Patents

Literature

32results about How to "Solve recruitment difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

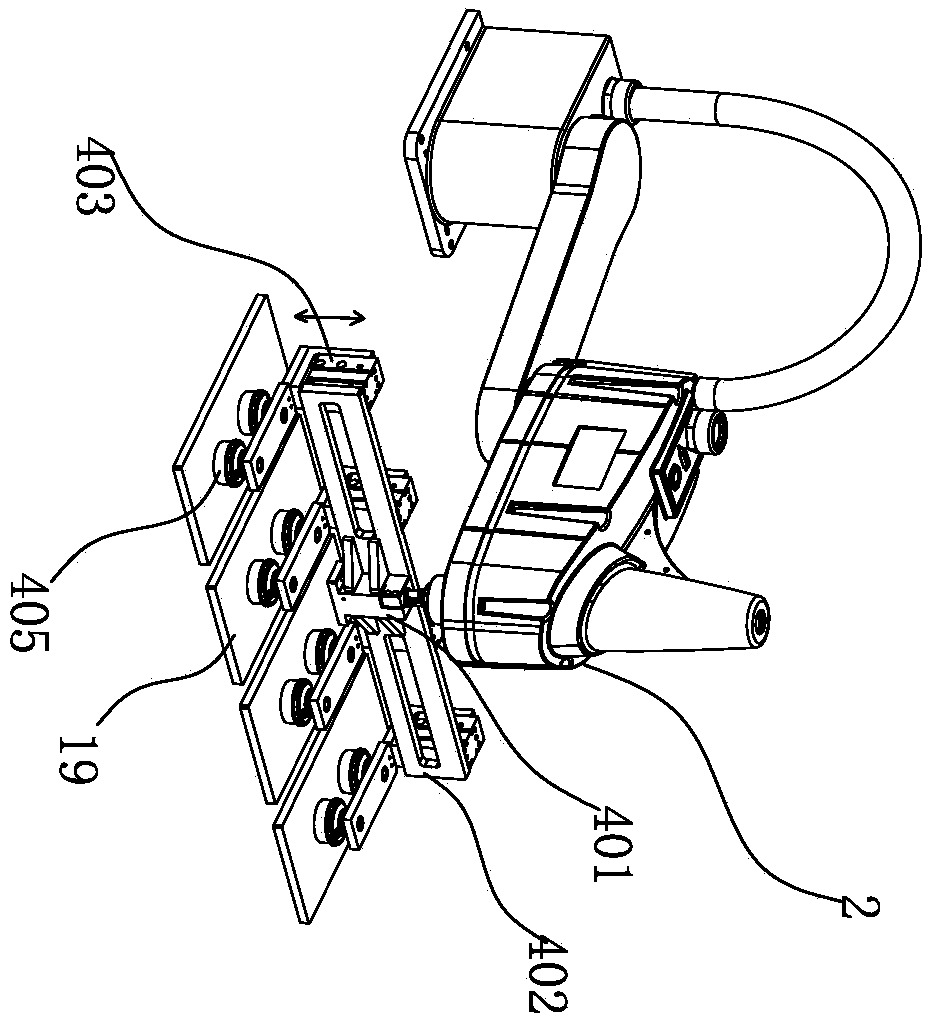

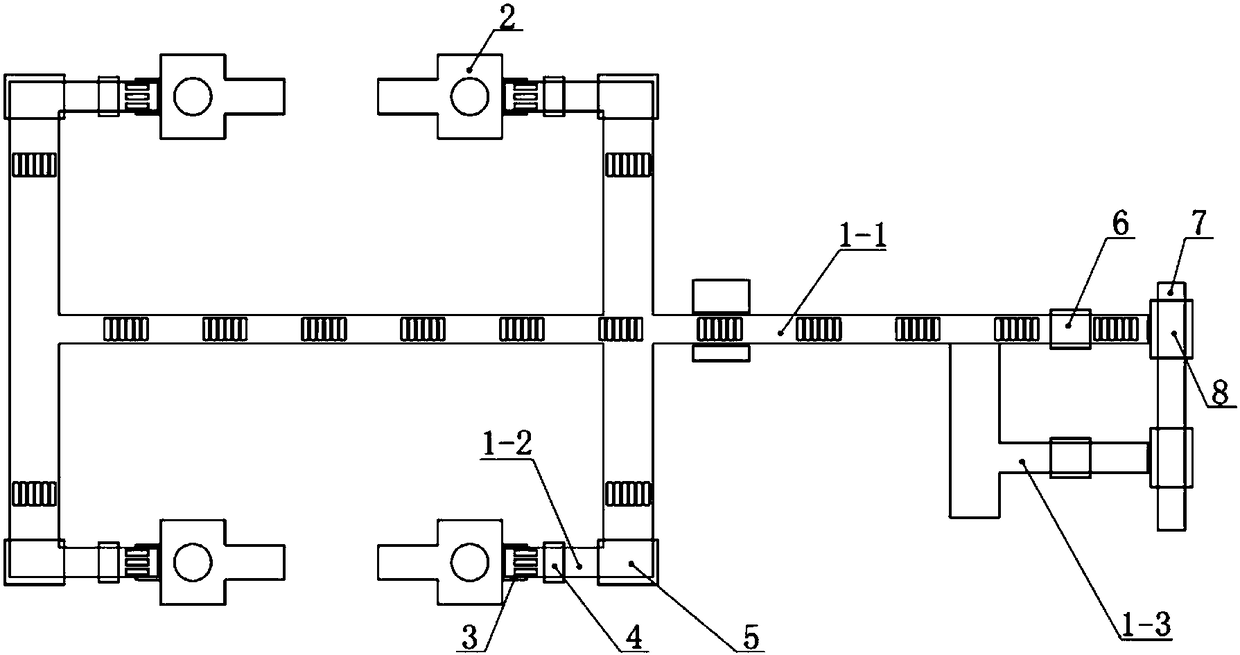

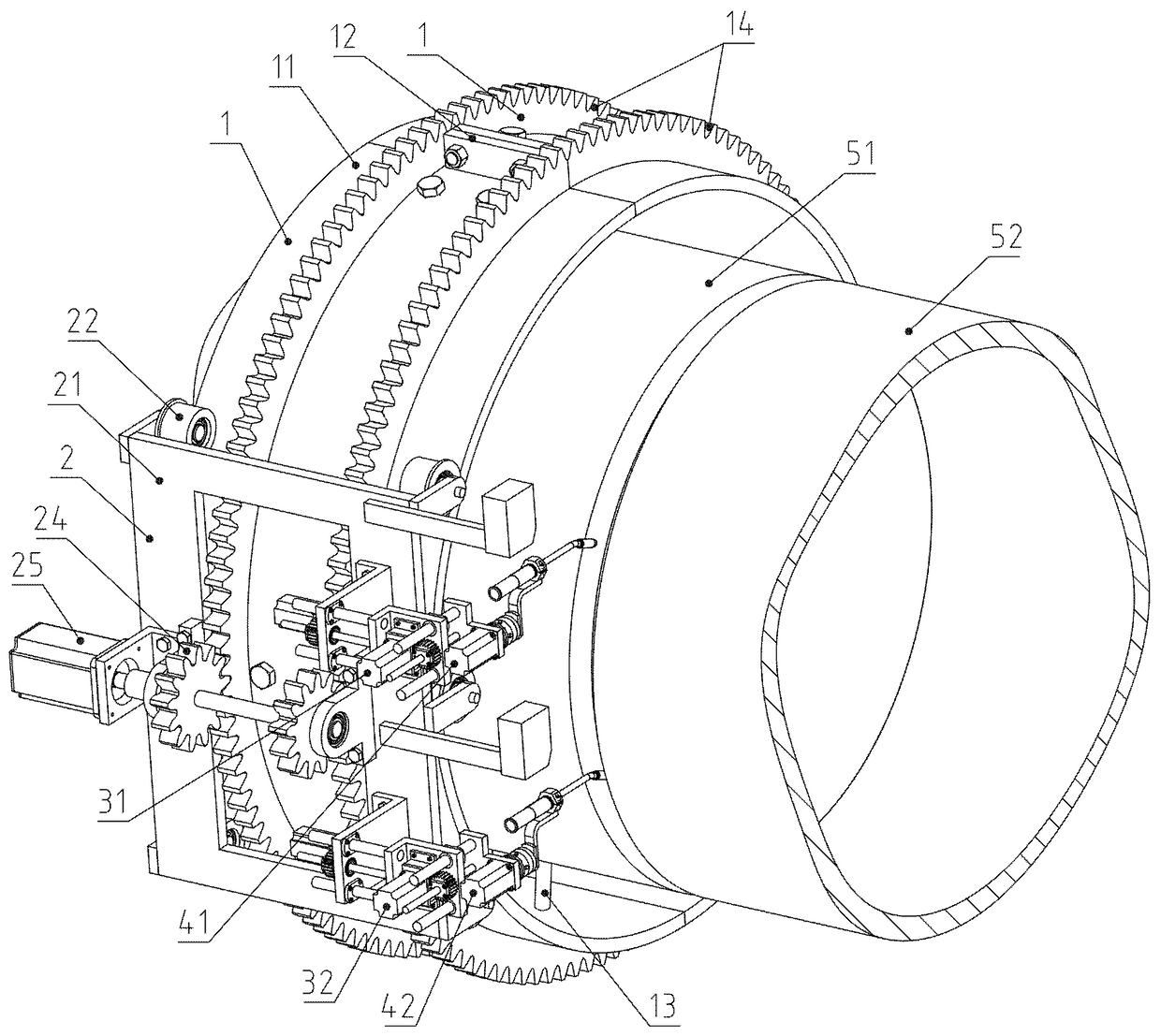

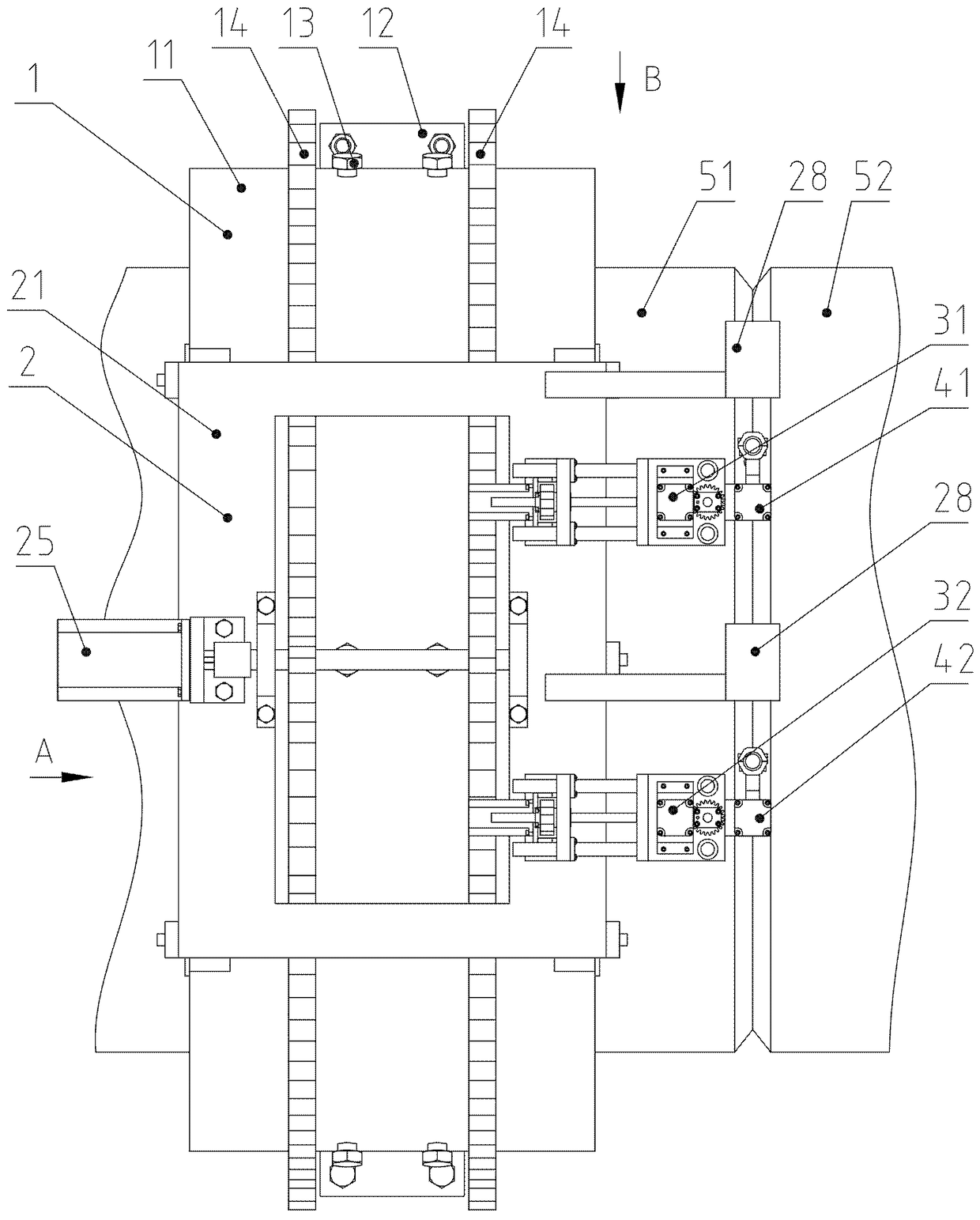

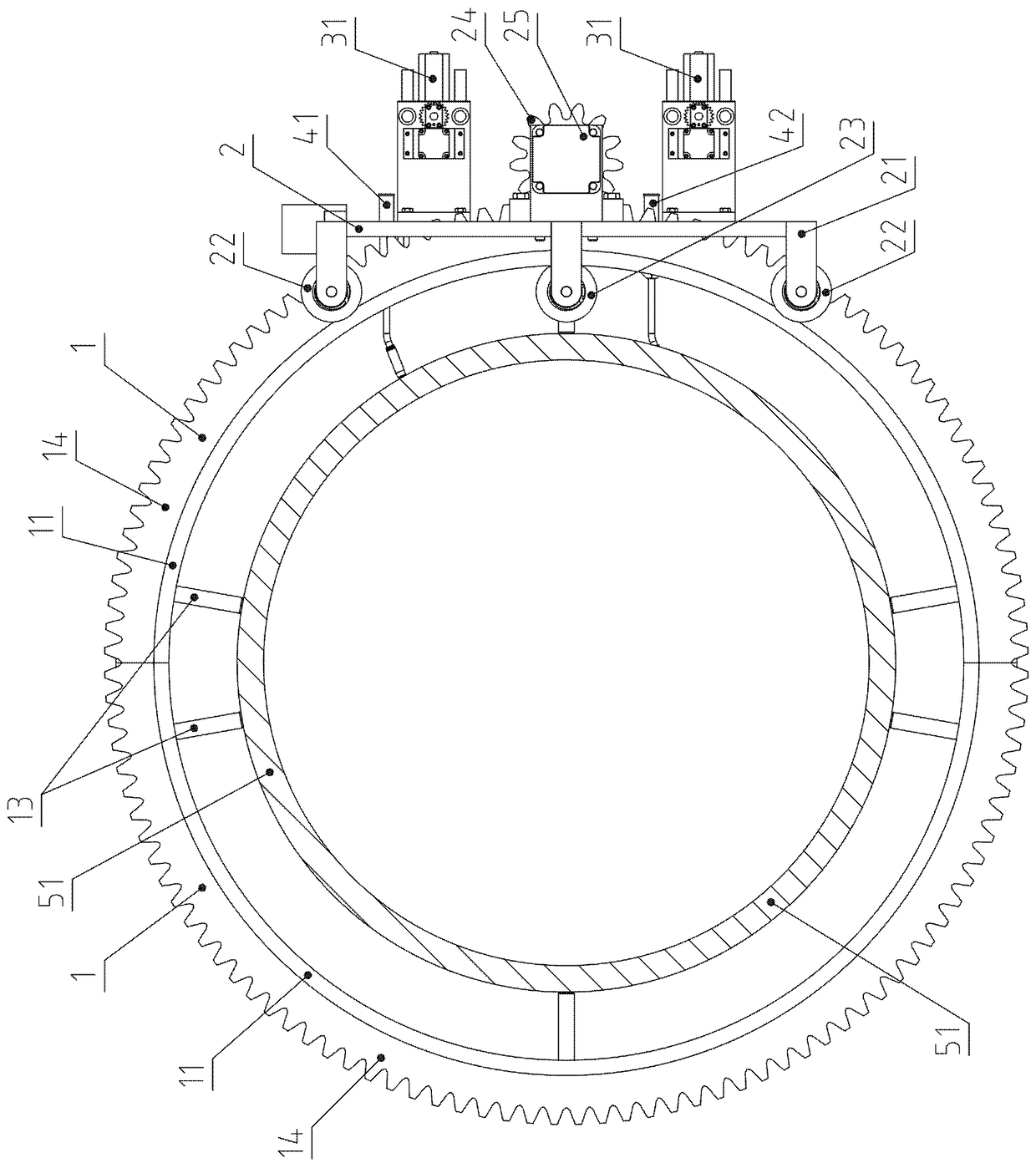

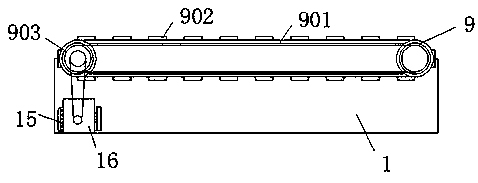

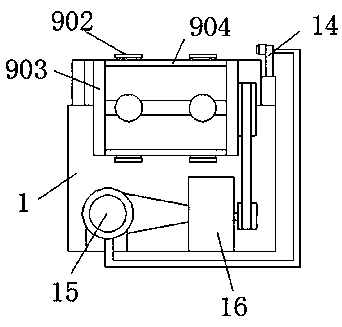

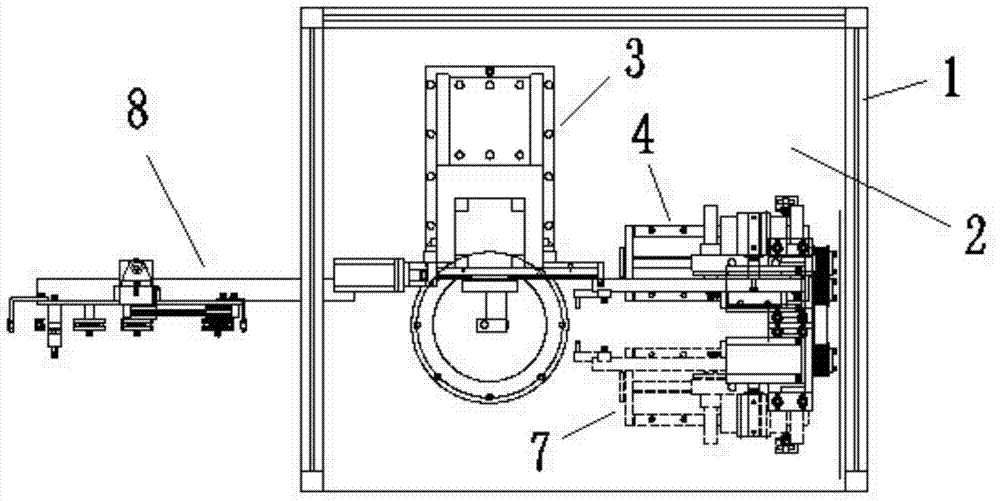

Large-diameter steel pipe double-welding-gun intelligent welding equipment

ActiveCN107414369AImprove welding efficiencyQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesMotor driveArchitectural engineering

