Patents

Literature

32results about How to "Avoid occupational hazards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

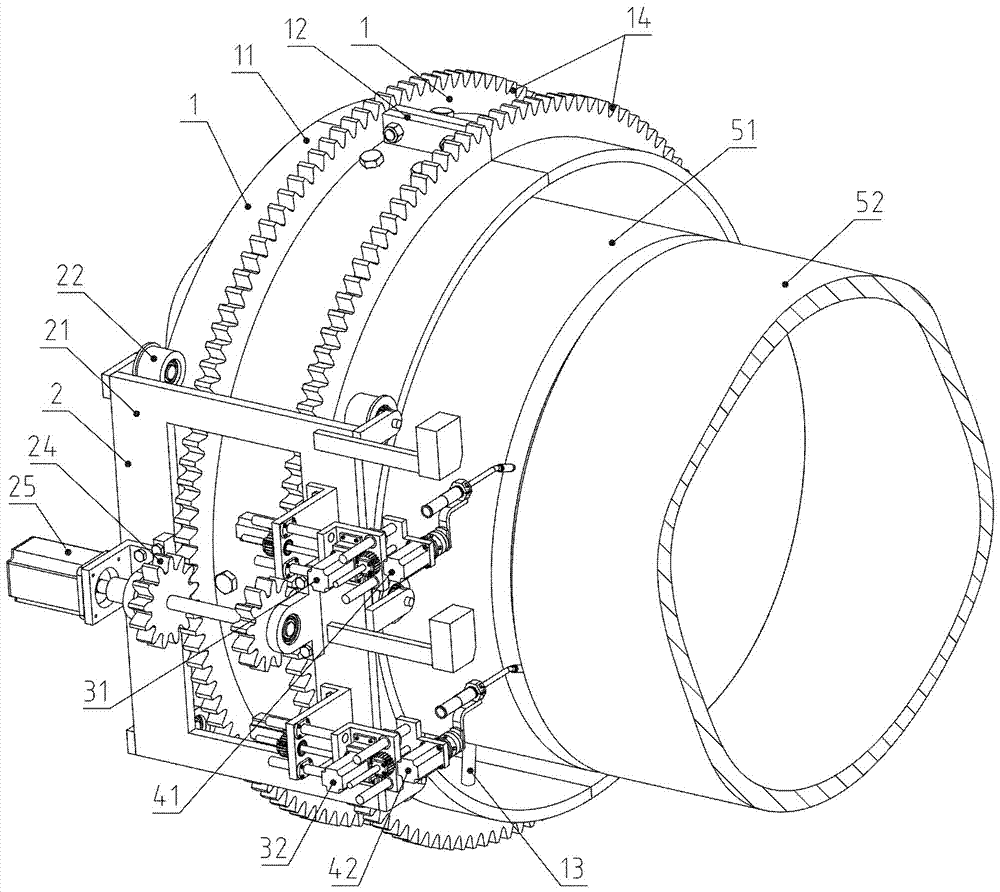

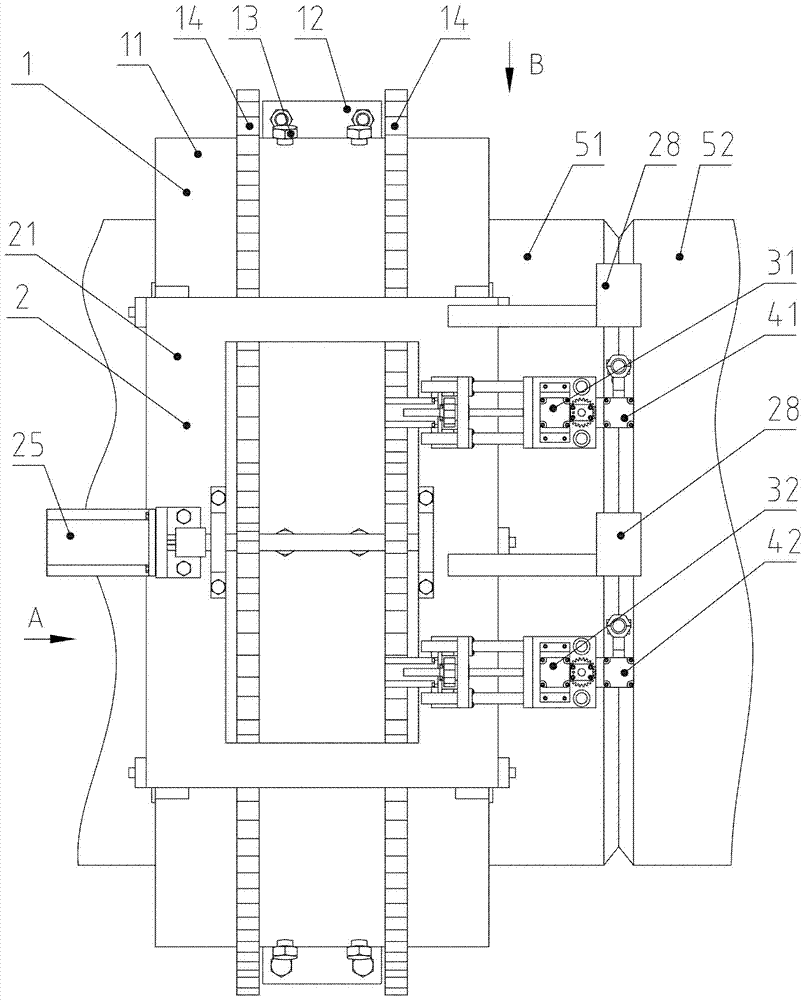

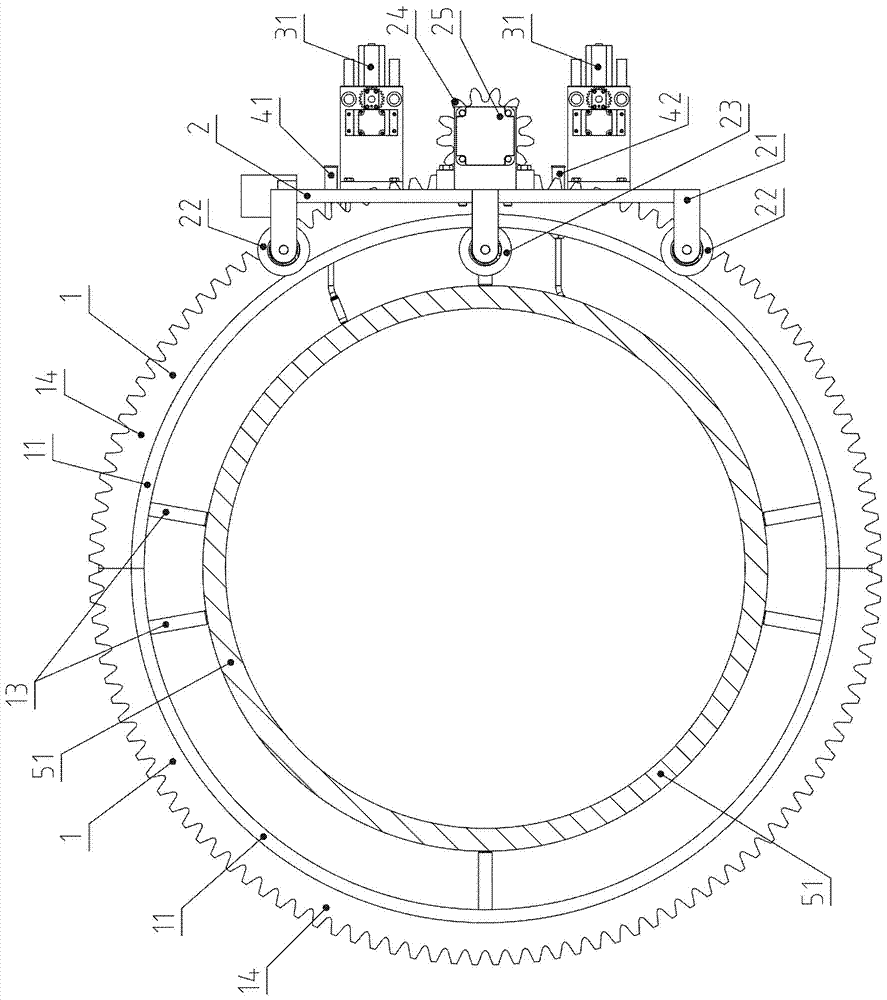

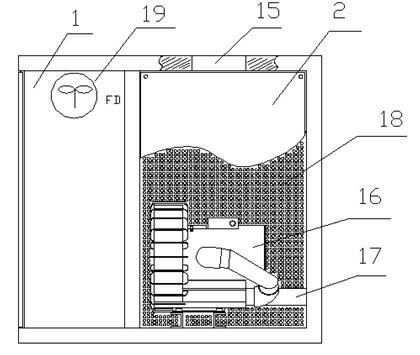

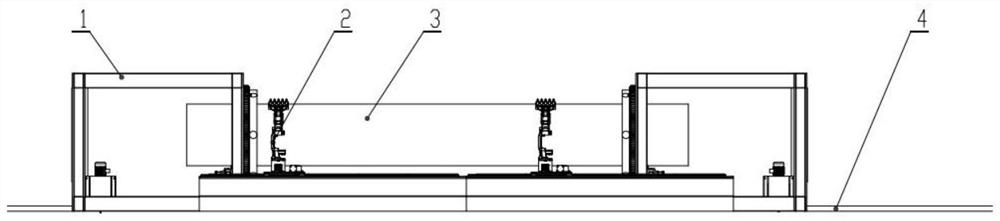

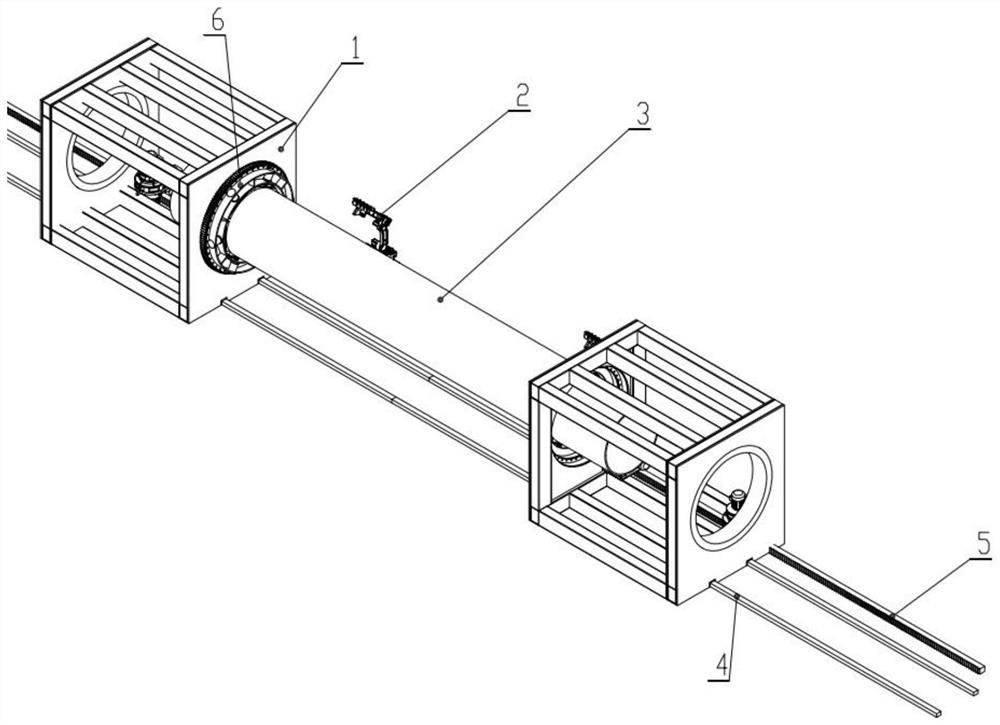

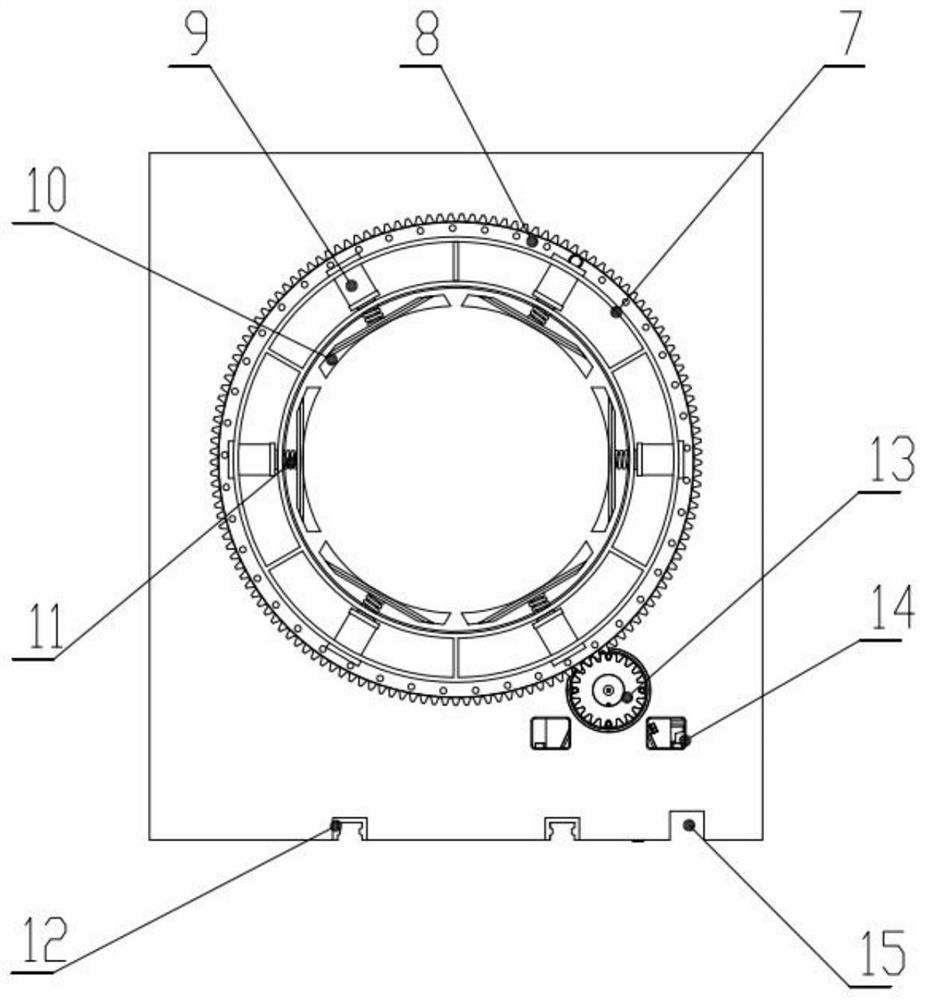

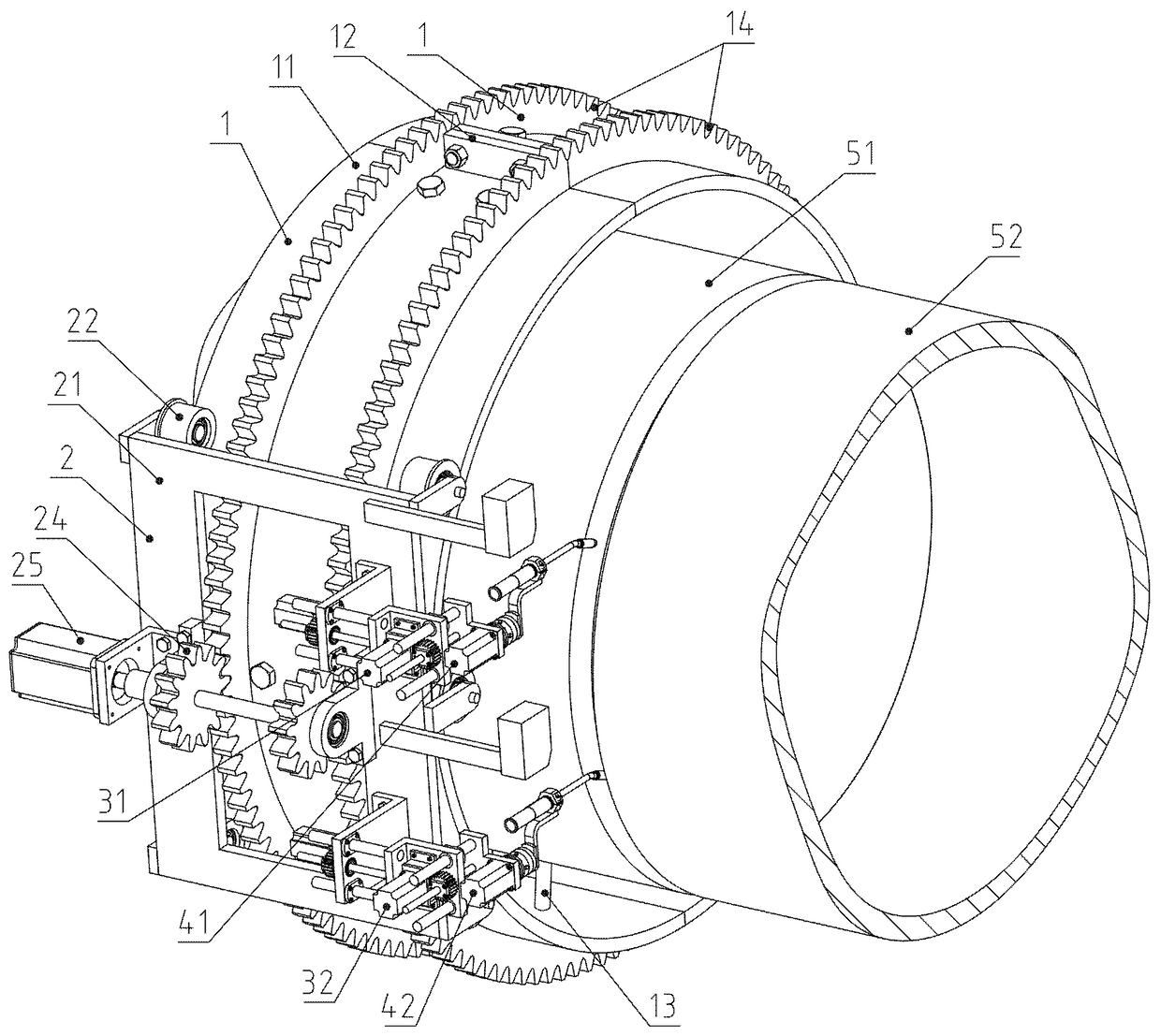

