Patents

Literature

57results about How to "Increase initial viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-soluble alcohol-soluble polyurethane and preparation method thereof

InactiveCN101230125AIncrease initial viscosityFast curingPolyureas/polyurethane adhesivesOligomerEmulsion

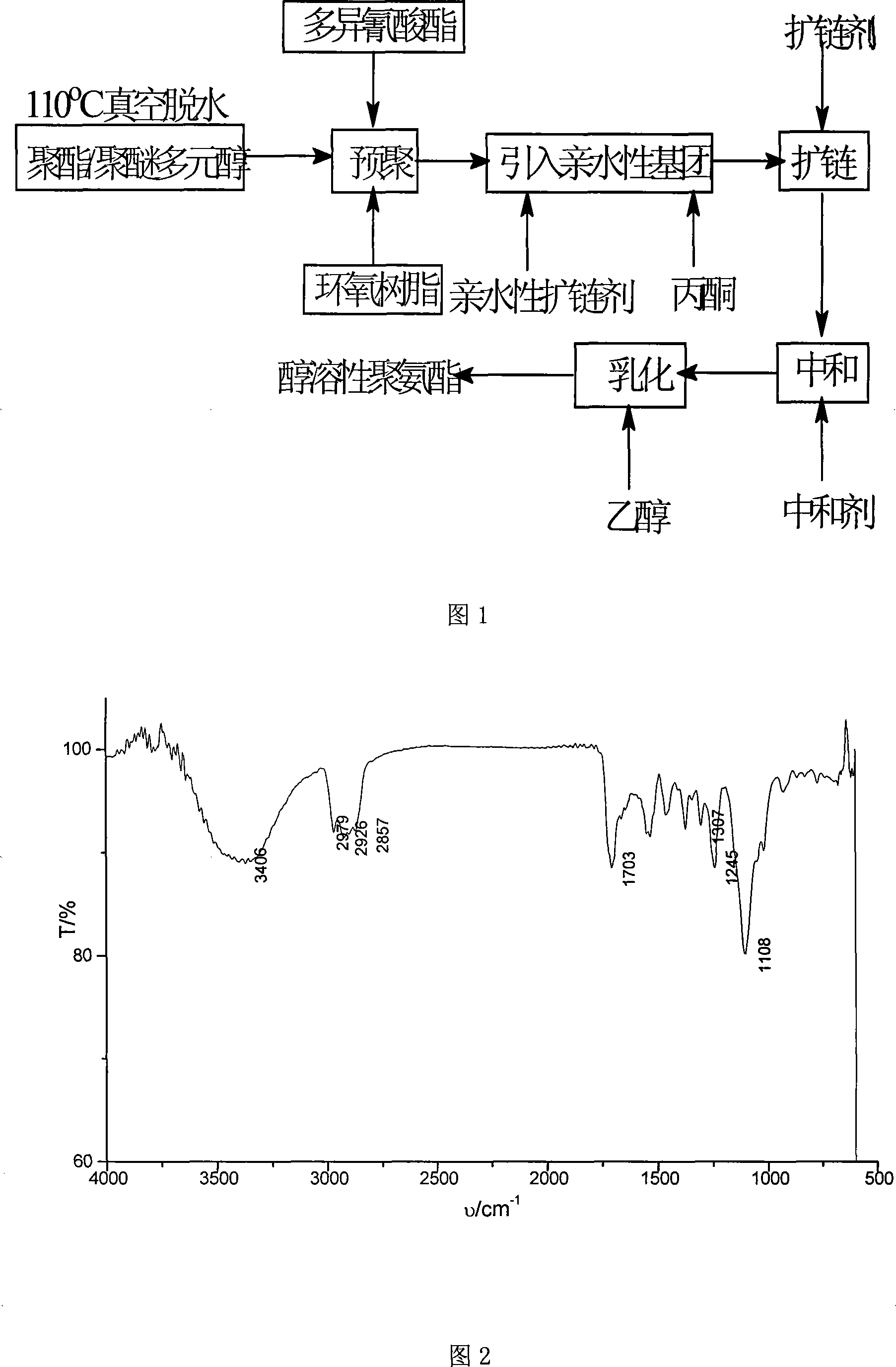

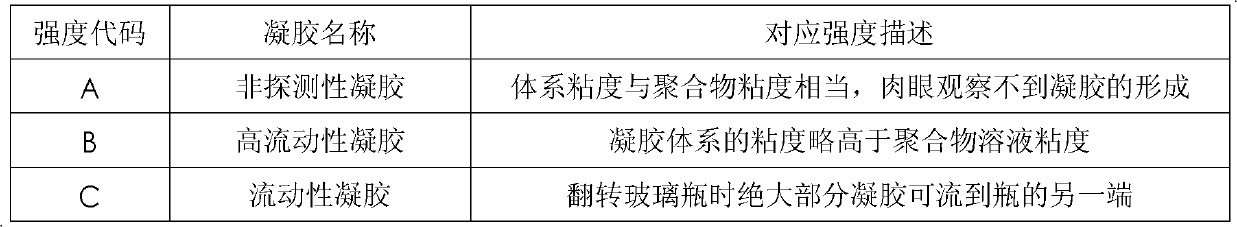

The invention relates to water soluble alcohol-soluble polyurethane and a preparation method thereof. The method is characterized in that 5 to 35 percent of oligomer polyhydric alcohol reacts with 5 to 30 percent of polyisocyanate for 2 to 2.5h at 70 to 90 DEG C, 1 to 20 percent of hydrophilic chain-extending agent and 1 to 2 percent of acetone are added, the temperature is maintained at 60 to 70 DEG C for 1 to 1.2h, then 2 to 15 percent of chain-extending agent and 0.3 to 0.5 percent of catalyst are added, after reaction is performed at 60 to 70 DEG C for 3 to 4h, the temperature is reduced to 30 to 50 DEG C for discharging, and then a pre-polymer is obtained; after being neutralized with 2 to 5 percent of trihexylamine, the pre-polymer is added into 10 to 70 percent of ethyl alcohol, and an emulsion product can be obtained after emulsification. In the invention, not only superior properties such as high initial viscosity, quick solidification, good stability, etc. of solvent-type polyurethane can be guaranteed, but also the solid content of polyurethane can be adjusted to the actually required value through water, the default of the prior alcohol-soluble polyurethane that the operation is inconvenient because of water insolubility is overcome, thereby the invention can be used in industries such as lumber, flexible package, compound lamination, etc.

Owner:ANHUI UNIVERSITY

Gelation-delayed in-situ polymerized water shutoff gel for high-temperature reservoirs

InactiveCN102382244AGood instant solubilityConvenient dispensing operationDrilling compositionSynaeresisVisual observation

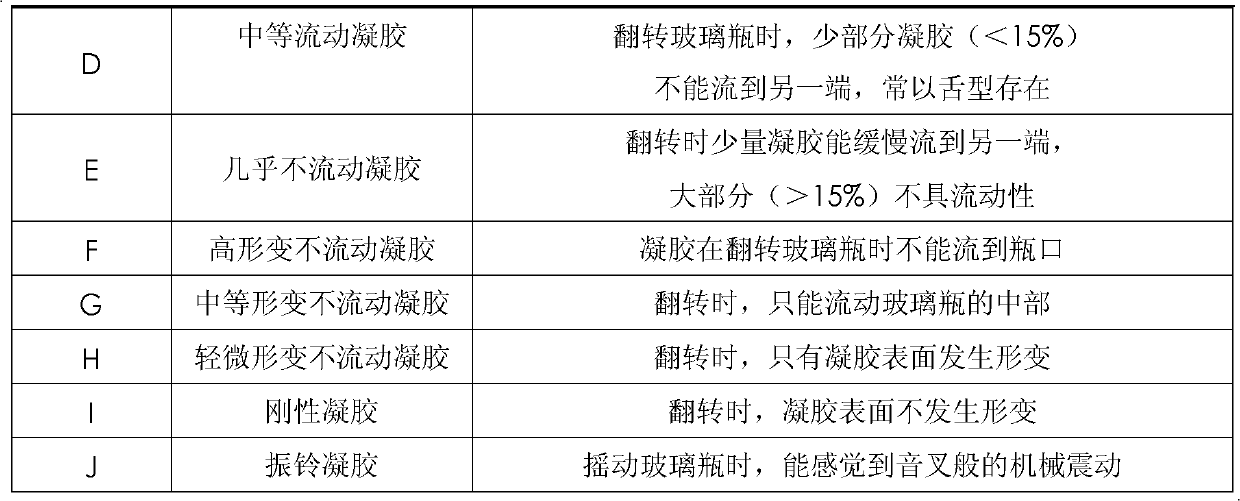

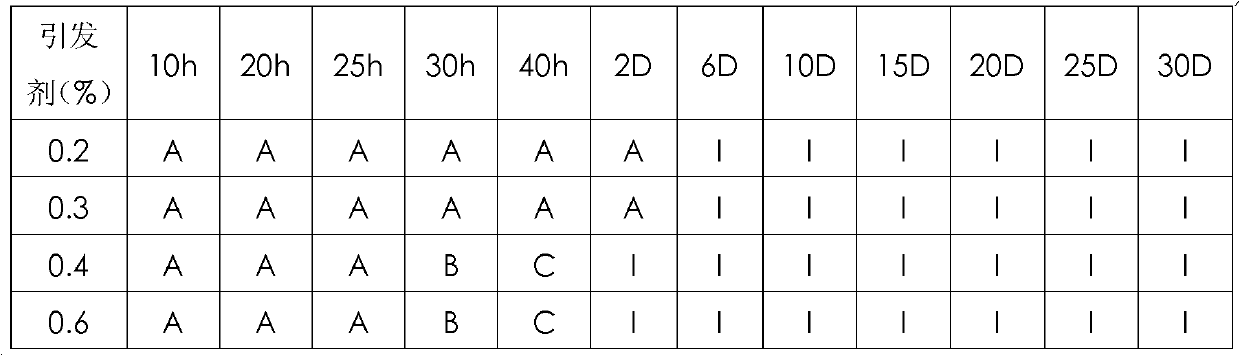

The invention relates to a gelation-delayed in-situ polymerized water shutoff gel for high-temperature reservoirs, which consists of 5 to 7 percent by weight of main agent, 1 to 2 percent by weight of solubilizer, 1 to 2 percent by weight of cross-linking agent, 0.1 to 0.8 percent by weight of initiator and the balance of water, the main agent consists of monomer A and monomer B, the mass ratio of the monomer A to the monomer B is 3:1 to 5:1, the monomer A is acrylamide, and the monomer B is ester. Under high temperature, the pumping time of the gel is relatively longer, the gelation time canbe controlled at 20 to 72 hours under 120 DEG C, the final set strength can reach visual observation code level I, the synaeresis of the gel does not take place in 90 days, and the gel can be used inwater shutoff operation for high-temperature reservoirs under 90 DEG C to 140 DEG C. Because the gel has the advantages of good pumping property, high plugging strength, long service life, simple construction process and the like, the gel has a broad application prospect in chemical profile modification and water shutoff for oil fields.

Owner:SOUTHWEST PETROLEUM UNIV

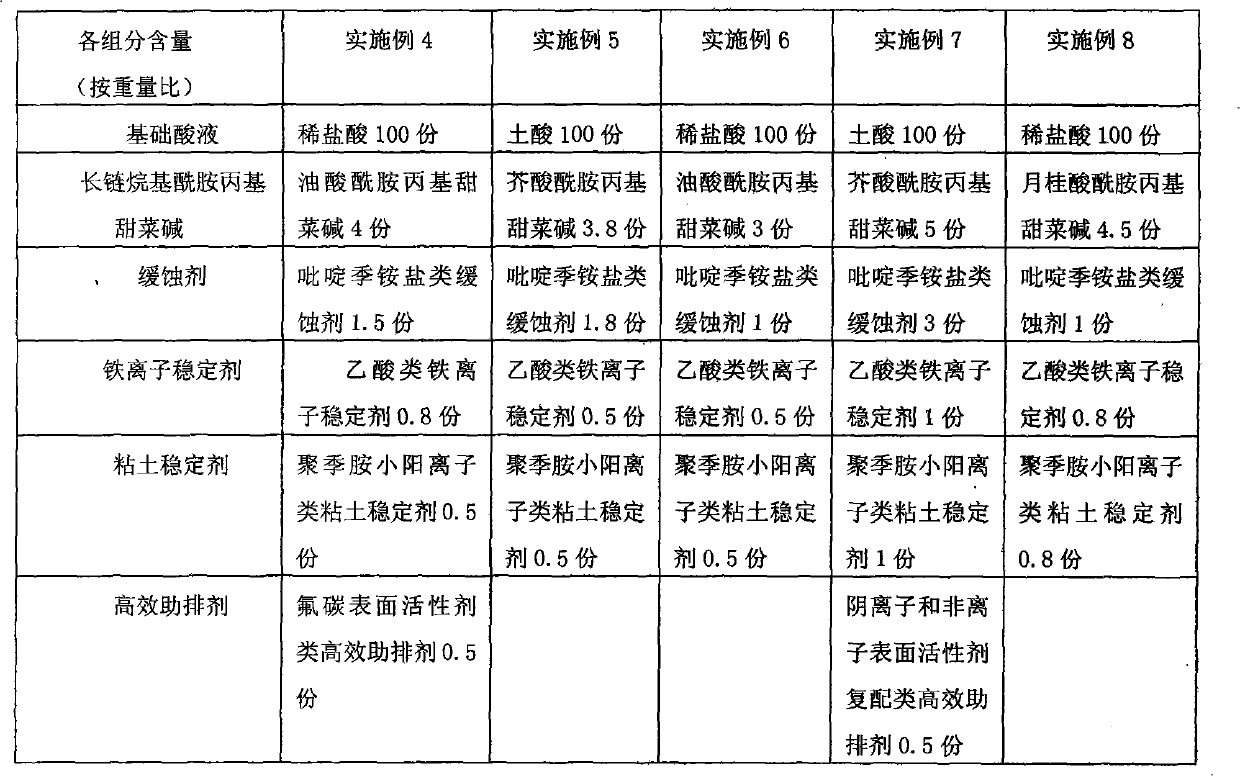

Viscosity-variable diverting acid for improving stratigraphic acidified section

InactiveCN102020983AViscosity auto-increasingConing reductionDrilling compositionBetaineActive agent

The invention discloses viscosity-variable diverting acid for improving a stratigraphic acidified section. An oil layer is uniformly acidified, and the coning of acid liquor in a high permeable stratum is reduced to ensure that part of acid liquor enters middle and low permeable target stratums so as to improve and expand an acidified sweep section. In the viscosity-variable diverting acid, each component is controlled by a pH value, and the viscosity-variable diverting acid mainly comprises the following components in part by weight: 100 parts of basic acid liquor, 3 to 5 parts of long chain alkylamide propyl betaine, 1 to 3 parts of corrosion inhibitors, 0.5 to 1 part of ferrous stabilizer and 0.5 to 1 part of clay stabilizer. The viscosity-variable diverting acid consisting of the components is injected into a target oil layer. In the acidification process, the initial viscosity of the acid liquor is lower, and the initial viscosity at the temperature of 20 DEG C is 10 to 15mPa.s, the acid liquor is easy to enter the high permeable stratum, and subsequent unreacted low-viscosity acid liquor automatically diverts to enter the middle and low permeable stratums. The long chain alkylamide propyl betaine serving as a diverter is an ampholytic surfactant, does not have any macromolecular residues after a gel is broken and does not have any secondary damage to a reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

Self-adhesive protective film and initial adhesion regulating method of self-adhesive protective film

InactiveCN102304329AImprove stabilityPrevent penetrationStampsFilm/foil adhesivesLow-density polyethyleneElastomer

The invention discloses a self-adhesive protective film and an initial adhesion regulating method of a self-adhesive protective film; the initial adhesion regulating method comprises the following steps of: processing the self-adhesive protective film with a low density polyethylene printing layer, a high density polyethylene blocking and an elastomer self-adhesive layer by adopting a three-layer co-extrusion blown film method or a three-layer flow casting method, wherein the elastomer self-adhesive layer is prepared by the following steps of: firstly mixing EVA (ethylene vinyl acetute) and PE (polyurethane), and then adding POP (4, 4'-diam-inodiphenyl ether) or POE (Polyolefin Elastomer) so as to regulate the initial adhesion of the self-adhesive protective film; wherein the higher the adhesion requirement of the initial adhesion is, the larger the addition amount of the POP (4, 4'-diam-inodiphenyl ether) or POE (Polyolefin Elastomer) is. The elf-adhesive protective film has the advantages of no peculiar smell, good stability, no addition of additive agents, easiness in tearing at high temperature, low cost compared with before and good transparency; after the self-adhesive protective film is adhered on the surface of a sheet material, the self-adhesive protective film can effectively prevent the surface of a sheet material from being damaged, and the initial adhesion of self-adhesive protective film is improved; and therefore, the film adhesion difficulty for users is small; the efficiency is high; and the cost is reduced.

