Patents

Literature

345 results about "Occupational disease" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An occupational disease is any chronic ailment that occurs as a result of work or occupational activity. It is an aspect of occupational safety and health. An occupational disease is typically identified when it is shown that it is more prevalent in a given body of workers than in the general population, or in other worker populations. The first such disease to be recognised, squamous-cell carcinoma of the scrotum, was identified in chimney sweep boys by Sir Percival Pott in 1775. Occupational hazards that are of a traumatic nature (such as falls by roofers) are not considered to be occupational diseases.

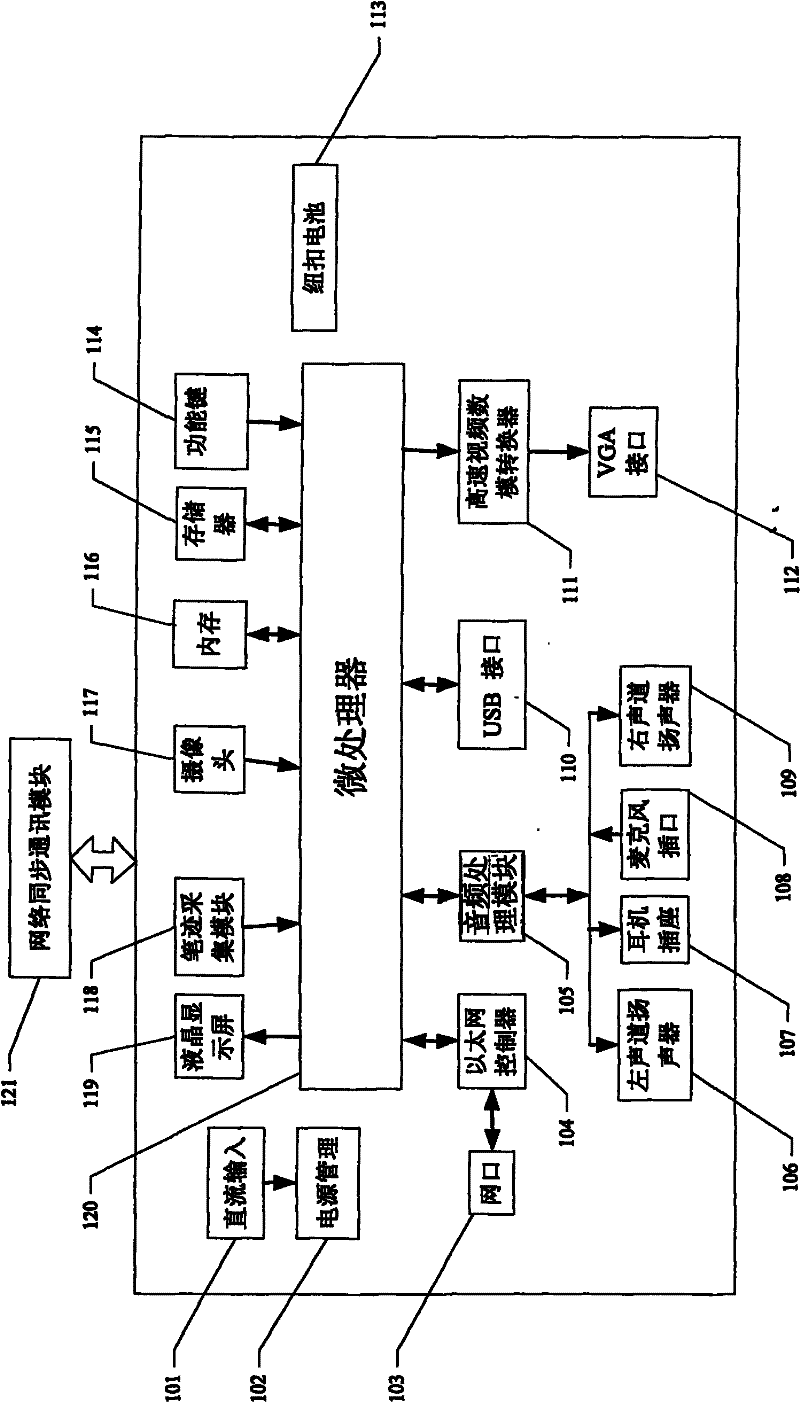

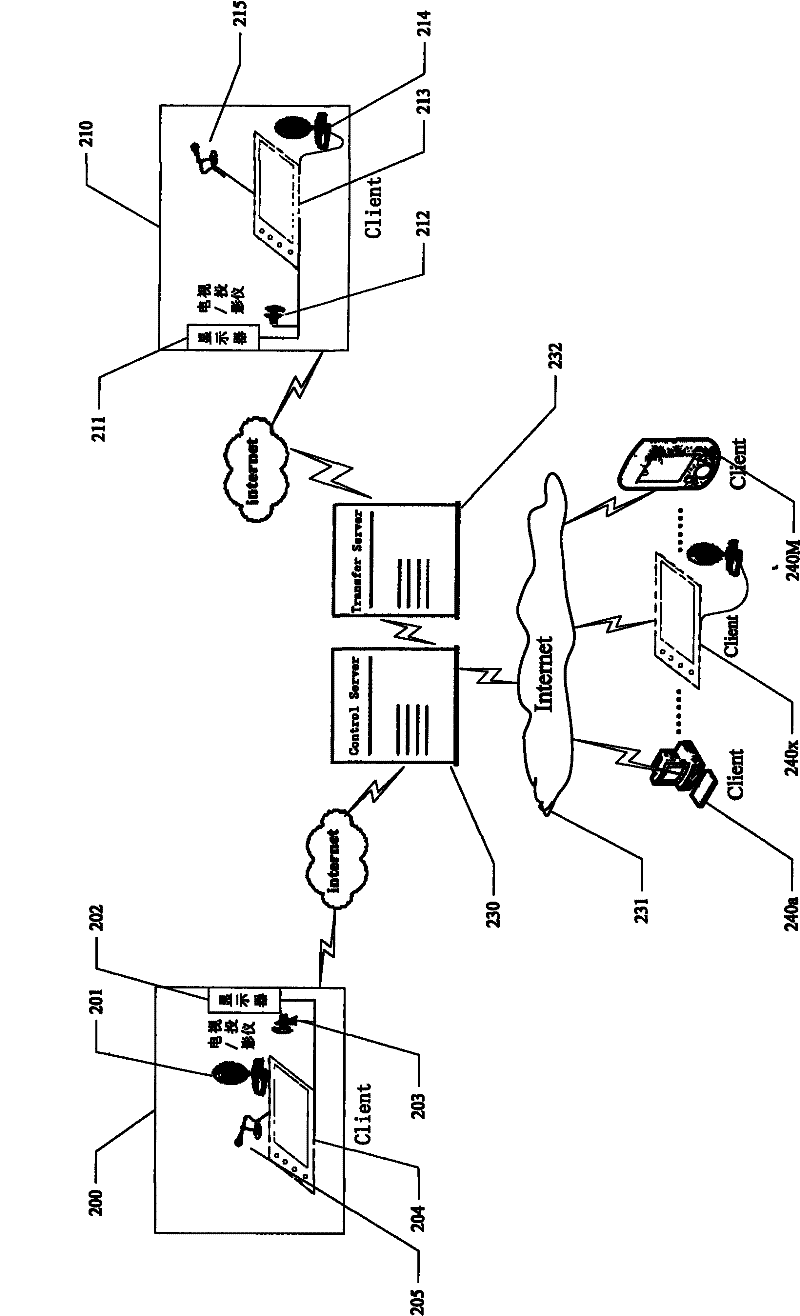

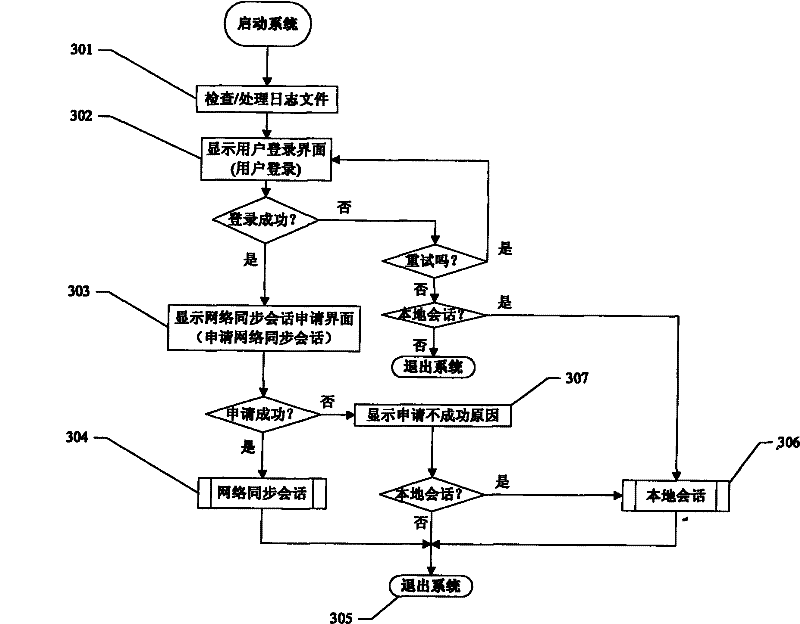

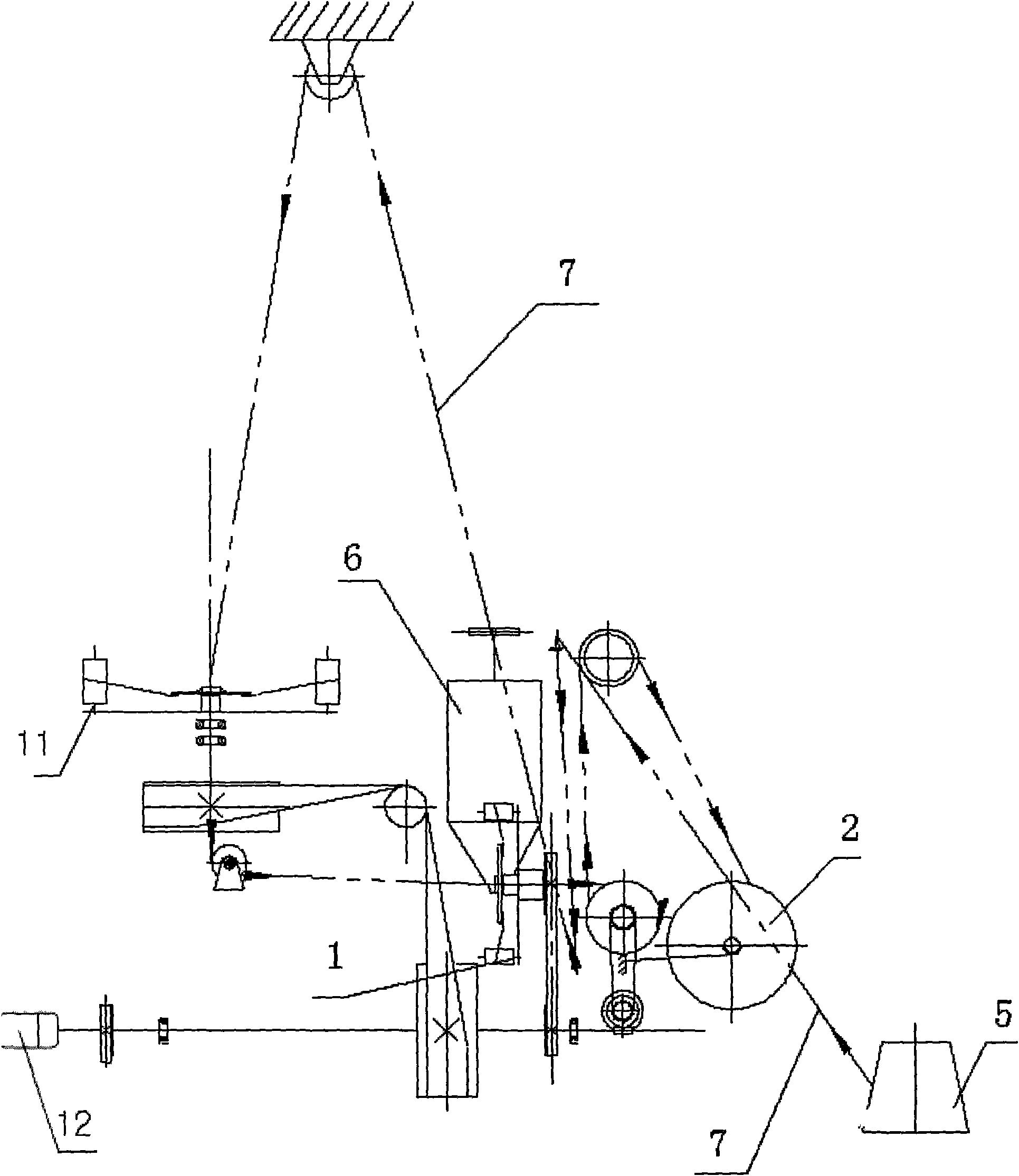

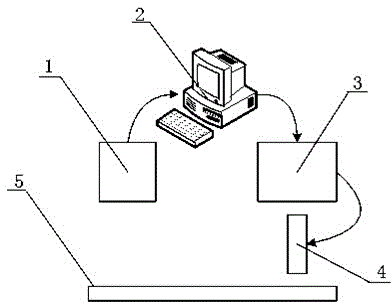

Terminal system for synchronous teaching or conferences and control method thereof

InactiveCN102209080AWith collection functionWith processing functionTransmissionElectrical appliancesHandwritingThe Internet

The invention discloses a terminal system for synchronous teaching or conferences. The system is characterized by also comprising a network synchronous communication module, wherein the network synchronous communication module is used for processing, playing and displaying session contents such as collected audio data, video data and handwriting data as well as documents opened by users, sending the processed session contents to a remote terminal through the Internet, and processing, playing and displaying the session content data received from the remote terminal. According to the invention, a traditional teaching method and an online teaching method are combined organically, therefore, the problems of teaching resource shortage and uneven prominent teacher resource distribution caused by geographical position, regional difference between the rich and the poor and other factors can be solved, severe occupational diseases caused by the traditional teaching method can be relieved, the defects of current long-distance teaching system and equipment can be overcome, and meanwhile, the teaching interaction can be improved and the study enthusiasm of students can be enhanced. The terminal system is also applicable to web conferences and local conferences.

Owner:刘盛举

Routine paraffin wax flaking HE dyeing non-xylol whole-course treatment liquid for biological organization sample

InactiveCN101344467AThoroughly dehydratedSpeed up productionPreparing sample for investigationParaffin waxNon toxicity

The invention aims at providing a pathological diagnosis reagent, which is mainly used for processing various tissue samples in the pathology department in all levels of hospitals, can satisfy the requirements of a global non-xylene HE dyeing treating fluid of routine paraffin slices of biological tissue samples that is required in the slicing technique of the tissue samples with manual operation or operation of an automatic dehydrator and in the HE dyeing technique of cast-off cells, and is separated into two parts of tissue dehydration and section staining. As a novel conservation-conscious environmental protection technique, the pathological diagnosis reagent quickens splicing speed and simultaneously leads the tissue not to become over shrunk, hardened, split and crisp and leads the cells and the tissue structure to be closer to original patterns; the pathological diagnosis reagent has more complete tissue dehydration and adopts various novel mixed reagents that are pure analyzing organic chemical reagents with low volatility or non-volatility, non-toxicity and non-pollution, thus replacing originally widely used xylene reagents that have toxicity and heavy environmental pollution and eliminating occupational diseases that are caused by the xylene reagents in the global slicing of tissue sample preparation and tissue slice HE dyeing.

Owner:赵晓辉

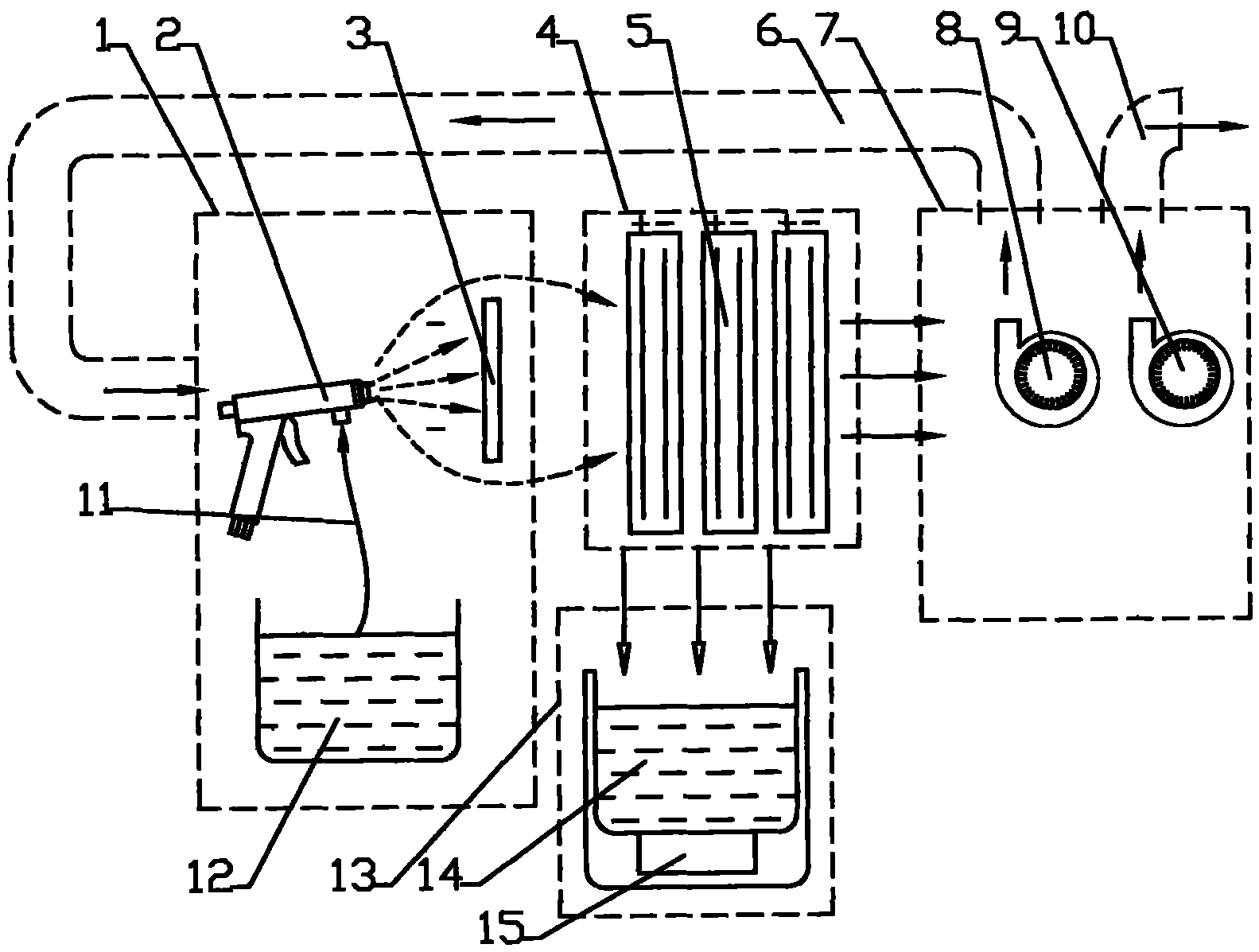

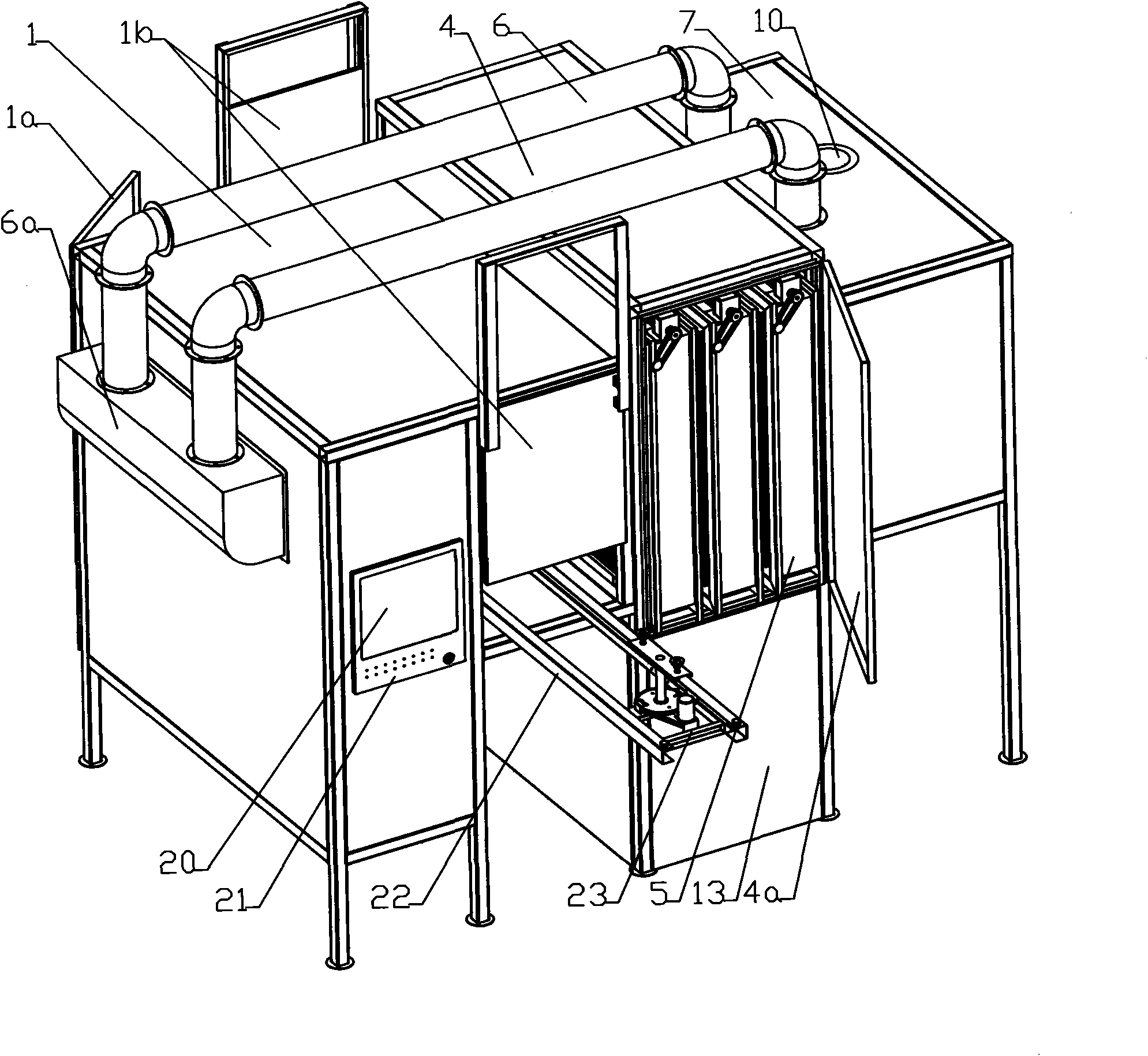

Spray booth for automatically recycling spray mist through electrostatic adsorption

The invention relates to a spray booth for automatically recycling spray mist through electrostatic adsorption, in particular to a spray booth for automatically recycling and treating spray mist generated during spraying operation. The spray booth comprises an electrostatic spray gun, a paint bucket providing paint to the spray gun, an air compressor providing high-pressure air and an enclosure which is provided with a workpiece fixing device and provides operation space for spraying. The enclosure comprises four operation chambers, including a spray chamber, an electrostatic chamber and a fan chamber which run through each other in sequence along the spraying direction, and a recycle chamber which is positioned below the electrostatic chamber and runs through the electrostatic chamber. The operators in the spray booth need to be equipped with masks and inflated protective clothing so that the operators can not breathe the toxic gases in the spray booth and can not have occupational diseases. The spray booth solves the problem that the existing machines have low spraying efficiency, even spraying but high price, low manual spraying cost, flexible operation but heavy labor intensity, poor operation conditions, etc, and has the characteristics of spray mist reduction and environmental protection, reduction of damage to the bodies of the operators and the environment, reduction of waste of paint resources, simple operation, high efficiency, etc.

