Patents

Literature

562results about How to "Reduce crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

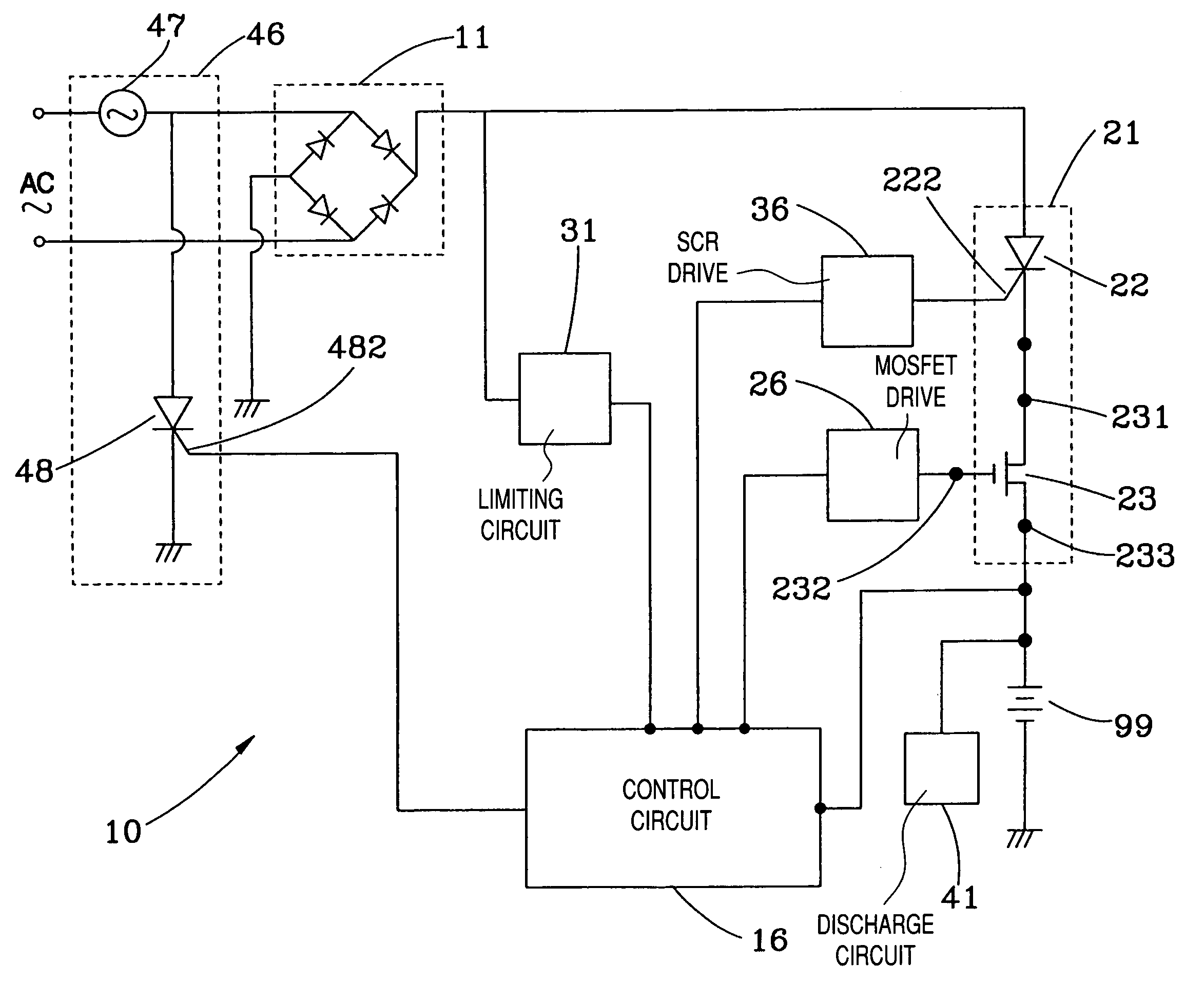

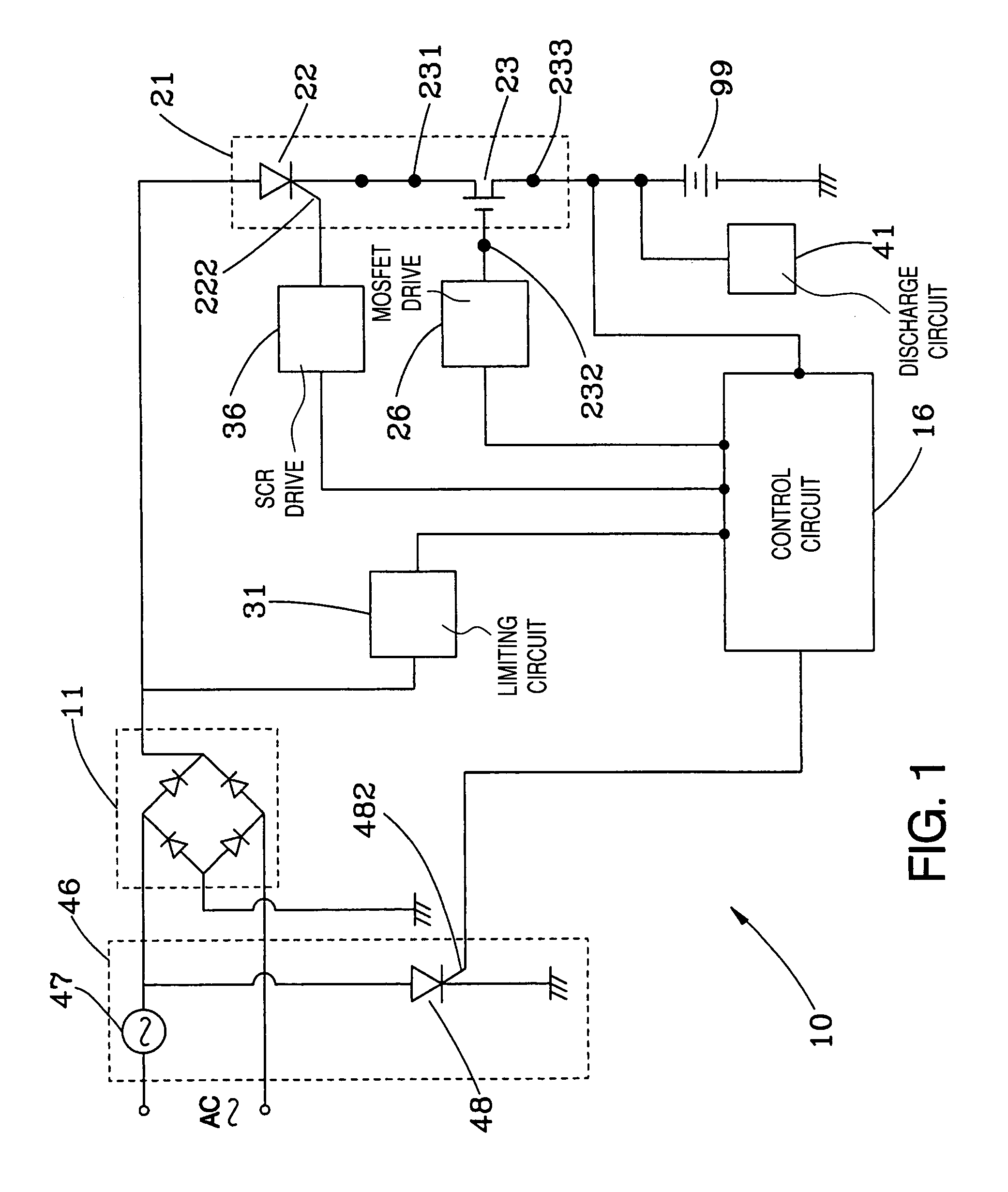

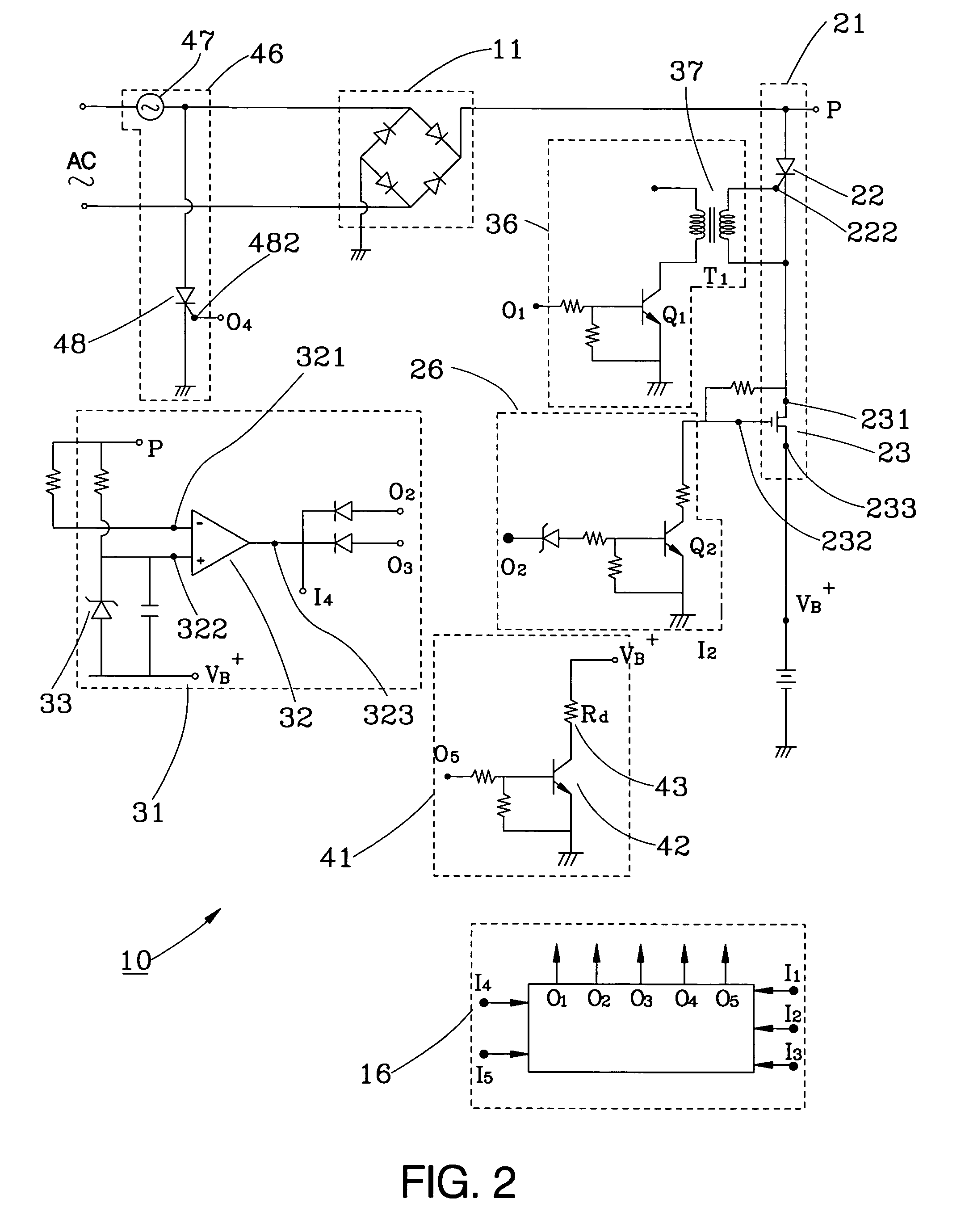

Battery charging and/or DC power supply circuitry

InactiveUS6977485B1Improved battery chargingSmall sizeAc-dc conversionElectric powerAC powerBattery charge

A battery charging and / or DC power supply circuitry employs a control circuit through an SCR drive circuit and an MOS drive circuit to control when to turn on / off a semiconductor switch unit and to turn on the semiconductor switch unit while an initial section of each positive half wave of an AC power source and an terminating section of the same are located below a predetermined level for intercepting partial power for charging. While charging a battery, the circuitry is lightweight, small-sized, and to enhance the life of the battery. While being a DC power supply, the circuitry is small-sized, high-efficiency, and low-cost.