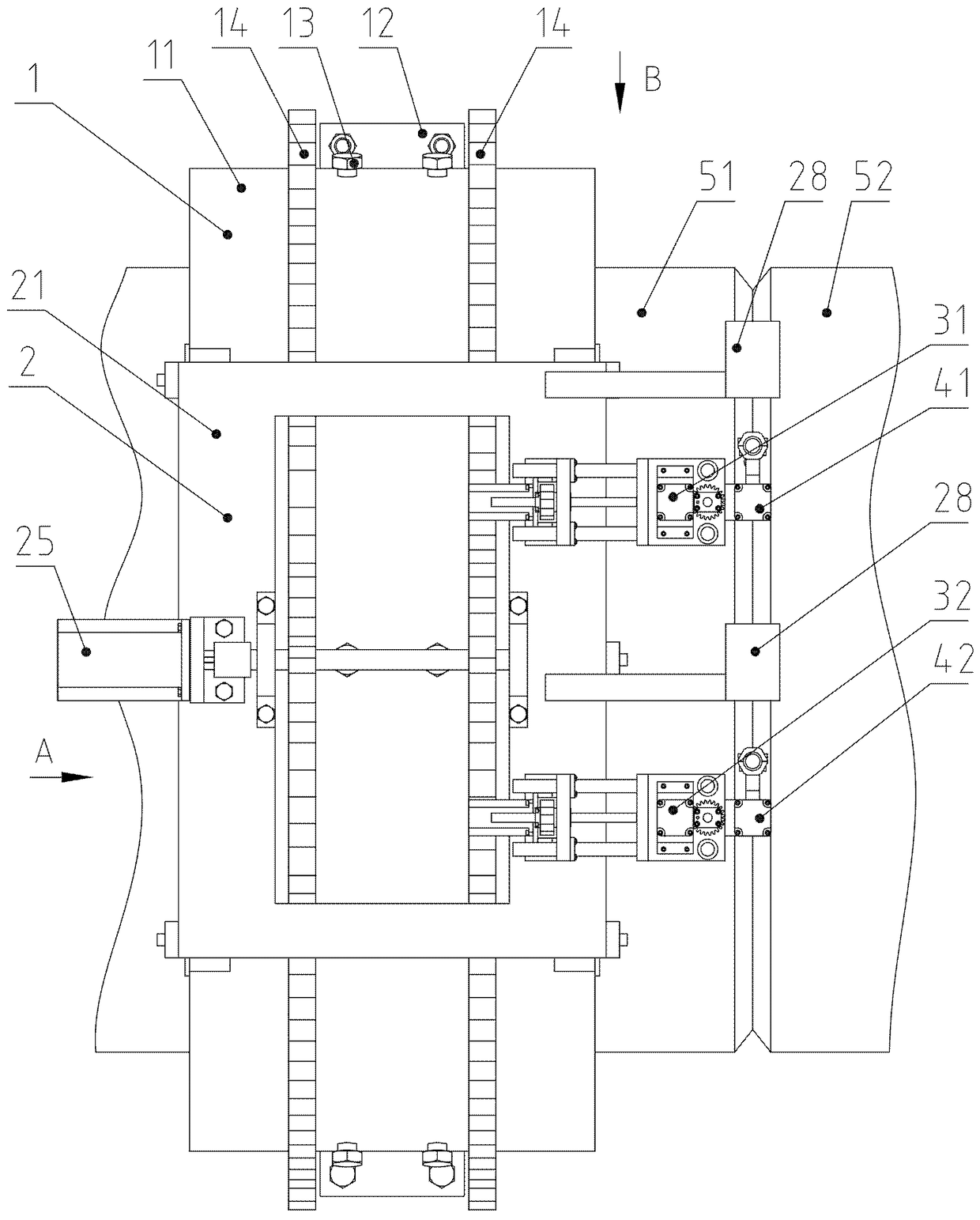

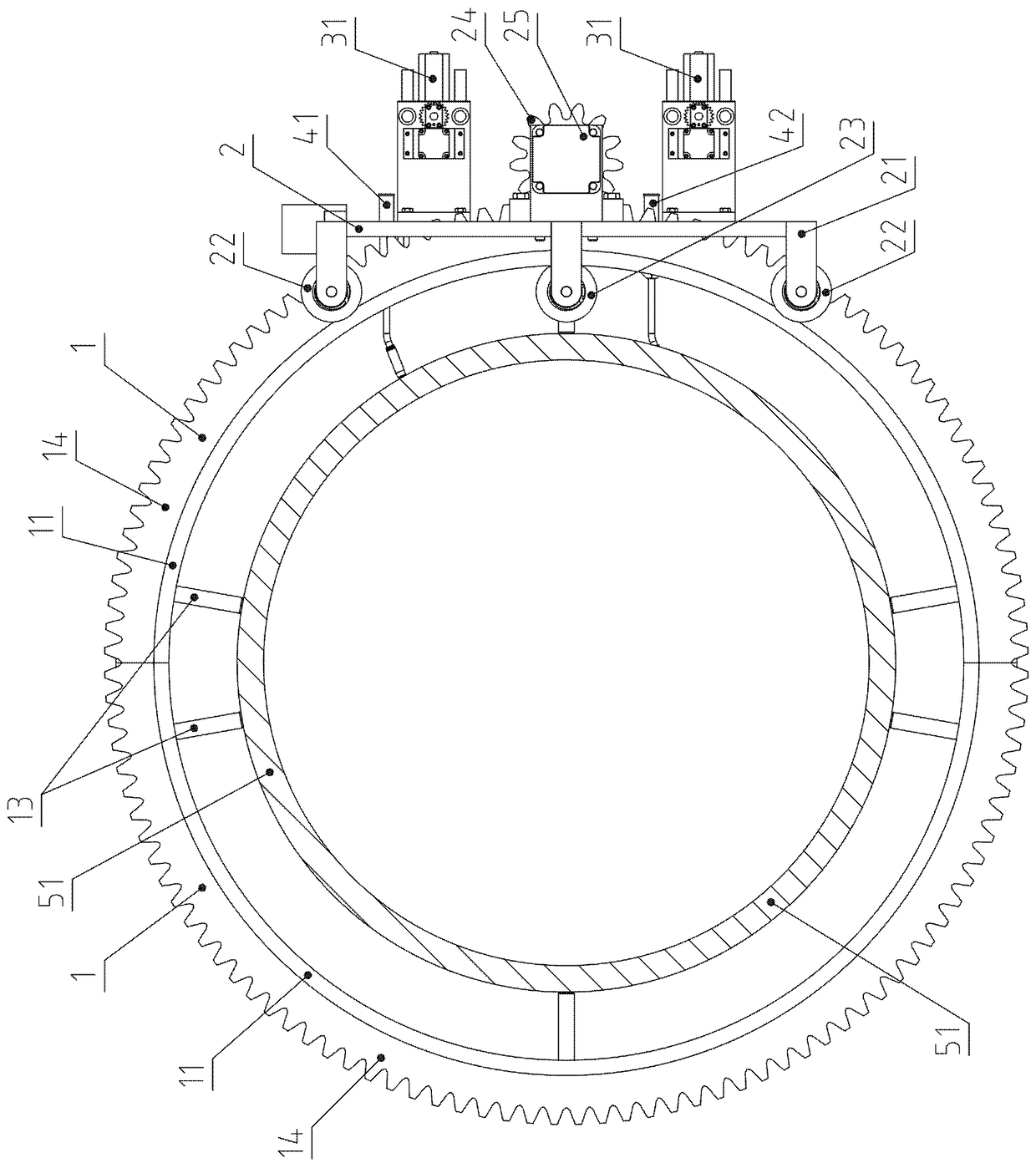

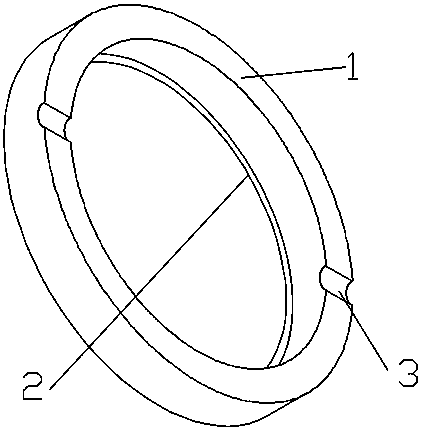

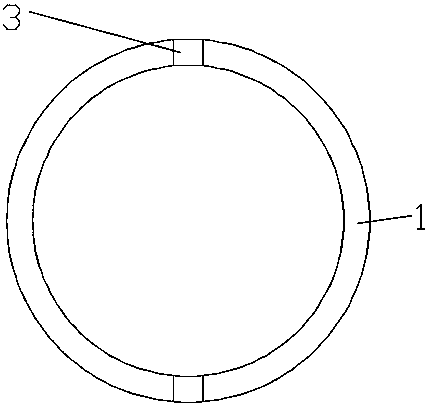

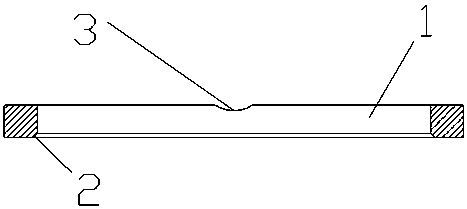

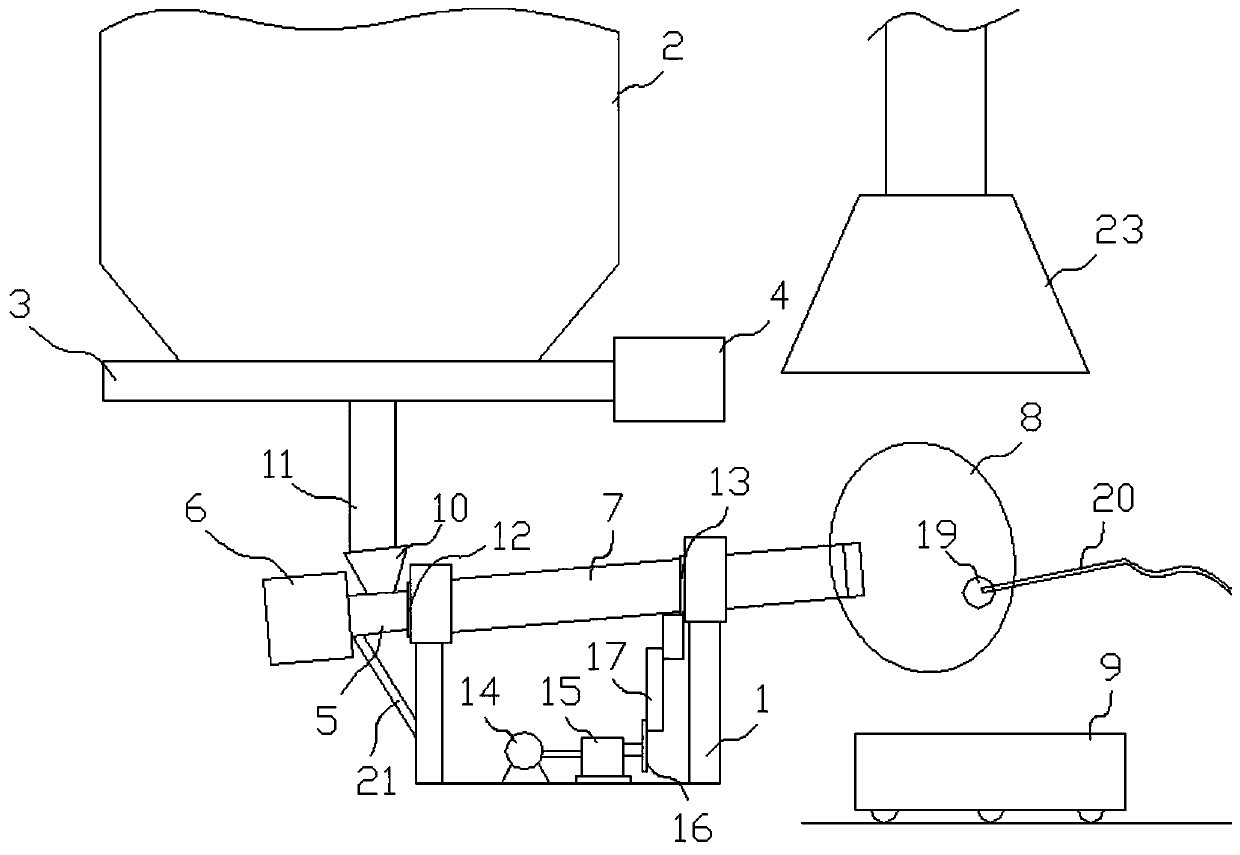

Large-diameter steel pipe double-welding-gun intelligent welding equipment

ActiveCN107414369AImprove welding efficiencyQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesMotor driveArchitectural engineering