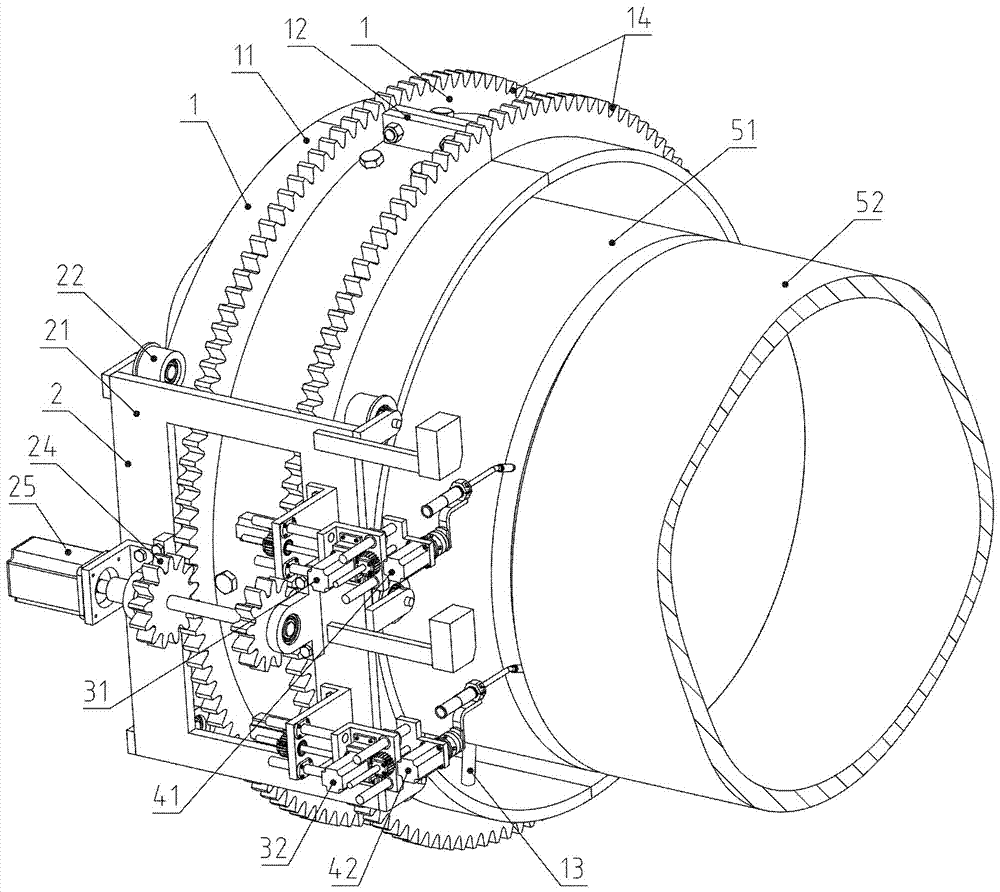

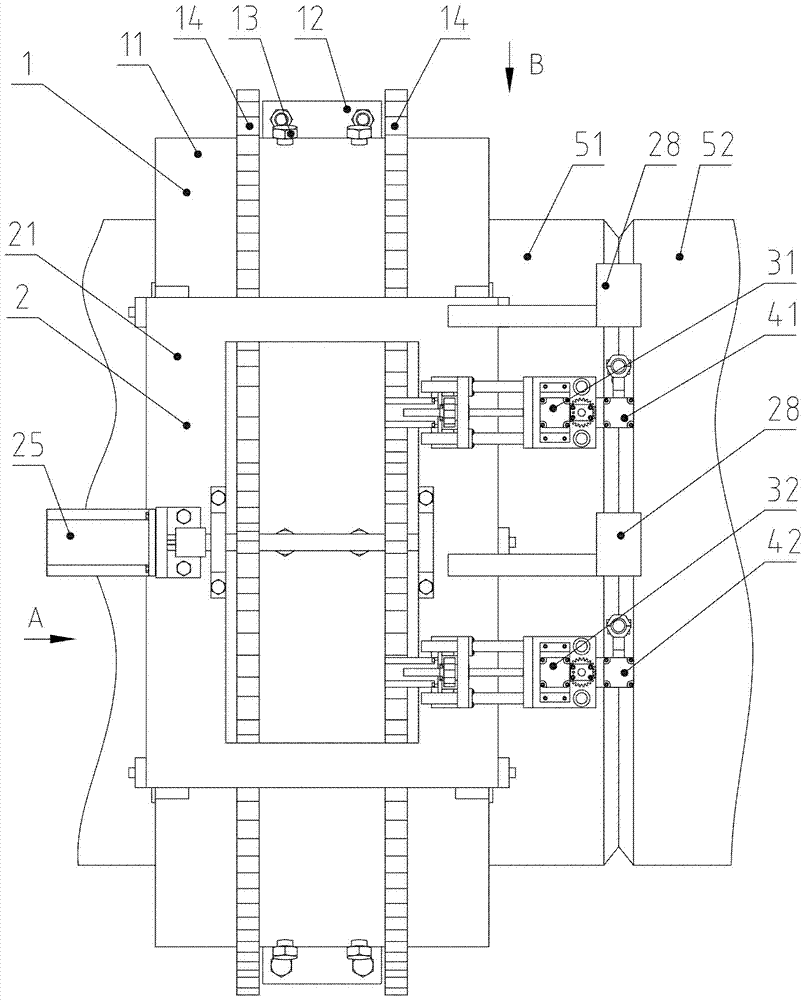

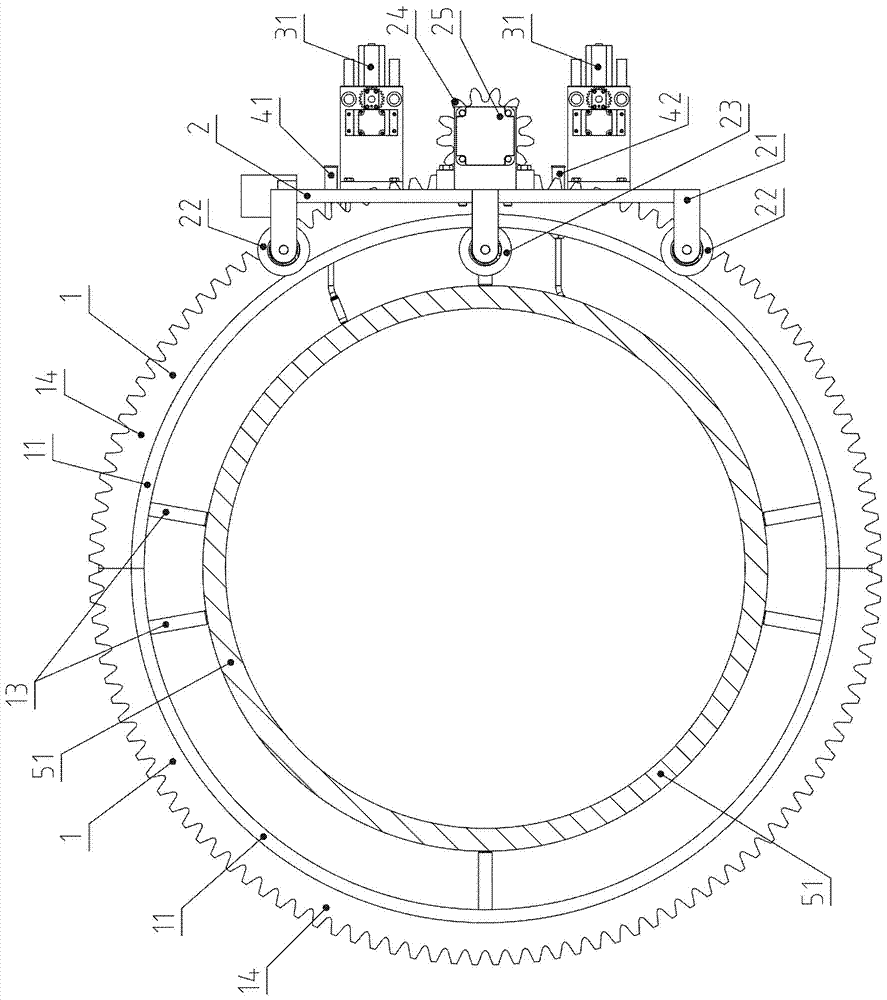

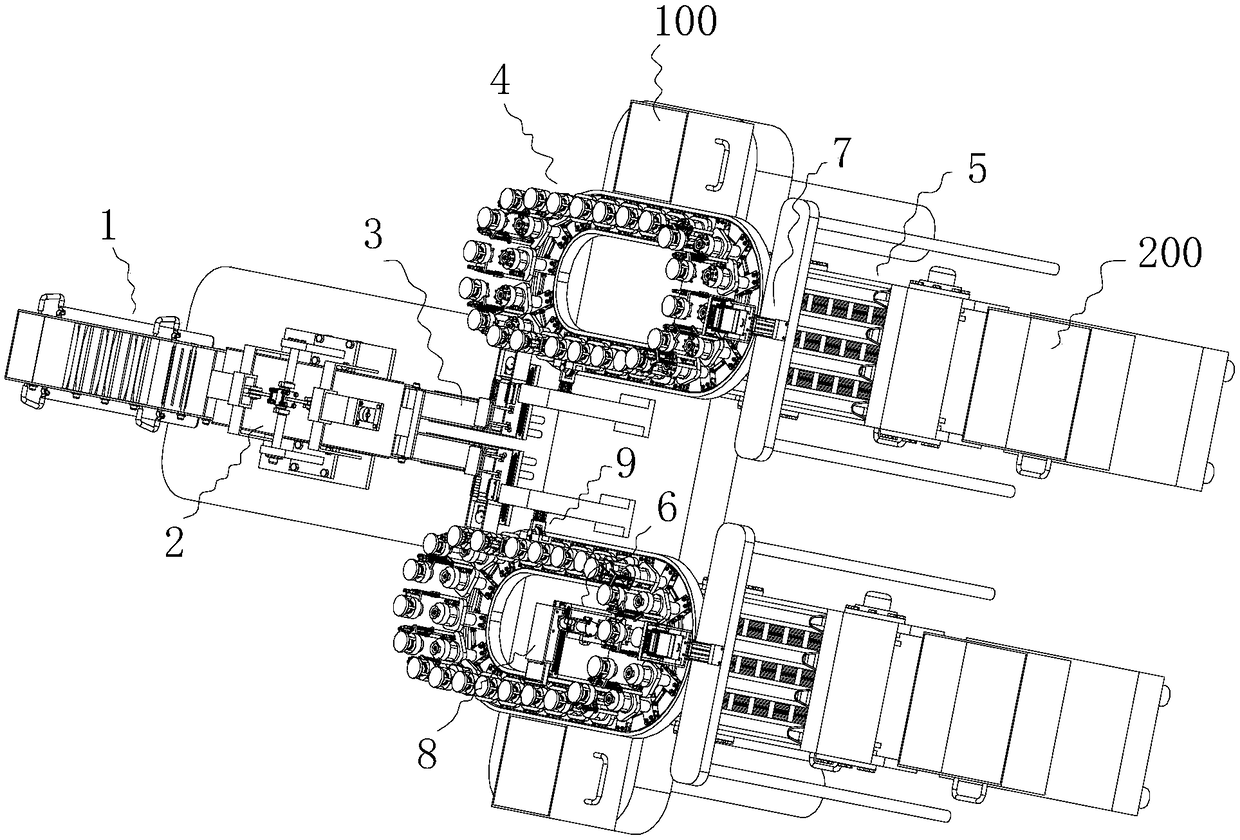

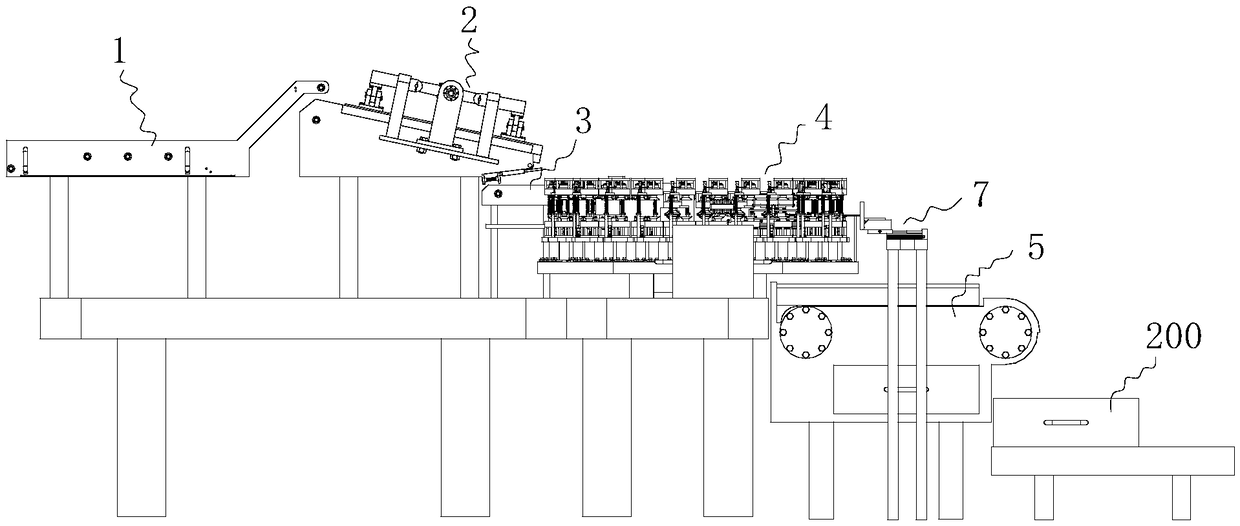

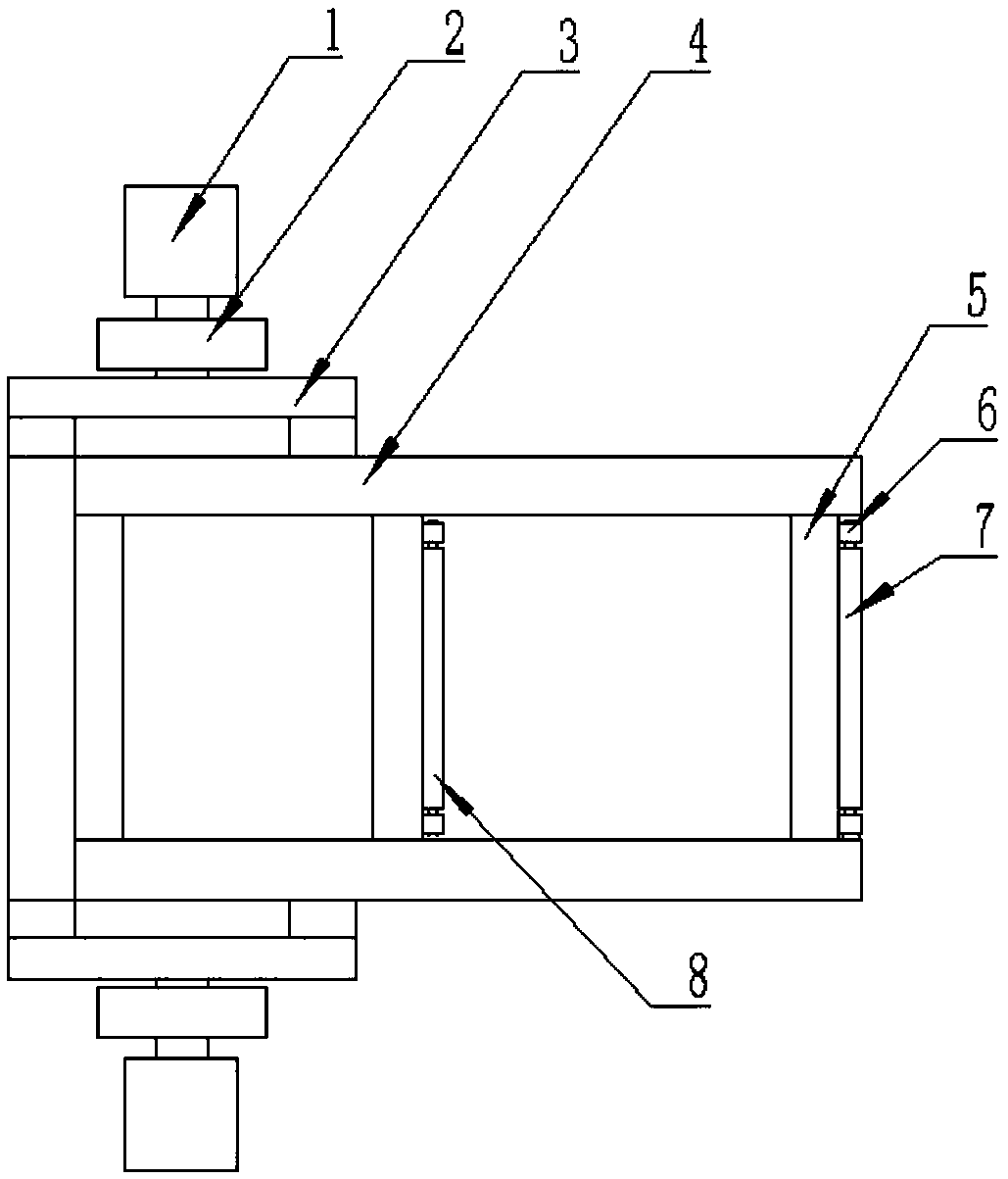

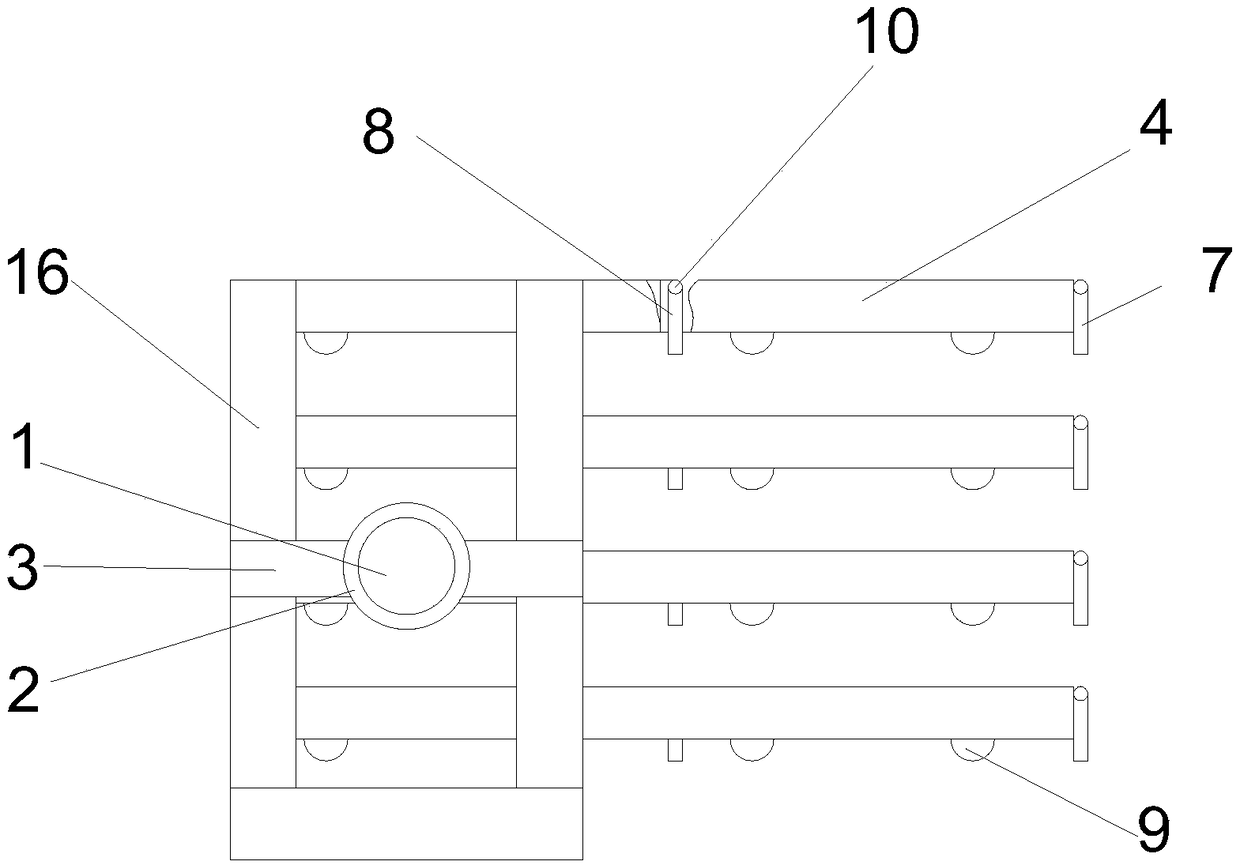

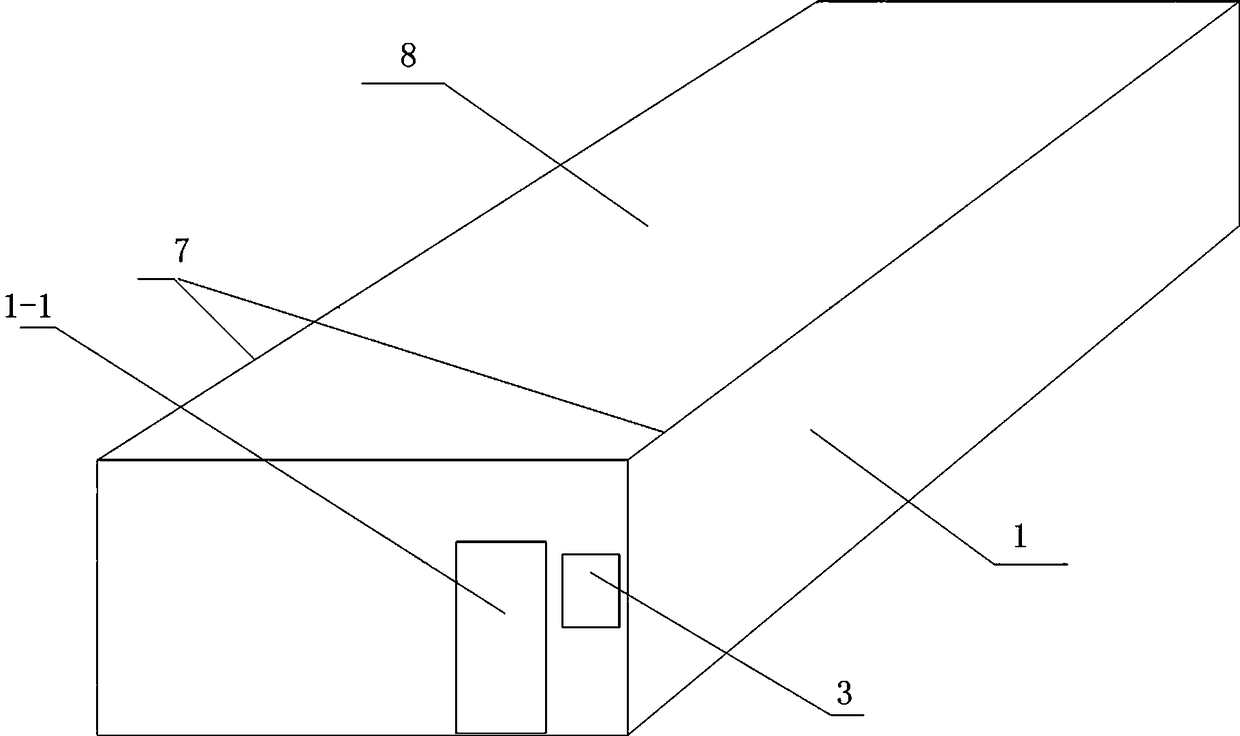

The invention belongs to the technical field of welding equipment, and relates to outdoor large-diameter pipe welding equipment, in particular to large-diameter steel pipe double-welding-gun intelligent welding equipment. Two semicircular rings surround a large-diameter pipe to be welded in middle, and the axes are overlapped; an annular motor drives an annular car to rotate along a ring; an axial motor drives welding guns to move in a direction parallel to the axes; a radial motor drives the welding guns to move in the radial direction; and a swing motor I drives the welding guns to swing. The large-diameter steel pipe double-welding-gun intelligent welding equipment can finish annular welding lines, can realize multi-layer and multi-way welding and swing welding, is high in welding efficiency, and guarantees the quality stability. The large-diameter steel pipe double-welding-gun intelligent welding equipment reduces labors and the labor intensity, prevents occupational injury, solves the problem of welder shortage, reduces the labor cost, uses double welding guns to improve the working efficiency twice, can weld multiple curved welding lines, is flexible in carrying, and is suitable for outdoor construction and use.

