Under-mine drilling machine drill rod counting method based on computer vision

A computer vision and counting method technology, applied in computer parts, computing, image data processing, etc., to reduce the cost of the mine, reduce the work flow, and improve the utilization of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

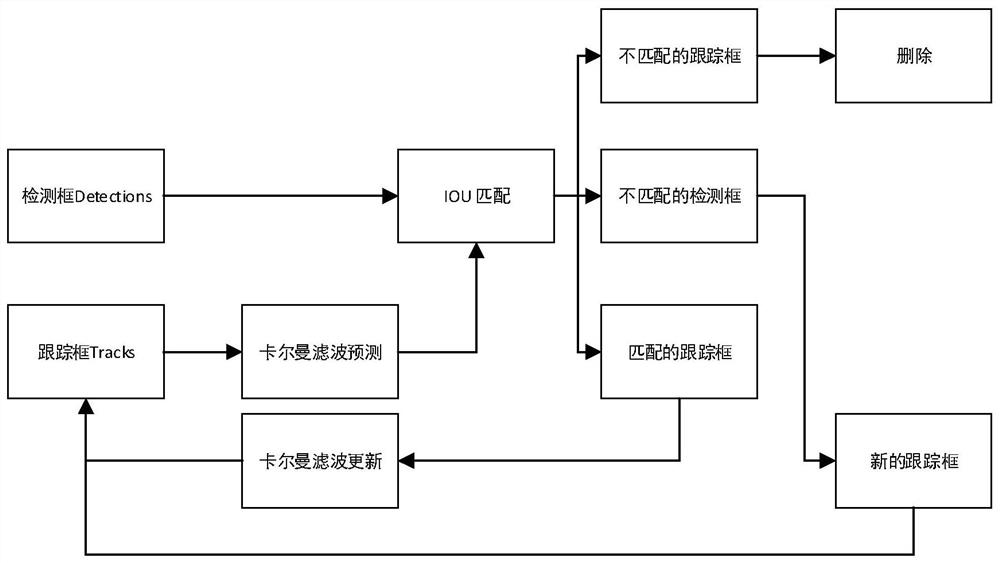

[0057] Embodiment one, refer to figure 1 , the computer vision-based method for counting drill rods of an underground drilling rig in this program specifically includes the following steps:

[0058] Step S1. Obtain the image data of the drill pipe, divide the image data of the drill pipe into two types of data, and use the two types of data as inputs for training the monitor network and training the re-identification network respectively;

[0059] Step S2, performing image enhancement processing on the two kinds of data;

[0060] Step S3, adding different proportions of Gaussian white noise to each cleaned image, simulating the influence caused by silicon dioxide and dust;

[0061] Step S4, after the sample picture is read, it is locked into a 416*416 image, the image includes three scales, and the image is cut into 13*13, 26*26, 52*52 areas respectively, and each area passes through Darknet;

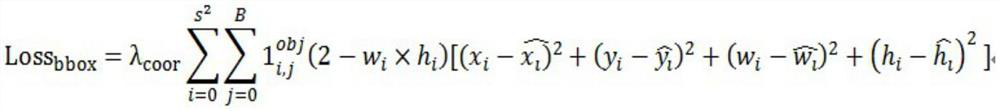

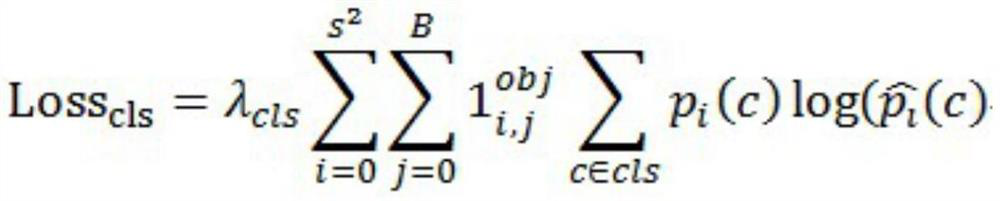

[0062] Step S5, perform classification and regression tasks on whether the image ...

Embodiment 2

[0068] Embodiment two, refer to figure 1 , this embodiment will describe Embodiment 1 in detail;

[0069] This implementation scheme uses the camera covered in the underground coal mine as the image data source, runs the entire calculation process in the server room, and can realize the parallel processing structure of multiple algorithms for one camera, with the following functional characteristics:

[0070] First, through an effective data enhancement method, the reliability of low-quality image data caused by the dark underground working environment is greatly improved.

[0071] Second, by migrating the idea of pedestrian re-identification, re-identify the drill pipes, and assign an independent and unique mark to each drill pipe, which is convenient for subsequent counting.

[0072] Due to the complex and changeable working environment under the mine, the picture is not clear in many cases, and a large number of flying catkins appear, which seriously affects the detector...

Embodiment 3

[0110] Embodiment three, this embodiment adopts specific case to illustrate;

[0111] 1. Collect 5,000 images of drill pipes in the mine, and the data enhancement methods are symmetrical inversion, center interception, rotation and grayscale transformation. The number of images after enhancement reaches the level of 50,000. 70% of them are used for the training set, 15% for the verification set, and the model that passes the verification will be tested on the remaining 15% of the test set.

[0112] 2. Intercept each drill pipe image in the data set to generate a classified data set. According to the angle of the drill pipe, the data is divided into 180 categories representing the state of the drill pipe from 0° to 179°. ResNet18 is used to train the classification dataset, 80% of which are used as training set and 20% are used as test set. Save the classification model as best_classify.pth.

[0113] 3. All images are re-converted to 416*416 pixels before being input into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com