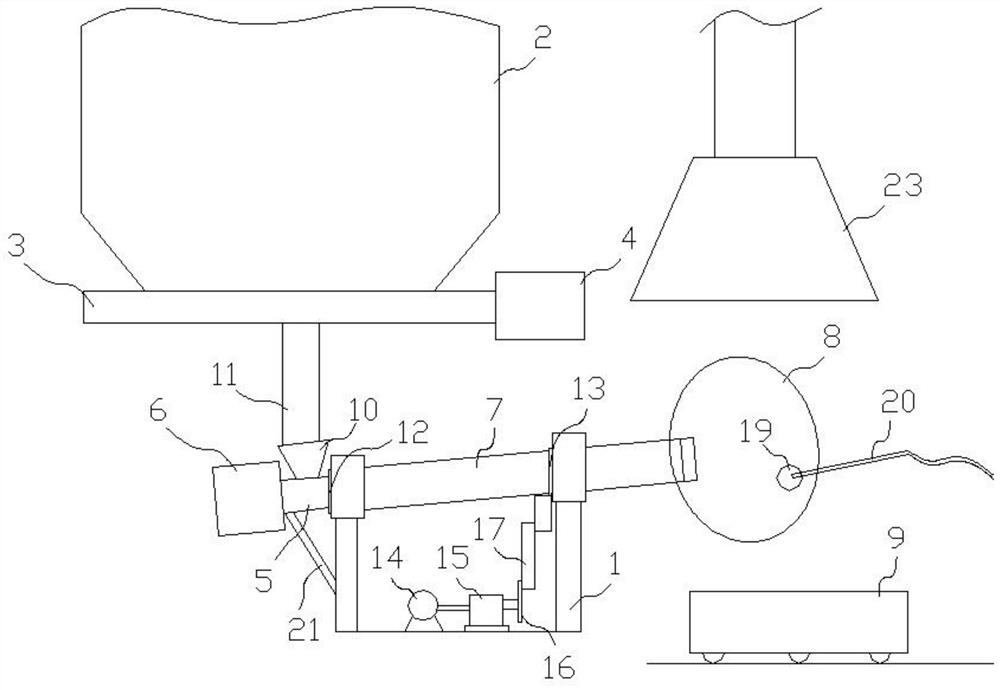

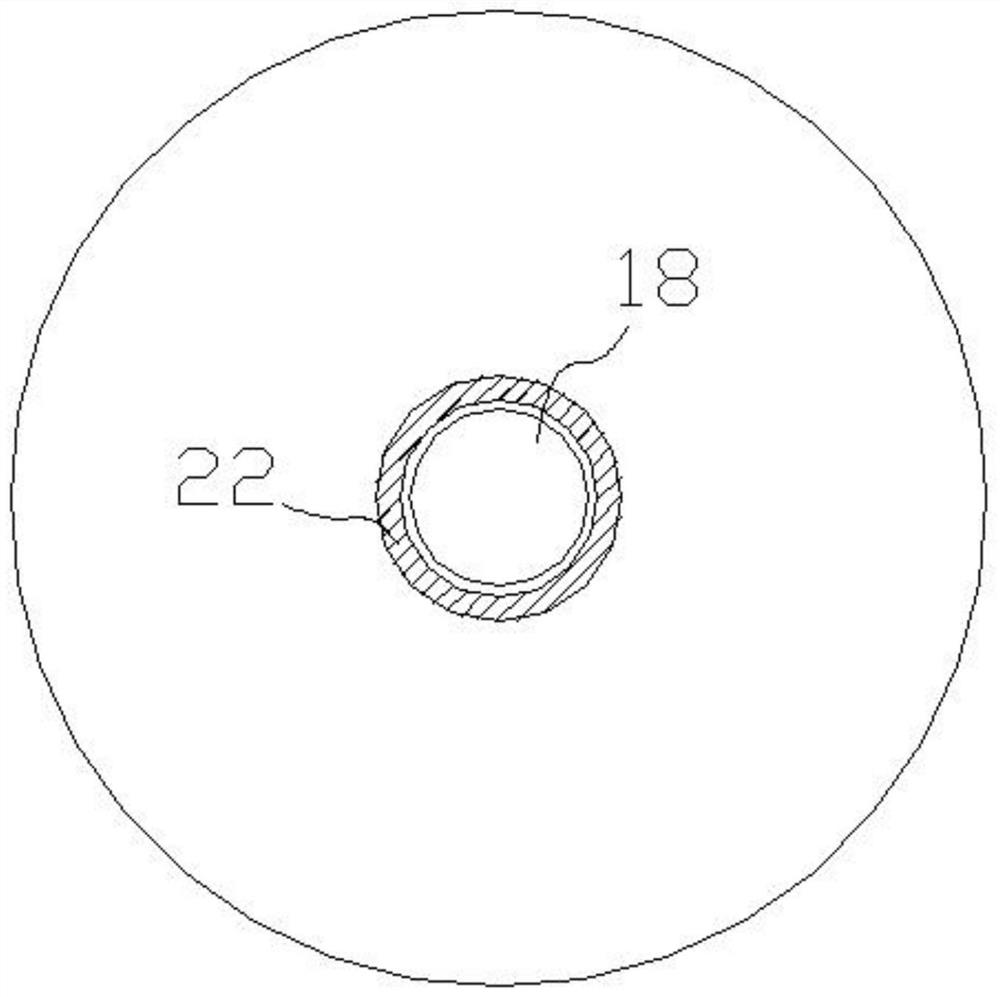

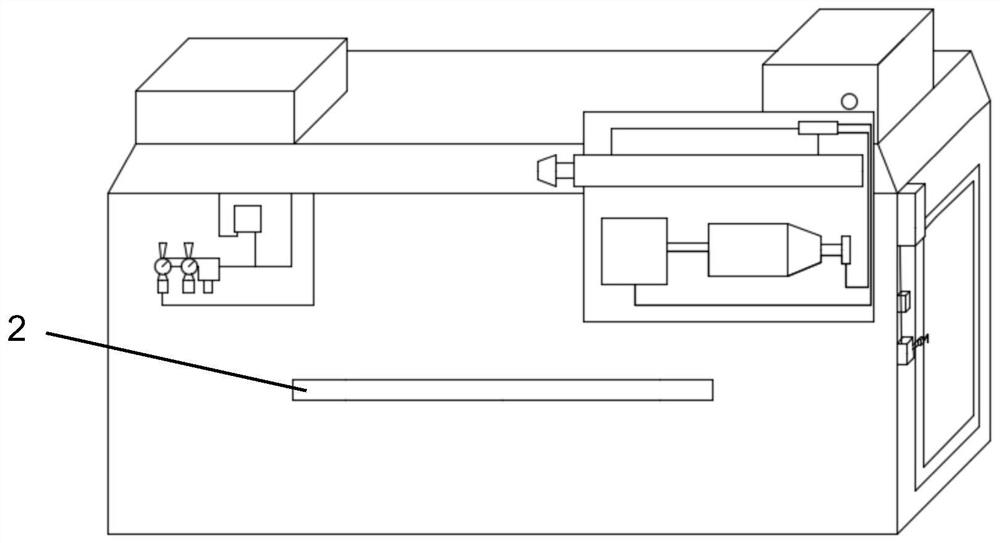

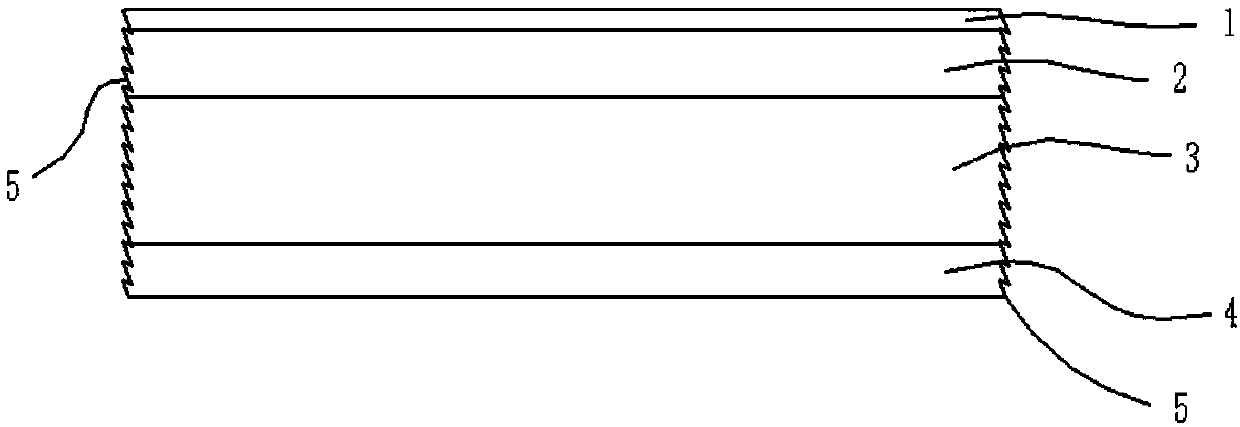

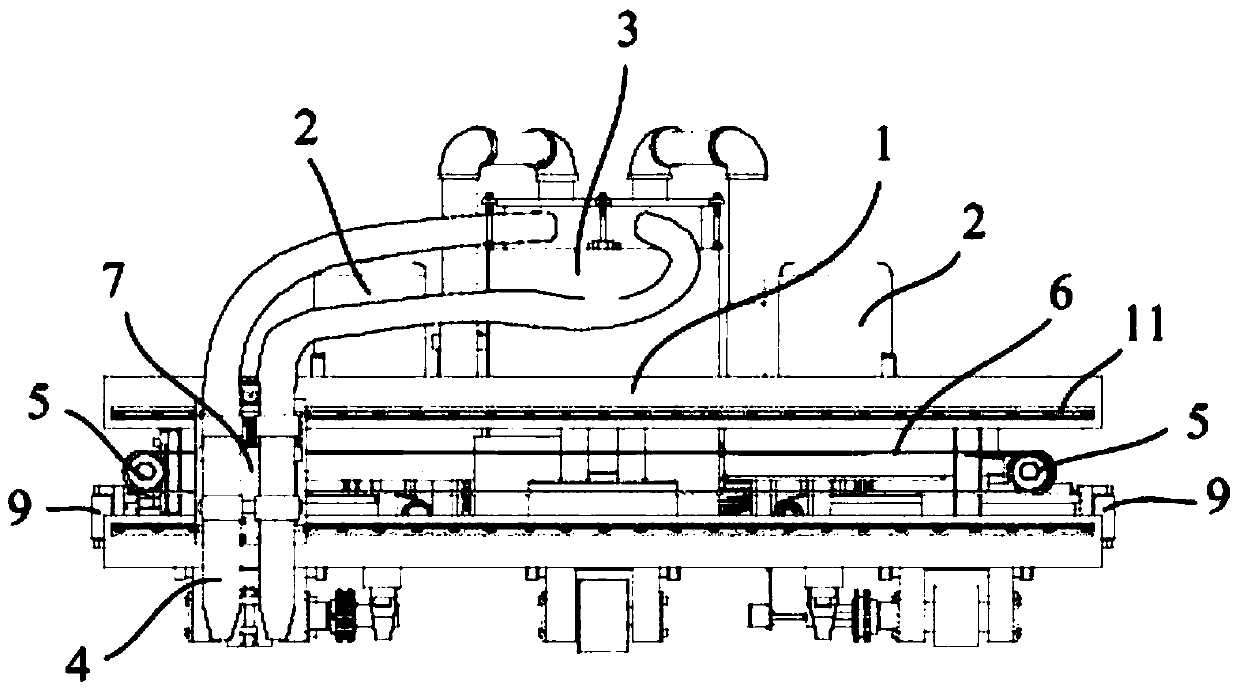

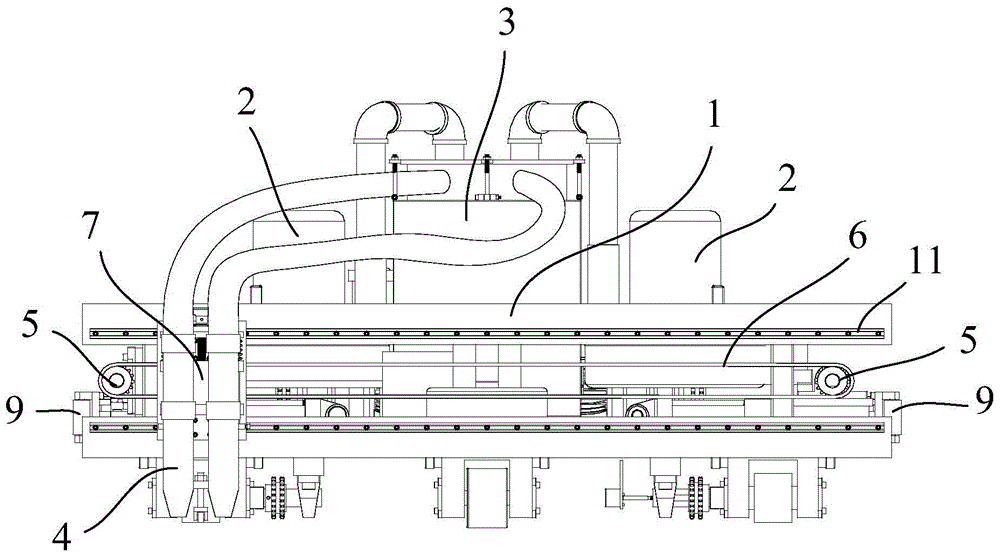

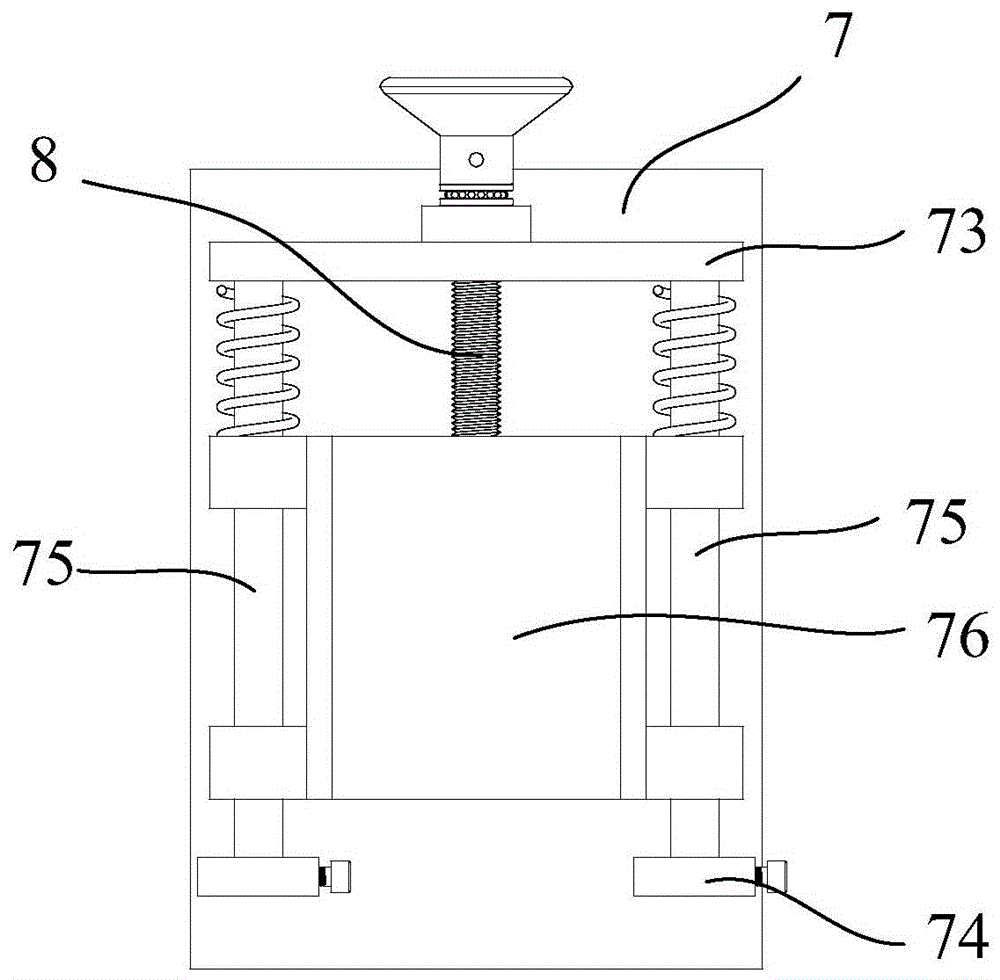

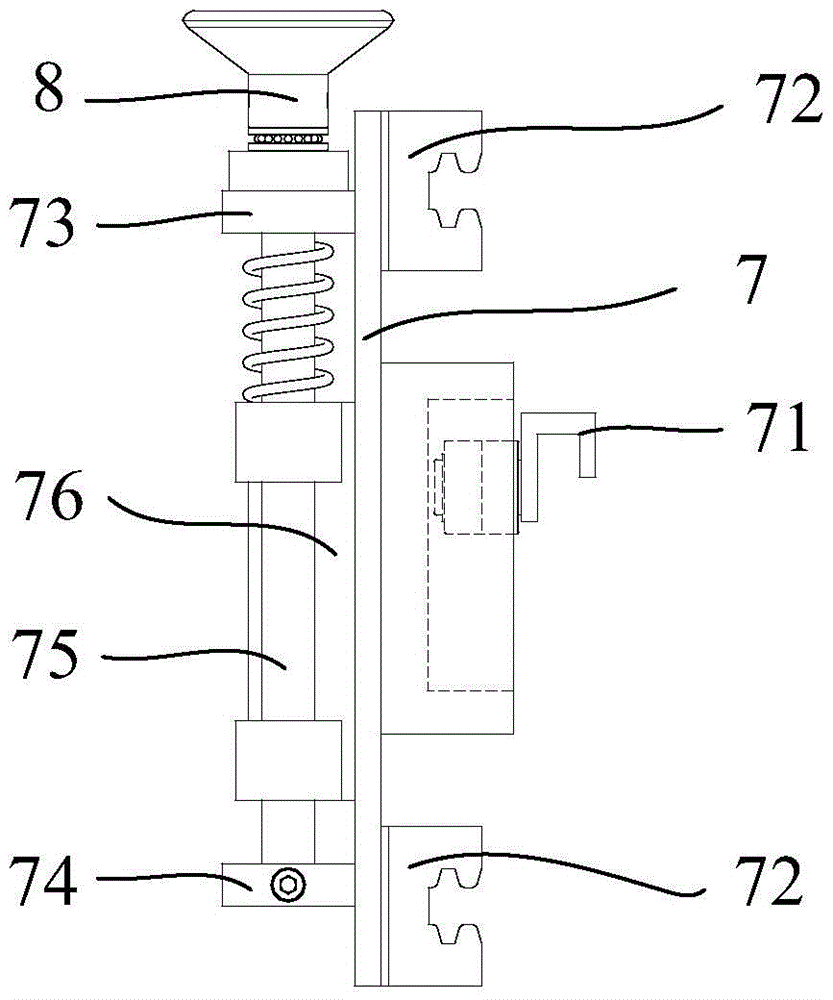

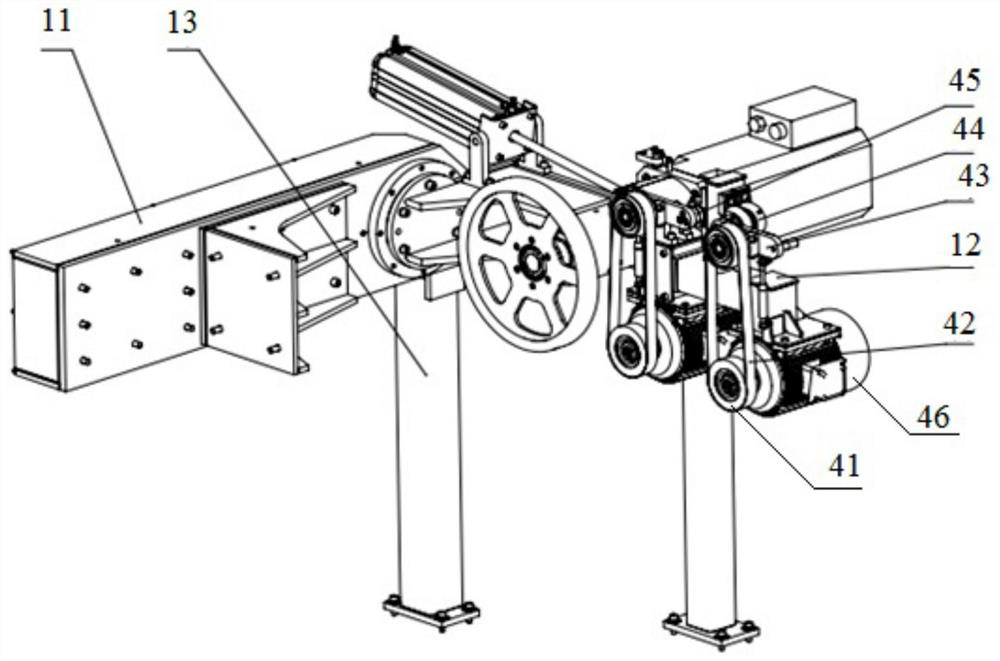

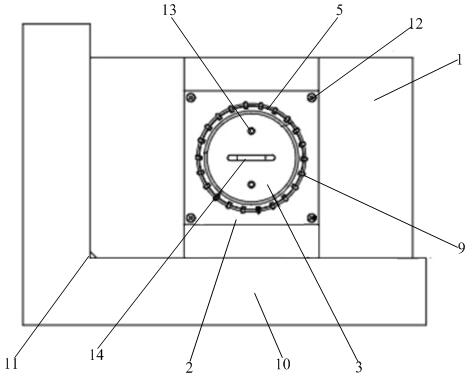

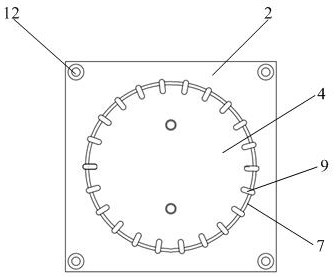

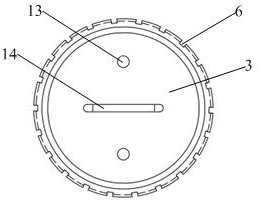

The invention belongs to the technical field of welding equipment, and relates to outdoor large-diameter pipe welding equipment, in particular to large-diameter steel pipe double-welding-gun intelligent welding equipment. Two semicircular rings surround a large-diameter pipe to be welded in middle, and the axes are overlapped; an annular motor drives an annular car to rotate along a ring; an axial motor drives welding guns to move in a direction parallel to the axes; a radial motor drives the welding guns to move in the radial direction; and a swing motor I drives the welding guns to swing. The large-diameter steel pipe double-welding-gun intelligent welding equipment can finish annular welding lines, can realize multi-layer and multi-way welding and swing welding, is high in welding efficiency, and guarantees the quality stability. The large-diameter steel pipe double-welding-gun intelligent welding equipment reduces labors and the labor intensity, prevents occupational injury, solves the problem of welder shortage, reduces the labor cost, uses double welding guns to improve the working efficiency twice, can weld multiple curved welding lines, is flexible in carrying, and is suitable for outdoor construction and use.