Owner:杭州腾赢工业设计有限公司

Green making technology of animal tissue paraffin section

A green making technology of animal tissue paraffin section disclosed in the invention aims at providing a technique of making a paraffin section of animal tissue applied to the agricultural university medicine and other majors, characterized by that the type of chemical reagents that are used is limited, the chemical reagents have no toxicity, and dehydrate the tissue thoroughly, accelerate making sections but not lead to excessive contraction and increasement of hardness of the tissue, and substitute dimethyl benzene used in the traditional making technology of the paraffin section which isharmful to human body, so as to eliminate the occupational diseases and environmental pollution caused by dimethyl benzene. The making technology comprises the following steps: carrying out fixation with a fixative solution (100ml of the fixative solution comprises 91 ml 85% alcohol, 4 ml methanol and 5 ml glacial acetic acid ), dehydrating the tissue with graded ethanol, then putting the fixative and dehydrated tissue in a mixed transparent reagent (comprising 14wt% of analytically pour n-butanol, 29wt% of acetone and 57wt% of absolute alcohol ) for standing for 3 hours, then carrying out normal waxing and embedding, using analytically pour turpentine (60 DEG C) for section staining, carrying out dewaxing twice, carrying out hydration under normal temperature, using haematoxylin for staining nuclei, decoloration and bluing, and using eosin for staining, dehydrating until get absolute alcohol, then carrying out air drying, and directly using the gum diluted by turpentine to sealing the section.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

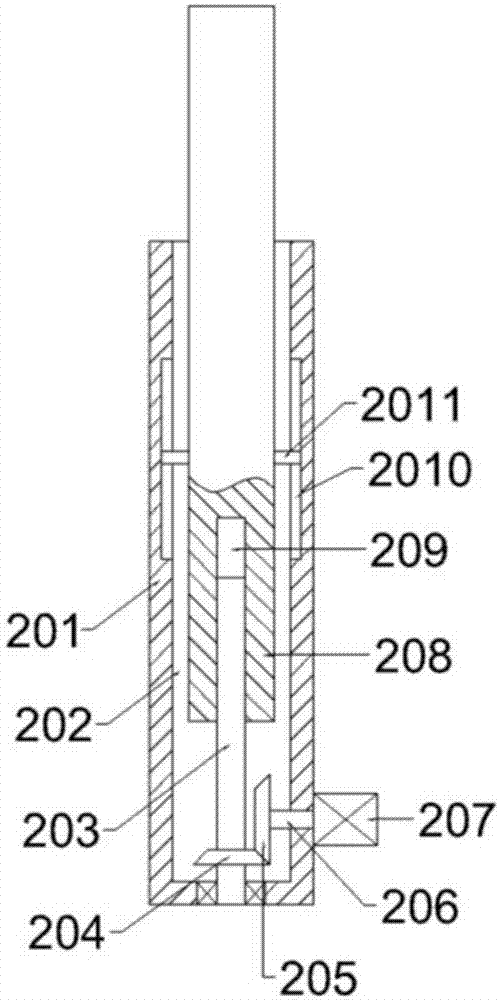

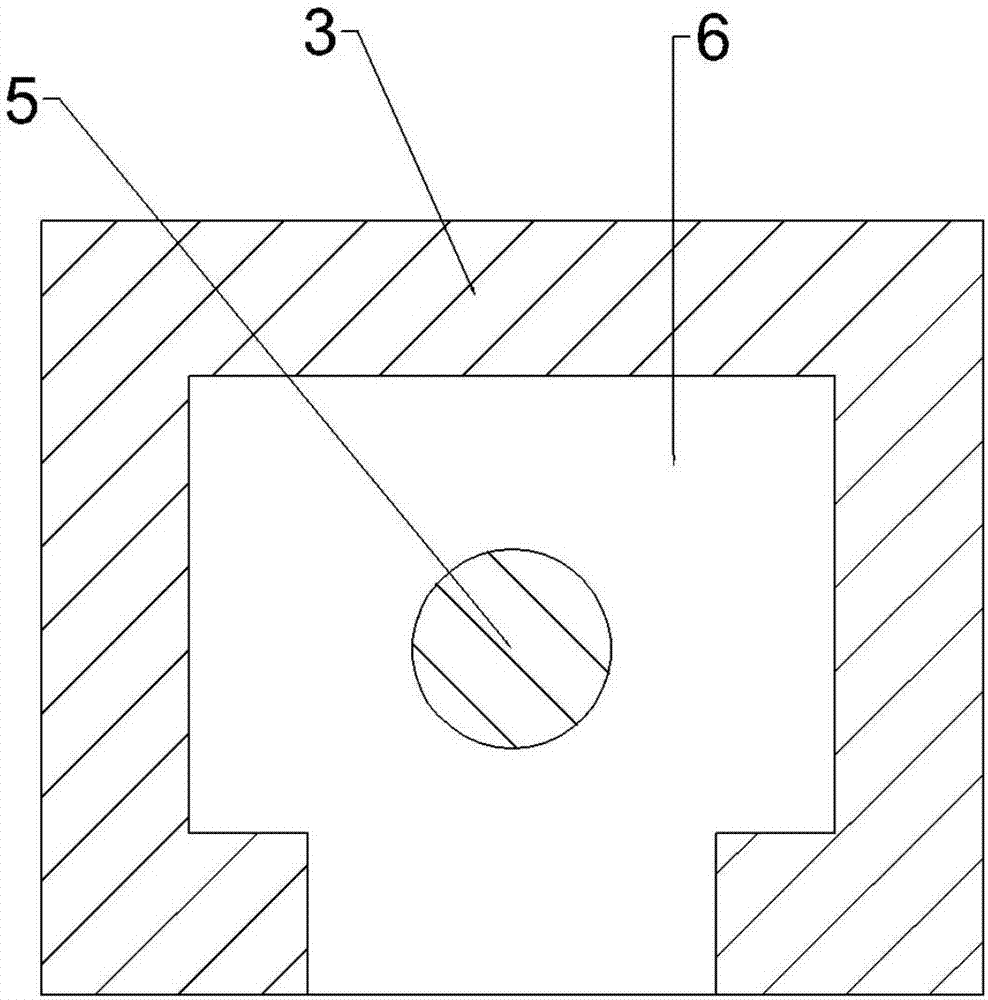

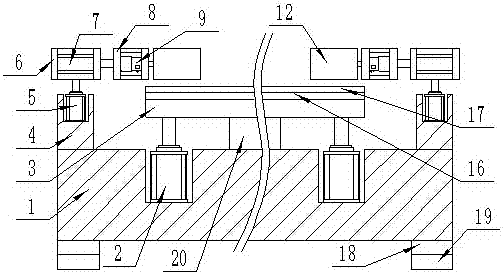

Building artificial stone block integrated machining equipment with reciprocating grinding function

InactiveCN107414625AImprove sanding effectImprove grinding efficiencyGrinding wheel securing apparatusGrinding carriagesProcess efficiencyEngineering

The present invention provides an integrated building artificial stone processing equipment with a reciprocating grinding function, which includes a base, a height adjustment device is fixedly connected to both ends of the base, and a support plate is fixedly connected to the top ends of the two height adjustment devices. The support plate is provided with a moving groove with the opening facing downwards, and the first moving block, the second moving block and the third moving block are arranged in the moving groove from left to right, and the first moving block, the second moving block and the The third moving block is provided with threaded through holes, and the three threaded through holes are jointly threaded with horizontal threaded rods, and the two ends of the horizontal threaded rods are erected at the two ends of the support plate. The invention has the following beneficial effects: it realizes the integrated treatment of grinding, polishing and cleaning, effectively improves the processing efficiency of stone materials, has a high degree of integration, effectively reduces labor input, keeps the operator away from the processing site, and reduces The incidence of occupational diseases among workers has been reduced.

Owner:刘丽

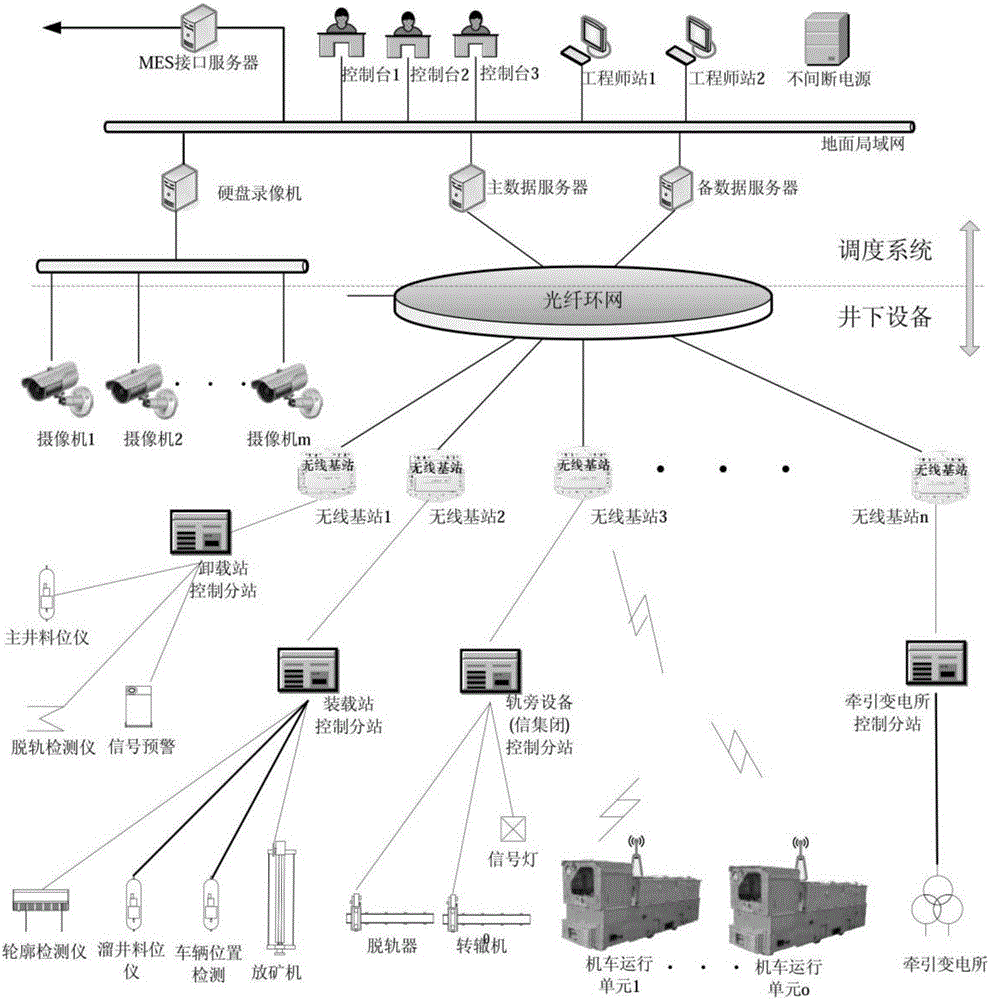

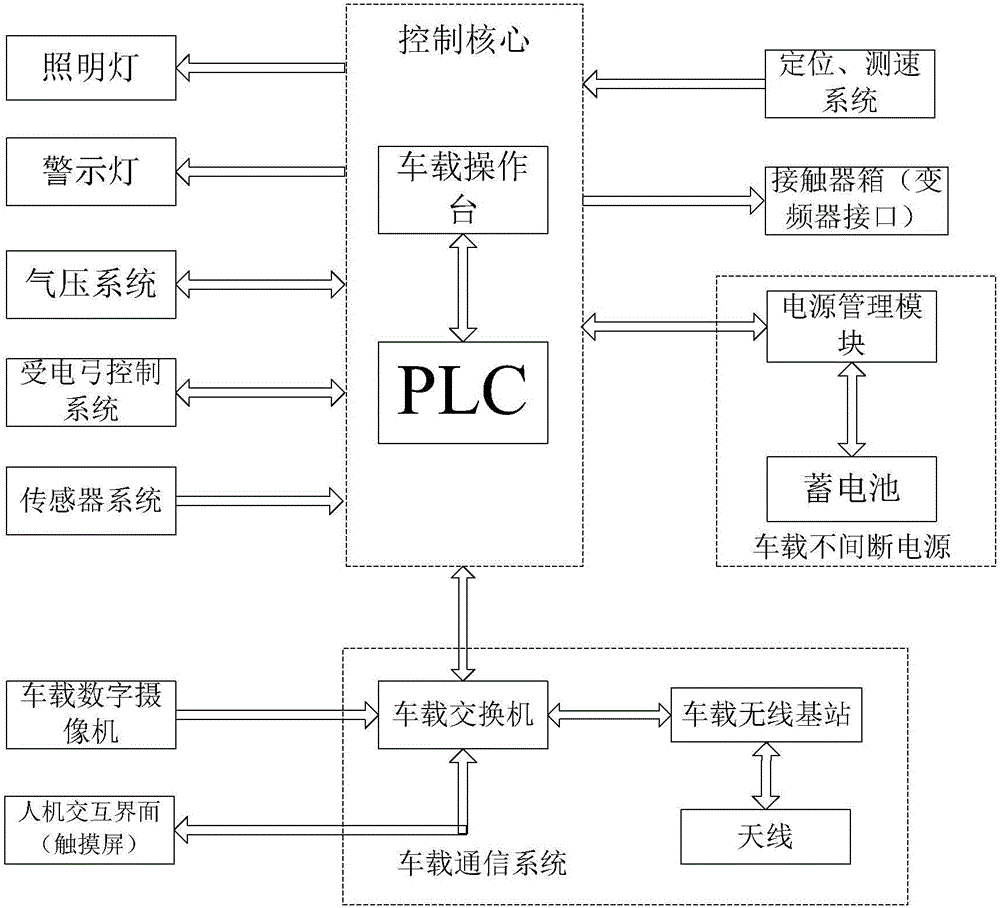

Unmanned transportation system of underground electric locomotive

ActiveCN105892397ARealize automatic liftingRealize automatic drivingProgramme control in sequence/logic controllersIntrinsic safetyCommunications system

The invention discloses an unmanned transportation system of an underground electric locomotive. The unmanned transportation system is characterized by comprising a dispatching system, a locomotive running unit, one or more loading station control units, one or more unloading station control units, a monitoring system, one or more trackside equipment control units, a communication system and a traction power supply monitoring system. The unmanned transportation system realizes the automatic operation of ore loading, transportation and unloading processes, ensures safe and efficient operation of the electric locomotive, simplifies the operation, improves the operation rate of the electric locomotive, and increases the ore yield. The unmanned transportation system integrates operations of underground electric locomotive drivers and ore drawing workers, ensures that the worker work position is transferred to the ground from the downhole, increases the safety, avoids the occurrence of occupational diseases, improves the intrinsic safety level, and improves the manual operation environment; and for a transport planning, the dispatching system automatically generates an order.

