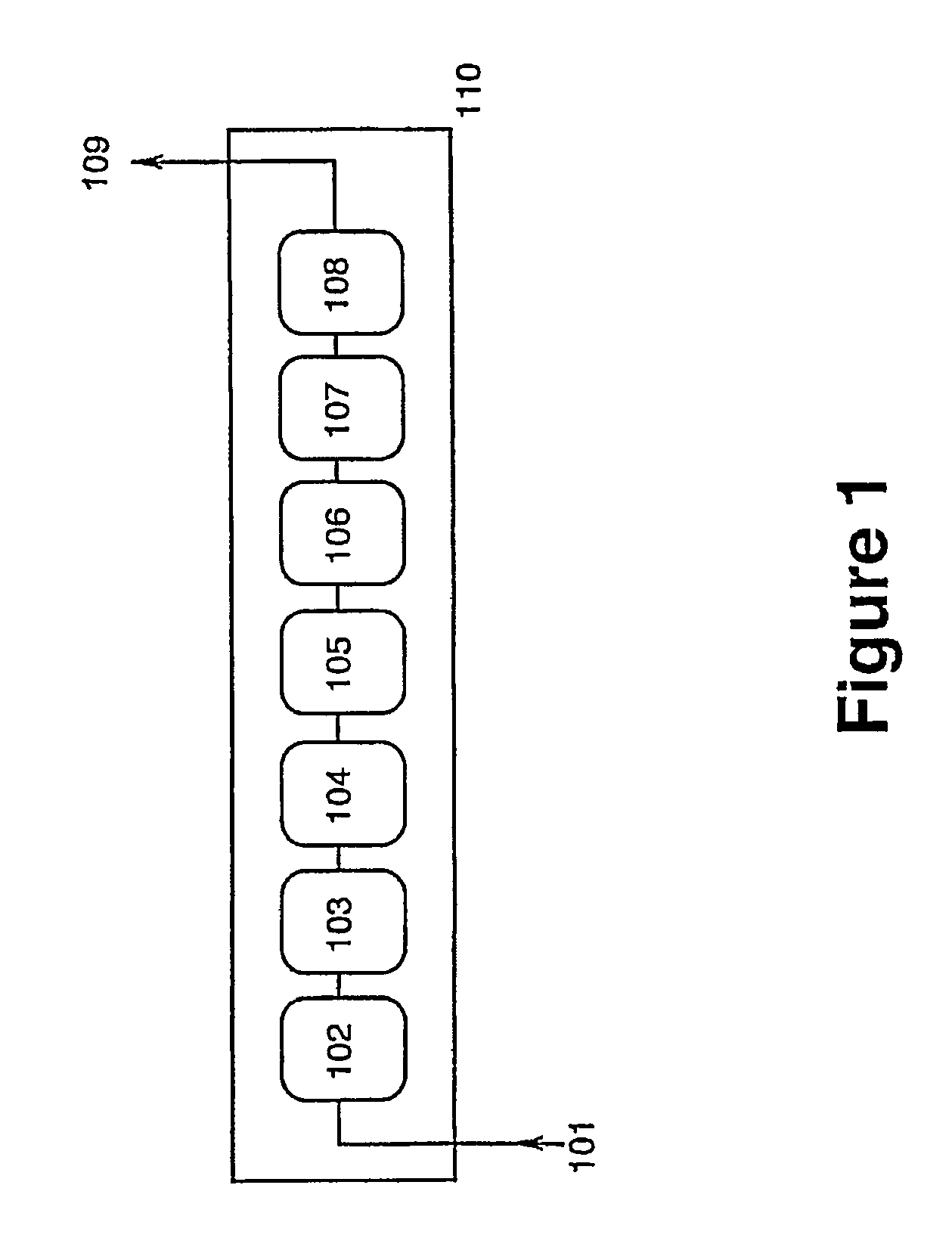

Multiwell strips

InactiveUS20130029343A1Facilitate optimal thermal transferRapid temperature measurementMicrobiological testing/measurementLaboratory glasswaresEngineering

Owner:4TITUDE

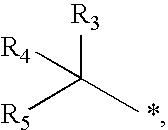

Method of increasing the oxidation stability of biodiesel

InactiveUS20060218855A1Improve Oxidation StabilityEasy to processOrganic chemistryFlushing devicesBiodieselHydrogen

The invention relates to a method of increasing the oxidation stability of biodiesel, which comprises adding a primary antioxidant having a melting point of less than or equal to 40° C. to the biodiesel to be stabilized in an amount of from 10 to 20 000 ppm (w / w), where the primary antioxidant comprises at least one compound having the structure where: R1, R2=hydrogen, a linear alkyl group having from 1 to 20 carbon atoms or where * is a carbon atom of the aromatic ring system, R3, R5=hydrogen, a linear alkyl group having from 1 to 20 carbon atoms, R4=hydrogen, a linear alkyl group having from 1 to 40 carbon atoms, where both the substituents of the type R1 and R2 and those of the type R3 and R5 are in each case identical or different.

Owner:DEGUSSA AG

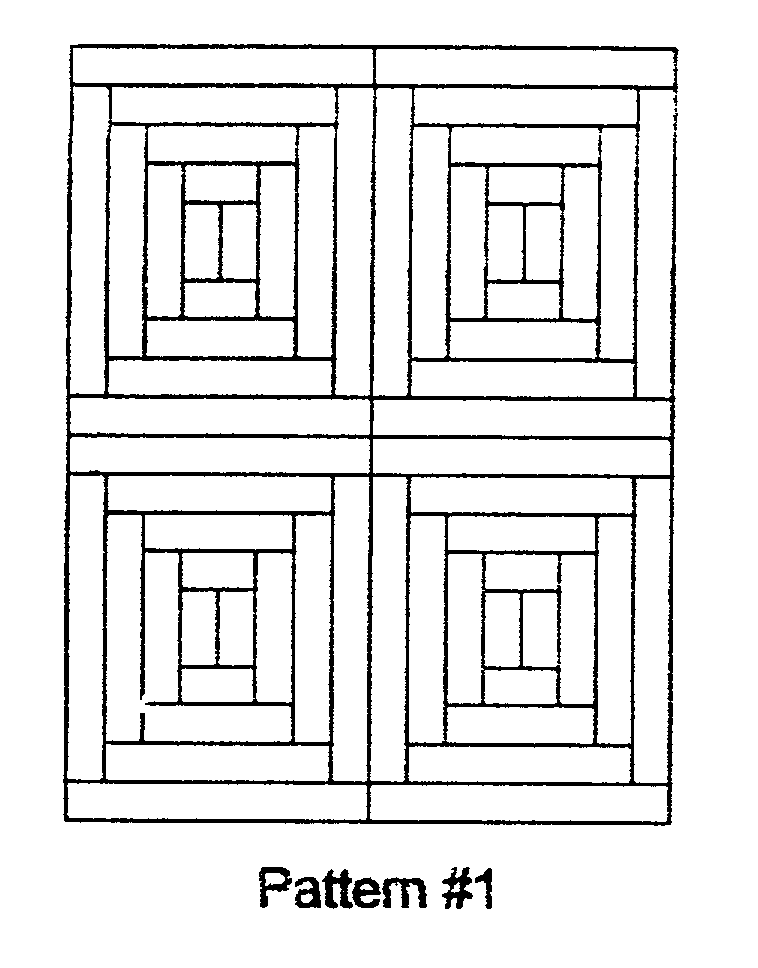

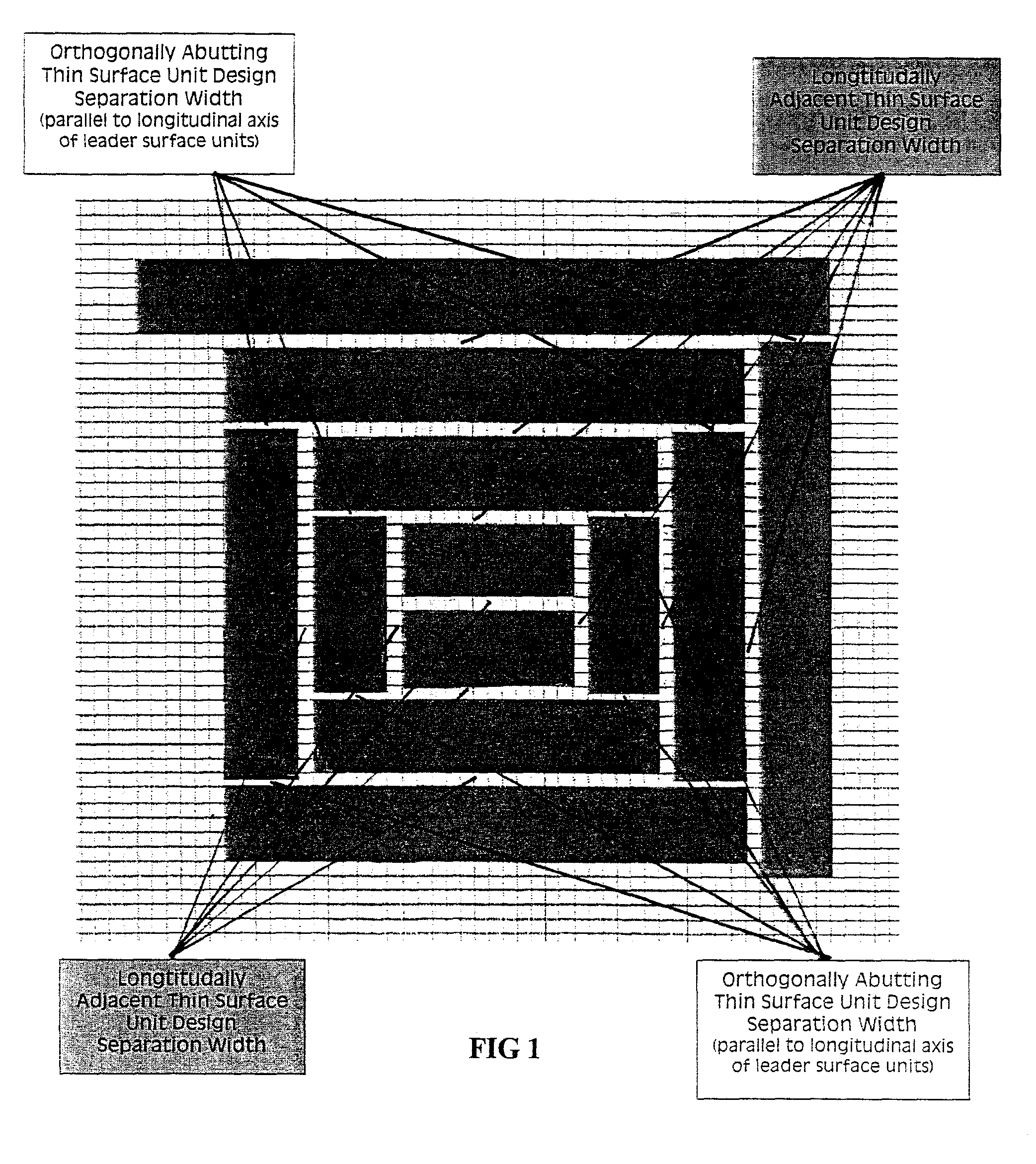

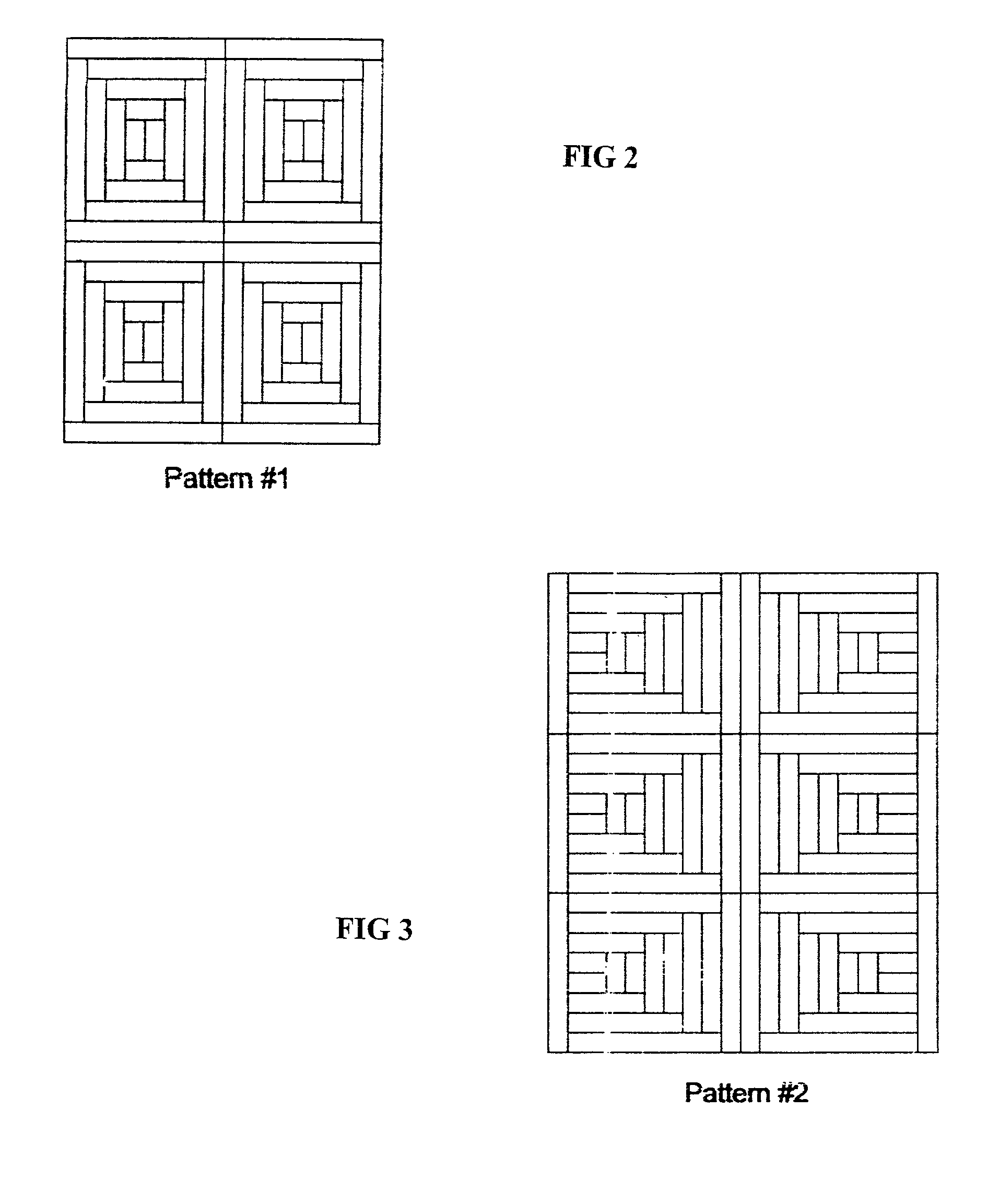

Relationally predimensioned stone surfacing system

InactiveUS7823358B2Improve overall surfacing processMinimize material wasteCovering/liningsDecorative surface effectsSurface finishingUnit system

A surfacing system including both methods and apparatus may in some embodiments comprise a single width relationally sized surfacing system and associated design patterns that involve discrete stone surface units in several embodiments. In at least one embodiment, surfacing units are stone. A multi-width surfacing unit system is also included as part of the invention, as are associated design patterns. Other embodiments include surface unit packaging apparatus and methods that reduce surface unit transport costs and breakage.