Owner:俞明高

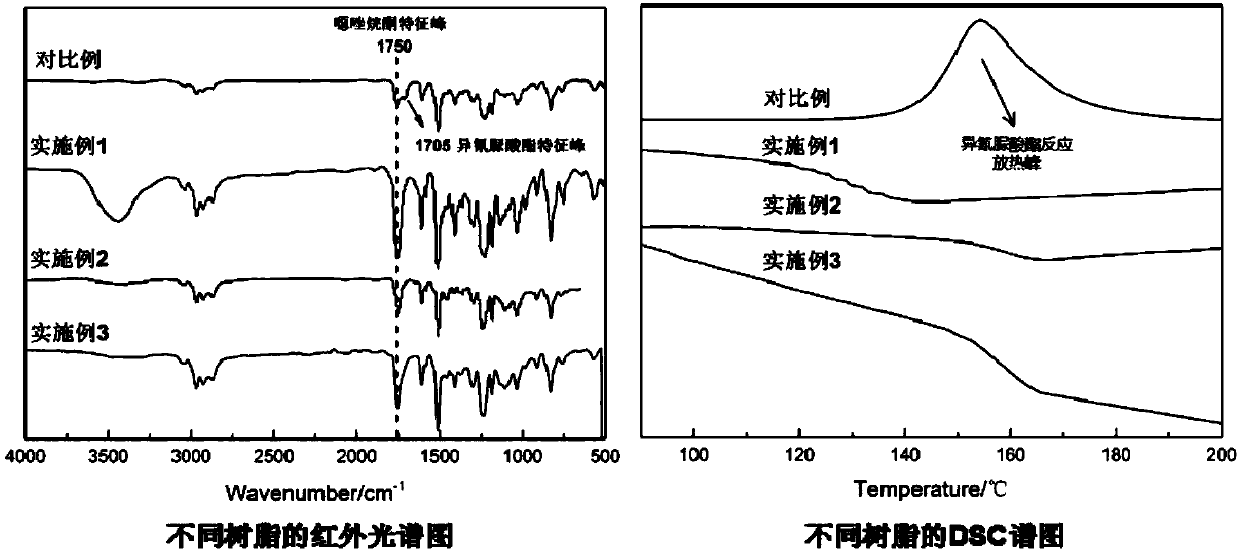

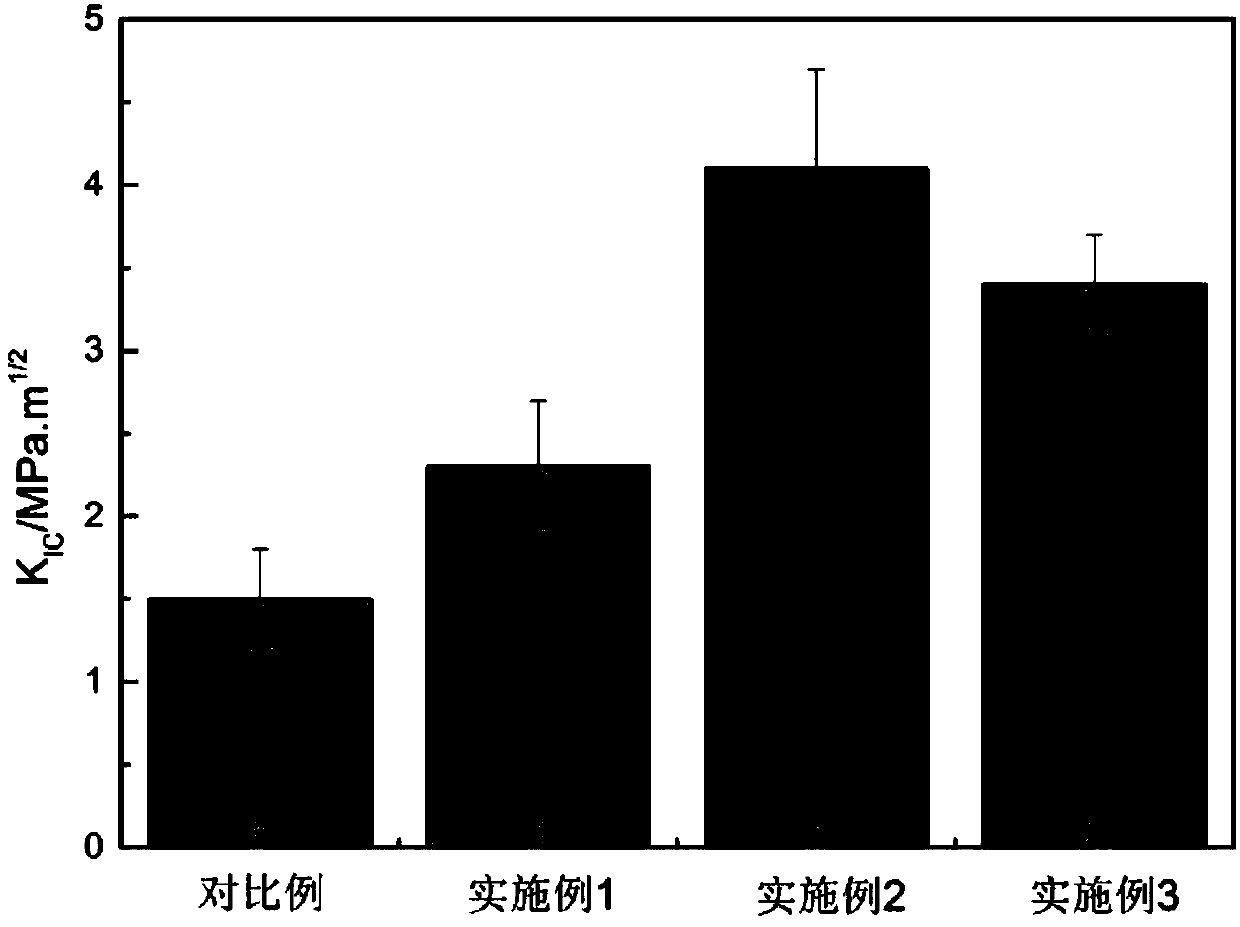

Interface bonding-enhanced aramid fiber composite material preparation method

The invention discloses an interface bonding-enhanced aramid fiber composite material preparation method. The method is characterized in that isocyanate and epoxy resin are used for preparing modifiedepoxy resin having a molecule main chain containing a five-membered ring structure according to controllable proportion and technical reaction; liquid epoxy resin and a curing agent are added for kneading to obtain a pre-dip material resin system with synchronously increased bonding property and toughness; a resin glue membrane is prepared, then is composited with aramid fiber or fabric to obtaina pre-dip material, and finally moulding preparation is carried out to obtain the interface bonding-enhanced aramid fiber composite material. The toughness of the modified epoxy resin system is increased, the bonding property of a resin matrix and aramid fiber are enhanced, the technical performance of the pre-dip material is good, a processing moulding window is wide, the interlayer shearing intensity of the composite material is obviously increased, and the modified epoxy resin system can be used for the composite material having the aramid fiber structure.

Owner:BEIJING UNIV OF CHEM TECH

Organic silicon perfusion resin and preparation method thereof

The invention relates to organic silicon perfusion resin and a preparation method thereof. The preparation method comprises the following steps: selecting at least one silane monomer expressed according to a structure formula RnSiX4-n as an initial material, wherein R is an organic group and can be alkyl, aryl or vinyl, X is a hydrolysable group and can be chlorine atom, alkoxy or acyloxy, n is equal to 0 or 1 and the initial material comprises a vinylsilane monomer or hydrogen-containing silane monomer; determining the proportion of the initial material according to a silicon resin R / Si value of 1.0-1.3, dropwise adding the initial material into a flask adding with water, weak-polarity solvent and HCl gas absorbent at 5-20 DEG C, carrying out hydrolysis reaction for 3-6 h, concentrating, separating a resin layer, carrying out reflux curing reaction at 80-120 DEG C for 2-5 h, washing with water, filtering, removing solvent for hydrolysis by decompression at 110-140 DEG C, and discharging when the cone-plate viscosity of the product is 1,500-3,000 CP at 60 DEG C. The organic silicon perfusion resin has no rapid heat release, does not generate bubble in the curing process and has higher heat resistance and excellent corona resistant performance.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

Oil extraction wastewater polymer preparation processing method

InactiveCN104250039AIncrease initial viscosityGuaranteed stabilityWaste water treatment from quariesMultistage water/sewage treatmentSewageOxidizing agent

The invention relates to an oil extraction wastewater polymer preparation processing method; reducing substances Fe<2+> and S2 causing serious influence on polymer solution viscosity in oil extraction wastewater are oxidized by an oxidant, sulfate reducing bacteria in the oil extraction wastewater is killed, organic matters in the oil extraction wastewater are absorbed by use of strong lipophilicity and super strong adsorption property of a diatomite filter, suspended impurities in the oil extraction wastewater can be removed by filtration, and high valent metal cations casing great influence on preparation polymer solution viscosity can be removed by ion exchange resin equipment. According to the oil extraction wastewater polymer preparation processing method, suspended matters, oil, the organic matters, the sulfate reducing bacteria, the high valent metal cations and the like causing serious influence on polymer solution viscosity in the oil extraction wastewater are removed, the initial viscosity of polymer solution prepared by the wastewater is improved, and the stability of the viscosity of the polymer solution is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Filling powder used for plywood

InactiveCN102382596AImprove bonding performanceIncrease surface contact areaNon-macromolecular adhesive additivesMacromolecular adhesive additivesAmyrisResin adhesive

The invention provides a filling powder used for plywood, which uses a technical scheme that: 45%-55% of heavy calcium carbonate, 30%-35% of pregelatinized starch, 3%-5% of cereal element powder and 5%-10% of wood powder are placed in a stirrer according to proportion, stirred and mixed to produce the filling powder. The filling powder used for plywood is a green environmental protection functional material with no toxicity, no flavour, fire resistance, deterioration resistance and mildew resistance. After mixing with a resin adhesive, the filling powder has the advantages of good cohesiveness, suspensibility, dispersibility, fluidity, adsorptivity and thixotropy. The solid content of the filling powder is higher than that of industrial flour, the price of the filling powder is lower than that of the industrial flour. The filling powder used for plywood is a mixture which has the advantages of simple production process, less investment equipment, convenient operation and large production capacity.