Owner:唐山威程科技有限公司

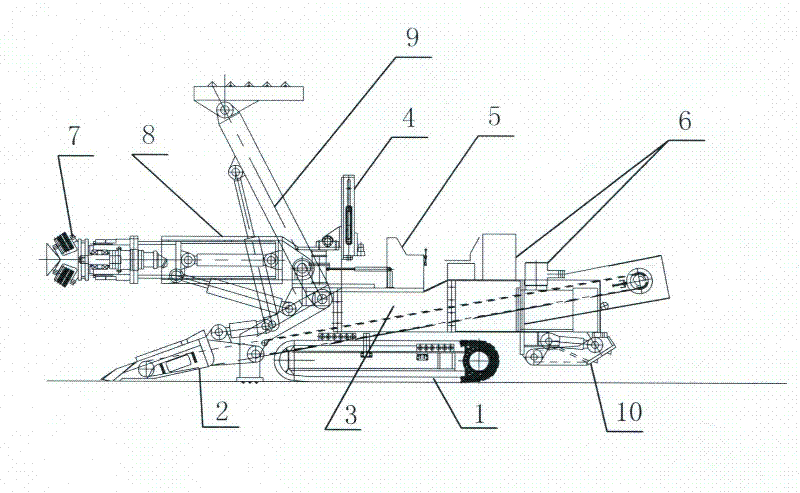

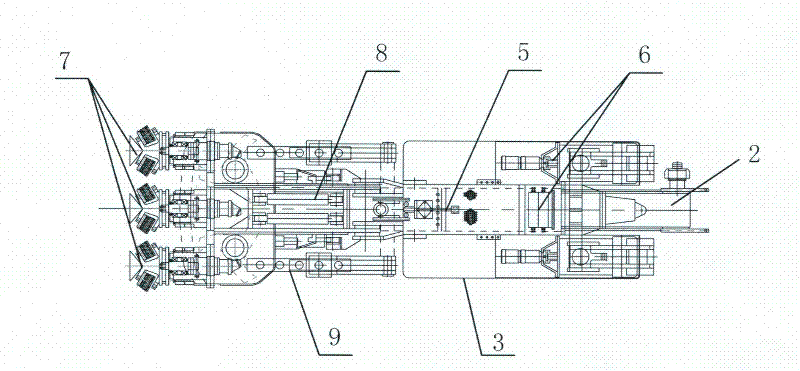

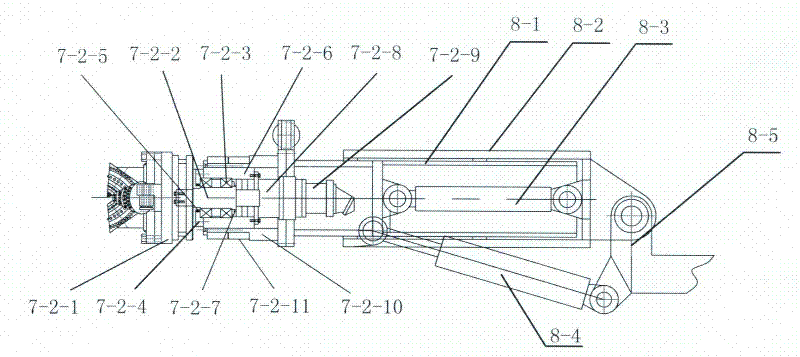

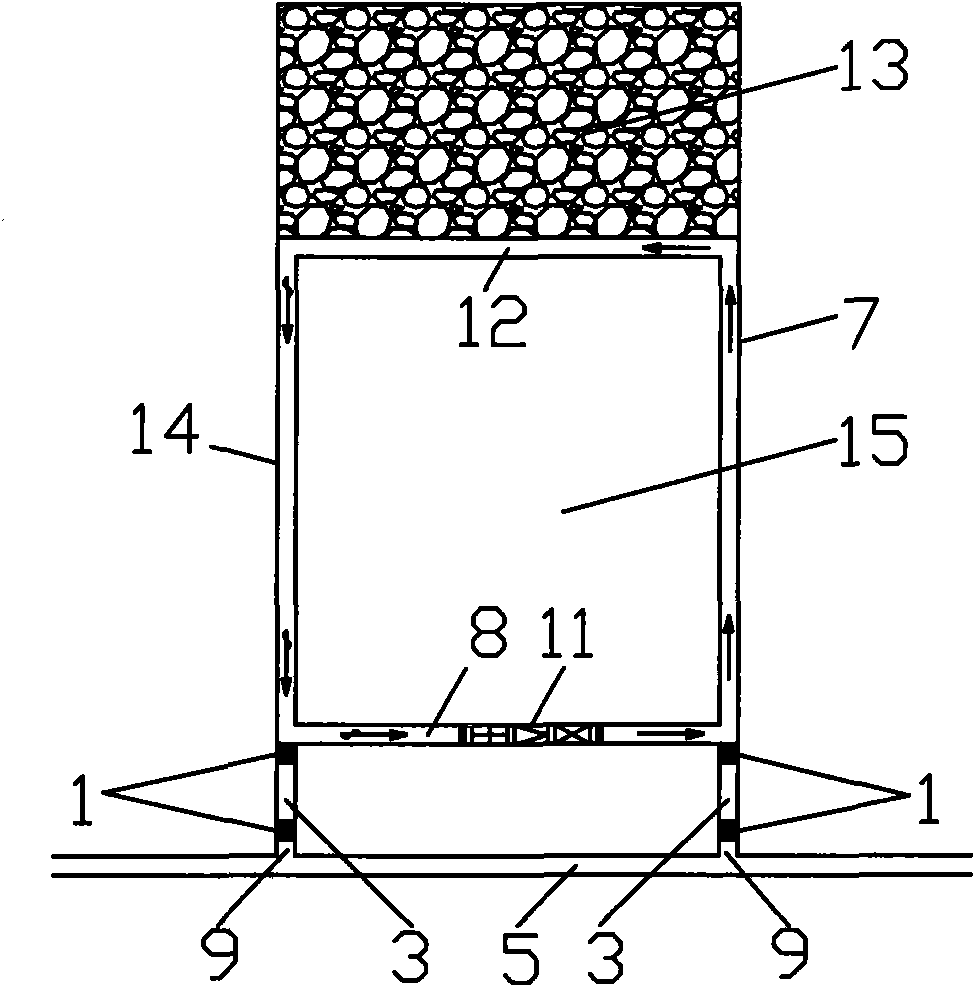

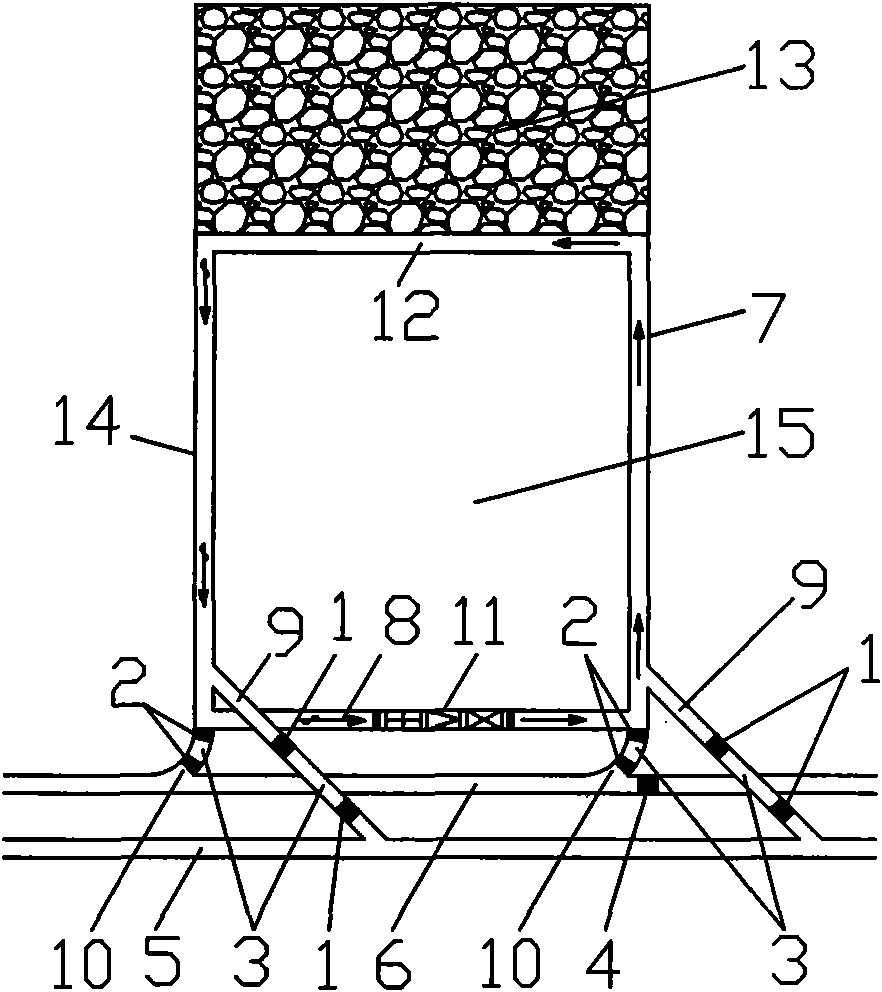

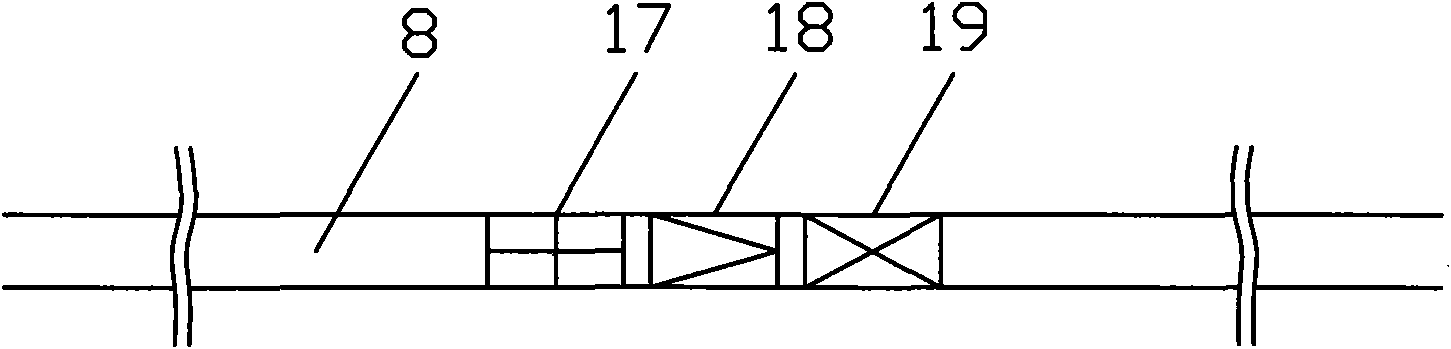

Comprehensive mechanized rock roadway tunneling machine

ActiveCN102364048ASimplify the construction processImprove securityTunnelsDriving meansControl systemUltimate tensile strength

The invention provides a comprehensive mechanized rock roadway tunneling machine, which comprises a caterpillar traveling part, a belt conveyer part, a body mounted on the caterpillar traveling part, a top slope anchor rod anchor cable drill, an operating table and a hydraulic and control system, and is characterized by also comprising at least one cutting device, a vertical swing pushing device, a temporary support, a front fixing device and a rear fixing device, wherein the cutting device is arranged on the vertical swing pushing device and is arranged on the front part of the body; the temporary support and the front fixing device are arranged on the two sides of the front part of the body; the top slope anchor rod anchor cable drill is arranged in the middle of the front part of the body; the operating table and the hydraulic and control system are arranged on the body; and the rear fixing device is arranged in the rear lower space of the body. By using the machine, mechanized construction level is further improved, labor intensity of construction personnel and the construction personnel are reduced, field operation environment is improved, occupational diseases are reduced, and safety and working efficiency are improved; and the machine can be suitable for rock roadway construction of various large, medium and small-sized mines.

Owner:马晓山

Coal mining method for co-mining gas in mine

ActiveCN102061918ALower oxygen levelsSuppress spontaneous combustionUnderground miningSurface miningHigh concentrationHigh pressure

The invention relates to a coal mining method for co-mining gas in a mine. A method for injecting nitrogen in a sealed manner is adopted to close an upper drift and a lower drift of a stope face to ensure that the concentration of gas in a closed space is over 20%, the concentration of oxygen is lower than 12%, so that the explosive hazard of the gas is eliminated, and high-concentration gas in a roadway is drained so as to be utilized. A safety pressure-relief roadway needs to be remained in the mine with dangers of coal and gas outburst, and is used for releasing high-pressure gas generated by coal and gas outburst, and improving disaster resistant capability of the mine. An air regulating system is arranged in the closed space for regulating air, and a worker operates in the closed space under the condition that the safety protection is well done. Due to adoption of the method, the problem of gas explosion is solved fundamentally, the utilization ratio of gas is improved, fire disasters of the coal mine are eliminated fundamentally, the oxidation corrosion of various metal equipments is reduced, and simultaneously the equipment does not have anti-explosion requirements. As workers breathe air carried per se, the occurrence of respiratory occupational diseases is avoided. Therefore, the coal mining method for co-mining gas has extremely large popularization value.

Owner:CHINA UNIV OF MINING & TECH

Environmentally friendly bio-soluble refractory fibre and production process thereof

InactiveCN101619508AHarm reductionPrevent cancerInorganic material artificial filamentsFilament/thread formingFiberSilicosis

The invention relates to an environmentally friendly bio-soluble refractory fibre and a production process thereof; the fibre comprises the following components according to the parts by weight: 58-76 parts of silicon dioxide, 24-38 parts of calcium oxide and 4-20 parts of magnesium oxide. The production process comprises the following steps: A. resistance furnace melting: silicon dioxide, calcium oxide and magnesium oxide are placed in a resistance furnace to melt to liquid at a raw material melting temperature of 1500-1800 DEG C; B. thread throwing: throwing the molten liquid to threads with high speed whirling rollers at a fiber forming temperature of 1400-1500 DEG C. The production process has the advantage that the process has little harm to human body and can effectively prevent occupational diseases such as silicosis and the like or canceration which is directly caused.

Owner:MORGAN KAILONG (JINGMEN) THERMAL CERAMICS CO LTD

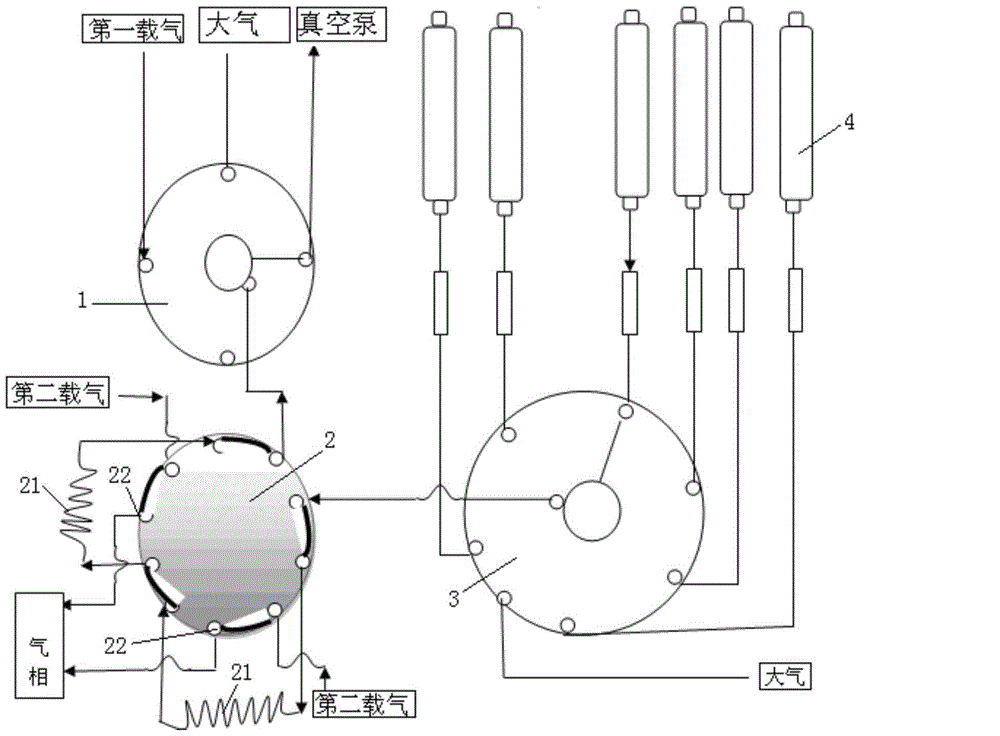

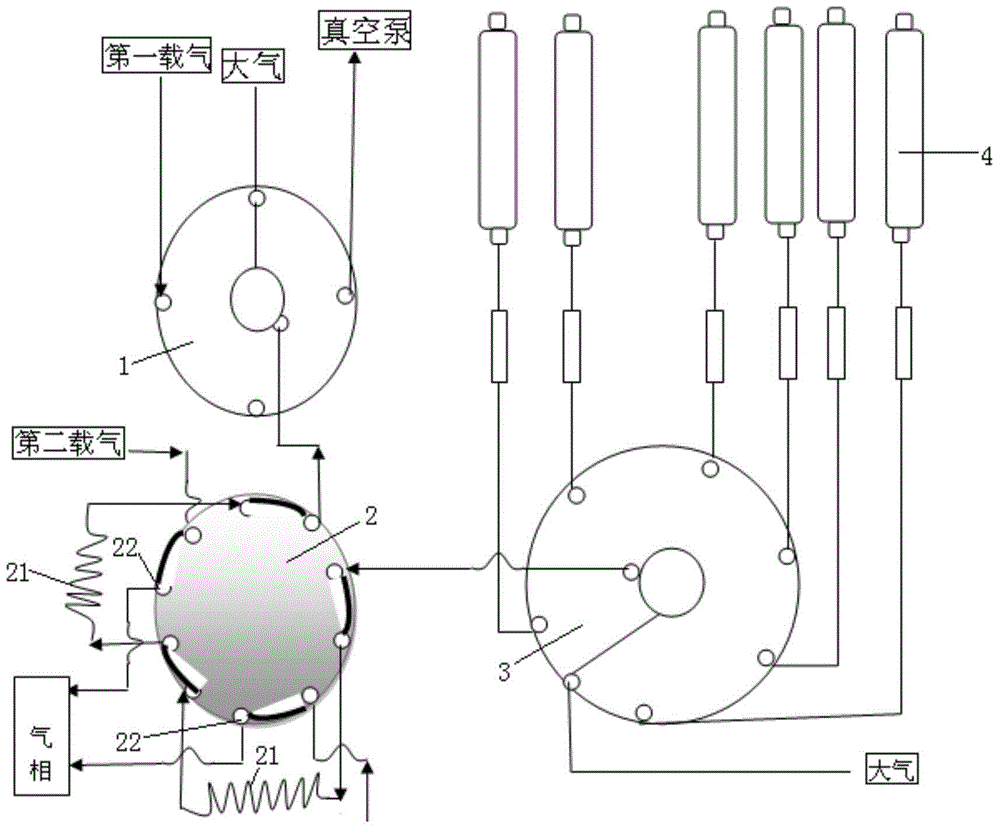

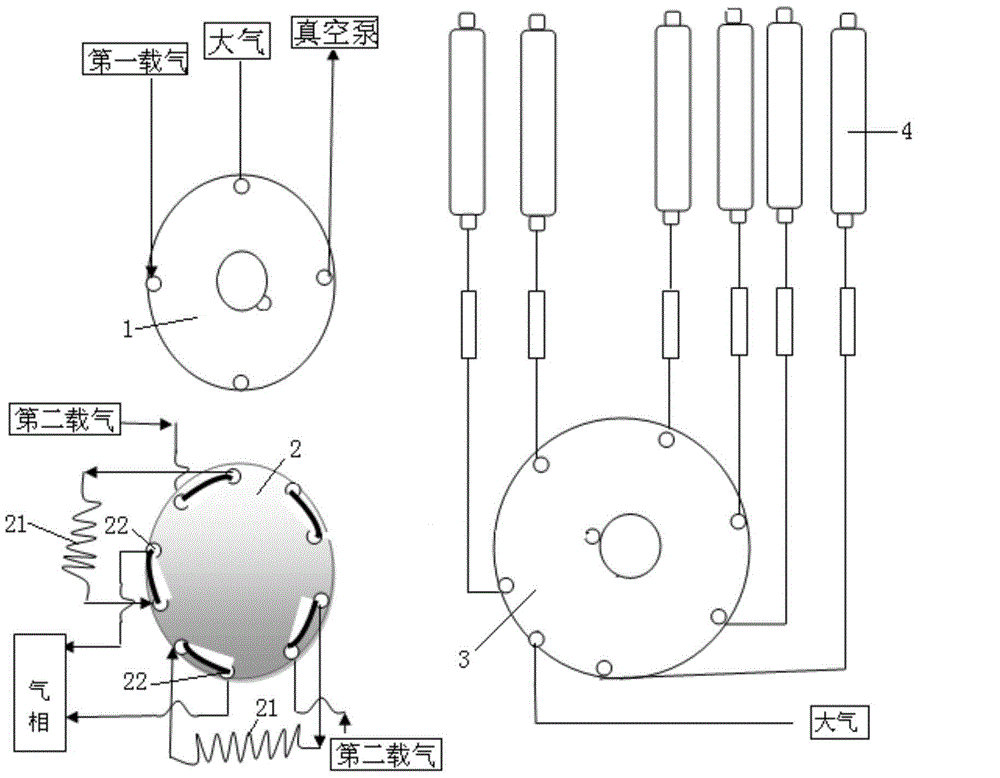

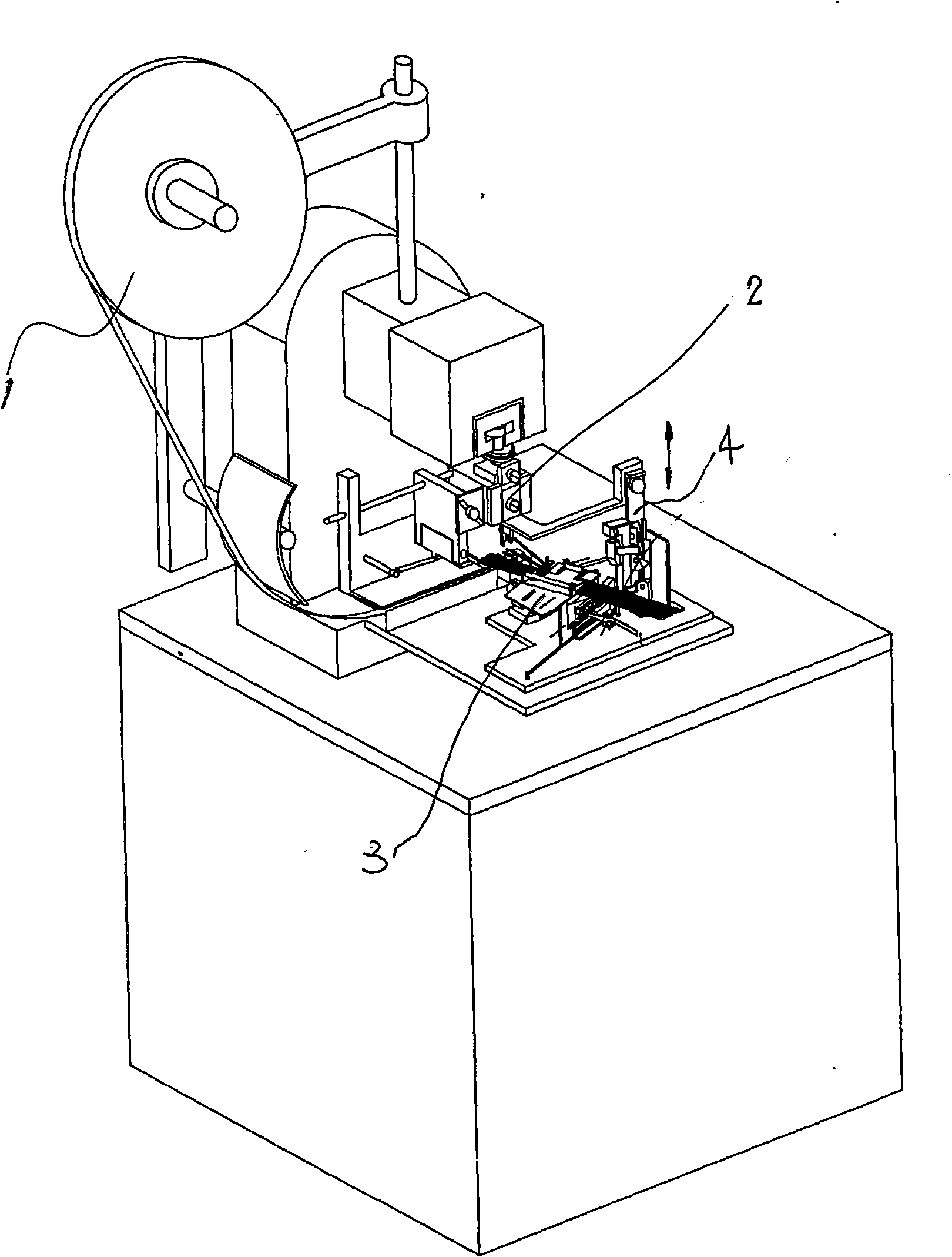

Automatic gas sample injection apparatus and use method thereof

InactiveCN104914198AAccurate injection volumeGood repeatabilityComponent separationInjection volumePetrochemical

The present invention relates to the technical field of detectors, more particularly to an automatic gas sample injection apparatus and a use method thereof. The automatic gas sample injection apparatus comprises a first selection valve, a switching valve and a second selection valve, wherein the first selection valve can be connected with the switching valve, a first carrier gas, atmosphere or a vacuum pump, the switching valve can be connected with a second carrier gas, a plurality of detection gas inlets, a plurality of quantitation rings or the second selection valve, and the second selection valve can be connected with atmosphere or a gas collection device. Compared with the automatic gas sample injection apparatus in the prior art, the automatic gas sample injection apparatus of the present invention has the following characteristics that: the automatic gas sample injection apparatus is the full-automatic sample injection without human intervention when using the gas bag or syringe to perform the sampling, the sample injection volume is accurate, the repeatability is good, the use and the maintenance are convenient, and the apparatus can be widely used in the fields of environmental monitoring centers, Centers for Disease control and Prevention, occupational disease prevention and treatment, petrochemical industry, and the like.

Owner:SHANGHAI LANBO TRADE CO LTD

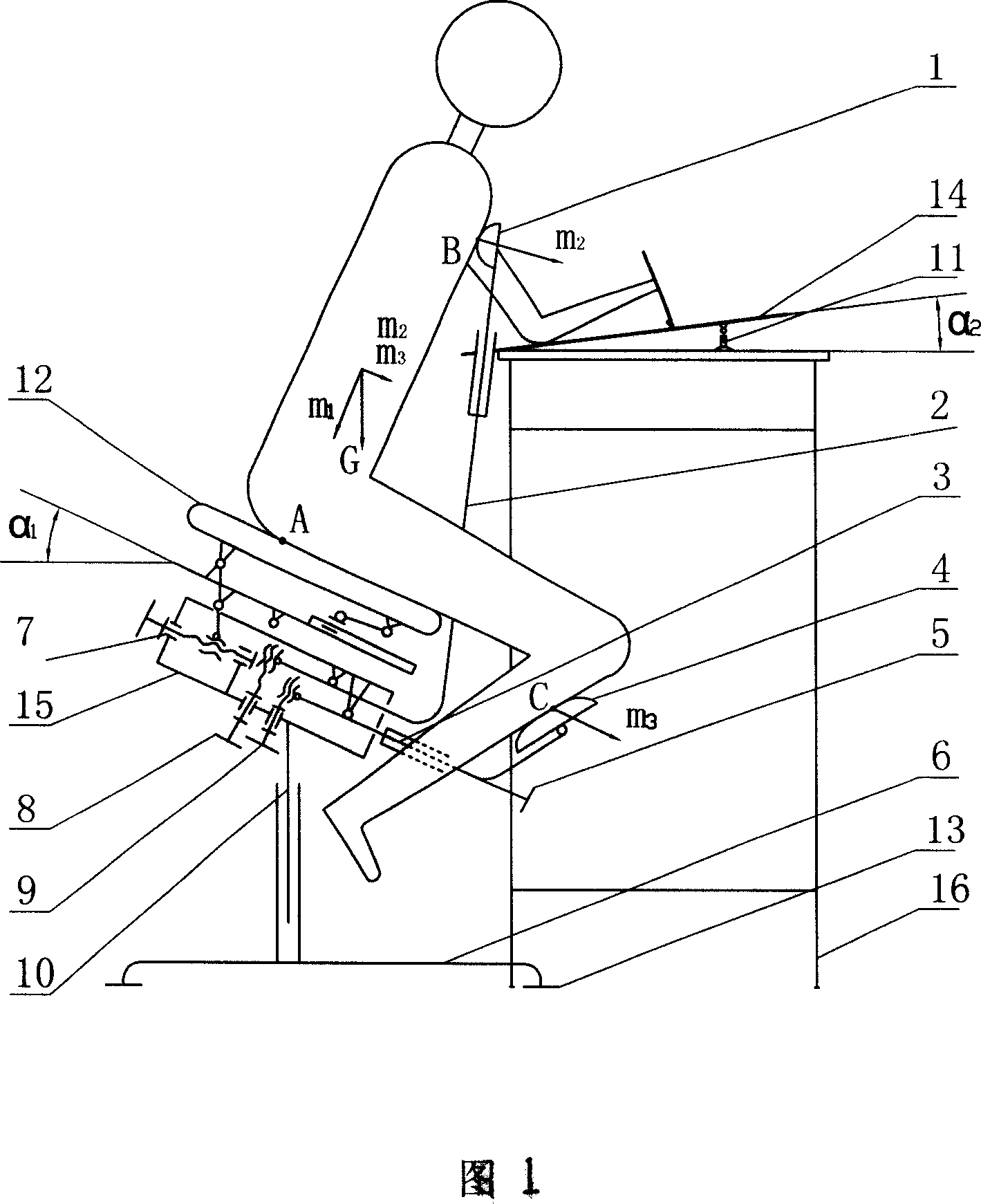

Sitting position correction health chair

InactiveCN101011204APrevention and treatment of myopiaAddress bad sitting habitsStoolsSchool benchesEngineeringChest protector

The invention relates to a state-correct health-care chair, comprising a base and a seat plate, wherein, the seat plate has a backward lifted angle; the front of seat plate is arranged with the chest protector for supporting the chest and the leg protector for supporting the legs. The invention has three-direction bearing angles and multipoint support to be adjusted freely in independent coordinate, therefore, the normal curvature of spine and the eye distance can be held in incline state, to improve the health of peope.

