Lignin reinforcing filled butadiene-acrylonitrile rubber hose

A technology of lignin and nitrile rubber, which is applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of carbon black dust pollution, endangering the health of employees, difficult to cure, etc., and achieve material cost reduction and production mode Effects of environmental protection and formulation cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

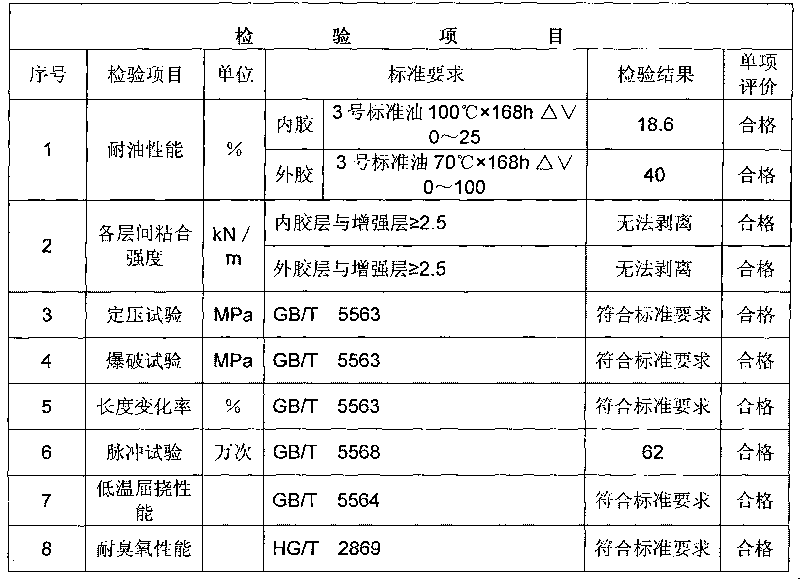

Examples

Embodiment 1

[0034] (1) Inner rubber layer formula:

[0035] Lignin-reinforced and filled nitrile rubber A1: according to another patent application of the applicant "a kind of industrial lignin-reinforced and filled blended elastomer material and its preparation method" (application number: 200810027887.8) disclosed method The mixed rubber masterbatch that prepares is specifically the steel wire winding acrylonitrile-butadiene rubber hose that adopts pine pulp lignin to reinforce filling acrylonitrile-butadiene rubber to manufacture, lignin in the mixed rubber masterbatch: acrylonitrile-butadiene rubber raw material=110: 100 (weight part ), the model of nitrile rubber raw material is NR35LM.

[0036]

components

Dosage

(parts by weight)

Lignin-reinforced filled nitrile rubber blend elastomer A1

100.00

Clay

14.40

2.40

0.48

Accelerator CBS

0.72

Amine antioxidant...

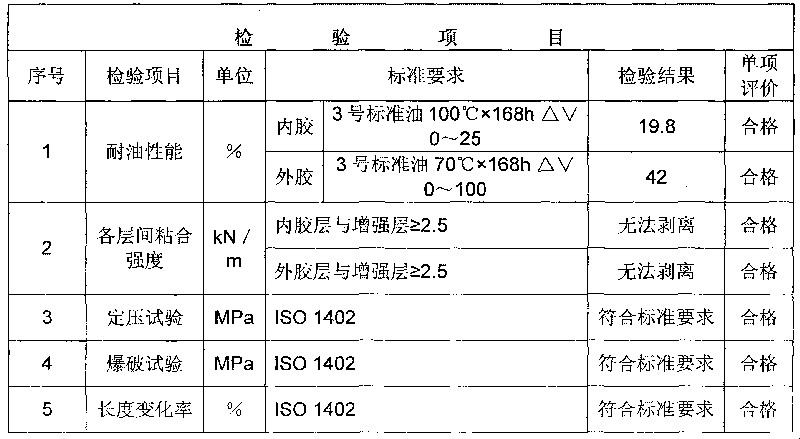

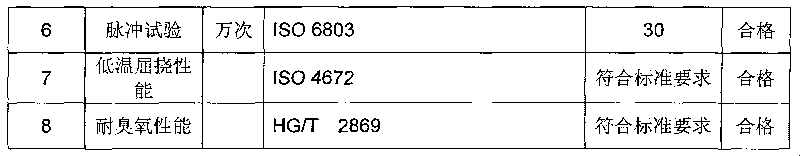

Embodiment 2

[0051] Steel wire braided nitrile rubber hose made of lignin, silica and filled with nitrile rubber.

[0052] Wherein, the nitrile rubber A3 of lignin and white carbon black and filling with reinforcement: is according to another patent application of the applicant " a kind of blended elastomeric material and preparation method thereof of industrial lignin reinforcement filling " (application No.: 200810027887.8) The mixed rubber masterbatch prepared by the disclosed method is specifically a steel wire wound acrylonitrile-butadiene rubber hose made of lignin reinforced filling nitrile rubber, wherein lignin in the mixed rubber masterbatch: acrylonitrile-butadiene rubber raw material = 100:100 (parts by weight).

[0053] (1) Inner rubber layer formula:

[0054]

components

Dosage

(parts by weight)

Lignin-reinforced filled nitrile rubber blend elastomer A3

100.00

Silica

2.50

Clay

20.00

2.50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com