Owner:BUFFALOSTONE

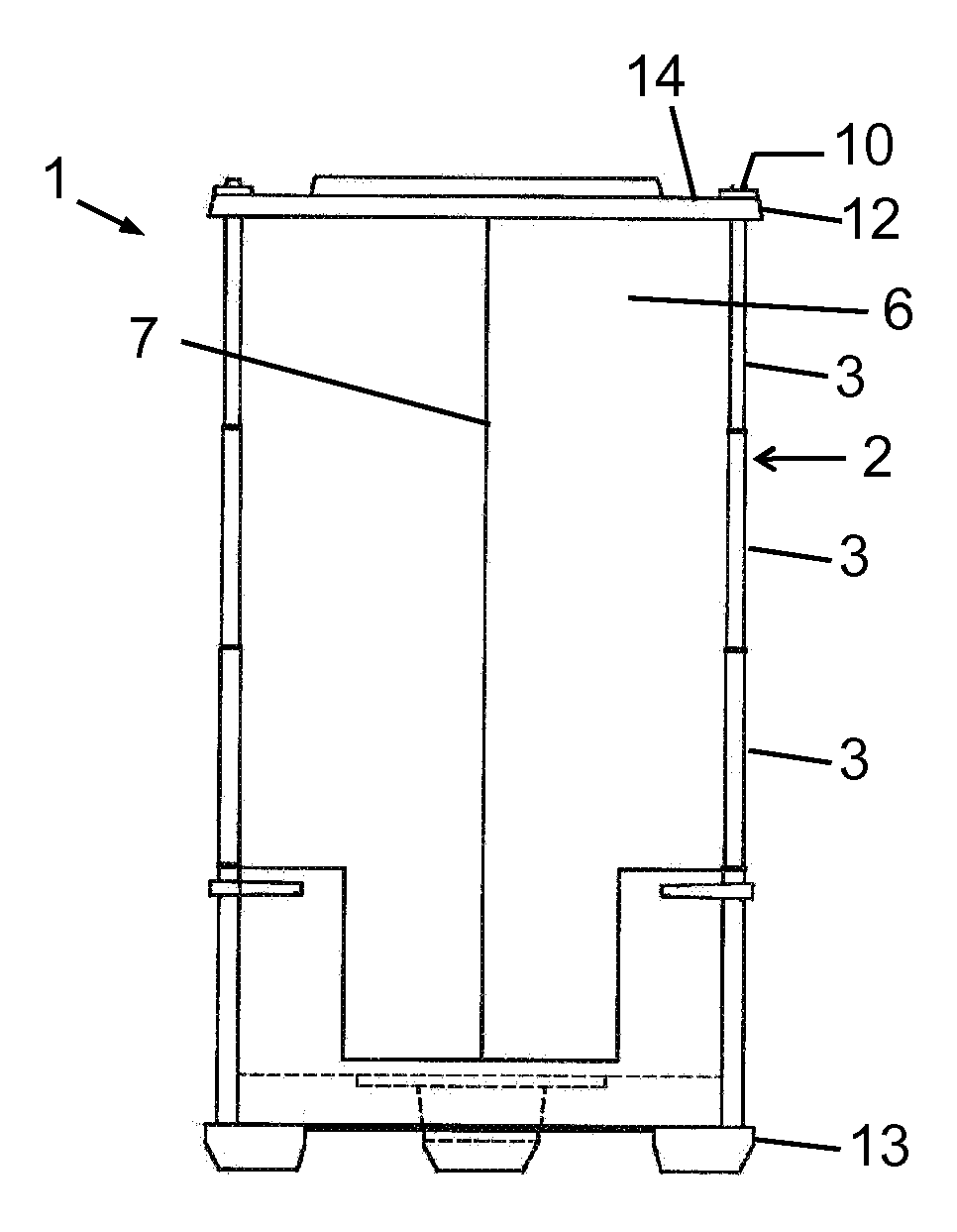

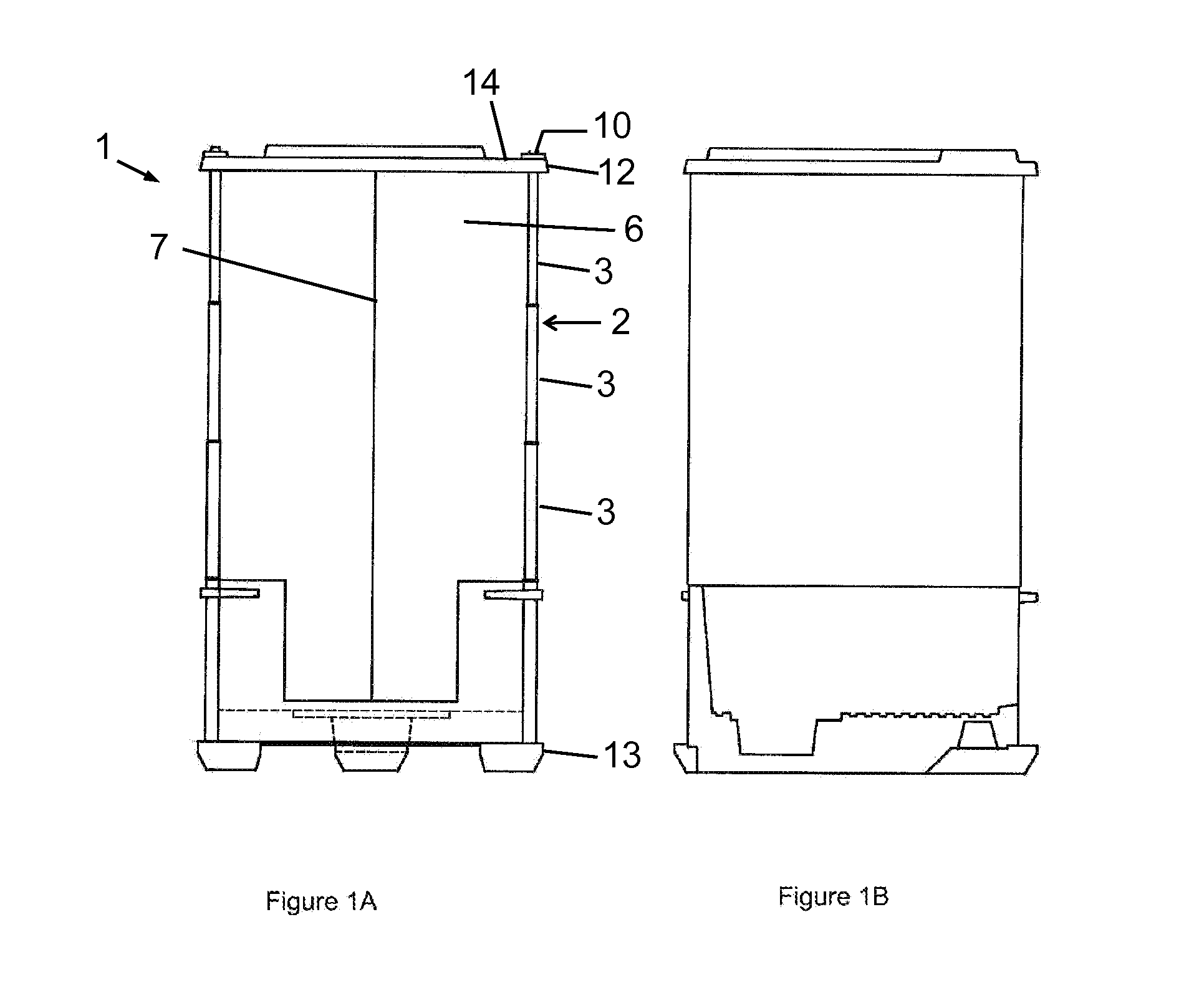

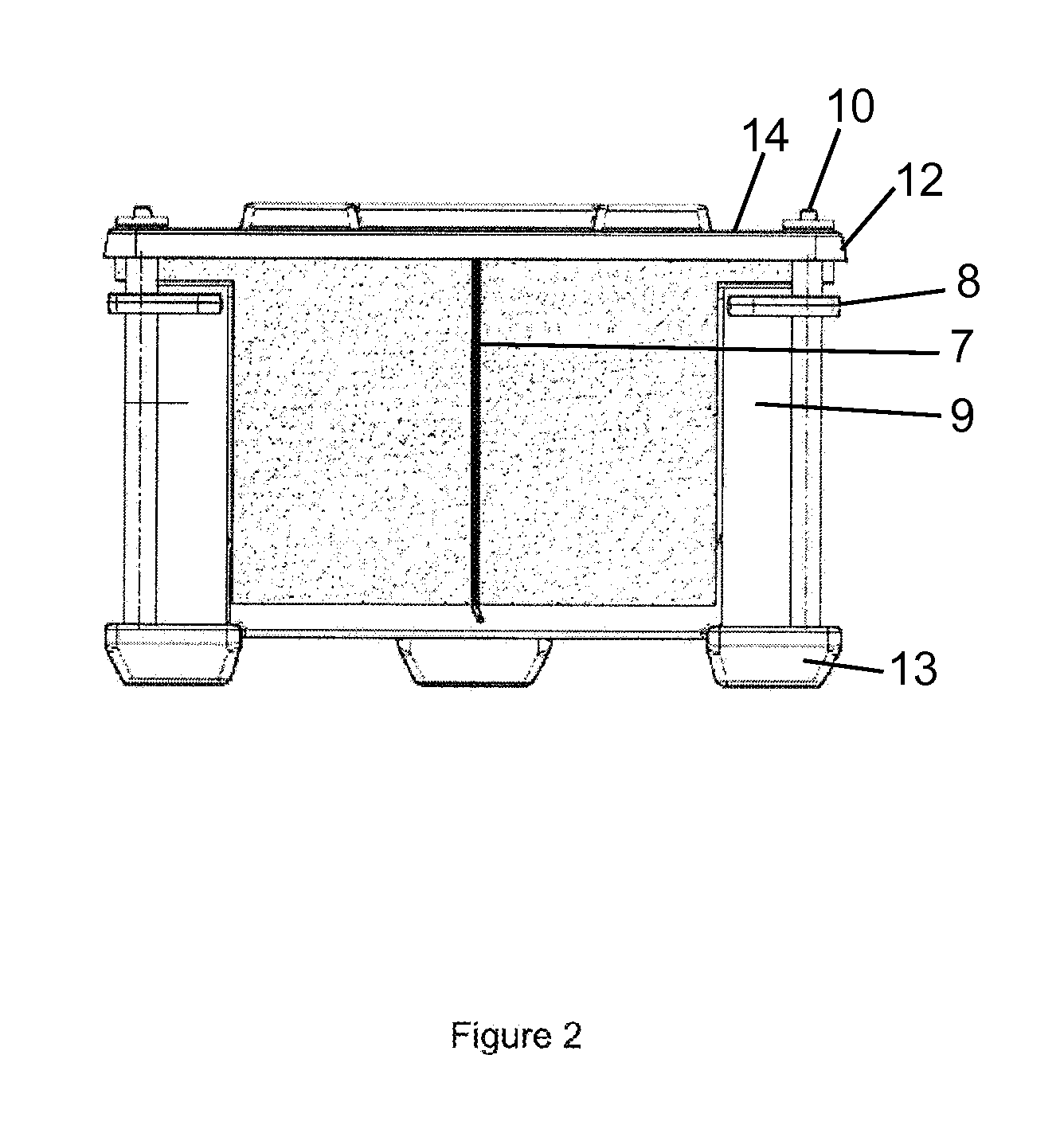

Foldable and stackable bathroom cabin

InactiveUS20130055499A1Easy and simple transportationEasy to foldBathsDouchesEngineeringHolding room

The invention relates to a foldable and stackable bathroom cabin having multiple purposes such as a dressing room and a storage room, as toilet and shower; which can be connected directly to the waste discharge network. It is equipped with four telescopic columns, foldable in sections controlled by means of casings, with securing mechanisms ending in the corresponding end deployment stops on the upper part of said columns. It is equipped with fabric tarpaulins for the walls and zipper closure on its front wall; and on the upper part of said columns there are arranged four cone-shaped stops for its support and balance during stacking of said cabins in the folded state. When folded, they allow storing up to 200 cabins in a space of 5.9×6.15×5.9 metres. The cabin is equipped with fittings for use in the modes of chemical recirculating toilets; squat toilets; dry toilets with mechanical waste discharge; and vacuum toilets.

