Patents

Literature

188 results about "Polyphenyl isocyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethane prepolymer, polyurethane grouting material and preparation method thereof

InactiveCN102093536AImprove foaming rateImprove shrinkage resistanceOther chemical processesPolyesterPolyphenyl isocyanate

The invention relates to a preparation method of a polyurethane prepolymer, which comprises: mixing polyisocyanate and an organic polyol compound for reaction, wherein the molar ratio of the -NCO in the polyisocyanate and the -OH in the organic polyol compound is (4-15):1; the polyisocyanate is two or more of polymethylene polyphenyl isocyanate (PAPI), methylene diphenyl diisocyanate (MDI) and carbodiimide modified MDI 5412; and the organic polyol compound comprises one or more of polyether glycol with functionality of 2 to 4 and number-average molecular weight of 300 to 5,000, polyester polyol and polyether-polyester polyol. The invention also relates to the polyurethane prepolymer and a polyurethane grouting material. The polyurethane grouting material is a single-component grouting material, has little toxicity to the environment and construction personnel and can well improve foaming rate and anti-contraction performance; during packaging, the need of independent packaging of a catalyst is obviated, so the packaging cost is lowered; and the material is more convenient to use and transport and has a more wide application range and a bright prospect.

Owner:SHANGHAI DONGDA CHEM

Hard polyurethane foam

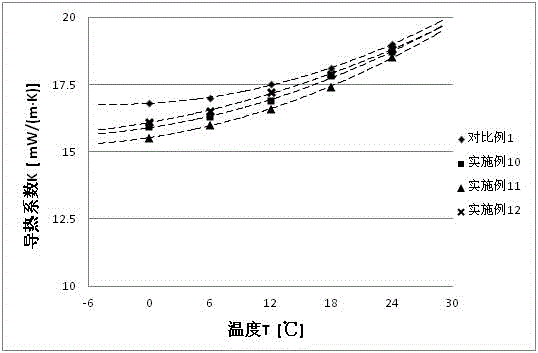

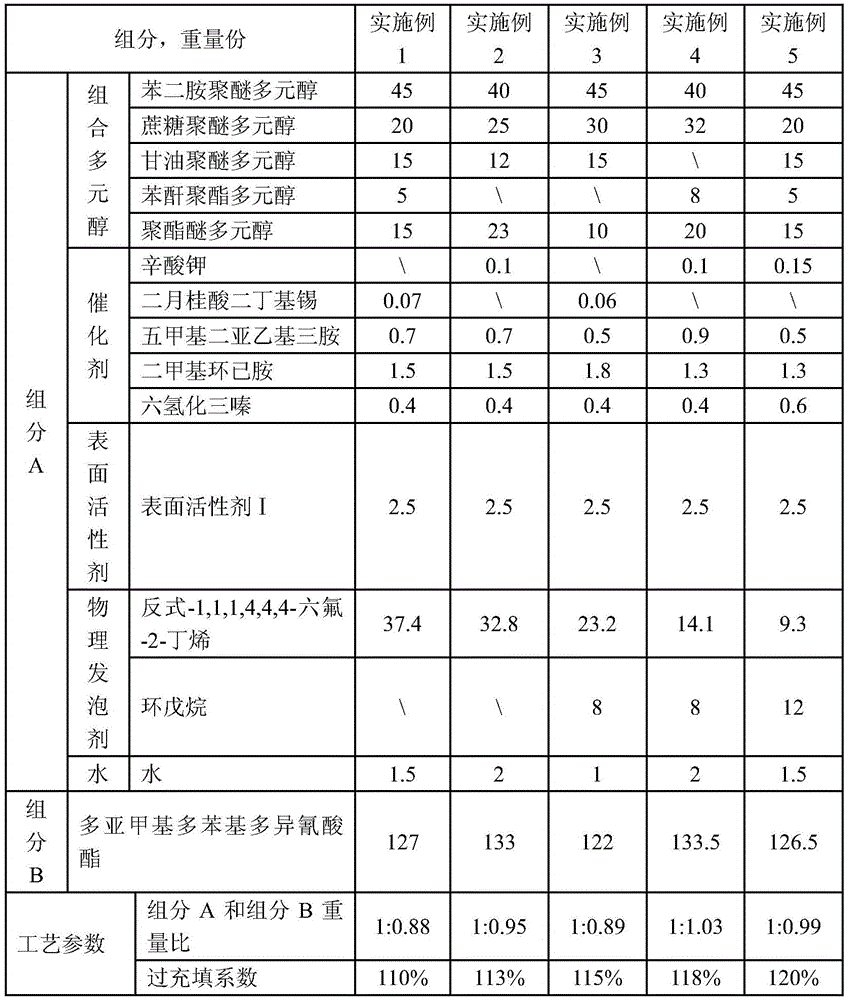

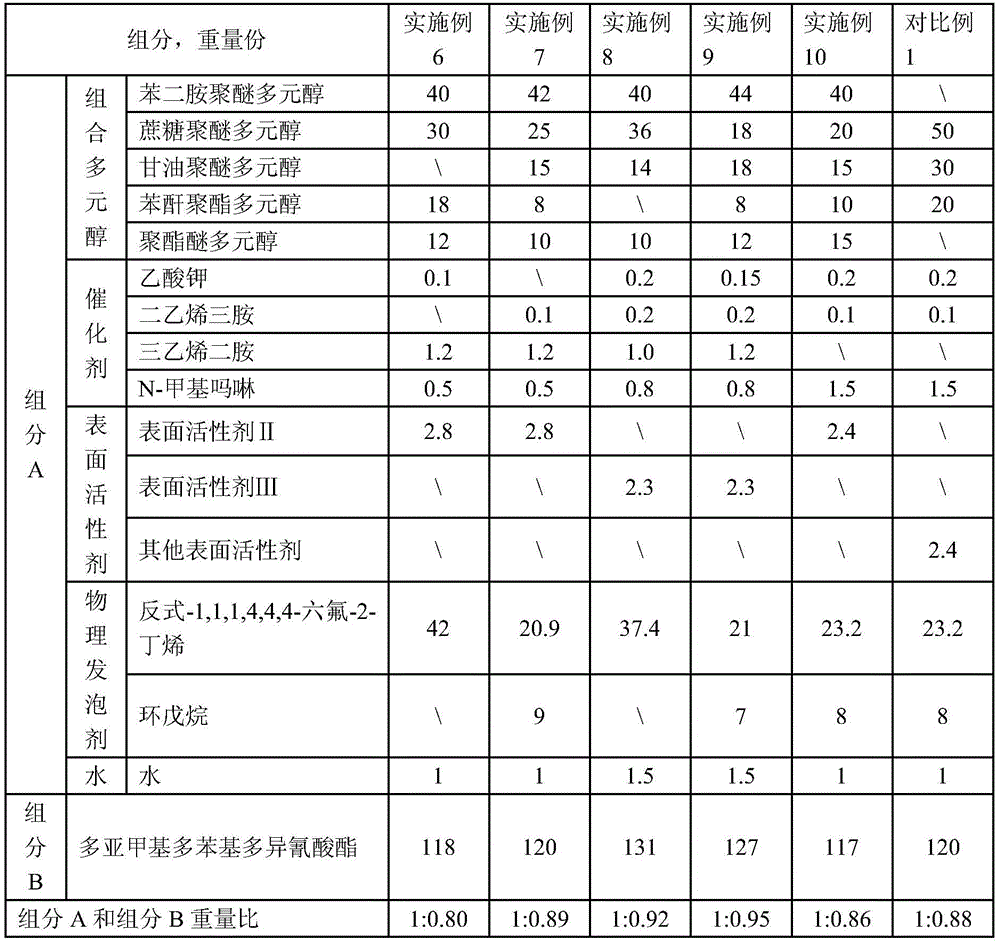

The invention relates to a hard polyurethane foam. The hard polyurethane foam is composed of a component A and a component B at a weight ratio of 1:0.7-1.2. The component A comprises, by weight, 100 parts of a compound polyhydric alcohol containing phenylenediamine polyether glycol and polyester ether polyhydric alcohol, 10 to 50 parts of a physical foaming agent containing trans-1,1,1,4,4,4-hexafluoro-2-butene, 1 to 4 parts of a catalyst, 1 to 5 parts of a surfactant, and 0.5 to 3.0 parts of water; and the component B is polymethylene polyphenyl isocyanate. The foams of the hard polyurethane foam are fine and uniform; heat conductivity coefficient is low; comprehensive properties are excellent; and K value<=19.0mW / (m.K) at 24 DEG C, and K value<=17.0mW / (m.K) at 0 DEG C.

Owner:NANJING HONGBAOLI POLYURETHANE

Polyurethane reinforcing and filling materials for coal mine

The invention relates to a polyurethane reinforcing and filling materials for coal mines. A component A is a polymethylene polyphenyl isocyanate, a component B is obtained via the follow steps: mixing and stirring the following ingredients: 33 to 70 wt% of polyether polyol, 0 to 40 wt% of polyester polyol, 0.1 to 1.5 wt% of composite catalyst, 6 to 30 wt% of composite flame retardant, 0 to 15 wt%of foaming agent, 0.5 to 2.5 wt% of stabilizer, 0.5 to 10 wt% of foam stabilizing agent, 0.1 to 5 wt% of antistatic agent , 5 to 25 wt% of plasticizer at 30 DEG C to 50 DEG C for 0.5 to 2 hrs; and when in use, the component A and the component B are together pressed into a coal (rock) layer according to the mass ratio of 1 to 2 : 1, penetrate into tiny cracks and expand, meanwhile react and generate CO2 gas and further expand, thereby effectively reinforcing and sealing processing areas. The compressive strength of polyurethane reinforcing and filling materials for coal mines is more than 55 MPa, the bond strength is more than or equal to 4 MPa, the foaming factor is less than or equal to two times. The invention can meet the need of coal mine safe production, and can be used for hydropower, construction, mining, transportation and other industries.

Owner:SHANXI ZHAOXIN BIO TECH

High-strength and high-toughness polyurethane material, as well as preparation method and use thereof