Owner:安徽颍瑞源焊管科技有限公司

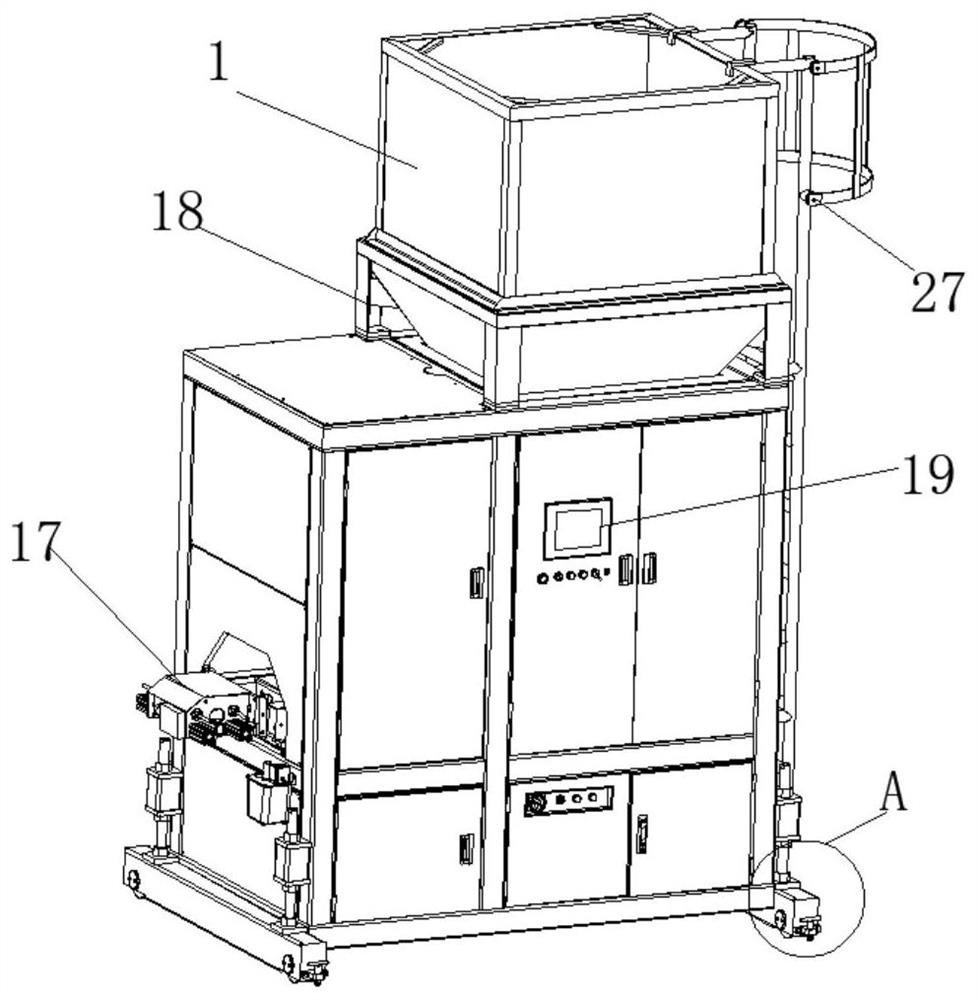

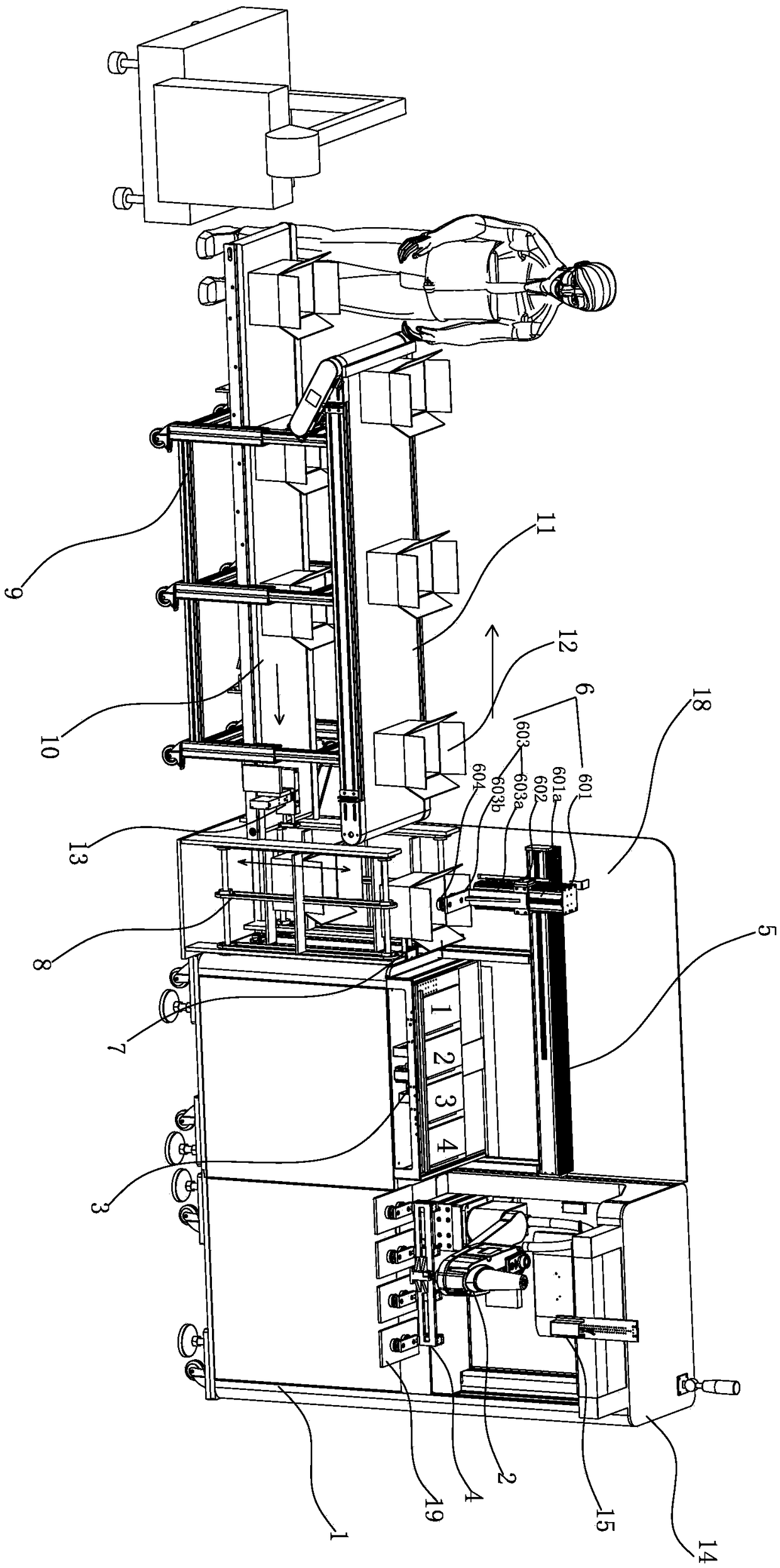

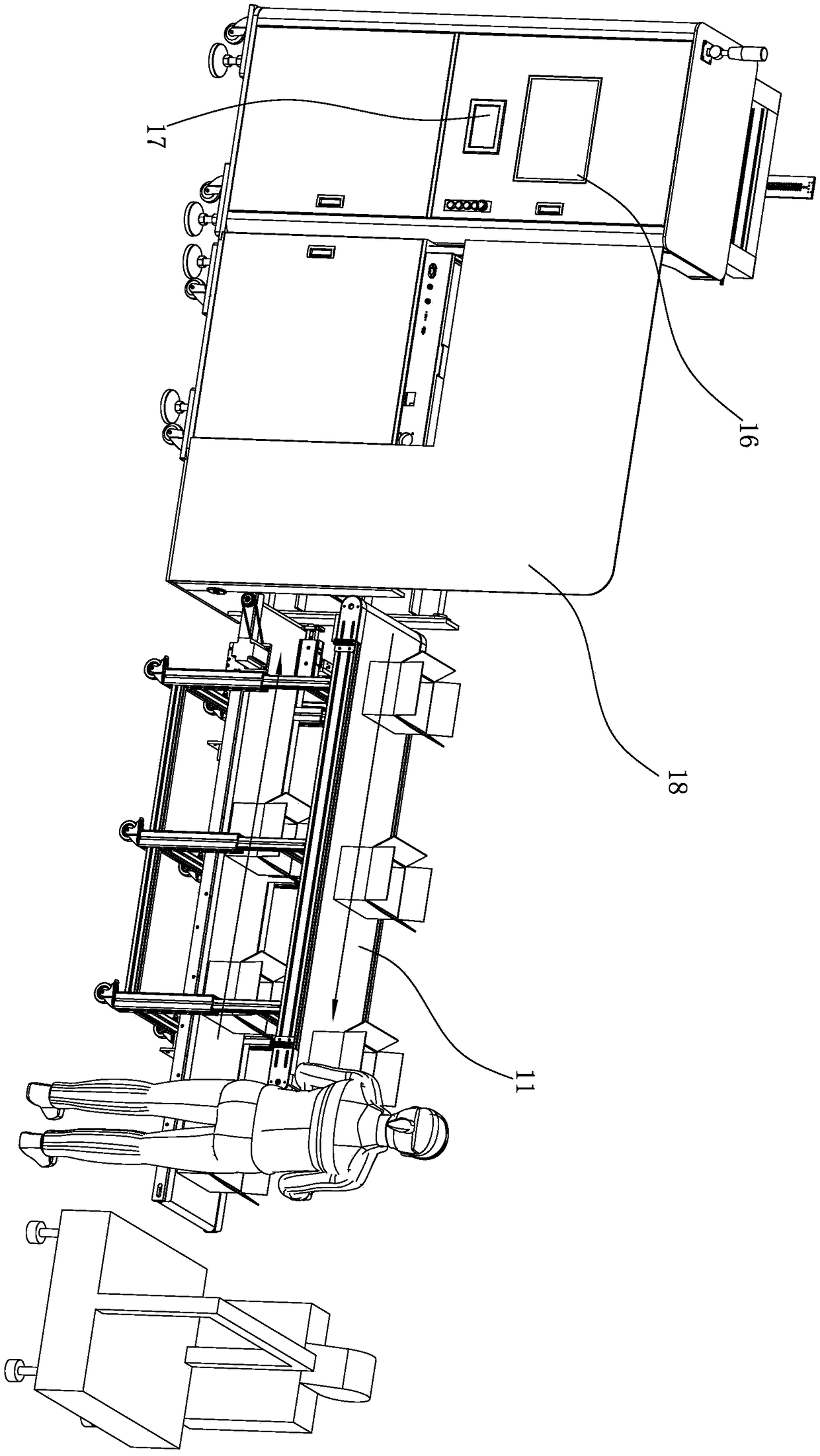

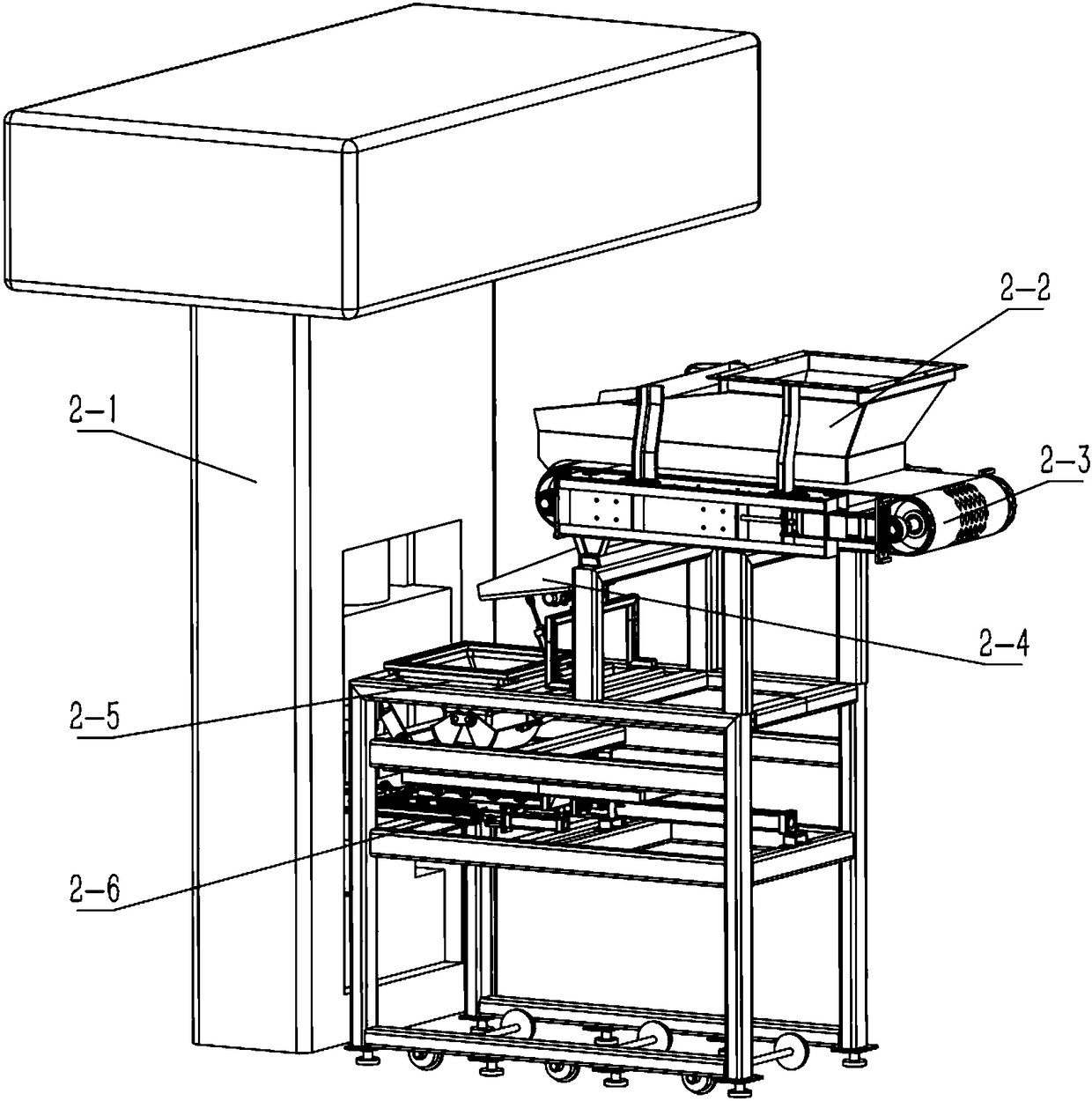

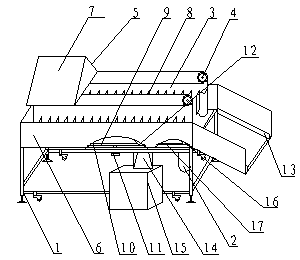

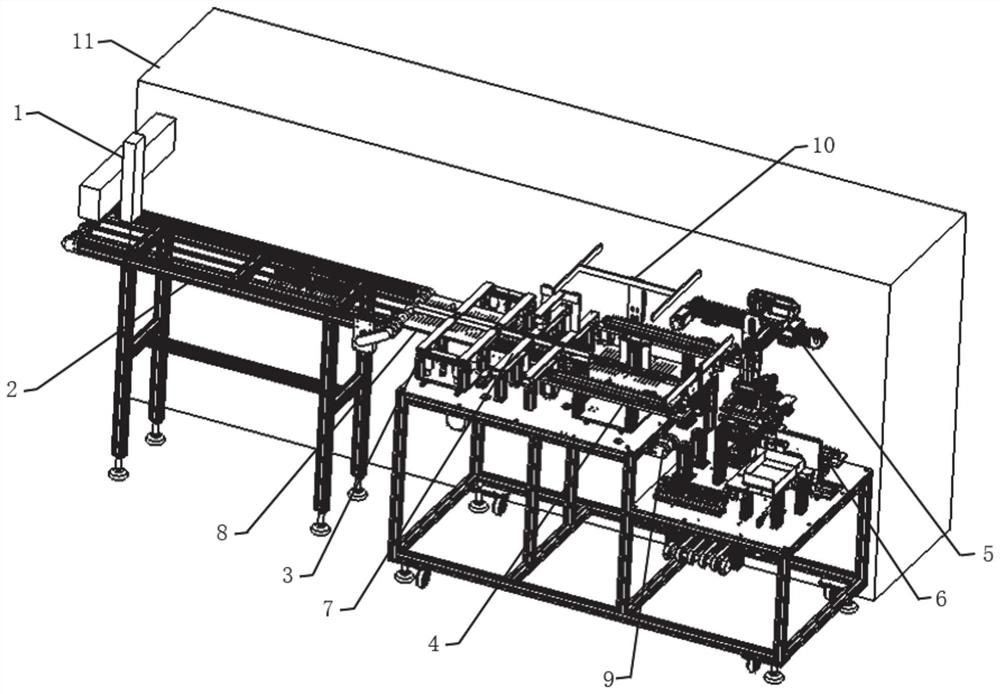

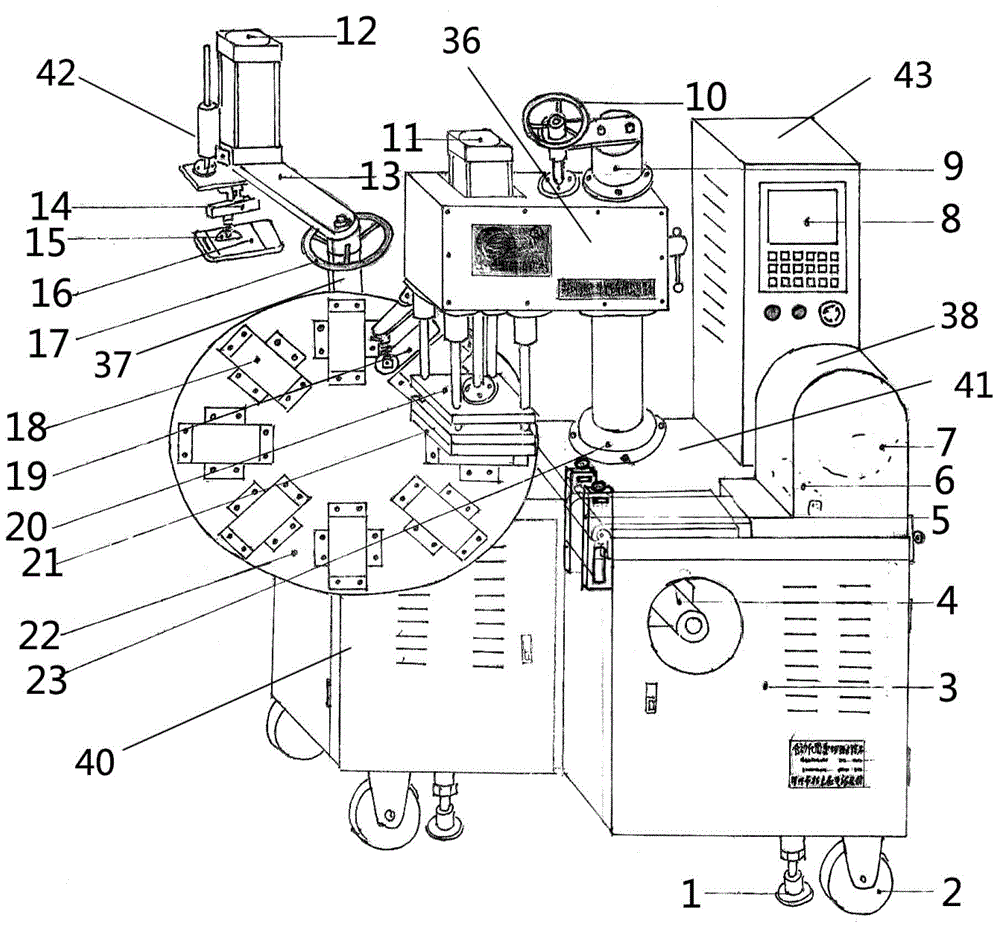

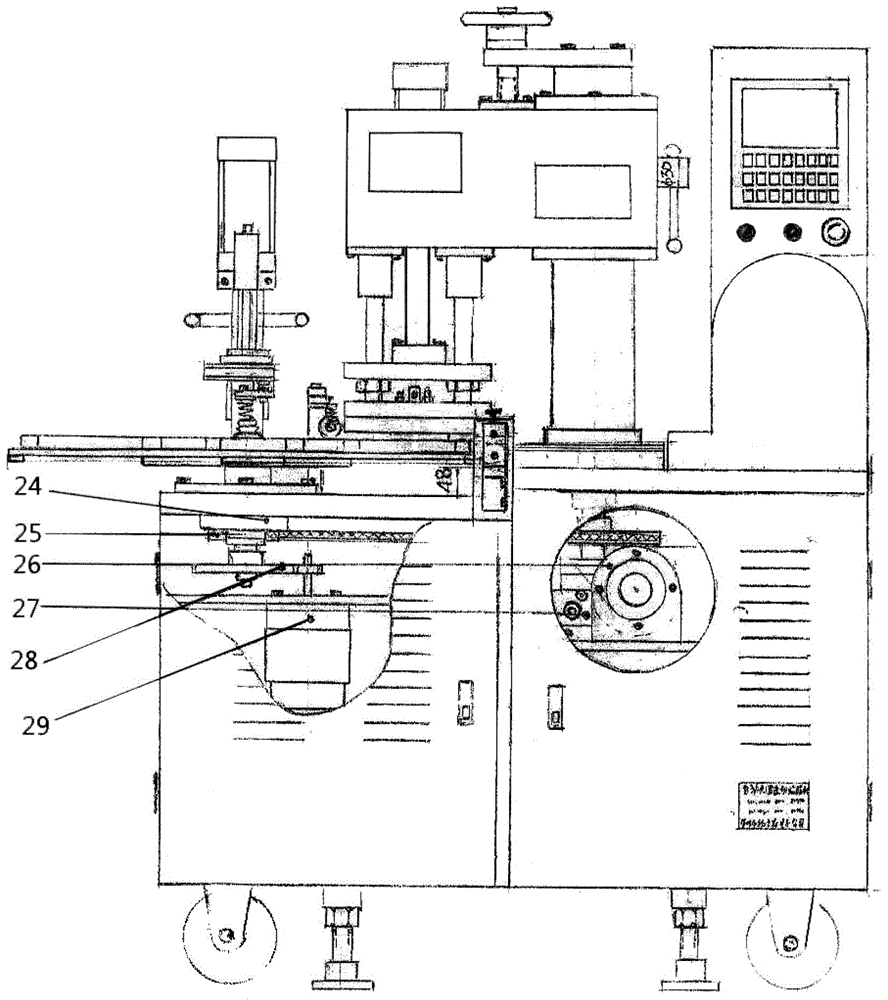

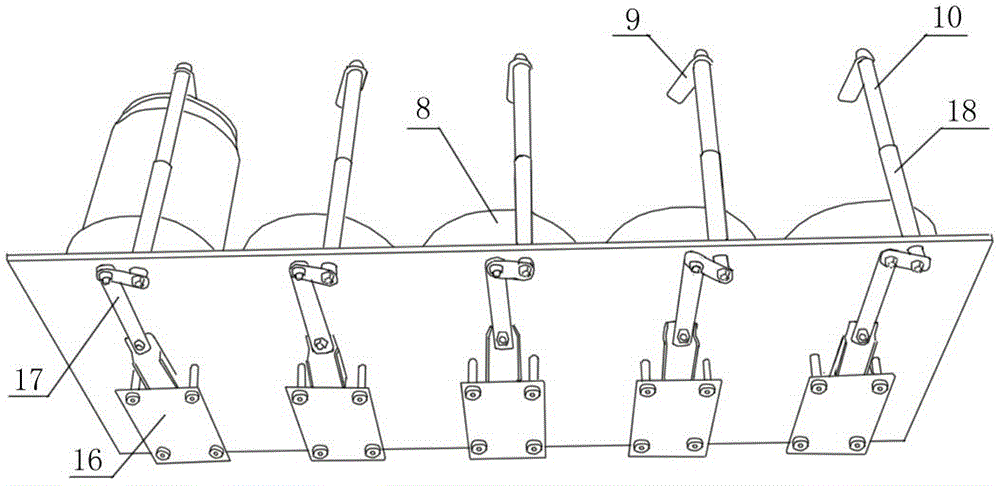

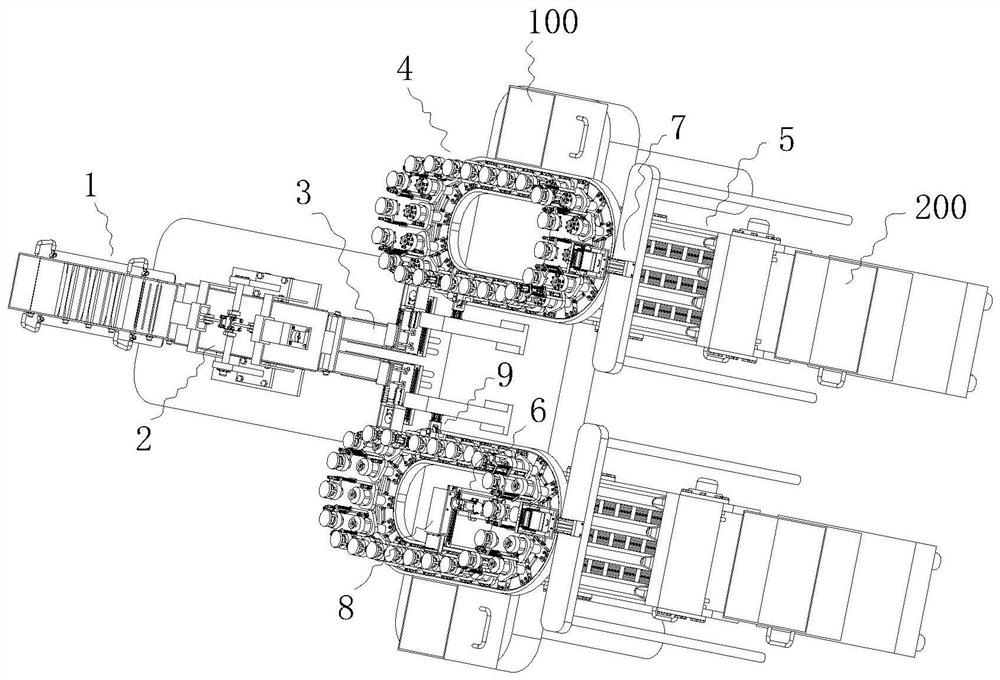

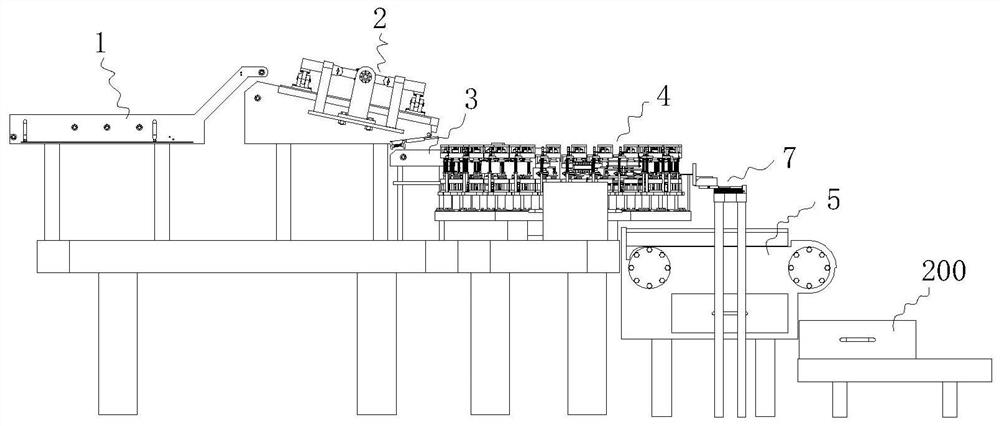

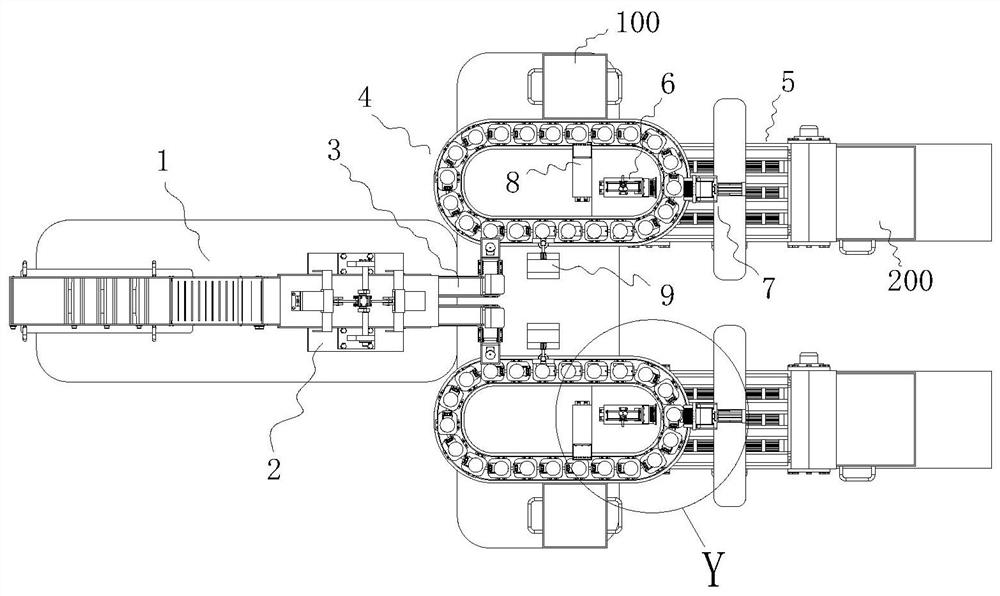

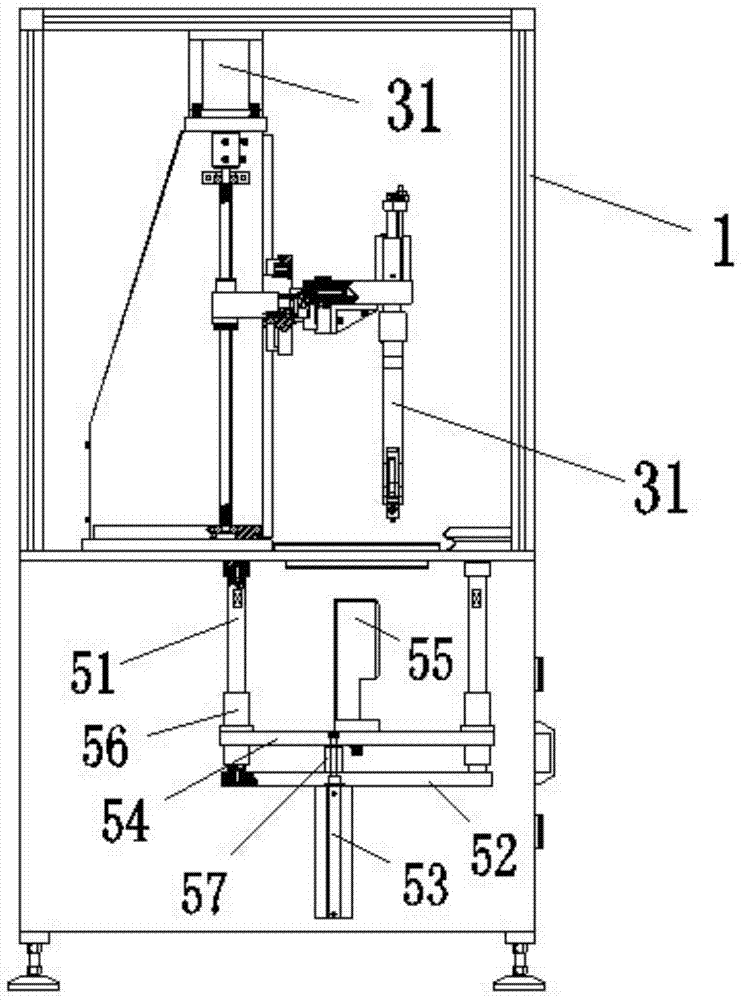

Multi-station reciprocating circulating scallop shell opening and meat taking machine