Owner:李树青

Aqueous sealing adhesive emulsion and preparation method thereof

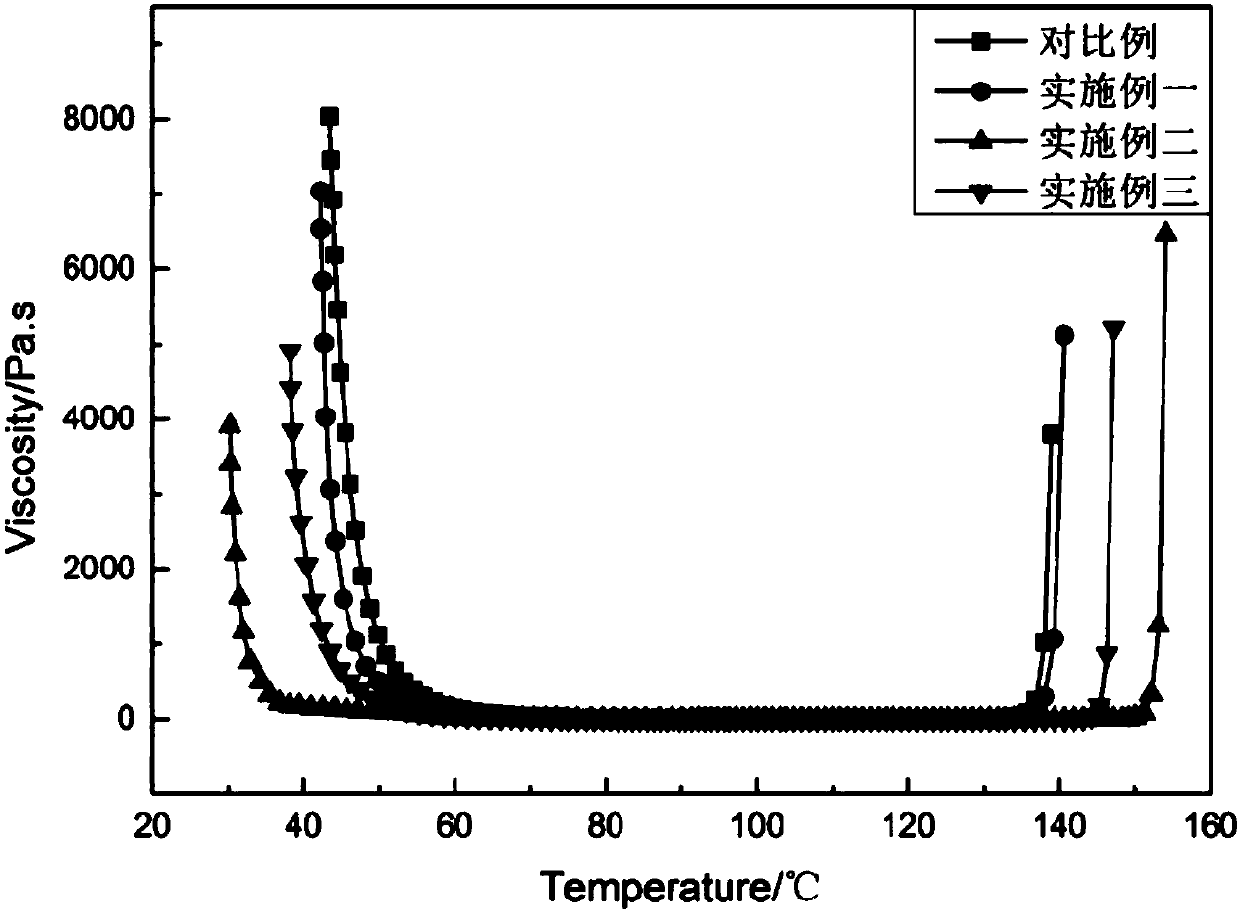

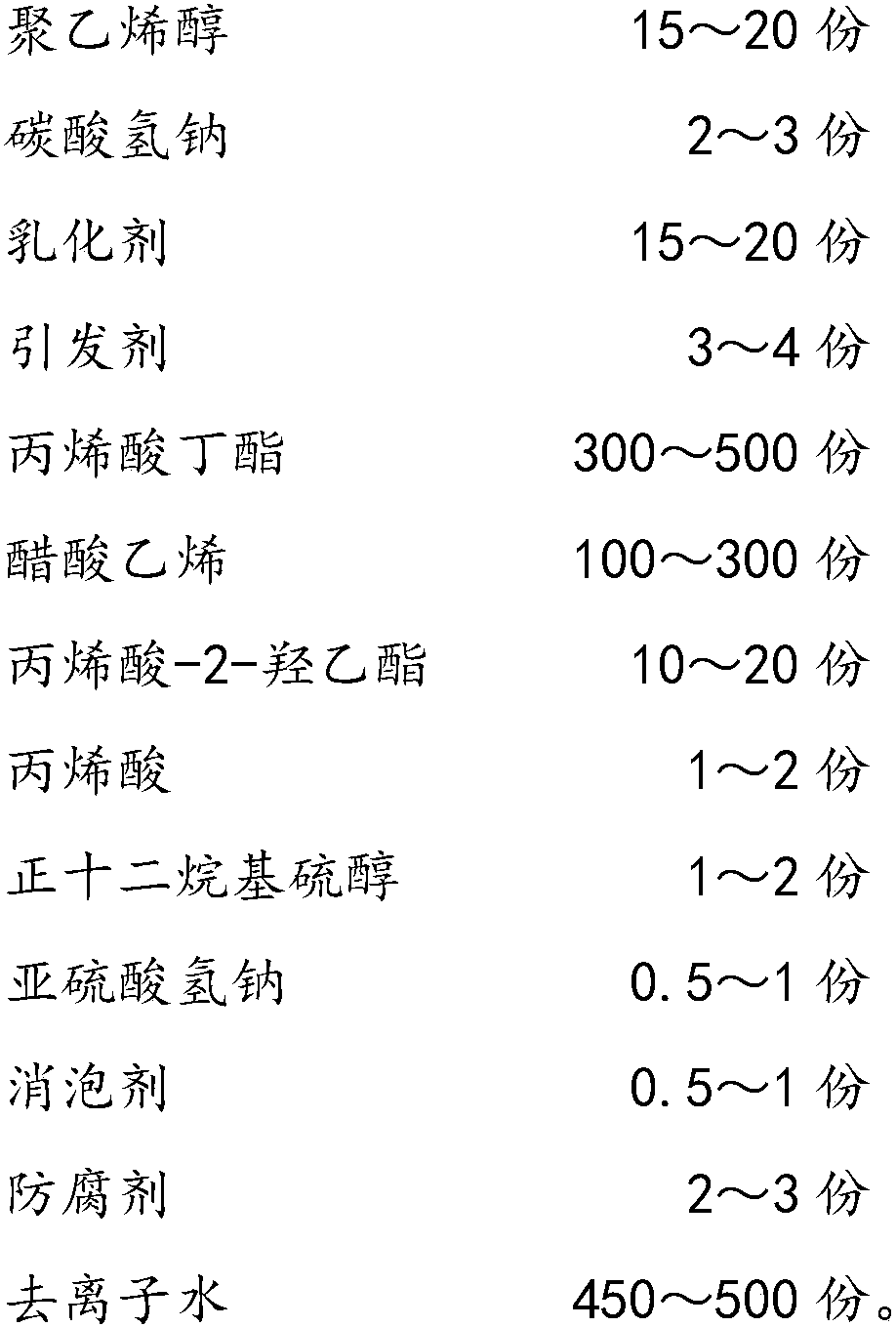

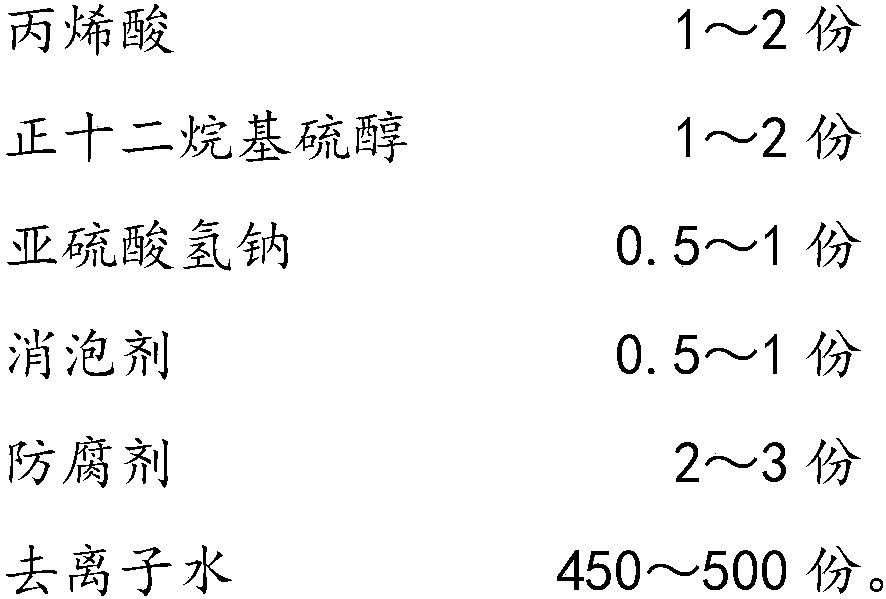

ActiveCN108034018AIncrease initial viscosityWith alkaline thickeningEster polymer adhesivesPolymer sciencePolyvinyl alcohol

The invention discloses an aqueous sealing adhesive emulsion and a preparation method thereof and belongs to the technical field of adhesives. An aqueous sealing adhesive prepared by the emulsion is high in adhesion strength, high in heat resistance and excellent in freezing resistance. The aqueous sealing adhesive emulsion is prepared from the following components in parts by weight: 15-20 partsof polyvinyl alcohol, 2-3 parts of sodium hydrogen carbonate, 15-20 parts of an emulgator, 3-4 parts of an initiator, 300-500 parts of butyl acrylate, 100-300 parts of vinyl acetate, 10-20 parts of acrylic acid-2-hydroxy ethyl ester, 1-2 parts of acrylic acid, 1-2 parts of N-dodecyl mercaptan, 0.5-1 part of sodium hydrogen sulfite, 0.5-1 part of a defoaming agent, 2-3 parts of an anticorrosion agent and 450-500 parts of deionized water. The aqueous sealing adhesive prepared by the aqueous sealing adhesive emulsion can be effectively applied to edge sealing or opening lapping of BOPP / paper, polishing / paper, PET / paper, paper / paper, ink / paper and UV polishing / paper.

Owner:BAODING SUNSHINE CHEM IND RES INST

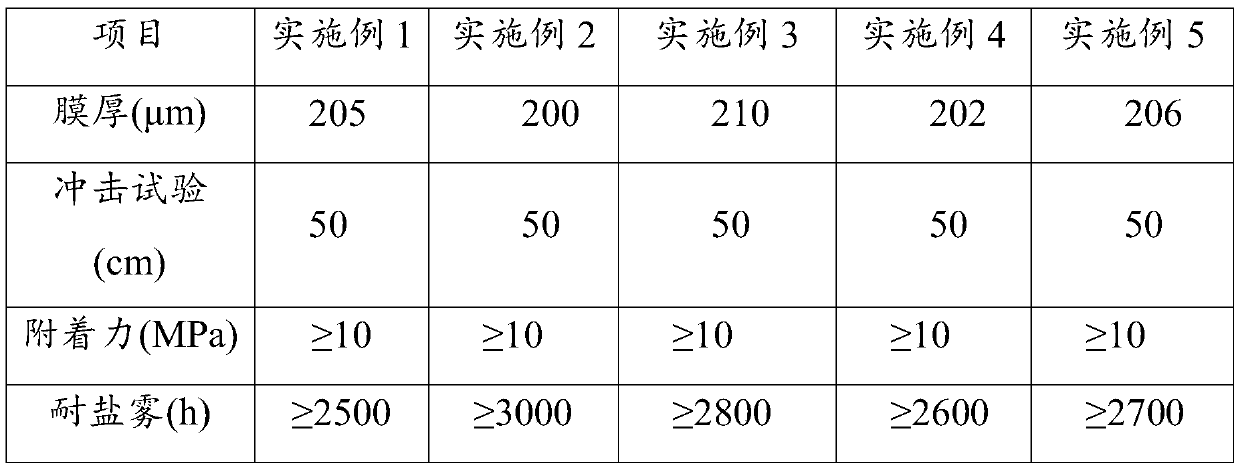

Thick coating type aqueous epoxy zinc-rich anticorrosive coating material and preparation method thereof

The invention relates to the technical field of coating materials, particularly to a thick coating type aqueous epoxy zinc-rich anticorrosive coating material and a preparation method thereof, whereinthe thick coating type aqueous epoxy zinc-rich anticorrosive coating material comprises a component A and a component B, the component A comprises, by mass, 5-10 parts of a curing agent, 0.5-2 partsof a dispersing agent, 0.05-1 part of a defoaming agent, 0.5-5 parts of a thixotropic agent A, 0.5-5 parts of a thixotropic synergist BYK-P 2720, 60-83 parts of zinc powder, and 8-20 parts of a cosolvent, and the component B comprises, by mass, 55-80 parts of an epoxy resin emulsion, 10-35 parts of water, 5-10 parts of a thixotropic agent B, and 5-10 parts of a thixotropic blocking agent BYK-P 2710. The thick-coating type waterborne epoxy zinc-rich anticorrosive paint disclosed by the invention has excellent sagging resistance, adhesive force, salt spray resistance and impact resistance.