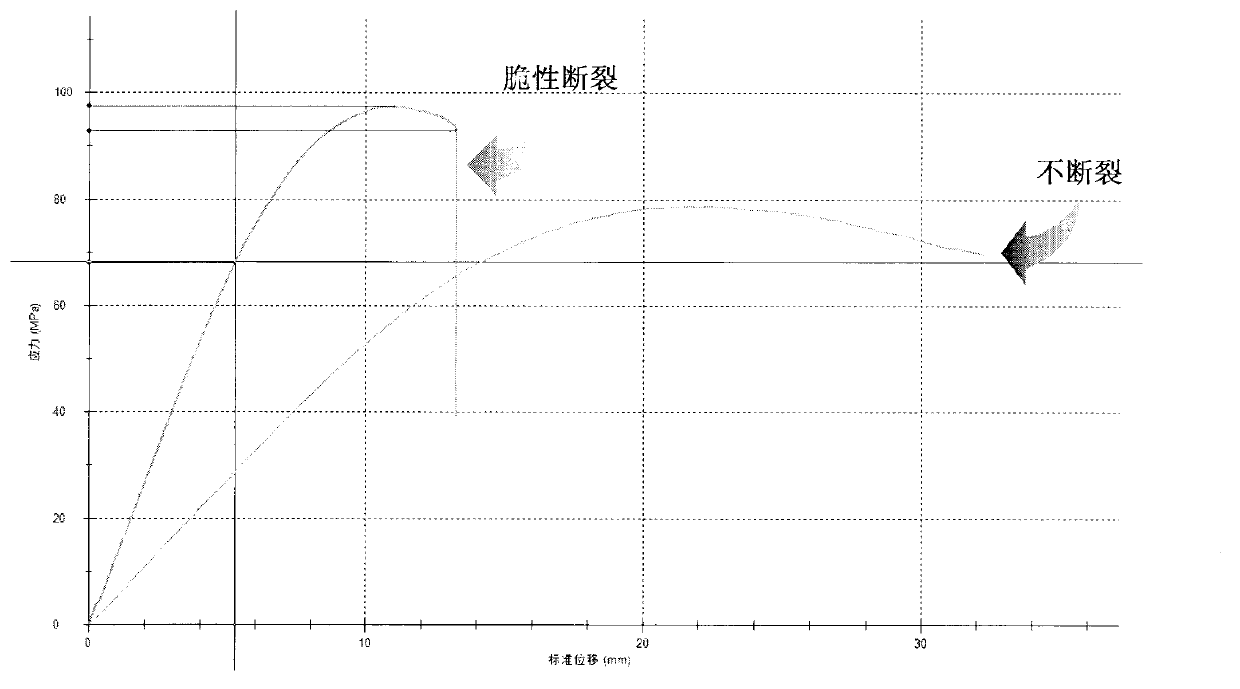

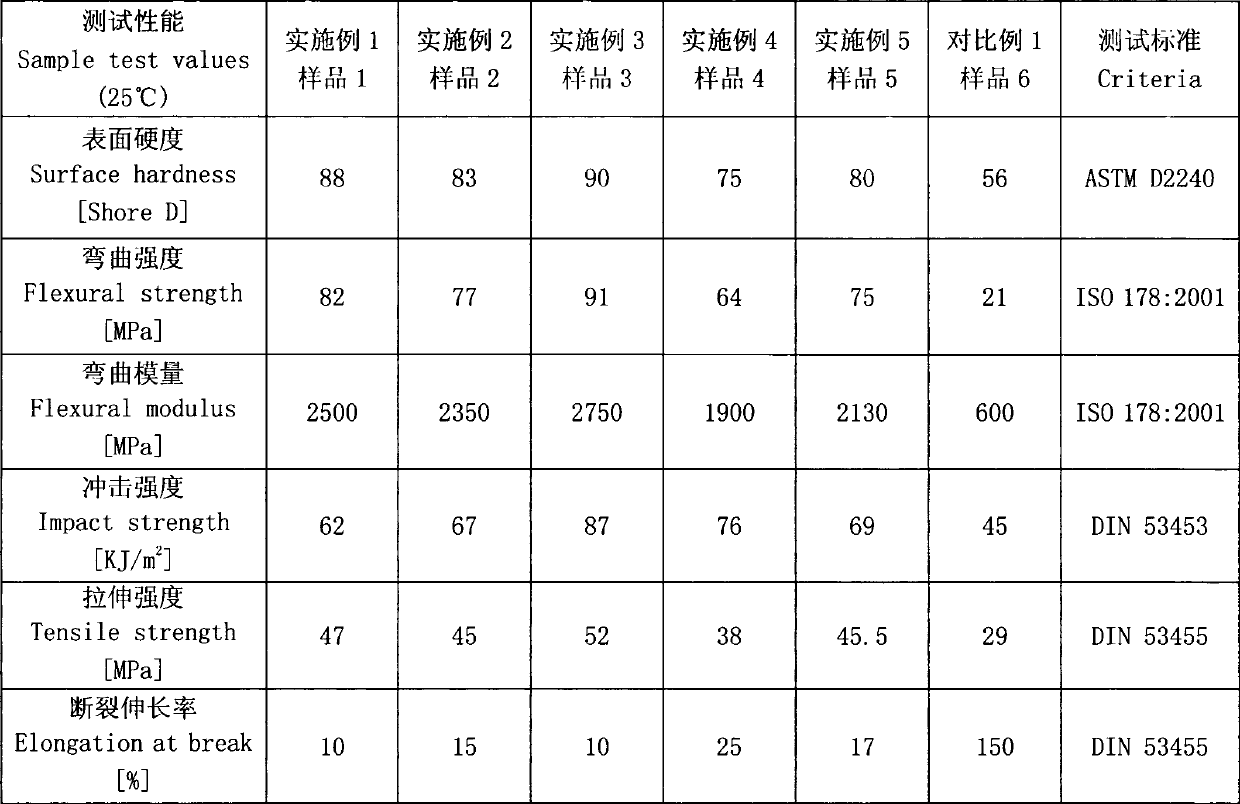

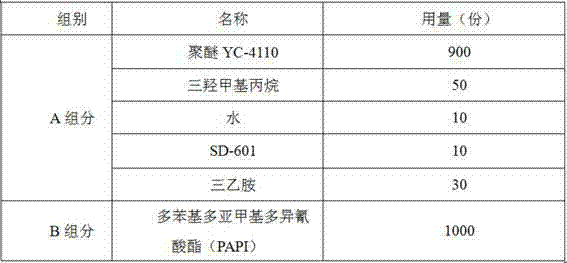

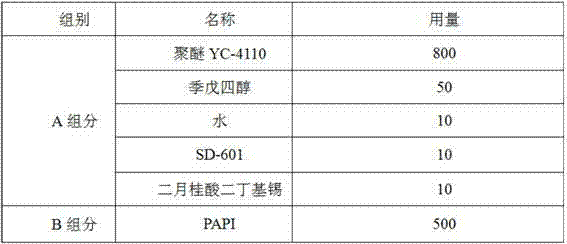

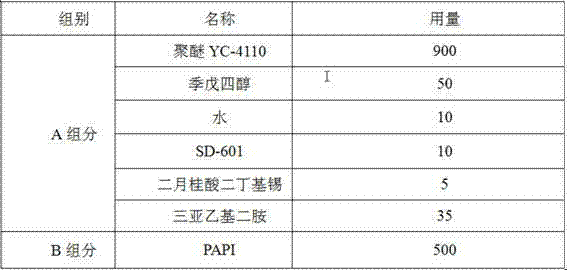

The invention discloses a high-strength and high-toughness polyurethane material and a preparation method thereof. The high-strength and high-toughness polyurethane material is prepared by the reaction of the following raw materials: an A component, a B component and a C component, wherein the A component comprises a polyurethane prepolymer and one or two or more of polymethylene polyphenyl isocyanate and diisocyanate derivatives; the B component comprises a small-molecular chain extender and one or two or more of high polymer polyols and high polymer polyamines; and the C component comprises a catalyst and an antioxidant, as well as one or two or more of optional components, namely a dewatering agent, a defoaming agent, a plasticizer and an anti-hydrolysis agent. The prepared polyurethane material has special high strength and good toughness, and can withstand high-strength impact and prevent fracture; and furthermore, the bending strength can achieve 75-95MPa, the bending modulus can achieve 1900-2950MPa, and the impact strength can achieve 60-95KJ / m<2>.

Owner:WANHUA CHEM GRP CO LTD +1

100% water-base foamed polyurethane foam and preparation method thereof

InactiveCN103012737AGood sound absorption and noise reductionGood moisture-wicking and self-dryingPolyesterFiber

The invention relates to the field of polyurethane, particularly a preparation method and application of 100% water-base foamed polyurethane foam. The 100% water-base foamed polyurethane foam is characterized by comprising a component A and a component B in a mass ratio of 1:1, wherein the component A is polymethylene polyphenyl isocyanate; the component B comprises polyalcohol, catalysts, foam stabilizer, pore opening agent, foaming agent, emulsifier and flame retardant; and the polyalcohol comprises polyether glycol, polyester polyol and flame-retardant polyether glycol. The invention is characterized by adopting high-proportion water. The invention adopts multiple assistants, and especially ingeniously uses three or two catalysts to ensure the open pore foam to have an open pore structure, the foam pores are compact and open, the meridian fibers of the foam pores are thin and soft, and the heat conductivity coefficient of the foam can still reach 0.036-0.040 (W / M.K).

Owner:JIANGSU STEADY NEW ENERGY TECH DEV

Single-component moisture-curing polyurethane adhesive and preparation method thereof

ActiveCN104263310AMeet the actual requirementsHigh activityPolyureas/polyurethane adhesivesPolyesterAdhesive cement

The invention discloses a single-component moisture-curing polyurethane adhesive and a preparation method thereof. The preparation method of the adhesive is characterized by comprising the following step: by adopting an organic solvent as a solvent, performing reaction on polyether glycol and / or polyester glycol, diphenyl methane diisocyanate, polymethylene polyphenyl isocyanate and triatomic primary alcohol of which the molecular weight is less than 200 to prepare the adhesive. The average degree of functionality of an obtained high-functionality NCO-terminated prepolymer is more than or equal to 3, and the single-component moisture-curing polyurethane adhesive disclosed by the invention is suitable for splicing and tenoning (or assembling) of woods and bonding and compounding of stone materials, fireproof plates, plastic aluminum plates, bakelite plates, oak boards, some metals such as aluminum and iron, zinc-plating plates, PVC membranes and the like, is especially suitable for adhesion of rosewoods and red woods, and can meet the special requirements of some products.

Owner:周建明

Maize stalk and/or wheat stalk composite board and its manufacturing method

InactiveCN101058207AUniform binderImprove surface bonding strengthFlat articlesDomestic articlesPolyphenyl isocyanateCorn stover

The invention relates to the compound board making using corn and wheat straw, comprising the material processing, mixed gluing, spreading, preheating, hot pressing and after treatment. It can recycle the corn and wheat straws, using polymethlene polyphenyl isocyanate and isocyanate solution in 1:1-1:2. 5 proportion to form the isocyanate adhesive, quick in high temperature solidification, strong in adhesion, low in formaldehyde emission, perfect for indoor decoration. It is highly biological.

Owner:SHIJIAZHUANG RAILWAY INST

Waterborne polyurethane grouting material and preparation method thereof

InactiveCN102093537AConvenient sourceAvoid poisoningOther chemical processesIsophorone diisocyanatePolymer chemistry

The invention discloses a preparation method of a waterborne polyurethane grouting material. The method is as follows: isocyanate, retarding agent and hydrophilic polyether polyol are mixed to react and obtain the finished product, wherein isocyanate is selected from diphenylmethane diisocyanate, liquefied diphenylmethane diisocyanate, polymethylene polyphenyl isocyanate isophorone diisocyanate, dicyclohexylmethylmethane-4,4'-diisocyanate, hexamethylene diisocyanate and polymethylene polyphenyl isocyanate or the mixture of toluene diisocynate and the isocyanates; and the degree of functionality of hydrophilic polyether polyol is 2-6, the ratio of ethylene oxide to propylene oxide is 99 / 1-60 / 40 and the molecular weight is 1000-20000. The invention also relates to the hydrophilic polyurethane grouting material prepared by the method. The preparation method of the invention is simple and convenient and has wide raw material sources; the prepared hydrophilic polyurethane grouting material does not contain organic solvent, thus avoiding the damage on the health of the constructor and promoting environmental protection; and the grouting material can have lower viscosity and good permeability and waterproof and leaking stoppage effect.

Owner:SHANGHAI DONGDA CHEM

Two-component polyurethane grouting material for repair and maintenance of road and preparation method thereof

InactiveCN102516492ASolve the problem of long-term closed traffic for repairsEffective penetrationRoads maintainenceFoaming agentPolyphenyl isocyanate

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Phase-change energy-storage polyurethane foam and preparation method thereof

The invention discloses a phase-change polyurethane foam and a preparation method thereof. The foam is prepared by subjecting a polyurethane foam raw material to processes of reacting, foaming, and curing; wherein the polyurethane foam raw material comprises polyether, polymethylene polyphenyl isocyanate, silicone oil, and methyl chloride; the reactions are carrier out after the mixing of a phase-change energy-storage microcapsule and the polyurethane foam raw material, the phase-change energy-storage microcapsule is composed of a capsule wall made of polyurethane-polysiloxane and a capsule core made of an organic phase-change material, and polycarbodiimide is taken as the cross-linking agent. The phase-change energy-storage microcapsule integrates the advantages of organic materials and inorganic materials together, namely has the organic materials' advantages of flexibility and elasticity, also has the inorganic materials' advantages of excellent mechanical performance and fire-retardant performance, and overcomes the shortage of easy separation between the conventional microcapsule and the foam substrate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation of polyurethane rigid foam wood-like material

The invention describes a preparation method of a rigid polyurethane foam wood-imitation material. The preparation method comprises the following steps: taking a mixture of polyether glycol, a catalyst, a foam stabilizer, a foaming agent, a fire retardant and the like as a white material, taking polymethylene polyphenyl isocyanate as a black material, injecting a certain amount of the mixed materials into a mould at temperature of 23-25 DEG C of the white material and the black material with mechanical stirring rate of 2000-3000r / min and mass ratio of the white material to the black material as 100 / 105-110, and demoulding after being at constant temperature of 35 DEG C for half an hour to obtain the rigid polyurethane foam wood-imitation material. The polyether glycol in the white material is a mixture of GR-4110, GR-403 and GE-210; the catalyst is a mixture of SFC, A33 and PC-41; the foam stabilizer is AK-8805, and the foaming agent is a mixture of HCFC-141b and H2O; and the fire retardant is DMMP. The black material is PM-200, Suprasec 5005 or Desmodur 44V20L.