Owner:MIGUEL SERDA JOAN

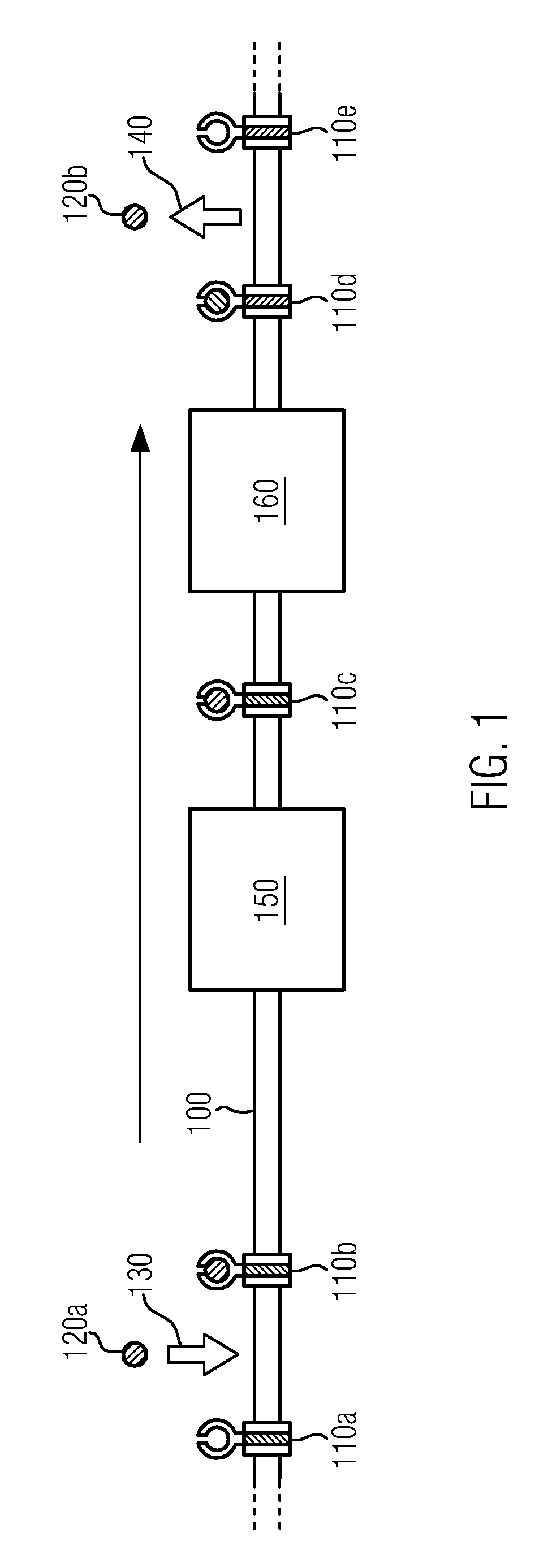

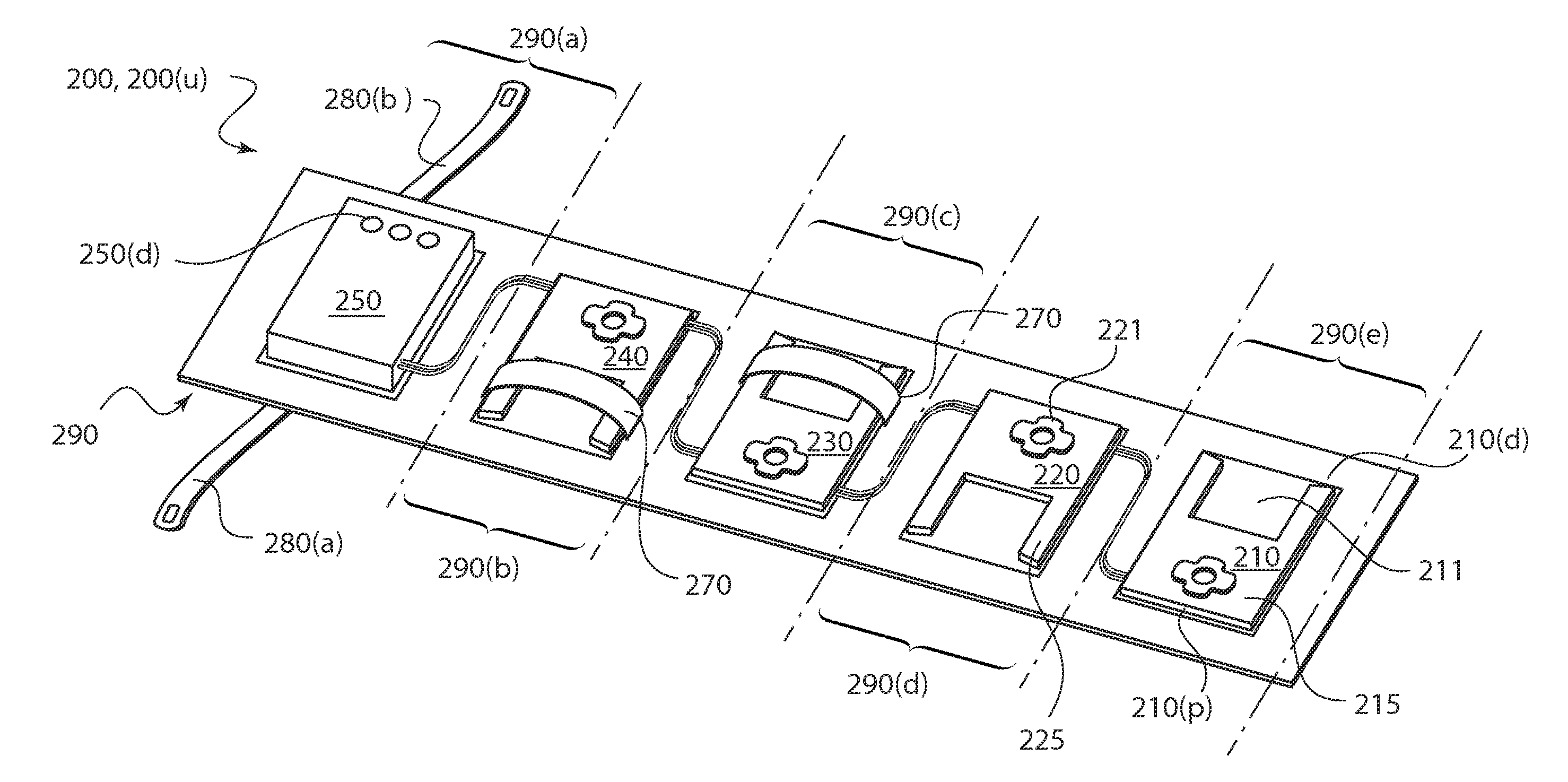

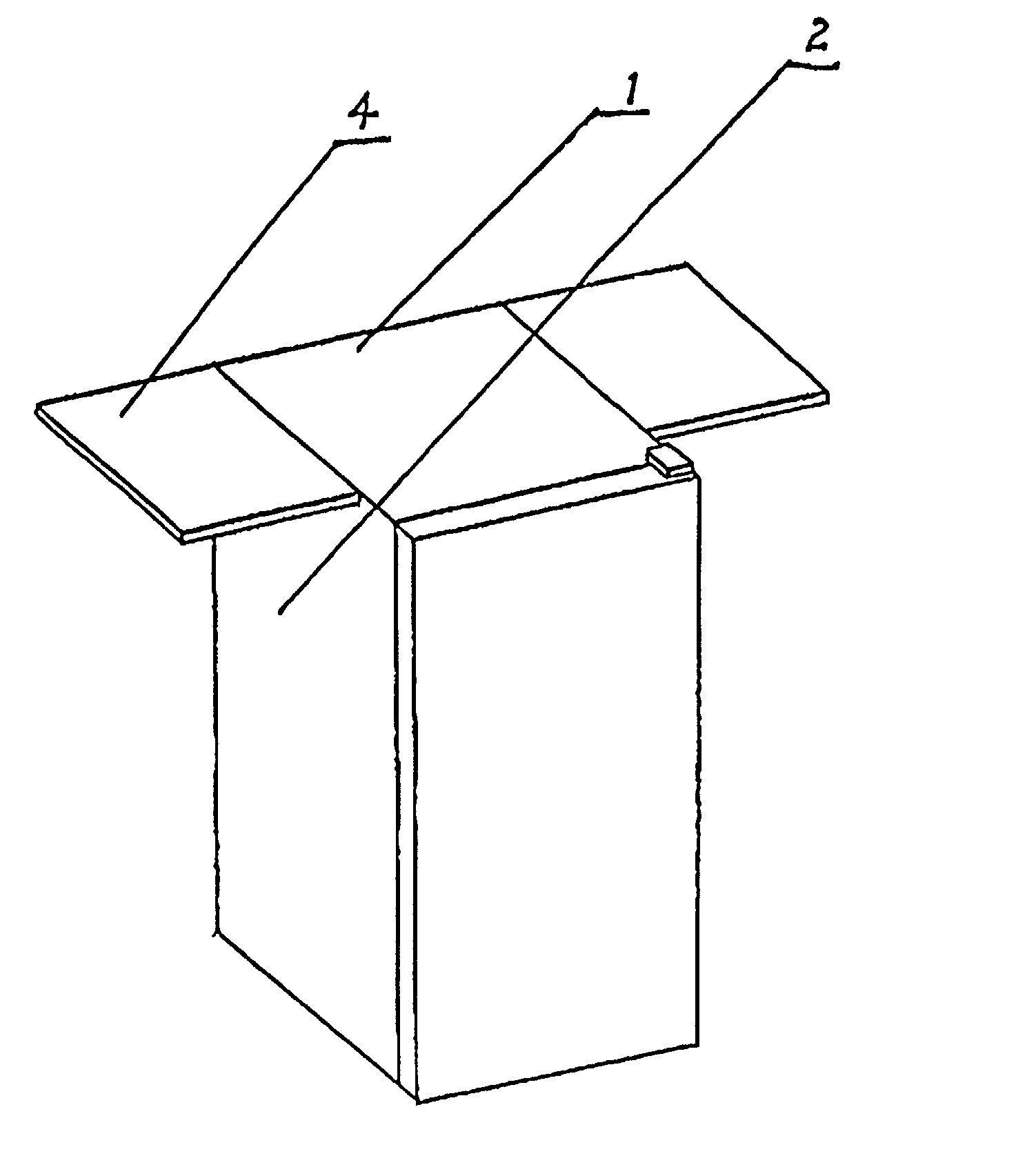

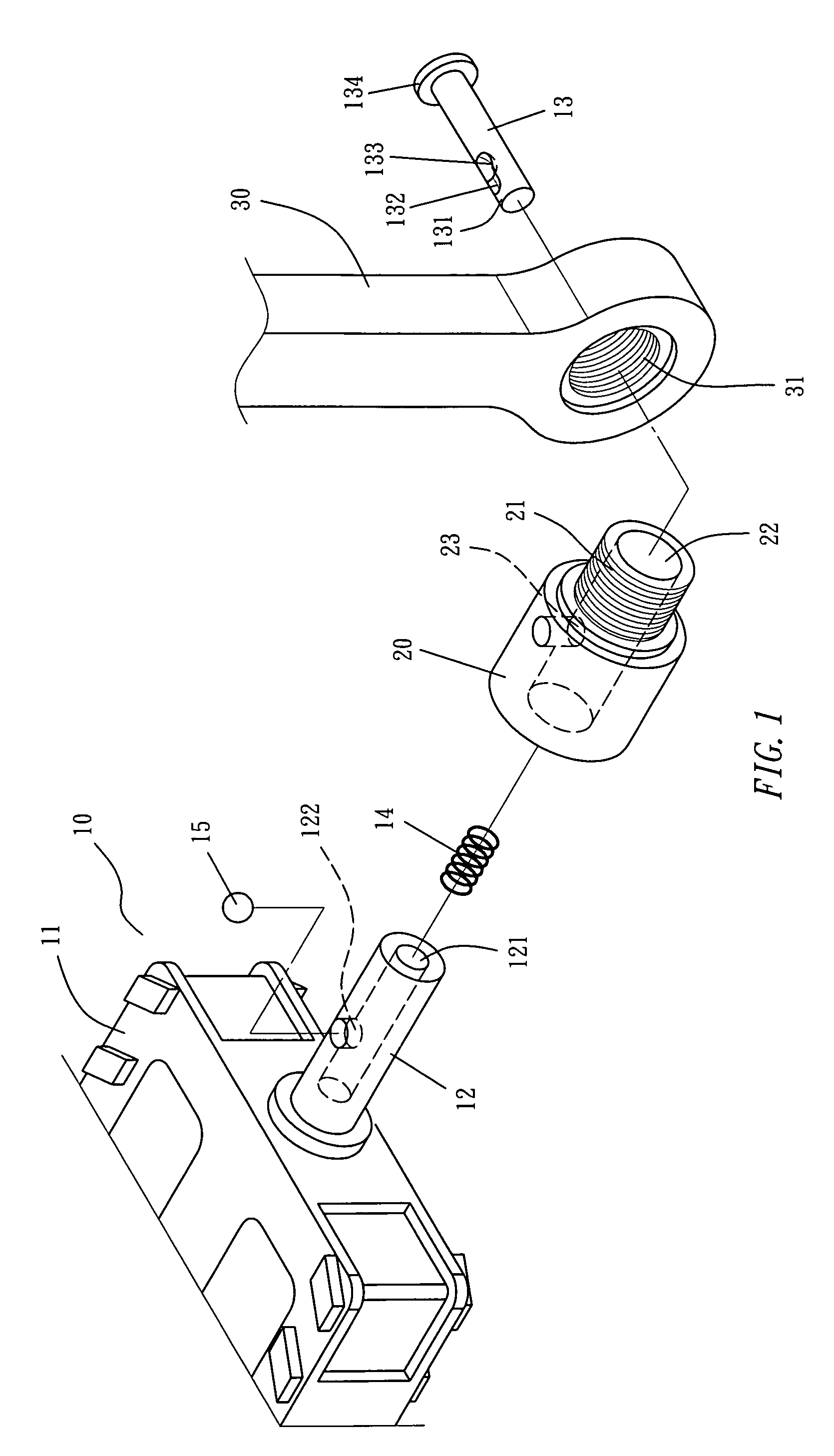

Foldable battery charger

ActiveUS20140002010A1Improve protectionIncreased durabilityBatteries circuit arrangementsElectric powerElectricityBattery charge

Owner:BREN TRONICS INC

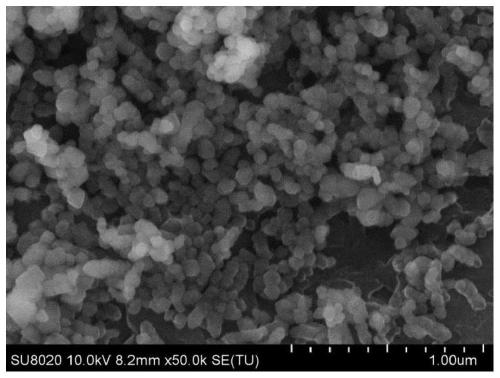

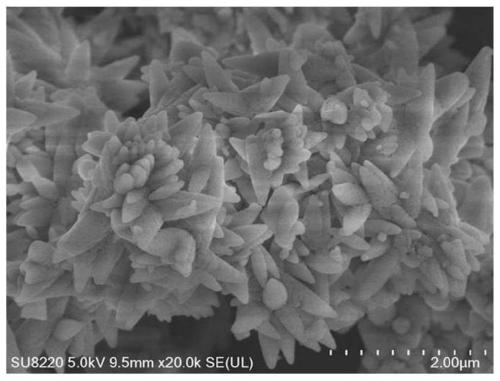

Process of preparing calcium carbonate by air bubble film method and application thereof

ActiveCN109824076AIncrease chance of contactIncrease reaction rateCalcium/strontium/barium carbonatesMaterial nanotechnologyDispersityCalcium hydroxide

The invention discloses a process of preparing calcium carbonate by an air bubble film method and application thereof and belongs to the technical field of preparation of inorganic nonmetal calcium carbonate powders. The process herein comprises carbonization and surface treatment; refined calcium hydroxide slurry is quickly carbonized in an air bubble film quick carbonizing reactor; a slurry fromthe reaction is subjected to suitable surface treatment as required; the treated slurry is filtered, drying is carried out before crushing, and screening is performed to obtain calcium carbonate powder uniform in particle size. The process herein has no need for adding a crystal form control agent; the crystal morphology is controllable; the finished product has uniform particle size and good dispersity; the process is simple and feasible and has low production cost; the prepared calcium carbonate powder is applicable to the industries of plastics, rubber, papermaking, foods, medicine, and cosmetics, and has good economic and social benefits.

Owner:GUANGXI UNIV +1

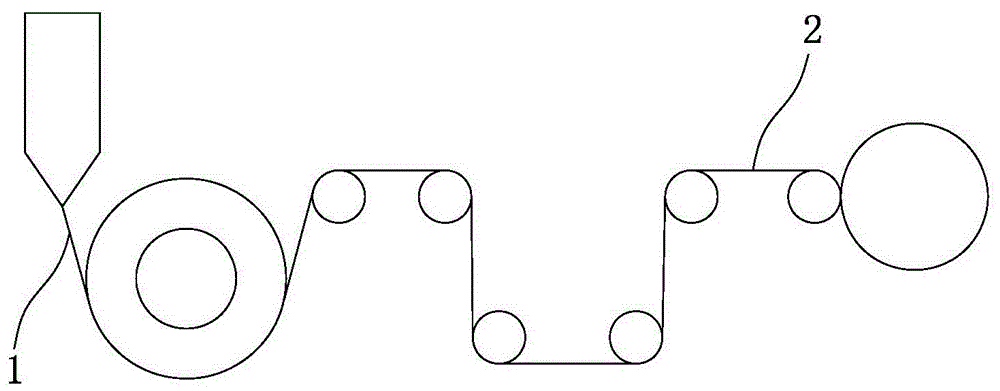

Production method for perforating thin film and vacuum perforating device of production method

ActiveCN106064490AThe role of preventing secondary pollutionReduce surface temperatureFlat articlesMetal working apparatusRoom temperaturePressure difference

The invention discloses a production method for a perforating thin film and a vacuum perforating device of the production method. The production method comprises the specific production steps that a cast film enters the vacuum perforating device, in a vacuum suction mouth area of a forming drum, due to the effect of inside-outside pressure difference, the perforating thin film of a funnel-shaped small hole structure is formed, and the hole shape of the perforating thin film is identical to that of a forming mesh cage on the outside of the forming drum; meanwhile, an ultrasonic atomization device located on the opposite face of the vacuum suction mouth area of the forming drum conducts surface spray cooling on the perforating thin film with small holes, and thus the surface temperature of the perforating thin film is lowered to 50 DEG C-room temperature; and according to the production method, the shape of the vacuum-perforated perforating thin film of the small hole structure can be set fast, flattening deformation does not occur to the perforating thin film when the perforating thin film enters a tension control procedure and a mechanical perforating procedure, and thus fast and synchronous production of small hole vacuum perforating production and large hole mechanical perforating production is achieved. Therefore, the functions of energy saving, cost reduction, improving of production efficiency and prevention of material secondary pollution are achieved.

Owner:XIAMEN YANJAN NEW MATERIAL CO LTD

Foldable battery charger

ActiveUS9160183B2Save on transportationClearance can be providedBatteries circuit arrangementsElectric powerElectricityBattery charge

Owner:BREN TRONICS INC

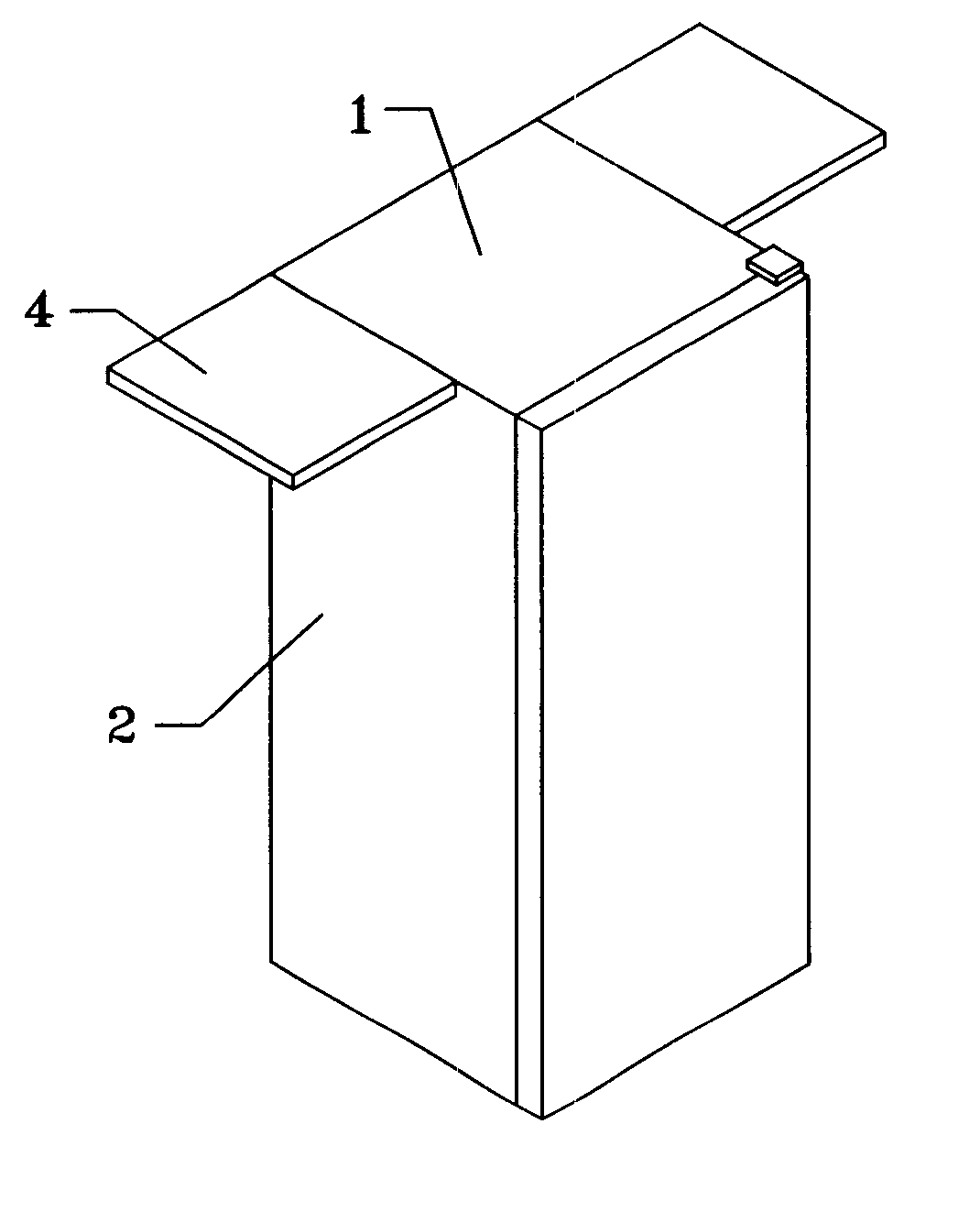

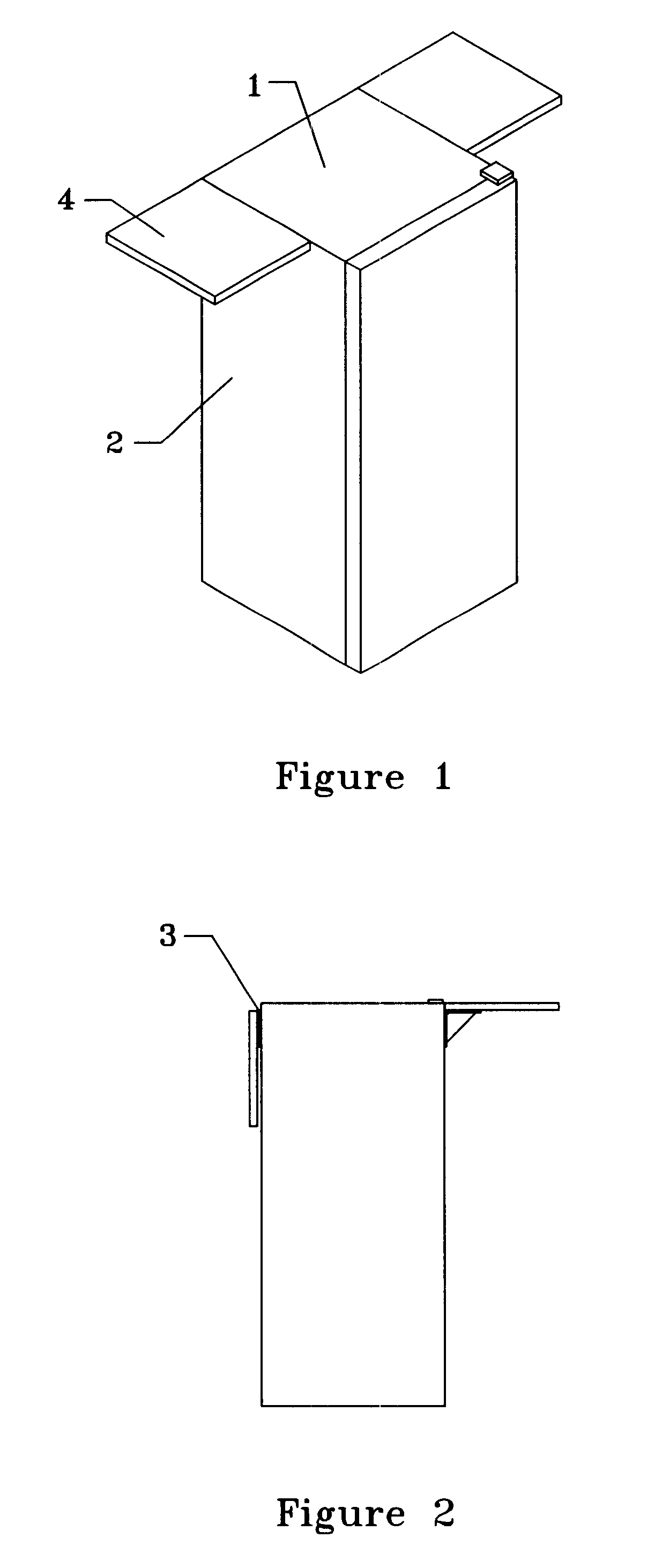

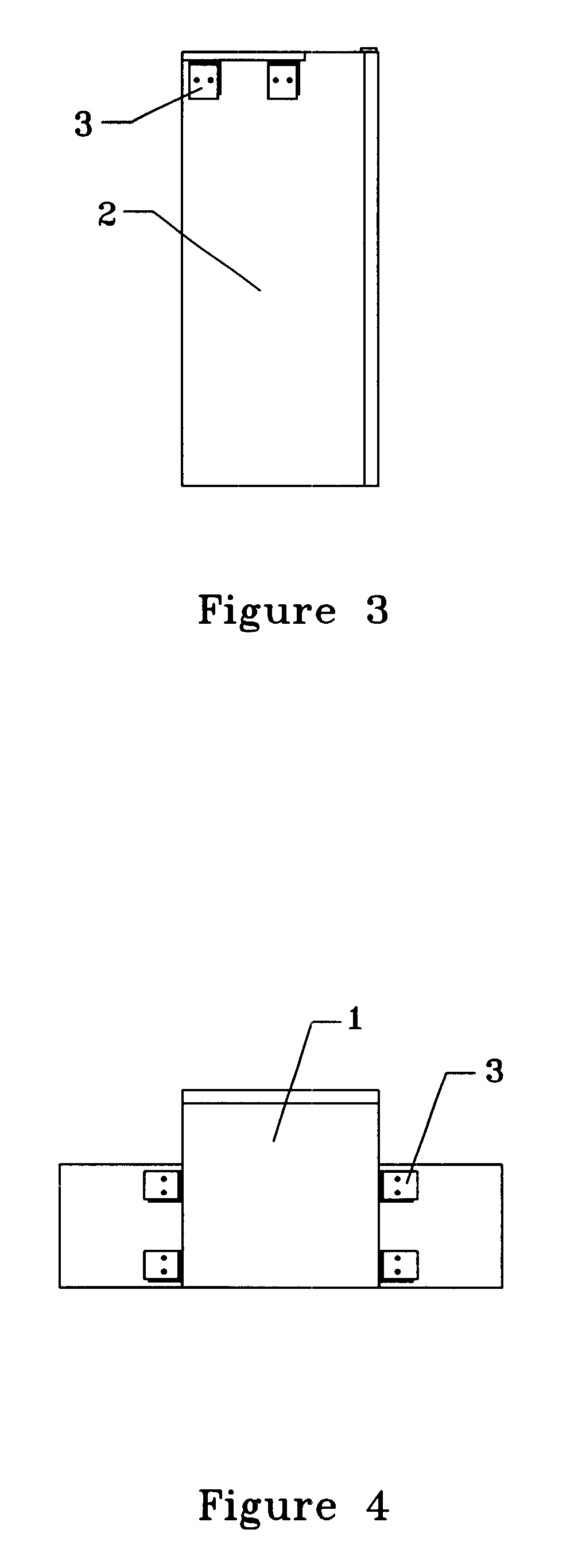

Refrigerator with a foldable table

InactiveUS6532756B1Save spaceLow costLighting and heating apparatusFurniture partsEngineeringRefrigerated temperature

This invention relates to a refrigerator with a foldable table, wherein the table can be unfolded when it is needed and can be folded when it is not needed. So the product of the present invention has the functions of both a refrigerator and a table, and also can save some room space providing a more reasonable room layout.