Owner:CHINA NAT OFFSHORE OIL CORP +3

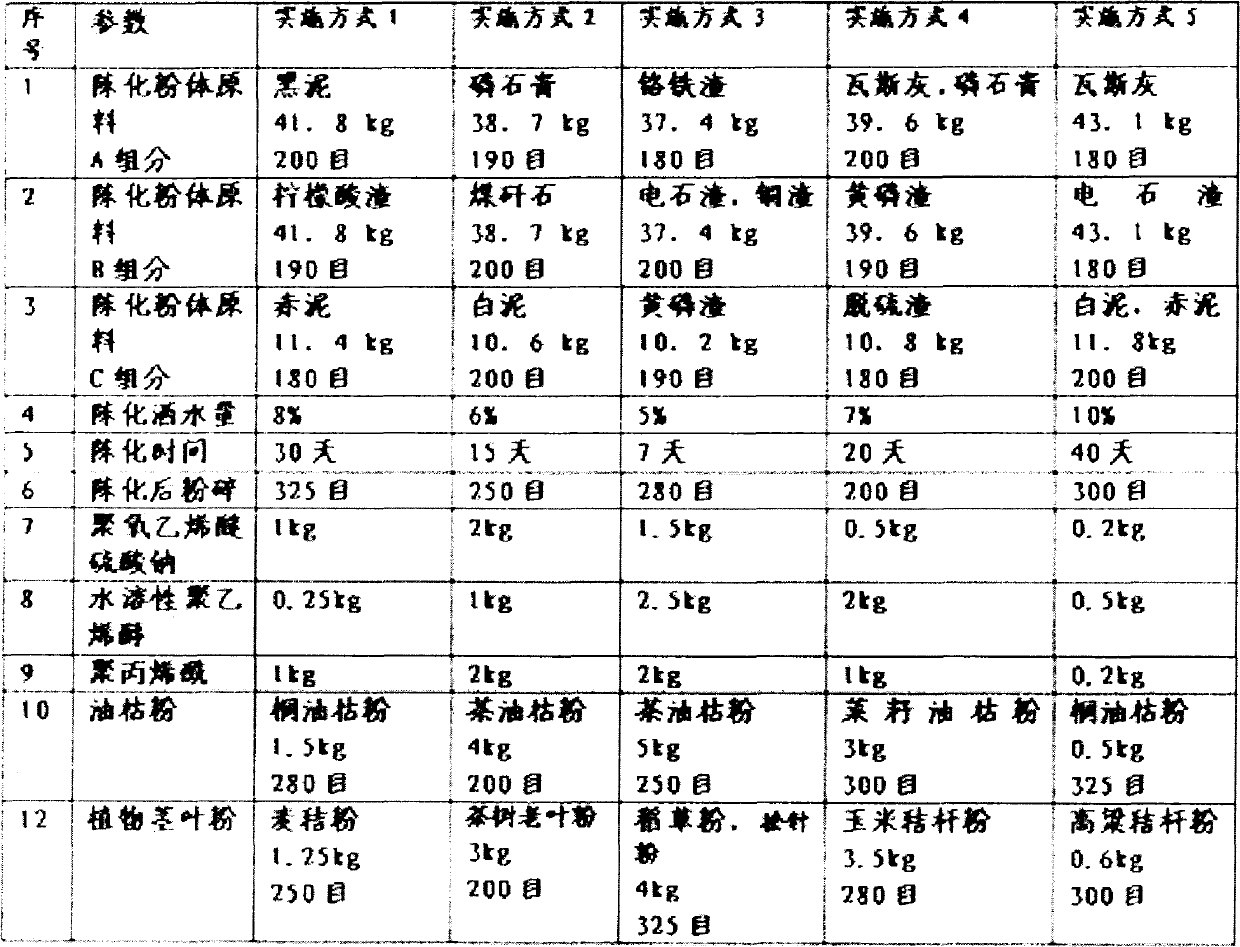

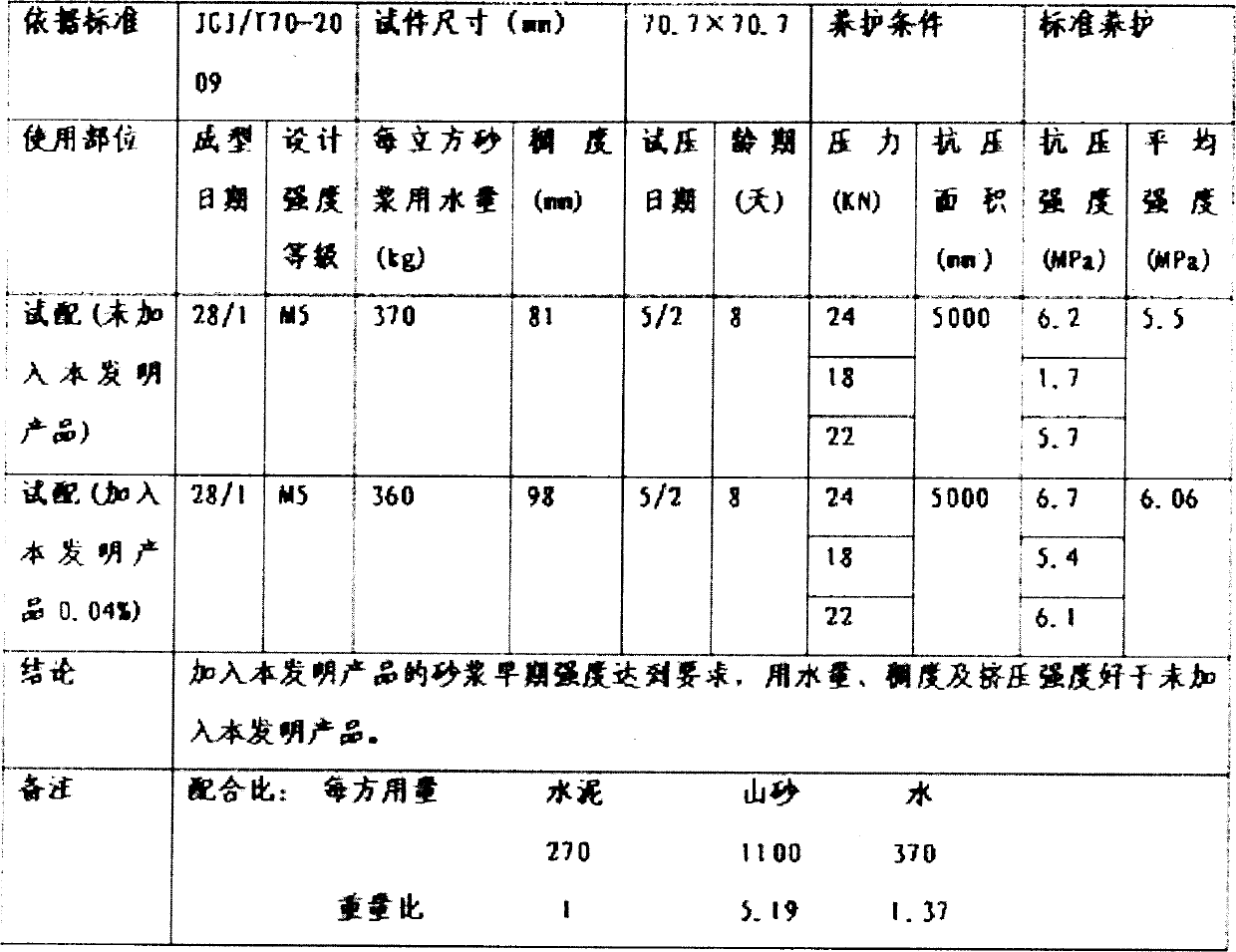

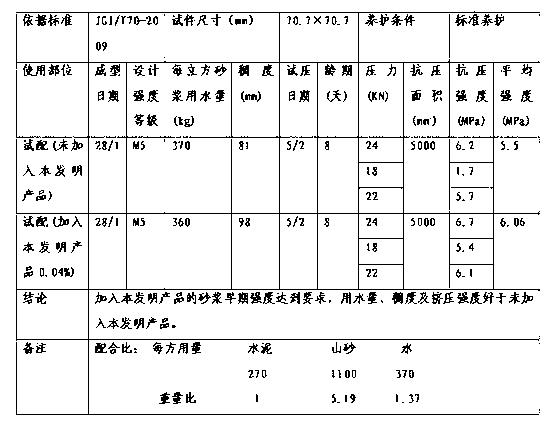

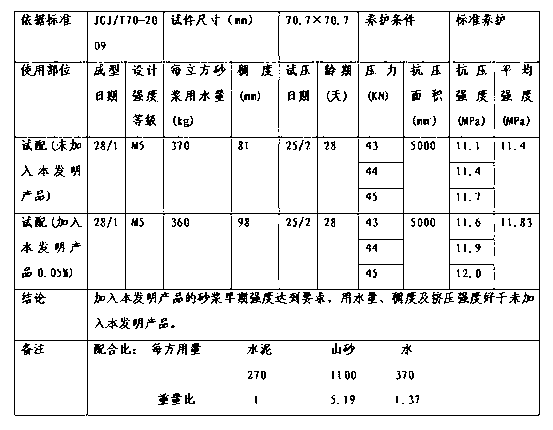

Masonry mortar plasticizer and preparation method thereof

InactiveCN102167539AHigh strengthGood dispersionSolid waste managementSodium BentoniteResource utilization

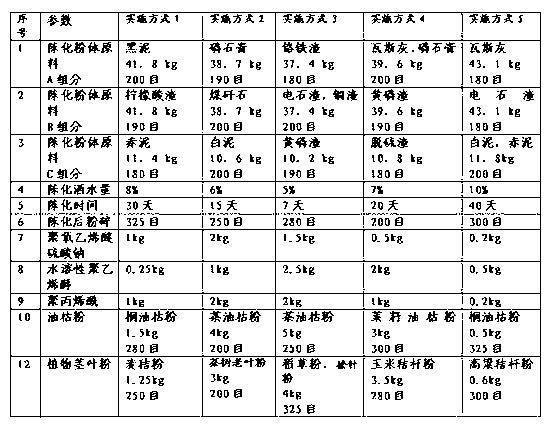

The invention relates to a masonry mortar plasticizer which consists of aged powder, polyoxyethylene ether sodium sulfate, water-soluble polyvinyl alcohol, polyacrylamide, oil cake powder and plant stem leaf powder, wherein the preparation method of the masonry mortar plasticizer comprises the following steps of: preparing the aged powder, the plant stem leaf powder, the oil cake powder, the polyoxyethylene ether sodium sulfate, the water-soluble polyvinyl alcohol and the polyacrylamide, burdening the aged powder, the plant stem leaf powder, the oil cake powder, the polyoxyethylene ether sodium sulfate, the water-soluble polyvinyl alcohol and the polyacrylamide according to proportions, evenly mixing and packaging to obtain the masonry mortar plasticizer product. A great amount of sites for stacking harmful waste can be saved, the expense of managing the industrial wastes is saved, the pollution of the industrial wastes to air, water body and soil and the consumption of cement is reduced, and the natural building materials such as lime, mountain flour and bentonite are saved. The masonry mortar plasticizer and the preparation method thereof disclosed by the invention have the advantages of advanced process, energy saving and environment friendliness, low prices and good quality of the product, reduced environment pollution, enhanced resource utilization ratio and remarkable economic and environment-friendly significances.