Owner:倪伟

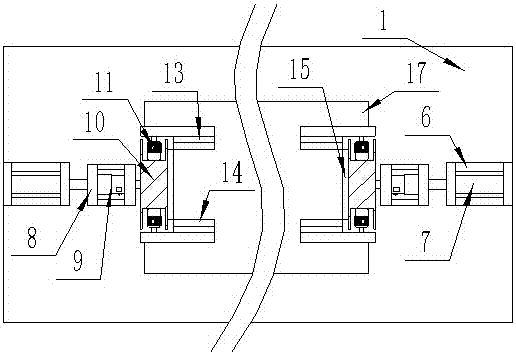

Auxiliary lifting device for material processing

InactiveCN107297682AEasy to adjustReduce Occupational DiseasesEdge grinding machinesGrinding drivesHydraulic cylinderEngineering

The invention discloses an auxiliary lifting device for material processing, which comprises a base, and two pairs of cylinder placement grooves are opened on the upper wall of the base, and the first hydraulic cylinder with the telescopic end facing upward is fixed in the cylinder placement groove, and the two pairs of cylinder placement grooves are fixed in the cylinder placement grooves. The telescopic end of the first hydraulic cylinder is fixed to the supporting plate, and a pair of installation rods are fixed on the upper wall of the base and located on both sides of the two pairs of cylinder placement grooves. End up second hydraulic cylinder. According to the invention, the workers can be adjusted at will according to their own heights, which is convenient for people to grind, and reduces the occurrence of occupational diseases of the workers. The automatic lifting, stepping up, rotating and changing surfaces can liberate manpower and is convenient to use.

Owner:肇庆市智高电机有限公司

Usage of human lysozyme in preparation of dermics

InactiveCN1593652ARich sourcesSimple preparation processPeptide/protein ingredientsAerosol deliveryAllergic reactionSkin lesion

The invention relates to the use of human lysozyme in pharmaceutical industry, in particular the use in preparing medicines for treating dermatosis, infection and ulceration caused by bacteria, fungus, viruses, allergic reaction, and occupational diseases, physical diseases, nerve dysfunctional diseases, and immunity diseases. The invention exploits the novel use of human lysozyme in medical treatment, the gene recombination lysozyme has rich source, the invention also features simple process for manufacturing, and ease in use.

Owner:张华

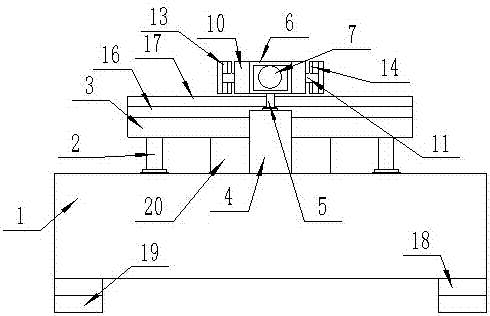

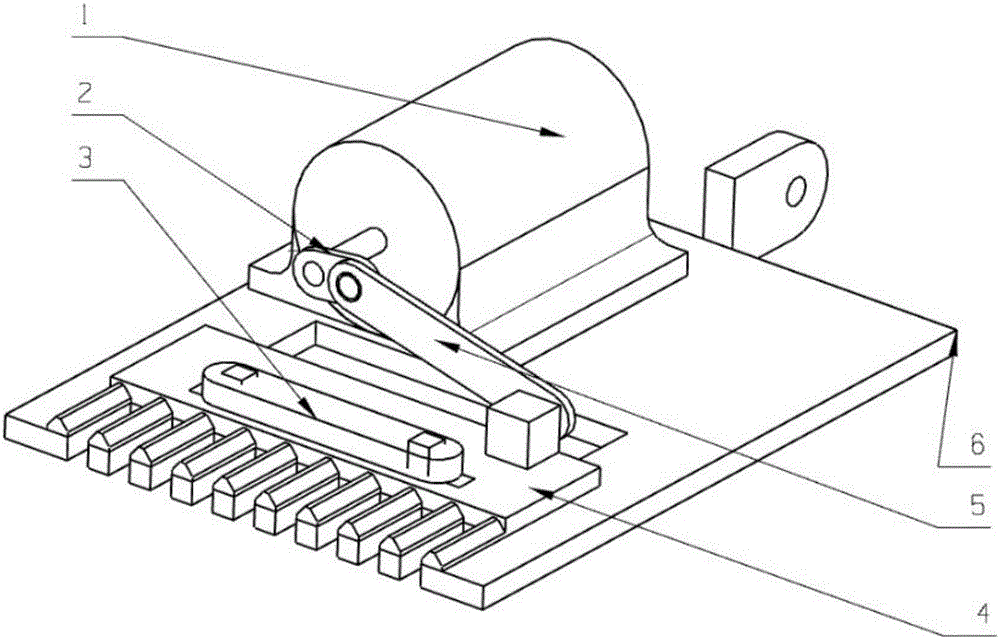

Cable terminal bonding machine

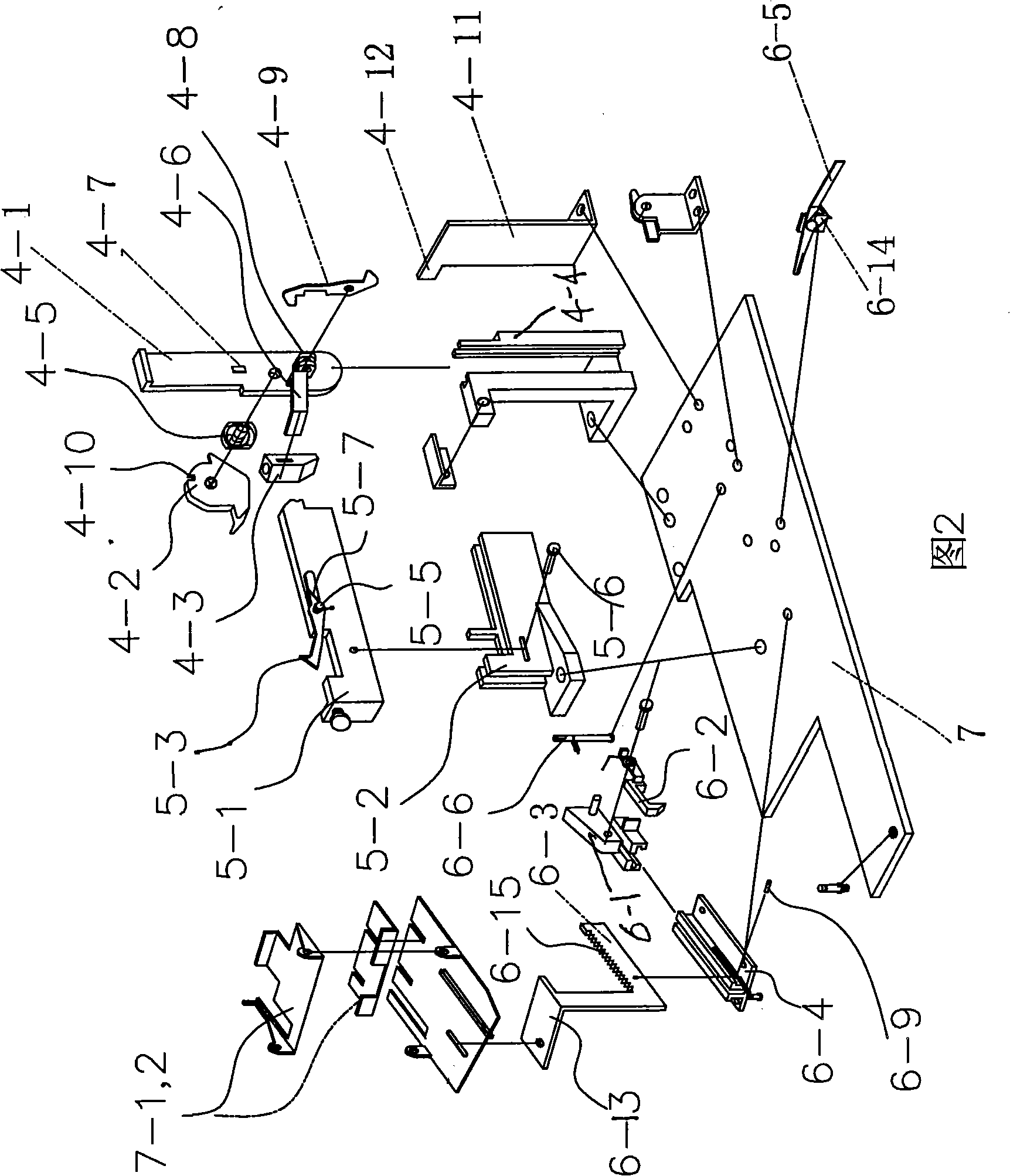

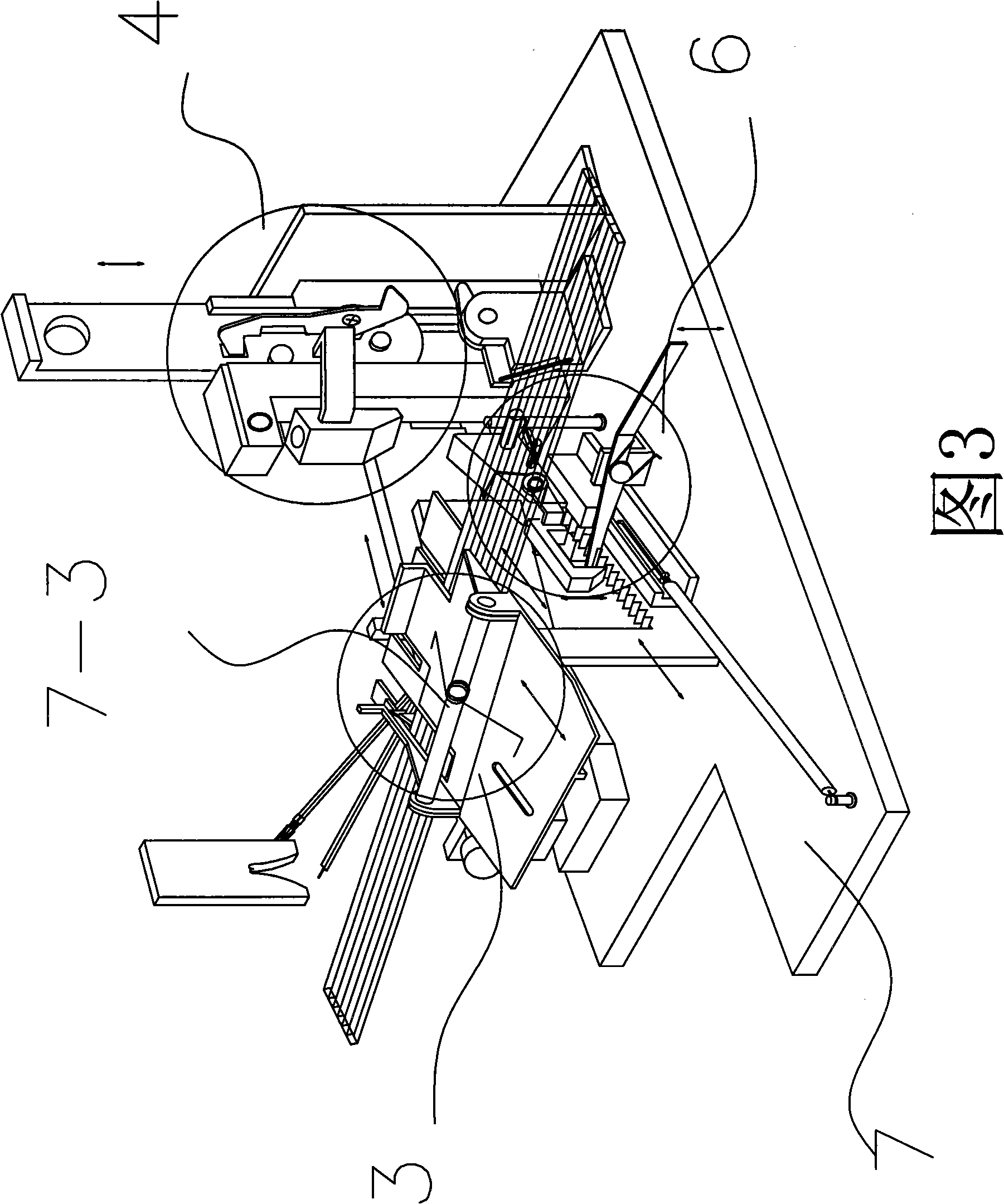

InactiveCN101335417AAvoid the hidden dangers of occupational diseasesImprove pass rateLine/current collector detailsPass rateSemi automatic

The invention relates a wire harness terminal pressing machine which comprises a terminal feeding mechanism and a terminal pressing mechanism. The wire harness terminal pressing machine is characterized in that the pressing machine also comprises a wire harness clamping device, a cam mechanism, a wire dividing mechanism, a stepping mechanism and a working table; the cam mechanism consists of a cam bracket, a cam, a bump and a bracket rail, the wire dividing mechanism consists of a sliding bump, a bump rail and a line drawing hook, and the stepping mechanism consists of a slider, a pallet, a claw plate, a claw plate rail and a limiting plate; the ram bracket of the ram mechanism is connected with the terminal pressing mechanism through a connecting plate, the ram which moves up and down on the ram mechanism contacts with a bevel-shaped bump of the sliding bump of the wire dividing mechanism, and the bump of the cam mechanism contacts with the slider of the stepping mechanism. The wire harness terminal pressing machine has the advantages that manual operation is shifted to the semi-automatic mechanically integrative operation; the pass rate of the production by the machine is high; no long time is required by an operator to get familiar with the process and the operator can master the operation in a short term; the risk of occupational disease of the operator can be prevented.

Owner:金周汶

Small mining combined dust remover

InactiveCN102003200ASuction in timeImprove dust removal efficiencyCombination devicesDust removalHydraulic motorEconomic benefits

The invention claims a small mining dry combined dust remover, which is in turn provided with an air inlet component, a centrifugal induced draught fan, a cylindrical dust remover and a cylindrical filter in a flowing direction of the air. The air inlet component is in the front of the centrifugal induced draught fan. An air wheel of the induced draught fan is driven by a hydraulic motor. The centrifugal induced draught fan comprises a casing, a mounting base and a centrifugal air wheel. The cylindrical dust remover is a cylindrical small-cyclone dust remover, in which a plurality of small-cyclone separators are arranged perpendicular to an axis of the cylinder. The combined dust remover has high dust removing efficiency; and the hydraulic system of a development machine drives the hydraulic motor draught fan to work. Furthermore, the cylindrical dust remover is shaped to be mounted on the development machine so as to cooperate with the development machine. The dust remover can timely suck and remove the dust during the cutting of the development machine safely and reliably, so the dust remover is very suitable for use in mining, tunnel and subway operation. The application of the technology can change operating environments, reduce the occurrence of occupational diseases and bring greater economic benefits to enterprises.