Owner:无锡双象新材料有限公司

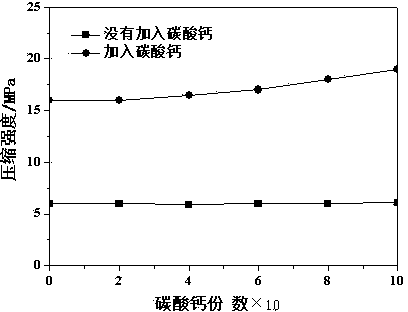

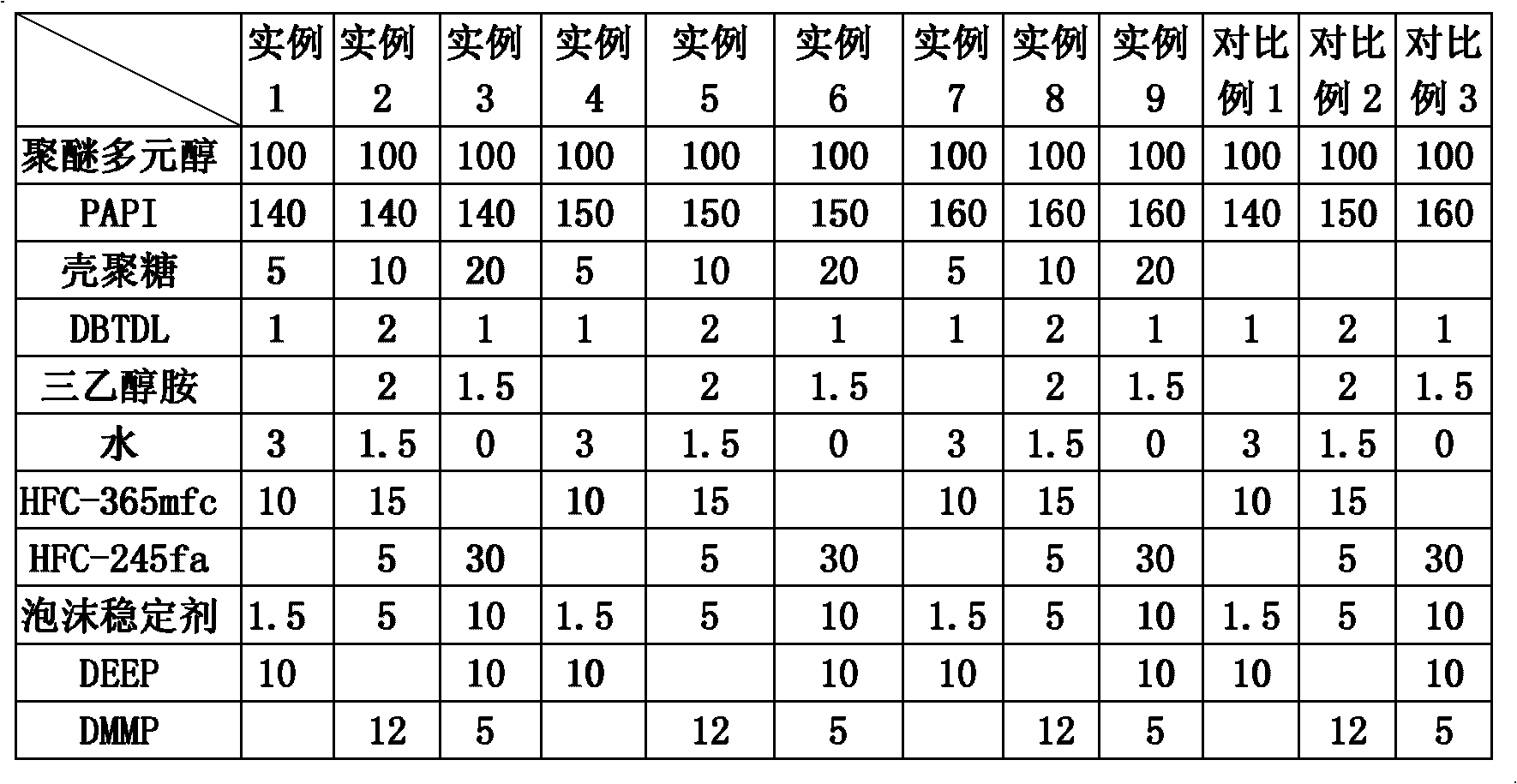

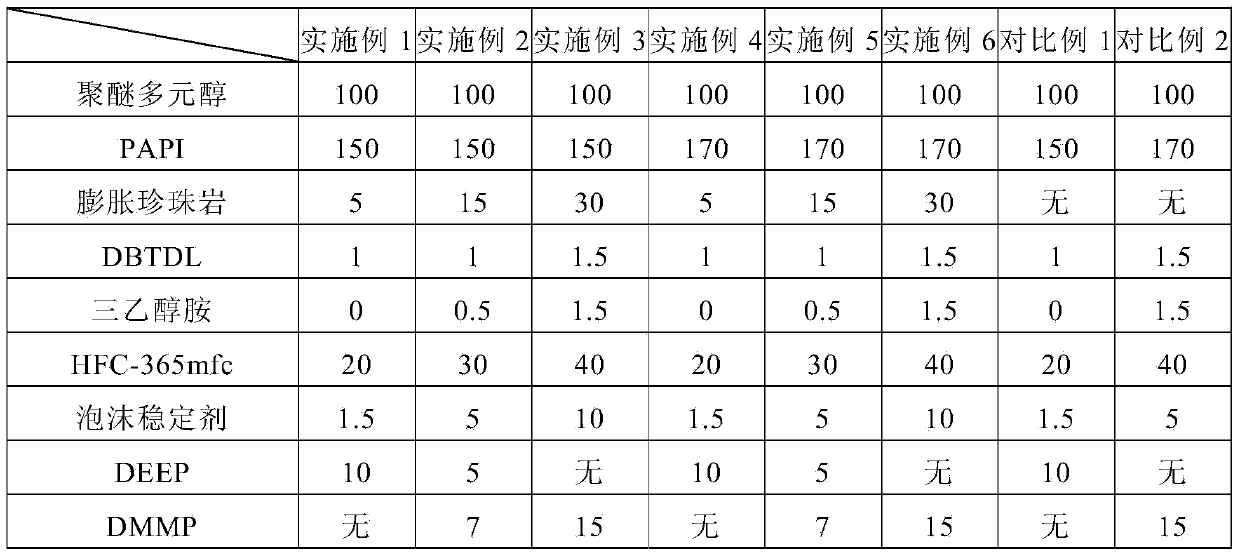

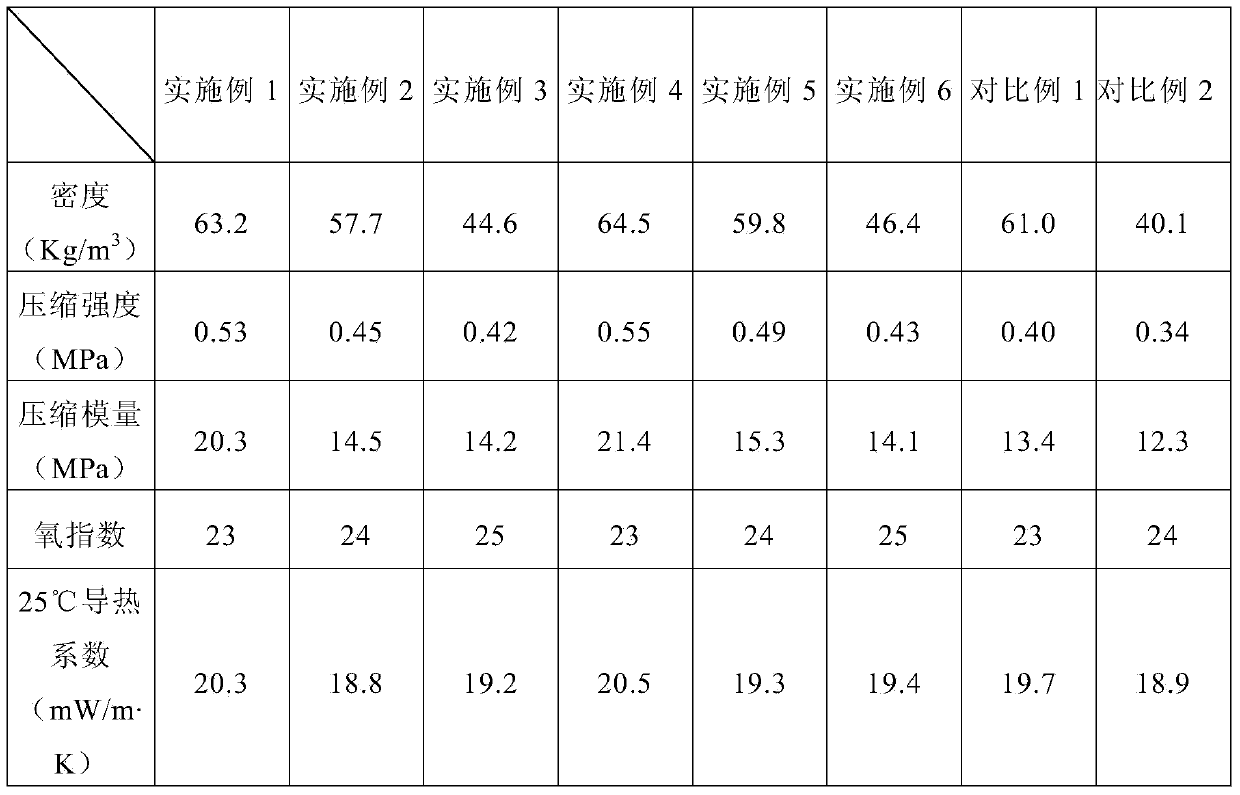

Chitosan-polyurethane composite rigid closed-cell foam material and preparation method thereof

The invention provides a chitosan-polyurethane composite rigid closed-cell foam material and a preparation method thereof, which belong to the technical field of polyurethane materials. The material comprises the following components in part by weight: 100 parts of polyether glycol, 140 to 160 parts of polymethylene polyphenyl isocyanate, 0 to 3 parts of physical foaming agent and water, 10 to 15 parts of flame retardant, 1 to 4 parts of catalyst, 1.5 to 10 parts of foam stabilizer and 5 to 20 parts of chitosan powder. The preparation method comprises the following steps: drying polyether glycol, polymethylene polyphenyl isocyanate and chitosan powder; placing the obtained product to room temperature for later use; adding chitosan powder into polymethylene polyphenyl isocyanate and mechanically stirring the two for 2 hours to obtain a component A; performing mixing treatment to obtain a component B; performing polymerization and polymerization treatment to obtain a pouring die billet; curing the pouring die billet after die release to obtain a foamed material. The foam material prepared by the method has the advantages of biocompatibility and degradability, and the preparation method ensures that every property of the material is equivalent to that of polyurethane foam materials containing no chitosan.