Owner:邓泽民

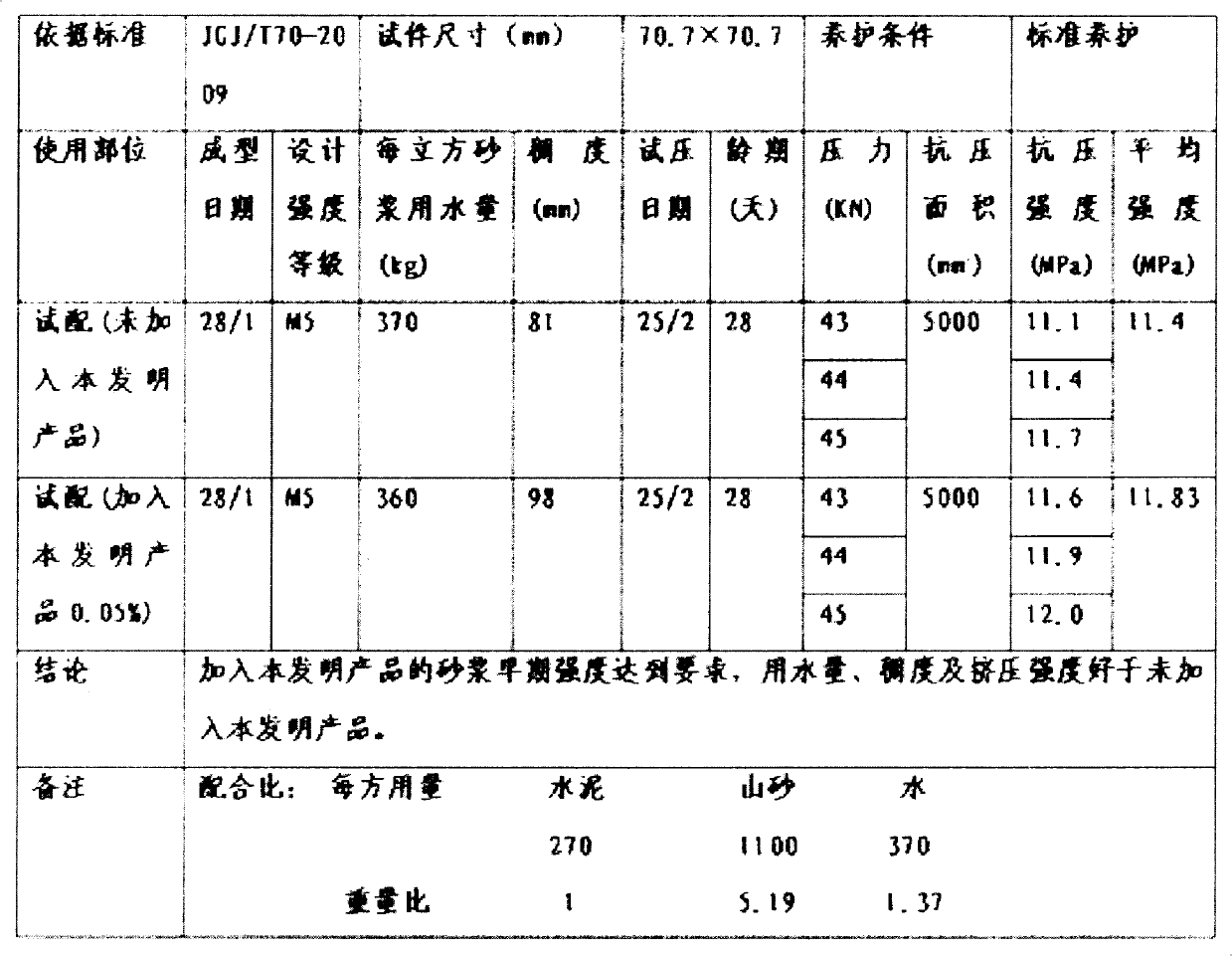

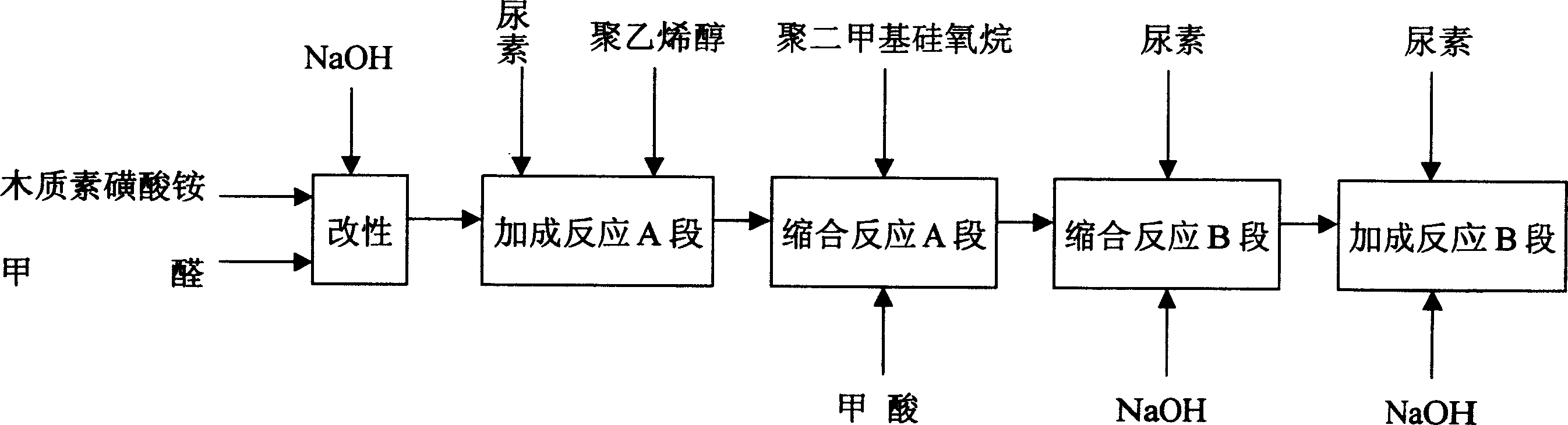

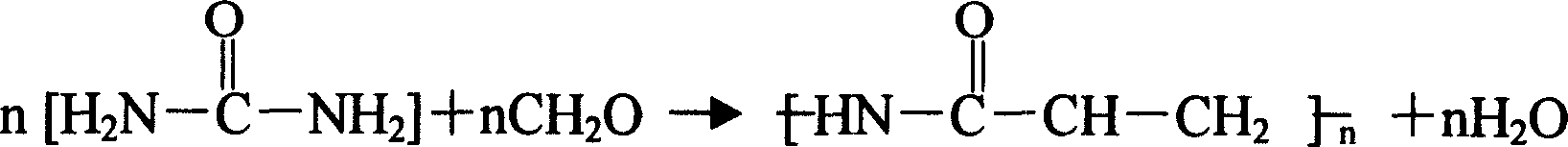

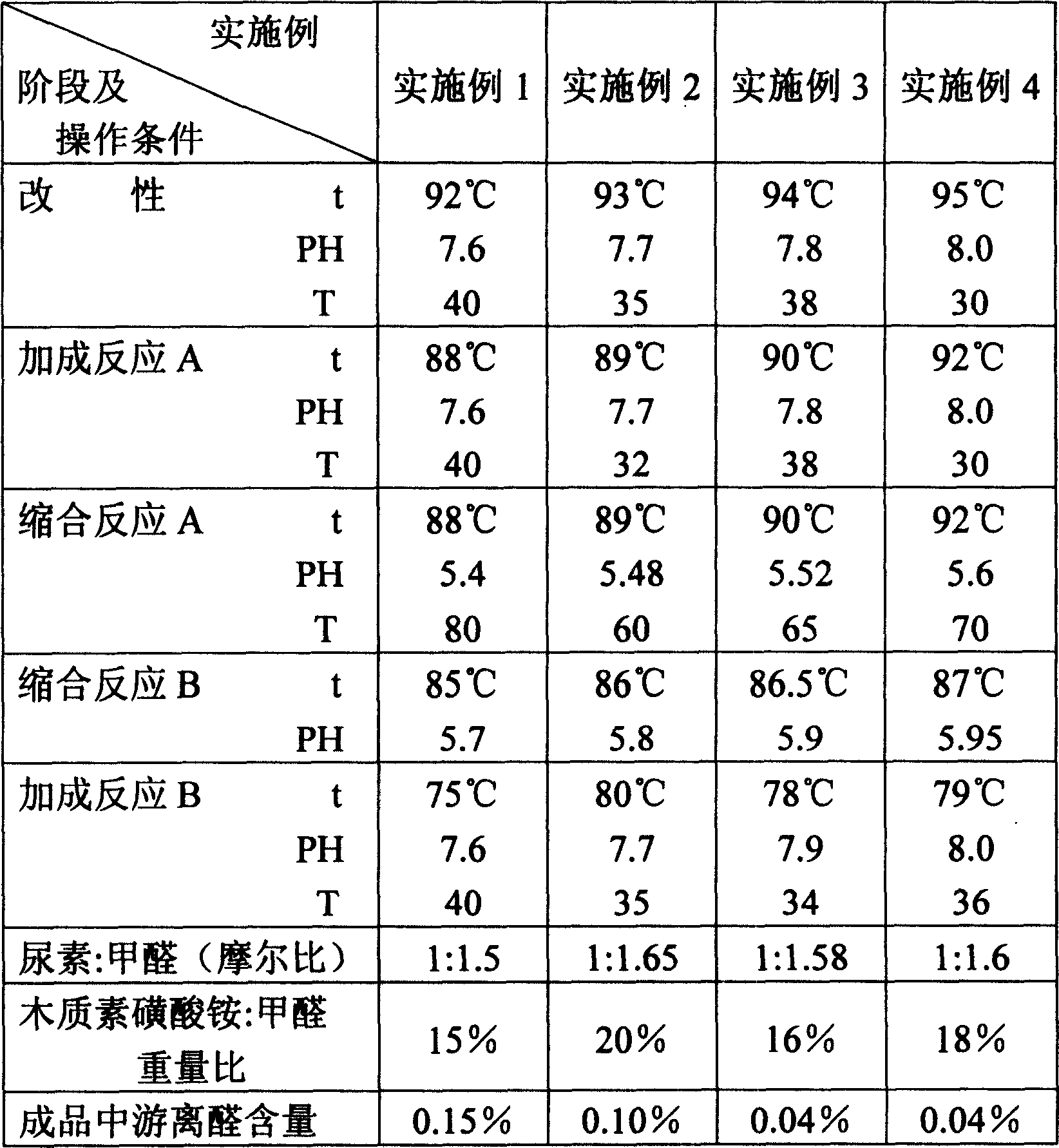

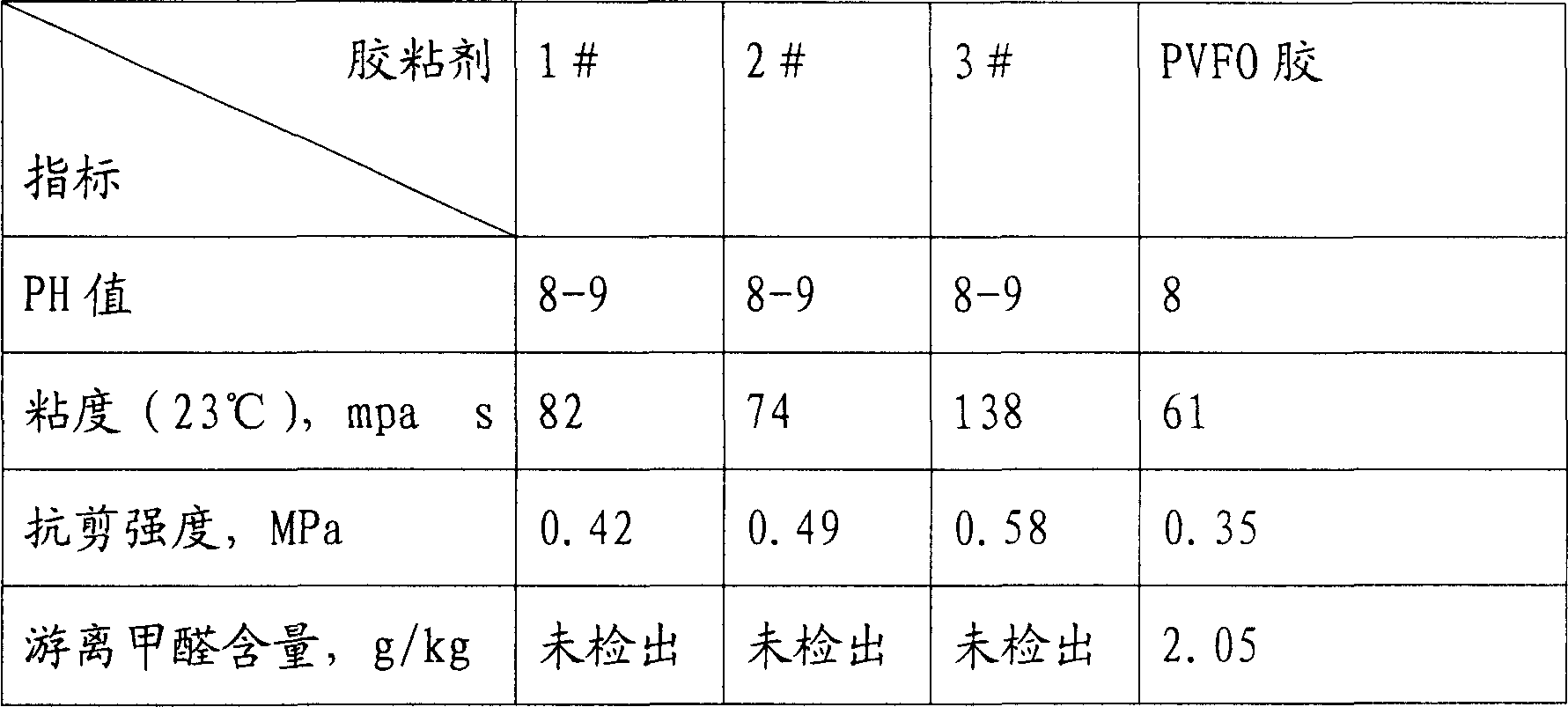

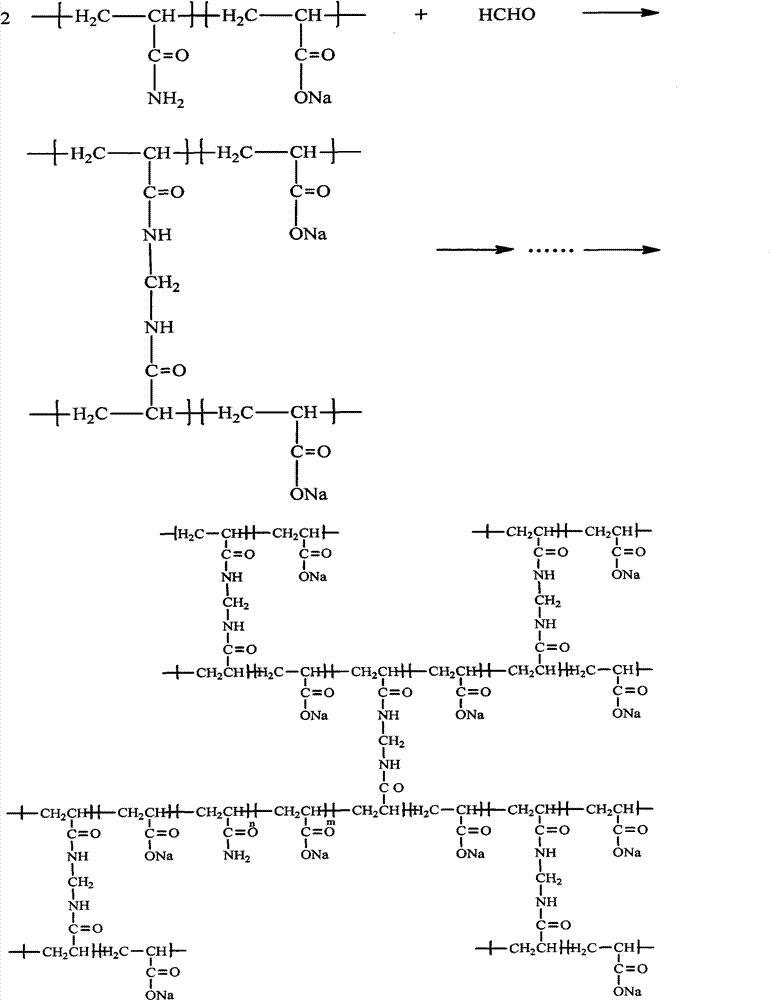

Method for producing composite SSL-UF urea-formaldehyde resin glue

InactiveCN1594479AHigh bonding strengthIncreased durabilityAldehyde/ketone condensation polymer adhesivesMethyl aldehydePVA - Polyvinyl alcohol

The invention discloses a method for producing composite SSL-UF urea-formaldehyde resin glue which comprises the steps of modifying, addition reaction section A, condensation reaction section A, condensation reaction section B, addition reaction section B, the composition include urea and formaldehyde by the ratio of 1 : (1.5-1.65), the content of lignosulfonic acid ammonium is 15-20% of the methyl aldehyde weight, the content of polyvinyl alcohol is 1-1.4% of urea.

Owner:曲韵丰

Nanometer composite polyvinyl alcohol adhesive and its preparation method

InactiveCN1807535ASimple and fast operationShort processUnsaturated alcohol polymer adhesivesHeat resistancePVA - Polyvinyl alcohol

This invention relates to a nanocomposite polyvinyl alcohol adhesive, which is composed of polyvinyl alcohol, water, and added nanobuckle stick dust or nanomontmorillonite. Mass ratios of those components are: polyvinyl alcohol1-3%, nanobuckle stick dust or nanomontmorillonite 1-6%, water 91-98%. This invention also supplies the preparing method for the adhesive: charge polyvinyl alcohol, nanobuckle stick dust or nanomontmorillonite into reaction bulb, agitate to homogeneous at the speed of 40-50 circles per minite at normal temperature, heat to 90-98deg C, agitate for 0. 5-1 hour at the speed of60-70 circles per minite, discharge and get the nanocomposite polyvinyl alcohol adhesive. The adhesive made by this invention has such advantages: high bond strength, good heat-durability, little cost, not environmental pollution, fitting environment requirements totally. At the same time, it is easy to prepare and process flow is short, these reduce process cost largely. It is a ideal substitute for traditional polyvinyl alcohol.

Owner:JIANGSU NDZ TECH

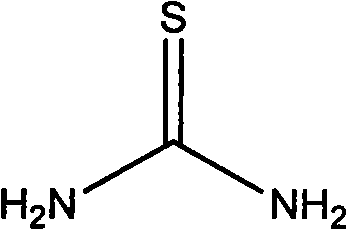

Method for improving viscosity stability of oil field polymer flooding

ActiveCN102952532AOvercoming the problem of excessive dosageReduce loss from oxidative degradationDrilling compositionPolymer scienceThiourea

The invention provides a method for improving the viscosity stability of oil field polymer flooding. With the method, a problem of polymer viscosity reduction under high-temperature and oxygen-containing conditions is solved. The invention adopts anionic polyacrylamide, hexamethylenetetramine, and thiourea. Thiourea is dosed before polymerization, and hexamethylenetetramine is dosed after polymerization, such that polymer solution viscosity stability is greatly improved. With the invention provided by the invention, displacing fluid viscosity stability is greatly improved, and polyacrylamide high-temperature resistance and oxidation resistance are improved. The process is simple, the cost is low, and the material is easy to transport and to store.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environment-friendly glue for corrugated board high-speed production line and preparation method thereof

InactiveCN104140772AFast bondingImprove adhesionNon-macromolecular adhesive additivesStarch adhesivesProduction lineAdhesive glue

The invention discloses an environment-friendly glue for a corrugated board high-speed production line. The glue is characterized by being prepared from the following raw materials by weight: 70% of water, 26.3% of corn starch, 1.8% of alkali lye, 0.5% of borax and 1.4% of a bridging agent. For the environment-friendly glue used for the corrugated board high-speed production line, the viscosity of a gluing machine is 18 s, the gelatinization temperature of the gluing machine is 56 DEG C, the viscosity of a single-side machine is 16 s, and the gelatinization temperature of the single-side machine is 58 DEG C. The invention also discloses a preparation method for the environment-friendly glue used for the corrugated board high-speed production line. The environment-friendly glue provided by the invention has the characteristics of low preparation and usage temperature, high adhesive strength, quick-drying performance, environment-friendliness and low usage cost; and the preparation method has the advantages of reasonable technology, easiness, low preparation temperature and capacity of improving adhesiveness of the adhesive glue.