Owner:HAIER GRP CORP +1

Light emitting diode (LED) backlighting source

InactiveUS20170032717A1Low costReduced material requirementsPlanar light sourcesPoint-like light sourceEngineeringLight-emitting diode

A light emitting diode (LED) backlighting source comprising at least one circuit board electrically connectable to a power source; a plurality of LEDs electrically mounted on the circuit board and able to be powered by a connected power source; wherein the circuit board is formed of a plurality of spaced finger portions and connecting portions wherein the finger portions and the connecting portions are electrically connected.

Owner:MICHAELIDIS SPIROS

Method for the assessment of particles and a system and device for use in the method

InactiveUS8906697B2Small amountSave on transportationExhaust apparatusChemiluminescene/bioluminescenceAnalyteSpatial image

A method and a device for the assessment of at least one parameter of particles in a liquid analyte material are disclosed. The method comprises providing a device having a sample compartment with an exposing domain, an inlet through which a volume of a liquid sample representing the analyte material can been introduced, and a flow system comprising at least a channel allowing at least a portion of the volume of the liquid sample to flow within the device. The volume of the liquid sample passes into the exposing domain of the sample compartment, which can quantitatively detect spatial image data and process the detected image electromagnetic signals from the sample in the exposing domain of the device. A spatial image representation of the exposing domain, and processing the detected image presentation obtaining the assessment of the at least one parameter is generated in the device.

Owner:CHEMOMETEC AS

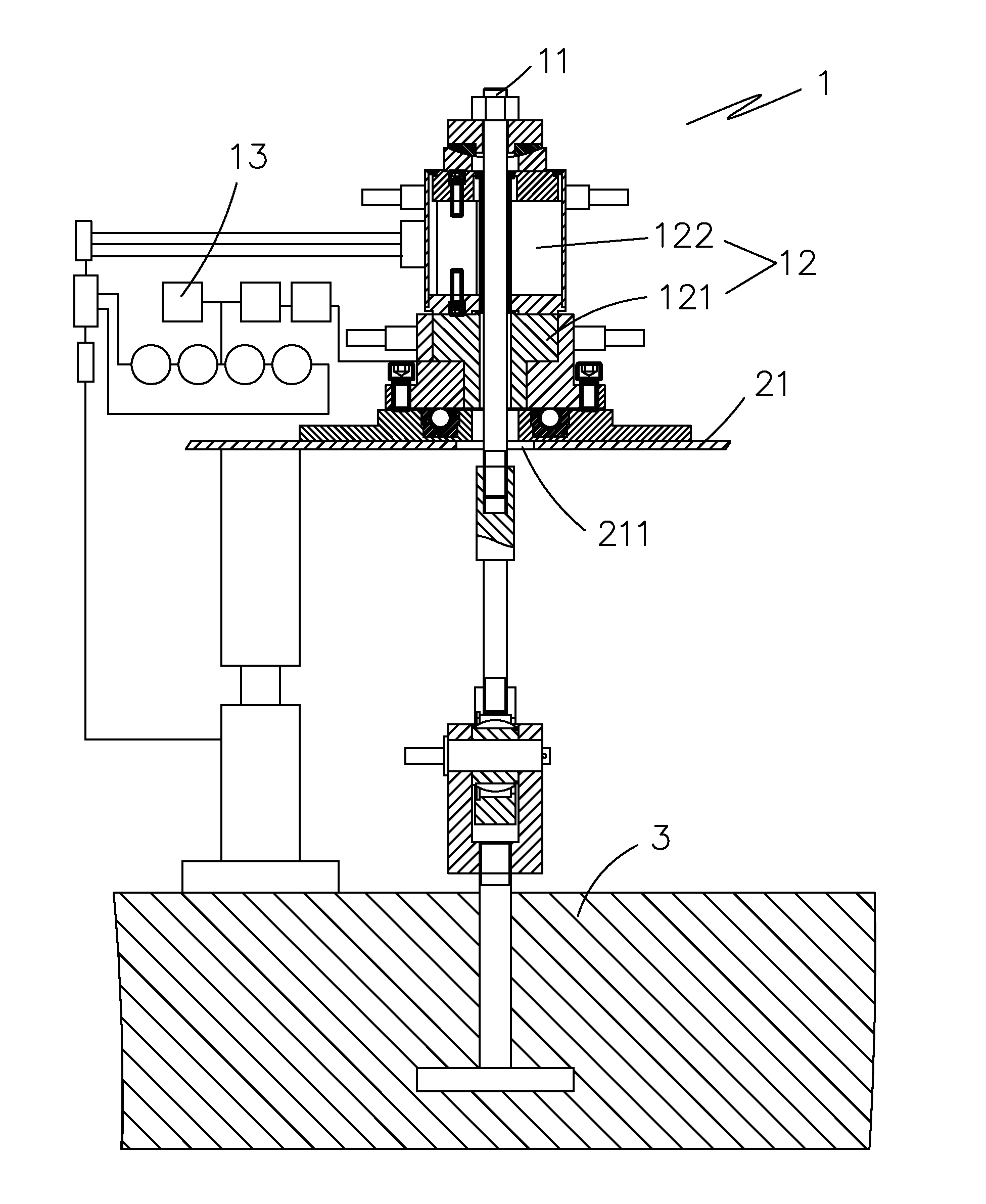

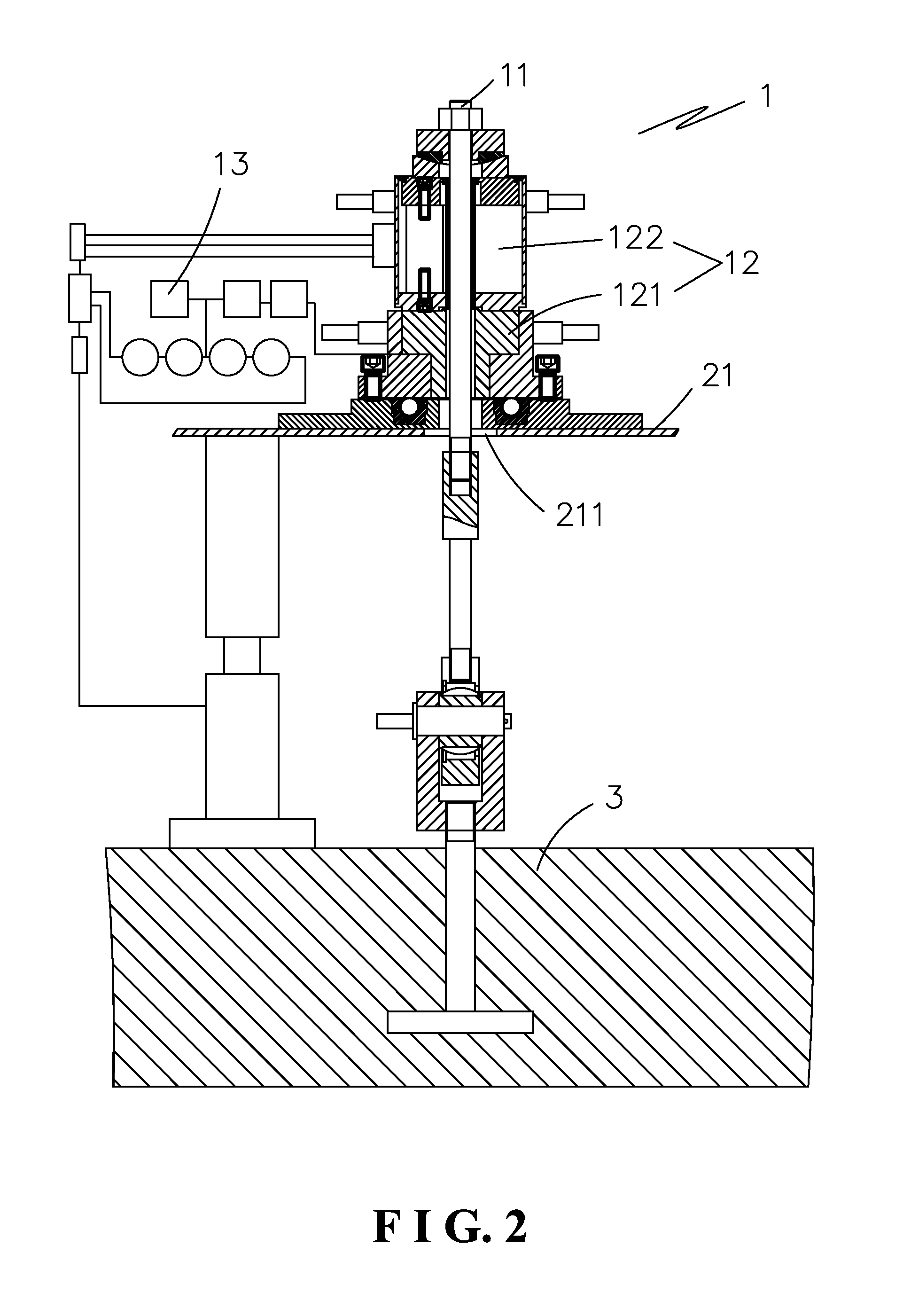

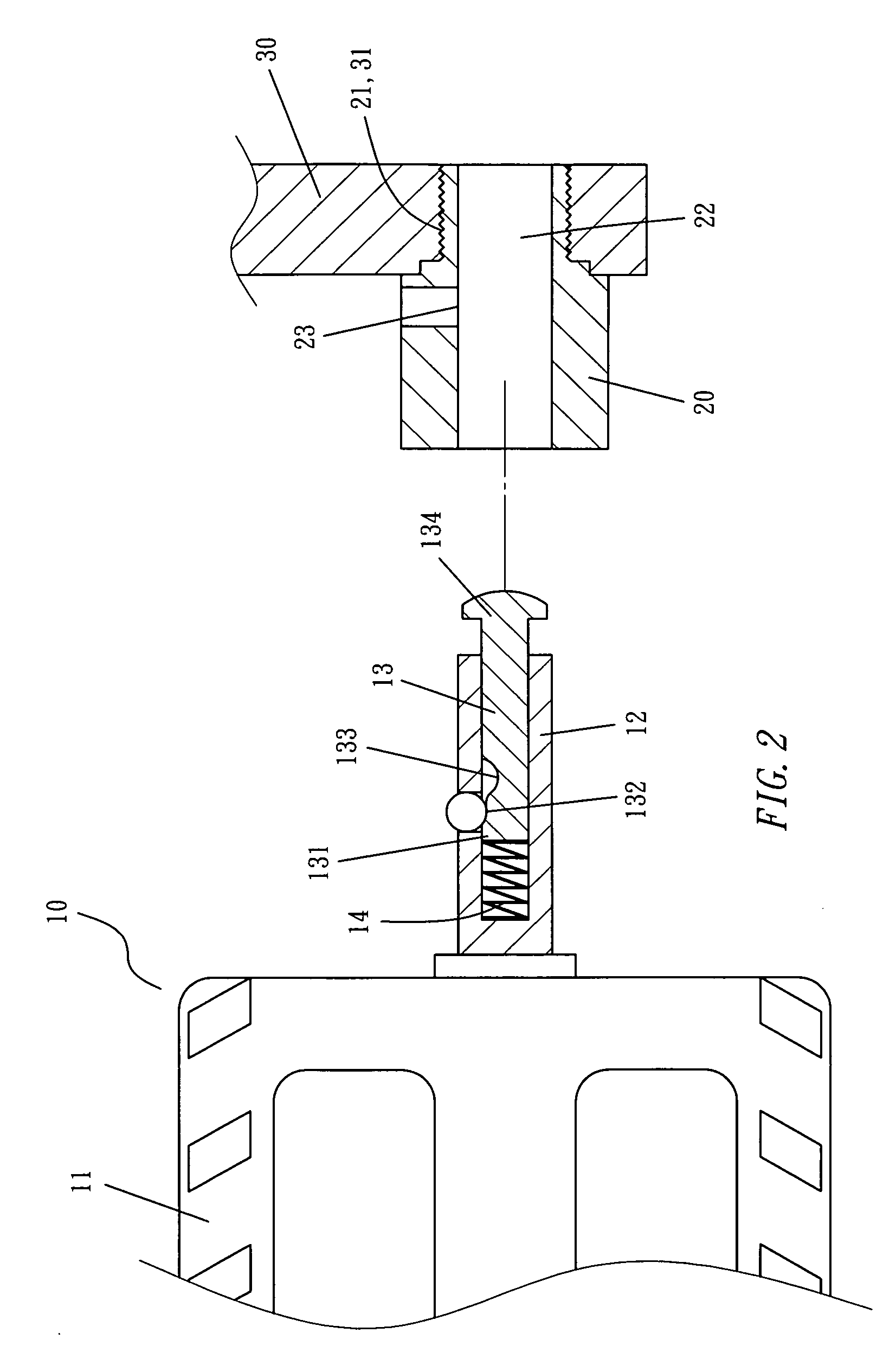

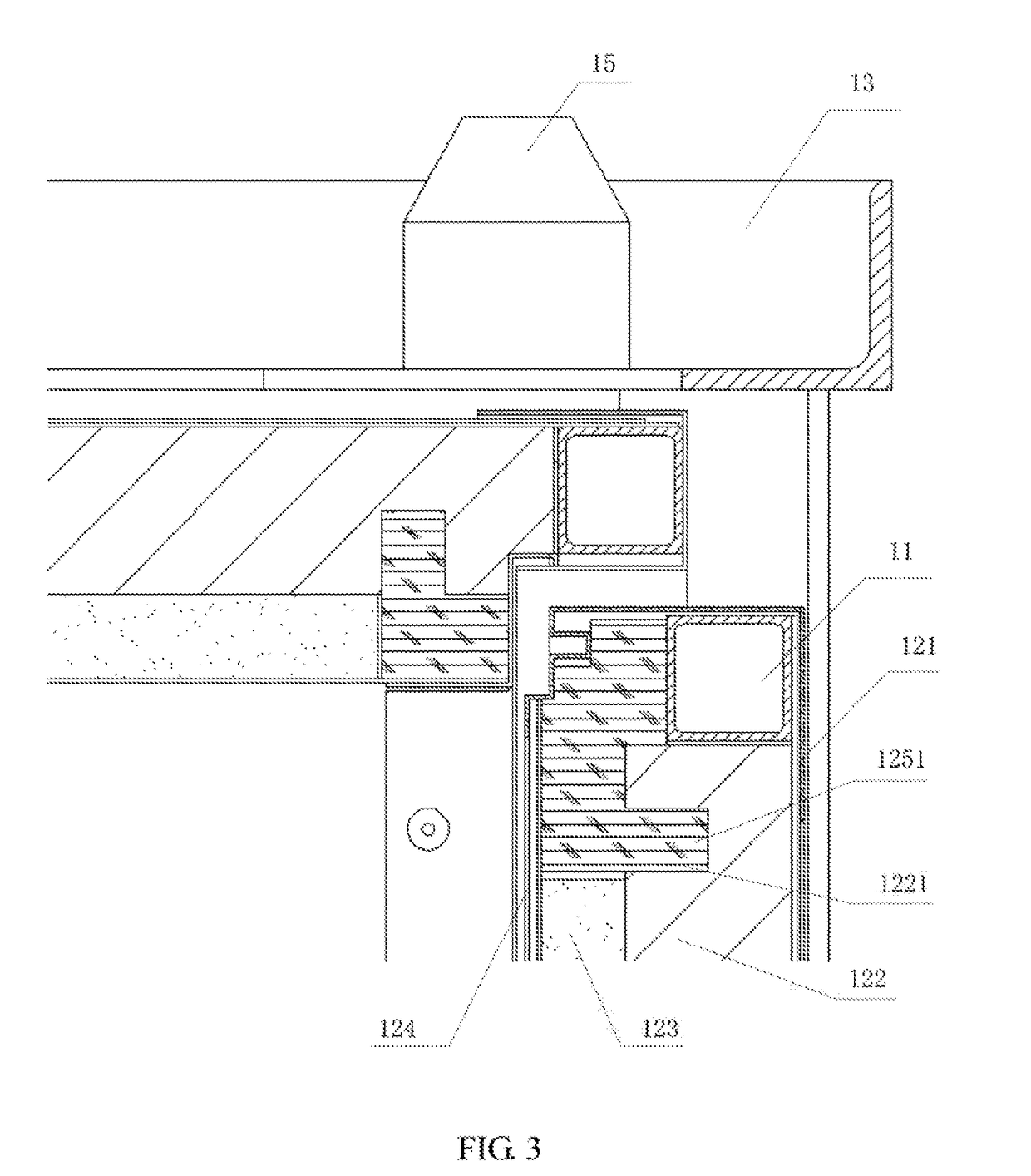

Verification system for large-scale weighing machine and self-location loading-unloading load measuring device

ActiveUS20130104620A1Improve efficiencySave on transportationWeighing apparatus testing/calibrationForce/torque/work measurement apparatus calibration/testingConstant loadMeasuring instrument

A verification system for a large-scale weighing machine comprises at least four tension frameworks penetrating through a weighing platform hole preset on a weighing platform surface of the weighing machine, for connecting to a weighing platform foundation and being disposed perpendicular to the weighing platform surface, at least four self-location loading-unloading load measuring devices disposed corresponding to the tension frameworks, and a constant-load control device connected with the loading-unloading mechanism and allows the loading-unloading mechanism to maintain constant applied load while loading. The self-location loading-unloading load measuring devices includes a self-location loading-unloading mechanism and a high-precision load measuring instrument adjacent to the top side of the loading-unloading mechanism. The high-precision load measuring instrument is at least three times larger than an accuracy of the weighing machine. The verification system has a rational structure and can greatly improve operating efficiency and safety and save cost.