Owner:MOBILETRON ELECTRONICS

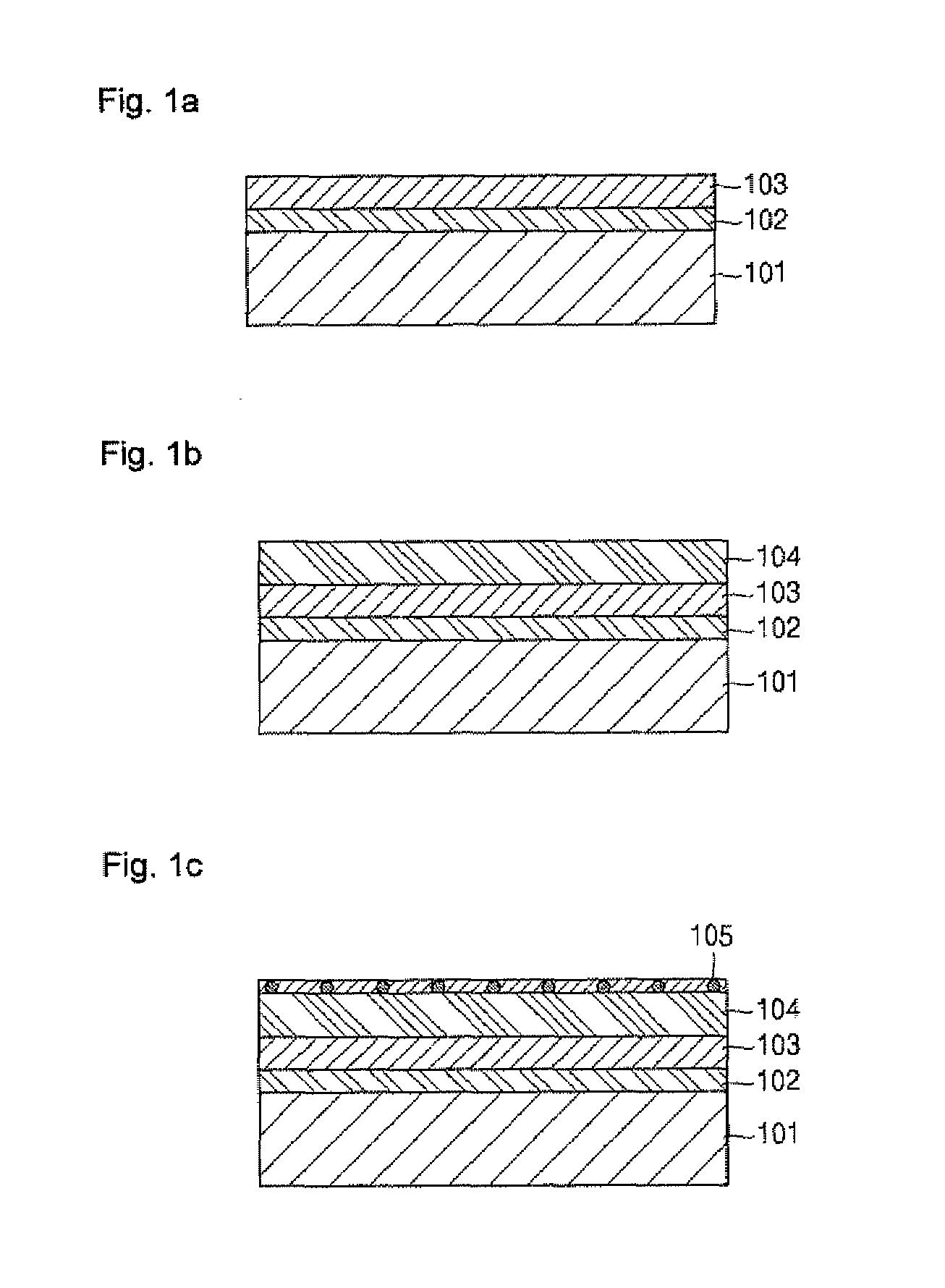

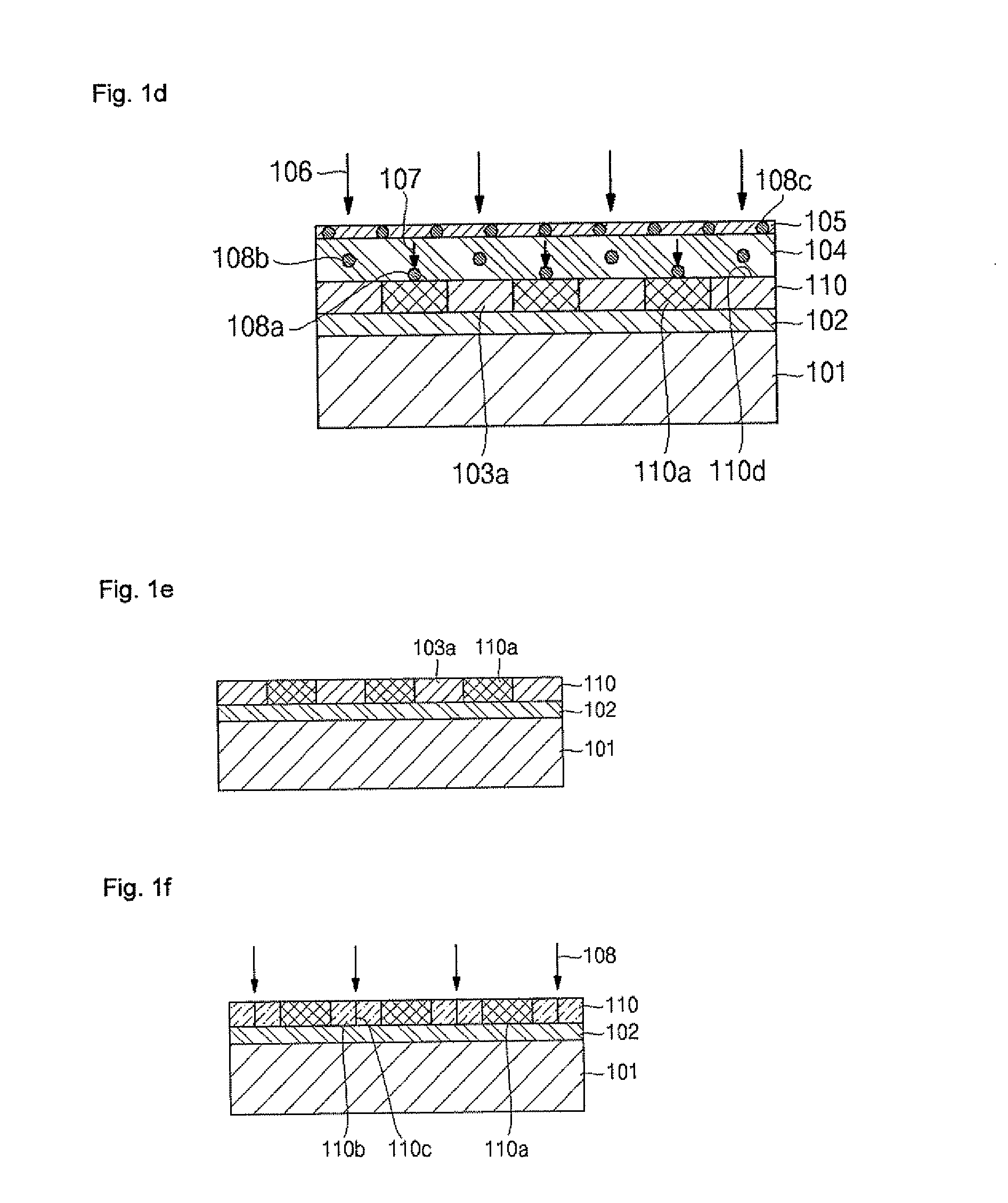

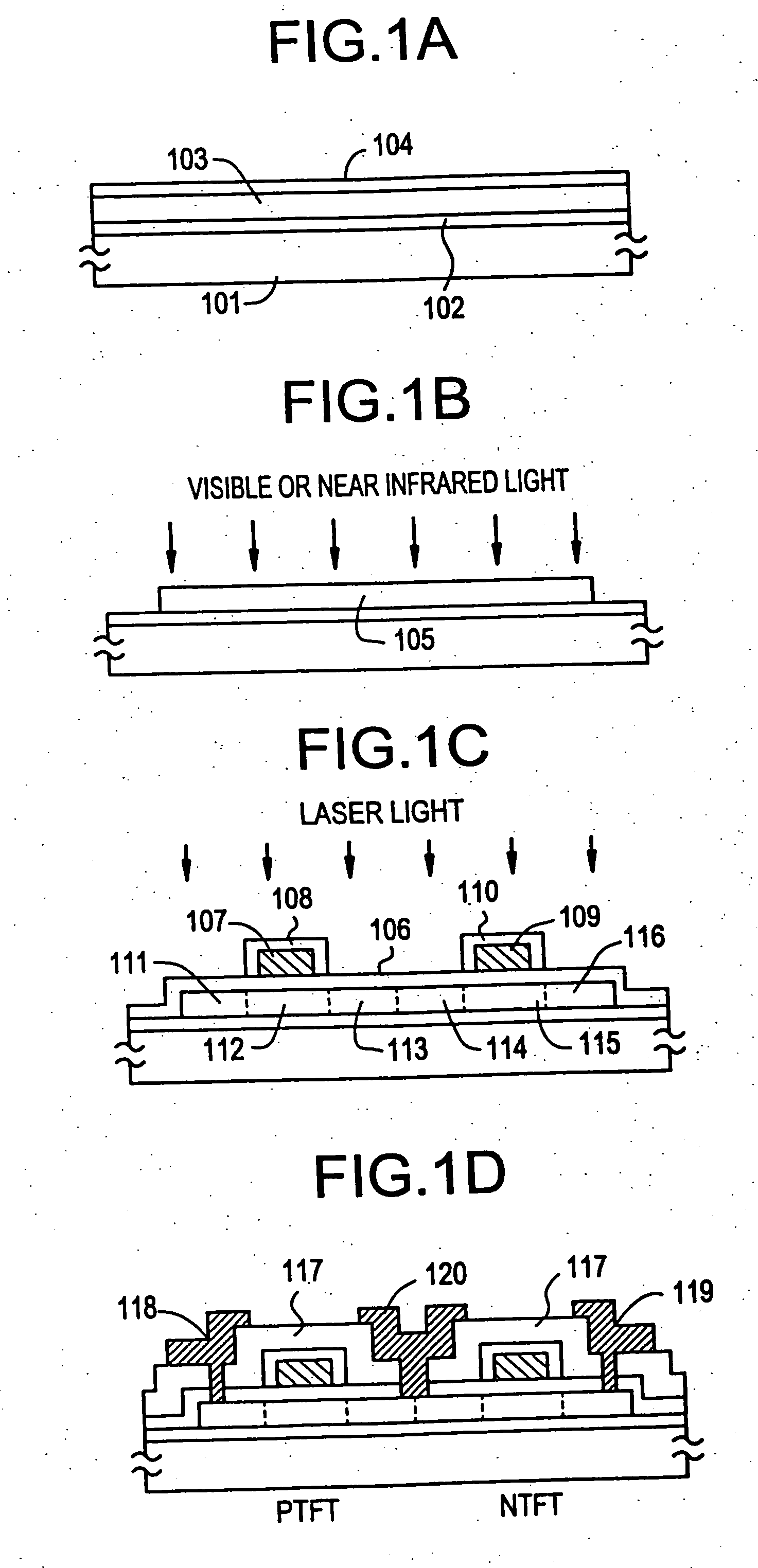

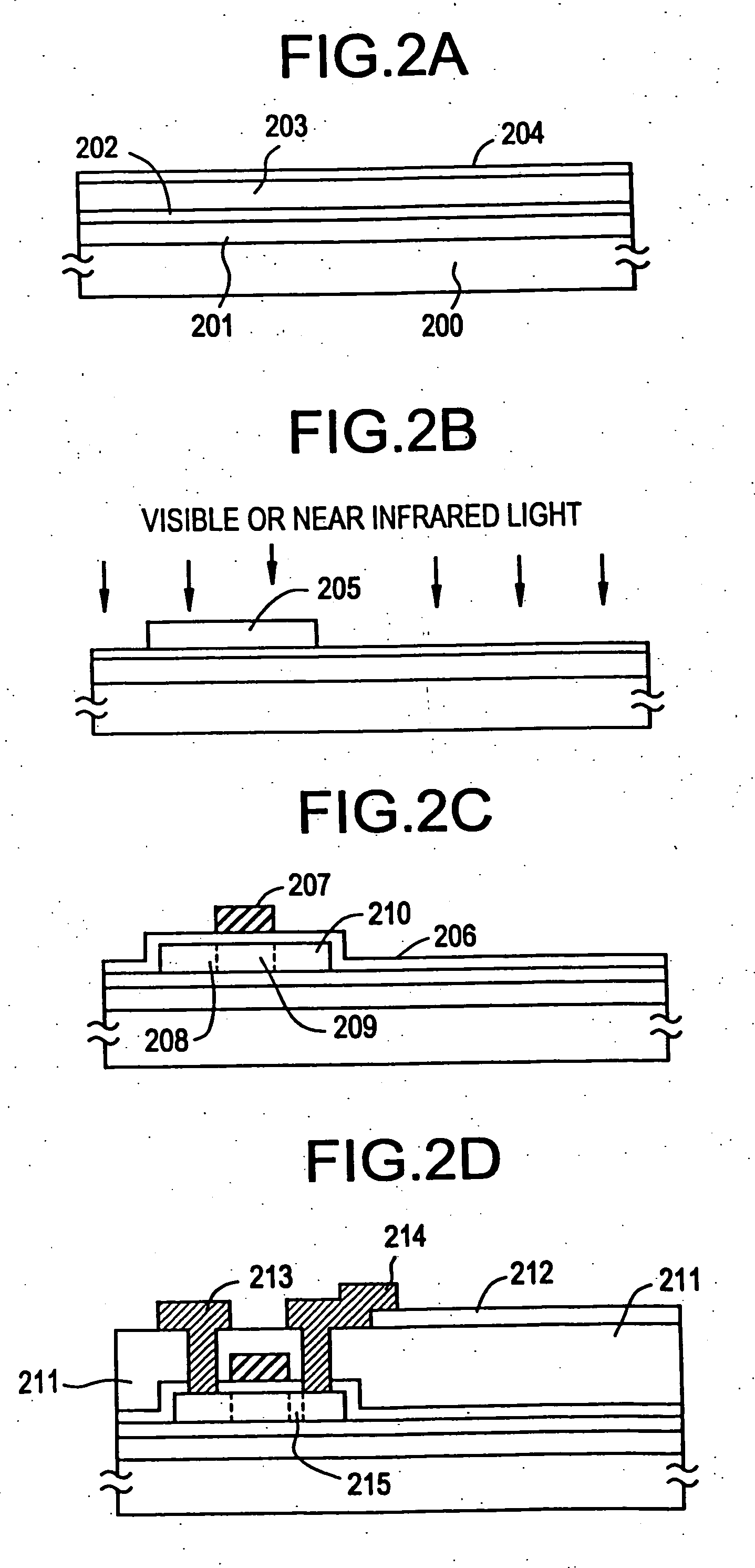

Process for fabricating semiconductor device

InactiveUS6051453AReduce the temperatureCrystal character can be improvedTransistorSolid-state devicesAmorphous siliconNear infrared radiation

A process for fabricating a semiconductor device comprising the step of, after patterning the silicon film crystallized to a low degree by thermally annealing an amorphous silicon film into an island by etching, irradiating an intense light of a visible light or a near infrared radiation to effect a short-period annealing (RTA) to the silicon film of low crystallinity. Thus, the crystallinity of the silicon film is improved and the silicon film is densified in a short-period.

Owner:SEMICON ENERGY LAB CO LTD

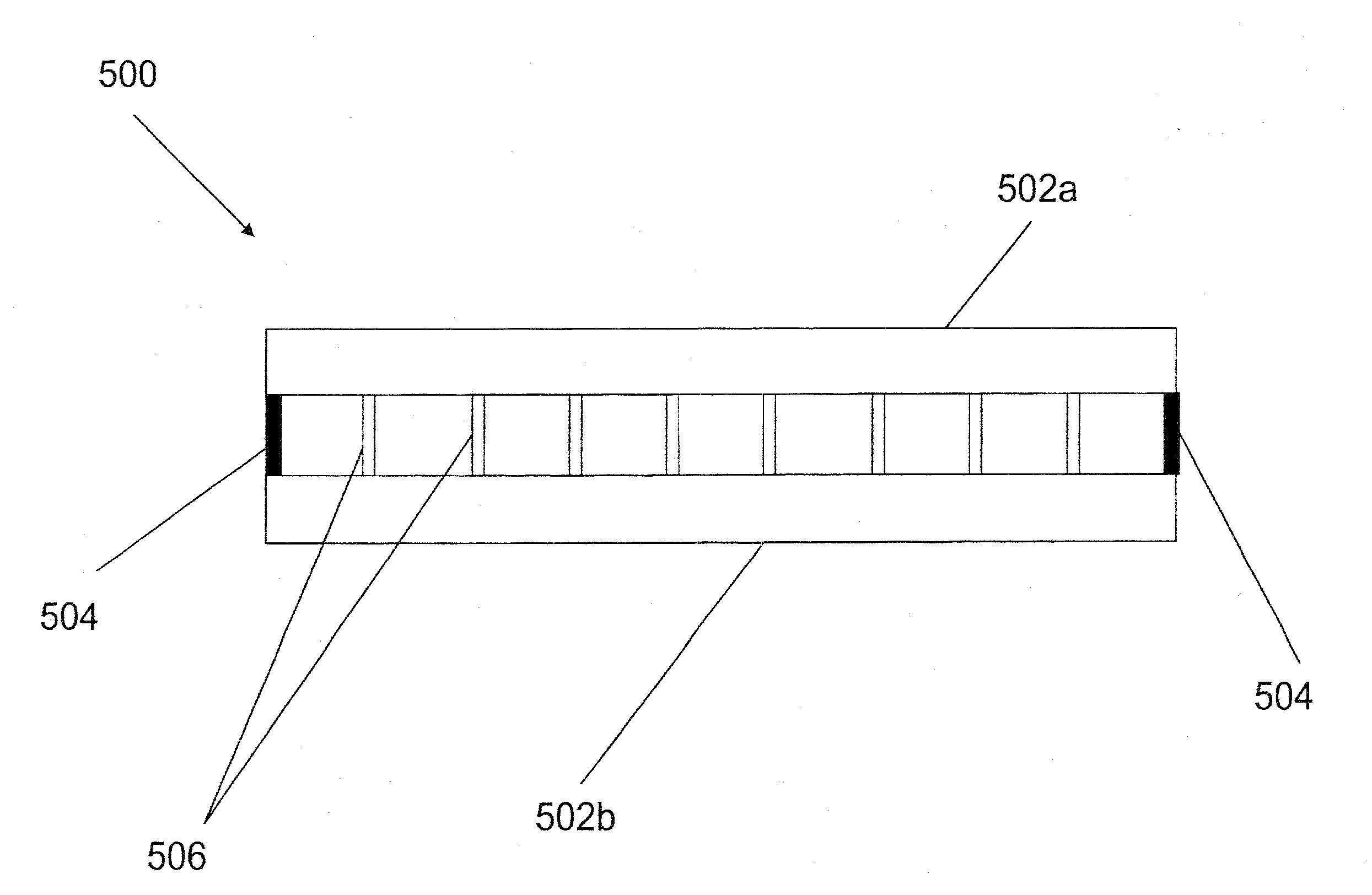

Coefficient of thermal expansion filler for vanadium-based frit materials and/or methods of making and/or using the same

ActiveUS20120213954A1Improve sealingReduce sealClimate change adaptationWindows/door improvementMetal chlorideFrit

Certain example embodiments relate to seals for glass articles. Certain example embodiments relate to a composition used for sealing an insulted glass unit. In certain example embodiments the composition includes vanadium oxide, barium oxide, zinc oxide, and at least one additional additive. For instance, another additive that is a different metal oxide or different metal chloride may be provided. In certain example embodiments, a composition may be combined with a binder solution that substantially or completely burns out by the time the composition is melted. In certain example embodiments, a CTE filler is included with a frit material. In certain example embodiments, a vacuum insulated glass unit includes first and second glass substrates that are sealed together with a seal that includes the above-described composition.

Owner:GUARDIAN GLASS LLC

Core glass in the alkali-zinc-silicate glass system for an fiber-optic light guide and fiber-optic light guide made with said core glass

ActiveUS20090163342A1Good chemical resistanceMeltability decreaseCladded optical fibreOptical waveguide light guideZincLight guide

Owner:SCHOTT AG

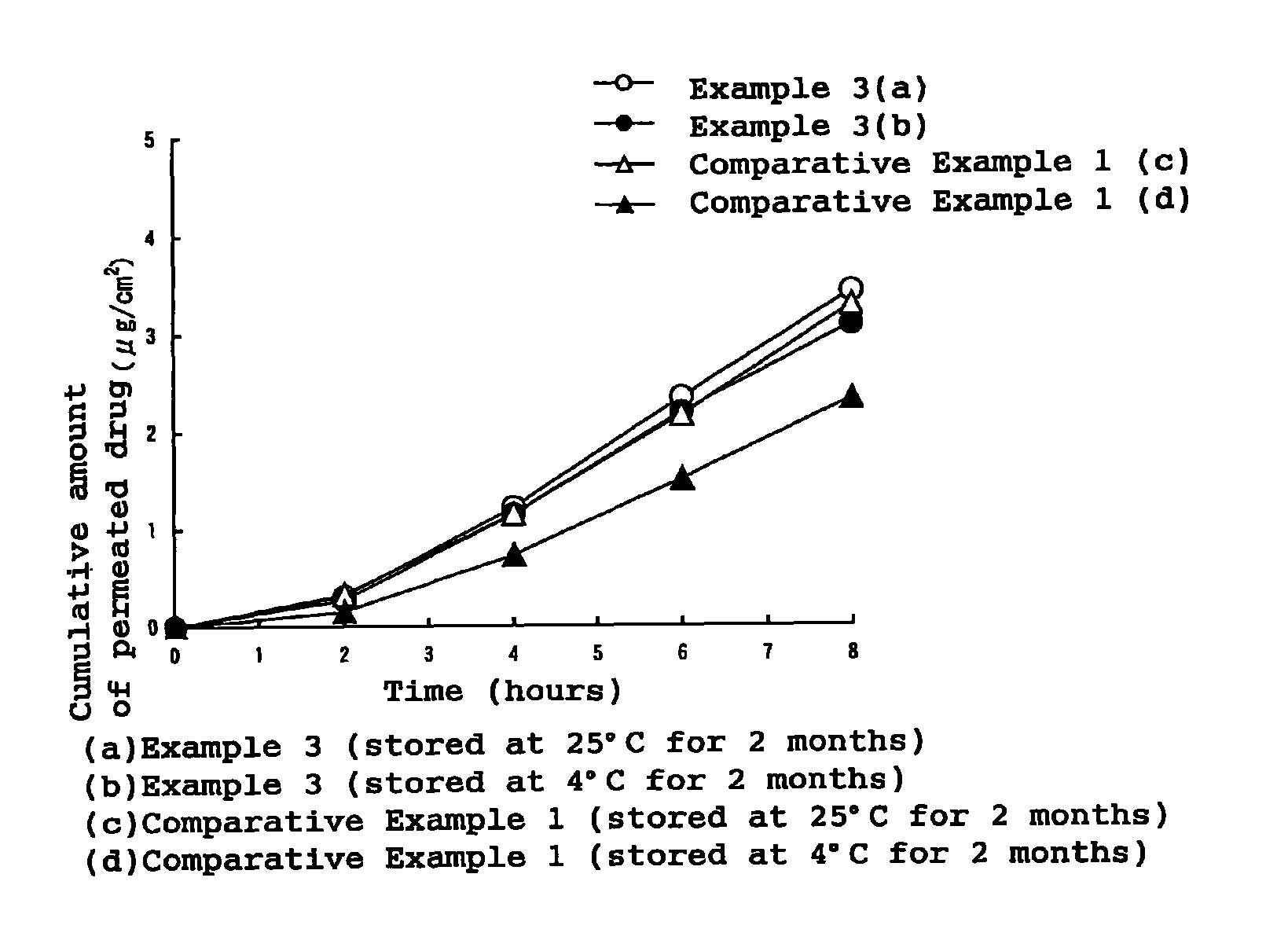

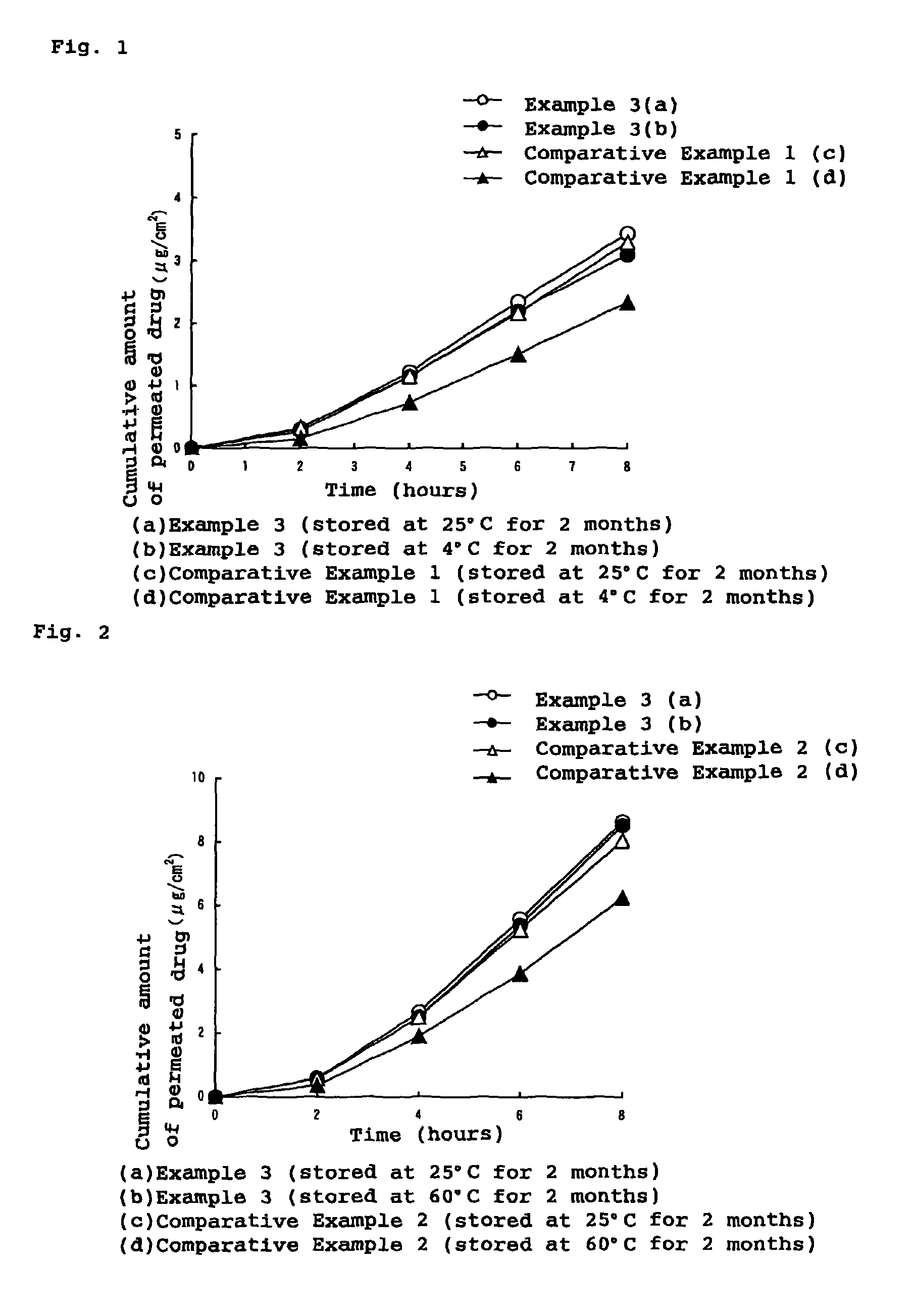

External patch containing estrogen and/or progestogen

InactiveUS8486442B2Stable drug releaseLess irritatingBiocideOrganic active ingredientsIrritationProlonged release

An external patch capable of stable prolonged release and transdermal absorption of active ingredient hormones (estrogens and / or progestogens) contained in a pressure sensitive adhesive layer, which external patch ensures low irritation on the skin. In particular, an external patch comprising a support and, superimposed thereon, a pressure sensitive adhesive layer, characterized in that the pressure sensitive adhesive layer comprises, as indispensable components, 5 to 50 wt. % of styrene / isoprene / styrene block copolymer, 20 to 70 wt. % of tackifier resin, 10 to 60 wt. % of softener and 1 to 20 wt. % of polyvinylpyrrolidone and contains, as an active ingredient, estrogen and / or progestogen.