Owner:杭州洪裕重工机械有限公司

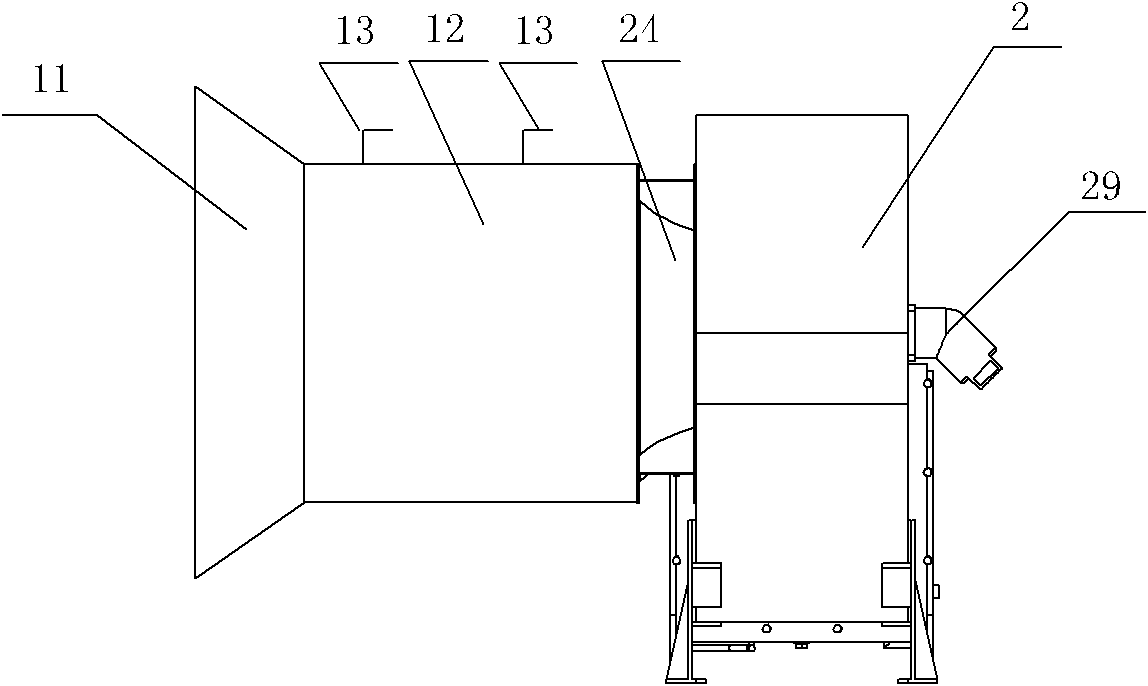

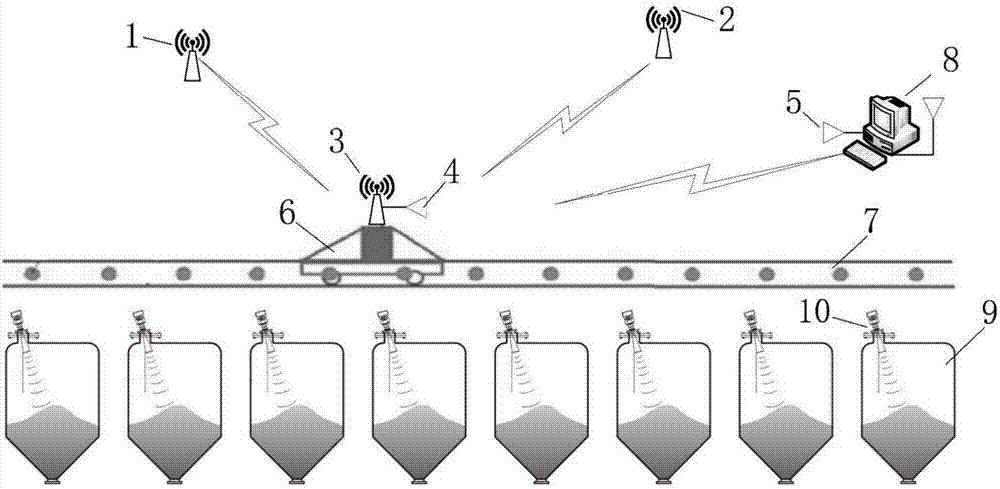

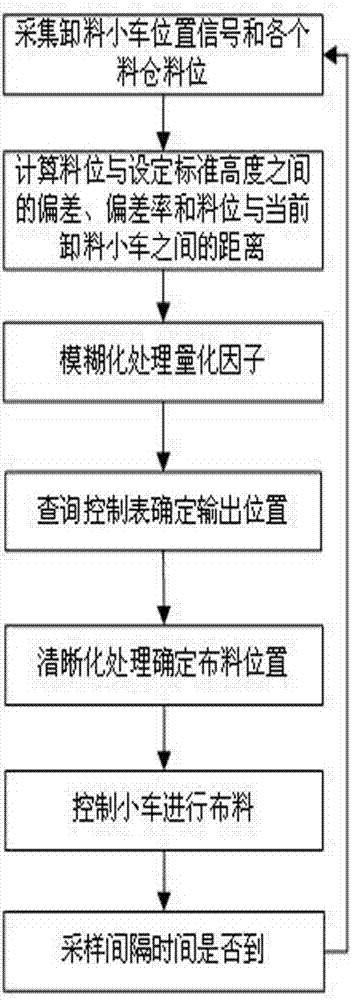

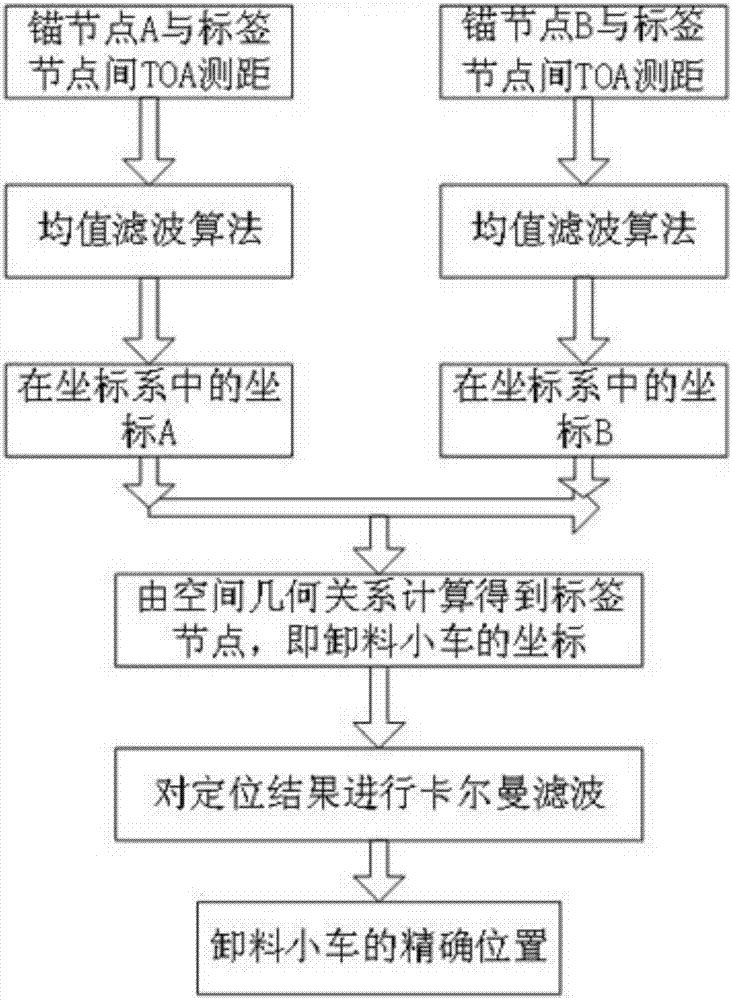

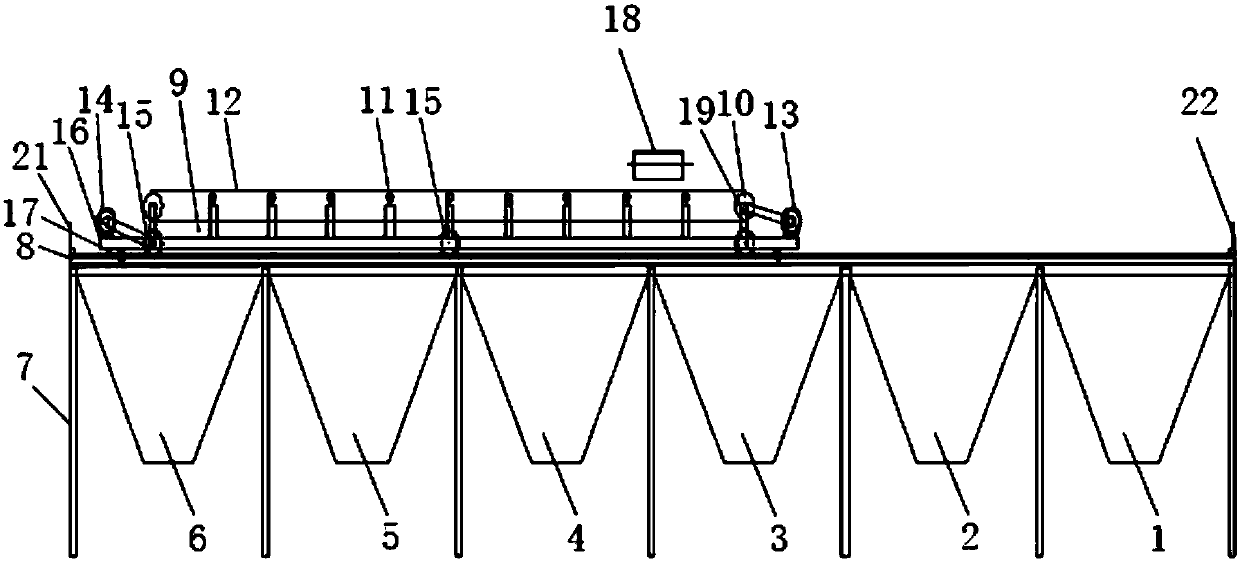

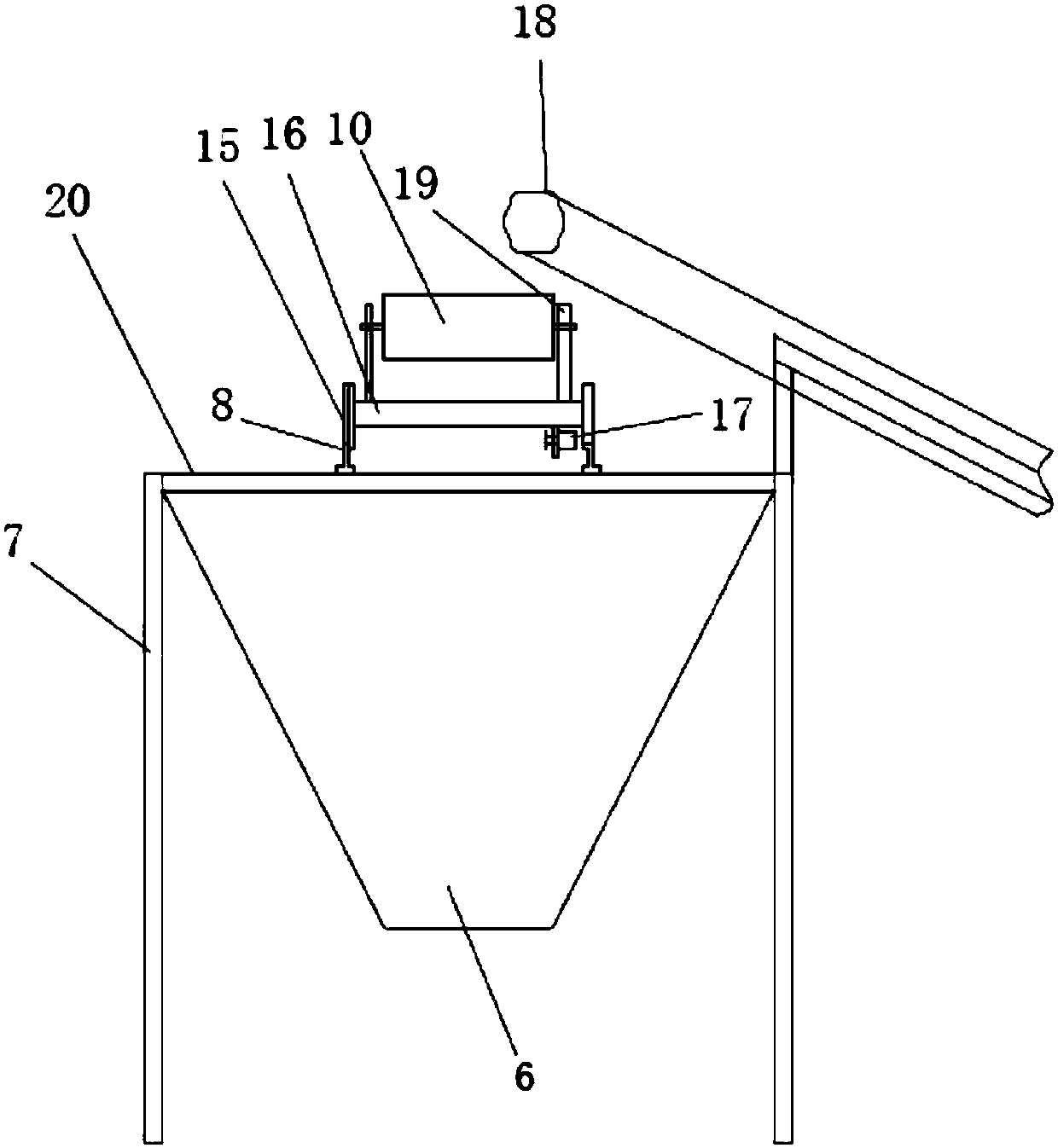

Automatic material distribution device and method for stock bins

InactiveCN107416541AKeep healthyRealize unattendedLarge containersControl devices for conveyorsEconomic benefitsEngineering

The invention belongs to the technical field of material distribution methods and particularly relates to an automatic material distribution device and method for stock bins. The automatic material distribution device for the stock bins comprises the stock bins, a belt conveyor arranged above the stock bins and a belt conveyor discharging trolley arranged on the belt conveyor. The automatic material distribution bin is characterized by further comprising a belt conveyor discharging trolley positioning device and a stock bin material position detection device. According to the automatic material distribution device and method for the stock bins, the full-automatic uniform material distribution can be achieved, the empty bin or the ore pressing accident is avoided, the unattended purpose can be achieved, the workers are downsized, the possibility of occupational diseases is lowered greatly, the health of the operation workers is guaranteed, and the purposes of downsizing the staff and improving the efficiency are achieved; and in addition, by the adoption of the automatic material distribution device and method for the stock bins, the economic benefits are increased, and the reliable reference can be provided for the daily overhauling work, so that the mechanical and electrical accidents are reduced, and the cost input is reduced.

Owner:ANSTEEL GRP MINING CO LTD

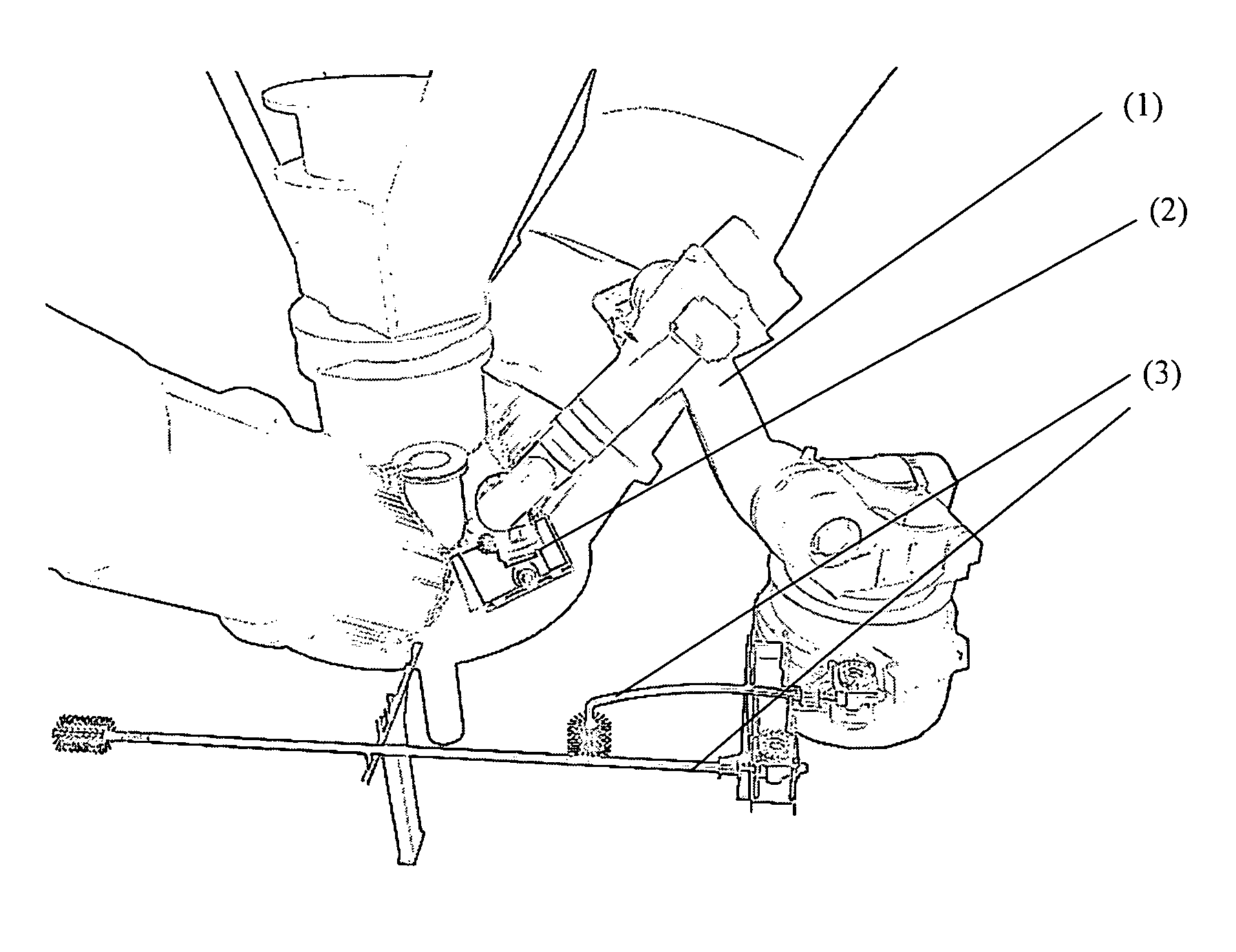

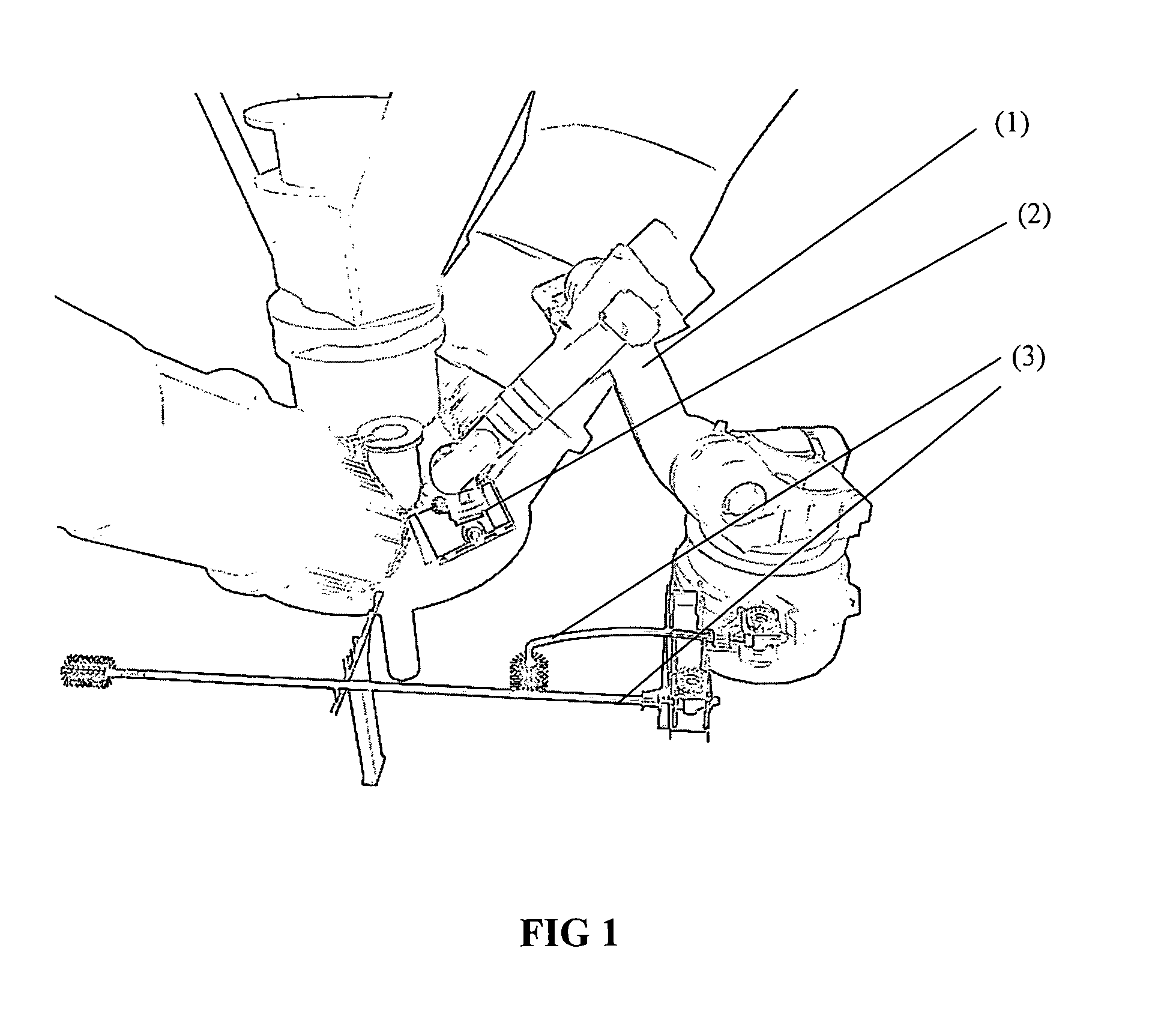

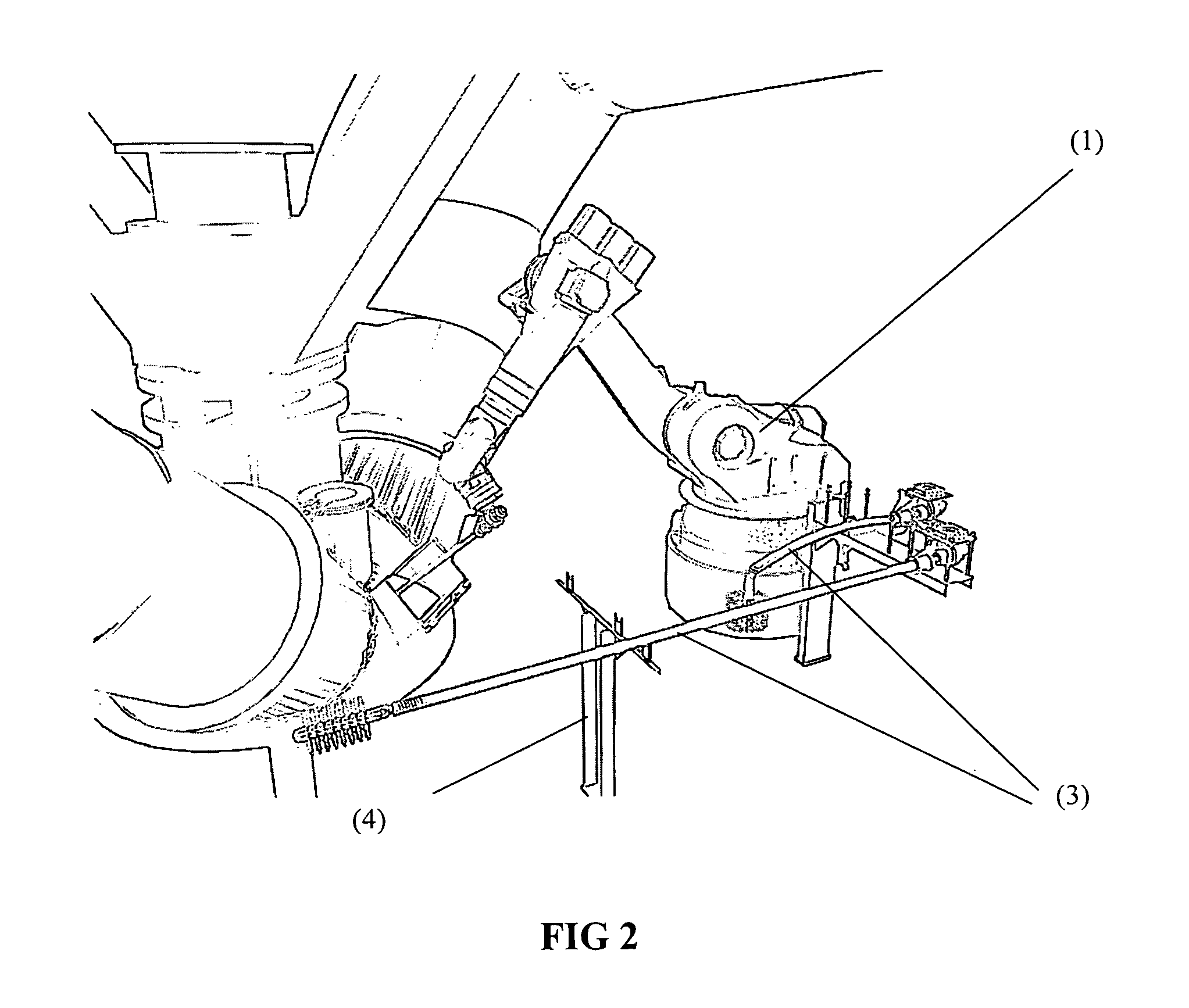

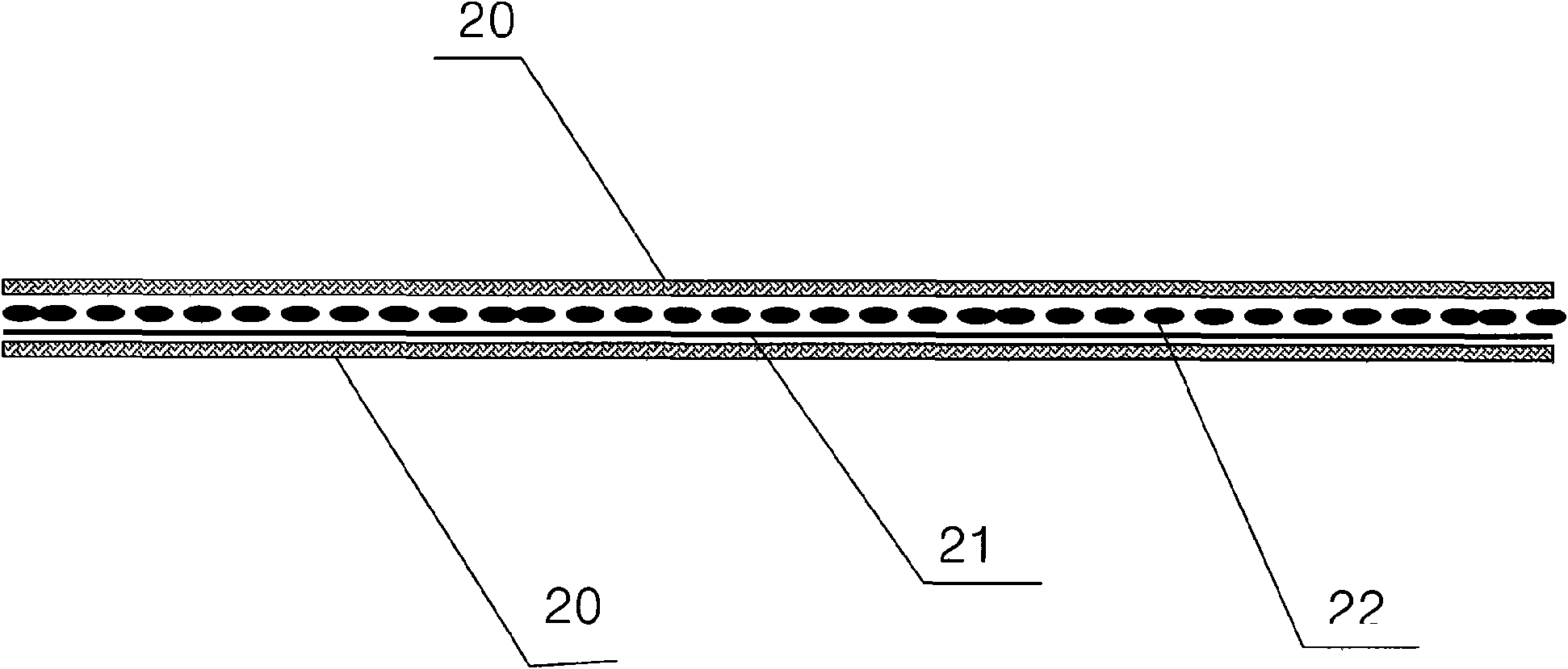

Robot system and method for copper concentrate injector cleaning in the flash furnace

At present, the flash furnace due to an increase in fusion forms accretions in the burner which causes that the “air umbrella” does not develop and in order to clean it manually the load must be lowered for safety reasons. One of the major disadvantages of all the tasks associated to the cleaning process is the exposure of the personnel to harsh environmental conditions. This in the medium and long term could generate serious occupational diseases to the operators in charge of carrying out such activity. Due to the above, a robot system and method have been developed for the automated cleaning of the burner thus minimizing the decrease of the load. The robotic system is composed mainly of an anthropomorphous robotic manipulator of at least 5 degrees of freedom, and a gripping mechanism which allows to take, manipulate and release several tools from a tool holder to carry out the cleaning process of the smelting furnace.