Owner:FUJIAN METROLOGY INST

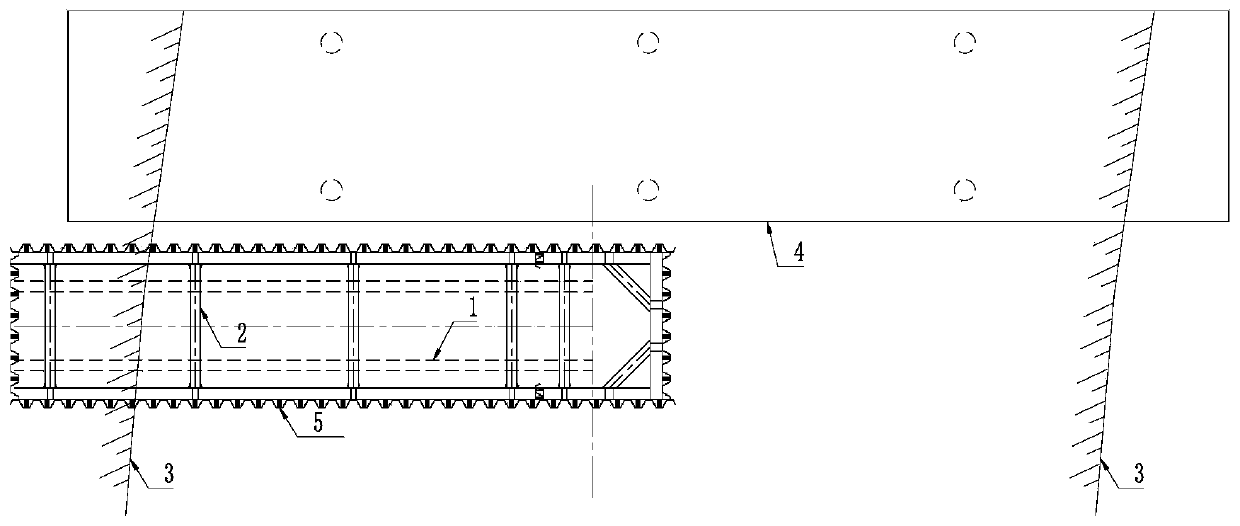

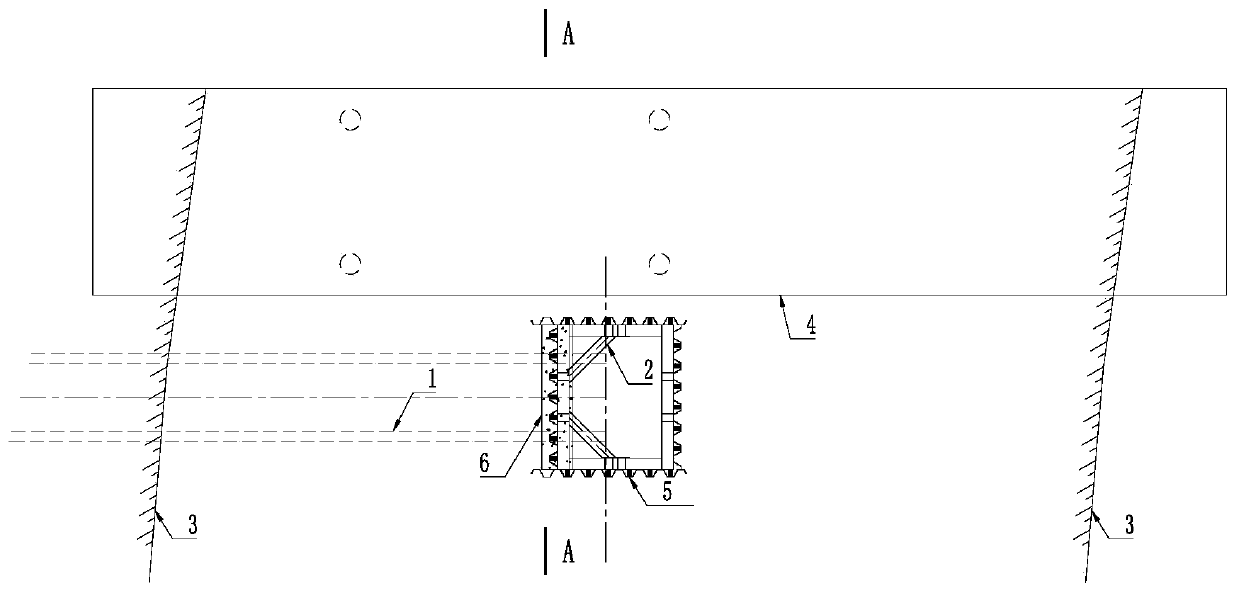

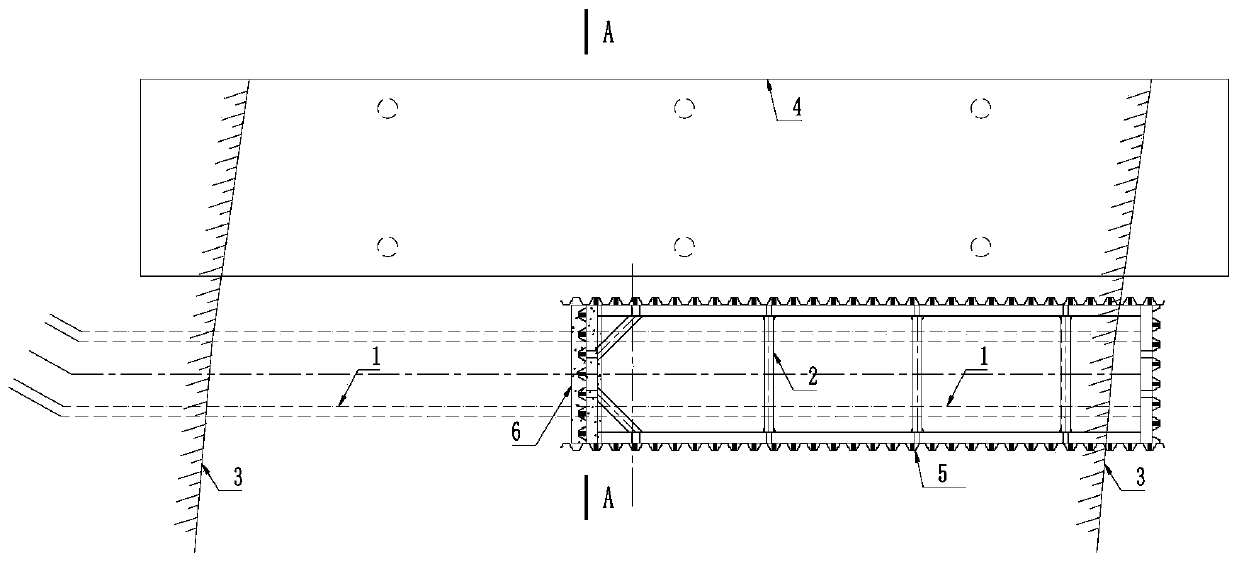

Construction method for pipe gallery to down-pass river channel

InactiveCN110565686AOmit fillingSave excavationArtificial islandsUnderwater structuresCofferdamSheet pile

The invention relates to the technical field of pipe gallery construction, and discloses a construction method for a pipe gallery to down-pass a river channel. The construction method comprises the following steps that S1, steel sheet piles are inserted from one side of the river channel to the opposite side to form a cofferdam until the end part of the cofferdam reaches a set position; S2, waterin the cofferdam is discharged, an installation groove is excavated and formed in the cofferdam, and the pipe gallery is installed in the installation groove until the pipe gallery is close to the endpart of the cofferdam; S3, a waterproof wall is arranged at the end part of the pipe gallery, a transfer weir is formed at the cofferdam through separation, moreover, the end part of the pipe gallery1 is located in the transfer weir, and the steel sheet piles not involved in the transfer weir are removed; S4: the steel sheet piles are inserted from the transfer weir to the opposite side to formthe next cofferdam until the end part of the next cofferdam is located at the next set position, the steel sheet piles at the end part of the last cofferdam are removed, and the step 2 and the step 3are performed; and S5, the step 4 is repeated until the pipe gallery is installed to the opposite side. According to the construction method, the problems of poor applicability of a flow division method, environmental damage of a phased soil cofferdam method and high cost of a pipe jacking construction method are effectively solved.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

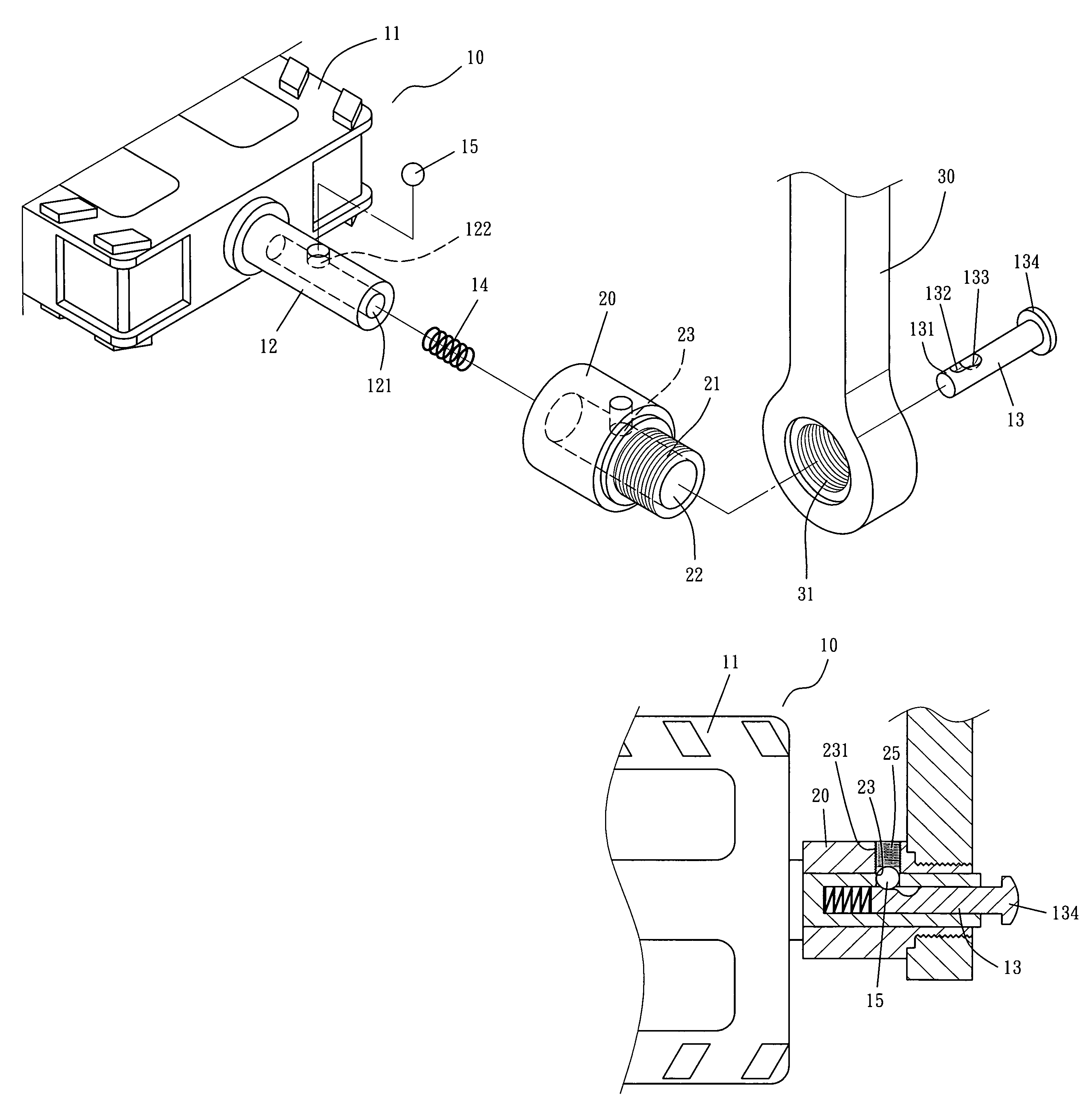

Adapter for foldable battery charger

ActiveUS9276424B2Save on transportationClearance can be providedBatteries circuit arrangementsElectric powerBattery chargeElectrical battery

Owner:BREN TRONICS INC

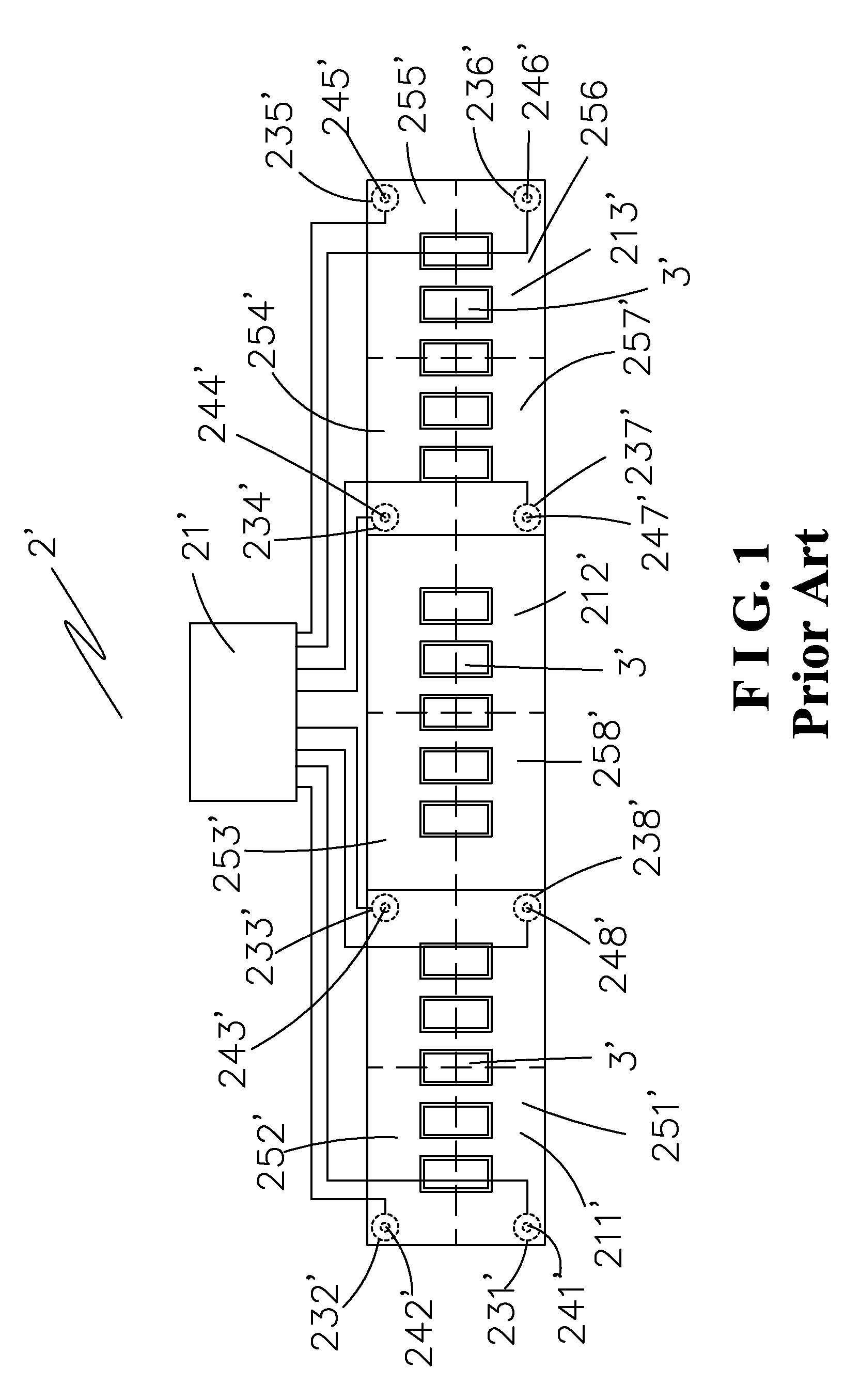

System for production and subsequent palletizing of tube segments, bags or sacks

InactiveUS7361130B2Save design spaceReduces mutual deviationPaper/cardboard wound articlesPile receiversEngineering

A system for the production and subsequent palletizing of tube segments, bags, or sacks has at least one functional unit for production of tube segments, bags, or sacks, at least one device for depositing and stacking, which places and stacks the finished tube segments, bags, or sacks, and at least one storage element such as a palette, in which the stack can be deposited. The system has at least one alignment unit for the stack of the tube segments, bags, or sacks, which reduces the mutual deviations of the edges of the tube segments, bags, or sacks.