Owner:TEIKOKU SEIYAKU KK TEIKOKU SEIYAKU CO LTD +1

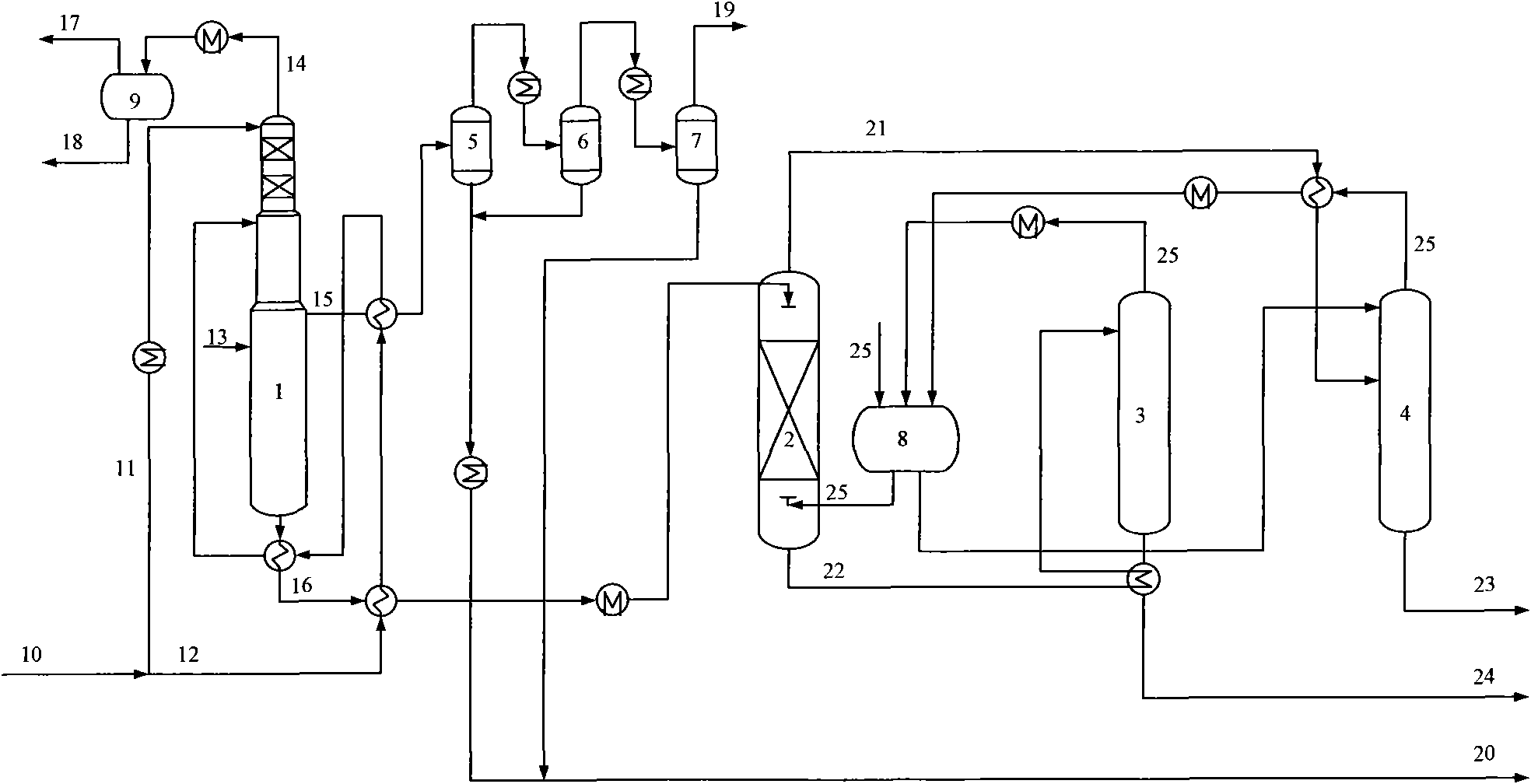

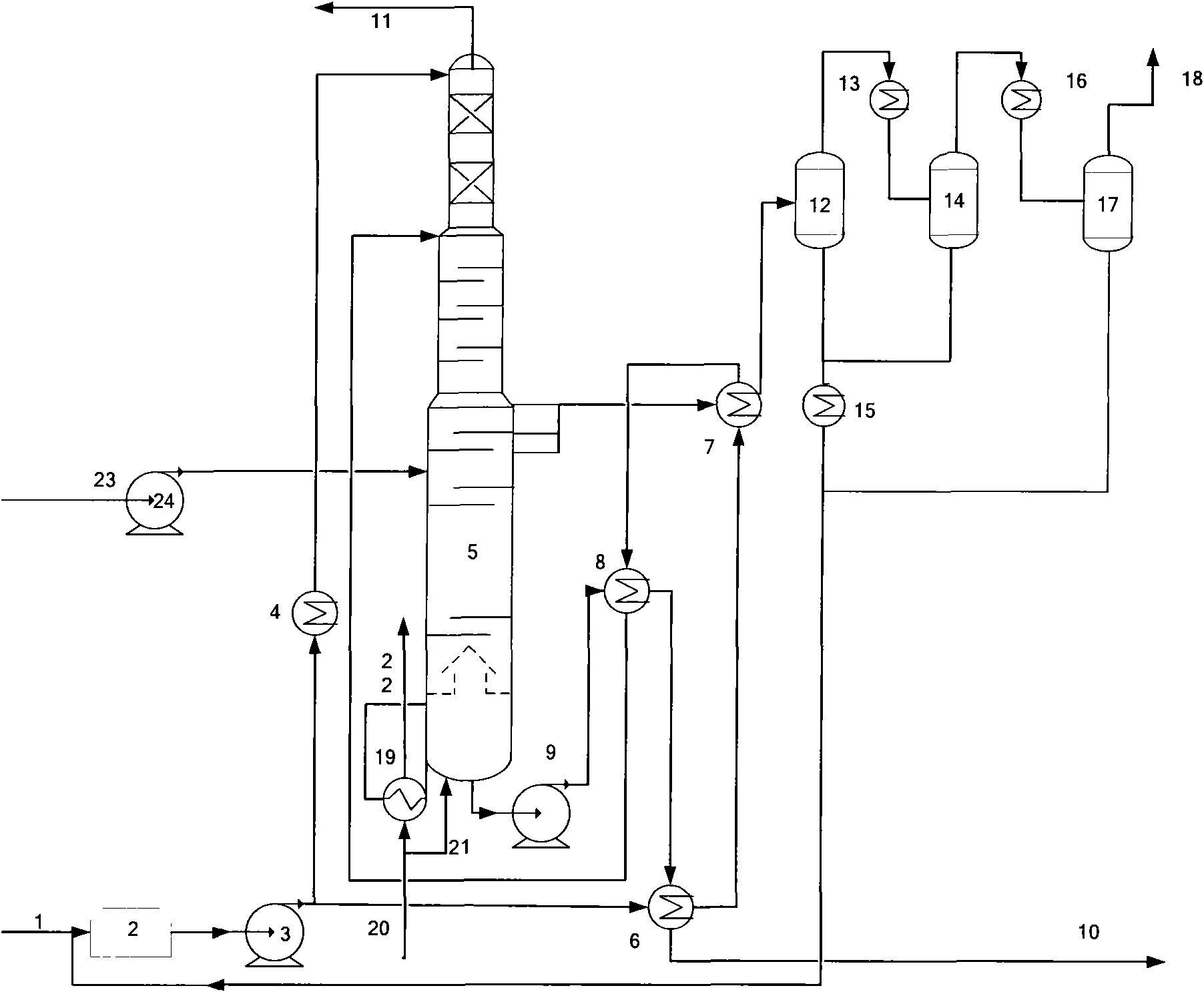

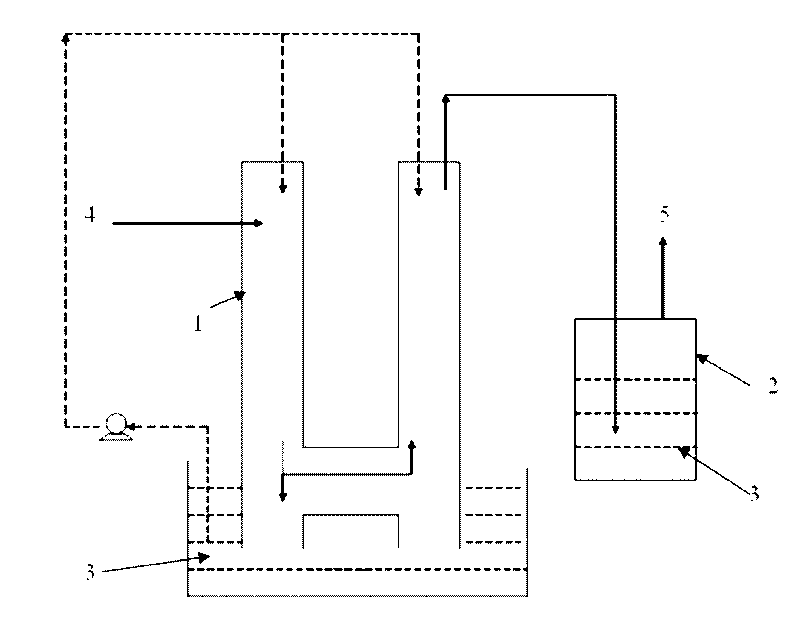

Method for treating coal gasification wastewater containing phenol and ammonia

InactiveCN101597124AEffective removal of fixed ammonia contentMeet the requirements of subsequent biochemical treatmentMultistage water/sewage treatmentWater/sewage treatment by degassingCoal gasification wastewaterHigh concentration

The invention relates to a method for treating coal gasification wastewater containing phenol and ammonia. The method comprises the following steps: single tower alkali injection and pressurization steam stripping removal of acidic gas and ammonia, three-level dephlegmation of lateral line tapped gas, extraction of phenol by diisopropyl ether and solvent recovery. The cold and hot coal gasification wastewater, according to a certain proportion, respectively enters a pressurization single tower from the upper part and middle upper part of a wastewater steam stripping tower, and acid gas is discharged from the tower top; the lateral line withdrawal mixed gas goes through three-level dephlegmation to obtain high-concentration ammonia, alkali is injected at the position below the lateral line to transform fixed ammonia into free ammonia which is to be removed; counter-current extraction is carried out on removed ammonia, residue of acid gas and diisopropyl ether to dephenolize; extraction solvent is recovered by a solvent recovery tower and a solvent steam stripping tower to obtain the byproduct, namely crude phenol. In the method of the invention, the process removing acid gas, free ammonia and fixed ammonia is carried out simultaneously on the coal gasification wastewater in the wastewater steam stripping single tower, as a result, high-concentration ammonia is obtained, the content of carbon dioxide, sulfureted hydrogen, free ammonia and fixed ammonia in tower kettle purified water is extremely low, encrustment is not prone to take place, and the purified coal gasification wastewater meets the requirement of follow-up biochemical treatment.

Owner:SOUTH CHINA UNIV OF TECH +2

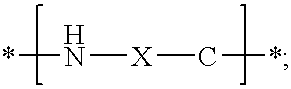

Polyamide composition

InactiveUS6887930B2Low water absorptionOvercome lack of heat resistanceCarboxylic acidTerephthalic acid

A polyamide composition comprising 50 to 90 parts by weight of (A) semiaromatic polyamides having dicarboxylic acid units containing 60 to 100 mole % of terephthalic acid units and diamine units containing 60 to 100 mole %, in total, of 1,9-nonanediamine units and / or 2-methyl-1,8-octanediamine units, and 50 to 10 parts by weight of (B) aliphatic polyamides in which the average of total carbon atoms of dicarboxylic acid units and diamine units per one amide group is 7 to 12; having excellent moldability, toughness, light-weightness, hot water and steam resistance, heat resistance, mechanical characteristics, low water absorption, chemical resistance and melt stability; and are applicable for molding at low temperature with a conventional steam-heating or a conventional hot-water-heating type mold to give molded articles having sufficient heat resistance, rigidity at high temperature and dimensional stability.

Owner:KURARAY CO LTD

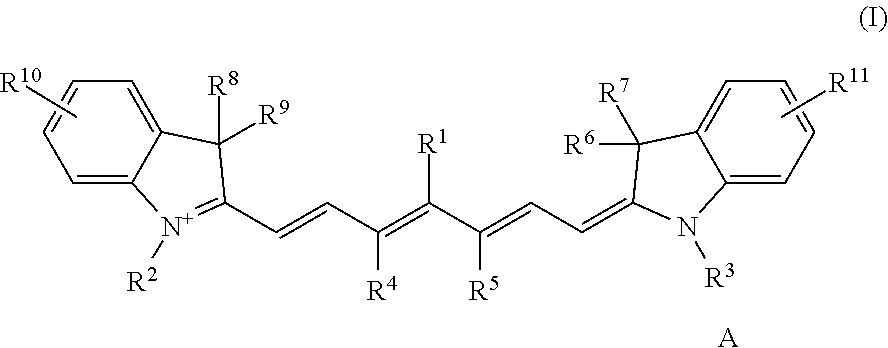

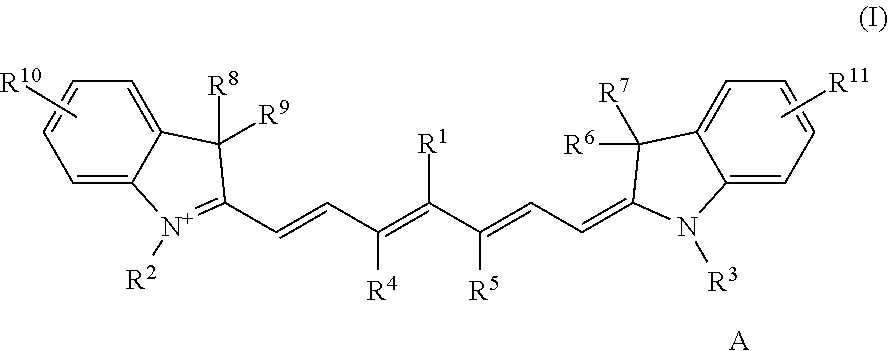

Negative-working lithographic printing plate precursors with IR dyes

ActiveUS8632941B2Increase speedReduce crystallizationPlaten pressesPhotosensitive materialsOrganic groupPhotochemistry

A lithographic printing plate precursor comprises an imageable layer comprising a free radically polymerizable component, an initiator composition capable of generating free radicals upon exposure to imaging infrared radiation, an infrared radiation absorbing dye that is defined by Structure (I) shown in the disclosure, which dyes comprise one or more ethylenically unsaturated polymerizable groups in an organic group that is attached to the methine chain. These infrared radiation absorbing dyes exhibit a reduced tendency to crystallize in the imageable layers in the presence of tetraaryl borate counter anions and therefore provide improved shelf life.

Owner:EASTMAN KODAK CO

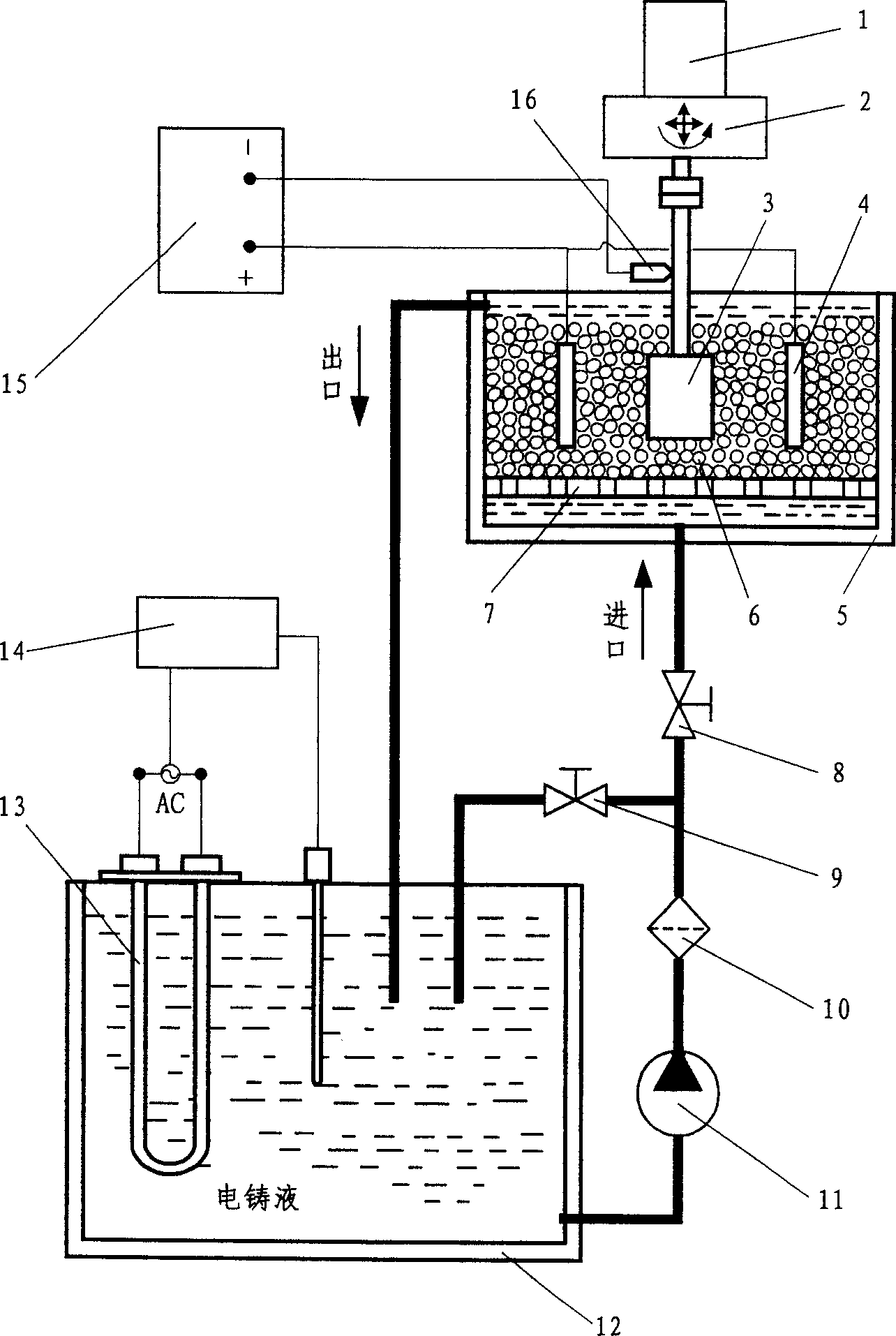

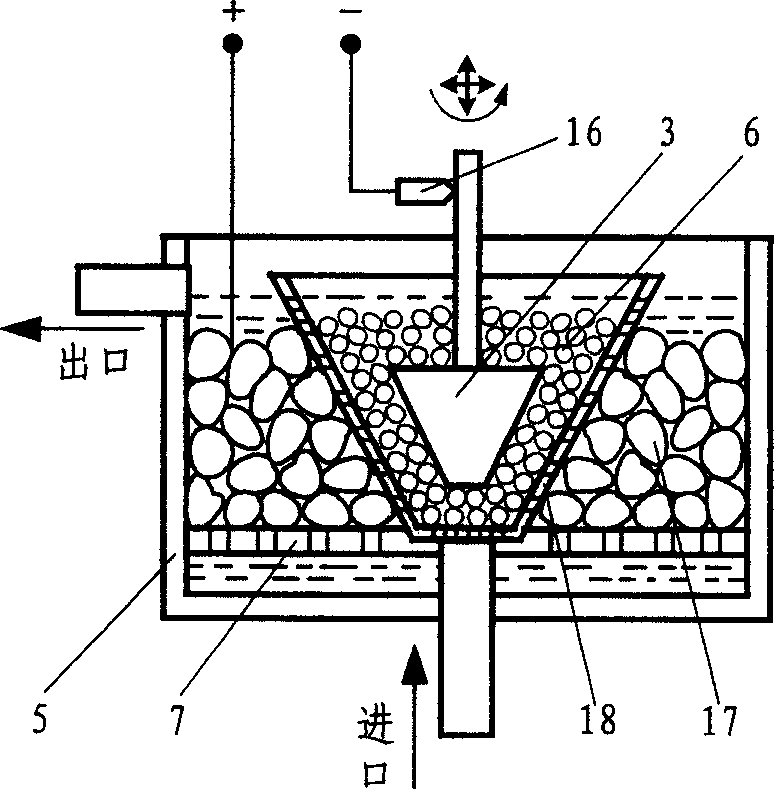

Precise electrotyping shaping technology and device by cathode motion prinding method

