Production method of waterproof and freezing-tolerant white emulsion

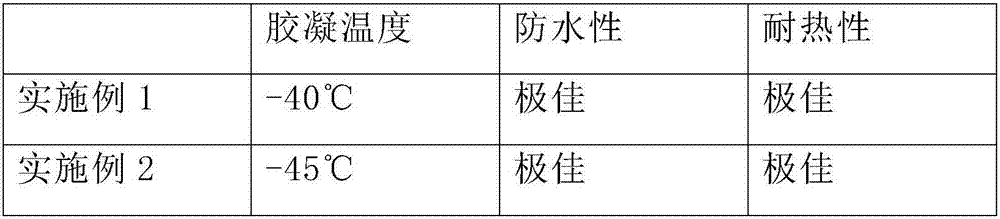

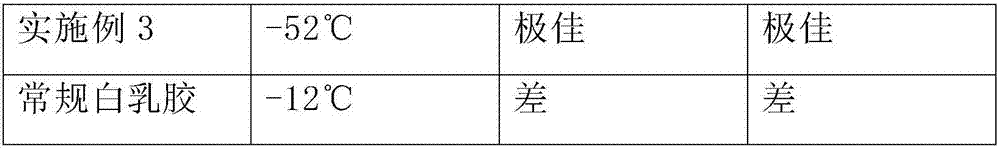

A production method and white latex technology, applied in the field of white latex, can solve the problems of poor water resistance and heat resistance, easy gelation, etc., and achieve the effects of easy processing, high bonding strength, good toughness and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of production method of waterproof freeze-resistant white latex, it is the following steps:

[0027] (1) Dibutyl phthalate and octanol are mixed, stirred to make it dissolve, for subsequent use, the mass ratio of dibutyl phthalate and octanol is 3:1;

[0028] (2) Add water to the jacketed reaction kettle, heat to 75°C, add polyvinyl alcohol under stirring, heat up to 90°C and keep warm until completely dissolved, the quality of the added dibutyl phthalate, polyvinyl alcohol, and water The ratio is 3:4:47.9;

[0029] (3) Inject cold water into the jacket of the reaction kettle to cool down the liquid in the kettle to 67°C, add vinyl acetate under stirring, the mass ratio of vinyl acetate to dibutyl phthalate is 44:3 ;

[0030] (4) Add the octanol solution of dibutyl phthalate to the reaction kettle, then add ammonium persulfate and stir well, and mix at 67°C for 1.5 hours to obtain white viscous vinyl acetate white latex. Packed in bottles or plastic bottles, t...

Embodiment 2

[0034] A kind of production method of waterproof freeze-resistant white latex, it is the following steps:

[0035] (1) Dibutyl phthalate and octanol are mixed, stirred to make it dissolve, for subsequent use, the mass ratio of dibutyl phthalate and octanol is 3:1;

[0036] (2) Add water to the jacketed reaction kettle, heat to 71°C, add polyvinyl alcohol under stirring, heat up to 90°C and keep warm until completely dissolved, the quality of the added dibutyl phthalate, polyvinyl alcohol, and water The ratio is 3:4:47.9;

[0037] (3) Inject cold water into the jacket of the reaction kettle to cool down the liquid in the kettle to 68°C, add vinyl acetate under stirring, the mass ratio of vinyl acetate to dibutyl phthalate is 44:3 ;

[0038] (4) Add the octanol solution of dibutyl phthalate to the reaction kettle, then add ammonium persulfate and stir well, and mix at 66°C for 1.3 hours to obtain white viscous vinyl acetate white latex. Packed in bottles or plastic bottles, t...

Embodiment 3

[0042] A kind of production method of waterproof freeze-resistant white latex, it is the following steps:

[0043] (1) Dibutyl phthalate and octanol are mixed, stirred to make it dissolve, for subsequent use, the mass ratio of dibutyl phthalate and octanol is 3:1;

[0044] (2) Add water to the jacketed reaction kettle, heat to 70°C, add polyvinyl alcohol under stirring, heat up to 90°C and keep warm until completely dissolved, the quality of the added dibutyl phthalate, polyvinyl alcohol, and water The ratio is 3:4:47.9;

[0045] (3) Inject cold water into the jacket of the reaction kettle to cool down the liquid in the kettle to 68°C, add vinyl acetate under stirring, the mass ratio of vinyl acetate to dibutyl phthalate is 44:3 ;

[0046] (4) Add the octanol solution of dibutyl phthalate to the reaction kettle, then add ammonium persulfate and stir well, and mix at 69°C for 1.5 hours to obtain white viscous vinyl acetate white latex. Packed in bottles or plastic bottles, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com