Owner:SHANGHAI JIAO TONG UNIV

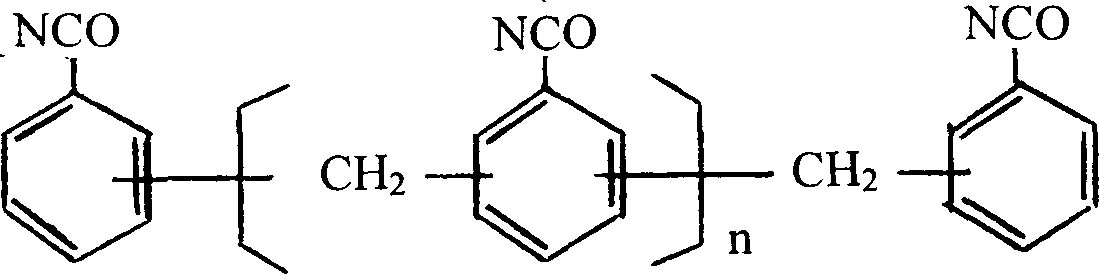

Polyurethane heat insulation foaming material and preparation method thereof

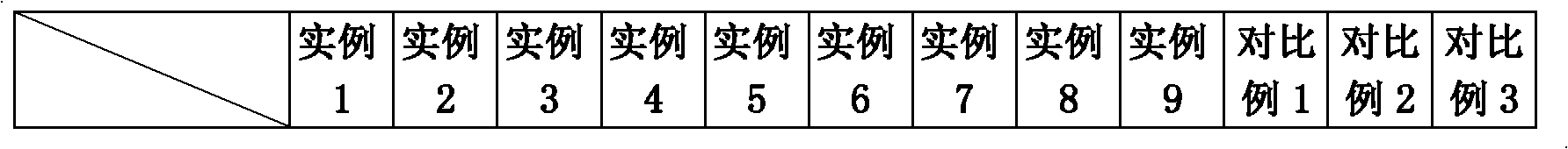

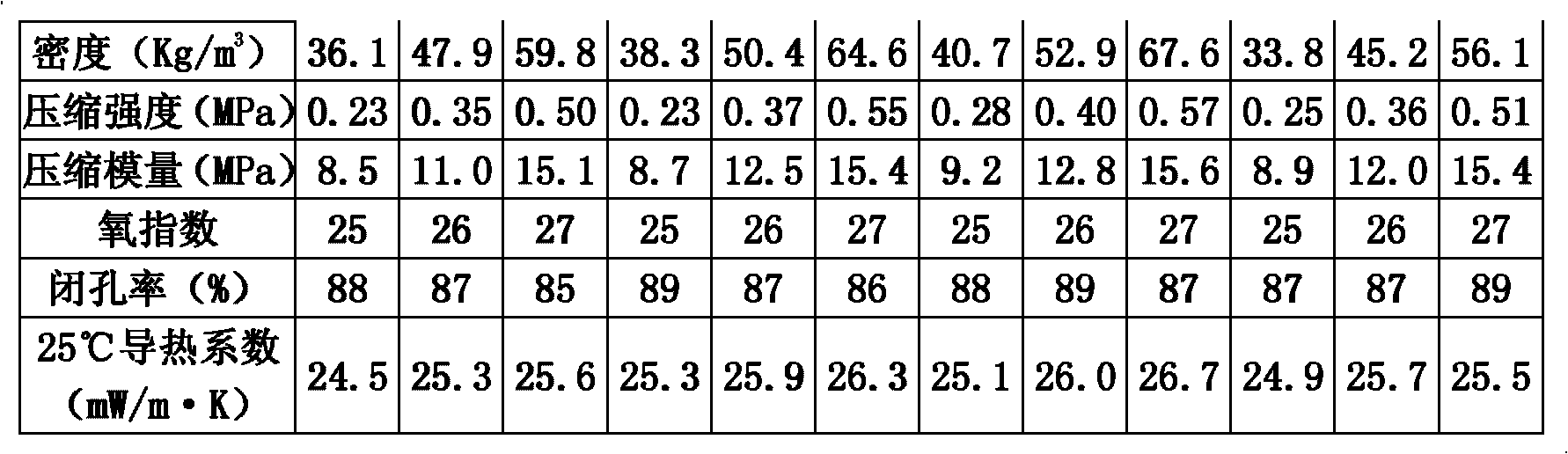

The invention discloses a polyurethane heat insulation foaming material and a preparation method thereof. The polyurethane heat insulation foaming material comprises the following components in parts by weight: 100 parts of polyether polyol, 150-170 parts of polymethylene polyphenyl isocyanate, 5-30 parts of expanded perlite, 20-40 parts of a physical foaming agent, 10-15 parts of a flame retardant, 1-3 parts of a catalyst and 1.5-10 parts of a foam stabilizer. The density of hard polyurethane foams prepared by the preparation method is smaller than 65Kg / m<3>, the thermal conductivity is smaller than 21mW / m.K, the compressive strength is greater than 0.42MPa, the compression modulus is greater than 14MPa, and the oxygen index is more than or equal to 23, so that the polyurethane heat insulation foaming material is suitable for the field of heat insulation.

Owner:SHANGHAI JIAO TONG UNIV

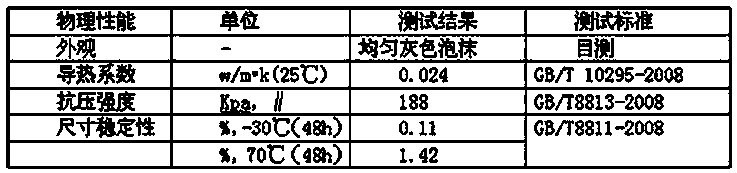

Spray rigid polyurethane foam heat insulation waterproof integrated material

InactiveCN102181144AFast curingWith thermal insulationHeat proofingBuilding insulationsEngineeringVolumetric Mass Density

The invention provides a spray rigid polyurethane foam heat insulation waterproof integrated material. The spray rigid polyurethane foam heat insulation waterproof integrated material is double-component foamed plastic which is formed by field spraying and consists of a component A and a component B in an equal volume ratio; the component A consists of 0 to 30 weight parts of toluene diisocynate, 0 to 30 weight parts of methylene diphenyl diisocyanate, and 70 to 100 weight parts of polymethylene polyphenyl isocyanate; the component B consists of 30 to 50 weight parts of polyatomic alcohol, 10 to 20 weight parts of catalyst, 5 to 10 weight parts of foam stabilizer, 10 to 30 weight parts of foaming agent, and 10 to 30 weight parts of fire retardant; the material comprises a foamed plastic layer with fire resistance, high intensity and density, and functions of watertightness, heat insulation, corrosion prevention, solvent resistance and the like; and the material can be mainly used for the watertightness, and heat insulation and the like of various roofs, wall bodies, and large-span light metal rooves with grid structures of industrial and civil buildings, and high-rise buildings, accessible rooves or roof gardens.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

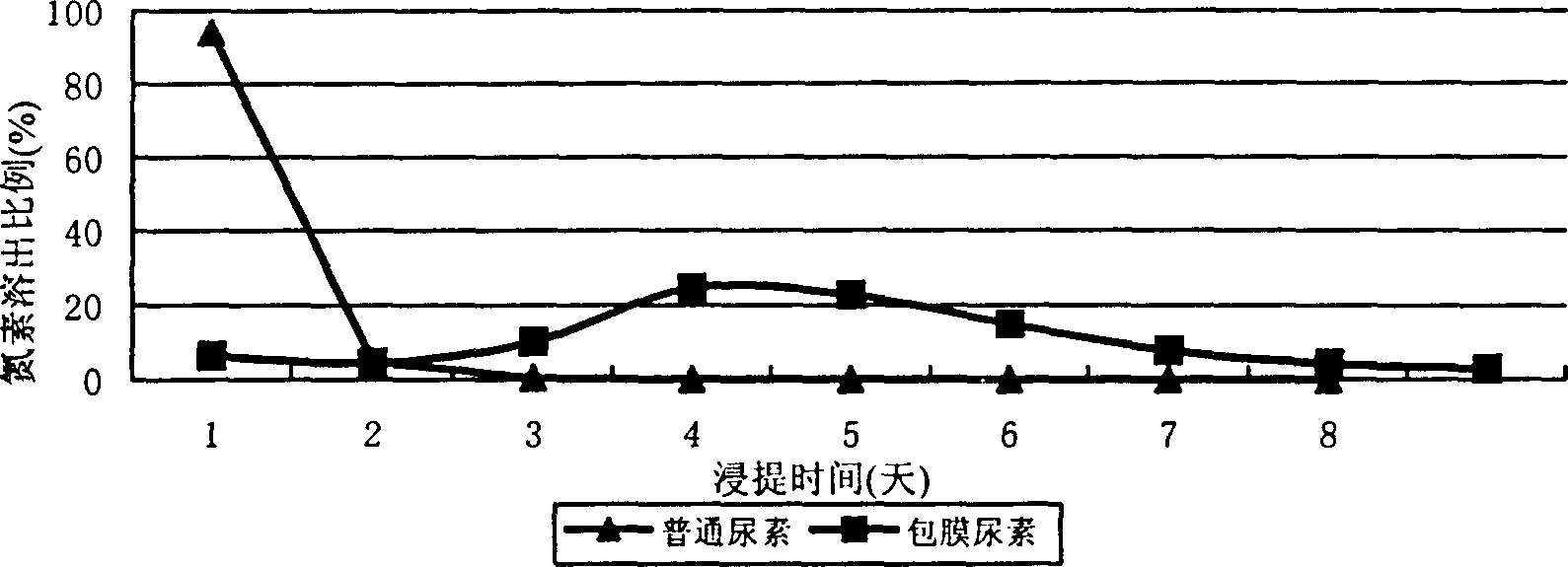

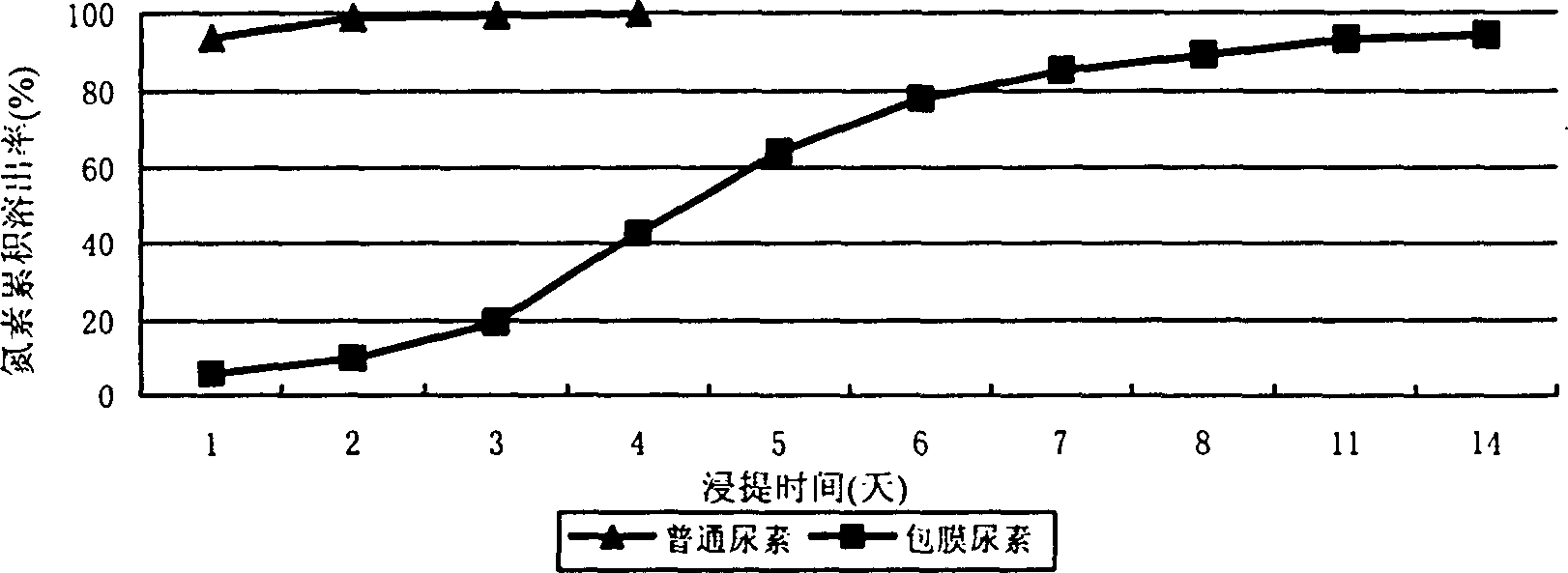

Release-controlled coated urea and its preparation method

InactiveCN1699293ALow costRich varietyUrea compound fertilisersFertilizer mixturesCoated ureaPolyphenyl isocyanate

The invention discloses a release-controlled coated urea which comprises a core layer of urea and a coated layer enclosing the surface of the urea, wherein the coated layer is formed from solid inorganic mineral powder and polymethylene polyphenyl isocyanate, the coated layer amounts to 15-30% of the total weight, its thickness is 100-120 microns.