InactiveCN1624205AEfficient removalReduce thicknessElectroforming processesLiquid tankMaterials science

A precise eelctroforming technology by the cathode moving friction method includes such steps as filling hard particles in electrocasting bath, burying the electrocasting core mould in the hard particles, and moving the core mould to make said hard particles to rub and impact the surface of core mould for removing air bubbles and deposited layer, decreasing the thickness of diffused layer and increasing electrocasting speed and quality. Its apparatus is composed of motor, electrocasting bath, partition, liquid tank, magnetic pump, filter, ball valve, overflow valve, temp controller, heater, power supply, conductive device and electroforming processing device composed by transmission, core mould, hard particles and anode.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

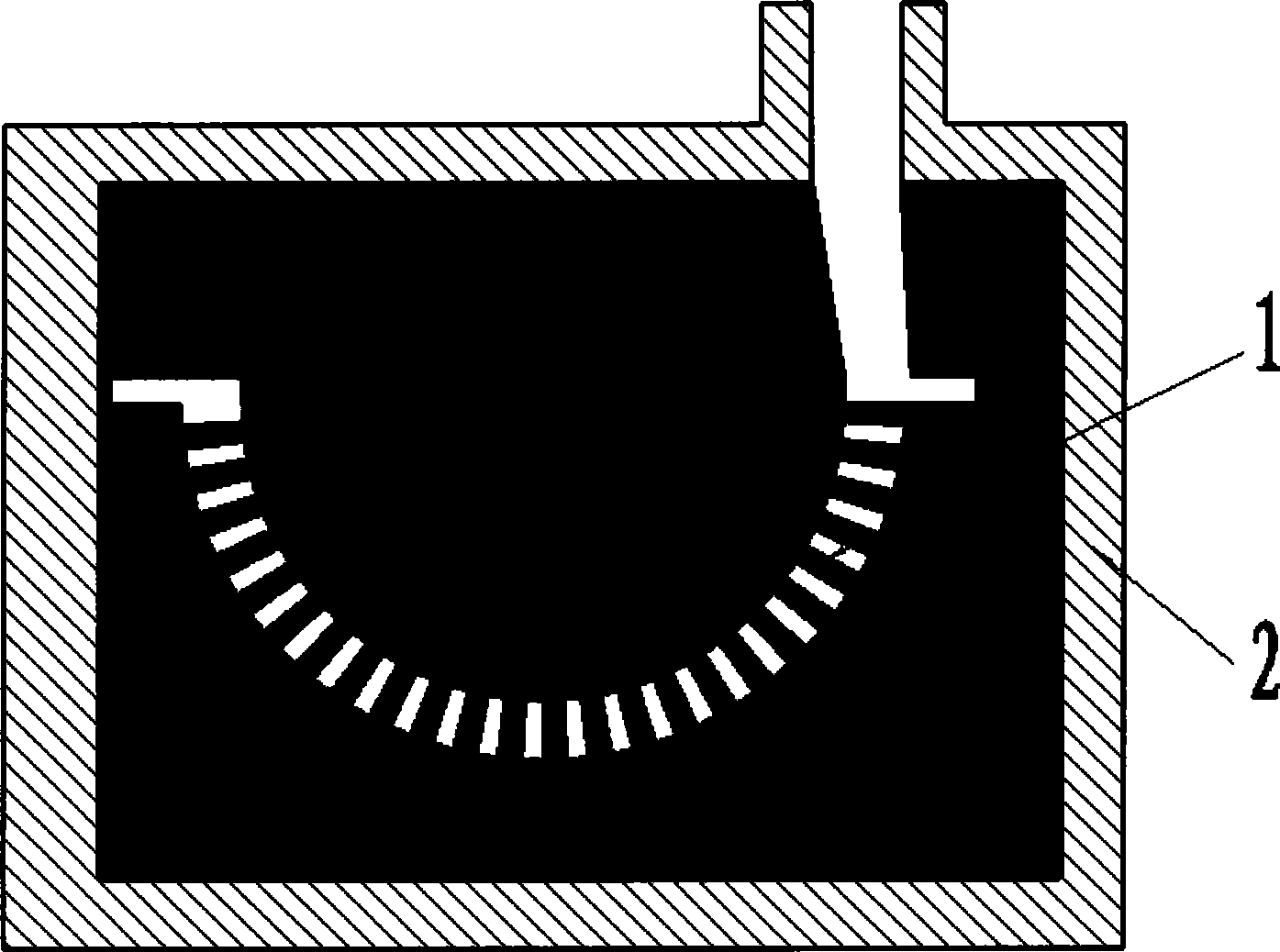

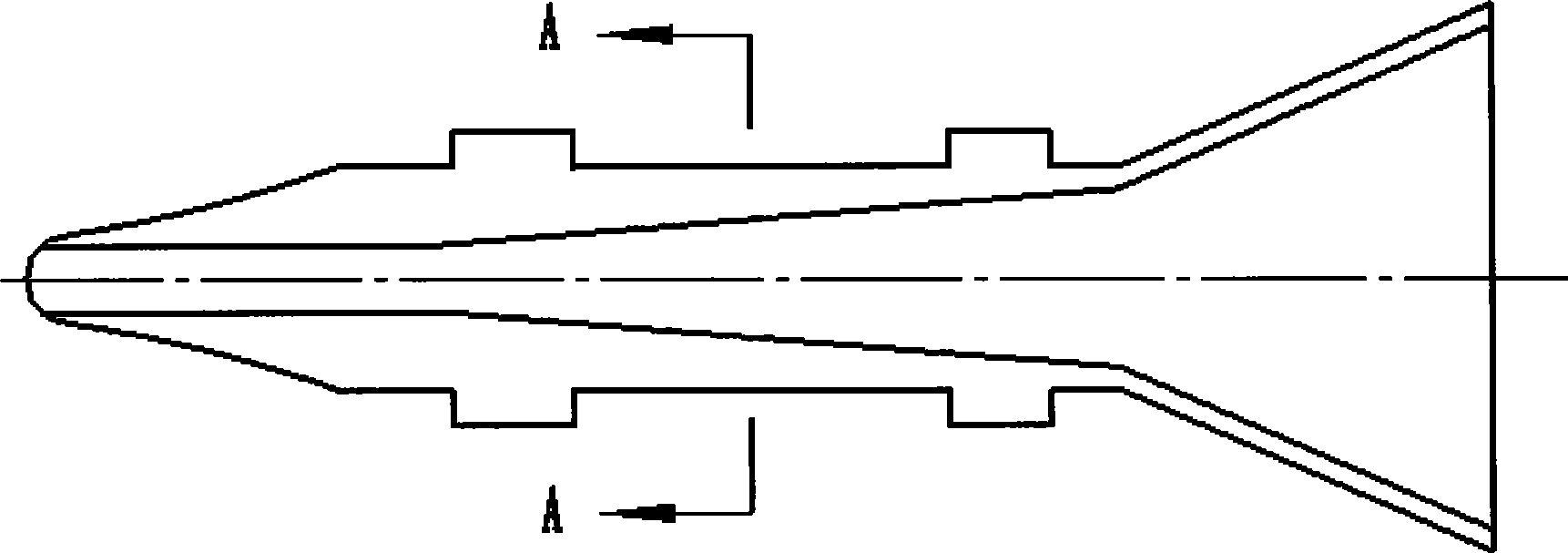

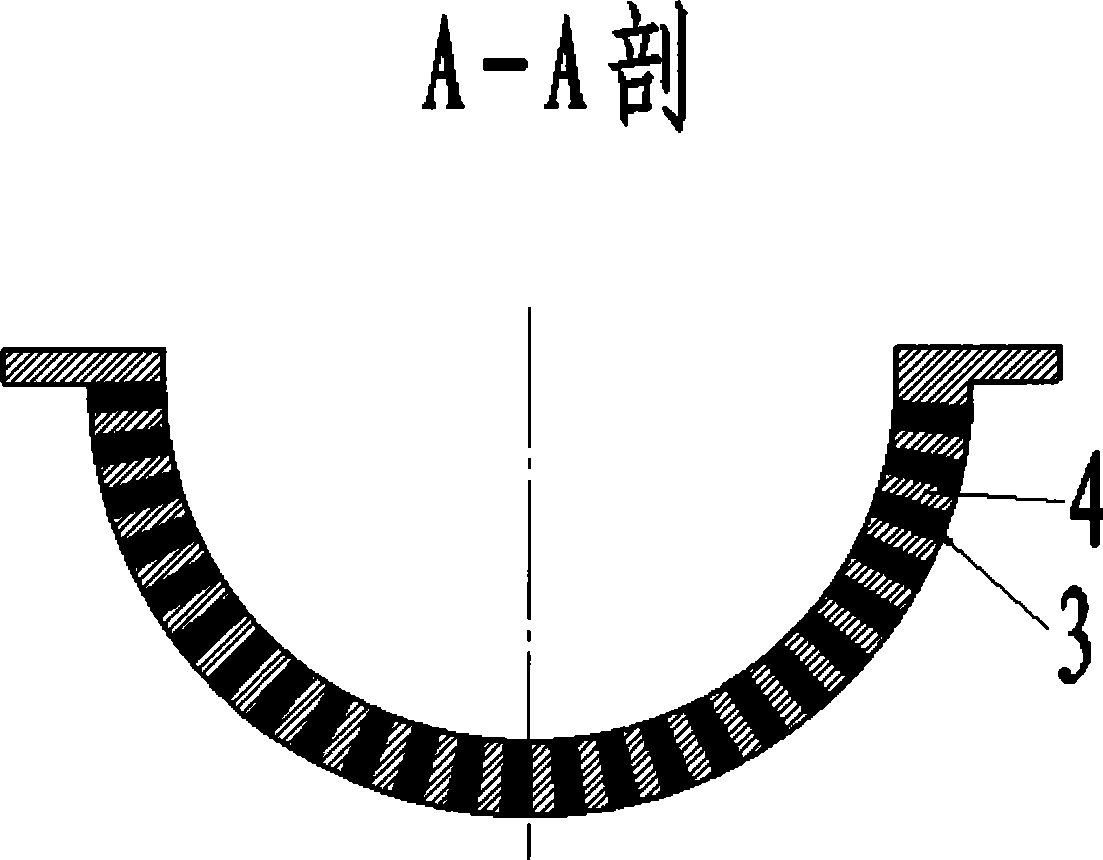

Manufacturing method for superlow shrinkage type PET industrial yarn

ActiveCN102797056AGuaranteed positionControl and reduce dwell timeArtificial thread manufacturing machinesMelt spinning methodsFiberYarn

The invention relates to a manufacturing method for superlow shrinkage type PET industrial yarn, which is characterized in that the superlow shrinkage type PET industrial yarn is manufactured through selecting and controlling cooling conditions, and the technological process is as follows: hyperviscous melting to polyester raw materials, metering, spanning, cooling, oil supplying, stretching, hot shaping, and reeled forming. For lowing the irregularity and shrinkage percentage of fiber, a slow cooling device is arranged in the production of industrial yarn, a precooling device adopted is a hollow stepped ring-shaped belt comprising an upper part and a lower part, through holes with the diameters of 5 to 7 mm are uniformly distributed in the upper part of the ring-shaped belt, through holes with the diameters of 3 to 4 mm are uniformly distributed in the lower part, and the hole arrangement densities are the same. The natural target of the PET industrial yarn is as follows: the fracture strength is equal or greater than 7.0 cN / dtex, the breaking elongation is 20.0 plus or minus 1.5 percent, and the dry heat shrinkage percentage under the test conditions of 170 DEGC, 0.05cN / dtex reaches 1.9 plus or minus 0.25 percent.

Owner:JIANGSU HENGLI CHEM FIBER

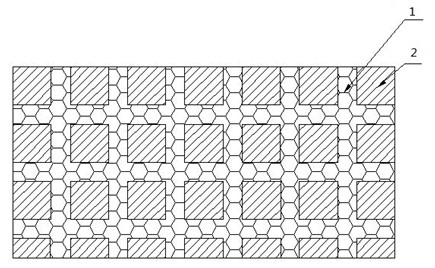

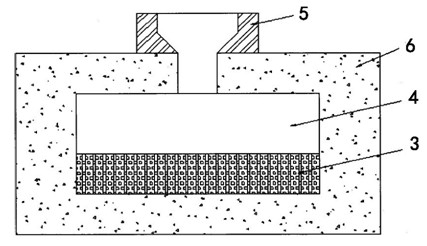

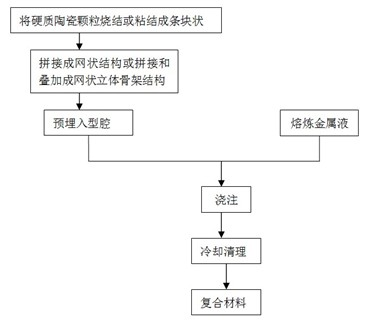

Method for preparing ceramic particle reinforced steel-based mesh material

The invention provides a method for preparing a ceramic particle reinforced steel-based mesh material, which comprises: forming a mixture of hard ceramic particles and alloy powder into strip blocks by powder sintering or by using and adhesive; joining the strip blocks into a corresponding mesh structure or joining and overlapping the strip blocks into mesh three-dimensional framework structure; and performing normal sand casting or lost foam casting, namely melting a substrate metal material, pouring the molten substrate metal material in a molding cavity, allowing the molten substrate metal material to cool and condense at room temperature, removing sand and obtaining the ceramic particle reinforced steel-based mesh material. The obtained ceramic particle reinforced steel-based mesh material gives full play to the high wear resistance of the ceramic particle hard phase and the toughness of the steel base; and the method with convenience for regulation and reliable process solves the problem of incomplete reaction of the composite material, nonuniform reinforcing phase particle distribution, pollution weakening on a reinforcing phase interface and the like and is used in wear resistance fields of mines, power, metallurgy, coal, building materials and the like.

Owner:KUNMING UNIV OF SCI & TECH

High-performance 3D printing supply alloy material

InactiveCN103804862AImprove impact performanceImprove the disadvantage of poor temperature resistanceGlycidyl methacrylateAcrylonitrile

The invention provides a high-performance 3D (Three Dimensional) printing supply alloy material. The high-performance 3D printing supply alloy material comprises, in parts by weight, 20.0-50.0 parts of polylactic acid, 50.0-80.0 parts of high impact polystyrene, 0.1-5.0 parts of compatilizer and 0.2-3.0 parts of auxiliaries, wherein the compatilizer comprises one or more than two, matched with each other in use, of a maleic anhydride grafted high polymer, a terpolymer copolymerized with styrene, acrylonitrile and glycidyl methacrylate (SAG), and a terpolymer copolymerized with methyl methacrylate, butadiene and a styrol copolymer (MBS). The high-performance 3D printing supply alloy plastics prepared from the high-performance 3D printing supply alloy material are non-toxic, low-carbon and environment-friendly, low in alloy material cost, excellent in combination properties, and very high in economic value and wide in market prospect.

Owner:芜湖瀚博电子科技有限公司

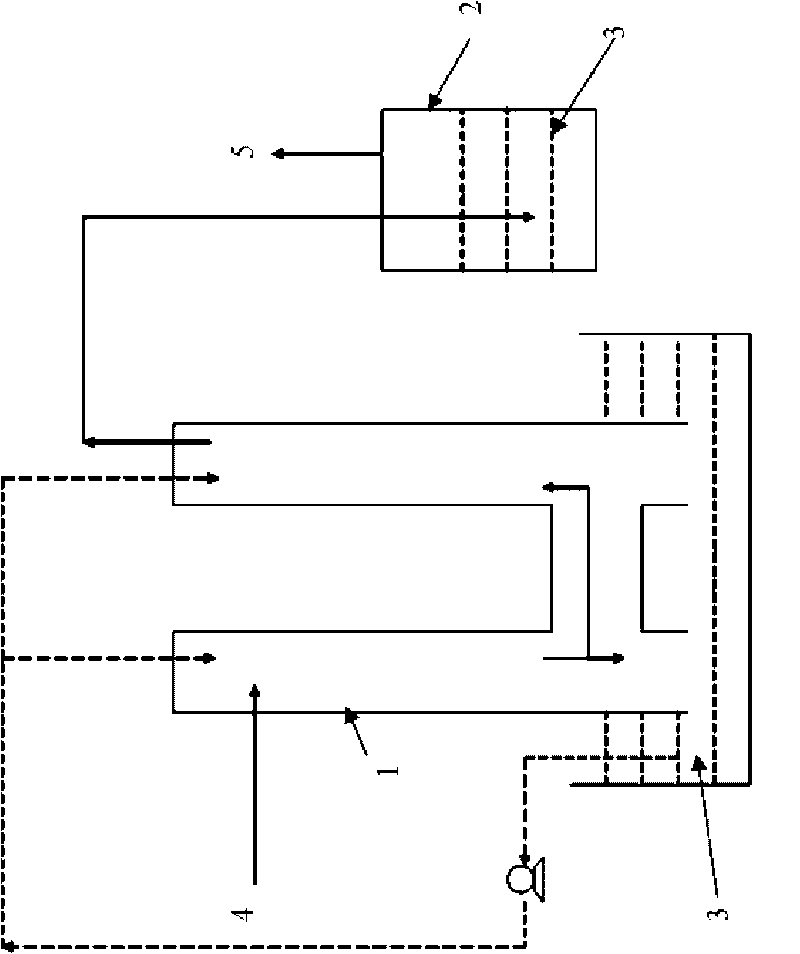

Method for treating coal gasification wastewater by single tower alkali injection and pressurization steam stripping

InactiveCN101597092ALow investment costLow running costWater/sewage treatment by degassingAmmonia preparation/separationHigh concentrationCoal gasification wastewater

The invention discloses a method for treating coal gasification wastewater by single tower alkali injection and pressurization steam stripping, comprising the following steps: the cold and hot coal gasification wastewater respectively enters a single tower from the upper part and middle upper part of a wastewater steam stripping tower, gas ammonia is extracted from the lateral line of the single tower which goes through three-level dephlegmation to obtain high-concentration ammonia, condensate returns to a stock tank; alkali is injected at the position below the lateral line to transform fixed ammonia into ammonia which is to be removed; the mass percentage concentration of alkali liquor is 20-40%, the use level of the alkali liquor is not more than that of mol number of fixed ammonia in the wastewater, and residue is extracted from the tower bottom and is subjected to follow-up extraction and dephenolizing process of coal gasification wastewater. In the method of the invention, the process removing acid gas, free ammonia and fixed ammonia is carried out simultaneously on the coal gasification wastewater in the wastewater steam stripping single tower, as a result, high-concentration ammonia is obtained, the content of carbon dioxide, sulfureted hydrogen, free ammonia and fixed ammonia in tower kettle purified water is extremely low, encrustment is not prone to take place, pH value is reduced to around 6, as a result, fine extraction conditions are created for the follow-up solvent extraction dephenolizing of the coal gasification wastewater. The method of the invention is suitable for the coal gasification wastewater and overall treatment process thereof.

