Method of increasing the oxidation stability of biodiesel

a biodiesel and oxidation stability technology, applied in the field of can solve the problems of high storage and transportation costs, achieve the effects of improving the economics or the use of primary antioxidants, increasing the oxidation stability of biodiesel, and improving the processability of primary antioxidants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

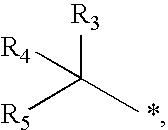

Image

Examples

example 1

Production of the Samples

[0165] In a glass beaker, the primary antioxidant is dissolved in biodiesel at 20° C. with stirring, and stirring is continued until a clear solution of the primary antioxidant in the biodiesel is obtained. The primary antioxidants used, the biodiesel used and the ratios are shown in Table 1.

example 2

Composition of the Primary Antioxidants Used

Primary Antioxidant 1

[0166] (procured from Degussa AG under the trade name IONOL 99):

>99.0% by weight of 2,6-di-tert-butylphenolof 2-tert-butylphenolof 2,4-di-tert-butylphenol

Primary Antioxidant 2

[0167] (procured from Degussa AG under the trade name IONOL K98):

>98.5% by weightof 6-tert-butyl-2,4-dimethylphenol of 4-tert-butyl-2,6-dimethylphenol anddi-tert-butylmethyl-phenols

Primary Antioxidant 3

[0168] (procured from Degussa AG under the trade name IONOL K65):

>55%by weightof 6-tert-butyl-2,4-dimethylphenol>15%by weightof 2,6-di-tert-butyl-4-methylphenol18-22%by weightof tert-butyl-2,5-dimethylphenolby weightof 4,6-di-tert-butyl-2-methylphenolby weightof di-tert-butyl-3-methylphenolby weightof 2,5-di-tert-butyl-4-methylphenol

Primary Antioxidant 4

[0169] (procured from Degussa AG under the trade name IONOL 75):

>75%by weightof 2,6-di-tert-butylphenolby weightof 2-tert-butylphenolby weightof 4-tert-butylphenolby weightof 2,4-di-...

example 3

Testing Procedure

[0170] The oxidation stability of the samples produced as described in Example 1 was examined at a test temperature of 110° C. in accordance with the test method DIN EN 14112.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com