Owner:上海市农业科学院环境科学研究所

Polyurethane foam two-component raw material suitable for low-temperature environment and construction method thereof

ActiveCN103923290AHigh viscosityGood foaming effectFoundation engineeringHeat proofingPolymer scienceFoaming agent

The invention relates to a polyurethane foam two-component raw material in compounds in the field of chemistry and a construction method thereof, and particularly relates to a polyurethane foam two-component raw material suitable for construction in autumn and winter for hydraulic concrete dam insulation engineering and the repair of cracks in a low temperature cold storage. The polyurethane foam two-component raw material comprises an isocyanate component and a polyol component, wherein the polyol component contains low-temperature and highly active polyether polyol which accounts for 15-45% of the total weight of the polyol component, the polyol component contains a physical foaming agent having a boiling point not higher than the construction temperature of 20 DEG C and accounting for 5-25% of the total weight of the polyol component, the isocyanate component is polymethylene polyphenyl isocyanate, a viscosity reducer, which accounts for 5-25% of the weight of polymethylene polyphenyl isocyanate, is added into polymethylene polyphenyl isocyanate and the viscosity of the polymethylene polyphenyl isocyanate is reduced to 100cps or less after the addition of the viscosity reducer. The polyurethane foam two-component raw material disclosed by the invention can be normally constructed at -30 DEG C and above ambient temperature.

Owner:WANHUA ENERGY-SAVING TECH GRP CO LTD

Moisture-curing polyurethane epoxy coal-tar bitumastic

InactiveCN101760135AUniform thicknessNo effect on cure speedAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyCyclohexanone

The invention relates to a moisture-curing polyurethane epoxy coal-tar bitumastic. The invention adopts a technical scheme that: the bitumastic is formed by a component A and a component B in a weight ratio of 1:1-1:2; and the preparation method comprises the following steps of: placing 37 to 40 parts of polymethylene polyphenyl isocyanate, 11 to 13 parts of polyether 330 or 3,030, 2 to 3 parts of polyether 635 or 450, 8 to 9 parts of DOP or DBP, 3 to 4 parts of epoxy resin, 0.002 to 0.003 part of phosphoric acid and 33 to 37 parts of solvent No.S10,000 or industrial xylene in a reaction kettle at the temperature of between 81 and 86 DEG C, preserving the heat for 2 hours, and cooling the raw materials to obtain the component A; and placing 62 to 66 parts of coal-tar, 9 to 10 parts of cyclohexanone, 10 to 11.5 parts of toluene, and 7 to 8 parts of solvent No.S1,000or industrial xylene in the reaction kettle at the temperature of between 115 and 120 DEG C, preserving the heat for 2 hours, and cooling the raw materials to obtain the component B. The coating applied by the bitumastic is waterproof and long in life time and can further protect equipment and pipes.

Owner:孙锡宁

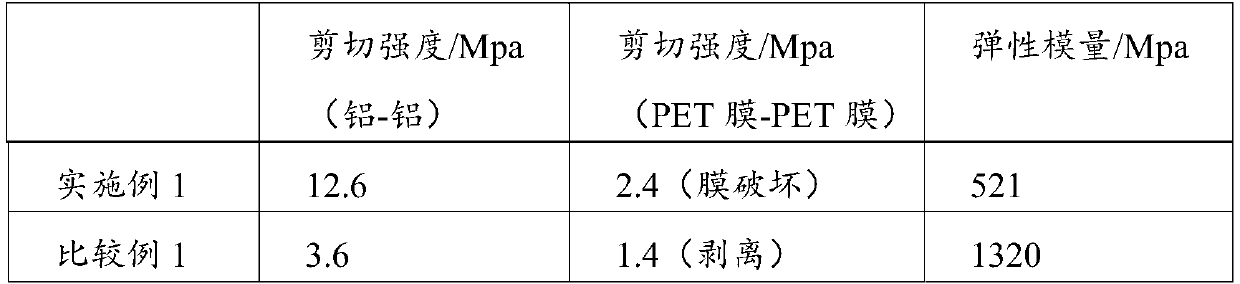

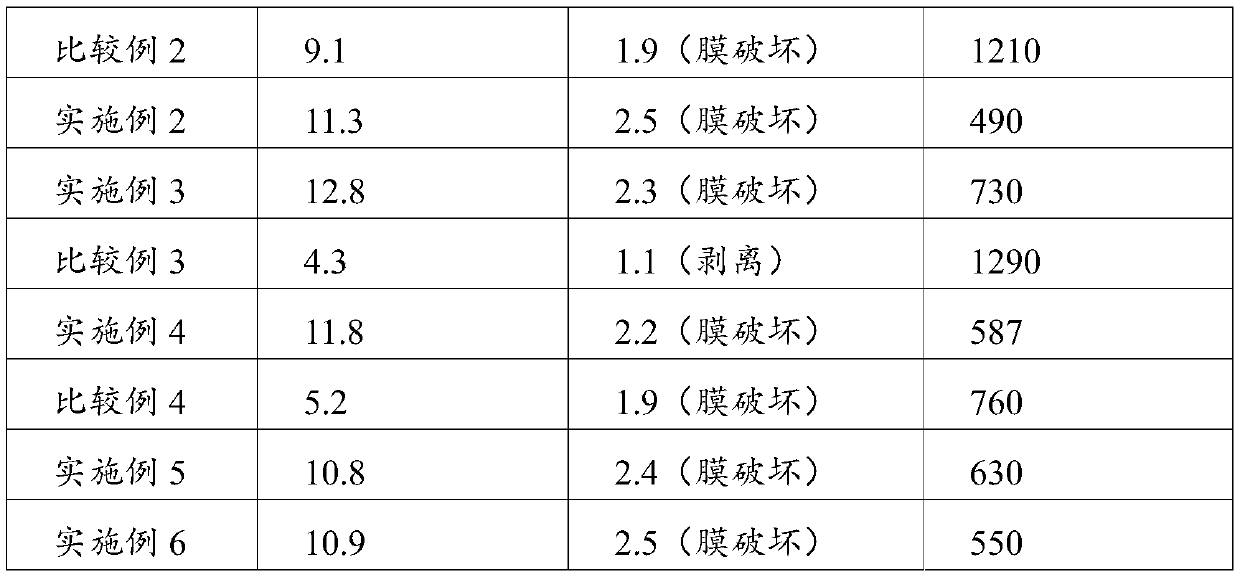

Bi-component polyurethane structural adhesive for bonding power batteries and preparation method thereof

ActiveCN111303820AHigh bonding strengthMedium elastic modulusNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention provides a bi-component polyurethane structural adhesive for bonding power batteries and a preparation method of the bi-component polyurethane structural adhesive. The polyurethane structural adhesive comprises a component A and a component B. The component A comprises 40-65 parts of polymethylene polyphenyl isocyanate, 30-50 parts of aluminum hydroxide, 2-5 parts of hydrophobic fumed silica and 0-5 parts of a plasticizer. The component B comprises the following components in parts by weight: 40-65 parts of bio-based polyol, 1-4 parts of fumed silica, 25-50 parts of a flame retardant, 1-5 parts of an adhesion promoter and 0.01-0.5 parts of a catalyst. The bio-based polyol is selected from one or more of rapeseed oil modified polyol, castor oil modified polyol, soybean oil modified polyol and palm oil modified polyol. The adhesion promoter is prepared by reacting aminophenylsilane with a silane modifier. The adhesive is relatively high in bonding strength and has a mediumelastic modulus. The flame-retardant effect is good, the adhesive has excellent adhesion performance to materials such as bare aluminum and PET films, and the adhesive can be used for structural adhesion of power battery PACKs.

Owner:HANGZHOU ZHIJIANG NEW MATERIAL CO LTD +1

Synthetic method of modified high-toughness epoxy vinyl ester resin

The invention relates to a synthetic method of modified high-toughness epoxy vinyl ester resin, belonging to the technical field of high-molecular polymers. The synthetic method is characterized by comprising the following steps of: (1) sequentially adding 40%-50% of bisphenol A type epoxy resin, 8%-20% of unsaturated monocarboxylic acid, 2.5%-11% of long-chained saturated dicarboxylic acid, 0.1%-1.0% of catalyst A, and 0.01%-0.1% of polymerization inhibitor into a reaction kettle; (2) controlling the temperature to be 100-130 DEG C to measure an acid value until the acid value is reduced to 10mgKOH / g below; and (3) cooling to about 100 DEG C, then adding 28%-40% of crosslinking agent, 1.0-5.0% of polymethylene polyphenyl isocyanate, and 0.05%-0.5% of catalyst B, and controlling the temperature to be 60-80 DEG C until the measured isocyanato concentration is zero, thus achieving the reaction endpoint. The synthetic method has the advantages that the long-chained saturated dicarboxylic acid is used for partially replacing an unsaturated monocarboxylic acid to react, dilution is carried out before the polymethylene polyphenyl isocyanate is added for chain extension, the chain extension reaction is thorough, and the toughness effect is good. The synthetic method is simple in technology, clear in endpoint, less in side effects, and free from generation of three wastes, and the quality is stable.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH +1

Hard polyurethane flame-retardant heat-insulation material for external walls and preparation method of hard polyurethane flame-retardant heat-insulation material

The invention discloses a hard polyurethane flame-retardant heat-insulation material for external walls. The material is composed of a component A and a component B; the component A is prepared from, by weight, 60-80 parts of polyether polyol, 30-40 parts of phenolic resin, 20-30 parts of brominated epoxy resin, 10-30 parts of vitrified microspheres, 10-20 parts of expanded vermiculite, 5-15 parts of nano silicon dioxide, 3-8 parts of glass fibers, 5-10 parts of sepiolite fibers, 5-15 parts of filler, 8-15 parts of a foaming agent and 5-10 parts of auxiliary agents; the component B is polymethylene polyphenyl isocyanate. The hard polyurethane flame-retardant heat-insulation material which integrates excellent flame retardation and mechanical performances is provided to solve the problem of mutual contradiction between flame retardation and mechanical performances of previous rigid polyurethane foam heat-insulation materials.