Owner:安徽颍瑞源焊管科技有限公司

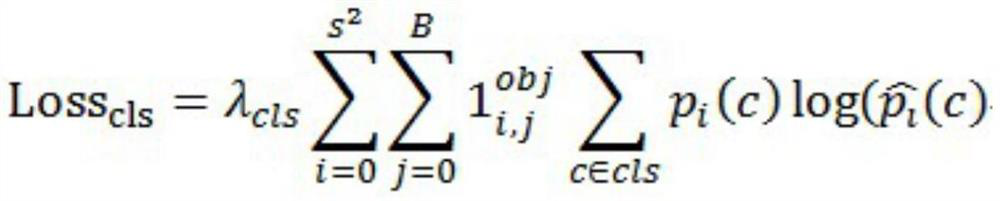

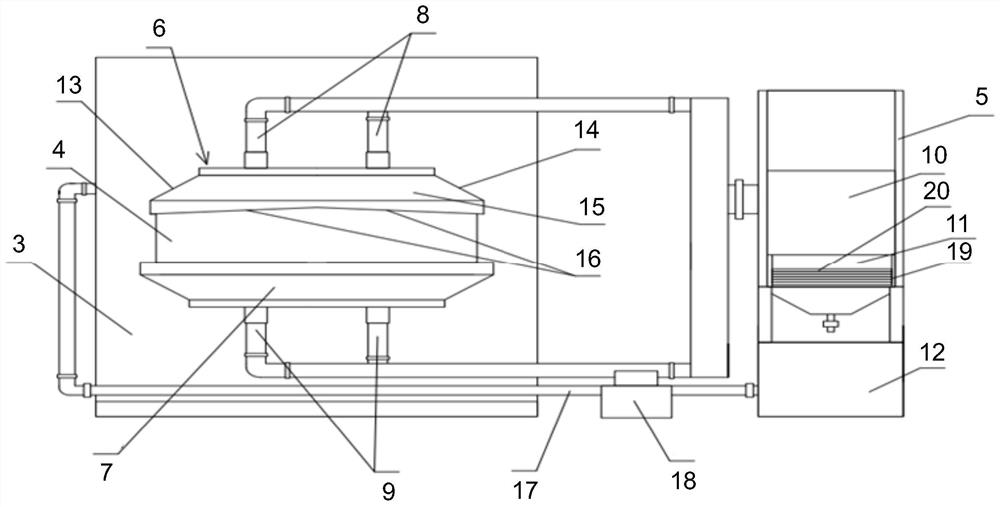

Surface-to-air-missile-type red lead energy-saving oxidizing furnace

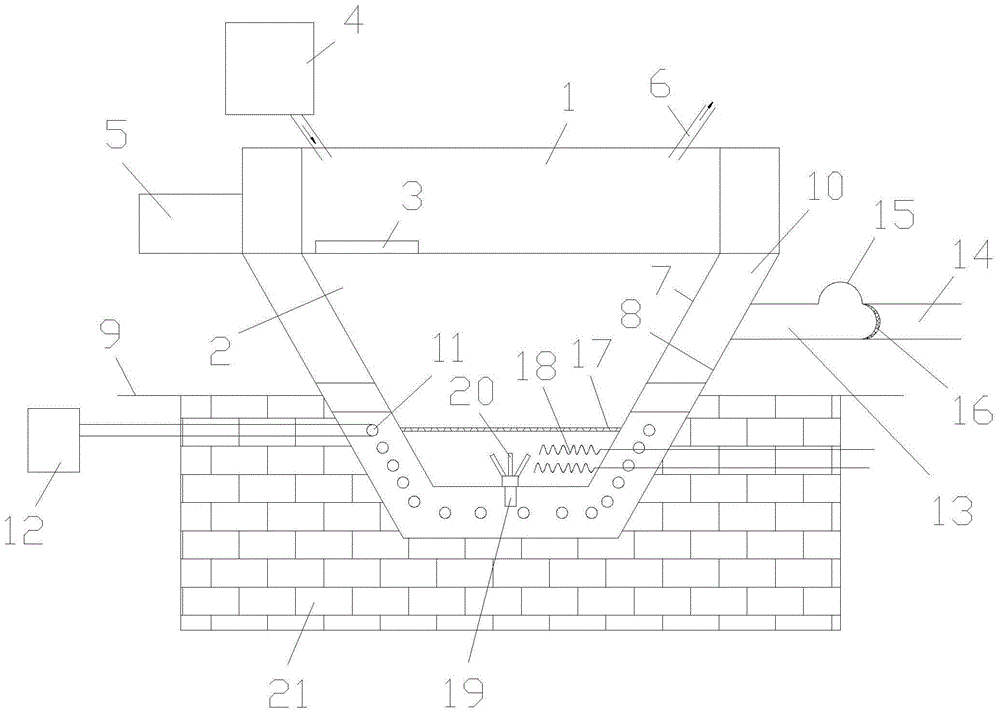

The invention discloses a surface-to-air-missile-type red lead energy-saving oxidizing furnace which comprises an oxidizing furnace body, wherein the oxidizing furnace body 1 is a cylinder structure, and is divided into an upper furnace body, a middle furnace body and a lower furnace body from top to bottom; and aluminum silicate fiber felt is wrapped around the outside of the oxidizing furnace body to achieve the effects of thermal insulation and sound insulation, and is fixed by a four-foot bracket. Heat generated by electric heating is blown by a Root's blower and directly sent into the oxidizing furnace via a heat transfer tube, thereby supplying heat to the raw material. The surface-to-air-missile-type red lead energy-saving oxidizing furnace can implement clean production to avoid environmental pollution, can implement quick preparation of red lead, enhances the production efficiency, maximally utilizes the energy, implements the microcomputer control on the oxidizing process, avoids the occupational hazards, and ensures good health of the staff.

Owner:JIESHOU CITY JUNMA IND & TRADE

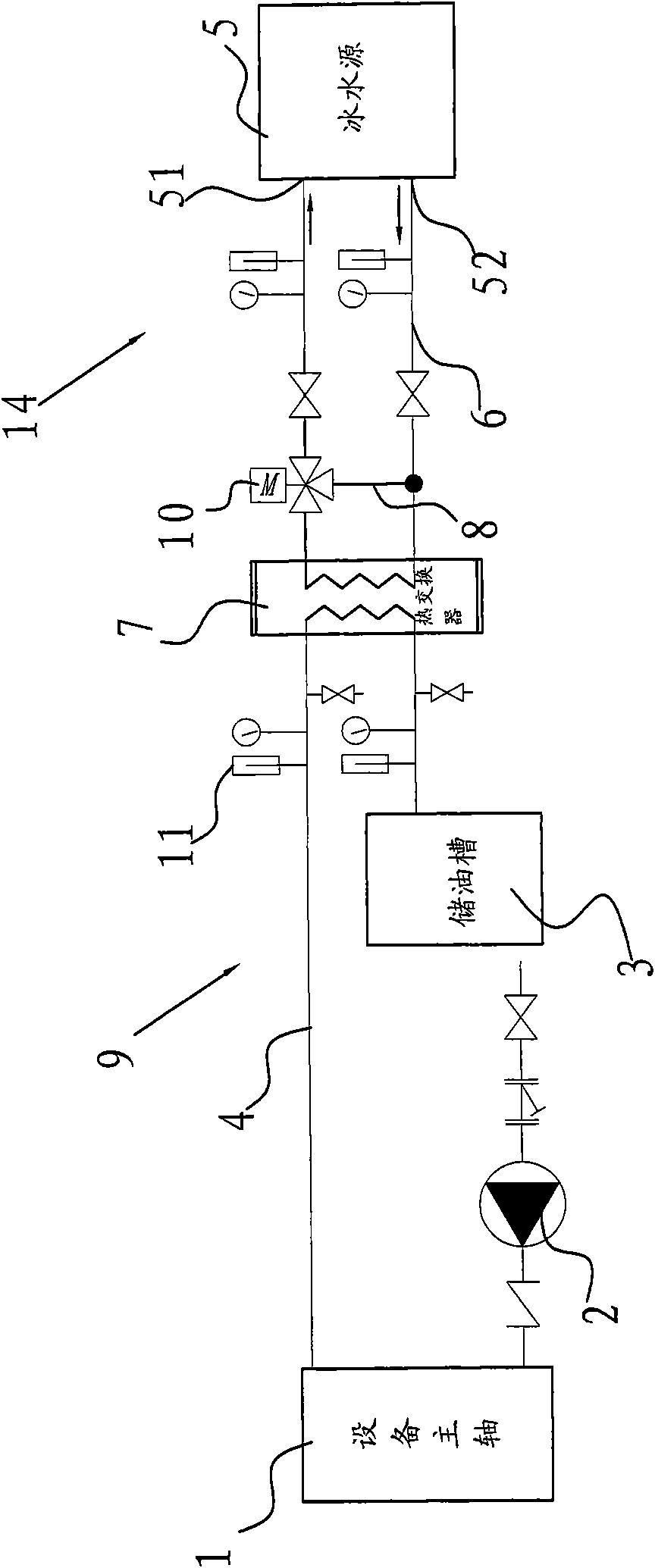

Liquid cooling system for device

The invention relates to a liquid cooling system for a device, which comprises a heat exchanger and two circulation loops including an oil circulation loop and an ice water circulation loop, wherein the oil circulation loop forms a closed loop by connecting an oil storage tank, a circulating pump, a main shaft of the device and the heat exchanger in turn through circulating oil pipes, and the ice water circulation loop forms a closed loop by connecting an ice water source and the heat exchanger in turn through circulating water pipes; and the cooling oil in the oil circulation loop and the ice water in the ice water circulation loop perform heat exchange in the heat exchanger so as to cool the oil temperature on the main shaft of the device. The liquid cooling system uses the circulation of a cooling medium ice water of the heat exchanger to take away the heat of oil cooling engine oil, and compared with the prior art, compressors and heat radiators for discharging the heat in a workshop out of the workshop are not needed. The liquid cooling system not only reduces the temperature of a working condition, but also removes a compressor radiator fan and prevents workers from being harmed by occupational diseases caused by dust and the like, and the working condition is comparatively comfortable.

Owner:KUNSHAN DINGXIN ELECTRONICS

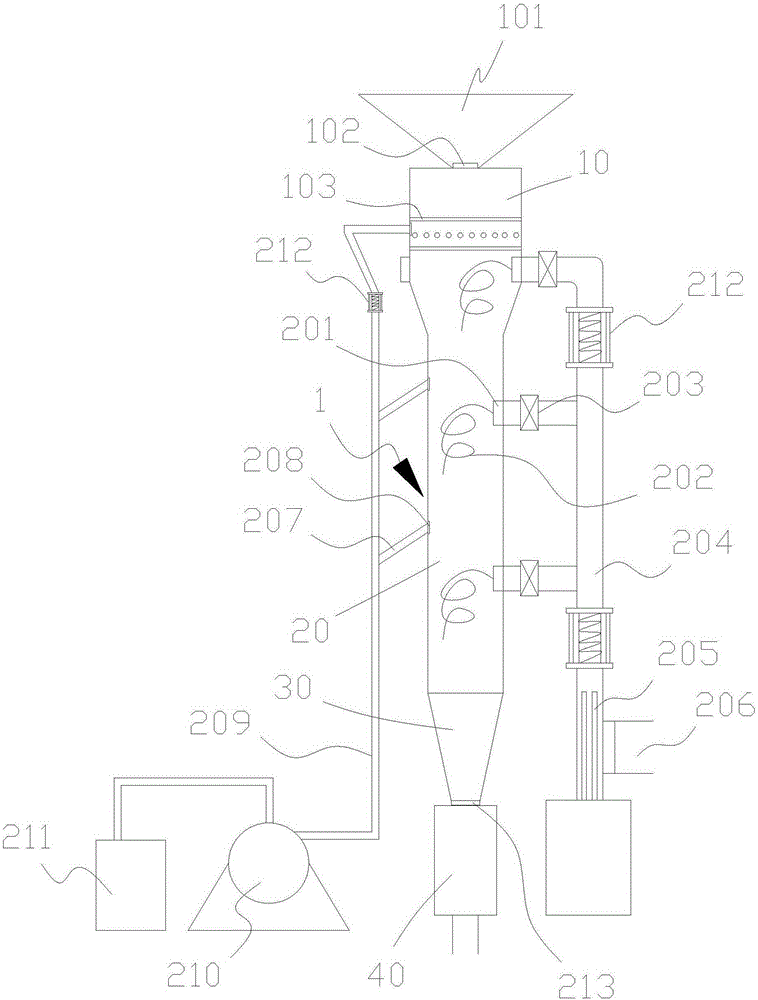

Water process energy-saving granulation technology for red lead production

A water process energy-saving granulation technology for red lead production comprises the following steps: (1) dedusting cooling (pretreatment); (2) screw conveying; (3) re-conveying; (4) deironing; (5) granulator starting; (6) water process granulation; and (7) exhausting dedusting. The technology has the advantages of simple process, easiness in operation, realization of automatic streamline working of the production flow of red lead, increase of the production efficiency, energy saving, consumption reduction, and avoiding of occupational hazards; and iron in lead powder is removed to provide guaranteeing for the production of the high-quality red lead product.

Owner:安徽徽能化工科技有限公司

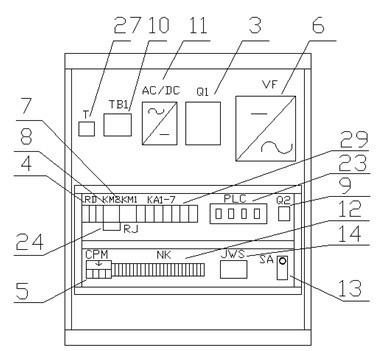

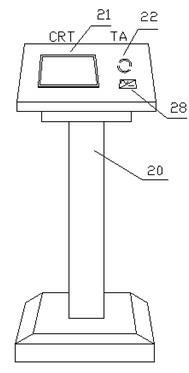

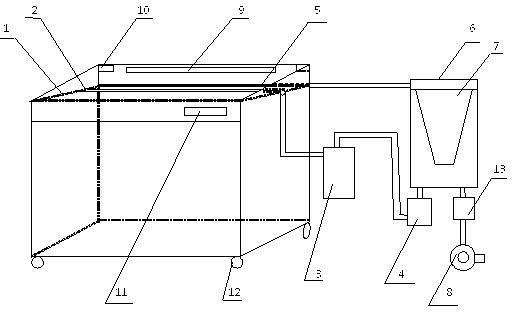

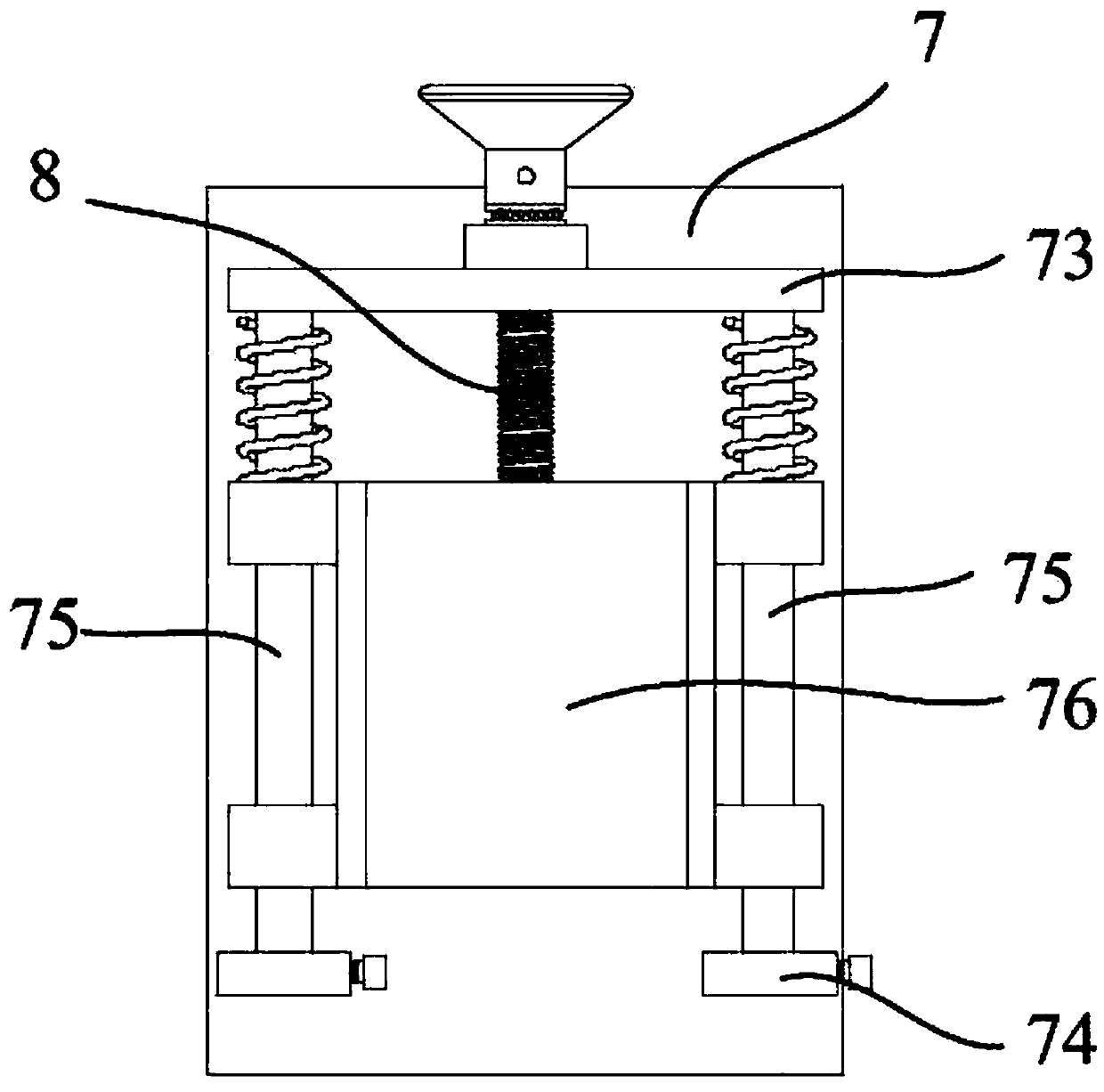

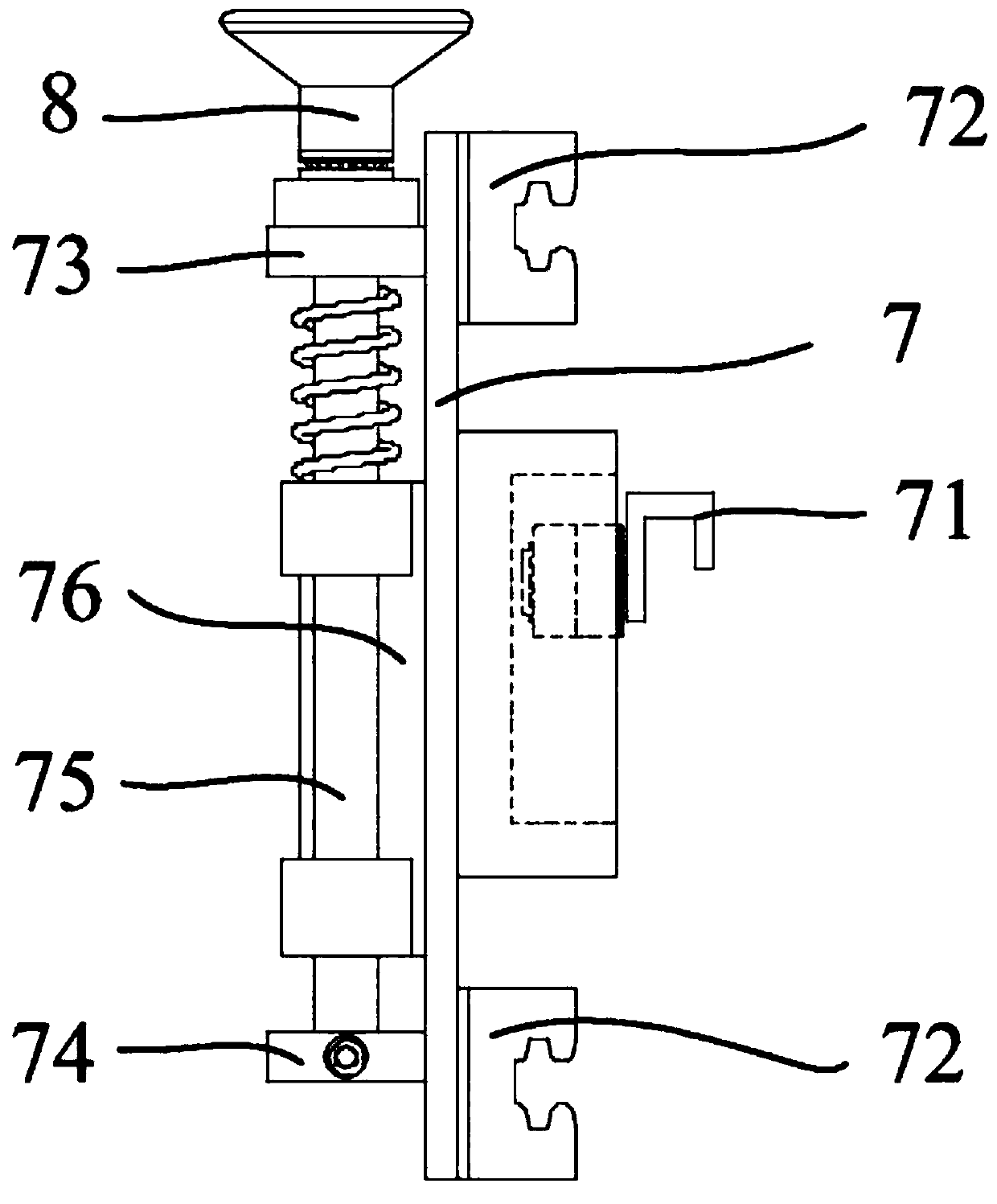

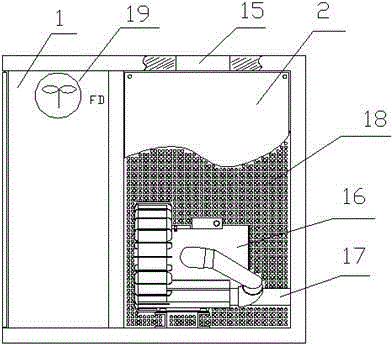

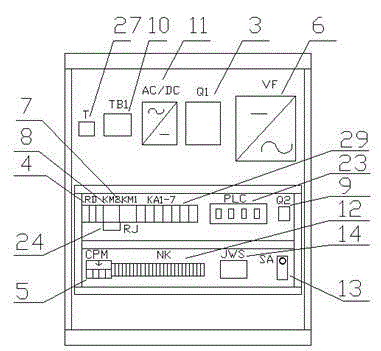

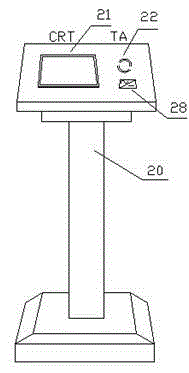

Intelligent control device for drying bright beads of fireworks and firecrackers

ActiveCN102564240AAvoid occupational hazardsFriendly operationFireworksFrequency changerHuman–machine interface