Owner:LD PACKING PRINTING SHANGHAI

Corrugated paper adhesive and preparation method thereof

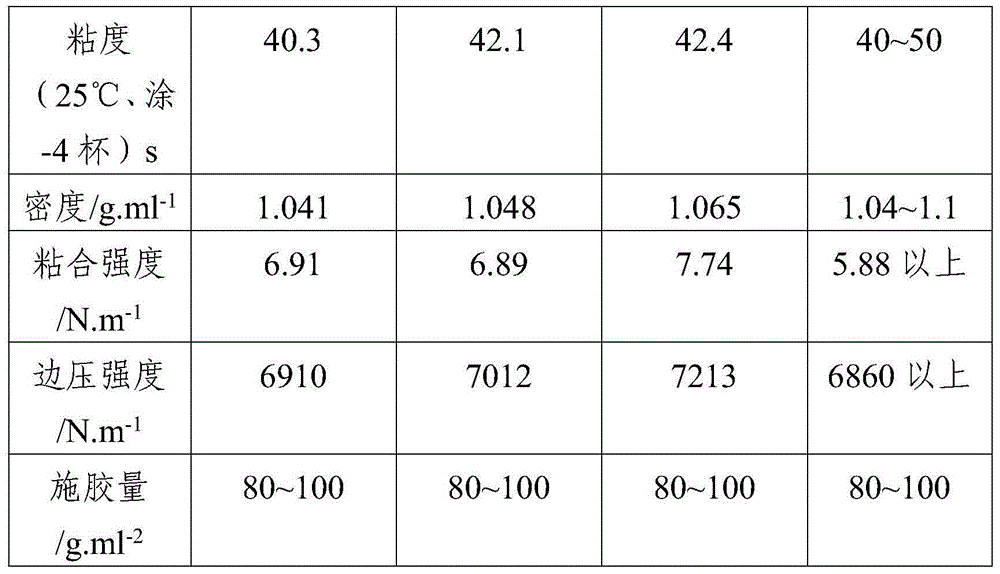

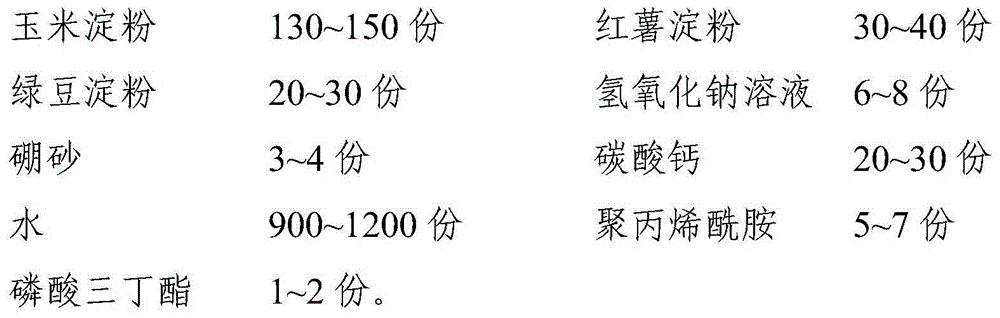

InactiveCN105315917AImprove stabilityEasy to useNon-macromolecular adhesive additivesStarch adhesivesAdhesivePotato starch

The invention discloses a corrugated paper adhesive and a preparation method thereof, and belongs to the technical field of adhesives. The corrugated paper adhesive is prepared from, by weight, 130-150 parts of corn starch, 30-40 parts of sweet potato starch, 20-30 parts of mung bean starch, 6-8 parts of a sodium hydroxide solution, 3-4 parts of borax, 20-30 parts of calcium carbonate, 900-1200 parts of water, 5-7 parts of polyacrylamide and 1-2 parts of tributyl phosphate. The preparation method includes the steps that firstly, water is added into a stirring barrel and heated to 50-60 DEG C, then corn starch and the sodium hydroxide solution are added, and constant-temperature stirring is kept; secondly, mung bean starch and sweet potato starch are added, and stirring continues; thirdly, calcium carbonate, tributyl phosphate, borax and polyacrylamide are added, the mixture is heated to 70-80 DEG C, constant-temperature stirring is kept for a period of time, then heating is stopped, and the finished adhesive product is obtained. The corrugated paper adhesive is high in initial adhesiveness, small in usage amount, reliable in adhesion, not likely to fail and good in stability.

Owner:ZUNYI GOUJIANG TOWN XINXINYUAN PAPER CO LTD

Production method of waterproof and freezing-tolerant white emulsion

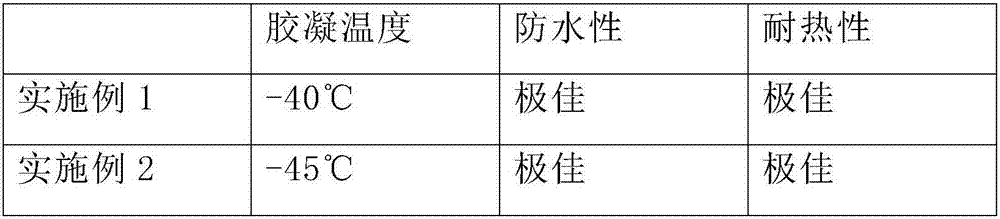

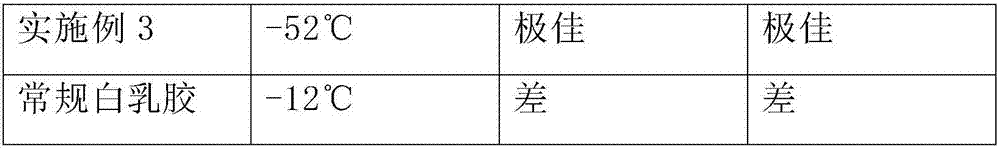

InactiveCN107488420AGood oil resistanceNo pollutionMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesCarvacryl acetateFreezing tolerance

The invention discloses a production method of a waterproof and freezing-tolerant white emulsion. The production method comprises the following steps: mixing dibutyl phthalate with octyl alcohol, and stirring till the dibutyl phthalate and the octyl alcohol are dissolved for later use; adding water into a reaction kettle with a jacket, heating to 60 to 80 DEG C, adding polyvinyl alcohol during stirring, heating to 90 DEG C, and preserving the heat till the polyvinyl alcohol is completely dissolved; injecting cold water into the jacket of the reaction kettle to cool the liquid in the kettle to 66 to 69 DEG C, and adding vinyl acetate during stirring; adding the octyl alcohol solution of the dibutyl phthalate into the reaction kettle, then adding ammonium persulfate, performing uniform stirring, mixing the components at 66 to 69 DEG C for 1 to 2 hours, so as to obtain white viscous vinyl acetate white emulsion, and packaging the white emulsion with a glass bottle or a plastic bottle. According to the production method of the waterproof and freezing-tolerant white emulsion, the production process of common white emulsion is improved; by adding of a modifier, the modified white emulsion which is not gelatinized at low temperature is obtained; when compared with the common white emulsion, the modified white emulsion has the advantage that the water resistance, the heat resistance and the freezing tolerance are all obviously improved.

Owner:李淑存

Plywood filling agent capable of capturing free formaldehyde

InactiveCN108977119AIncrease initial viscosityReduce usageNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolycarbonateTea leaf

The invention belongs to the technical field of plywood processing and in particular relates to a plywood filling agent capable of capturing free formaldehyde. The plywood filling agent is prepared from the following raw materials in parts by weight: 12 to 18 parts of wollastonite powder, 3 to 5 parts of a stellerite molecular sieve, 1 to 2 parts of mirabilite, 18 to 22 parts of tea leaf dreg powder, 1.8 to 2.6 parts of aromatic hydrogen oil, 6 to 10 parts of polycarbonate diol, 2 to 4 parts of dimethyl-beta-propiothetin and 22 to 26 parts of corn husk puffed ultra-micro powder. Compared withthe prior art, the plywood filling agent has the following advantages that the filling agent is reasonably matched and the initial viscosity of resin is increased; the utilization of cereal crops is reduced and mildewing is avoided; the corn husk puffed ultra-micro powder, the stellerite molecular sieve and the mirabilite have a synergistic effect and can be used for effectively absorbing the freeformaldehyde, so that the plywood filling agent is suitable for being popularized.

Owner:阜南盛原木业有限公司

Acupuncture point hot compress agent and acupuncture point hot compress paster comprising same

InactiveCN104739639AWell balanced yin and yangImprove microcirculationDevices for heating/cooling reflex pointsUltrasound therapyPolyesterToluene diisocyanate

The invention provides an acupuncture point hot compress agent and an acupuncture point hot compress paster comprising the same. The acupuncture point hot compress agent comprises, by mass, 0.05%-20% of polyether polyol, 0.05%-30% of polyester polyol, 1%-70% of toluene diisocyanate, 0.05%-5% of stone needle powder, 0.05%-5% of vanillyl butyl ether, 0.05%-5% of dipotassium glycyrrhizate, 0.05%-5% ofindustrial salt and the balance water. The acupuncture point hot compress paster is composed of an outer non-woven cloth layer, a middle hot compress agent layer and an inner anti-adhesive layer. After adhering to acupuncture points of the human body, the acupuncture point hot compress paster can facilitate microcirculation of the human body and regulate metabolism by physically rubbing against related acupuncture points and plays a role in activating blood circulation, tonifying qi, dredging the meridian, strengthening vital qi to eliminate pathogenic factors, balancing yin and yang and the like. The acupuncture point hot compress paster is good in effect and convenient to carry, takes effect rapidly and has no adverse reaction. The acupuncture point hot compress paster is suitable for acupuncture point adhering massage conducted on sub-healthy people for improvement and rehabilitation treatment according to the theory of traditional Chinese medicine, so that uncomfortable symptoms of sub-healthy people are ameliorated.

Owner:创邦医疗健康科技(云南)有限公司

Environmental-friendly double-component polyurethane adhesive

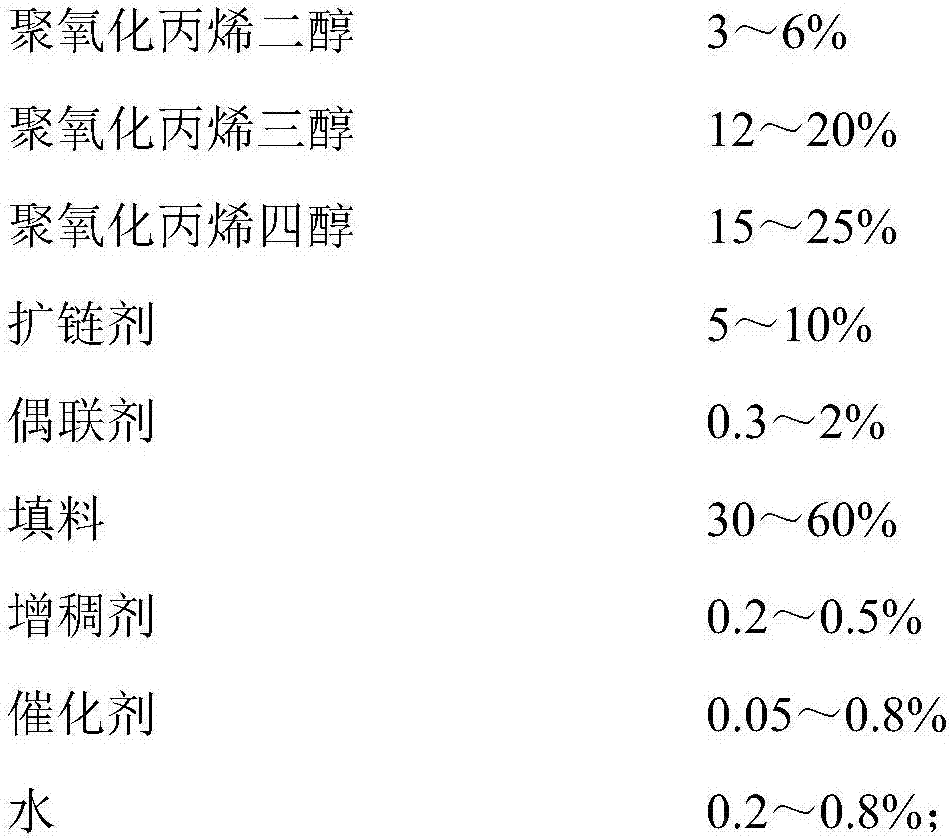

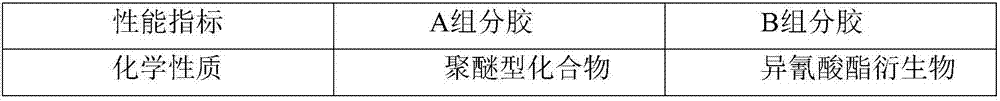

ActiveCN107312490AHigh initial viscosityFast curingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolypropyleneWool

The invention relates to an environmental-friendly double-component polyurethane adhesive, and belongs to the technical field of polyurethane. The adhesive is prepared from a component A and a component B in a mass ratio of 1:(5-1), wherein the component A is prepared from the following raw materials in percentage by mass: 3-6% of polypropylene oxide diol, 12-20% of polypropylene oxide triol, 15-25% of polypropylene oxide tetrol, 5-10% of a chain extender, 0.3-2% of a coupling agent, 30-60% of packing, 0.2-0.5% of a thickening agent, 0.05-0.8% of a catalyst and 0.2-0.8% of water; the component B is prepared from the following raw materials in percentage by mass: 30-50% of diphenyl methylene diisocyanate, 20-47% of polymethylene poly-phenyl isocyanate and 3-5% of a plasticizer. The environmental-friendly double-component polyurethane adhesive provided by the invention is mainly used for binding substrates and is applicable to adhesion of stainless steel plates, aluminum alloy plates, inorganic calcium silicate boards and rock wool plates, the component A and the component B are mixed according to a ratio and are subjected to chemical cross-linking reactions, and excellent properties of high initial viscosity, high curing speed and good binding properties are achieved.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Self-heating inorganic adhesive and its preparation method and use method in inorganic artificial board production

InactiveCN108587482AIncrease initial viscosityObvious price advantageNon-macromolecular adhesive additivesInorganic adhesivesFiberAdhesive

The invention discloses a self-heating inorganic adhesive. The self-heating inorganic adhesive comprises two components and concretely comprises an inorganic adhesive semi-finished product and a quicklime gelatin capsule in a weight ratio of (40-60): (10-25). The inorganic adhesive semi-finished product is prepared from 30-60 parts by weight of water, 20-30 parts by weight of aluminum hydroxide, 20-35 parts by weight of phosphoric acid, 10-20 parts by weight of calcium sulfate, 4-10 parts by weight of fly ash, 3-5 parts by weight of calcium carbonate, 2-4 parts by weight cooked glutinous riceflour and 0.3-0.7 parts by weight of curcumin. The invention also discloses a preparation method of the self-heating inorganic adhesive. Through use of the cooked glutinous rice flour as the initial adhesive, the initial viscosity of the adhesive is effectively increased. Through use of the inorganic adhesive in the production of agricultural and forestry residual fiber (planing) boards, the problems of loosing in the board blank transportation and loading and unloading are solved. Compared with other initial adhesives, the cooked glutinous rice flour has obvious price advantages.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

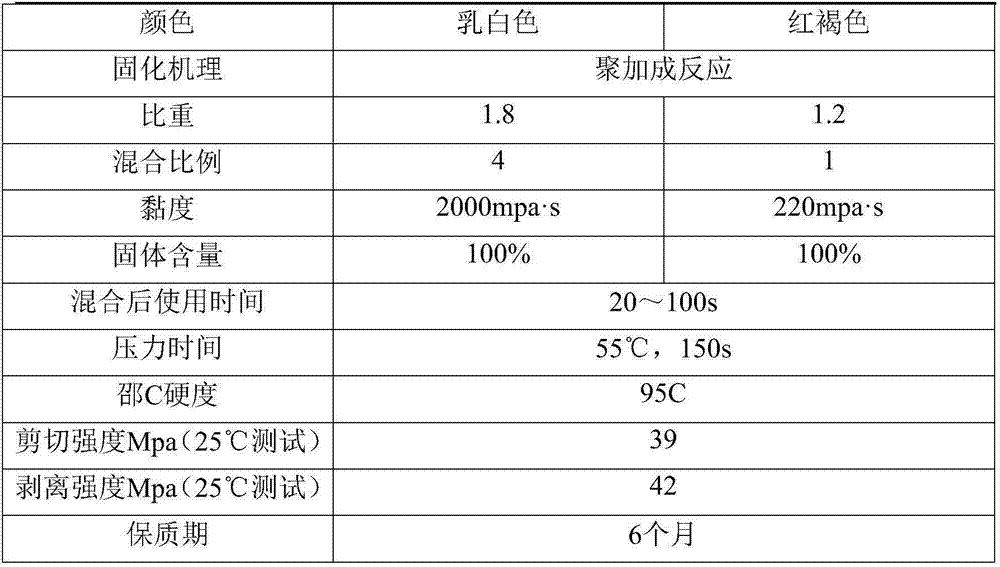

Preparation method for water-based heat-conducting environmentally-friendly adhesive

InactiveCN111363513AWill not affect performanceImprove water resistanceNon-macromolecular adhesive additivesAcid polymer adhesivesProcess engineeringMetal particle

The invention belongs to the technical field of adhesives, and specifically relates to a preparation method for a water-based heat-conducting environmentally-friendly adhesive. The water-based heat-conducting environmentally-friendly adhesive prepared by using the preparation method disclosed by the invention has excellent initial adhesion, can be used for adhering different types of base materials, provides a comprehensive solution, and has the advantages of no bubbles, no edge warping, water boiling resistance and high temperature resistance. Meanwhile, the problem that a high-initial-adhesion water-based adhesive is low in viscosity in winter is solved; meanwhile, a positioning adhesion effect can be rapidly achieved; safety and environmental protection are guaranteed; meanwhile, a product has excellent initial adhesion strength, washing resistance, heat conduction and high-temperature resistance; a toxic and harmful cross-linking agent is not used; and good heat conduction performance is achieved on the premise that heat conduction metal particles are not contained.