Owner:WINDMOELLER & HOELSCHER GMBH

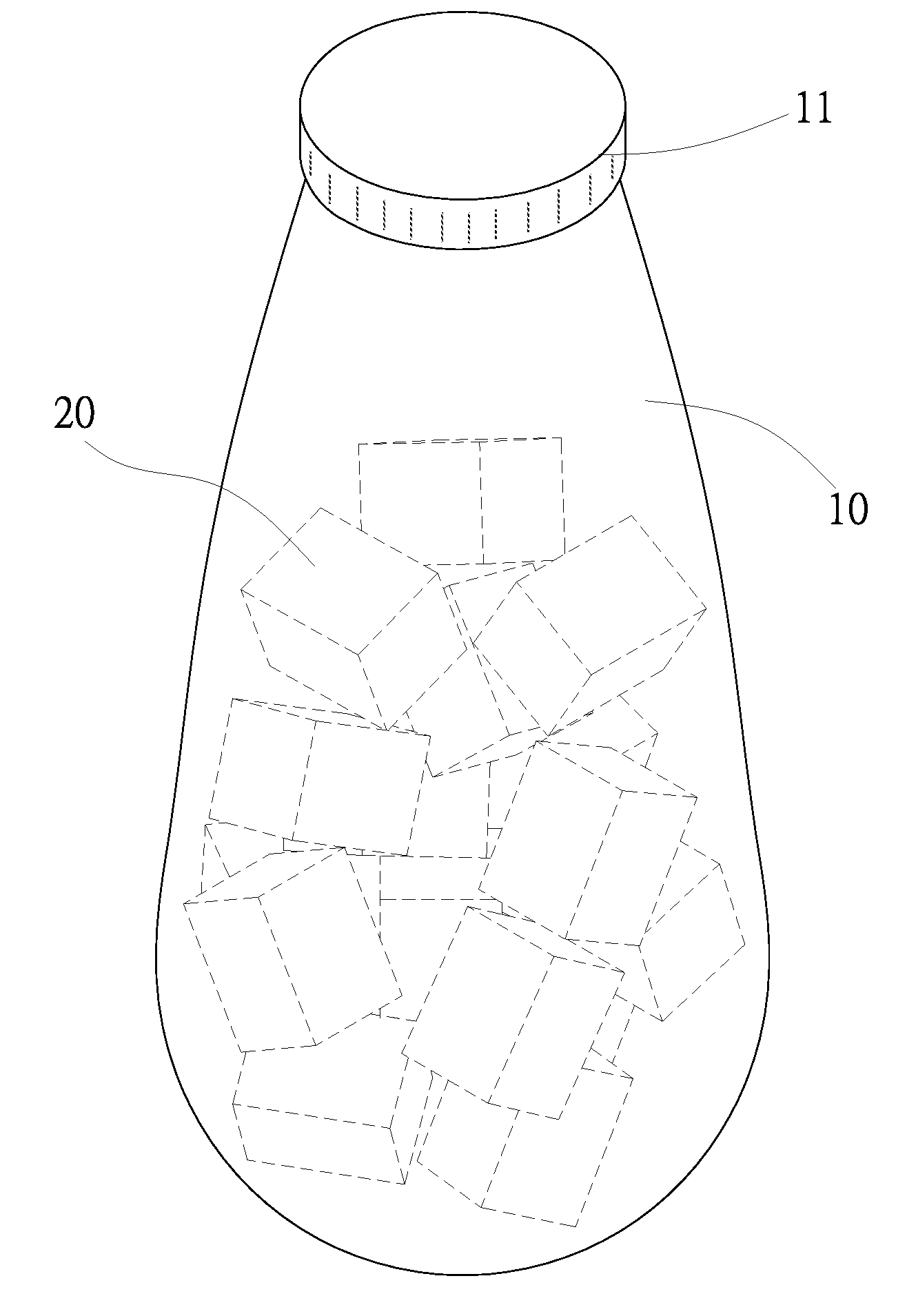

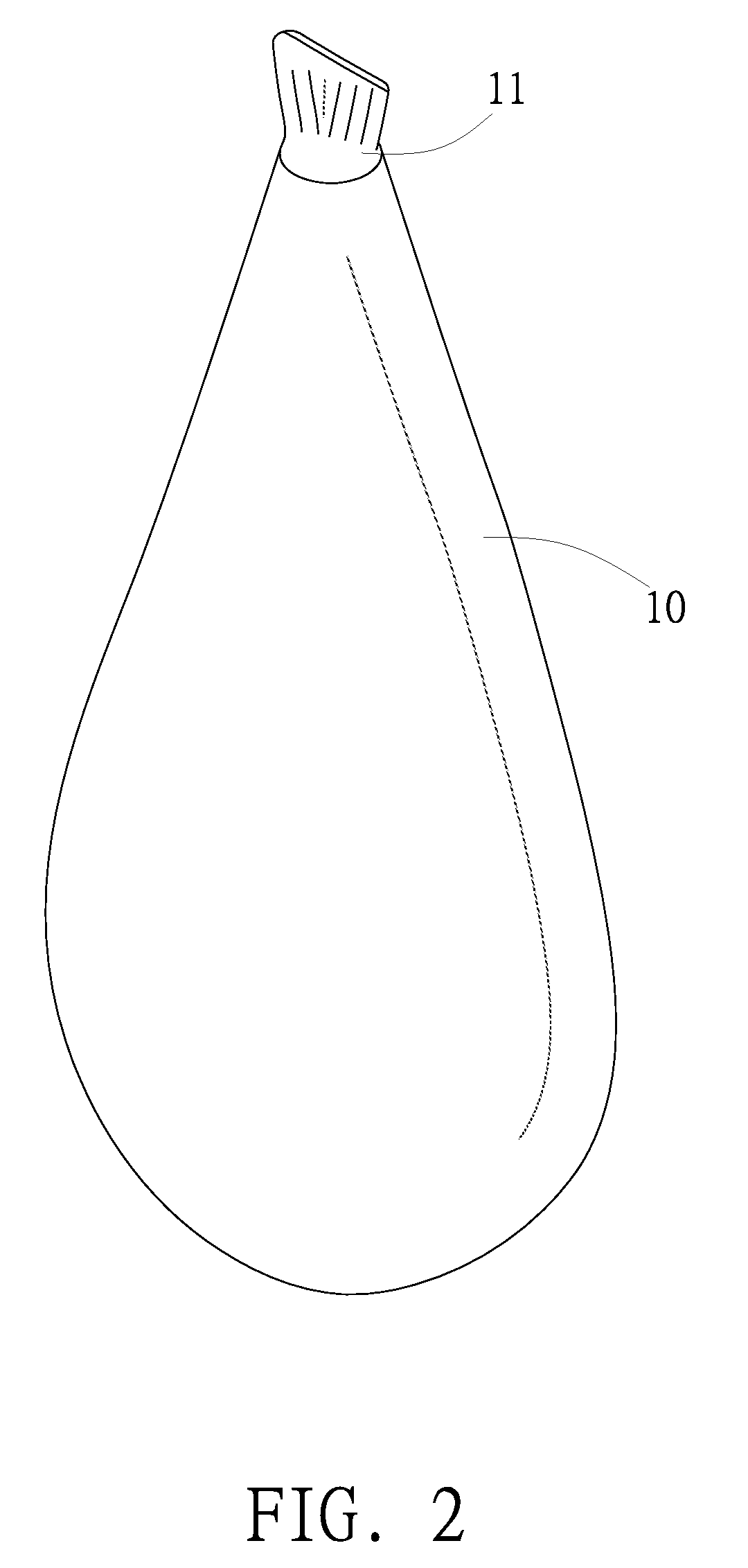

Frozen solid state heat relieving thirst quencher

InactiveUS20130266698A1Easy to transportEasy to optimizeReady-for-oven doughsFrozen sweetsEngineeringHigh body temperature

The present invention relates to a frozen solid state heat relieving thirst quencher, mainly configured to comprise a container or bag of soft or hard materials for convenient hand-carry applications. The container is filled with the heat relieving thirst quencher which can be presented in its solid state through a freezing process, thereby allowing convenient portability and readiness to serve anytime by direct consumption so as to achieve the heat relieving and thirst quenching effects such as stamina supplementation, electrolyte replenishment and body temperature reduction and the like. Meanwhile, in case of sport injuries or insect stings, it can be used for ice covering and swelling subsiding purposes. When the internal heat relieving thirst quencher is totally molten, it can be frozen once again to return to its solid state thus enabling practical usage advantages for various objectives and convenient portability.

Owner:EUCO TECH CO

Refrigerator with a foldable table

InactiveUS20030041611A1Space saveCost savingLighting and heating apparatusFurniture partsEngineeringRefrigerated temperature

This invention relates to a refrigerator with a foldable table, wherein the table can be unfolded when it is needed and can be folded when it is not needed. So the product of the present invention has the functions of both a refrigerator and a table, and also can save some room space providing a more reasonable room layout.

Owner:HAIER GRP CORP +1

Bike pedal assembly structure

InactiveUS20100212454A1Minimized footprintSave spaceControlling membersMechanical apparatusEngineeringAssembly structure

A bike pedal assembly structure is disclosed, which involves a bracing joint connecting to a crank, and a pivotal shaft of the pedal and a control bar are penetrated into a joining cylinder of the bracing joint for a joining. By depressing the pressing head of the control bar, the pivotal shaft of the pedal and the control bar can be dismounted from the joining cylinder. The pedal can even be mounted to the same structure in a reverse position for the prevention of the possibilities in forgetting to place it somewhere or even in losing it. Since the store of the pedals is located at the space between the cranks of both sides, which means deadly save the space.

Owner:WANG CHUNG HAN

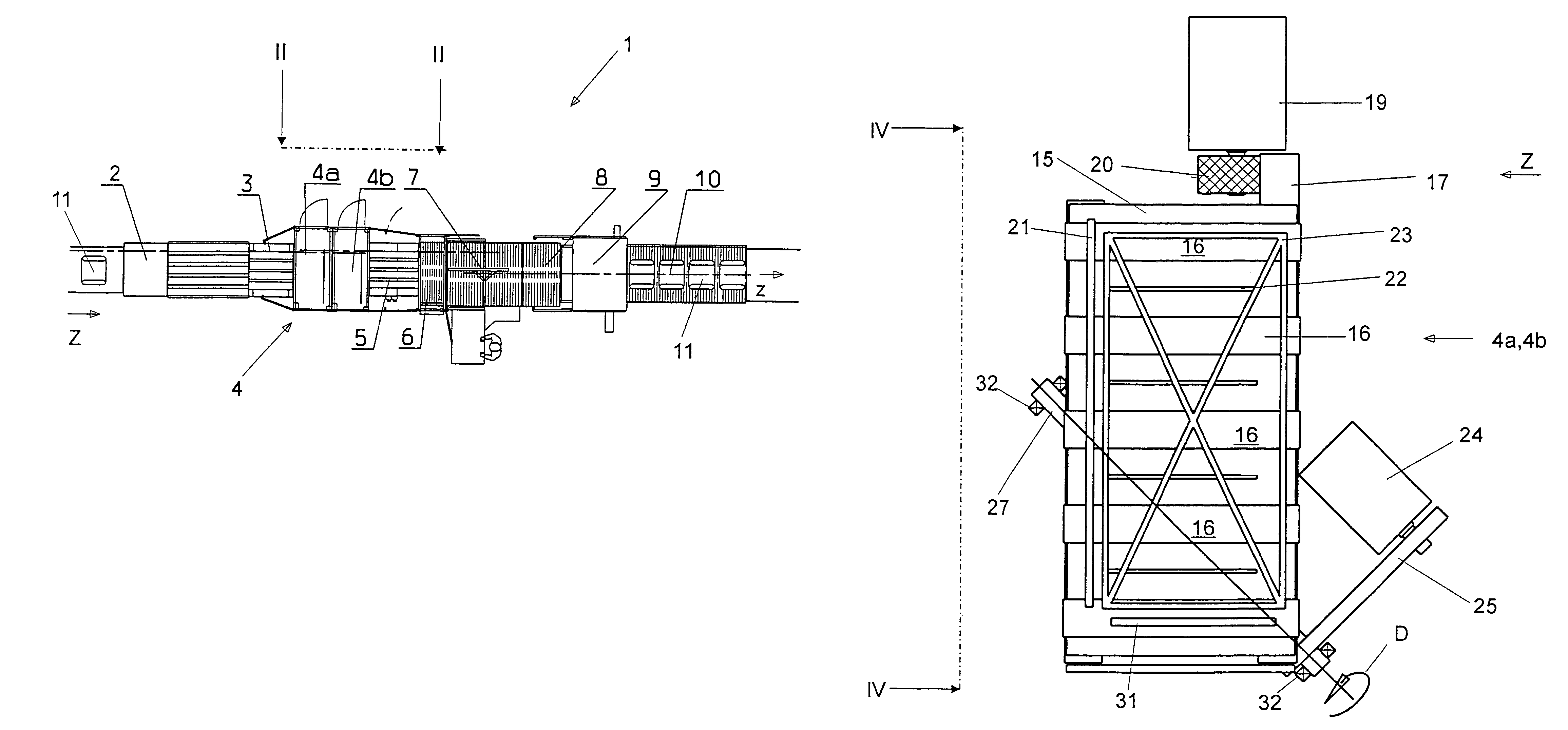

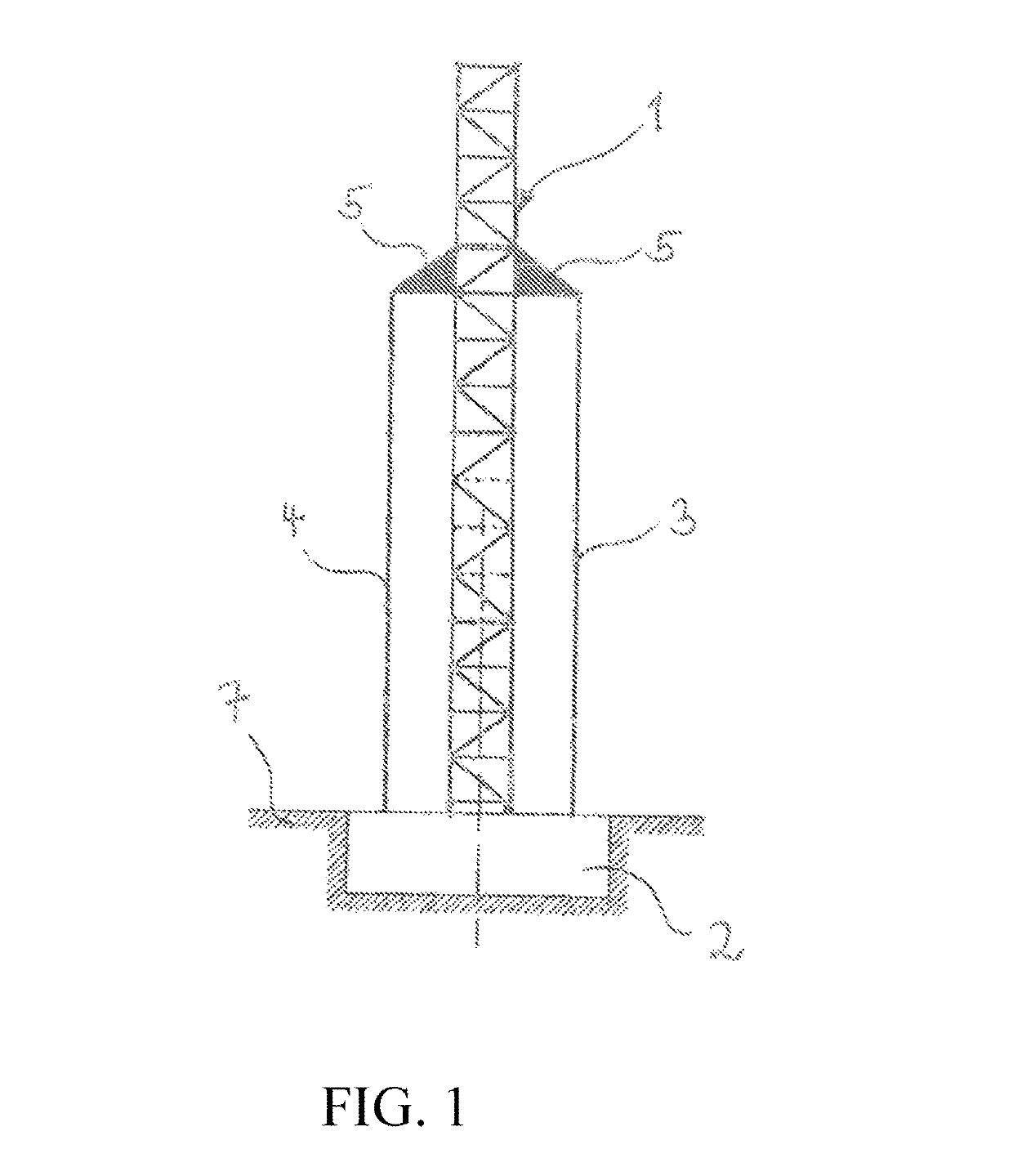

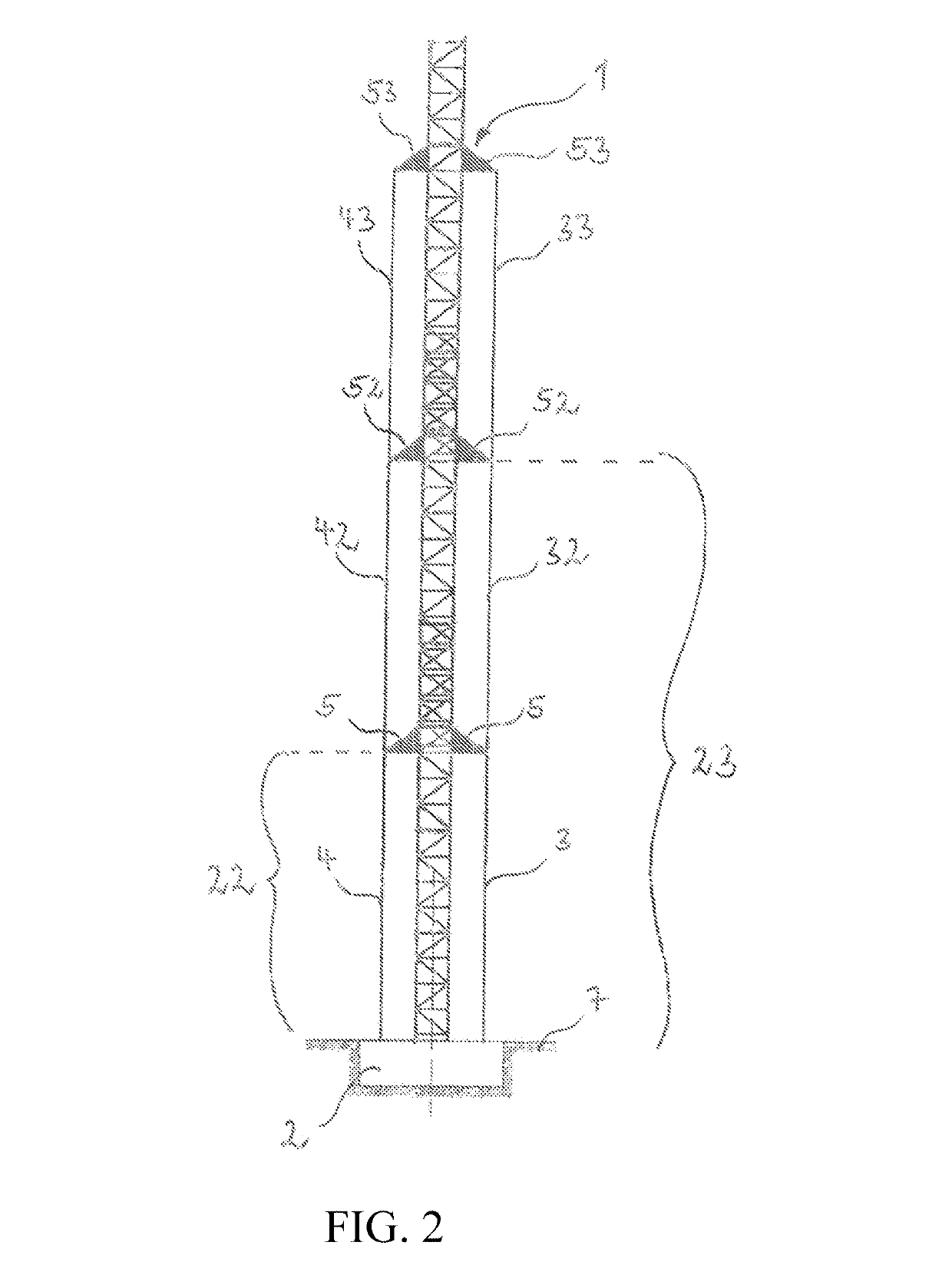

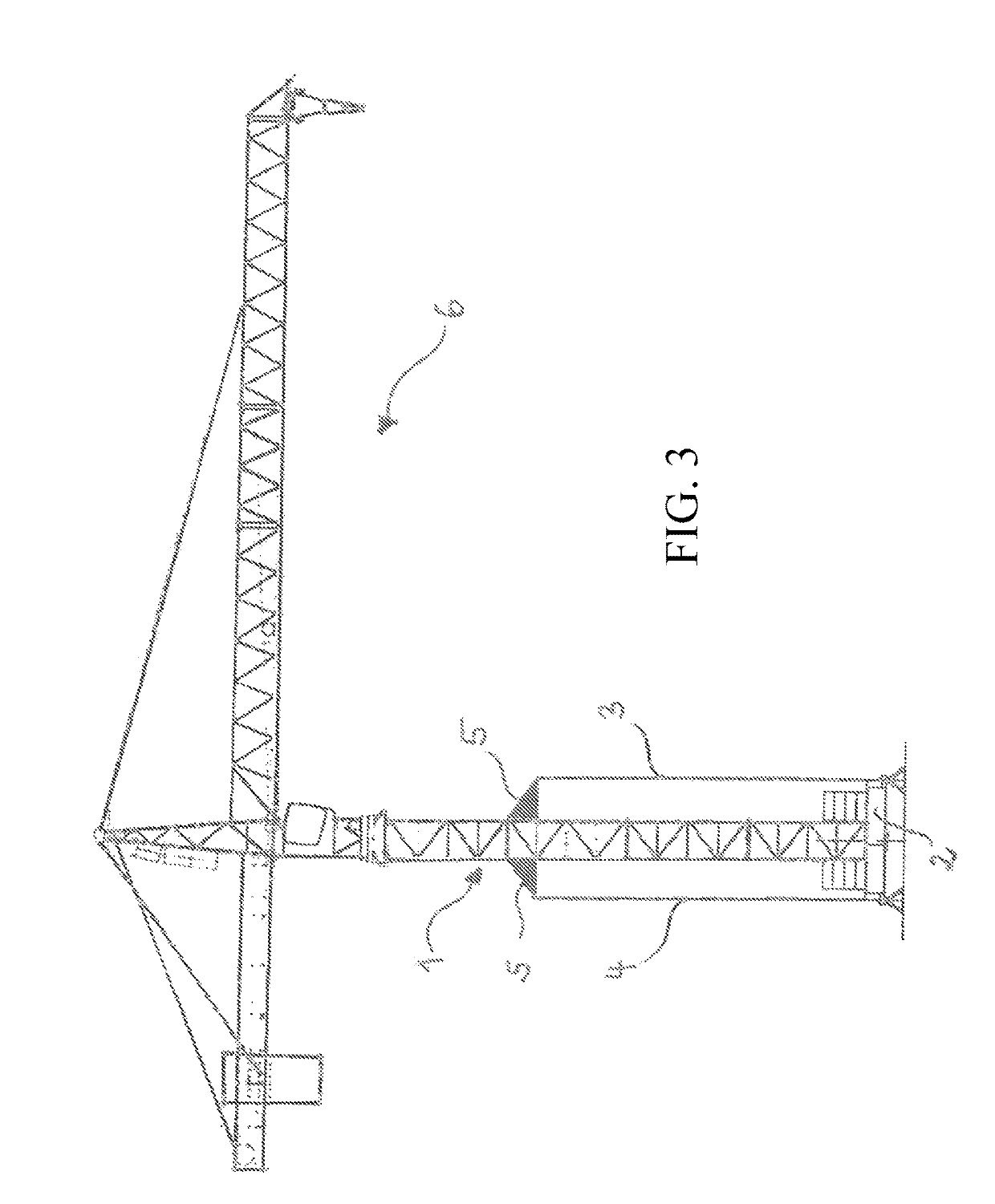

Crane tower

The present invention relates to a crane tower comprising a crane tower base, which has a crane tower or a crane tower element fixed thereto and from which the crane tower extends upwards, and a tension element for bracing the crane tower 1 on the crane tower base. The tension element has one of its two ends connected to the crane tower base and its respective other end connected to the crane tower or to a coupling element that is connected to the crane tower. The crane tower is characterized in that the tension element extends outside of the crane tower. It is thus possible to reduce the dimensions of the crane tower without causing any change of bending resistance or to increase the bending resistance on the basis of the same dimensions.