Owner:SOUTH CHINA UNIV OF TECH +2

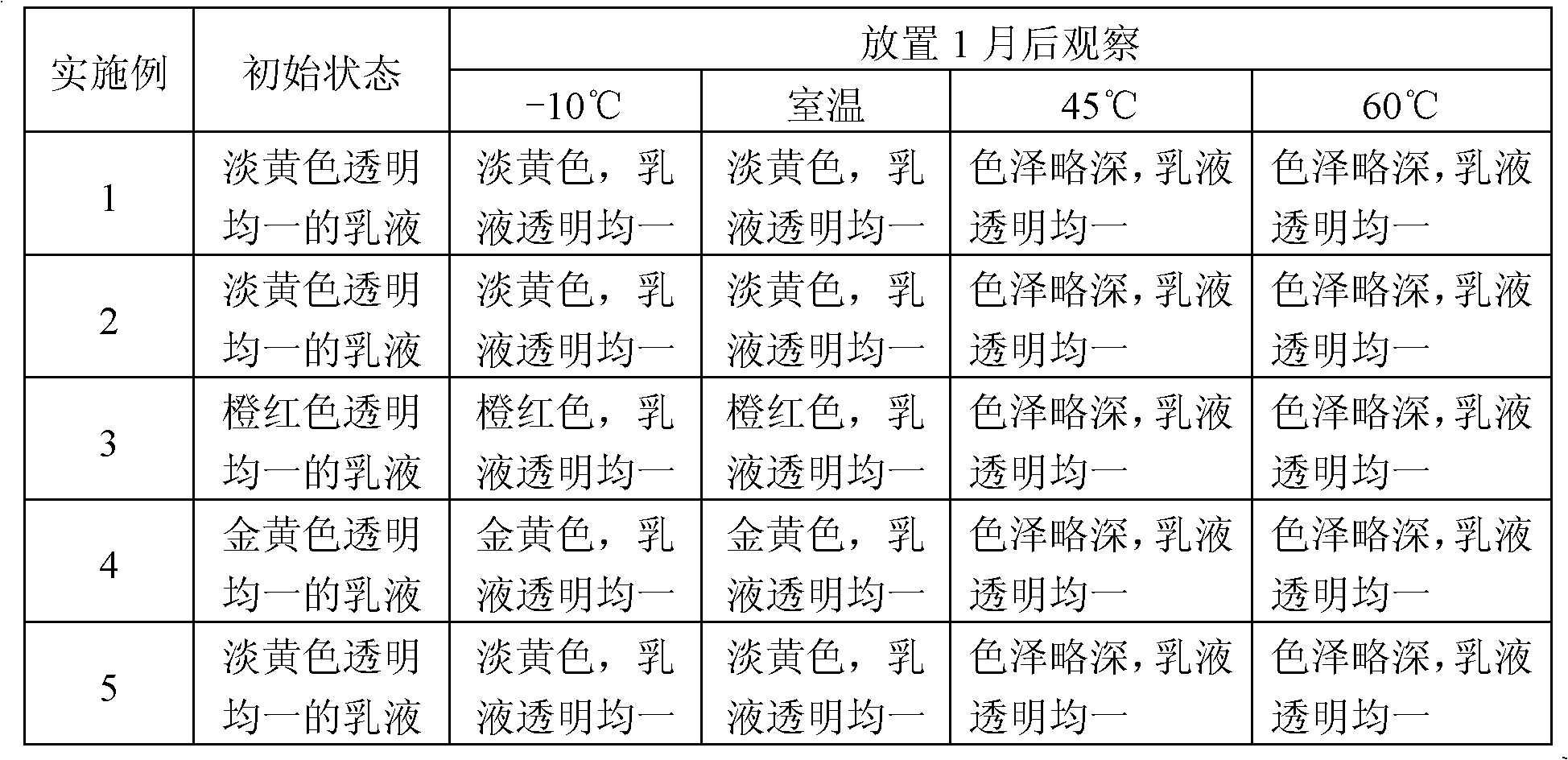

Self-microemulsion and preparation method thereof

ActiveCN102423297AImprove applicabilityLarge oil loadEmulsion deliveryOil/fats/waxes non-active ingredientsOil phaseMicroemulsion

The invention discloses a self-microemulsion and a preparation method thereof, relates to a microemulsion and provides the self-microemulsion with the advantages of wide regional applicability, stable transmission, wide temperature range, high oil carrying amount and transparency as well as the preparation method thereof. The self-microemulsion consists of the following components in parts by mass: 10-40 parts of oil phase, 0-5 parts of oil phase emulsifying agent, 20-40 parts of main body emulsifying agent, 20-50 parts of assisted emulsifying agent, 5-15 parts of aqueous media, 0-2 parts of functional additive and 20-40 parts of main body emulsifying agent. The preparation method comprises the following steps of: feeding oil-soluble products into stirring equipment; adding carried oil and the oil phase emulsifying agent; mixing and heating the mixture until the mixture is dissolved for later use; adding the main body emulsifying agent, the assisted emulsifying agent, the aqueous media and the functional substance in another stirring equipment; stirring, mixing and heating the mixer until the mixture is dissolved for later use; and adding the dissolved aqueous phase in an oil phase vessel, stirring until the emulsion is transparent and cooling to be normal temperature to obtain a product.

Owner:XIAMEN KINGDOMWAY BIOTECH CO LTD +1

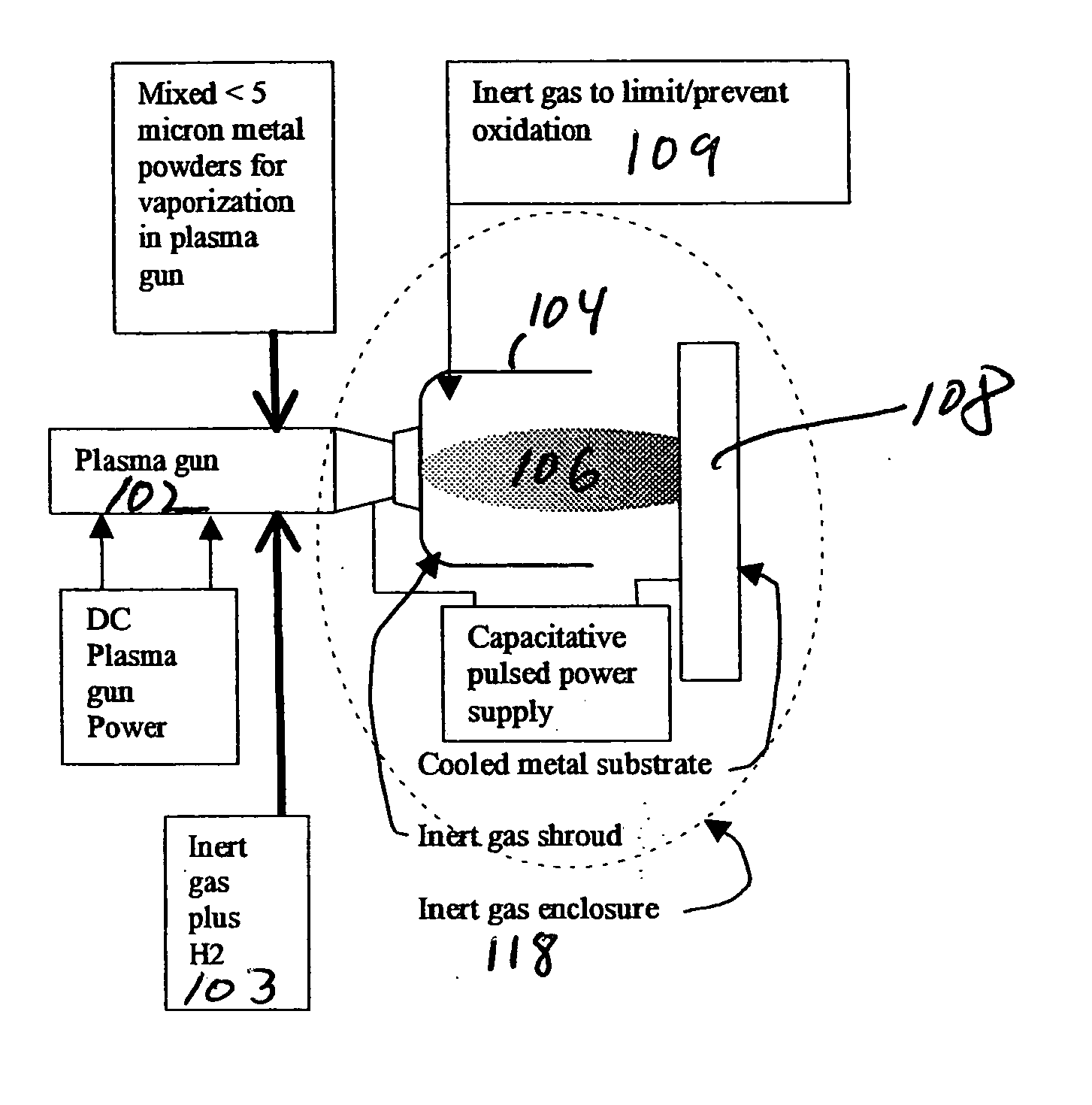

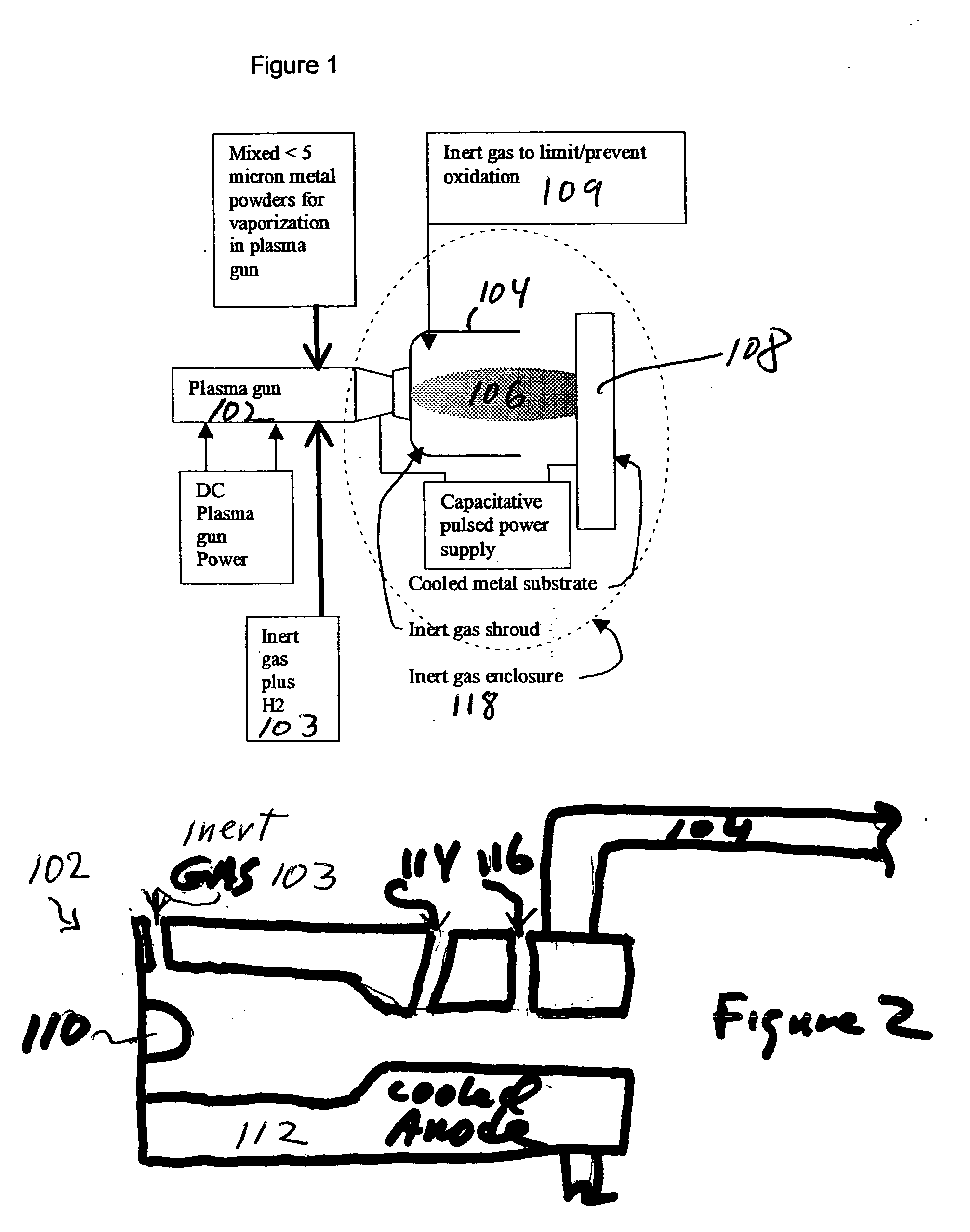

Amorphous metal deposition and new aluminum-based amorphous metals

InactiveUS20050123686A1Improve toughnessIncrease impactLiquid surface applicatorsMolten spray coatingHigh densityMetal alloy

Methods for applying an amorphous metal alloy to a substrate, comprising the steps of vaporizing an amorphous metal alloy composition, in a plasma spray gun to form a metal alloy vapor plasma plume, directing the metal alloy vapor plume onto a cooled substrate, maintained and condensing and rapidly solidifying the amorphous metal alloy composition vapor on the substrate, to form an amorphous metal layer deposit of high density and strength.

Owner:MYRICK JAMES J

Process for treating residual liquid and tail gas in polysilicon production by improved Siemens method

InactiveCN101700466AReduce crystallizationCrystal looseDispersed particle separationSilicon compoundsProduct gasChloride

The invention relates to a process for treating a tail gas, in particular to a process for treating a residual liquid and a tail gas in polysilicon production by an improved Siemens method. The invention provides a process for treating the residual liquid and the tail gas in polysilicon production by the improved Siemens method, which is difficult to block a pipeline. The process comprises the following steps of: carrying out neutralization reaction on the high-boiling substance residual liquid, the chlorosilane tail gas and eluent; emptying the gas after the neutralization reaction; treating the liquid after the neutralization reaction to neutrality and then carrying out harmless treatment, wherein the eluent is lime milk with the volume percentage of 10-30 percent. When the lime milk eluent of the process is used, calcium chloride is slowly crystallized, and crystals are quite loose, are easy to clean and can not block the pipeline; compared with sodium hydroxide, 8-10 percent of eluent can be saved, and the production cost is saved.