Owner:含山县金中环装饰材料有限公司

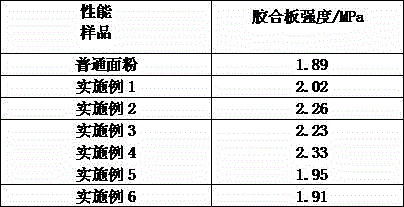

Thickening composition for adhesive for plywood and preparation method of thickening composition

ActiveCN104312490AEasy to useImprove adsorption capacityStarch adhesivesUnsaturated alcohol polymer adhesivesWood veneerAdhesive

The invention discloses a thickening composition for an adhesive for plywood. The composition is prepared from the following raw materials in parts by weight: 60-100 parts of flour, 30-50 parts of lignin, 30-50 parts of tapioca flour, 3-5 parts of polyvinyl alcohol, 3-5 parts of silicon aluminide and 5-10 parts of a mildew preventive. The invention further discloses a preparation method of the thickening composition for the adhesive for plywood. The preparation method comprises the following steps: A, thermally dissolving polyvinyl alcohol; B, mixing the flour, lignin and tapioca flour in proportion to obtain a mixture; and C, adding the mildew preventative into the mixture in the step B, and then dropwise adding polyvinyl alcohol and silicon aluminide while stirring. The tapioca flour is good in viscidity, so that the composition has very strong adsorbability. Lignin and a wood veneer have relatively strong affinity. The flour is more flexible due to polyvinyl alcohol. According to the composition disclosed by the invention, not only is the production cost lowered, but also the adhering property is further enhanced.

Owner:新沂市超华木业有限公司

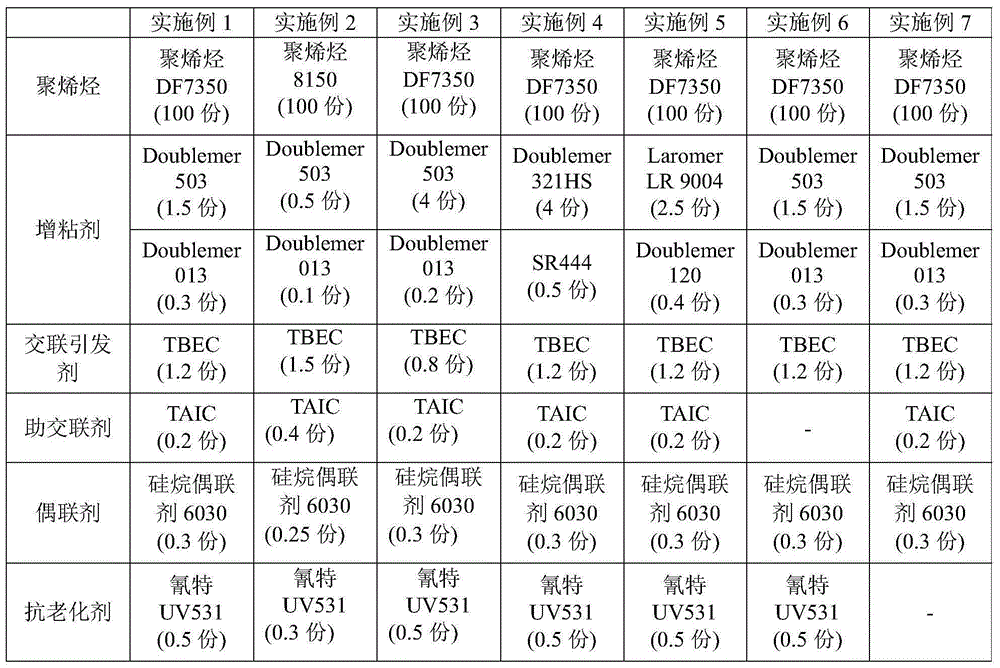

Resin composition and solar cell encapsulation adhesive film

InactiveCN106479428AIncrease initial reaction speedIncrease initial viscosityFilm/foil adhesivesPolyureas/polyurethane adhesivesPolyolefinAdhesive

The invention relates to the field of solar cell encapsulation adhesive films and discloses a resin composition. The resin composition is characterized by containing polyolefin, a cross-linking initiator, a coupling agent and a tackifier, wherein the tackifier contains a (methacrylate) acrylate oligomer and a (methacrylate) acrylate monomer. The solar cell encapsulation adhesive films prepared from the resin composition disclosed by the invention are not prone to bubbling during lamination and viscous adhesive overflow at edges.

Owner:BYD CO LTD

Masonry mortar plasticizer and preparation method thereof

InactiveCN102167539BHigh strengthGood dispersionSolid waste managementPolyvinyl alcoholNatural building

The invention relates to a masonry mortar plasticizer which consists of aged powder, polyoxyethylene ether sodium sulfate, water-soluble polyvinyl alcohol, polyacrylamide, oil cake powder and plant stem leaf powder, wherein the preparation method of the masonry mortar plasticizer comprises the following steps of: preparing the aged powder, the plant stem leaf powder, the oil cake powder, the polyoxyethylene ether sodium sulfate, the water-soluble polyvinyl alcohol and the polyacrylamide, burdening the aged powder, the plant stem leaf powder, the oil cake powder, the polyoxyethylene ether sodium sulfate, the water-soluble polyvinyl alcohol and the polyacrylamide according to proportions, evenly mixing and packaging to obtain the masonry mortar plasticizer product. A great amount of sites for stacking harmful waste can be saved, the expense of managing the industrial wastes is saved, the pollution of the industrial wastes to air, water body and soil and the consumption of cement is reduced, and the natural building materials such as lime, mountain flour and bentonite are saved. The masonry mortar plasticizer and the preparation method thereof disclosed by the invention have the advantages of advanced process, energy saving and environment friendliness, low prices and good quality of the product, reduced environment pollution, enhanced resource utilization ratio and remarkable economic and environment-friendly significances.

Owner:邓泽民

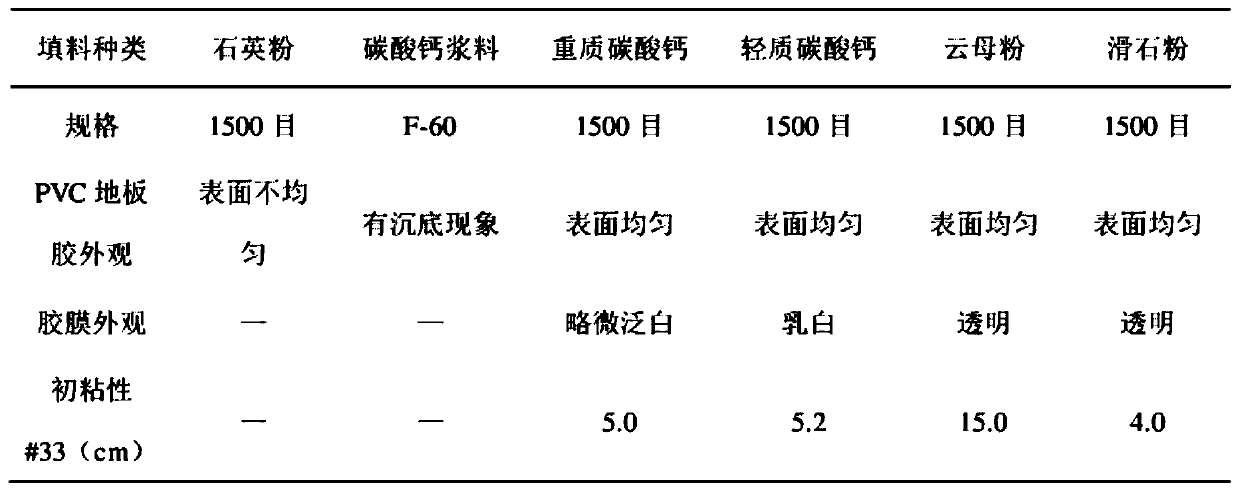

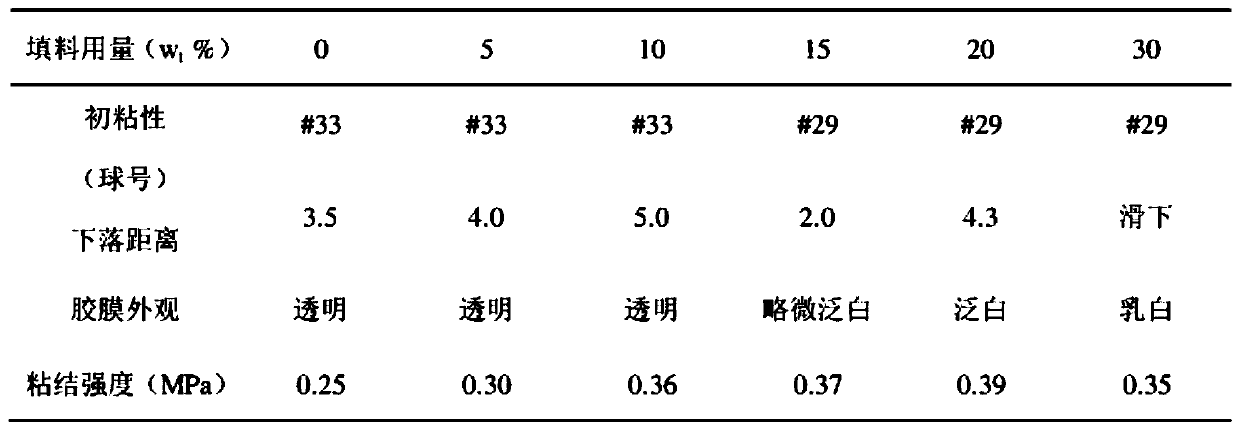

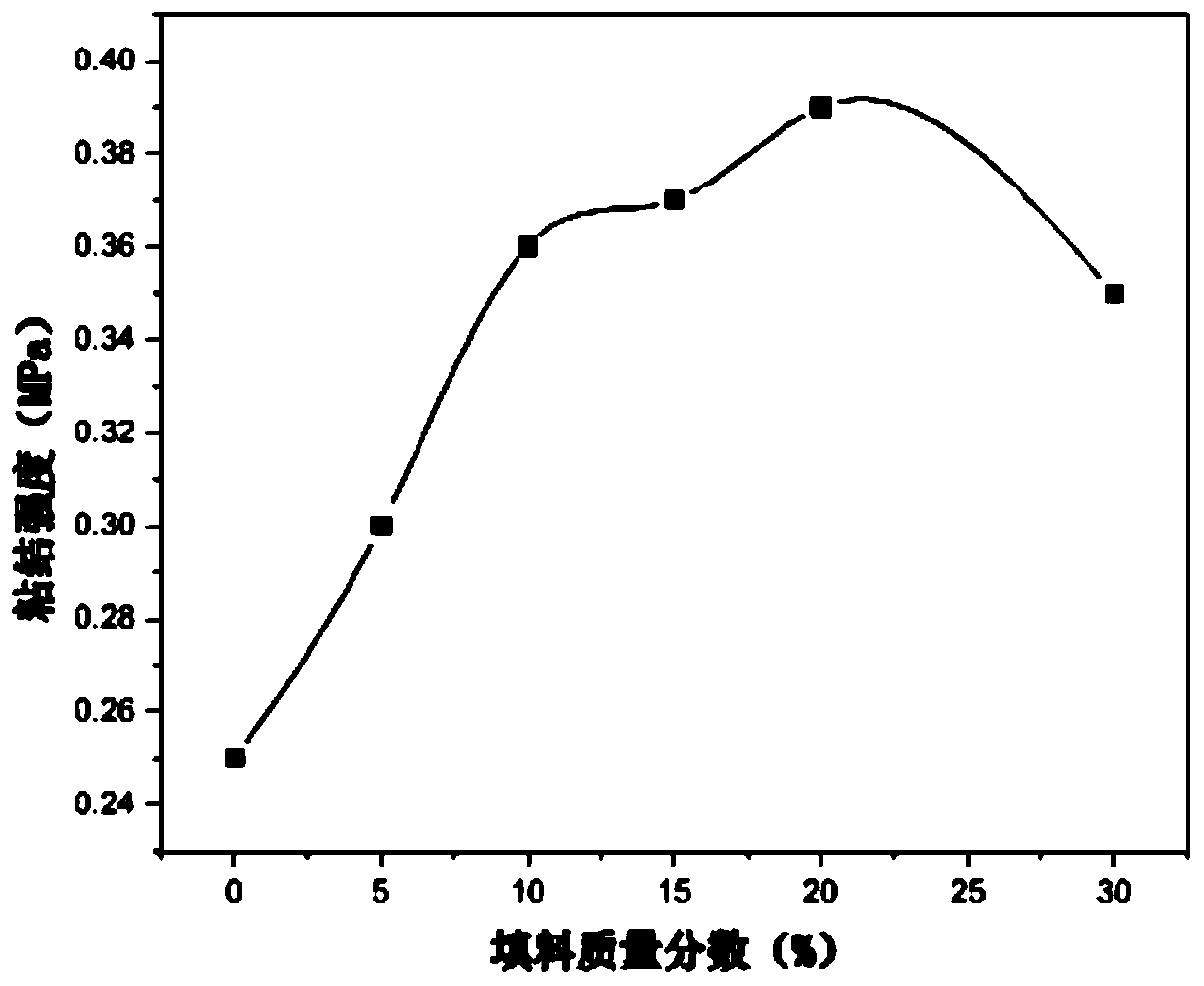

Preparation method for self-adhesive PVC floor

InactiveCN110511508AImprove freeze-thaw stabilityHigh bonding strengthNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveFreeze thawingEmulsion

The invention provides a preparation method for a self-adhesive PVC floor. The self-adhesive PVC floor comprises a PVC substrate layer, a UV treatment layer, an adhesive layer and a protective paper layer. The preparation method comprises the following steps: S1, preparation of the PVC substrate layer; S2, preparation of the UV treatment layer; S3, preparation of a rough friction surface; S4, preparation of protective paper; and S5, preparation of the adhesive layer. According to the invention, an acrylate emulsion is polymerized by adopting acrylic acid and methacrylic acid with a mass fraction of 2% to 5%, so oil resistance, solvent resistance and adhesive strength of the acrylate emulsion are significantly improved; freeze-thaw stability of the emulsion and wettability of the emulsion to a pigment filler can be improved; the polymerized emulsion can be endowed with the characteristic of thickening; meanwhile, through addition of different varieties of filling materials with different parts by mass and various auxiliary agents with different parts by mass, a floor adhesive is optimized; a PVC floor adhesive with good initial viscosity and high bonding strength is prepared; and the service life of a PVC floor is prolonged.