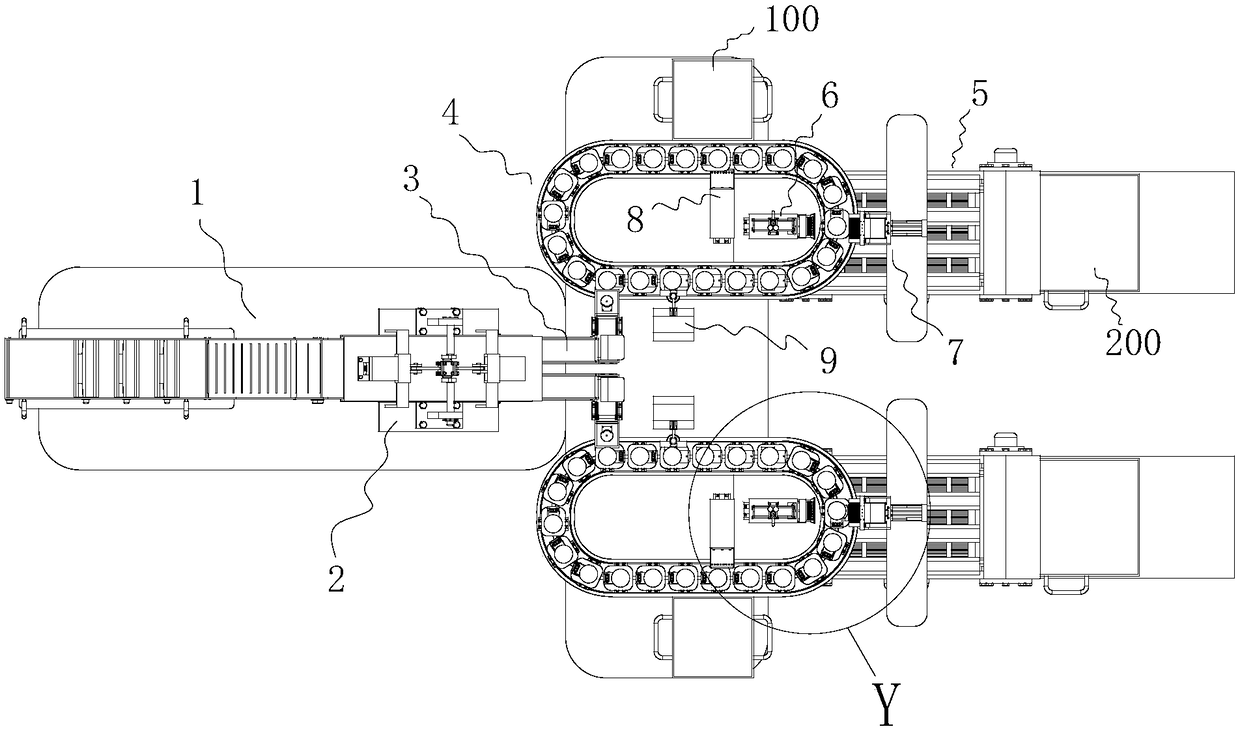

The invention discloses a multi-station reciprocating circulating scallop shell opening and meat taking machine. The machine comprises a scallop conveying guiding device, a scallop shell body levelingand tail fixing device, a scallop clamping and transporting device, a scallop tail cutting device, a scallop shell and scallop meat separating device and a scallop shell pushing device, wherein the scallop conveying guiding device is used for guiding scallops one by one, the scallop shell body leveling and tail fixing device is used for leveling the scallops and fixing the tails of the scallops,the scallop clamping and transporting device is used for clamping and transporting the scallops, the scallop tail cutting device is used for cutting the tails of the scallops, the scallop shell and scallop meat separating device is used for removing the scallop meat, and the scallop shell pushing device is used for pushing out empty the scallop shells. The multi-station reciprocating circulating scallop shell opening and meat taking machine can clean, guide and level the scallops, accurately position the tails of the scallops, achieve continuous conveying, accurately cut the tails of the scallops, completely taken the scallop meat out of the inner portions of the shell bodies of the scallops, accurately cut sand pockets adhered to the scallop meat, and separate the turtle rims and scallopcolumns of the scallop meat, so that the labor is saved, the production efficiency is improved, and the fresh taste of the scallop meat is effectively ensured.

