Self-microemulsion and preparation method thereof

A self-microemulsion, selected technology, applied in the field of microemulsion, can solve the problems such as the lack of a clear description of the temperature stability range of the final product, stability defects, etc., and achieve wide geographical applicability and transportation stability, good applicability, excellent The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

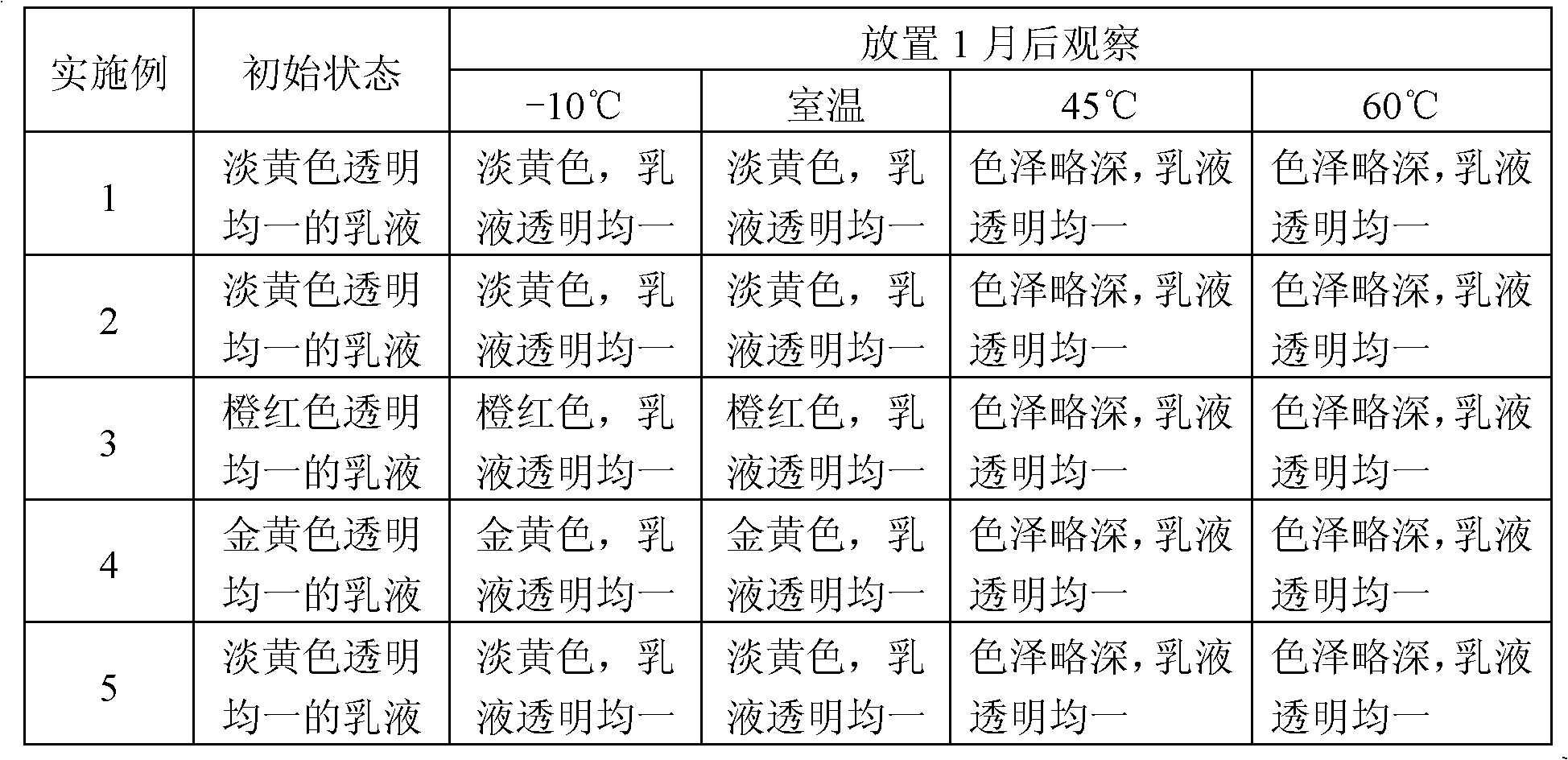

Examples

Embodiment 1

[0032] Preparation of DHA self-microemulsion

[0033] The DHA self-microemulsion was prepared according to the following operations by using the following components by mass: DHA oil was added to the vegetable oil, and then the oil phase emulsifier was added, and then heated and stirred evenly after evacuating nitrogen for three times; then adding a quantitative co-emulsifier glycerin, Add the main emulsifier ten polyglycerol monooleate and sodium stearoyl lactylate. The functional substance pullulan is dissolved in quantitative pure water, and finally added to the mixing system. Heat at 60-65°C and stir until the final system is uniform and transparent, keep it warm for 10-30 minutes, and get the final product after cooling down to room temperature.

[0034] DHA oil: 10-30;

[0035] Sunflower oil (vegetable oil): 5-20;

[0036] Span 80: 1~5;

[0037] Ten polyglycerol monooleate: 15-25;

[0038] Sodium stearoyl lactylate: 1-5;

[0039] Glycerin: 15-25;

[0040] Water: 8~1...

Embodiment 2

[0044] Preparation of ARA self-microemulsion

[0045] The ARA transparent self-microemulsion was prepared by the same operation as described in Example 1, but the following parts by mass of the self-microemulsion system components were used.

[0046] ARA oil: 5-15;

[0047] Sunflower oil (vegetable oil): 5-20;

[0048] Glyceryl monooleate: 1~5;

[0049] Ten polyglycerol monooleate: 15-25;

[0050] Sodium glutamate: 1~5;

[0051] Glycerin: 20-30;

[0052] Water: 8~15;

[0053] Dextran: 0-2.

[0054] The final product obtained is a light yellow transparent and uniform emulsion, in which the ARA oil phase loading is as high as 15%, and has a high oil loading. The content is determined by the method of the national standard GB / T 26401-2011, and the microemulsion preparation with the ARA content between 3% and 15% can be prepared. The emulsion has good stability and can be stored stably in the range of -10-60°C. Take about 1g of this product and add it to 100ml of deionize...

Embodiment 3

[0056] Preparation of coenzyme Q10 self-microemulsion

[0057] Coenzyme Q10 self-microemulsion was prepared according to the following operation by using the following mass fraction components: Add coenzyme Q10 to caprylic glyceride, then add the oil phase emulsifier Span 60, avoid light and pump nitrogen for three times, then heat and stir until solid The material is completely dissolved; then a quantitative co-emulsifier glycerin is added, and then the main emulsifier Tween 60 and sodium stearate are added. The functional substance mannitol is dissolved in quantitative pure water, and finally added to the mixing system. Avoid light and oxygen, heat at about 65°C and stir until the whole system is uniform and transparent, keep it warm for 10-30 minutes, and get the final product after cooling down.

[0058] Coenzyme Q10: 5-20;

[0059] Glyceryl caprylate: 5-20;

[0060] Span 60: 1~5;

[0061] Tween 60: 15-25;

[0063] Glycerin: 20-30;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com