Process for treating residual liquid and tail gas in polysilicon production by improved Siemens method

A Siemens method and tail gas treatment technology, applied in the direction of silicon compounds, separation methods, and dispersed particle separation, etc., can solve problems such as weak neutralization and treatment capacity of chlorosilane tail gas and residual liquid, damage to pipelines, nozzles, valves, and potential safety hazards. To achieve the effect of prolonging production running time, saving production cost and cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

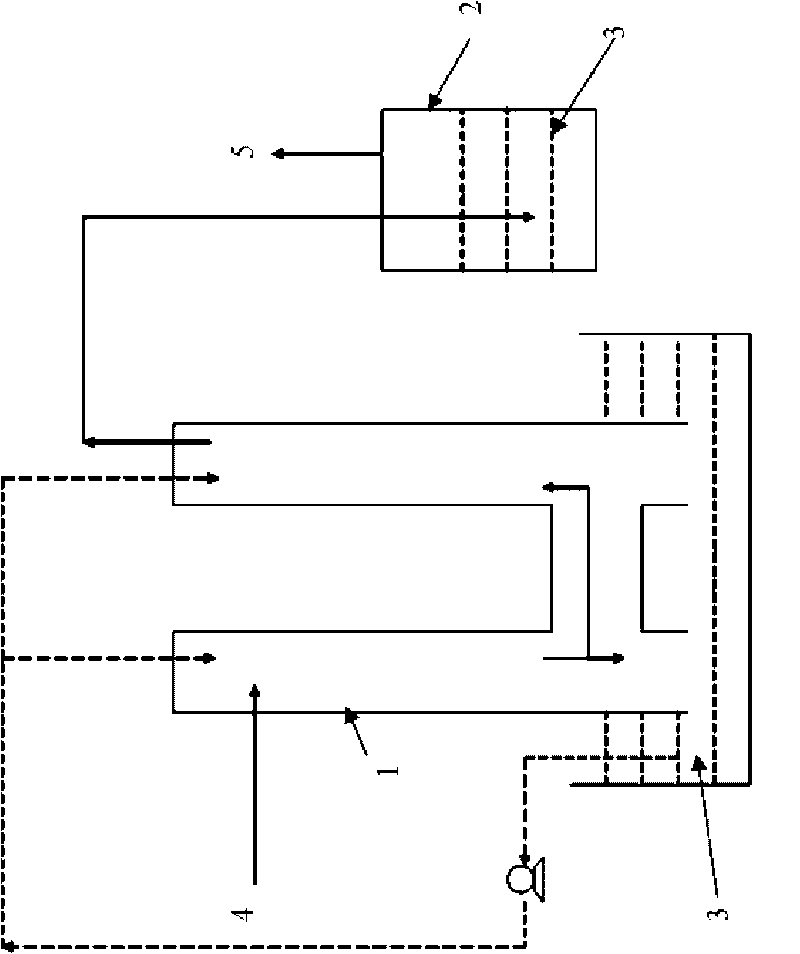

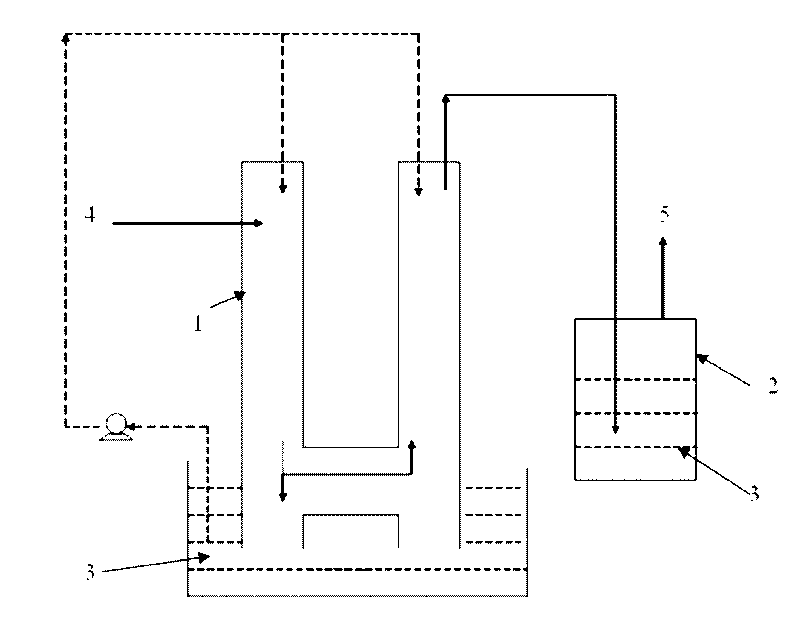

Image

Examples

Embodiment 1

[0022] Tail gas (containing about 80% trichlorosilane, 10% dichlorosilane, 2% hydrogen chloride, 8% silicon tetrachloride) and raffinate (containing about 90% silicon tetrachloride, 7% dichlorosilane , 2% hydrogen chloride, 1% polychlorosilane) into the washing tower, and the washing agent is 10% milk of lime. There is a circulation tank at the bottom of the leaching tower to collect the liquid flowing down from the waste liquid leaching tower, and pump it back into the top of the waste liquid leaching tower for recycling. The gas discharged after the neutralization reaction is mainly nitrogen, hydrogen and a small amount of hydrogen chloride, undissolved chlorosilane and other mixtures. Up to standard (content standard: HCl is less than 100mg / m 3 , chlorosilanes were not detectable) and the purified gas obtained after that was directly evacuated.

[0023] When the pH value of the eluent in the circulation pool is ≤8, add or replace with fresh eluent.

[0024] After the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com