Owner:秦皇岛润昌科技开发有限公司

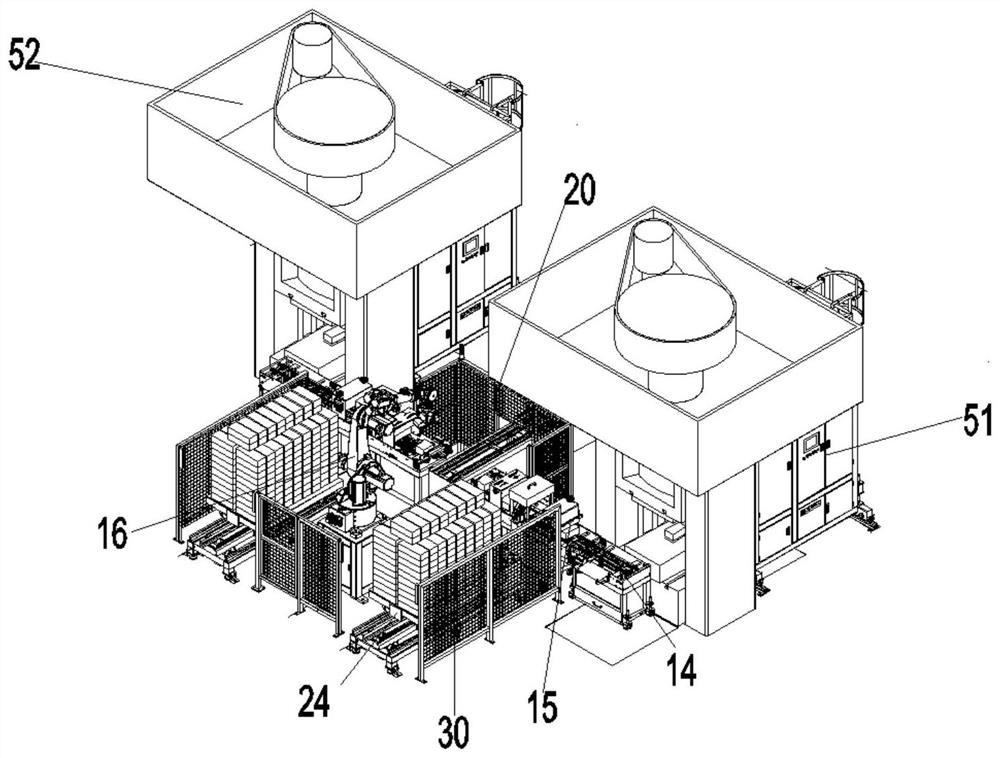

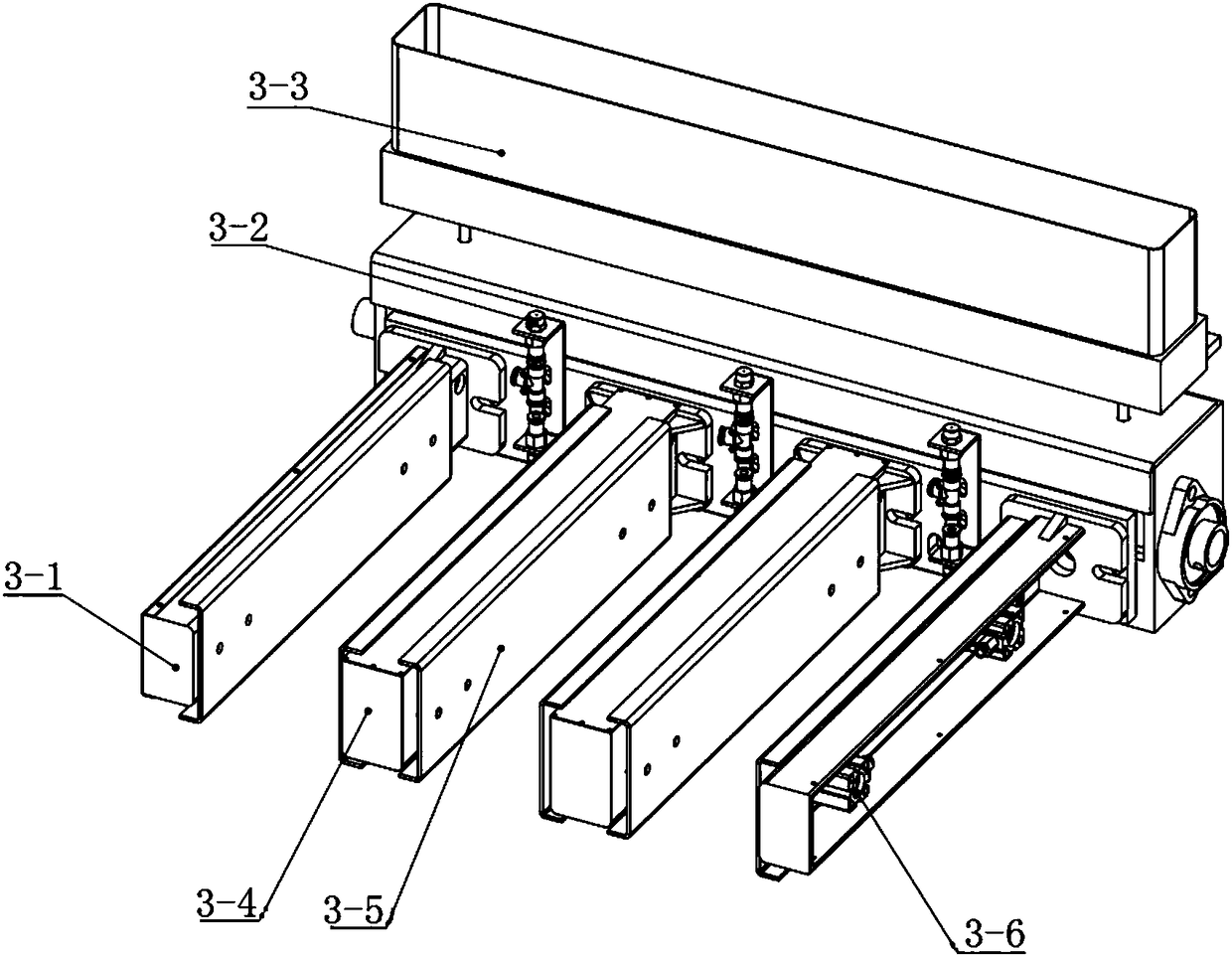

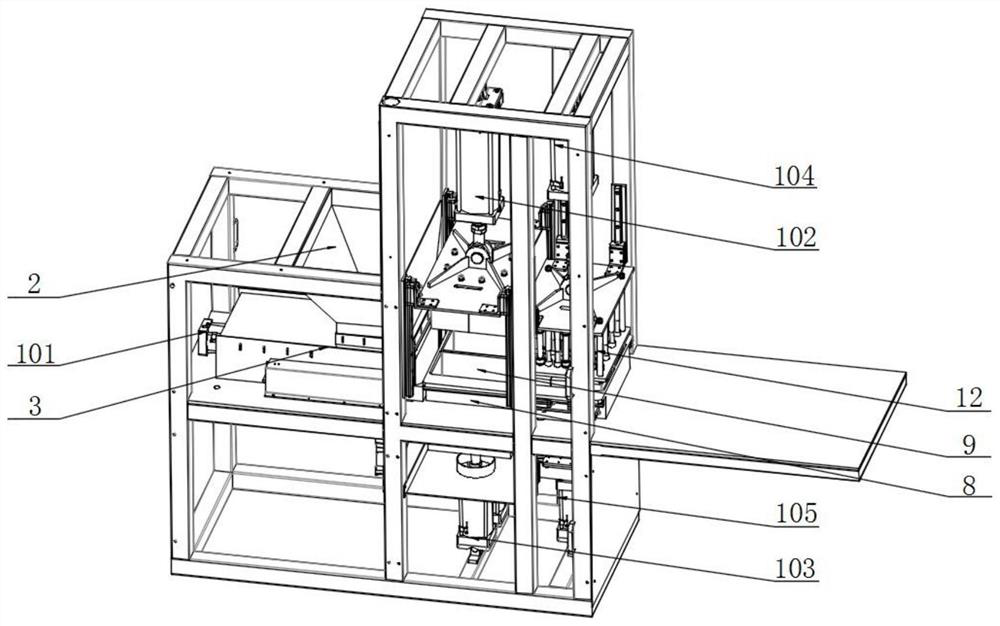

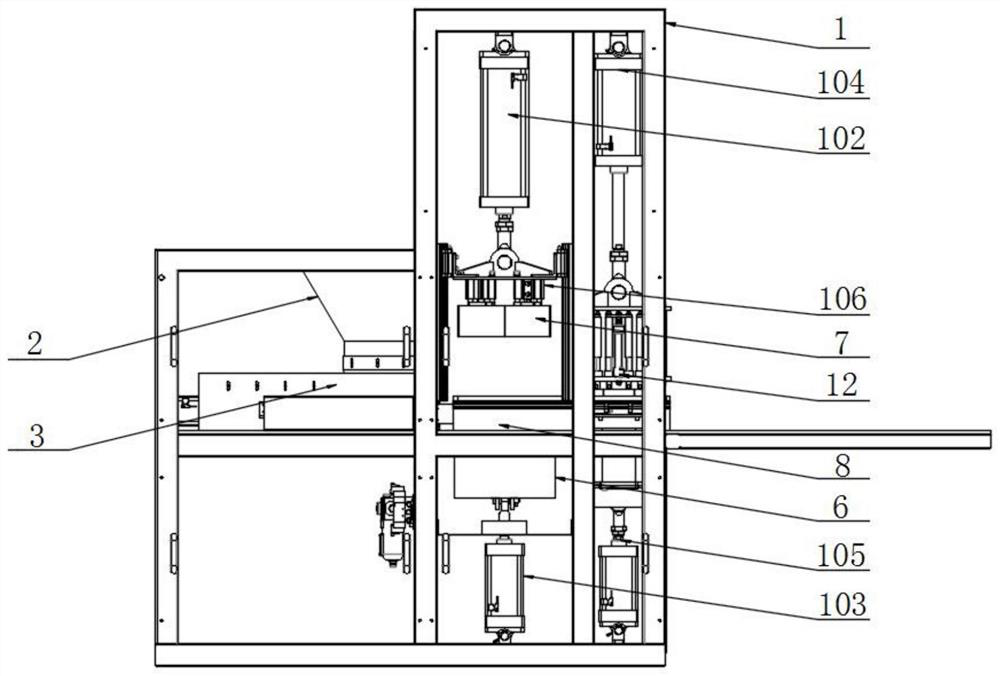

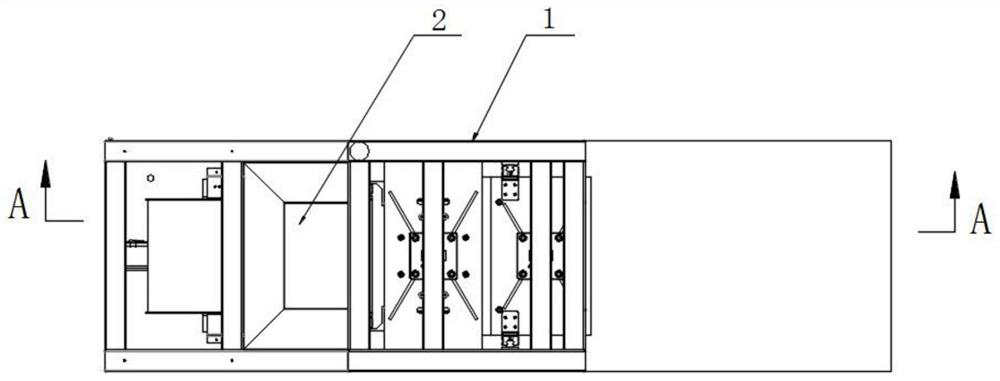

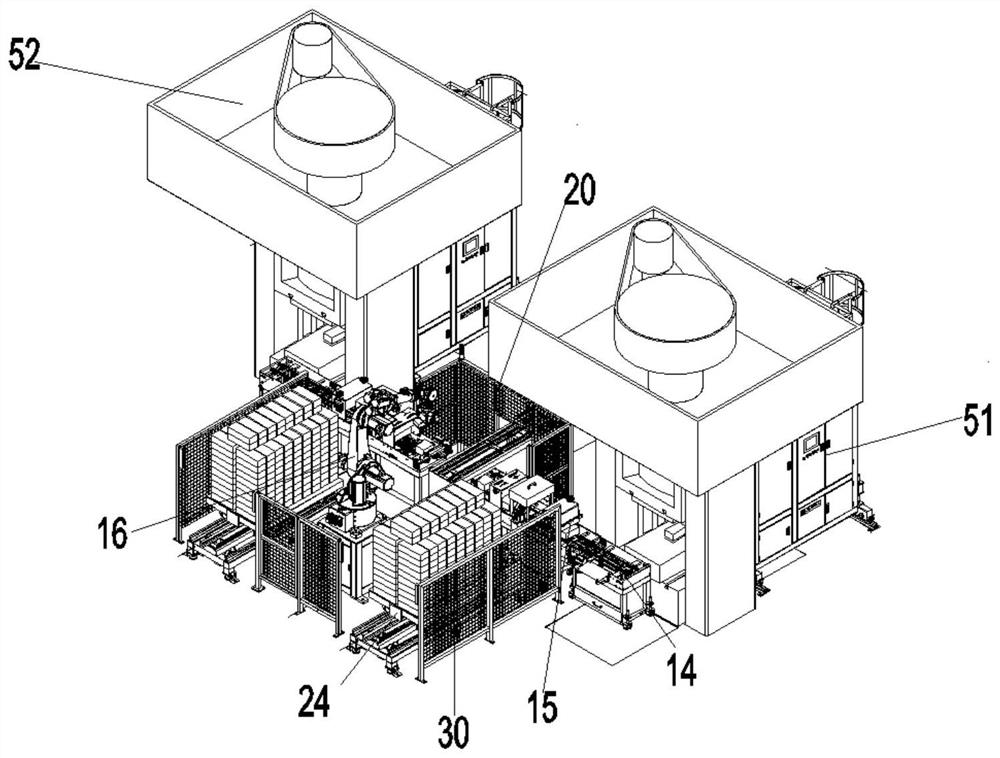

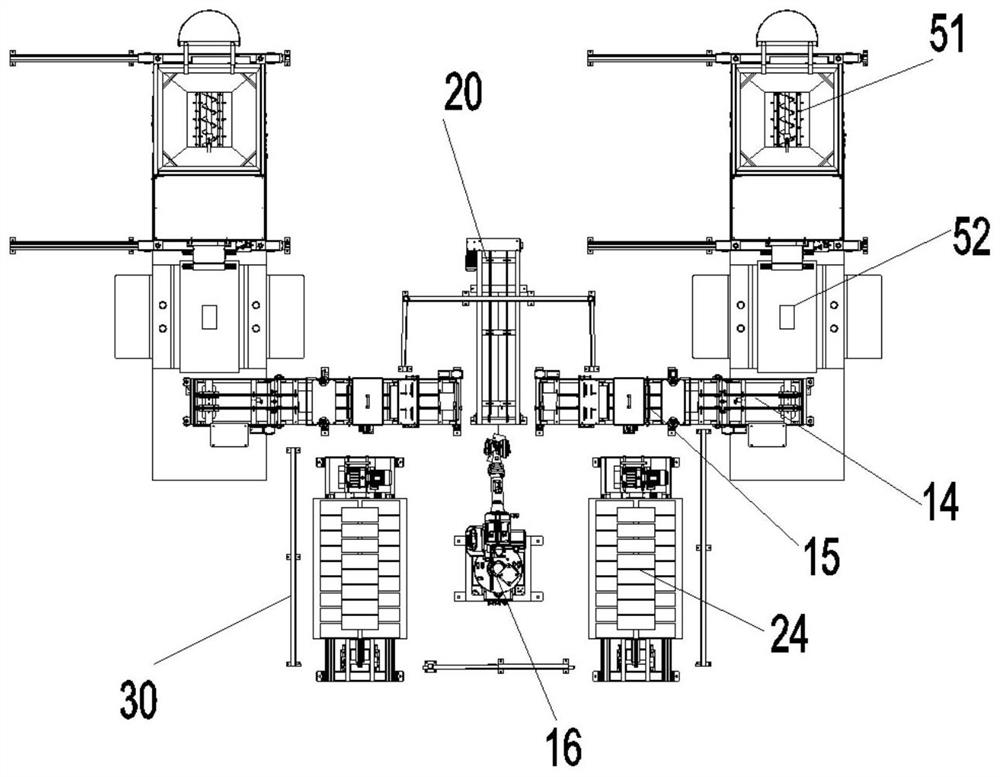

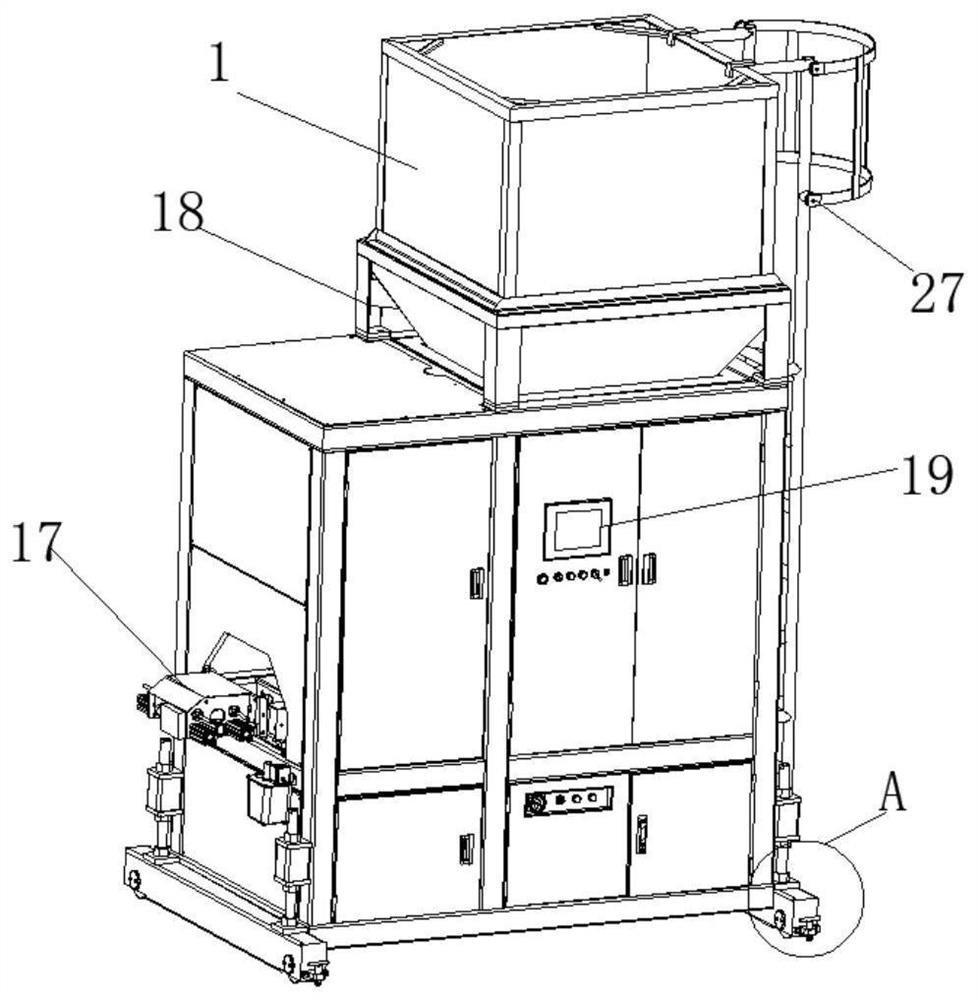

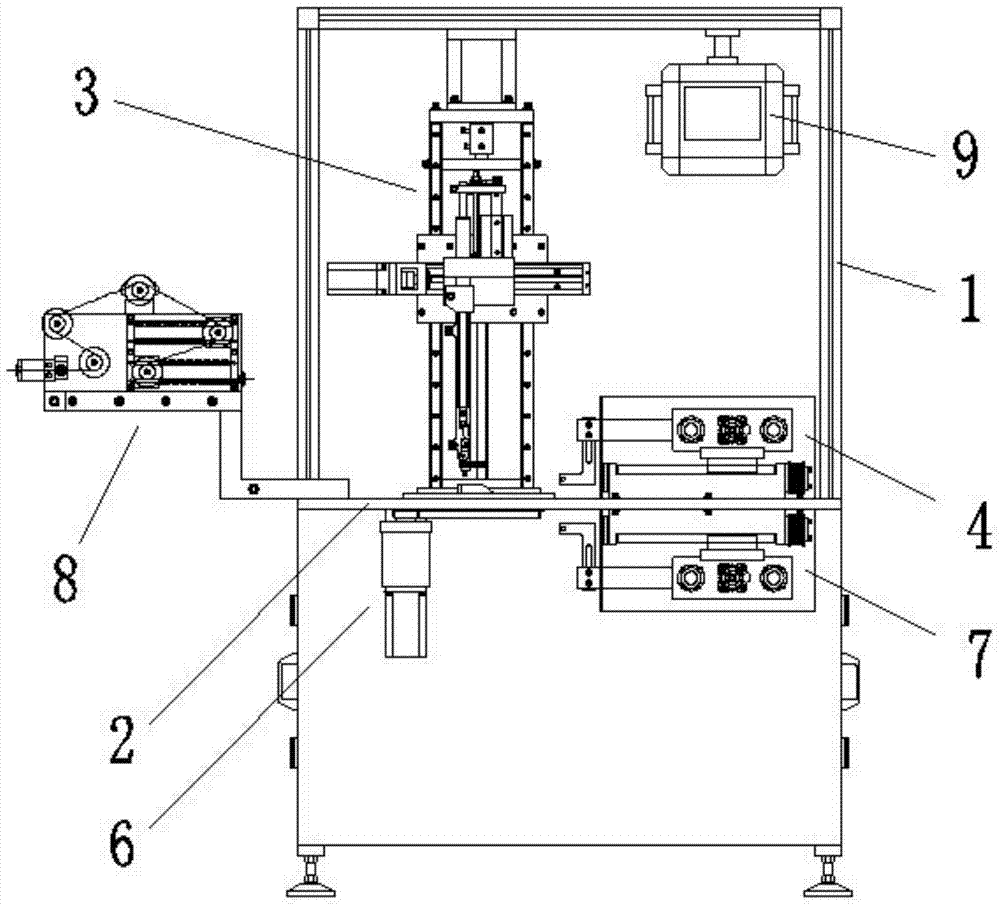

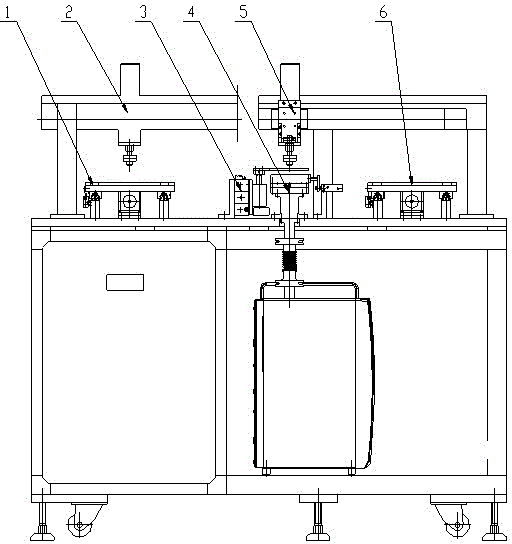

Full-automatic production system for refractory bricks

ActiveCN111702949AOvercoming automationOvercome efficiencyDischarging apparatusMixing operation control apparatusFire brickProcess engineering

The invention discloses a full-automatic production system for refractory bricks. The system is sequentially provided with automatic weighing and distributing devices, pressing machines, brick receiving and conveying tables, detecting machines, a defective product conveying table, a brick taking and stacking device and kiln car positioning areas according to refractory brick forming procedures. According to the system, raw materials are automatically detected and screened after being pressed and formed through the automatic weighing and distributing devices and the pressing machines, the bad bricks are automatically removed, the qualified bricks are stacked and loaded into a kiln car through the brick taking and stacking device, and finally, the kiln car full of the qualified bricks is fedinto a kiln through an intelligent control system for firing, and the finished bricks are obtained; and the full-automatic operation is achieved, the defects that refractory brick manufacturing in the prior art is low in automation degree, low in manufacturing efficiency and the like are overcome, and therefore, the labor cost is reduced, the working efficiency is improved, and meanwhile, the safety risk is greatly reduced, the life safety of people is guaranteed, the influence of dust on the health of people in the brick pressing process is reduced, the labor intensity is reduced, and the problem of difficulty in recruiting workers is solved.

Owner:CHANGXING RONGLI MACHINERY

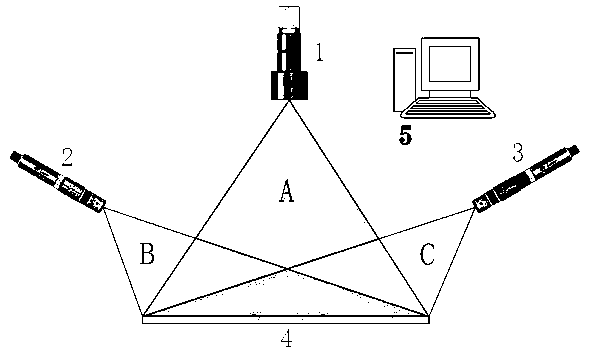

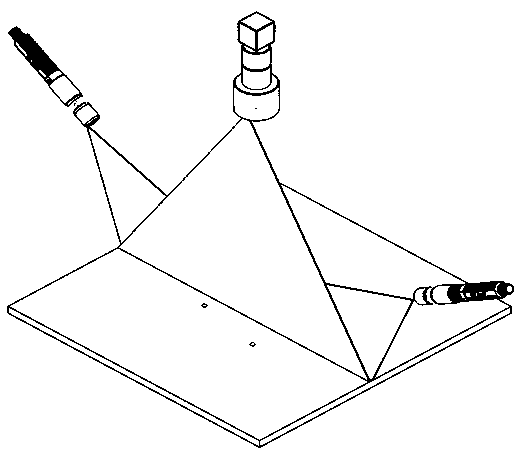

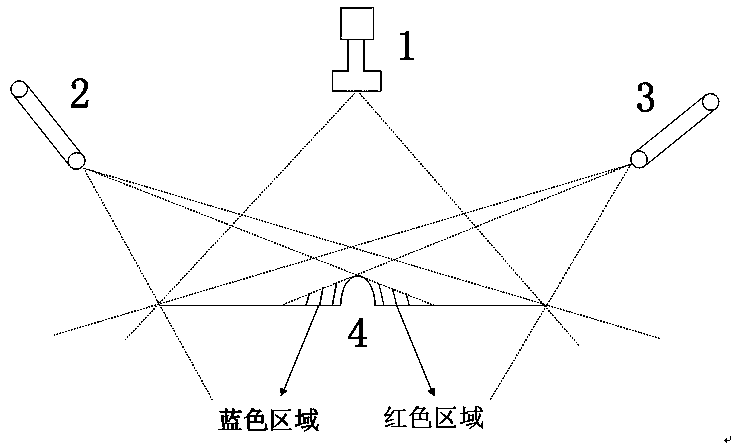

Laser-based large-area glass plate local convex-concave defect detection method

InactiveCN108645862ASolve the problem that local convex and concave defects cannot be detectedSolving Yield ProblemsScattering properties measurementsOptically investigating flaws/contaminationEngineeringLaser light

The invention relates to a laser-based large-area glass plate local convex-concave defect detection method. The method is characterized in that a laser line generating unit shapes laser lights emittedby two line lasers from a point shape into a line shape, the network port of a color line array industrial camera is connected with the network port of an industrial computer through a network cable,the two line laser device sources are respectively placed on the left side and the right side of a glass plate transmission line, and are located at the same plane height, an included angle between every laser device and a glass plate is 20 DEG, and the laser lines of the two laser devices are superposed on the glass plate; and the color line array industrial camera is arranged perpendicular to the glass plate and is located at the middle position of the glass plate transmission line, and the color line array camera collects images and performs operations when passing through the glass platetransmission line. The method solves the problem of accurate positioning of the type of a defect and timely feedback of the type to a former corresponding process in the glass production process, andalso solves the yield problem of large-area glass.

Owner:长春新产业光电技术有限公司

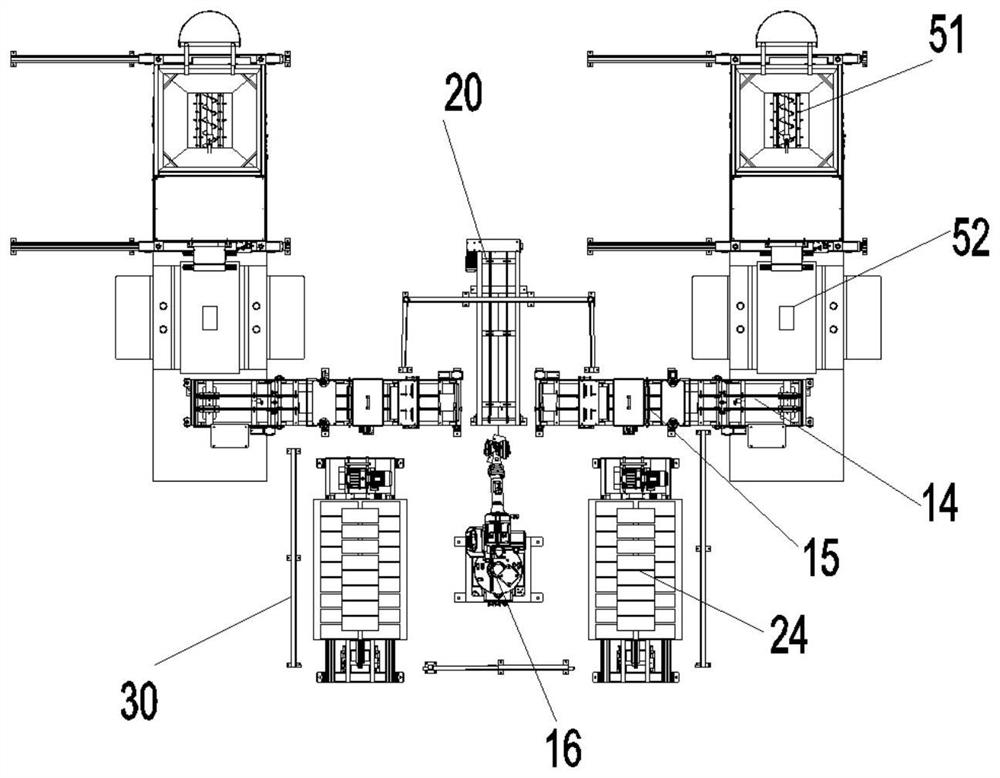

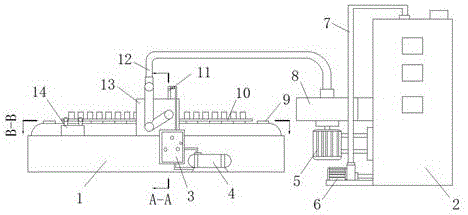

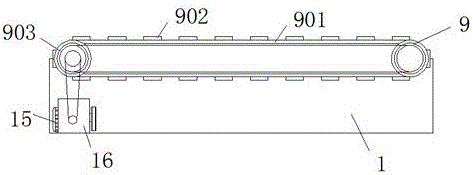

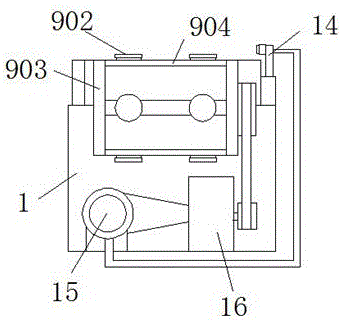

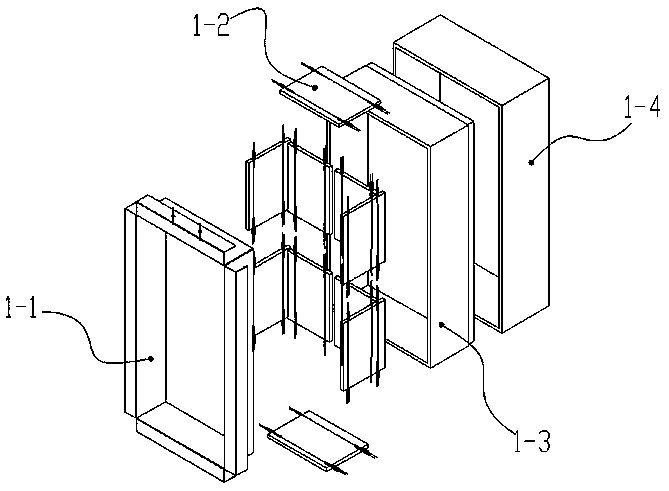

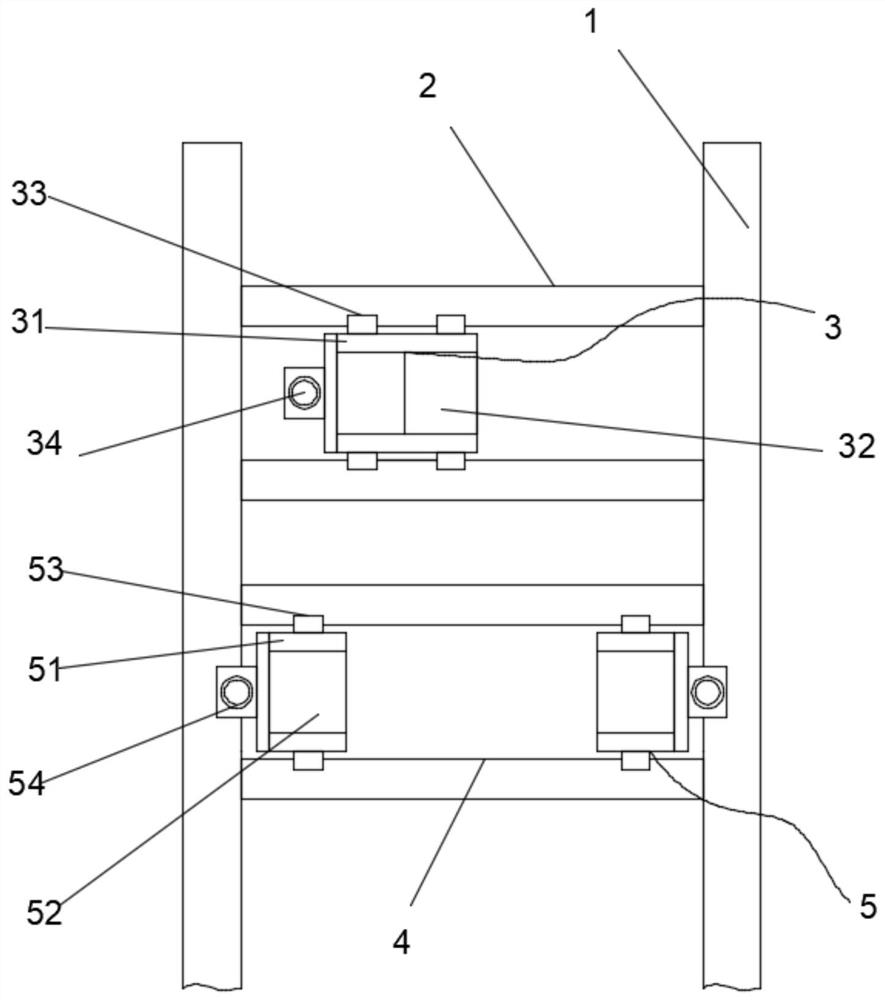

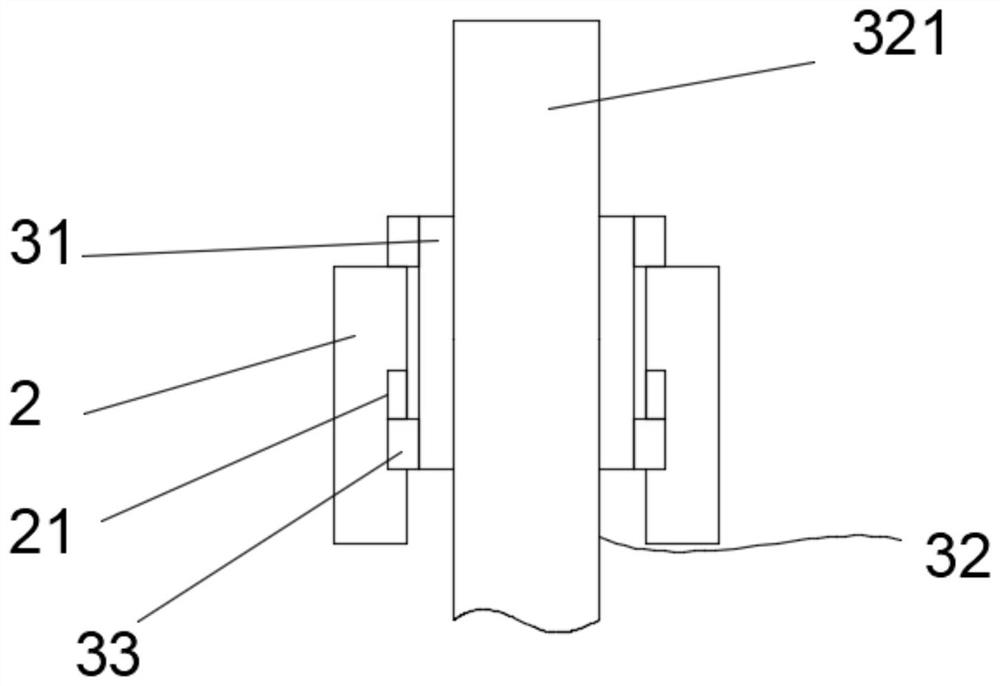

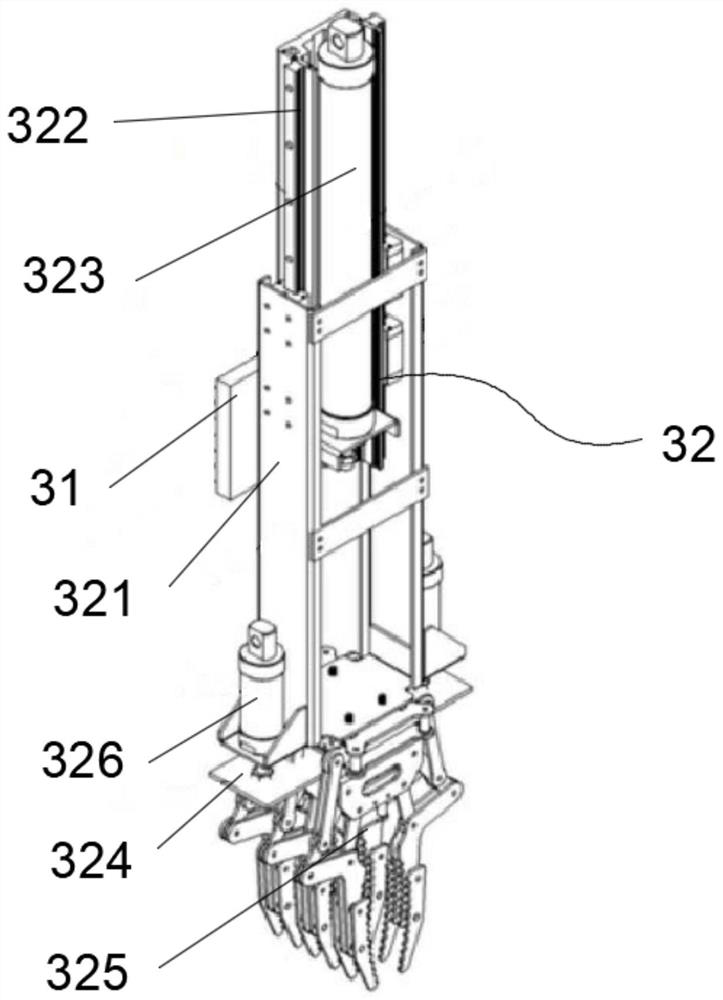

Intelligent identification robot for ceramic tile carrying

InactiveCN108861537AAvoid suffering fromSolve recruitment difficultiesConveyor partsSprocketEngineering

The invention provides an intelligent identification robot for ceramic tile carrying. The intelligent identification robot comprises a cabinet, a four-shaft robot, a Y-shaft adjusting mechanism, a ceramic tile grabbing mechanism, an X shaft, a Z-shaft discharge mechanism, a first box push mechanism, a chain wheel lifting device, a machine frame, lower-layer conveying belt, an upper-layer conveyingbelt and a second box push mechanism, wherein the four-shaft robot and the Y-shaft adjusting mechanism are arranged on the upper surface of the cabinet, the ceramic tile grabbing mechanism is arranged on the four-shaft robot, the X shaft is arranged on the cabinet and located above the Y-shaft adjusting mechanism, the Z-shaft discharge mechanism is movably arranged on the X shaft, the first box push mechanism is arranged on the cabinet and located below the Z-shaft discharge mechanism, the chain wheel lifting device is arranged on the side edge of the cabinet and located below the Z-shaft discharge mechanism, the machine frame is arranged on the side edge of the chain wheel lifting device, the lower-layer conveying belt and the upper-layer conveying belt are arranged on the machine frame,and the second box push mechanism is arranged on the machine frame and used for pushing a box body on the lower-layer conveying belt into the chain wheel lifting device. Compared with the prior art,human intervention is not needed in the whole process, workers avoid suffering from occupational diseases after working in the severe environment for a long time, the problem of labor shortage is solved, the production efficiency is improved, and the production cost is reduced.