The invention relates to an intelligent control device for drying bright beads of fireworks and firecrackers. The intelligent control device comprises a human-machine interface operating system, a PLC (programmable logic controller) and a frequency converter control system, a drying air heater and an air supply system thereof, and a temperature-humidity sensor control system. The intelligent control device has the advantages that the technical level in the intelligent monitoring for the temperature and the humidity of a drying chamber for drying the bright beads is improved, the human-machine separation is realized, major production safety accidents about drying the bright beads in the production process of the fireworks and the firecrackers are effectively prevented and avoided, and the occupational hazard of firework agents to operators is prevented; simultaneously, due to the PLC and the frequency converter control system, the production process for drying the bright beads in the production process of the fireworks and the firecrackers is optimized; due to a frequency converter is adopted to drive the drying air heater, the speed adjusting performance is excellent, the power-saving effect is obvious, closed-loop control for the temperature and the humidity of the drying chamber is realized, the operating frequency of the hot air heater is accurately adjusted, the quality of products is improved, the production cost is reduced, the automation and the intelligentization in production of the bright beads of the fireworks and the firecrackers are realized, and the supporting platform of new technologies and safety technologies is improved.

Owner:天津瑞华云电力电子技术有限公司

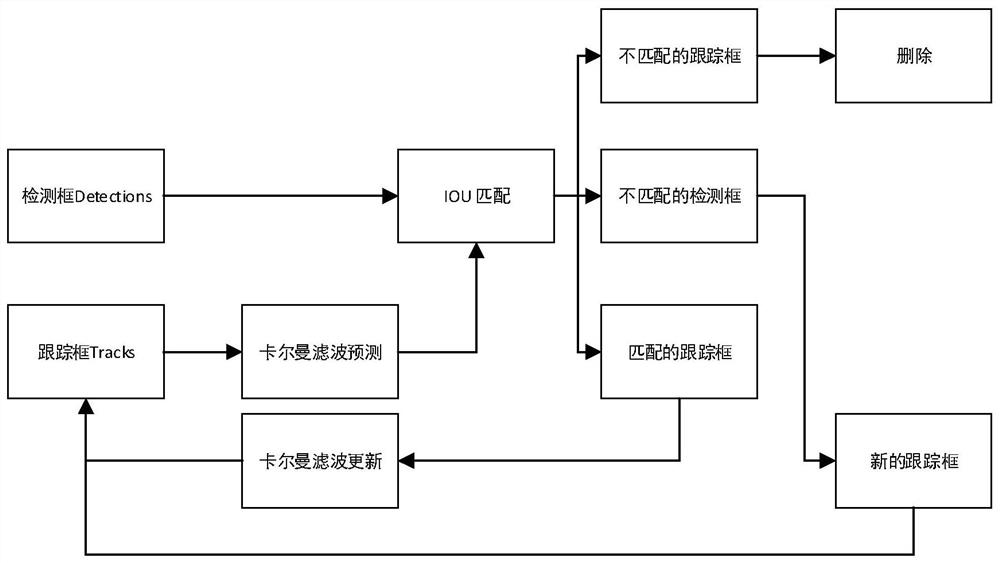

Under-mine drilling machine drill rod counting method based on computer vision

PendingCN113344882ARealize discoveryImplement trackingImage enhancementImage analysisComputer graphics (images)Engineering

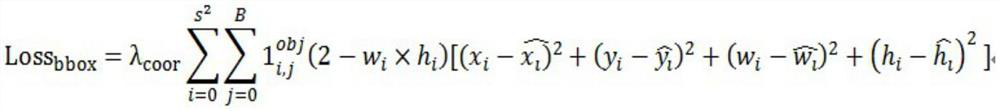

The invention discloses an under-mine drilling machine drill rod counting method based on computer vision, the method comprises the following steps: S1, acquiring drill rod image data, and dividing the drill rod image data into two types of data; s2, performing image enhancement processing on the two kinds of data; s3, adding Gaussian white noise of different proportions into each cleaned image; s4, locking the sample picture as a 416 * 416 image after being read in, wherein each image area passes through Darknet; s5, performing classification and regression tasks on the image candidate frame and the central point, width and height of the candidate frame, and modifying the output of the classification task to be 1; s6, monitoring the network to output a plurality of detection candidate frames by training a minimum loss function; s7, taking the test frame with the maximum confidence coefficient in the test frames as an input frame, sequentially calculating the IOU of the overlapped test frames, and when the calculated IOU value is greater than a set threshold value, filtering and repeating the step S7; and S8, carrying out tracking calculation on the monitored target by adopting image classification, a Kalman filtering algorithm and a Hungary algorithm.

Owner:成都光束慧联科技有限公司

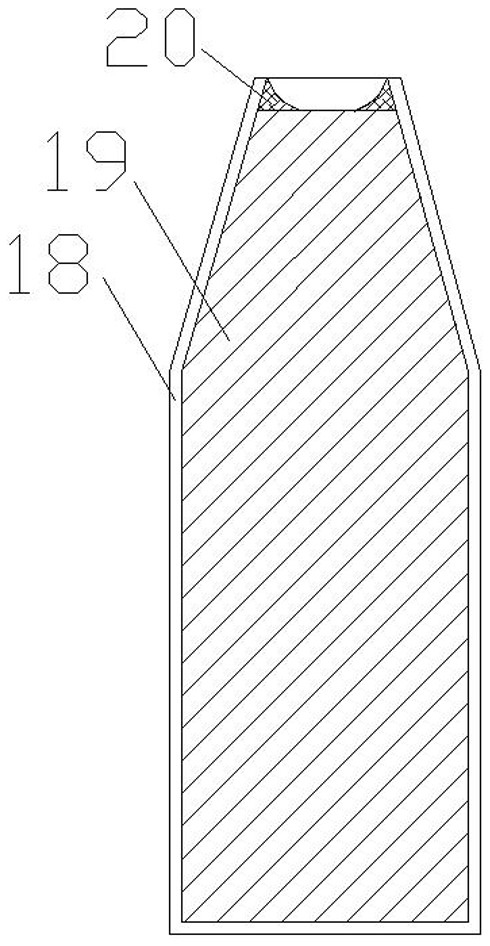

Taper double control automatic vacuum lead smelting furnace

The invention discloses a taper double control automatic vacuum lead smelting furnace. The taper double control vacuum lead smelting furnace integrates a preheating cabin with a melting cabin, the solar heating and the electric heating are automatically switched, and the taper vacuum lead smelting furnace fully uses waste heat. In the production process, not only can the solar thermal energy be effectively used, but also the heat energy generated in the production process is also fully recycled, and the energy-saving goal is achieved; the lead fume generated in the lead melting furnace is collected in an airtight mode and passes through an oxidizing furnace, then the original lead smoke and the lead smoke generated by the oxidizing furnace are discharged to a tail gas purifying system in an airtight mode, and the occupational hazard and the environmental pollution are fundamentally prevented from occurring effectively.

Owner:ANHUI UNIV OF SCI & TECH

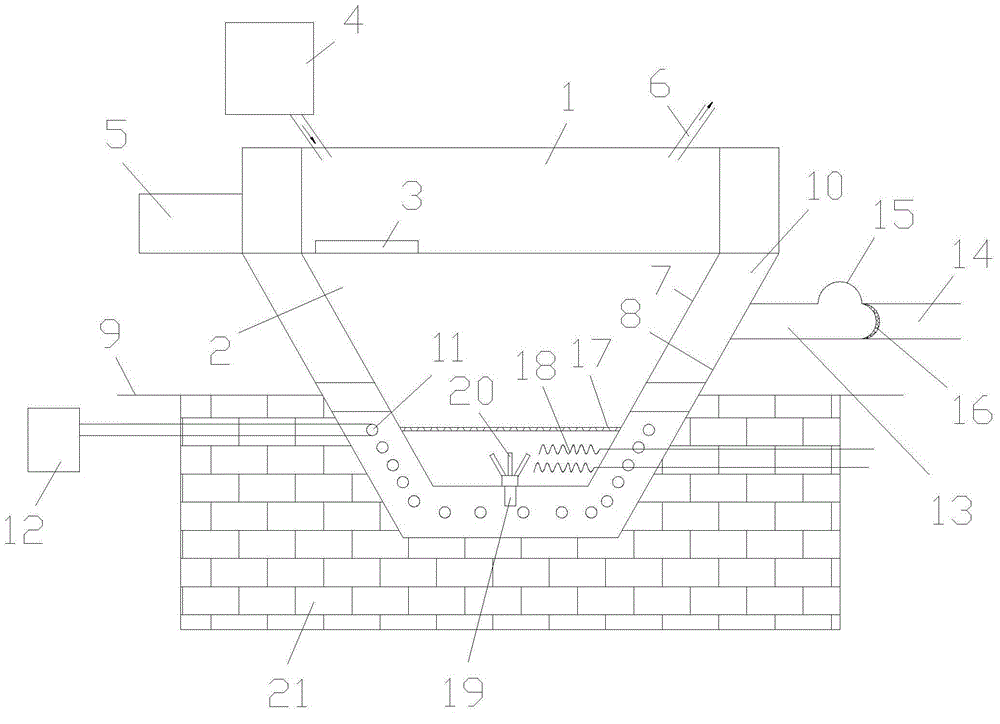

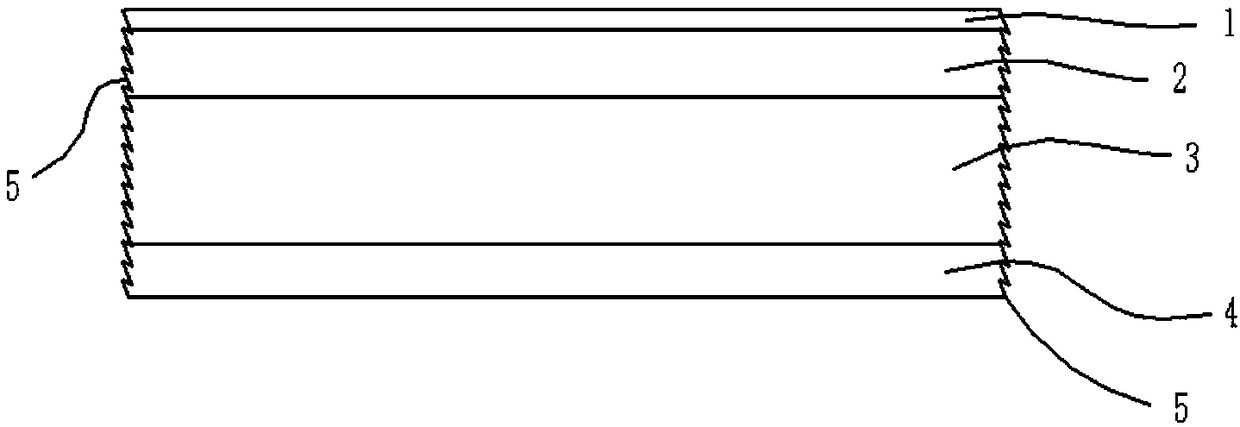

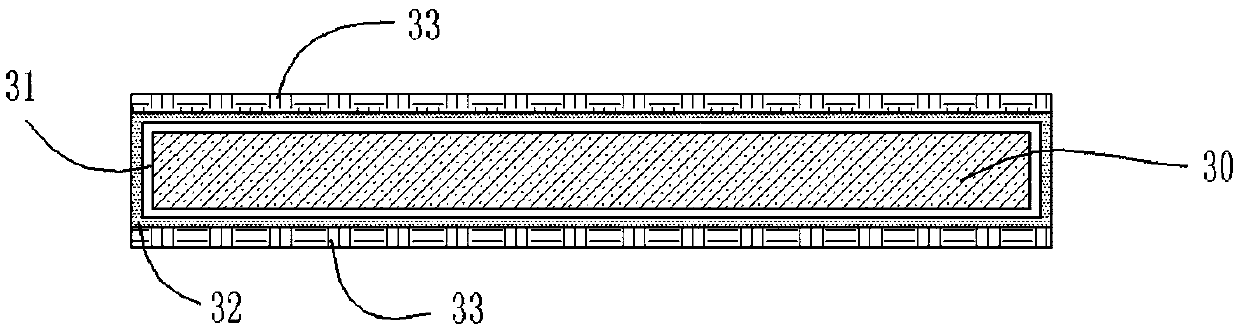

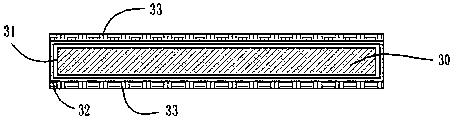

Modified fibre enhanced foaming cement composite floor and preparation method thereof

ActiveCN108824760ALighten the loadIncrease the use of spaceCovering/liningsFlooring insulationsThermal conductivityCement composites

The invention discloses a modified fibre enhanced foaming cement composite floor. The modified fibre enhanced foaming cement composite floor comprises a wearing layer, a decorative layer, an insulating layer and an interface connecting layer. The decorative layer is arranged below the wearing layer, the insulating layer is arranged below the decorative layer, and the interface connecting layer isarranged below the insulating layer. The preparation method comprises the steps of preparing modified fibre, making an insulation plate, making the insulating layer, and post processing of the insulating layer. The modified fibre enhanced foaming cement composite floor has the advantages of high compressive strength, sound insulation, low thermal conductivity, steady chemical property, environmental protection, small deformation and the like. The construction only needs to use special adhesive mortar to paste directly in the base layer, the working procedure is few, the construction is quick,and the efficiency is high. Product tight seam splices, maintenance and replacement are convenient.