Owner:LIEBHERR WERK BIBERACH

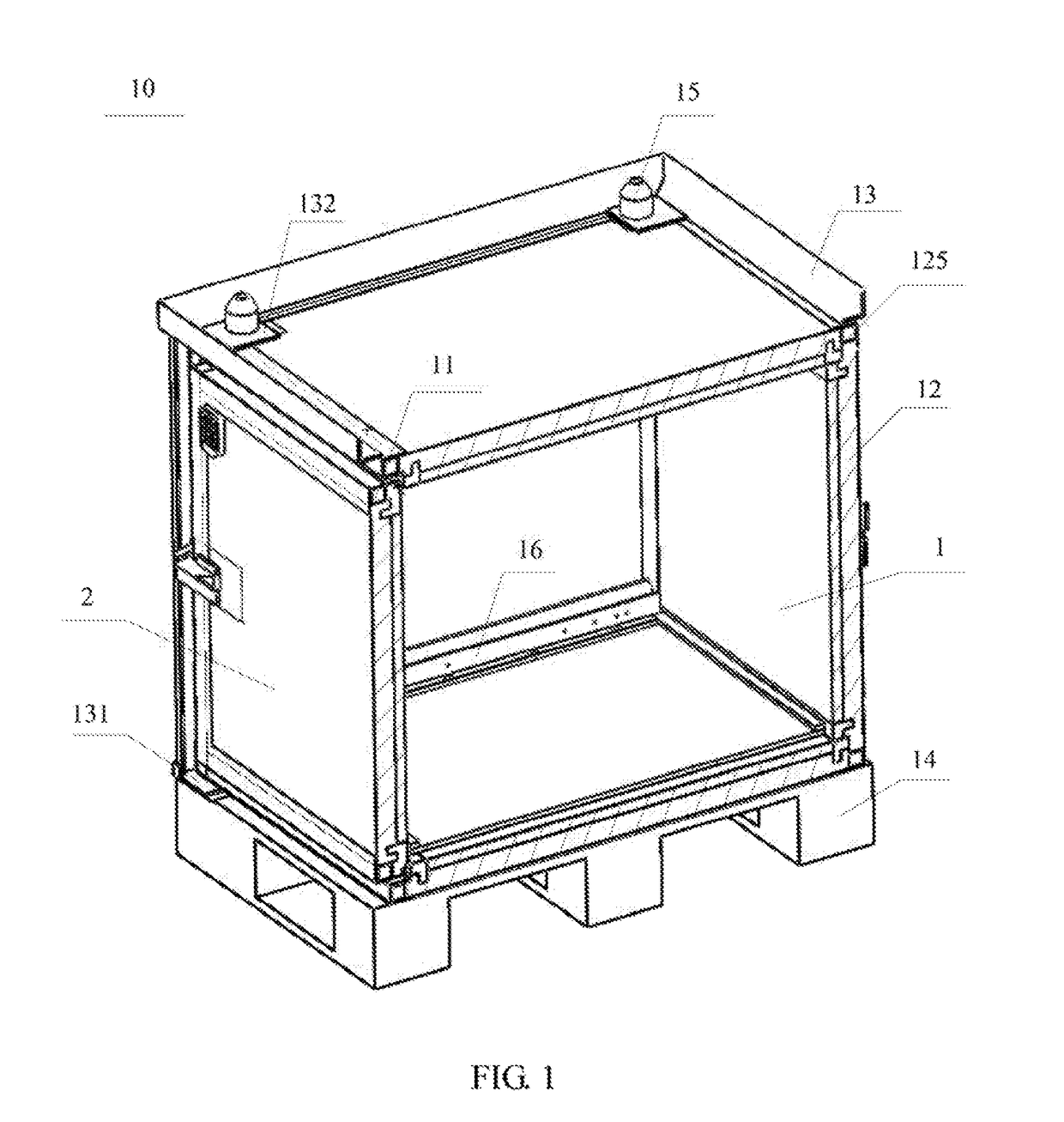

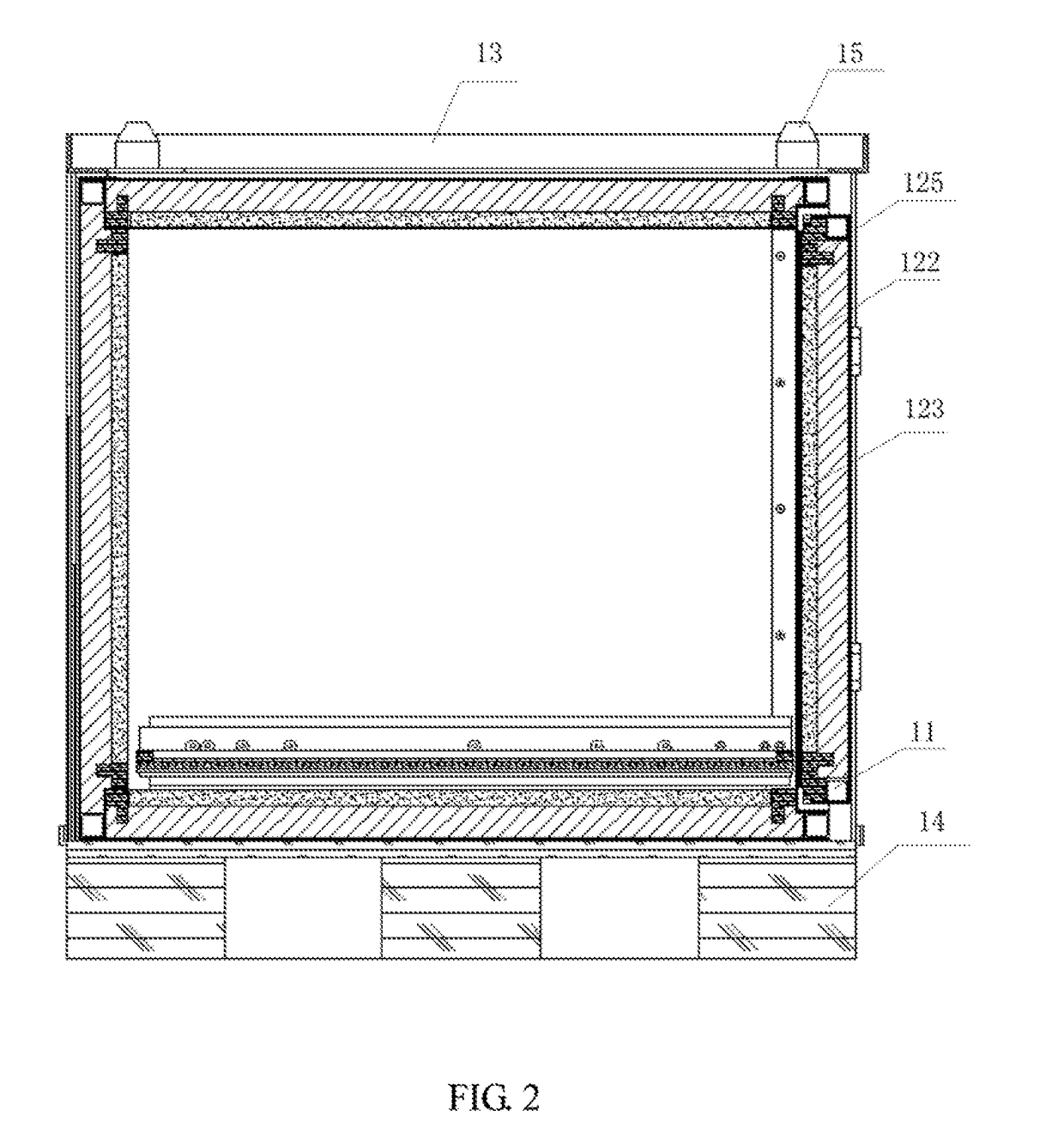

Insulating container, transportation device and transportation method

ActiveUS20180362243A1Simple methodConvenience to workDomestic cooling apparatusLighting and heating apparatusPolystyreneHigh intensity

An insulating container comprises a container body and a container cover connected to the container body. The container both and the container cover each comprises a frame and a plate arranged on the frame. The plate comprises, from inside out, an external high strength sheet, an extruded polystyrene sheet, phase-change insulating sheets made of phase-change material, and an internal sheet. A phase-change process of the phase-change insulating sheets cooperates with a refrigeration system of the transportation device to precisely control the temperature of the insulating container and a refrigerator truck to be near a phase-change temperature. In the present disclosure, the phase-change insulating sheets made of the phase-change material remain to be in a solid state before or after occurrence of a phase change, so that the structure of the insulating container does not change with the phase change and a leakage problem of the phase-change material does not exist.

Owner:SOLEE WUHAN SCI & TECH

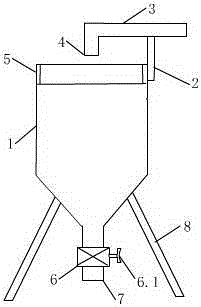

Over-ground slurry settling, filtering and separating apparatus capable of obtaining clear water

The invention provides an over-ground slurry settling, filtering and separating apparatus capable of obtaining clear water. One side of the upper portion of a settling cylinder with the lower portion provided with a taper and with the upper portion provided with an opening is fixedly provided with a slurry conveying tube support, the slurry conveying tube support is fixedly provided with a slurry conveying tube, the slurry conveying tube is downward provided with a slurry conveying port vertical to the slurry conveying tube, the tapered end of the lower portion of the settling cylinder is connected with a residue discharge tube, the residue discharge tube is provided with a residue discharge valve provided with a valve handle, and the tapered portion of the lower portion of the settling cylinder is provided with a supporting rack. A filtering ring is arranged at the upper edge of the settling cylinder, the filtering ring is provided with an external layer net and an internal layer net, the inner side of the external layer net is provided with an external layer filter cloth, the outer side of the internal layer net is provided with an internal layer filter cloth, and a filter layer is arranged between the internal layer filter cloth and the external layer filter cloth. The apparatus is arranged over-ground, and saves energy and the transportation process; and the upper portion of the apparatus is provided with the filtering ring, so overflow slurry water is clean and can be directly used. The apparatus is suitable for being applied as a slurry separation apparatus.