Owner:中源智人科技(深圳)股份有限公司

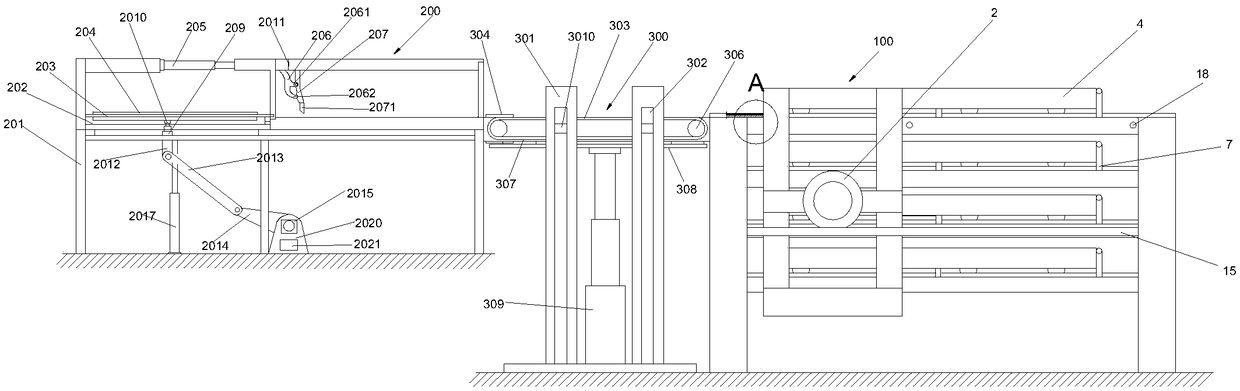

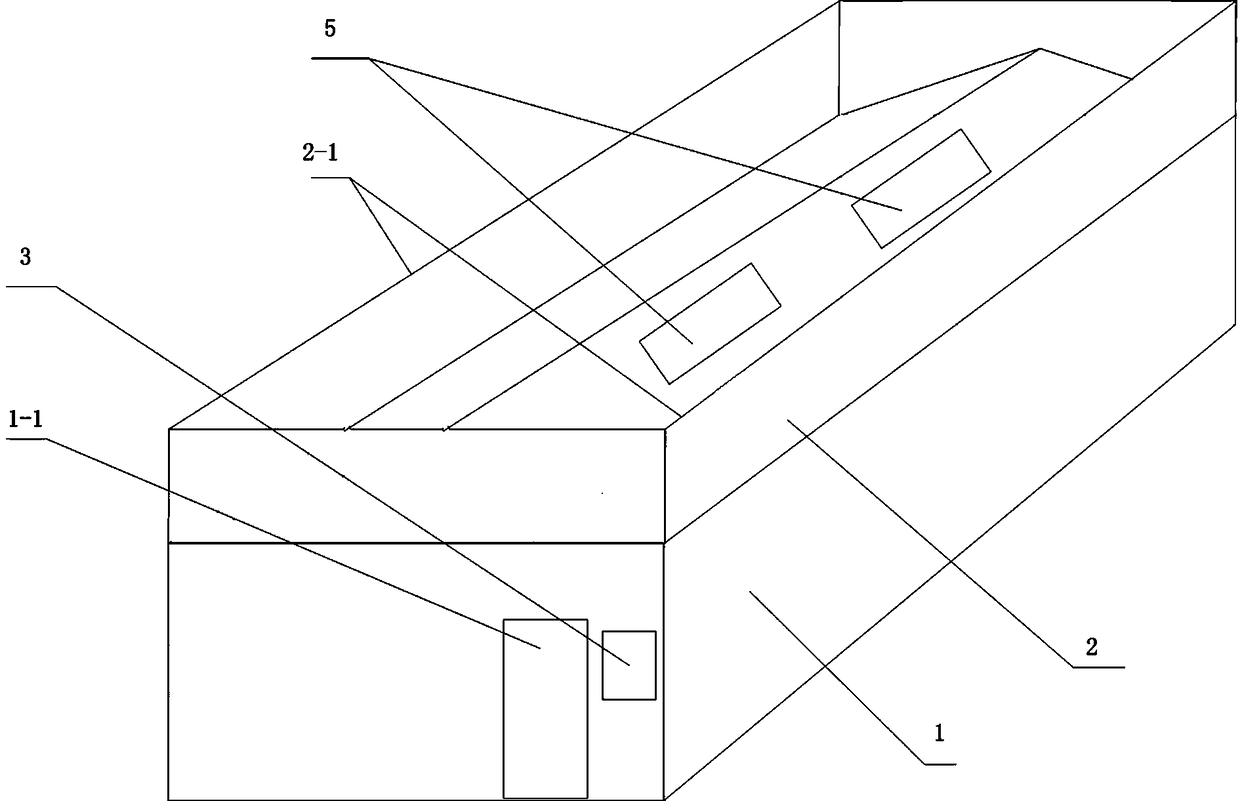

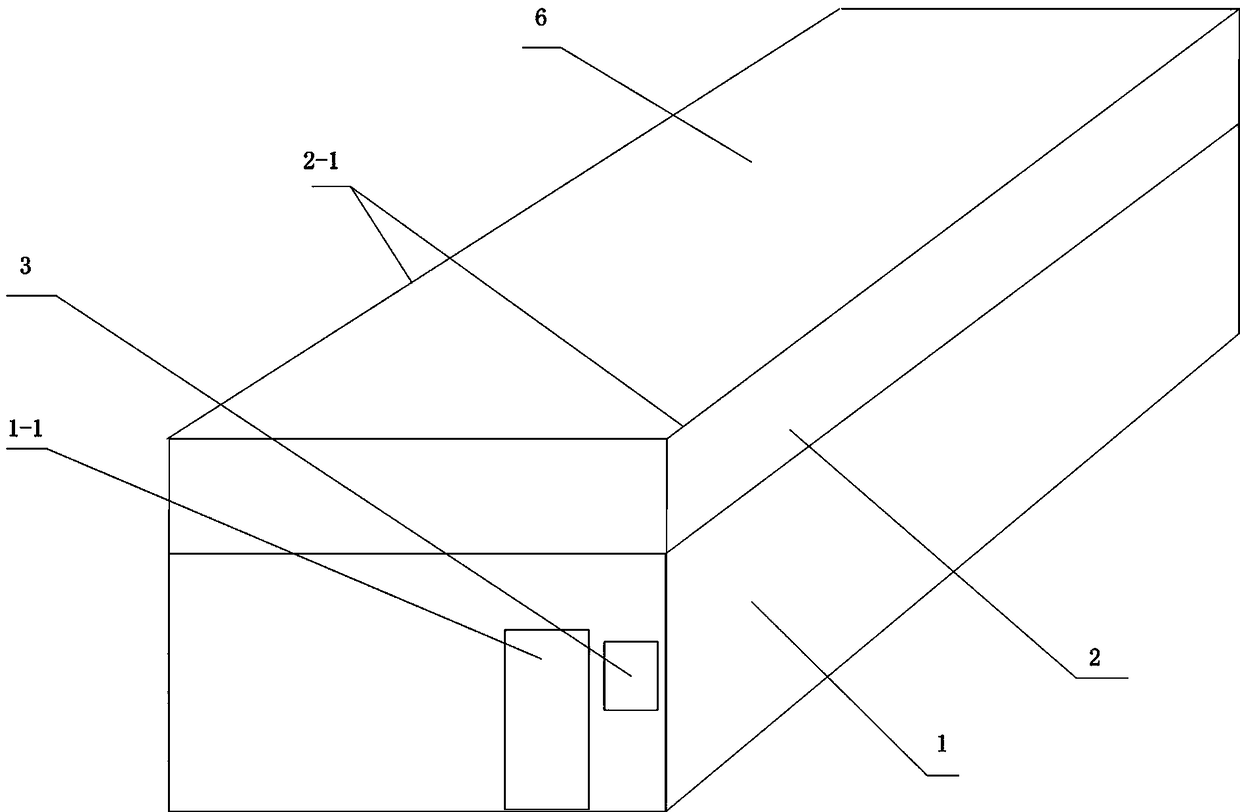

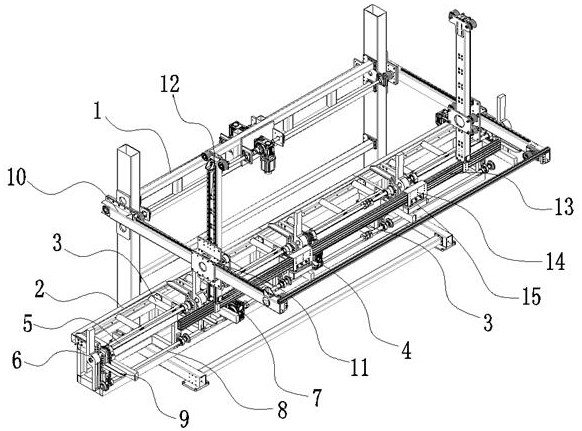

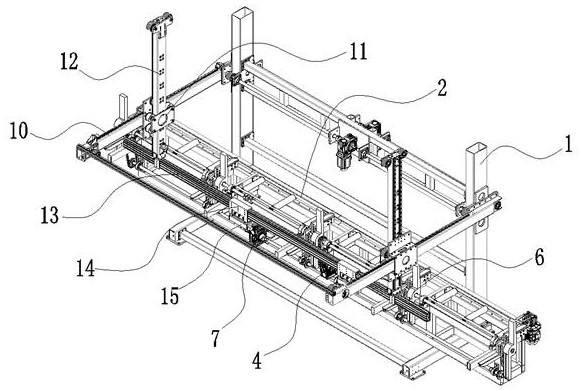

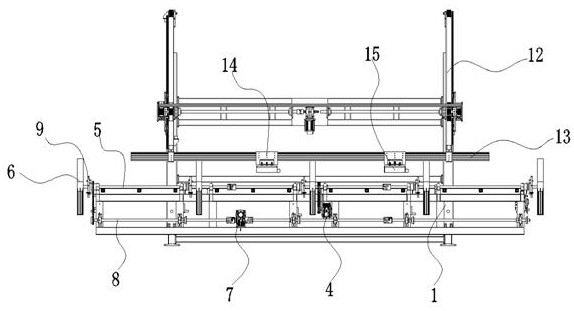

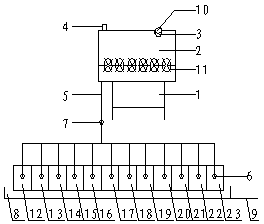

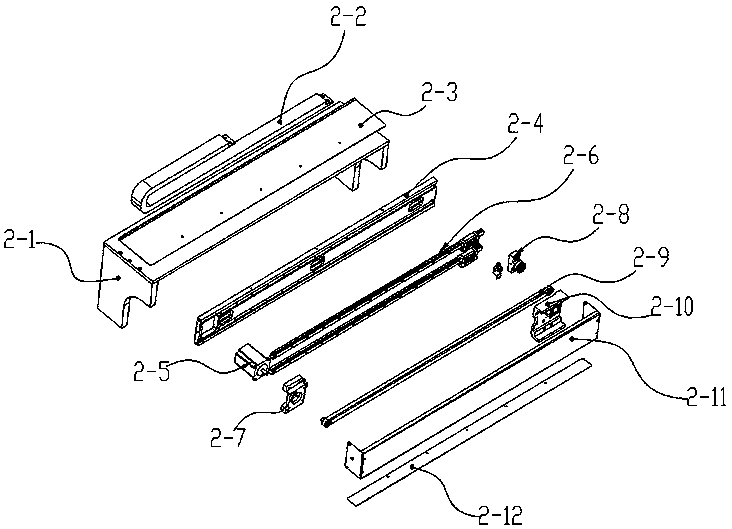

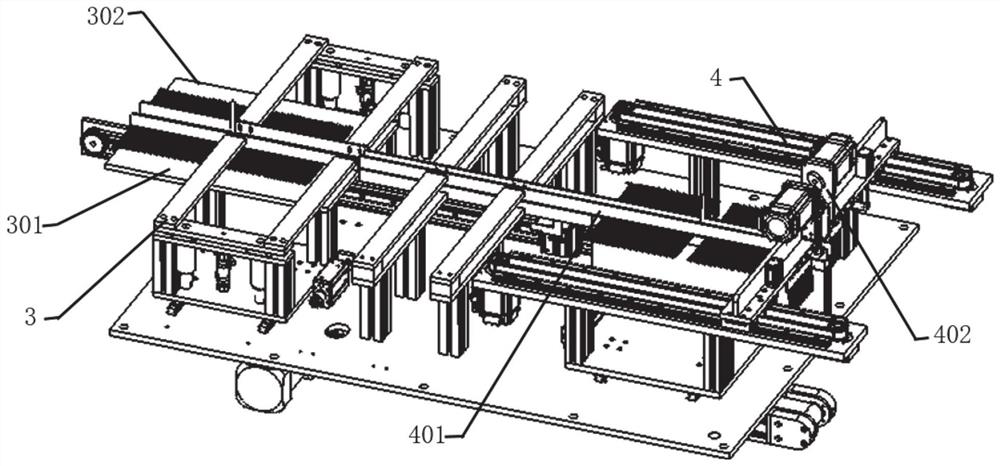

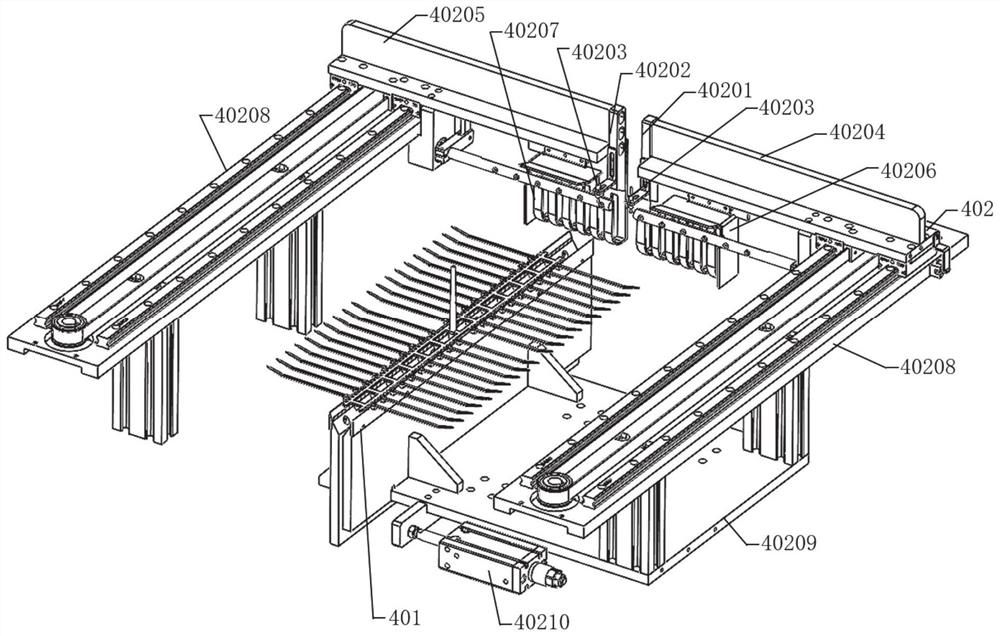

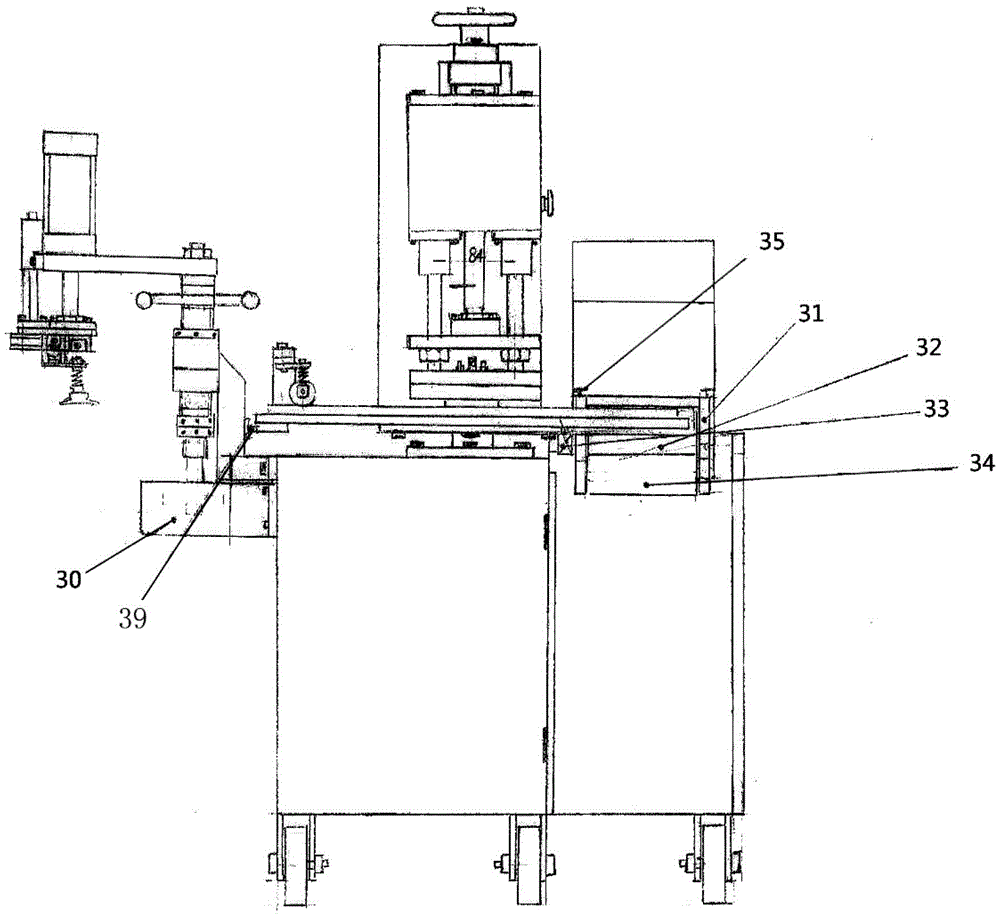

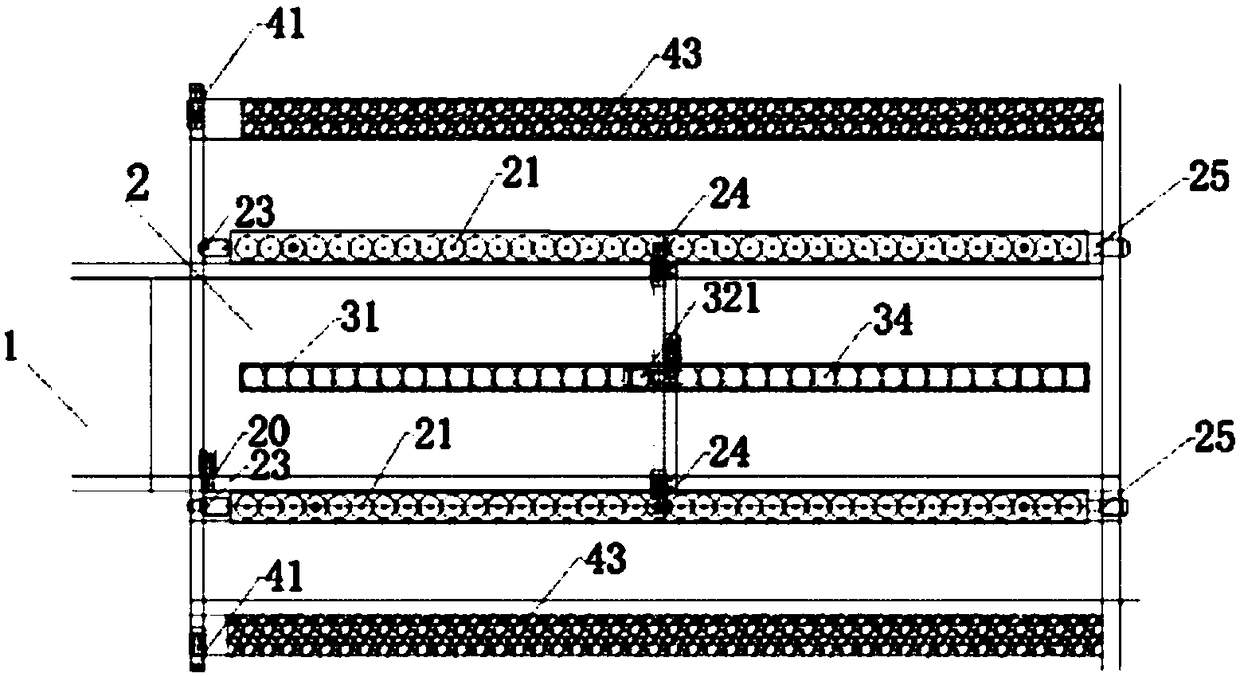

Board pushing system of multi-layer hot press

PendingCN109049177AGuaranteed stabilityRealize feedingPlywood pressesVeneer pressesProduction lineEconomic benefits

The invention discloses a board pushing system of a multi-layer hot press, which is capable of achieving automatic feeding, and simultaneously feeding a multi-layer board into and out of the multi-layer hot press. The board pushing system of the multi-layer hot press comprises a board pushing device, a feeding device and a multi-layer board conveying device. The multi-layer board conveying devicecomprises a supporting platform and a walking mechanism. The board pushing device comprises a base device, a conveying device and a pushing device. The feeding device is installed between the board pushing device and the multi-layer board conveying device. According to the board pushing system of the multi-layer hot press, the feeding and discharging of the boards can be achieved quickly, the processing efficiency is improved, and the construction of an automatic production line for board processing is facilitated. In addition, the problem of difficulty in recruitment can be solved, and the economic benefits can be improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Intelligent planting greenhouse and control method

ActiveCN108901474AReduce labor costsLower quality requirementsClimate change adaptationGreenhouse cultivationSocial benefitsGreenhouse

The invention relates to an intelligent planting greenhouse and a control method. The intelligent planting greenhouse comprises a pinnacled greenhouse body, a top rectangular frame, a greenhouse door,a control box, a monitoring unit, an outer sunshade curtain, an inner sunshade curtain, etc. The control method comprises the following steps: acquiring the information of indoor and outdoor environments through sensors, and controlling an executing mechanism according to the acquired information. The intelligent planting greenhouse and the control method provided by the invention have the following advantages: the labor cost of a large-scale planting greenhouse can be effectively reduced; the degree of automation is high; high practicability is achieved; and certain economic benefits and social benefits can be generated.

Owner:HEBEI NORMAL UNIV

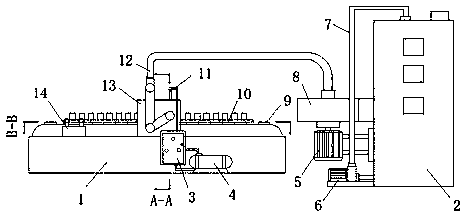

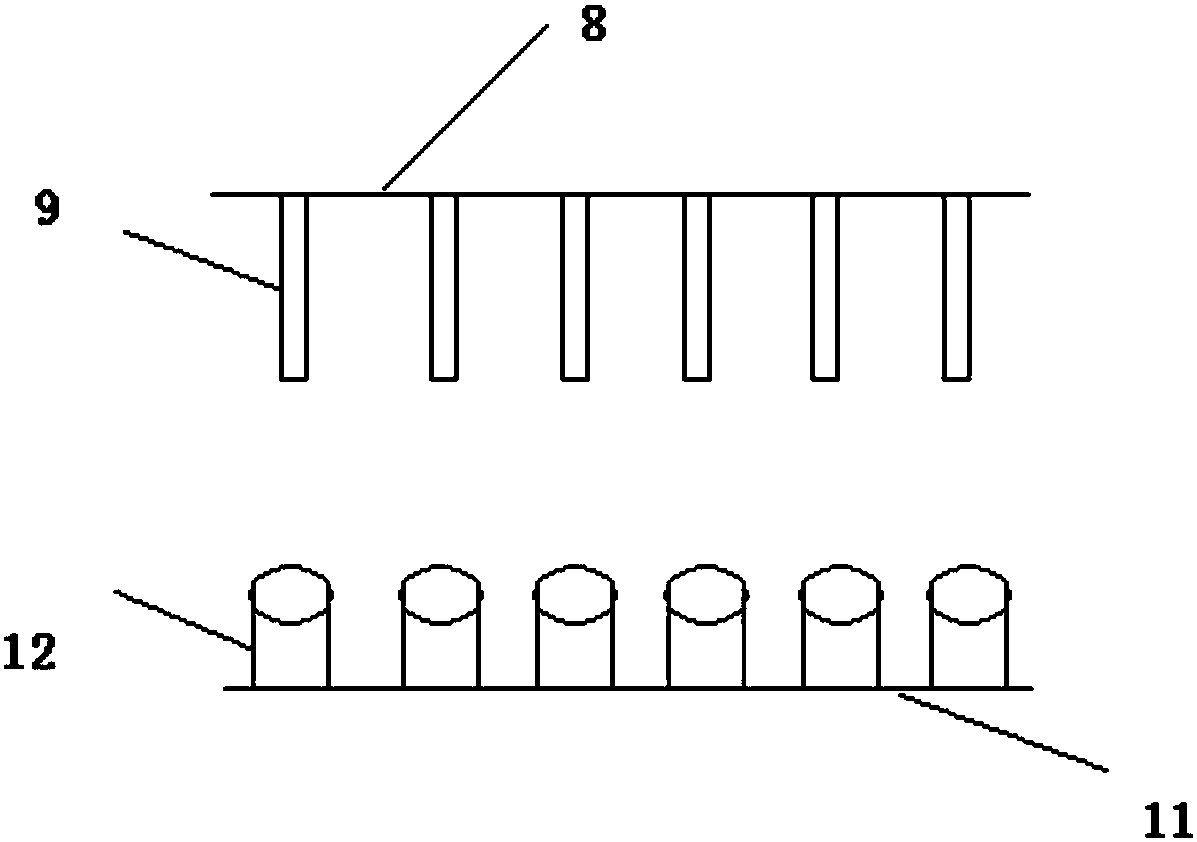

Ceramic dust suction-blowing integrated machine

ActiveCN106345748APrevent escapeSolve recruitment difficultiesUsing liquid separation agentDirt cleaningAir pumpElectric machinery

The invention discloses a ceramic dust suction-blowing integrated machine. The ceramic dust suction-blowing integrated machine comprises a worktable and a dust collecting box. The middle portion of the worktable is fixedly provided with a suction hood, and the middle portion of the front side of the worktable is fixedly provided with a control box; an air pump is arranged at the right side of the control box, a conveyer is arranged on the worktable, and the suction hood stretches across the conveyer; a pallet is arranged on the conveyer, and a dust-suction pipe is provided on the suction hood; high-pressure blow pipes are fixedly arranged side by side at one side, located at the dust-suction pipe, of the upper surface of the suction hood; the lower end of each high-pressure blow pipes is located at the connection portion of the inside of the suction hood and the dust-suction pipe; the upper end of each high-pressure blow pipes is connected with an air pump through a high-pressure air pipe; a servo motor and a reduction gearbox are fixedly arranged at one side, located at a induction switch, of the inside of the worktable; the middle portion of the left side of the dust collecting box is provided with a blast box; the middle portion of the lower surface of the blast box is provided with a dust collecting motor, and the dust collecting motor is fixed on the dust collecting box through a fixing bracket; the lower portion, located at the dust collecting motor, of the bottom of the dust collecting box is provided with a water pump. The ceramic dust suction-blowing integrated machine is safe and reliable, and the labor intensity is reduced.