Owner:LESHAN LEDIAN TIANWEI SILICON TECH CO LTD

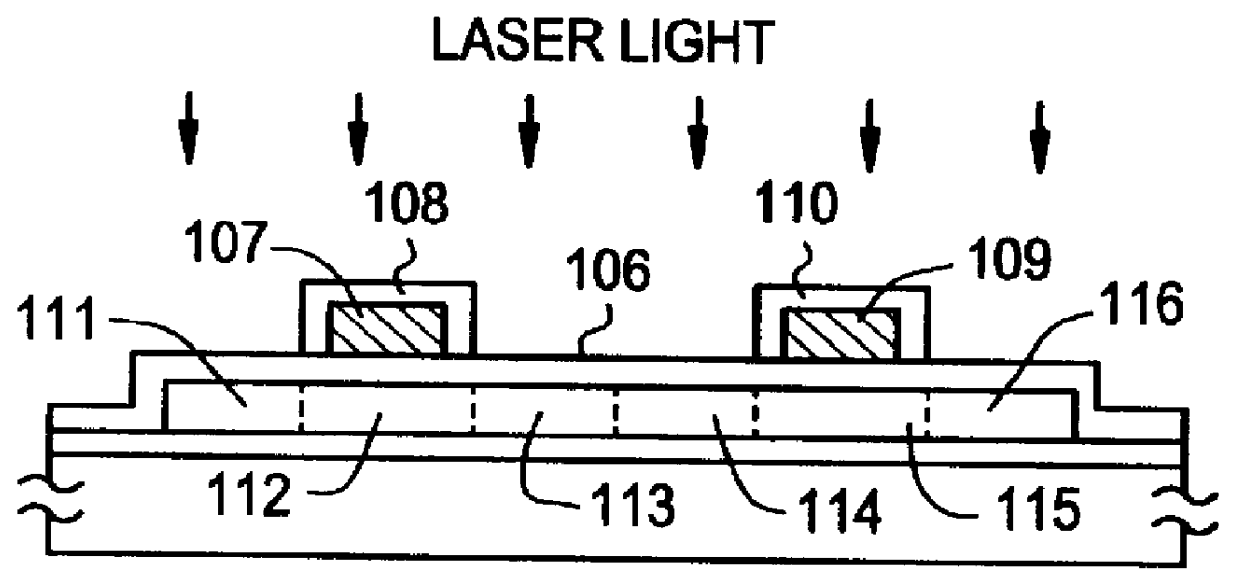

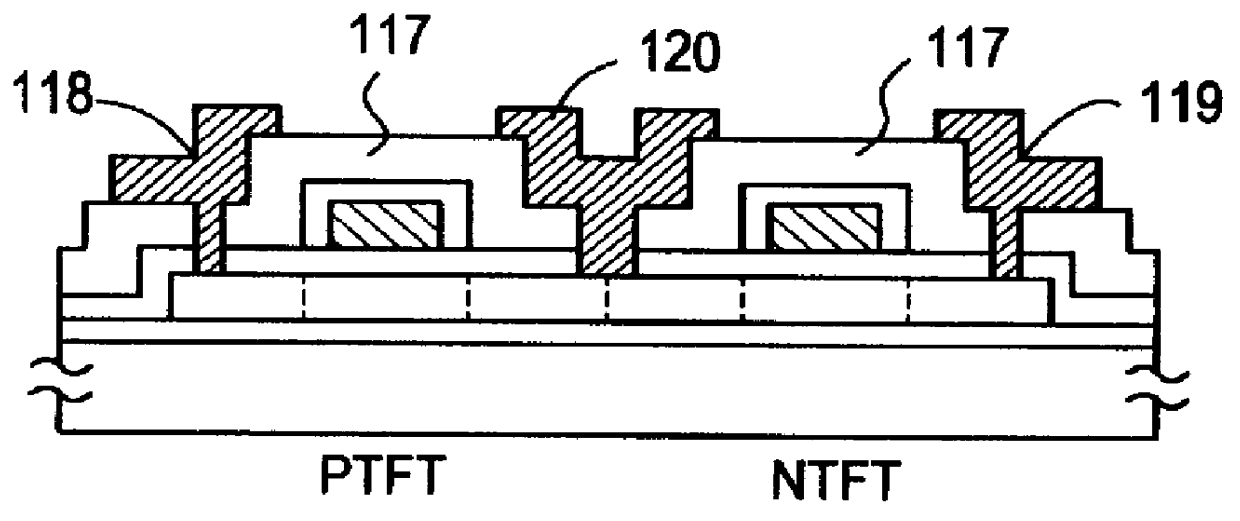

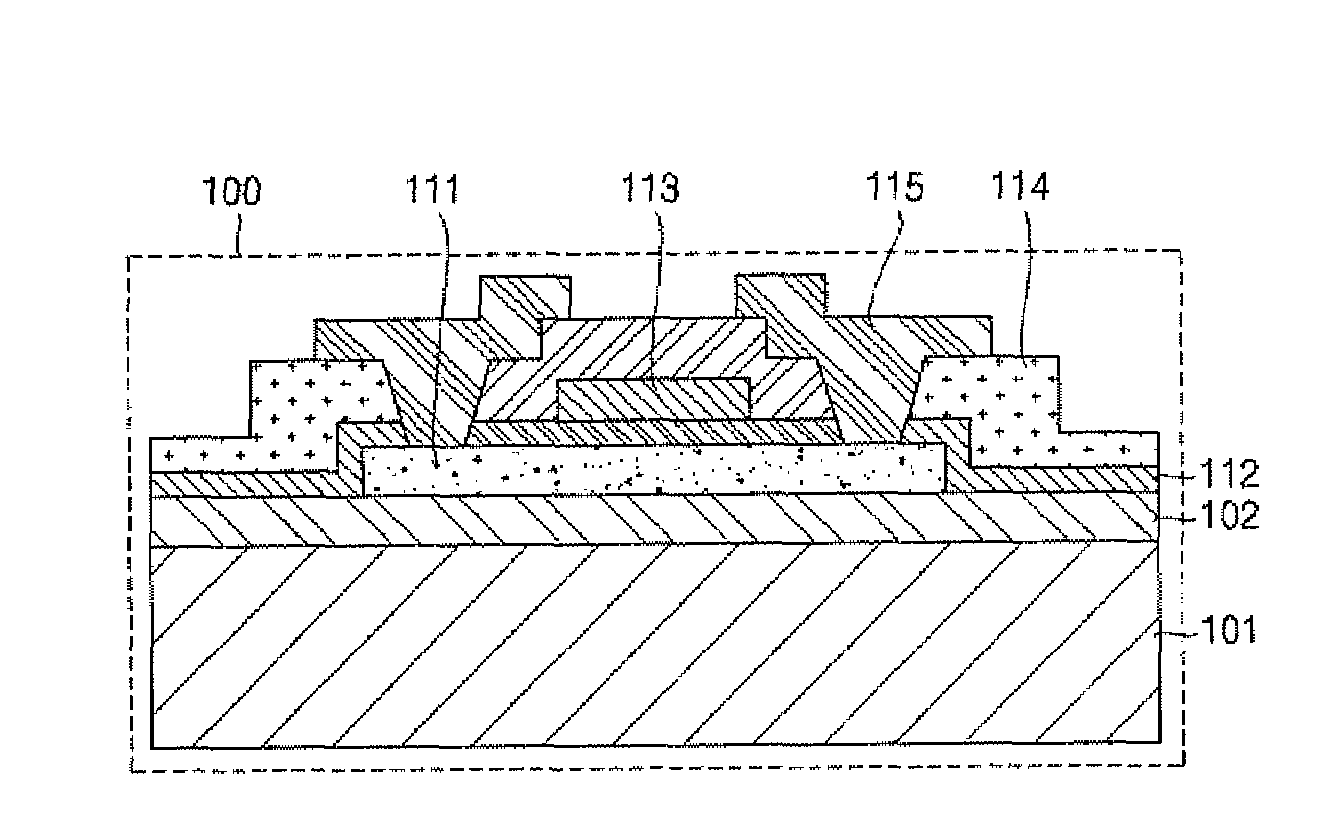

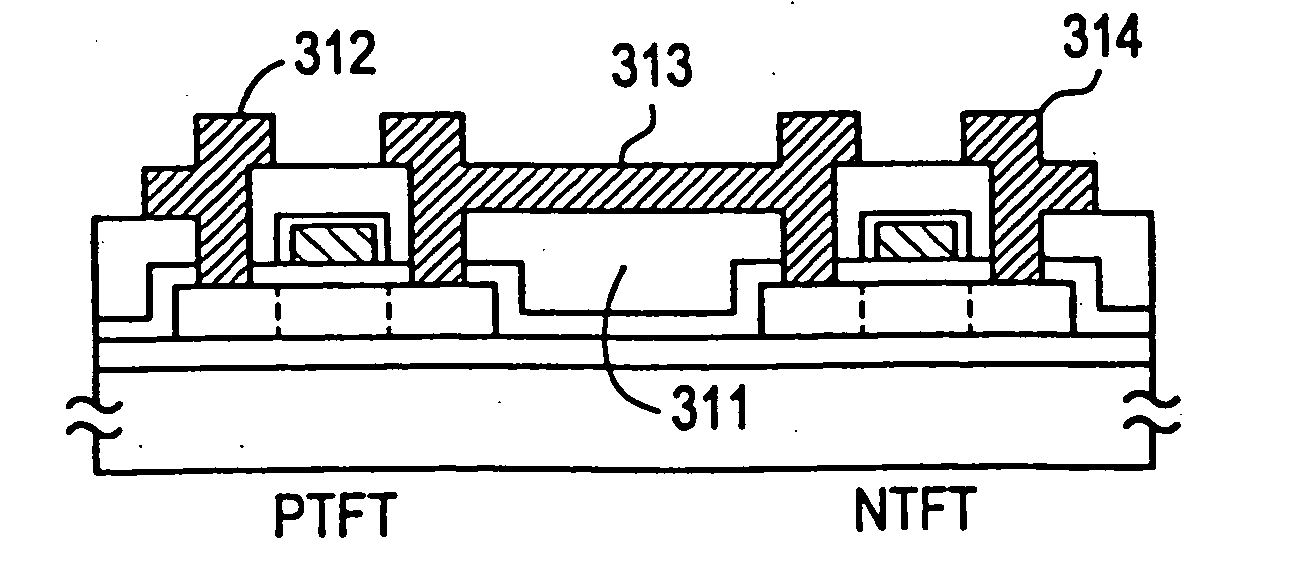

Transistor, fabricating method thereof and flat panel display therewith

InactiveUS20080157083A1Control concentrationMinimise currentSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceFlat panel display

A transistor includes a substrate, an active region including a source region, a channel region, and a drain region which are crystallized using an SGS crystallization method and are formed on the substrate so that a grain size of a first annealed portion and a second annealed portion are different from each other, a gate insulating layer formed on the active region, and a gate electrode formed on the gate insulating layer.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

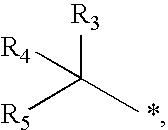

Method of increasing the oxidation stability of biodiesel

InactiveUS20060218855A1Improve Oxidation StabilityEasy to processOrganic chemistryFlushing devicesBiodieselHydrogen

The invention relates to a method of increasing the oxidation stability of biodiesel, which comprises adding a primary antioxidant having a melting point of less than or equal to 40° C. to the biodiesel to be stabilized in an amount of from 10 to 20 000 ppm (w / w), where the primary antioxidant comprises at least one compound having the structure where: R1, R2=hydrogen, a linear alkyl group having from 1 to 20 carbon atoms or where * is a carbon atom of the aromatic ring system, R3, R5=hydrogen, a linear alkyl group having from 1 to 20 carbon atoms, R4=hydrogen, a linear alkyl group having from 1 to 40 carbon atoms, where both the substituents of the type R1 and R2 and those of the type R3 and R5 are in each case identical or different.

Owner:DEGUSSA AG

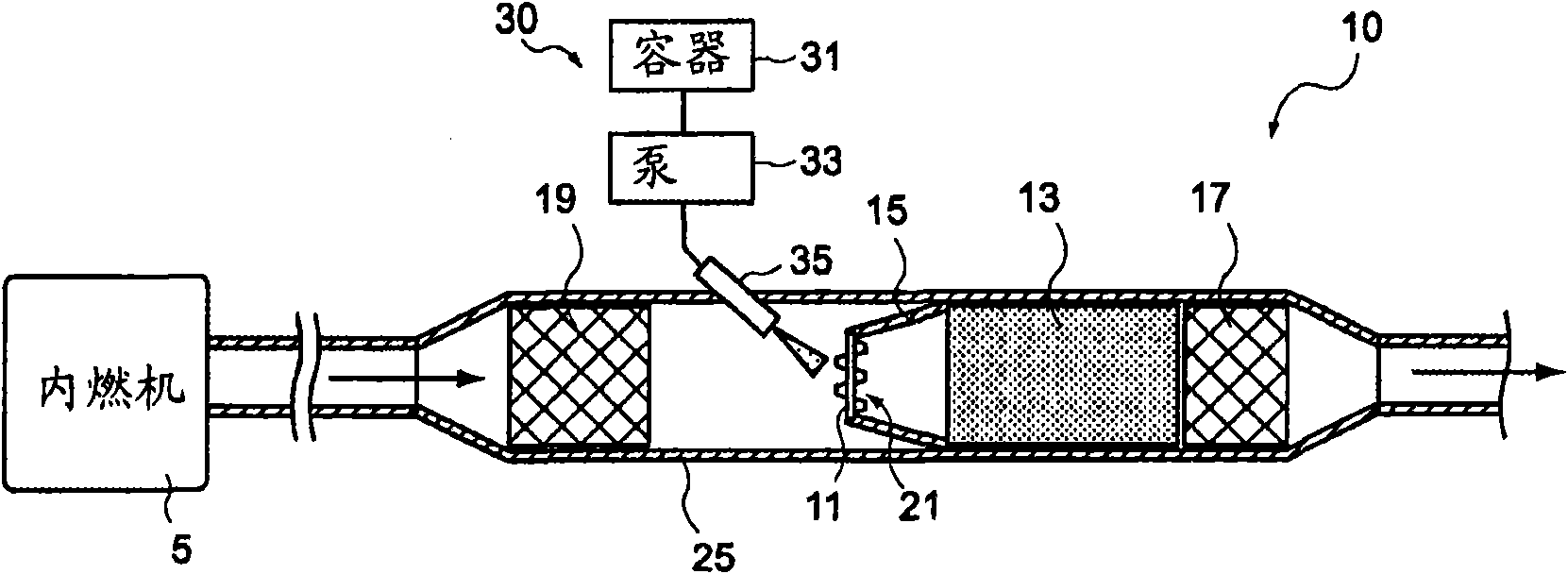

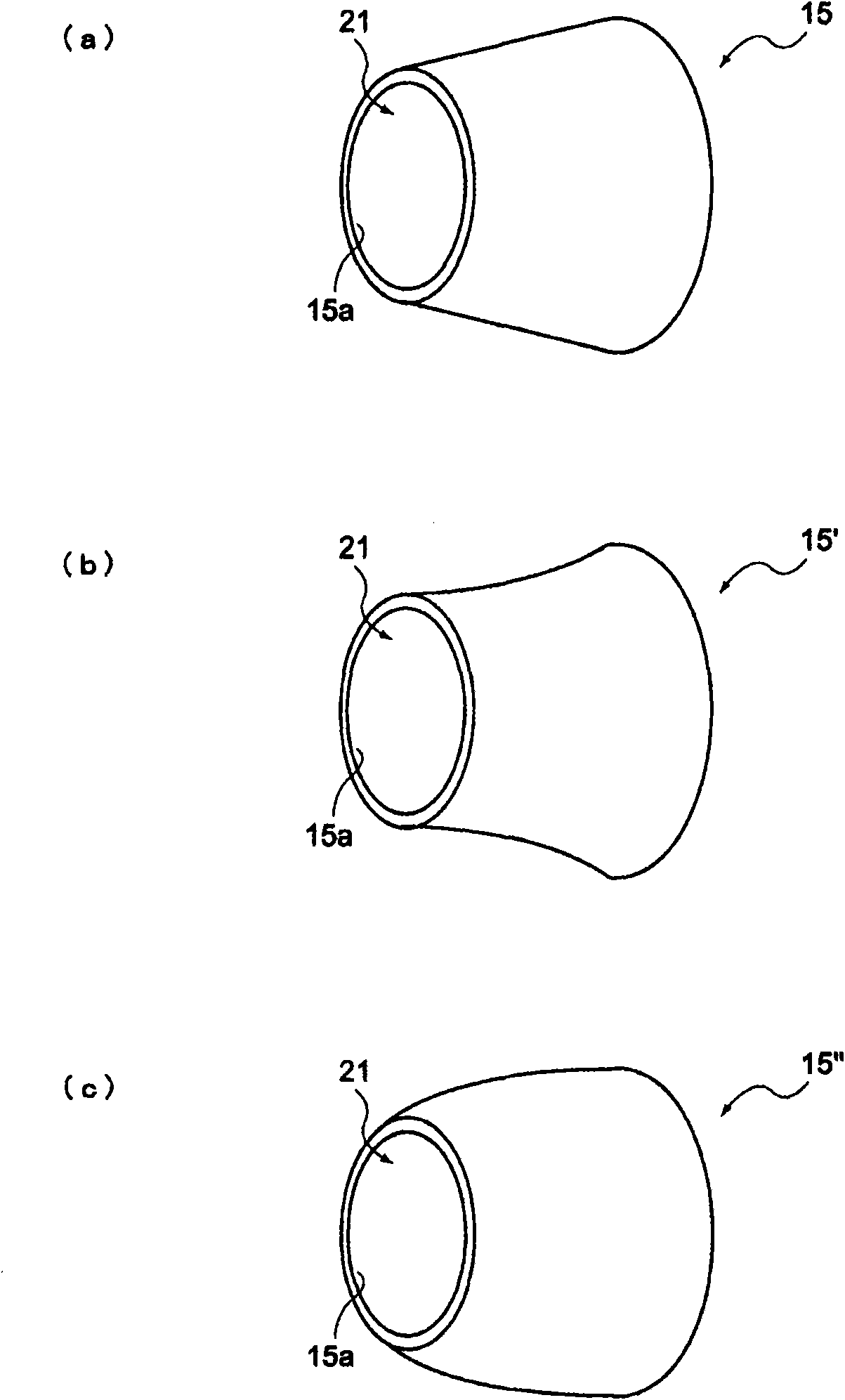

Exhaust gas purification apparatus for internal combustion engine

InactiveCN101627190AImprove reduction efficiencyIncrease flow rateInternal combustion piston enginesFlow mixersExternal combustion enginePulp and paper industry

This invention provides an exhaust gas purification apparatus for an internal combustion engine, which can realize the flow of an exhaust gas with a reducing agent uniformly dispersed therein into an NOx catalyst disposed on the downstream side of the exhaust gas purification apparatus. The exhaust gas purification apparatus for an internal combustion engine comprises an NOx catalyst disposed in an exhaust path in the internal combustion engine and a reducing agent jetting part for injecting a reducing agent into the exhaust path on the upstream side of the NOx catalyst. The exhaust gas purification apparatus is characterized in that a throttle part is provided at a position on the downstream side of the reducing agent jetting part in its reducing agent jetting position and on the upstream side of the NOx catalyst so that the sectional area of the flow path in the throttle part is smaller than the sectional area of the exhaust path and the sectional area of the NOx catalyst and the throttle part comprises means for diffusing the reducing agent.

Owner:BOSCH CORP

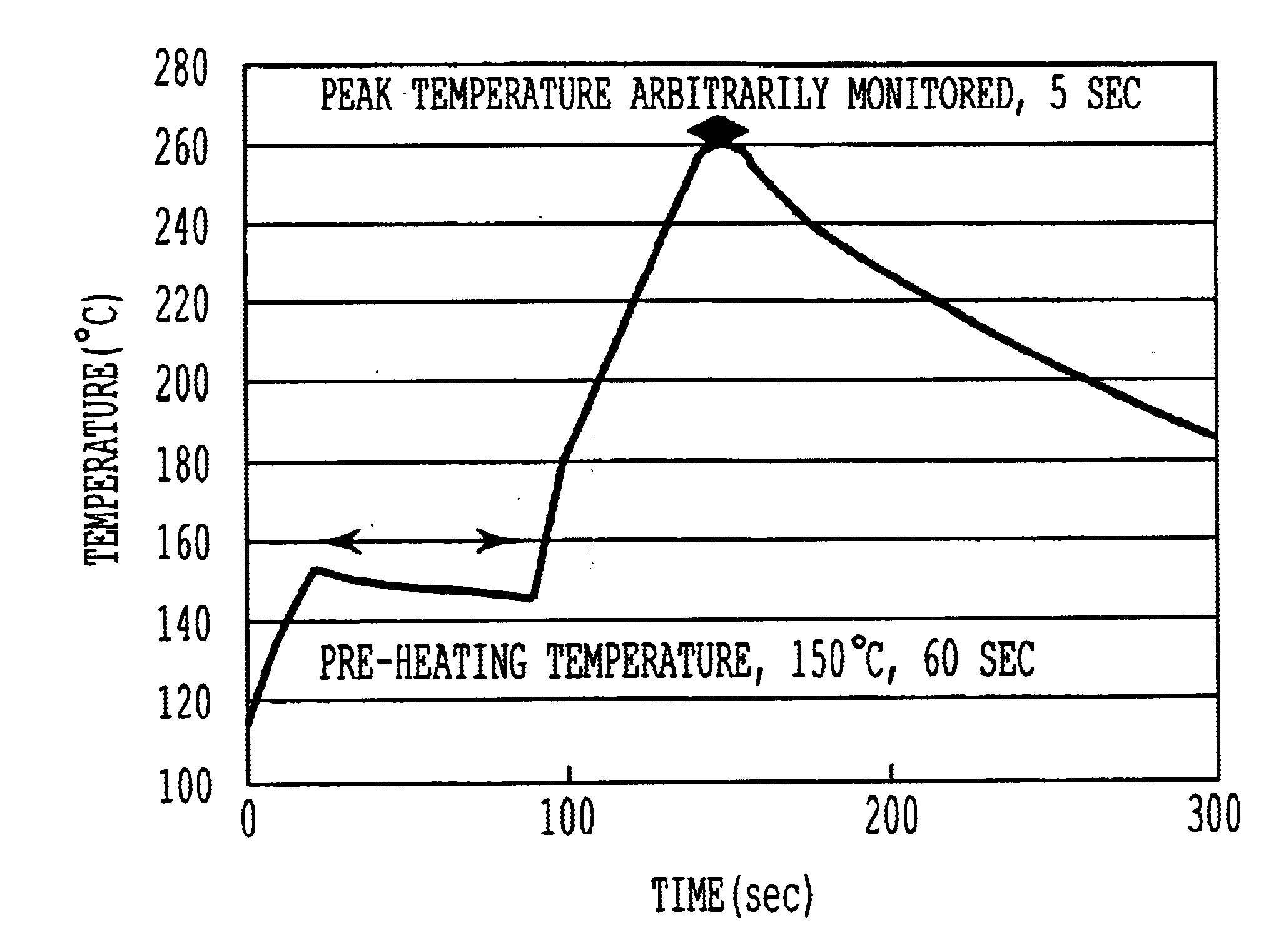

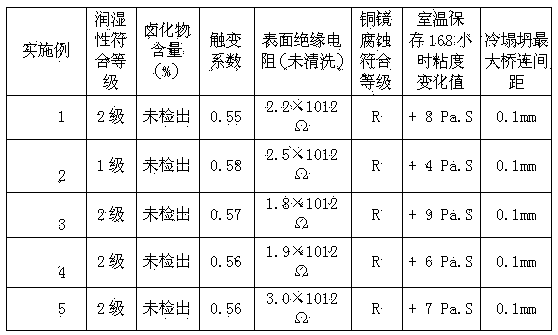

High-performance lead-free halogen-free soldering flux for soldering paste and preparing method of soldering flux

InactiveCN104175024AGuaranteed stabilityExtended storage timeWelding/cutting media/materialsMetal working apparatusOrganic acidBenzotriazole

The invention relates to the technical field of welding materials, in particular to a high-performance lead-free halogen-free soldering flux for soldering paste and a preparing method of the soldering flux. The high-performance lead-free halogen-free soldering flux for the soldering paste comprises the following ingredients in percentage by mass: 20 percent to 30 percent of solvents, 30 percent to 50 percent of rosins, 3 percent to 8 percent of surfactants, 2 percent to 5 percent of thixotropic agents, 5 percent to 10 percent of organic acid, 2 percent to 5 percent of organic amine and 2 percent to 5 percent of corrosion inhibitors. The high-performance lead-free halogen-free soldering flux and the preparing method provided by the invention have the beneficial effects that various kinds of rosins are adopted for compounding, the crystallization separation of single rosin in the saturation state is reduced, and the stability of the soldering flux is guaranteed; the organic acid and the organic amine are matched to be used, and generated active substances can destroy oxide films at the surfaces of tin powder and a bonding pad at high temperature, so that the effect of soldering aids is achieved; benzotriazole is adopted as the corrosion inhibitors, so the service life and the preservation time of the soldering paste can be effectively prolonged.

