Reaction thickening type two-component polyurethane glass adhesive and preparation method thereof

A two-component polyurethane, two-component polyurethane technology, applied in the field of adhesive glue, can solve the problems of difficult mixing, tube burst, difficult extrusion of glue guns, etc., to promote mixing and dispersion, high tensile shear The effect of good strength and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

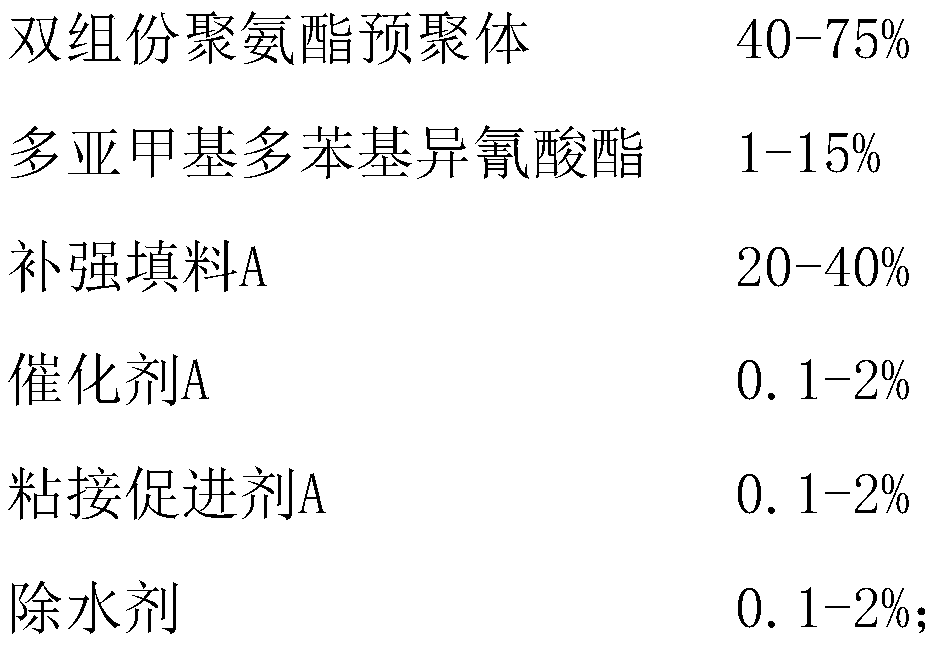

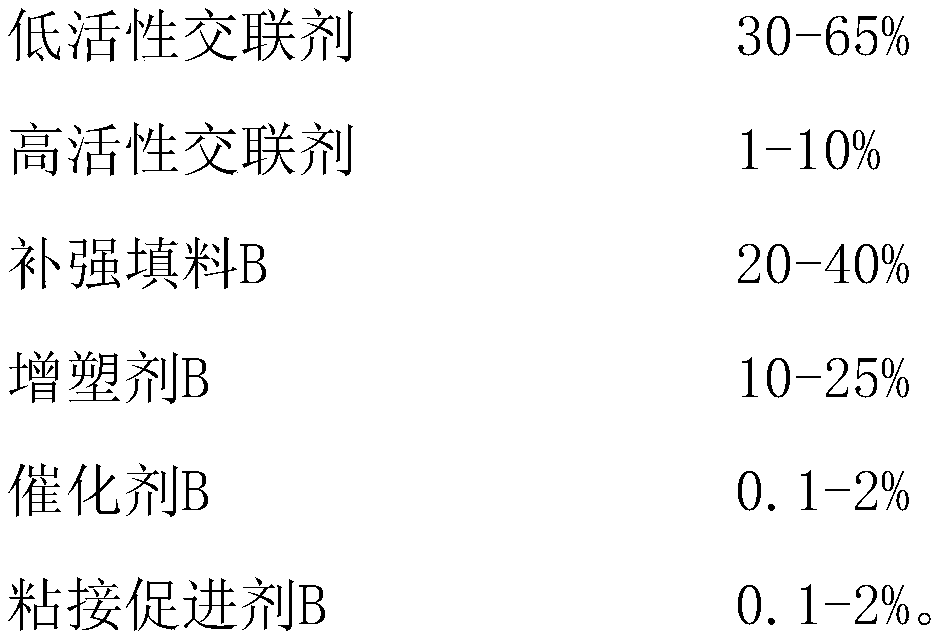

Method used

Image

Examples

Embodiment 1

[0047] A preparation method of a reactive thickening type two-component polyurethane glass adhesive glue includes the following steps:

[0048] Step 1: Prepare a two-component polyurethane adhesive prepolymer: add 100g of polyether glycol with a molecular weight of 2000, 260g of polyether triol with a molecular weight of 5000 and 100g of dioctyl phthalate into the vacuum reactor In the vacuum, dehydration is carried out at 120℃ for 4h, the moisture content of the mixture is controlled to be ≤100ppm, and then after cooling to 85℃, 70g of diphenylmethane diisocyanate is added to react for 4h under nitrogen protection to obtain a two-component Polyurethane prepolymer.

[0049] Step 2: Preparation of component A: Add 424g of the two-component polyurethane prepolymer prepared in step 1 and 95g of polymethylene polyphenyl isocyanate into the reaction device at a temperature of 45°C and a vacuum of 0.09±0.005MPa Stir for 30 min under the conditions of, to prepare the premix ①; then 120g ...

Embodiment 2

[0053] A preparation method of a reactive thickening type two-component polyurethane glass adhesive glue includes the following steps:

[0054] Step 1: Preparation of two-component polyurethane adhesive prepolymer: 120g of polyether glycol with a molecular weight of 2000, 270g of polyether triol with a molecular weight of 5000 and 110g of dioctyl phthalate are added to the vacuum reactor In the vacuum, dehydration is carried out at 120℃ for 4h, the moisture content of the mixture is controlled to be ≤100ppm, and then after cooling to 85℃, 70g of diphenylmethane diisocyanate is added to react for 4h under nitrogen protection to obtain a two-component Polyurethane prepolymer.

[0055] Step 2: Preparation of component A: Add 488g of the two-component polyurethane prepolymer prepared in Step 1 and 56g of polymethylene polyphenyl isocyanate into the reaction device at a temperature of 45°C and a vacuum of 0.09±0.005MPa Stir for 30 min under the conditions of, to obtain the premix ①; th...

Embodiment 3

[0059] A preparation method of a reactive thickening type two-component polyurethane glass adhesive glue includes the following steps:

[0060] Step 1: Prepare a two-component polyurethane adhesive prepolymer: add 100g of polyether glycol with a molecular weight of 2000, 260g of polyether triol with a molecular weight of 5000, and 110g of dioctyl phthalate into the vacuum reactor In the vacuum, dehydration is carried out at 120℃ for 4h, the moisture content of the mixture is controlled to be ≤100ppm, and then after cooling to 85℃, 70g of diphenylmethane diisocyanate is added to react for 4h under nitrogen protection to obtain a two-component Polyurethane prepolymer.

[0061] Step 2: Preparation of component A: Add 442g of the two-component polyurethane prepolymer prepared in Step 1 and 118g of polymethylene polyphenyl isocyanate into the reaction device at a temperature of 45°C and a vacuum of 0.09±0.005MPa Stir for 30 minutes under the conditions of ① to obtain the premix ①; then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com