Owner:醴陵市和泰陶瓷制造有限公司

Intelligent manufacturing production-line for refractory bricks

InactiveCN108327060AIncrease productivityReduce investmentCeramic shaping plantsProduction lineBrick

The invention discloses an intelligent manufacturing production-line for refractory bricks, and belongs to the technical field of refractory brick manufacturing. The intelligent manufacturing production-line for the refractory bricks comprises an intelligent control system, a conveying assembly line, an automatic material-distributing and brick-pressing device, an automatic brick-clamping mechanical hand, a visual inspection device, an automatic line-moving device, an automatic plate-superposing device and a circulating vehicle driving device. By digital and automatic facilities being introduced or existing devices being updated intellectually, each process of refractory brick manufacturing can be automatically performed, operating workers are reduced, standardized production is realized,the whole producing process is carried out without artificial participation, and automation operation is completely realized. Further, the refractory bricks are made by using an intelligent assembly line, personal injuries of production process and risks of safety production is greatly reduced, influence of dust on personnel health during brick pressing is reduced, labor intensity is lowered, production efficiency is improved, production capacity is expanded, and great benefits are brought to enterprises and local economy.

Owner:希望银蕨智能科技有限公司

Automatic stacking machine for C-shaped steel and Z-shaped steel

PendingCN113148672AIncrease the scope of applicationImprove work efficiencyStacking articlesDe-stacking articlesPhysicsElectric machinery

The invention discloses an automatic stacking machine for C-shaped steel, Z-shaped steel and steel bar truss plates, and relates to the technical field of C-shaped steel stacks, Z-shaped steel stacks and steel bar truss plate stacks. The automatic stacking machine specifically comprises a main frame and a conveying frame. The main frame is formed by welding rectangular pipes. The conveying frame is fixedly installed at the bottom of the main frame, and conveying carrier rollers are arranged on the surface of the conveying frame. The conveying frame further comprises a first turnover arm, a second turnover shaft and a second turnover arm, wherein the first turnover arm is mounted on the surface of a first turnover shaft in a sleeving connection manner; the second turnover shaft is connected to the side face of a second turnover motor; and the second turnover arm is connected to the outer wall of the first turnover shaft in a sleeving manner. According to the automatic stacking machine for the C-shaped steel and the Z-shaped steel, the C-shaped steel, the Z-shaped steel, columnar profiles and steel bar truss plates can be clamped and turned over, the application range of the automatic stacking machine is widened, meanwhile, the profiles can be stacked in order, and therefore the manual turnover and stacking mode is replaced, the working efficiency is improved easily, the stacking uniformity is improved, and the automatic stacking machine solves the problems about industrial automation and recruitment difficulty for production enterprises, and achieves the aim of people substitution with machines.

Owner:辽宁鑫硕智能机械有限公司

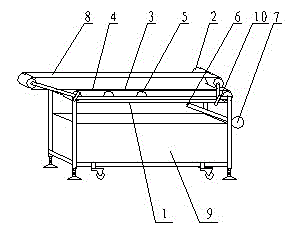

Cleaning and disinfection part of automatic production line for fillet processing

InactiveCN103583664ASolve recruitment difficultiesImprove efficiencyFish washing/descalingFood preparationProduction lineSpray nozzle

The invention provides a cleaning and disinfection part of an automatic production line for fillet processing. After one day's work is finished, the machine is not turned off, sanitizer is placed in a water tank through a sanitizer feeding port arranged on the water tank, a seal cover is covered, an electric stirring device is turned on to uniformly stir the sanitizer and water, then the switch on a water outlet pipe is turned on, all parts are cleaned and disinfected by high-pressure water spray nozzles at all the parts, sewage after cleaning flows to water receiving tanks arranged under all the parts, finally, sewage accommodated by the water receiving tanks flows to a sewer through a sewer pipe.

Owner:宫锡和

Full-automatic machine for producing bean curd sticks

PendingCN110178910ASolve recruitment difficultiesReduce labor costsCheese manufactureMental healthHygiene

The invention relates to a full-automatic machine for producing bean curd sticks, and relates to the technical field of food processing. The full-automatic machine is characterized in that a transverse module fixing bracket is fixed on the upper face plate of a machine frame; the upper surface of the transverse module fixing bracket is fixed with a guide plate; a drag chain is arranged on the guide plate; one end of the drag chain is fixedly connected with the guide plate, and the other end of the drag chain is fixedly connected with a lifting module; the front side face of the transverse module fixing bracket is fixed with a transverse module fixing plate; the front side face of the transverse module fixing plate is fixed with transverse linear guides in an up-down symmetry manner; the transverse linear guides are slidably connected with a lifting module fixing plate through sliders thereon. According to the full-automatic machine, all processes of the production shaping of the bean curd sticks are completed through control of programming; a traditional manual or semi-automatic production state is shifted to an automatic food production state; the problems of difficulties in factory recruitment, labor cost reduction, production efficiency improvement, product price reduction, reduction of influence of a harsh working environment on the physical and mental health of personnel,improvement of hygiene and food safety and the like are solved.

Owner:深圳市括弧科技有限公司

Fish head removing part of automatic production line for fillet processing

InactiveCN103583665ASolve recruitment difficultiesImprove efficiencyFish filletingFisheryProduction line

The invention provides a fish head removing part of an automatic production line for fillet processing. A fish slides downwards from a fish feeding slide, then directly falls on a triangular fish head and tail recognizer; the triangular fish head and tail recognizer separates the fish head and the fish tail as per the weight difference of the fish head and the fish tail; as the fish head is heavier than the fish tail, the fish head slides downwards firstly, the fish head and the fish tail enter two conveyor belt partitions arranged under the fish head and tail recognizer respectively; the fish head is in contact with a height adjusting plate arranged on a slide arranged on the inner side of a baffle; the height of the fish head to be removed can be set through a height adjusting knob arranged under the height adjusting plate according to the height of the fish head; driven by the two conveyor belts, the fish with the fish head facing downwards moves forwards along the slide, and the fish head is separated from the fish body when the fish moves to a head separating cutter; the fish head under the head separating cutter and along the fish head slide slides to a fish head basket arranged under fish head slides on the two sides of a bracket; the fish body without the fish head moves forwards continuously on the head separating cutter, then enters the downwards slanting fish body slide behind the head separating cutter, and finally enters the next procedure.

Owner:宫锡和

Viscera removing part of fish slice processing automatic production line

InactiveCN103598310ASolve recruitment difficultiesImprove efficiencyFish processingProduction lineFish fillet

The invention provides a viscera removing part of a fish slice processing automatic production line. After the fish is transmitted from a fish slide of the last process, because a fish pressure conveyer belt is longer than a fish conveyer belt and directly extends to the upward side of the fish slide of the last process, the fish on the fish slide is directly conveyed on two fish conveyer belts, because a bone removing machine operates from the back of a fish and takes out the fish bone, the abdomen of the fish is connected to be a slice, when the fish is transmitted forward on two fish conveyer belts, the abdomen rightly goes through a scraper, a hair brush and a high pressure water nozzle which are arranged between two fish conveyer belts, the arc-shaped scraper firstly scraps and clean the viscera, the hair brush scraps and cleans further, and then the high pressure water nozzle completely cleans the abdomen which is scraped and cleaned for two times, the viscera cleaned for three times enter a viscera containing basket arranged below two fish conveyer belts, and the fish enters the next process under the drive of the two fish conveyer belts and the fish pressure conveyer belt.

Owner:宫锡和

Bionic flapping koji-making device and koji-making method thereof

PendingCN113717808AReduce manufacturing costSolve recruitment difficultiesAlcoholic beverage preparationProcess engineeringIndustrial engineering

The invention discloses a bionic flapping koji-making device and a koji-making method thereof. The bionic flapping koji-making device comprises a rack, a receiving hopper, a feeding frame, a first power mechanism, a pre-pressing mechanism and a flapping mechanism, wherein the receiving hopper is arranged on the rack; the feeding frame is arranged on the rack below the receiving hopper, and the first power mechanism is arranged on the rack on one side of the feeding frame and used for driving the feeding frame to reciprocate in a horizontal direction. The device and method replace a traditional manual method of koji making, reduce intensity of manual labor, improve efficiency of koji making, and have a high degree of automation. In addition, the flapping mechanism simulates a manual koji treading mode, the flapping mechanism can quickly flap the koji blocks to extract slurry on surfaces of the koji blocks, meanwhile, a problem that traditional manual koji treading force is inconsistent can be well solved, and production quality of the koji blocks is guaranteed. In addition, the produced koji blocks are tight outside and loose inside, subsequent fermentation of the koji blocks is facilitated, and wine brewing quality of the koji blocks is guaranteed.

Owner:XIAMEN AEROSPACE SIERT ROBOT SYST CO LTD

Ribbon cutting and packaging system

InactiveCN113665898AEnsure quality stabilityLabor savingWrapper twisting/gatheringPackaging automatic controlVisual inspectionStructural engineering

The invention discloses a ribbon cutting and packaging system, and relates to the related field of cutting and packaging. The ribbon cutting and packaging system comprises an injection molding machine, an injection molding machine mechanical arm, an automatic conveying belt, a material pushing mechanism, an automatic ribbon feeding mechanism, a visual inspection system, an automatic positioning and compacting mechanism, an automatic cutting mechanism, a waste discharge mechanism, an automatic ribbon grabbing mechanism and an automatic packaging unit. full-page ribbons injection-molded by the injection molding machine are automatically grabbed on the injection molding machine through the injection molding machine mechanical arm and placed on the automatic conveying belt, so that the full-page ribbons are automatically conveyed to an inlet of the automatic ribbon feeding mechanism, pushing is carried out through the material pushing mechanism, automatic positioning is carried out through the automatic ribbon feeding mechanism, the visual detection system automatically detects and eliminates defective ribbons, the automatic cutting mechanism automatically cuts the ribbons according to the required number, the cut ribbons are are put into bags and sealed into bagged ribbons through the automatic ribbon grabbing mechanism and the automatic packaging unit, then the bagged ribbons automatically fall onto the conveying line and are conveyed to a preset place, and the whole process is fully automatically completed.

Owner:东莞市八九十智能科技有限公司

Large-diameter steel pipe double welding torch intelligent welding equipment

ActiveCN107414369BImprove welding efficiencyQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesMotor driveArchitectural engineering

The invention belongs to the technical field of welding equipment, and relates to outdoor large-diameter pipe welding equipment, in particular to large-diameter steel pipe double-welding-gun intelligent welding equipment. Two semicircular rings surround a large-diameter pipe to be welded in middle, and the axes are overlapped; an annular motor drives an annular car to rotate along a ring; an axial motor drives welding guns to move in a direction parallel to the axes; a radial motor drives the welding guns to move in the radial direction; and a swing motor I drives the welding guns to swing. The large-diameter steel pipe double-welding-gun intelligent welding equipment can finish annular welding lines, can realize multi-layer and multi-way welding and swing welding, is high in welding efficiency, and guarantees the quality stability. The large-diameter steel pipe double-welding-gun intelligent welding equipment reduces labors and the labor intensity, prevents occupational injury, solves the problem of welder shortage, reduces the labor cost, uses double welding guns to improve the working efficiency twice, can weld multiple curved welding lines, is flexible in carrying, and is suitable for outdoor construction and use.

Owner:安徽颍瑞源焊管科技有限公司

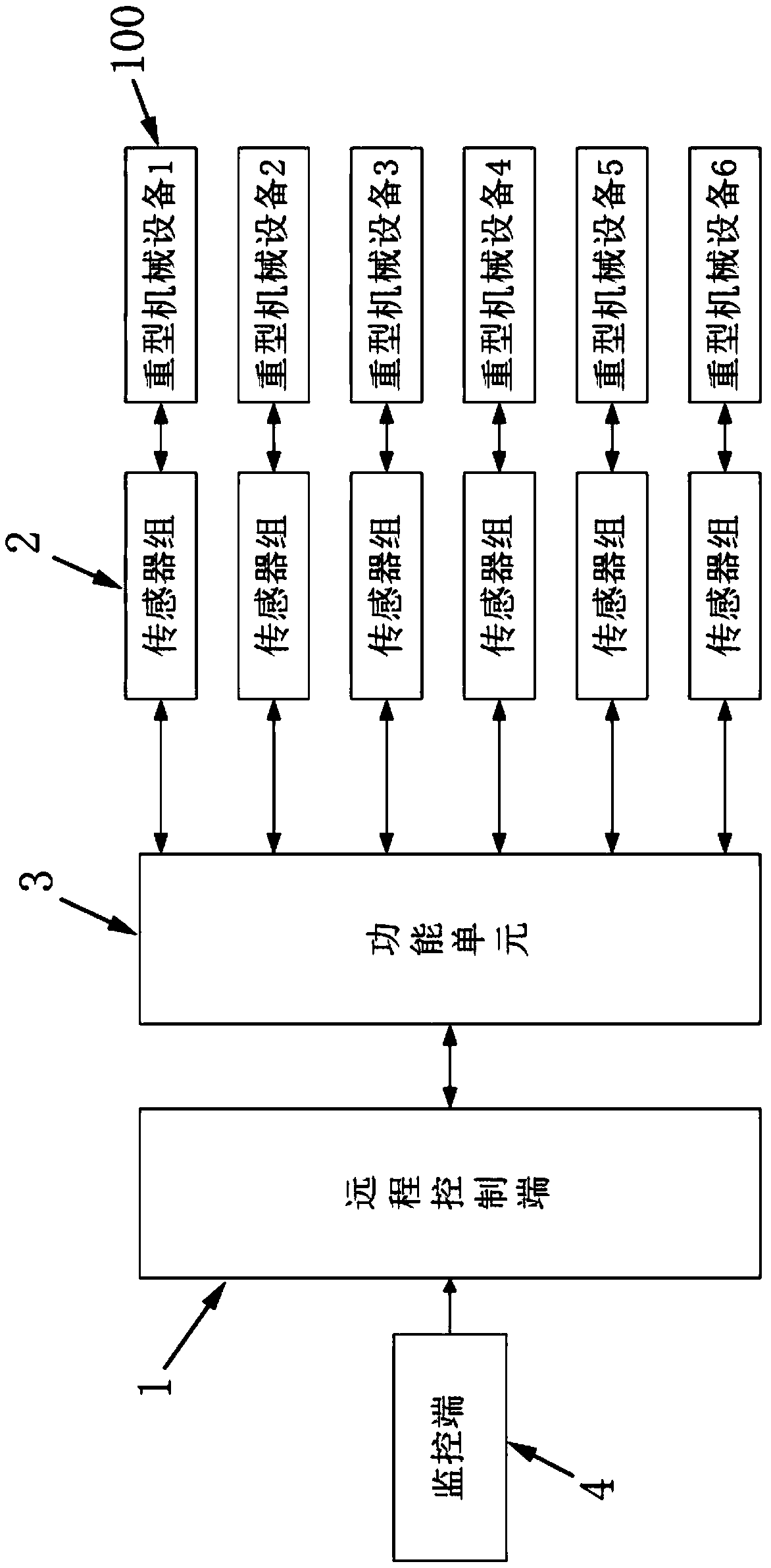

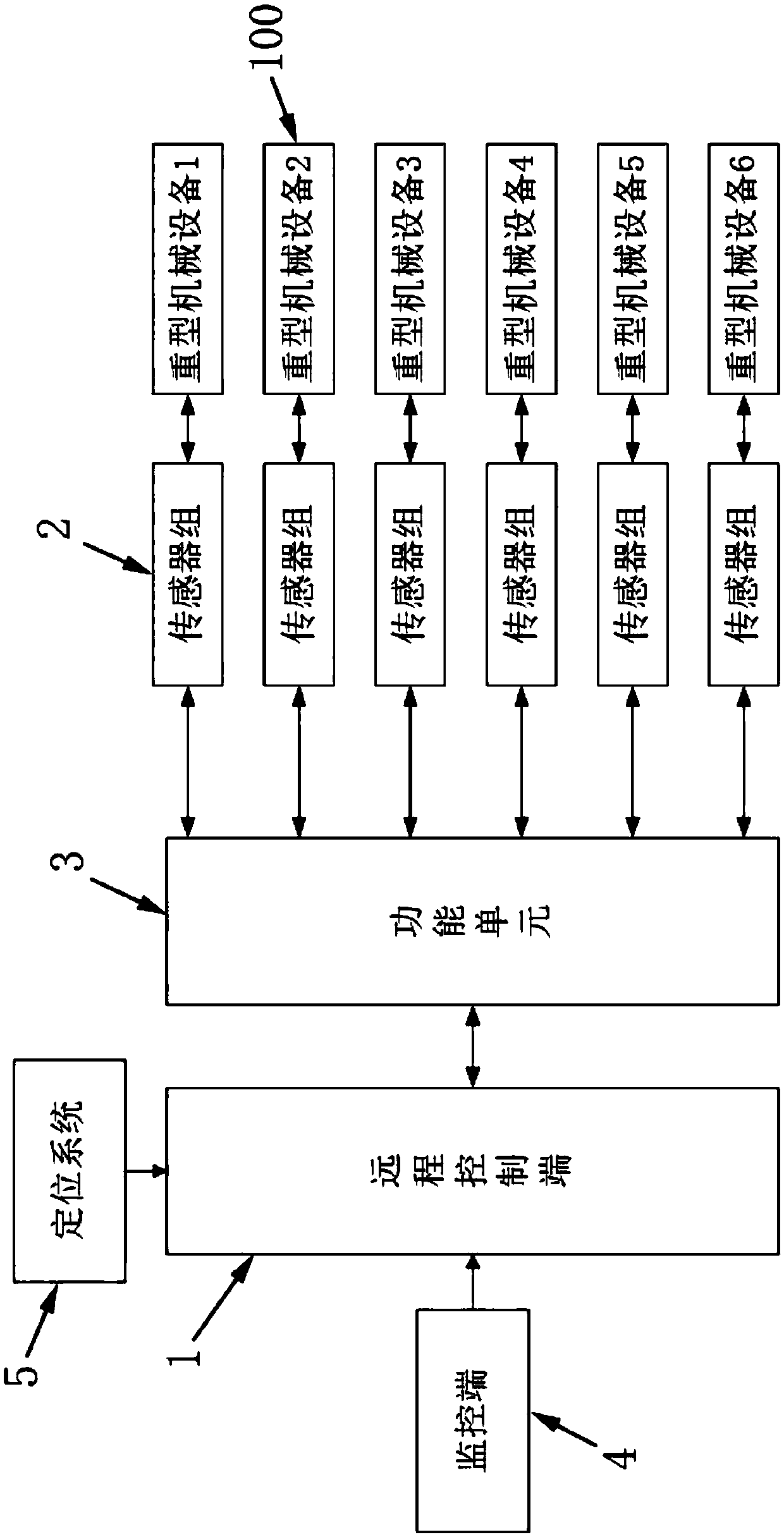

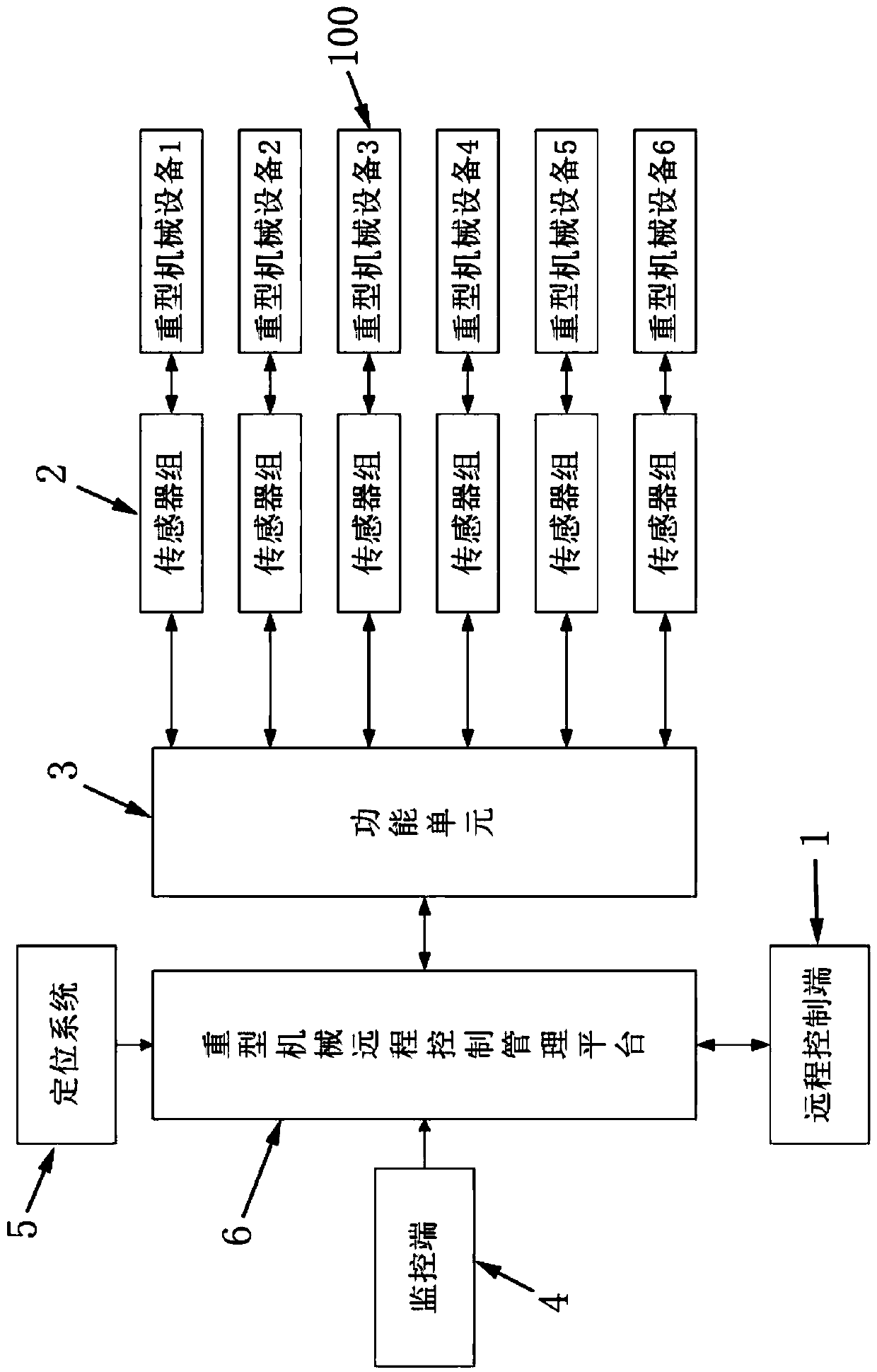

Heavy machinery remote controlling system

InactiveCN109683496AIncrease incomeSolve recruitment difficultiesProgramme control in sequence/logic controllersControl systemWorking environment

The invention discloses a heavy machinery remote controlling system. The system comprises a remote control end, a sensing assembly group, a functional unit and a monitoring end, wherein the remote control end is used for controlling at least one piece of heavy machinery equipment to operate, the sensing assembly group comprises a plurality of sensors of different types, the sensors are uniformly distributed on the heavy machinery equipment, the sensors are used for monitoring the working condition of the heavy machinery equipment, a self operation condition and working environment information,the functional unit is used for receiving monitoring information transmitted by the sensors and transmitting the received monitoring information to the remote control end in real time, and the monitoring end is used for transmitting monitored construction site or operator operation site situations to the remote control end. Compared with the prior art, the system has the advantages that the operators can remotely control local heavy machinery equipment. The invention further provides a heavy machinery remote controlling method.