Owner:HEFEI WANZHIJING DOORS & WINDOWS CO LTD

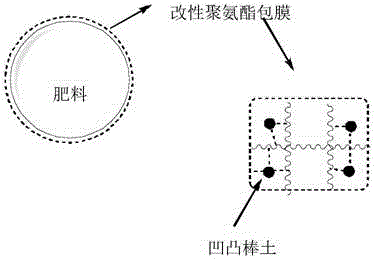

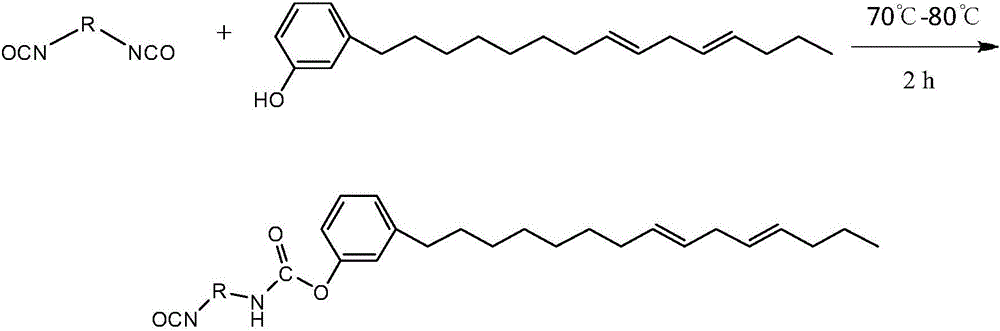

Composite modified polyurethane coating slurry, controlled release fertilizer and preparation method of controlled release fertilizer

ActiveCN106800472AWide variety of sourcesGood adhesionAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersControlled releaseAlcohol

The invention discloses composite modified polyurethane coating slurry, a controlled release fertilizer and a preparation method of the controlled release fertilizer. The preparation method of the polyurethane coating controlled release fertilizer comprises the following steps: (1) vegetable oil polyhydric alcohol and attapulgite are uniformly mixed at a preset ratio to obtain an A component; (2) polymethylene polyphenyl isocyanate and cardanol with a mole ratio of 10-15% react for 1-3h at 70-80 DEG C to obtain a B component; (3) the A component and the B component are uniformly mixed in proportion to obtain vegetable oil based attapulgite hybridized composite modified polyurethane coating slurry; (4) a to-be-coated granular fertilizer is preheated; (5) the composite modified polyurethane coating slurry is sprayed on the surface of the preheated granular fertilizer; (6) the vegetable oil based polyurethane coating slurry is repeatedly sprayed for 3-6 times after the vegetable oil based polyurethane coating slurry is solidified to obtain the vegetable oil based attapulgite hybridized composite modified polyurethane coating controlled release fertilizer.

Owner:上海永通生态工程股份有限公司

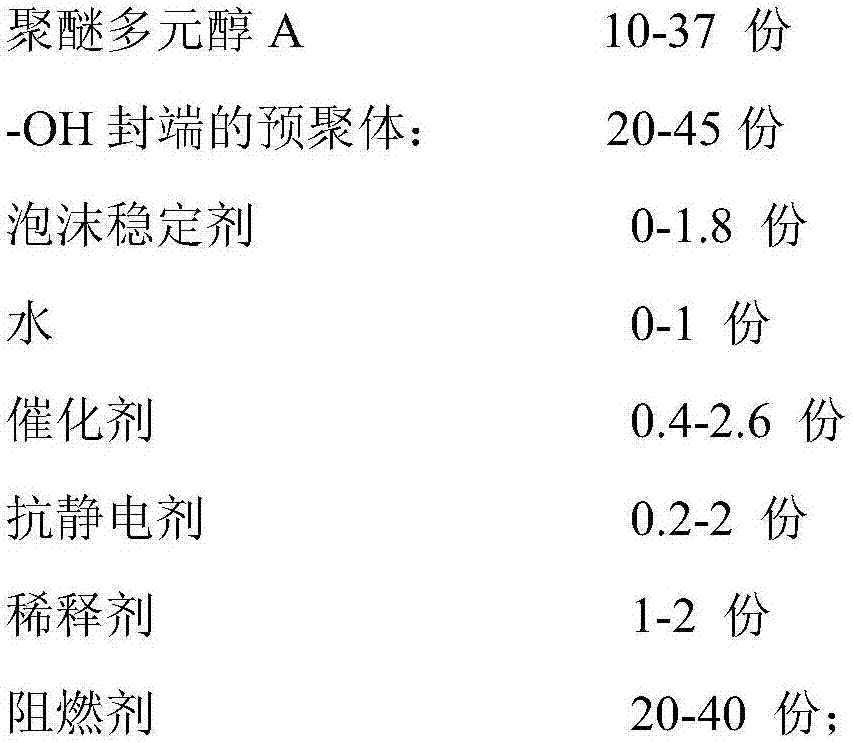

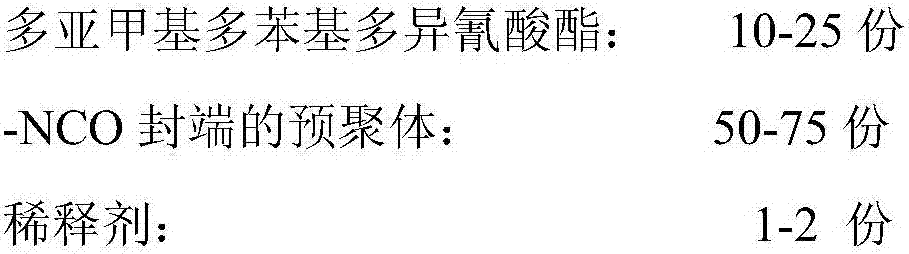

Macromolecule grouting reinforcement material for coal mines and preparation method of macromolecule grouting reinforcement material

InactiveCN107417876AReduce heat of reactionLow reaction temperatureReaction temperatureFire retardant

The invention relates to a macromolecule grouting reinforcement material for coal mines and a preparation method of the macromolecule grouting reinforcement material. The macromolecule grouting reinforcement material contains a component A and a component B, wherein the component A contains the following components in parts by weight: 10-37 parts of polyether polyol A, 20-45 parts of a -OH-terminated prepolymer, 0-1.8 parts of a foam stabilizer, 0-1 parts of water, 0.4-2.6 parts of a catalyst, 0.2-2 parts of an antistatic agent, 1-2 parts of a diluent and 20-40 parts of a flame retardant; and the component B contains the following components in parts by weight: 10-25 parts of polymethylene polyphenyl isocyanate, 50-75 parts of a -NCO-terminated prepolymer, 1-2 parts of a diluent and 10-30 parts of a flame retardant. According to the macromolecule grouting reinforcement material, the reaction heat is greatly reduced, so that the reaction temperature in the use process of the material is decreased, and the safety hazards in the use process of the material are eliminated; the mechanical property and flame-retardant anti-static property of the material can meet underground use requirements; and the material is low in odor, non-toxic, non-corrosion and harmless to a human body.

Owner:山东润义金新材料科技股份有限公司

All-water foamed molding slow-rebound bloating foamed cotton of MDI (polymethylene polyphenyl isocyanate) with density of 45kg/m<3> and preparation method

The invention discloses all-water foamed molding slow-rebound bloating foamed cotton of MDI (polymethylene polyphenyl isocyanate) with the density of 45kg / m<3>. For the isocyanate in the MDI system, the functionality is 2-3 and the NCO value is 26-30; the polyether polyol is prepared by mixing the following materials: polyol A with the functionality being 3 and the hydroxyl value being 32-60mgKOH / g, polyol B with the functionality being 2 and the hydroxyl value being 240-260mgKOH / g, polyol C with the functionality being 3 and the hydroxyl value being 240-260mgKOH / g, polyol D with the functionality being 3 and the hydroxyl value being 20-28mgKOH / g; and a foaming agent is H2O. The molding slow-rebound bloating foamed cotton disclosed by the invention has the advantages that due to use of MDI for production, the harm can not be caused to a human body, water generates trace carbon dioxide in the foaming reaction, and the pollution to the atmosphere is almost zero; in conclusion, the use is safe and the processing is no-pollution.

Owner:FUJIAN GENEROUS SLEEP TECH CO LTD

Ultrahigh-density high-strength polyurethane spray-coating material, and preparation method and application thereof