Owner:HOWARD HUGHES MEDICAL INST +1

Fireworks safety firing cable and manufacturing method thereof

InactiveCN101619009APut an end to the malpractice scattered in the production siteReduction of more hazardous processesFusesYarnOrganic solvent

The invention discloses a fireworks safety firing cable and a manufacturing method thereof. The fireworks safety firing cable comprises an ignition-composition core and cotton yarn attached with firing cable compositions; and the manufacturing method is mainly characterized by comprising the following steps: adding an appropriate amount of organic solvents into the prior firing cable compositions, and evenly stirring to enable the compositions to be in a thick fluid flurry state; and evenly attaching the fluid slurry onto priming cotton yarn as a firing cable composition core by improving the structure of a priming machine. The invention has the advantages that a plurality of process flows with higher hazards are reduced in the processing process of firing cable compositions, the defect that composition powder is interspersed in production places is avoided in the cotton yarn wrapping process, and the production security is improved qualitatively; the quality of the product is improved, and the phenomena of composition interruption, shortage and leakage are prevented from generating; no dust pollution is generated in production and application, and production personnel are avoided from being injured by occupational diseases, such as silicosis, and the like.

Owner:鲁向华

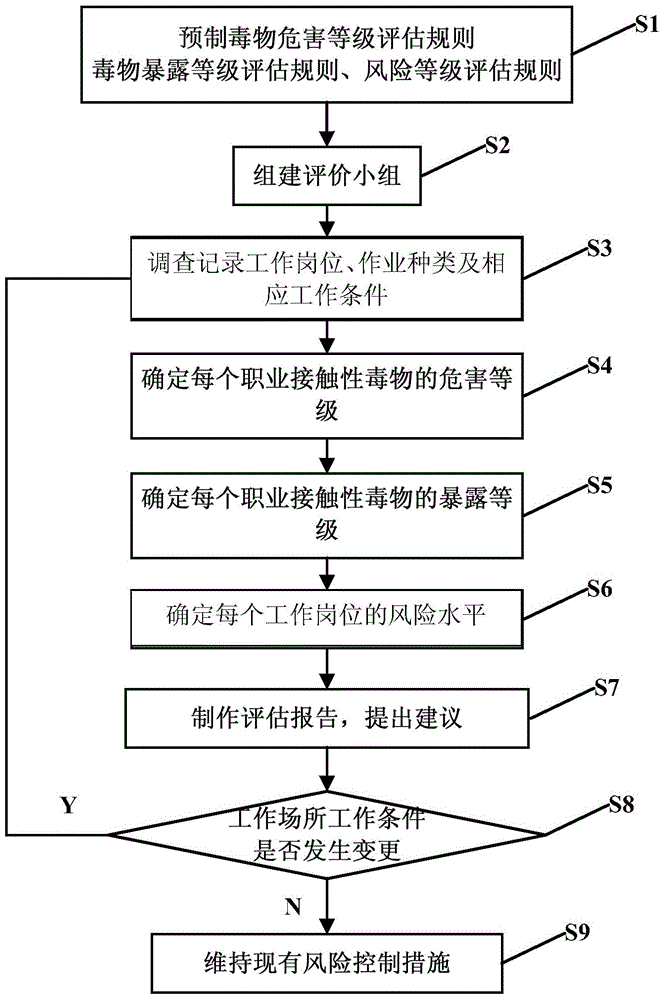

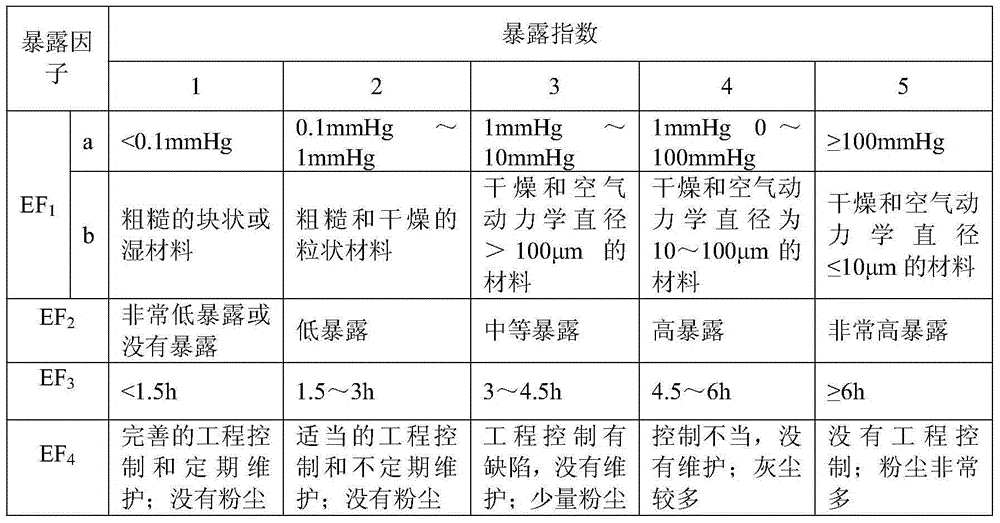

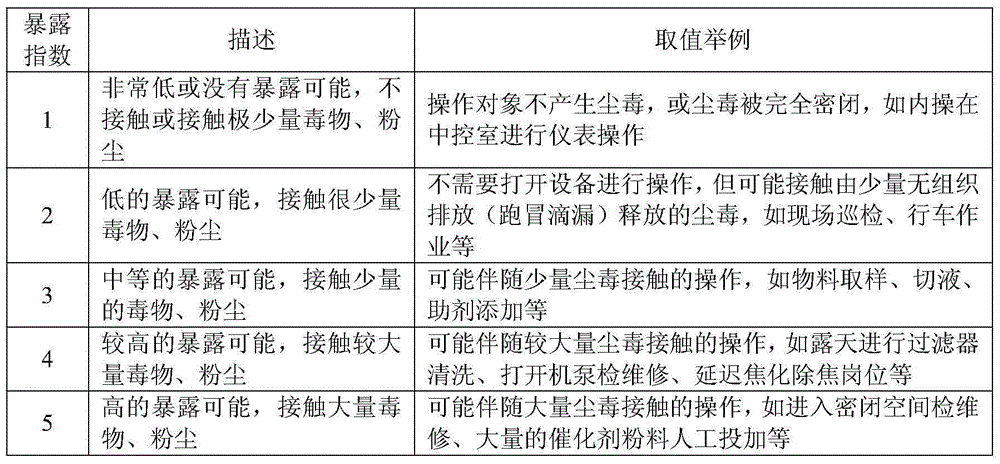

Chemical poison occupational hazard risk grade evaluation method for petrochemical enterprises

ActiveCN104091086ALow costImprove Occupational Health Management EfficiencySpecial data processing applicationsEngineering controlsEngineering

The invention discloses a chemical poison occupational hazard risk grade evaluation method for petrochemical enterprises, and relates to the field of occupational health. The method includes the following steps of investigating and recording operating posts and corresponding operation types in a place to be evaluated, investigating and recording the working time, occupational exposure poisons, the working equipment airtight degree, working equipment operation time of workers and an engineering control measure corresponding to each operation type, determining the hazard grade and the exposure grade of each occupational exposure poison, obtaining the risk grade of each occupational exposure poison in each operation type and risk level grades of the corresponding operating posts according to the poison hazard grades, the poison exposure grades and risk grade evaluation rules, and making a risk evaluation report and a risk control and management report. According to the chemical poison occupational hazard risk grade evaluation method for the petrochemical enterprises, occupational disease prevention resources are used reasonably, the occupational health management efficiency is obviously improved, and the occupational health prevention and control cost of the petrochemical enterprises can be effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

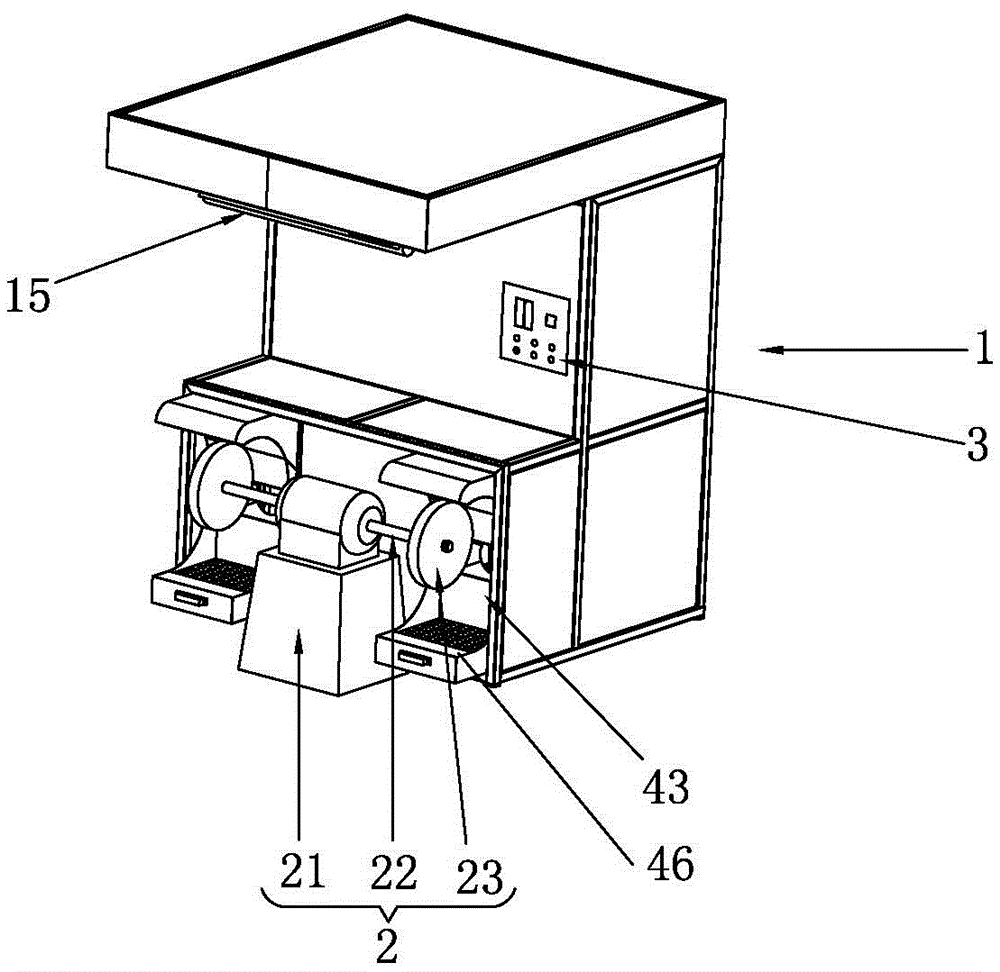

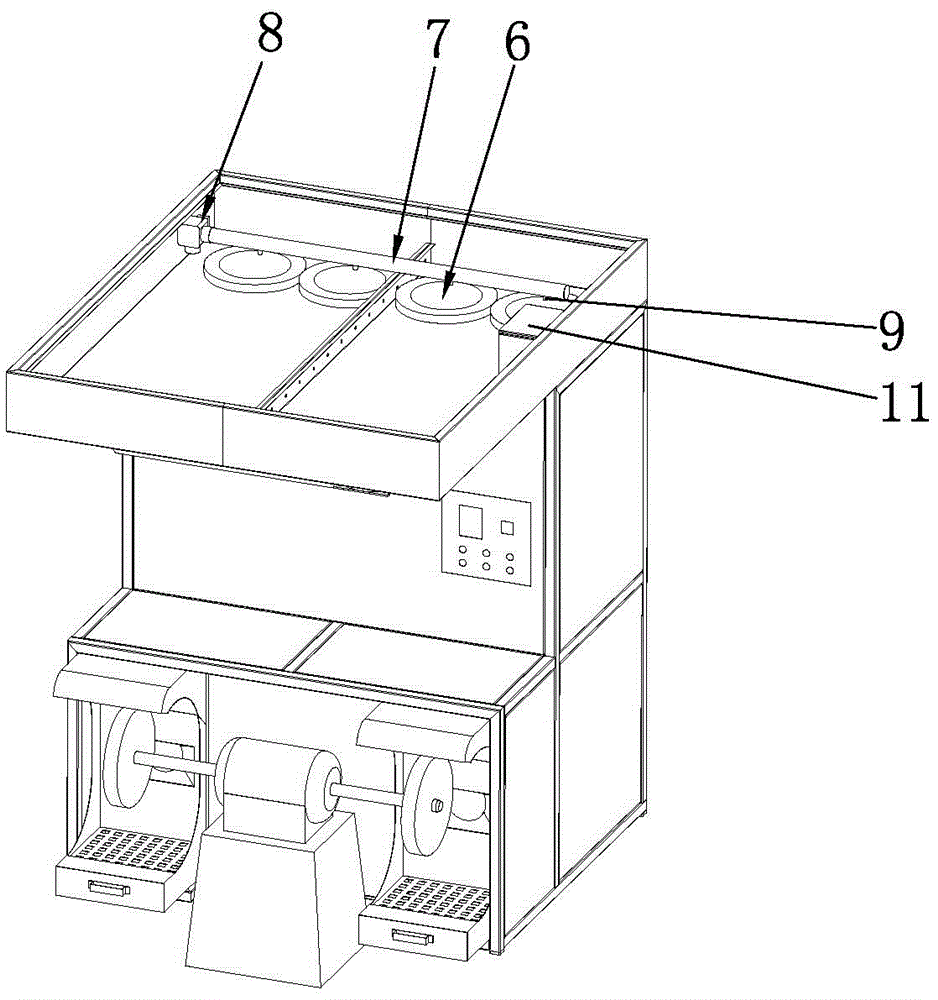

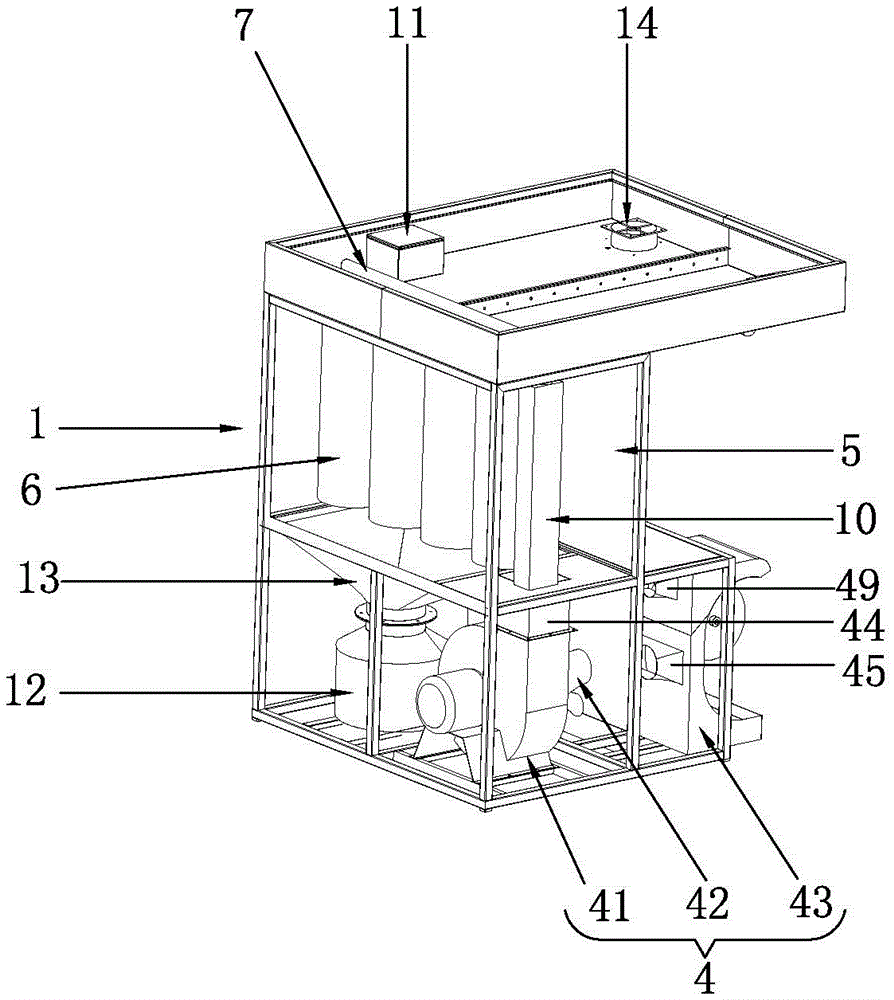

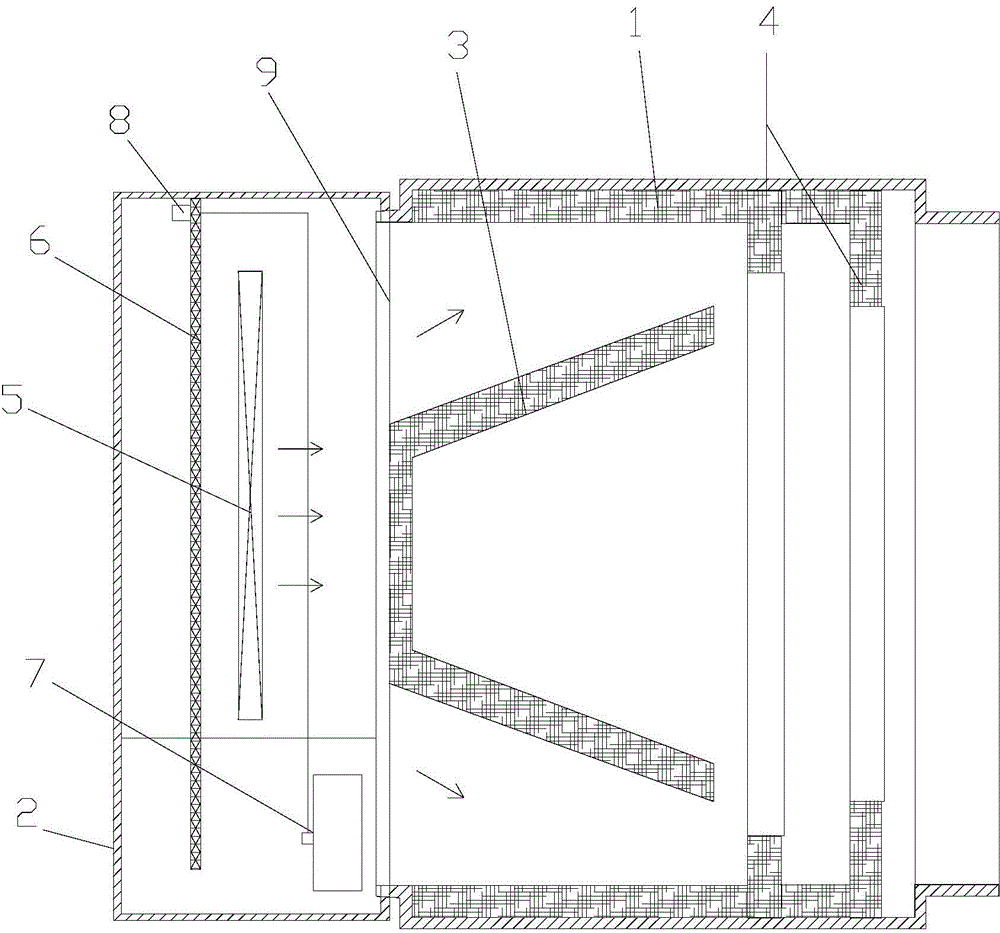

Integrated grinding and polishing dust catcher

InactiveCN105818001AEfficient collectionProtect physical and mental healthDispersed particle filtrationTransportation and packagingEngineeringProduct gas

The invention provides an integrated grinding and polishing dust catcher. The integrated grinding and polishing dust catcher comprises a box type rack, a grinding and polishing machine and a control electric box, the inner part of the lower end of the box type rack is provided with a dust extraction device, the grinding and polishing machine is arranged in front of a dust extraction inlet of the dust extraction device, a dust accumulation filter cavity is arranged at the upper end of the box type rack, a dust accumulator is arranged below the dust accumulation filter cavity, a plurality of dust filter elements and a blowing pipe are arranged at the top of the dust accumulation filter cavity, a pulse electromagnetic valve controlling the air inflow of the blowing pipe is arranged at the air inlet end of the blowing pipe, and a plurality of nozzles in one-to-one correspondence with the dust filter elements are arranged on the blowing pipe. Dust-containing air enters the dust extraction device from the dust extraction inlet and is then adsorbed to the outer surfaces of the dust filter elements. Filtered clean air is discharged out from the top via the dust filter elements. Pulsating dust-cleaning is carried out on the dust filter elements by utilization of compressed air, and dust blown to fall is accumulated in the dust accumulator, effectively collected and treated in a centralized and unified manner, so that the physical and psychological health of workers is protected, and the occurring rate of occupational diseases is reduced.

