Polyurethane foam two-component raw material suitable for low-temperature environment and construction method thereof

A polyurethane rigid foam and low-temperature environment technology, which is applied in polyurea/polyurethane coatings, thermal insulation, infrastructure engineering, etc., can solve problems such as high viscosity and inability of spraying machines to work smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

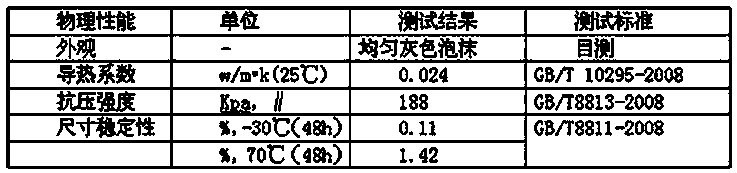

[0032] Polyol component:

[0033]

[0034] Isocyanate component:

[0035] Polymethylene polyphenylisocyanate PM-200 (Wanhua Chemical Group Co., Ltd. ) 95wt%, viscosity reducer fluorodichloroethane (HCFC-141b) 7wt%;

[0036] Equipment: H25 spraying machine (Graco, USA)

[0037] The mixing ratio of the two components is: isocyanate component: polyol component = 100:100 (volume ratio);

[0038] Ambient temperature: -20 degrees

[0039] Production steps:

[0040] (1) Insert the two-component feeding pumps of the spraying machine into the corresponding raw material barrels, turn on the power and the air compressor and other preparations;

[0041] (2) Set the heating temperature of spraying machine raw materials and pipelines to 55°C;

[0042] (3) Use a spray gun to spray the raw material on the substrate, and spray more than 5 layers to complete the foam with a thickness of 8cm;

[0043] The color of the prepared foam is uniform gray, and various physica...

Embodiment 2

[0046] raw material:

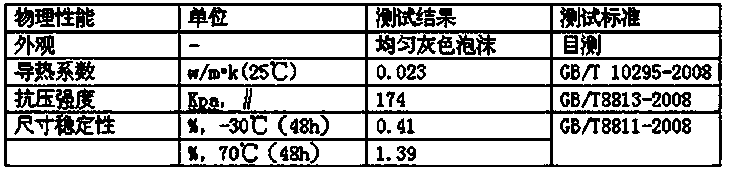

[0047] Polyol component:

[0048]

[0049] Isocyanate component:

[0050] Polymethylene polyphenylisocyanate PM-200 (Wanhua Chemical Group Co., Ltd.) 95wt%, viscosity reducer diethyl ethyl phosphate (DEEP) 5wt%;

[0051] Equipment: H25 spraying machine (Graco, USA)

[0052] The mixing ratio of the two components is: isocyanate component: polyol component = 100:100 (volume ratio);

[0053] Ambient temperature: -30 degrees

[0054] Production steps:

[0055] (1) Insert the two-component feeding pumps of the spraying machine into the corresponding raw material barrels, turn on the power and the air compressor and other preparations;

[0056] (2) Set the heating temperature of the raw materials and pipelines of the spraying machine to 65°C, and preheat the substrate if necessary;

[0057] (3) Use a spray gun to spray the raw material on the substrate, and spray more than 5 layers to complete the foam with a thickness of 8cm;

...

Embodiment 3

[0061] raw material:

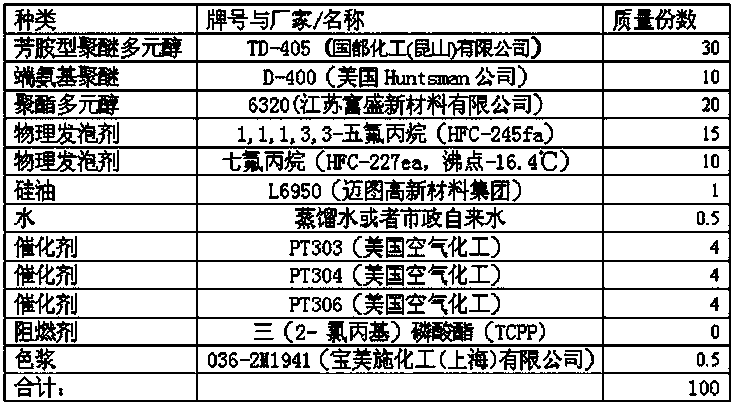

[0062] Polyol component:

[0063]

[0064] Isocyanate component:

[0065] Polymethylene polyphenylisocyanate PM-200 (Wanhua Chemical Group Co., Ltd.) 75 wt%, viscosity reducer tris (2-chloropropyl) phosphate (TCPP) 25 wt%;

[0066] Equipment: HVR (Graco, USA)

[0067] The mixing ratio of the two components is: isocyanate component: polyol component = 150:100 (volume ratio);

[0068] Ambient temperature: -30 degrees

[0069] Production steps:

[0070] (1) Insert the two-component feeding pumps of the spraying machine into the corresponding raw material barrels, turn on the power and the air compressor and other preparations;

[0071] (2) Set the heating temperature of the raw materials and pipelines of the spraying machine to 65°C, and preheat the substrate if necessary;

[0072] (3) Use a spray gun to spray the raw material on the substrate, and spray more than 5 layers to complete the foam with a thickness of 8cm;

[0073...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com