Owner:SHANGHAI XINCHU INTEGRATED CIRCUIT

Fully automatic production system for refractory bricks

ActiveCN111702949BReduce health impactRealize fully automatic operationDischarging apparatusMixing operation control apparatusFire brickProcess engineering

The invention discloses a fully automatic production system for refractory bricks. According to the forming process of refractory bricks, an automatic weighing and distributing device, a press, a brick receiving and conveying platform, a testing machine, a defective product conveying platform, brick picking and stacking equipment, and kiln car positioning are sequentially arranged. In the area, the raw materials are pressed and formed by automatic weighing and distributing devices and presses for automatic detection and screening, and bad bricks are automatically removed. The system sends a full car of kiln cars into the kiln for firing to obtain finished bricks, which realizes fully automatic operation and overcomes the shortcomings of low automation and low manufacturing efficiency in the existing refractory brick manufacturing, thereby not only reducing labor costs, but also improving At the same time, the safety risk is greatly reduced, the safety of people's lives is guaranteed, the impact of dust on the health of personnel during the brick pressing process is reduced, the labor intensity is reduced, and the problem of difficult recruitment is solved.

Owner:CHANGXING RONGLI MACHINERY

A ceramic soot suction and blowing all-in-one machine

ActiveCN106345748BPrevent escapeSolve recruitment difficultiesUsing liquid separation agentDirt cleaningAir pumpElectric machinery

The invention discloses a ceramic dust suction-blowing integrated machine. The ceramic dust suction-blowing integrated machine comprises a worktable and a dust collecting box. The middle portion of the worktable is fixedly provided with a suction hood, and the middle portion of the front side of the worktable is fixedly provided with a control box; an air pump is arranged at the right side of the control box, a conveyer is arranged on the worktable, and the suction hood stretches across the conveyer; a pallet is arranged on the conveyer, and a dust-suction pipe is provided on the suction hood; high-pressure blow pipes are fixedly arranged side by side at one side, located at the dust-suction pipe, of the upper surface of the suction hood; the lower end of each high-pressure blow pipes is located at the connection portion of the inside of the suction hood and the dust-suction pipe; the upper end of each high-pressure blow pipes is connected with an air pump through a high-pressure air pipe; a servo motor and a reduction gearbox are fixedly arranged at one side, located at a induction switch, of the inside of the worktable; the middle portion of the left side of the dust collecting box is provided with a blast box; the middle portion of the lower surface of the blast box is provided with a dust collecting motor, and the dust collecting motor is fixed on the dust collecting box through a fixing bracket; the lower portion, located at the dust collecting motor, of the bottom of the dust collecting box is provided with a water pump. The ceramic dust suction-blowing integrated machine is safe and reliable, and the labor intensity is reduced.

Owner:醴陵市和泰陶瓷制造有限公司

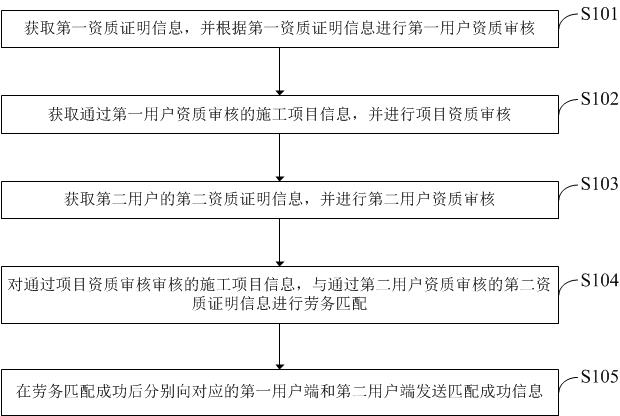

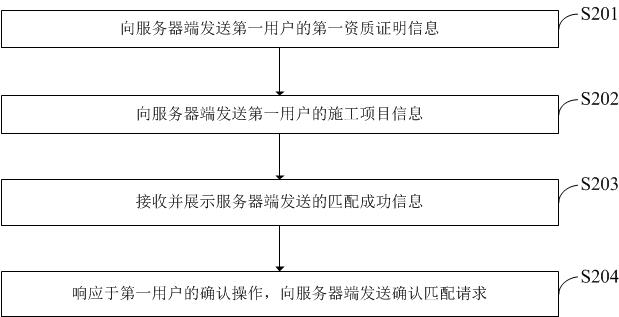

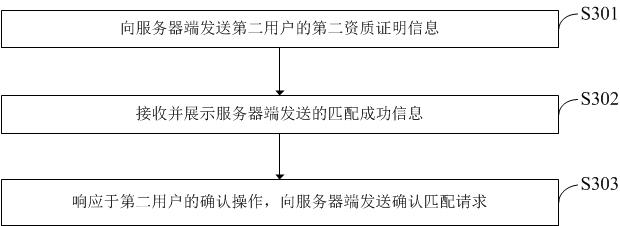

Labor resource data processing method and device

PendingCN113822644ASolve recruitment difficultiesReduce incidenceFinanceOffice automationConstruction workerBuilding construction

The embodiment of the invention discloses a labor resource data processing method and device. The labor resource data processing method comprises the following steps: acquiring first qualification proof information of a first user and performing first user qualification auditing; obtaining the construction project information of the first user passing the first user qualification auditing, and performing project qualification auditing; obtaining second qualification proof information of a second user, and performing second user qualification auditing; performing labor service matching on the construction project information passing the project qualification auditing and auditing and the second qualification proof information passing the second user qualification auditing and auditing; and after the labor service matching is successful, respectively sending matching success information to the corresponding first user side and the second user side, wherein the matching success information comprises the corresponding construction project information and the second qualification proof information. By adopting the technical scheme, the problem of difficulty in recruitment can be solved for a building construction unit, the problem of finding intentional work for building workers can be solved, and the occurrence rate of labor and capital disputes can be effectively reduced.

Owner:郑州咚咚点兵信息技术有限公司

Robot for intelligently selecting gangue in raw coal

InactiveCN111906054AEfficient separationSolve recruitment difficultiesSortingProcess engineeringTico Robot

The invention discloses a robot for intelligently selecting gangue in raw coal. The robot comprises a frame, wherein a first sliding rail is assembled on the inner wall of the frame, a mechanical gripper device is assembled in the first sliding rail in a sliding mode, a second sliding rail is assembled on the inner wall of the frame, and a mechanical shifting hand device is assembled in the secondsliding rail in a sliding mode. According to the robot, the robot based on an intelligent gangue selecting system is designed, the robot comprises a mechanical shifting hand and a mechanical gripper,the functions of accurate positioning, rapid selecting, classified putting and the like are realized through the cooperative use of the mechanical shifting hand and the mechanical gripper, efficientseparation of the coal and the gangue is realized, manual labor is replaced, the problem that the recruitment of gangue selecting workers is difficult is solved, and the requirement for a conveying belt is reduced; the robot can be installed by improving a traditional production line, and the whole production line is prevented from being modified; and the gangue selection is intelligently controlled, so that the net selection rate is improved, and meanwhile, the adverse effect on a human body when radioactive isotopes are used for selecting the gangue is avoided.

Owner:唐山市德丰机械设备有限公司

A fully automatic vacuum protective film labeling machine

ActiveCN103342178BSolve recruitment difficultiesAutomated program highLabelling deformable materialsCircular discPunching

The invention relates to the technical field of production machinery, and particularly relates to a full-automatic vacuum protection film labeling machine which comprises a conveying device, a punching device, a disc, fixtures, a spring flexible wheel, a sucking member oscillating device and a PLC (Programmable Logic Controller), wherein the conveying device is positioned on a first electric cabinet, the sucking member oscillating device and the PLC are positioned on a third electric cabinet, the sucking member oscillating device is arranged on a synchronizing wheel shield, the synchronizing wheel shield is fixed on a second electric cabinet through a bolt, the disc is positioned on a second electric cabinet, the fixtures are arranged on the disc, the spring flexible wheel is arranged between the fixtures, and a vacuum absorbing device is arranged on the punching device. The full-automatic vacuum protection film labeling machine has the advantages of high automation degree, accuracy in location and control, stable work, convenience in operation, and energy and labor hour saving, and adapts to the national advocacy of energy saving and environmental friendliness. A manual re-labeling complex procedure is replaced incomparably, and the problem of difficulty in recruiting workers in labor-intensive industries is solved.

Owner:漳州市博嘉自动化机械设备有限公司

Fully automatic electrolytic polishing equipment

InactiveCN106400100BSolve the problem of high currentAvoid short circuitElectrolysis componentsElectrolysisResource utilization

Owner:湖北帕尔森机电设备有限公司

Continuous digester for processing environment-friendly and energy-saving type aquatic products

InactiveCN103704539ASolve recruitment difficultiesSave human effortFood preparationTemperature controlPower controller

The invention provides a continuous digester for processing environment-friendly and energy-saving type aquatic products. The continuous digester comprises an original device body and a motor. The continuous digester is characterized in that an interlayer is arranged blow the device body and is internally provided with heat energy conduction liquid; a plurality of electromagnetic ovens are arranged below the interlayer; the device body is provided with a temperature controller and a power supply controller; the electromagnetic ovens are electrically connected with the power supply controller. The device body is internally provided with a temperature sensor; the temperature sensor is electrically connected with the temperature controller. The device is internally provided with a plurality of idler wheels; the idler wheels are provided with a plurality of kelp density sharing teeth; the idler wheels are connected with the motor by hinges. The device body is externally provided with a heat-preservation layer and is provided with a fixed heat-preservation cover and a movable heat-preservation cover. When the continuous digester is used, only a power supply needs to be switched on and water in the device body can be heated. The continuous digester for processing the environment-friendly and energy-saving type aquatic products has the beneficial effects that environment-friendly and energy-saving effects are achieved and manpower and material resources are saved; the efficiency is high and the effect is good; the problem that enterprises cannot easily employ workers is also solved.

Owner:宫锡和

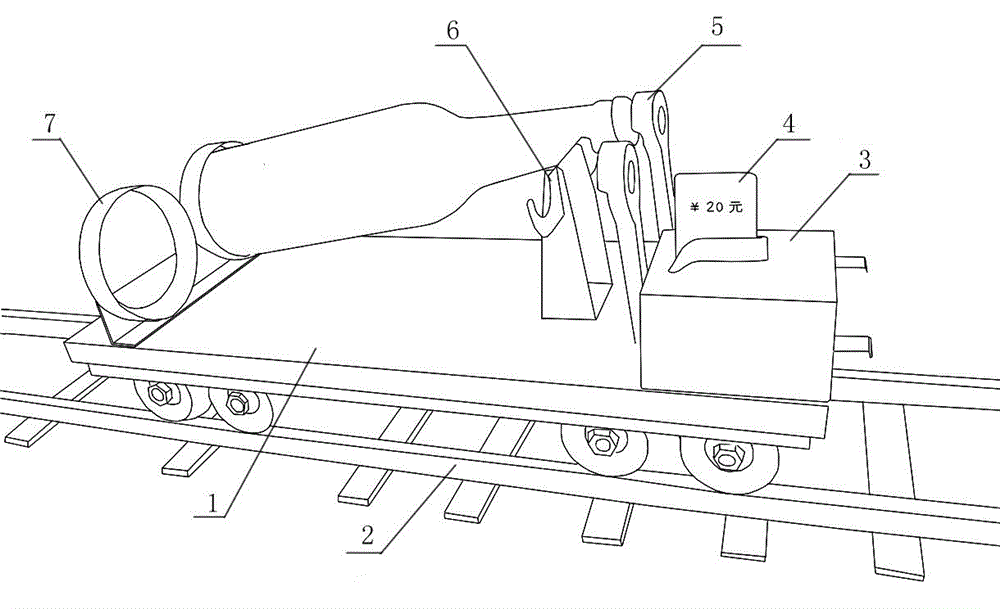

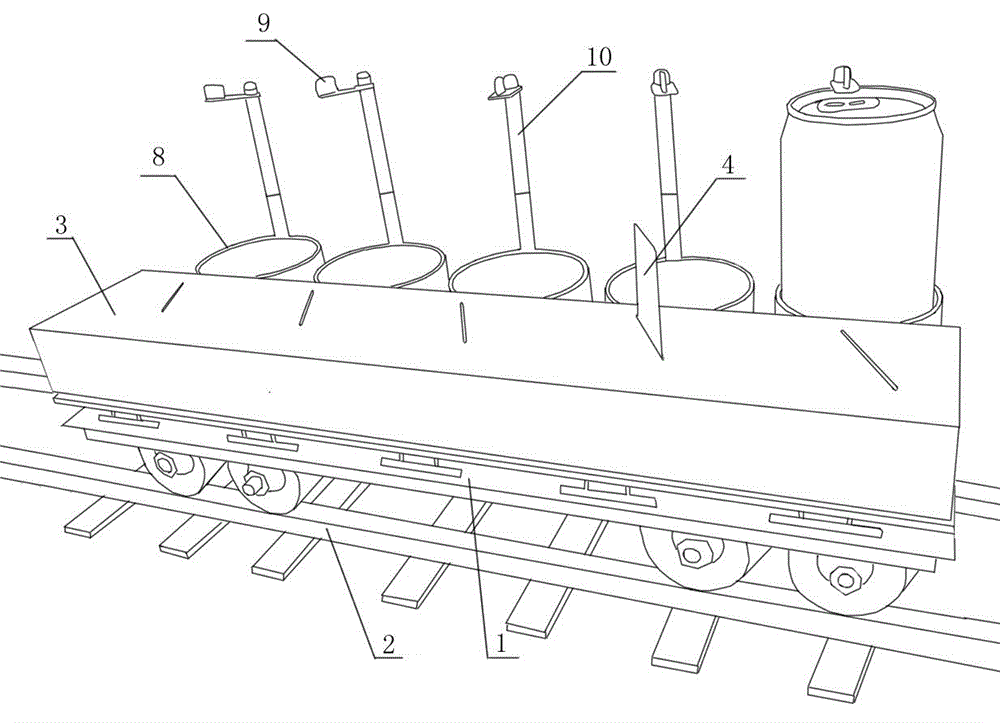

Food product automatic conveying and automatic purchasing device and food product automatic conveying and automatic purchasing method for restaurant

InactiveCN103494486BSolve recruitment difficultiesReduce laborTable equipmentsLocking mechanismEngineering

Owner:李贺顺

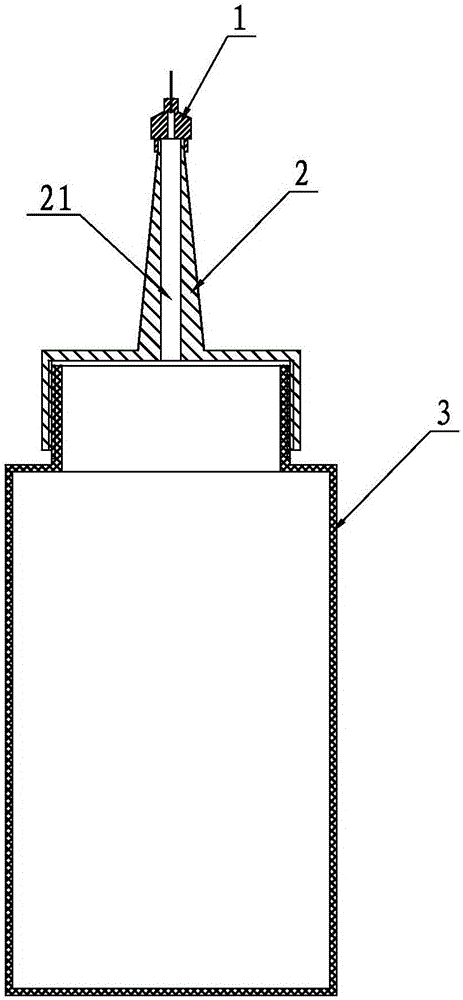

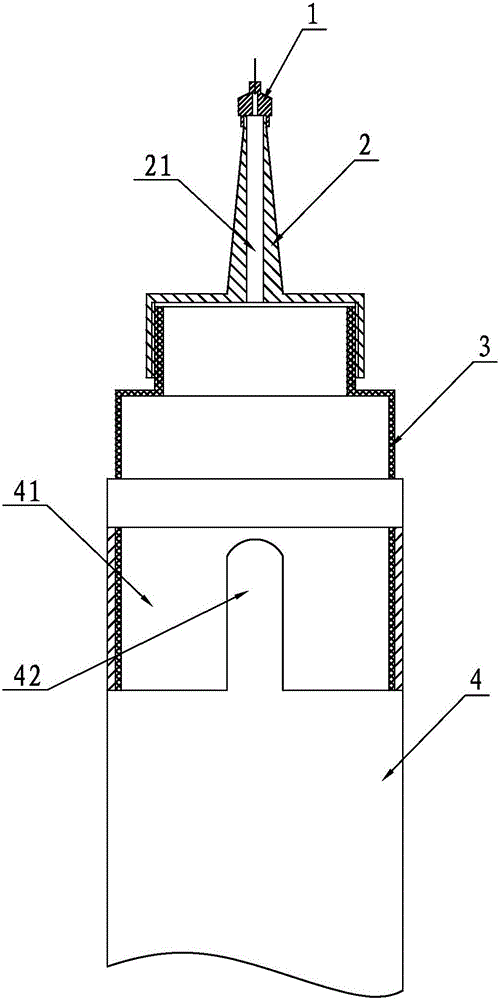

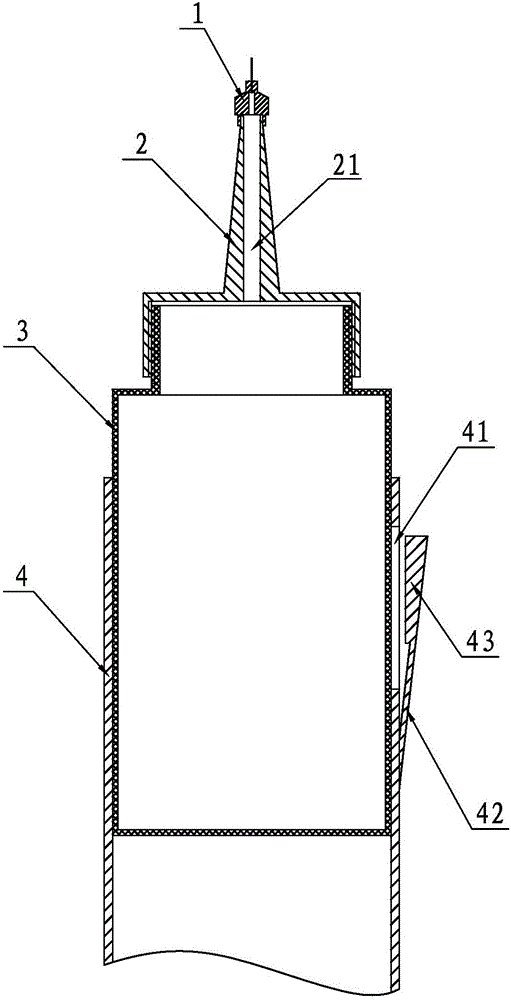

Coloring machine for manually coloring artware

A shader for manual coloring crafts, including a coloring needle, a feeding cap, a soft liquid storage bottle and a pressurizer. On the opening of the liquid storage bottle, there is a liquid outlet through hole in the center of the feeding cap, the colored needle and the inner cavity of the soft liquid storage bottle are connected through the liquid outlet through hole of the feeding cap, and the pressurizer is set in the soft On the outside of the liquid storage bottle, the inner diameter of the pressurizer is transitionally matched with the outer circle of the soft liquid storage bottle, and the pressurizer has a gap in the contact section with the soft liquid storage bottle. Using this shader, the fatigue strength of workers' hands is greatly reduced, the work efficiency is significantly improved, the price is low, the replacement is convenient, the cost and environmental hazards caused by cleaning the bottle body are avoided, and the safety hazards and safety hazards caused by flammable solvents are eliminated. The harm caused by toxic solvents to the health of operators and the difficulty of recruiting workers have also been solved.

Owner:谢钧

A multi-station reciprocating circulation type scallop shell opening and meat taking machine

ActiveCN108887372BLabor savingIncrease productivityBivalves processingEngineeringMechanical engineering

The invention discloses a multi-station reciprocating circulation type scallop shell opening and meat harvesting machine, which comprises a scallop conveying guide device for guiding the scallops one by one, a scallop shell leveling tail for leveling the scallops and positioning the tail Positioning device, scallop gripping and conveying device for gripping scallops and transporting scallops, scallop tail cutting device for cutting scallop tails, shell and shell separation device for shoveling scallop meat, and a device for pushing out empty scallop shells Shell ejection device. The invention can clean, guide and level the scallops, accurately position the tails of the scallops, realize continuous transportation, accurately cut the tails of the scallops, completely take out the shellfish from the inside of the scallop shell, and clean the shellfish. The gizzard attached to the top is accurately cut, and then the skirt and shell of the scallop meat are separated, which saves labor, improves production efficiency, and effectively ensures the fresh taste of scallop meat.

Owner:秦皇岛润昌科技开发有限公司

An electric tricycle stator winding machine

ActiveCN105356698BReduce the need for operational expertiseSolve recruitment difficultiesManufacturing dynamo-electric machinesWinding machineEmployee recruitment

Owner:JIANGSU NIDE AUTOMATION TECH

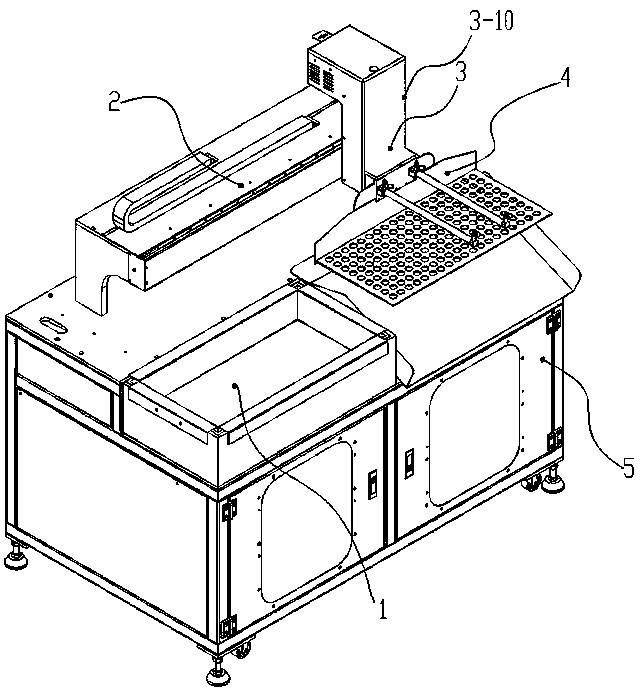

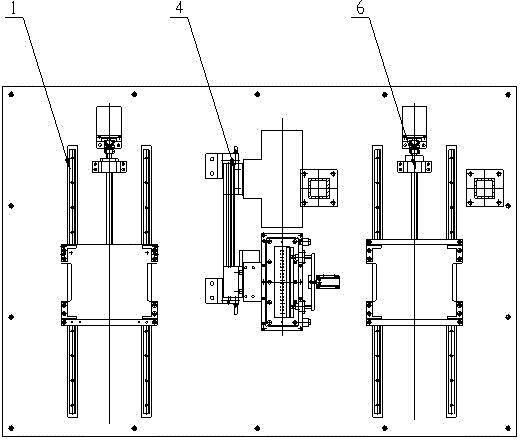

Automatic ceramic base body microleakage detector and detection method thereof

ActiveCN102749178BReduce work intensityAvoid damageDetection of fluid at leakage pointSortingManipulatorUltimate tensile strength

The invention discloses an automatic ceramic base body microleakage detector which comprises a material feeding part, a material loading mechanical arm, a case cover mechanical arm, a material receiving mechanical arm, a leakage detection working part and a material receiving part, wherein the leakage detection work part comprises a helium leakage mass spectrometer; the material feeding part is used for placing ceramic bases arranged in an array; the material loading mechanical arm is used for drawing discharge materials in the material feeding part and then moving the discharge materials to the leakage detection working part; the case cover mechanical arm is used for moving to the leakage detection working part and can form a seal cavity with the leakage detection working part; the helium leakage mass spectrometer is used for detecting the leakage of the ceramic base bodies; and the material receiving mechanical arm is used for drawing the whole discharge materials in the leakage detection working part and placing the materials into the material receiving part according to the leakage detection qualification condition of the materials. By using the scheme of the invention, the labor intensity of ceramic base body leakage detection can be effectively decreased, the human misoperation is reduced, the detection is reliable, the grading is accurate and the detection quality is improved.

Owner:CHAOZHOU THREE CIRCLE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com