Owner:黄山市润亿建筑装饰材料有限公司

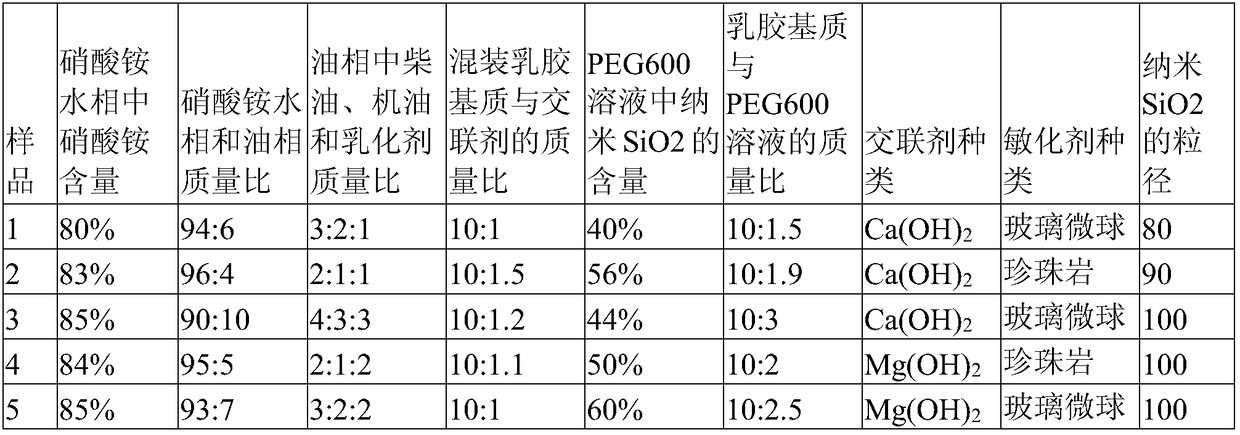

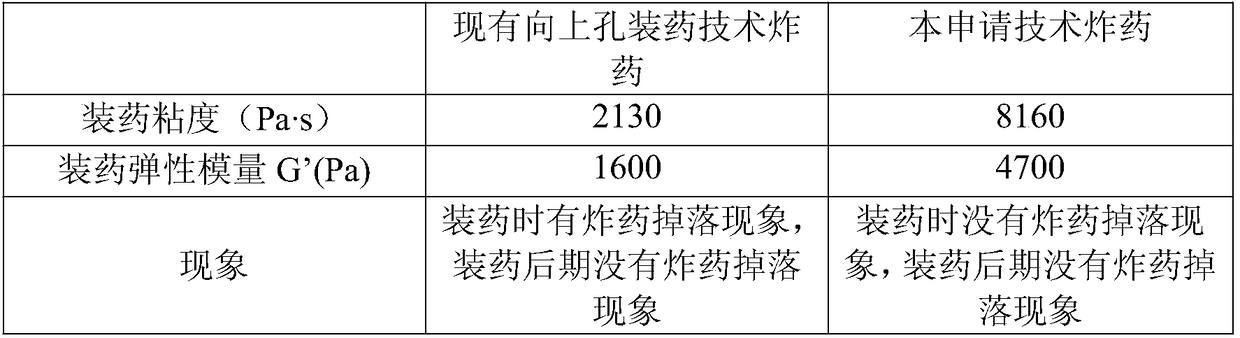

Mixed loading emulsion explosive used for upward hole charge and preparation method of mixed loading emulsion explosive

InactiveCN108299134AIncrease initial viscosityHigh viscosityNon-explosive/non-thermic compositionsExplosive ingredient compoundingExplosive AgentsEmulsion explosive

The invention discloses a mixed loading emulsion explosive used for upward hole charge and a preparation method of the mixed loading emulsion explosive, the preparation steps comprise steps of (1) preparation of a mixed loading emulsion matrix: an ammonium nitrate water phase is heated, an oil phase is taken for heating, the ammonium nitrate water phase and the oil phase are mixed and stirred, andthe mixed loading emulsion matrix is prepared; (2) mixing of the mixed loading emulsion matrix and a cross-linking agent: the mixed loading emulsion matrix and the cross-linking agent are mixed; (3)mixing of a PEG / SiO2 shear thickening liquid: the emulsion matrix and a PEG 600 solution containing nanometer SiO2 are mixed; (4) tail end static sensitizing: the mixed emulsion matrix is subjected tostatic sensitizing at the charge tail end through a sensitizing agent, and the mixed loading emulsion explosive used for upward hole charge is formed. The mixed loading emulsion explosive prepared with the method has higher viscosity at the charge initial stage, crosslinking solidification is combined, the emulsion explosive is not easy to fall from explosive holes, material waste is reduced, andthe energy and the resource are saved.

Owner:CHINA GEZHOUBA GRP YIPULI CO LTD

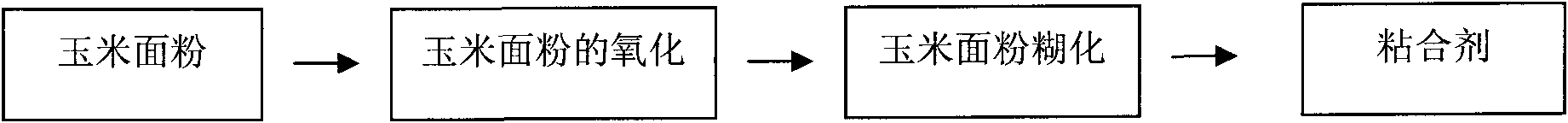

Process for manufacturing manganese ion corn flour adhesive

InactiveCN101812275AWide range of raw materialsExtensive sources of raw materialsStarch derivtive adhesivesAdhesiveManganese

The invention discloses a process for manufacturing manganese ion corn flour adhesive, and relates to a natural high polymer adhesive. The process comprises the following steps: putting pretreated corn flour into a three-mouth bottle provided with a stirring device, adding 30 milliliters of water into the three-mouth bottle, stirring the mixture, adding hydrogen peroxide and potassium permanganate into the three-mouth bottle with stirring to perform oxidation, dripping 30 percent caustic soda solution after the mixture is oxidized for 30 to 40 minutes to continuously oxidize the mixture for 1 hour, dripping the rest alkali drips into the three-mouth bottle after the oxidation is finished, pasting the mixture for 30 minutes, adding borax into the three-mouth bottle, and continuously stirring the mixture for 10 minutes to obtain the manganese ion corn flour adhesive. The process has the advantages of low cost, good initial viscosity, quick drying, gelling resistance, high bonding strength, no toxicity and good environmental effect.

Owner:HARBIN BAISHUN PACKAGING

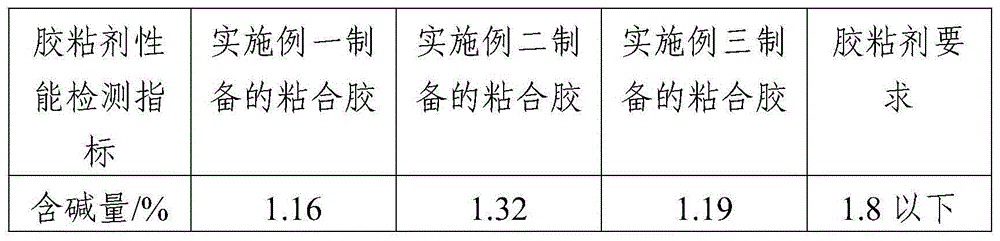

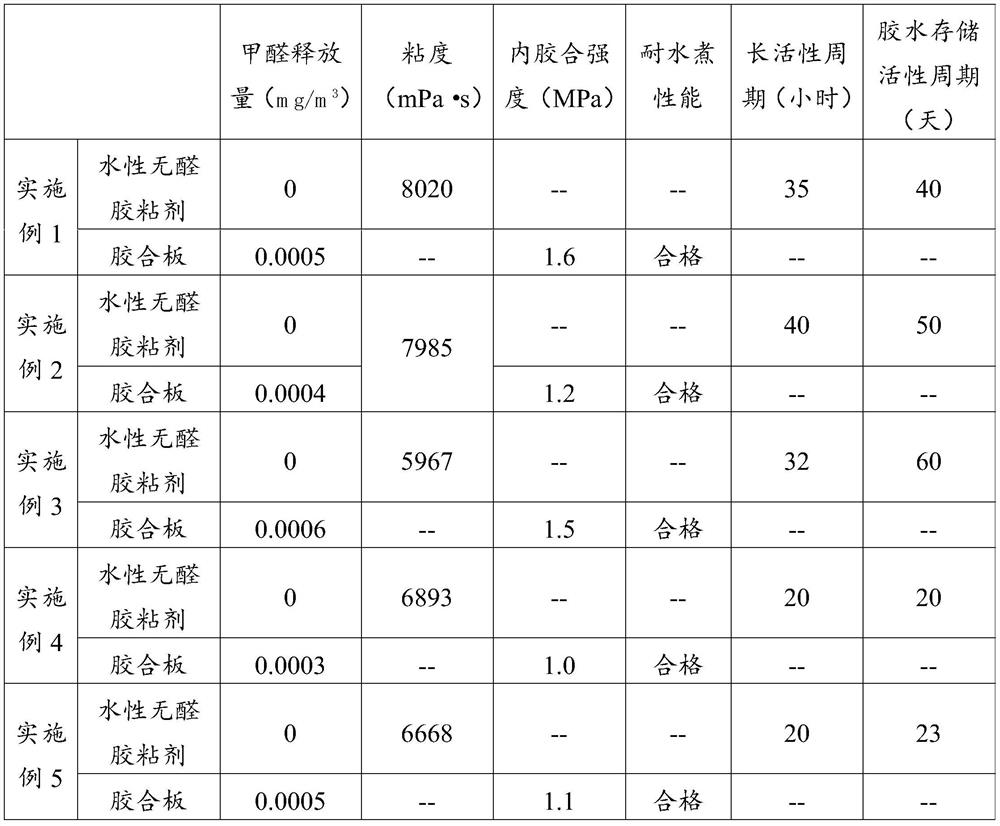

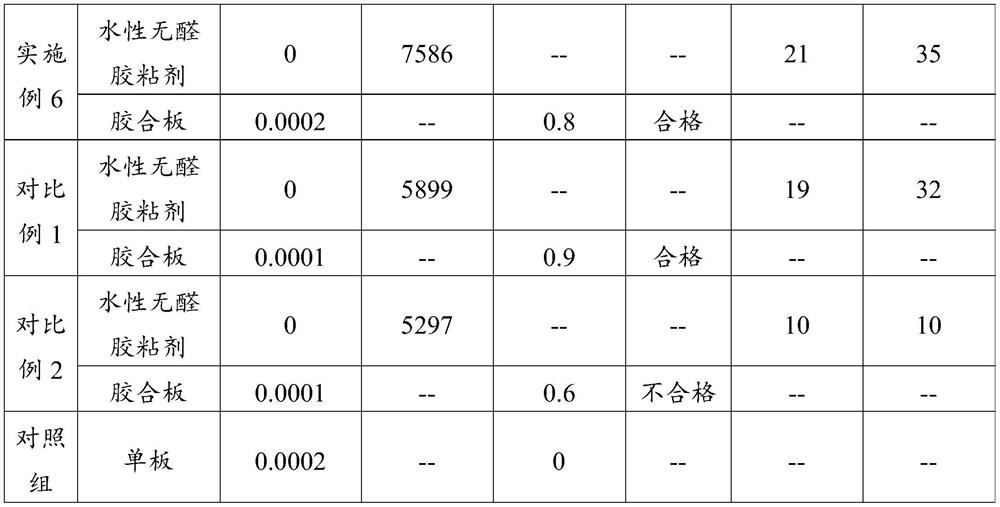

Water-based formaldehyde-free adhesive as well as preparation method and application thereof

InactiveCN113493664AReduce reactivityImprove structural strengthMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAdhesive cementPolymer science

The invention discloses a water-based formaldehyde-free adhesive as well as a preparation method and application thereof. The method comprises the following steps: (1) dissolving a water-soluble poly-multistructure compound in water at 0-200 DEG C to obtain a high polymer solution; (2) adjusting the temperature to 0-200 DEG C, adding an active auxiliary agent into the high polymer solution, adjusting the pH value to 2-10, and carrying out a stirring reaction for 1.0-72 h to obtain a hydrogel-like material; (3) reacting the hydrogel-like gel with an emulsion and a surfactant to form an emulsion / composite hydrogel system; and (4) adding a reinforcing material into the emulsion / composite hydrogel system to adjust the pH value to 2-11, and reacting to obtain the water-based formaldehyde-free adhesive. According to the invention, a water molecule, emulsion and hydrogel-like co-embedded film structure is constructed, so that the problem that a water reactive compound and a water-based compound are difficult to coexist is solved. Moreover, the prepared water-based formaldehyde-free adhesive has the effects of high stability, long activity period, toughening, water resistance, high adhesion and no formaldehyde release, and is suitable for artificial boards.

Owner:广东木森态新材料科技有限公司

Low-formaldehyde high-strength adhesive and preparation method thereof

InactiveCN103805101ALayer and high strengthImprove performanceNon-macromolecular adhesive additivesAdhesiveAmination

The invention discloses a low-formaldehyde high-strength adhesive and a preparation method thereof. The adhesive comprises the following raw materials: deionized water, formaldehyde, urea, polyvinyl alcohol, biomass, acetic acid, sodium hydroxide, a curing agent and tannin. The preparation method comprises the following steps: adding the deionized water and the polyvinyl alcohol to a reaction pot according to the ratio; heating to completely dissolve the polyvinyl alcohol; adding the biomass and evenly agitating after completely dissolving; dropwise adding the acetic acid to agitate after the solution is cooled; adding the formaldehyde to carry out condensation reaction; dripping the sodium hydroxide to adjust the pH value to neutral property after cooling; adding the urea to carry out amination treatment; adding the tannin and the curing agent to evenly agitate; dropwise adding the sodium hydroxide to adjust the pH value after sampling and checking out; and cooling, filtering and discharging, bulking by a barrel, so as to obtain the low-formaldehyde high-strength adhesive. An adhesive prepared by adopting a traditional technical formula is high in free formaldehyde content in general, and generates a great harm to a human body. The adhesive disclosed by the invention has the advantages of low free formaldehyde, high bonding strength, rapid curing, low cost and the like according with the standards.

Owner:GUANGXI JISHUN ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com