Owner:东莞市高端环保科技有限公司

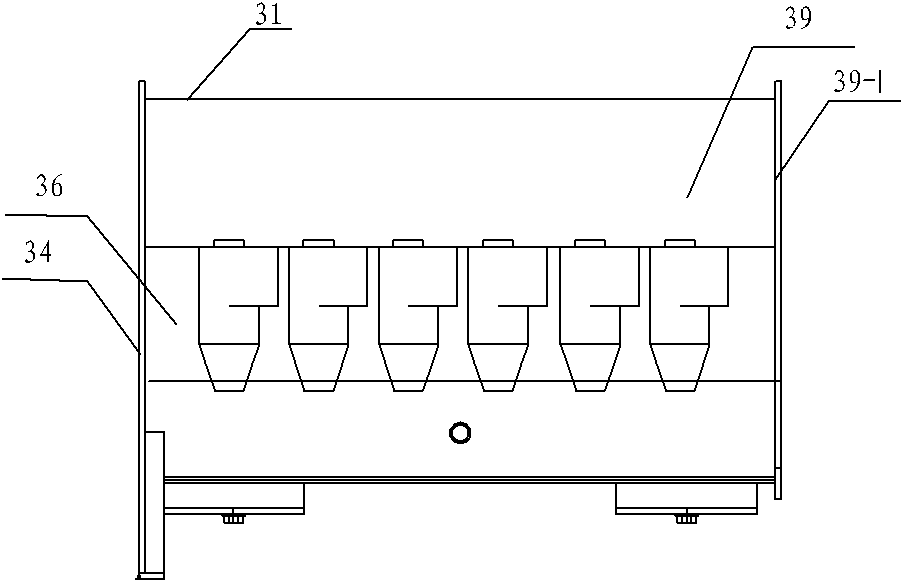

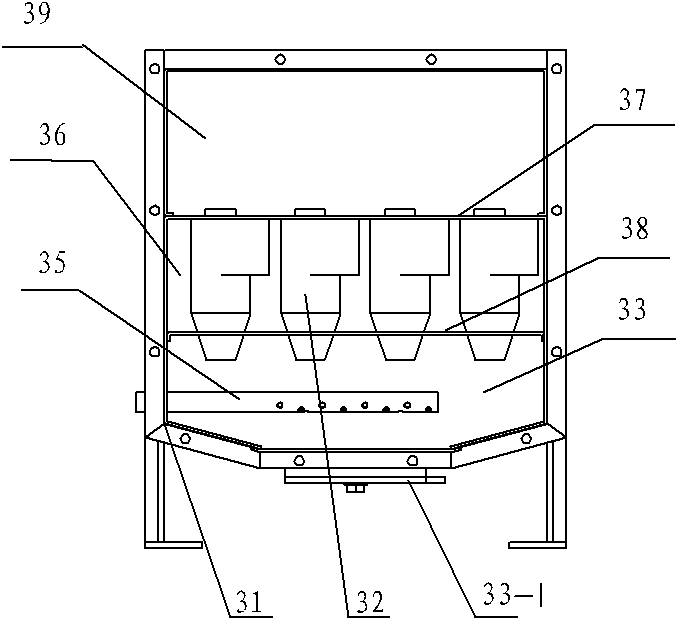

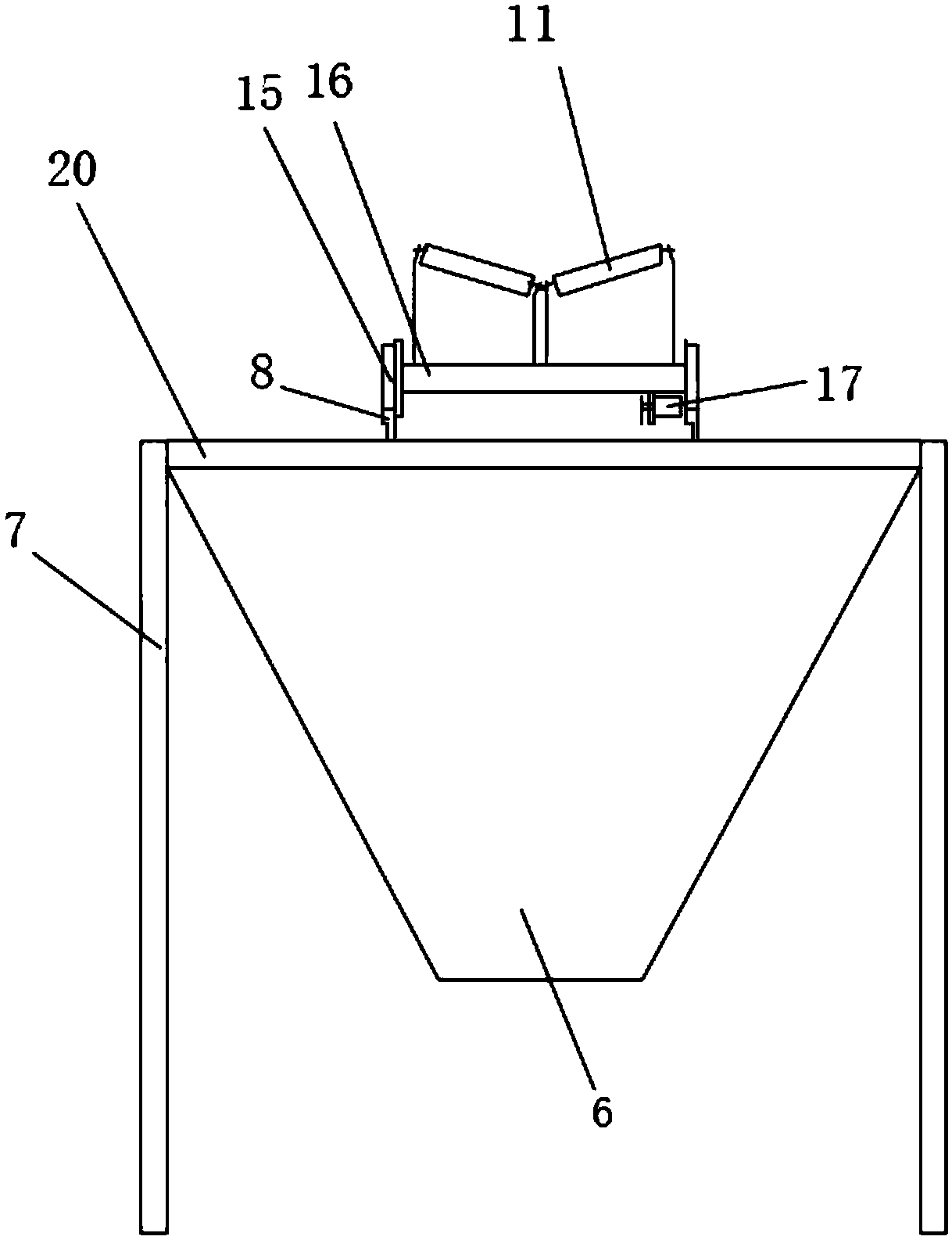

Multi-storage bin automatic material distribution device

PendingCN107758371ACompact structureReasonable designControl devices for conveyorsLoading/unloadingVehicle frameElectric machine

The invention provides a multi-storage bin automatic material distribution device, and belongs to the field of material distribution of storage bins. The multi-storage bin automatic material distribution device comprises a rack, the storage bins and a material distribution mechanism, wherein the plurality of storage bins are fixedly mounted on the rack; the material distribution mechanism is positioned above the storage bins, and comprises a material distribution vehicle, a vehicle traveling orbit, a transmission mechanism and a driving mechanism; the material distribution vehicle comprises wheels, a frame and a traveling driving motor which drives the material distribution vehicle to travel along the vehicle traveling orbit; a material detection switch is further arranged on the frame; the transmission mechanism is arranged above the material distribution vehicle, and comprises a belt, and two belt pulleys and a plurality of belt carrier rollers which are fixed to the frame through belt pulley supporting frames and support the belt; and the driving motor is a belt driving motor, is fixedly mounted at one end of the frame and is in transmission connection with the belt pulleys. According to the multi-storage bin automatic material distribution device, the structure is compact, design is reasonable, material distribution is automatic, labor intensity of workers is reduced, material distribution working efficiency is improved, production cost is reduced, worker operation is reduced, the morbidity of occupational diseases is decreased, and the device is good for harmonious andsound development of enterprises and workers.

Owner:HEBEI INST OF MACHINERY ELECTRICITY

Air purification dust removal device

InactiveCN105080261AThe working environment is clean and tidyReduce incidenceCombination devicesEngineeringHigh pressure

The present invention relates to the technical field of air purification, in particular, relates to an air purification dust removal device comprising a dust removal box, one side of the dust removal box is provided with a water tank, the dust removal box is fixed with a tapered filter net by a bracket, the inner wall of the dust removal box is provided with an annular ladder filter net, the tapered filter net is located at the middle part of the annular ladder filter net, one side of the tapered filter net is provided with a suction fan, the outer side of the suction fan is provided with an absorption plate, the adsorption plate is provided with water holes, the water tank is provided with a water pump, a high pressure nozzle is arranged above the adsorption plate, the high pressure nozzle and the water pump are connected, and the high pressure nozzle is used for spraying water onto the adsorption plate. The clean production workshop environment can be ensured; and the incidence of occupational diseases can be reduced.

Owner:TIANJIN YUANGAO AIR PURIFYING TECH CO LTD

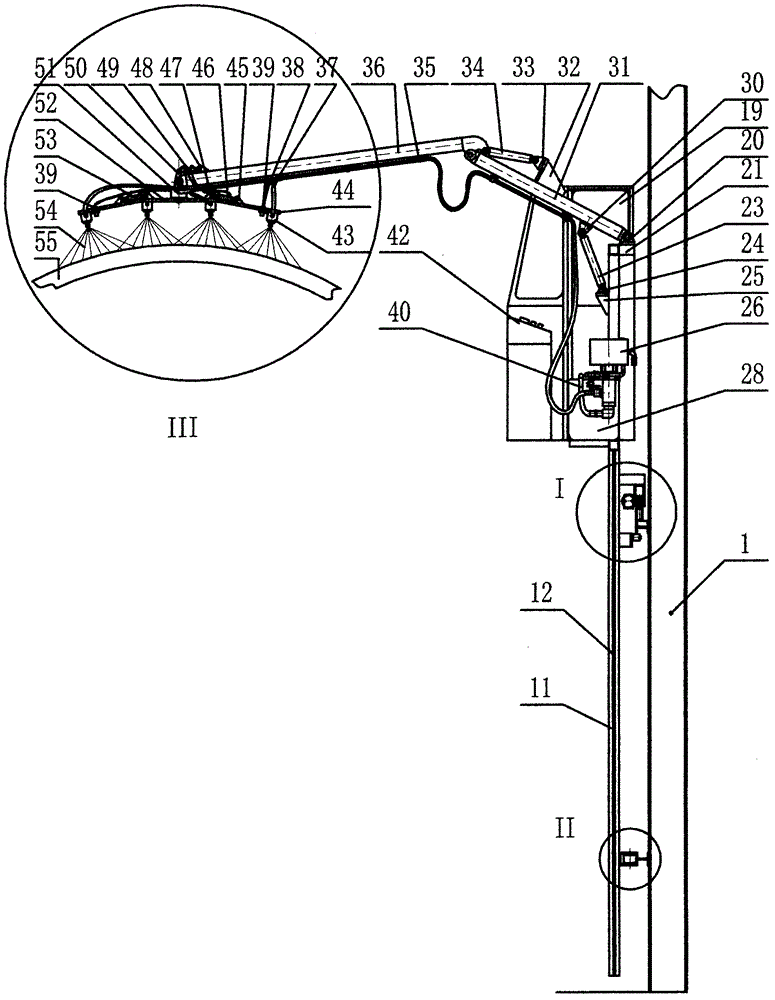

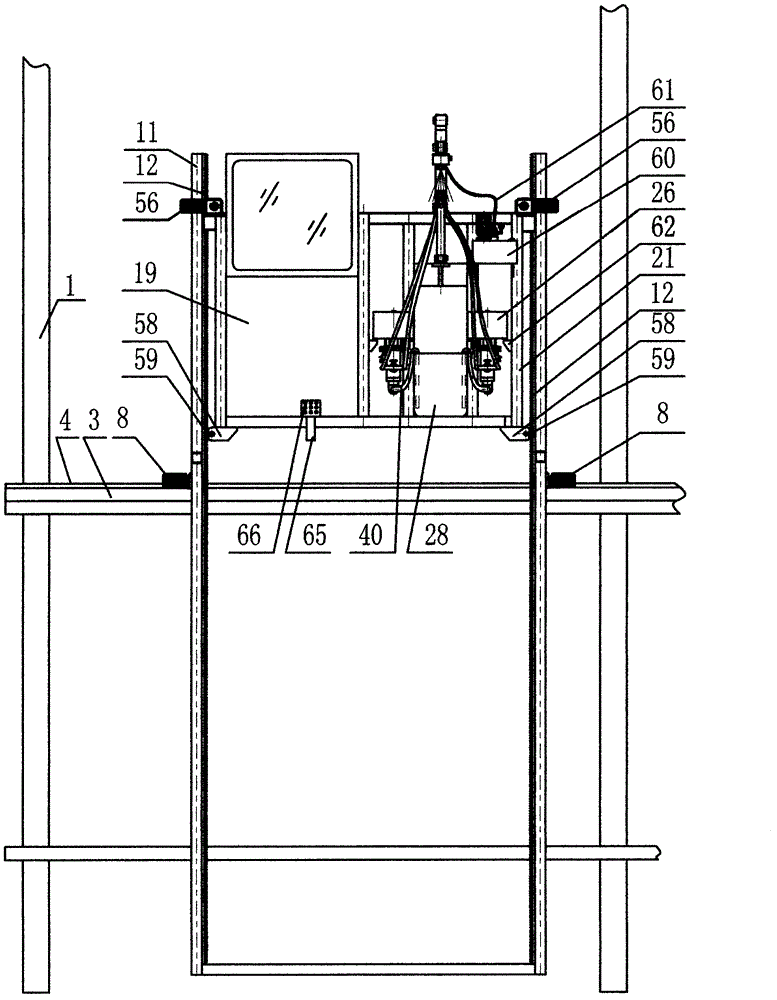

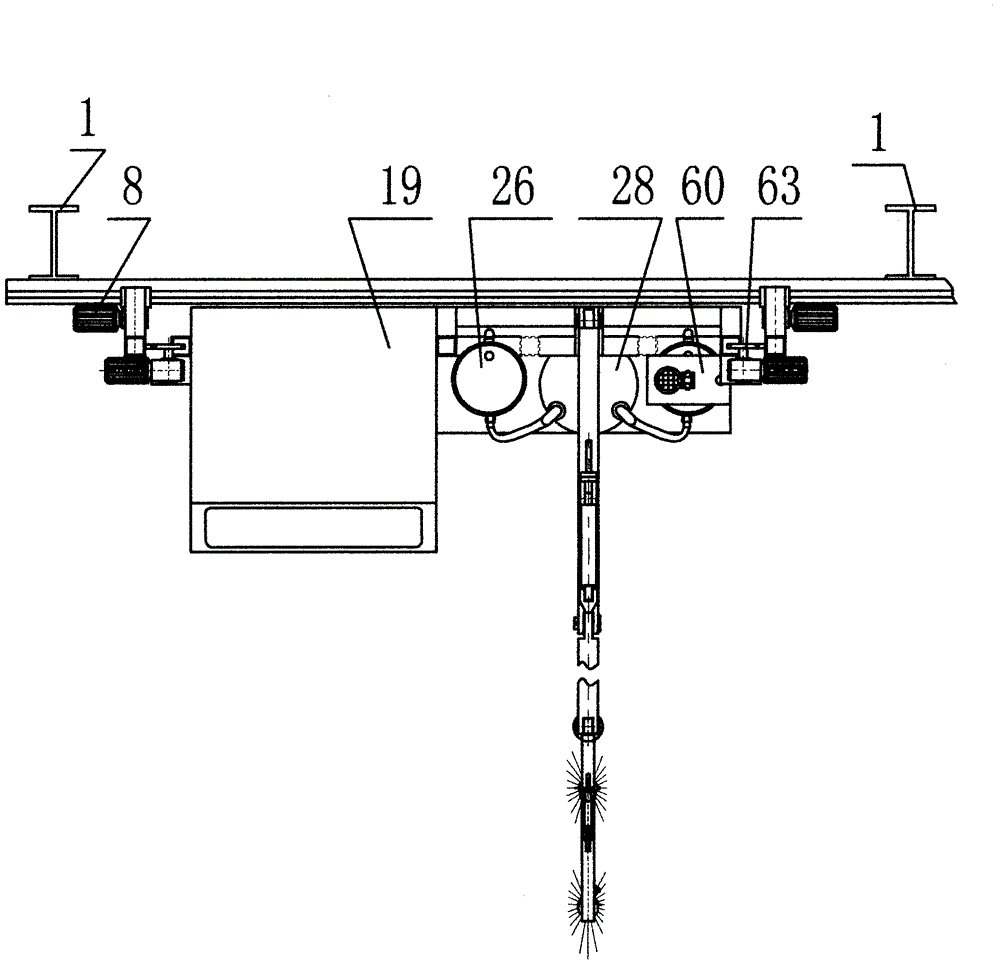

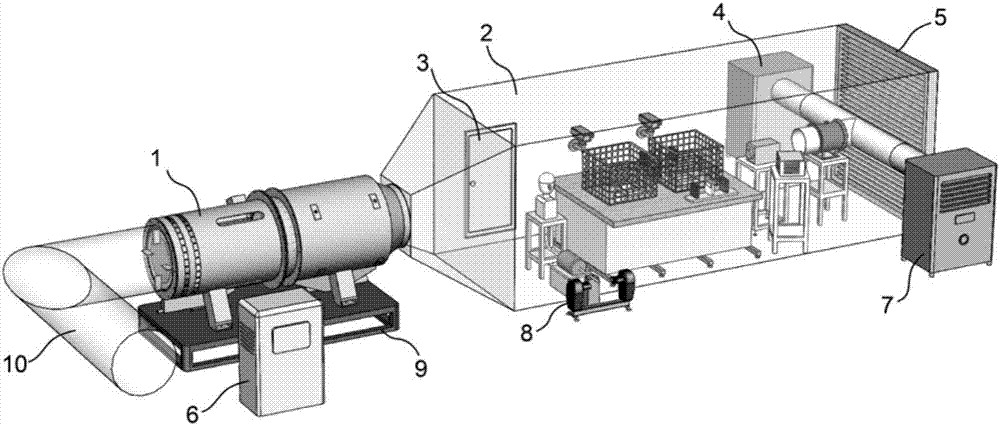

Automatic paint sprayer for spraying outer wall of wind power tower

The invention relates to the field of wind power tower spraying, in particular to an automatic paint sprayer for spraying the outer wall of a wind power tower and solves unreasonableness factors of the traditional manual spraying method, such as low efficiency of manual spraying and severe work environment causing proneness to occupational diseases. The wind power tower has great diameter, a worker stands on the ground and works with the face up, and much paint drops to the ground and is unnecessarily wasted under the action of gravity. The automatic paint sprayer comprises an operating chamber, a frame, a lifting mechanism, a travelling mechanism, airless spraying units, an extension arm mechanism and a hydraulic system; the airless spraying units and multiple spray guns run together, leading to high operating efficiency; the lifting and extension arm mechanisms are provided, the spray guns can be extended right over the wind power tower for operating, the paint naturally drops onto the surface of the wind power tower under the action of gravity, and less paint is lost; the operating chamber is isolated from the external environment, indoor air is cyclically provided from compressed air, and operators can work in the fresh environment.

Owner:HARBIN SIGNIFICANTLY TECH +2

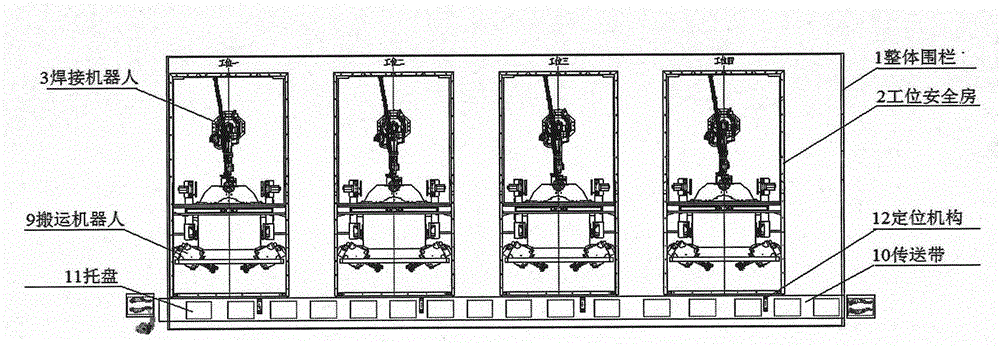

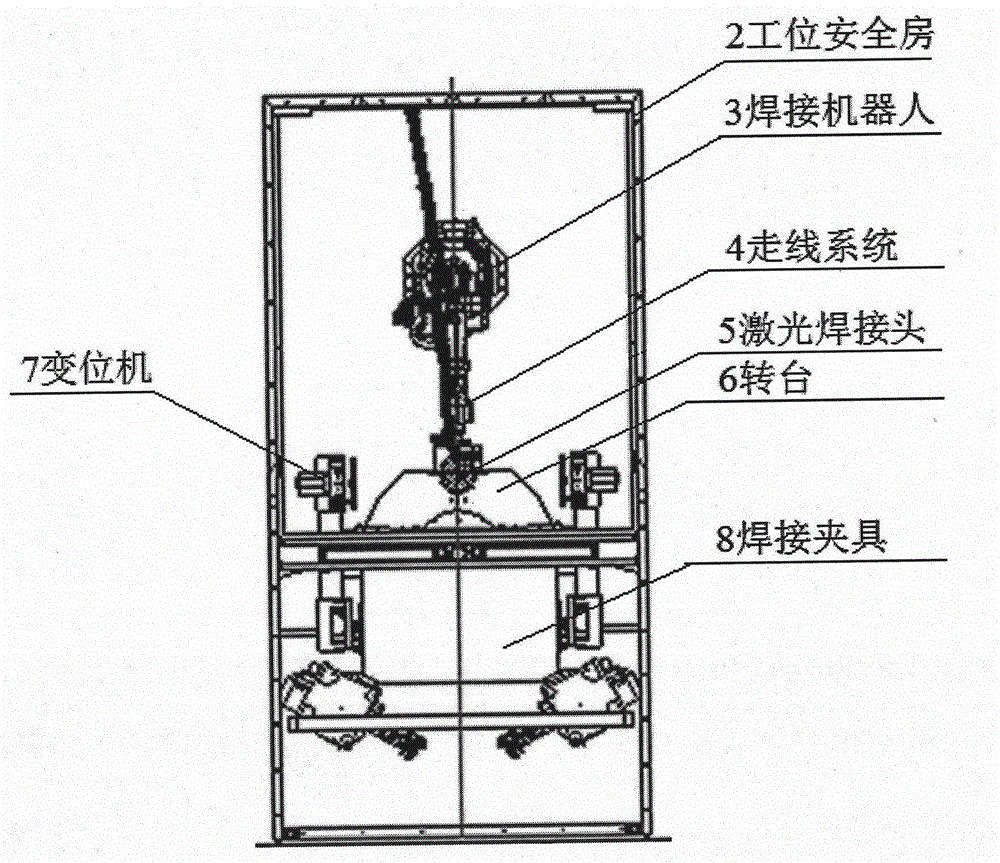

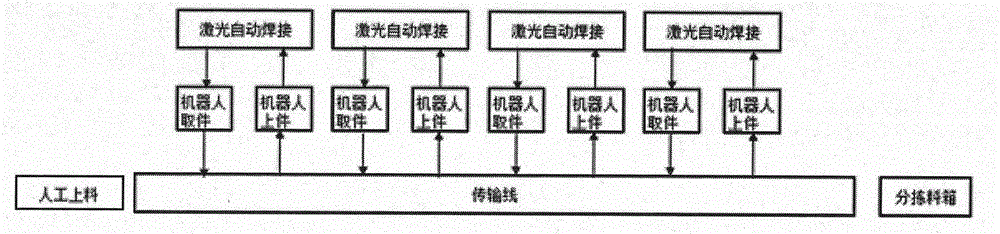

Full-automatic robot laser welding system

The invention provides a full-automatic robot laser welding system which consists of an overall fence 1, a laser welding device, a conveying mechanism and a transfer robot 9, wherein the overall fence 1 is arranged outside the laser welding device, the conveying mechanism and the transfer robot 9; the transfer robot 9 is arranged on the laser welding device; the conveying mechanism is arranged outside the laser welding device, and the vertical straight line distance between the furthest transverse end of the conveying mechanism and the laser welding device is shorter than the longest arm length of an unfolded operation arm of the transfer robot on the same laser welding device. By virtue of the full-automatic robot laser welding system, the logistics expenditure is effectively reduced, closed operation is adopted, manual operation steps are reduced, and injuries or occupational diseases brought to working personnel can be effectively avoided; according to the full-automatic robot laser welding system, by virtue of intelligent operation, the overall safety and reliability of the system are improved, the production efficiency is improved, and energy consumption is reduced.