Owner:上海天行新型材料有限公司

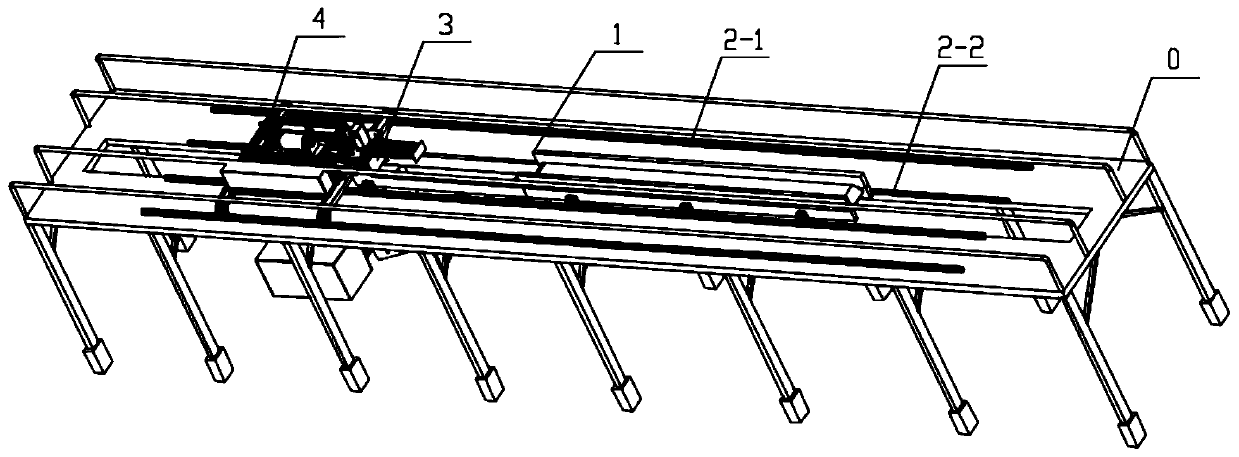

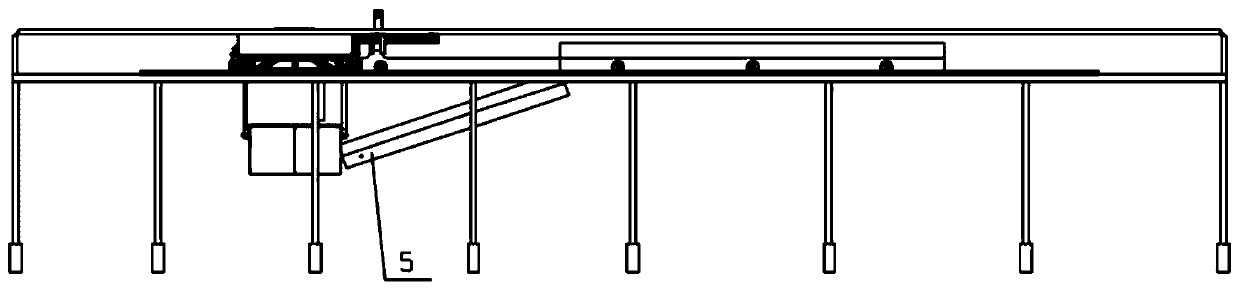

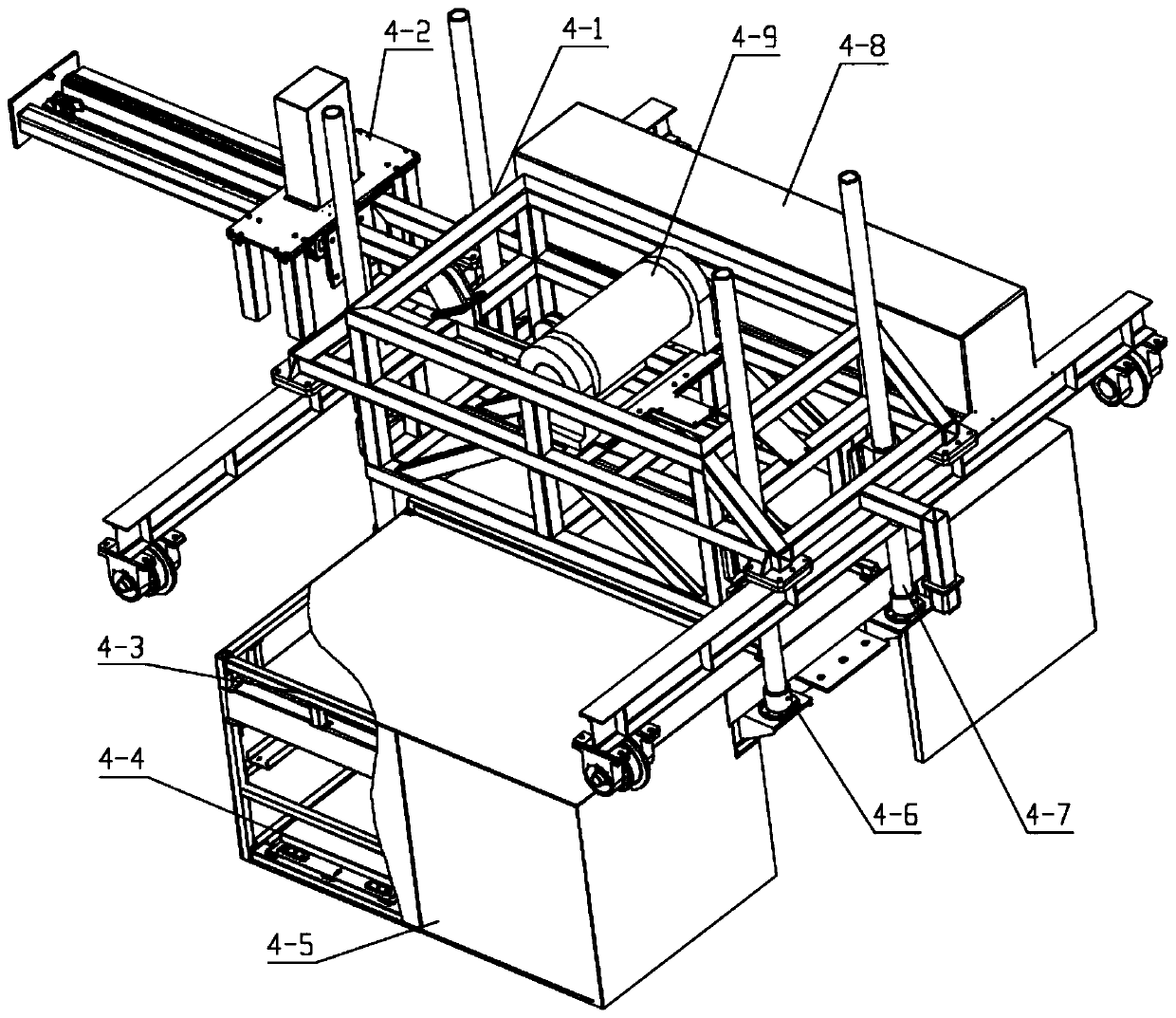

Automatic truck loading device for bagged powder materials

PendingCN110255230APrevent proliferationReduce manufacturing costLoading/unloadingEngineeringConveyor belt

The invention discloses an automatic truck loading device for bagged powder materials. The device comprises a belt conveying trolley, a guide rail, a first winch, a truck loading part, a conveyor belt and a supporting platform, wherein the belt conveying trolley is connected to an inner guide rail; the first winch is arranged at the front end of the belt conveying trolley; the rear end of the conveyor belt is hinged with the middle part of the belt conveying trolley, and the front end of the conveyor belt is connected to a steel wire rope of the first winch; and the front end of the conveyor belt is corresponding to a gap in a cover surface in position. According to the device, the truck loading part and the belt conveying trolley move to adjust the truck loading height and length in order to fit different trucks; a grabber is capable of being close to the bottommost layer of a carriage to the maximum through a Z-direction cylinder by moving, and thus the problem that dust flies in the carriage while the bagged powder materials are conveyed into the carriage can be completely solved; the flying dust is further prevented from spreading through a dust collecting cover; two groups of clamping claws alternatively work and can be interlinked through a plurality of shafts, so that the truck loading efficiency is extremely improved; machines replace workers, so that the occupational hazard is avoided; the working efficiency is improved; and the production cost is decreased.

Owner:徐州思迈德智能装备有限公司

Automatic metal pipeline outer wall plastic coating machine

PendingCN112108291AImprove spraying effectAvoid Occupational HazardsSpraying apparatusStructural engineeringManufacturing engineering

The invention discloses an automatic metal pipeline outer wall plastic coating machine which comprises a fixing frame rail, an intelligent plastic spraying system and two rotary driving fixing frames;the two rotary driving fixing frames of the same structure are symmetrically arranged and installed on the fixing frame rail and can move along the fixing frame rail; when a to-be-sprayed pipeline isinstalled between the two rotary driving fixing frames, the two rotary driving fixing frames retreat to the tail ends of the two sides of the fixing frame rail, and after the to-be-sprayed pipeline is inserted into center holes of the rotary driving fixing frames on the two sides, the rotary driving fixing frames on the two sides advance to a machining position and clamp the to-be-sprayed pipeline; and the intelligent plastic spraying system is arranged on one side or two sides of the to-be-sprayed pipeline and used for coating the to-be-sprayed pipeline with plastic. The automatic metal pipeline outer wall plastic coating machine is high in intelligent degree, high in productivity, high in plastic spraying quality uniformity and good in plastic spraying effect, and is excellent large-diameter metal pipeline plastic spraying equipment.

Owner:HARBIN KENENG CLADDING TECH +2

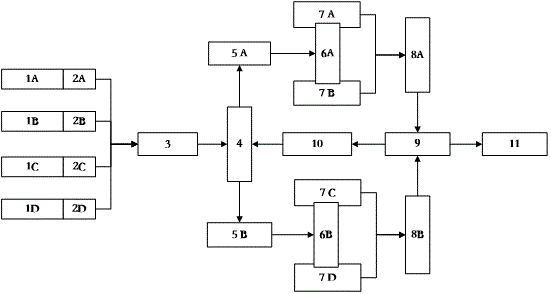

System of premixing regenerated tobacco leaf production raw materials according to formula

InactiveCN105581365AMeet the needs of premixingImprove uniformityTobacco preparationAgricultural engineeringEngineering

The invention relates to a system of premixing regenerated tobacco leaf production raw materials according to a formula. The system is characterized by comprising a stored material conveying machine, a metering device, a first-level belt conveyor, a bidirectional belt conveyor, two second-level belt conveyors, two transverse movement and material distribution machines, four formula cabins, two third-level belt conveyors, a material distribution device, a fourth-level belt conveyor and a fifth-level belt conveyor. The system has the advantages of being good in tobacco raw material mixing uniformity, large in raw material processing capacity, simple in equipment and process procedure, high in equipment use efficiency, high in operability and capable of avoiding hazards of occupational disease.

Owner:ZHONGYAN SHIWEICE (YUNNAN) RECONSTITUTED TOBACCO CO LTD

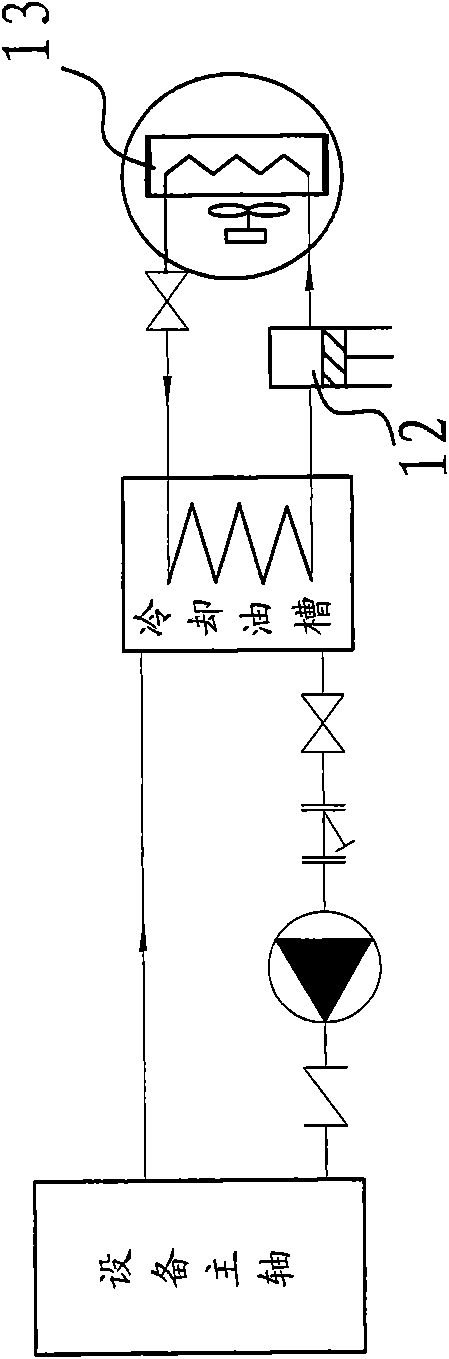

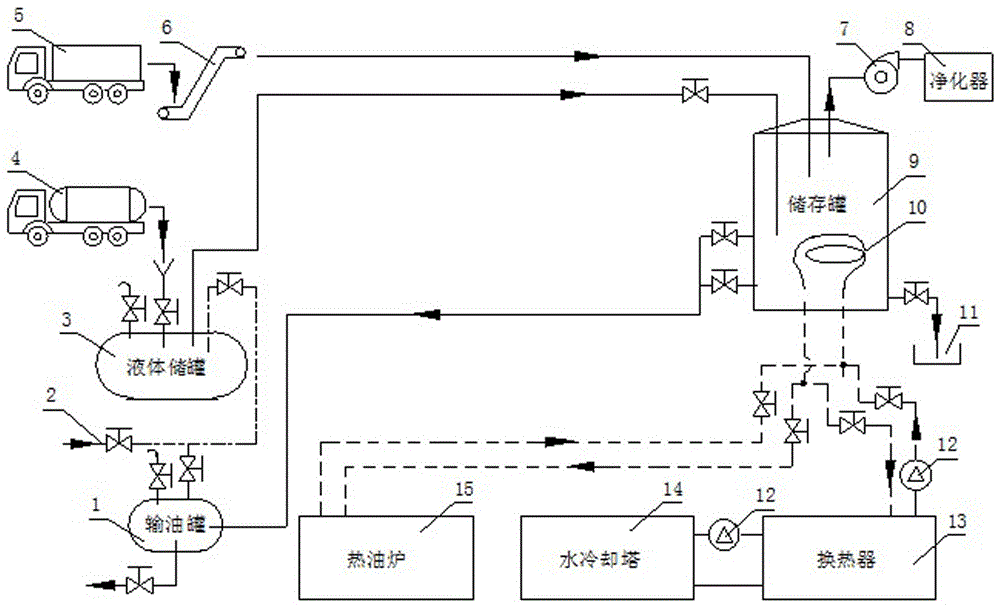

Environment-friendly bitumen dissolving and conveying system and method in carbon product industry

InactiveCN106190212AFree from occupational injuryFree from pollutionWorking-up pitch/asphalt/bitumen by meltingLiquid storage tankDelivery system

The invention discloses an environment-friendly bitumen dissolving and conveying system and method in the carbon product industry. A heat exchange pipe in a storage tank of the system is connected with a heat exchanger and a hot oil furnace through control valves respectively. The upper end of the storage tank is provided with a solid bitumen inlet, a liquid bitumen inlet and a smoke exhaust port. The liquid bitumen inlet is communicated with a liquid storage stank through a pipeline and a control valve. The smoke exhaust port is connected with a purifier through a fan. The lower end of the storage tank is communicated with an oil conveying tank through a pipeline and a control valve. The oil conveying tank and the liquid storage tank are connected with a compressed air pipe through control valves respectively. A discharge pipe is arranged on the oil conveying pipe. An internal liquid sensor and a temperature sensor are arranged in the storage tank. Raw materials are under completely sealed conditions since entering stations, automatic production is realized, the working environment is good, bitumen-induced occupational injuries and pollution of bitumen to the air are avoided, energy conservation and environmental protection are achieved, and damage to pumps and valves due to bitumen solidification cannot be caused.

Owner:冯建国 +1

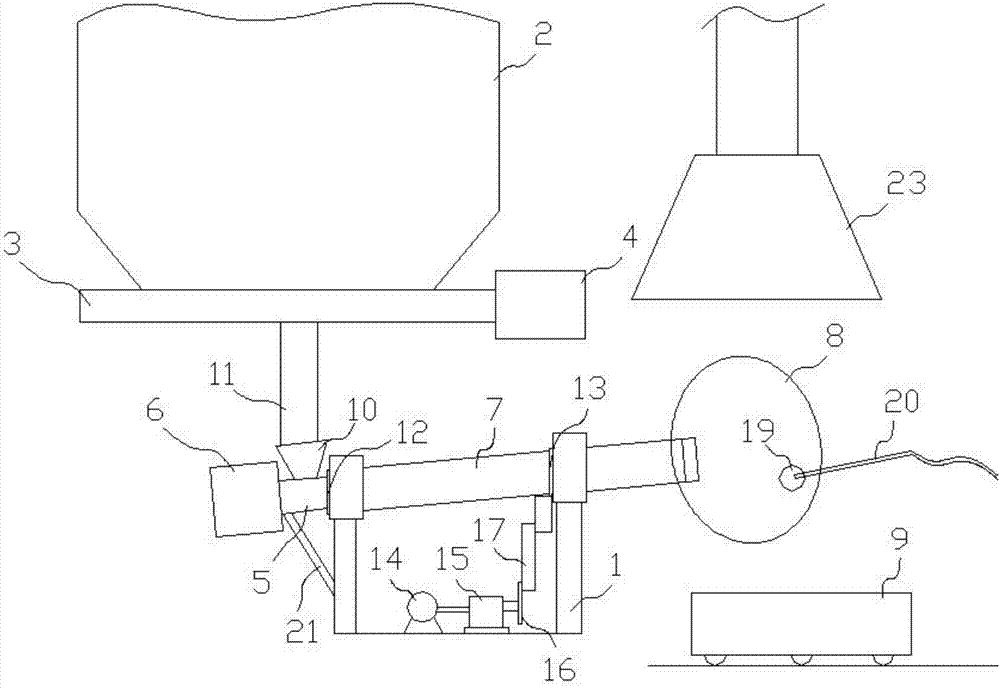

Large-diameter steel pipe double welding torch intelligent welding equipment

ActiveCN107414369BImprove welding efficiencyQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesMotor driveArchitectural engineering

The invention belongs to the technical field of welding equipment, and relates to outdoor large-diameter pipe welding equipment, in particular to large-diameter steel pipe double-welding-gun intelligent welding equipment. Two semicircular rings surround a large-diameter pipe to be welded in middle, and the axes are overlapped; an annular motor drives an annular car to rotate along a ring; an axial motor drives welding guns to move in a direction parallel to the axes; a radial motor drives the welding guns to move in the radial direction; and a swing motor I drives the welding guns to swing. The large-diameter steel pipe double-welding-gun intelligent welding equipment can finish annular welding lines, can realize multi-layer and multi-way welding and swing welding, is high in welding efficiency, and guarantees the quality stability. The large-diameter steel pipe double-welding-gun intelligent welding equipment reduces labors and the labor intensity, prevents occupational injury, solves the problem of welder shortage, reduces the labor cost, uses double welding guns to improve the working efficiency twice, can weld multiple curved welding lines, is flexible in carrying, and is suitable for outdoor construction and use.