Owner:JIANGSU BOQIAN NEW MATERIALS

Honey processing process

InactiveCN103549250AHigh purityTargetedFood thermal treatmentMulti-step food processesHeating timeFiltration

The invention relates to a honey processing process. The honey processing process is characterized by comprising the following steps: (1) raw honey inspection; (2) (a) melting, wherein the heating temperature is 45-60 DEG C, and the heating time is 30-60 minutes or 4-8 hours according to the state of raw honey; (b) filtration, namely carrying out pressure filtration in a sealing device at the temperature higher than 40 DEG C so as to remove impurities and larger crystals; (3) vacuum concentration; (4) cooling. According to the honey processing process, the filtration step sequentially comprises rough filtration, fine filtration and refined filtration, wherein the temperature of the fine filtration is higher than that of the rough filtration, and the temperature of the refined filtration is higher than that of the fine filtration. The different processing time can be set according to different states of the raw honey, so that the pertinence is strong, not only can melting quality and the smooth operation of subsequent steps be guaranteed, but also the efficiency is increased, and the unnecessary time waste is reduced; besides, the filtration is performed three times, and the filtering temperatures are different, so that the efficiencies of each filtration process and the whole filtration are increased, and the purity of finished honey is improved.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

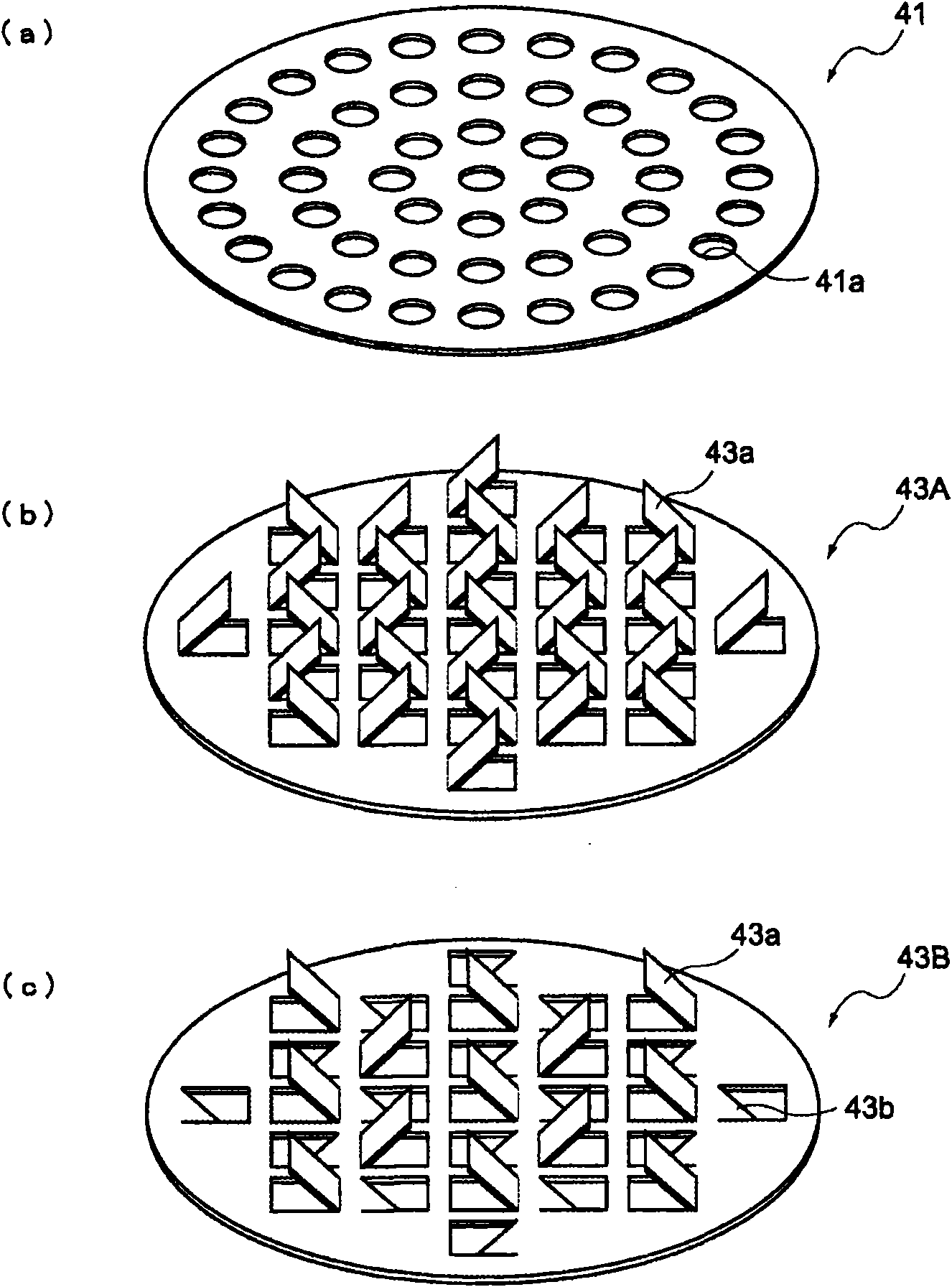

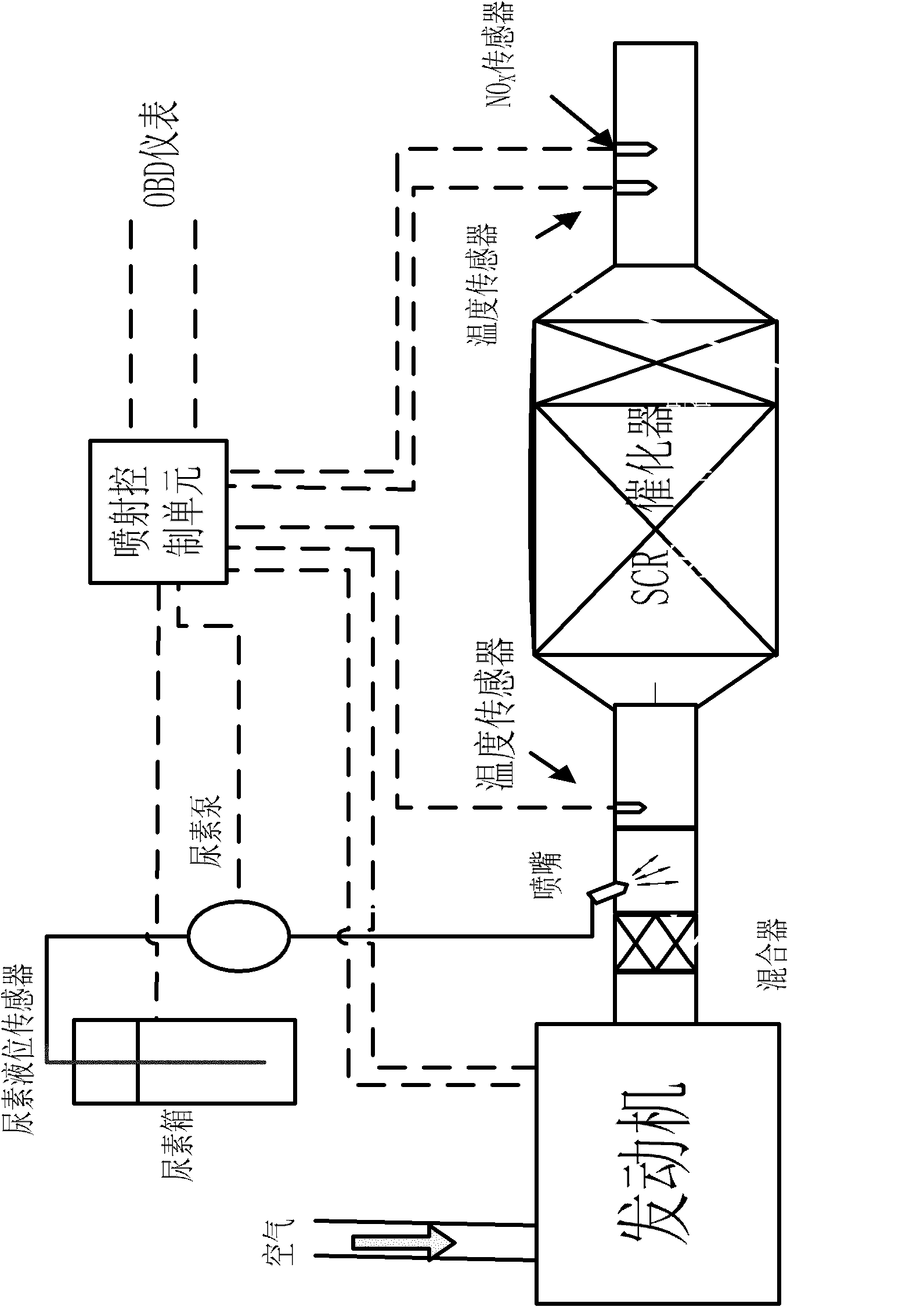

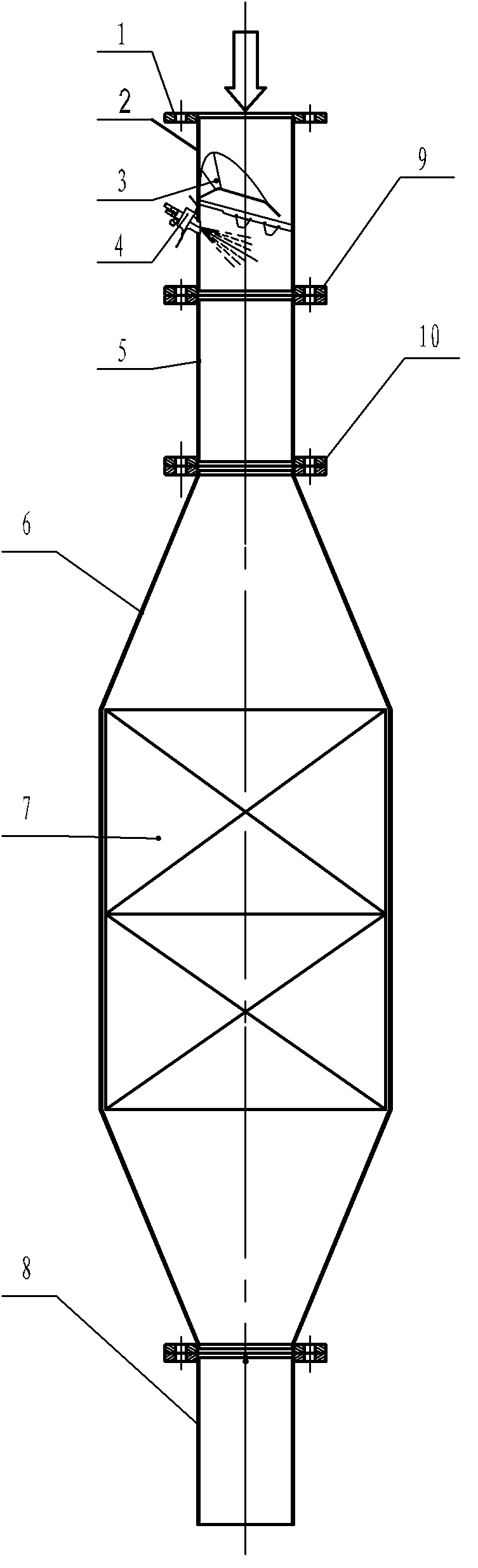

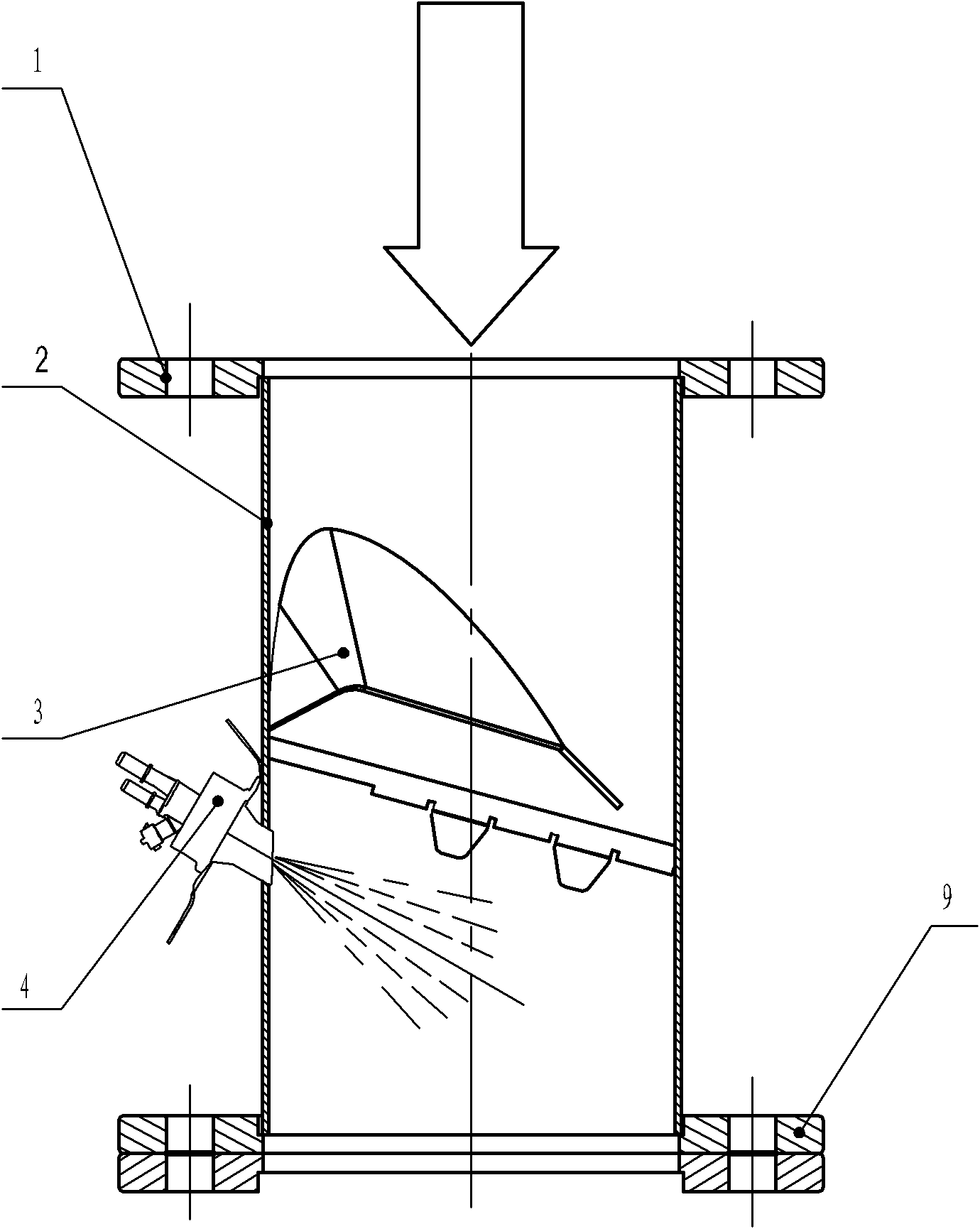

Hybrid unit of SCR (selective catalytic reduction) system for vehicle urea

ActiveCN102022165AReduce crystallizationWell mixedInternal combustion piston enginesExhaust apparatusUreaAqueous solution

The invention discloses a hybrid unit of an SCR (selective catalytic reduction) system for vehicle urea, comprising a pipe body, a hybrid unit rib device and a nozzle, wherein the nozzle is aslant arranged on the wall surface of the pipe body; the hybrid unit rib device tightly abuts against the nozzle and is installed on the front end of the nozzle; the hybrid unit rib device comprises four ribs, the middle of the first rib and the second rib forms a fluid path similar to an atomizing pattern; the first rib and the second rib have certain gradient and twists towards the central area; the third rib has a baffle-shaped structure and is arranged near the pipe wall, the installation direction is vertical to the atomizing axis, and the third rib twists towards the wall surface; and the fourth rib is arranged along the atomizing axis direction and is composed of a group of blades alternately twisted left and right. The invention can bring the effect that a urea aqueous solution injected by the nozzle and tail gas are fully mixed before entering an SCR catalytic converter, thus reducing urea crystallization formed on the wall surface; and meanwhile, the hybrid unit has compact structure and is easy to process and install, and the effect of the hybrid unit is verified.

Owner:HANGZHOU YINLUN TECH CO LTD +1

Method for preparing composite wear-resistant foreplate

InactiveCN101412095AInhibited DiffusionReduce the temperatureGuiding/positioning/aligning arrangementsWear resistantHardness

The invention discloses a method for preparing a composite antiwear guide plate, which comprises the following steps: alloy dust core bars are bound into bundles and arranged in a guide plate casting mould cavity, and the volume of the alloy dust core bars accounts for 20 to 60 percent of the total volume of the guide plate; molten matrix metal is cast into the guide plate casting mould cavity, the alloy dust core bars are melted and dissolved under the heat effect of the matrix metal, a great number of alloy elements and the molten matrix metal generate metallurgical combination reaction so as to generate a highly dispersed alloy structure on the original position; and finally the alloy structure is cooled and solidified, and the bar-shaped hard phase is metallurgically and transitionally combined into a whole with the matrix metal, thereby preparing the composite guide plate which takes the high-strength and high-ductility metal as the matrix and contains a certain number of metallurgically combined bar-shaped hard points. The composite anti-wear guide plate has high strength and high ductility of the matrix metal and high hardness and high wear resistance of the hard phase, can simultaneously bear high pressure and strong wear, and has the characteristics of long service life, low price, simple preparation and so on.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Elimination of crystalline silica from white foam glass by chemical additions

InactiveUS20050261121A1Reduce analysisReduce crystallizationGlass shaping apparatusFoaming agentSulfur

A method of making a foam glass preparation is provided. The following are mixed together: powdered or ground glass, at least one non-sulfur based foaming agent, and at least one additive that reduces the crystalline silica content in the foam glass derived from the preparation to less than 1% (volume basis).

Owner:EARTHSTONE INT

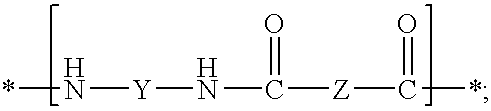

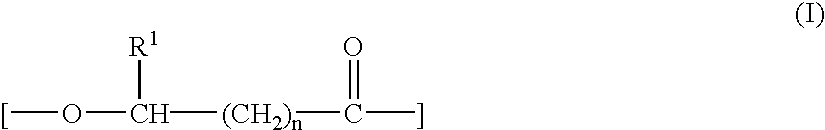

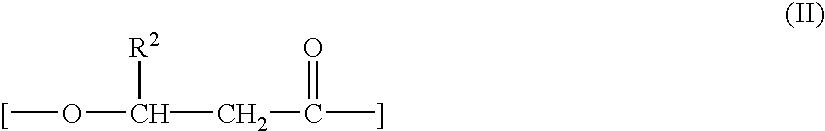

Plastic products comprising biodegradable polyester blend compositions

The present invention relates to tough and ductile biodegradable, aliphatic polyester blend compositions and methods for preparing such compositions. It relates to products made out of such blend compositions, including, but not limited to, films, fibers, nonwovens, sheets, coatings, binders, foams and molded products for packaging. The products exhibit a desirable combination of high strength, ductility and toughness, while maintaining flexibility, biodegradability and compostability. The products are useful for a variety of biodegradable articles, such as diaper topsheets, diaper backsheets, disposable wipes, shopping and lawn / leaf bags, agricultural films, disposable garments, medical disposables, paper coatings, biodegradable packaging, binders for cellulose fibers or synthetics, and the like. The polyester blend of the present invention comprises: (a) a copolymer comprising two randomly repeating monomer units wherein the first randomly repeating monomer unit has the structure: wherein R<1 >is H, or C1 or C2 alkyl, and n is 1 or 2. The second RRMU comprises at least one monomer selected from the group consisting of the structures (II) and (III): wherein R<2 >is a C3-C19 alkyl or C3-C19 alkenyl, and wherein m is from 2 to about 16; wherein at least about 50 mole % of the copolymer comprises RRMUs having the structure of the first RRMU of formula (I). and wherein the polyhydroxyalkanoate is present at a level of at least about 20%, by weight, of the total of the polyhydroxyalkanoate and the aliphatic ester polycondensate. wherein R<1 >is H or a C1-2 alkyl and n is 1 or 2; and the second randomly repeating monomer unit has the structure: wherein R<2 >is a C3-19 alkyl or alkenyl; and (b) an aliphatic ester polycondensate synthesized from an aliphatic polyhydric alcohol and an aliphatic polycarboxylic acid compound.