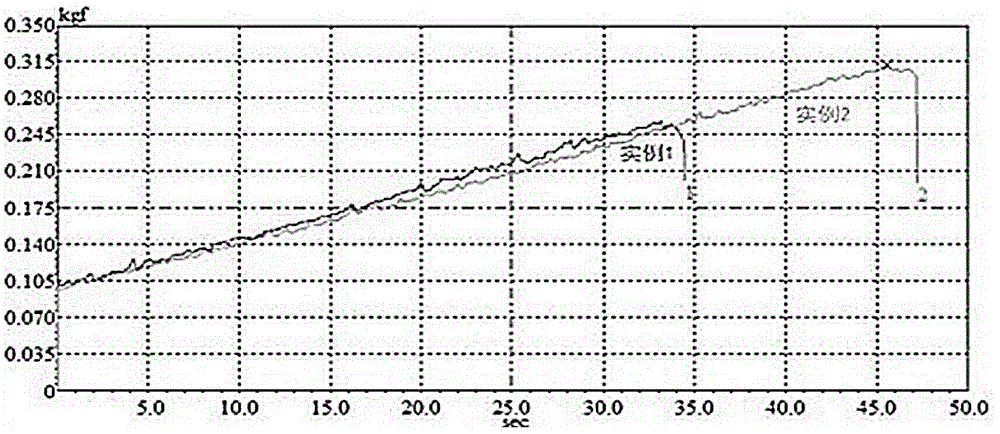

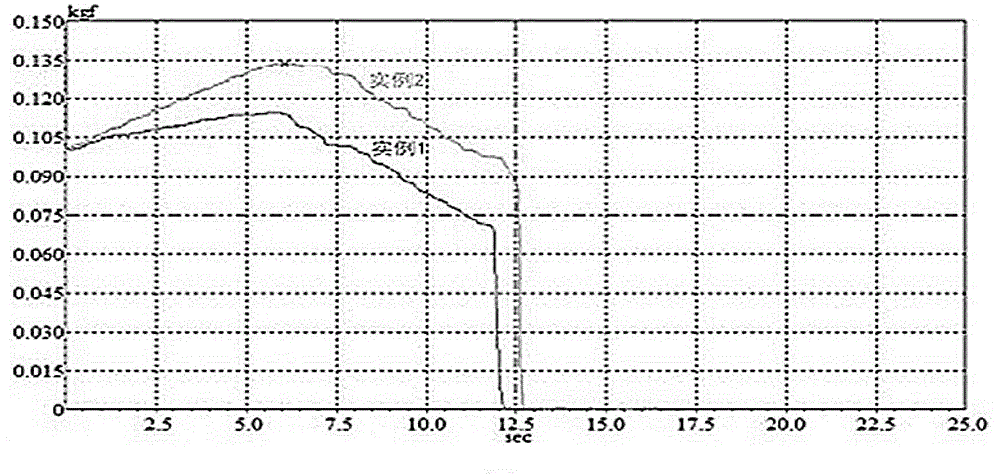

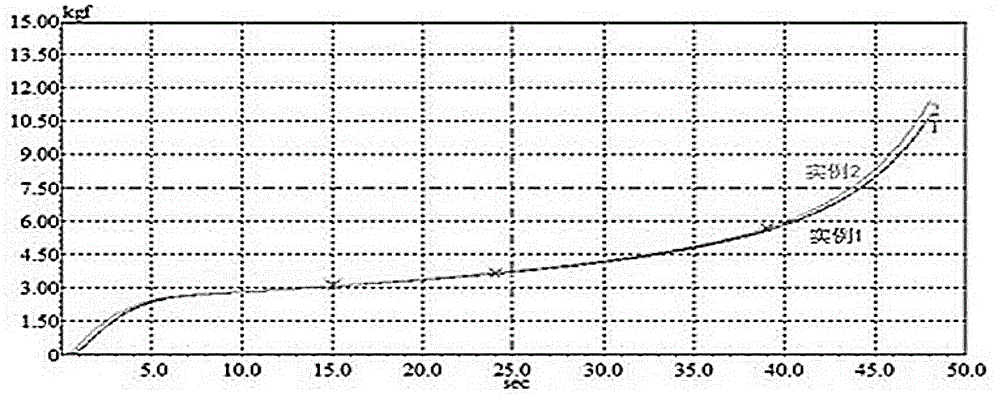

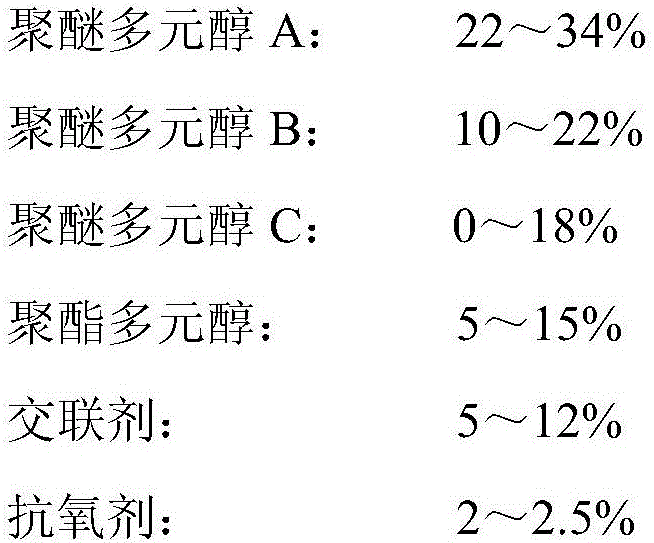

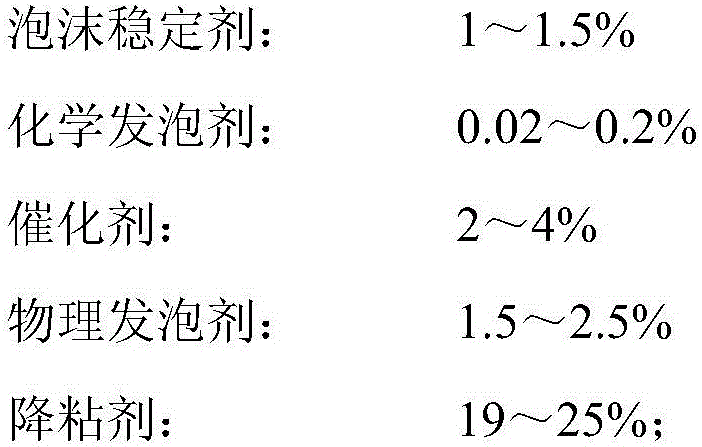

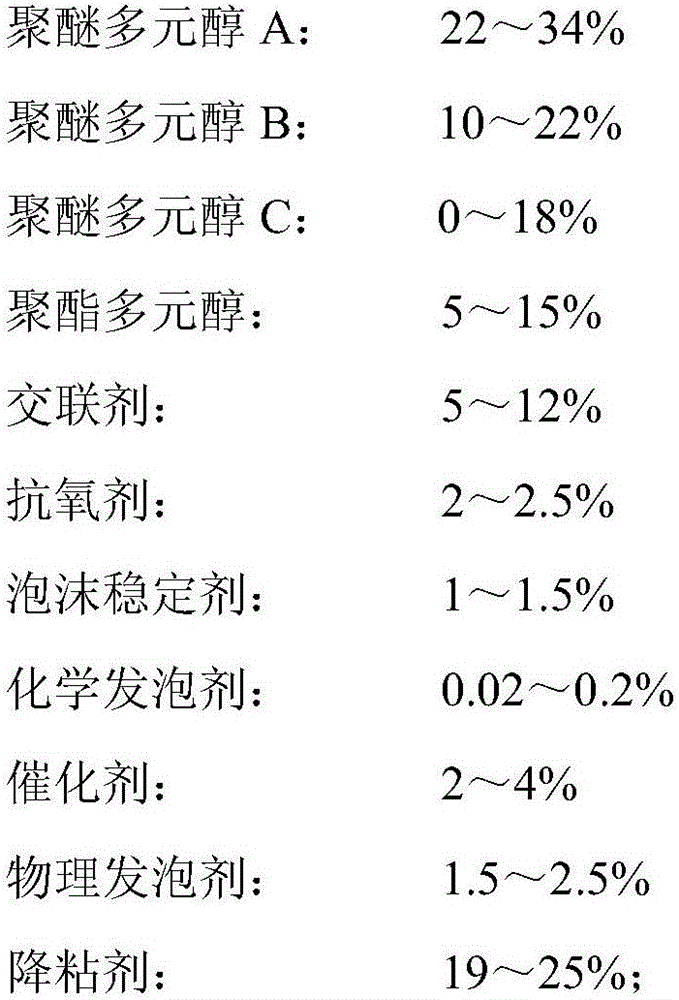

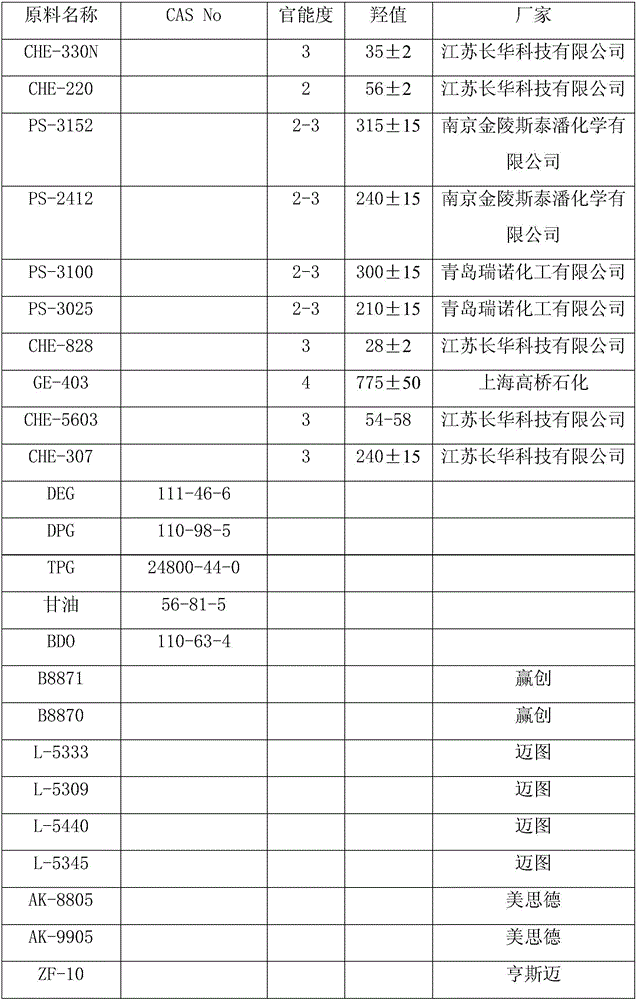

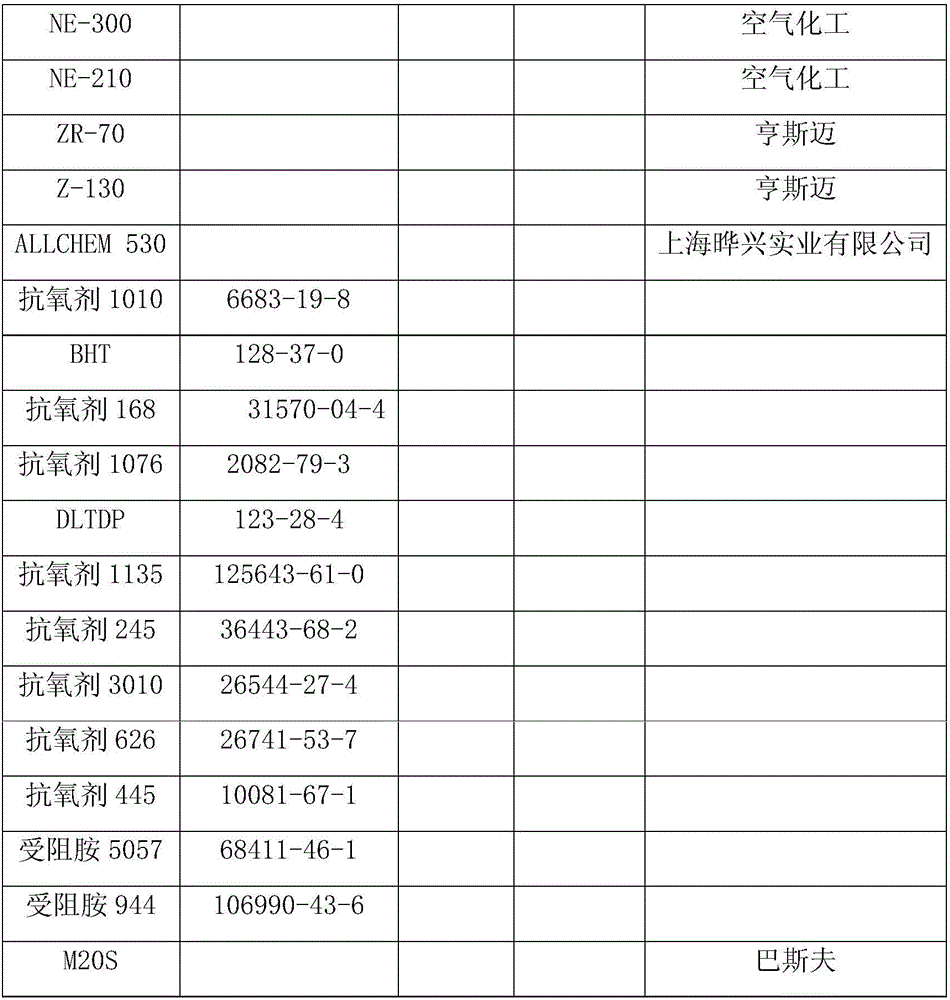

The invention belongs to the technical field of polyurethane, and in particular relates to an ultrahigh-density high-strength polyurethane spray-coating material, and a preparation method and application thereof. The material consists of a component A and a component B, wherein the component A comprises the following components in percentage by mass: 22 to 34 percent of polyether polyol A, 10 to 22 percent of polyether polyol B, 0 to 18 percent of polyether polyol C, 5 to 15 percent of polyether polyol D, 5 to 12 percent of a crosslinking agent, 2 to 2.5 percent of an antioxidant, 1 to 1.5 percent of a foam stabilizer, 0.02 to 0.2 percent of a chemical foaming agent, 2 to 4 percent of a catalyst, 1.5 to 2.5 percent of a physical foaming agent and 19 to 25 percent of a viscosity reducer; and the component B is polymethylene polyphenyl isocyanate. The material provided by the invention has the characteristics that construction tolerance is high, and the prepared foam plastic has high density, high compression strength, high viscosity with a base material, high surface hardness and the like, and can be widely applied to heat-preserving protection engineering needing to tolerate external pressure.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Automobile roof polyurethane composition

The invention relates to an automobile roof polyurethane composition which mainly solves the problems existing in the prior art such as high VOC value and great odor due to relatively high aldehyde content. With the adoption of the technical scheme of the invention, the low-VOC low-odor automobile roof composition is composed of a component A and a component B, wherein a ratio of the weight percentage of the component A to the component B is 1:(1.1-2.0); the component A comprises polyether polyol, polyester polyol, polypolyols, a chain extender, a foam stabilizer, a catalyst, water and at least one aid of colorants, antioxidants and dispersing agents; and the component B refers to polymethylene polyphenyl isocyanate or modified polymethylene polyphenyl isocyanate. The problems are well solved, and the composition can be used in industrialized production of the low-VOC low-odor automobile roof composition.