Owner:安徽颍瑞源焊管科技有限公司

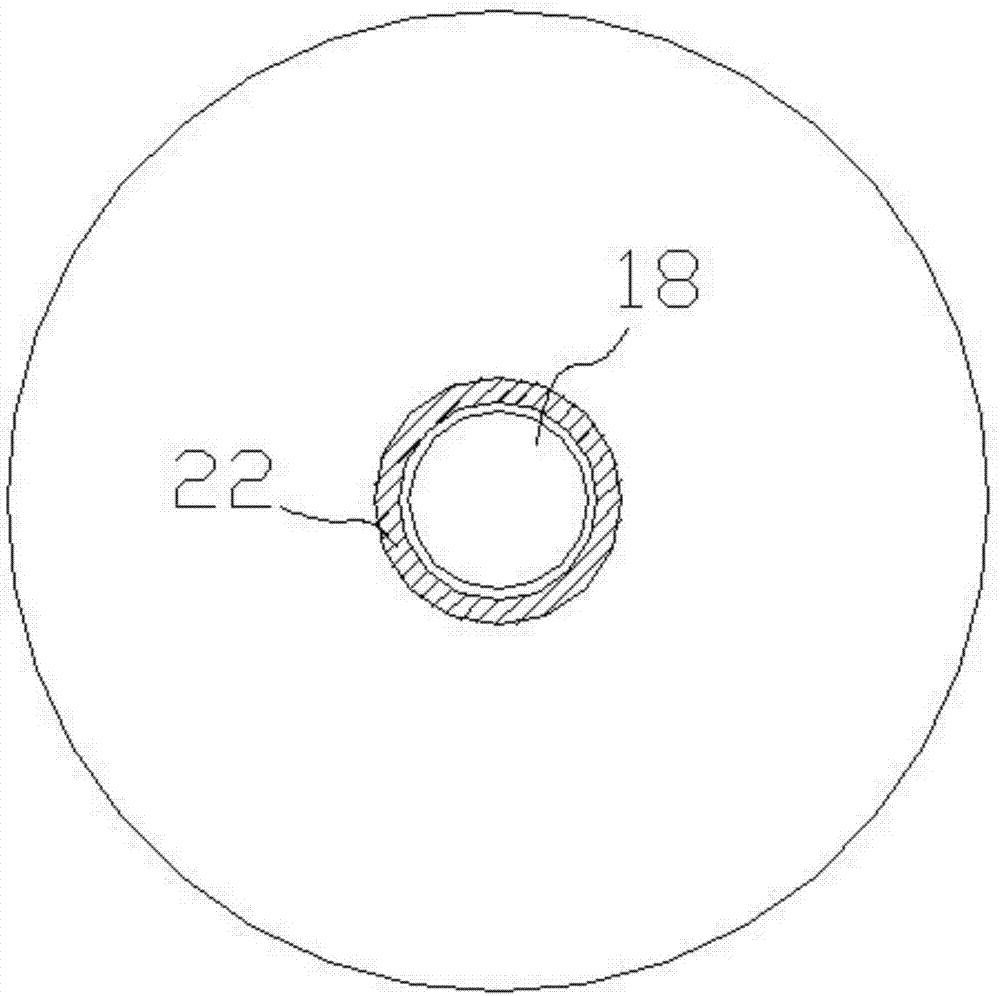

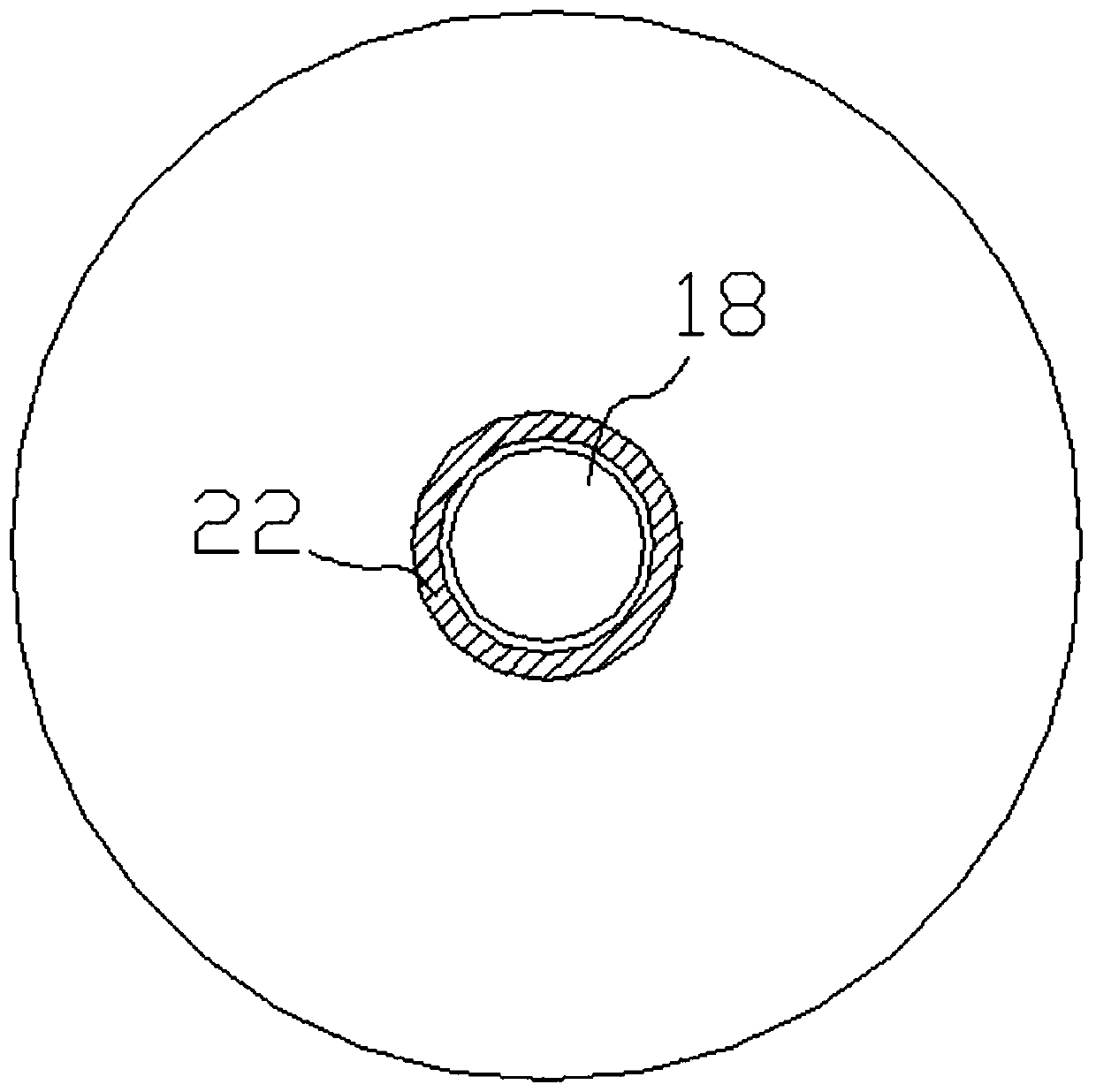

Novel hydraulic wear-resisting sealing ring and machining process

PendingCN110725954AAvoid occupational hazardsAvoid harmEngine sealsDomestic articlesNonferrous metalFilling materials

The invention discloses a novel hydraulic wear-resisting sealing ring and a machining process. The novel hydraulic wear-resisting sealing ring comprises a sealing ring body, a groove and an oil discharge trough. The groove is formed in the edge of one side of the inner diameter of the sealing ring body. The oil discharge trough is correspondingly formed in the other face, opposite to the groove, of the sealing ring body. The machining process comprises the following steps of firstly, raw material selecting, secondly, raw material mixing, thirdly, injection molding, fourthly, turning and fifthly, checking and packaging. Components comprise, by weight percent, 100-150 parts of modified TPU, 2-3 parts of a tackifier, 2-3 parts of phyllosilicate powder, 2-3 parts of a release agent and 2-3 parts of color masters. According to the novel hydraulic wear-resisting sealing ring and the machining process, the occupational hazard brought by the situation that employees are in contact with the dust process is thoroughly eradicated; and the process that nonferrous metal (bronze powder) is used as a filling material is omitted, and the danger brought by the nonferrous metal to the environment iseradicated.

Owner:GUANGZHOU CITY BANSHANG RUBBER PROD CO LTD

Surface-to-air missile type red lead energy-saving oxidation furnace

The invention discloses a surface-to-air-missile-type red lead energy-saving oxidizing furnace which comprises an oxidizing furnace body, wherein the oxidizing furnace body 1 is a cylinder structure, and is divided into an upper furnace body, a middle furnace body and a lower furnace body from top to bottom; and aluminum silicate fiber felt is wrapped around the outside of the oxidizing furnace body to achieve the effects of thermal insulation and sound insulation, and is fixed by a four-foot bracket. Heat generated by electric heating is blown by a Root's blower and directly sent into the oxidizing furnace via a heat transfer tube, thereby supplying heat to the raw material. The surface-to-air-missile-type red lead energy-saving oxidizing furnace can implement clean production to avoid environmental pollution, can implement quick preparation of red lead, enhances the production efficiency, maximally utilizes the energy, implements the microcomputer control on the oxidizing process, avoids the occupational hazards, and ensures good health of the staff.

Owner:JIESHOU CITY JUNMA IND & TRADE

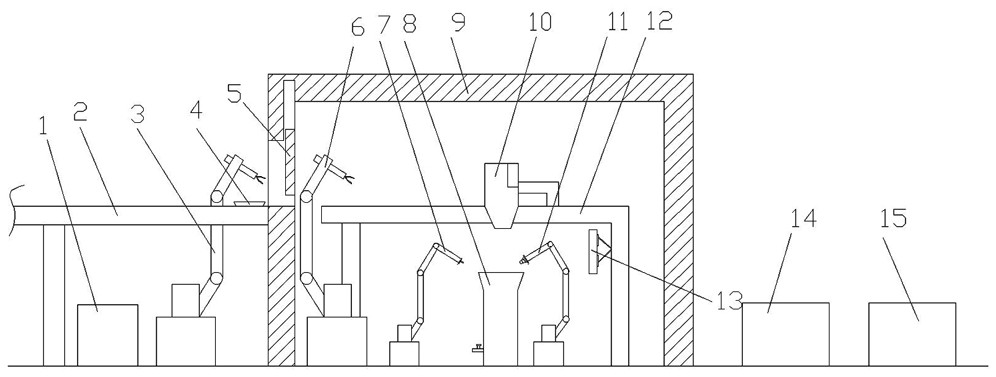

Grenade powder surface finishing equipment

The invention discloses grenade powder surface finishing equipment which comprises an anti-explosion chamber, a conveying device and a finishing device. An anti-explosion window used for transmitting grenades is arranged on one side of the anti-explosion chamber, and the anti-explosion window can be automatically closed and opened in the working process; the conveying device is arranged close to the outer part of the anti-explosion window and comprises a conveying belt and a tray which is arranged on the surface of the conveying belt and is used for placing grenades, and a transfer manipulator is arranged on one side of the conveying device; the trimming device is arranged in the anti-explosion chamber and comprises an overturning mechanical arm close to the inner side of the anti-explosion window and a workbench close to the overturning mechanical arm, the overturning mechanical arm is used for receiving and overturning the grenades from the transferring mechanical arm, and a grenade body bin matched with the grenades in external size is arranged on the workbench. Compared with the prior art, the equipment is reasonable in design, simple in structure, capable of achieving automatic, rapid and safe milling, drilling, smashing and purging of flanges on medicine surfaces, high in safety and high in efficiency, and the labor intensity of workers is effectively reduced.

Owner:HENAN NORTHERN HONGYANG ELECTROMECHANICAL CO LTD

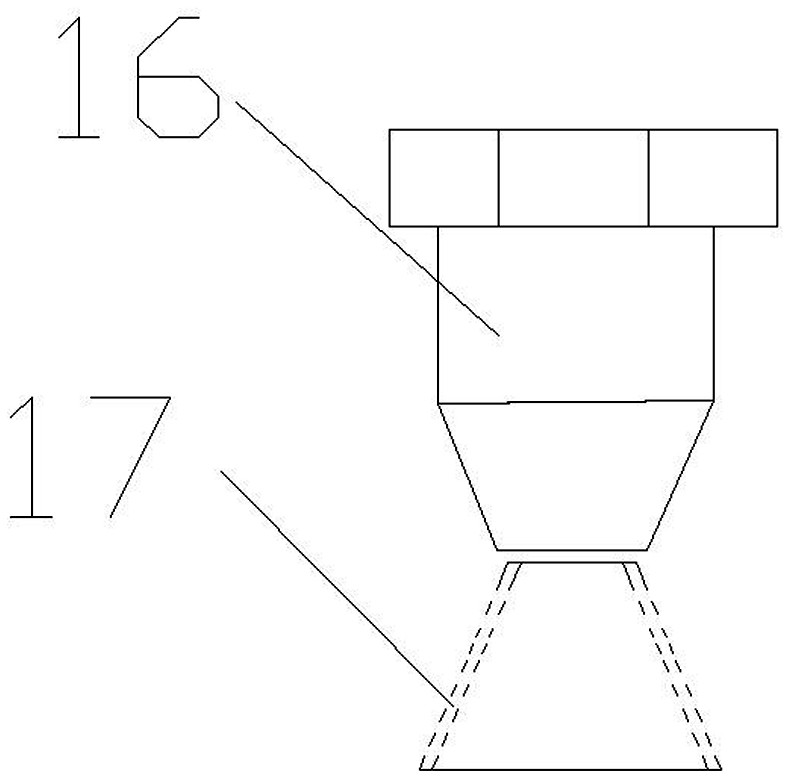

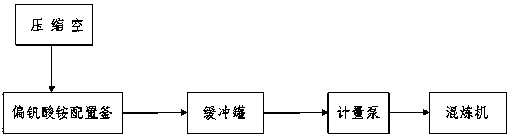

Automatic conveying method for ammonium metavanadate solution

InactiveCN108870079AReduce exposureAvoid occupational hazardsPipeline systemsEcological environmentBuffer tank

The invention discloses an automatic conveying method for ammonium metavanadate solution. A compressed air source is introduced by an exhaust hole in an ammonium metavanadate solution configuration kettle, a buffer tank is additionally arranged, a process pipeline is installed from the bottom of the configuration kettle to the buffer tank, a pipeline is installed from the buffer tank to an inlet of a metering pump, and the ammonium metavanadate solution is sent to a mixing machine through the metering pump. The method has the advantages that sealing and conveying of the ammonium metavanadate solution are realized, personnel contact is reduced, and occupational health and ecological environment of workers are protected; and the labor intensity of workers is reduced; and the adding amount ismore accurate during the material mixing process.

Owner:新疆中泰国信节能环保有限公司

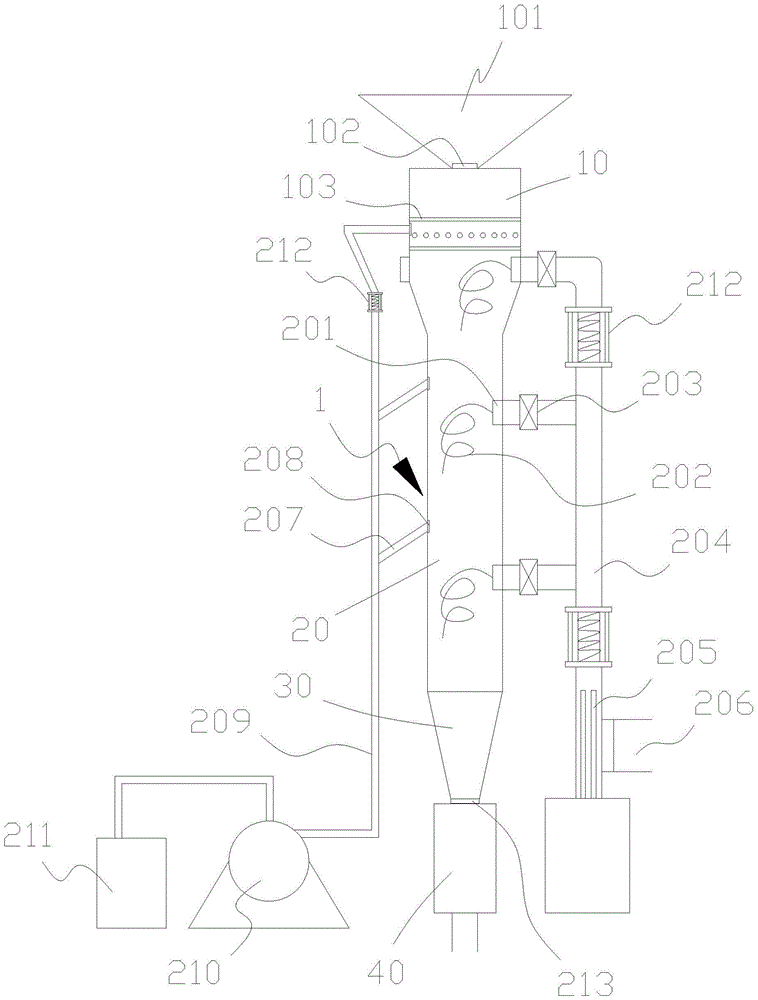

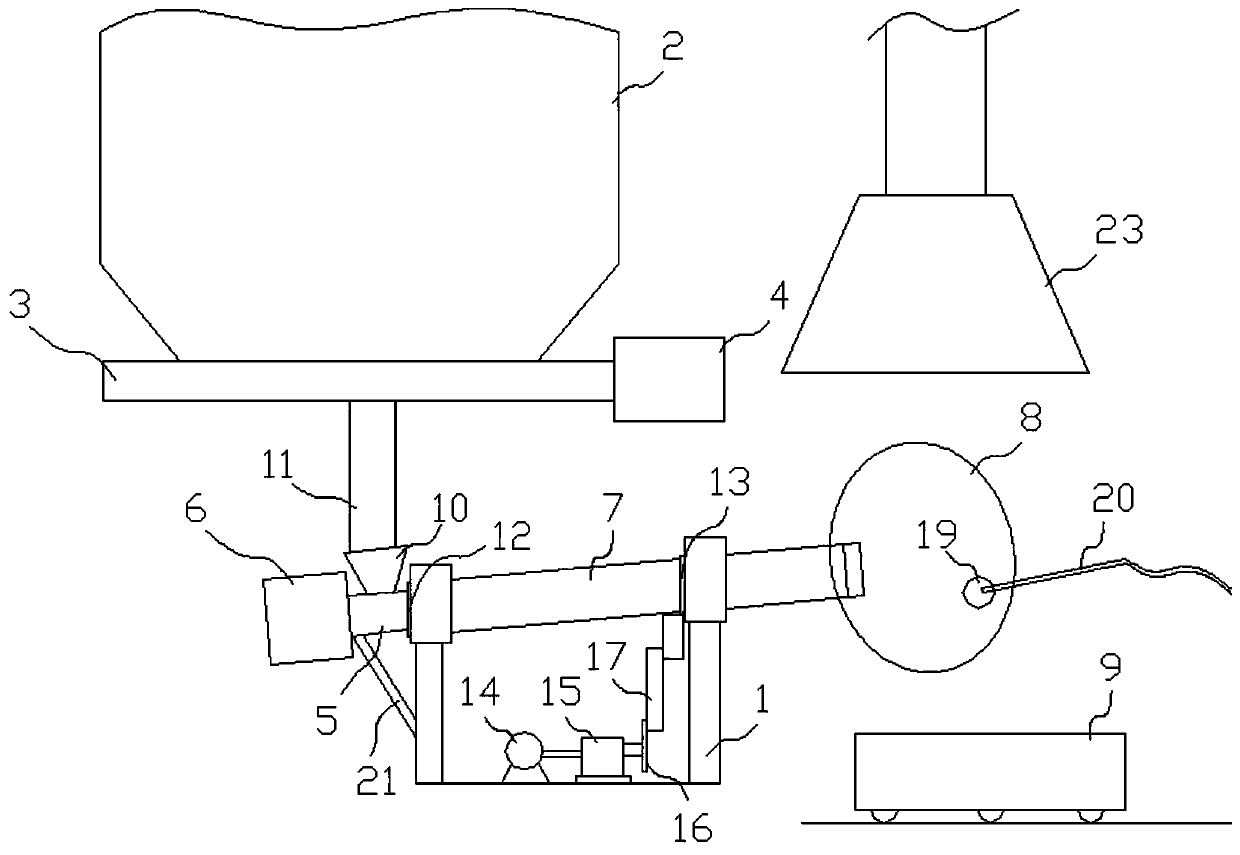

A water-based energy-saving granulation device for red lead production

ActiveCN107470312BImprove qualitySimple structureDispersed particle filtrationChemical industryPipe waterTap water

A water-based energy-saving granulation device for red lead production, comprising: a bracket, a bag filter, a discharge auger, a discharge motor, a feed auger, a feed motor, a tube barrel, a granulation cylinder and a storage box, the The granulation cylinder is installed on the bracket, the feeding auger is installed in the tube, one end extends to the granulation cylinder, and the other end is connected to the feeding motor, and the discharge auger is horizontally installed at the bottom of the bag filter , one end of the discharge auger is connected to the discharge motor, and the outlet of the discharge auger is connected to the inlet of the feed auger; a tap water pipe is installed next to the granulation cylinder, and the outlet of the tap water pipe Connect the hose and install a gate valve to control the water output. The other end of the hose is equipped with a faucet, and the outlet of the granulation cylinder goes deep into the interior of the granulation cylinder. The invention automates the red lead production process, improves production efficiency, saves energy and reduces consumption, and avoids occupational hazards; removes the iron element in the lead powder, and provides guarantee for the production of high-quality red lead products.