Owner:THE PROCTER & GAMBLE COMPANY

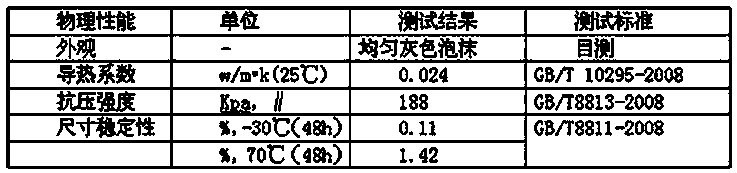

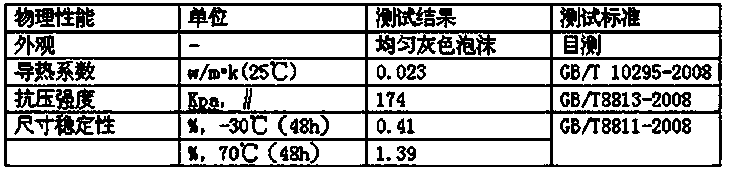

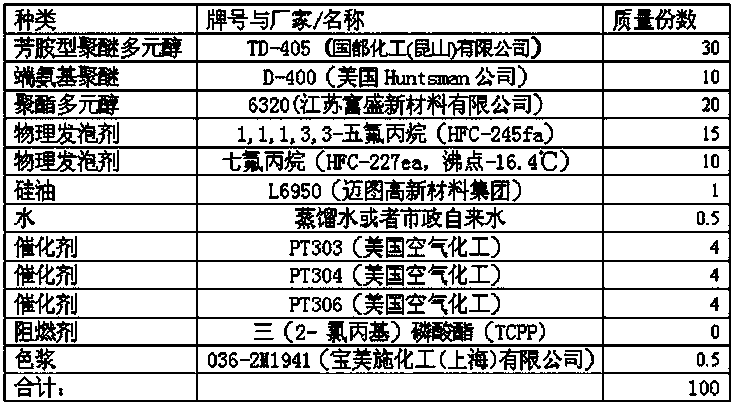

Polyurethane foam two-component raw material suitable for low-temperature environment and construction method thereof

ActiveCN103923290AHigh viscosityGood foaming effectFoundation engineeringHeat proofingPolymer scienceFoaming agent

The invention relates to a polyurethane foam two-component raw material in compounds in the field of chemistry and a construction method thereof, and particularly relates to a polyurethane foam two-component raw material suitable for construction in autumn and winter for hydraulic concrete dam insulation engineering and the repair of cracks in a low temperature cold storage. The polyurethane foam two-component raw material comprises an isocyanate component and a polyol component, wherein the polyol component contains low-temperature and highly active polyether polyol which accounts for 15-45% of the total weight of the polyol component, the polyol component contains a physical foaming agent having a boiling point not higher than the construction temperature of 20 DEG C and accounting for 5-25% of the total weight of the polyol component, the isocyanate component is polymethylene polyphenyl isocyanate, a viscosity reducer, which accounts for 5-25% of the weight of polymethylene polyphenyl isocyanate, is added into polymethylene polyphenyl isocyanate and the viscosity of the polymethylene polyphenyl isocyanate is reduced to 100cps or less after the addition of the viscosity reducer. The polyurethane foam two-component raw material disclosed by the invention can be normally constructed at -30 DEG C and above ambient temperature.

Owner:WANHUA ENERGY-SAVING TECH GRP CO LTD

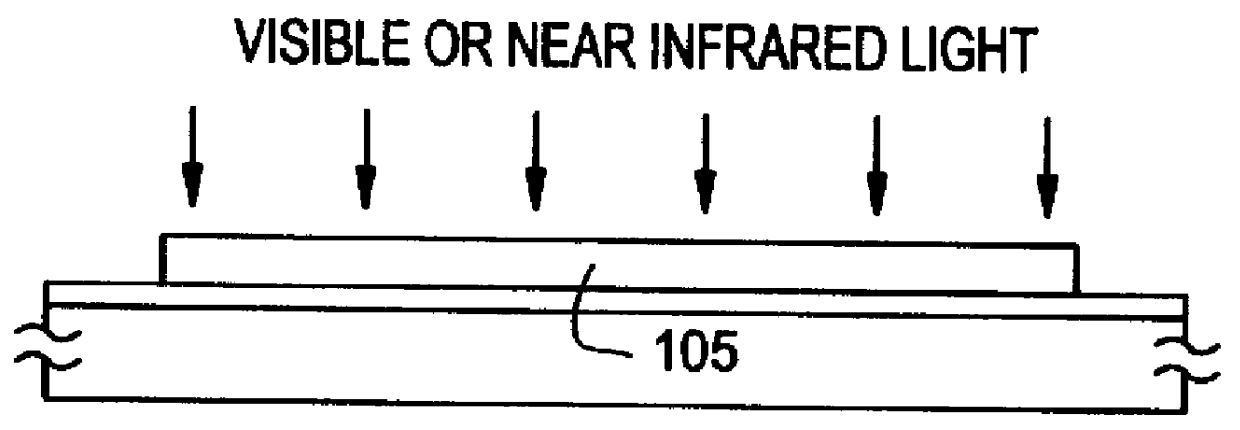

Process for fabricating semiconductor device

InactiveUS20060113541A1Reduce the temperatureCrystal character can be improvedTransistorSolid-state devicesDevice materialAmorphous silicon

A process for fabricating a semiconductor device comprising the step of, after patterning the silicon film crystallized to a low degree by thermally annealing an amorphous silicon film into an island by etching, irradiating an intense light of a visible light or a near infrared radiation to effect a short-period annealing (RTA) to the silicon film of low crystallinity. Thus, the crystallinity of the silicon film is improved and the silicon film is densified in a short-period.

Owner:SEMICON ENERGY LAB CO LTD

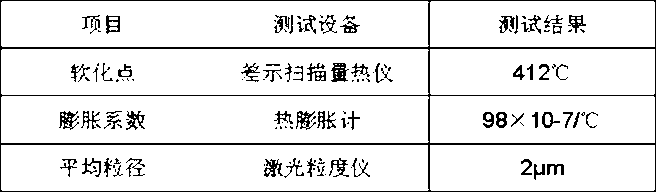

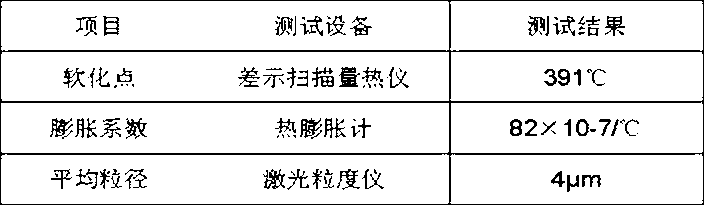

Lead-free glass powder for silver paste on back of crystalline silicon solar cell and preparation method thereof

The invention relates to a lead-free glass powder for silver paste on the back of a crystalline silicon solar cell and a preparation method thereof. The lead-free glass powder comprises the following raw materials in parts by weight: 40-70 parts of Bi2O3, 5-15 parts of B2O3, 0.5-5 parts of ZrO2, 10-20 parts of SiO2, 5-20 parts of ZnO, 1-5 parts of TiO2, 5-20 parts of Al2O3 and 1 part of P2O5. The preparation method comprises the following steps of: placing the raw materials in a mixer, and uniformly mixing to form a mixture; preheating a quartz crucible to 600-800 DEG C, placing the mixture in the quartz crucible and carrying out heat preservation for 20 minutes; then smelting for 20 minutes to 40 minutes at 900-1200 DEG C; pouring molten glass into deionized water for quenching, carrying out wet-process ball milling on the quenched glass to 2-5mu m, and drying to obtain the lead-free glass powder. The lead-free glass powder has the advantages that the technological process is simple, time consumption for smelting is short and cost is low; when in use, the lead-free glass powder has good wettability with silver powder and a silicon substrate; and after the lead-free glass powder is sintered, the adhesive force between the lead-free glass powder and the silicon substrate is above 5N.

Owner:JIANGSU ZHENGNENG ELECTRONICS TECH CO LTD

Skin-friendly drug complexes for transdermal administration

InactiveUS20080138391A1Good skin permeabilityImprove skinPharmaceutical non-active ingredientsSynthetic polymeric active ingredientsDiseaseWhole body

The present invention generally relates to pharmaceutical compositions for the treatment of various diseases and disorders, in particular the use of novel complexes of amine drugs with polyacrylic acid carbomer polymers. The compositions of the present invention can be administered transdermally or transmucosally to patients in need thereof for a systemic or for a local therapeutic effect. The compositions of the present invention present the additional benefits of being free or substantially free of excipients which may potentially be responsible for skin local reactions and unpleasant smell.

Owner:ANTARES PHARMA IPL

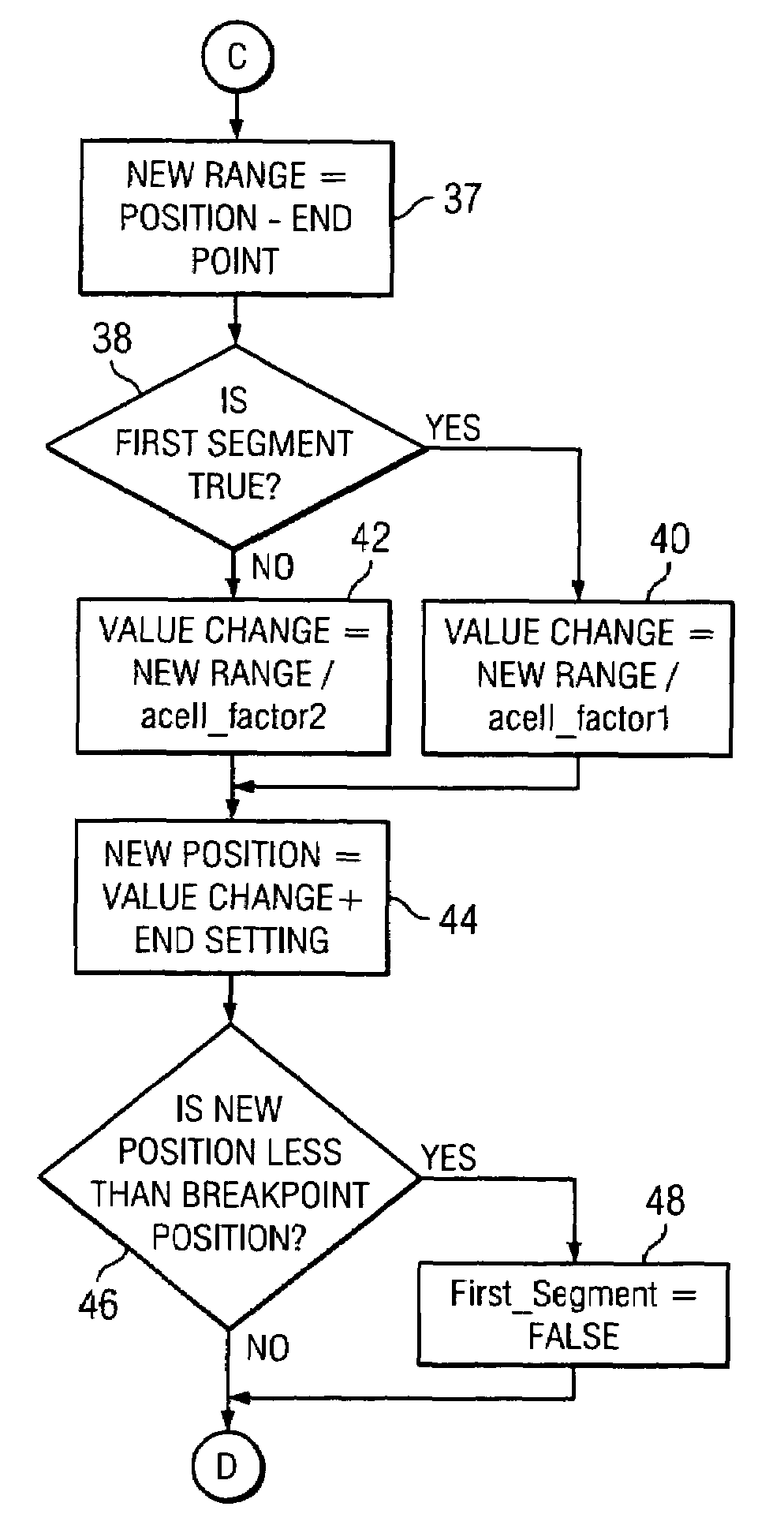

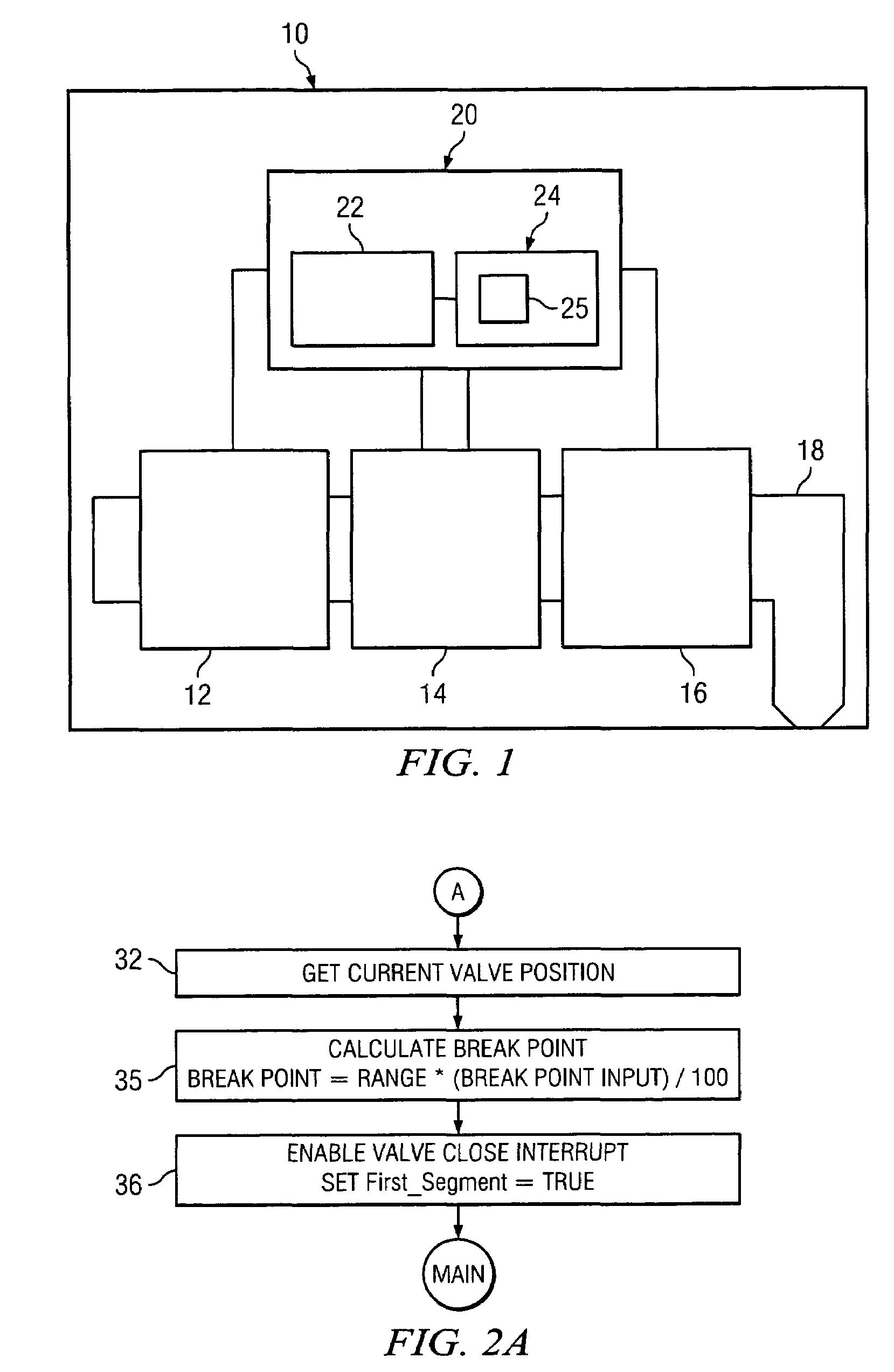

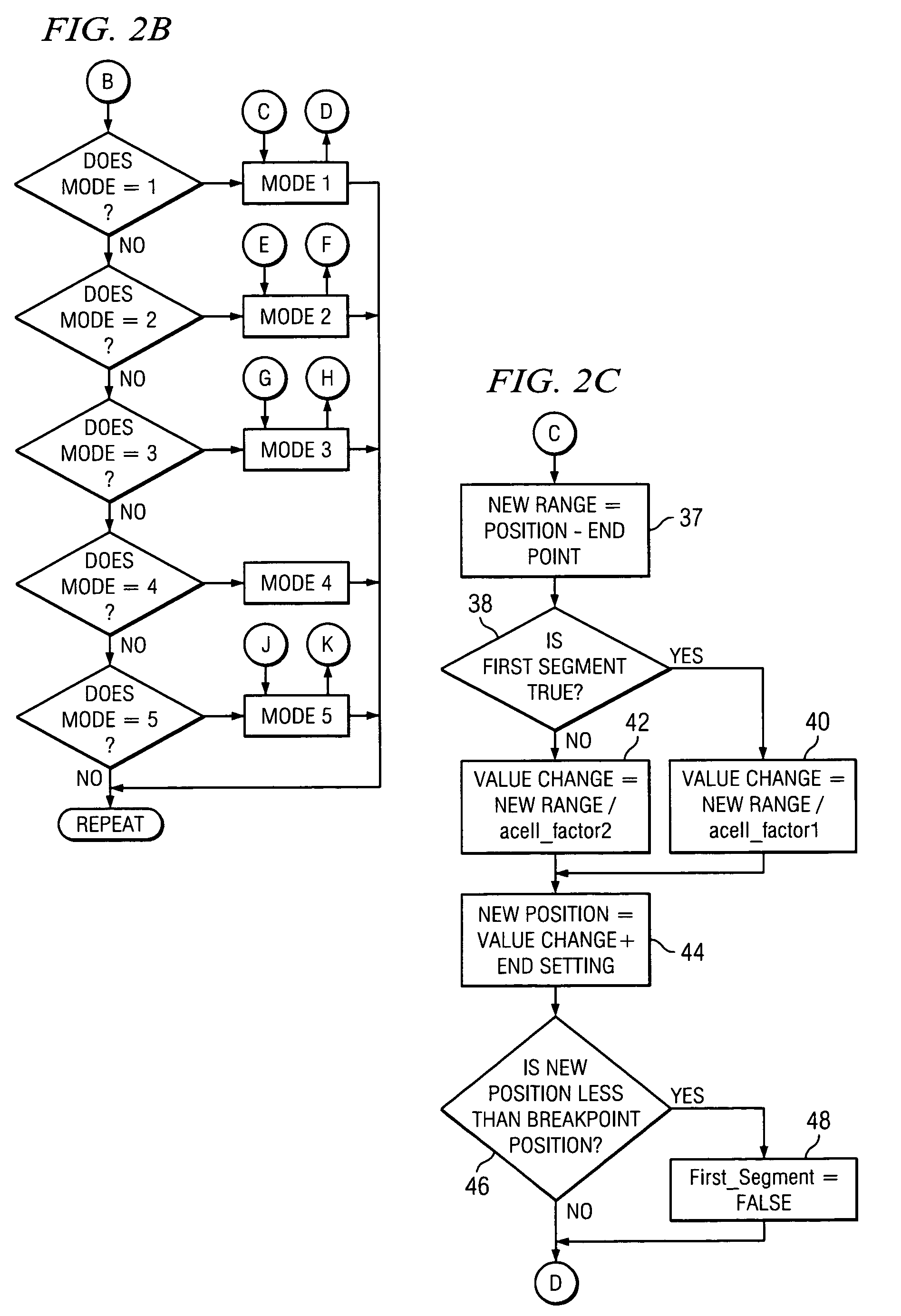

System for controlling fluid flow

ActiveUS7107128B2Reduce the possibilityReduce crystallizationFlow control using electric meansSemiconductor/solid-state device manufacturingControl signalRate parameter

Embodiments of the present invention provide systems and methods of controlling fluid dispense to ensure clean break off of fluid at the end of a dispense process and to reduce crystallization of fluid in the dispense nozzle. One embodiment of the present invention can include a controller that can, generate a flow control signal to cause a control valve to close according to a first close rate parameter for a first segment of the close range and to generate the flow control signal to cause the control valve to close according to a second close rate parameter for a second segment of the close range.

Owner:ENTEGRIS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com