Owner:孙德东

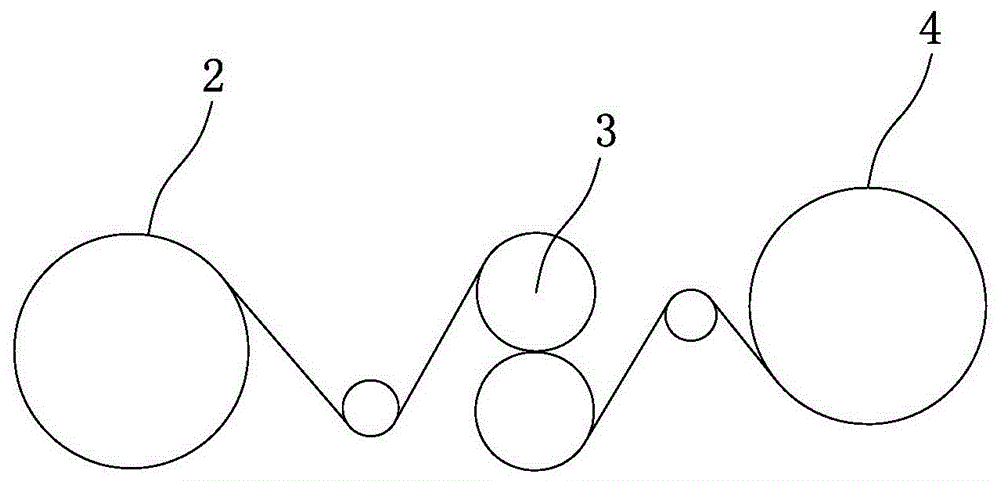

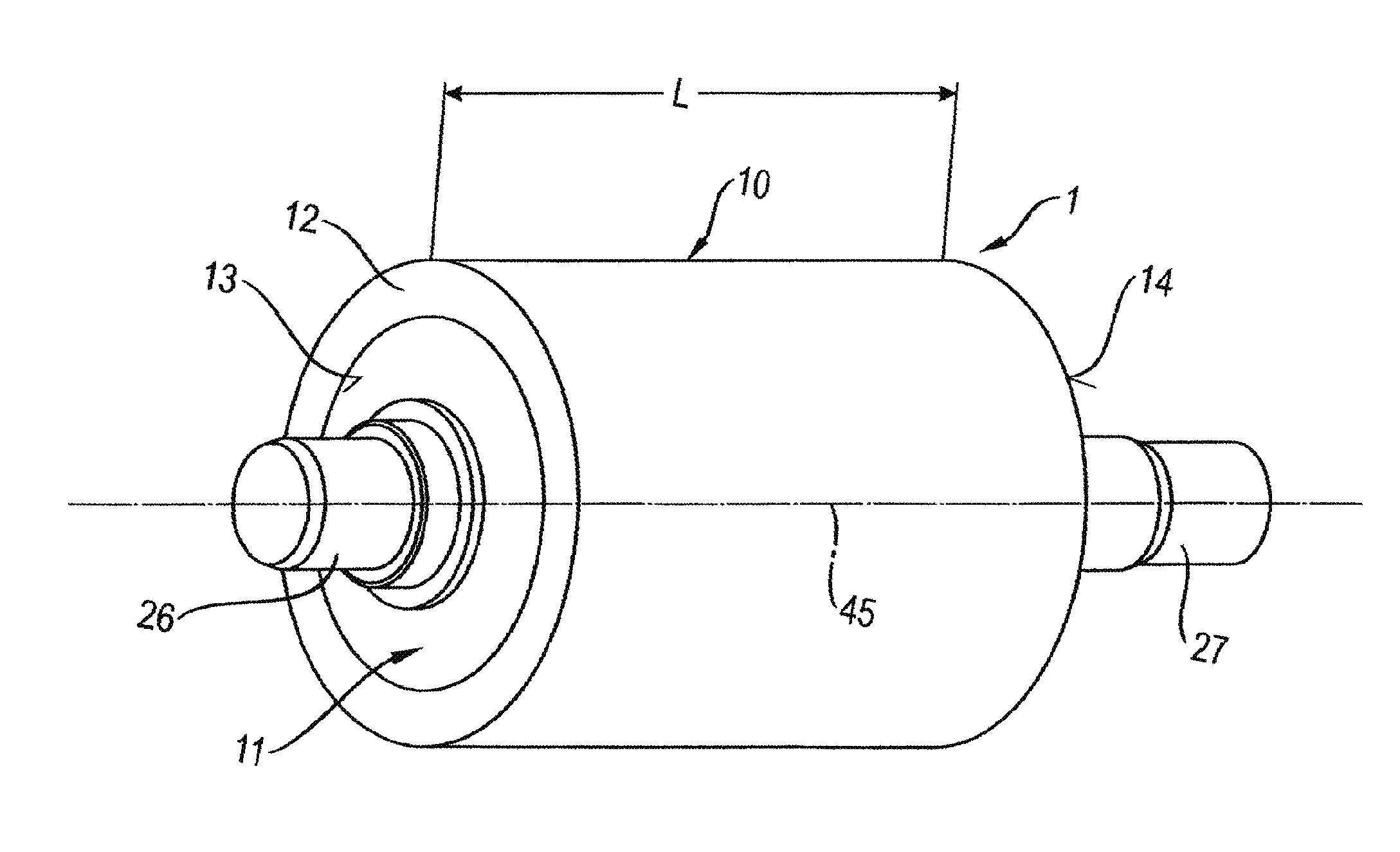

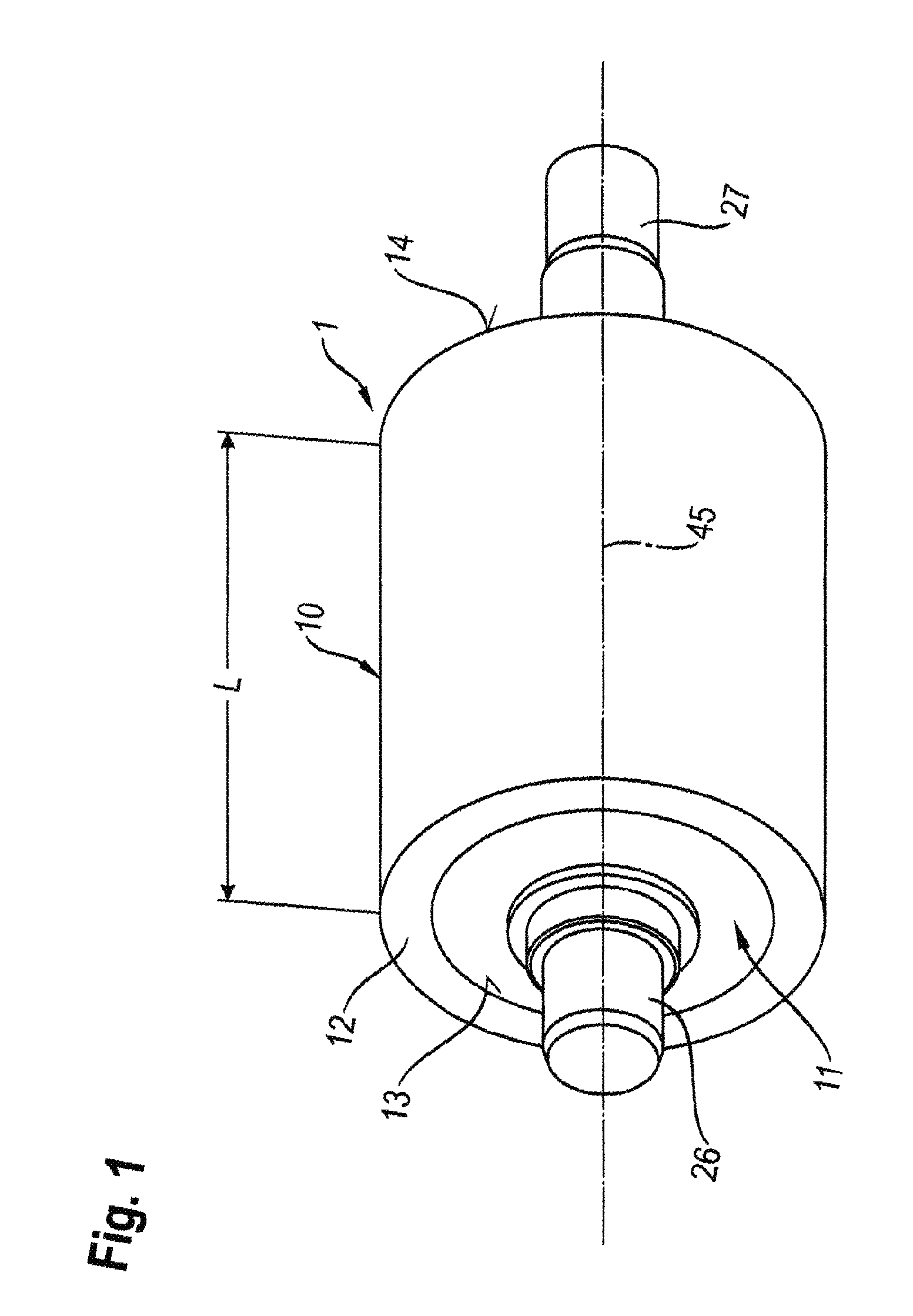

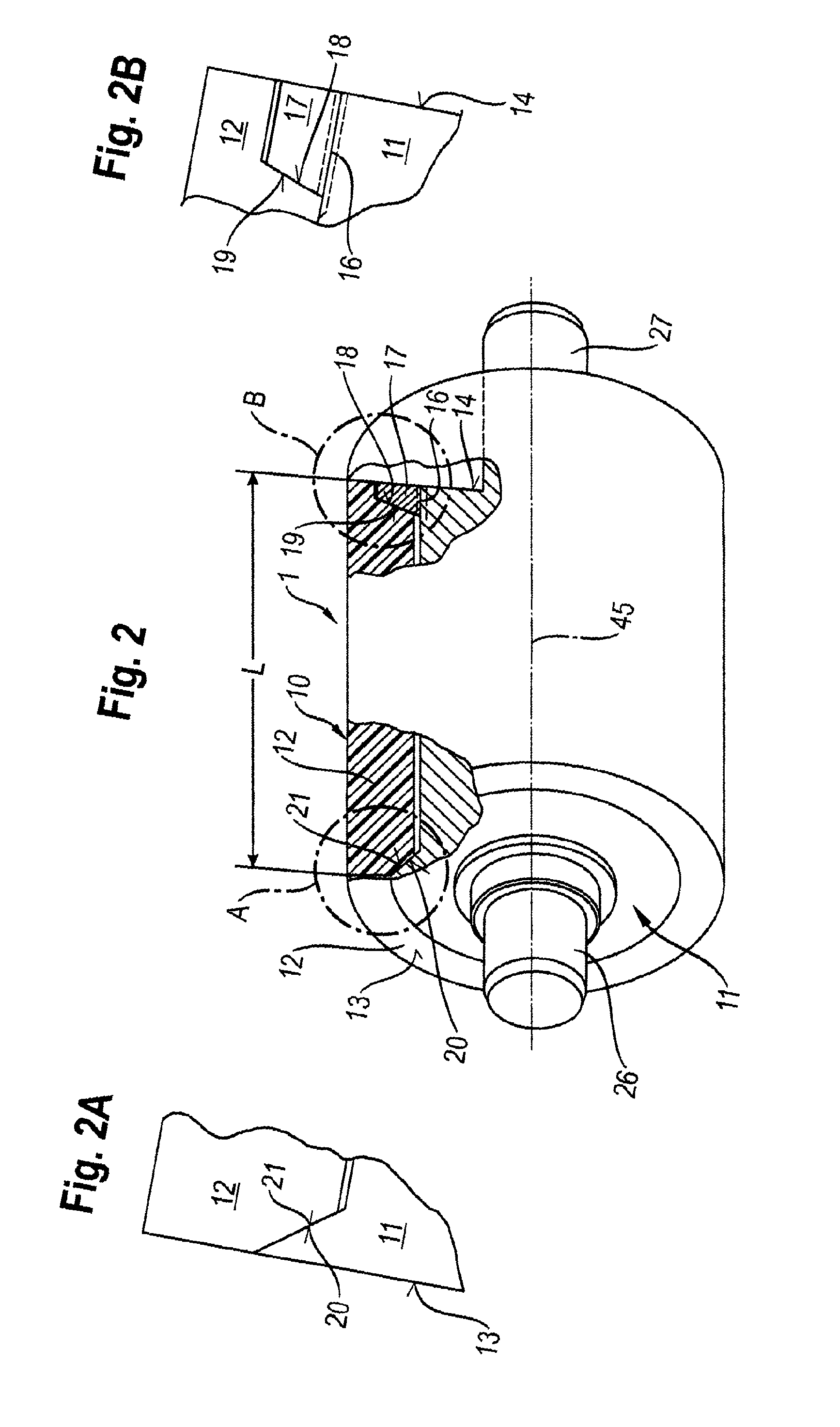

Guide Roller Of A Pair Of Feed Rollers Of A Granulating Device

InactiveUS20170036215A1Facilitate pulling offEasy to pushShaft and bearingsFilament handlingEngineeringMechanical engineering

Owner:MAAG AUTOMATIK GMBH

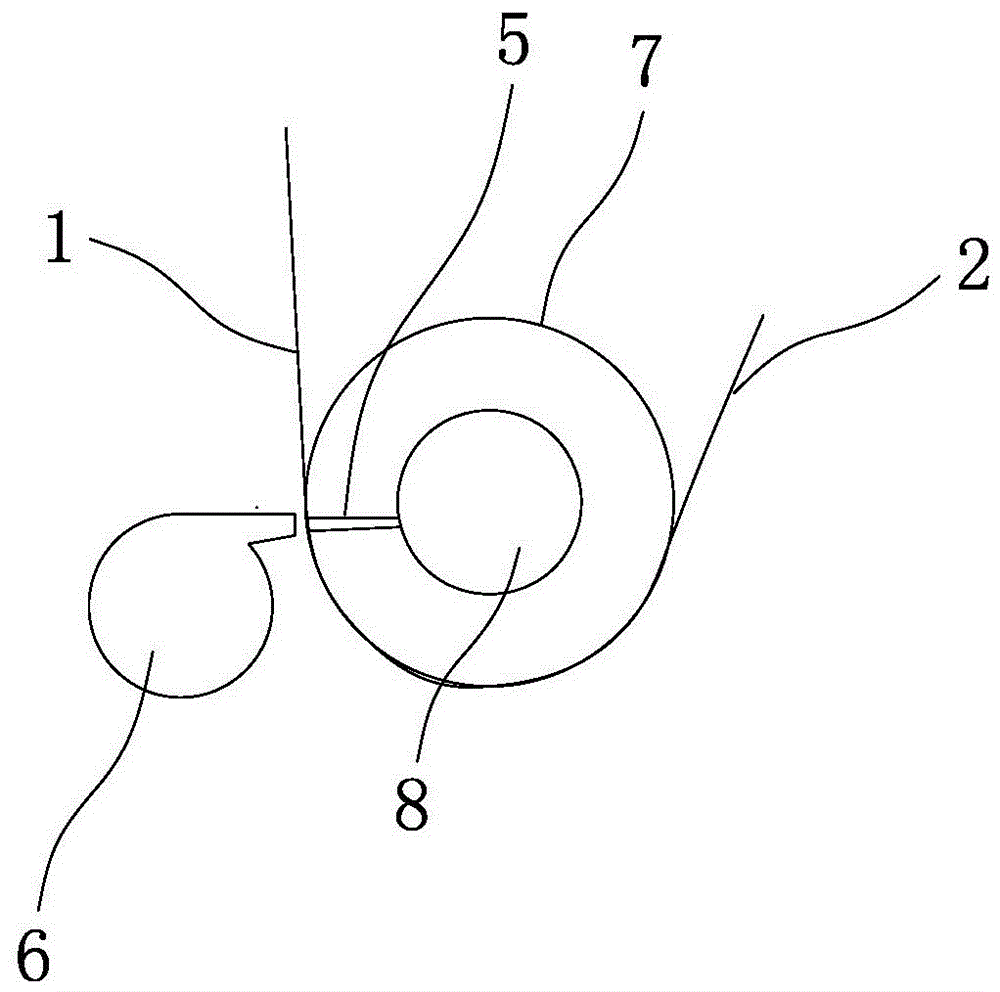

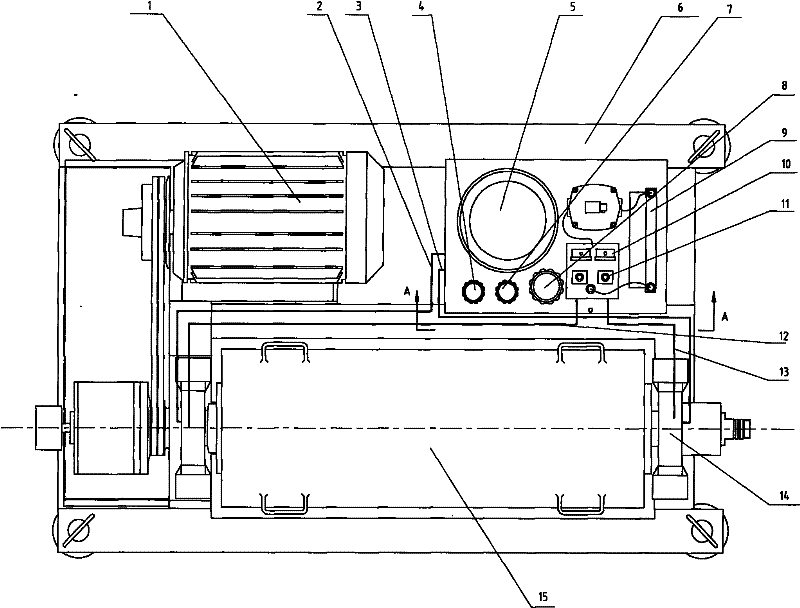

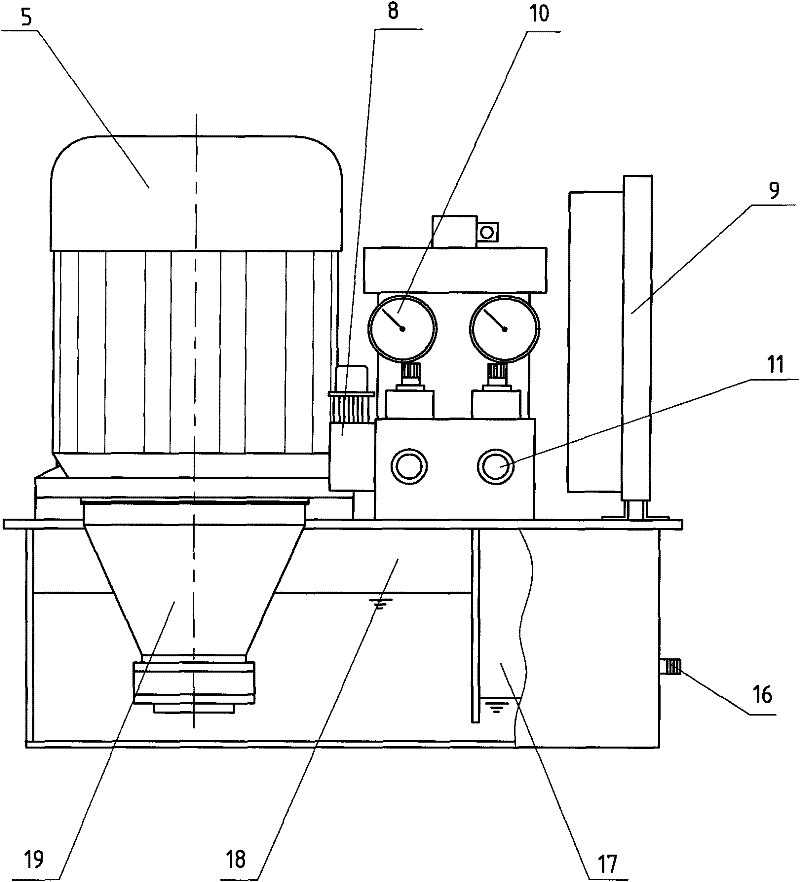

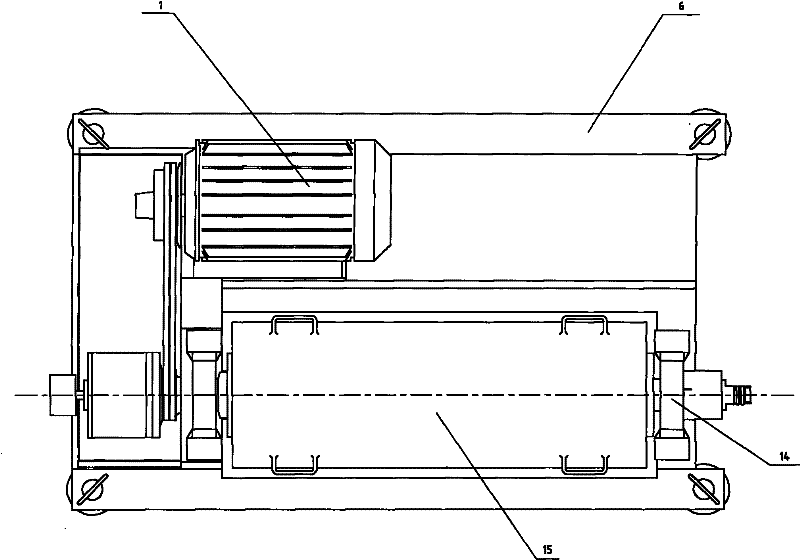

Integrated arrangement structure of decanter centrifuge and hydraulic station

The invention relates to a centrifuge structure in the field of machines, in particular to an integrated arrangement structure of a decanter centrifuge and a hydraulic station. In a rectangular frame (6), one side is provided with an accumbent decanter centrifuge barrel (15), the end of the other side is provided with a motor (1), and power is transmitted to the input shaft end of the centrifuge barrel (15) through a belt. The structure is characterized in that: the hydraulic station is arranged in a rear space of the motor (1) and is a vertically arranged rectangular body; an oil pump motor (5) drives an oil pump (19); the oil pump (19) is respectively connected to the two ends of the centrifuge barrel (15) by front and rear oil inlet pipes (12 and 13) through two oil inlet speed regulating valves (11); an oil supply box (18) and an oil return box (17) are parallelly arranged on the lower part; the lower parts of the two oil boxes are communicated with each other; and the upper part of the oil supply box (18) is connected with a vacuum pump (8). Through the technical scheme, the residual space on the frame (6) is fully utilized, so that the space of a factory building is saved, the problem of transportation and installation inconvenience of a split structure is solved, engineering progress is accelerated, and efficiency is improved.

Owner:SHANGHAI CENTRIFUGE INST

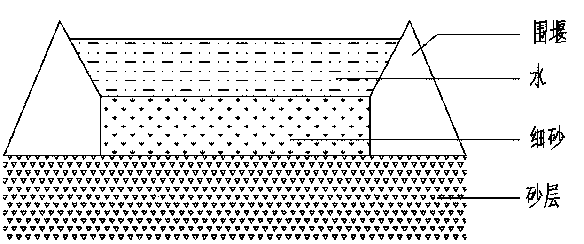

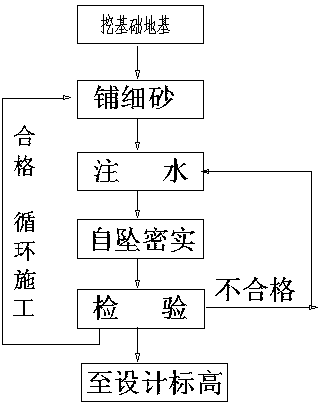

Photovoltaic power station base construction process achieved through sand falling under action of water

InactiveCN103938643ALow costReduce construction difficultyFoundation engineeringCofferdamPhotovoltaic power station

A photovoltaic power station base construction process achieved through sand falling under the action of water includes the following steps that (A) according to the requirement of the specification of a photovoltaic assembly, a photovoltaic assembly base foundation is dug; (B) fine sand is poured onto a foundation sand layer for pavement, and a cofferdam is built through sand and soil on the basis of the fine sand; (C) water is injected into the cofferdam and then stands still, so that the fine sand falls under the action of scouring force of the water and self-gravity and becomes compact, and the water and the fine sand seep into the sand layer; (D) quality detection is carried out, if compactness does not meet the requirement, the step (C) is repeatedly carried out until the compactness meets the requirement, and if the compactness meets the requirement, the step (B) and the step (C) are repeatedly carried out until the sand reaches a designed height. According to the process, the structure is simple, construction is convenient to carry out, and the process is especially suitable for being used for manufacturing a photovoltaic power station base in a desert.

Owner:REALFORCE POWER

Method for preparing wet-process phosphoric acid by using hydrochloric acid to infiltrate low-and-medium-grade phosphorite

ActiveCN106672930AReduce security risksReduce miningCalcium/strontium/barium chloridesCalcium/strontium/barium sulfatesPregnant leach solutionPhosphoric acid

The invention relates to a method for preparing wet-process phosphoric acid by using hydrochloric acid to infiltrate low-and-medium-grade phosphorite. The method includes: directly filling a jamb with low-and-medium-grade phosphorite which is not subjected to flotation; adopting hydrochloric acid infiltration to prepare wet-process phosphoric acid; enabling sulfuric acid to react with leachate to generate ardealite. The objective of directly filling or filling bed holes with ardealite by a pump can be achieved by adopting two different modes for adding sulfuric acid, so that the objectives of fixing mining layers and lowering risk of collapse of mining holes are achieved, and a series of environment problems caused by storage of ardealite are solved. The method has the advantages of mild reaction condition, high yield and high reaction speed, and a series of industrial processes like phosphorite exploitation, beneficiation, transportation and mine hole filling are omitted directly, so that production process is greatly simplified, emission of three wastes is avoided, one-time leaching efficiency of final phosphorus is up to 52.79%, and multiple leaching efficiency can reach higher than 85%.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com