Owner:国融新兴投资有限公司

Mulberry leaf shearing device

InactiveCN105052396AImprove labor efficiencyNovel ideaPicking devicesAgricultural engineeringKnife blades

The invention discloses a mulberry leaf shearing device which comprises a lower blade, an upper blade and a driving device. The upper blade is provided with a limiting groove, the upper blade is movably connected to the lower blade through a limiting assembly and the limiting groove, blade teeth on the upper blade can move back and forth along the limiting groove to be cooperated with blade teeth of the lower blade for cutting, and the driving device is connected with the upper blade through a crank-link mechanism and used for driving the upper blade to move back and forth. According to the mulberry leaf shearing device, the blades are driven by the driving device to cut mulberry leaves, the labor efficiency is greatly improved, and mulberry planters can be kept away from the occupational disease.

Owner:GUANGXI UNIV

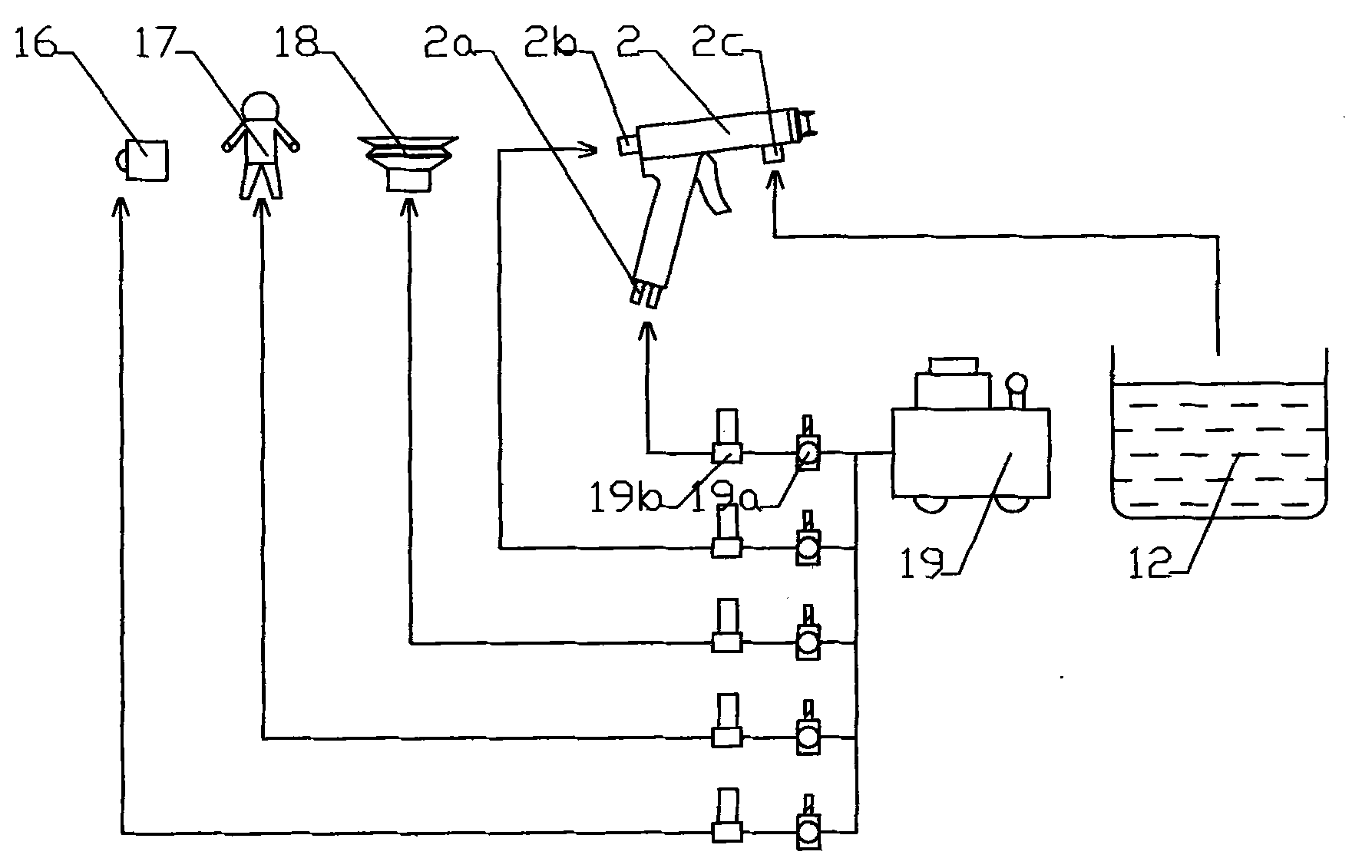

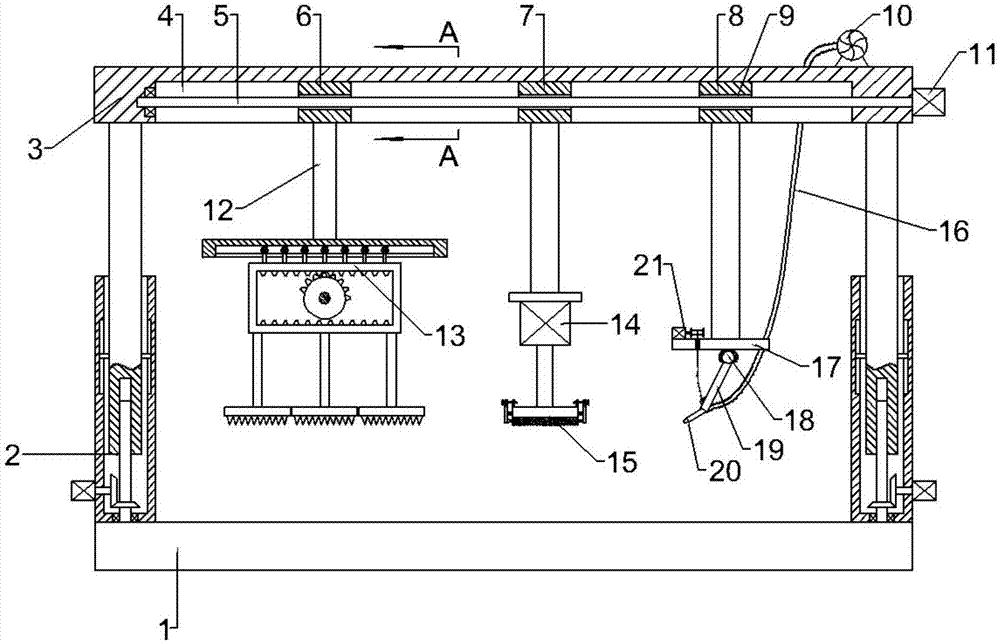

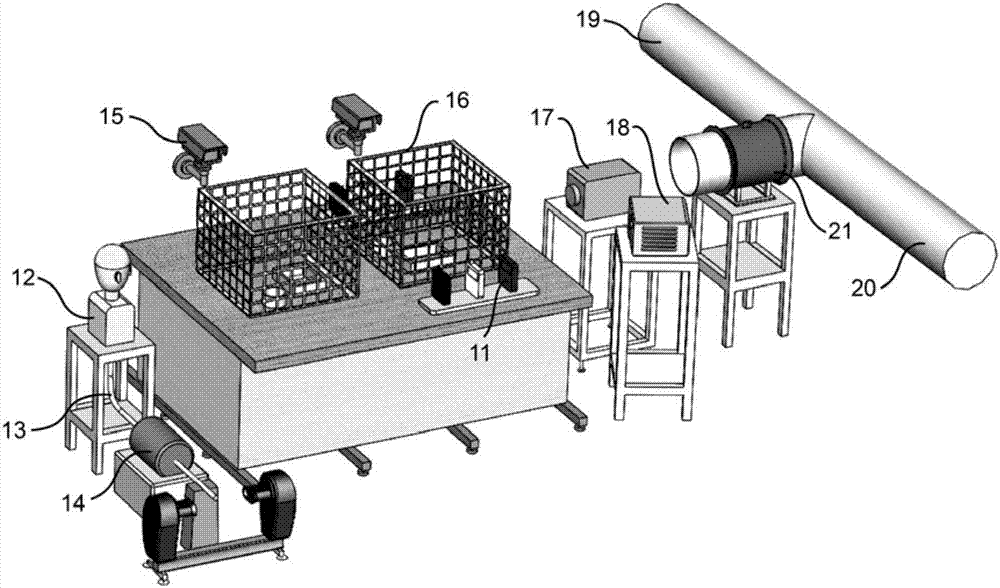

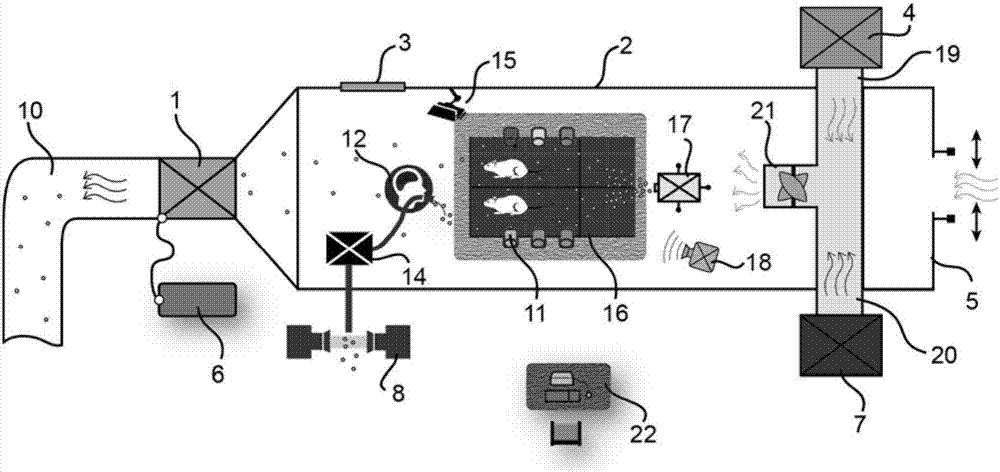

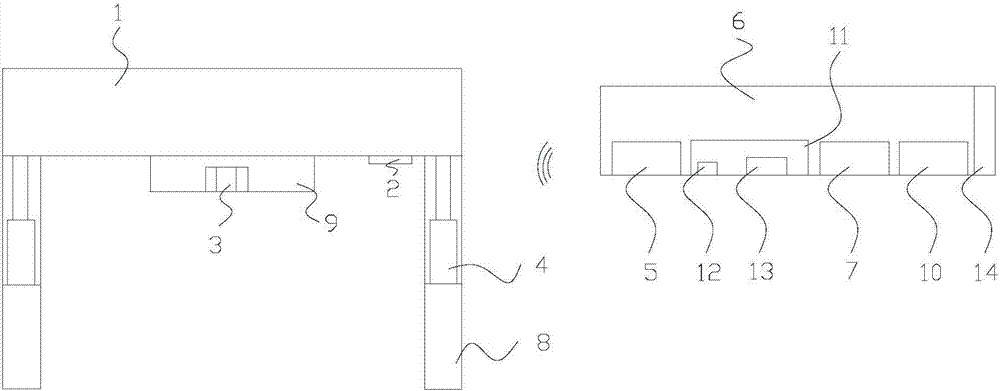

Simulation system and industrial and mining environment dust simulation method

ActiveCN107422109ARealize breathing operation simulationRemove threatBiological testingRespirable dustAmbient pressure

The invention discloses a simulation system used for safety and health of industrial and mining environment dust occupational diseases and an industrial and mining environment dust simulation method. The simulation system and the simulation method can realize simulation of an industrial and mining dust environment; simulation of each influence factor of an operating environment is realized by virtue of an axial flow fan, a dust emitter, a noise simulator, a temperature regulator, an air pressure controller and a humidity regulator mainly; determination analysis of each influence factor in the environment is realized by virtue of a dust sampler, a temperature sensor, a humidity sensor, an oxygen content sensor, an atmosphere sensor, a toxic and harmful gas sensor, an air speed sensor and the like; finally two analysis methods that a human respiratory organ simulator is used for simulating human respiration and organs of a mouse are used for damaging the simulation are utilized for analyzing health condition of personnel in factors and under conditions of different dust environments, temperatures and humidities, ambient pressures, oxygen contents and the like, a damage mechanism of respirable dust in the industrial and mining dust environment on a human respiratory system and deposition law of the respirable dust can be obtained by combining with animal anatomy, and finally a dust pathogenic mechanism is revealed.

Owner:SHANDONG UNIV OF SCI & TECH

Intelligent, healthy and liftable office table and chair system

InactiveCN106923492AReduce occupational diseasesReduce medical costsStoolsOptical sensorsPhysical well beingEngineering

The invention discloses an intelligent, healthy and liftable office table and chair system. The intelligent, healthy and liftable office table and chair system comprises a table top and a chair cushion, wherein the bottom of the table top is supported by table legs, an electric push rod is mounted in each table leg, the electric push rods are in threaded fixation to four corners of the bottom surface of the table top, an electric push rod control box is mounted at the lower side of the table top, a signal receiver is mounted in the electric push rod control box, an electric push rod control panel connected with an external power supply is mounted at the edge of the bottom surface of the table top, a gravity sensing device, an optical fiber sensor, a control cabinet and a vibrator are mounted in the chair cushion, a wireless signal generator and a lithium battery are mounted in the control cabinet, and a control panel is mounted on the side surface of the chair cushion. With the intelligent, healthy and liftable office table and chair system, the work efficiency can be improved, the occurrence of the office occupational diseases is reduced, the pain caused by the diseases is alleviated, the body health of people is guaranteed, and finally, the medical cost of the society and the country is reduced.

Owner:SHANGHAI TEAMMAX FURNITURE CO LTD

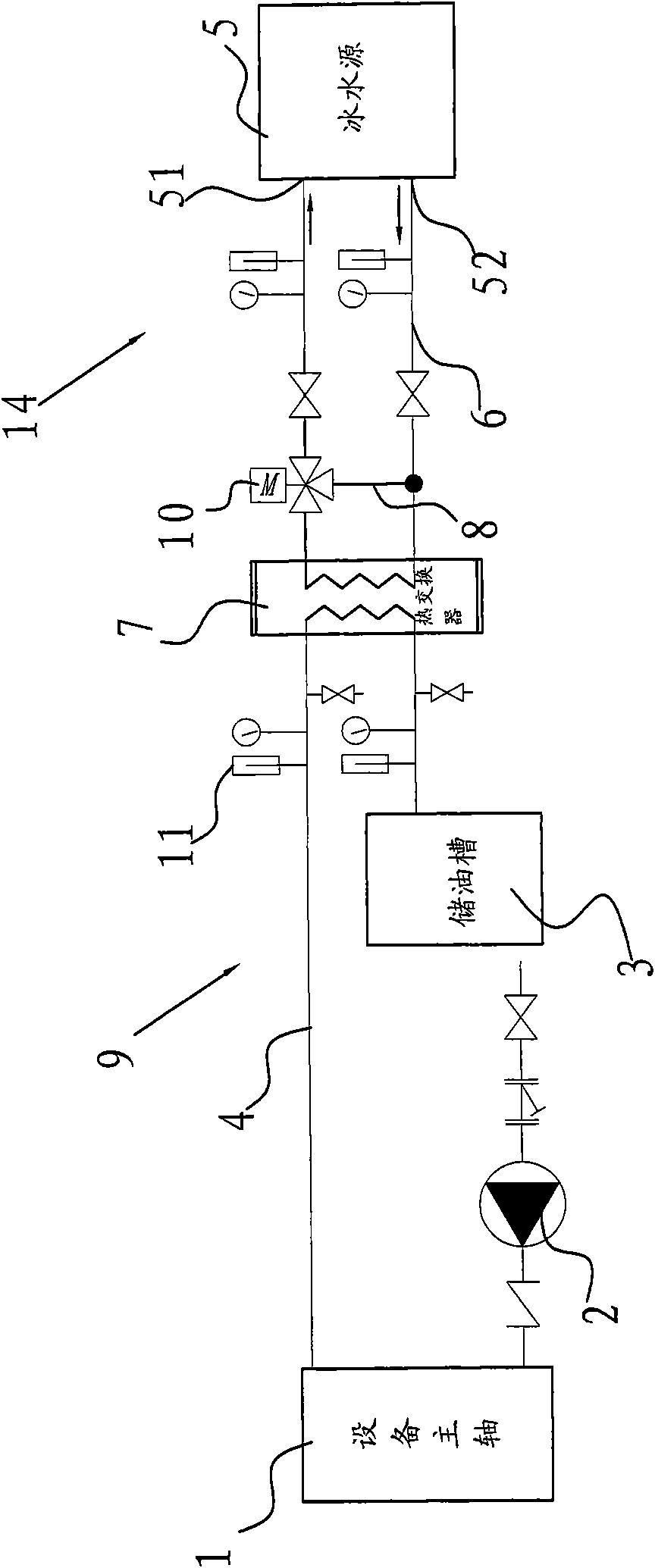

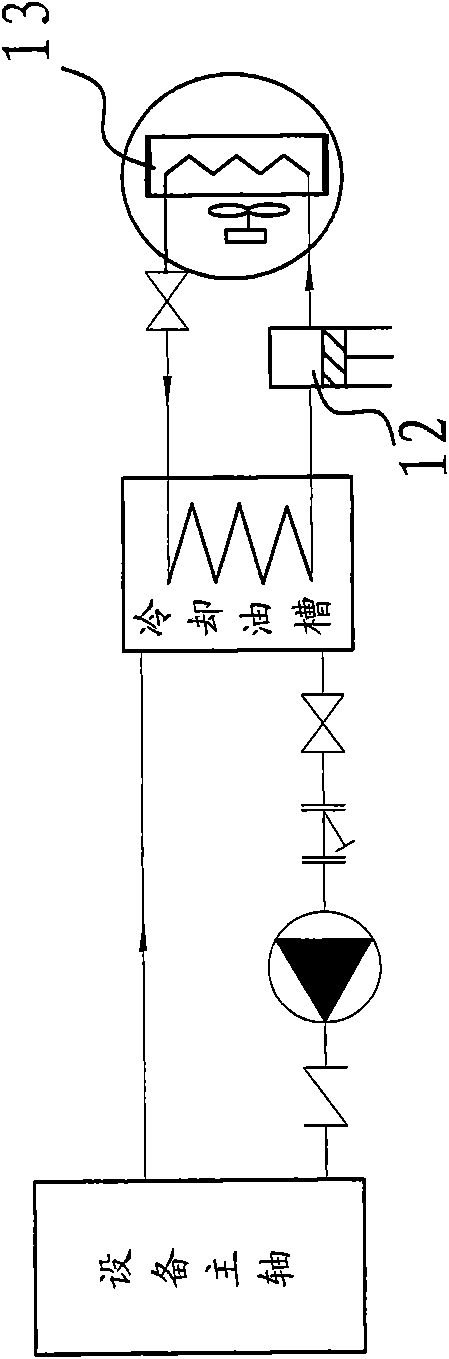

Liquid cooling system for device

The invention relates to a liquid cooling system for a device, which comprises a heat exchanger and two circulation loops including an oil circulation loop and an ice water circulation loop, wherein the oil circulation loop forms a closed loop by connecting an oil storage tank, a circulating pump, a main shaft of the device and the heat exchanger in turn through circulating oil pipes, and the ice water circulation loop forms a closed loop by connecting an ice water source and the heat exchanger in turn through circulating water pipes; and the cooling oil in the oil circulation loop and the ice water in the ice water circulation loop perform heat exchange in the heat exchanger so as to cool the oil temperature on the main shaft of the device. The liquid cooling system uses the circulation of a cooling medium ice water of the heat exchanger to take away the heat of oil cooling engine oil, and compared with the prior art, compressors and heat radiators for discharging the heat in a workshop out of the workshop are not needed. The liquid cooling system not only reduces the temperature of a working condition, but also removes a compressor radiator fan and prevents workers from being harmed by occupational diseases caused by dust and the like, and the working condition is comparatively comfortable.

Owner:KUNSHAN DINGXIN ELECTRONICS

Welding seam tracking method in membrane wall welding process

InactiveCN103551710AGuaranteed accuracyEnsure reliabilityArc welding apparatusProduction rateWorking environment

The invention relates to a welding seam tracking method in a membrane wall welding process. The method comprises the following steps: additionally arranging a self-adaptive welding gun adjusting device on each welding gun; collecting video information of a welding seam of a flat steel bar and an adjacent steel pipe through a laser vision sensing device at the front part of each welding gun; transmitting the video information to a vision identification server for analysis; providing the current position and angle information of the welding seam for each self-adaptive welding gun adjusting device through the vision identification server; transmitting adjustment data to a control servo drive mechanism through each self-adaptive welding gun adjusting device, so as to adjust the position of each welding gun in a real-time manner. According to the invention, the method solves the problem that the synchronous tracking of a plurality rows of welding seams is more difficult in the membrane wall welding, overcomes the interference to an image by factors such as strong arc light reflected by a surface in the welding process, can be used for obtaining clear, stable and real-time welding seam image information, and can guarantee the processing quality; the welding production efficiency is improved, the welding quality is stabilized, and moreover, the harm of an occupational disease is alleviated or eliminated as a welder can be kept far away from a harmful work environment.

Owner:SHANGHAI INST OF PROCESS AUTOMATION & INSTR +1

Process for pelletizing of iron oxide red pigment

InactiveCN1793241AReduce moisture contentReduce energy consumptionInorganic pigment treatmentAdhesiveEnergy consumption

The invention discloses iron red pigment granulation method. It includes the following steps: putting iron red flour into granulating disc; spraying by water; sieving to gain the grain with 0.05-2.5mm grain diameter; spraying adhesive; and drying. The weight ration of iron red flour and water is 1:0.1-0.2. The use level of adhesive is 5-12% of the iron red flour. The method is convenient for industrialization, and has low energy consumption. It overcomes the defect of rising of the powder iron red dust, and has important meaning in environmental protection and reducing occupational disease.

Owner:杭州萧山永丰化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com