Owner:安徽徽能化工科技有限公司

Conical double control automatic vacuum lead melting furnace

Owner:ANHUI UNIV OF SCI & TECH

Oil mist collecting and filtering device for oiling machine

InactiveCN111714981AImprove working environmentProtect your healthGas treatmentDispersed particle filtrationSuction tubingOil mist

The invention discloses an oil mist collecting and filtering device for an oiling machine. The device is arranged on the outlet side of the oiling machine and comprises an oil suction hood structure arranged on the outlet side of the oiling machine and an oil collecting tank communicated with the oil suction hood structure through an oil pipe structure; and the oil suction hood structure comprisesan upper oil suction hood arranged above the outlet side of the oiling machine and a lower oil suction hood arranged below the outlet side of the oiling machine. The oil pipe structure comprises an upper oil suction pipe connected to the upper oil suction hood and a lower oil suction pipe connected to the lower oil suction hood. A fan device, a filtering device and an oil collecting tank are sequentially arranged in the oil collecting tank from top to bottom; and the upper oil suction pipe and the lower oil suction pipe are both connected with the fan device. The problems that oil mist driftsaway from the outlet side of an oiling machine, the ground and surrounding equipment are polluted by oil liquid, and the cleaning is difficult are solved.

Owner:BAOSHAN IRON & STEEL CO LTD

Medium-thickness steel plate splicing back-gouging-free welding technology

InactiveCN108788411AEnsure penetration welding thicknessAvoid pollutionArc welding apparatusSheet steelButt joint

The invention provides a medium-thickness steel plate splicing back-gouging-free welding technology, and relates to the technical field of steel structure engineering. The medium-thickness steel platesplicing back-gouging-free welding technology comprises the steps that groove preparation is conducted on steel plates, and grooves of the steel plates are single-edge V-shaped grooves; 5-10-degree reversible deformation is reserved for the two steel plates according to the thickness of the steel plates; butt-joint spot welding is conducted on the two steel plates, and the spot welding thicknessis controlled to be above 5 mm; and submerged arc welding is conducted on the two steel plates, and the fully-penetrated electric welding thickness is guaranteed. According to the medium-thickness steel plate splicing back-gouging-free welding technology, a back gouging technology is omitted, the operation environment can be improved, noise is reduced, environmental protecting and energy source saving are achieved, and physical and psychological health of staff are facilitated.

Owner:SHANDONG ELECTRIC POWER CONSTR NO 2

Negative-pressure drainage experimental animal arrangement equipment

The invention provides negative-pressure drainage experimental animal arrangement equipment. The equipment comprises an experimental animal operating platform which tilts outwards, a waste liquid drainage slot along the lowest end of a bevel edge, an operating control panel for controlling functions of the equipment, and movable caster wheels, wherein the waste liquid drainage slot is connected to a waste liquid collecting barrel; a negative-pressure suction opening is arranged at the rear part of the waste liquid drainage slot; a negative-pressure sealed cabin controlled by a negative-pressure fan is arranged at the lower part of the negative-pressure suction opening, and the cabin is internally equipped with a solid matter filtration and collection bag and an adsorption tank; a waste water pump at the lower part of the negative-pressure sealed cabin is connected to the waste liquid collecting barrel; the experimental animal operating platform is internally equipped with an ultraviolet sterilizing lamp and a sterilizing and washing system; the operating control panel for achieving the functions is arranged on the front face of the equipment; and the movable caster wheels are arranged on the bottom of the equipment. The negative-pressure drainage experimental animal arrangement equipment has the beneficial effects of effectively filtering and collecting spewed odor, fur and dust during the experimental operation process in the case of experimental animal arrangement, automatically draining pollutants such as manure, body fluid, blood and the like of an experimental animal, effectively protecting an operator from being polluted, improving the operating environment and enhancing the operating efficiency.

Owner:TIANJIN HOPE IND & TRADE

A modified fiber-reinforced foamed cement composite floor and its preparation method

InactiveCN108824760BReduce loadIncrease the use of spaceCovering/liningsFlooring insulationsCement compositesCompressive strength

Owner:上海天行新型材料有限公司

Container wood floor dust removing device

InactiveCN111251390AMeet the needs of comprehensive dust removalChange the cleaning methodBark-zones/chip/dust/waste removalReciprocating motionAgricultural engineering

The invention discloses a container wood floor dust removing device. The container wood floor dust removing device comprises motors, a walking trolley, a fan, a dust bucket and a dust collecting pipe.The motors comprise a walking motor and a transverse moving motor, and the walking motor is connected with the walking trolley. The fan, the dust bucket and the dust collecting pipe are arranged on the walking trolley and are connected in sequence. A transverse sliding rail is arranged on one side of the walking trolley, the transverse sliding rail is perpendicular to the walking direction of thewalking trolley, and the dust collecting pipe can be driven by the transverse moving motor to slide back and forth along the transverse sliding rail. Thus, after the container wood floor dust removing device enters a container, the dust collecting pipe can move forwards along with the walking trolley, and meanwhile can do reciprocating motion along with the transverse sliding rail in the transverse direction. Thus, the dust collecting range of the dust collecting pipe can cover the wood floor of the container. According to the container wood floor dust removing device, the cleaning manner ofthe wood floor of the container is changed, original manual disordered cleaning is changed into automatic orderly cleaning, the work environment of a workshop in a box of the container is improved, the labor intensity is reduced, and meanwhile occupational hazards are avoided.

Owner:徐州林域木业有限公司

Intelligent control device for drying bright beads of fireworks and firecrackers

ActiveCN102564240BAvoid occupational hazardsFriendly operationFireworksFrequency changerHuman–machine interface

The invention relates to an intelligent control device for drying bright beads of fireworks and firecrackers. The intelligent control device comprises a human-machine interface operating system, a PLC (programmable logic controller) and a frequency converter control system, a drying air heater and an air supply system thereof, and a temperature-humidity sensor control system. The intelligent control device has the advantages that the technical level in the intelligent monitoring for the temperature and the humidity of a drying chamber for drying the bright beads is improved, the human-machine separation is realized, major production safety accidents about drying the bright beads in the production process of the fireworks and the firecrackers are effectively prevented and avoided, and the occupational hazard of firework agents to operators is prevented; simultaneously, due to the PLC and the frequency converter control system, the production process for drying the bright beads in the production process of the fireworks and the firecrackers is optimized; due to a frequency converter is adopted to drive the drying air heater, the speed adjusting performance is excellent, the power-saving effect is obvious, closed-loop control for the temperature and the humidity of the drying chamber is realized, the operating frequency of the hot air heater is accurately adjusted, the quality of products is improved, the production cost is reduced, the automation and the intelligentization in production of the bright beads of the fireworks and the firecrackers are realized, and the supporting platform of new technologies and safety technologies is improved.

Owner:天津瑞华云电力电子技术有限公司

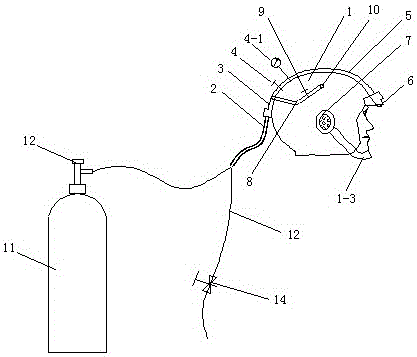

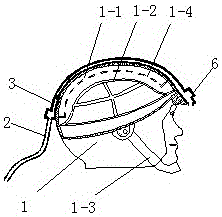

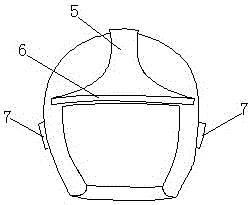

Air curtain dustproof helmet and method

Owner:CHINA UNIV OF MINING & TECH

A container wooden floor dust removal equipment

ActiveCN104799764BMeet the needs of comprehensive dust removalChange the cleaning methodSuction cleanersReciprocating motionWorking environment

The invention discloses a dust removing device for a wood floor of a container. The device comprises a motor, a travelling trolley, an air blower, a dust bucket and a dust collecting tube, wherein the motor comprises a travelling motor and a transverse moving motor; the travelling motor is connected with the travelling trolley; the air blower, the dust bucket and the dust collecting tube are arranged on the travelling trolley and sequentially connected; a transverse slide rail is arranged at one side of the travelling trolley and is in the direction vertical to the travelling direction of the travelling trolley; the dust collecting tube can be driven by the transverse moving motor to slide along the transverse slide rail by reciprocating. When the device enters the container, the dust collecting tube can move forwards along with the travelling trolley and can also transversely move along with the transverse slide rail by reciprocating; therefore, the dust collecting range of the dust collecting range can cover the wood floor of the container. According to the device, the wood flour removing mode of the wood floor of the container is changed; the original manual irregular removal is replaced by automatic regular removal, so that the working environment of a workshop in the container can be improved, the labor intensity can be reduced, and meanwhile, occupational hazard can be avoided.

Owner:CIMC CONTAINERS HLDG +2

A water-based energy-saving granulation process for producing red lead

ActiveCN107487781BImprove qualitySimple processChemical industryRed leadWater productionPre treatment

A water process energy-saving granulation technology for red lead production comprises the following steps: (1) dedusting cooling (pretreatment); (2) screw conveying; (3) re-conveying; (4) deironing; (5) granulator starting; (6) water process granulation; and (7) exhausting dedusting. The technology has the advantages of simple process, easiness in operation, realization of automatic streamline working of the production flow of red lead, increase of the production efficiency, energy saving, consumption reduction, and avoiding of occupational hazards; and iron in lead powder is removed to provide guaranteeing for the production of the high-quality red lead product.

Owner:安徽徽能化工科技有限公司

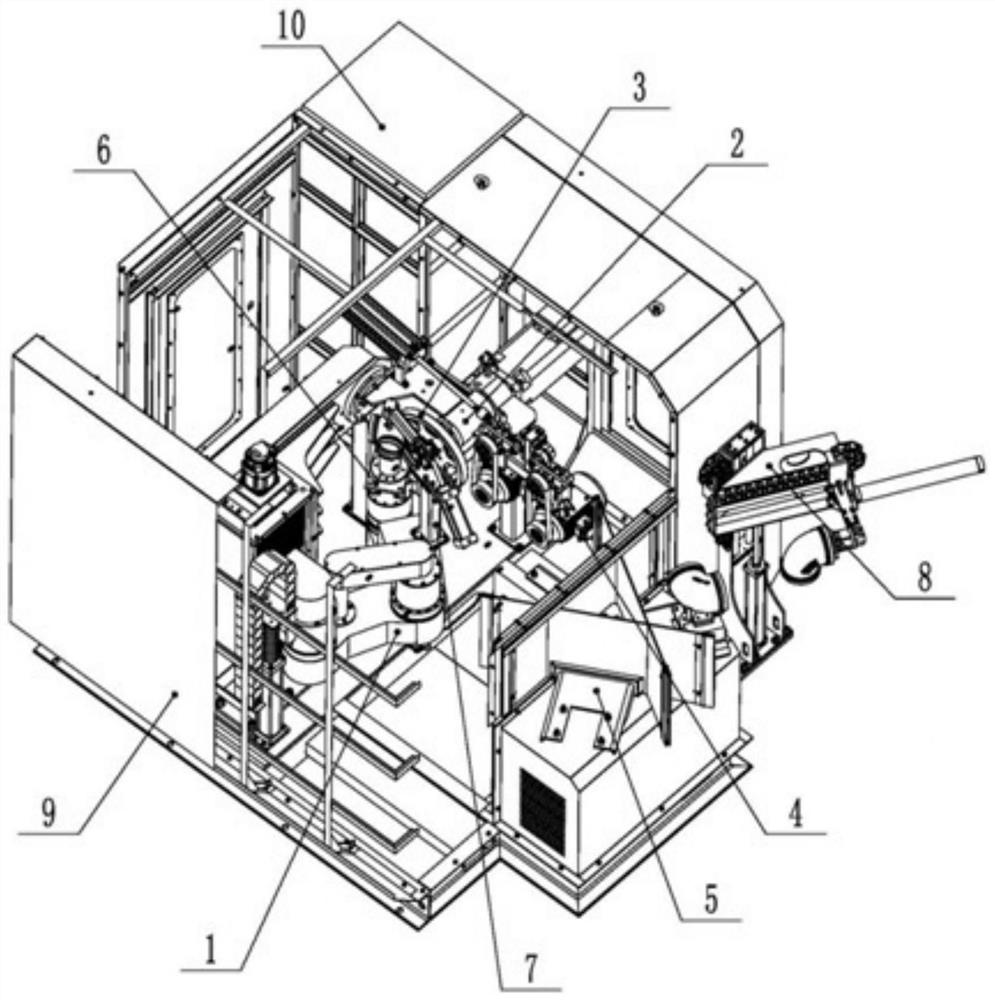

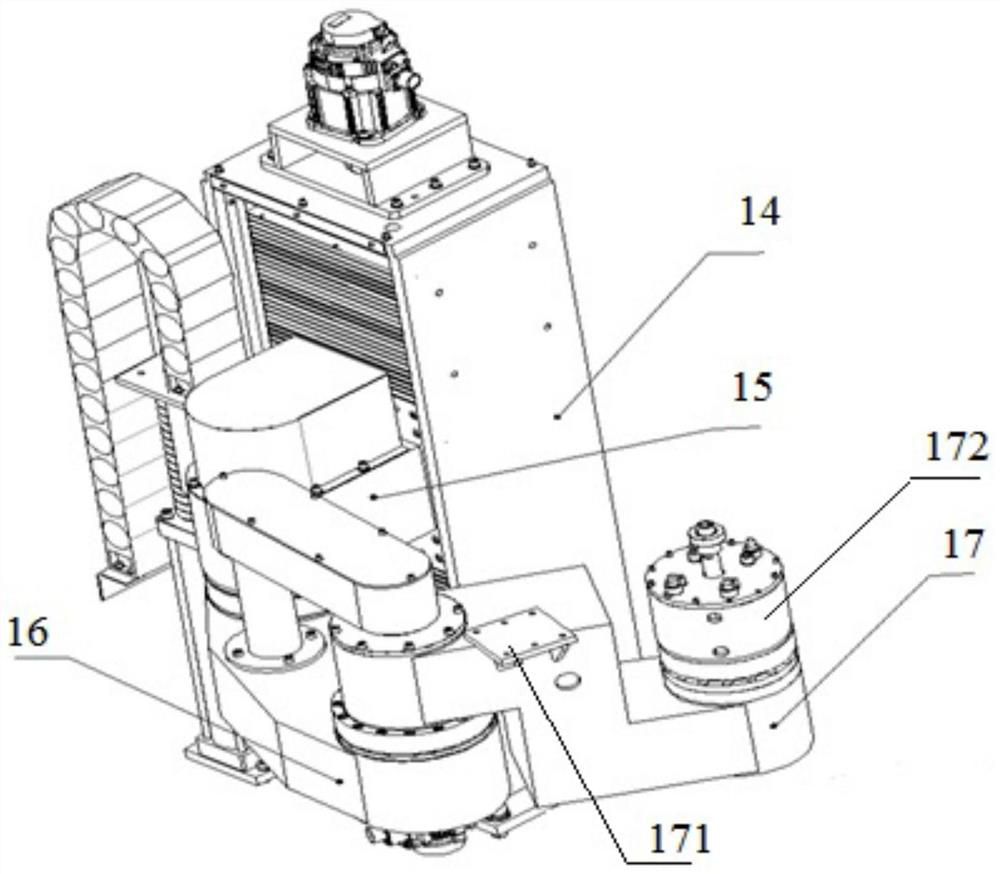

A multi-station grinding robot

ActiveCN111347328BEfficient use of processing timeCompact spaceGrinding drivesBelt grinding machinesHigh-speed grindingPipe fitting

The invention discloses a layout structure of a multi-station grinding robot, which is used for grinding casting burrs such as grooved elbows, elbows and tees, including a robot body, a grinding head device, a multi-station displacement device, Quick-change tooling, pressing device, automatic unloading device, tray-type protective cover, robot control cabinet; the grinding head device includes a high-speed grinding spindle, an internal grinding groove grinding wheel and an abrasive belt device; one end of the grinding head device It is fixedly connected to the robot body through welding parts, and the other end is supported by a support column fixedly arranged on the bottom surface of the tray shield; there are three stations in the multi-station device that use partitions to separate the loading, processing and unloading stations. The processing, blanking and loading work are carried out at the same time, and the processing time is effectively used. One worker can operate two or more equipment at the same time; the internal groove grinding wheel grinds grooved pipe fittings, the space is compact, and the teaching is consistent. Good performance, high efficiency, good grinding effect.

Owner:山东泰开电力电子有限公司

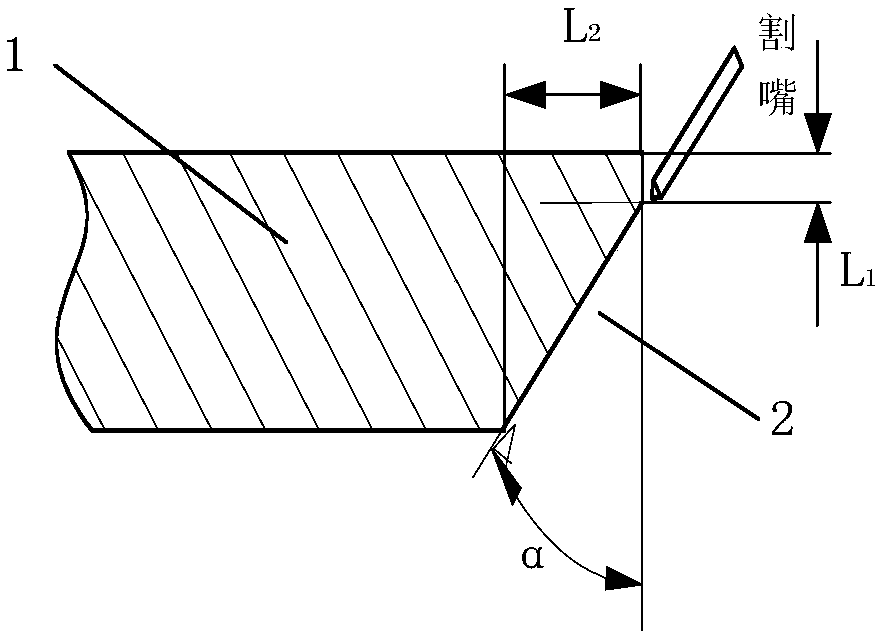

Method and corollary equipment for cutting NOL ring test sample strip by water jet

PendingCN114800696ASimplify the operation processEliminate cutting safety hazardsWithdrawing sample devicesMetal working apparatusTest sampleStructural engineering

The invention discloses a method and corollary equipment for cutting NOL ring test splines by water jet, a water jet cutting method is adopted to cut an NOL ring, a notch is smooth and burr-free, the operation process is simple, potential safety hazards are avoided, batch cutting of the NOL ring test splines can be realized, and the cutting efficiency is high. According to the corollary equipment, the lower clamping ring and the upper clamping ring are adopted to form the cavity for clamping the NOL ring, and in addition, the design of the notch and the positioning plate is matched, so that the requirements of the cutting size and the cutting precision of the NOL ring test sample strip can be effectively met.

Owner:CHINA BLUESTAR CHENGRAND CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com