Owner:江苏长顺高分子材料研究院有限公司

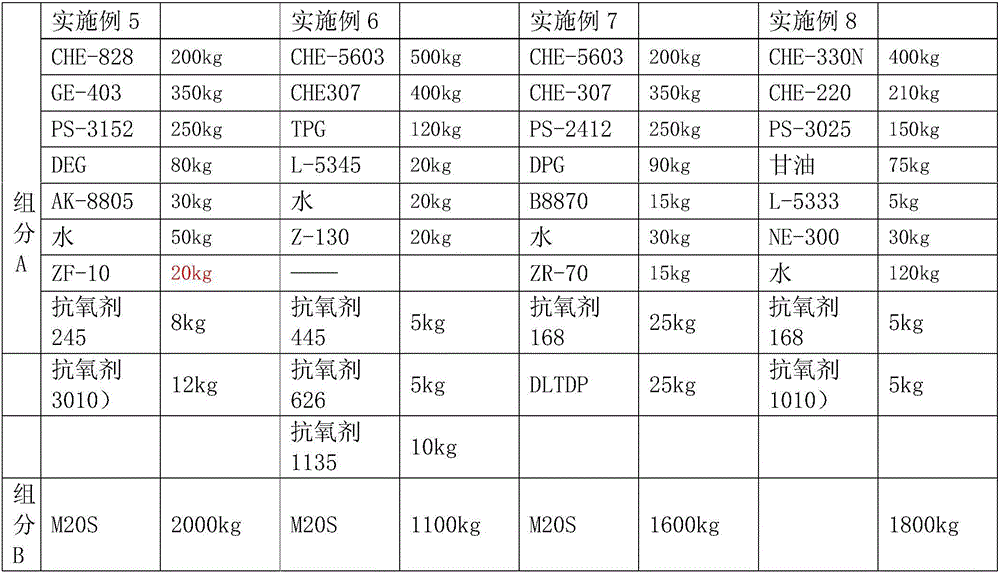

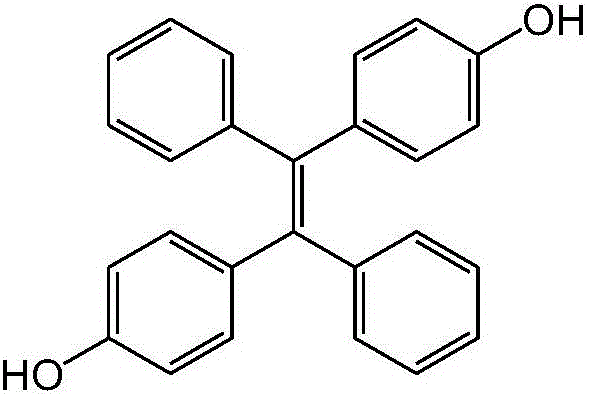

Isocyanate curing agent with fluorescence characteristic and preparation method thereof

InactiveCN106632977AReduce productionSimple manufacturing processLuminescent paintsPolyurea/polyurethane coatingsPolyphenyl isocyanateRotary evaporator

The invention discloses an isocyanate curing agent with fluorescence characteristic and a preparation method thereof. The raw materials for preparing the isocyanate curing agent with fluorescence characteristic include polymethylene polyphenyl isocyanate and (E)-4,4'-dihydroxyl tetraphenylethylene, wherein the mass ratio of the polymethylene polyphenyl isocyanate to (E)-4,4'-dihydroxyl tetraphenylethylene is (99:1)-(80:20). The preparation scheme comprises the following steps: dissolving the polymethylene polyphenyl isocyanate and (E)-4,4'-dihydroxyl tetraphenylethylene in certain solvent, stirring and heating for reacting for certain time; cooling; and evaporating with a rotary evaporator to remove the solvent to obtain the designed product solvent. In the invention, the preparation technology of fluorescent paint is simplified, and the defect of aggregation-induced quenching effect easily caused by adopting traditional organic fluorescent molecules is overcome.

Owner:SUZHOU JIREN HIGH TECH MATERIAL CO LTD

Reaction thickening type two-component polyurethane glass adhesive and preparation method thereof

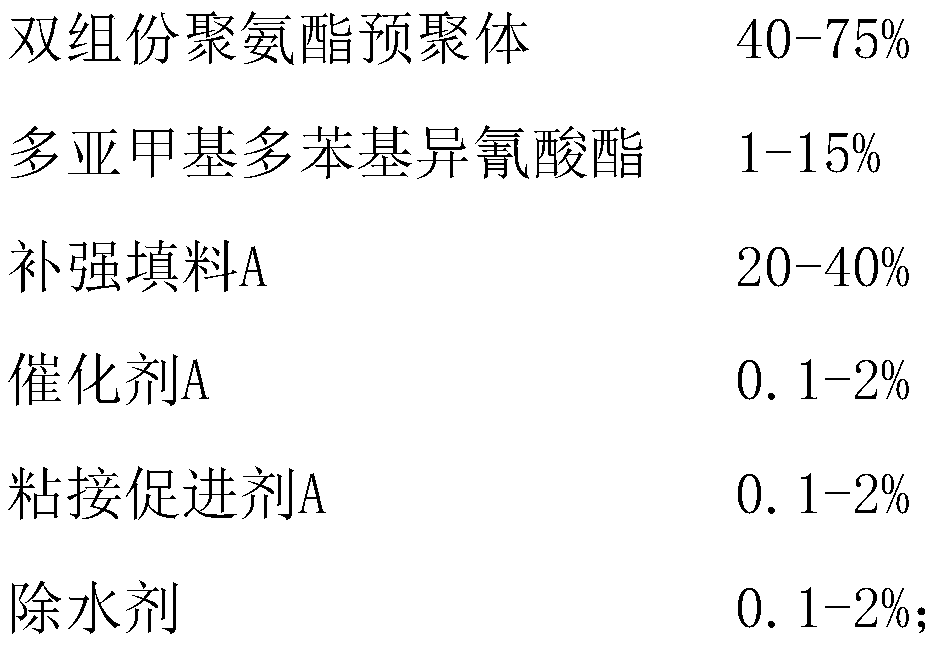

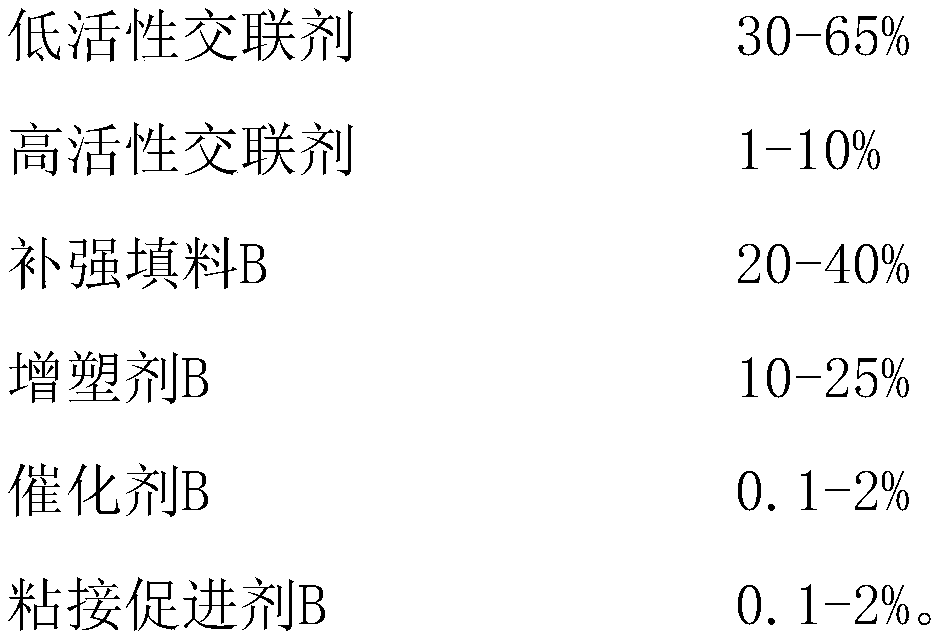

InactiveCN110093137AEnsure construction mixGuaranteed thicknessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesLow activityPlasticizer

The invention relates to the technical field of adhesives, in particular to a reactive thickening type two-component polyurethane glass adhesive and a preparation method thereof. The preparation method comprises the following steps of: mixing and stirring a component A and a component B in a volume ratio of 1: 0.8-1.2 for 5-20min to prepare the glass adhesive. The component A comprises 40-75% of atwo-component polyurethane prepolymer, 1-15% of polymethylene polyphenyl isocyanate, 20-40% of a reinforcing filler A, 0.1-2% of a catalyst A, 0.1-2% of an adhesion promoter A and 0.1-2% of a water removal agent. The component B comprises 30-65% of a low-activity cross-linking agent, 1-10% of a high-activity cross-linking agent, 20-40% of a reinforcing filler B, 10-25% of a plasticizer B, 0.1-2%of a catalyst B and 0.1-2% of an adhesion promoter B. The preparation method of the invention has simple operation, convenient control, low production cost and high product quality, and can be used for large-scale production.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD +1

Fire-retardant high-flexibility two-shot grouting material and preparation method thereof

The invention relates to a fire-retardant high-flexibility two-shot grouting material and a preparation method thereof, and aims at solving the technical problems that an existing grouting material is poor in stability, poor in flexibility, low in compressive strength and high in cost. Polypropylene glycol (PPG), water glass, an emulsifier, a catalyst, sorbitol and water are adopted to form a component A; polymethylene polyphenyl isocyanate and acetyl citrate are taken as a component B; and the component A and the component B are mixed at the weight ratio of (0.65-1.3) to 1 when used. The grouting material disclosed by the invention is simple to prepare, low in cost, stable in performance, low in viscosity, controllable in curing time, excellent in flame resistance after being cured, high in strength, good in tenacity, good binding power, and free of foaming in a water environment, can still keep relatively high mechanical property, and is suitable for rapid reinforcement and seal leakage treatment of broken seam, terrane, concrete cracks, highway cracks and roadbeds.

Owner:HENAN POLYTECHNIC UNIV

Environment-friendly high-buffering-property polyurethane packaging material

The invention discloses an environment-friendly high-buffering-property polyurethane packaging material. The packaging material is formed by mixing a combined polyether raw material and polymethylene polyphenyl isocyanate, wherein the combined polyether raw material is composed of, by proportion, 40-45 parts of polyether trihydric alcohol, 30-40 parts of polyether glycol, 3-8 parts of chain extenders, 2-5 parts of foam stabilizers, 20-30 parts of water, 0.3-0.6 part of dimethylamino ethylether and 0.3-0.5 part of triethylene diamine. The proportion of the polymethylene polyphenyl isocyanate to the combined polyether raw material is 0.8-1.0:1. The material has a good buffering property, the buffering property is three times that of a general foaming material, and the material has good elasticity, and can be used repeatedly, and foamed and formed into the packaging material anytime and anywhere within a short time; as the water is used for replacing other foaming agents, intensity is low, the production cost is reduced, substances damaging an ozone layer are avoided, pollution is really reduced, and the environment-friendly effect of the foaming agent is completely achieved.

Owner:河南铎润新材料有限公司

Polyurethane external-wall heat-insulation material

InactiveCN1709937ALow costSimple construction operationClimate change adaptationPassive housesPorosityPolyphenyl isocyanate

This is a kind of polyurethane outer wall thermal insulation material belonging to chemical technology field. The invention is double components reaction. The First Component is the mixture of polyether polyols, PET alcoholysis and various auxiliary agents, and the Second Component is polyarylpolymethylene polyphenyl isocyanate (PAPI). When used, mix according to proportion can adopt smearing method to construct. Because of adding PET alcoholysis, it can observably improve the foam porosity structure of product. The obtained product has certain toughness, and the break elongation ratio is improved. It can form compact and hard epidermis when frothing, so it has certain waterproof effect besides thermal insulation. It can be applied for outer wall thermal insulation with both effects of reducing energy waste and waterproofness. The PET alcoholysis is made from PET waste material, so its cost is lower than polyether polyols,. Its addition can reduce the cost of outer wall thermal insulation material. Besides it provides new mentality for the use of PET waste material.

Owner:SHENYANG JIANZHU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com